Page 1

Page 2

\

PFAFF

71

INSTRUCTIONS

Foreword

Your

dream

has

come

machine

jobs

This

number

have

Follow

pleasure.

If

you

to

help

which

that

may

instruction

of

important

forgotten

these

have

you

at

will

come

book

some

simple

any

any

enable

up

sewing

sewing

time.

true.

in

will

details.

instructions

problems,

you

a

help

You

home.

jobs.

to

you

Keep

are

now

master

understand

and

sewing

please

it

the

all

handy

contact

proud

ordinary

the

as

with

owner

sewing,

machine

a

reference

your

your

and

Plaff

Pfaff

G.M.PFAFF

Karisruhe-Durlach

Western

of

a

Pfaff

embroidering

familiarize

book

in

will

become

dealer.

Germany

71,

case

He

AG

Branch

will

and

you

you

the

a

be

sewing

darning

with

should

lasting

glad

a

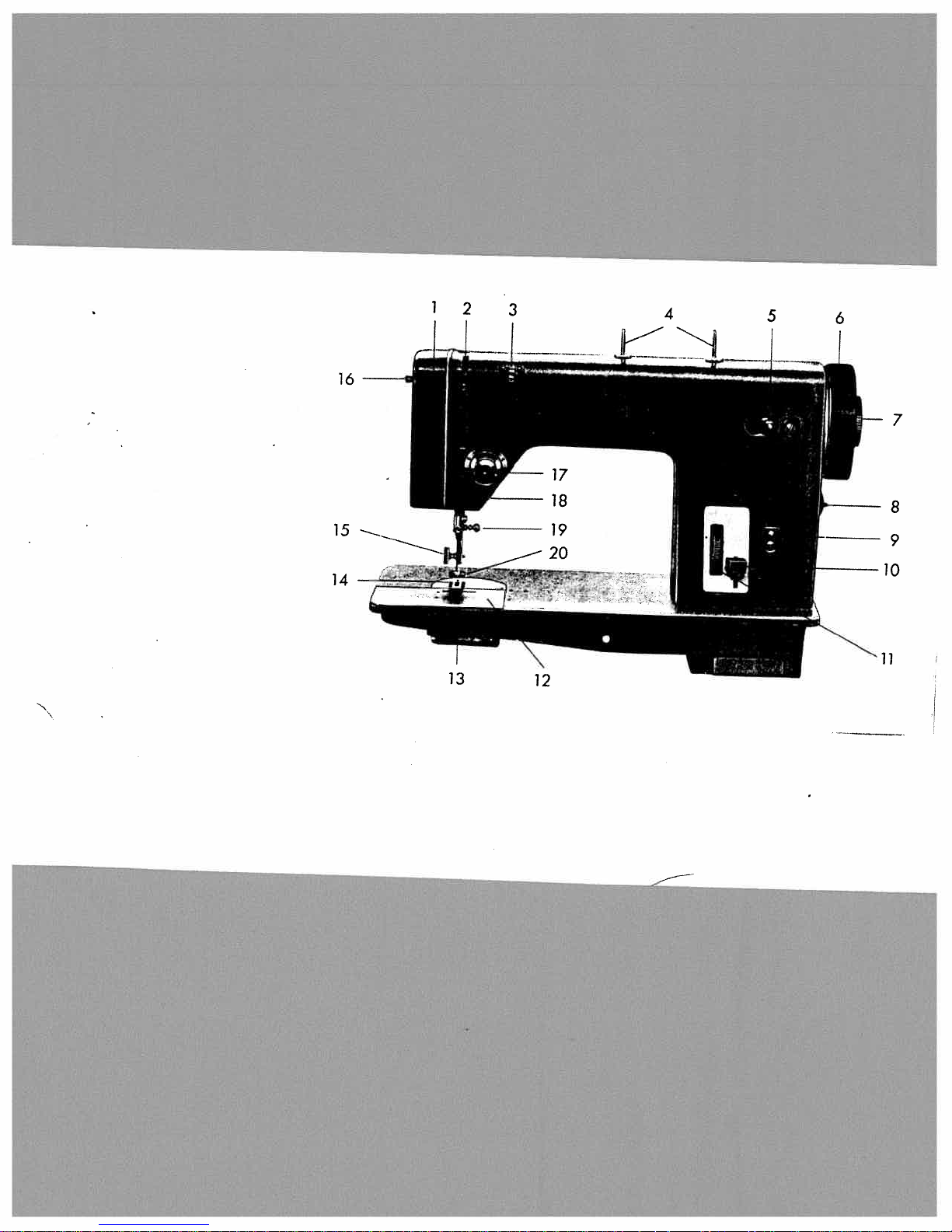

Page 3

Page 4

1.

2.

3.

4

5.

&

7.

8.

9,

10.

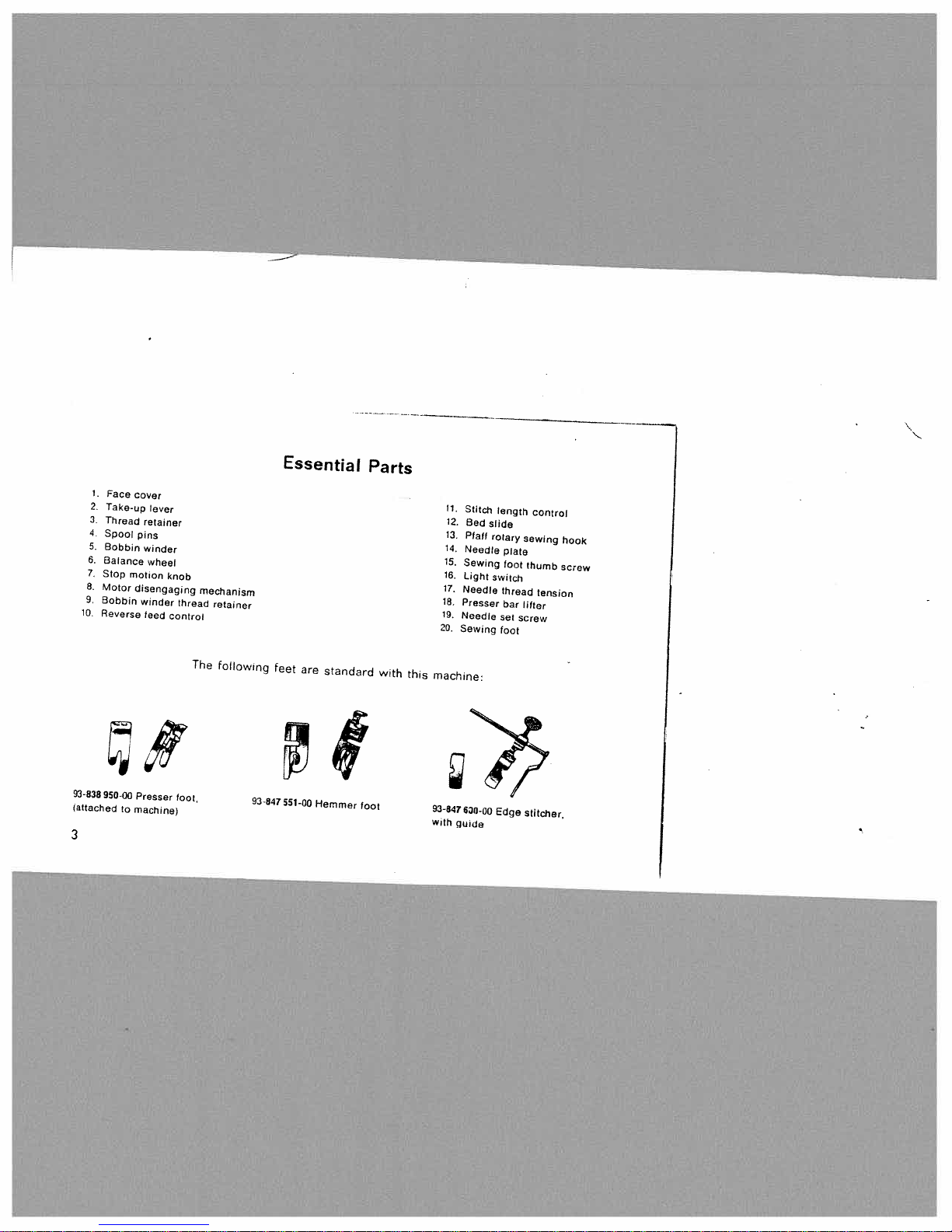

93-838

(attached

3

Face

Take-up

Thread

Spool

Bobbrn

Balance

Stop

Motor

Bobbin

Reverse

950-00

cover

pins

motion

disengaging

winder

Presser

to

machine)

lever

retainer

winder

wheel

feed

knob

thread

control

loot,

mechanism

retainer

The

fo(Iowing

93-847551-00

Essential

feet

are

Hemmer

standard

Parts

foot

with

this

Ii.

Stitch

12.

Bed

13.

PlaIt

14.

Needle

15.

Sewing

18.

Light

17.

Needle

18.

Presser

19.

Needle

20.

Sewing

machine:

93-847630-on

with

guide

slide

rotary

switch

Edge

length

plate

toot

thread

bar

set

foot

sewing

thumb

lifter

screw

Stitcher,

control

hook

screw

tension

Page 5

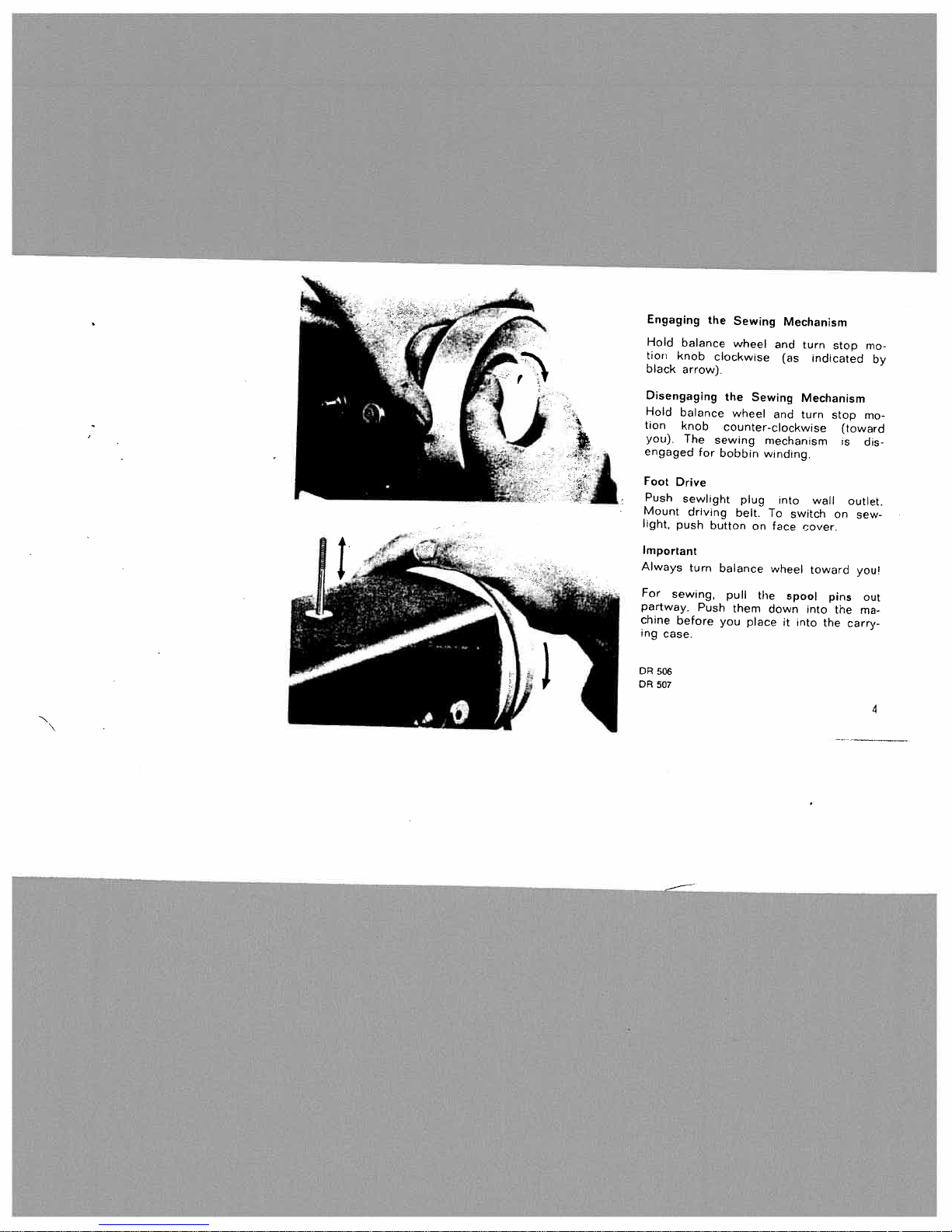

Engaging

Hold

tion

knob

black

Disengaging

Hold

balance

tion

you).

engaged

Foot

Drive

Push

Mount

light,

push

Important

Always

For

sewing,

partway.

chine

before

ing

case.

DR

506

DR

507

the

balance

arrow).

knob

The

for

sewlight

driving

turn

Push

clockwise

sewing

button

Sewing

wheel

Mechanism

and

(as

the

Sewing

wheel

plug

belt.

them

mechanism

winding.

To

on

the

down

place

and

into

switch

face

wheel

spool

it

counter-clockwise

bobbin

balance

pull

you

turn

stop

indicated

Mechanism

turn

stop

wall

on

cover.

toward

pins

into

the

into

the

mo

mo

(toward

is

dis

outlet.

sew-

youi

out

ma

carry

by

4

Page 6

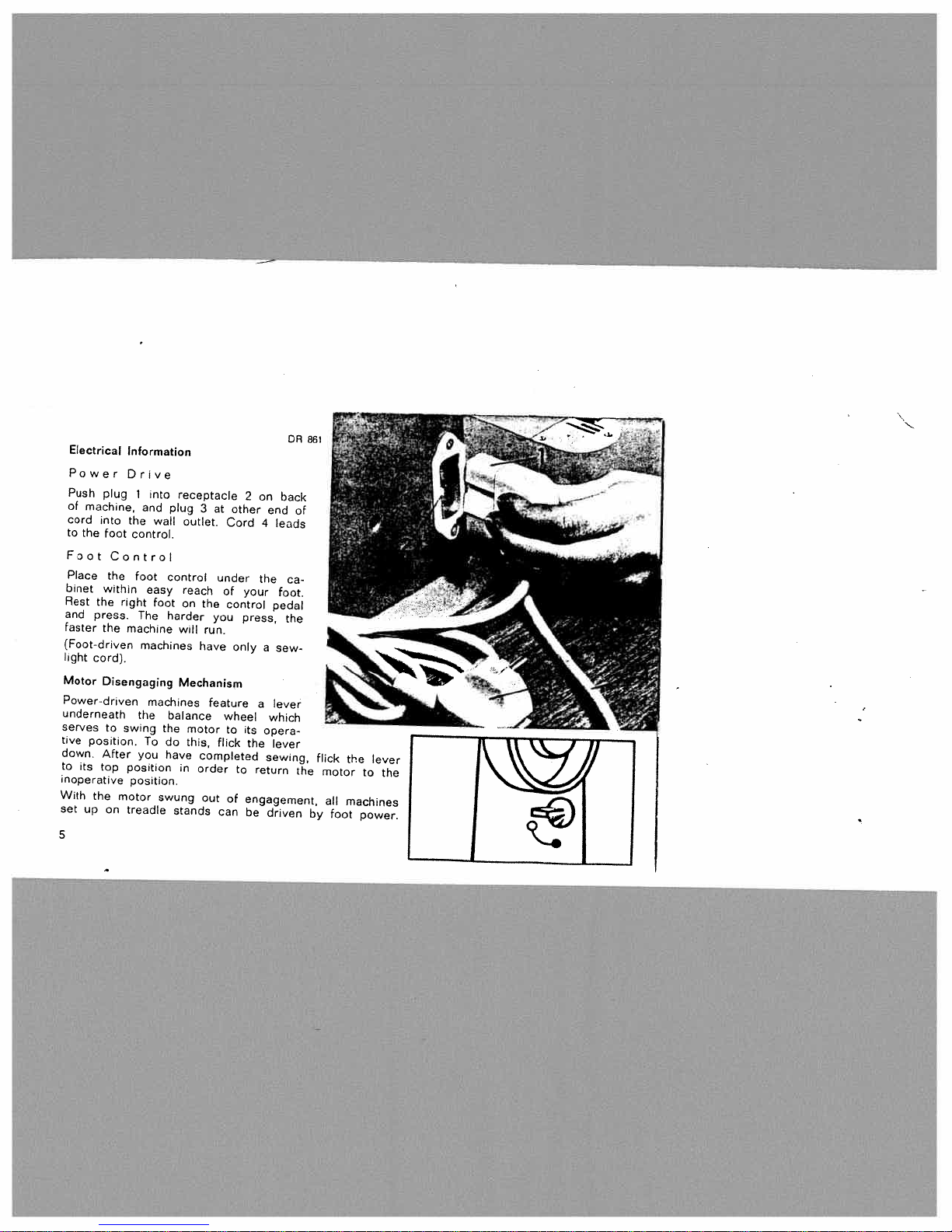

Electrical

Power

Push

plug

of

machine,

cord

into

to

the

Foot

Place

binet

within

Rest

the

and

press.

faster

the

(Foot-driven

light

cord).

Motor

Disengaging

Power-driven

underneath

serves

tive

position.

down.

After

to

its

top

inoperative

With

the

set

up

5

foot

Control

the

right

to

motor

on

swing

Information

Drive

1

into

and

plug

the

wall

control.

foot

control

easy

foot

The

harder

machine

machines

machines

the

balance

the

To

do

you

have

position

position.

swung

treadle

receptacle

3

outlet.

reach

on

the

will

run.

have

Mechanism

feature

motor

this,

completed

in

order

out

stands

at

under

of

you

wheel

flick

can

2

other

Cord

your

control

press,

only

to

its

the

to

of

engagement,

be

on

end

4

the

a

a

which

opera

sewing,

return

driven

back

leads

foot.

pedal

sew-

lever

lever

the

OFt

ca

of

the

861

by

flick

motor

all

foot

the

lever

to

machines

power.

the

Page 7

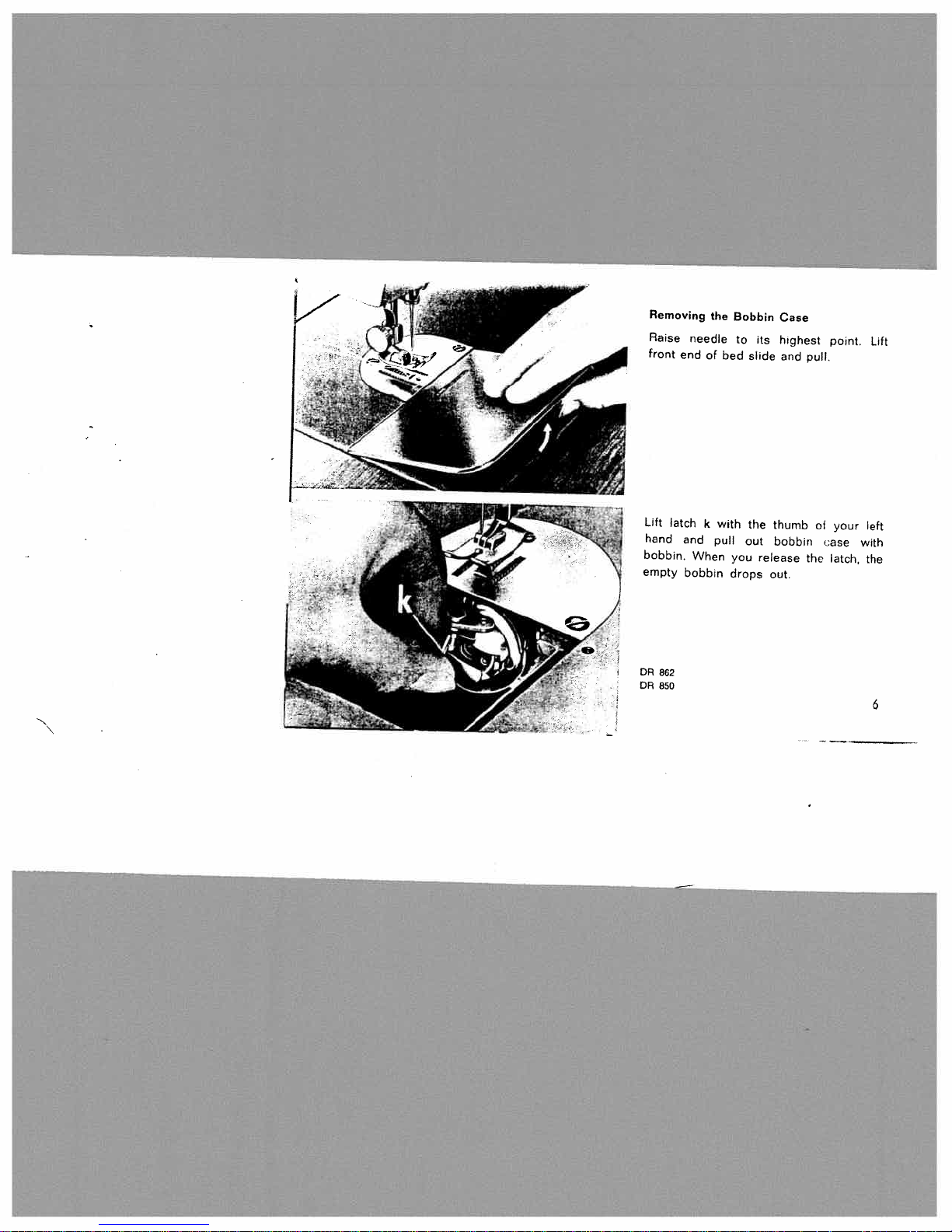

Removing

Raise

front

Lift

hand

bobbin.

empty

DR 862

DR

850

end

latch

needle

of

k

arid

When

bobbin

the

pull

bed

with

Bobbin

to

out

you

drops

its

slide

the

release

Case

highest

and

thumb

bobbin

out.

pull.

ol

the

point.

case

latch,

your

Lift

left

with

the

6

Page 8

\

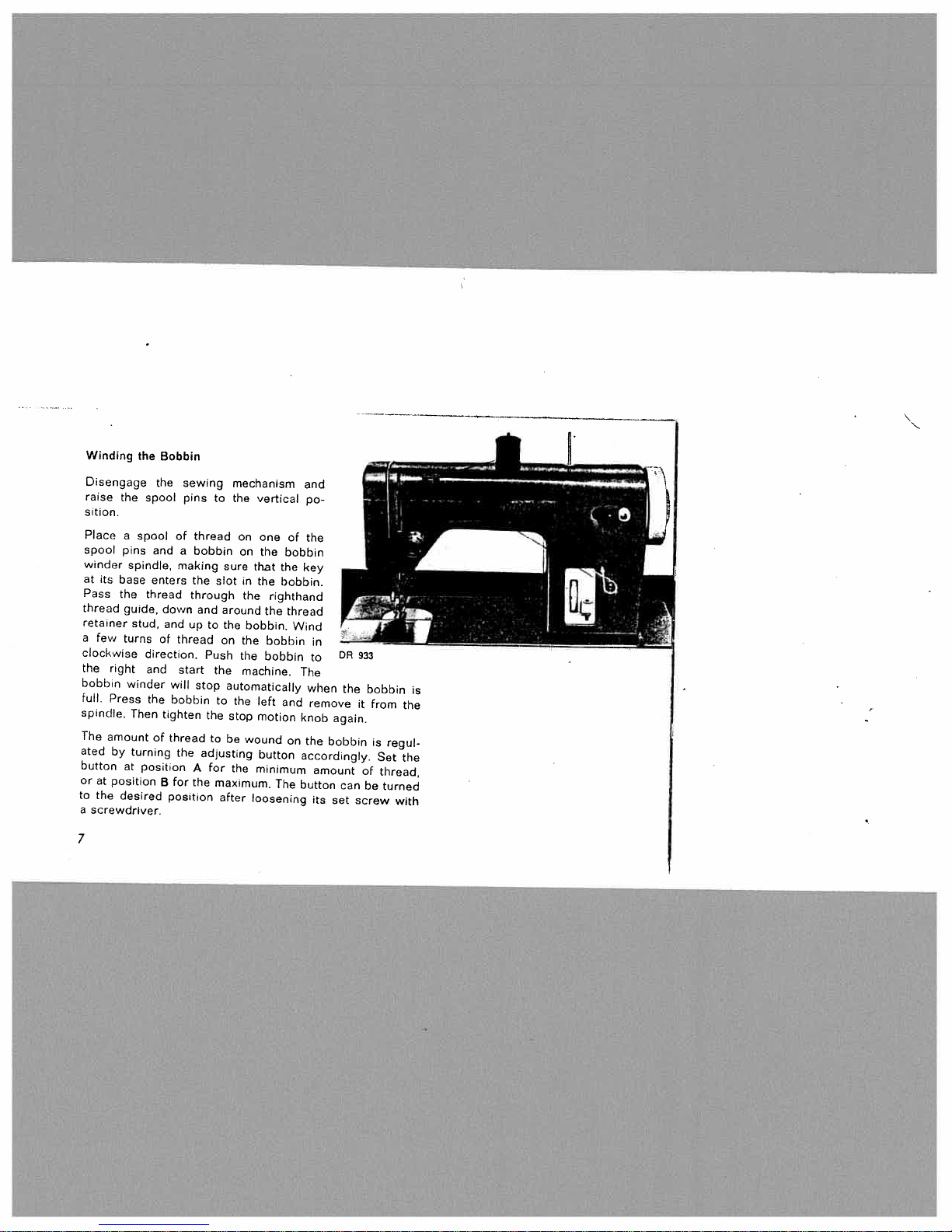

Winding

Disengage

raise

sition.

Place

spooi

winder

at

its

Pass

thread

retainer

few

a

clockwise

the

right

bobbin

full.

Press

spindle.

The

amount

ated

by

button

or

at

position

to

the

a

screwdriver.

7

the

the

a

spool

pins

spindle,

base

the

guide,

stud,

turns

winder

Then

turning

at

desired

Bobbin

the

spool

and

enters

thread

down

and

of

direction.

and

the

tighten

of

position

B

position

sewing

pins

of

a

making

up

thread

start

will

bobbin

thread

the

for

to

thread

bobbin

the

slot

through

and

to

Push

the

stop

to

the

to

adjusting

for

A

the

maximum.

mechanism

the

vertical

on

one

on

the

sure

that

in

the

the

around

the

the

bobbin.

on

the

bobbin

the

bobbin

machine.

automatically

the

left

stop

motion

be

wound

button

the

minimum

after

loosening

and

of

bobbin

the

key

bobbin.

rightharid

thread

Wind

The

and

knob

on

the

accordingly.

The

button

po

the

in

to

when

remove

amount

its

the

again.

bobbin

can

set

bobbin

it

from

of

be

screw

is

Set

thread,

turned

is

the

regul

the

with

Page 9

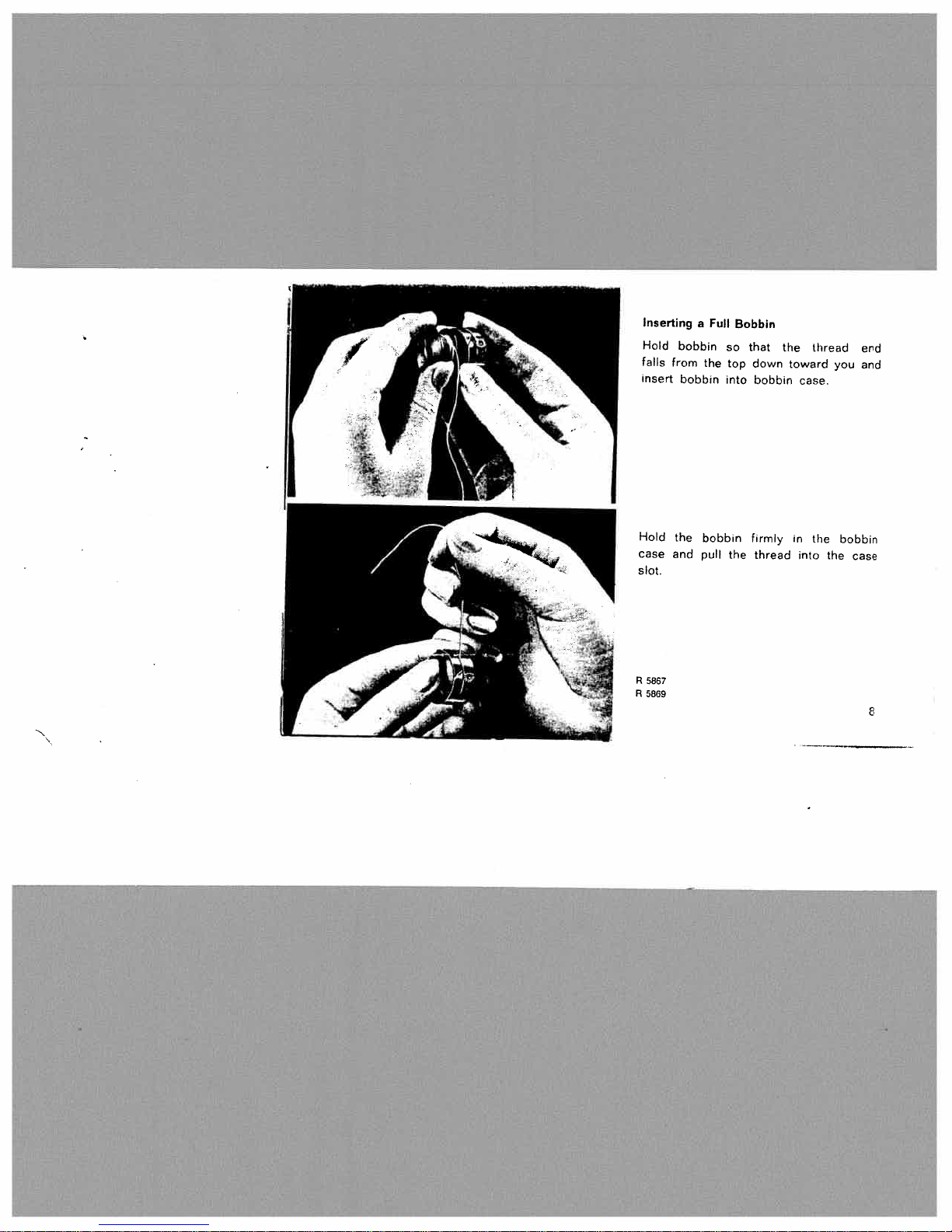

Inserting

Hold

falls

insert

Hold

case

slot.

R

5867

R

5869

bobbin

from

bobbin

the

and

a

Full

the

bobbin

pull

Bobbin

so

top

into

the

that

down

bobbin

firmly

thread

the

toward

in

case.

into

thread

the

the

you

bobbin

end

and

case

8

Page 10

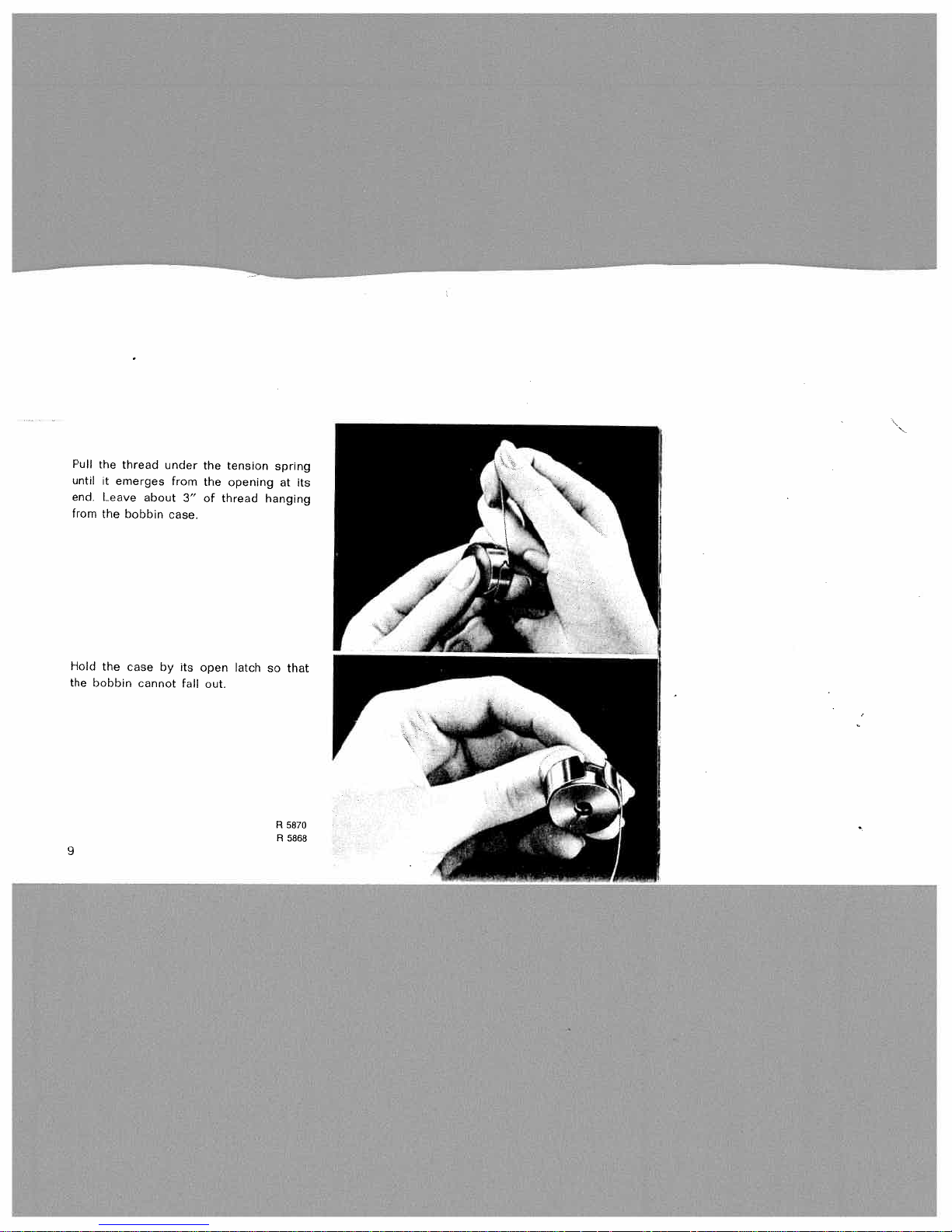

Pull

until

end.

from

Hold

the

9

the

it

Leave

the

the

bobbin

thread

emerges

about

bobbin

case

cannot

under

case.

by

from

its

fall

3” of

open

the

the

out.

tension

opening

thread

latch

spring

at

hanging

that

so

R

5870

Ft

5868

its

Page 11

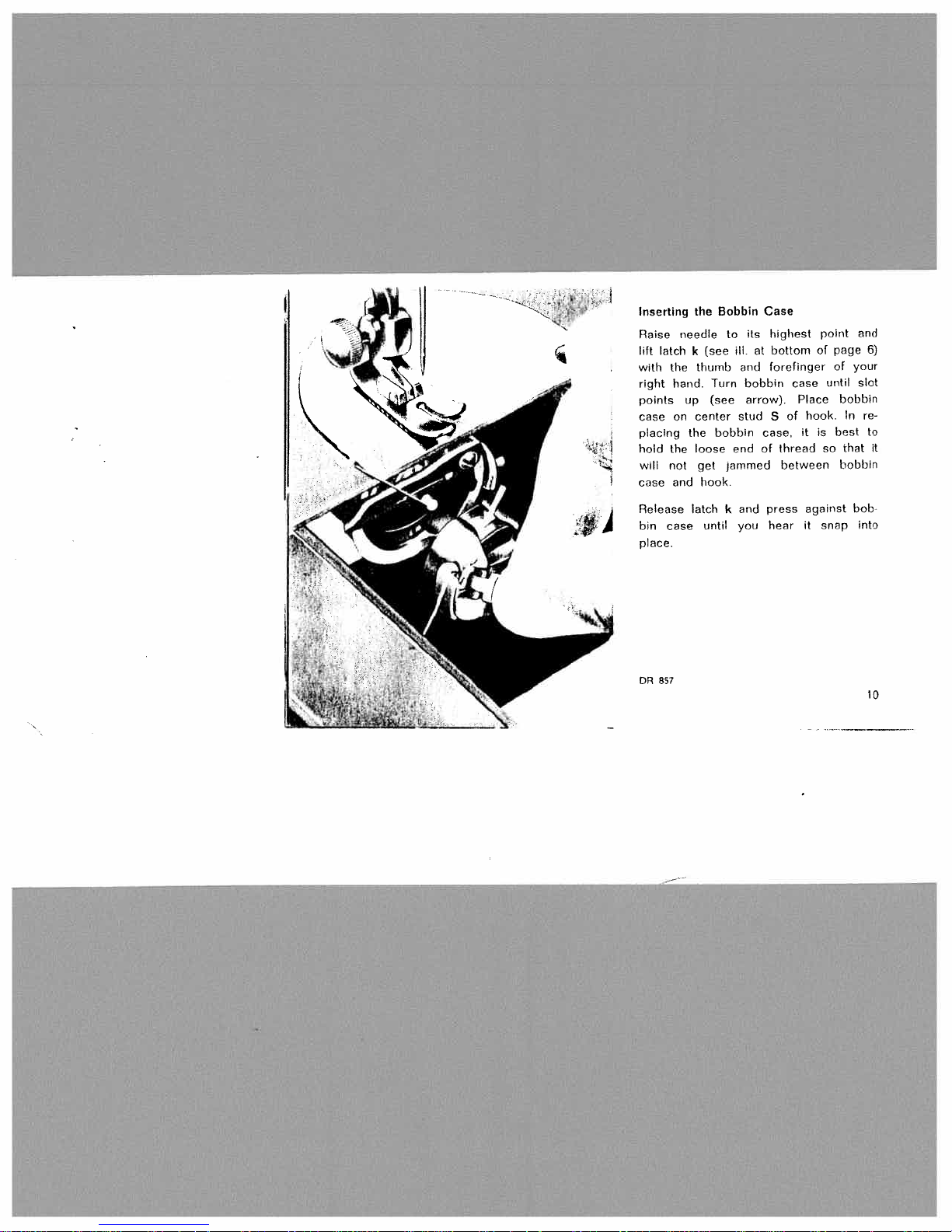

Inserting

Raise

lilt

latch

with

the

right

points

case

placing

the

hold

will

not

case

Release

bin

case

place.

857

DR

the

needle

k

thumb

hand.

up

center

on

the

loose

get

hook.

and

latchkand

(see

Turn

(see

bobbin

until

flobbin

to

ilL

and

stud

end

jammed

you

Case

its

at

bobbin

arrow).

case,

of

press

hear

highest

bottom

forefinger

case

Place

hook.Inre

of

S

it

thread

between

against

it

point

of

is

so

snap

page

of

until

best

and

your

slot

bobbin

that

bobbin

bob

into

6)

to

It

10

Page 12

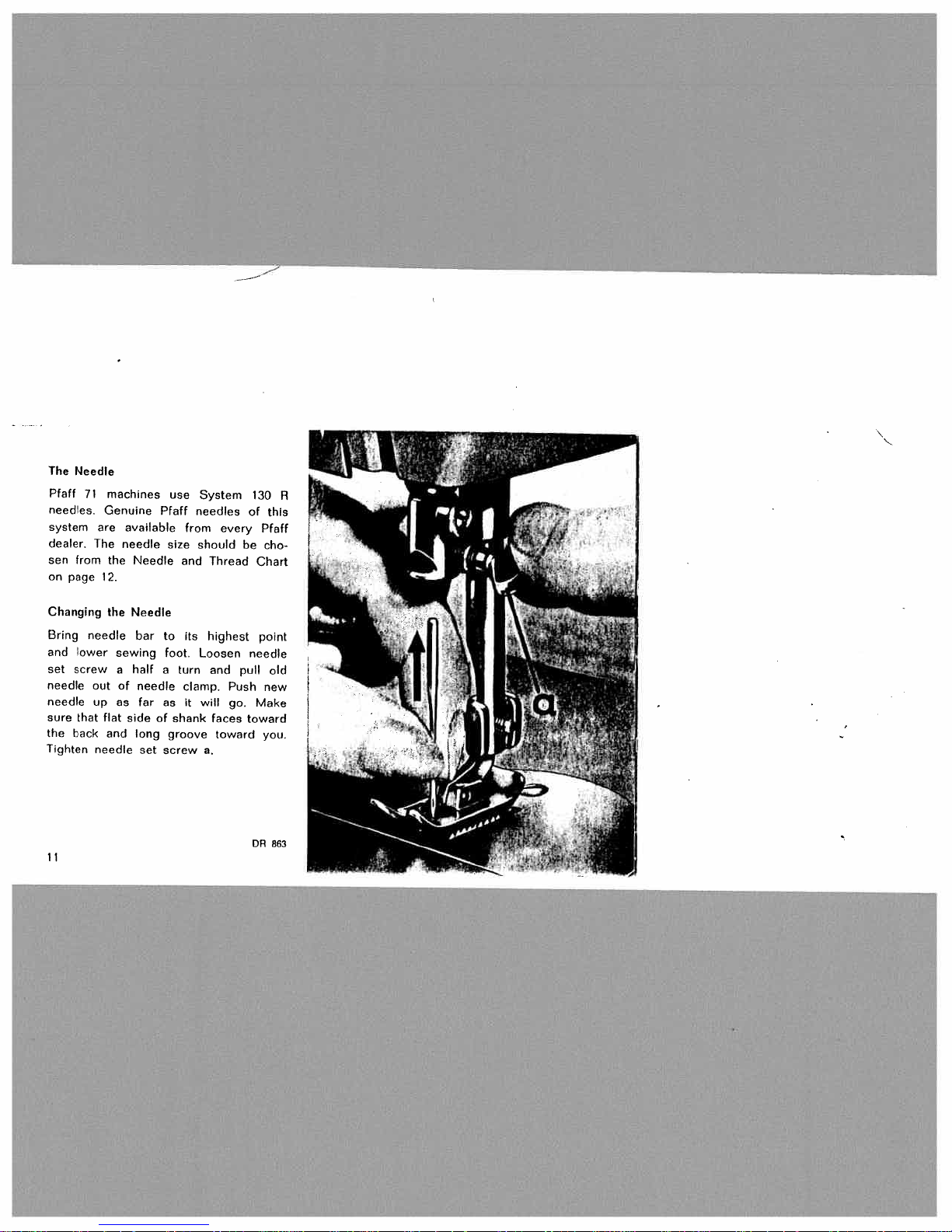

The

Needle

Pfaff

needles.

system

dealer.

from

sen

on

page

71

The

machines

Genuine

are

available

needle

the

12.

Needle

use

Plaff

size

from

and

System

needles

every

should

Thread

be

130

of

Chart

I

R

this

Pfaff

cho

Changing

Bring

and

lower

set

screw

needle

needle

sure

that

the

back

Tighten

11

needle

out

up

flat

and

needle

the

sewing

a

of

as

Needle

bar

half

needle

far

side

long

set

to

foot.

a

as

of

screw

Its

turn

clamp.

it

shank

groove

highest

Loosen

and

will

faces

toward

a.

pull

Push

go.

point

needle

new

Make

toward

you.

DR

old

863

Page 13

Size

Needle

60

or

70

80

90

100

80

to

thread

size

60

by

Determined

Chart

Thread

and

Needle

Silk

Cotton

Mercerized

Fabrics

of

Fabrics

Fine

Types

to

000

0

80

to

chiffon,

georgette,

as

such

twist

100

silk.

lawn,

voile,

batiste,

B

&

twist

A

to

70

80

cot-

shirt-

and

silks

Fabrics

woolens,

dress

sheer

as

draperies.

Lightweight

such

ing,

tons,

c

&

8

50

wool-

lightweight

Fabrics

as

Medium

such

ens,

twist

to

70

bro-

rayon,

silks,

muslin,

heavy

madras,

cades,

Fabrics

gabardine.

and

Heavy

D

&

C

to

40

fab-

denim,

slipcover

coating,

as

such

corduroy,

twist

50

light-

tickings,

canvas.

bed

rics,

weight

by

fabric

50

of

to

40

Determined

weight

Acetate

etc.

orion,

Rayon,

nylon,

plastics,

Synthetics,

including

dacron,

Page 14

Upper

Raise

spool

Place

and

lead

of

thread

thread

retainer

snaps

the

thread

Pull

the

sion

discs

it

far

into

the

spring.

against

tension.

Bring

and

go

through

thread

the

needle

dz

Threading

the

pins

spool

on

and

into

thread

to

the

slot

As

the

take-up

pass

the

down

presser

up

to

on

1

the

thread

retainer

right

the

pull

the

eyelets.

the

into

between

(see

3

right

so

and

under

youdothis,

casting

lever

the

thread

hole

and

into

front

from

bar

lifter

the

vertical

oneofthe

behind

(see

2

and

left

it

toward

It

suffices

left

eyelet.

any

ill,

at

bottom)

that

it

the

press

between

4

as

from

its

end

at

slot

back.

to

and

ill.).

slips

high

5.

spool

both

of

you

two

thread

the

spool

right

Then

swing

position.

Seize

the

to

and

properly

as

Lead

scrolls

thread

until

draw

of

check

thread

it

to

thread

the

pins

the

it

ten

jerk

and

will

left

the

13

,

Page 15

Drawing

Hold

hand.

until

again.

draw

needle

under

R

8213

needle

Turn

the

Lightly

bobbin

hole.

the

Up

balance

needle

sewing

the

thread

thread

Place

Bobbin

pull

foot.

moves

needle

both

lightly

wheel

up

Thread

in

toward

down

through

threads

your

thread

and

left

you

up

to

the

back

14

Page 16

Correct

The

both

the

brics,

prevent

15

Tension

tensions

threads

material.

set

puckering.

Regulation

are

interlock

When

both

tensionsalittle

properly

in

stitching

balanced

the

center

sheer

lighter

if

of

fa

to

Both

Upper

Upper

tensions

tension

tension

tension

tension

properly

too

too

too

too

tight or

loose

loose

tight.

balanced

lower

or

lower

Page 17

Regulating

Turn

tension

tension

left

to

The

numbers

cate

different

on

ease

the

Upper

knob

heavier

tension

on

degrees

the

Tension

right

materials.

lighter

on

tension

tension.

of

to

increase

Turn

fabrics.

dial

it

indi

Regulating

The

bobbin

ing,

except

justment

screw

Turn

left

or

DR

580

H

8029

the

Lower

Tension

special

made

bobbin

for

looser

rarely

by

case.

tighter

tension.

needs

sewing

small

a

tension

jobs.

knurled

adjust

Ad

tension

for

is

on

the

right

it

for

16

Page 18

Stitch

The

stitch

gulate

sewing

The

numbers

stitch

the

longer

trol

is

Feeding;

the

inch

length,

ed

number

slot

the

Regulation

Length

length

the

stitch

backwards.

on

length

the stitch).

on

set

maximum

mm).Toregulate

(4

turn

the

is

arrow).

(see

(the

O’,

fully

control

length

the

higher

the

stitch

control

visible

and

control

When

machine

serves

length

until

at

limit

to

indicate

the

the

the

the

to

number.

the

ceases

is6to

stitch

desir

top

it

con

re

in

the

of

Reverse

To

sew

finger-tip

control

sumes

This

feature

beginning

darning

17

Sewing

in

control

is

forward

or

rips.

reverse,

released,

sewing.

ideal

is

end

down.

for

of

simply

machine

the

backtacking

seam

a

press

When

and

OR

DR

the

the

the

for

008

009

re

Page 19

Fundamentals

•

Never

run

•

Place

both

•

Always

do

presser

creative

thumb

bring

completed

machine

is

guide

the

screw

•

With

now.

Enjoy

To

this

have

The

to

exchange

a

threaded

threads

the

will

the

foot

sewing

sewing

securely

take-up

a

feed

work.

No.

of

Machine

back

seam.

the

93-838

with

foot

again.

machine

under

lever

material

Never

95OQO

your

loosen

the

to

try

Pfaff.

Operation

unless

sewing

its

highest

under

to

hasten

attached

thumb

you

foot

the

screw

have

before

position

sewing

feeding

to

your

14

fabric

by

(page

under

you

put

before

foot

automatically.

pushing

machine,

3).

the

fabric

you

you

Make

begin

or

sewing

into

pulling

can

sure,

the

rind

All

start

you

foot.

machine.

after

you

the

sewing

tighten

you

have

fabric

18

Page 20

_‘%_

8228

R

——

Z.._,

.,

..,

Inserting

Large

square

a

down

it

edges

19

holes

(inner

(outer

Patches

can

opening

seam).

be

seam).

patched

exactly

Cut

on

into

quickly.

the

corners,

fabric

Trim

away

threads.

fold

down

ragged

Cut

raw

the

edges

patch

edges

around

slightly

and

stitch

the

larger

hole,

along

and

cutting

sew

folded

Page 21

Zipper

Attach

wrong

the

of

left

to

Use

Insertion

edge

side

fabric

edge

right

edge

stitcher

of

to

of

fabric.

overlap

zipper,

of

foot

No.

Position

the

stitch

as

93-847

zipper,

across

guide.

a

of

600-00

zipper

Turn

end

without

depends

fabric

andupthe

R

guide.

to

8226

on

right

other

Pm

whether

side.

side

or

baste

or

not

you

Flunastraight

in

one

continuous

closed

want

zipper

the

seam

operation

on

edge

close

20

Page 22

Hemming

Hemmer

dispensable

hem.

form

fabric

hemmer

raw

edge

of

hemmer

the

to

foot

facilitate

foot.

is

if

Clip

in

No.

you

Feed

foot

off

line

93-847

want

the

insertion

fabric

with

opening.

551-00

to

corner

so

the

sew

left

into

that

is

in

a

uni

the

of

the

the

edge

Avoid

ugly

ing.Todo

the

needle

foot

before

hem.

21

endsbyslowing

press

this,

plate

you

the

the

on

cometothe

fabric

left

down

feed

against

sideofthe

end

of

DR

DR

the

JL4

870

509

Page 23

Quilting

Edge

stitching

preceding

stitcher

over

seam.

No.

the

93-647

entire

Attractive

600-00

surface

tea

used

of

cosies,

the

with

fabric.

slippers,

the

quilting

Always

seat

OR

003

guide

pads

gauge

the

and

sews

gauge

covers

parallel

finger

can

be

rows

along

quilted

of

the

22

Page 24

Dropping

Remove

drop

the

arrow).

position

23

rear

feed

and

The

and

the

the

ever

up

lever

the

Machine

bed

down

(as

wilt

fabric

Feed

cover

slantwise,

indicated

be

will

and

by

retained

cease

press

then

the

feeding.

OR

white

in

855

the

this

The

machine

hoop

feed

embroidery

is

and

dropped

button

for

darning.

sewing.

to

To

raise

the

down

position.

and

machine

let

it

feed,

return

press

to

its

the

original

lever

I

Page 25

Darning

page

(See

darning.)

for

Clamp

out

following

back

machine

the

turn

back

short

with

the

in

8288

R

with

fabric

small

and

and

unworn

Darning

for

23

arid

the

forth

running

fabric

forth

stitches.

preparing

into

fabric

across

at

at

over

area

Hoops

your

darning

mediumsized

grain.

hole

the

high

angles

right

preceding

anchors

This

the

around

hoops,

First

speed.

machine

holes

stitch

with

and

threads

hole.

cut

the

Then

sew

work

24

Page 26

Darning

No.

Triangular

spots

stitches

be

ing

normal

the

operate

rhythm

25

93-839

are

darned.

foot

material

with

with

950-00

tears,

best

back

To

and

position.

the

your

Sewing

darned

and

do

set

with

reverse

forth

the

While

right

small

this,

your

Foot

by

over

needle

feed

hand.

rips

making

attach

darning,

left

the

plate

hand

control

the

or

OR

area

in

thin

close

to

sew

the

guide

and

in

559

Page 27

Cording

cord

To

needle

Twin

(3/32”),

2.5

Cording

tucks

Pin

and

a

For

see

Wider

each)

plate

needles

1.2-mm

narrow

ill.)

cording

and

on

feet

and

your

3.0,

are

a

slot.

are

and

are

made

twin

cording

1.6-mm

a

is

twin

PlaIt

available

4.0

available

with

needle.

use

made

needle

71,

(5/32”)

twin

with

use

needle

for

in

cording

cording

needle.

with

cording

a

millimeters.

varieties,

three

foot

foot

cording

needle

a

foot,

distances

No.

No.

foot

distance

of

as

93-847

93-847

No.

twin

a

(3/64”).

1.2

follows:

680-00

675-00

93-847

2.0

of

above-mentioned

The

the

les,

592-00

93-113

speciai

on

Changing

Foot

Bring

loosen

ordinary

Insert

needle

will

it

the

of

Tighten

needle,

(7

(5

671-00

2.5

or

cording

request

take-up

needle

needle

twin

clamp

go.

shank

needle

and

1.6

grooves.

grooves.

millimeters.

needle

with

Needle

the

needle

and

Make

(1/16”),

(3

teet,

and

lever

set

out

sure

faces

set

needle

a

3/64”

1/16”

grooves.

System

and

plate

extra

at

and

to

screw

of

into

push

that

toward

screw

1

8,

130

needle

slot

highest

reedle

it

a

p’ate

2.0

wide

wide

5/64”

twin

are

cost.

the

and

a,

opening

as

up

the

the

securely.

with

(5/64”).

each)

each;

wide

need

plate

supplied

Sewing

point,

clamp.

far

flat

back.

No

pull

of

as

side

865

OP

N

I,

—.

26

Page 28

Turn

foot

It

is

guide

Thread

Pin

with

Set

Upper

Place

both

the

discs

threads

front

The

threads

Thread

Slightly

thread

correctly,

27

sewing

and

best

tucks

sewing

the

a

thread

rear

of

to

bobbin

Tension

tension

tighten

to

attached.

Size

and

machine

Thread

spool

and

upper

through

back.

in

your

increase

the

foot

turn

silk

retainer

center

thread

bobbin

thumb

screw

out

narrow

in

the

for

of

thread

tension

the

hole

is

left

hand.

the

depending

b

screw

cording

needle

medium

on

openings

tension

3.

at

drawn

bobbin

thread

screw

securely.

each

discs,

Raise

its

up

on

b

b

completely

are

and

stitch

2,

end.

as

thread

the

should

to

the

made

on

length.

of

the

as

and

take-up

Pull

instructed

type

appear

left

if

with

the

bobbin.

two

illustrated

the

lever

threads

tension,

of

and

you

a

spool

other

on

fabric

as

take

No.

on

4

into

and

a

want

50

pins.

page

between

to

page

used.

faint

out

to

embroidery

its

highest

slot

14.

increase

zigzag

the

slip

Pass

13.

5,

If

the

To

and

the

sewing

on

both

Lead

center

position

thread

do

or

tension

line

foot.

a

cording

thread,

thread

one

this,

decrease

on

and

each

hold

the

Slip

wider

ends

thread

and

has

foot

front

needle

both

the

other

on

between

pass

been

cording

with

cording

through

tension

both

from

needle

needle

Set

side.

the

Page 29

Filled

If

you

Pfaff

size

Remove

front

Cording

want

recommends

want.

you

the

needle

of

to

bed

make

slide

plate

that

cording

you

and

slot

I

insert

pass

(see

prominent

of

bobbin

forward

the

the

foot

ball

more

hole

thread

in

the

on

g

filler

(together

under

your

cording

located

cord

ends).

the

ap

in

back

with

bed

filmy

a

the

ill,

filler

filler

on

fabrics

page

cord.

cord

from

26).

under

the

Pull

slide

Its

Lay

needle

thickness

below

the

the

filler

a

and

depends

through

end

cording

and

cord

place

in

cording

your

render

or

uniform

one

it

(see

cording

of

as

Tucks

place

a

tucks,

ill,

spacing

the

guide.

opposite)

fot.

the

grooves

For

use

between

preceding

of

a

adjust

the

which

the

larger

is

Spacing

To

parallel

seam

foot

spacing

able

part

ensure

into

and

guide

every

of

Between

tucks,

use

between

F.

OR

521

28

Page 30

Various

Attractive

tained

cal

curved

want

fabric

turn

sewing.

fabric

stitch,

sume

To

tucks

seam

left

29

and

fabric,

stitching.

produce

of

seam

Cording

by

tucks

to

turn

(up

To

halfway,

turn

close

new

of

cording

combining

diagonal

(see

a

to

needle

lower

stitch

fabric

a

together,

tuck

preceding

Effects

effects

tucks

adjoining

corner,

foot,

an

let

needle

all

corduroy

extremely

horizontal,

leave

eye

acute

the

tuck.

may

or

only),

and

angle,

way,

effect,

placing

ill),

needle

make

close

be

verti

stitching

If

lift

foot,

continue

turn

one

and

sew

right

DR

473

DR

474

DR

475

ob

you

in

re

to

Page 31

Ornamental

Two-Needle

Two-needle

slot

andaNE

effects

canbeobtained

Presser

toot

with

needle

available

Sewing

effects

1.6

No.93-838954-00

slot

your

at

Ptatt

Decorative

canbeobtained

needle.

twin

using

by

dealer)

Effects

by

The

stitch

varicolored

Straight-Stitch

Stitch

Attach

hemstitching

on

page

than

The

tension

page

Beautiful

handkerchiefs,

with

fabric

will

etc.

fabrics

using

Length:

for

thread

27).

Pfaff’s

be.

are

length

presser

11.

ordinary

are

hemstitching

yarn,

Fcr

best

are

presser

can

thread.

Medium.

foot

needle,

Turn

size,

the

doilies

System

the

this

suited

not

foot

No,

be

set

Hemstitching

93-838

No.

System

needle

out

needles.

threading

same

as

effects

and

twin

130

more

pronounced

reason,

to

recommended.

93-838

desired.

as

954-00,

Zwi-Ho,

130

screw

set

procedure

cording

for

on

forth,

so

needle.

batiste,

organdy,

hemstitching,

954-00

Particularly

and

blouses,

can

The

the

with

insert

instructed

as

little

a

and

work

dresses.

obtained

be

harder

hemstitching

georgette,

while

needle

nice

twin

further

thread

(see

the

woolly

30

Page 32

Procedure

Fold

fabric

so

that

a

turn

the

needle

wing

and

to

needle

sew

holes

mark

second

it

seamline

stitches

has

row.

made

or

along

Guide

and

trace

trccad

fabric

enlarged

seamline

in.

in

previously.

At

such

on

fabric.

Sew

first

row.

Guide

the

end

of

U

seam,

a

way

that

wing

turn

needle

fabric

fabric

penetrates

half

Imitation

east

tional

seams

first

one.

may

be

embroidery

31

hemstitching

two

straight

may

obtained

operations,

or

be

stitched

Exciting

and

darning

curved

decorative

by

using

thus

If

desired

parallel

threads.

requires

addi

ornamental

to

effects

varicolored

DROOl

at

the

.,

1

Page 33

Your

who

siderably

Such

grams,

ing

effects

Pfaff

will

be

enlarge

additional

sewing

can

be

used

glad

to

the

applications

on

wool,

can

alsobeobtained

offer

range

for

you

and

many

additional

various

of

applications

include

straight-stitch

with

sewIng

felling,

the

sewing

feet

your

of

granite

embroidery

multi-stitch

operations.

and

attachments

machine.

stitching,

with

ruffler

four-ply

and

your

See

which

embroidering

thread.

the

bias

Pfaf[

binder.

dealer

will

mono

Interest

con

32

Page 34

Care

Regular

machine

require

If

your

screw

and

cleaning

oil

regular

machine

on

underside

Maintenance

and

only,

All

lubrication.

is

a

oiling

moving

Portable

of

base.

will

and

Electric,

increase

rotating

remove

the

parts

service

the

machine

unde

life

the

of

base

your

bed

machine.

plate

first.

To

and

do

Use

in

this,

sewing

the

loosen

ann

____

11

e

,

:

-

-

i1t

DA

33

852

Page 35

Do

From

plate

a

move

Take

bin

ing

DR

DR

The

most

drop

you

not

soft

and

hook.

886

887

raceway

important

of

oil

sew.

lubricate the

time

to

and

clean

brush.

accumulations

out

the

clean

in

into

time,

Take

bobbin

the

the

oiling

the

the

sewing

raceway

bobbin

remove

machine

a

toothpick

of

case

vicinity

point.

packed

with

of

hook

Put

each

winder.

the

feed

the

the

needle

and

is

with

bob

sew

the

one

day

re

lint.

34

Page 36

Removing

To

change

at

the

cover

needle

by

the

the

pulling

Face

hght

bar

Cover

end,

ft

upwards

bulb

or

remove

oil

the

the

parts

face

Replacing

Slip

up

35

tip

until

the

Face

Cover

d

into

slot

e

and

push

face

DR

DR

cover

024

512

it

snaps

into

place.

Page 37

Changing

The

nates

To

face

turn

When

sure

voltage.

press

face

OR

505

built-in

the

change

cover,

left,

inserting

its

bulb

cover.

and

voltage

Slide

the

area

push

15-watt

the

pull

bulb

in,

Light

of

light

a

and

stitching

the

out.

new

agrees

pins

Bulb

sewing

bulb,

bulb

turn

light

into

perfectly.

remove

into

with

socket

right.

light

its

bulb,

illumi

socket.

make

the

slots,

Replace

the

line

36

Page 38

Tro

1.

u

ble

Machine

Shooti

Skips

119

Stitches

Cause:

Needle

Wrong

Needle

Machrne

Needle

thread.

37

ncorrectly

needle

bent

threaded

too

fine

inserted.

improperly

or

too

thick

for

the

Remedy:

Push

be

you.

Always

Insert

Check

ed

Select

page

needle

up

as

far

as

it

will

go

instruct

Chart

and

toward

on

sure

that

long

groove

use

System

new

needle.

and

on

page

proper

correct

threading

13.

needle

12.

130

A

from

faces

needles.

as

Page 39

2.

Needle

Thread

Cause:

The

above-mentioned

thread

Thread

Poor,

Hook

or

needs

3.

Needle

breakage.

tension

knotty

raceway

oiling.

Breaks

Breaks

may

cause

too

tight.

or

rotten

thread

used.

is

jammed

with

thread

Remedy:

See

Adjust

Use

Clean

remedies

tensions

good-quality

and

oil

listed

hook

as

instructed.

threads

raceway.

under

1.

only.

above.

Cause:

Bent

needle

strikes

point

of

too

it

sewing

heavy.

bends

and

hook,

Needle

too

thin

or

thread

Fabric

pulls

strikes

needle

needle

N

so

plate.

Remedy:

Replace

further

Use

(see

Don’t

the

material

correct

page

force

needle

damage.

14).

the

lightly.

needle

at

feeding

once

and

to

thread

motion.

prevent

sizes

Guide

38

Page 40

Bobbin

4.

Machine

Cause:

Feed

dog

Machine

length

control

Accumulations

feed

teeth,

5.

Motor

Cause:

Motor

disengaging

Thread

Jamming

The

Pfaff

improperly.

motor

in

If

this

action

raceway,

39

case

dropped.

does

Idles

lotary

most

jerk

inserted

Feeds

If

thread

instances

should

the

not

set

of

hook

balance

incorrectly.

Improperly

Feed

on

“O’.

lint

packed

lever

raised.

will

should

will

net

free

wheel

because

not

happen

be

the

stitch

between

normally

sufficient

jammed

back,

to

then

jam,

jam

to

thread,

rock

Press

it

Remedy:

Raise

Regulate

Take

with

Remedy:

Flick

even

in

the

overcome

put

it

back

snap

off

a

lever

if

hook

a

against

into

feed

stiff

the

hard

dvop

and

dog

stitch

needle

brush.

down

machine

raceway,

working

forth.

bobbin

place.

(see

length,

of

kerosene

plate

(see

case

page

as

page

should

the

of

23).

desired.

and

power

the

into

until

you

remove

5).

be

handled

of

mechanism.

the

hook

hear

lint

the

Loading...

Loading...