Page 1

481

Service

PFAFF

INDUSTRIEMASCHINEN

Manual

GMBH

KAiSERSLAUTERN

Page 2

Instructions

and

Illustrated Guide for

for Adjusting

Tape-Recorded

the

Instructions

Pfaff 481

Important

Never

damage

length

with the reverse-feed control depressed, that means with the machine

wardsata

note

use a

C-clamp

Its

special

of "0"on

stitch

on the needle bar of

coating.

Model

lengthof1.5

Furthermore,

N machines have to be carried out at a stitch length of 1.5mmand

mm.

Pfaff

480 series

all adjustments

machines

which

are to be made at a

because this

set

for sewing back

would

stitch

The machine can be blocked at certain positions by Inserting a 5-mm-thlck pin In one of

the holes In the bearing plate

the

pin,

be sure to push ItInuntil

which

Is located underneath the face cover.

Itenters the slotInthe disc

behind

the bearing plate. For

When

Inserting

easy Identification, the Individual holes are marked by the numbers 1 to 5 or by the appro

priate adjustment data. The abbreviations used In this connection stand for the

n. o. T. =

n. u. T. =

o. T. N. =

o. T. F. =

Schl.-H. = 1.8 mm

past

the

topofthe

past

the

bottom of

topofneedle

topoftake-up

past the

bar

stroke

lever

bottom of

needle

the

stroke

bar

needle

the

stroke

bar

needle

stroke

bar

following:

stroke

The following tools, gauges and accessories are required for adjusting the Pfaff481;

1

setofscrewdrivers

1

setofalien

1

setofspanners

1

22-mm

spanner

1

metal

rule

1 cylindrical pin, 5 mm dia..

1

universal

1

wrapper

1

stripofwhite

gauge.

with

keys

System

paper,

with

ranging

from

Order

blades

from

7 to 14 mm

Order

Nr.

61-111642-19

134

needles

sewing

thread

from

2 —10mm

1.5

to 6 mm

wide

No. 13-030341-05

and

material

wide

for

testing

purposes.

Page 3

1.

Preparations

for

adjusting

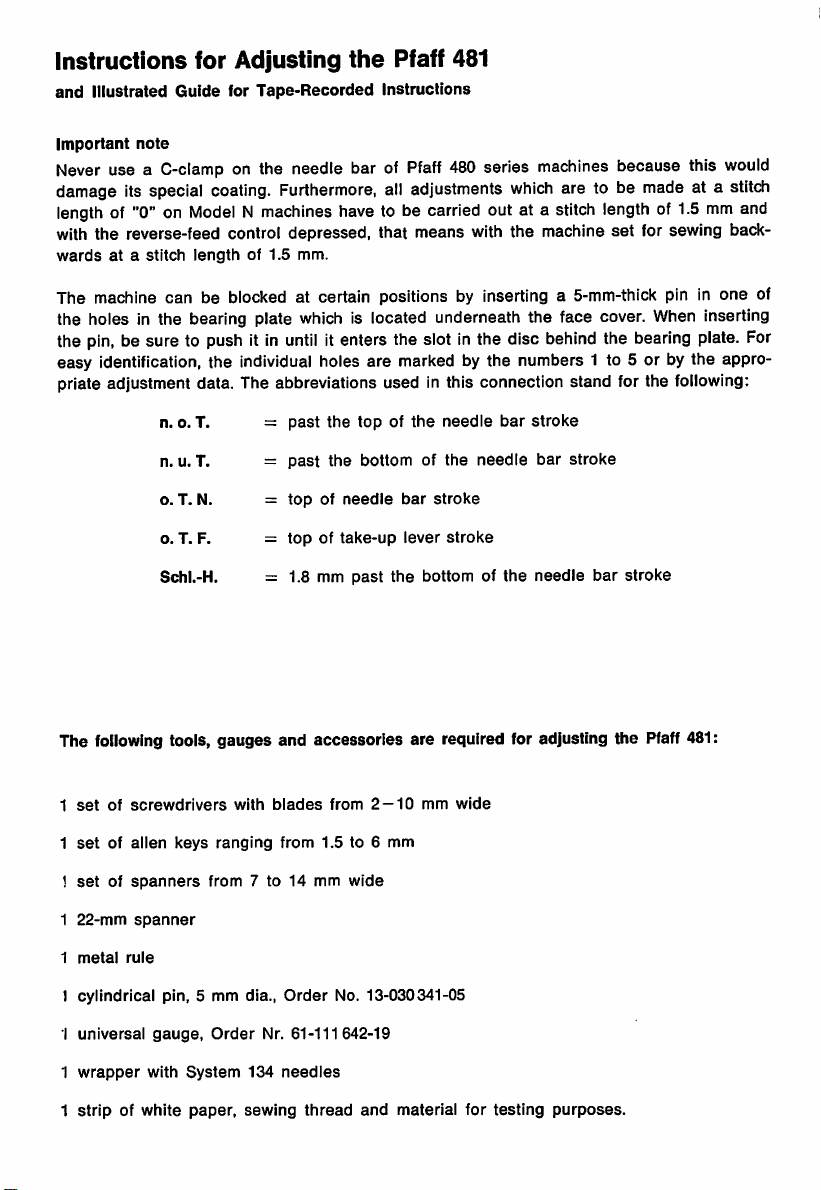

Note:

The machine can be blocked at different positions by inserting the 5-mm-

thick pin in the appropriate hoie of the bearing plate. For easy identifica

tion,

the

priate

holes in

adjustment

the

bearing plate

data

(Fig. 1.0.1.).

are

marked by numbers or

the

appro

Fig.

1.0.1.

1.1.

1.2.

1.3.

1.3.1.

1.3.2.

1.4.

Remove

Take

To

Turn

Push

bearing

The

the

belt

out

both

screws

block

the

machineatthe

the

balance

the

pin into

plate.

functionofeachofthe

guard.

of

the

wheeltobring

the

hole

five

1.4.1. Hole 1 (0.6 n. o. T.) = 0.6 mm

1.4.2.

1.4.3.

1.4.4.

1.4.5.

Hole

2 (o. T. F.) =

Hole

3 (0.6 n. u. T.) = 0.6 mm

Hole

4 (Schl.-H. 1.8) = 1.8 mm

Hole

5 (o. T. N.) =

topoftake-up

topofneedle

face

cover

various

the

until it

holesisas

past

lever

past

past

bar

1

and

positions,

needle

enters

the

topofthe

stroke.

the

bottomofthe

the

bottomofthe

stroke.

remove

it.

proceedasfollows:

bartothe

the

follows:

desired

slotinthe

needle

needle

needle

bar

position.

disc

stroke.

bar

stroke.

bar

behind

stroke.

the

Page 4

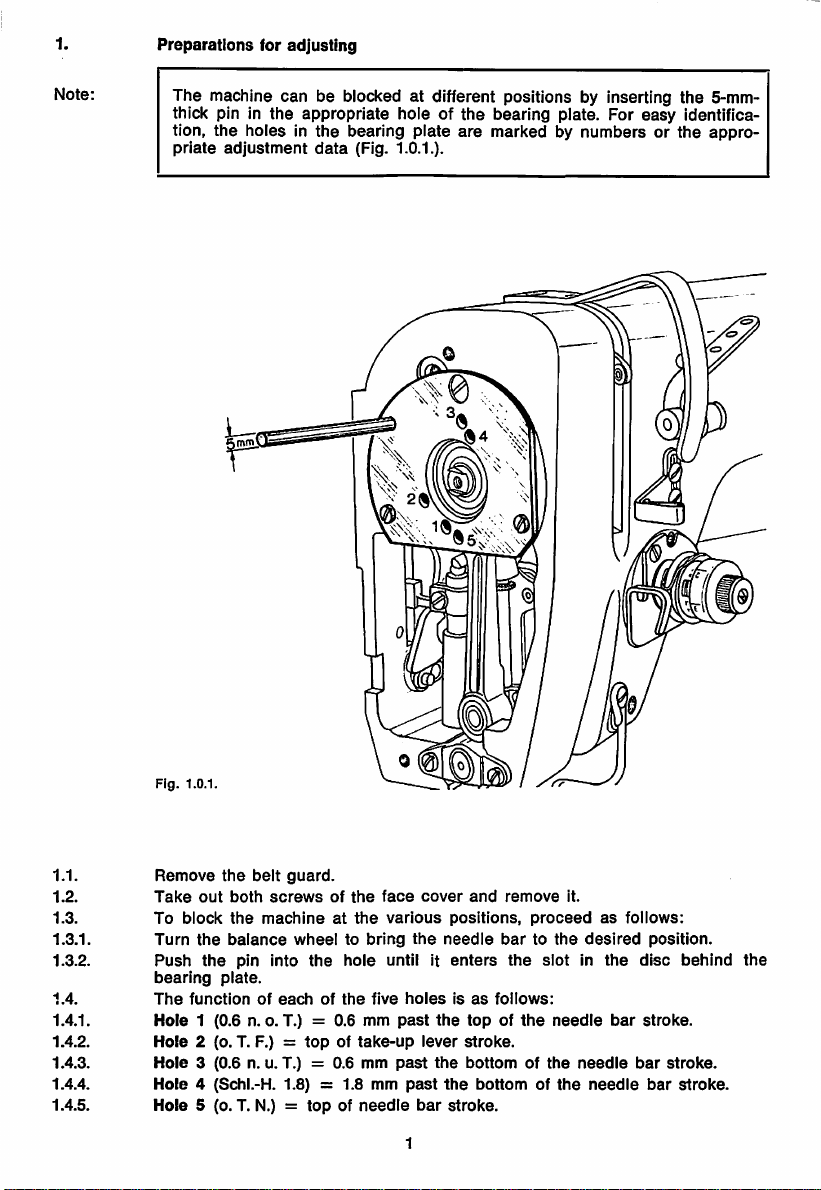

2.

Zeroing

the

feed

motion

Correct

setting:

The

stitch

feed

length

dog

must

control

not move

setat"0".

when

you turn

%

the

balance

wheel with

the

2.1.

2.2.

2.3.

2.4.

2.4.1.

2.4.2.

2.4.3.

2.4.4.

2.4.5.

2.4.6.

2.4.7.

2.4.8.

Fig. 2.0.1.

Remove

Raise

Remove

Adjustment

Turn

Take

gasket,

Take

Loosen

tobeturnedonits

To

crank3(see

Rotate

shaft

no

Tighten

Check

the

needle

the

presser

the

knee

proceduretobe

the

stitch

iength

out

the16screwsofthe

making

the

oil

sponge

both

clamp

faciiitate

longer

the

until

both

this

adjustment,

Fig. 2.0.1.).

balance

the

feed

moves.

clamp

adjustment

sure

from

the

bar

iifter.

lever

together

controlto"0".

that

the

outofthe

screws

2 of

shaft

against

insertascrewdriver

wheel

andatthe

dog

(or

screws

2 of

(see

topofpage).

needle

with

applied

gearcase

oil, if

gearcase.

feed

rather

feed

bar.

its

joint

when

the

cover

any,isdrained

crank1just

resistance.

same

the

screwdriver

crank

1.

and

tilt

the

machine

gearcaseisopen

and

remove

off

intoacontainer.

sufficientlytoallow

in

the

slotoffeed

time

adjust

feed

in feed rock

back.

(Fig. 2.0.1.)

the

cover

crank1on

shaft

the

rock

crank

with

crank

its

shaft

Its

3)

Page 5

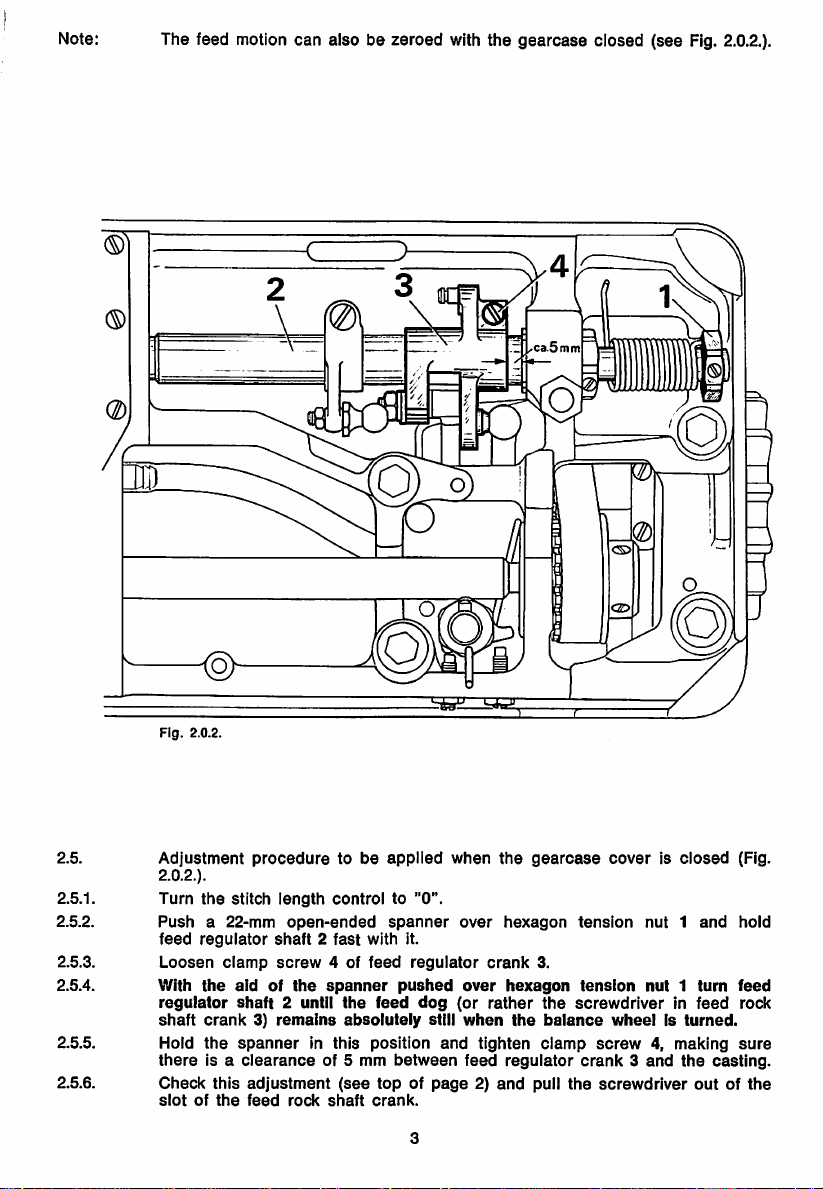

Note:

The feed motion

can

also be zeroed with the

gearcase

ciosed (see Fig.

Qb

2.O.2.).

Fig.

2.5.

2.5.1.

2.5.2.

2.5.3.

Adjustment

2.O.2.).

Turn

Pusha22-mm

feed

Loosen

2.5.4. With

regulator

shaft

2.5.5. Hold

there

2.5.6.

Check

slotofthe

2.0.2.

proceduretobe

the

stitch

iength

regulator

the

crank3)remains

the

is a

this

shaft2fast

clamp

screw

aidofthe

shaft

2 until

spannerinthis

clearance

adjustment

feed

controlto"0".

open-ended

4 of

spanner

the

absolutely

of 5 mm

(see

rock

shaft

applied

spanner

with

feed

feed

position

it.

regulator

pushed

dog

still

between

when

and

over

over

(or

when

tighten

feed

topofpage2)and

crank.

the

hexagon

crank

hexagon

rather

the

regulator

^ r

gearcase

tension

3.

tension

the

screwdriverInfeed

balance

clamp

screw4,making

crank3and

pull

the

coverisclosed

nut1and

nut1turn

wheelIsturned.

the

screwdriver

(Fig.

hold

feed

rock

sure

casting.

outofthe

Page 6

Feed

lifting

motion

Correct

setting:

The feed dog should be at Its highest point when

the

needle bar Is at a

position 0.6 mm past the bottom of its stroke (pin in hole 3). In this position,

the

notchinthe

below

the

feed

centerofthe

lift

shaft

eccentric

(Fig. 3.O.2.).

should

be

positioned

perpendicularly

I."

Fig.

3.0.2.

3.1.

3.2.

3.3.

3.4. In

3.5.

3.6.

Fig.

Loosen

Bring

block

Turn

dot

this

Leave

Check

3.0.1.

both

screws2of

the

needle

the

machineInthis

feed

lift

line

eccentric

In Fig. 3.O.2.), I. e.

position,

the

pin In

this

adjustment

bartoa

securely

the

holeofthe

feed

lift

eccentric

position

0.6 mm

positionbyInserting

1 until its

the

tighten

feed

notch

dogisat

both

bearing

(see

topofpage).

points

screws

plate.

1.

past

its

2.

the

the

exactly

highest

bottom

pin In

of its

hole

3.

downwards

point.

stroke

(see

and

dash-

Page 7

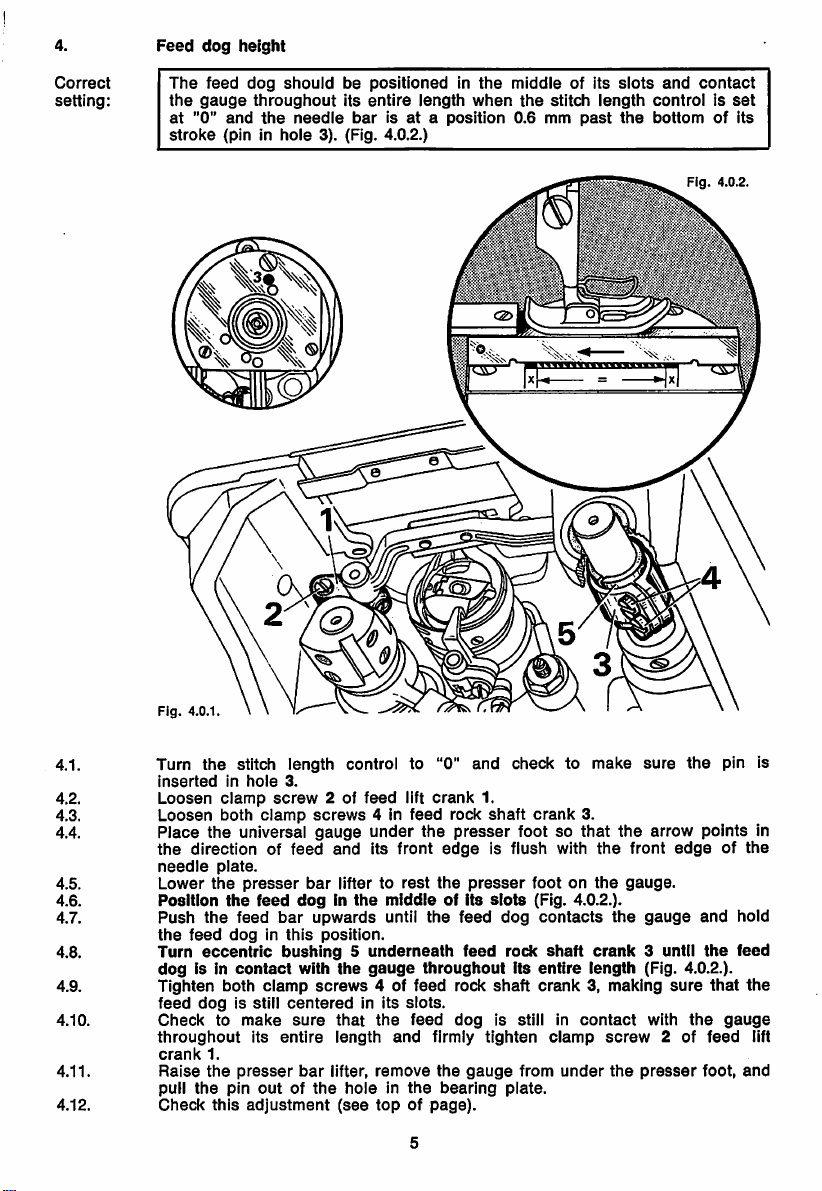

Feed

dog

height

Correct

setting:

The

the

at

"0"

stroke

feed

gauge

and

(pin in

dog

should

throughout

the

needle

hole

be

positionedinthe

its

entire

barisataposition

3). (Fig. 4.0.2.)

length

when

middle

the

0.6 mm

of its

stitch

past

slots

length

the

and

contact

controlisset

bottom

of its

Fig.

4.0.2.

4.1. Turn the stitch length control to "0" and check to make

4.2.

4.3.

4.4.

inserted

Loosen

Loosen

Place

the

4.5.

4.6.

4.7.

needle

Lower

Position

Push

the

4.8. Turn

dog

4.9. Tighten both

4.10.

4.11.

4.12.

feed

Check

throughout

crank

Raise

pull

Check

in

hole

clamp

both

the

universal

direction of

plate.

the

presser

the

feed

the

feed

feed

doginthis

eccentric

is in

contact

dog

is still

to

make

its

1.

the

presser

the

pin

outofthe

this

adjustment

3.

screw

2 of

screws

gauge

and

bar

lifter to

upwards

position.

feed

4 in

under

its front

middleofits

until

ciamp

feed

doginthe

bar

bushing5underneath

with

the

screws

that

length

lifter,

holeinthe

(see

gauge

4 of feed rock

the

remove

topofpage).

clamp

centeredinits

sure

entire

bar

lift

feed

the

rest

the

throughout

slots.

feed

and

crank

rock

presser

edge

the

dog

firmly

the

bearing

1.

shaft

is flush with

presser

slots

feed

dog

feed

rock

shaft

is still in

tighten

gauge

plate.

crank

foot so

footonthe

(Fig. 4.O.2.).

contacts

shaft

its

entire

crank

clamp

from

under

3.

that

the

the

crank

length (Fig. 4.O.2.).

3, making

contact

screw

the

sure

the

front

gauge.

3 until

presser

the

arrow

edgeofthe

gauge

sure

with

the

2 of

pin is

points

and

the

that

gauge

feed

foot,

in

hold

feed

the

lift

and

Page 8

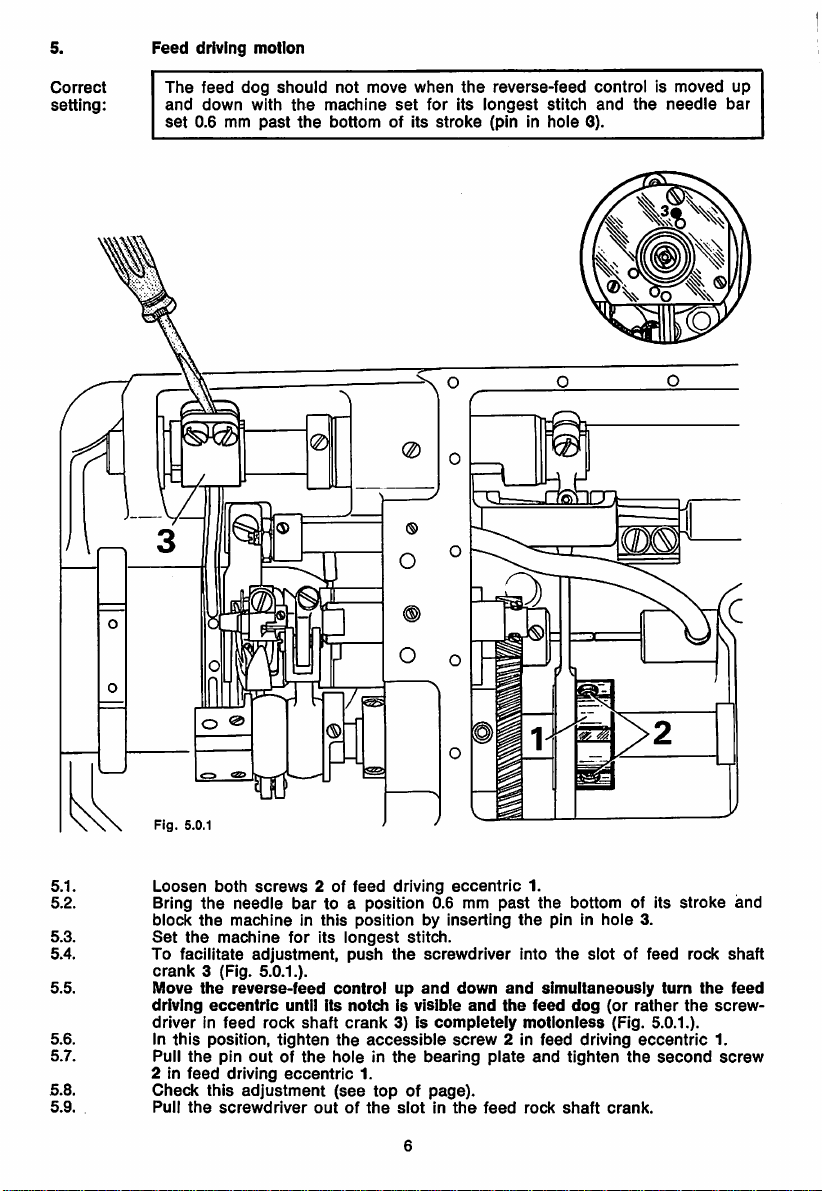

5.

Feed

driving

motion

Correct

setting:

The

and

set

feed

down

0.6 mm

dog

with

past

should

the

the

QC

not move

machine

bottom

set

of Its

when

for

stroke

the

reverse-feed

Its

longest

(pin In

stitch

hole

control

and

3).

Is moved up

the

needle

bar

6.1.

5.2.

5.3.

5.4.

5.5.

5.6.

5.7.

5.8.

5.9.

Loosen

Bring

block

Set

both

the

needle

the

machineInthis

the

machine

To facilitate

crank

3 (Fig. 5.0.1.).

Move

the

driving

reverse-feed

eccentric

driverInfeed

In

this

position,

the

feed

this

the

pin

driving

screwdriver

Pull

2 In

Check

Pull

screws

bar

for

adjustment,

until its

rock

shaft

tighten

outofthe

eccentric

adjustment

2 of

feed

to a

driving

position

positionbyinserting

Its

longest

push

stitch.

the

controlupand

notch

is visible

crank

3) is

the

accessible

holeinthe

1.

(see

topofpage).

outofthe

slotInthe

eccentric

0.6 mm

screwdriver

down

and

completely

screw

bearing

plate

feed

1.

past

the

the

Into

and

simultaneously

the

feed

motionless

2 In

feed

and

rock

bottom

pin In

the

dog

driving

tighten

shaft

of Its

hole

3.

slotoffeed

(or

rather

(Fig. 5.0.1.).

eccentric

the

second

crank.

turn

stroke

rock

the

the

and

shaft

feed

screw

1.

screw

Page 9

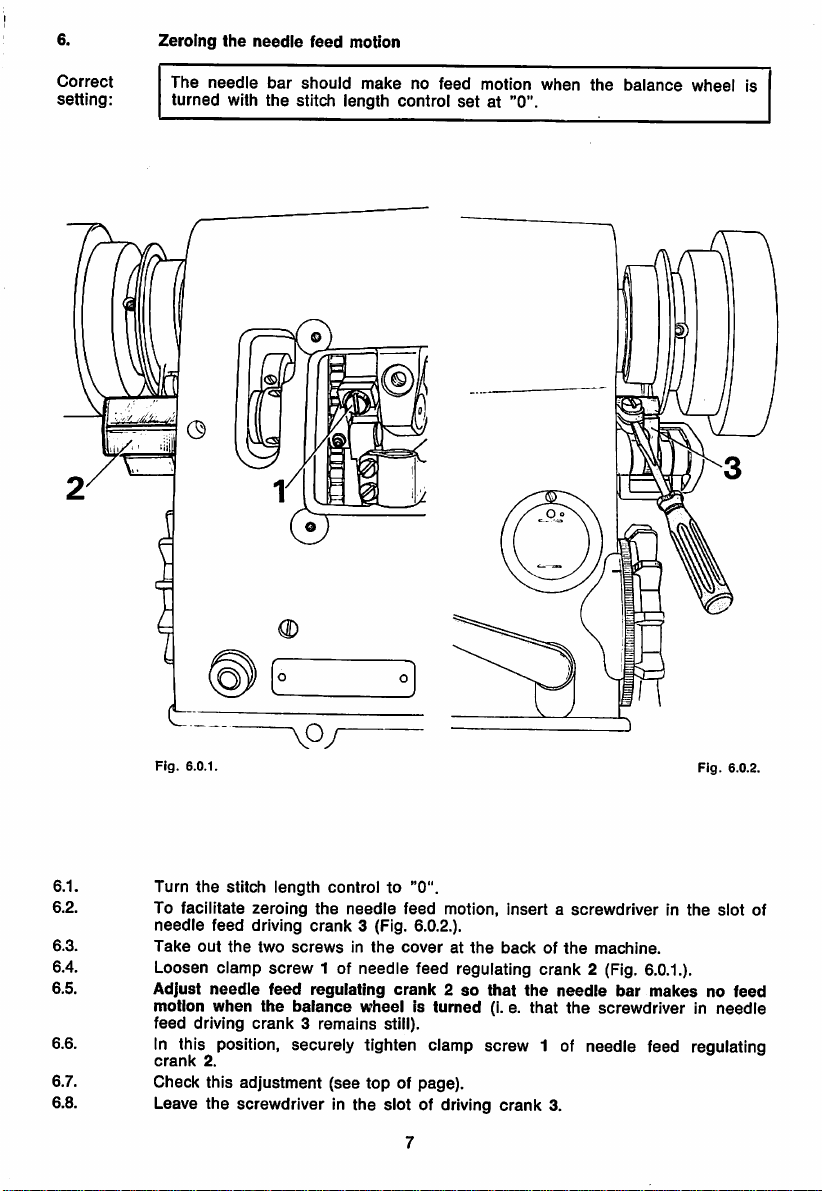

6.

Zeroing

the

needle

feed

motion

Correct

setting:

The

turned

needle

with

bar

the

should

stitch

make

length

no feed motion when

control

setat"0".

the

balance

wheel is

Fig.

6.0.1.

6.1. Turn

6.2. To facilitate

6.3.

needle

Take

the

stitch

feed driving

out

the

length

zeroing

two

screwsinthe

controlto"0".

the

needle

crank

3 (Fig. 6.O.2.).

feed

motion,

coveratthe

insertascrewdriverinthe

backofthe

machine.

6.4. Loosen clamp screw 1 of needle feed regulating crank 2 (Fig.

6.5. Adjust

motion

feed

needle

when

driving

feed

regulating

the

balance

wheelisturned

crank3remains

crank2so

still).

that

(I.e.

the

that

needle

bar

the

screwdriverinneedle

Fig.

6.0.2.

slot

6.0.1.).

makesnofeed

6.6. In this position, securely tighten clamp screw 1 of needle feed regulating

crank

2.

6.7. Check this adjustment (see top of page).

6.8. Leave the screwdriver in the slot of driving crank 3.

of

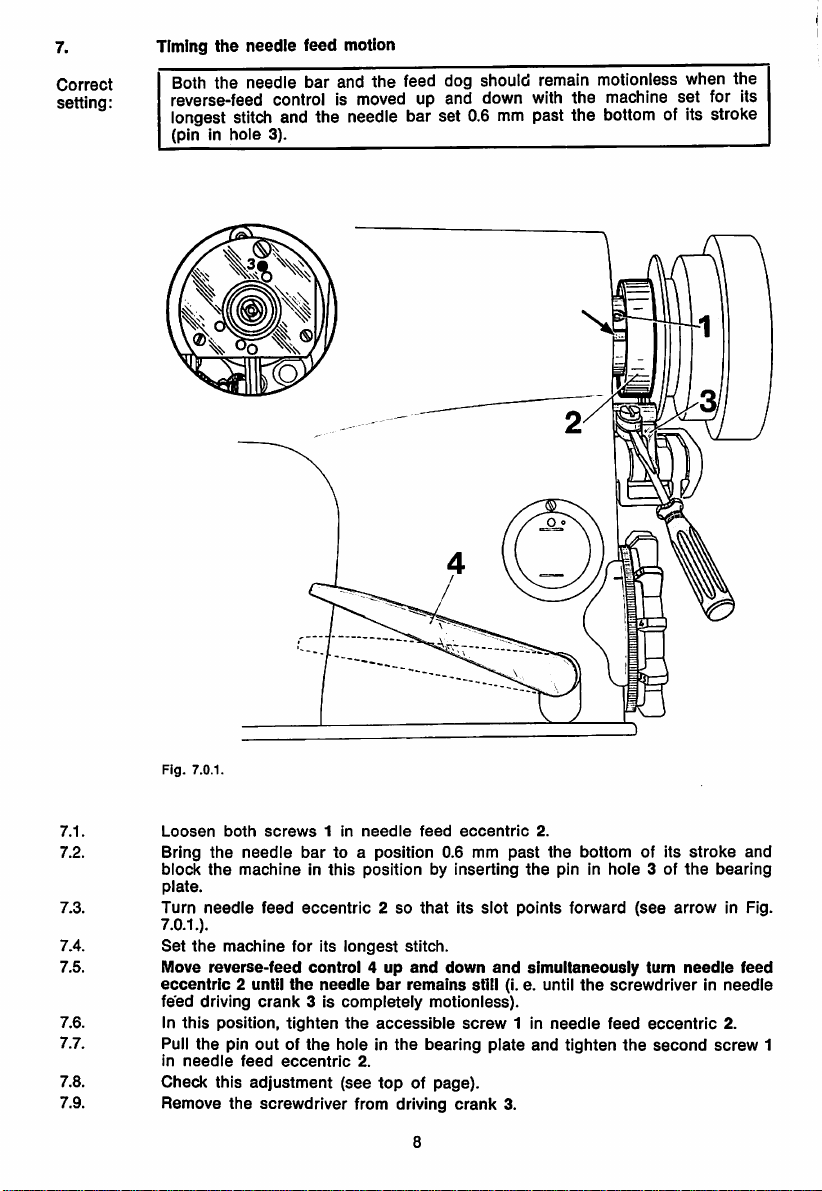

Page 10

7.

Timing

the

needle

feed motion

Correct

setting:

Both the needle bar and

reverse-feed control Is moved up and down with the machine

the

feed dog should remain motionless when the

set

for Its

longest stitch and the needle bar set 0.6 mm past the bottom of Its stroke

(pin In

hole

3).

Fig. 7.0.1.

7.1.

7.2. Bring

7.3.

7.4.

7.5.

7.6. In

Loosen

block

the

plate.

Turn

needle

7.0.1.).

Set

the

Move

reverse-feed

eccentric

feed

driving

this

both

screws

the

needle

machineInthis

feed

machine

2 until

crank

position,

7.7. Pull the pin out of

in

needle

feed

eccentric

7.8.

7.9. Remove

Check

this

the

adjustment

screwdriver

1 in

needle

feed

eccentric

bar

to a

position

0.6 mm

positionbyInserting

eccentric2so

for its

longest

control4up

the

needle

3 Is

completely

tighten

the

the

hole In the bearing plate and tighten

2.

(see

from driving

that

Its

stitch.

and

bar

down

remains

motionless).

accessible

topofpage).

crank

8

slot

and

still (I. e. until

screw

2.

past

the

the

pin In

points

forward

simultaneously

1 In

needle

3.

bottom

the

of Its

3 of

(see

turn

stroke

the

arrow

needle

hole

screwdriverInneedle

feed

eccentric

the

second

and

bearing

In Fig.

feed

2.

screw

1

Page 11

8.

Centering

the

needleinthe

needle

hole

Correct When the feed dog is at Its highest point, the needle should be positioned

setting; exactly In the middle of the needle hole both lengthwise and crosswise

(Fig. 8.O.3.).

Ffg.

8.0.3

Fig.

8.0.1.

Fig.

8.0.2.

8.1. Bring

8.2. Insert a new System 134 needle Into the needle bar and push It up as far

8.3.

It will

Turn

the

the

go,

needle

making

stitch

bar

sure

length

to Its

its

control

highest

long

groove

to "0".

point

and

faces

remove

toward

the

the

presser

left.

foot.

as

8.4. Loosen clamp screw 1 of needle feed driving crank 2 (Fig. 8.0.1.).

8.5. Loosen screw 3 In the lug of the needle bar frame (Fig.

8.O.2.).

8.6. Rotate the balance wheel and simultaneously adjust the position of needle bar

frame 4 until the needle enters

8.7. Bring

the

wiseofthe

the

needle

needle Is

centered

sewing

bar

to Its lowest point

exactly In

direction (Fig.

the

needle hole In the feed dog.

and

adjust

the

needle hole, both lengthwise

needle

8.O.3.).

bar

frame 4sothat

and

cross

8.8. In this position, tighten clamp screw 1 In driving crank 2.

8.9.

8.10. Check this adjustment

Turn

the

stressInneedle

balance

wheel

bar

frame4,and

a few

(see

top of page).

turnstoensure

tighten

screw

that

3.

the

needle

barIsnot

under

Page 12

Eliminating

feed

differences

Correct

setting;

With

the machine set for Its longest stitch, both the feed dog and the needle

should

turned.

make

feed

strokes

of the same

length

when

the

balance

(2)

wheel

is

9.1.

9.2.

9.3.

9.4.

9.5.

9.6.

Fig.

9.0.1.

Set

the

machine

Loosen

Move

the

it in

Tighten

Check

adjust,Ifnecessary.

Check

stud

the

nut1on

hinge

toward

opposite

nut1on

whether

this

stud

the

adjustment

for Its

hinge

2 in

the

regulating

direction

hinge

needle

longest

stud

the

stud

(see

stitch.

2 of

regulating

forkofregulating

shaft

increases

2.

feed

is still

topofpage).

10

crank

decreases

it.

zeroed

3.

crank3,as

the

needie

properly

appropriate.

feed

stroke,

(see

Chapter6)and

Moving

moving

Page 13

10.

Hook

shaft

bearing

and

gear

play

Correct

setting;

There should be a clearance of 0.3 mm between sewing hook and oil

distributor ring when the hook point is opposite the needle and both

parts

are

play

0.1 mm

between

the

apart

(Fig. 10.0.2.). Also

gears.

Fig.

10.0.2

there

should

be a minimum of

these

C®

10.1.

10.2.

10.3.

10.4.

10.5.

10.6.

10.7.

10.8.

10.9.

10.10.

10.11.

10.12.

10.13.

Fig,

10.0.1

Remove

Loosen

of oil

Loosen

the

Turn

10.0.1.) Is

play

Loosen

Push

Bring

strike

Reposition

0.4 mm

turn

ring.

With

Loosen

Reposition

spur

needle

screw

distributor

alien

bedplate

eccentric

visible

nor

stand

both

the

sewing

the

needle

the

sewing

between

the

bearing

the

bearinginthis

both

gear.

plate

1 of oil

ring

screw

(Fig. 10.0.2.).

hook

from

too

close

hook

set

hook

bar

hook.

hook

shaft

hook

and

screws

spur

gear

and

regulating

3.

4 of

eccentric

shaft

below

together.

screws

against

to its

bearing

point

that

position,

8 in

7 on Its

feed

dog,

valve2and

bearing5so

and

6.

the

lowest

5 in

and

needle.

the

hook

large

tighten

spur

shaft

turn

the

stitch

length

the

5 on

recess

have

control

oil

hook

the

two

shaft

that

swivel

spur

bearing

the

gears

oil distributor ring.

point,

making

the

remainsincontact

gear

casting

Make

alien

7.

sure

until

sure

screw

that

the

there

however

with

4.

until It Is exactly in line with

to "0".

tubeofvalve2out

the

top

surface

(see

arrow in Fig.

neither

too

much

needle

does

not

is a

clearance

that

you do not

the

oil

distributor

the

small

Tighten both screws 8 securely, making sure that the second screw of spur

gear 7 — as

of

the

shaft.

seen

in its direction of rotation — is positioned in the groove

Do not tighten hook set screw 6 as yet and leave the oil tube swivelled away.

11

of

of

Page 14

11.

Needle

bar

height,

hook

timing

and hook-to-needle clearance

Correct

setting:

The needle bar should be set

eyeIspositioned

11.0.2.).

(pin

The

In hole 4), the hook-to-needle clearance

0.8

mm

amountofneedle

vertically

below

rise

so that the top edge of the needle

the

bottom

requiredtoform

edge

0.1

mm.

of the

the

hook

loopIs1.8

point

Fig. 11.0.2

(Fig.

mm

Fig.

11.0.1.

11.1.

11.2. Make

11.3. Loosen both clamp screws 2 In needle bar connecting stud 1.

11.4.

11.5. Move the needle bar up or down until there is a clearance of 0.8 mm between

Bring

the

needle

though

machine In this position by Inserting the pin In hole 4.

sure

that the

the

stitch length control Is

sure

bar to a

point

needle

1.8

mm

does not

set

past the

strike

at "0".

bottomofIts

the

sewing

stroke,

hook.

making

Block

the

Turn the sewing hook on Its shaft until Its point Is exactly opposite the center

lineofthe

the top edge of the needle eye and the bottom edge of the hook point

11.0.2.);

needle

needle.

(Fig.

the hook point Is now positioned approximately In the middle of the

scarf.

11.6. In this position, tighten both clamp screws 2, making sure that the needle set

11.7.

Adjustthe sewing hook

exactlytothe

right.

until

there is a clearance of

0.1

mm

between Its point

screw

points

and the needle (center of scarf); make sure that the position finger Is still In

the

11.8. In this position, tighten

11.9.

11.10.

slotofthe

Pull the pin out of the hole In the bearing plate and tighten the second hook

set

screw.

Check

this

bobbin

adjustment

case.

the

accessible

(see

topofpage).

hook

set

screw.

12

Page 15

12.

Vertical position of bobbin

case

opener

Correct

setting:

When at its left point of reversal, bobbin

case

opener finger 3 stiouid be

positioned vertically so that it is exactly opposite the lug of bobbin

base

4 (Fig. 2.O.2.).

Fig.

12.0.2

m

case

12.1.

12.2.

12.3.

11.4.

12.5.

Fig.

12.0.1.

Loosen

Turn

the

screw

balance

1 of

wheeltobring

Turn bushing 2 until

case

base

4.

In

this

Check

position,

this

tighten

adjustment

eccentric

opener

screw

(see

bobbin

the

case

opener

finger 3 Is exactly

1 of bushing 2.

top

of page).

13

opener

finger

shaft

bushing 2.

to its left

opposite

point

the

lug of bobbin

of reversal.

Page 16

13.

Correct

setting:

Positionofbobbin

There

should be a

1 and bobbin

is at

the

position finger 6 and bobbin case base 5

case

opener

clearance

case

base 5 (Fig.

left of its stroke,

of 0.8 mm

there

13.0.2.).

Furthermore, when opener finger 1

shouldbea

between

clearance

(Fig.

bobbin

13.0.3.).

lug on collar 4 should be up against the stop of opener

13.0.1.).

case

opener

finger

of 0.3 mm

between

In this position, the

finger1(Fig.

Fig.

13.0.3.

13.1.

Fig.

Loosen

13.0.2.

screw3of

collar

4.

13.2. Loosen clamp screw 2 of opener finger 1 just sufficiently to allow it to be

13.3. Reposition opener finger 1 on its shaft until there is a clearance of 0.8 mm

turnedonIts

betweenitand

13.4. Rotate

13.5. Turn

opener

finger 6

opener

13.6. In

13.7.

13.8. In

13.9.

this

Push

collar

the

stopofopener

this

Check

shaft

against

the

bobbin

balance

wheel until

finger 1 until

and

the right wall of the position siot In the bobbin

finger 1

position,

position,

this

contacts

tighten

4 up

against

tighten

adjustment

finger

resistance.

case

base

there

the

clamp

opener

1.

screw

(see

topofpage).

5 (Fig. 13.0.2.).

opener

finger 1 is at

is a

clearance

lug of bobbin

screw

2 of

finger 1

3 of

14

and

collar

case

opener

turnitso

4.

the

left of its

stroke.

of 0.3 mm between position

case

base

base

5 (Fig. 13.0.3.).

finger 1.

that

its lug is up

when

against

Page 17

14.

Correct

setting:

Timing

When

in hole 4),

the

the

bobbin

needle

opener

case

bar

finger 3

opener

has

risen

should

1.8 mm from

be at

the

the

bottom

right of its

of its

stroke

stroke

(pin

(Fig. 14.0.2.).

Fig.

14.0.2.

14.1.

Loosen

both

screws

2 of

bobbin

case

opener

eccentric

1.

14.2. Bring the needle bar to a position 1.8 mm past the bottom of its stroke and

block

the

machine in

this

position by inserting

the

pin in

hole

4.

14.3. To facilitate determining the exact point of reversal insert a small screwdriver

in

the

slotofthe

14.4. Turn

opener

14.5. In this position, tighten

14.6. Pull the pin out of the hole in the bearing plate and tighten

2

also.

14.7. Puii

of

the

page).

screwdriver

clampofopener

eccentric 1 until

the

outofthe

finger

opener

accessible

clamp

15

3.

finger 3 is at its right point of reversal.

screw

2 of

opener

eccentric 1.

the

slot

and

check

this

second

adjustment

(see

screw

top

Page 18

15.

Correct

setting;

Oil

tube

Oil

tube1should

15.0.2.).

In oil

distributor

m

ring

be

positionedinthe

Fig.

15.0.2.

hole

of oil

distributor

ring 2 (Fig.

Fig.

15.0.1.

15.1.

Insert

If

necessary,

oil

tube

1 into

turn

the

the

oil

15.1.1. On subcl. -900 machines

have loosened the three

15.2. Tighten

screw

3 of oil regulating valve 4 (Fig. 15.0.1.).

hole

of oil distributor ring 2

distributor

the

screws

ring

accordingly.

oil distributor ring cannot be turned until you

on the front

16

side

(see

arrow in Fig. 15.0.2.);

of the hook shaft bearing.

Page 19

16.

Oil

check

valve

Correct

setting:

There

shouldbea

centrifugal

governor

clearance

and

push

of 1.0 mm

rod 4 of

between

the

oil check valve (Fig. 16.0.2.).

actuating

rod 3 of

Fig. 16.0.2

the

Fig.

16.0.1

16.1.

16.2. Push actuating rod 3 to

Loosen

screw1of

oil

check

valve

2.

the

leftasfarasit will go.

16.3. Push push rod 4 into oil check valve 2 until a resistance is felt.

16.4.

16.5. In this position, tighten

16.6. Check

16.7. Soak the oil sponge with oil and replace it in the

16.8. Clean

16.9. Replace the

Reposition oil check valve 2 until there is a clearance of 1.0 mm between

actuating

rod 3

this

and

adjustment

push

(see

rod 4.

screw

1 of oil check valve 2.

top

of page).

gearcasesothat

recessIsat

legs,

the

the

gasket

tightening

bottom

faceonthe

gearcase

the

screwsofthe

left

and

the

oil

gearcase

tubeisplacedontop

and

the

gasketofthe

of it.

cover and simultaneously screw on the two machine

cover

crosswise.

17

gearcase

its large

cover.

Page 20

17.

Hook

lubrication

Correct

setting:

After

of oii

cutout

the

shouid

above

machine

appear

the

has

hook

runatfuli

on a

pieceofpaper

raceway.

speed

for

about

placed

ten

seconds,

over

the

a fine

needle

trace

plate

17.1.

17.2.

17.3.

17.4.

17.5.

17.6.

17.7.

17.8.

Fig

Turn in regulating

then

back

about

Switch on the machine

Turn

regulating

Let

the

machine

Placeapiece

Let

the

of oii

If

oilIsemitted,

machine

has

appearedonthe

too

much oil Is emitted, turn regulating

screw

three

screw

run

about

of white

run

turnitout

1 of oii regulating valve 2 as farasit will go,

turns.

and

run it until the sewing hook

1 in

paper

about

somewhat.

completely

one

over

ten

paper

minute.

the

seconds.

opposite

and

needle

Check this adjustment (see top of page).

18

then

plate

Then

the

screw

starts

out

half a turn.

cutout.

checktosee

hook

raceway.

1 In a little; or If

emitting oil.

if a

fine

too

and

trace

little

Page 21

18.

Clearance

between

presser

foot

and

needle plate

Correct

setting:

When

between

the

presser

presser

bar

lifter Is

raised

foot and needle plate (Fig. 18.0.2.).

there

shouldbea

clearance

of 7.0 mm

Fig.

18.0.1

Fig.

18.0.2

19

Page 22

18.1.

Replace

the

feed

dog.

18.2. Screw on the needle plate, making sure that the feed dog moves freely In

Its

slots.

18.3.

18.4. Lower the

18.5. Reduce the

18.6.

18.7. Loosen

18.8.

18.9.

18.10.

18.11.

18.12.

18.13. Rotate

Replace

the

presser

until

the

presser

Push

the

rear

7-mm-thlck

until It Is

the

clamp

the

machine

Raise

presser

Turn

the

balance

Adjust

the

In

Its

needle

Press

presser

and

tighten

Remove

needle

the

plate.

the

the

needle

paralleltothe

presser

foot.

foot onto

pressure

of the

foot Is

bladeofthe

positioned

screw

arm.

positionofthe

hole.

clamp

gauge

balance

holeofthe

3 of

bar

lifter 1.

wheel

bar

lifting

screw3securely.

from

wheel to

edgesofthe

the

needle plate by operating

presser

pressed

against

bar

the

universal

below

the

presser

until

presser

bracket4downwards

under

presser

bar

lifting bracket 4 Inside

the

needleIsdownInthe

footsothat

the

presser

see

whether

foot, I. e.

feed

dog.

presser

bar lifter 1.

by turning out regulating screw 2

needle

plate only slightly.

gauge

under

the

presser

foot fulcrum.

the

onto

foot

the

needleIscentered

whether

presser

needle

needleIscentered

the

raised

and

lower

the

the

sidesofthe

the

hole.

front

lifting

foot

foot from

onto

correctly In

foot

end

exactly

lever

the

are

of

5

18.14.

Check

this

adjustment

(see

topofpage).

20

Page 23

19.

Tension

release

mechanism

Correct

setting:

When

0.5 mm

the

apart

presser

(Fig. 19.0.2.).

•jp.:

bar

lifter is

raised

both

tension

/

discs

shouldbeat

Fig.

least

19.0.2

Fig. 19.0.1.

19.1.

19.2.

19.3.

Operate

Loosen

Adjust

between

presser

screw2of

tension

both

tension

bar

tension

reiease

18.4. In this position, tighten

18.5.

19.6. Check

When

fully

the

presser

activated.

this

adjustment

foot is lowered

lifter 1toraise

release

lever3so

discs

when

screw

2 of tension release lever 3 securely.

(see

top

of page).

21

lever

that

the

onto

the

there

presser

the

presser

3.

is a

needle

foot.

clearanceofat

bar

lifter is

plate,

raised.

the

tension

least

0.5

should

mm

be

Page 24

20.

Thread ched< spring

and

thread

regulator

Correct

setting:

The stroke of thread check spring 4 should be about 7.0 mm

The

positionofthread

regulator

6 is dependent on the

(Fig.

type

of thread and

20.0.2.).

material used and should be adjusted according to the appearance of the

seam.

0

20.1.

20.2.

20.3.

20.4.

20.5.

20.6.

20.7.

Loosen

tension

Turn

about

In

them

thread

Check

Loosen

Push

In

dependent

accordingtothe

both

barrel

tension

7.0

mm (Fig. 20.0.2.).

this

position,

alternately).

check

this

both

thread

this

position,

spring

adjustment

screws

regulator

on

screws

3 tobeturnedinthe

barrel

1 of

thread

3 until

the

tighten

both

Special

forashorterorlonger

5 of

sewing

(see

topofpage).

thread

screws

6 upasfarasit willgo(Fig. 20.0.1.).

tighten

the

both

type of

appearance

screws5.(The

thread

of

tension

tension

strokeofthe

1 of

tension

operations

regulator

the

22

and

seam.)

6.

material

flange2just

flange.

thread

flange2evenly

may

makeitnecessarytoset

stroke.

position of

used

sufficientlytoallow

check

the

thread

and

shouldbeadjusted

spring

amounts

(by

tightening

regulator

to

the

is

Page 25

21.

Knee

lever

rest

position

Correct

setting;

When at rest, knee lever connecting rod 1 should extend at right angles to

the front

edge

of the bedplate (Fig. 21.0.2.).

Fig.

21.0.2

Fig.

21.0.1.

21.1.

21.2.

Raise

Push

and

the

presser

knee

lever

turn

It slightly until It

connecting

21.3. Loosen locknut 4 of

21.4. Turn

stop

front

screw

edgeofthe

to

the

21.5. In this position, lock

21.6. Pull

knee

lever

connecting

foot.

stop

5 until

stop

rod 1

snapsInplace.

screw

knee

bedplate.

screw

rod 1

together

5 (Fig. 21.0.1.).

lever

5 by tightening nut 4.

out

23

with joint 2 on

connecting

of joint 2.

rod 1

extendsatright

knee

lever

shaft

angles

3

Page 26

22.

Correct

setting:

Knee

lever

play

When

the presser

positioned

1.3mmbetween

below

footIsdown

the

needle

lifting

lever 1 and

on the

plate,

there

lifting

needle

should

bracket 2

plate and the

be a

clearanceofabout

(Fig.

22.0.2.).

feed

Fig.

dog Is

22.0.2

O

Fig.

22.0.1.

22.1. Lower the feed dog below the needle plate and let the presser foot down on

22.2. Loosen both clamp screws 4 of crank 3 on the vertical knee lever shaft.

22.3.

22.4.

22.5. Pull out the gauge and Insert the knee lever connecting rod Into its joint.

22.6.

22.7. Pull

the

needle

plate.

Adjust crank 3 so that there Is a clearance of about 1.3 mm between

lever 1

and

lifting bracket 2. (Use

the

gauge

for this adjustment.)

lifting

In this position, tighten both clamp screws 4, making sure the vertical knee

lever

shaft

Check

the

hasnoend

this

adjustment

knee

lever

play.

(see

connecting

topofpage).

rod

out

24

of Its

socket.

Page 27

23.

Adjusting

the

knee

lever

motion

Correct

setting:

When

the knee lever is at the extreme right of its travel, the presser foot

should have risen at least 7.0

mm

above the needle plate and the presser

bar lifter should have dropped down by its own weight.

Fig.

23.0.1.

L J

II

23.1.

Insert

the

knee

lever

F .

23.0.2

connecting

rod in its

K.;i

socket.

•

23.2. Loosen iocknut 1 of stop screw 2 (Fig. 23.0.1.).

23.3.

23.4. Raise the presser bar

Turn

stop

screw2out

a few

turns.

lifter,

place the 7-mm-thick blade of the universal gauge

under the presser foot and lower the presser bar lifter again (Fig. 23.0.2.).

23.5.

23.6. Hold the knee lever in this position and turn In stop

23.7. Pull out

Push the knee lever to the right

this motion, the

go, then

out

the

presser

foot must not yet lift off the gauge.

again by half a turn. Lock

gauge

and

draw

the

until

a noticeable resistance is felt; during

screw2as

stop

screw

2 by tightening nut 1.

knee

lever

out

of its socket.

farasIt will

23.8. Let the machine down again, replace the knee lever and ched< this adjustment

(see

topofpage).

25

Page 28

24.

Bobbin

winder

When the bobbin winder Is engaged, the winder spindle should be driven

reliably;

must

not

when

contact

the

bobbin

drive

wheel

winder

1.

is disengaged,

however,

friction

wheel

The bobbin winder should stop automatically when the thread wound on the

bobbin has reached a point about 1.0mmbelow Its

rim

(Fig.

24.0.2.).

Fig.

3

24.0.2.

24.1.

24.2.

24.3.

24.4.

24.5.

24.6.

24.7. If

24.8. If

24.9. If

24.10.

Fig.

24.0.1

Take

out

the

three

screws

Raise

the

presser

Loosen

Set

drive

both

wheel1so

driven reliably

when

the

bobbin

Tighten

Placeabobbinonthe

and

machine.

stud

full

the

Check

both

engage

the

bobbin

6 In

the

bobbinistoo

enough,

the

thread

machine

this

stop

bar

screws

when

winderisdisengaged.

screws

the

bobbin

winder

latch

pushitaway

piles

up on

arm

accordingly.

adjustment

retaining

lifter

and

2 In

drive

wheel

close

to

bobbin

drive

friction

wheel

spindle,

the

2 of

winder

winderbypushing

stops

too

4.

full,

(see

earlyornotatall,

push

regulating

from

the

one

sideofthe

topofpage).

26

the

rear

arm

engage

the

bobbin

1.

wheel3that

winderisengaged,

1.

thread

the

against

stud6toward

bobbin.

Then

bobbin,

cover.

winder.

machine

Its

loosen

tighten

adjust

friction

but

spindle.

screw

the

screw

wheel3will

will

notbedriven

for

bobbin

Then

5 of

bobbin,

5 of

the

thread

winding

start

regulating

if it is

stop

latch

guide

be

the

not

4.

on

Page 29

25. Presser foot pressure and final worksteps

25.1.

Replace and screw on the face cover, both rear arm covers and the belt guard.

25.2. Thread the machine, place a piece of fabric under the presser foot and lower

the

25.3.

25.4.

presser

Turn in pressure regulating screw 7

material Is

Test-sew

foot

ensured

on

the

onto

it.

evenattop

machine.

speed.

(Fig.

25.0.1.)

until proper feeding of the

27

Page 30

Contents

1.

Preparations

2.

Zeroing

3.

Feed

4.

Feed

5.

Feed

6.

Zeroing

7.

Timing

8.

Centering

9.

Eliminating

10.

Hook

11.

Needle

12.

Vertical

for

adjusting

the

feed

motion

lifting

motion

dog

height

driving

motion

the

needle

the

needle

the

needleinthe

feed

differences

shaft

bearing

bar

height

positionofbobbin

feed

motion

feed

motion

and

gear

and

hook-to-needle

needle

play

case

....

....

hole

....

opener

.

clearance

.

Positionofbobbin

13.

14.

Timing

15. Oil

16.

17.

Hook

18.

19.

Tension

20.

21.

22.

23.

Adjusting

24.

25.

the

tube

Oil

check

lubrication

Clearance

Thread

check

Knee

lever

Knee

lever

Bobbin

Presser

winder

foot

bobbin

and

valve

between

release

rest

play

the

pressure

oil

distributor

mechanism

spring

position

knee

case

case

presser

and

lever

and

opener

opener

ring

foot

thread

motion

final

....

....

....

and

needle

regulator .

....

worksteps

plate

.

28

Page 31

Nr.

236-12-13285

engl.

1072

CMMTf

PrintedinGermany

Loading...

Loading...