Page 1

R8617

(PFAFFJ

Standard

P

FAFF

High-Speed

Organized

Instructions

AG

Industrial

.KAISERS

Sewing

with

Machine

463

Sewing

drop

LA

feed

UTERN

Division

Machine

BRANCH

Page 2

PFAFF

463

Standard

High-Speed

Organized

Instructions

with

Sewing Machine

drop

feed

Page 3

CONTENTS

Page

Foreword

1. Setting Up the Mochine .

2. Mounting the V-Belt

3. Test-Running the Machine .

4. Winding the Bobbin

5. Threading the Needle .

6. Regulating the Stitch Length

7. Lifting the Presser Bar .

8. Regulating the Pressure on the Material

9.

Lubrication

3

4

5

6

7

9

9

10

11

11

Page 4

Foreword

Thescope of this booklet is confined to such instructions os are conditioned by

voriotions in the design of the new Pfoff 463 high-speed sewing machine as

compared

An outstanding feature of the Pfoff 463 is the incorporation of seaied-for-life

ball

automotic lubrication system.

Another salient feature is the arrangement of the feed driving and feed lifting

eccentrics

from the arm shaft by a Synchroflex belt

of helical

with previous Pfaff high-speed seamers.

and

needle

bearings

on

the

bottom

of the latest design which

rather

than

gears.

the

obviate

arm

shoft.

The

bottom

and

drives the hook shaft by means

the use of an

shaftisdriven

These driving elements

by means of an oil-soaked foam rubber sheet. The only

are

enclosed in an oiltight

gear

case

and

part

are

lubricated

that requires

special lubrication is the sewing hook. Lubrication of this port is accomplished

by means of a reservoir oiling system incorporating a centrifugal switch.

Since

the

arm

shaftisbeltedtothe

motor,

the

machine

canbetilted

bock

without removing the V-belt.

Additional features of the new high-speed seamer

control,

separate

forward-reverse feed control, built-in bobbin winder

are

a novel stitch length

and

built-in lifting lever.

Operators will like the modern functional design and the streamlined belt

guard

which is

attached

to the machine arm.

G,M.PFAFF

AG

Page 5

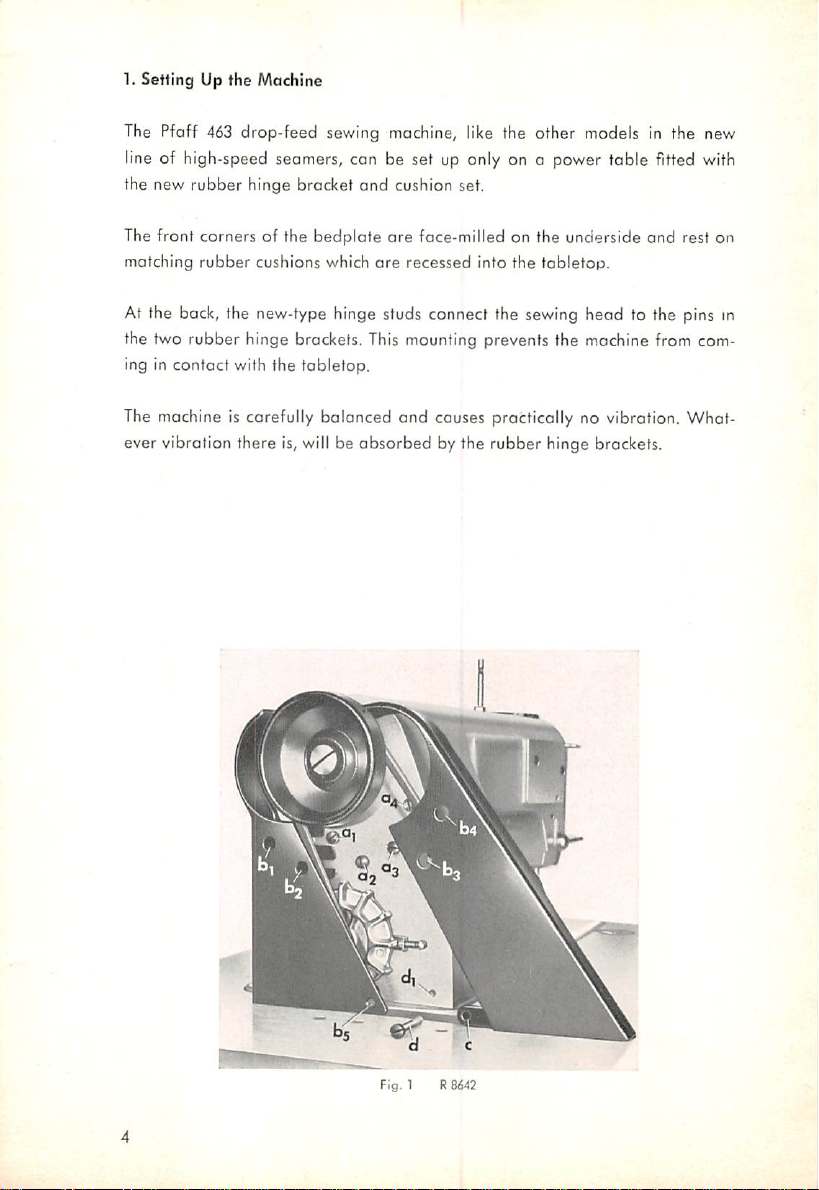

1. Setting Up the Machine

The Pfaff 463 drop-feed sewing machine, like the other models in the new

line of high-speed seomers, con be set up only on o power table fitted with

the new rubber hinge bracket

and

cushion set.

The front corners of the bedplate

matching

rubber

cushions which

are

face-milled on the underside and rest on

are

recessed into the

tabletop.

At the back, the new-type hinge studs connect the sewing head to the pins in

the two rubber hinge brockets. This mounting prevents the machine from com

ing in contact with the tabletop.

The machine is carefully balanced and causes procticatly no vibration. What

ever vibration there is, will be absorbed by the rubber hinge brackets.

Fia.

1

Re(S42

Page 6

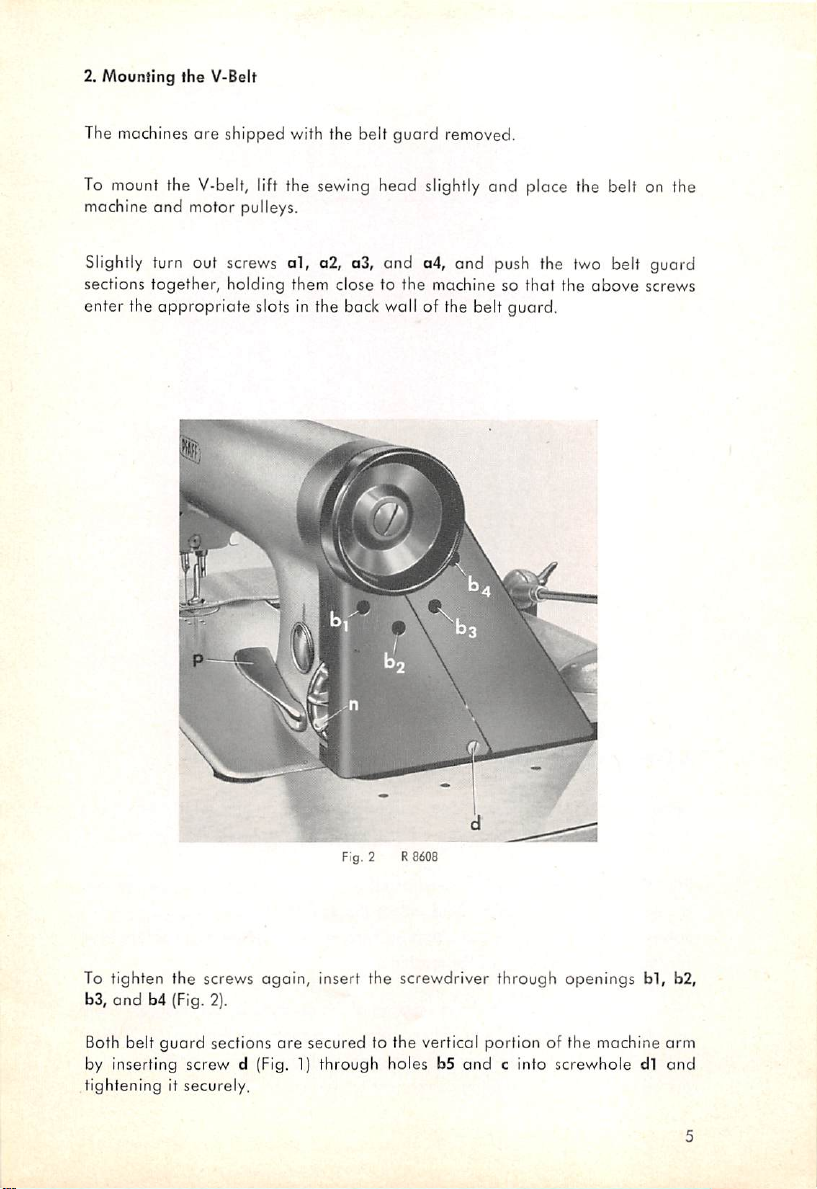

2. Mounting the V-Belt

The machines ore shipped with the belt guard removed.

To mount the V-belt, lift the sewing head slightly and place the belt on the

machine

and

motor pulleys.

Slightly turn out screws

sections together, holding them close to the machine so

ol,

a2, a3, and a4, and push the two belt guard

that

enter the appropriate slots in the back wall of the belt guard.

the

above

screws

Fig. 2 R8608

To tighten the screws again, insert the screwdriver through openings

b3,

and

b4 (Fig. 2).

Both belt

by inserting screw d (Fig. 1) through holes b5

tightening it securely,

guard

sections

ore

secured

to the vertical portion of the machine

and

c into screwhole dl

bl,

b2,

arm

and

Page 7

Fig. 3

RSd-iS

3. Test-Running the Machine

Before you tesf-run the mochine, carefully remove all dirt which may have

accumulated in transit. Use only a brush

The

Pfoff

463

must

neverberinsedorcleaned

a

donger

solves the greose. For the

for the

that

regular

the cleaning fluid enters the sealed-for-life

same

reason,

servicing of the machine.

and

a cleaning rag for this purpose.

with

kerosene

because

bearings

there

and

dis

kerosene or gasoline must not be used

Never attempt to eliminate hard working of the machine by squirting oil freely

into the bearings which, you believe, may be responsible for this fault. If oil

enters the sealed-for-life bearings, the grease will be thinned

the

bearings,

thus eliminating

permonent

lubrication.

and

flung out of

is

Page 8

4. Winding the Bobbin

The new high-speed seamer is fitted with a bobbin winder which is incor

porated in the face cover rother than mounted at the balance-wheel end, as

customary. Arranged at a convenient height, it is easy to operate end enables

the operator to wind bobbins

quickly

and neatly.

The bobbin winder driving

motion

emanates from the take-up crank. When the

bobbin winder is engaged, driving crank F at the rear end of spindle 17 is

pushed into the circular path of stud K which engages the crank and in this

way drives the bobbin winder (Fig.3).

The bobbin winder spindle is carried in a self-lubricating sinter-metal bearing

which requires no additional lubrication. To

engage

the bobbin winder, simply

depress stop latch a located above the bobbin winder spindle (Fig. 5). This

action causes the spindle to move slightly to the right in which position it is

Fig. 4

R

8928

Page 9

retained

until

sufficient

thread

has

been

wound on the bobbin pushes the com up

wound

and

on

the

bobbin.

The

thereby stops the bobbin winder.

thread

amountofthread

The

to be wound on the

bobbin

can be

regulated

by loosen

ing screw b and setting cam a higher or lower, as may be required. Set the

cam higher for more

Figs. 4

and

5 show how to

Place the spool of

thread

the

stand,

from spool11up

downtothread

thread,

thread

guide

or lower, for less

guide

the

thread

on spool pin 11

and

through the top

12 on

the

rear

thread.

to the

bobbin

winder.

and

bobbin 16 on spindle 17. Lead

thread

guide

of the threod

arm

cover,

through

thread

retainer

13 below thread guide 2, through thread guide 14 and around thread tension

15tobobbin

16.

T"

PFAFI

To facilitate

bobbin 16 first,

threading,

and

then to lead the

if is

recommended

ing on the material to be sewn, the

Fig. 5 R

thread

thread

8929

to wind a few clockwise turns on the

around

thread

tension 15. Depend

should be wound tighter or looser.

Page 10

The thread tension is regulated by turning thumb nut 18 back of the tension

discs. Turn

looser

tension.

the

nut

counter-clockwise

for a

tighter

tension,

or clockwise for a

If the threod should pile upatone

tension stud. The set screw securing this stud in position can be reached from

below.

5. Threading the

Needle

end

of the bobbin, adjust the position of the

Because of the high speed of the seamer the smooth possoge of the thread to

the needle is especially importont.

Lead the thread from spool pin 1 up to the top thread guide of the thread

stand and down to thread guide 2. It is recommended to lead the thread first

through the vertical hole from top to bottom and then through the transverse

hole of the guide, as shown in Fig. 4 and 5, in

order

to prevent it from snarl

ing up on the guide and breaking,

Now lead the thread through two or three holes of thread retainer 3, as may

be required,

clockwise

around and between tension discs 4, through thread

check spring 5, under stock threod regulator 6, through thread guide 7, from

right to left through the hole in take-up lever 8, through thread guides 7 and 9

and from left to right through needle eye 10.

6. Regulating the Stitch Length

The stitch length is regulated by means of stitch length control n

large diameter of this control

regulation. When control n is turned by one tooth, the

by

Vfii".

The stitch length is indicated on the teeth in millimeters.

mokes

for an exceedingly fine

stitch

(Fig.

6). The

stitch

length

length is increased

Fig. 6 R8607

Page 11

In

ordertoovoid

stitch

length

disco(Fig.

length.

control

6).

This

that

the

n has

disc

mustbepressed

stitch

been

length

provided

setting

willbedisturbed

withalocking

back

slightly

while

deviceinthe

when

setting

sewing,

form

the

stitch

of

Finger-tip control p serves to reverse the direction of feed and is used for

tacking.

stitches of the length set.

When

actionand the

If

forword to backward sewing.

Upon

stitch

is

then

7. Liftingthe Presser Bar

Since

the

mechonism

To mount the knee lever, push it over the lower end of vertical shaft r under

the

place

coupling sleeve q

When

leverpis

leverpis

desired,

special

length

desired

released,

machine

the

machine

request,

limiting

for

backtacking

the

device

limitedbyturningingrub

the arm standard of the

rear

edgeofthe

in the machine arm so that it isnot visible on the outside.

tabletop.

ofter

tronsverse

bed

The

leverisheldinplacebyangular

driving

(Fig.

7).

pressed

resumes

willbefitted

plate,itwas

down,

the

the

directionoffeedisinstantly

forward

stitching.

withasmall

Pfaff

463

high-speed

for

backward

the

endsofseams.

screw

new

sewing

Sof

crankRon

high-speed seamer has been set closer to

possibletoenclose

pinuhas

entered

machine

sewsinreverse,

treadle

seamer can be

if a shorter

The

lengthofreverse

shaftL(Fig.

bracketswhich

the

cutoutstin

reversedbyspring

for

switching

fitted

backward

10).

the

presser

the

bock-

making

from

with

stitch

stitches

bar

lifting

snaps

into

right-angled

a

is

When

the

coupling

bracketsmustbecompressed

Motionistransmitted

crank,aconnection

A

small

hond

lever

in

its

highest

after it has been raised by knee action

10

position.

sleeveispushed

to open it

from

the

vertical

and a

bellcrank

Cat the

back

This

leverisflicked

of the

shaft

lever

(Fig.

onto

slightly.

to the

which

machine

to the

9).

the

end

of the

presser

raises

the

servestolock

lefttoretain

shaft,

resilient

footbymeans

presser

foot.

the

presser

the

presser

of a

foot

foot

Page 12

Fig. 7 Attoching the knee lever

R&408

To facilitate the tilting bock of the sewing head without removing the knee

lever completely, the knee lever rock shaft is no longer screwed to the ongulor

sleeve, but rather held in place by a spring-loaded pin. As a result, the knee

lever can be pulled forward off the shaft with a slight jerk.

A new feature of the knee lever is its hinged foam-rubber-podded knee plate

which adapts itself well to the shape of the leg. If desired, the knee plate can

be locked by tightening a square bolt.

8. Regulating the Pressure on the Material

A

powerful

flat spring in the

machine

arm

exerts

the necessary pressure on the

sewing foot. The amount of pressure is regulated by turning a small set screw

which can be reached by inserting a screwdriver through the hole 19 at the

right of the spool

pressure (Fig. 4).

9.

Lubrication

pin.

Turn

the

screw

in for more pressure, or out, for

less

Recent advances in the design of needle beorings hove mode it possible to

ensure satisfactory permanent lubrication of this new high-speed sewing

machine without the use of an

automatic

lubrication system.

11

Page 13

Since the use of sealed-fcr-IIfe bearings does not require the machine to be

oiltight, the incorporation of various feeding

accomplished.

to this high-speed sewing machine.

The incorporotion of sealed-for-life boll ond needle bearings requires the use

of 0 reservoir oiling system merely for the sewing hook. From o reservoir built

This

feature opens a practically unlimited

mechanisms

Fteld

can be easily

of application

into the machine arm, oil is fed to the sewing hook through a plastic oil tube.

The oil flow is controlled by shut-off valve V which is built into the oil tube.

When the machine is running, the stud of centrifugal switch F on the hook

shaft

actuates

same valve prevents oil from seeping out when the machine is inoperative.

the valve stem

and

opens

hook lubrication shut-off valve V. The

Theoil level con be inspected through the oil sight glass. Ifit is below the mark

on the oil sight glass, the reservoir should be refilled by inserting the spout of

an ordinary oil can into the small hole v above the oil sight gloss.

The flow of oil to the sewing hook con, in addition, be regulated by screw w

(Fig. 8). Turn this

screw

in for less oil,orout,

for

more

oil.

The correct setting con be obtained through the following test:

Remove

ing.

needle plate and feed dog and place a sheet of paper over the open

Run

the machine for about ten seconds. The setting is correct if two thin

lines of spray oil have appeared on the paper. Adjust the flow of oil at screw w

to suit special

operating

conditions (Fig. 8).

0

fig.

8 R 8603

12

Page 14

In

conlrasttothe

end of the

machine

sealed-for-life

which

requirenolubrication

boll

and

needle

of all,

lubricated from the hook oil reservoir by means of a

(Fig. 9).

bearingsofthe

take-up

wick

enclosed in a tube

needle-bar

lever

linkzis

:fi:

rv.i

;a.i

Fig. 9

Face

cover

removed

Flat spring B exerls pressure on the presser foot,

highest position ofter it hos

The oil supply in Ihe foam-rubber-lined reservoir x ond y for Ihe upper and lower needle bar

bushings should be replenished more or less frequently according to the time the machine is in

operation

From

eoch

doy.

the foam-rubber-lined reservoirs x and y, oil is supplied to the upper and

been

raised by Ihe knee lever.

Lever

C serves to retain ihe presser foot in its

R

8605

lower needle bor bushings (Fig. 9). The oil supply in these reservoirs should be

replenished frequently, particularly whilethe machine is being run in.

13

Page 15

The feed driving and feed regulating

mechanisms

as well as the hook shaft

driving gears in the gear cose ore lubricated by means of two oil-soaked foam

rubber

sheets.

To change the oil (once a year is sufficient), tilt back the machine and remove

the

gear

case cover. The foam rubber sheet should be woshed thoroughly in

order to remove the metal grit which has accumulated on it.

In most

(Nos.

same

(No. 120110).

instances,

69299

oil as is used in the hook lubrication system, namely 2.7°E/50°C

and

however,

69302)

it will be

better

to insert new

foam

which must be soaked with 17 oz, or 160 ccm, of the

rubber

sheets

When you replace the foam rubber sheet, make sure that it fits properly. The

large spur gear should run freely in the cutout of the sheet. The oscillating feed

rockshaft is grease-lubricated. Grease nipple N closes the left end of the shaft

(Fig. 8).

When screwing on the gear cose cover, make sure that the gasket is not

defective and that the

from

seeping

Note

out.

screws

are lightened

uniformly

in order to prevent oil

In replenishing the oil supply for the sewing hook, take care that no air bubble

forms in the oil line to the centrifugal switch because this would interrupt the

flowofoil.

The simplest procedure for removing an air bubble from the oil line ahead of

the centrifugal

switch

is as follows:

Pull

the left end of the oil tube off the

nipple and hold it up so that the air bubble rises to the surface. Then replace

the oil

tube

on the nipple carefully.

An air bubble which may hove formed in the left section of the oil tube is of no

consequence because itcan escape

14

through

the regulating valve

(Fig.

10).

Page 16

s

Fig. 10 Bottom view of the Pfoff 463

The

gear

cose cover and the foom

rubber

sheet

are

removed.

R

8606

The lower drive shaft carries the feed driving eccentric and the hook shaH driving gear in the

gear

case, ond the mechanical opener driving mechanism and the feed lifting eccentric near its

left

end.

The hook shofi carries centrifugal switch F whose stud pushes the valve s'em to the right and

opens hook lubrication shut-off valve V. The same valve prevents the oil from seeping out when

the

machineisinoperative.

The stitch length setting is transmitted from the stitch length control to

in the

gear

case,

the feed rock

feed

bar.

Upon

special

request, the machine can be fitted with o stitch length limitoting device for back

ward

sewing. To limit the length of the reverse stitch, turn in

shaft,

and an

adjustable

crank which, in turn, transmits it to the

shaft

L, a

crank

grub

screw S of crank R on shofI L.

mechanism

15

Page 17

Fig. 11 R8604

Page 18

No.

PFAFF

10769

engl. R962 Printed in Germany

Loading...

Loading...