Page 1

z

I

C

A

0

Page 2

INSTRUCTIONS

FOREWORD

You

are

now

the

proud

owner

and

workmanship

modern

Your

PFAFF

these

simple

high

which

speed

sewing

is

60

easy

instructions

it

to

and

of

embodies

machines

operate,

sewing

FOR

FA

a

P

are

for

requiring

will

USING

F

F

60

straight

of

the

same

industrial

but

become

little

a

THE

stitching

high

standards

purposes.

attention

lasting

machine.

and

pleasure.

PFAFF

The

as

used

service.

Just

materia

in

today’s

follow

6C

G.M

PFAFF

AG

Page 3

Chapter

1.

Foreword

What

2.

Do

3.

4.

To

Relative

5.

To

6.

To

7.

To

8.

Toinsertthe

9.

To

10.

To

11.

needle

To

12.

To

13.

To

14.

Correct

15.

To

16.

To

17.

belongs

you

engage

change

wind

take

thread

operate

draw

regulate

regulate

adjust

remove

know

the

sizes

the

under

the

the

off

bobbin

the

the

threader

the

up

the

the

tension

the

the

your

to

your

sewing

needles

of

needle

bobbin

needle

built-in

under

upper

lower

regulation

stitch

top

machine?

machine?

mechanism

and

thread

case

the

in

thread

tension

tension

length

cover

thread

bobbin

case

Index

ge

1

2

3

5

6

7

10

15

16

19

20

21

22

23

24

Chapter

Correct

18.

of

To

19.

To

20.

Servicing

21.

To

22.

The

23.

8

24.

9

25.

26.

27.

28.

29.

30.

31.

32.

33.

regulation

sewing

the

off

take

off

take

and

remove

light

sew

the

for

Hints

sewing

of

Edgestitching

Quilting

Hemming

folder

The

ruffler

The

ruffling

Elastic

PFAFF

The

Darning

and

Embroidering

foot

face

the

balance

the

maintenance

shuttle

the

detection

trouble

No.25594

25547

No.

5-stitch-ruffler

mending

of

the

plate

pressure

wheel

and

elimination

50100

No.

Page 4

needles

29070

short

long

43729

No.

guide

25576

25579

25997

treadle

in

lieu of

machine?

262

No.25553

stands

No.

53003

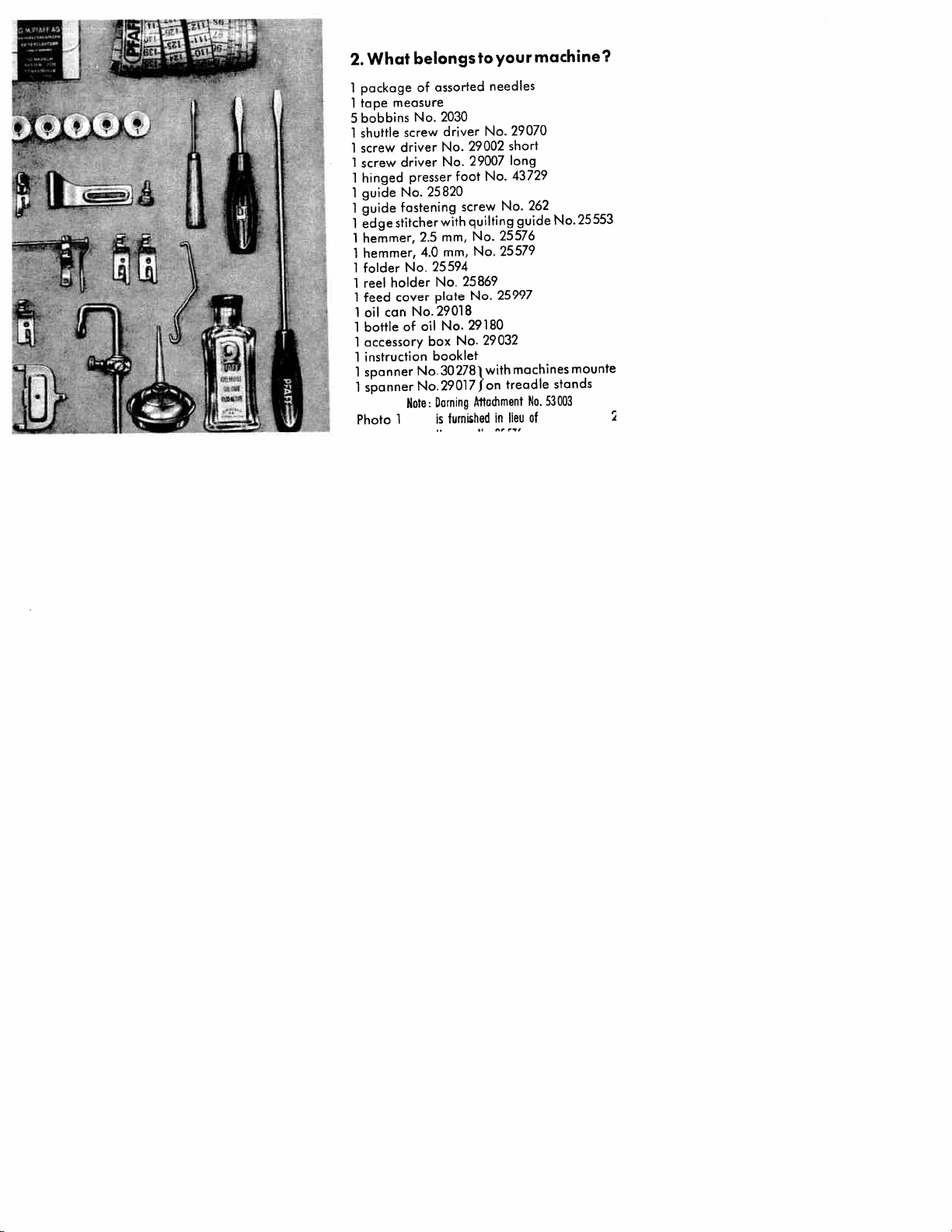

What

2.

package

1

tape

1

bobbins

5

shuttle

1

screw

1

1

screw

hinged

1

guide

1

1

guide

edge

1

hemmer,

1

hemmer,

1

folder

1

reel

1

1

feed

1

oil

bottle

1

accessory

1

instruction

1

spanner No30278lwithmachinesmOuflte

1

spanner

1

Photo

beongstoyour

assorted

of

measure

No.

screw

driver

driver

presser

25820

No.

fastening

stitcher

2.5

4.0

25594

No.

No.

holder

plate

cover

No.29018

can

oil

of

box

booklet

No.

Darning

Note:

is

1

2030

driver

29002

No.

29007

No.

foot

screw

quilting

with

No.

mm,

No.

mm,

25869

No.

29180

No.

No.

290171

Attachment

furnished

No.

No.

29032

on

2

Page 5

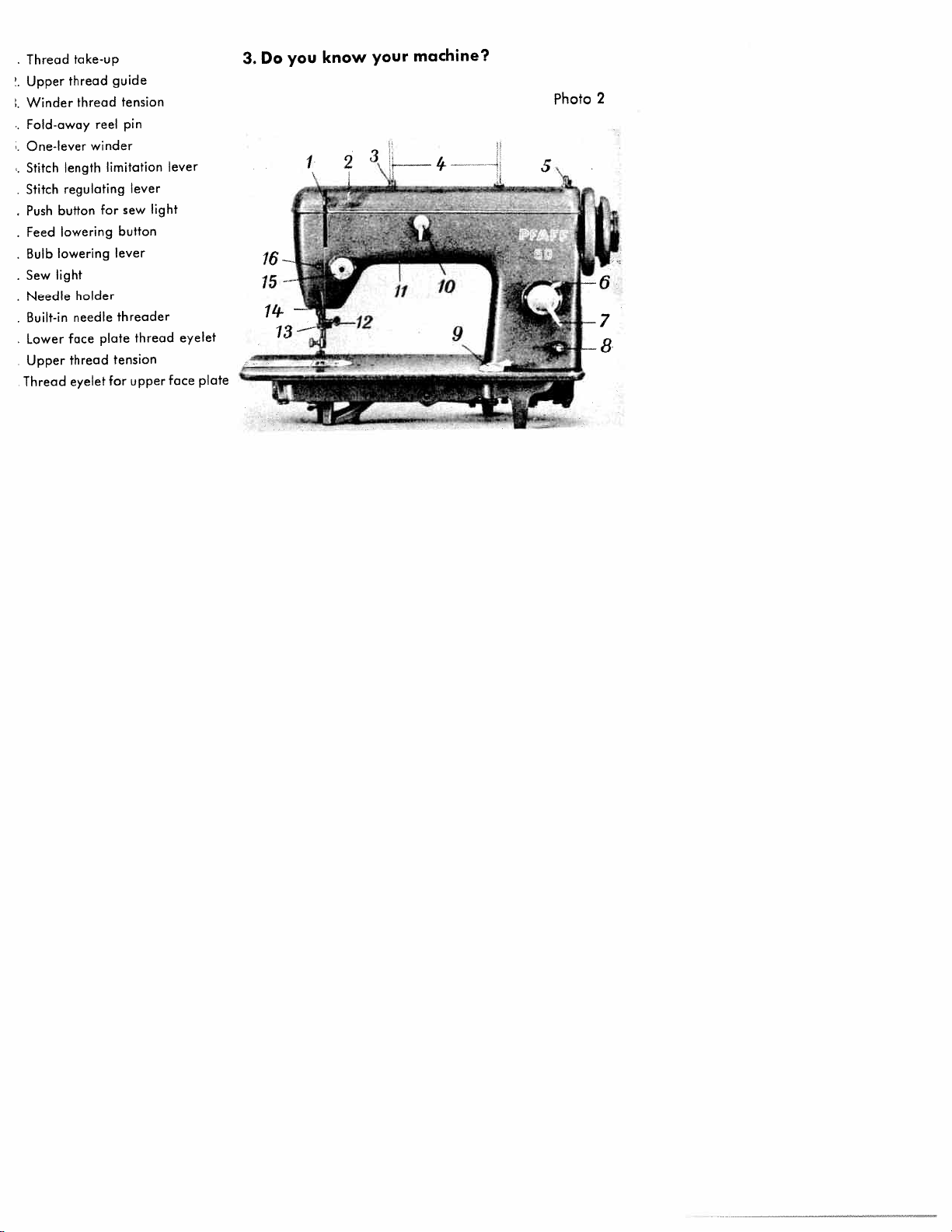

Thread

Upper

Winder

Fold-away

One-lever

Stitch

Stitch

•

Push

•

Feed

•

Bulb

•

Sew

•

Needle

Built-in

Lower

Upper

Thread

take-up

thread

thread

winder

length

regulating

button

lowering

lowering

light

holder

needle

face

thread

eyelet

guide

tension

pin

reel

limitation

sew

for

button

lever

threader

plate

tension

for

lever

thread

upper

light

lever

eyelet

face

plate

3.

Do

you

know

your

machine?

Photo

2

Page 6

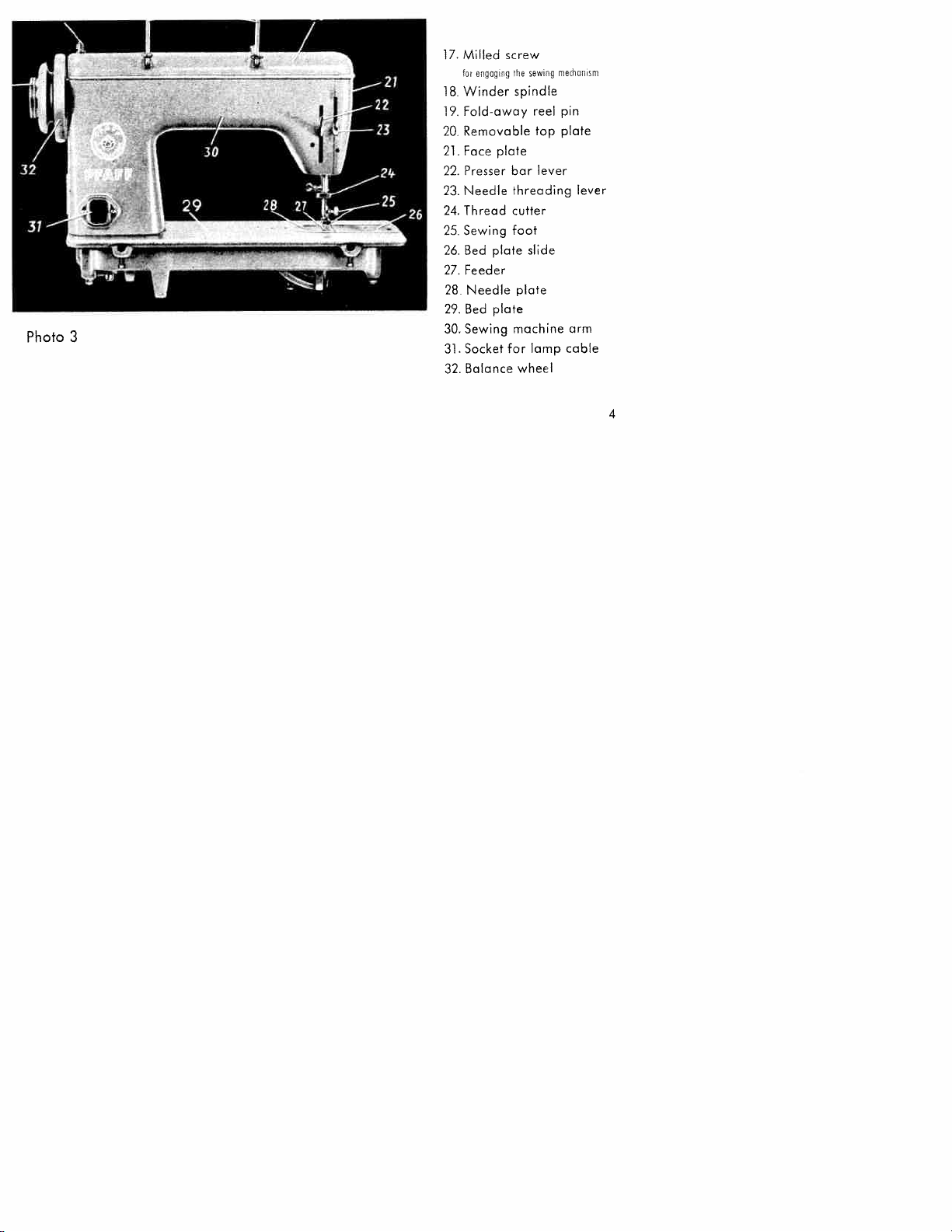

Photo

17.

18.

19,

20

21

22.

23.

24.

25.

26.

27.

28

29.

3

30.

31

32.

screw

Milled

for

Winder

eogog

rg

he

spindle

Foldawoy

Removable

plate

Face

Presser

bar

Needle

Thread

Sewing

Bed

threading

cutter

foot

plate

Feeder

Needle

plate

Bed

Sewing

Socket

machine

for

Balance

sewi

reel

top

slide

plate

lamp

wheel

09

lever

mechorr

pin

plate

arm

cable

sin

lever

4

Page 7

•

Operation

of

Machine

the

engage

To

•

balance

old

in

:rew

winding,

r

by

sm

irection.

the

direction

the

disengage

turning

sewing

wheel

that

mechanism

tighten

and

arrow.

of

sewing

screw

opposite

in

milled

mecha

Photo

4

Page 8

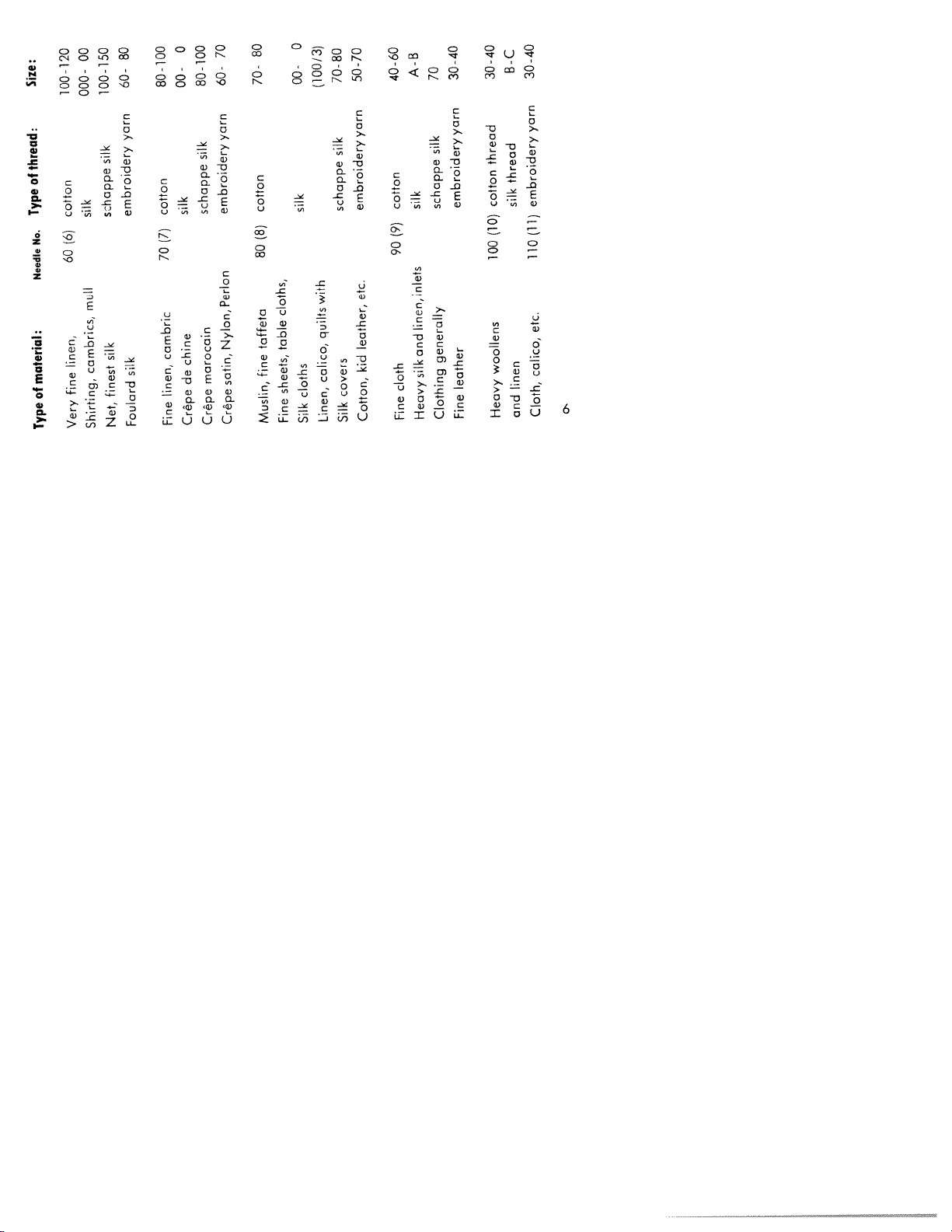

Size:

00

100-120

000-

150

100-

80

60-

0

80-100

00-

70

60

80-100

80

70-

0

00-

/3)

(100

50-70

70-80

A-B

40-60

70

30-40

B-C

30-40

30-40

thread:

of

Type

No.

Needle

material:

of

Type

Cotton

silk

(6)

60

mull

linen,

cambrics,

fine

Shirting,

Very

yarn

silk

embroidery

schappe

silk

silk

finest

Foulard

Net,

cotton

silk

(7)

70

cambric

chine

de

linen,

Fine

Crepe

yarn

silk

embroidery

schappe

Perlon

Nylon,

marocain

satin,

Crêpe

Crêpe

cotton

(8)

80

cloths,

taffeta

table

fine

sheets,

Fine

Muslin,

silk

cloths

Silk

silk

schappe

with

quilts

calico,

covers

Linen,

Silk

yarn

cotton

embroidery

(9)

90

etc.

leather,

kid

cloth

Fine

Cotton,

silk

silk

inlets

linen,

and

silk

Heavy

yarn

embroidery

schappe

generally

leather

Fine

Clothing

thread

thread

cotton

silk

(10)

100

woollens

linen

Heavy

and

yarn

embroidery

110(11>

etc.

calico,

Cloth,

Page 9

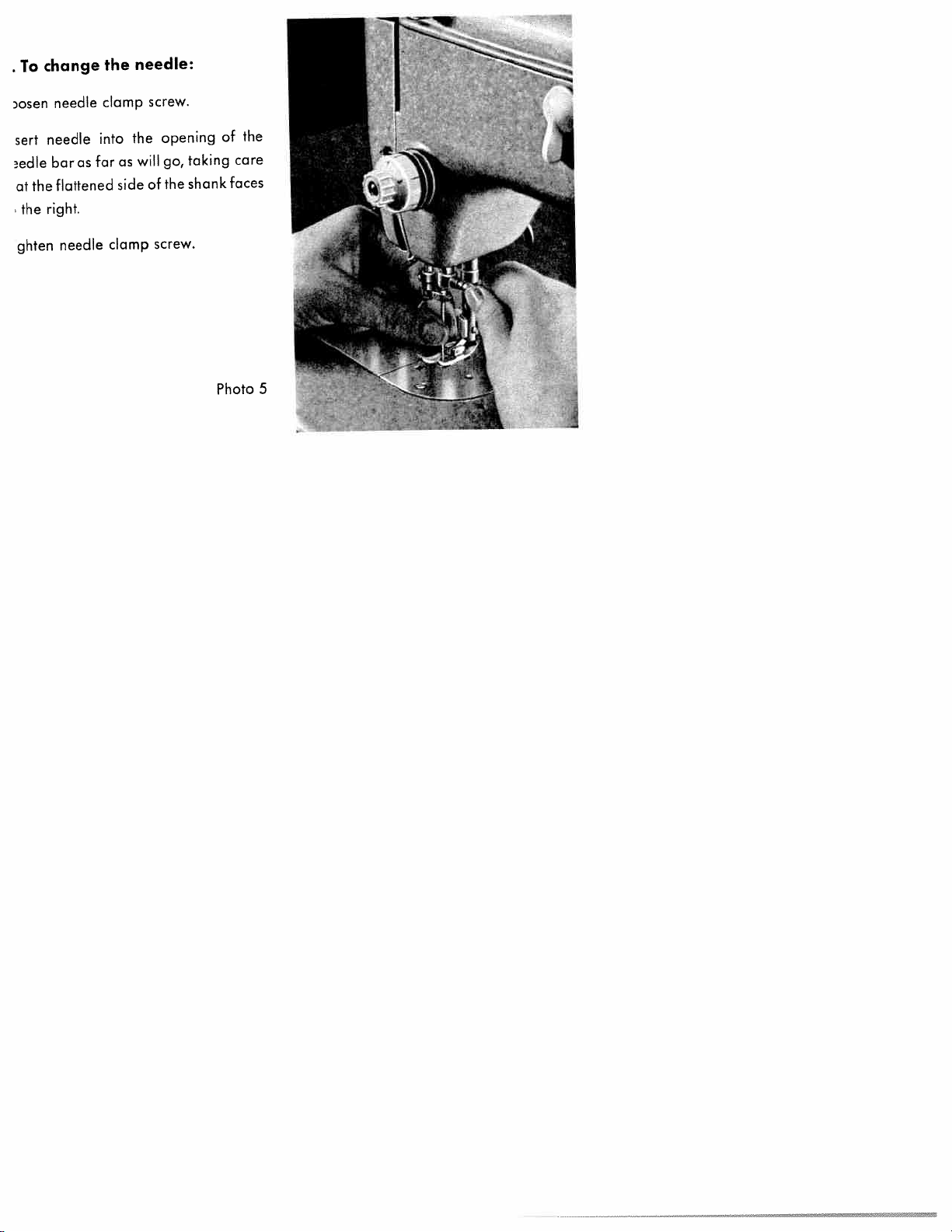

•

To

osen

sert

edIe

at

the

ghten

change

needle

needle

bar

flattened

the

right.

as

needle

the

clamp

into

far

clamp

needle:

the

will

as

side

screw.

opening

go,

of

the

screw.

taking

shank

the

of

care

faces

Photo

5

Page 10

:‘

Photo

6

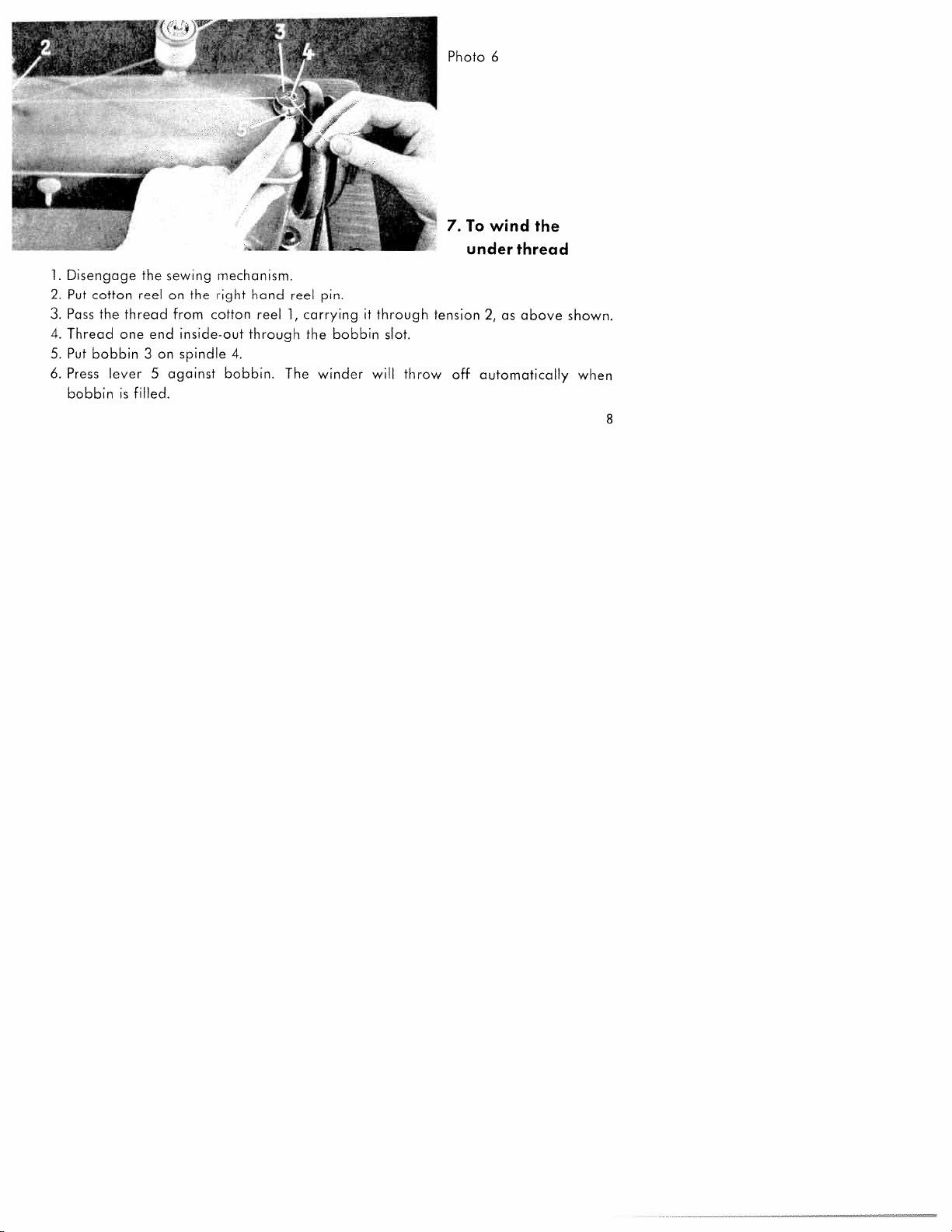

1.

Disengage

2.

Put

cotton

Pass

3.

4.

5.

6.

the

Thread

Put

Press

bobbinisfilled.

one

bobbin

lever

the

sewing mechanism.

reelonthe

thread

3

end

on

5

from

inside-out

spindle

against

right

cotton

4,

bobbin.

hand

reel

through

reel

pin.

carryingitthrough

1,

bobbin

the

The

winder

will

slot.

throw

7.Towind

under

tension

2,asabove

off

automatically

the

thread

shown.

when

8

Page 11

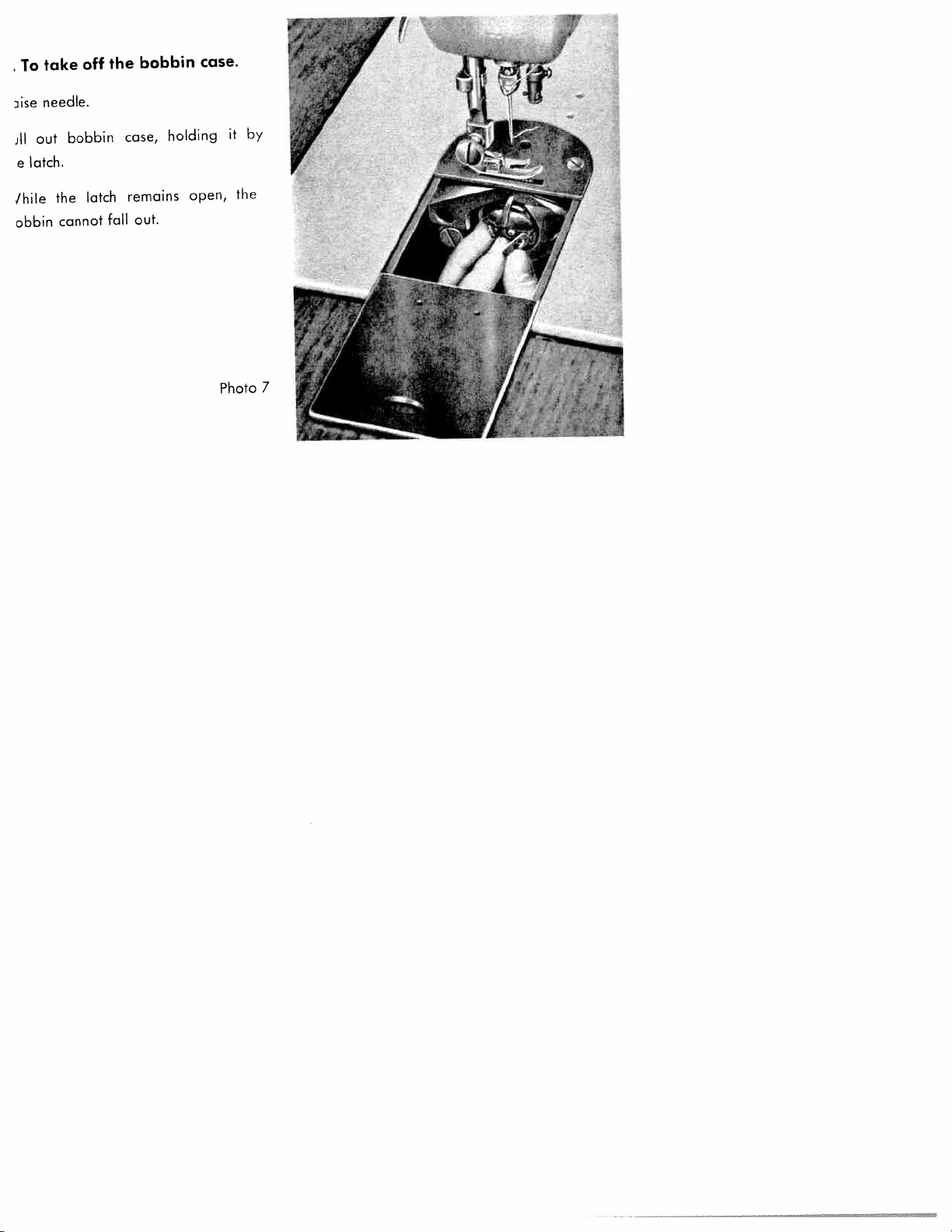

To

iise

ill

e

take

needle.

out

latch.

off

bobbin

the

bobbin

case,

case.

holding

by

it

/hile

obbin

the

cannot

latch

fall

remains

out.

open,

the

Photo

7

Page 12

9.

.4—

To

in

insert

the

the

bobbin

bobbin

case.

r

Proceed as

endtoface

Photo

8

showninthe

operator.

photo,

thread

10

Page 13

MDJ

pOøJ4

oIs

ij6noi1i

so

pOOJ4SflhIi

6

O4Od

Page 14

Retain

thread

it

shows

of

that

Photo

bobbin

beneath

up

spring.

10

in

again

bobbin

tension

the

underneath

case and

spring

the

draw

until

end

12

Page 15

1d

ddle

index

e

bbin

bobbin

finger

finger

cannot

case

of

fall

your

holds

out.

with

left

the

thumb

hand;

opened

while

latch,

Photo

and

11

Page 16

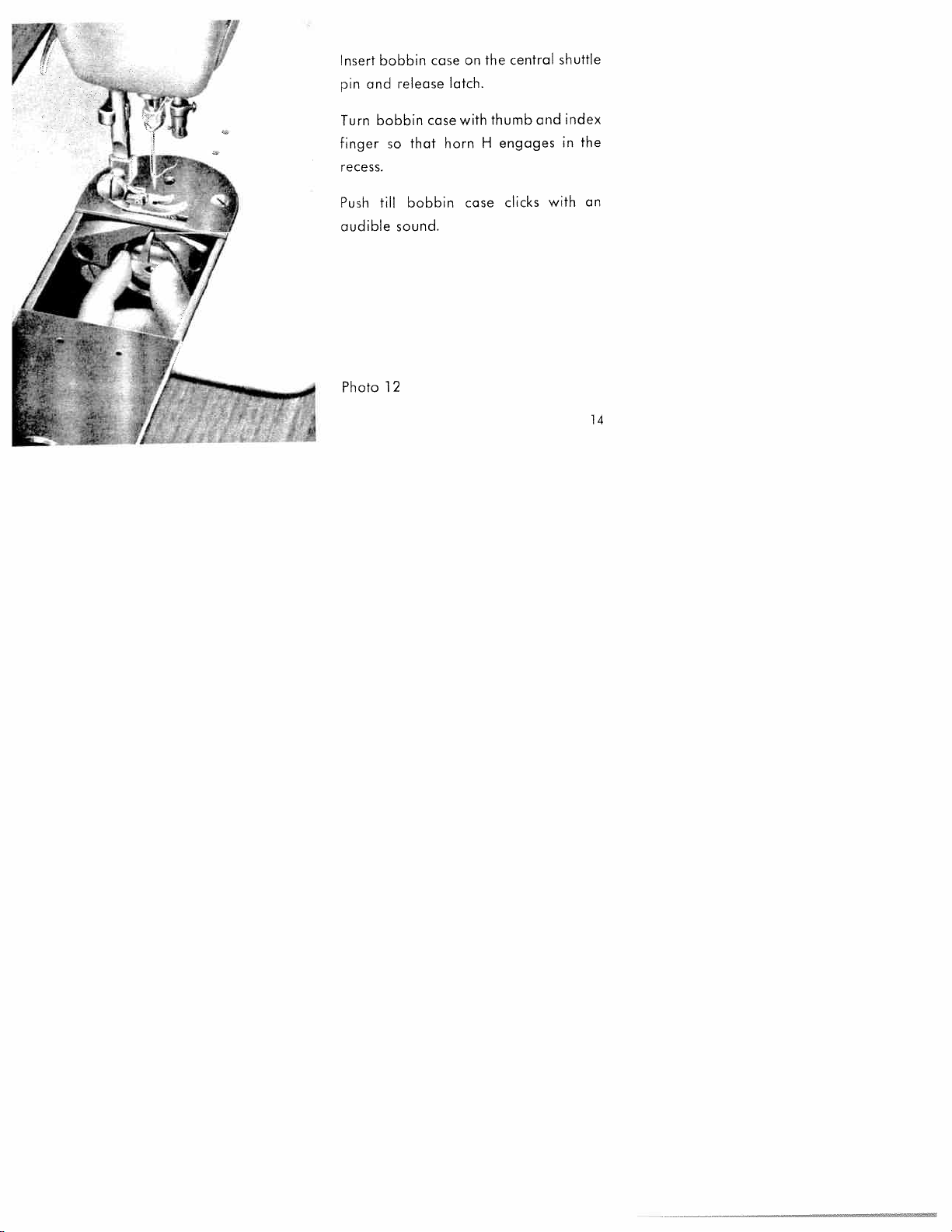

J

4

and

shuttle

index

in

with

the

an

14

central

latch.

with

horn

on

case

the

thumb

engages

H

clicks

Insert

bobbin

pin

I

and

Turn

finger

recess.

Push

audible

Photo

bobbin

till

12

release

so

bobbin

sound.

case

case

that

Page 17

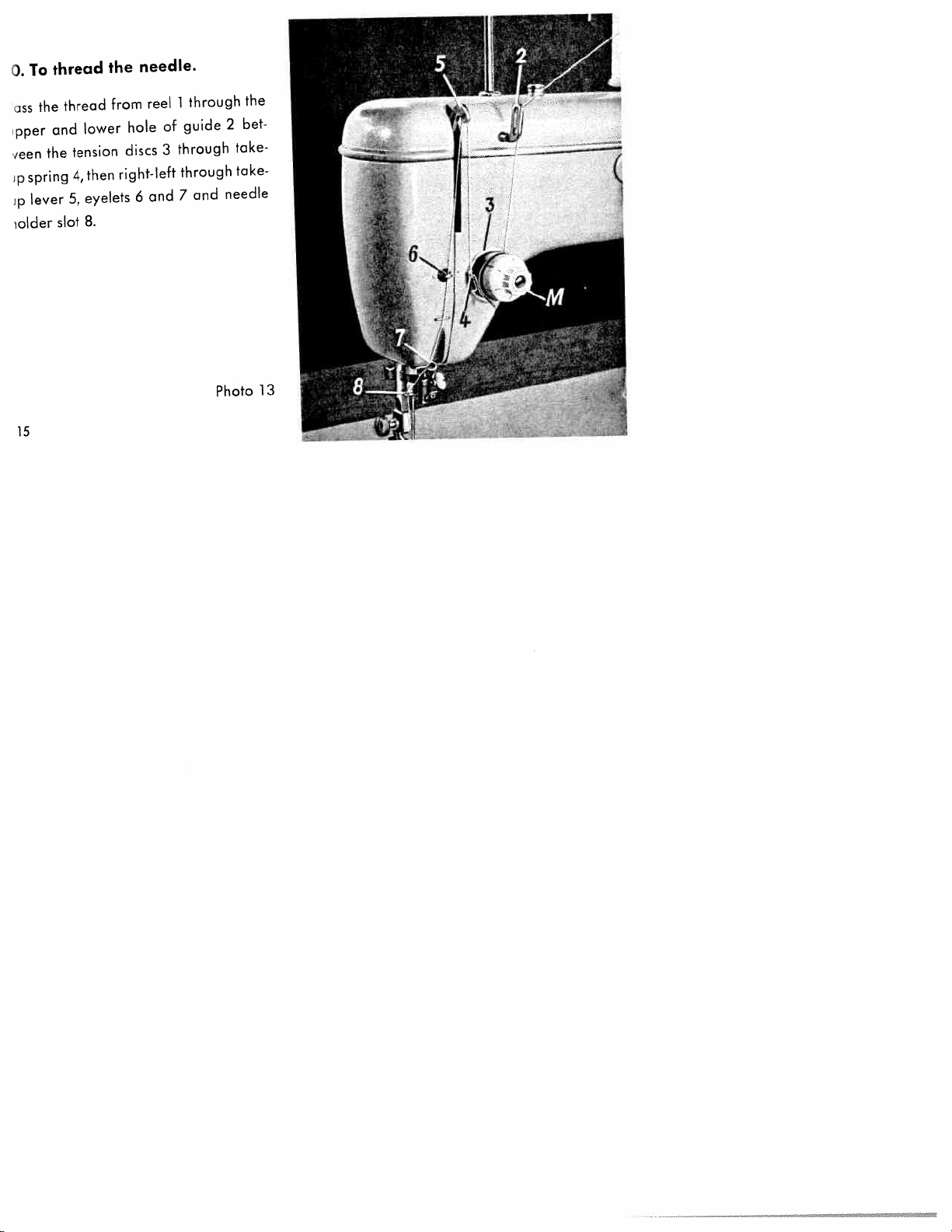

0.

To

thread

the

needle.

ss

pper

‘een

spring

p

lever

p

older

the

and

the

thread

tension

4,

5,

slot

from

lower

then

eyelets

8.

reel

of

hole

3

discs

right-left

and

6

through

1

guide

through

through

and

7

2

take

take

needle

Photo

the

bet

13

Page 18

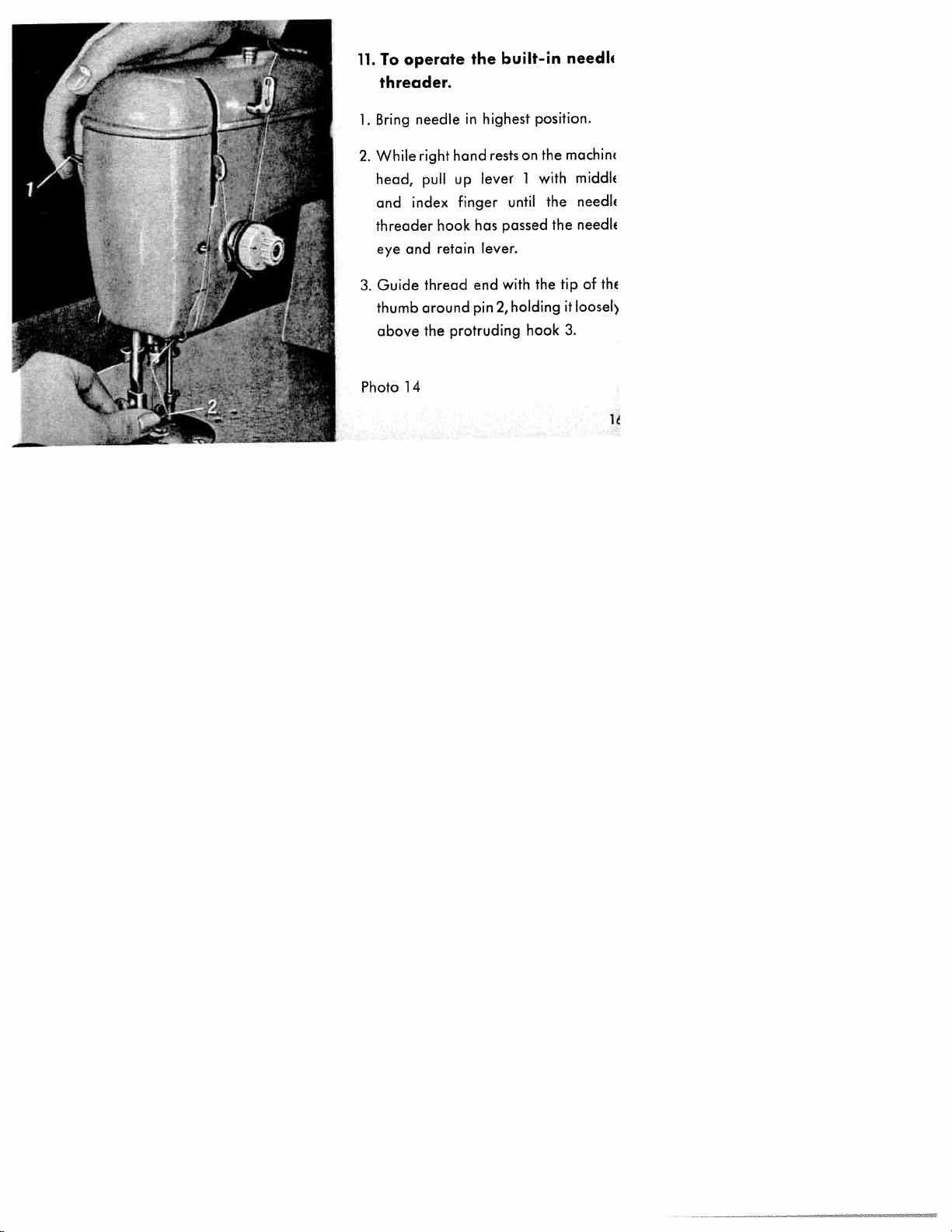

11.

To

threader.

operate

the

built-in

needh

Bring

1.

While

2.

head,

and

threader

eye

Guide

3.

thumb

above

Photo

needle

right

pull

index

and

thread

around

the

14

in

hand

up

finger

has

hook

retain

end

pin

protruding

highest

rests

lever

until

passed

lever.

with

holding

2,

position.

on

the

with

1

the

the

hook

machim

middle

needlf

needk

the

tip

it

loosel)

3.

of

thE

Page 19

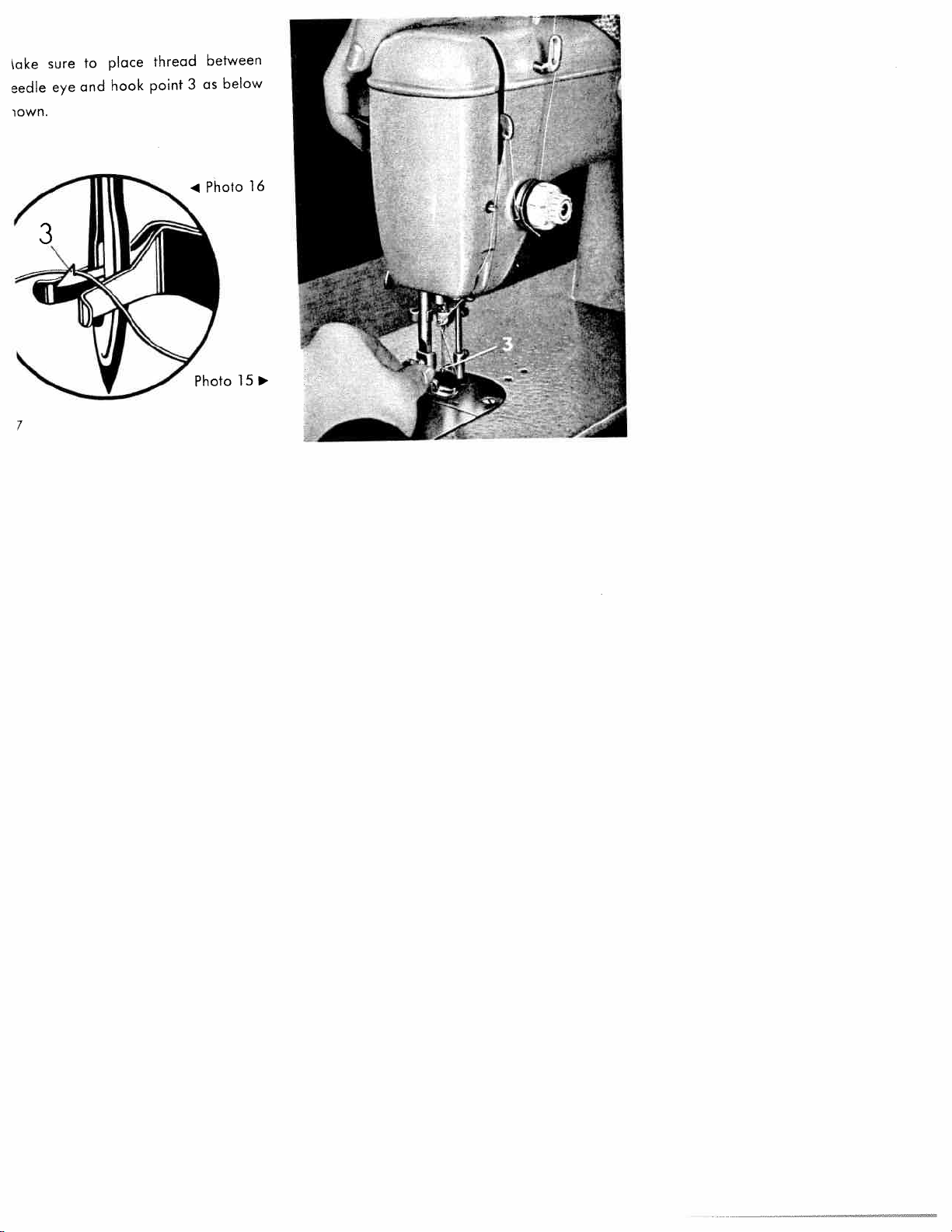

ake

eedle

own.

sure

eye

to

and

place

hook

thread

point

between

as

3

below

Page 20

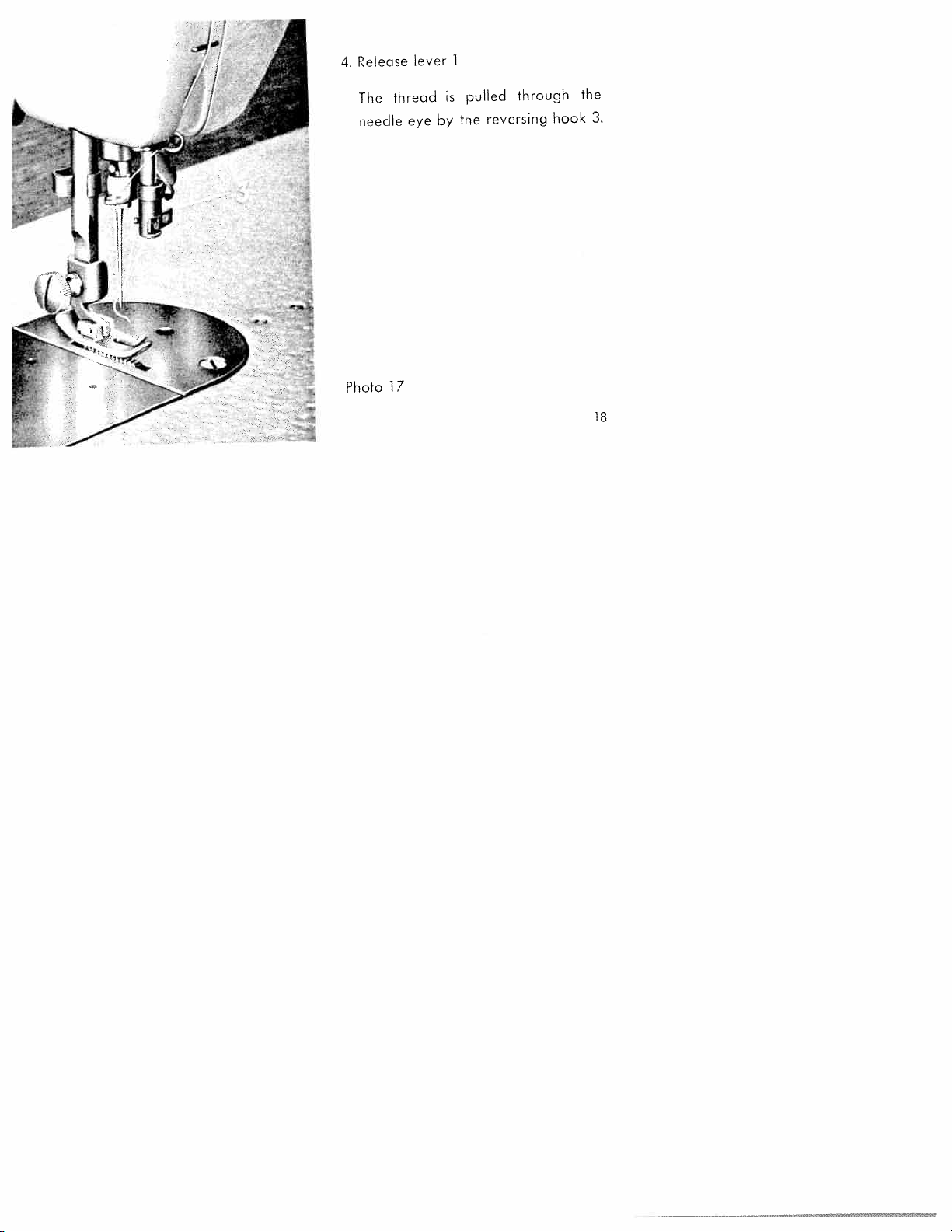

Release

4.

lever

1

I

The

needle

Photo

thread

eye

17

by

is

pulled

the

through

reversing

hook

the

3.

18

Page 21

2.

1.

To

Hold

draw

the

end

up

of

the

the

underthread.

upperthread.

2.

3.

4.

Turn

once

slightly

By

thread,

the

in

hole

Lay

presser

balance

gone

the

shape

the

in

both

foot.

of

and

a

until

loop

plate.

bock

wheel

down

drawing

underthread

needle

threads

up

up

will

through

needle

again.

the

come

under

Photo

has

upper

up

the

the

18

Page 22

Important:

this

In

jamrnng

thread.

threads

both

Make

take-up

highest

beginning

seam.

manner

and

In

this

when

sure

is

you

slip-offs

you

case

starting

thatthe

always

position

or

eliminate

of

heed

to

thread

in

when

ending

thread

upper

the

not

sew.

its

a

hold

To

13.

turn

to

A

tension

materials.

A

turn

tension

19

Photo

regulate

the

right

stitching

for

the

to

stitching

for

left

the

thicker

)c

4

upper

will

will

thinner

tension.

increase

heavier

and

decrease

fabrics.

the

the

20

Page 23

To

4.

lighter

irns

of

Id

irns

nsion.

regulate

tension

the

*m

of

of

the

smatl

that

lower

the

obtained

is

tension

screw

screw

screw

driver.

will

tension.

by

with

increase

Photo

left

the

Right

the

20

Page 24

///

Upper

Upper

lower

tension

Photo

Perfect

Photo

tension

tension

Photo

tension

too

21

stitch

too

too

22

too

23

weak

tight.

tight

weak

or

or

lower

Correct

l5.

perfect

with

lower

material

threads

results

tension

interlocking

the

in

neat

in

regulation

upper

of

centre

elastic

and

and

of

seams.

the

22

Page 25

To

16.

Set

1.

for

accordance

Push

2.

right

the

To

3.

A

23

adjust

stitch

the

stitch

stop

set

shift

the

to

the

length

desired

regulation

obtain

to

length.

reverse

to

left

with

stop.

stitch

limitation

stitch

scale.

the

lever

forward

a

stitching,

length.

lever

length

A

turn

Photo

to

stitch

lever

B

in

the

of

24

Page 26

.4

17.

With

no

The

taken

Photo

remove

To

oil

aU

soiling

one-piece

with

off

25

points

the

of

both

the

covered

top

stop

material!

cover

hands

cover.

up,

con

there

be

easil’

7

is

2

Page 27

lB.

Correct

pressure

regutation

the

on

of

material

the

assures

prevents

feeder.

left

A

pressure

the

right

a

increase

heavy

25

uniformity

injury

c—€(

turn

for

turn

)m

the

materials.

of

the

of

of

thin

of

pressure

stitch

material

screw

and

that

for

length

V

flimsy

screw

thick

by

will

fabrics;

Photo

and

the

ease

will

and

26

Page 28

.

r

19.

is

the

of

El

(

‘-4

1

take

To

necessary

only

presser

attachments.

1.

Remove

downwards

left,

the

When

2.

engages

L

in

the

inserting

When

pin

guide

27

Photo

replacing

slot

off

bar

screw

take

catches

F

in

K.

for

and

it

the

the

the

when

the

k,

oFf.

let

while

make

notch

face

face

proper

in

having

face

pushing

sure

N

plate,

hole

plate

fastening

plate

that

and

H.

to

see

turn

slide

it

part

pin

that

to

S

26

Page 29

O.

To

take

off

the

balance

wheel

the

or

)alance

Loosen

•

Loosen

the

•

Lift

balance

removal

wheel

screw

milled

left.

carrier

wheel

of

and

•

ring

odd

a.

screw

1

and

thread

arm

(photo

remove

shaft

b,

between

bushing.

turning

take

29),

thread.

to

it

28

Photo

off

Page 30

When

sure

replacing

that

its

bentup

the

carrier

parts

face

ring,

make

outside.

the

If

tighten

Photo

milled

large

firmly, turn

29

screw

carrier

should

ring

for

not

180°.

28

Page 31

Servicing

Zi.

egular

pply

not

)o

Photo

and

oil

forget

only

30

and

proper

at

to

maintenance.

oiling

points

the

rear

the

oil

serves

marked

arm

increase

to

by

shaft

arrows.

bushing,

the

life

half

your

of

covered

machine.

the

by

winder

wheel.

Page 32

The

Brush

oiling

off

pornis

regularly

underneath

lint

and

fluff

the

machine

between

needle

plate,

feeder

and

Photo

shuttlel

31

30

Page 33

Apply

the

n

dry

A

a

race

race

drop

of

will

of

the

wear

oil

from

shuttle.

off

time

rapidly.

time

to

Photo

32

4

Page 34

22,

To

remove

Cc

)mes

necescu

nta

ed

iito

)L)Cn

wing

A

/

Pu

J

)fO

wnwards.

33

the

y

the

ace

screwaand

shuttle

when

thread

push

has

bow

Page 35

.

Turn

is

Take

3.

central

33

balance

the

at

extreme

off

pin.

wheel

shuttle,

that

so

right.

holding

the

shuttle

it

Photo

the

at

34

Page 36

23.

The

sew

light

1,1

I

1

switched

is

button

(photo

and

exchange

To

the

bulb

the

to

Photo

is

left

D,

4).

held

into

left

35

on

located

The

by

and

the

and

and

bulb

spring.

a

the

retain

socket,

release

off

at

has

bulb

by

the

a

press

there.

it

turning

it.

pressing

vertical

bayonet

lever

Press

it

push

arm

cap

S

the

slightly

to

34

Page 37

nsert

)ins

ocket.

kess

f

he

fresh

a

easily

will

slightly,

bulb

is

bulb

then

now

slide

firmly

so

into

turn

the

that

the

shortly

it

secured.

slots

Photo

guiding

the

of

the

to

36

Page 38

Hints

24.

Skipping

for

stitches:

of

the

detection

and

elimination

of

sewing

trouble

Cause:

Needle

Wrong

Needle

Machine

Needle

thread

the

improperly

bent.

not

either

used.

is

properly

too

needle

is

inserted.

being

thin

used.

threadened.

thick

too

or

for

Remedy:

Needle

the

with

correct

The

the

on

a

Insert

Check

dance

Select

on

chart

must

long

bed

new

and

with

needle

page

be

groove

needle

plate

needle.

correct

chapter

in

6.

pushed

facing

system

slide.

threadening

10.

accordance

up

to

is

the

left.

stop,

stamped

accor

in

the

with

36

Page 39

hread

breaking

ause:

•hread

he

breaking

aforementioned

may

reasons.

occur

for

any

of

Remedy:

opposite

See

page.

Thread

of

Jse

ace

ammed

rhread

tension

inferior

being

the

having

dry

race.

tight.

too

knotty

or

odd

or

slipped

thread.

threads

the

off

having

reel.

Adjust

upper

accordance

best

Only

quality

good

and

Clean

chapters

put

not

Do

horizontal

the

with

sewing

oil

21

and

the

and

of

race

reel

reel

lower

chapters

machine

should

silk

in

22.

on

holder.

tensions

and

13

thread

used.

be

accordance

vertical

the

14.

or

with

n

a

but

Page 40

Tightness

Cause:

belt

Drive

short,

too

or

bearings.

the

on

Shuttle

odd

race

thread.

Mechanism

feeder

The

winder

The

ration.

ape

Thread

wheel

has

and

performance

of

too

being

causing

being

clogged

is

the

jams

engaged,

is

wound

bushing.

long

excessive

or

dry

up

needle

between

up

slips

and

pressure

obstructed

inferior

by

plate.

braking

off

by

oil.

the

balance

Remedy:

Shorten

belt

lengthening.

bias.

the

on

and

Clean

only

Use

salad

never

Unscrew

and

both

readjust

Disengage

Remove

of

and

needle.

thin

a

and/or

Cut

shuttle

oil

PFAFF

oil

feeder

properly.

winder.

unwind

the

sewing

glycerin.

or

insert

belt

race.

and

thread

piece

a

straight,

machine

needle

the

with

for

not

oil,

plate

aid

38

Page 41

4eedle

:ause:

eedle

shuttle.

he

breakage

bent

is

and

Remedy:

of

point

the

by

hit

is

Replace

damage.

needle

at

prevent

to

once

more

‘.leedle

hick.

Jpper

)ending

needle

he

to

ue

ushed.

lobbin

being

thread

needle.

the

case

too

tension

bent

is

material

not

thin

hits

and

being

properly

or

being

inserted.

thread

too

needle

pulled

too

tight,

plate

or

Study

Either

needle.

not

Do

crease

assure

so

When

until

needle

ease

force

pressure

inserting

clicks

it

and

tension

the

better

with

thread

or

feeding

thicker

on

feeding.

bobbin

the

audible

an

chart

on

a

use

movement,

material

case

sound.

page6,

thicker

in

and

press

Page 42

Ugly

Cause:

Tension

Thread

seams

not

to

properly

heavy,

regulated.

knotty

or

hard.

Remedy:

Adjust

chapters

with

only

Use

tension

first-class

a

accordance

in

and

13

14.

type

of

thread.

Under

Race

Odd

the

thread

to

thread

upper

dry.

unevenly

having

thread

infested

tension

wound.

discs.

between

winding

For

finger

your

tension.

Apply

Loosen

one

tension

but

or

do

over

two

and

not

run

the

drops

remove

thread

the

winder

of

over

thread

oil.

thread.

40

Page 43

4oisy

ause:

or

mt

way

ace

‘leed

nserted.

:eeder

vachine

erosene

performance

thread

odd

shuttle.

the

of

(after

plate

needle

jams

run

has

been

have

having

removal)

plate

or

dry

used.

infested

properly

not

cut-outs.

inferior

in

oil

the

or

Remedy:

and

Clean

chapters

Unscrew

feeder,

also

Clean

chapters

with

21

and

oil

and

needle

then

oil

way

race

22.

plate

readjust.

machine

and

21

according

if

and

line

in

22.

to

necessary,

Page 44

Inaccurate

feeding

Cause:

Feeder

level

enough

and

Lint

dented

the

Pressure

material.

the

NB:

zero

in

being

that

so

from

fluff

on

machine

If

position.

arranged

the

needle

having

rows.

sewing

teeth

does

at

will

plate.

infested

being

not

not

too

feed

too

come

between

in

weak

at

low

all,

a

up

for

see

Remedy:

Have

fully

Take

using

Increase

(chapter

whether

feeder

project

off

graver.

a

feeder

raised

from

needle

pressure

18).

lowered

is

so

the

plate

by

its

that

needle

remove

and

tightening

stitch

or

teeth

plate.

screw

regulator

will

lint,

V

42

Page 45

How

•

Edge

5.

several

‘ith

with

one

connection

43729.

o.

edgestitcher

the

se

be

to

re

use

to

stitching

parallel

special

the

taken

attachments

the

seams

guide

standard

the

with

No.25553

closely

to

the

No.

is

25820

if

edge.

Photo

easily

foot

seams

37

Page 46

QuiItng

26.

quilting

The

cularly

seams

of

directions

other.

each

guide

The

preceding

Photo

suited

over

and

38

guide

is

row.

taking

for

entire

the

at

passed

No.25553

accurate

surface

distance

any

always

is

in

along

parti

rows

both

from

the

44

Page 47

ea-cOSieS,

few

ist

a

stitch.

uilting

slippers,

many

of

cushions,

objects

etc.,

using

Photo

are

the

39

Page 48

27.

Hemming

hems

Neat

etc.

wear,

hemmers

facilitate

To

hemmer,

the

material.

Photo

40

on

can

Nos.

insertion

25576

clip

handkerchiefs,

produced

be

25579.

and

the

of

corner

the

off

under

with

material

of

the

in

the

46

Page 49

nsertonly

hemmer

the

Df

folded

he

left

he

47

as

edge

much

edge

of

as

the

material

required

is

the

of

hemmer.

the

in

for

material

mouth

guiding

along

Photo

41

Page 50

avoid

To

seam,

for

seam

little.

a

Photo

an

to

ugly

slightly

inch

slow

42

or

corners

press

before

so

down

at

down

the

end

the

the

end

the

feeding

the

of

material

the

of

motion

48

Page 51

The

!8.

erves

operations.

2

seam:

irst

•ach

nwards

width

a

n

that

ure

olded

folder

durably

to

other

so

once

Place

with

that

of

the

abt.

and

No.25594

2

join

both

right

the

lower

the

of

/o

projecting

stitched.

then

plies

layers

edge

an

edge

of

on

side

inch.

material

top

facing

projects

Make

only

is

Photo

of

43

Page 52

Second

seam:

upstanding

down

stitch

44

Photo

edge

to

Unfold

through

left.

the

both

plies,

the

run

folder

the

and

50

Page 53

9.

s

The

No.

(at

used

ruffling

25547

extra

an

for

3

attachment

charge)

purposes:

For

I.

whereby

passed

more

The

lower

movement.

the

ply

ruffling

the

through

lessofthe

or

depends

of

unruffled

the

slot

the

upper

ruffling

on

lower

of

the

ply

foot.

the

of

feeding

Photo

ply

is

the

45

Page 54

Instead

2.

used

of

both

for

with

Photo

of

and

foot.

the

edges

subsequent

eyelets

46

upper

an

through

fed

Stitching

result

will

application

hooks.

or

ply,

this

durable

in

ribbon

a

the

ribbon

of

is

guiding

along

ruffles

ribbons

52

Page 55

Attractive

3.

ply

with

tains,

53

will

the

be

etc.)

ruffling

obtained

ruffling

effects

foot

on

overseaming

by

used

(as

single

a

on

Photo

cur

47

Page 56

30.

Elastic

ruffling

on

etc.,

elastic

The

around

After

bobbin

ing

Photo

blouses,

easy

is

thread

elastic

the

an

case

2

of

48

childrens

accomplish

to

the

in

thread

bobbin.

appropriate

tension,

threads

or

3

dresses,

bobbin.

be

must

regulation

simultaneous

possible.

is

using

by

wound

aprons,

thin

firmly

the

of

stitch

54

Page 57

The

fl.

No.

(at

will

rhis

;titching

:or

making

every

at

r

55

PFAFF

50100

extra

an

permit

at

5-stitch-ruffler

charge)

ruffling

Moreover,

will.

at

ruffle

a

stitch.

th

5

each

and

it

single

straight

con

Photo

be

stitch

set

49

Page 58

ruffles

Broad

pleats.

to

Generally,

making

the

to

right-folded

surfaces,

large

supplied

used.

50

Photo

the

with

be

may

attachment

left

of

ruffles

the

the

strechted

folded

for

or

special

ruffling

attachment

ironed

or

lends

ruffles.

ruffling

is

itself

For

plate

to

of

be

56

Page 59

Darning

32.

reparing

Take

I.

feeder.

(photo

Insert

.

shown

according

plate

Screw

3.

Nr.

Suspend

4.

No.46

for

presser

off

To

4)

feed

in

slide.

on

53003.

128

and

mending:

do

the

to

cover

photo

photo

to

darning

presser

on

mending

foot

this,

front.

plate

51

attachment

bar

face

and

turn

No.

and

with

52

plate.

lower

lever

25997

secure

the

with

Photo

the

c

as

it

bed

hook

51

Page 60

Release

5.

Insert

6.

in

and

hoop.

presser

stretch

lever.

bar

defective

material

feed

The

guiding

material.

the

Photo

52

and

cover

increases

plate

facilitates

tension

the

the

of

58

Page 61

presser

he

resser

therwise

be

,oud

timely

he

stitches

hort

bar

must

bar

the

disengaged.

mending

will

lever

point

upper

prevent

the

of

downwards

thread

thin

of

holesl

suspended

tension

with

spots

Photo

as

53

‘43

Page 62

F

Fill

token

Photo

angulor

closely

54

cuts

in

with

both

darning

directions.

stitches

60

Page 63

If

the

piece,

place

machine

the

then

taken

are

holes

following

threads

the

follow

the

in

small,

the

operating

smallest

with

other

cutout

texture

one

in

high

at

darning

direction.

defective

the

threads.

direction

speed

Photo

First

with

and

stitches

55

Page 64

N

[

the

If

insert

The

along

In

ches

Photo

the

holes

a

patch

the

case

are

piece

cut

stitched

56

are

is

of

big,

the

of

cut

edges.

very

to

as

it

same

size

large

shown

advisable

is

material.

and

holes,

on

fastened

pat

the

photo

to

56.

62

Page 65

embroidering,

For

material

The

the

with

preliminary

a

As

necessary

filled

are

Attend

design.

practice

in

one

stretched

is

exercise,

properly.

the

of

the

acquired,

is

free

machine

the

in

slow

embroidery

Embroidering

33.

adjusted

is

and

hoop

treadling

select

courses

only

then

of

in

a

the

guided

the

plain

your

of

some

under

machine

linear

PFAFF

manner

the

recommended.

is

design

dealer

for

as

needle

and

mending.

in

see

to

get

accordance

Until

the

that

acquainted

the

lines

with

63

the

various

embroidery

styles.

Loading...

Loading...