Page 1

m

®

PFAFF

CIfafD

Instruction

Book

Page 2

(PFAFP

f

469

High-Speed

Differential-Feed

Lockstitch

Instruction

Sewing

Machine

Book

G-M

PFAFFAG

KAISERSLAUTERN

BRANCH

Page 3

Foreword

The

scope

of this book is confined to such instructions as are conditioned by variations in the

design of the Pfaff 469 high-speed differential-feed sewing machine as compared with other

Pfaff

high-speed

An

outstanding

bearingsinthe

Another salient feature is the arrangement of the feed driving and feed lifting eccentrics on the

bottom

rather

belt

and

drives

in an oiltight gear case and are lubricated by an oil-soaked foam plastic sheet. The assemblies

controlling the differential-feed are disposed on two shafts inside and outside the gear case.

The sewing hook is lubricated by means of a gravity lubrication system incorporating a

centrifugal

Since the arm shaftisbeltedto the

the

V-belt.

Additional features of this

forward-reverse

Operators will like the modern functional design and the stream-lined belt guard which is

attachedtothe

feature

machine

than

the

switch.

seamers.

the

hook

feed

control,

machine

ofthe

Pfaff

469

isthe

incorporationdfsealed-for-life

arm

and

the

needle

head.

arm

shaft.

The

bottom

shaftisdriven

shaft

by means of helical gears. These driving elements are

motor,

the

new

high-speed

built-in

arm.

bobbin

seamer

winder

'

from

the

machine

c^n be tilted back without

are a novel stitch length control,

and

built-in

lifting lever. •

arm

ball

and

shaftbya

needle

cleated

enclosed

remoylng

separate

G.M.PFAFF

AG

Page 4

R

8766

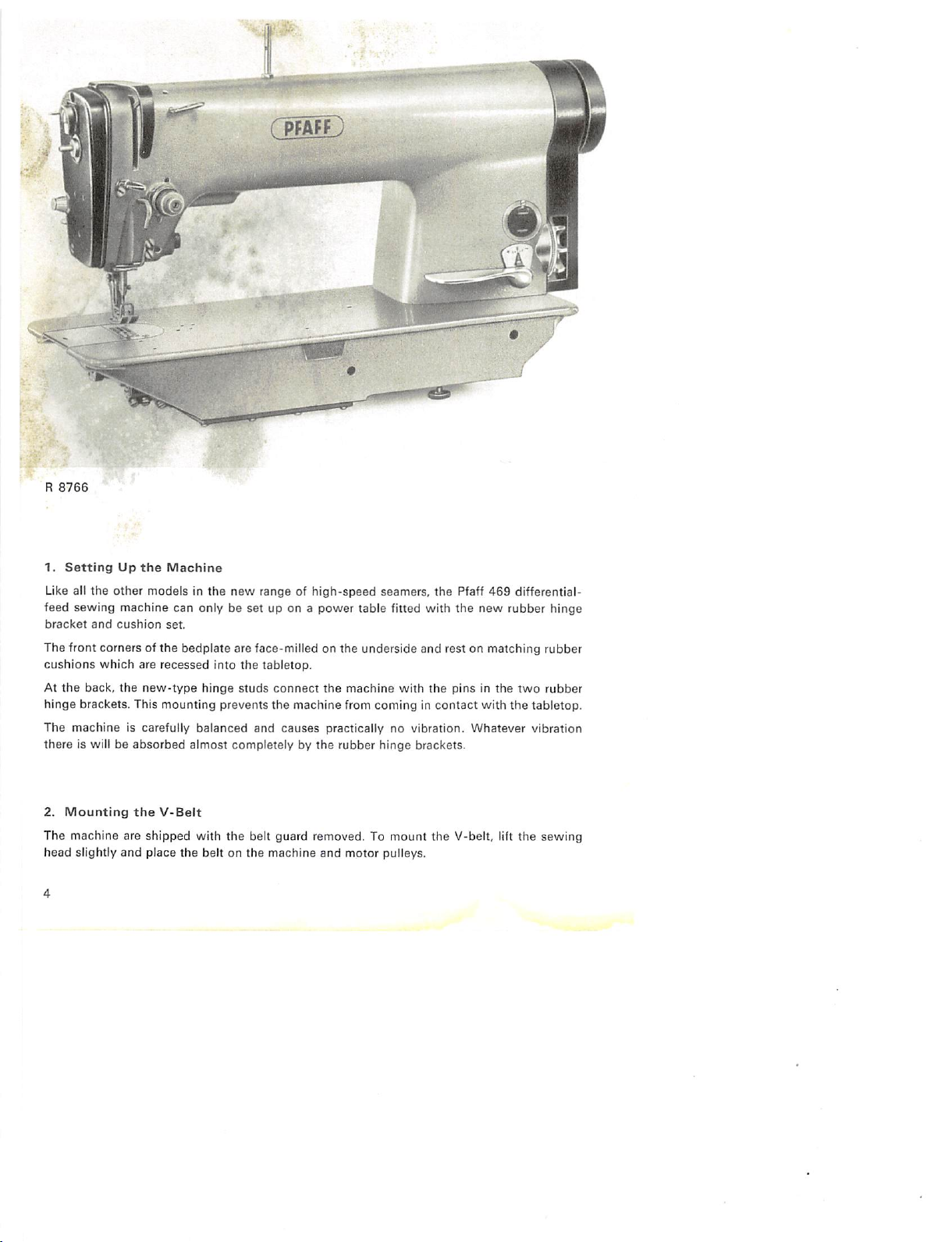

1.

Setting

Like all

feed

bracket

The front corners of

cushions

At

the

hinge

The

there

2.

Mounting

the

sewing

and

which

back,

brackets.

machine

Is will be

Up

the

other

modelsinthe

machine

cushion

are

the

new-type

This

is carefully

absorbed

the

Machine

can only be

set

the

bedplate are face-milled on

recessed

hinge

mounting

balanced

almost

V-Belt

The machine are shipped with

head

slightly

and

place

the

beltonthe

new

rangeofhigh-speed

set

up on a

power

the

into

the

tabletop.

studs

connect

prevents

the

and

completelybythe

the

belt guard removed. To mount

machine

the

machine

causes

practically no vibration.

rubber

and

seamers,

table

the

fitted with

Pfaff

the

469

new

underside and rest on matching

machine

from

motor

with

the

pinsinthe

comingincontact

hinge

brackets.

the

V-belt, lift

pulleys.

with

Whatever

differential-

rubber

hinge

rubber

two

rubber

the

tabletop.

vibration

the

sewing

Page 5

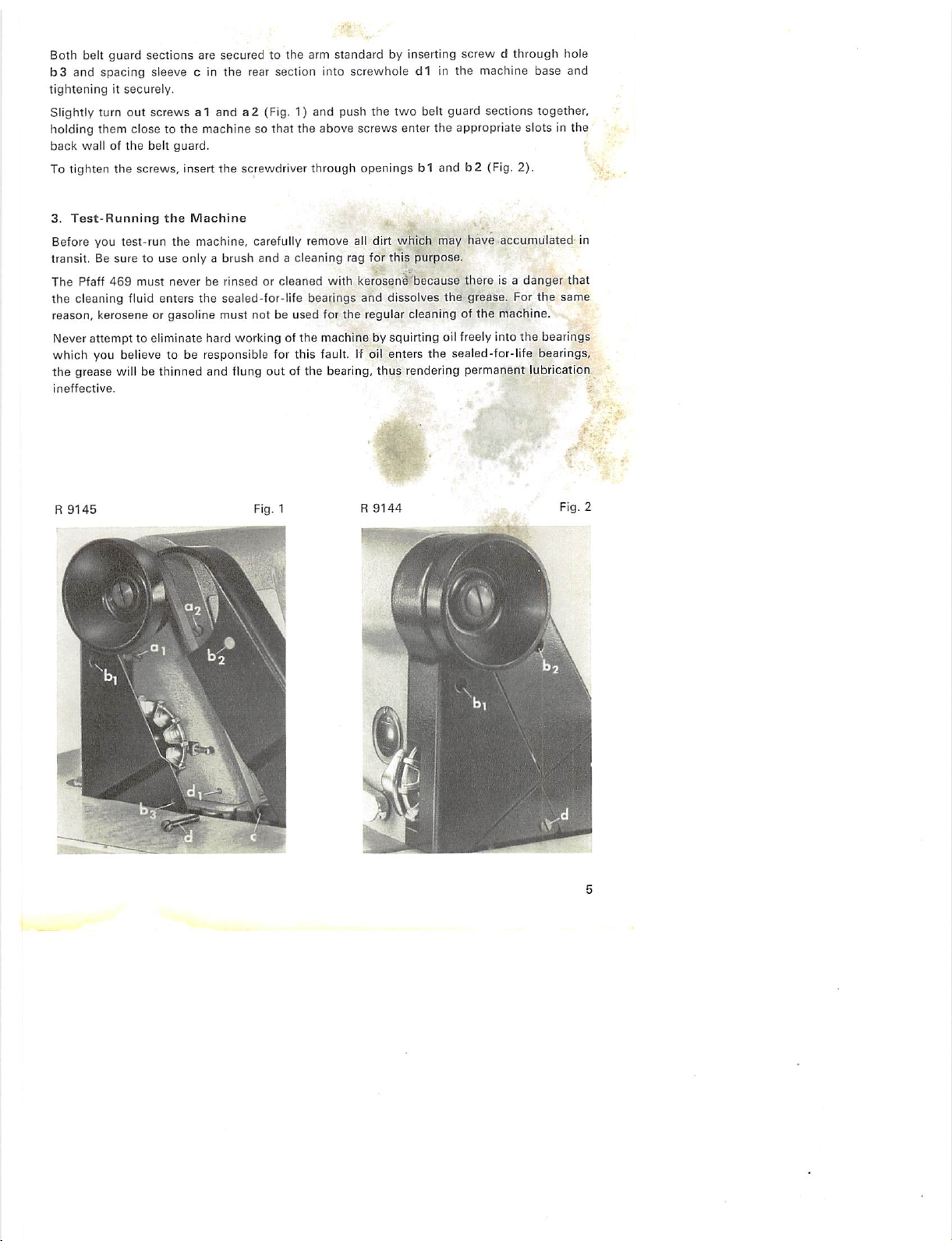

Both belt guard sections are secured to the arm standard by inserting screw d through hole

b3

and spacing sleeve c in the rear section into screwhole d1 in the machine base and

tighteningitsecurely.

Slightly turn

holding them

back

To tighten

3.

Test-Running

Before you test-run

transit. Be

The

Pfaff

out

wallofthe

the

suretouse

469

screws a1 anda2(Fig. 1) and push the

closetothe

belt

screws, insert

must

machine so

guard.

the

the

Machine

the

machine, carefully remove all dirt

onlyabrush

neverberinsedorcleaned

that

the

screwdriver through

andacleaning

above

with

two

screws

enter

openings

which

rag for

this

purpose.

kerosene'because

belt guard sections together,

the

appropriate slots in

b1 andb2(Fig. 2).

may

have

accumulated

there

is a

danger

the

that

the cleaning fluid enters the sealed-for-life bearings and dissolves the grease. For the same

reason, kerosene or gasoline must not be used for the regular cleaning of the machine.

Never

attempt

to eliminate hard working of

the

machine by squirting oil freely into

the

bearings

which you believe to be responsible for this fault. If oil enters the sealed-for-life bearings,

out

the grease will be thinned and flung

ineffective.

9145

R

of the bearing, thus rendering permanent lubrication

R

Fig. 1

9144

Fig.

in

;

2

Page 6

4.

Winding

the

Bobbin

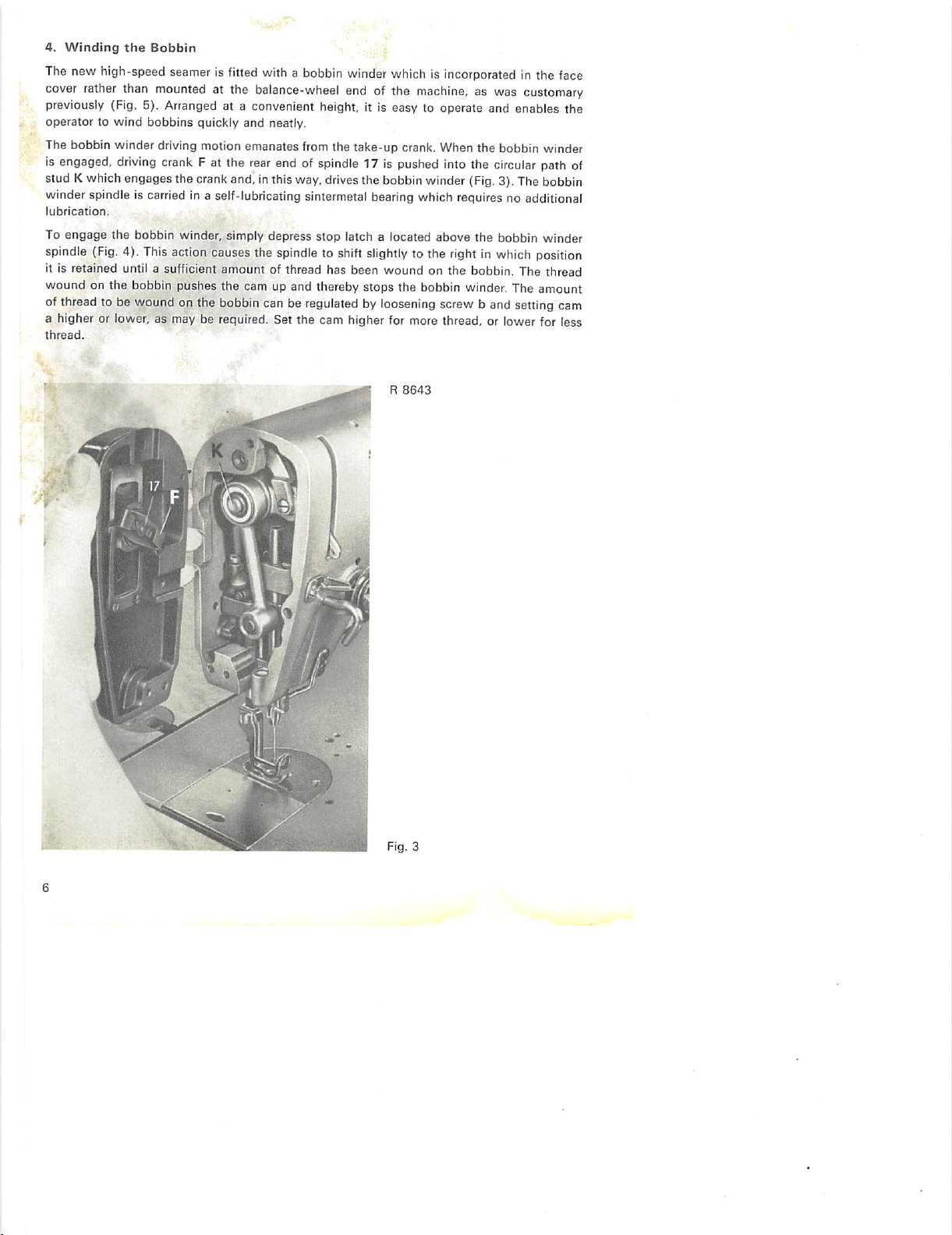

The new high-speed seamer is fitted with a bobbin winder which is incorporated in the face

cover

rather

than

mounted

previously (Fig. 5).

operatortowind

The bobbin winder driving motion emanates from the take-up crank. When the bobbin winder

is engaged,

stud K

driving

which

winder spindleis

lubrication.

To

engage

the

spindle

It is retained until a sufficient amount of thread has been wound on the bobbin. The thread

wound on the bobbin pushes the cam up and thereby stops the bobbin winder. The amount

(Fig.

ofthreadto be woundon the

a higher or lower, as may be required. Set the cam higher for more thread, or lower for less

thread.

Arranged

bobbins

crank F at the

engagesthe crankand, inthis

carried

bobbin winder, simply

4). Thisaction causes the

at the

balance-wheel

end

of the

machine,aswas

customary

at a convenient height, it is easy to operate and enables the

quickly

and

rear

neatly.

end of

way,

spindle

17 is pushed into the

drives

the

bobbin

winder

(Fig.

circular

3).The

path of

bobbin

in a self-lubricating sintermetal bearing which requires no additional

bobbin

depress

can be

stop

latch a located

spindle

to shift

regulatedbyloosening

slightly

R

above

the

to the

rightinwhich

screw b and settingcam

8643

bobbin

winder

position

4

Fig. 3

Page 7

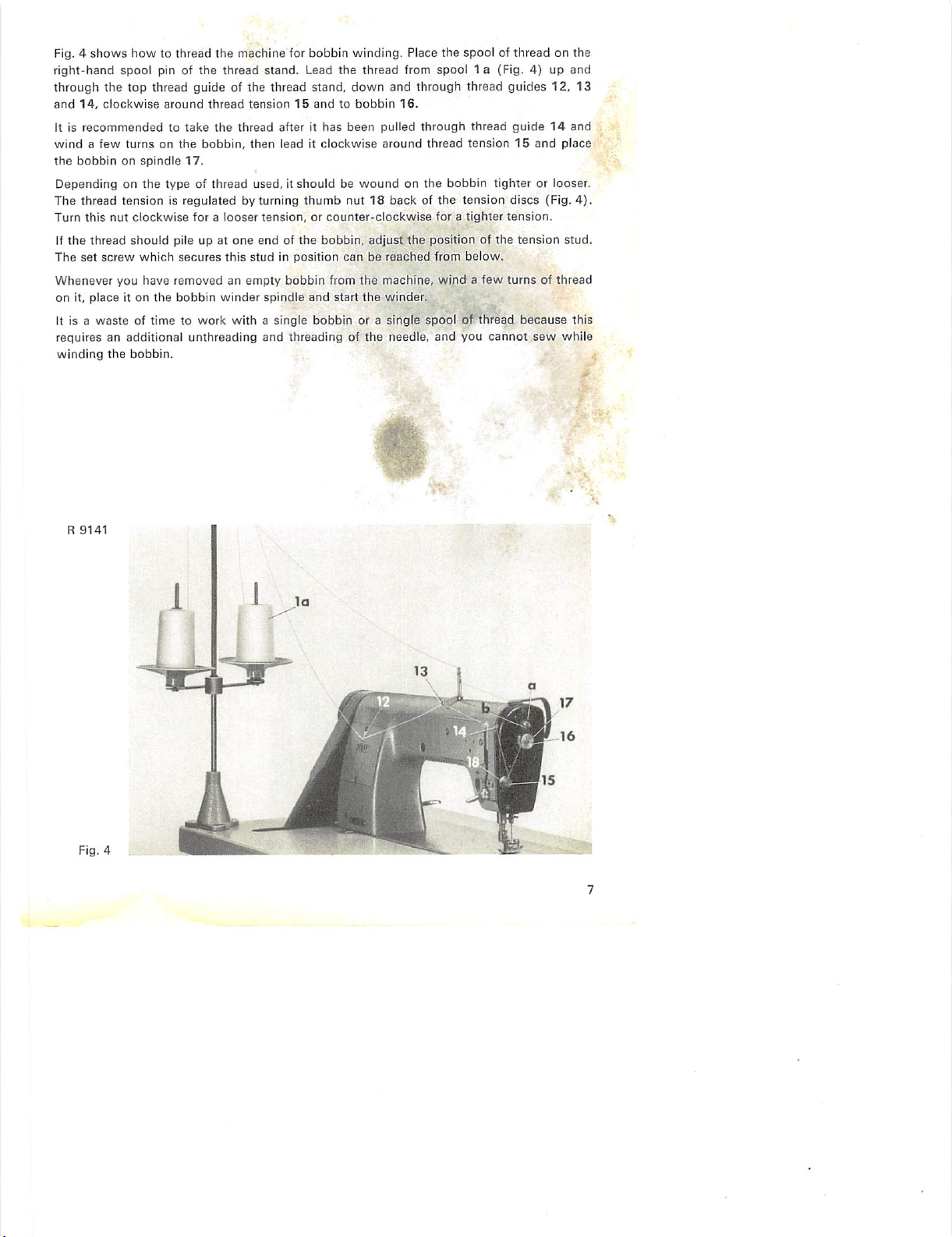

Fig, 4

shows

how

to thread

right-hand spool pin of

through

and

it is

windafew

the

Depending on

The

Turn

if

The

the top thread guide of the thread stand,

14,

clockwise

recommendedtotake

bobbinonspindle

thread

this

nut

the

thread

set

screw

around

turnsonthe

the

type of thread used, it

tensionisregulatedbyturning

clockwise

should

which

the

thread

bobbin,

17.

foralooser

pile up at

secures

the

machine for bobbin winding. Place

thread

stand.

Lead the thread from spool1a(Fig. 4) up and

tension15andtobobbin

the

thread

afterithas

then

leaditclockwise

shouldbewoundonthe

thumb

tension,orcounter-clockwise

one

endofthe

this

studinposition

bobbin,

Whenever you have removed an empty bobbin from

on it,

place

it on

the

bobbin

winder

spindle

and

start

It is a

wasteoftimetowork

withasingle

bobbin

requires an additional unthreading and threading of

winding

the

bobbin.

down

and

through

16.

been

pulled

through

around

thread

nut18backofthe

foratighter

adjust

the

positionofthe

canbereached

the

machine, wind a

the

winder.

or a

single

the

spoolofthread

needle,

from

and

the

spoolofthreadonthe

thread

guides

12,

thread

guide14and

tension15and

place

bobbin tighter or looser.

tension

discs

(Fig.

tension.

tension

stud.

below.

few

turns

of thread

because

you

cannot

sew

while

13

4).

this

R

9141

Fig. 4

Page 8

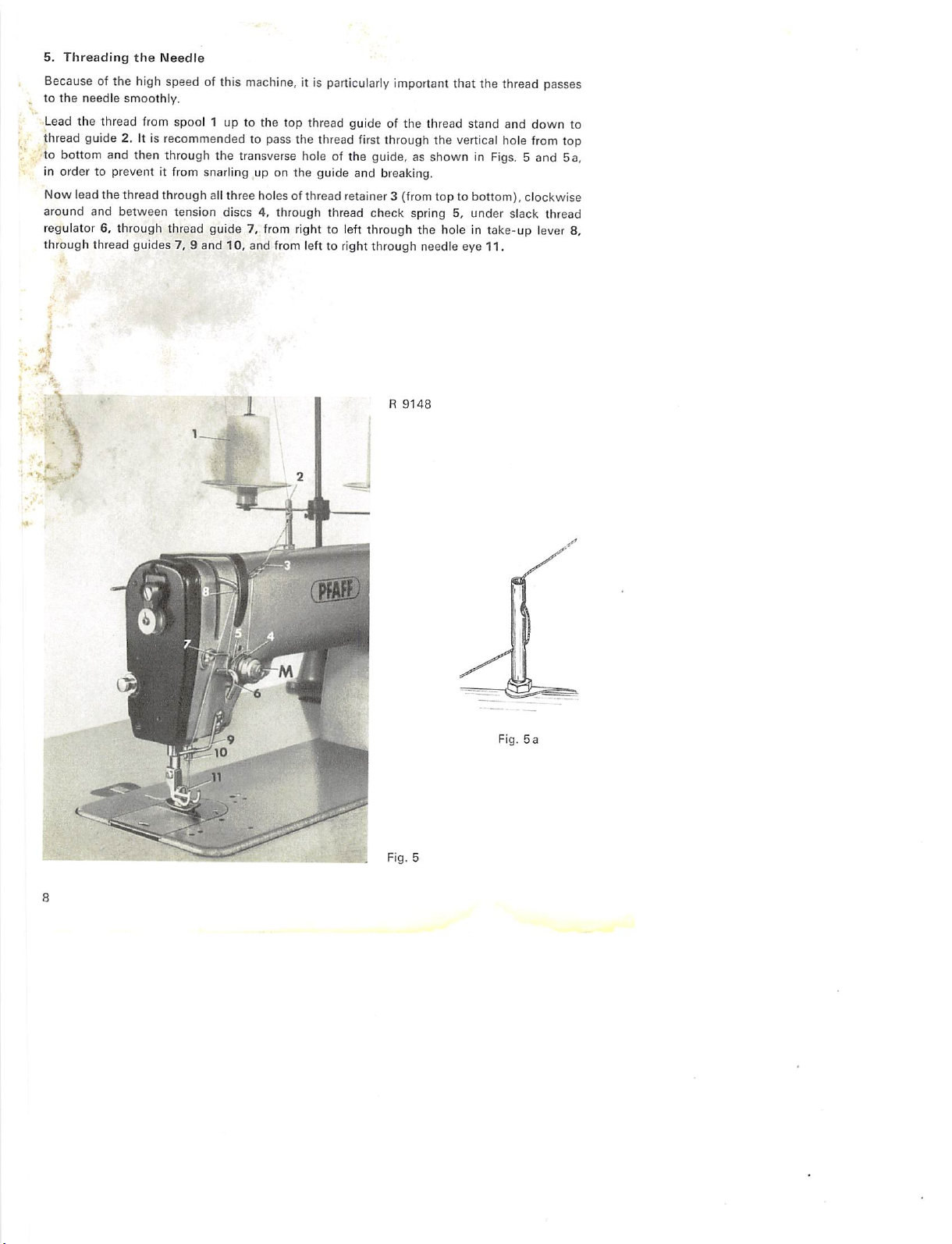

5.

Threading

the

Needle

Because of the high speed of this machine, it is particularly importantthat the thread passes

to

the

needle

smoothly.

Lead

the

thread from spool 1 up to the top thread guide of

thread guide 2. it is recommended to pass the thread first through the

to bottom and then through the transverse hole of the guide, as shown in Figs. 5 and

the

thread

stand

vertical

and

hole

down

from

top

5a,

in order to prevent it from snarling up on the guide and breaking.

Now lead the thread through all three holes of thread retainer 3 (from top to bottom), clockwise

around and between tension discs 4, through thread check spring 5, under slack thread

regulator 6, through thread guide 7. from right to left through the hole In take-up lever 8.

through

thread

guides

7, 9

and

10,

and from left to right

through

R

9148

needle eye

11.

to

Fig.

5a

m

Fig. 5

Page 9

6.

Regulating

Two

separate

The

large

regulation.

by Vss". or

of

the

stitch

In

ordertoavoid

controlStis

pushed

Finger-tip control T serves to reverse

When

lever T is

set.

When

the

machine

If

desired,

backward

the

Stitch

controls

diameterofstitch

When

this

controlisturnedbyone

0.5

mm.

The

length

controlinmillimeters

that

securedinposition

back

slightly

when

pressed

lever

T is

released,

will

resume

the

machine

sewing.

Length

servetoregulate

length

controlStmakes

stitch

lengths

the

stitch

length

by a locking lever

setting

the

down,

the

machine

the

directionoffeedisinstantly

forward

can

stitching.

be fitted with a

the

lengthofstitch

tooth,

from 0 to 5/2

(Fig.

6).

setting

will be

stitch

length.

the

direction of feed

will

sew

second

and

reverse

the

direction

for an

exceedingly

the

stitch

lengthisincreasedordecreased

stitches

per

inch

disturbed

markedSpin Fig. 6. This lever

in reverse, making

treadle

while

andisoperated

reversedbyspring

for

switching

fine

stitch

are marked on

sewing,

for backtacking.

stitchesofthe

from

stitch

action

forward

of feed.

length

the

teeth

length

must

length

•

••

be

and

to

;

7. Regulating the Pressure on the Material ?

A

powerful

The

insertingascrewdriver

screw

flat

springinthe

machine

arm

exerts

the

necessary

amountofpressureisregulatedbyturningasmall

in for

more

pressure,orout

through

hole19on

for

less

the

pressure.

rightofthe

set

screw

-

pressure

which

spool

onthe

sewing

canbereachecf'by,

pin

(Fig.

6a).

fqiSt.

Tur^

r - ^

the

;

Fig. 6

R

9386

R

Fig.

6a

9147

Page 10

8.

Lifting

Since

lifting

To

The

has

pushed

(see

Motion

and a

lock

foot after it has been raised by knee action.

To

facilitate

knee

spring-loaded pin V (Fig. 7). As a

with

A new feature of this knee lever is a hinged knee platefitted with a foam plastic pad which is

contouredtohug

the

the

mechanism

mount

arm

the

Presser

standard

knee

Bar

has

been

couldbe enclosedinthe

lever,

pushitover

leverisheldinplacebyangular

entered

cutouts

t in

right-angled

onto

the

end

ofthe

shaft,

Fig.

7).

istransmitted

bellcrank

the

presser

lever

rock

a jerk.

tilting

from

lever

which

foot

inits

the

sewing

shaftis no

the

operator's

the

vertical

raises

highest

longer

head

screwed

knee.

set

closer

to the

machine

the

lower

bracketswhich

coupling

resilient

position.

bracketsmustbecompressedtoopenitslightly

shaftto the

the

presser

This

back

without

to the

result,

the knee lever can be

rear

edgeofthe

armso that it isnot

endofvertical

snaps

sleeveq(Fig.

presser

footby

foot.Asmall

leverisflicked

removing

angular

sleeve,

bedplate,

visible

shaftrunder

into

place

after

7).

When

the

coupling

means

ofa

crank,

hand

leverC(Fig.9)serves

to the

lefttoretain

the

knee

lever

but

rather

heldinplace

pulled

forward

the

presser

onthe outside.

the

tabletop.

transverse

pin

sleeve

aconnection

the

presser

completely,

off its shaft

bar

the

bya

u

is

to

R

9158

Fig. 7

10

Page 11

9.

Lubrication

Recent

advancesinthe

permanent

system.

Thankstothe

an oiltight

installed, a

speed

With

bearings,

The

to

the

is

opened

whenitstops,

The

lubricationofthis

basesothat

feature

sewing

all

essential

there

oil

reservoirofthe

sewing

by centrifugal

oil level in

incorporationofsealed-for-life

which

machine.

points

is no

needtoprovideagravity

hook

throughaplastic

thus

preventing

the

reservoirofthe

sight glass. If it is below

spout

of an ordinary oil

sewing

requirements.

hook,inaddition,

Turn

this

designofneedle

machine

various

opens

of friction

hook

lubrication

switch

the

mark on

can

into

bearings

without

feed

mechanisms

up a practically unlimited field of

having

systemislocatedinthe

tube.

The

F on

the

hook

any

oil

leakage

hook

lubrication

the

oil

the

small

hole

canberegulatedbyscrew

screw

in for less oil, or

have

madeitpossibletoensureasatisfactory

the

incorporation

bearings,

been

lubrication

oil

shaft

sight

above

the

machine

and

special

fitted

with

saaled-for-life

system,

except

machine

flowiscontrolledbyshut-off

when

the

machineisrunning,

(Fig.

10).

system

canbeinspected

glass, top up

the

oil

the

sight

w (Fig. 8)tosuit

out

for

more

oil.

of an

automatic

does

not

havetohave

attachments

canbeeasily

applicationstothis

ball

for

the

sewing

arm

and

valveVwhich

through

reservoir by inserting

glass.

The

flow

different

lubrication

high

and

needle

hook.

supplies

and

closed

the

of oil to

operational

y.

oil

oil

the

the

R

8603

Fig. 8

11

Page 12

The

correct

setting

for

normal

Remove

the

machine

spray

oil

operation

needle

plate

and

feed

dog

for about ten seconds at top speed. The setting is

appearonthe

paper.

can be

determined

and

placeasheetofpaper

by a

over

simple

the

opening.

correct

if two thin lines of

test,asfollows:

Then

run

In contrast to the sealed-for-life ball and needle bearings in the needle head which must

n|ver be

oiled,

take-up

lever

link

z is

lubricated

bya

wick

whichisenclosed

inan

oil

tubeand

is soaked with oil from the hook oil reservoir (Fig. 9).

To oil the needle bar bearings, put a few drops of oil into the foam-plastic-lined oil dents x

and y on the upper and lower needle bar bushings (Fig. 9). This should be done rather fre

quently during the first few weeks of operation. Occasionally, also apply some oil to the

presser

bar.

R

8900

Fig. 9

Pressureonthe

bv fiat

foot

has

action,

by

lever

12

spring

been

it Is

retainedinthis

C.

materialisexerted

B. After

the

raised

by

presser

knee

position

Page 13

The

feed

driving

and

feed

the

gear

case

are

lubricatedbytwo

regulating

mechanisms

oil-soaked

foam

as well as

plastic

the

sheets

hook

(pad

shaft

driving

lubrication).

gears

in

Oil has to be changed only once a year. To do this, tilt the machine back and unscrew the ' > ,

gear

case

cover.

If

the

foam plastic

to

remove

In

most

instances,

ones

which

must be well

same

thatisusedinthe

the

may be

metal

soaked

sheets

are to be re-used, they should first be

grit

which

has

accumulatedonthem.

however,

ordered

with

hook

it will be

by Nos.

sewing

lubrication

bettertoreplace

91-069

machine oil

system.

299-05

(2.7'E/50''C),

the

old

and

91-069302-05.

washed

foam

Order No.

in gasoline in

plastic

sheetsbynew

These

280-1-120110,

new

'

order,'

sheets

the

To soak both sheets thoroughly requires about 4 fl. oz., or 130 cu. cm., of oil.

When replacing the foam plastic sheets, make sure they fit properly

and

the

large

spur

gear

runs freely in the cutout of the large sheet. As you replace the gear case cover, check to see

that the gasket is not defective and make sure you tighten all screws evenly in order to prevent

oil

from

seeping

The oscillating feed rock shaft is grease-lubricated.

at

the

left

out.

endofthe

shaft

(Fig.

10).

Qrea^

is replenished through nipple N

'

.-'m

Note

When

filling

oil tube

the hookoil

leading

to shut-off

reservoirortopping

valveV(Fig.

Itup,take care that no air bubbles

10) because this would

interrupt

remain

the flow of

inthe

If an air bubble should nevertheless have formed ahead of shut-off valve V, pull the oil tube

offthe shut-off valve

nipple,

holditsend upso that the airbubble risesto the surface.Cautiously

replace the oil tube on the nipple, making sure no air is trapped in It.

An air bubble which may have formed In the short section of the oiltube is immaterial because

it can escape through oil flow regulating valve w (Fig. 10).

oil.

13

Page 14

R

8767

Fig.

10

The gear case cover and foam-plastic sheet P are

the machine. Bottom drive shaft A carries both feed driving eccentrics

removed.

To absorb dripping oil, place a collucotton pad under

SI

and S2 and hook shaft driving gear T

in the gear case, and feed lifting eccentrics H1 and H2 as well as bobbin case opener eccentric K near its left end.

The hook shaft carries centrifugal switch F whose stud pushes the valve stem to the right when the machine is in

operation, thereby opening hook lubrication shut-off valve V. When in its inoperative position, the valve stem

should be positioned

is

notinoperation.

'/i'".

or 1.5 mm. from the stud. The valve prevents the oil fromseeping out when the machine

The stitch length setting of the front feed dog is transmitted to shaft L, the left crank mechanism in the gear case,

the

inner

feed rock

shaft,

and

the

left

adjustable

The stroke of the back feed dog Is varied by means of two large thumb screws, a and b, on shaft

crank

which,

in turn,

transmits

it to

the

left feed bar.

IVI

and lever c

which connects with the treadle chain. This lever varies the stroke of the right feed bar by means of the right crank

mechanisminthe

14

gear

case.

Page 15

R

8412

Fig. 11

The

clearance

dogs are at the beginning or endtdf t^eir strokes Instretching and gathering, respectiveiy. •

10.

between both feed dogs is

Differential

Feed

smallest

when the

differential

feed is disengaged or when both feed

In order to produce durable seams or preventseam puckering, the sewing industry frequently

employs machines fitted with differential feed which can be set to gather or stretch the fabric

while

sewing.

To this end, the Pfaff 469 is equipped with two feed dogs arranged in tandem. For ordinary

sewing, both feed dogs are set so that their length oftravelis the same. Ifthey are set to move

differentially,

the

machine

gathersorstretches,

The Pfaff 469 is set for ordinary sewing, gathering or stretching by turning the two large

thumb

screwsaandbbelow

the

bedplate

(Fig.

10).

11.

Setting

the

Machine

for

Ordinary

Sewing

Toset both feed dogs so that their length of travel is the same, turn in thumb screws a and b

as faras they

will

go. Set thestitch

length

control

on"0" and checkto see that crankc,

which

connects with the treadle pitman, is in its horizontal position. To double-check this setting,

watch

the

feed motion

Ifadjustment is

required,

and

check

whether both feed

dogs

turn both thumb screws in or out, as

rise and fall exactly perpendicularly.

mayberequired.

The machine can now be set for any desired stitch length without disturbing the relative

positionsofthe

12.

Setting

To

produceagathering

the

feed

Machine

dogs.

effect,

for

the

Gathering

stroke

ofthe

front

feed

dog

mustbelonger

thanthe

stroke

ofthe rearfeed dog. This is accomplished byturning out thumb screw a (Fig.10).

Thedifferential feed motionis controlled by a smalltreadle.The harderthis treadle is depressed,

the

longer

the

stroke

ofthe

front

feed

dog

will

be and the

more

the

fabric

willbegathered.

15

Page 16

For

gathering,

is

dependent

Igngth

desired can be easily determined by a few test runs.

Each

thumb

Thjs

spring

vibration.Inaddition,

tbe screw in or out for adjustment.

Whenthe smalltreadle is released, both feed dogs again move

the

machine

Ifthe

machine

thumbscrew b

treadle

13.

Setting

To convert the Pfaff:469 frofn.'gathering to stretching, or vice versa, requires no exchanging

pr interchanging of fee(;| dbgs„^ -

•^eginbyturning

in unison and their Ipngth of travel corresponds to the stitch length set.

For stretching,

dogsothat

with the stitch length set. The amount of stretching is regulated by turning thumb screw b out,

as appropriate. To establish the correct relationship between both feeding motions requires

but

little

the

stitches

on the

increases.

How

screw

secures

ceasesgathering and

is to be

(Fig.

depressed

thd

all

Machine

thumb

the

stroke of the front feed dog must be shorter than

the

former retains

practice.

must

notbeset

stitch

length

set,

far

thumb

screwahastobe

hastwo

the

flat

spotsonits

screwinposition

this

spring

makesiteasiertocound

used

for

continuous

10) as faras it

the

time.

for

Stretching

resumes

sci^wainasfarasit

the

material slightly while

will

too

long

I.e.

the

amountofgathering

threaded

and

preventsitfrom

ordinary

gathering,

go.This

eliminates

willgoso

because

turned

stud

sewing,

its

the

the

strokeofthe

decreases

out

for

the

which

are

turning

as a

the

numberofturns

forward

making

stitchesof the lengthset.

setting

can be

the

necessityofkeeping

that

both

feed

the

stroke of

latter

advances

front

feed

dog

as the

stitch

amountofgathering

engagedbya

resultofmachine

in unison. As a result,

fixedbyturning

dogs

it in

when

turning

the

move

forward

the

rear feed

accordance

spring.

small

in

Fig.

R

8411

Theclearance between both feed dogs is largestwhen both feed dogs are at the

in gathering and stretching, respectively.

16

12

beginning

or end of theirstrokes

Page 17

Fig.

13

Tv^'

R

8770

A

f -.

:vy

-

.-^'.

When setting the machine for stretching, care must be taken that thumb screw b is not turned

out

beyond

Setting the machine for a longer stitch

The maximum

forward stroke and turning

stroke.

When

the

point at which

amount

the machine is set for stretching, depressing the small treadle will decrease

the

front feed dog begins to feed in reverse.

will

automatically increasethe amount of stretchih||.

of stretching will be obtained by setting the rear feed dog for its longest

out

thumb

nut b to

set

the

front feed dog for its maximum backward

the

amount

of stretching and switch the machine to ordinary sewing. The operator can thus reduce the

amountofstretching,asdesired,

or eliminate

stretching

altogether.

6.-

k f:

14.

Setting

the

Machine

for

Alternate

Gathering

and

Stretching

Afterturning thumb screws a and b out as far as they will go, practised operators will be able

to

stretch

and

gather

the

fabric alternately

Ifyou start sewing with this setting and without actuating the

while

sewing.

small

treadle,

the

fabric

will

be stretched more or less, depending on the stitch length set. The more you depress the

treadle,

the

more

the

amount

ordinary sewing and then to gathering. The

the

treadleispressed

of stretching will be reduced until the machine

down

as far as it will go.

maximum

amount of gathering is obtained when

changes

over to

Changing over from gathering to stretching and vice versa by simply pressing the treadle down

more or less requires a great deal of skill on the part of the operator. Most operators will

therefore prefer to set the desired amount of gathering or stretching by turning the regulating

screwsInor

out,asmayberequired.

17

Page 18

Ascale and a pointerare providedon the armstandard as a

feed.

Pointer

Z indicates the amount of gathering or stretching on the scale. Thegraduations

visual

aid in setting the differential

from 0 to + indicate the amount of gathering, while the graduations between 0 and — indicate

the amount of stretching. The graduation marks on the scale enable the operator to restore

any desired setting without having to sew a trial seam first (Fig. 13).

15.

Varieties

To suit different operational requirements, the Pfaff 469 can be easily converted into the

following varieties by exchanging its organizational parts.

Model

•A

•A

•A

B

B

C

C

(1.0)

(1.4)

(1.8)

(2.0)

Needle

Hole

Dia.

in

mm

1.0

1.2

1.4

1.6

1.8

2.0

2.2

*) If desired, fitted

**) Primarily

•*•)

dm=mean

16.

The

A trimming

position

The

vertical trimmer is

whether

The

knife driving

motion

bracket

holder

Thanks

intended

diameter.

Pfaff

469-431

machine

among

the

the

machineisset

mechanismisarrangedatthe

emanates

via a

bracket

to its

fromaneccentric

connection,anoscillating

movesupand

favorable

mechanismiscapable

The

trimmerisengaged

reachofthe

its

rear

a

locking

in

the

end,

latch

engaging

operator

via a link,

which

shaft

Max.

Stitch

Length,

'

Machine

Speed

in

in s.p'.m.

-:-5q00 .

7^'"

514

514

514

514

with

for

organized

subclassesofthe

arrangedtothe

kinematical

of paring

and

rotates

keeps

flange.

:5606

-

5000

4800

4800

4300

4300

Needle

System

stretching.

with

for

ordinary

down

design

the

edgeofthe

and

disengagedbyoperating

protrudes

the

knife

the

knife

r.p.m.

^Dia•*

in

11.8-•

118

118

112

112

100

100

mm

133.

differential feed,

Pfaff

469.

right of

the

sewing,

gatheringorstretching.

backofthe

on

the

arm

shaft

frame,acrank

on a

post.

and

its

fabric

from

under

the

engaging

engaging

lever

Motor

Pulley

Order

16-4371^0-55

16-437.120-55

16-437120-55

16-437110-55

16-437110-55

16-437090-55

16-437090-55

the

Pfaff

needle

and

andistransmitted

andaball-joint

pad

and

reservoir

while

the

a lever

machine

shaft.Acam

engagedineither

Needle Needle

Size

No.

469-431

in

100-110

occupiesaprominent

producesaclean

machine

arm.

to

connection.

lubrication,

machine

operatesattop

whichisarranged

arm.

When

this

securedonthis

oneoftwo

V100

90-100

The

the

lever is

System

mm

60

134

70

134

80

134

134

134

120 134

140

134

cut,

regardless

knife driving

knife

holder

The

the

trimming

speed.

within

actuated,

shaft

operates

notches

knife

easy

Page 19

The

trimming

margin,

i.e.

the

distance

from

the

trimmed

edge

to the

lineofstitching,ispre

determined and can only be changed by replacing the needle plate insert.

Setting the knife higher or lower is accomplished by shortening or lengthening the drive

connection. The setting is correct ifthe upper end of the cutting edge is

about

Vaa",or 1.0 mm,

below the cutting edge of the stationary knife when the top knife is at the lowest point of

its

stroke.

Attachedtothe

knife

holderbymeansofa

shim

prevfeusly,

the

knifeisnow

securedInplace

by adjustable jaws, but must still be pushed up as far as it will go.

The

knife

holder

canbeadjusted

The only time

exchangedtoobtain

Todothis,

the

lowest

adjust

the

the

engage

point

latter so

of its

knife holder has to be adjusted is after

a different trimming margin.

the

trimming

stroke.

that

the

lengthyvise

mechanism

Loosen

knife

and

and

the

two

contacts'the

crosswise.

rotate

the

balance

set

screwsonthe

stationary knife on

the

needle plate insert has been

wheel

until

the

frontofthe

knife

the

needle plate insert.

knife

holder

is at

and

Tighten both screws securely. Makesure the knife is set,correctiy lengthwise. Its lengthwise

setting is correct if it is centered in

right-hand

After

Needle

(2.5-7.0

-431/4

(8.0-12.0

side

of the knife holder and move

the

adjustment,

plate

inserts are

mm) in

stepsofabout

machines

canbesupplied

mm)instepsofabout

tighten

available

the

needle plate cutout. To

this

screw

for trimming

for

Upper

and

plate

insert)

Subclass-431/1

Subclass

-431

the

securely.

or

0.5

mm. On

trimming

or

1.0

mm.

lower

knives

are

availableinthe

/2

adjust,'loosen

the

screwonthe

knife forward or backward, as may be required.

margins

margins

Tool-steel

plate

Tool-steel

plate

special

(the

insert

insert

ranging

ranging

from

request,

from

latter

incorporatedinthe

following

top

knife

with

cutting

top

knife

and

about

Vaa" to

subclass

about

varieties:

and

tool-steel

edge

carbide-edged

-431/2

to

'/si"

and

'Vaa"

needle

needle

needle

Unless

specified

fitted with a

because

edge

trimming

being

both

even

the

otherwiseonthe

carbide-edged

the

when

margin of

most

customary.

top

knife

Subclass

Subclass

top

and

order,

knife

the

-431

-431/4

subclass

and

needle

/3

needle

plate

Carbide-edged

plate

insert

Carbide-edged

needle

-431

machines

plate

insert

put to hard use. In this case. Model A

Ve".or3.0

mm,

and

Model C

machines

top

knife

and

with

cutting

edge

top

knife

and

plate

insert

willbesuppliedinversion

insert. This version is

retainanexceptionally

and

B machines will be fitted for a

for

®/32",or4.0

mm,

tool-steel

carbide-edged

rated

very highly

keen

these

needle

/4

cutting

margins

19

Page 20

Fig.

14

fijpOOS

Fig..l,^,

R

8973

Employed

of

suited

Fig.

collars

for

16

for

and

the

the

simuliahgoLs

cuffs

previdti^io

stitchinji-„^'d

fining'Stitching

:ti^frt|^^er?ldoally^.^

productionof^{(c^i^lg^de,''e(c.

R

8999

previoH^.to

V..'

simultart^usfy.

Fig.

17

and

Irimrnmg

lurning

v-

the

over.

front

The

edgeofa

edge

tapeIsattached

sackcoal

R

9043

The knife actuating lever has a handy plate which

protrudes from under the machine arm. from the rear (cover removed).

20

Knife

drivingmechanism of the Pfaff469.431, as seen

Page 21

17.

Treadle

The Pfaff

the

differential

If

the

be called in to

Differential

feed

Operation

469

without thread trimmer is supplied with

feed

functions

adjust

control

and

reverse

the

performedbythe

the

differential

Forward

sewing

directionoffeedbyfoot

left

treadle

aretobe

feed

regulating

'•

•t..

•••*'.•

-v.

shaft

fc." •

two

treadles if it is desired to control 5,

action

(Fig.18).

reversed

(Fig.

18a),amechanic

crank. "

ReV6|ij|4^.Forward

couuiRS' sewing

A"

mi^

\

1

'

Fig.

18

1

}

/

Reserve

sewing

On Pfaff469-000 machines fitted with Stop,motor and automatic thread trimmer, the two ^V

treadles perform the functions illustrated in

i •

1

,-A. ' - i

''lO'

•'Li'ii.iii ti-'i

".C

•?.

V • '

'e

-1

f

"Figs.

19 and 19a. ;

*> V

•^Ifeire^ial

control

Differential

feed

control

Fig.

19

Raising

the

needle

trimming

the

threads

Whenthe tip of the

treadle is

depressed,

and

right

the

Forward

sewing

Lowering

the

treadle is

faster

needle

pressed

the

machine will sew.

Fig.

Raising

trimming

down, the

sewing

19a

the

the

machine

Reverse

needle

threads

sews

and

forward.

Forward

sewing

Lowering

the

needle

The

more

the

When the treadle is released again, the machinestops. When depressing the heel of the right

treadle,

the

needleislowered

for

turning

corners.

21

Page 22

Depressing

settingofthe

the

tipsofboth

differential

treadles

feed.

causes

the

machinetogatherorstretch,

depending

depressing the heel of the left treadle, the needle is-raisedand both threads are trimmed,

leaving ends of the proper length for starting the next seam.

The addition of new functions and the advantage afforded by combining

treadle

have

Pfaff

necesSit&ted a redistribution of

469-900/2

ma^nesiare so

designed

these

functionsonboth

that

sewing

and

thread

important phases of machine operation, are controlled by'the right treadle.

differential

thread

The

feed

trimmer, are

various

and

reversing

controlledbythe

possibilities

the

directir^offeed,

existing-t^e

likeonall

left treadle.

illustratedinFigs.20and

machines

20a.,,

all

functions in one

treadles.

trimming,

the

two

Varying

havingnoautomatic

onthe

most

the

Differential

feed

control

Fig.

20

r*-.'

Reverse

sewing

Reverse

Fig.

20a

;

:

sewing

F'orward^

1

1

.•

1

1

T T

\

- 1

•

. . Raising

"trimming

Forward

j

I

i

the

the

sewing

.

.MM

needle

threads

•—

Neutral

. \

:,V \

and

Neutral

• 'i'

.i-f b'ViT

\

•i-;,ne6dle

position

/

position

/

After

needle

After

needle

/•

sowing:

down

thread

up

sewing:

down

trimming;

^After

thread

trimming:

needle

up

Differential

feed

control

22

/

Raisng

the

needle

and

trimming

the

threads

Page 23

18.

If

desired,

Inching

every

Device

Pfaff

469

featuringanautomatic

needle

positioner

and

thread

trimmer

can,#

in addition, be fitted with an inching device which permits slow stitch-by-stitch sewing.'

This device is attached to the Stop motor and controlled by depressing the right treadle,'

When

the

tip of

the

right

treadleisdepressed

continuetopress

down

the tip of the

reached. Ifyou want to sew at top speed right away,

farasit

When

on

is

After

When

take-up

The

will

go.Inthis

you

havetoturnacornerorsewanintricatd^Section

the

treadle

until

If

you

allow

the

lowered

press

machines,orthe

needletobe

All

trimming

19.

Machines

equipped

initiating

for

On

pressure exerted subsequently, which moves

also

even

When

automatically,Tobring

down

the

sewing

has

raisedtoIts

the

treadleisreturned

lever

remains

work

can

nowbeeasily

machines

Raising

repositioning

these

raises

fitted

without

the

fitted

with a knee lever for raising not only

the

thread trimming action. This feature makes it possible to raise

machines,

the

after

the

pressure on

you operate

way,

the

inching

the

inching

device

becomes

treadletoreturn

heel of

the

been

completed,

heelofthe

right

left

highest

to its

to its

the

treadle.

press

treadle

point

neutral

at its highest point and the needle19positioned outside the

renrtoved

with

automatic

being

slowed

Needle

with

automatic

the

work.

a light

needletoits

the

treadle to resume

without

pressure

the

down

needle

highest

knee lever

thread

Thread

against

point.

lightly,

treadle,

device

operative

neutral

position,

needle

of a

The

work

down

on

subcl.

and

both

position

and

new

trimmer

first.

Trimming

positioner

the

the

A locking lever

and

the

sewing,

the

inching

deviceisenergized.

thp.sevyi.pp,

will

subcl.

can

the

threadst6f^e

.speed

mcr^ii^

quickly

depress of the treadle as

norbecome'b{3eralii^-'

ofthe

seam,

relieve

and

the

the

needleofsubcl.

-900

thenbeturned

heel

of the-'right

-900

machines.

after

the

machine

machine

trimrnedtothe

threadat-itsve

sews

to its

and

sewingberesumed.

treadleonsubcl.

This

workbeln$ertedv,^.j.,,"

canbeswitched

and

thread

the

presser foot,

knee

plate

raises

knee lever

treadle has been relieved.

the

through

retains

locking lever is released,

from

trimmer

but

the

presser

the

the

full

can,inaddition,

also

last third of its travel,

needleatthis

until

top speed is

the

stitchbystitch.

-900/2

machines

lowest

action

causes

proper

been

trimmed,

speedtothread

the

needle

the

presser foot

foot

andastronger

As you '

pressure

position,

-900/2

the

length.

the

material.

be

without

position

23

Page 24

Contents

Foreword

1. SettingUpthe Machine^', .

2. Mounting the V-Belt _ .

3.

Test-Running

Winding

4.

Threading

5.

6.

Regulating

7.

Regulating

8. Lifting

9.

Lubrication-.,.

10.

Differential

11.

Setting

12. Setting the Mactfne for Gathering .

13.

Setting

14.

Setting

15.

Varieties

16.

The

Pfaff

17.

Treadle

18.

Inching

19.

Raising

the

Machine

the

Bobbin

. ' . ' .

the

Needle

the

Stitch

Length

the

Pressureonthe

the

Presser

Bar

^^,

. s . •

Fe^;

-i,

the

Macl^e^fer

the

Macl^e'foj'.Stretching

the

Machine

.

...

469-431

Operation

Device

the

Needle

Ordinary

fdr

Alternate

. <

.

without

>

Material

Sewing.,5

Gathering

Thread

Trimming

and

,

.

Stretching

- .

3

4

4

5

6

8

9

9

10

11

15

15

15

16

17

18

18

21

23

23

24

Loading...

Loading...