Page 1

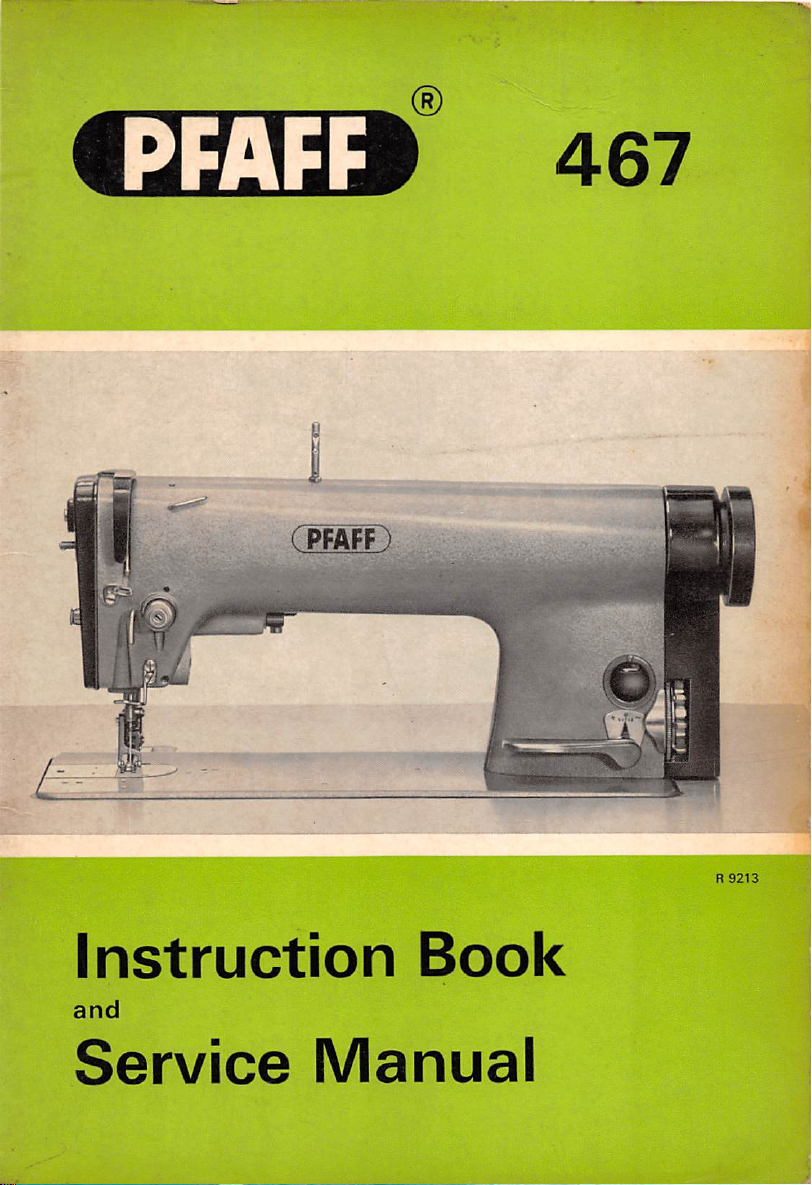

PFAFF

(PFAFF

467

Instruction

and

Service

Book

Manual

R

9213

Page 2

(PHEE)

467

High-Speed

Sewing

with

Variable

Drop

Lockstitch

Machine

Feed

Top

Feed

Instruction

and

Service

Equipped

and

Book

Manual

G

M*PFAFFAG

KAISERSLAUTERN

BRANCH

Page 3

Foreword

This

instruction

sewing

questions

function

her

Since

creepofthe

operationofthe

A

positioner

The

time-wasting

freetomanipulate

so

The

by all

in

alike.

machine.

and

machine

the

special

incorporation

soon.

instructions

who

the

Pfaff

relatedtosewing

operationofthe

and

Pfaff

467isequipped

toporbottom

Service

and

thread

motions

service

467

book

contains

Though

not

exhaustively,itoffers

various

attain

maximum

ply in

top

feed

control

Manualisavailable

trimmer

of an

and,

the

for

mechanics

our

machinesinthe

make

greater

automatic

thus,

work

(Order

and

demands

much

valuable

intended

as a

information

full-scale

textbook

sufficient

mechanismstoenable

efficiencyasquicklyaspossible.

with

variable

stitching

shouldbestudied

affords

can

containedinthe

top

feed

"problem"

for

Pfaff

machines

No.

12310).

needle

positioner

notable

advantages.

achieveamuch

field

because

on

the

mechanical

very

second

the

which

materials,

carefully.

467-900

and

higher

partofthis

additional

skillsofassemblers

about

the

Pfaff

capableofanswering

informationonthe

every

operatortogettoknow

canbeset

thread

The

the

chapters

fitted

trimmer

operator

so as to

with

has

automatic

eliminates

outputofwork

book

willbewelcomed

mechanisms

467

high-speed

construction,

eliminate

dealing

both

without

incorporated

and

with

needle

many

her

hands

tiring

adjusters

all

any

the

G.M.PFAFF

AG

Page 4

R

9372

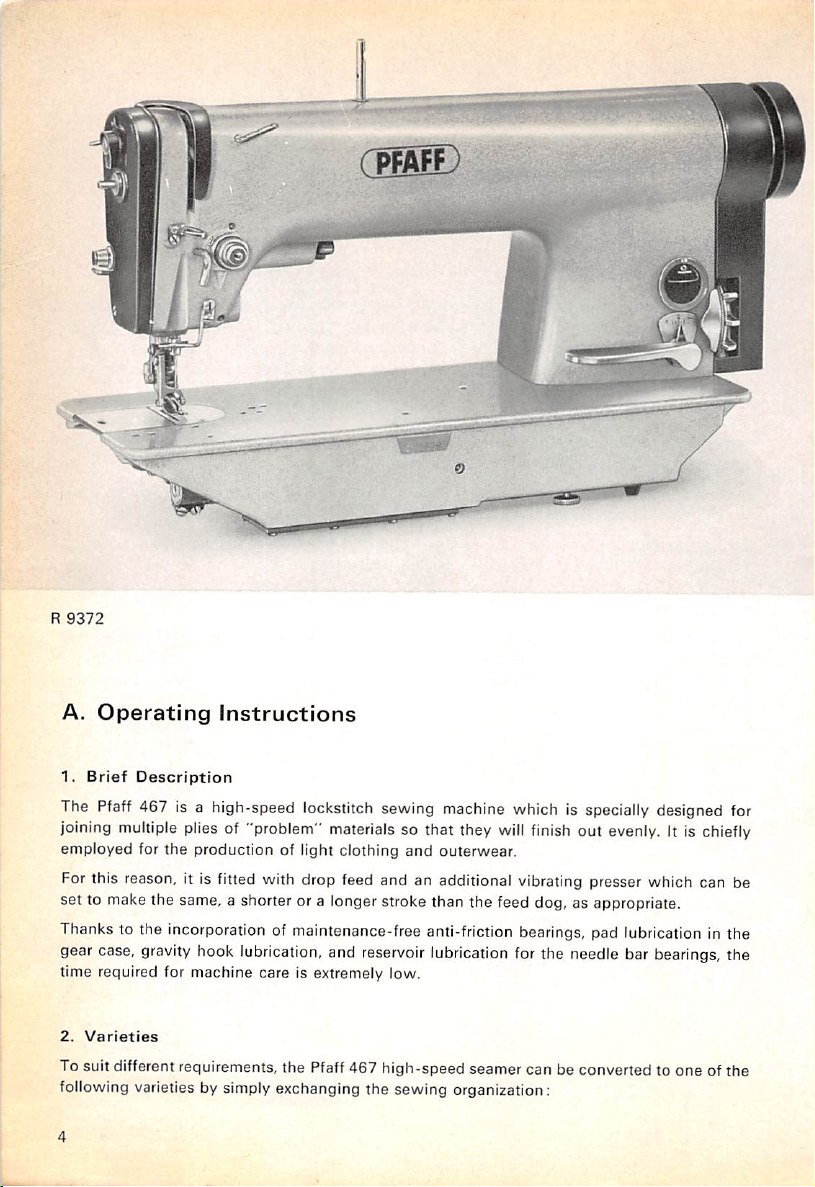

A.

Operating

1.

Brief

Description

Instructions

The Pfaff 467 is a high-speed lockstitch sewing machine which is specially designed for

finish

joining multiple plies of "problem" materials so that they will

employed for

the

production of light clothing

and

outerwear.

out evenly. It is chiefly

For this reason, it is fitted with drop feed and an additional vibrating presser which can be

set

to make the same, a shorter or a longer stroke than the feed dog, as appropriate.

Thanks to the incorporation of maintenance-freeanti-friction bearings, pad lubrication in the

gear case,

time required for machine care is extremely low.

2.

To suit different requirements, the Pfaff 467 high-speed seamer can be converted to one of the

following varieties by simply exchanging the sewing organization:

Varieties

gravity

hook lubrication, and reservoir lubrication for the needle bar bearings, the

Page 5

Model

A

A

A

B

B

3.

(1.0)

Standard

(1.4)

Standard

(1.8)

Mounting

Needle

Hole

in

1.0

1.2

1.4

1.6

1.8

the

mm

Die.

V-Belt

Max.

Stitch

Length

in

s.p.m.

5)4

5)4

5)4

5)4

S'A

The machines are shipped with

head

slightly

and

place

the

beltonthe

Slightly

holding

In

To

Both

b3

tighteningItsecurely.

the

tighten

belt

and

turn

them

back

spacing

out

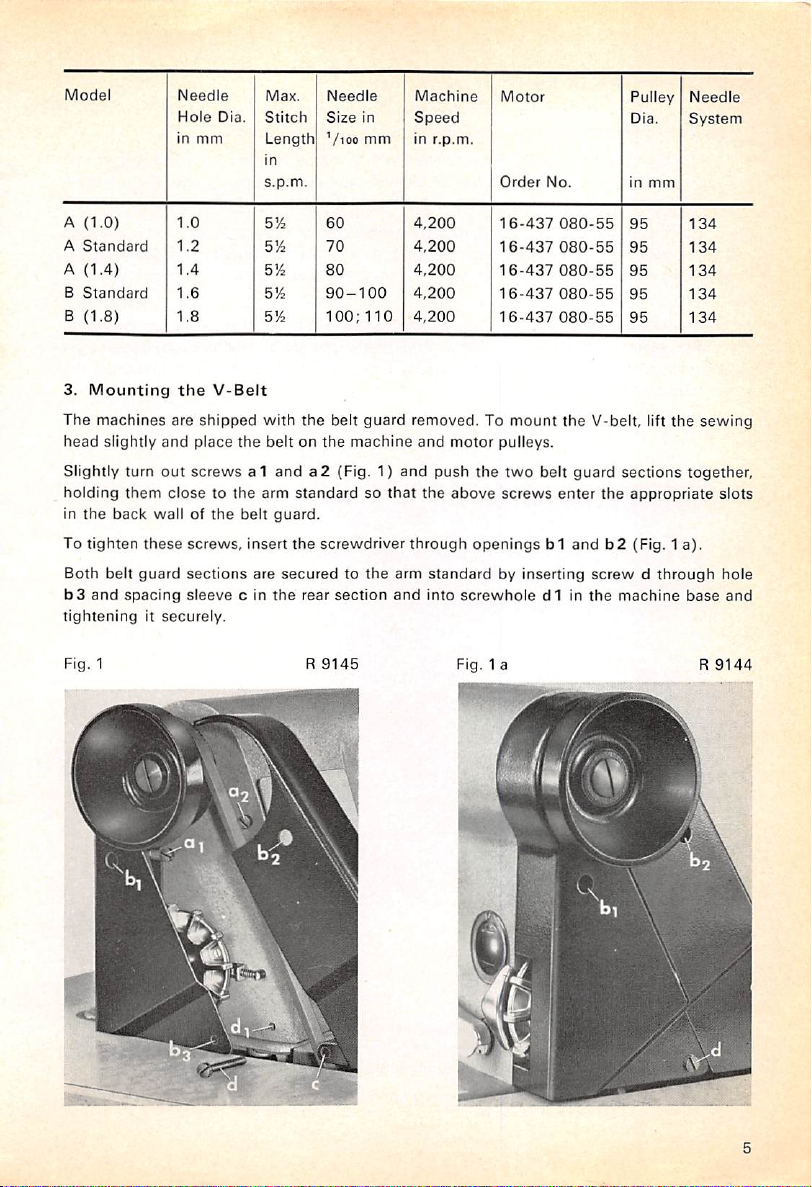

screwsa1anda2(Fig. 1)

closetothe

wallofthe

these

guard

screws,

sections

sleeve

arm

belt

insert

are

c In

guard.

the

Needle

Size

'/loo

60

70

80

90-100

100:110

the

belt guard removed. To mount

machine

standardsothat

the

screwdriver

securedtothe

rear

section

in

mm

Machine

Speed

In

r.p.m.

4,200

4,200

4,200

4,200

4,200

and

and

push

the

through

arm

standardbyInserting

and

Into

motor

the

above

Motor

Order

16-437

16-437

16-437

16-437

16-437

pulleys.

two

screws

No.

080-55

080-55

080-55

080-55

080-55

the

belt

enter

V-belt, lift

guard

the

Pulley

DIa.

In

95

95

95

95

95

sections

appropriate

openingsb1andb2(Fig. 1 a).

screwdthrough

screwhole

d1Inthe

machine

mm

Needle

System

134

134

134

134

134

the

sewing

together,

base

slots

hole

and

Fig. 1

R

9145

Fig. 1 a R

9144

Page 6

4.

Test-Running

Before

you

test-run

transit.Besuretouse

The

Pfaff

463

must

the

cleaning

reason,

Never

which

grease

ineffective.

Before

sameasthat

right

motor

fluid

enters

keroseneorgasoline

attempttoeliminate

you

believetobe

will be

thinned

you

connect

indicatedonthe

direction. If

terminal

the

box.

the

Machine

the

machine,

onlyabrush

neverberinsedorcleaned

the

hard

responsible

and

the

machinetothe

pulley

carefully

andacleaning

sealed-for-life

must

notbeused

workingofthe

for

flung

outofthe

rating

plateofthe

turnsinthe

this

electric

wrong

remove

bearings

fault. If oil

all dirt

rag for

this

with

kerosene

and

dissolves

for regular

machinebysquirting

bearings,

circuit,

motor,

cleaningofthe

enters

thus

checktosee

and

direction, merely

which

purpose.

because

the

sealed-for-life

rendering

that

the

exchange

may

there

the

oil

freely

permanent

that

motor

have

grease.

machine.

the

line

pulley

accimulated

is a

danger

For

the

into

the

bearings,

lubrication

voltageisthe

turnsinthe

two

wiresinthe

In

that

same

bearings

the

5.

Removing

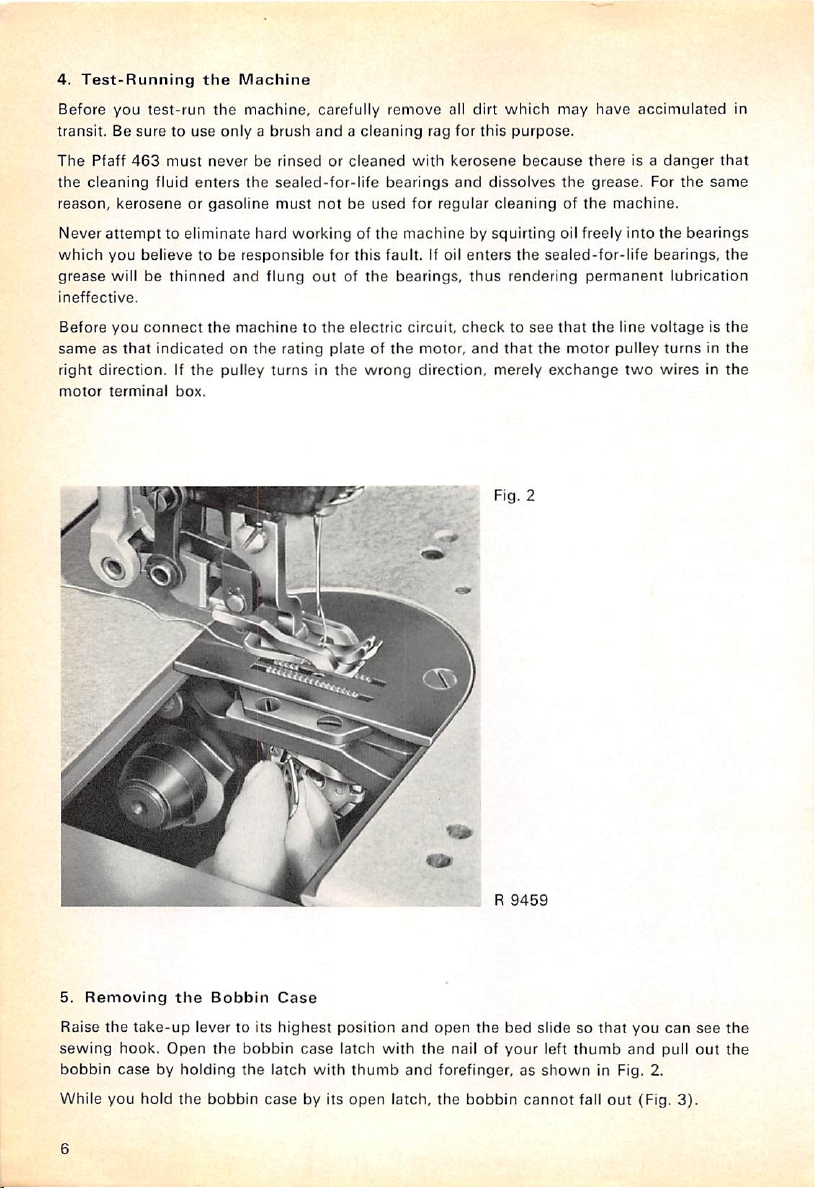

Raise

sewing

bobbin

While

the

the

take-up

hook.

lever to its

Open

casebyholding

you

hold

the

Bobbin

the

bobbin

bobbin

the

case

Case

highest

latch

case

with

by its

position

latch

thumb

open

and

open

with

the

nail of

and

forefinger,asshown

latch,

the

. R

the

bobbin

9459

bed

slidesothat

your

cannot

left

thumb

in Fig. 2.

fall

out

you

and

(Fig.

can

pull

3).

see

out

the

the

Page 7

R

5868

R

6.

Winding

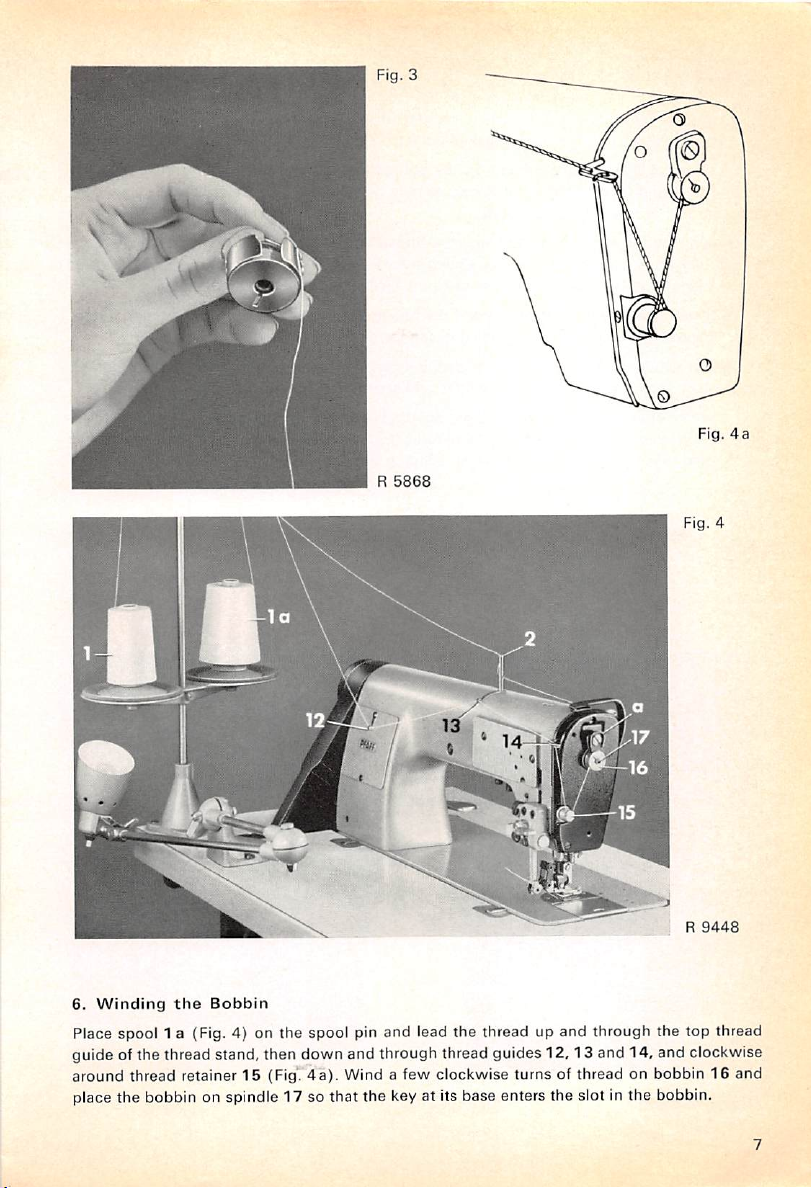

Place spool 1 a (Fig. 4) on the

guide of the thread stand, then down and through thread guides

around thread retainer15(Fig'.

the

Bobbin

spool

pin and lead

4a).

Wind a few clockwise turns of thread on bobbin16and

the

thread up

and

through the top thread

12,13

and 14, and clockwise

place the bobbin on spindle 17 so that the key at its base enters the slot in the bobbin.

Fig.

9448

4a

Page 8

To

engage

running.

position

The

The

and

more

Dependingonthe

thread

the

If

the

The

Whenever

on

it,

It is a

into

rethreaded

the

bobbin

This

action

it is

retained

thread

woundonthe

amountofthreadtobe

setting

stop

latchahigherorlower,asmayberequired.

thread,orlower

typeofthread

tensionisregulatedbyturning

nut

clockwise

thread

set

screw

placeiton

you

for a

should

pileupat

securing

have

removedanempty

the

wasteoftimetowork

action

only

when

when

the

winder,

causes

the

until a

sufficient

bobbin

woundonthe

for

less

looser

tension,orcounter-clockwise

this

studinposition

bobbin

winder

withasingle

the

machineisrunning

machine

simply

bobbin

thread.

one

idles

depress

winder

amountofthread

pushes

the

used,

the

thumb

endofthe

canbereached

bobbin

spindle

and

bobbin

while

winding

stop

latch

a (Fig. 9)

spindletoshift

latchupand

bobbin

canberegulatedbyloosening

slightlytothe

has

been

thereby

Set

thread

shouldbewound

nut18backofthe

for a

bobbin,

from

start

and

adjust

the

the

because

the

the

bobbin.

the

from

machine,

winder.

the

needle

positionofthe

the

bobbin

while

wound

stops

the

stop

tighterorlooser.

tension

discs

tighter

tension.

left.

windafew

winder

hastobe

the

rightinwhich

on

the

the

bobbin

latch

(Fig.

tension

turnsofthread

canbethrown

unthreaded

machine

bobbin.

winder.

screw

higher

9).

is

b

for

The

Turn

stud.

and

Fig. 5

a

5867

R

Fig. 6

R

5869

Page 9

z

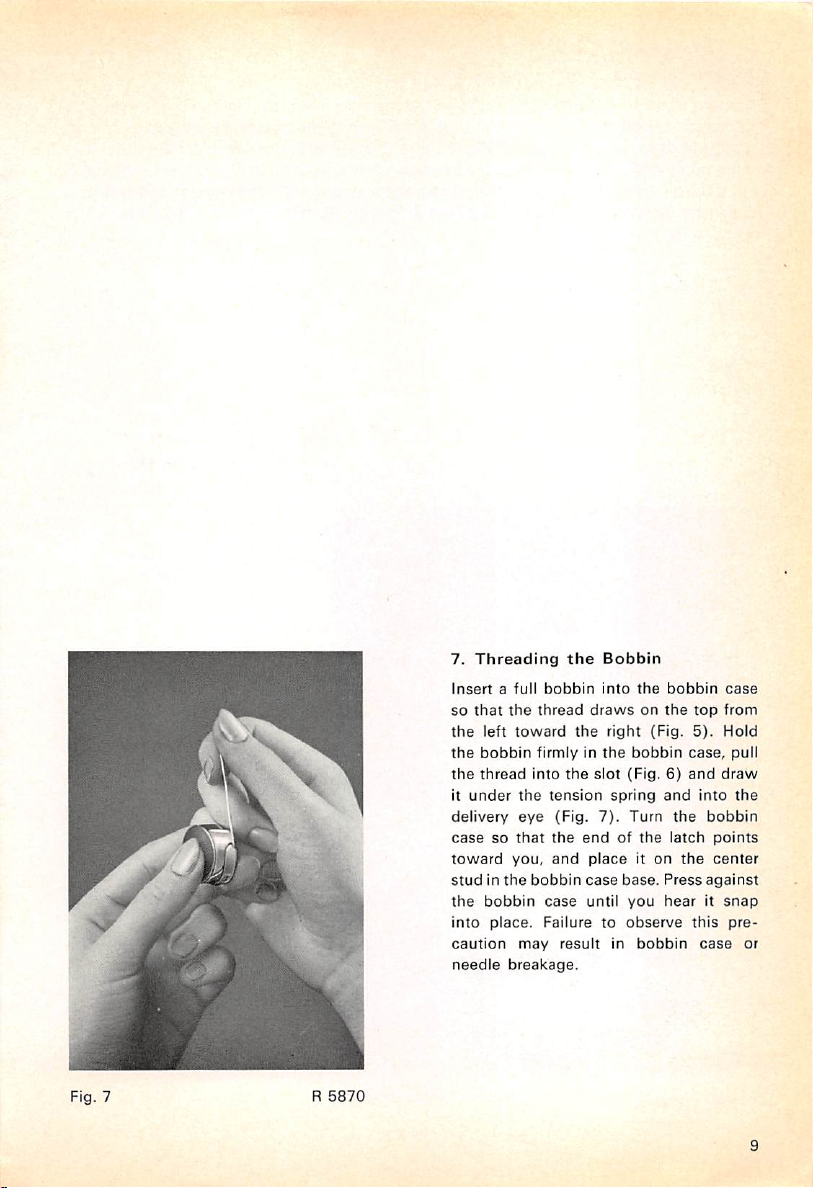

7.

Threading

Insertafull

so

that

the

the

left

toward

the

bobbin

the

thread

it

under

the

delivery

casesothat

toward

studinthe

the

into

caution

needle

eye

you,

bobbin

place.

may

breakage.

the

Bobbin

bobbin

Into

thread

drawsonthe

the

right

firmly in

into

bobbin

the

bobbin

the

slot

(Fig.6)and

tension

case

Failuretoobserve

(Fig.

the

and

result

spring

7).

Turn

endofthe

place

case

base.

until

you

in

the

bobbin

(Fig.

and

the

latch

it on

Press

hearitsnap

bobbin

case,

the

top

5).

into

bobbin

against

this

case

case

from

Hold

pull

draw

the

points

center

pre

or

Fig. 7 R

5870

Page 10

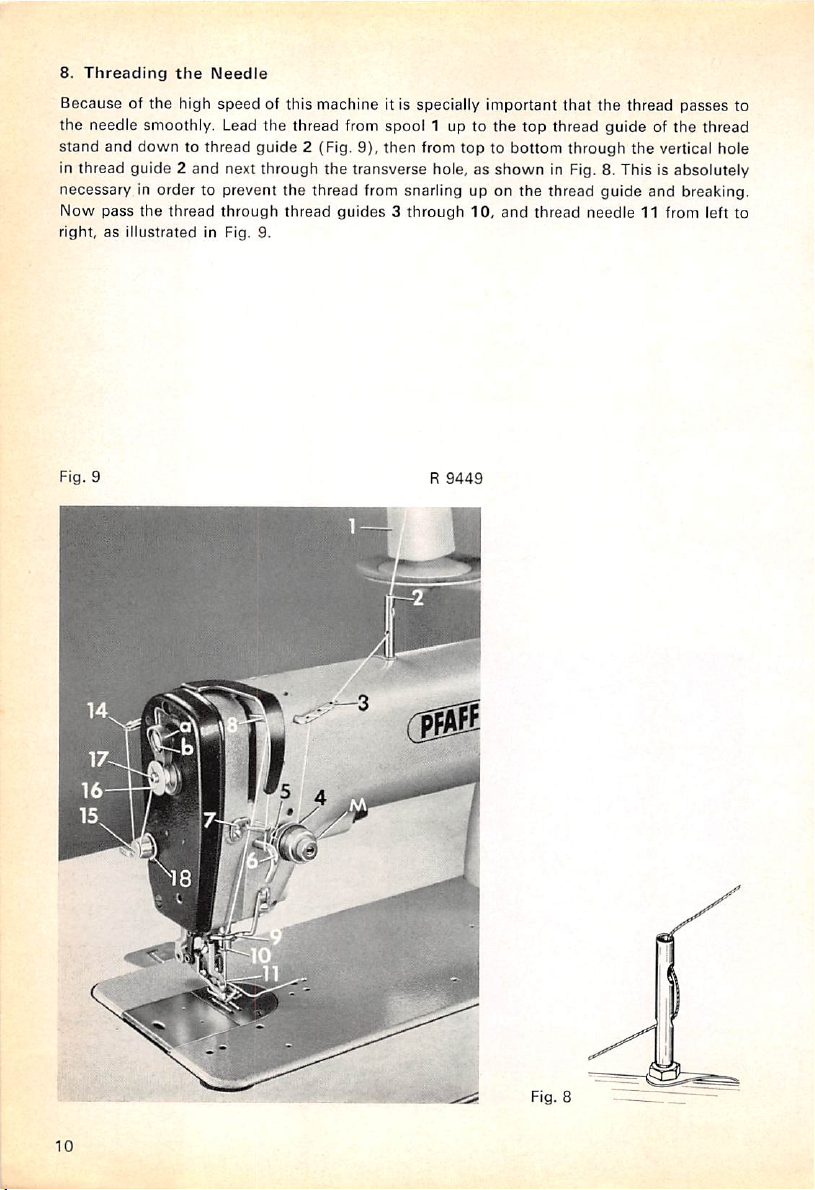

8.

Threading

Because of the high

the

needle smoothly. Lead

stand

and

in thread guide 2

necessary in order to prevent

Now

pass

right,

as

the

Needle

speed

down

to thread guide 2 (Fig. 9), then from top to bottom

and

next through

the

thread

through

illustrated in Fig. 9.

of this machine it is specially important

the

thread from spool 1 up to

the

transverse hole, as

the

thread from snarling up on

thread

guides3through

10.

the

shown

the

and

top thread

thread

that

the thread

guide

through

in Fig. 8. This is absolutely

thread

guide

needle

passes

of the thread

the

vertical hole

and breaking.

11 from left to

to

Fig. 9

/

U

R

9449

Fig. 8

10

Page 11

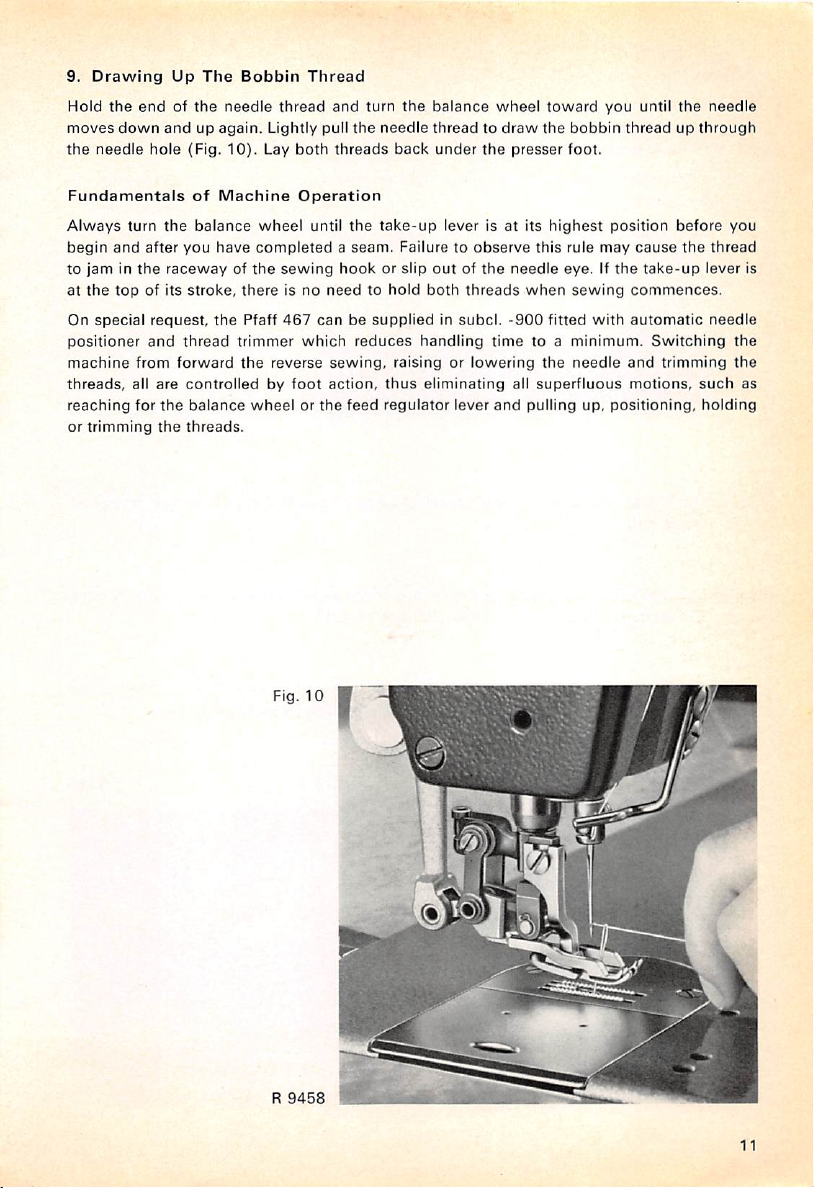

9.

Drawing

Hold

moves

the

the

down

needle

Up

endofthe

andupagain.

hole

(Fig.

The

Bobbin

needle

10).

thread

Lightly

Lay

Thread

both

and

pull

threads

the

turn

the

needle

back

balance

wheel

threadtodraw

under

the

presser

toward

the

foot.

you

bobbin

until

the

needle

threadupthrough

Fundamentals

Always

begin

to

at

On

turn

and

jaminthe

the

top

special

positioner

machine

threads,

reaching

or

all

for

trimming

of

the

balance

after

you

racewayofthe

of its

stroke,

request,

and

thread

from

forward

are

controlledbyfoot

the

balance

the

threads.

Machine

wheel

have

completedaseam.

sewing

thereisno

the

Pfaff

467

trimmer

the

reverse

wheelorthe

Fig.

Operation

until

the

take-up

lever

Failure to

hookorslip

needtohold

outofthe

both

canbesuppliedinsubcl.

which

reduces

sewing,

action,

feed

handling

raisingorlowering

thus

eliminating

regulator

10

observe

threads

lever

is at its

needle

-900

time

all

and

highest

this

rule

eye.Ifthe

when

sewing

fitted

to a

minimum.

the

needle

superfluous

pulling up,

position

may

cause

commences.

with

automatic

and

motions,

positioning,

before

the

take-up

Switching

trimming

you

thread

lever

needle

such

holding

is

the

the

as

R

9458

11

Page 12

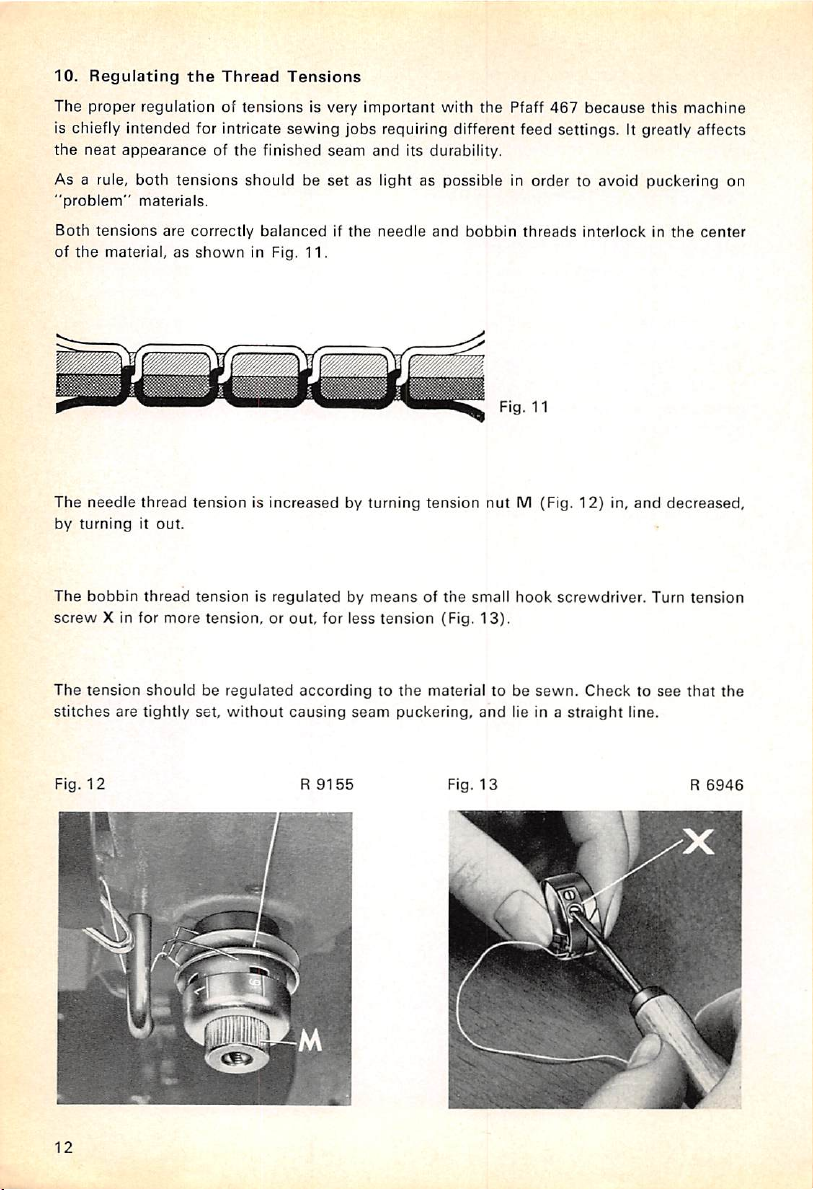

10.

The

Regulating

proper

the

Thread

regulationoftensions

Is chiefly intended for intricate

the

neat

appearanceofthe

As a rule, both

"problem"

Both

tensions

of

the

material, as

The

needle

by

turningitout.

The

bobbin

screw

X in for

tensions

materials.

are

thread

thread

more

shouldbeset

correctly

shown

in Fig.

tensionisincreasedbyturning

tensionisregulatedbymeansofthe

tension,orout,

Tensions

is very

sewing

jobs

finished

balancedifthe

seam

11.

for

less

Important

with

the

Pfaff

467

because

this

machine

requiring different feed settings. It greatly affects

and

its durability.

as light as possible in order to avoid puckering on

needle

and

bobbin

threads

tension

tension

(Fig.

nut

small

13).

Fig. 11

M (Fig.

hook

Interlockinthe

12)

in,

screwdriver.

and

decreased,

Turn

tension

center

The

tension

stitches

Fig.

12

12

shouldberegulated

are

tightly

set,

without

accordingtothe

causing

seam

R

9155

materialtobe

puckering,

Fig.

and

13

sewn.

lie in a

Checktosee

straight

line.

that

R

the

6946

Page 13

The

gradeofthread

call

forathin

are

unsuitable

You

will

ment

when

be

too

tightorthe

the

lower

and

soft

for

almost

havetohave

you

come

tension

too

used

playsanimportant

thread,

while

any

fabric.

a little

experienceinorder

acrossaseamasthe

lower

tension

too

tight.

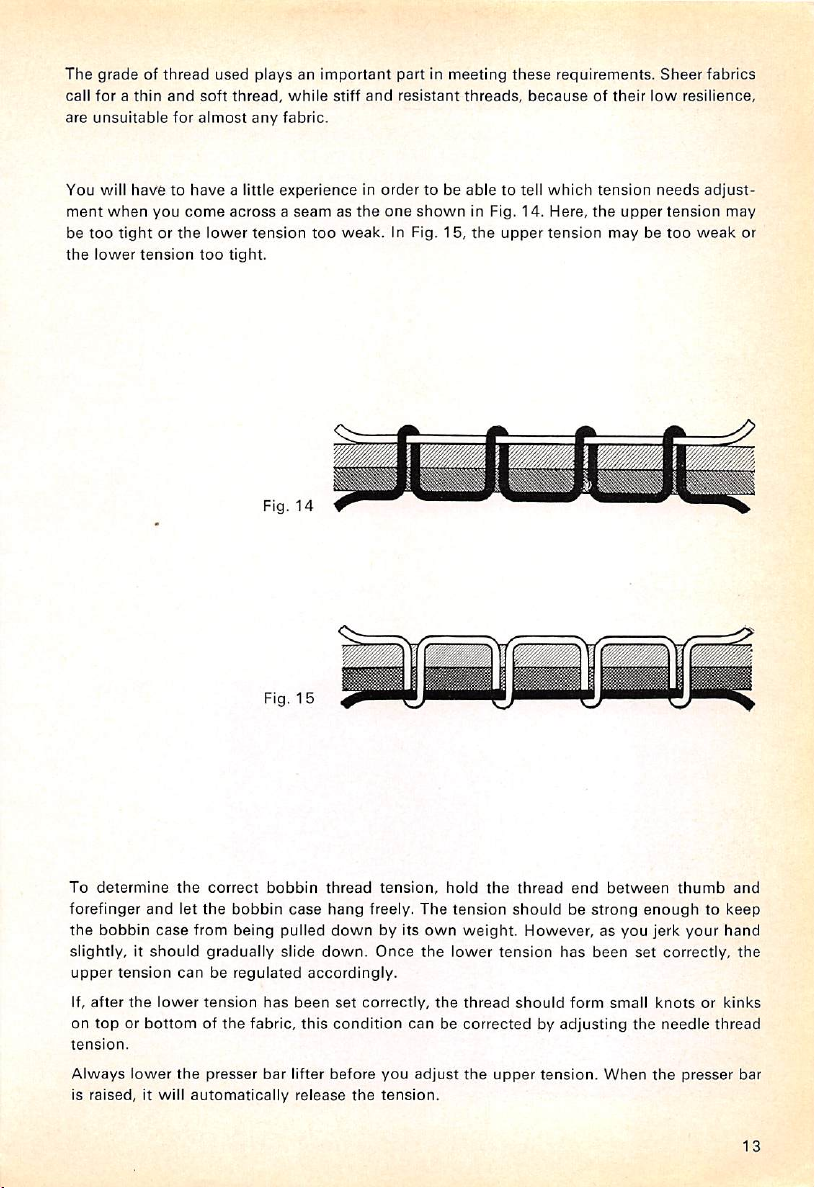

Fig.

14

stiff

weak.

partinmeeting

and

resistant

to be

one

shown

In Fig.

15,

threads,

able

in Fig.

the

these

requirements.

becauseoftheir

to tell

which

14,

Here,

upper

tension

tension

the

upper

maybetoo

Sheer

low

needs

resilience,

tension

weak

fabrics

adjust

may

or

To

determine

forefinger

the

bobbin

and

the

let

case

slightly,itshould

upper

tension

If,

after

on

toporbottomofthe

tension.

Always

is

raised,

canberegulated

the

lower

lower

the

it will

Fig.

correct

the

bobbin

from

being

gradually

tension

has

fabric,

presser

bar

automatically

bobbin

case

pulled

slide

lifter

15

thread

hang

downbyits

down.

accordingly.

been

set

this

condition

before

release

tension,

freely.

Once

correctly,

The

own

the

hold

the

the

tension

weight.

lower

thread

canbecorrectedbyadjusting

you

adjust

the

upper

the

tension.

thread

end

shouldbestrong

However,asyou

tension

should

has

form

tension.

between

been

small

When

set

the

thumb

and

enoughtokeep

jerk

your

hand

correctly,

knotsorkinks

needle

the

thread

presser

the

bar

13

Page 14

11.

The

Regulating

maximum

the

stitch

Stitch

Length

lengthofthe

Pfaff

467

is 5!^

per

inch, or

4.5

mm.

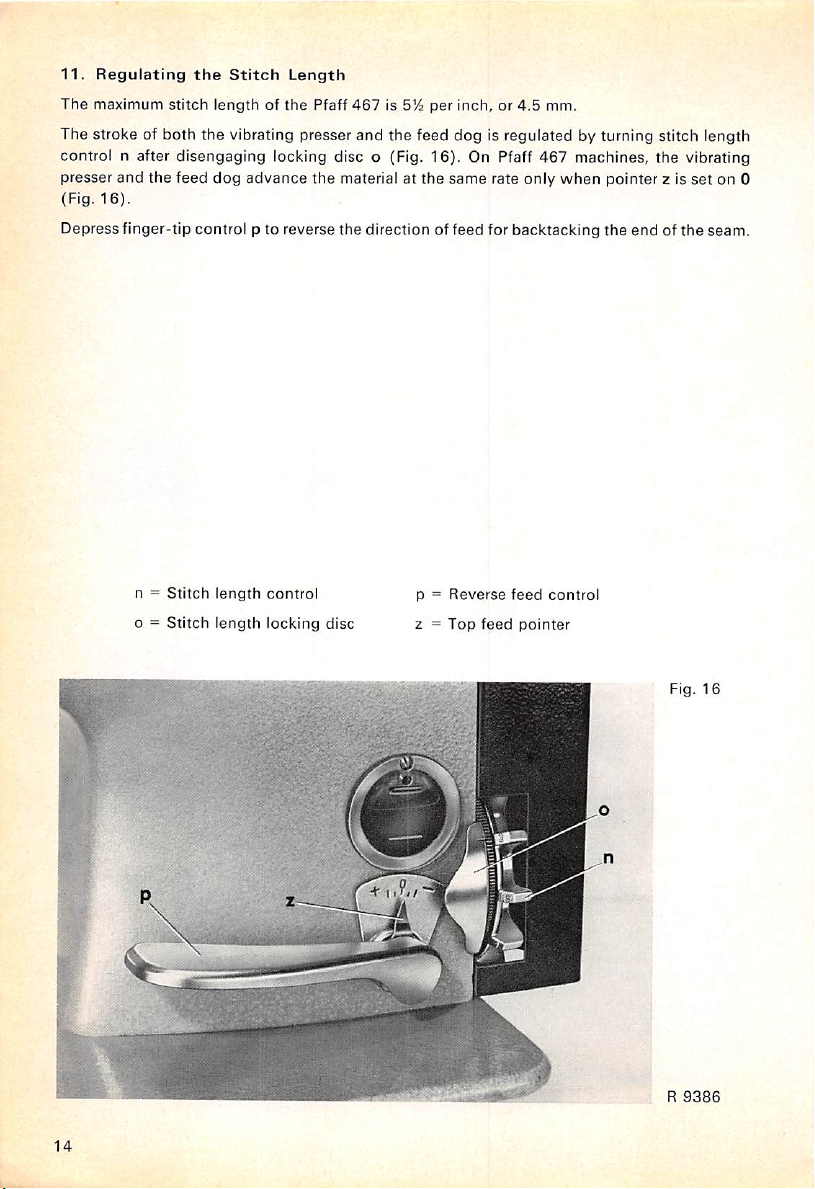

The stroke of both the vibrating presser and the feed dog is regulated by turning stitch length

control n after disengaging locking disc o (Fig. 16). On Pfaff 467 machines, the vibrating

presser

and

the

feed

dog

advance

(Fig.

16).

Depress finger-tip control p to reverse

n =

Stitch

length

o =

Stitch

length

control

locking

the

material at

the

disc

the

same

rate

direction of feed for backtacking the

p =

Reverse

2 =

Top

feed

only

feed

pointer

when

control

pointer

endofthe

z is

set

on 0

seam.

Fig.

16

R

9386

14

Page 15

12.

Varying

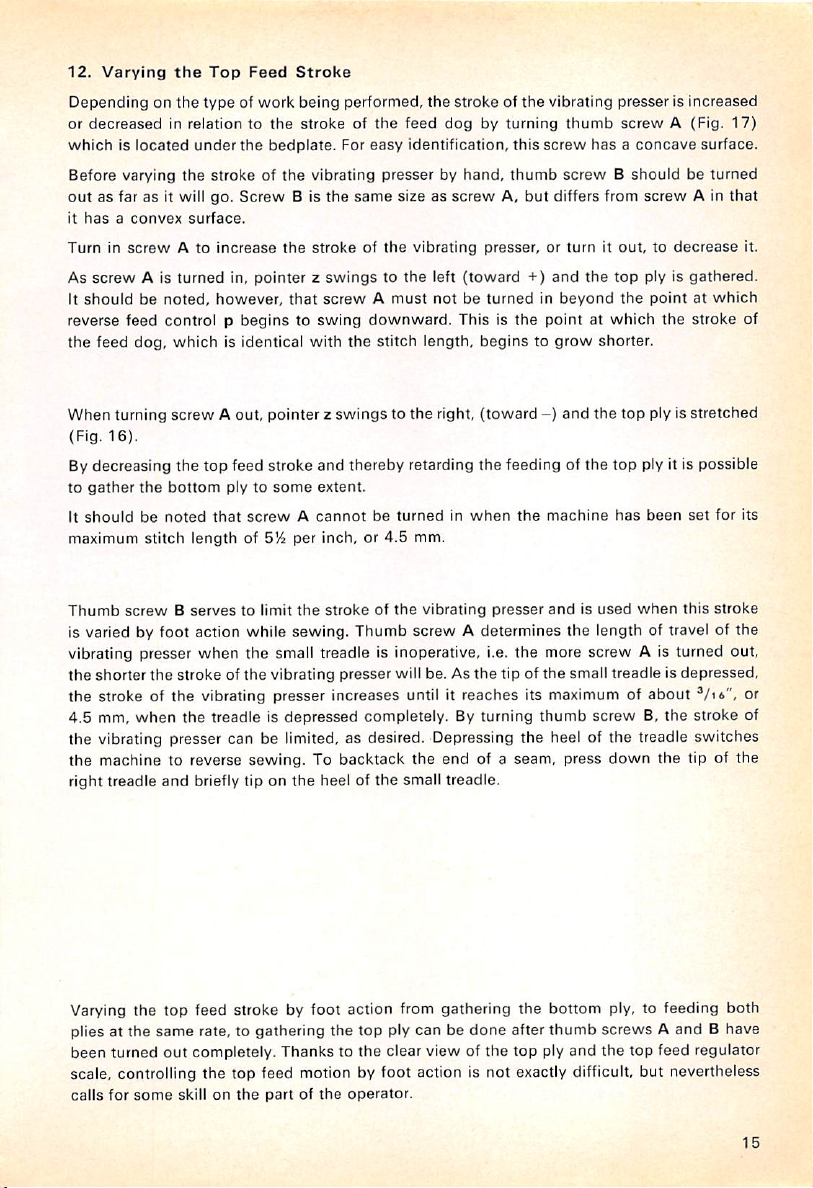

Dependingonthe

or

decreasedinrelationtothe

whichislocated

Before varying the stroke of the vibrating presser by hand,

out

as farasit will

it

hasaconvex

Turninscrew

As

screw

It

shouldbenoted,

reverse feed control p

the

feed

the

Top

typeofwork

under

go.

surface.

A to

A is

turned

dog,

whichisidentical

Feed

Stroke

being

strokeofthe

the

bedplate.

Screw

B is

the

increase

however,

the

strokeofthe

in,

pointerzswingstothe

that

screwAmust

begins

to swing

with

performed,

feed

For

easy

identification,

same

sizeasscrewA,but

vibrating

downward.

the

stitch

the

strokeofthe

dogbyturning

this

thumb

vibrating

thumb

screw

screw

differs from

presser,orturnitout,todecrease

left

(toward+)and

notbeturnedinbeyond

This is

the

point at

length,

beginstogrow

presserisIncreased

screwA(Fig.

hasaconcave

B should be

screw

the

top

ply is

the

pointatwhich

which

the

shorter.

17)

surface.

turned

A in

that

gathered.

stroke of

When turning screw A out, pointer z swings to the right, (toward-)and the top ply isstretched

(Fig.

16).

Bydecreasing the top feed stroke and thereby retarding the feeding of the top ply it is possible

to

gather

the

bottom

ply to

some

extent.

It

shouldbenoted

maximum

Thumb

stitch

screwBserves

that

screwAcannotbeturnedinwhen

length

of S'A per inch, or

to limit

the

strokeofthe

4.5

mm.

vibrating

the

presser

machine

andisused

has

been

when

set

this

for

stroke

is varied by foot action while sewing. Thumb screw A determines the length of travel of the

vibrating presser when the small treadle is inoperative, i.e. the more screw A is turned out,

the

shorter

the

stroke of

the

vibrating presser will be. As

the

tip of the small treadle is

depressed,

the stroke of the vibrating presser increases until it reaches its maximum of about Vi6", or

4.5 mm,

when

the

treadle is

depressed

completely. By turning

thumb

screwB,the

stroke of

the vibrating presser can be limited, as desired. Depressing the heel of the treadle switches

the machine to reverse

right treadle

and

sewing.

briefly tip on

To backtack the end of a seam, press

the

heel of

the

small treadle.

down

the

tip of the

it.

its

Varying

the

top feed stroke by foot action from gathering the

bottom

ply, to feeding both

plies at the same rate, to gathering the top ply can be done after thumb screws A and B have

been

turned

out

completely. Thanks to

the

clear view of

the

top ply

and

the

top feed regulator

scale, controlling the top feed motion by foot action is not exactly difficult, but nevertheless

calls

for

some

skill on

the

partofthe

operator.

15

Page 16

3

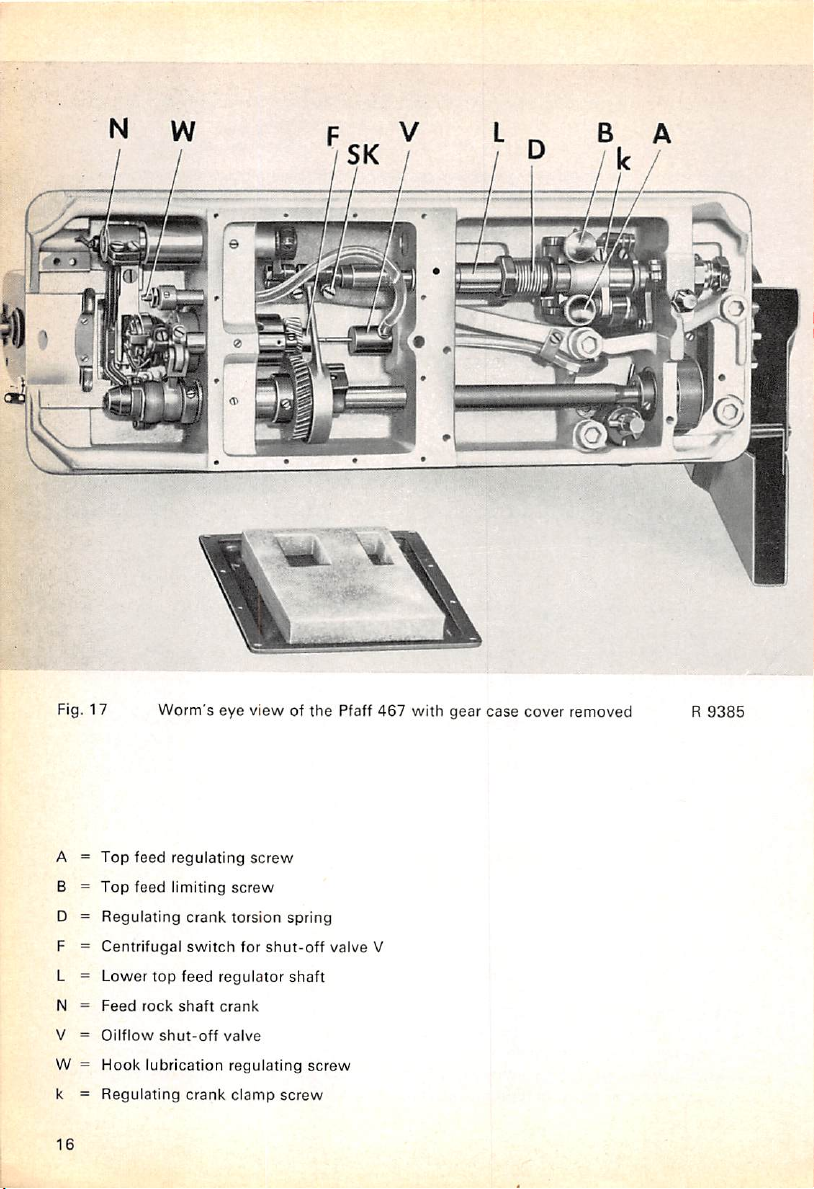

Fig. 17 Worm's eye view of

A =

Top

feed

B =

D =

F =

L =

N =

V =

W =

k =

16

Top

feed

Regulating

Centrifugal

Lower

top

Feed

rock

onflow

shut-off

Hook

lubrication

Regulating

regulating

limiting

crank

switch

feed

shaft

crank

screw

screw

torsion

for

regulator

crank

valve

regulating

clamp

shut-off

screw

the

spring

shaft

screw

Pfaff

valve

467

V

with

gear

case

cover removed R

9385

Page 17

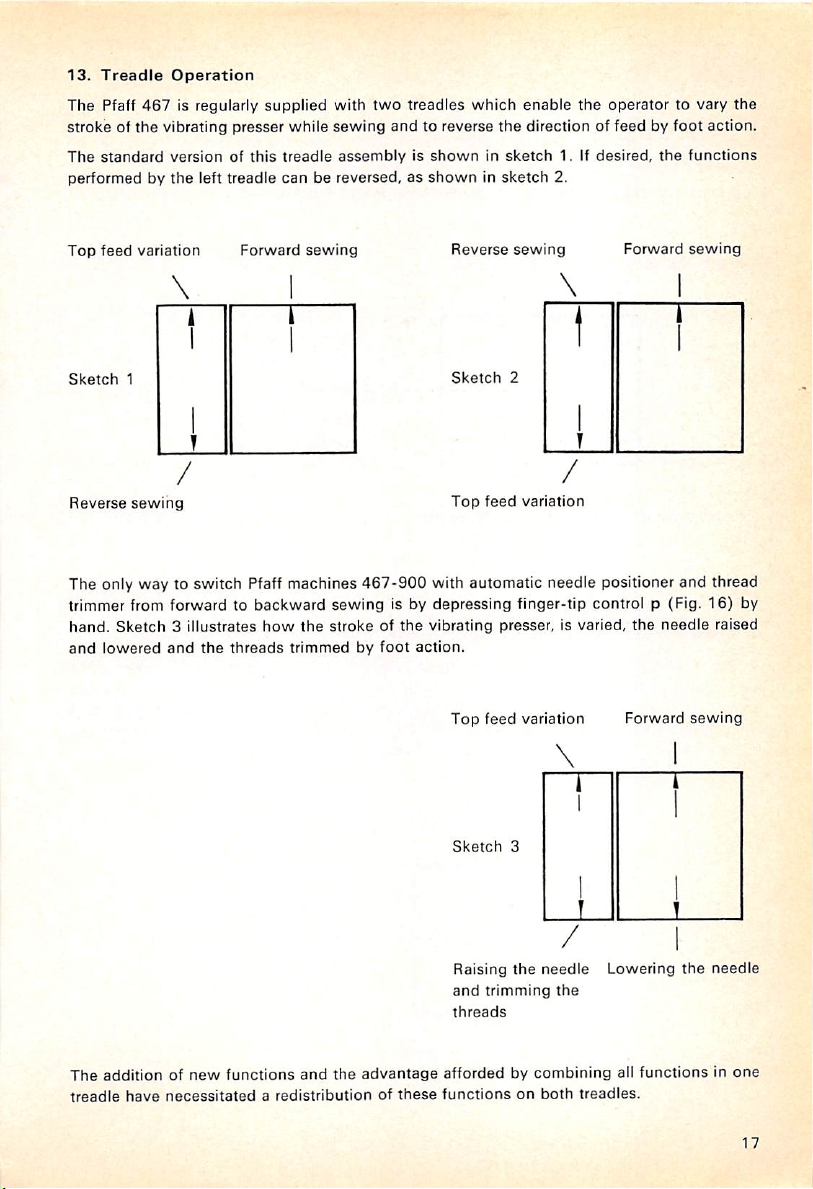

13.

Treadle

The Pfaff

strokeofthe

The

standard

Operation

467

vibrating

versionofthis

performedbythe

is regularly supplied with

presser

while

sewing

treadle

assemblyisshowninsketch

left

treadle

canbereversed,asshowninsketch

two

treadles which enable

andtoreverse

the

operator to vary the

the

directionoffeedbyfoot

1. If

desired,

2.

the

action.

functions

Top

feed

Sketch

Reverse

variation

1

sewing

Forward

sewing

The only way to switch Pfaff machines

467-900

Reverse

Sketch

Top

with automatic needle positioner and thread

feed

sewing

2

variation

Forward

trimmer from forward to backward sewing is by depressing finger-tip control p (Fig.

hand.

Sketch

and

lowered

3 illustrates

and

the

how

threads

the

strokeofthe

trimmedbyfoot

vibrating presser, is varied,

action.

Top

feed

variation

the

needle

Forward

\

sewing

16)

raised

sewing

by

The

additionofnew

treadle

have

functions

necessitatedaredistributionofthese

and

the

advantage

Sketch

3

Raising

the

needle

and

trimming

threads

the

affordedbycombining

functionsonboth

treadles.

Lowering

all

functionsinone

the

needle

17

Page 18

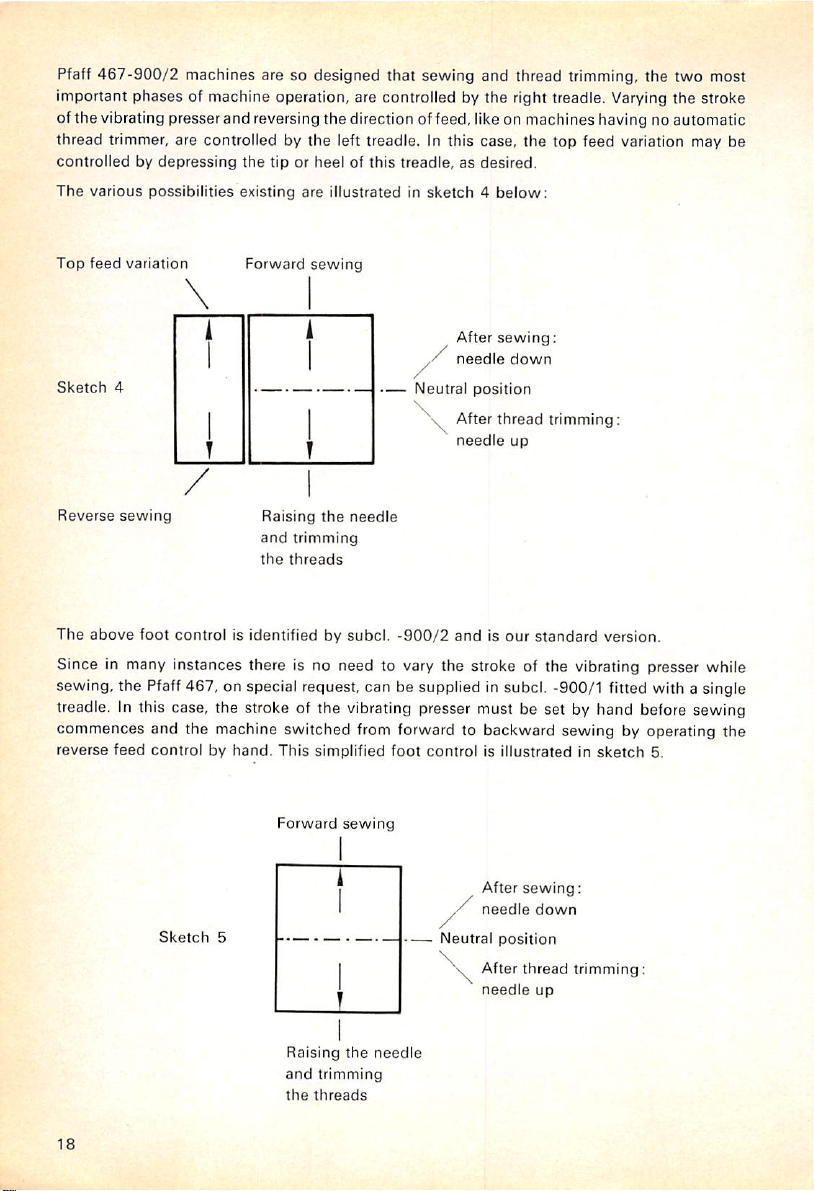

Pfaff

467-900/2

machines are so

designed

that

sewing

and

thread trimming, the

two

most

important phases of machine operation, are controlled by the right treadle. Varying the stroke

of

the

vibrating

thread trimmer, are controlled by

controlledbydepressing

The

various

Top

feed

Sketch

variation

4

presserand

possibilities

reversing

the

tip or

existing

Forward

the

direction of feed, like on machines having no automatic

the

left treadle. In this case, the top feed variation may be

heelofthis

are

illustratedinsketch4below;

sewing

treadle,asdesired.

After

needle

—

Neutral

position

Afterthread

needle

sewing:

down

trimming:

up

Reverse

The

above

sewing

and

foot

controlisidentifiedbysubcl.

Raising

trimming

the

threads

the

needle

-900/2

andisour

standard

version.

Since in many instances there is no need to vary the stroke of the vibrating presser while

sewing, the Pfaff 467, on special request, can be supplied in subcl. -900/1 fitted with a single

treadle. In this case, the stroke of the vibrating presser must be set by hand before sewing

commences and the machine switched from forward to backward sewing by operating the

reverse

feed

controlbyhand.

Sketch

This

simplified

Forward

5

Raising

and

trimming

the

threads

sewing

the

foot

controlisillustratedinsketch

After

needle

Neutral

position

After

needle

needle

sewing:

down

thread

up

5.

trimming:

18

Page 19

If

the

machine is fitted with an additional inching device, this device is

motor

and

controlledbydepressing

is

depressed

continuetopress

attained.Ifyou

downasfarasit will

When

on

the

becomes

If

you

machinesislowered

position,

be

resumed.

After

-900/2

the

needle

When

take-up

above

The

work

Machines

trimming

slightly,

the

down

wanttosewathigh

you

havetoturnacornerorsewanintricate

treadle until the inching device

operative

allow

press

sewing

machines,orthe

to be

the

treadleisreturnedtoits

lever

the

needle

can

fitted

without

and

the

treadletoreturntoits

automatically.Tobring

down

has

been

raised

remainsatits

plate.

nowbeeasily

with

slowing

inching

the

go.

the

the

heelofthe

completed,

heelofthe

to its

automatic

the

the

deviceisenergized

tip of

the

machine

sews

neutral

right

depress

left

highest

point

neutral

highest

point

removed

and

thread

machine

treadle

for

forward

treadle,

speed

the

right

the

pressure on

stitchbystitch.

position,

the

needle

treadle.

the

heelofthe

treadleonsubcl.

and

both

position

and

the

needleispositioned

new

workbeinserted.

trimmer

down

canbeswitched

first.

for

slow

sewing

away,

sectionofthe

the

of a

The

work

threads

after

attachedtothe

sewing.

quickly

the

needleofsubcl.

the

When

the

tip of

this

stitch-by-stitch

speed

increases

press

seam,

the

relieve

sewing.

until

top

tipofthe

the

treadle until the inching device

-900/1

and

subcl.

-900

can

thenbeturned

right

treadleonsubcl.

-900

machines.

to be

trimmedtothe

threads

machine

have

about

from full

to its

and

-900/1

This

action

proper

been

trimmed,

or

speedtothread

Stop

treadle

As you

speed

treadle

pressure

-900/2

lowest

sewing

and

causes

length.

8.0

mm,

is

the

Raising

Machines

equipped

Initiating

On

these

pressure

be

re-positioned.

the

Needle

fitted

with

withaknee

the

thread

machines,

exerted

subsequently

without

needle

lever

trimming

a light

positioner

which

action.

pressure

also

Thread

raises

against

raises

Trimming

and

not

only

the

the

automatic

the

knee

plate

needle

thread

presser

raises

to its

foot,

highest

trimmer

but

also

the

presser

pointsothat

can,inaddition,

the

needle,

without

foot

andastronger

the

work

be

can

19

Page 20

14.

Lifting

Both

The

presser

pushitover

angular

in

right-angled

When

compressedtoopenitslightly.

Motionistransmitted

andabellcrank

(Fig.

This

leverisflickedtothe

To facilitate

the

knee

byaspring-loaded

withaslight

A

new

touredtohug

the

the

vibrating

bar

the

bracketswhich

coupling

the

coupling

lever

20)

serves

the

lever

rock

jerk.

featureofthe

the

Presser

presser

lifting

lower

Bar

and

mechanismisenclosedInthe

endofvertical

snaps

sleeveq(Fig,

sleeveIspushed

from

the

which

raises

to lock

the

lefttoretain

tilting

backofthe

shaftisno

pin v

(Fig.

knee

lever

operator's

the

presser

Into

vertical

the

vibrating

sewing

longer

18)sothat

is its

knee.

foot

shaftrunder

place

after

18).

onto

the

shafttothe

presser

bar.Asmall

presser

the

presser

head

screwedtothe

the

hinged

are

mountedonthe

machine

the

transverse

endofthe

presser

and

the

bar

afterithas

without

angular

knee

lever

arm.Tomount

tabletop.

driving

shaft,

barbymeans

hand

leveratthe

presser

removing

sleeve,

canbepulled

foam-plastic-padded

presser

The

leverisheldinplace

pin u

has

resilient

foot

been

bracketsmust

of a

crank,aconnection

backofthe

in their

raisedbyknee

the

knee

but

rather

forward

knee

plate

bar.

the

entered

highest

lever

completely,

heldinplace

off

whichiscon

knee

cutouts

machine

position.

its

lever,

by

t

be

action.

shaft

Fig.

18

R

9158

20

Page 21

15.

Regulating

The

amountofpressure

the

Pressure

materialinordertoensure

of

the

fabric.

in

our

high-speed

spring

whichisincorporatedinthe

pressureonthe

The

pressureonthe

by

insertingashort

Turn

the

regulating

seamers,

presser

material is

screwdriver

screw

on

the

Material

to be

exertedbythe

smooth

feeding

the

conventional

machine

bar.

regulatedbyturningalong

in for

through

more

aperture19(Fig.

pressure,orout.

vibrating

presser

and

mustbeadaptedtothe

spiral

spring

has

been

arm

and

exertsaresilient

set

screw

19)

backofthe

for

less

pressure.

the

presser

thickness

replaced

and

which

footonthe

and

the

by a

long

easily

regulated

canbereached

spool

pin.

nature

flat

R

9147

21

Page 22

16.

Selecting

Pfaff

machines

diameter

Insert

the

sure

the

The

appearanceofthe

thread

and

the

Correct

467inModelsAandBuse

of ®/6a", or

needle

short

into

groove

2.0

mm.

the

openingofthe

faces

finished

fabric.

Lightweight

Needle

System

needle

toward

the

right.

seamisdependentonthe

fabrics

shouldbesewn

bar

134,

round-shank

and

push

correct relationship

with

ugly needle marks. When thick thread is used In a thin needle,

Thin thread used In a thick needle may

Select

the

proper

needle

and

thread

Needle

Size

Cotton

sizes

cause

skipped stitches.

from

the

Silk

chart

below:

needles

having a

it upasfarasit will

between

a thin

needleinordertoavoid

the

thread Is likely to break.

Synthetic

go.

shank

Make

needle,

70-80

80-90

90-100

100-110

110-120

Be

suretobuy

branded

100

80

70

50

35

needles

only. Never

use

100

80

60

50

40

rusty

120-100

90-80

70-60

50

40

needles.

Only superflnished needles ensure trouble-free sewing and prevent thread breakage. Rough-

surfaced needles tend to overheat quickly and burn the thread. This is particularly true of

synthetic threads which are very sensitive to heat and fuse easily.

For stitching synthetic threads, we recommend that you use superfinished, chromium-plated

needles

which

maybeobtained

from

us.

22

Page 23

17.

Machine

Although

hook

lubrication

maintenance,

To oil

the

plastic-lined

be

done

onceortwiceaweek,

each

week.

Care

the

Pfaff

system

several

needle

bar

dentsXand

Occasionally

467isequipped

and

pad

lubricationinthe

bearings

bearings,

y (Fig.

nevertheless

remove

20)onthe

depending

putafew

Fig.

20

with

the

drops

seaied-for-iife

gear

havetobe

face

cover

and

upper

and

on

how

many

of oil on

the

anti-friction

case

and,

carefully

putafew

lower

needle

hours

presser

bearings,anautomatic

thus,

requires

lubricatedbyhand.

drops

bar

the

machine

bar

felt

little

of oil into

bushings.

is in

washer.

additional

the

This

should

operation

foam-

R

9447

23

Page 24

Oilshould also be applied to the top feed drive joints and to the oiling points marked by arrows

in Fig.

40.

The oil level In the hook lubrication system can be inspected through the oil

is

below

the

mark, top up

at

the

top of

the

oil

quantity

If oil bubbles

adjusted,

of oil In

call

excess,orshort,ofthe

should

your

In order to ensure trouble-free sewing, form

and

removing

vicinityofthe

When

you

at the

needle-bar

oil

the

sewing

the

needle

endofthe

the

sight

glass. Make sure

reservoir by inserting the

the

oil level

proper

amount

spout

does

may

occur in the hook oilline or the oilflow to the

maintenance

lint

that

hook,

bar

man.

has

accumulated

usingabrush

bearings,

takeabrush

for

the

between

this

habit of tilting

feed dog and needle plate

purpose.

and

remove

machine. In this way, you prevent the particles of dressing which,

of the oil can into the aperture

not rise

above

cause

irregularities in

sewing

the

machine back

the

dust

which

sight

glass. If it

the

red mark. Any

the

hook has to be

onceaday

and

has

accumulated

oilflow.

in the

in most instances, contain plastic, from mixing with the oil and forming an undesirable film

on

the

parts.

The

machine

shouldbecleaned

with a dry, soft rag on

the

underside regularly.

24

Page 25

B.

Service

18.

The

When

mounting

the

motor

The

various

DIN

42691

a

hinge

bolt

be

requiredtotension

Although

to

withstand

we

urge

youtoadjust

too

loose

Thereisno

Instruction

V-Belt

the

pulley

becauseadistorted

motors

specifications.

and,

after

the

anti-friction

great

because

hard-and-fast

Drive

V-belt

usedtodrive

stress

both

tensioniscorrect,ifyou

pulleys.

Tighten

loose

of

the

the

hinge

while

sewing.Amotor

V-belt.

bolt

for

They

loosening

the

belt

bearings

and

eliminate

the

V-belt

conditions

rule

can

nutorthe

the

first

time,

care

belt

wears

the

Pfaff

467

are

pivotally

nut

correctly

Kl or a

connectedtothe

screw,

(Fig,

21).

incorporatedinthe

the

risk of

tensionsometiculously

may

cause

excessive

for

tensioning

compress

binding

that

hangsinthe

the

the

belt

screwonthe

shouldbetaken

out

rapidly.

are

standard

motors

canbeswungtoany

new

high-speed

excessive

V-belt,

about

V-belt

heatingorseizingofthe

that

the

wear.

butitmaybeassumed

% ofaninch

motor

bracketsothat

freely greatly

that

it is

not

forced

conformingtoGerman

motor

bracketbymeans

position

seamers

beltIsneither

are

too

that

midway

between

it will

reduces

the

that

designed

machine,

tight

the

not

service

onto

of

may

nor

belt

both

come

life

Fig.

R

21

9157

25

Page 26

19.

Timing

The

thread

occursasthe

ward

canbeadjustedbyturning

On

the

loosening

to time

you

must

The

thread

goods.

To

increaseordecrease

mechanism.

If

turning

and

take

of

the

the

Check

check

spring

lever

descends,

strokeofthe

new

set

the

be fully

the

out

thread

thread

high-speed

screwk(Fig,

thread

check

conversant

check

springiscorrectly

Turnitclockwisetoincrease

tension

stud

the

complete

check

spring

Spring

servestoassist

butisnot

check

the

regulator,asappropriate.

seamer,

34)onthe

spring

the

thread

the

take-up

yet

required

is limited by a

check

undersideofthe

spring correctly right away,

with

its

function.

timed

if it is

the

check

spring

tension,

the

tension,orcounter-clockwise,todecrease

withascrewdriver

tension

mechanism.

regulator.

Then

should

Slightly

readjust

lever in

for

spring

without

through

simply

prove

takingupthe

the

formationofthe

stoponthe

regulator

tension

trying

acting

turn

the

impossible,

loosen

the

strokeofthe

slack

stitch.

check

spring

canbeturned

barrel. In

out

different settings first,

when

the

needle

tension

studinthe

loosen

the

set

screwatthe

spring

thread

The

regulator

easily

ordertobe

reaches

screw

k (Fig.

meticulously.

which

down

tension

rear

and

after

able

the

it.

34)

end

26

Page 27

20.

Setting

The

needle

seam.

Correlating

referredtoas

If

the

exchanged,

the

needle

needle

needle

The

amountofneedle

the

Needle

and

hook

The

proper

timing of

the

needle

"adjusting

amountofneedle

beginbyroughly

bar

set

screw,

the

barsothat

plate

(Fig.

22).

BaratCorrect

motions

both

and

hook

the

needle

bar

rise

setting

move

its

bottom

rise

required

Height

mustbeproperly

motions

requires

synchronizedinordertoobtainaperfect

utmost

motionssoastoensure

rise".

mustbereset,

the

needle

the

needle

endisabout

to form

for

bar to

bar

connecting

Va",or13.0

the

loop

accuracy.

instance,

the

correct

on Pfaff

proper

loop

after

the

positionasfollows:

link to its

mm,

467

lowest

above

machines,

formation

needle

position,

the

top

i.e.

by which the needle has to rise from the lowest point of its stroke, normally is

or

1.8

mm.

To

set

this

amount

by us

(Order

Turn

the

balance

the

gauge

onto

No.

880137/00onthe

This

done,

pull

the

clamp

strikes

correctly, it is

No.

91-129

604-01).

wheel

until

the

needle bar, pushing it

needle

out

the

gauge

the

needle

recommended

the

needle

bar,

push

and

cautiously turn

bar

bushing.

bar

against

it up

Now

that

has

you use

reached

the

the

all-purpose

lowest

point

gauge

of its

the lower needle bar bushing. Place clamp

against

the

gauge

and

screwitdown

the

begin

balance

to time

wheel in

the

sewing

sewing

hook,

normally

bar

has

been

Loosen

and

set

surfaceofthe

the

distance

about

Vi6",

supplied

stroke.

Slip

(Fig.

23).

direction until

is

Fig. 22

R

9470

27

Page 28

21.

Timing

When

the

needle

Vaa",or0.8

If

adjustmentisrequired,

Then

the

turn

the

needle

thread

mm,

the

sewing

Sewing

has

passed

loop,

above

Hook

the

the

pointofthe

the

topofthe

remove

the

hookonits

Fig.

R

9537

lowest

point

of its

stroke

and

sewing

hook

shouldbeopposite

needle

eye.

needle

plate

and

loosen

hook

shaft,asmayberequiredtomeet

23

risen V<6", or

set

screws1and2(Fig.

the

1.8

its

above

center

mm, to form

line

and

24).

condition.

Fig.

24

R

9488

28

Page 29

At

the

same

time,

set

the

both

parts

When

hook,

(Fig. 25)

being

adjusting

take

care

which

.004",

the

lateral

that

the

serves to

hookasclosetothe

or 0.1

mm.

positionofthe

hubofthe

conduct

balancing

oil to

needleaspossible,

sewing

collar

the

sewing

hook,

does

hook

for

not

and

example,

bear

was

Emerging from oil flow regulating valve R (Fig. 24), the oil flows

oil retainer ring LR which is

borehole

in its

hub

from

which

capped

oil

drips

over

into

the

the

hook

shaft

oil

grooveinthe

bearing bushing and has a small

the

proper

against

introduced

through

balancing

clearance

after

oil

copper

inserting a

retainer

some

collar.

between

ring LR

time ago.

tube

new

1 into

Fig.

R

25

O

9169

29

Page 30

22.

Dismantling

Practised

when

when

If

as

thread,

1.

2.

3.

4.

5. Let

6.

operators

beginning or ending a

beginningtosew,

thread

should

you

turn

the

dismantle

Pull

out

Raise

needle

If not,

beginbyunscrewing

Loosen

binding

of

actionofthe

Seize

the

machine

the

sewing

Take

out

gib

d. Do

the

Sewing

who

have

will hardly

happentojaminthe

balance

the

bobbin

together

the

not

the

knee

bar

screw

head

three

confuse

wheel

sewing

lever

and

sewing

case

with

hook

and

take-up

e (Fig.

cap

the

down

hook

Hook

formed

the

habit

seam,

or of laying both

ever

encounter

racewayofthe

back

and

forth slightly. If

hook,asinstructed

tilt

the

machine

lever,

provided

bobbin

case

29)

and

swing

hook.

by its

latch

with

bobbin.

again

and

unscrew

gib

screws

el.

e2

gibdwith

thread

of raising

the

take-up

threads

thread

jamminginthe

sewing

below:

back.

the

position

opener

thumb

needle

ande3(Figs.26and

pull-off

hook,

this

action

balance

finger

bracket

fingerKforward

and

forefinger

plate

flangef(Fig.

lever

back under

however,

fails to

wheel

can

A (Fig.

and

and

feed

28)

28).

to its

highest

the

hook

try to pull it

free

still be

27).

outofthe

pull it

dog.

and

remove

sewing

raceway.

the

jammed

turned.

outofthe

point

foot

out

range

hook

Fig.

26

R

9486

30

Page 31

7.

Rotate

on

outofsewing

seen

of

the

thread

that

sewing

balance

pull-off

hookg.This

point

1 of

hookgand

Fig.

27

R

9162

wheel

until

sloti(Figs.27and28)

flangef.Wheninthis

position is

the

bobbin

case

flange

thread

pull-off

flange

is in line

position,

also

the

bobbin

illustrated in Fig.28from

mustbepositioned

f.

with

case

between

the

first

base

whichitmay

the

set

screw

canbetaken

two

points

f 1

be

Fig.

R

28

ei

e2

©3

d

5086

31

Page 32

8. Seize the bobbin case base by its center stud and tilt it out of the sewing hook, pulling

it

down

andtothe

left.

9. Thoroughly clean the hook raceway and the bobbin case flange and remove all lint with

a

pointed

wooden

10.

Before you replace the bobbin

instrument,

never

withascrewdriver.

case

base, it is best to

screw

on bobbin

case

position

finger bracket A.When replacing the bobbin case base, make sure finger h on bracket A

enters

slot

I in

the

rim of

the

bobbin

case

base.

Also

11.

checktosee

about

V64", or 0.5 mm, wide between the tip of position finger h and the bottom of slot i.

Replace

hook

gibdand

turninset

screws

el,

e2

and

e3.

that

there

is a

clearance

12. Swing the mechanical opener back to its original position and adjust as instructed in

Chapter 24. This tricky job

should

be performed by your

maintenance

man.

23.

The

Mechanical

Opener

Allmodels of the Pfaff 467 are regularly fitted with a positive mechanical opener. The doublerevolution rotary hook of the Pfaff 467 enters the needle thread loop at every other revolution

and

passesitaround

On

machines

slightly in

oder

the

stationary

havingnomechanical

to make an

opening

bobbin

opener,

through

case.

the

which

needle

thread

it can pass.

hastoturn

the

bobbin

case

The friction between hook raceway and bobbin case flange and the attendant pressure of the

position finger against the wall of the position slot increase in proportion to the sewing

speed

so that the needle thread has to overcome a stronger resistance when opening a clearance gap.

On machines fitted with mechanical opener, the opener finger slightly rotates the bobbin case

at

the

right

time

and

thread

can

pass

on

the

needle thread will remain

exposed

to additional stress, particularly at higher

contrarytothe

freely

between

directionofsewing

position

finger

the

same, regardless of

and

position

sewing

hook

slot.

the

sewing

speeds.

rotationsothat

This

ensures

speed

because

Since

the

danger

that

the

needle

the

tension

it is not

of thread

breaking has been largely eliminated, it is possible to use threads of a lower tensile strength

even

for

high-speed

sewing

operations.

Another advantage afforded by the mechanical opener is that even lightweight fabrics can be

sewn

at full

speed

while

the

machineisbeing

32

run in, or

afteranew

hook

has

been

inserted.

Page 33

24.

Timing

Accurate

so

that

you

tackle

advantage

There

1.

2.

On

the

lifting

over,

and

carries

opener

crank

case

opener

if the

rotates

slot

and

the

Mechanical

settingofthe

they

prefertorenderitinoperative

this

adjustment,

affordedbythis

are

two

different

The

adjustmentofthe

the

timingofthe

new

high-speed

shaftonthe

the

feed

shaft.

mechanism

opener

left of

lifting

the

feed

The

throwofthis

and

finger

canbeadjustedbyloosening

finger on its

opener

finger at its extreme left position

the

latter

counter-clockwise

ensure

that

shouldbe.012",or0.3

shaftistimed

(Fig. 29)

correctly. To

and

rotate the rear eccentric on

Opener

bobbin

case

opener

it is

imperative

device

are

discussedindetail.

adjustments

mechanical

seamers,

the

shaftofthe

lifting

eccentric

mechanical

sewing

required:

opener

the

feed

hook,asseen

Pfaff

and,

eccentricistransmittedtothe

the

bobbin

case

shaft,asappropriate.

just

the

needle

thread

mm,

wide

(Fig.

time

the

seemstopresentaproblemtomany

rather

opener

467

behind

thangoto

that

you revert to

drive,

finger.

rock

shaftisarrangedonthe

from

is of

the

it, an

the

and

the

rotating

eccentric

troubleofadjusting

Chapter23againinwhich

hook-endofthe

rather

which

eccentric

opener

shaft.

The

oscillating

The

mechanical

contacts

sufficiently to

can

pass

31).

Prerequisite for

mechanical

the

feed lifting shaft.

binding

through

screw

e (Fig.

openerisset

the

projection on the bobbin

center

the

position

the

clearance

thisisthat

opener,

loosen

both

right,

machine.

than

the

drives

the

connecting

motionofthe

29)

and

correctly

finger in

gap

freely.

the

mechanical

set

screwsaand

mechanics

it.

and

the

oscillating

bobbin

turning

on its

case

the

position

This

Before

the

feed

More

type

case

rod, a

bobbin

the

shaft

and

gap

opener

b

Fig.

R

29

'4

9163

33

Page 34

The bobbin case opener is timed correctly if the bobbin case opener eccentric is at its extreme

left position

when

the

needle bar has passed

the

lowest

point of its stroke

and

risen . or

1.8 mm. When the eccentric is at this position, the clearance gap between the opener finger

and

the

wallofthe

position

slotiswidest.

To make sure the mechanical opener has been timed correctly, check to see that the opener

finger

contacts

has cast off the loop and its point has reached a position

and

top

Since

the

positions,

motion of

the

projection on

i.e.atnortheast.

the

opener

the

bobbin

finger is very

case

slow

and

begins

to rotate it

about

midway between the right

and

hardly perceptible, we recommend

when

the hook

that you push the bobbin case over to the right at the bottom and place a thin piece of paper

between the finger and the projection on the bobbin case. When the finger begins to hold

the

paper

bobbin

case.

In adjusting

in place, it has reached

the

mechanical opener, care

the

position at which it will normally begin to rotate

should

be taken

that

there is a clearance of .03",

the

or 0.8 mm, between the opener finger and the face of the bobbin case (Fig. 30), and of .012",

or 0.3 mm,

between

the

opener

finger and

the

wall of the position slot (Fig.

31).

Fig.

30

25.

Dismantling

There are

In

the

first,

two

take-up

Fig. 31

the

procedures

link

Link

Take-up

that

may be followed;

Lis

left

inthe

machine

and is

disconnected

from

take-up

lever

F by

turning out screw z (Fig. 34). Swing the take-up lever up, and the link down, as shown in

Fig. 32. Pull the

34

take-up

lever

through

the

slot

and

out of

the

machine.

Page 35

Fig.

R

9161

Turn

the

balance

wheel

until

take-up

the machine arm rear cover (Fig.

needle bar is at its

machine.

Now

connecting

lowest

pull

the

link, forward

point, and let

take-up

outofthe

32

crank

33).

Loosen

the

crank,

together

needle bar crank.

set

screws3and4appearinthe

these

take-up

screws,

lever drop back

with

the

turn

take-up

the

balance

through

lever

aperture

underneath

wheel

the slot into the

and

the

until the

needle

bar

Fig.

R

33

9485

35

Page 36

The second possibility consists in dismantling the complete take-up leverassembly, including

the

take-up

To do this, pull the lower oil tube off the nipple of shut-off valve V (Fig. 42) and drain the oil

into a clean vessel. Unscrew the oil reservoir back of the oil sight glass and detach from the

reservoir the oil

To facilitate seizing the take-up link hinge stud, replace plug screw 1 (Fig. 34) by a M 4 set

screw. Loosen the three set screws that can be reached from above and pull the hinge stud,

together

To dismantle the

above, swing take-up link L down onto the take-up crank at its left position, and pull the

take-up

When

extends

link.

with

assembly

replacing

beyond

tube

conducting

the

oil

tube,

take-up

outofthe

the

oil

tube,

the oil holes in

oil to

the

take-up

forward

lever assembly, loosen

outofthe

needle

bar

checktosee

the

take-up

crank.

that

link hinge stud.

machine.

take-up

crank

the

wickinthe

link hinge stud.

set

screws3and

oil

tubeisnot

4, as instructed

torn

off

and

26.

Changing

the

Needle

Bar

To dismantle the needle bar, remove needle, needle plate, feed dog, bobbin case position

finger

bracket

and

link (Fig. 34)

sewing

and

hook.

Loosen

pull the needle bar

binding

down

and

screws

q and r in the

out

of the machine. In order to

needle

bar

connecting

save

the

time-consuming repetitionof timingthe sewing hook and the mechanicalopener, itis recom

mended to loosen set screws p (Fig. 34) and g (Fig. 23) of needle bar frame S, screw z

(Fig.

34) in the take-up

take-up

of the machine. The needle bar can now be easily exchanged.

link

Land

In replacingthe needle bar

hole exactly. Before you tighten set screws p and g securely, turn the balance wheel to make

surethe

any

Todothis,

Take

appropriate.

36

needleiscentered

play.Ifnecessary,

loosen

a screwdriver and turn the eccentric stud underneath this screw to the

link,

pull

the

adjust

eccentric

and take-up crank set screws 3 and 4

needle

bar

frame,

together

frame,

take care that the needle is centered sideways inthe needle

correctly

the

stud set

and the

position

screw

front-end

ofthe

g and

needle

turn

with

parts

inthe

out

the

needle

needle

take-up

work

bar

(Fig.

33). Swing away

lever

smoothly

holeinsewing

frame

topset

assembly,

without

having

direction.

screw

rightorleft,

out

as

p.

Page 37

27.

Dismantling

Flat

spring

end

restsona

The long pressure regulating

end

exerts resilient

can

be easily

The

Pfaff

467

ball

whichisembeddedingrease

The

upper

the

B (Fig.

stud

pressure

removed

has

two

endofthe

Presser

34)isabout

screwed

into

screw

on a

from

the

presser

jnner

presser

Bar

8",or20.0

the

depresses

steel

machine

bars,

one

and

bar

mm,

long

and

back

wailofthe

machine

flat spring B more or less so

ball at

the

topofthe

arm

after

turning

inside

the

other.

locatedatthe

carries

topofthe

a bracket,

The

while

slightly

and

presser

out

the

pressure

inner

the

bearing enclosing the vibrating presser fulcrum stud. The hollow

another

The

bottomofthe

bracket

at its

presser

footisattachedtothe

outer

top

presser

end

Fig.

bar.

and

the

vibrating

left-hand

34

presser

sideofthe

lever

assembly

mounting

bent.

Its

seml-clrcular

protrudingonthe

that

its long tapering

bar.

The

presser

pressure

presser

regulating

spring

engages

bar.

lower

end

outer

presser bar carries

carries

at its

bracket

locatedatthe

bar

the

bottom

rear

inside.

spring

screw.

steel

a roller

end.

R

9447

37

Page 38

28.

Conversion

To convert

tilt

the

machine

Relieve

the

(Fig.

19).

Before you install a new vibrating presser,

bracket

andonthe

to

Another

the

machine to

back

and

pressureofthe

vibrating

another

strip

presser

presser

Subclass

subclass, remove presser foot, needle plate and feed dog,

the

vibrating presser.

bar

springbyturning

checktosee

are

clean.

out

pressure

that

the mounting surfaces on

regulating

screw

the

Loosen binding screw K (Fig. 40) on the driving lever and check to make sure the vibrating

presser

The

should

sure

After all the parts replaced have

29.

works

smoothly.

guide

should

haveavertical

clearanceof.004",

or 0.1

be replaced by new ones. As you replace the feed dog

the

former

moves

Setting

the

freely in

Feed

the

feed

been

DogatCorrect

slots.

adjusted

Height

correctly, reset

mm,

maximum.

and

the

Worn

the

needle

presser foot pressure.

connections

plate, make

To facilitate this adjustment, it is recommended to use all-purpose gauge No. 91 -129 604-01

which is pushed over the feed slot so that its

plate. This

gauge

is held in place by the presser foot (Fig. 35). If

are in line with the

the

feed

edges

dog

of the needle

has

been

set

edges

correctly, all its teeth should contact the bottom of the recess on the underside of the gauge

when

the

feed

dog

Prerequisite

correctly, as

To

set

the

is at its

for

setting

instructedinChapter

feed

dogatthe

the

highest

feed

correct

point.

dogatthe

35.

height,

correct

heightisthat

proceedasfollows:

its

motion

has

been

timed

19

Fig.

35

R

9534

38

Page 39

Fig.

R

36

9526

Checktosee

feed

dogatthe

feed

lifting link

The front

which

screw

crank

as crank TS is slowly

that

feed

lifting

eccentric

correct

height,

loosen

HG,asappropriate.

Fig.

37

R

9159a

endofthe

hasaneccentric

feed dog is adjusted vertically by turning feed rock

left

end.Todo

9 on the right clamp crank K9

TS.

Turning feed rock

shaftSWnow

swung

from its foremost position

HE is at its

binding

this,

and

highest

screwGS(Fig.

remove

the

the

two binding

will present no difficulty

point. To

36)

gear

case

screwsuand

toward

set

the

and

adjust

shaft

cover

and

becauseitstarts

the

needle. The

v on feed driving

easily secured in position by pressing against its end. Then the crank can be

and

turning

the

shaft

canberepeated

until

the

feed

dogissetatthe

correct

rear

edgeofthe

the

SW

loosen

shaft

swung

height.

position

(Fig.

binding

revolving

can

of

37)

be

back,

39

Page 40

Push

the

shaft

toward

Set

the

machine

rock

shaft

Tighten

30.

When

will

When

a

shouldbecenteredinthe

binding

Adjusting

you

go,

then

the

clearanceofabout

for its

crankisnot

screwsuandvsecurely.

the

Presser

mount

the

presser

tighten

the

presser

bar is raised, i.e.

^/i6", or

1

the

right

longest

distorted

set

screw

needle

and

tighten

stitch,

turn

on its

Foot

footonthe

securely.

the

5.0

mm,

holeofthe

the

shaft

machine,

presser

between

presser

binding

and

screw

balance

the

feed

push

bar

lifter is flicked to

presser

foot.

9 on

clamp

wheel

and

checktosee

dogiscenteredinthe

it up

against

the

the

foot

and

needle

Fig.

38

crankK9securely.

that

the

feed

bracketasfarasit

left,

there

should

plate

and

the

needle

feed

slot.

be

R

9540

If adjustment is required, push all-purpose gauge No. 91

-129604-01,

which is 5.0 mm thick,

horizontally between presser foot and needle plate (Fig. 38). Then loosen grub screw G

(Fig. 40) on the driving lever connection and push the fulcrum stud out of its bearing. Next,

loosen binding screws a and b on the two presser bar brackets (Fig. 34).

Adjust the presser foot until the needle is centered correctly in its needle hole and tighten

binding screw b on the lower bracket securely. Replace the fulcrum stud in the driving lever

bearing, making sure that it enters the hole easily and the vibrating presser moves freely.

If there should be a bind, straighten the driving lever.

Tighten the screw on the upper presser bar bracket only after the vibrating presser has been

adjusted

As you tighten grub

40

properly.

screw

G, make sure it

engages

the

flat

spot

on the fulcrum stud.

Page 41

31.

Adjusting

Lower

the

wheel

until

at

its

extreme

positionisconcealedbythe

link V (Fig.

right

position

of its

1.8

bracket

against

As

youdothis,

The

inner

binding

rotate

slightlysothat

pressure

screwa.Then

pushing

After this

presser

the

rolleratthe

left,asseen

34)

when

mm

gauge

the

and

outer

screw

a on

against

check

it in

the

adjustment,

the

Vibrating

bar so

whichisvisible

the

roller isatits

blade

rollerat

note

the

presser

the

the

driving

the driving elements

whether

opposite

tighten

that

the

topofthe

from

presser

under

the

topof

following:

bars

slotted

elements

the

direction

binding

Presser

presser

small

the

needle-bar

bar

below

extreme

the

the

are

presser

vibrating

slightly.

foot

restsonthe

two-armed

endofthe

and

the

needle

the

lower

left.

vibrating

presser

two-armed

connected

bar

bracket

become

and

screw

wedged.Toavoid

the vibrating presser while tightening binding

presser

K on

needle

lever