Page 1

PFAFF

5642

Service

Manual

296-12-13925

Justieranl.

engi.

7.92

Page 2

Notesonsafety

•

The

machine

operatedbypersons

•

The

machine

•

Useofthe

•

When

bobbin)

must

be isolated from

mains

On

mechanically

the

motor

• General servicing work

• Repairs, conversion

or

persons

• For

service

compressed

Exceptionstothis

technicians.

• Work on

appropriately

must

must

machine

gauge

part

during

threading,

plug.

has

stopped.

with

appropriate

or repair work on

air

supply

the

electrical

trained

onlybecommissioned

with

appropriate

onlybeused

without

are

exchanged

the

operated

must

and

special

for

the

safety

when

the

mains by switching off

clutch

motors

onlybecarried

maintenance

training.

pneumatic

system.

are

only

adjustments

equipment

persons.

in full

training.

the

purpose

devices

(e.g.

needle,

workplace

knowledgeofthe

intended.

belonging

presser

is left,

and

the

without

systems

and

start

out

by appropriately trained

work

must

the

function

checks

must only be carried

to it is

foot,

during

not

needle

service

instruction

permitted.

plate,

work,

book

feed

the

main switch or disconnecting

inhibitor it is

necessary

to wait until

persons.

only be carried

machine

made

out

by electrical

outbytechnicians

mustbeisolated

by appropriatelytrained

engineers

and

dog

and

machine

the

from

the

• Work on parts and systems under electric current are not permitted, except as specified

in

regulations

• Conversions or

adherencetoall

• For repairs, only

Please

note:

This service manual

Divergencies in

DIN

57105orVDE 0105.

changestothe

safety

regulations.

replacement

applies

the

illustrations have no bearing on

machine must be authorized by us and only be made on

parts

approved

for

the

single-needle-aswell as for

by us

the

must

be used.

adjustments.

the

multi-needle version.

or

Tools,

gauges

Setofscrewdrivers

Set

of alien

and

other

with

keys

from 1.5to6 mm

equipment

blades

from2to10mm

needed

for

Adjustment pin, 3 mm dia. (flattened to 2.3 mm at

Positioning pin, 5 mm dia.,

Positioning pin, 6 mm, with 3 mm end dia.,

C-clamp,

Adjusting

Metal

Packetofsystem

Sewing

part

gauge(5and

rule,

part

thread

No.

08-880137-00

No.

5640

and

part

7 mm),

08-880218-00

needles

testing

fabric

No.

13-030341-05

part

No. 61-111643-54

part

adjustment

one

end), part No. 61-111643-55

No. 61-111643-53

Page 3

Contents

Notesonsafety

The

most

important

1 Preliminary

2

Looper

3

Feed

Spreader

4

5

Feed

6

Feed

6.1

Crosswisetosewing

6.2Insewing

7

Feed

8

Positionofneedleinneedle

8.1

Crosswisetosewing

8.2Insewing

9

Looper-to-needle

sewing

9.1 In

9.2

Crosswisetosewing

10

Needle

11

Spreader

11.1 In

sewing

adjustmentofneedle

drive

lifting

eccentric

drive

driving

dog

position

direction

dog

height

direction

direction

bar

height

position

direction

11.2 Crosswise to sewing direction

12

Needle

guard

13

14

15

16

17

18

Regulating

Needle

Stitch

Fabric

Knee

Tension

thread

length

clearance

lever

release

the

rest

eccentric

eccentric

eccentric

clearance

looper

regulation

limitation

position

adjustment

and

needle

direction

direction

direction

thread

and

and

data

hole

and

take-up

stroke

In brief 4

bar

height

bar

frame

drive

looper

lever

guard

limitation

Page

2

6

7

9

10

11

12

12

13

14

15

15

16

17

17

18

19

20

20

21

22

23

24

25

26

28

29

Page 4

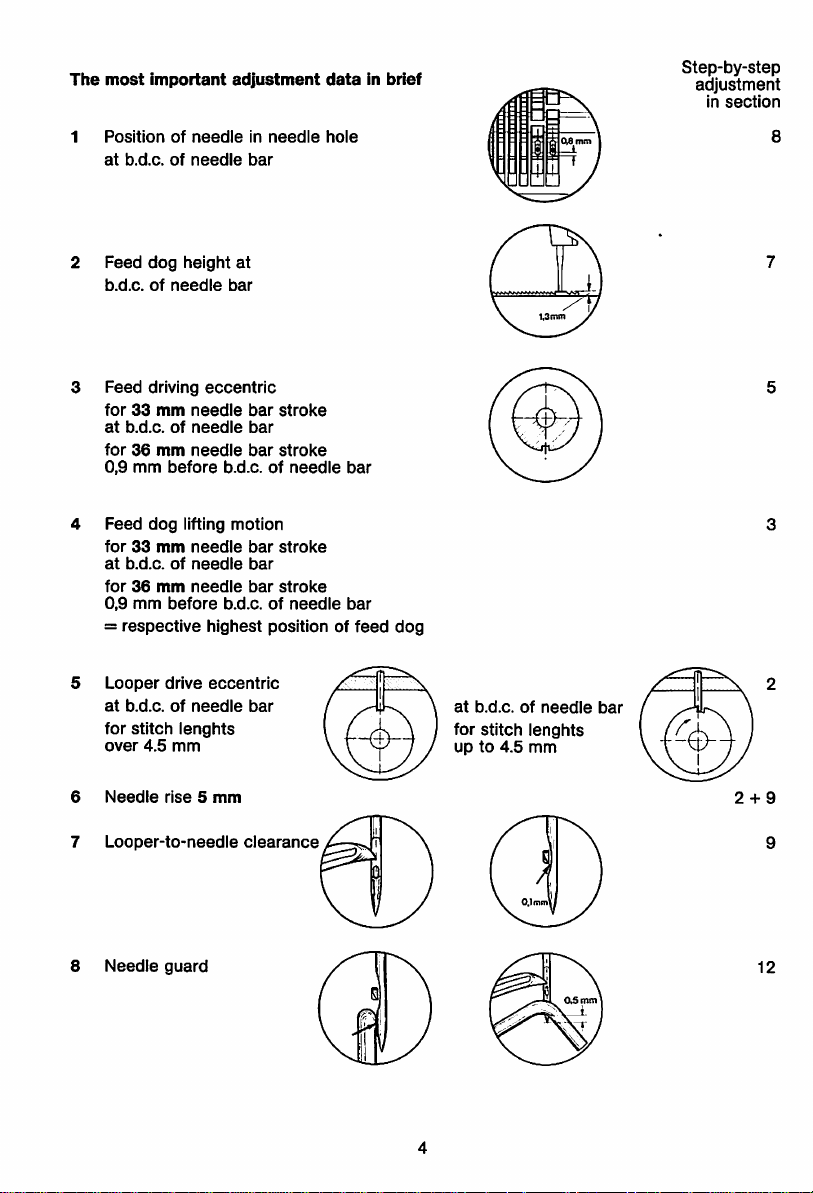

The

most

1

Position

at

Feed

b.d.c.ofneedle

Feed

for33mm

at

for36mm

0,9

Feed

for33mm

at

for36mm

0,9

=

important

of

needle

b.d.c.ofneedle

dog

height

driving

eccentric

mm

mm

dog

needle

needle

before

lifting

needle

needle

before

b.d.c.ofneedle

b.d.c.ofneedle

respective

adjustment

in

needle

bar

at

bar

bar

stroke

bar

bar

stroke

b.d.c.ofneedle

motion

bar

stroke

bar

bar

stroke

b.d.c.ofneedle

highest

positionoffeed

dataInbrief

hole

bar

bar

dog

Step-by-step

adjustment

In

section

8

Looper

at

b.d.c.ofneedle

for

stitch

over

6

Needle

7

Looper-to-needie

8

Needle

drive

4.5

mm

rise5mm

guard

eccentric

lenghts

bar

clearance

at

b.d.c.ofneedle

for

stitch

upto4.5

bar

lenghts

mm

2 + 9

12

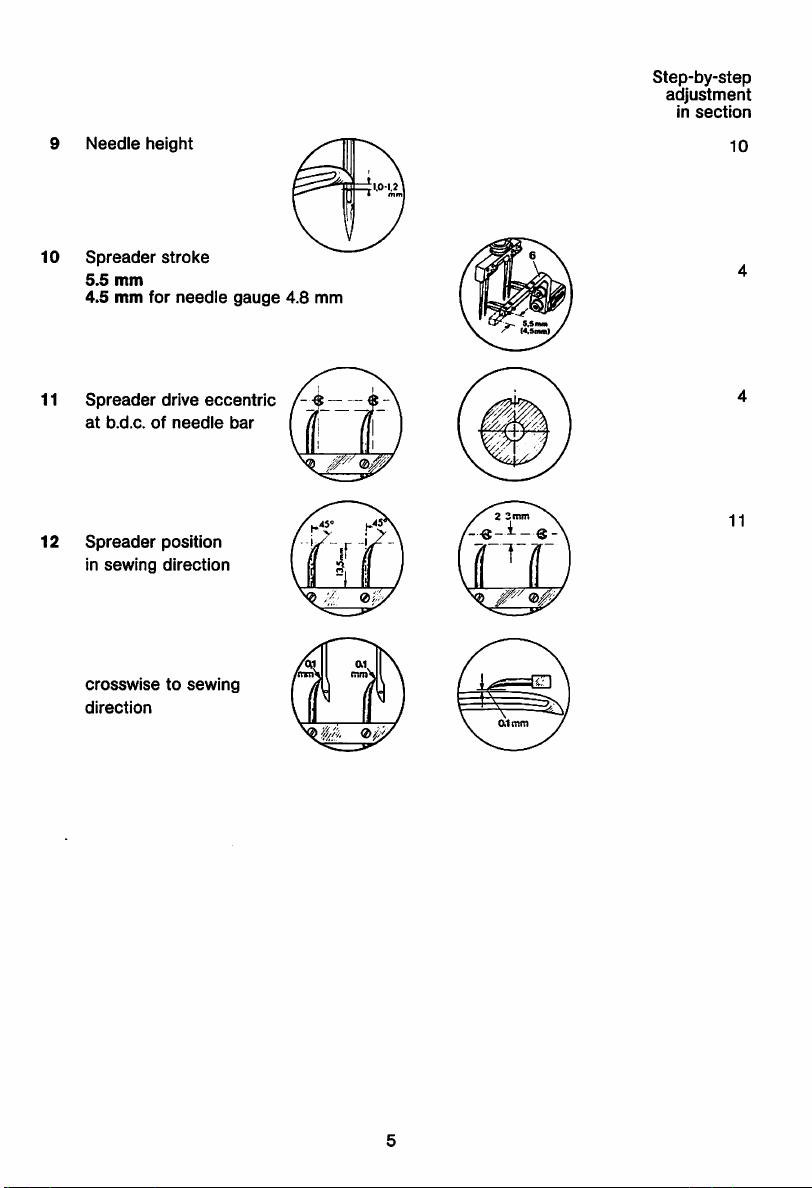

Page 5

9

10

11

12

Needle

height

Spreader

5.5

mm

4.5mmfor

Spreader

at

b.d.c.ofneedle

Spreader

in

sewing

stroke

needle

drive

eccentric

position

direction

gauge

bar

4.8

mm

(4,5aMl)

Step-by-step

adjustment

in

section

10

11

crosswisetosewing

direction

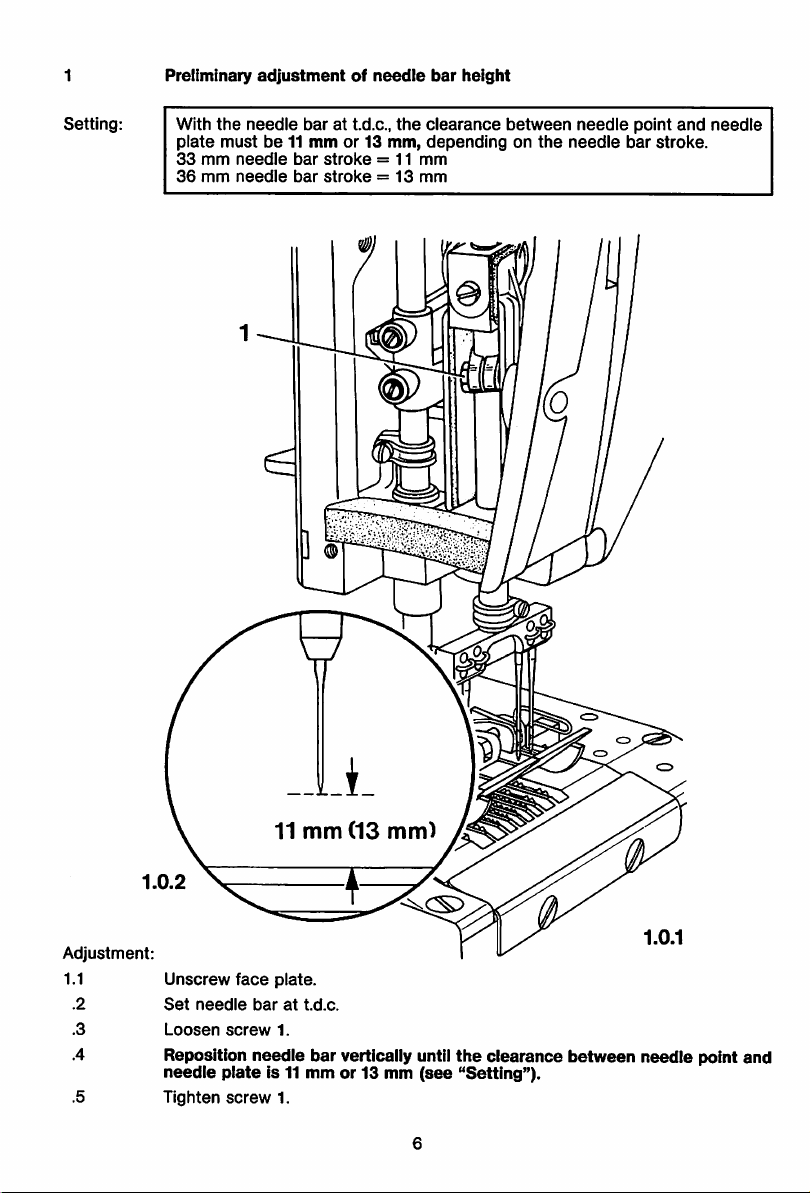

Page 6

Preliminary

adjustmentofneedle

bar

height

Setting:

With

the

plate

33

36

needle

mustbe11mmor 13

mm

needle

mm

needle

bar

at t.d.c.,

bar

stroke

bar

stroke=13

j ^

the

clearance

mm,

dependingonthe

= 11

mm

mm

between

needle

needle

point

bar

and

stroke.

needle

Adjustment:

1.0.2

Unscrew

Set

Loosen

Reposition

needle

Tighten

needle

plate

face

plate.

barattd.c.

screw

1.

needle

bar

is 11 mmor13 mm

screw

1.

vertically until

(see

the

clearance

"Setting").

between

needle

point

and

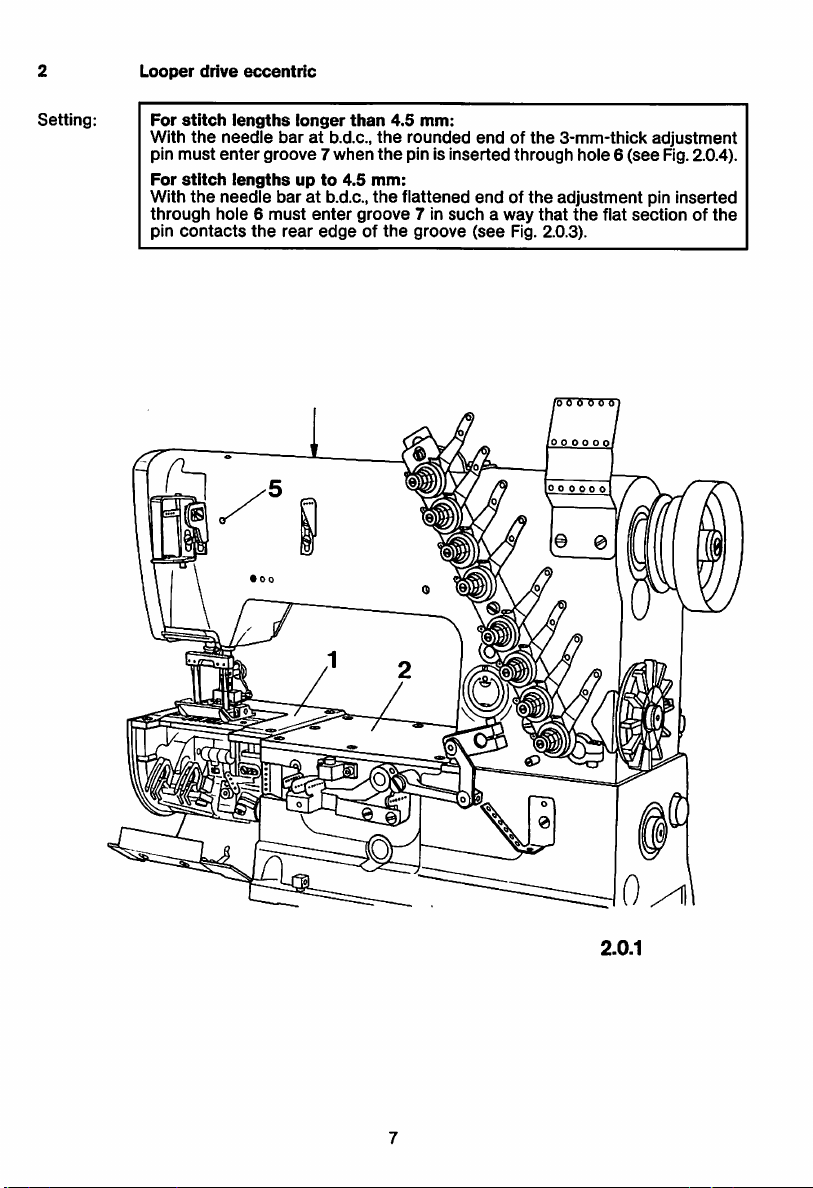

Page 7

2

Looper

drive

eccentric

Setting:

For

stitch

With

pin

must

For

stitch

With

the

through

pin

contacts

lengths

the

needle

enter

lengthsupto

needle

hole6must

longer

baratb.d.c.,

groove

baratb.d.c.,

the

rear

than

7 when

4.5

mm:

the

enter

groove

edgeofthe

4.5

mm:

the

rounded

the

pin is insertedthrough hole6

flattened

groove

7 in

suchaway

endofthe

endofthe

(see

Fig. 2.0.3).

that

3-mm-thlck

(see

adjustment

the

flat

o o O O O O

adjustment

Rg. 2.0.4).

pin

inserted

sectionofthe

2.0.1

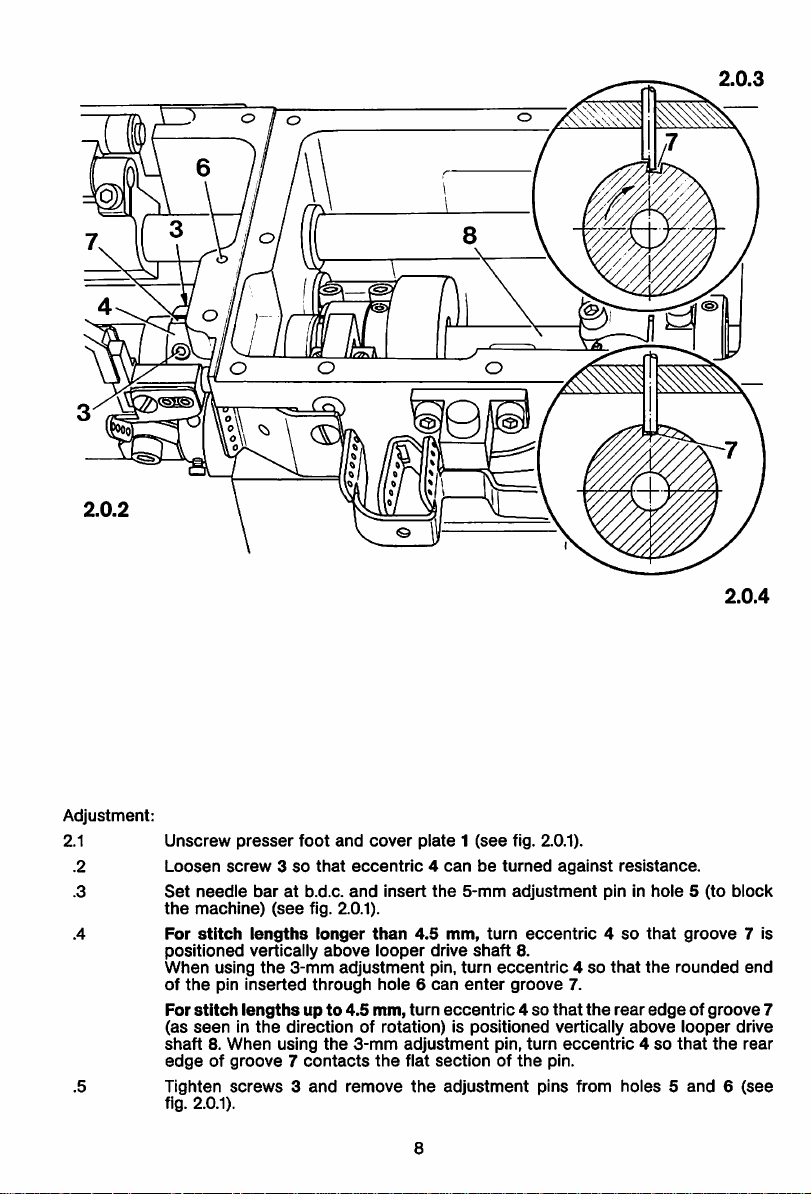

Page 8

2.0.3

2.0.4

Adjustment:

2.1

.2

.3

Unscrew

Loosen

Set

the

For

positioned

When

of

For

(as

shaft8.When

edgeofgroove7contacts

Tighten

fig. 2.0.1).

presser

screw3so

needle

machine)

stitch

using

the

pin

inserted

stitch

lengthsupto

seeninthe

screws3and

foot

and

that

baratb.d.c.

(see

fig. 2.0.1).

lengths

vertically

the

longer

3-mm

above

adjustment

through

directionofrotation)ispositioned

using

the

cover

plate1(see

eccentric4canbeturned

and

insert

the

than

4.5

looper

mm,

drive

pin,

hole6can

4.5

mm,

turn

eccentric4so

3-mm

adjustment

the

flat

sectionofthe

remove

the

8

adjustment

fig. 2.0.1).

5-mm

adjustment

turn

shaft

turn

eccentric4so

enter

groove

pin,

8.

against

eccentric4so

resistance.

pin in

that

7.

that

the

rear

vertically

turn

eccentric4so

pin.

pins

from

hole5(to

that

the

groove

rounded

block

7 is

end

edgeofgroove

above

looper

drive

that

the

rear

holes5and6(see

7

Page 9

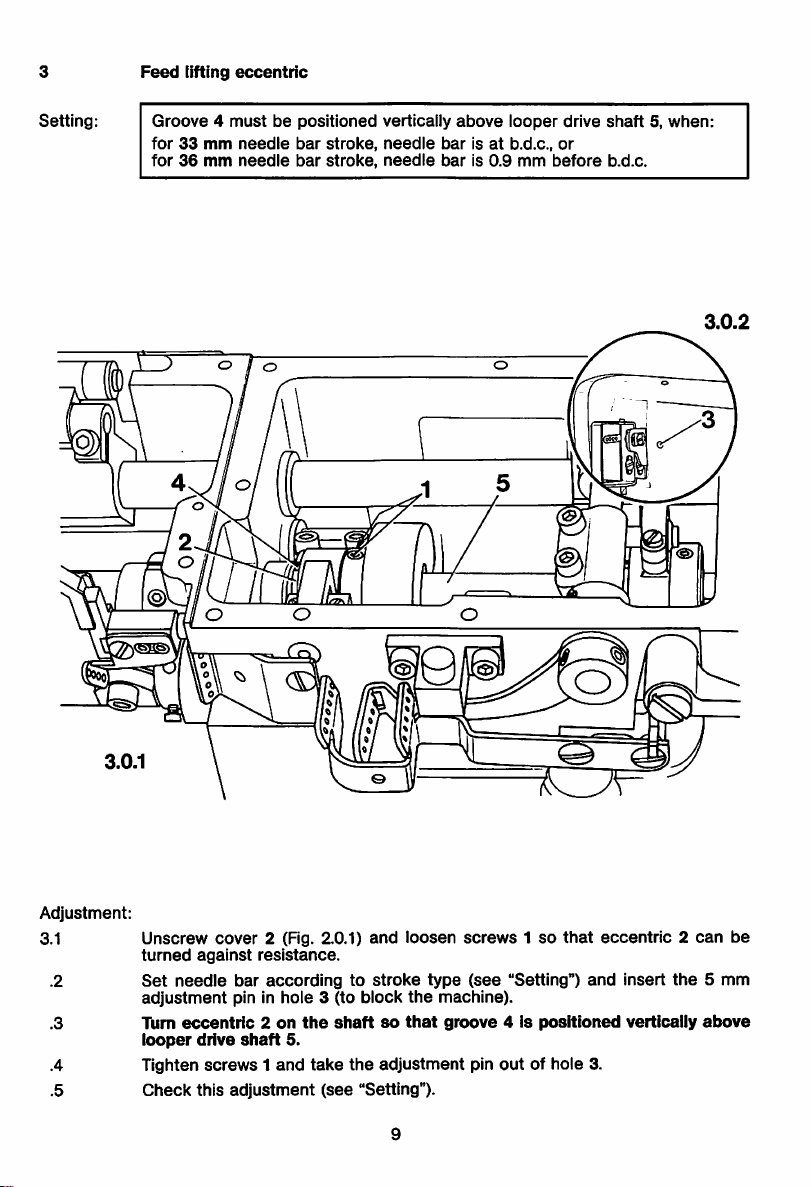

3

Feed

tiffing

eccentric

Setting:

Groove4mustbepositioned

for33mm

for36mm

needle

needle

bar

bar

stroke,

stroke,

vertically

needle

needle

above

barisat

baris0.9

looper

b.d.c.,

mm

drive

or

before

shaft5,when:

b.d.c.

3.0.2

Adjustment:

3.1

.2

Unscrew

turned

Set

adjustment

.3 Turn

looper

.4 Tighten

.5

Check

cover

against

needle

2 (Fig. 2.0.1)

resistance.

bar

accordingtostroke

pin In

eccentric2on

drive

shaft

screws1and

this

adjustment

hole

the

5.

take

and

3 (to

block

shaftsothat

the

adjustment

(see

"Setting").

loosen

type

the

screws1so

(see

machine).

groove4is

pin

out

that

"Setting")

positioned

of hole 3.

eccentric2can

and

Insert

the

vertically

be

5 mm

airave

Page 10

4

Spreader

drive

eccentric

Setting:

4.0.2

With

the

vertically

The

needle

4.8

needle

above

strokeofspreader

gauge,orneedle

mmiscontained,

baratb.d.c.,

looper

drive

bracket6mustbe5.5

gauge

this

stroke

groove

shaft

4 of

5.

combinationsinwhich

mustbe4.5

eccentric2mustbepositioned

mm.Onmachines

mm.

the

needle

with

4.8

gauge

mm

of

Adjustment:

4.1

.2

.3

.4

Loosen

Set

the

Tum

looper

Reposition

(4.5

.5 Tighten

.6

.7 Fit

Check

screws1so

needle

bar

machine).

eccentric2on

drive

shaft

eccentric

mm)

(see

screws1and

this

adjustment

the

covertothe

that

at b.d.c.

the

5.

2 axlallysothat

"Setting").

take

gear

eccentric2canbeturned

and

insert

the

5-mm

adjustment

shaftsothat

the

adjustment

(see

"Setting").

case.

groove

the

strokeofspreader

pin

10

against

4 Is

positioned

outofhole

resistance.

pin in hole 3 (to block

vertically

bracket

6 Is

above

5.5

mm

3.

Page 11

5

Feed

driving

eccentric

and

needle

bar

frame

drive

Setting: Groove 4 of

when:

for33mm

for36mm

5.0.2

feed

needle

needle

driving

bar

bar

eccentric

stroke,

stroke,

2 must be positioned exactly

needle

needle

barisat

baris0.9

b.d.c.,

mm

before

above

shaft 5,

or

b.d.c.

5.0.1

Adjustment:

5.1

.2

.3

Unscrew

Loosen

Set

the

screws1so

needle

adjustment

Turn

feed

at)ove

Tighten

Loosen

housing

linesofdrive

Fig. 5.0.3).

Tighten

Check

Replace

driving

the

center

screws

screws6and,

(see

screws6and

this

gear

gear

coveratthe

that

bar

accordingtostroke

pin in

hole

3 (to block

eccentric2on

of

shaft

1.

arrow

making

in Fig. 8.0.3),

crank8and

take

adjustment

(see

cover.

undersideofthe

eccentric2canbeturned

type

(see

"Setting")

connecting

crank8so

rod7are

pin

outofhole

its

5.

sure

tum

connecting

the

adjustment

the

machine).

shaftsothat

that

drive

"Setting").

11

machine

stand.

against

and

groove

4 is

rod7does

that

the

paralleltoeach

3.

resistance.

insert

positioned

not

imaginary

the

exactly

contact

other

5-mm

the

center

(see

Page 12

6

6.1

Feed

dog

position

Crosswisetosewing

direction

Setting:

The

them.

feed

dog

mustbecenteredInthe

needle

plate

slots

and

move

freely In

Adjustment:

6.1.1

.2

.3

.4

.5

.7

Unscrew

Loosen

Set

Fit

Position

feed

the

cover

slots.

cover

plateatthe

screws

1, 2, 3,

maximum

plate

together

feed

mechanism7so

Push fixing collars 5

and

4.

Check

this

adjustment

stitch

and

and

length.

with

6 up

(see

4.

backofthe

needle

plate.

that

against

"Setting").

12

arm-bed.

the

feed

feed

mechanism7and

dog

is laterally

centeredinthe

tighten

screws

3

Page 13

6.2

In

sewing

direction

Setting: With

hole4with

for33mm

for36mm

6.0.5

the

maximum stitch length

Its

3-mm

end,

needle

bar

needle

bar

when:

stroke,

stroke,

set,

needle

needle

the

6-mm

barIsat

barIs0.9

adjustment

b.d.c.,

or

mm

before

pin

b.d.c.

must

fit Into

6.0.3

Adjustment:

6.2.1

.2

.3

.4

.5

Set

the

type

(see

Insert

insert

that

the

Tighten

Check

maximum

stitch

"Setting").

the

5-mm

adjustment

the

6-mm

3-mm

adjustment

endofthe

screws5and6,and

this

adjustment

0

length

and

position

pin In

hole

1 (to

pininhoie2,repositioning

adjustment

(see

take

"Setting").

the

13

pin

adjustment

fits

the

block

needle

into

bar

accordingtostroke

the

machine).

connecting

hoie

4.

pins

outofholes1and

pin3so

2.

Page 14

Feed

dog

7

height

Setting:

7.0.2

With

the

the

front

(see

Fig. 7.0.3).

When

position

needle

teethofthe

using

the

contact

baratbottom

feed

dog

adjustment

the

gauge

dead

must

gauge,

(see

center

protrude

the

Fig. 7.0.4).

and

the

maximum

from

the

teethofthe

3

mm

needle

feed

stitch

length

plateby1.3

dog

mustinthis

3

mm

set,

mm

7.0.4

Adjustment:

7.1

.2

.3

.4

.6

.7

.8

.9

.10

.11

Unscrew

Loosen

Set

Loosen

stitch

Set

the

Tighten

Tighten regulating

teethofthe

plate

(The inclination of

Remove

the

cover

plate

and

the

needle

plate.

nut 1

and

turn

out

regulating

needle bar at t.d.c., push locking lever 3 to

screw4,replace

length.

cover

plate

screw

2 by 2 to 3 turns.

the

and

needle

left and swing out

plate,

and

set

the

the

loopers.

maximum

needle bar at b.d.c. and Insert the 5-mm adjustment pin in hole 5 (to block

machine).

screw4Just

feed

by 1.3 mm or,

cover

lightly.

screw2through

dog

(as

when

the

feed

plate

and

needle

seeninfeeding

the

using

gauge

dog

results from this

plate.

hole In

the

direction)

needle

protrude

No. 61-111643-37,

procedure.)

plate

from

contact

until

the

the

the

needle

gauge.

front

Lock regulating screw 2 with nut 1, tighten screw 4, and take the 5-mm adjust

ment

pin

Replace

Check

outofhole

cover

this

adjustment

plate

5.

and

needle

(see

plate

"Setting").

14

and

fix

them

with

the

screws.

Page 15

8

Position

of

needleinneedle

hole

8.1

Setting:

Crosswisetosewing

Crosswisetothe

in

the

center

(see

ti

direction

sewing

dash-dot

direction,

the

line in Fig. 8.0.4).

needles

must

enter

0 6 6 6 6 6)

000000

© ©

the

needle

holes

Adjustment:

8.1.1

.2

.3

.4

.5

.6

8.0.1

Insert

new

Loosen

Turn

Make

needle

Adjust

are

cutout,

Tighten

screws1(see

the

balance

sure

holes

the

exactly

adjustitaccordingly.

screws

(system

5640)

arrows

wheeltoset

that

the

needles

(as

seeninfeed

needle

bar

framesothat,

centeredinthe

1.

needles

in Figs. 8.0.1

the

are

the

direction);

needle

15

(the

long

groove

and

8.0.2)

needles

same

just

distance

adjust

crosswisetothe

holes,ifthe

must

and

above

from

the

needle

take-up

facetothe

screw3(see

the

needle

the

front

holder,ifnecessary.

feed

direction,

lever

strikes

8.0.2

right).

Fig. 8.0.3).

holes.

edgesofthe

the

needles

against

its

Page 16

8.2

In

sewing

direction

Setting:

With

the

the

needles

needle

and

baratb.d.c.,

the

front

edgesofthe

there

mustbea

needle

distanceof0.8

holes.

O o <9

mm

8.0.3

between

8.0.4

Adjustment:

8.2.1

Set the needle bar at b.d.c. and insert the 5-mm adjustment pin In hole 2 (to

block

the

machine).

Unscrew

Loosen

is a distanceof 0.8 mm

holes

Tighten

Check

the

coveratthe

screw3and

(Fig. 8.0.4).

screw3and

this

adjustment

backofthe

position

between

take

the

(see

machine.

the

needle

the

needles

adjustment pin

"Setting").

barinsewing

and

the

out

of hole 2.

directionsothat

front

edgesofthe

there

needle

Page 17

9

9.1

Looper-to-needle

In

sewing

direction

clearance

.Setting:

Requirement:

9.0.2

Ata needle bar position 5.0mm past

tioned

exactlyatthe

Theloopers mustbe inserted

needle

center

fully

b.d.c.,

lines.

the looper points must be posi

inthe guide slotof the looper

the looper drive eccentric must be adjusted according to chapter 2.

0

o

holders

and

Adjustment:

9.1.1

.2

.3

Remove cover plate with needle plate and unscrew

Set

needle

barata position 5.0 mm

Adjust the looper holders so that

center

lines.

Tighten

clamp

screw

1.

past

b.d.c.

and

the

looper points are opposite the needle

17

the

feed dog.

loosen

screw

1.

Page 18

9.2

Crosswisetosewing

direction

Setting:

When

the

clearance

looper

points

of 0.1 mm

are

between

a

opposite

looper

Q o

the

points

needle

and

center

needles.

lines,

A

there

must

be a

Adjustment:

9.2.1

.2

.3

.4

.5

.6

.7

.8

.9

.10

.11

9.0.3

Loosen

Is

placed

Loosen

Making

looper

Tighten

Loosen

Adjust

of

0.1

Tighten

Replace

Adjust

clearance

Tighten

Check

screws1and

In a

grooveInholder

screws

sure

that

holder3so

screws

screws

the

loopersothat

mm.

screws

the

other

the

looperssothat

of

0.1

screws

this

adjustment

2.

2.

4 of

4.

mm.

1.

the

that

the

loopers

take

out

looper

pointIsopposite

the

looper

right

between

and

(see

"Setting").

the

loopers

3.

looper

tighten

between

18

point

just

its

(except

contacts

a little.

point

screws

their

the

and

1 lightly.

points

the

needle

the

the

right one).

center

needle.

needle

and

the

The

line,

thereisa

needles

right

looper

re-posltlon

clearance

thereisa

Page 19

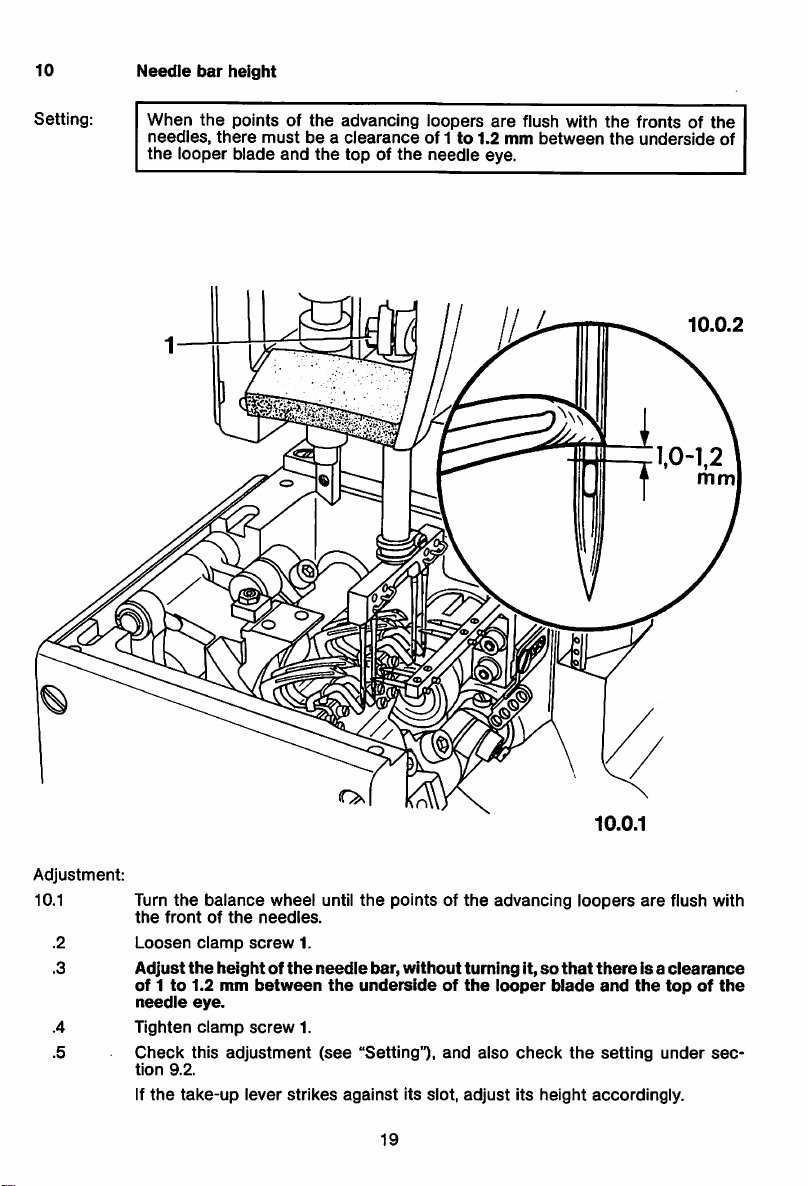

10

Needle

bar

height

Setting:

When

the

needles,

the

looper blade

pointsofthe

there

mustbea

and

advancing

clearance

the

top of

loopers

of 1to1.2mmbetween

the

needle

are

eye.

flush with

the

the

fronts of

underside

the

of

Adjustment:

10.1

.2

.3

.4

.5

Turn

the

frontofthe

Loosen

Adjust

of1to

needle

Tighten

Check

tion

9.2.

if

the

the

balance

clamp

the

wheel

needles.

screw

heightofthe

1.2mmbetween

eye.

clamp

screw

this

adjustment

take-up

lever

until

1.

needle

1.

(see

strikes

the

pointsofthe

bar,

the

without

undersideofthe

"Setting"),

against

its slot,

19

and

m

advancing

tuming

it,sothat

looper

blade

also

check

adjust

its height accordingly.

10.0.1

loopers

thereisa

the

and

setting

are

the

under

flush with

clearance

topofthe

sec

Page 20

11

11.1

Spreader

in

sewing

position

direction

Setting:

Note:

11.0.3

The

spreader

be

13.5

Also, with

distance

The

looper

flush

with

However,

have

dropped

1

points must have a 45®-incllnatlonto

mm

away

from

the

the

from

threads

the

undersideofthe

before

off

11.0.2

maximum

the

spreader

mustberetainedbythe

the

needle

the

stitch

thread

spreader.

spreader

length

pointstothe

ioopers.

drops

bracket.

set

needle

spreaders

off

and

the

the

the

needle

centers

looper,

right,

and

baratb.d.c.,

mustbe2to3 mm.

until

the

needle

the

looper

they must

points

thread

must

the

are

Adjustment

11.1.1

Set

the

Position

thereisa

in

this

right.

Tighten

Loosen

Adjust

the

spreader

Tighten

Check

maximum

spreaders2so

distance

position,

screws

screw4and

spreader

screw

this

turn

1.

bracket3so

points

4.

adjustment

stitch

length

that

of

13.5

mm.

spreaders2so

set

needle

and

the

(see

and

loosen

between

baratb.d.c.

that

thereisa

needle

"Setting").

20

their

that

centers.

screws

points

their

distance

1.

points

and

spreader

are

inclined

of2to3mm

brackets

45°tothe

between

3

Page 21

11.2

Crosswisetosewing

direction

and

looper

Setting:

Note;

11.0.6

At t.d.c. of

between

At l.d.c. of

between

the

spreader

spreader

the

spreader

spreader

brackets3there

point

and

brackets3there

point

and

The spreaders must not touch

11.0.5

0,1 -

0,2

mm

\

looper

spreader

the

mustbea

(Fig. 11.0.5).

mustbea

(Fig.11.0.6).

loopers at any position.

clearance

clearance

of 0.1to0.2

of 0.1to0.2

mm

mm

Adjustment:

11.2.1

Loosen

directly

Adjust

0.2 mm

Tighten

Turn

Position

the

spreader

Tighten

Check

screw4and

above

the

height of

above

screw

the

balance

spreader

screws

this

adjustment

the

the

4.

wheel

bracket3so

points

5.

turn

the

backsofthe

spreader

backsofthe

until

spreader

and

the

loopers

(see

"Setting").

balance

loopers.

bracket

loopers

that

there

21

wheel until

2 so

(Fig. 11.0.5).

bracket

is a

(Fig. 11.0.6).

the

spreaders2are

that

the

spreader

3 is in l.d.c.

clearanceof0.1to0.2mmbetween

and

points

loosen

11.0.4

positioned

are

0.1

screw

to

5.

Page 22

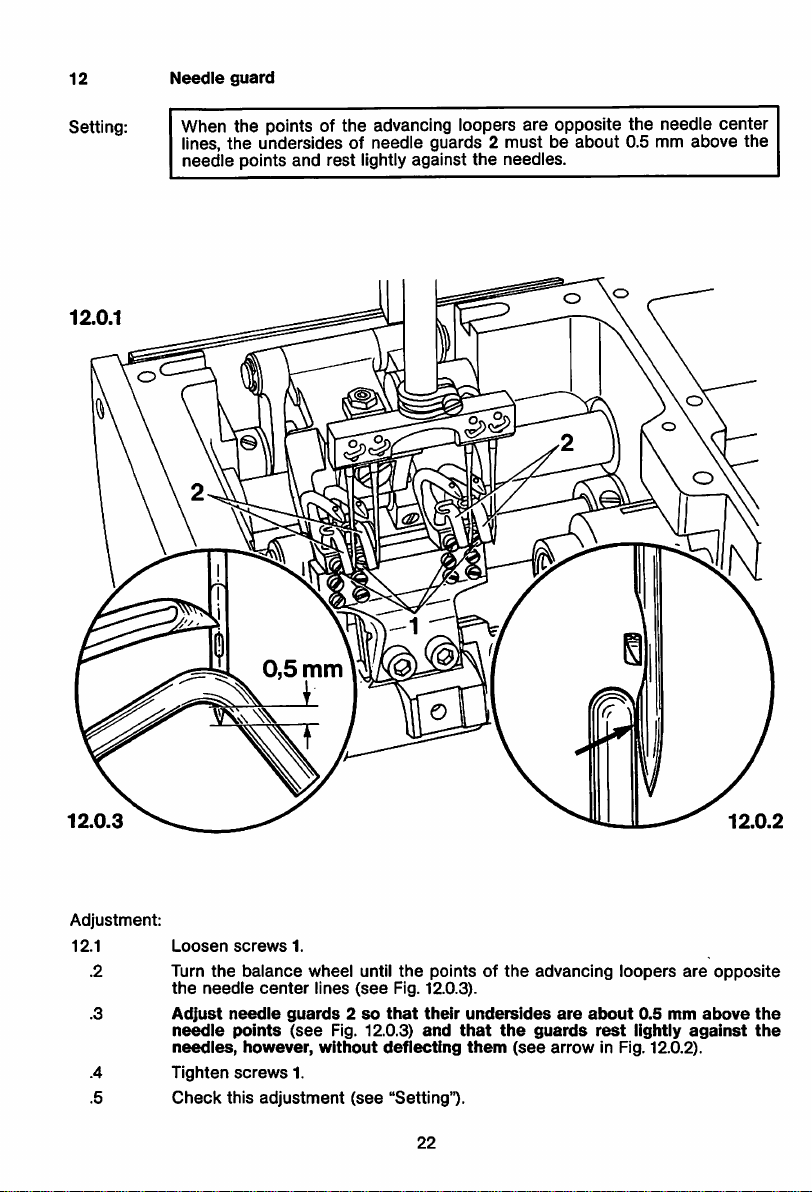

12

Needle

guard

Setting: When the points of the advancing loopers are opposite the needle center

lines,

the

needle

undersidesofneedle

points

and

rest

lightly against

guards 2

the

mustbeabout

needies.

0.5 mm

above

the

o

Adjustment:

12.1

.2 Turn

.3

.4

.5

Loosen

the

the

needle

Adjust

needle

needles,

Tighten

Check

screws

balance

needle

points

however,

screws

this

1.

wheel

center

lines

guards2so

(see

without

1.

adjustment

until

(see

Fig. 12.0.3).

that

Fig. 12.0.3)

deflecting

(see

"Setting").

the

pointsofthe

their

and

22

undersides

that

the

them

(see

advancing

are

about

guards

arrow

loopers

0.5

rest

mm

lightly

in Fig. 12.0.2).

are

above

against

opposite

the

the

Page 23

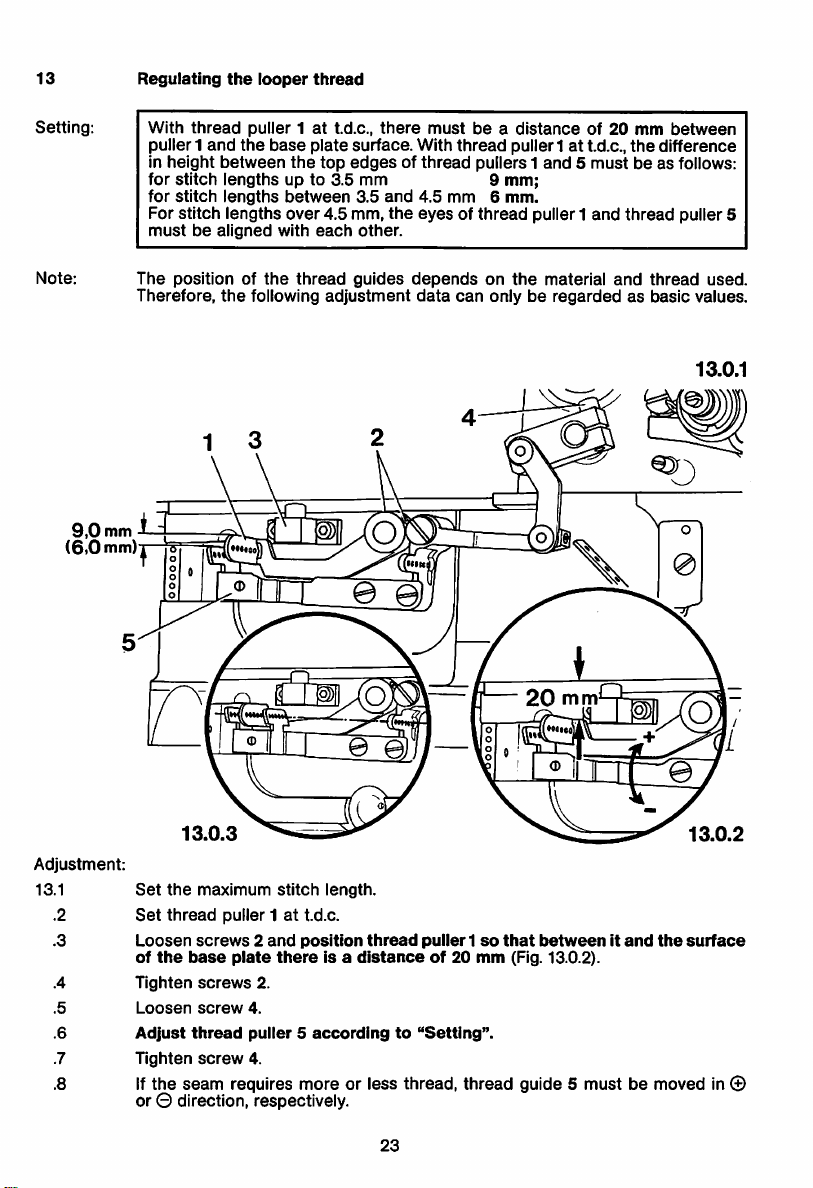

13

Regulating

the

looper

thread

Setting:

Note:

9,0

(6.0

With

puller1

in height

for

for

For

mustbealigned

The

Therefore,

mm

mm)

thread

and

between

stitch

lengths

stitch

lengths

stitch

lengths

position of

the

'•••do

puller 1attd.c.,

the

base

plate

the

top

there

surface.

mustbea

With

edgesofthread

up to 3.5 mm 9 mm;

between

over

with

the

following

4.5 mm,

each

thread

adjustment

3.5

and

other.

guides

the

4.5 mm 6

eyesofthread

dependsonthe

data

thread

puller 1attd.c.,

pullers 1

and5mustbeas follows:

mm.

distanceof20

puller1

and

material

can

onlyberegardedasbasic

mm

the

thread

and

between

difference

puller 5

thread

values.

13.0.1

used.

Adjustment:

13.1

.2

.3

.4

.5

.6

.7

.8

13.0.3

Set

the

Set

thread

Loosen

of

the

Tighten

Loosen

Adjust

Tighten

If

the

maximum

screws2and

base

screws

screw

thread

screw

seam

stitch

length.

puller 1att.d.c.

plate

position

thereisa

2.

4.

puller5accordingto"Setting".

4.

requires more or less thread, thread guide 5 must be moved in ©

or © direction, respectively.

thread

distanceof20

puller1so

23

that

mm

(Fig. 13.0.2).

betweenitand

the

13.0.2

surface

Page 24

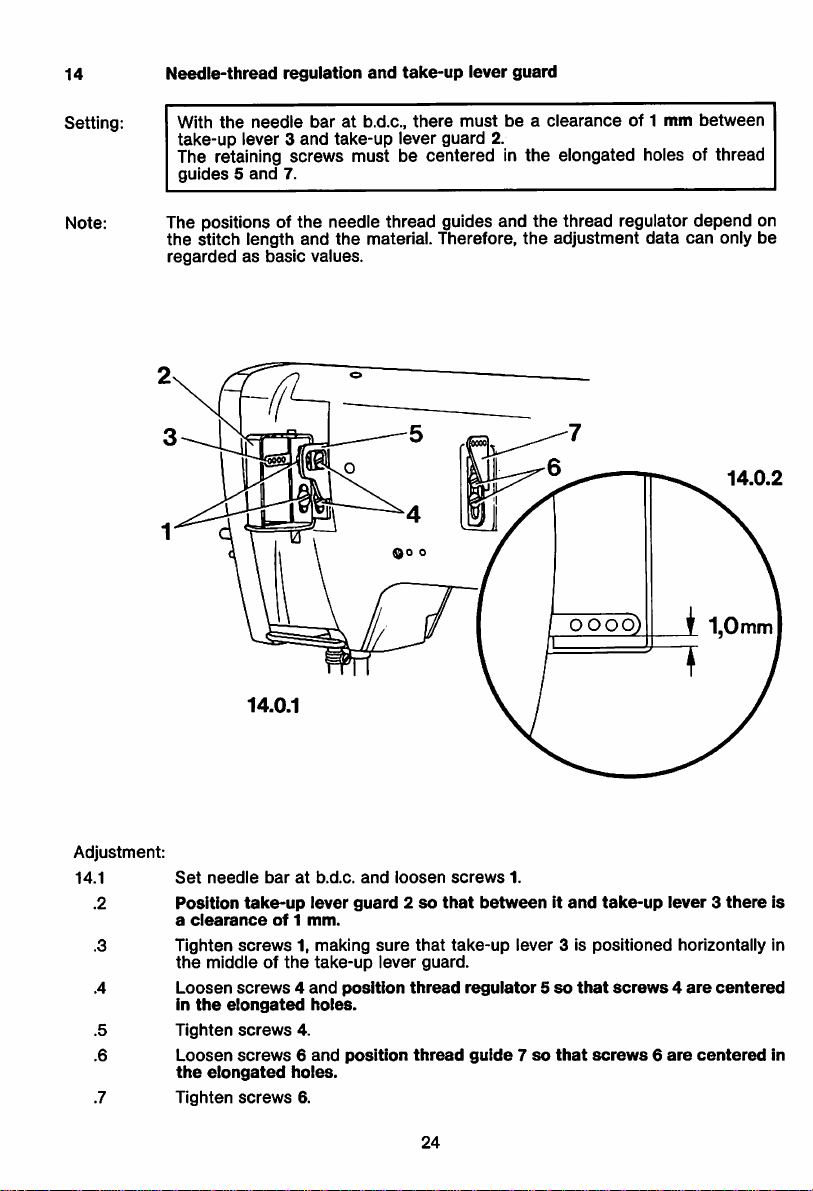

14

Setting:

Needle-thread

With

the

take-up

needle

lever 3

regulation

baratb.d.c.,

and

take-up

and

take-up

there

lever guard 2.

lever

mustbea

The retaining screws must be centered In

guides5and

7.

guard

clearance

the

elongated holes of thread

of 1

mm

between

Note:

The positions of

the

stitch

regardedasbasic

length

14.0.1

the

needle thread guides and

and

the

material.

Therefore,

values.

the

thread regulator

the

adjustment

data

depend

can

only

on

be

14.0.2

Adjustment:

14.1

Set

needle

Position

a

clearance

Tighten

the

middleofthe

Loosen

in

the

Tighten

Loosen

the

elongated

Tighten

baratb.d.c.

take-up

lever

of1mm.

screws1,making

take-up

screws4and

elongated

screws

screws6and

screws

holes.

4.

holes.

6.

and

guard2so

sure

lever

position

position

loosen

that

thread

thread

screws

that

take-up

guard.

24

1.

betweenItand

lever

regulator5so

guide7so

3 is

positioned

that

that

screws6are

take-up

lever3there

screws4are

horizontally In

centered

centered

is

in

Page 25

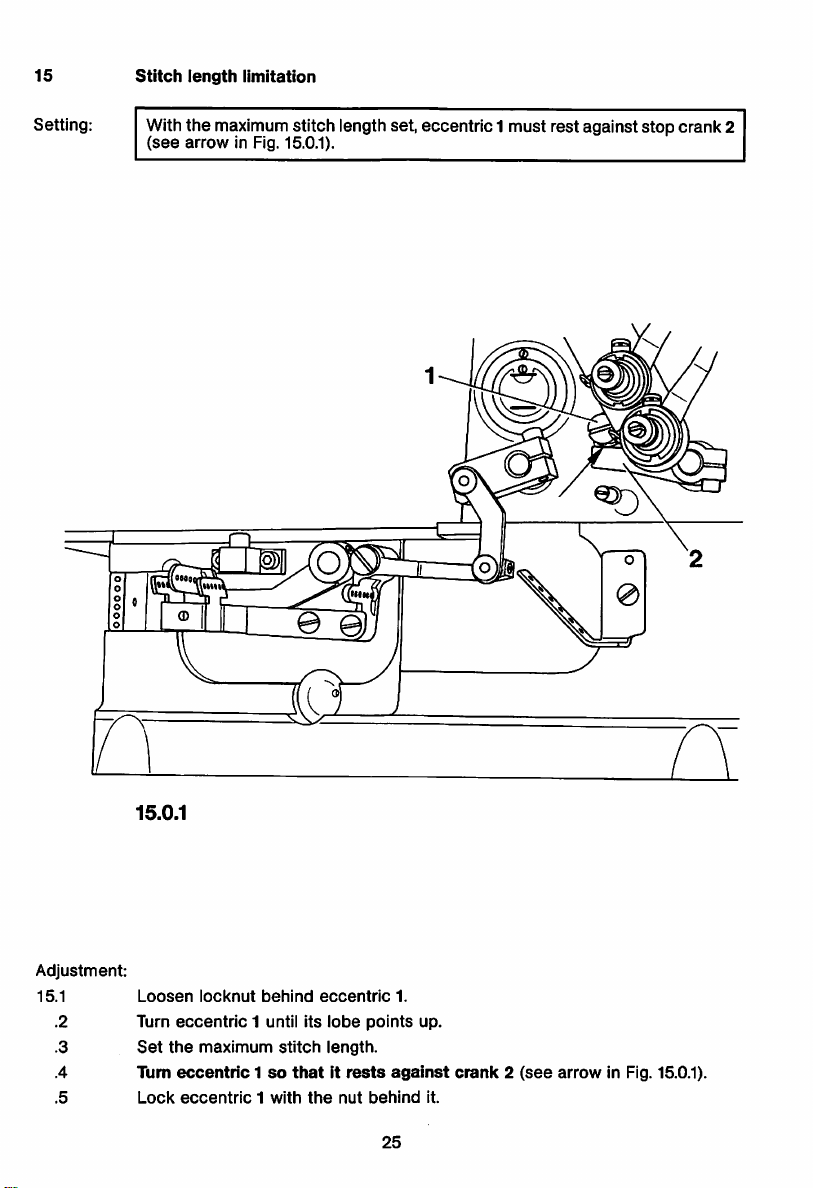

15

Stitch

length

limitation

Setting:

With

(see

the

maximum stitch length set, eccentric1 must rest againststop crank2

arrow

in Fig. 15.0.1).

Adjustment:

15.1

.2

.3

.4

.5

15.0.1

Loosen

Turn

eccentric

Set

the

Turn

eccentric1so

Lock

eccentric1with

iocknut

1 until its

maximum

behind

stitch

thatitrests

the

eccentric

lobe

length.

nut

points

against

behind

25

1.

up.

crank2(see

it.

arrow

in Fig. 15.0.1).

Page 26

Fabric

16

clearance

Setting:

0,3

min

With presser bar lifter 3 raised, there must be a clearance of 7 mm between

presserfoot and needle plate. On machines withfloatingfoot, raisingpresser

bar

lifter 3

must

begins

to lift

clearofthe

On machines with plain hinged

0.3

mm

first raise

iowered

between

and

the

collar 6

presser

16.0.3

the

presser

needle

bar

plate.

presser

and

presser

bar

foot is resting on

by 0.3 mm

foot,

there

bushing 7

the

needie

before

must

when

plate.

the

be a

presser

clearance

the

feed

foot

dog

of

is

16.0.1

16.0.2

26

Page 27

Adjustment;

16.1

Set

needle

baratt.d.c.

.2 Reduce the pressure on presser bar 1 by turning out the regulating screw (see

arrow

in Fig. 16.0.3).

.3 Refit feed dog, cover plate with needle plate, and

.4*

Turn

knurled

nut2until

its

face

sideisflush

with

presser

the

screw.

foot.

.5 Raise the presser bar lifter,loosen screws 4, and place the 7-mm adjustment

gauge

under

the

presser

.6 Push presser bar 1 down until the presser foot rests

gauge

(without pressure),

sewing

presser

direction.

foot.)

(The

foot

and

needles

hinge.

is parallel with

mustbecentered

the

needle

in

lightly

on the adjustment

plate

cutoutasseen

the

needle

holesofthe

.7 Tightenscrews 4 and take the adjustment gauge out from under the presserfoot.

.8* Lower

presser

bar lifter 3 just sufficiently to allow

the

presser

foot to

contact

needle plate with its entire straight sole without exerting any pressure.

.9* Inthis position, loosen screw 5, push collar 6 down until it contacts presser bar

bushing7,then

.10 On

machines

clearanceof0.3 mm

Is

lowered

.11 Turn in

the

pressureonthe

.12* Turn knurled nut 2 to adjust

at varying

.13

Screwonthe

tighten

with plain hinged

betweenItand

and

the

presser

pressure

regulating

presser

speeds

face

(and

plate.

screw5again.

presser

presser

footIsrestingonthe

screw

barsothat

the

proper

the

pressuresothat

material

does

foot

adjust

collar6so

bar

bushing7when

needle

(see

arrow in Fig. 16.0.3) to

feeding is

ensured

proper

not flag).

plate.

even at

feeding Is

that

the

increase

top

ensured

there

feed

speed.

in

the

Is a

dog

the

even

* =

Does

not

applytopresser

feet

without

knurled

nut

2.

27

Page 28

Knee

lever

rest

17

position

and

stroke

limitation

Setting;

When

the

own weight,

more

than7mm.

Also,

the

foot.

17.0.1

knee

knee

lever Is fully

and

the

lever

presser

must

actuated,

foot

must

haveaslight

the

presser

lift

clearofthe

amountofplay

bar

before

lifter

needle

must

plate

lifting

drop

by a little

the

presser

by its

Adjustment:

17.1

.2

.3

.4

.5

.6

.8

.9

.10

Make

sure

that

foot

onto

Loosen

TurnInscrew

Turn

screw1backbyabout

the

knee

Loosen

Raise

the

ment

gauge

Push

the

adjustment

Hold

the

Release

the

nut.

Check

this

the

the

needle

nutofscrew1and

1 until

lever

mustbeat

nutofscrew2and

presser

under

knee

gauge.

knee

leverinthis

the

knee

adjustment

knee

lever is

platebymeansofthe

turn

the

presser

half a

about

turn

foot

with

the

levertothe

the

presser

right

position

lever,

turn

screw2backbyabout

(see

"Setting").

inserted

out

screw

foot

turn

right

the

screw

lifting

foot

from

until

and

28

in its

connection,

lifting lever.

by a

few

beginstolift

and

tighten

anglestothe

out

by a

lever

and

place

the

rear.

the

presser

turn

the

left

then

lower

turns.

from

the

needle

its locknut. (In

base

plate.)

few

turns.

the

10-mm-thick

foot

beginstolift

screwinas

half a

turn

and

the

presser

plate.

this

position,

adjust

off

the

farasit willgo.

lock

it with

Page 29

18

Tension

release

Setting:

When

the

tensions6mustbereleased.

presser

foot Is raised with

•

00

the

knee

lever by

fo 6 6 6 6 6

about

10 mm,

thread

Adjustment:

18.1

.2

.3

18.0.2

Loosen

Raise

the

screw

presser

Turn fixing

pieceofcrank

this

position,

In

by

about1mm.

Tighten

Check

clamp

this

Screwoncover

1.

foot

collar

2 (In

4.

push

screw

adjustment

plateatthe

with

the

knee

leverbyabout

directionofarrow)

tension

release

1.

(see

"Setting").

backofthe

29

plate

until

crank

5 fully

machine.

10 mm

and

3 Is

resting

downwards,

retain this position.

against

then

the

angle

haveItreturn

Page 30

PFAFF

PFAFF

Postfach

KonigstraRe

D-6750

Telefon;

Telefax;

Telex:

Weber

PrintedinWest-Germany

3020/3040

154

Kaiserslautern

(0631)

(0631)17202

45753

200-0

Loading...

Loading...