Page 1

Instruction

Book

CPFAFFD®

76

CPFAFP)

77

Page 2

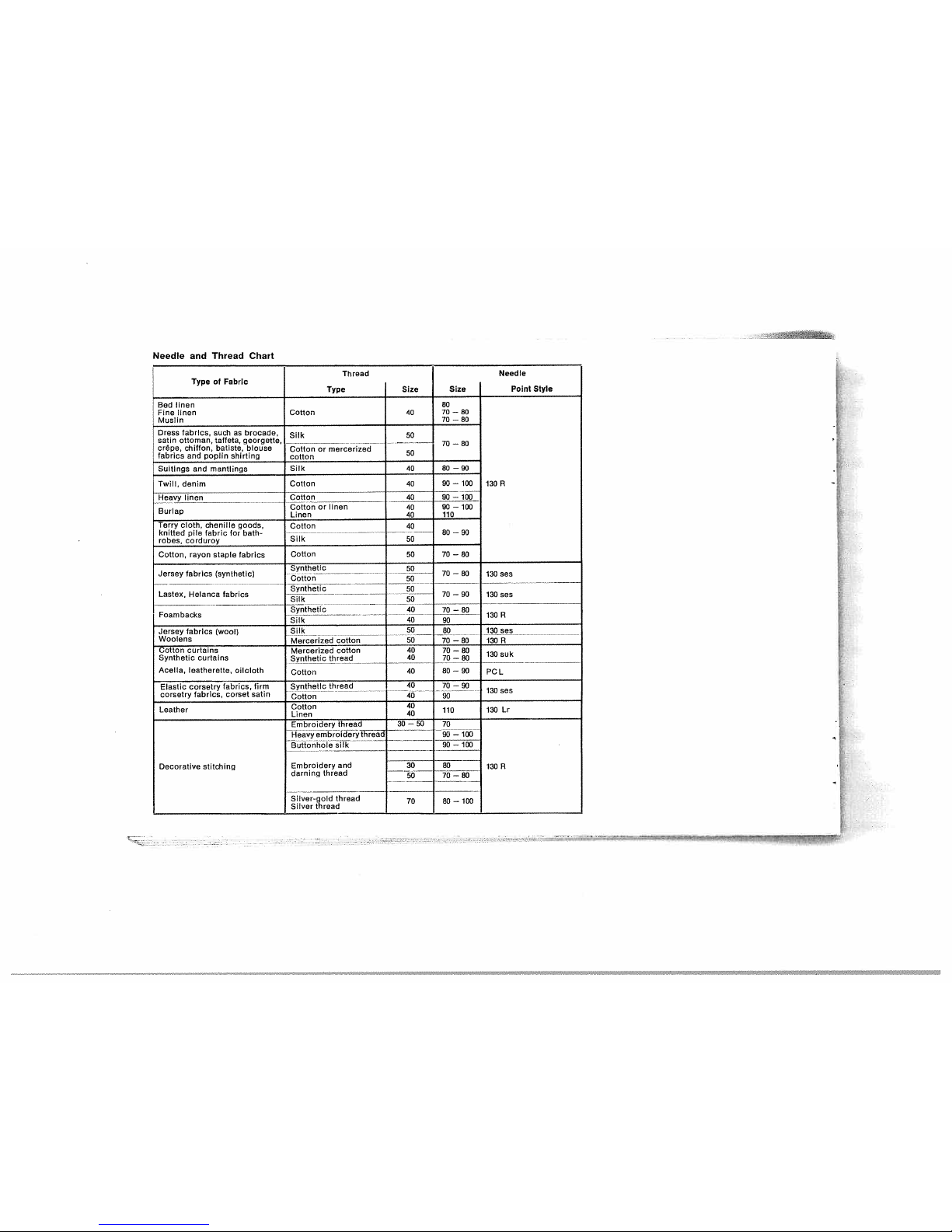

Needle

and

Thread

Chart

Thread

Needle

Type

of

Fabric

Type

Size

Size

Point

Style

Bed

linen

80

Fine

linen

Cotton

40

70

80

Muslin

70—80

Dress

fabrics,

such

as

brocade,

Silk

so

satin

ottoman,

taffeta,

georgette,

70

—

80

crêpe,

chiffon,

batiste.

blouse

Cotton

or

mercerized

fabrics

and

poplin

shirting

cotton

so

Suitings

and mantlings

Silk

40

80

—

90

Twill,

denim

Cotton

40

90—

100

130ff

Heavy

linen

Cotton

40

90—100

Cottonorlinen

40

90—100

Burlap

Linen

40

110

Terry

cloth,

chenille

goods,

Cotton

40

knitted

pile

fabric

for

bath-

—

80

—

90

robes,

corduroy

Silk

50

Cotton,

rayon

staple

fabrics

Cotton

50

70

—

80

Synthetic

—

Jersey

fabrics

(synthetIc)

70

—

80

130

sea

Cotton

50

Synihettc

50

Lastex,

Helanca

fabrics

———

70

—

90

130

ses

Silk

50

Synthetic

-

40

70—80

Foambacks

130

R

Silk

40

90

Jersey

fabrics

(wool)

Silk

50

80

130

sea

Woolens

iercerized

cotton

50

70—80

130ff

Cotton

curtains

Mercerized

cotton

40

70

—

80

130

suk

Synthetic

curtains

Synthetic

thread

40

70—80

Acella,

teatherette,

oilcloth

Cotton

40

80—90

PCL

Elastic

corsetry

fabrics,

firm

Synthetic

thread

40

70

—

90

130

ses

corsetry

fabrics,

corset

satin

Cotton

-

40

90

Leather

Cotton

110

130

Lr

Linen

40

Embroidery

thread

30—50

70

Heavyembrokierythread

—

90—100

Buttonhole

silk

—

90

—

100

Decorative

stitching

Embroidery

and

30

80

130

R

darning

thread

Silver-gold

thread

70

80

—

ioo

Silver

thread

Page 3

Instructions

CPFAFFI

76and77

Foreword

Your

new

Pfaff

sewing

machine

will

enable

you

to

master

a

large

variety

of

sewing,

embroidering

and

darning

jobs

easily

and

quickly.

This

instruction

book

has

been

compiled

in

order

to

familiarize

you

thoroughly

with

all

the

sewing

jobs

coming

up

in

a

home.

We

suggest

that

you

try

out

the

various

sew

ing

techniques

discussed

in

this

book

so

that

you

will

become

well

acquainted

with

your

machine.

If

you

have

any

sewing

problems,

please

do

not

hesitate

to

contact

your

Pfaff

dealer

who

will

be

glad

to

help

you

at

any

time.

We

hope

you

will

always

enjoy

sewing

with

your

Pfaff.

G.

M.

PFAFF

AG

Karisruhe-Durlach

Branch

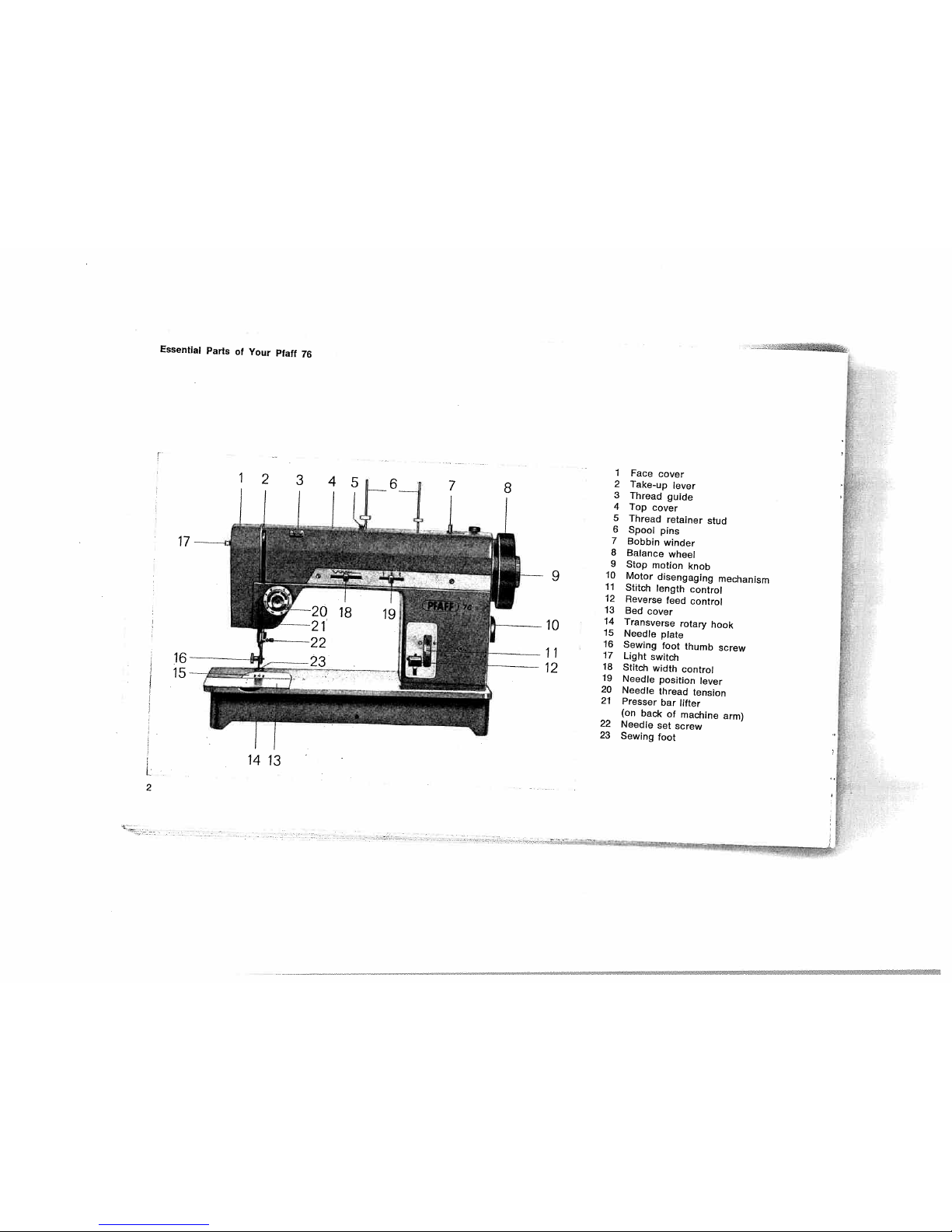

Page 4

Essential

Parts

of

Your

Pfaff

76

1

Face

cover

2

Take-up

lever

3

Thread

guide

4

Top

cover

5

Thread

retainer

stud

6

Spool

pins

7

Bobbin

winder

8

Balance

wheel

9

Stop

motion

knob

9

10

Motor

disengaging

mechanism

11

Stitch

length

control

12

Reverse

feed

control

13

Bed

cover

14

Transverse

rotary

hook

15

Needle

plate

16

Sewing

foot

thumb

screw

17

Light

switch

18

Stitch

width

control

19

Needle

position

lever

20

Needle

thread

tension

21

Presser

bar

lifter

(on

back

of

machine

arm)

22

Needle

set

screw

23

Sewing

foot

LHL1fl

17

16

15

18

10

2

Page 5

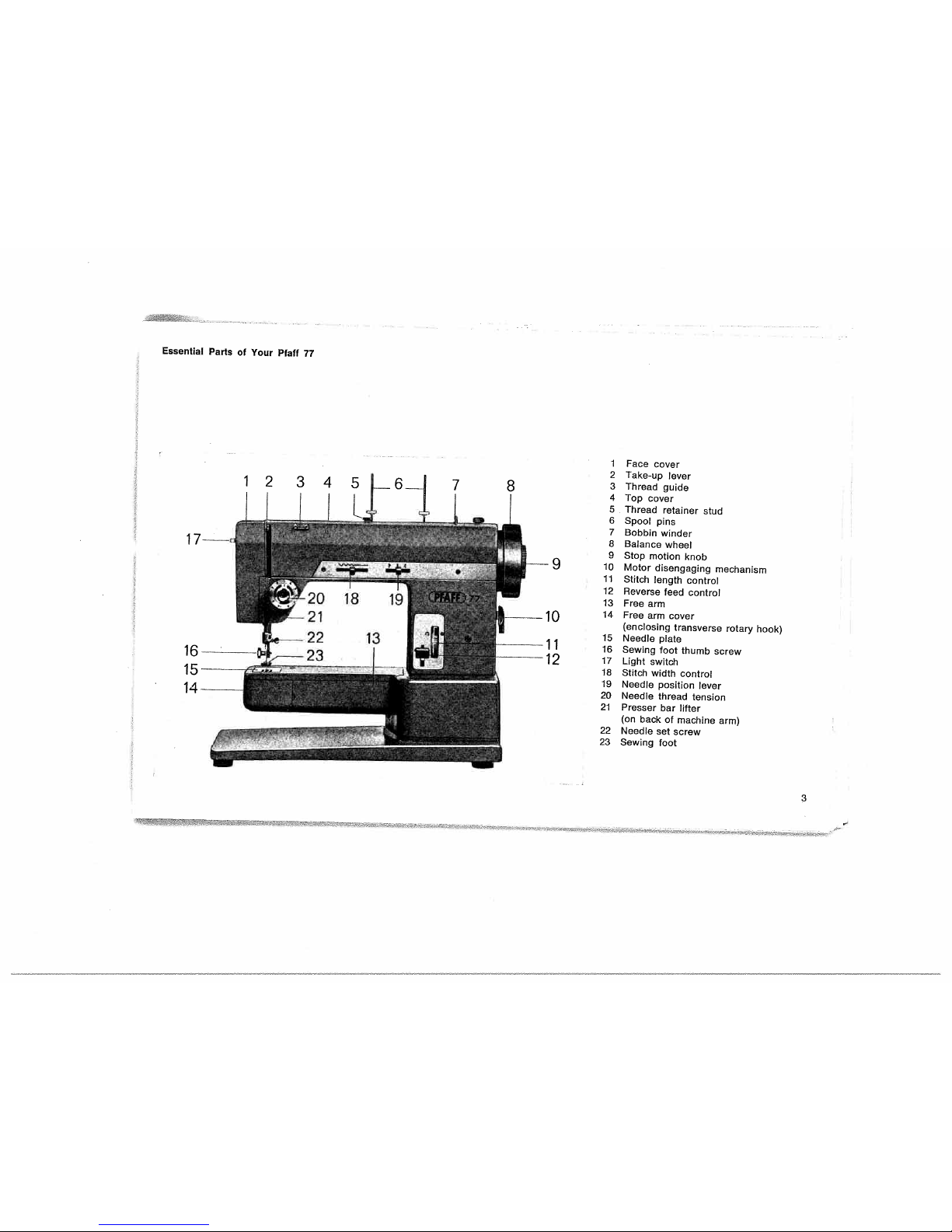

Essential

Parts

of

Your

Pfaff

77

1

Face

cover

2

Take-up

lever

3

Thread

guide

4

Top

cover

5

Thread

retainer

stud

6

Spool

pins

7

Bobbin

winder

8

Balance

wheel

9

Stop

motion

knob

10

Motor

disengaging

mechanism

11

Stitch

length

control

12

Reverse

feed

control

13

Free

arm

14

Free

arm

cover

(enclosing

transverse

rotary

hook)

15

Needle

plate

16

Sewing

foot

thumb

screw

17

Light

switch

18

Stitch

width

control

19

Needle

position

lever

20

Needle

thread

tension

21

Presser

bar

lifter

(on

back

of

machine

arm)

22

Needle

set

screw

23

Sewing

foot

3

4

5

I—6_

U

1

7—

16

15

14

3

Page 6

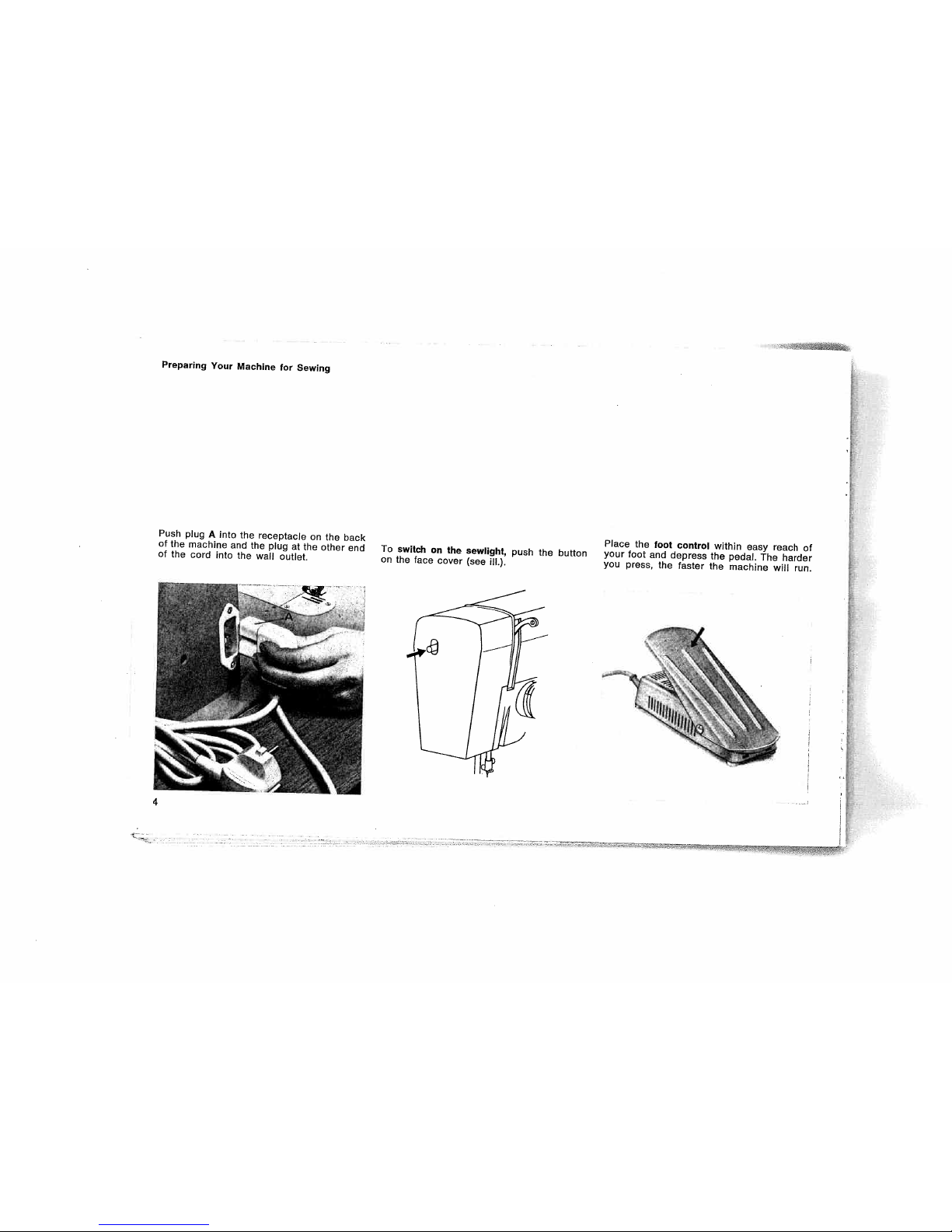

Preparing

Your

Machine

for

Sewing

Push

plug

A

into

the

receptacle

on

the

back

of

the

machine

and

the

plug

at

the

other

end

of

the

cord

into

the

wall

outlet.

To

switch

on

the

sewlight,

push

the

button

on

the

face

cover

(see

ill.).

Place

the

foot

control

within

easy

reach

of

your

foot

and

depress

the

pedal.

The

harder

you

press,

the

faster

the

machine

will

run.

4

Page 7

The

machines

feature

a

lever

(10)

under

neath

the

balance

wheel

which

serves

to

swing

the

motor

to

Its

operative

position.

To

engage

the

motor,

flick

this

lever

down.

After

you

have

completed

sewing,

flick

this

lever

to

its

top

position.

5

Page 8

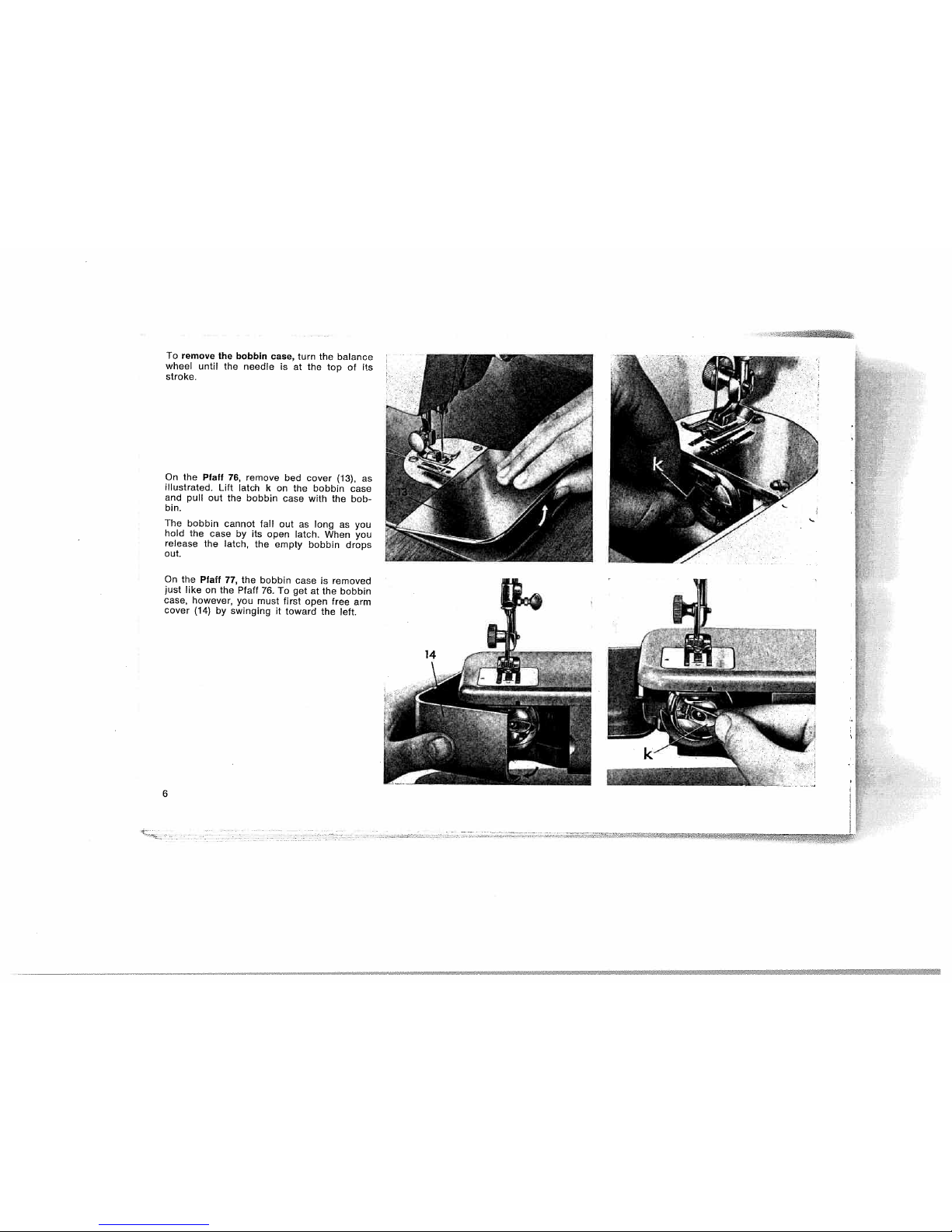

To

remove

the

bobbin

case,

turn

the

balance

wheel

until

the

needle

is

at

the

top

of

its

stroke.

On

the

Piaft

76,

remove

bed

cover

(13),

as

illustrated.

Lift

latch

k

on

the

bobbin

case

and

pull

out

the

bobbin

case

with

the

bob

bin.

The

bobbin

cannot

fall

outaslong

as

you

hold

the

case

by

its

open

latch.

When

you

release

the

latch,

the

empty

bobbin

drops

out.

On

the

Pfaff

77,

the

bobbin

case

is

removed

just

like

on

the

Pfaff

76.

To

get

at

the

bobbin

case,

however,

you

must

first

open

free

arm

cover

(14)

by

swinging

it

toward

the

left.

6

k-

I

I

Page 9

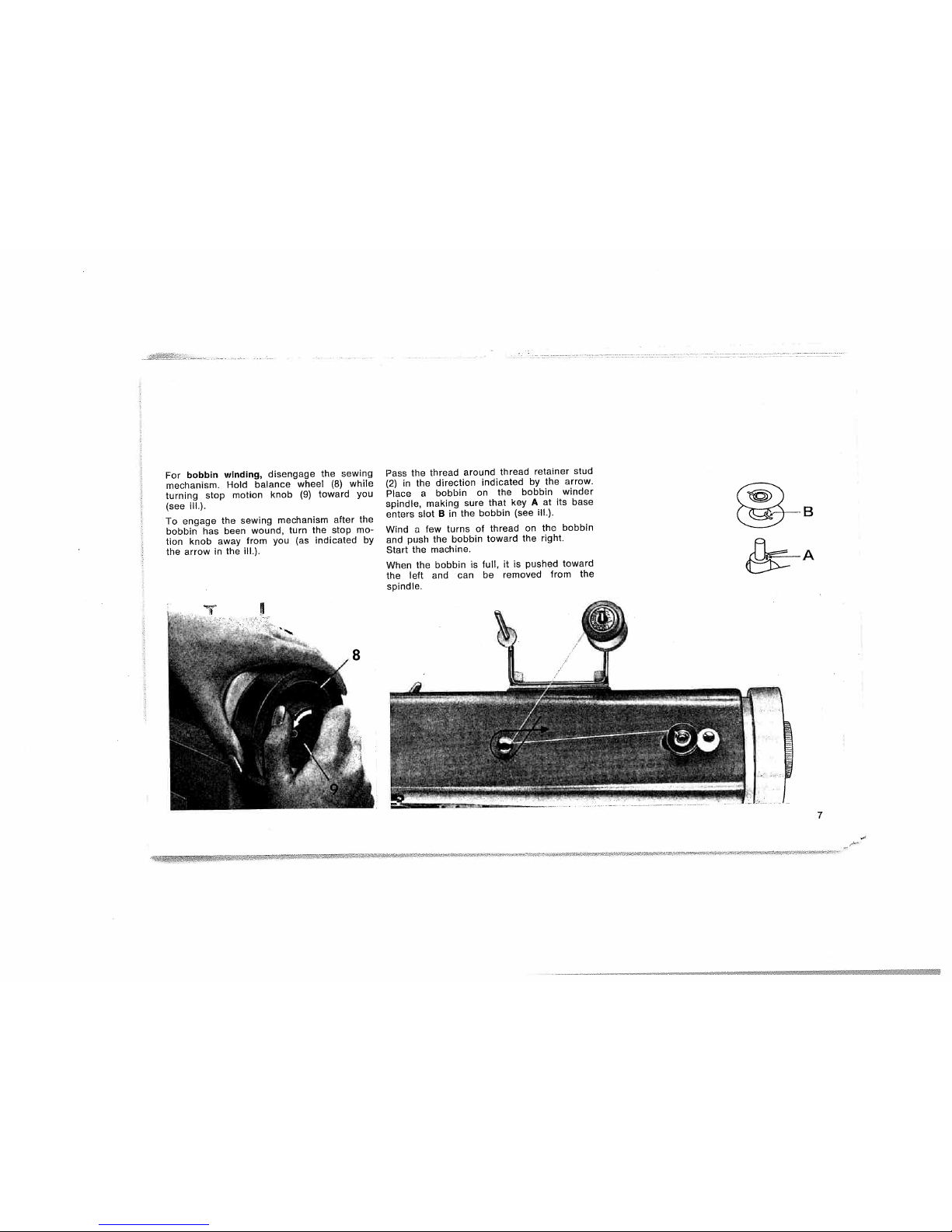

For

bobbin

winding,

disengage

the

sewing

mechanism.

Hold

balance

wheel

(8)

while

turning

stop

motion

knob

(9)

toward

you

(see

ill.).

To

engage

the

sewing

mechanism

after

the

bobbin

has

been

wound,

turn

the

stop

mo

tion

knob

away

from

you

(as

indicated

by

the

arrow

in

the

ill,).

Pass

the

thread

around

thread

retainer

stud

(2)

in

the

direction

indicated

by

the

arrow.

Place

a

bobbin

on

the

bobbin

winder

spindle,

making

sure

that

key

A

at

its

base

enters

slot

B

in

the

bobbin

(see

ill.).

Wind

a

few

turns

of

thread

on

tho

bobbin

and

push

the

bobbin

toward

the

right

Start

the

machine.

When

the

bobbin

is

full,

it

is

pushed

toward

the

left

and

can

be

removed

from

the

spindle.

if

11..

7

Page 10

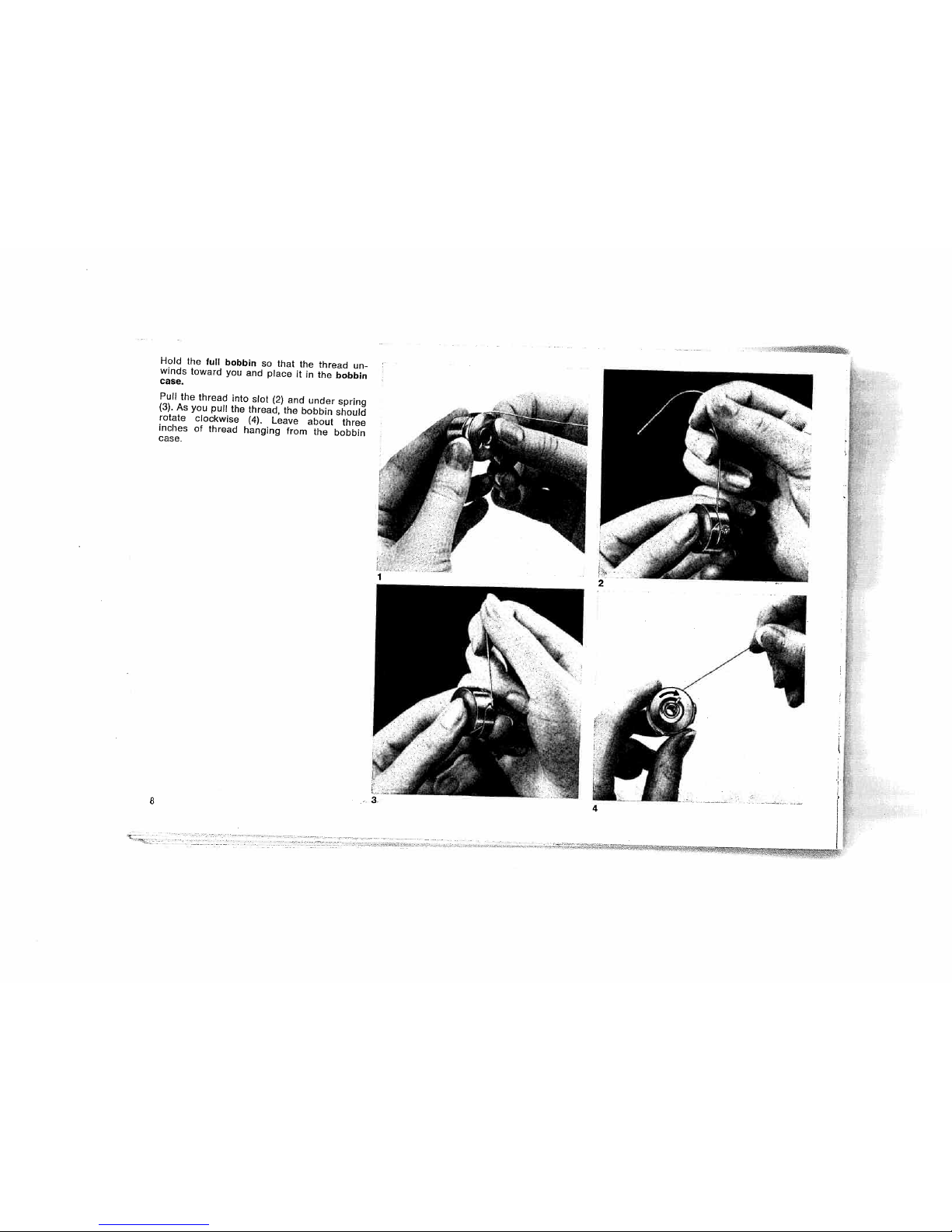

Hold

the

lull

bobbin

so

that

the

thread

un

winds

toward

you

and

place

it

in

the

bobbin

case.

Pull

the

thread

into

slot

(2)

and

under

spring

(3).

As

you

pull

the

thread,

the

bobbin

should

rotate

clockwise

(4).

Leave

about

three

inches

of

thread

hanging

from

the

bobbin

case.

8

Page 11

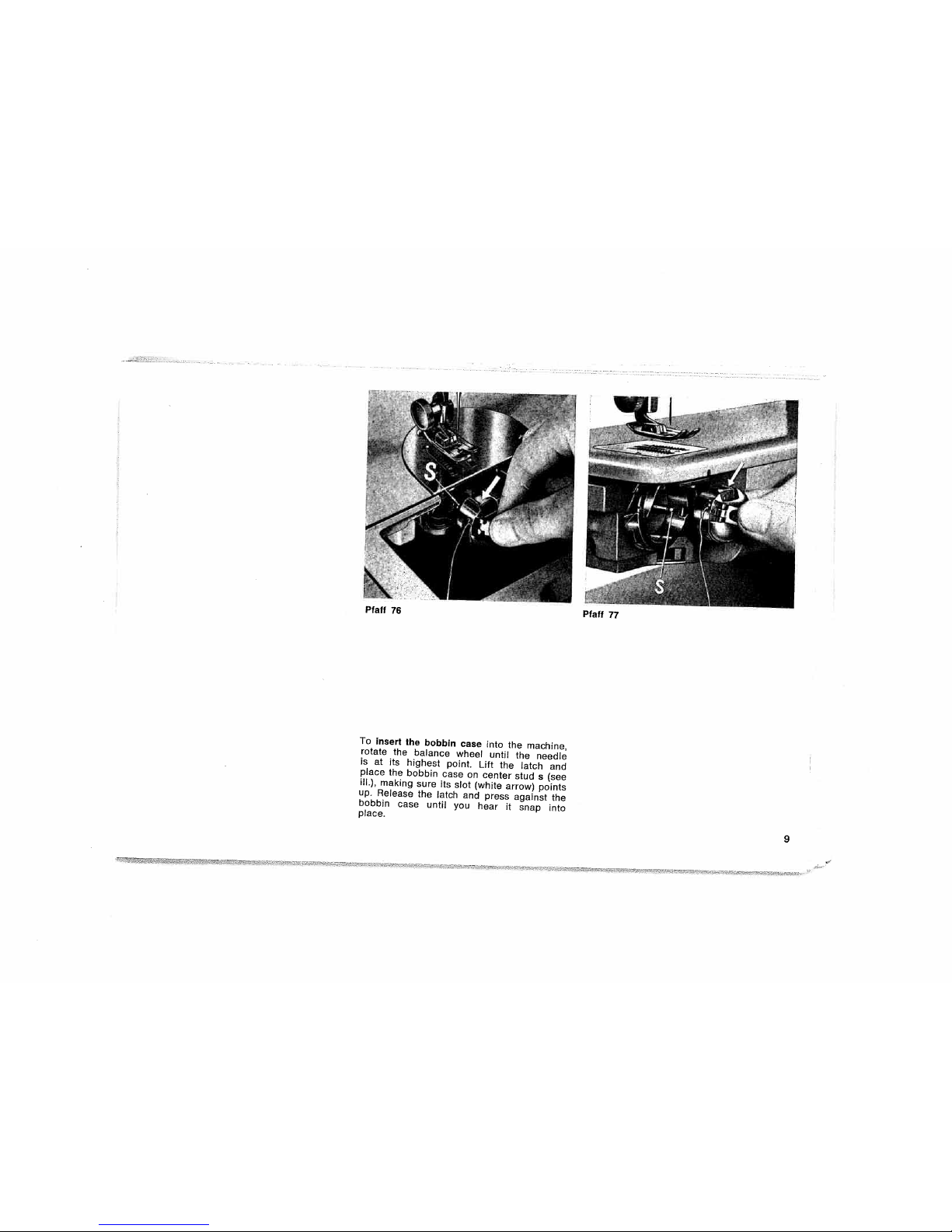

To

insert

the

bobbin

case

into

the

machine,

rotate

the

balance

wheel

until

the

needle

is

at

its

highest

point.

Lift

the

latch

and

place

the

bobbin

case

on

center

stud

s

(see

ill.),

making

sure

its

slot

(white

arrow)

points

up.

Release

the

latch

and

press

against

the

bobbin

case

until

you

hear

it

snap

into

place.

9

Pfaff

76

Pfaff

77

Page 12

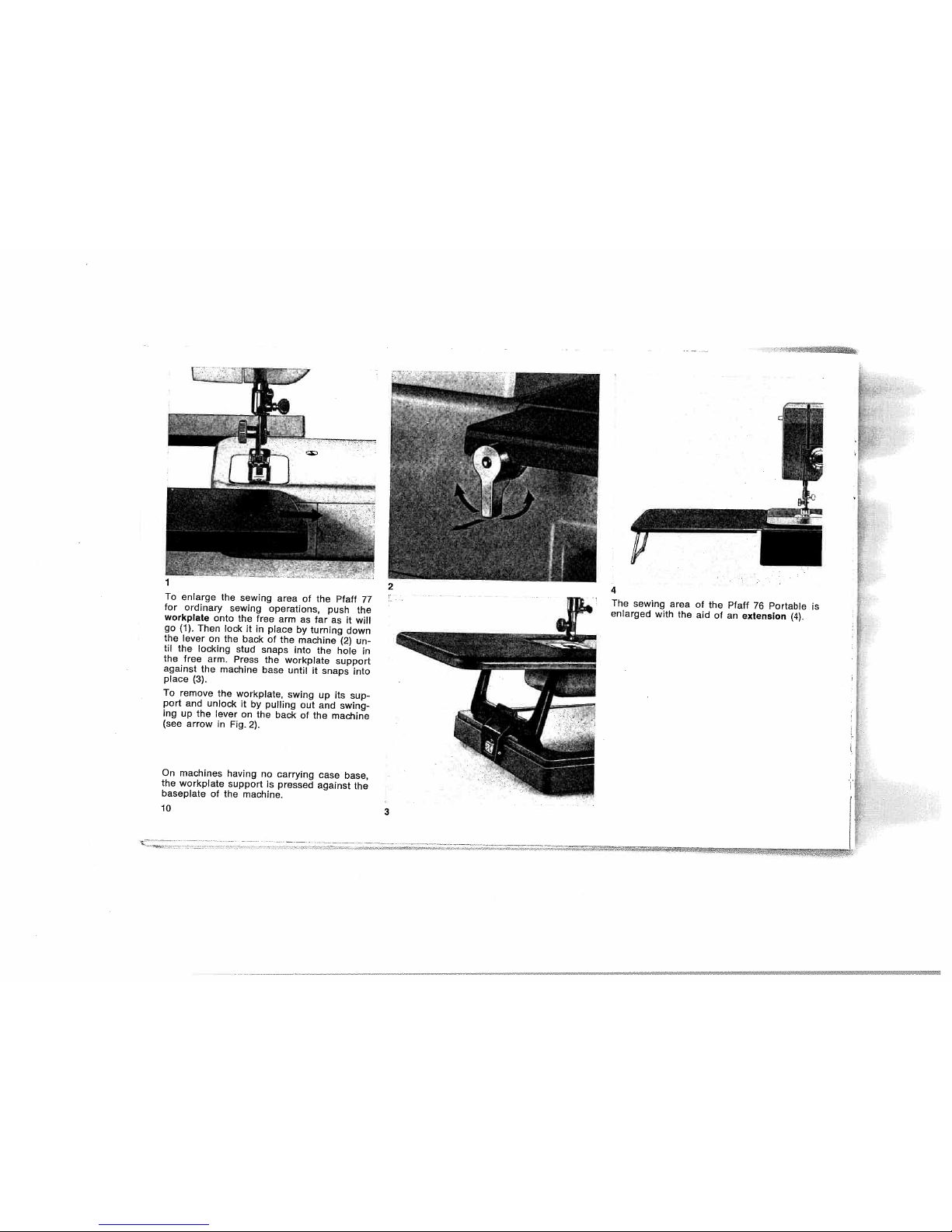

To

remove

the

workplate,

swing

up

its

sup

port

and

unlock

it

by

pulling

out

and

swing

ing

up

the

lever

on

the

back

of

the

machine

(see

arrow

in

Fig.

2).

On

machines

having

no

carrying

case

base,

the

workplate

support

is

pressed

against

the

baseplate

of

the

machine.

1

2

To

enlarge

the

sewing

area

of

the

Pfaff

77

for

ordinary

sewing

operations,

push

the

workplate

onto

the

free

arm

as

far

as

it

will

go

(1).

Then

lock

it

in

place

by

turning

down

the

lever

on

the

back

of

the

machine

(2)

un

til

the

locking

stud

snaps

into

the

hole

in

the

free

arm.

Press

the

workplate

support

against

the

machine

base

until

it

snaps

into

place

(3).

4

The

sewing

area

of

the

Pfaff

76

Portable

is

enlarged

with

the

aid

of

an

extensIon

(4).

1

J

10

3

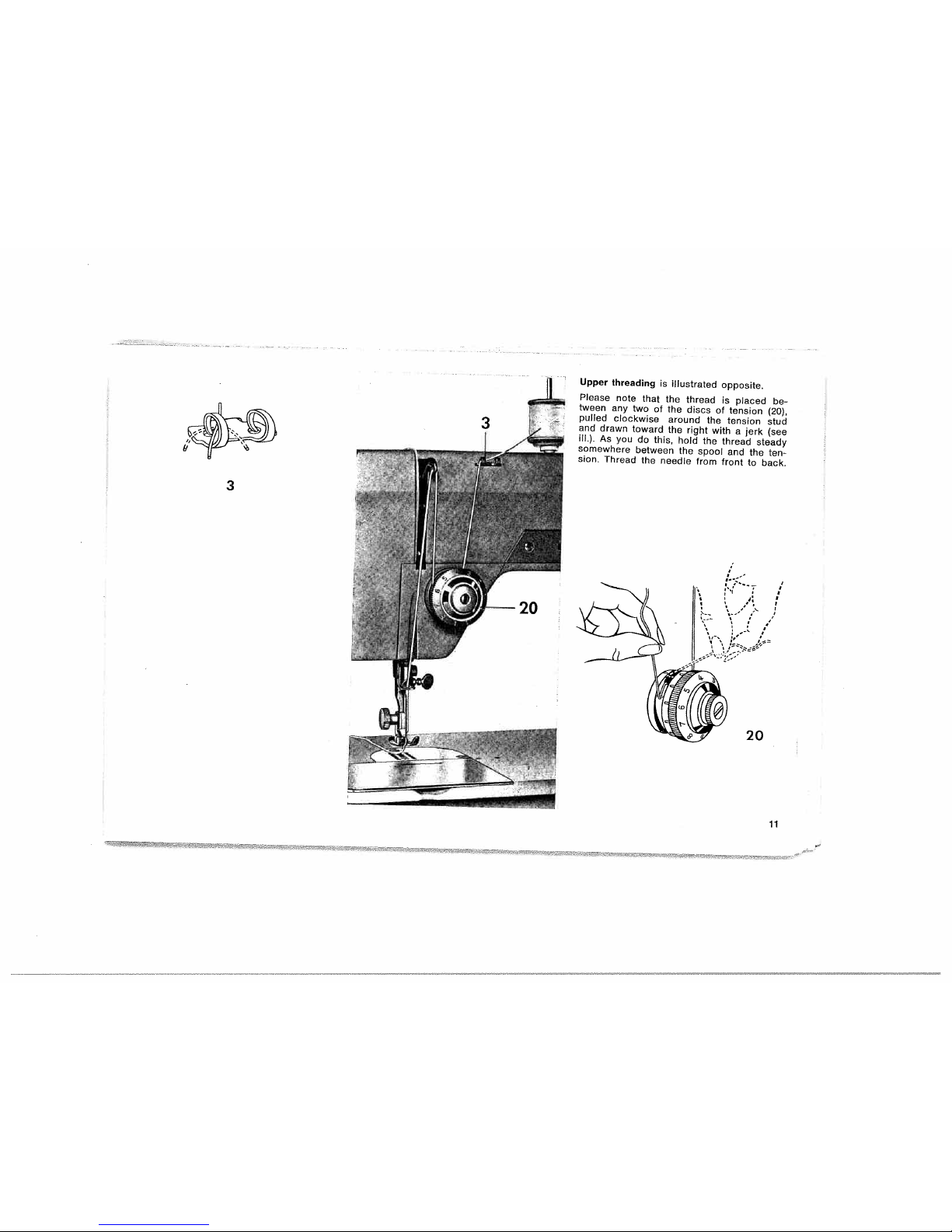

Page 13

Upper

threading

is

illustrated

opposite.

Please

note

that

the

thread

is

placed

be

tween

any

two

of

the

discs

of

tension

(20),

pulled

clockwise

around

the

tension

stud

and

drawn

toward

the

right

with

a

jerk

(see

ill.).

As

you

do

this,

hold

the

thread

steady

somewhere

between

the

spool

and

the

ten

sion.

Thread

the

needle

from

front

to

back.

V

3

20

11

Page 14

The

sewing

foot

is

raised

and

lowered

by

operating

the

presser

bar

lifter

on

the

back

of

the

machine

(see

ill.).

A

=

Presser

bar

lifter

up

B

=

Presser

bar

lifter

down

12

To

draw

up

the

bobbin

thread,

hold

the

needle

thread

and

lower

the

sewing

foot.

Turn

the

balance

wheel

toward

you

a

full

turn.

Pull

the

needle

thread

to

draw

up

the

bobbin

thread.

Place

both

threads

back

under

the

sewing

foot

after

it

has

been

raised

again.

Page 15

Fundamentals

of

Machine

Operation

For

ordinary

sewing,

needle

position

lever

(19)

should

be

in

its

center

position.

Make

sure

the

take-up

lever

is

at

its

highest

point

before

you

begin

and

after

you

have

completed

a

seam

(2).

Always

rotate

balance

wheel

(8)

toward

you

(see

arrow).

As

you

do

this,

check

to

make

sure

the

stop

motion

knob

is

tightened

firmly.

A

13

Page 16

Begin

by

sewing

a

straight-stitch

seam.

To

this

end,

push

stitch

width

control

(18)

to

the

right

as

far

as

it

will

go.

The

stitch

length

is

regulated

by

turning

stitch

length

control

(11).

The

number

indi

cating

the

stitch

length

chosen

should

be

opposite

the

dot

on

the

left-hand

side

of

the

slot.

For

ordinary

sewing

operations,

set

the

stitch

length

control

on

“2”.

Place

the

material

under

the

sewing

foot

and

lower

the

presser

bar

lifter.

Place

the

foot

control

within

easy

reach

of

your

foot

and

press

down

the

pedal.

The

harder

you

press,

the

faster

the

machine

will

run.

L

I

.1

14

Page 17

15

To

sew

in

reverse

or

backtack

the

end

of

a

seam,

simply

depress

fingertip

control

(12).

The

stitch

width

is

regulated

by

pushing

stitch

width

control

(18)

toward

the

left,

as

may

be

desired.

Various

zigzag

sewing

operations

are

dis

cussed

on

page

26

and

the

following

pages.

Page 18

Balanced

tensions

are

essential

for

sewing.

Both

tensions

are

correctly

balanced

if

the

needle

and

bobbin

threads

interlock

in

the

center

of

the

material.

The

bobbin

thread

tension

is

regulated

by

turning

the

small

knurled

screw

on

the

bob

bin

case.

Turn

this

screw

right

(with

your

thumb

nail)

for

a

tighter

tension,

or

left

for

a

looser

ten

sion.

If

the

same

size

threads

are

used

in

the

needle

and

on

the

bobbin,

there

is

no

need

to

adjust

the

bobbin

thread

tension.

This

tension

is

set

correctly

if

a

slight

re

sistance

has

to

be

overcome

when

pulling

the

thread.

Numbers

0

to

10

indicate

different

degrees

of

tension

on

the

upper

tension

dial.

The

higher

the

number,

the

tighter

the

tension.

For

ordinary

sewing

operations,

the

upper

tension

should

be

set

at

about

5.

bottom

top

Upper

tension

too

tight

or

lower

tension

too

loose.

bottom

top

16

Upper

tension

too

loose

or

lower

tension

too

tight.

bottom

top

Both

tensions

correctly

balanced.

Page 19

The

accessory

box

which

belongs

to

your

machine

contains

several

sewing

feet

for

special

sewing

operations.

To

change

the

sewing

foot,

bring

the

needle

to

its

highest

point

and

raise

the

foot.

Turn

out

screw

16

until

the

sewing

foot

can

be

removed,

tilt

ing

it

sideways

(see

ill.).

The

new

foot

is

attached

in

the

reverse

order.

To

change

the

needle,

bring

the

needle

bar

to

its

highest

point

and

tower

the

sewing

foot.

Loosen

needle

set

screw

22

and

pull

the

old

needle

out

of

the

needle

clamp.

Insert

the

needle

and

push

it

up

as

far

as

it

will

go,

making

sure

that

the

flat

side

of

its

shank

faces

toward

the

back.

Tighten

screw

22

securely.

Use

System

130

R

needles

for

ordinary

fabrics

Consult

the

Needle

and

Thread

Chart

on

the

front

inside

cover.

17

Page 20

Darning

To

prepare

your

machine

for

darning,

pro

ceed

as

follows:

Replace

the

ordinary

sewing

foot

by

darn

ing

foot

No.

91-102826-91,

attaching

it

from

the

rear

so

that

spring

clip

c

rests

on

needle

set

screw

(22).

Tighten

sewing

foot

thumb

screw

(16).

Lower

the

presser

bar

lifter.

Now

drop

the

machine

feed.

On

the

Pfaff

76,

this

is

done

by

removing

bed

cover

(13)

and

pressing

the

drop

feed

lever

down

slant-

wise,

as

indicated

by

the

white

arrow.

To

raise

the

machine

feed,

press

this

lever

down

and

let

it

return

to

its

original

position.

On

the

Pfafl

77,

the

machine

feed

is

dropped

by

simply

turning

the

thumb

screw

on

the

underside

of

the

free

arm.

To

raise

the

ma

chine

feed

again,

turn

this

screw

in

the

op

posite

direction.

F

4

11

18

Page 21

Darning

sheer

and

soft

materials

is

greatly

facilitated

by

placing

them

in

darning

hoops.

Draw

up

the

bobbin

thread

and

hold

both

threads

lightly

with

your

left

hand

while

the

first

stitches

are

being

made.

Trim

the

threads

and

start

stitching

back

and

forth

across

the

hole

in

sewing

direction.

Make

sure

the

threads

are

anchored

in

the

unworn

area

around

the

hole.

Turn

the

fabric

at

right

angles

and

sew

back

and

forth

over

the

preceding

work

with

short

stitches.

Select

the

darning

hoops

in

a

size

matching

the

darning

job

to

be

performed.

If

the

needle

thread

should

break,

the

upper

tension

is

too

tight.

19

Page 22

Zipper

Insertion

Attach

zipper

foot

without

quilting

gauge.

Stitch

length:

1.5

to

2.

Central

needle

position.

84

Baste

closed

zipper

on

the

fabric,

then

open

it.

Stitch

close

to

the

left

edge

of

the

zipper

for

about

1

inch,

guiding

the

right

edge

of

the

foot

along

the

zipper

teeth

(1).

Leave

the

needle

in

the

material,

raise

the

zipper

foot

and

close

the

zipper

(2).

Continue

stitching

until

you

reach

the

end

of

the

zipper.

Then

stitch

across

this

end

(3)

and

up

to

the

other

side.

The

finished

zipper

closure

is

shown

in

Fig.

4.

20

Page 23

Flat

Felled

Seams

Attach

flat

feller

No.

93-847561-00.

Stitch

length:

1.5

to

2.

Flat

felled

seams

are

used

to

durably

join

two

pieces

of

fabric

and

are

usually

straight-stitched.

First

Seam:

Lay

pieces

together

with

the

right

sides

facing

and

the

bottom

piece

protruding

about

1/8

inch.

Make

sure

the

fabric

enters

the

flat

feller

evenly

and

the

bottom

fabric

is

folded

over

the

edge

of

the

top

piece

(see

ill.),

but

the

top

piece

is

not

folded.

Open

the

two

pieces.

Second

Seam:

Lightly

tension

the

fabric

by

pressing

it

against

the

needle

plate

in

front

of

the

foot.

Insert

the

seam

ridge

into

the

felling

foot

and

stitch

down

(see

ill,

at

right).

847

561

8

Use

zipper

foot

No.

93-847

600-00

with

quilting

gauge

for

sewing

parallel

seams

over

the

entire

surface

of

the

fabric.

Quilting

21

Page 24

Hemming

Stitch

length:

1.5

to

2

847

551

Fold

the

beginning

of

the

fabric

edge

twice,

making

a

hem

about

1

/s

inch

wide

and

several

inches

long.

Place

the

material

under

the

hemmer

foot

and

lower

the

same.

Make

3

to

4

straight

stitches

to

secure

the

folded

edge

in

place.

Draw

the

fabric

into

the

hemmer

by

pulling

both

threads

backwards,

as

shown

in

the

drawing.

Feed

the

fabric

edge

into

the

hemmer

foot

scroll

with

your

right

hand

(see

ill.),

making

sure

that

the

scroll

is

well

filled

with

fabric

at

all

times

and

the

fabric

does

not

slip

side

ways

under

the

right

half

of

the

foot.

To

produce

an

elastic

hem

on

soft

fabrics,

use

zigzag

stitches.

Set

the

stitch

width,

as

instructed

on

p.

25.

22

Page 25

Cording

Use

ordinary

sewing

foot

No.

93-838

954-00,

and

insert

a

twin

needle

(which

can

be

ob

tained

from

your

Pfaff

dealer).

Stitch

length:

1.5

to

2.

Cording

is

made

with

two

needle

threads.

When

threading

the

needles,

make

sure

to

lead

each

thread

between

a

separate

pair

of

tension

discs

(see

ill.).

To

render

your

cording

more

prominent,

in

sert

a

filler

cord.

Select

the

twin

needle

gauge

and

the

size

of

the

filler

cord

to

suit

the

type

of

material

used.

The

thicker

the

fabric

the

wider

the

needle

gauge.

Lace

the

filler

cord

through

hole

g,

as

illus

trated.

Hold

both

needle

threads

lightly

and

rotate

the

balance

wheel

to

draw

up

the

bobbin

thread.

The

smallest

distance

between

cording

seams

made

with

the

ordinary

sewing

foot

is

approx.

1/4

inch.

For

narrower

cording,

use

one

of

the

cording

feet

listed

below.

To

make

different

size

cording,

the

follow

ing

twin

needles

and

cording

feet

can

be

supplied

at

extra

cost:

Twin

needles

for

needle

distances

of

1.2

(/e4”),

1.6

(Vie”),

18,

2.0

(5/e4),

2.5

(/32”),

3.0

and

4.0

(/32”)

mm.

Cording

foot

No.

93-847

671-00,

with

3

grooves

is

used

for

heavy

materials,

cording

foot

No.

93-847

675-00

with

5

grooves

for

medium-heavy

fabrics,

and

cording

foot

No.

93-847

680-00

with

7

grooves

for

lightweight

materials.

Ptaff

77

Pfaff

76

23

Page 26

Use

a

thread

which

is

not

too

heavy

and

matches

the

material

being

hemstitched

(preferably

a

No.

50

embroidery

thread).

Insert

a

System

130

Twin

hemstitch

needle.

Make

sure

the

needle

and

bobbin

threads

are

the

same

size.

The

threading

procedure

is

the

same

as

for

cording

work.

Slightly

in

crease

the

needle

thread

tension.

The

hemstitching

effect

is

produced

by

the

left

wing

needle

penetrating

the

fabric.

Turn

the

fabric

by

half

a

turn

and

sew

the

second

seam,

guiding

the

material

so

that

the

wing

needle

enters

the

needle

holes

it

has

made

in

the

fabric

previously.

You

can

produce

a

nice

hemstitching

effect

along

the

hemmed

edge

of

the

fabric

by

guiding

the

material

so

that

the

right

needle

stitches

into

the

fabric

close

to

the

hem.

Hemstitching

Stitch

length:

2

to

2.5

-lOOI79

IV”

I.

24

Page 27

The

stitch

length

is

regulated

by

turning

stitch

length

control

(11)

(see

ill.).

The

larger

the

number,

the

longer

the

stitch.

The

Zigzag

Seam

The

stitch

width

is

regulated

by

pushing

stitch

width

control

(18)

toward

the

left,

as

may

be

desired.

Never

change

the

stitch

width

setting

unless

the

needle

is

outside

the

fabric.

18

25

Page 28

Overcasting

Edges

with

Zigzag

Stitches

Attach

ordinary

sewing

foot.

Stitch

length:

2.

838

954

u

To

overcast

the

edges

of

light

and

medium-

weight

fabrics,

set

the

machine

for

its

maxi

mum

stitch

width.

Soft

and

flimsy

fabrics

are

best

overcast

with

a

zigzag

stitch

of

medium

width.

Make

sure

the

needle

takes

one

stitch

into

the

fabric

and

the

other

over

its

edge.

This

will

cover

the

fabric

edge

securely.

26

Page 29

Inserting

Patches

Set

the

stitch

length

control

on

“1”

and

the

stitch

width

control

in

the

middle

of

its

slot

and

stitch

along

the

edge

of

the

patch.

Set

the

stitch

length

control

on

“O5”

and

the

stitch

width

control

at

the

extreme

left

of

its

slot

and

sew

over

first

seam.

At

the

corners,

stop

the

machine

with

the

needle

down

in

the

material

on

the

right

of

its

throw.

Then

turn

the

fabric

so

that

the

corners

are

stitched

twice

(see

ill.).

Trim

away

the

excess

material

on

the

wrong

side.

Elastic

materials

are

patched

in

the

same

manner.

Stitch

width:

medium.

838

954

Larger

holes

can

be

patched

quickly.

Trim

away

the

ragged

edges

around

the

hole,

cutting

exactly

along

the

fabric

weave.

Cut

a

patch

about

/2

inch

larger

than

the

hole

and

place

it

under

the

hole,

matching

its

grain

to

that

of

the

fabric.

27

Page 30

Inserting

Lace

Stitch

length:

1

838

954

u

Place

the

lace

on

the

material

and

stitch

it

down

with

straight

stitches

on

both

sides

(1).

Cut

the

fabric

open

under

the

lace

insertion

(2)

and

iron

it

on

both

sides

of

the

lace.

Sew

over

the

edges

of

the

lace

with

short

zigzag

stitches

of

medium

width

(3).

Trim

the

fabric

edges

away

on

the

wrong

side

(4).

28

Page 31

4-

()

3r

C’D

Changing

the

Needle

Position

Some

special

sewing

jobs

are

made

with

the

needle

switched

to

the

right

or

left

of

the

needle

plate

slot.

This

is

done

by

moving

lever

(19)

to

the

right

and

left,

respectively.

The

needle

position

lever

is

indispensable

for

sewing

buttonholes.

Lever

at

left

center

right

C)

29

Page 32

Sewing

Buttonholes

Attach

buttonhole

foot

No.

847616

to

the

machine

and

set

the

slide

on

the

buttonhole

gauge

to

the

buttonhole

length

desired.

The

number

indicating

the

buttonhole

length

should

be

in

line

with

the

right

edge

of

the

slide.

The

buttonhole

is

the

right

length

when

the

beginning

of

the

first

seam

reaches

the

red

end

of

the

slide

indicator

(see

arrow).

Flick

the

needle

to

its

left

position

and

put

the

stitch

width

control

in

notch

R

1

(see

ill).

When

using

No.

50

embroidery

thread,

set

the

stitch

length

control

so

that

both

dots

are

opposite

each

other

(see

ill.).

For

heavier

threads,

slightly

increase

the

stitch

length.

To

obtain

more

prominent

buttonholes,

place

a

filler

cord

of

medium

size

in

the

left

groove

of

the

sewing

foot.

All-purpose

sewing

foot

No.

91-100

179-00

may

also

be

used

for

this

operation.

1

2

I

30

3

Page 33

Sew

the

first

seam

over

the

filler

cord.

When

the

buttonhole

is

the

right

length,

leave

the

needle

in

the

fabric

on

the

right

of

its

throw.

Lift

the

sewing

foot,

turn

the

fabric

around

clockwise

by

half

a

turn,

place

the

filler

cord

aroL.!nd

the

needle

and

pull

it

forward,

placing

it

in

the

left

groove

of

the

foo.

Lower

the

foot

and

take

one

stitch

by

hand.

Move

stitch

width

control

(18)

to

the

second

notch,

R

2,

make

4

or

6

bartack

stitches,

slightly

holding

the

material

to

reduce

the

length

of

bar.

Push

stitch

width

control

(18)

back

to

the

first

notch

R

1

and

sew

the

second

button

hole

seam,

stopping

about

/io

inch

from

the

end

of

the

first

seam.

Slightly

pull

the

filler

cord

and

trim

it

close

to

the

bar

(5).

Push

stitch

width

control

(18)

to

the

second

notch

R

2

and

sew

the

second

tack,

slightly

holding

the

material

to

reduce

the

length

of

bar.

Flick

the

stitch

width

control

all

the

way

to

the

right

and

make

3

to4fastening

stit

ches.

Open

the

buttonhole

with

your

seam

ripper

which

is

included

in

the

accessory

box.

31

Page 34

Monogram

Embroidery

Regulate

the

stitch

width

to

suit

the

size

of

the

monogram.

Remove

the

sewing

foot

and

drop

the

ma

chine

feed.

Lower

the

presser

bar

lifter.

Trace

the

monogram

on

the

fabric

and

place

the

material

in

darning

hoops.

Let

the

needle

stitch

into

the

fabric

at

the

beginning

of

the

design

and

draw

the

bob

bin

thread

up

through

the

fabric.

Hold

both

thread

ends

and

start

your

machine.

Slowly

move

the

hoops

in

“writing’

direc

tion,

without

turning

them,

while

the

ma

chine

is

running

at

high

speed.

To

give

your

monogram

dimensional

quality,

embroider

the

outlines

twice.

93100179

Button

Sewing

Flick

the

needle

to

its

right

position

and

drop

the

machine

feed.

Place

the

button

under

the

foot

and

align

so

hat

needle

will

enter

the

right

hole

(see

ill.).

Raise

the

needle,

but

retain

the

foot

in

its

lowered

position.

Regulate

the

stitch

width

until

the

needle

alternately

stitches

through

both

holes.

Sew

on

the

button.

Move

the

stitch

width

control

toward

the

right

and

make

two

or

three

tying

stitches.

-

I:

32

Page 35

Fold

the

hem

(2)

and

place

the

fabric

under

the

sewing

foot

so

that

the

folded

edge

is

in

line

with

the

left

groove

of

the

foot

(see

ill.).

Regulate

the

stitch

width

so

that

the

needle

takes

the

left

stitch

exactly

in

the

folded

edge,

catching

merely

one

fabric

yarn

(see

ill.).

1=71

°°

Baste

the

hem

or

pin

it

about

/16

inch

from

the

fabric

edge,

as

illustrated

(1).

Then

flick

the

needle

to

its

right

position

and

set

the

stitch

length

control

at

“4”.

Reduce

the

needle

thread

tension

by

one

grade.

Bindstitching

Apply

clear-view

sewing

foot

No,

91-100

179-00.

Please

note:

Fold

the

hem

of

heavy

woolens

only

once

(3)

and

finish

the

raw

edge

with

zigzag

stitches

before

it

is

hemmed.

Fold

3

33

Page 36

Ornamental

Sewing

You

can

make

exciting

fashion-stitch

designs

by

varying

stitch

length,

stitch

width

and

needle

position.

Some

of

the

designs

you

can

make

are

illustrated

on

this

page.

Additional

ornamental

efFects

are

obtained

by

sewing

over

a

filler

cord.

Sewing

Curtains

Stitch

length:

2.5to3

Stitch

width:

medium

—

838

954

93-OU’7

Use

a

thin

Chart)

needle

(see

Needle

and

Thread

Ease

the

needle

thread

tension

somewhat.

Hold

synthetic

materials

a

little

taut

while

sewing.

34

I

I

I

I

Page 37

To

make

appliqué,

proceed

as

follows:

1.

Trace

the

design

on

the

right

side.

2.

Set

the

stitch

length

control

on

“1’

and

stitch

along

the

outlines.

3.

Sew

the

fabric

to

be

appliquéd

to

the

right

side

with

long

stitches

(1).

4.

Follow

the

outlines

of

the

design

on

the

wrong

side

with

a

narrow

zigzag

stitch

(stitch

length

control

on

“1’),

as

shown

(2).

5.

Trim

the

excess

material

close

to

the

seam

on

the

right

side

(3).

6.

Sew

over

the

edges

of

the

appliqué

with

closely

packed

zigzag

stitches

(stitch

length:

0.2;

stitch

width:

medium),

as

il

lustrated

(4).

Appliqué

work

—-

3.G79

1

lb

3

4

35

Page 38

To

change

the

light

bulb,

remove

the

face

cover

by

pulling

it

in

the

direction

indicated

by

the

arrow.

Push

the

light

bulb

into

its

socket,

turn

left

and

pull

out.

Insert

the

new

bulb

so

that

its

pins

slide

into

the

socket

slots.

Press

the

bulb

in

and

turn

right.

As

you

replace

the

face

cover,

slip

tip

d

into

slot

c,

then

push

against

the

face

cover

until

it

snaps

into

place.

36

Page 39

Machine

Care

Longevity

and

smooth

machine

performance

are

dependent

on

regular

cleaning

and

prop

er

oiling.

Since

your

Pfaff

sewing

machine

has

been

made

from

high-grade

materials,

there

are

only

a

few

oiling

points

left.

The

raceway

in

the

sewing

hook

is

the

most

important

oiling

point.

From

time

to

time,

put

a

drop

of

oil

into

the

hook

raceway

(see

ill,

at

left

and

center).

Do

not

oil

the

bobbin

winder.

The

other

oiling

points

in

the

machine

are

illustrated

below.

(Remove

the

face

cover

as

instructed

on

p.

36).

37

Page 40

r

•

From

time

to

time,

clean

the

parts

in

the

machine

arm

and

in

the

vicinity

of

the

sew-

•

ing

hook

with

a

soft

brush.

To

this

end,

remove

the

needle,

the

sewing

foot

and

the

bobbin

case

with

the

bobbin.

On

Plaff

77

machines,

loosen

the

set

screw,

lift

the

front

of

the

free

arm

cover

and

pull

the

cover

out

lengthwise

of

the

arm

(1

&2).

Pfaff

76

machines

are

tilted

back.

On

port

able

machines,

loosen

the

screw

on

the

bot

tom

of

the

machine

base

and

tilt

the

machine

back

cautiously

(3).

2

38

3

Page 41

Trouble

Shooting

When

operated

properly,

your

sewing

ma

chine

will

hardly

develop

any

trouble.

Please

remember

to

restore

the

normal

set

ting

after

you

have

completed

your

sewing

job

(buttonhole

sewing

or

darning,

for

in

stance)

by

switching

the

machine

back

to

straight

stitching,

flicking

the

needle

posi

tion

lever

to

its

central

position,

raising

the

machine

feed

and

setting

the

stitch

length

control

on

“2.

If

trouble

should

occur,

check

the

foIIowing

•

The

needle

must

not

be

damaged

and

must

be

inserted

correctly.

•

Selectthe

correct

needle

and

thread

from

the

Needle

and

Thread

Chart.

•

Check

whether

the

needle

has

been

threaded

correctly.

•

Use

only

high-grade

machine

thread

or

sewing

silk.

•

Check

to

see

that

the

bobbin

case

has

been

inserted

correctly.

•

Both

tensions

must

be

balanced

correctly.

•.

Don’t

force

the

feeding

motion,

merely

guide

the

material

lightly.

•

Clean

and

oil

the

machine

as

instructed.

•

Make

sure

there

are

no

pieces

of

thread

wedged

between

the

tension

discs.

To

remove

them,

pull

a

narrow

fabric

strip

between

the

tension

discs.

•

The

Pfaff

rotary

hook

will

not

normally

jam,

even

if

the

machine

should

be

handled

improperly.

If

thread

should

happen

to

jam

in

the

hook

raceway,

It

is

sufficient

to

put

a

drop

of

oil

into

the

raceway,

jerk

the

balance

wheel

back

and

then

rock

it

back

and

forth,

without

applying

force.

39

Page 42

Page

Appliqué

Work

35

Blindstitching

33

Buttonholes

30

Button

Sewing

32

Changing

the

Light

Bulb

36

Changing

the

Needle

17

Changing

the

Needle

Position

29

Changing

the

Sewing

Foot

17

Cleaning

37

Cording

23

Darning

18

Darning

Foot

18

Drawing

Up

the

Bobbin

Thread

.

.

12

Dropping

the

Machine

Feed

.

.

.

18

Electrical

Equipment

4

Engaging

and

Disengaging

the

Sewing

Mechanism

7

Essential

Parts

of

Pfaff

76

2

Essential

Parts

of

Pfaff

77

3

Flat

Felled

Seams

21

Foot

Control

4

Foreword

1

Fundamentals

of

Machine

Operation

13

Hemming

22

Hemstitching

24

Inserting

a

Full

Bobbin

8

Inserting

Lace

Inserting

Patches

Inserting

the

Bobbin

Case

.

Machine

Care

Monogram

Embroidery

.

Motor

Disengaging

Mechanism

Ornamental

Sewing

Overcasting

Edges

Preface

Quilting

Raising

and

Lowering

the

Sewing

Regulating

the

Stitch

Length

Regulating

the

Thread

Tension

Removing

the

Bobbin

Case

.

Removing

the

Face

Cover

.

Reverse

Sewing

Sewing

Curtains

Straight

Stitching

Trouble

Shooting

Upper

Threading

Winding

the

Bobbin

Workplate

of

Pfaff

76

Workplate

of

Pfaff

77

Zigzag

Stitching

Zipper

Insertion

Page

28

27

9

.37

32

5

34

26

21

12

14

16

6

36

15

34

14

39

11

7

10

10

25

20

Contents

I;

I-

Foot

40

Page 43

CPFAFFD®

No.

20886

engl.

(US.)

HR

469

Printed

in

Germany

*

.

*.

Loading...

Loading...