Page 1

581

583

INSTRUCTION MANUAL

This instruction manual applies to machines

from the following serial numbers onwards:

# 2 771 790

296-12-19 139/002

Betriebsanleitung engl. 04.11

Page 2

This Instruction Manual is valid for all models and subclasses listed in the

chapter "Specifi cations".

The adjustment manual for the machines can be downloaded free of

charge from the internet address

www.pfaff-industrial.com/pfaff/de/service/downloads

As an alternative to the internet download the adjustment manual can also be

ordered in book form under part no. 296-12-19 140/002.

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or

in part, is only permitted with our previous authorization and with written reference to the

source.

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Page 3

Index

Contents ..................................................................................Page

1 Safety .................................................................................................................................... 5

1.01 Directives ...............................................................................................................................5

1.02 General notes on safety ......................................................................................................... 5

1.03 Safety symbols ......................................................................................................................6

1.04 Important points for the user ................................................................................................. 6

1.05 Operating and specialist personnel ........................................................................................ 7

1.05.01 Operating personnel .............................................................................................................. 7

1.05.02 Specialist personnel ............................................................................................................... 7

1.06 Danger warnings .................................................................................................................... 8

2 Proper use............................................................................................................................. 9

3 Specifi cations ..................................................................................................................... 10

3.01 PFAFF 581, PFAFF 583 ........................................................................................................ 10

3.02 Versions and subclasses ...................................................................................................... 11

4 Disposal of Machine .......................................................................................................... 12

5 Transportation, packing and storage ................................................................................ 13

5.01 Transportation to customer‘s premises ............................................................................... 13

5.02 Transportation inside the customer‘s premises ................................................................... 13

5.03 Disposal of packing materials ..............................................................................................13

5.04 Storage ................................................................................................................................ 13

6 Explanation of symbols ..................................................................................................... 14

7 Controls .............................................................................................................................. 15

7.01 On/off switch ....................................................................................................................... 15

7.02 Pedal .................................................................................................................................... 15

7.03 Raising the presser foot ....................................................................................................... 16

7.04 Feed regulator disk / Reverse feed lever .............................................................................. 16

7.05 Keys on the machine head (only for machines with -911/..) ................................................. 17

7.06 Control panel ........................................................................................................................ 17

8 Installation and commissioning ....................................................................................... 18

8.01 Installation ............................................................................................................................ 18

8.01.01 Adjusting the table-top height .............................................................................................. 18

8.01.02 Assemble the mounted motor ............................................................................................. 19

8.01.03 Fit the belt guard of the fl ange-motor .................................................................................. 19

Page 4

Index

Contents ..................................................................................Page

8.01.04 Mounting the sewing head .................................................................................................. 20

8.01.05 Mount upper machine cover ................................................................................................ 20

8.01.06 Mounting the spool holder .................................................................................................. 21

8.02 Connecting the plug-in connections and earth cables ......................................................... 21

8.03 Commissioning the machine ............................................................................................... 22

8.04 Switching the machine on/off .............................................................................................. 22

8.05 Basic position of the machine drive unit ............................................................................ 23

8.05.01 On machines with PicoDrive and control unit P41 PD1 ....................................................... 23

8.05.02 With drive system MD-4-58-220-CE .................................................................................... 23

8.06 Mount and connect approach barrier .................................................................................. 24

8.07 Checking the start inhibitor function .................................................................................... 24

9 Preparation ........................................................................................................................ 25

9.01 Inserting the needle ............................................................................................................. 25

9.02 Winding the bobbin thread, adjusting the thread tension .................................................... 26

9.03 Removing / Inserting the bobbin case ................................................................................. 27

9.04 Inserting the bobbin case / Adjusting the bobbin thread tension ......................................... 27

9.05 Threading the needle thread / Adjusting the needle thread tension .................................... 28

10 Care and maintenance ....................................................................................................... 29

10.01 Servicing and maintenance intervals ................................................................................... 29

10.02 Cleaning the machine .......................................................................................................... 29

10.03 Topping up the oil tank ......................................................................................................... 30

10.04 Parameter settings ............................................................................................................... 31

10.04.01 Parameter list for PicoDrive with control unit P41 PD2 .......................................................31

10.04.02 Parameter list for drive system MD-4-58-220-CE ................................................................32

11 Mounting the table top ..................................................................................................... 33

11 .01 Table top cutout ................................................................................................................... 33

11 .02 Mounting the table top (with drive system MD-4-58-220-CE) ............................................. 34

11 .03 Mounting the table top (with PicoDrive and control unit P41 PD2) ..................................... 35

12 Block diagram .................................................................................................................... 36

12.01 PFAFF 581 + 583 with MD-4-58-220-CE ............................................................................. 36

12.02 PFAFF 581 + 583 with PicoDrive and control unit P41 PD2 ............................................... 37

13 Wearing parts ..................................................................................................................... 38

Page 5

Safety

1 Safety

1

.01 Directives

This machine is constructed in accordance with the European regulations contained in the

conformity and manufacturer’s declarations.

In addition to this Instruction Manual, also observe all generally accepted, statutory and

other regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organizations are to be strictly adhered to!

1.02 General notes on safety

● This machine may only be operated by adequately trained operators and only after having

completely read and understood the Instruction Manual!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read be-

fore operating the machine!

● The danger and safety instructions on the machine itself are to be followed!

● This machine may only be used for the purpose for which it is intended and may not be

operated without its safety devices. All safety regulations relevant to its operation are to

be adhered to.

● When exchanging sewing tools (e.g. needle, roller presser, needle plate and bobbin),

when threading the machine, when leaving the machine unattended and during mainte-

nance work, the machine is to be separated from the power supply by switching off the

On/Off switch or by removing the plug from the mains!

● Everyday maintenance work is only to be carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualifi ed service staff

or appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

The only exceptions to this rule are found in the regulations EN 50110.

● Modifi cations and alterations to the machine may only be carried out under observance

of all the relevant safety regulations!

● Only spare parts which have been approved by us are to be used for repairs! We express-

ly point out that any replacement parts or accessories which are not supplied by us have

not been tested and approved by us. The installation and/or use of any such products can

lead to negative changes in the structural characteristics of the machine. We are not liable

for any damage which may be caused by non-original parts.

5

Page 6

Safety

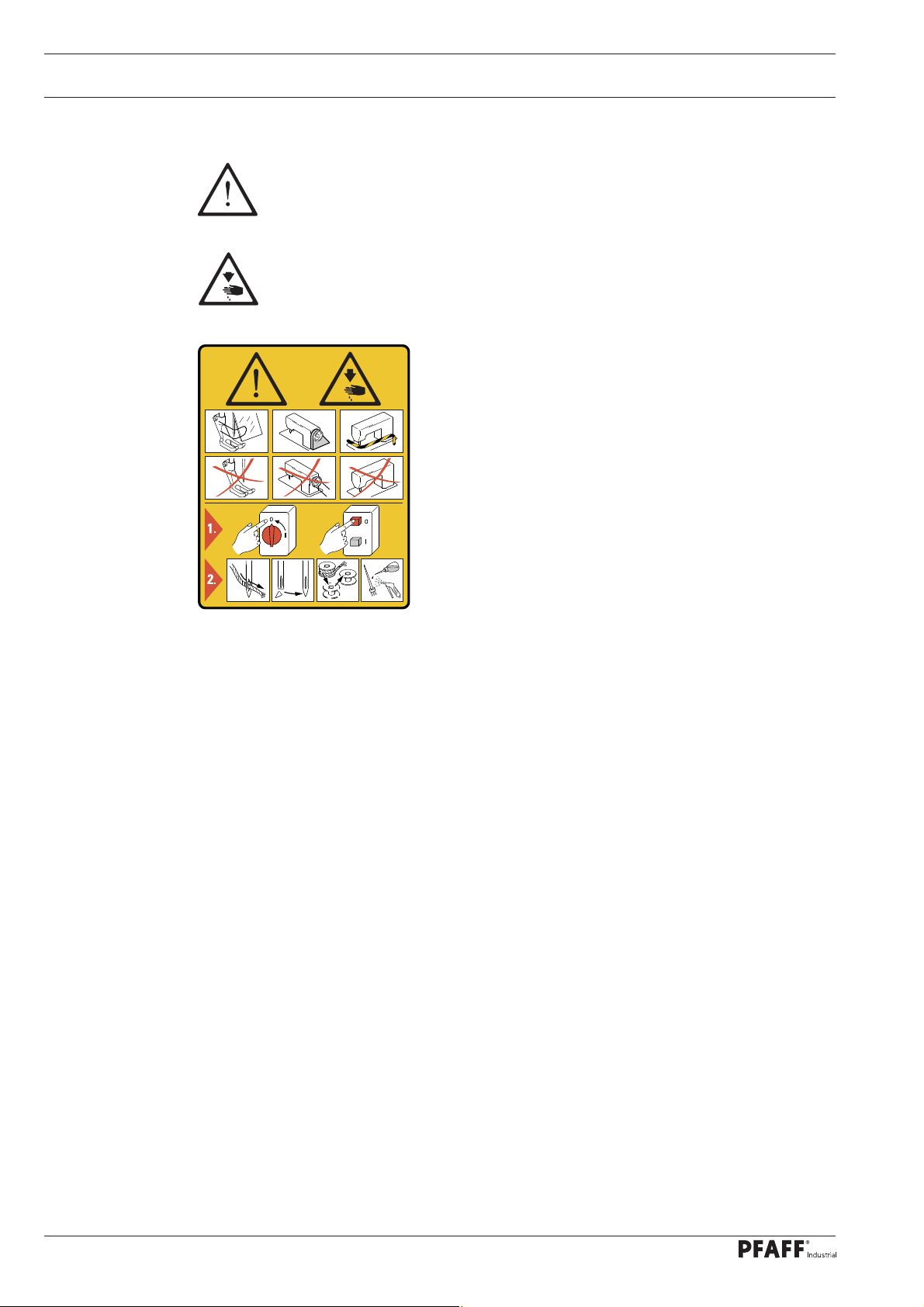

1.03 Safety symbols

Danger!

Points to be observed.

Danger of injury for operating and specialist personnel!

Do not operate without fi nger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

I

Caution

1.04 Important points for the user

● This Instruction Manual is an integral part of the machine and must be available to the

operating personnel at all times.

● The Instruction Manual must be read before operating the machine for the fi rst time.

● The operating and specialist personnel is to be instructed as to the safety equipment of

the machine and regarding safe work methods.

● It is the duty of the user to only operate the machine in perfect running order.

● It is the obligation of the user to ensure that none of the safety mechanisms are removed

or deactivated.

● It is the obligation of the user to ensure that only authorized persons operate and work

on the machine.

Further information can be obtained from your PFAFF agent.

6

Page 7

Safety

1.05 Operating and specialist personnel

1

.05.01 Operating personnel

Operating personnel are persons responsible for the equipping, operating and cleaning of

the machine as well as for taking care of problems arising in the sewing area.

The operating personnel is required to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● never use any working methods which could adversely affect the safety of the machine!

● not wear loose-fi tting clothing or jewelery such as chains or rings!

● also ensure that only authorized persons have access to the potentially dangerous area

around the machine!

● always immediately report to the person responsible any changes in the machine which

may limit its safety!

1.05.02 Specialist personnel

Specialist personnel are persons with a specialist education in the fi elds of electrics, electro-

nics and mechanics. They are responsible for the lubrication, maintenance, repair and adjust-

ment of the machine.

The specialist personnel is obliged to observe the following points and must:

● always observe the Notes on Safety in the Instruction Manual!

● switch off the On/Off switch before carrying out adjustments or repairs, and ensure that

it cannot be switched on again unintentionally!

● wait until the luminous diode on the control box is no longer blinking or on before begin-

ning adjustment or repair work.

● never work on parts which are still connected to the power supply! Exceptions are explai-

ned in the regulations EN 50110.

● replace the protective coverings and close the electrical control box afer all repairs or

maintenance work!

7

Page 8

Safety

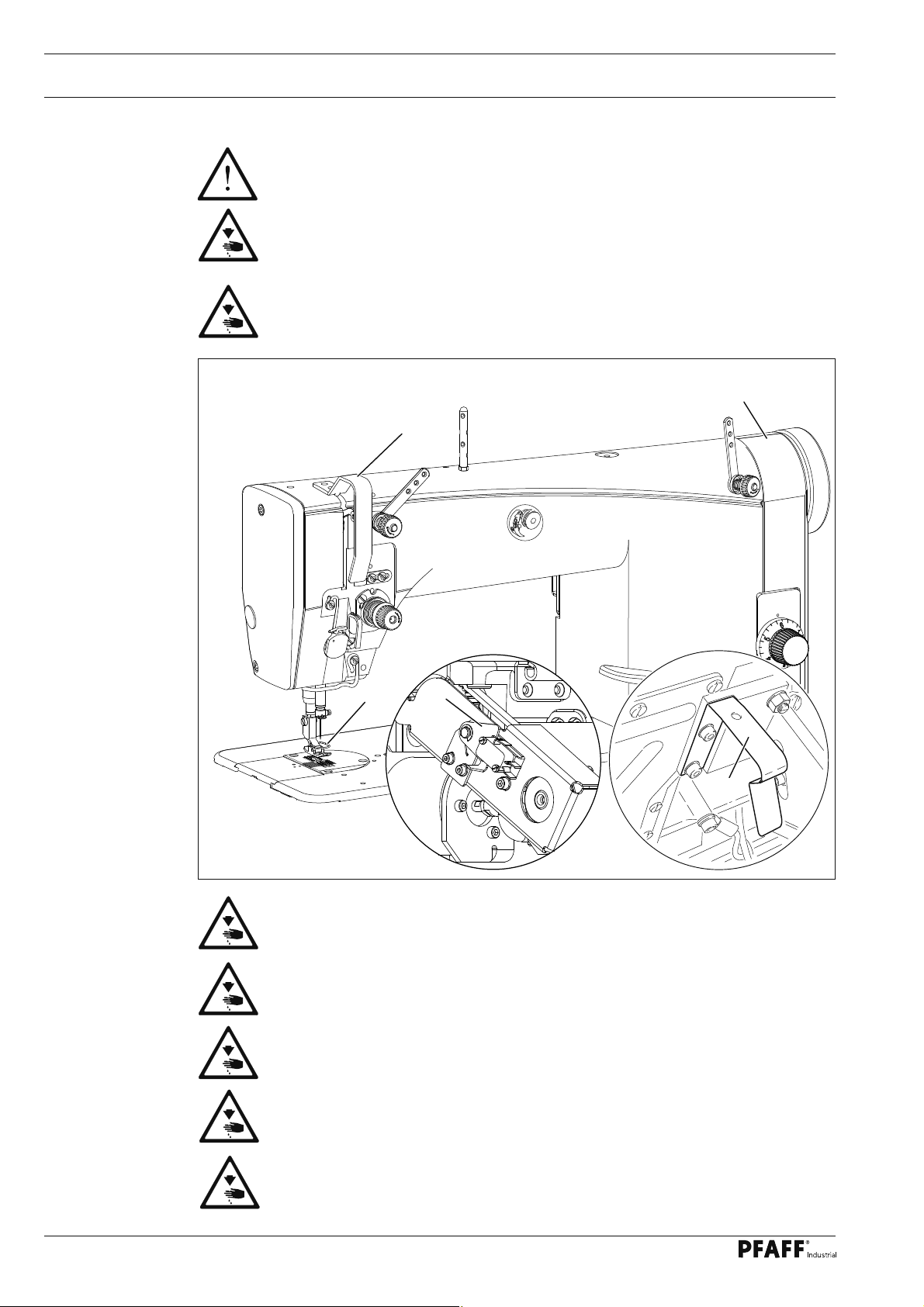

1.06 Danger warnings

A working area of 1 m must be kept free both in front of and behind the machi-

ne, so that easy access is possible at all times.

Never put your hands or fi ngers in the sewing area during sewing!

Danger of injury by the needle!

While setting or adjusting the machine do not leave any objects on the table nor

in the needle plate area! Objects may be trapped or fl ung out of the machine!

4

2

Fig. 1 - 01

1

Do not run the machine without fi nger guard 1!

Danger of injury by up and down movement of needle!

Do not run the machine without take-up lever guard 2!

Danger of injury by moving take-up lever!

Do not operate without start inhibitor 3!

Danger of injury if the machine is started accidentally!

Do not operate the machine without machine cover 4!

Danger of injury from moving parts!

3

5

Do not operate the machine without tilt lock 5!

Danger of crushing between sewing head and table!

8

Page 9

2 Proper use

The PFAFF 581 is an single-needle ultra-high-speed seamer with compound feed

The PFAFF 583 is an single-needle ultra-high-speed seamer with drop feed

These machines are used in the industry for sewing lockstitch seams.

Proper use

Any and all uses of this machine which have not been approved of by the

manufacturer are considered to be inappropriate! The manufacturer cannot be

held liable for any damage caused by the inappropriate use of the machine!

The appropriate use of the machine includes the observance of all operational,

adjustment, maintenance and repair measures required by the manufacturer!

9

Page 10

Specifi cation

3 Specifi cations

3.01 PFAFF 581, PFAFF 583

Stitch type: ........................................................................................................301 ( lockstitch )

Needle system: .................................................................................................................... 134

Needle size in 1/100 mm:

Version A: ........................................................................................................................ 60 - 70

Version B: ...................................................................................................................... 80 - 100

Version C: ..................................................................................................................... 110 - 140

Fabric clearance: ........................................................................................................9 - 13 mm

Clear workspace width: ................................................................................................260 mm

Clear workspace height: ...............................................................................................130 mm

Bed-plate dimensions: ........................................................................................ 476 x 177 mm

Sewing head dimensions:

Length: ............................................................................................................. approx. 550 mm

Width: .............................................................................................................. approx. 180 mm

Height (above table): ........................................................................................ approx. 300 mm

Max. stitch length: ............................................................................................................6 mm

Max. speed

Version A: ................................................................................................................... 5500 spm

Version B: ................................................................................................................... 5500 spm

Version C: ................................................................................................................... 5000 spm

Subclass -944/07: ....................................................................................................... 3500 spm

Power connection:

Operating voltage: ......................................................... 230 V ± 10 %, 50/60 Hz, single-phase

Max. input: ...................................................................................................................... 400 VA

Fuse: .................................................................................................................... 1 x 16 A, inert

Noise data:

Noise emission level at workplace with a sewing speed of 4800 spm: ............ L

< 82 dB(A)

pA

(Noise measurement in accordance with DIN 45 635-48-A-1, ISO 11204, ISO 3744, ISO

Net weight of sewing head: ..................................................................................approx. 40 kg

Gross weight of sewing head: ..............................................................................approx. 48 kg

Subject to technical alterations

KpA = 2,5 dB

■

10

Page 11

Specifi cation

3.02 Versions and subclasses

Version A: ...........................................................................................for sewing light materials

Version B: .................................................................................... for sewing medium materials

Version C: .......................................................................... for sewing medium-heavy materials

Work aids:

Subclass -900/.. ................................................................................................ thread trimmer

Subclass -909/.. .................................................................................................Thread trapper

Subclass -910/.. ............................................................................................ automatic foot lift

Subclass -911/.. ................................................................ automatic back-tacking mechanism

11

Page 12

Disposal of Machine

4 Disposal of Machine

● Proper disposal of the machine is the responsibility of the customer.

● The materials used for the machine are steel, aluminium, brass and various plastic

materials. The electrical equipment comprises plastic materials and copper.

● The machine is to be disposed of according to the locally valid pollution control regula-ti-

ons; if necessary, a specialist ist to be commissioned.

Care must be taken that parts soiled with lubricants are disposed of separately

according to the locally valid pollution control regulations!

12

Page 13

Transportation, packing and storage

5 Transportation, packing and storage

5

.01 Transportation to customer‘s premises

The machines are delivered completely packed.

5.02 Transportation inside the customer‘s premises

The manufacturer cannot be made liable for transportation inside the customer‘s premises

nor to other operating locations. It must be ensured that the machines are only transported

in an upright position.

5.03 Disposal of packing materials

The packing materials of this machine comprise paper, cardboard and VCE fi bre. Proper dis-

posal of the packing material is the responsibility of the customer.

5.04 Storage

If the machine is not in use, it can be stored as it is for a period of up to six months, but It

should be protected against dust and moisture.

If the machine is stored for longer periods, the individual parts, especially the surfaces of

moving parts, must be protected against corrosion, e.g. by a fi lm of oil.

13

Page 14

Explanation of symbols

6 Explanation of symbols

In this instruction manual, work to be carried out or important information is accentuated by

symbols. These symbols have the following meanings:

Note, information

Cleaning, care

Lubrication

Maintenance, repairs, adjustment, service work

(only to be carried out by technical staff)

14

Page 15

Controls

77-005

7 Controls

7

.01 On/off switch

● The power supply to the machine is

switched on or off by turning switch 1.

1

Fig. 7 - 01

7.02 Pedal

0 +1

● With the on/off switch on

0 = Machine stop

+1 = Sew

- 1 = Raise presser foot (for

machines with -910/..)

- 2 = Trim thread (for machines

with -900/..)

-1 -2

Fig. 7 - 02

15

Page 16

Controls

7.03 Raising the presser foot

Fig. 7 - 03

7

.04 Feed regulator disk / Reverse feed lever

Fig. 7 - 03a

16

Fig. 7 - 04

-

+

Page 17

Controls

7.05 Keys on the machine head (only for machines with -911/..)

● As long as key 1 is pressed during sew-

ing, the machine sews in reverse.

1

Fig. 7 - 05

7.06 Control panel

The description can be found in the separate instruction manual for the motor.

17

Page 18

Installation and commissioning

8 Installation and commissioning

The machine must only be mounted and commissioned by qualifi ed personnel!

All relevant safety regulations are to be observed!

If the machine is delivered without a table, it must be ensured that the frame

and the table top which you intend to use can hold the weight of the machine

and the motor. It must be ensured that the supporting structure is suffi ciently

sturdy, including during all sewing operations.

8.01 Installation

The site where the machine is installed must be provided with suitable connections for the

electric current, see Chapter 3 Specifi cations.

It must also be ensured that the standing surface of the machine site is fi rm and horizontal,

and that suffi cient lighting is provided.

The method of packaging used requires that the table top be lowered for trans-

port. The following is a description of how to adjust the height of the table top.

8.01.01 Adjusting the table-top height

1

1

2

18

Fig. 8 - 01

● Loosen screws 1 and 2 and set the desired table-top height

● Tighten screws 1 well.

● Adjust the position of the pedal so that you can operate it comfortably and tighten screw 2.

Page 19

Installation and commissioning

8

.01.02 Assemble the mounted motor

7

7

5

6

1

Fig. 8 - 02

● Fix bearing plate 1 on to motor 2 using screws 3, as shown in fi g. 8-02.

● Mount drive belt wheel 4 onto motor shaft and attach with screws 5.

● Tilt bearing plate 1 with motor 2 slightly to the side and lay drive belt 6 onto the drive belt

wheels.

4

3

2

● Align bearing plate 1 of motor 2 with machine housing and attach with screws 7.

● Tighten drive belt by pivoting the motor, looses screws 3 slightly to do so.

.01.03 Fit the belt guard of the fl ange-motor

8

2

● Attach belt guard 1 with screws 2.

2

Fig. 8 - 03

1

19

Page 20

Installation and commissioning

8.01.04 Mounting the sewing head

1

● Attach the hinges 1 with two screws

each in the relevant bore holes on the

base plate.

● Insert the sewing head with hinges 1 into

the rear rubber pads.

Fig. 8 - 04

.01.05 Mount upper machine cover

8

1

● Attach machine cover 1 with screws 2.

1

2

20

Fig. 8 - 05

Page 21

Installation and commissioning

8.01.06 Mounting the spool holder

● Mount the spool holder as shown in

Fig. 8-08.

● Insert the spool holder into the hole in

the table top and fasten it with the nuts

enclosed.

Fig. 8 - 06

8.02 Connecting the plug-in connections and earth cables

1

Fig. 8 - 07

● Connect all plug connections as described in the operations manual of the drive

● The following ground cables must be attached in order to discharge static electricity.

● Attach ground cables for machine, main switch, control unit and motor to ground point 1.

21

Page 22

Installation and commissioning

8.03 Commissioning the machine

● Check machine and in particular

electric lines for damage before fi rst

commissioning.

Fig. 8 - 08

1

Do not operate the machine if there is any discrepancy.

The machine may only be connected to an earthed socket!

Have home position of the machine drive verifi ed by certifi ed technicians

before fi rst commissioning! Have settings carried out my technicians where

required (see chapter 8.05)

● Remove pin 1 of the oil reservoir 2

(Fig. 8 - 08).

The pin serves only to protect

the machine from damage

during transport and must not

be used when sewing.

● Clean the machine thoroughly and oil it

(see chapter 10 Care and maintenance).

● Have skilled personnel check if the ma-

chine can be operated with the available

mains voltage.

22

8.04 Switching the machine on/off

● Switch the machine on (see Chapter 7.01, On/off switch).

Page 23

Installation and commissioning

8.05 Basic position of the machine drive unit

8

.05.01 On machines with PicoDrive and control unit P41 PD2

● Switch on the machine.

● Call up the parameter input by pressing the "scroll" key.

● To switch the function keys to input (LED in the TE key lights up), press the TE key.

● By pressing the corresponding +/- keys, select parameter "798" and service level C,

see Chapter Selecting the User Level in the separate Control Panel Instruction Manual.

● Select parameter "799" by pressing the corresponding +/- keys.

● Check whether the value is set at "2" and alter if necessary.

● Switch the machine off and then on again.

● Select parameter "800" by pressing the corresponding +/- keys.

● Check whether the value is set at "0" (balance wheel turns towards the operator) and alter

if necessary.

● Select parameter "802" by pressing the corresponding +/- keys.

● Check whether the value is set at "0" (= no reduction ratio) and alter if necessary.

● .By pressing the corresponding +/- key, select parameter "700"

● Sew a stitch by operating the pedal.

● Turn the balance wheel in the sewing direction until the descending needle is level with

the top edge of the needle plate.

● Conclude the adjustment of the sewing motor by pressing the "scroll" key

.05.02 With drive system MD-4-58-220-CE

8

● Press and hold button and switch on machine

● Parameter 176 is displayed.

AB

S

A

● Call up parameter 181.

● Call up input level.

● Sew a stitch with the pedal function.

● Turn the handwheel in rotational direction until the needle point (approaching from above)

is on the upper edge of the needle plate.

● Confi rm entry.

AB

S

D

S

● Call up parameter 192 .

Call up input level.

Press button D+ to turn function "off".

Press button "S" to exit input.

23

Page 24

Installation and commissioning

8.06 Mount and connect approach barrier

2

4

3

5

6

Fig. 8 - 09

● For machines delivered without table, plate 1 (included in the accessories) must be

mounted underneath the table top in such a way that the switching plate 2 is fl ush with

plate 1 when the sewing head is tilted upright.

● Loosen screws 3 and align carrier 4 in such a way that switching plate 2 is free when the

sewing head is on its side, and pressed, when the sewing head is upright.

● Connect connectors of the approach barrier on contacts 5 (red/blue) and 6 (grey/pink).

8.07 Checking the start inhibitor function

● Switch the machine on at the main switch and tilt back the sewing head.

1

24

● The error message "Er 0 16" (on MD-4-58-220-CE) or "Error 9 (on PicoDrive P41 PD2)

must appear on the control panel.

● If the message does not appear, check the setting of safety switch 2.

● After the sewing head has been returned to the upright position, the machine is ready

for operation again.

Page 25

Preparation

9 Preparation

All regulations and instructions in this Instruction Manual are to be observed!

Special attention is to be paid to the safety regulations!

All preparation work is only to be carried out by appropriately trained personnel.

Before all preparation work, the machine is to be separated from the electricity

supply by removing the plug from the mains or switching off the On/Off switch!

9.01 Inserting the needle

Switch off the machine!

Danger of injury due to uninten-

tional starting of the machine!

1

Only use needles from the sy-

2

stem intended for the machine,

see Chapter 3 Specifi cations.

Fig. 9 - 01

● Raise needle bar.

● Loosen screw 1 and insert needle 2 until

you feel it stop.

● The long needle groove must be aligned

in the direction of the machine head.

● Tighten screw 1.

25

Page 26

Preparation

9.02 Winding the bobbin thread, adjusting the thread tension

5

1

4

2

3

Fig. 9 - 02

● Place an empty bobbin 1 onto bobbin shaft 2.

● Thread the bobbin in accordance with Fig. 9-02 and wind it clockwise around bobbin 1

a few times.

● Switch on the bobbin winder while at the same time pressing bobbin winder spindle 2

and lever 3.

26

The bobbin fi lls up during sewing.

● The tension of the thread on bobbin 1 can be adjusted with knurled screw 4.

● The bobbin winder stops automatically when bobbin 1 is full.

● Remove the fi lled bobbin 1 and cut the thread on knife 5.

Page 27

Preparation

9.03 Removing / Inserting the bobbin case

Switch off the machine!

1

2

Removing the bobbin case:

● Tilt back the machine.

● Raise latch 1 and remove bobbin case 2.

Inserting the bobbin case:

● Press bobbin case 2 until you feel it snap

into the bobbin case base.

Danger of injury due to uninten-

tional starting of the machine!

Fig. 9 - 03

9.04 Inserting the bobbin case / Adjusting the bobbin thread tension

● Insert the bobbin into the bobbin case.

● Pass the thread through the slot under

the spring according to Fig. 9-04.

● Pass the thread through the notch.

5 cm

● Adjust the thread tension by turning

screw 1.

When the thread is pulled, the

bobbin must rotate in the direc-

tion of the arrow.

1

Fig. 9 - 04

27

Page 28

Preparation

9.05 Threading the needle thread / Adjusting the needle thread tension

Fig. 9 - 05

Switch off the machine!

Danger of injury due to unintentional starting of the machine!

● Thread the machine as shown in Fig. 9-05.

-

1

+

28

● Adjust the needle thread tension by turning disk 1.

Page 29

Care and maintenance

10 Care and maintenance

10

.01 Servicing and maintenance intervals

Clean the hook compartment ................................Daily, several times if in continuous use

Clean the entire machine ..................................................................................once a week

Check oil level .................................................................................................once a month

These maintenance intervals are calculated for the average running time of a

single shift operation. If the machine is operated more than this, shorter inter-

vals are recommended.

10.02 Cleaning the machine

The cleaning cycle required for the machine depends on following factors:

● Single or several shift operation

● Amount of dust resulting from the workpiece

It is therefore only possible to stipulate the best possible cleaning instructions for each indi-

vidual case.

For all cleaning work the machine must be disconnected from the mains

by switching off the on/off switch or by removing the mains plug!

Danger of injury if the machine suddenly starts up .

The following tasks are recommended dur-

ing single shift operation to avoid operation-

al errors:

● Tilt machine backwards.

● Clean the clamps and clamp area daily, or

more often during long-term usage.

● When righting the sewing head, ensure

pressing the anti-tipping device 1.

1

Return the machine to its upright position using both hands!

Danger of injury by crushing be-

tween the edge of the

machine and the table top!

Fig. 10 - 01

29

Page 30

Care and maintenance

10.03 Topping up the oil tank

The oil reservoir must alway-

shave oil in it.

1

● If necessary fi ll oil into hole 1 up to the

marking 2.

Use both hands to set the

sewing head upright!

Danger of crushing between

2

the sewing head and the table

top!

Only use oil with a mean

viscosity of 22.0 mm

and a density of 0.865 g/cm

2

/s at 40°C

3

at

Fig. 10- 02

15°C.

We recommend PFAFF sewing machine oil, part no. 280-1-120 144.

30

Page 31

Care and maintenance

10.04 Parameter settings

Parameter settings are described in the separate operations manual for

the drive, and may only be changed by qualifi ed technicians!

10.04.01 Parameter list for PicoDrive with control unit P41 PD2

Group

Parameter

Description

1

105 Speed for start backtackl B, C 300 - 2000 1500

110 Speed for end backtack B, C 300 - 2000 1500

6

606 Speed min B, C 30 - 300 180

User lever

Setting range

Set value

607 Speed max. B, C 300 - 6000

609 Cutting speed 1 B, C 60 - 300 220

668 Thread wiper/thread blower

B, C 0 - 1 0

1 = on; 0 = off

7

700 Needle position 0

B, C 0 -255 *

(needle reference position

702 Needle position 1 (needle lowered) B, C 0 - 255 79

703 Needle position 2 (take-up lever raised) B, C 0 - 255 222

705 Needle position 5 (end cutting signal 1) B, C 0 - 255 175

706 Needle position 5 (start cutting signal 2) B, C 0 - 255 135

707 Needle position 9 (start thread tension

B, C 0 - 255 190

release/start thread catcher)

797 Hardwaretest (OFF / ON ), B, C OFF

799 Selected machine class C 1 - 3 1

8

800 Rotating direction of the motor C 0 - 1 1

802 Main drive reduction ratio

C 0 - 1 0

0 = 1:1, 1 = variable

▲

9

985 Switch on angle for thread trapper B, C 0 -255 67

986 Switch off angle for thread trapper B, C 0 -255 206

989 Thread trapper at beginning of seam

B, C 0 - 2 0

0 = no

1 = yes

2 = Thread clamp with sewing foot lift

See Chapter 3 Specifi cations

*

Adjustment see Chapter 8.05 Basic position of the machine drive unit.

31

Page 32

Care and maintenance

10.04.02 Parameter list for drive system MD-4-58-220-CE

Parameter

1

4

5

46

47

61

81

84

85

87

179

181

210

211

Description

Speed max. 50 - 9999

Speed for start backtackl 50 - 8000 1500

Speed for end backtack 50 - 8000 1500

Rotating direction of the motor CW - CCW CW

Selected machine class 0 - 101 62

Cutting speed 1 50 - 500 220

Needle position 6 (start cutting signal 2) 0 - 360° 40°

Needle position 5 (end cutting signal 1) 0 - 360° 90°

Needle position 9 (start thread tension

release/start thread catcher)

Tension release after thread lever position at t.d.c. 0 - 1500ms 20ms

Needle position 2 (take-up lever raised) 0 - 359° 83°

Needle position 1 - needle lowered (192 = off) 0 - 255 250

Switch on angle for thread trapper 0 - 359° 20°

Switch off angle for thread trapper 0 - 359° 90°

Setting range

▲

0 - 360° 120°

Set value

236

See Chapter 3 Specifi cations

*

Adjustment see Chapter 8.05 Basic position of the machine drive unit.

Machine version

2 = 581 + 583

0 - 4 2

32

Page 33

Mounting the table top

XX

11 Mounting the table top

11

.01 Table top cutout

54

X

R19

R19

AA

0

R19 - 0,5

C

B

C

120

11,5

±0,1

19

0

R19 - 0,5

30°

C-C

B-B

Z

(2x)

B

(2x)

25,5

- 0,5

45°

(4x)

R10

45°

B

0

41,5 - 0,2

509

906-4001-155

Vers. 24.03.10

±0,3

71,5 339,6

R10

(2x)

(4x)

R10

0

(4x)

0

R19 - 0,5

a 0,3 A

+0,2

(2x)

9,8 0

R10

±0,1

20

479

18

180,5

W

- 0,5

40 85

29,4 - 0,2

(2x)

4,5

(2x)

0

(2x)

58

79,5 - 0,2

A-A

Y

85

40

R30

18

YY

45°

(2x)

R10

+0,2

9,8 0

A

a 0,3 A

45°

±0,1

±0,1

R10

R10

25,4

25,4

(2x)

+0,2

17 0

R30

41,5 - 0,2

+0,2

17 0

0

33

Page 34

Mounting the table top

11 .02 Mounting the table top (with drive system MD-4-58-220-CE)

100

50

35

Stand position

906-3750-005/895

215

1060

Table top cutout 906-4001-155

Table top order number 906-7001-469

M8x30 DIN 7965-St

Screwed inserts (3x)

115

33,25

66,5

Controlbox MD-4-95-220-CE

280

160

91-265 438-95

Vers. 24.03.10

34

Drawer

View:

Underside table top

35 186

120102,5102,5

500

Page 35

Mounting the table top

11 .03 Mounting the table top (with PicoDrive and control unit P41 PD2)

50

35

9550

215

Stand position

1060

20250

906-3750-005/895

100

Table top cutout 906-4001-155

Controlbox P 41 PD2

415

90

Table top order number 906-7001-469

20

30

Speedcontrolunit

Drawer

View:

Underside table top

35 186

120102,5102,5

91-265 453-95

Vers. 12.04.10

500

35

Page 36

Block diagram

12 Block diagram

12

.01 PFAFF 581 + 583 with MD-4-58-220-CE

581

583

Control panel

C 200 - 1.0

36

Speedcontrolunit

Control unit MD-4-58-220-CE

power switch

Mains plug

Page 37

Block diagram

12.02 PFAFF 581 + 583 with PicoDrive and control unit P41 PD2

581

Speedcontrolunit

583

BDF - PICO TOP

PC

Control unit P40 PD

for

software

download

power switch

Mains plug

37

Page 38

Wearing parts

13 Wearing parts

11-108 174-15

91-154 518-05

91-100 296-25

(3x)

91-000 407-15

(2x)

This is a list of the most important wearing parts.

A detailed parts list for the complete machine is included with the accessories.

In case of loss, the parts list can be downloaded from the internet address

www.pfaff-industrial.com/pfaff/de/service/downloads As an alternative to

the internet download the parts lists can also be ordered in book form under

part no. 296-12-19 139.

91-701 179-15

91-167 865-92

11-108 174-25

91-009 026-05

91-000 250-15

91-000 390-05

91-006 814-05

91-163 263-91

91-175 690-05

91-002 134-05

91-265 450-91

11-174 912-15 (2x)

91-265 455-91

91-265 227-05 (6x)

System 134

91-265 461-05

11-108 225-15

91-168 144-05

38

Page 39

Wearing parts

99-137 151-45

91-171 049-05

11-330 166-15 (2x)

91-171 042-05

95-774 464-05

91-700 996-15

Unterklasse -900/..

11-317 001-15

91-265 407-01

91-168 498-15

91-700 249-15

95-721 193-91

11-174 089-15

39

Page 40

PFAFF Industriesysteme

und Maschinen AG

Hans-Geiger-Str. 12 - IG Nord

D-67661 Kaiserslautern

Phone: +49 - 6301 3205 - 0

Fax: +49 - 6301 3205 1386

E-mail: info@pfaff-industrial.com

Hotlines:

Technical ser vice: +49 - 175/2243-101

Application consultance: +49 - 175/2243-102

Spare-parts hotline: +49 - 175/2243-103

Printed in Germany

© PFAFF Industriesysteme und Maschinen AG 2009, PFAFF is the exclusive trademark of VSM Group AB.PFAFF Industriesysteme und Maschinen AG is an authorized licensee of the PFAFF trademark.

Loading...

Loading...