Page 1

®442-R

441

-O

442-0

Service

Manual

Pfaff, D

6750

Kaiserslautern,

Postfach

3020/3040,

Telex:

045753

Page 2

Important

note:

ThisServiceManual applies also to the Raff 441-0 and 442-0. Deviations in the illustrations do not

affect

the

adjustment of the machines.

The

Sen/ice

Manual is

based

on a two-needle machine.

When adjusting a single-needle machine,

simply

ignore the adjustment procedure for the left

needle and the left sewing hook. A separate Service

Manual

is available for adjusting the

Pfaff

441-R

(0)-705/03: -755/03.

Tools,

gauges

and

other

items required for adjusting

Raff

machines

442-R, 441-0

and

442-0

1

setofscrewdrivers

with

blades

from2to10mm

wide

1

set

ofwrencheswithopeningsfrom 7 to 14 mm wide

1

set

of alien keysfrom 2 to 6 mm

1 feed dog

gauge,

part No.

91-129995-05

1 adjusting

gauge,

part No. 91

-129573-91

1 C-clamp,

part

No.

880137/00

1

metal

rule

1 wrapper of needles: system 134 (for7 mm fabric clearance)

system

134-35

(for 9 mm fabric clearance)

2 strips of white

paper

Sewing thread and testing material

Technical

data

Maximumsewing

speed:

5000 s.p.m.

Balance

wheel:

65

mm

eff.

dia.

Drive:

clutchmotor0,550 kW(% HP)

lever-operated Stop motor 0,550 kW(% HP)

electronic-stop-motor 0,550 kW(%HP)

Needle system: 134 (for7 mm fabric clearance)

134-35

(for 9 mm fabric

clearance)

Fabric

clearance:7or9mm

Page 3

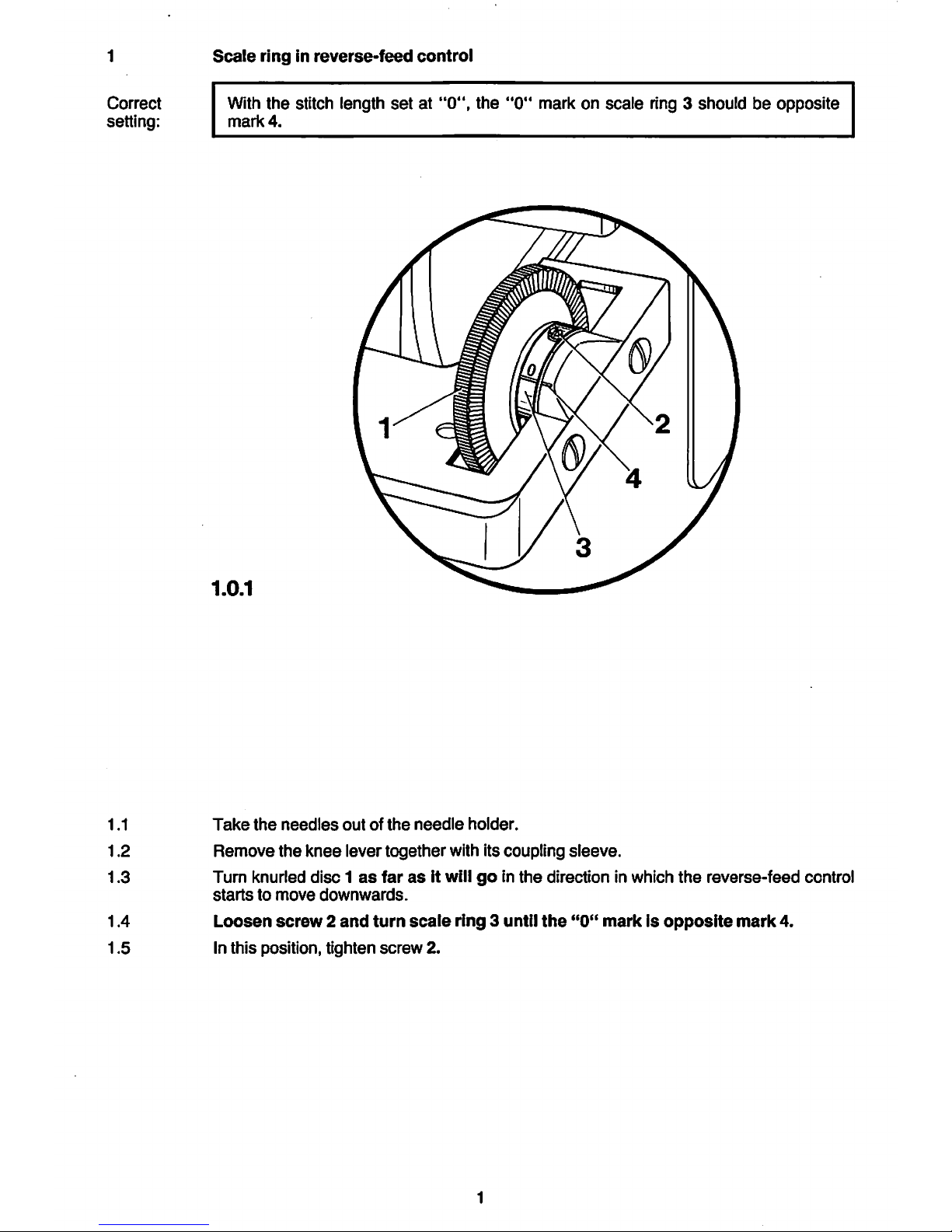

Correct

setting:

Scale

ringinreverse-feed

control

With the stitch length

setat"0",

the

"0"

mark on scale ring 3 should be opposite

mark

4.

1.0.1

1.1

Take

the

needles

outofthe

needle

holder.

1.2

Remove

the

knee

levertogether with its coupling

sleeve.

1.3

Tum

knurled

disc1as

farasit willgoin

the

direction in which

the

reverse-feed

control

starts

to

move

downwards.

1.4

Loosen

screw2and

turn

scale

ring

3 until

the

"0"

markIsopposite

mark

4.

1.5

Inthis position, tighten

screw

2.

Page 4

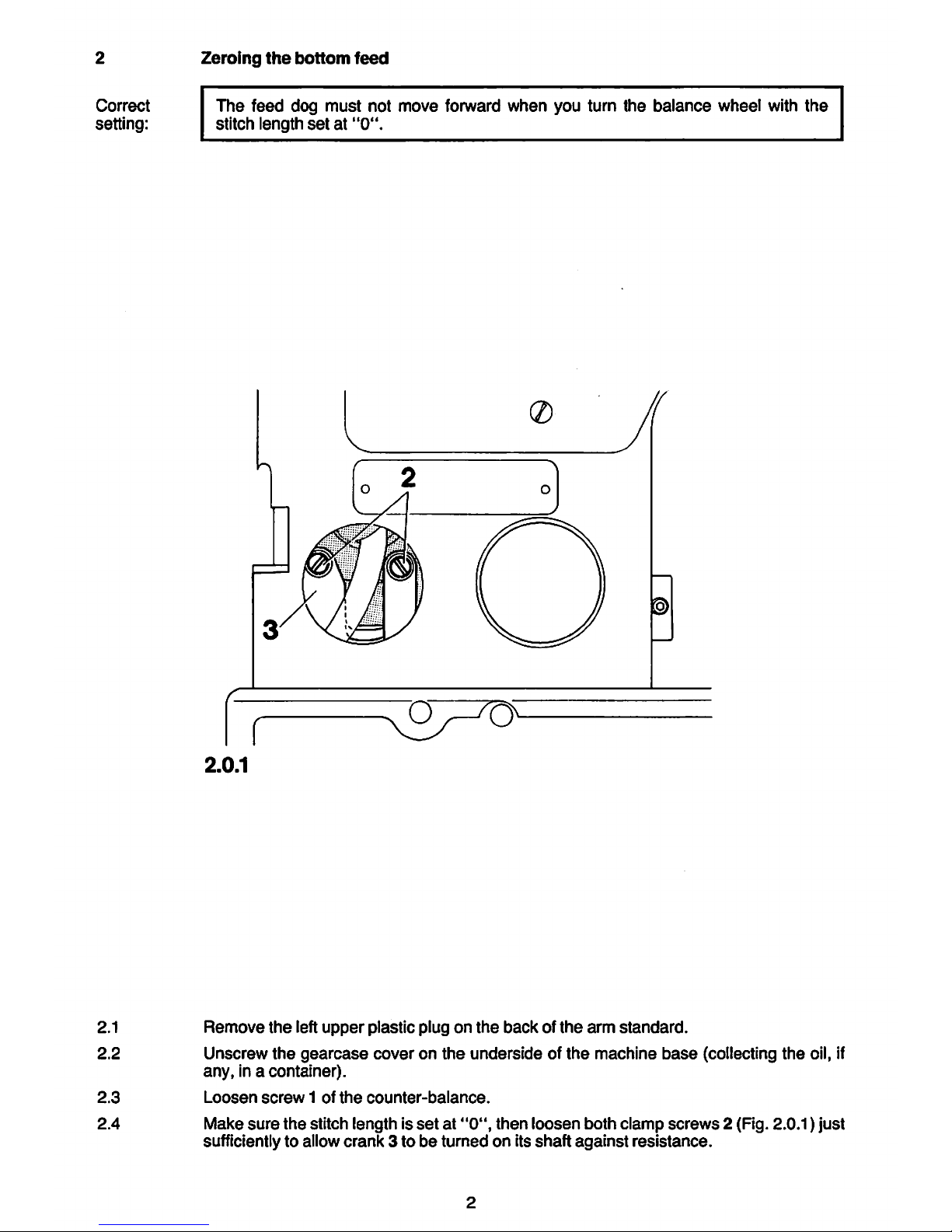

Correct

setting:

Zeroing

the

bottom

feed

The

feed

dog

must

not

move

forward

when

you turn

the

balance

wheel

with

the

stitch length

setat"0".

2.0.1

2.1

Remove

the

left

upper

plastic plug on

the

backofthe

arm

standard.

2.2

Unscrew

the

gearcase

coveronthe

undersideofthe

machine

base

(collecting

the

oil, if

any,

in a container).

2.3

Loosen

screw1of

the

counter-balance.

2.4

Make

sure

the

stitch length is

setat"0",

then

loosen

both

clamp

screws

2 (Fig. 2.0.1)

just

sufficiently to allow

crank

3 tobeturnedonits

shaft

against

resistance.

Page 5

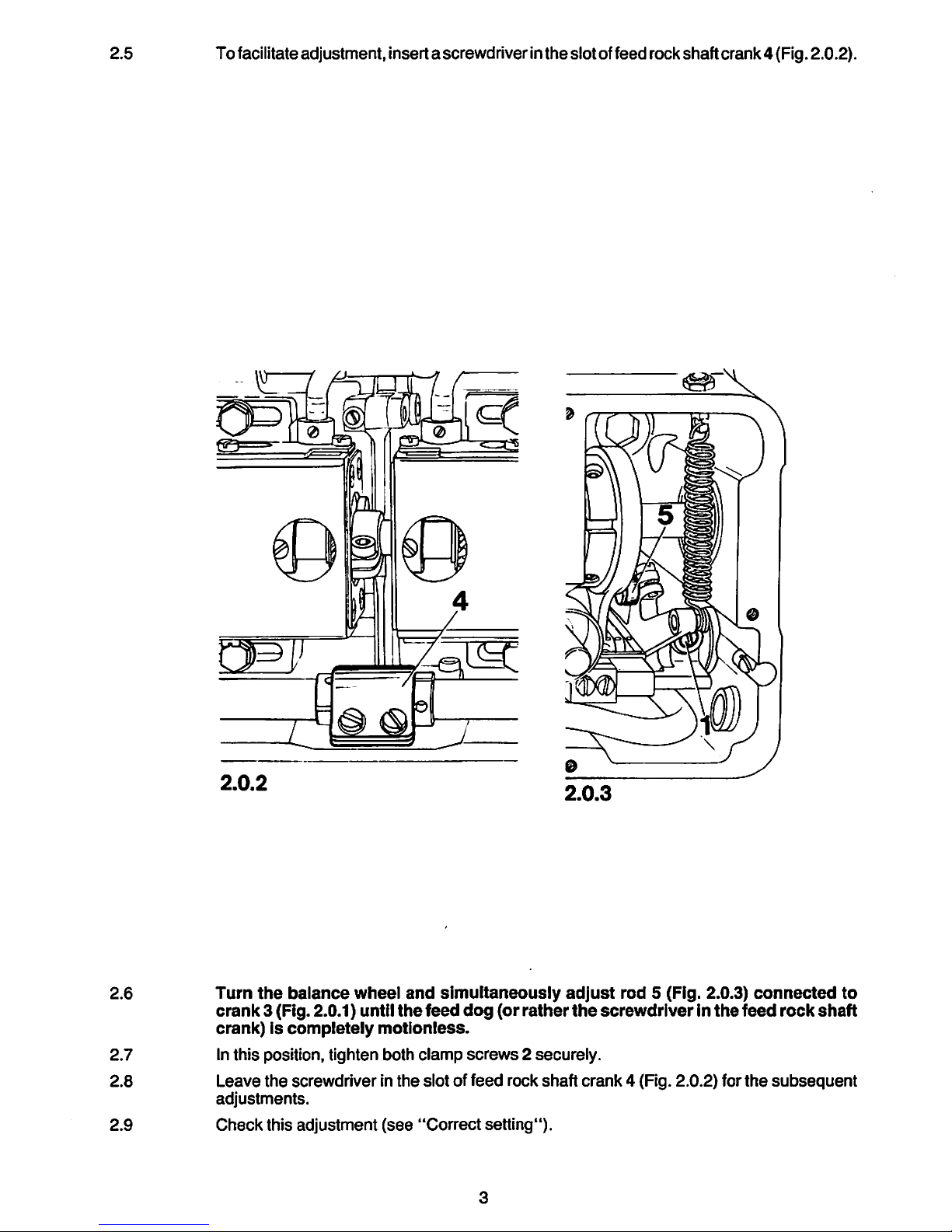

2.5

Tofacilitateadjustment, inserta screwdriverinthe slot offeedrockshaftcrank4 (Fig. 2.0.2).

2.0.2

2.0.3

2.6

Turn

the

balance

wheel

and

simultaneously

adjust

rod

5 (Fig. 2.0.3)

connected

to

crank

3 (Fig. 2.0.1) until

the

feed

dog

(or

rather

the

screwdriverinthe

feed

rock

shaft

crank)Iscompletely

motionless.

2.7

Inthis position, tighten both

clamp

screws2securely.

2.8 Leave the screwdriver in the slot of

feed

rock shaftcrank 4 (Fig. 2.0.2) for

the

subsequent

adjustments.

2.9

Check

this

adjustment

(see

"Correct

setting").

Page 6

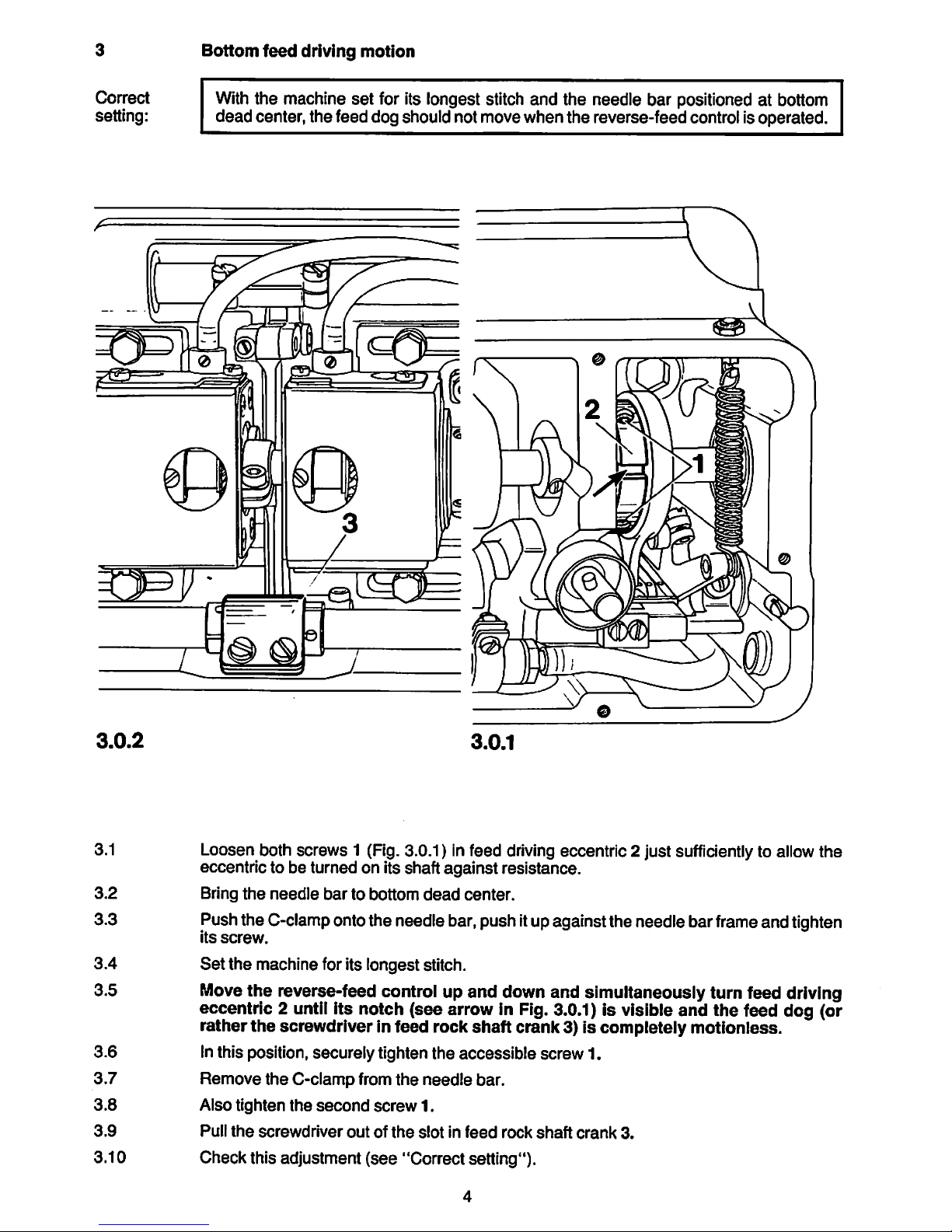

Correct

setting:

3.0.2

Bottom

feed

driving

motion

With the machine

set

for its longest stitch and the needle bar positioned at bottom

deadcenter, the feed dog should not move when the reverse-feedcontrol is operated.

J

3.0.1

3.1 Loosen both screws 1 (Fig. 3.0.1) In feed drivingeccentric 2 just sufficientlyto allow the

eccentric to be turned on its shaft against resistance.

3.2

Bring

the

needle

bar

to bottom

dead

center.

3.3 Pushthe C-clampontotheneedlebar,push itupagainsttheneedlebarframeandtighten

its

screw.

3.4

Set

the

machine for its longest stitch.

3.5 Movethe reverse-feed control up and down and simultaneously turn feed driving

eccentric 2 until its notch (see arrow in Fig.3.0.1) is visible and the feed dog (or

rather

the

screwdriverin feed rock

shaft

crank3) is completely motionless.

3.6 Inthis position, securely tighten the accessible screw 1.

3.7

Remove

the

C-clamp

from

the

needle

bar.

3.8

Also tighten

the

second

screw

1.

3.9

Pull

the

screwdriver

outofthe

slotinfeed

rock

shaft

crank

3.

3.10 Check this adjustment (see "Correct setting").

Page 7

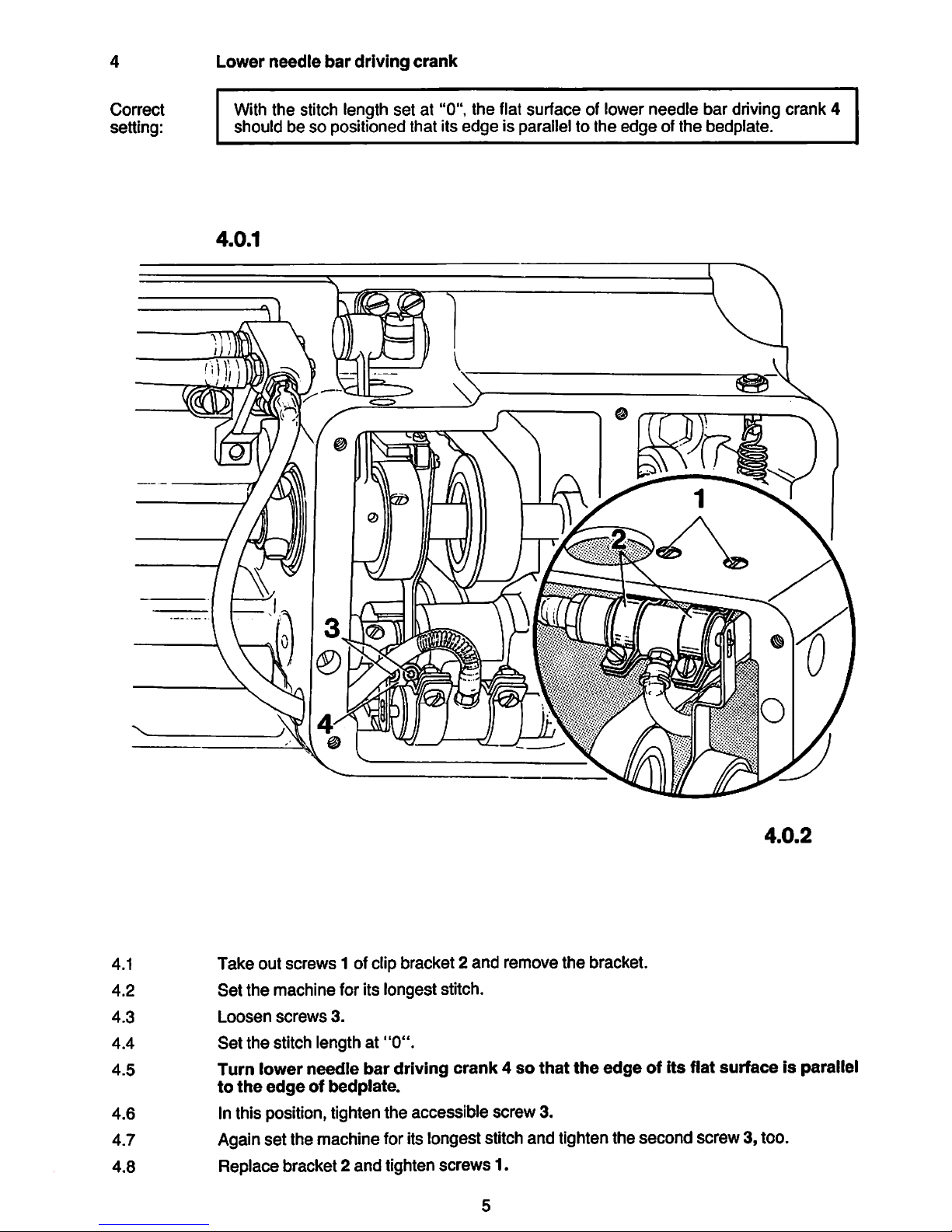

Correct

setting:

Lower

needle

bar

driving

crank

With the stitch length

set

at "0", the flat surface of lower needle bar driving crank 4

shouldbeso

positioned that its

edge

is parallel to

the

edgeofthe

bedplate.

4.0.1

4.0.2

4.1

Take

out

screws

1 of clip bracket 2

and

remove

the

bracket.

4.2

Set

the

machine for its longeststitch.

4.3

Loosen

screws

3.

4.4

Set

the

stitch length at

"0".

4.5 Turn lower

needle

bar

driving

crank4so

that

the

edge

of its flat

surface

is parallel

to

the

edgeofbedplate.

4.6 Inthis position,tightenthe accessible screw 3.

4.7 Againset the machineforitslongeststitchand tightenthe second screw3, too.

4.8 Replace bracket 2

and

tighten

screws

1.

Page 8

Correct

setting:

5.1

5.2

5.3

5.4

Counter-balance

With

the machine set for its longest stitch, counter-balance 2 should move freely

when

the reverse-feed control is operated.

5.0.1

Set

the

machine for its longest stitch.

Makesure screw 1 ofcounter-balance 2 is loose (Fig.5.0.1), move the latteras faras it

will

go, turning it inthe direction indicated by an arrow.

Turnthe counter-balancebackbyabt.1 mmagain,and inthis

position

tighten

screw1.

Check this adjustment

(see

"Correct setting").

Page 9

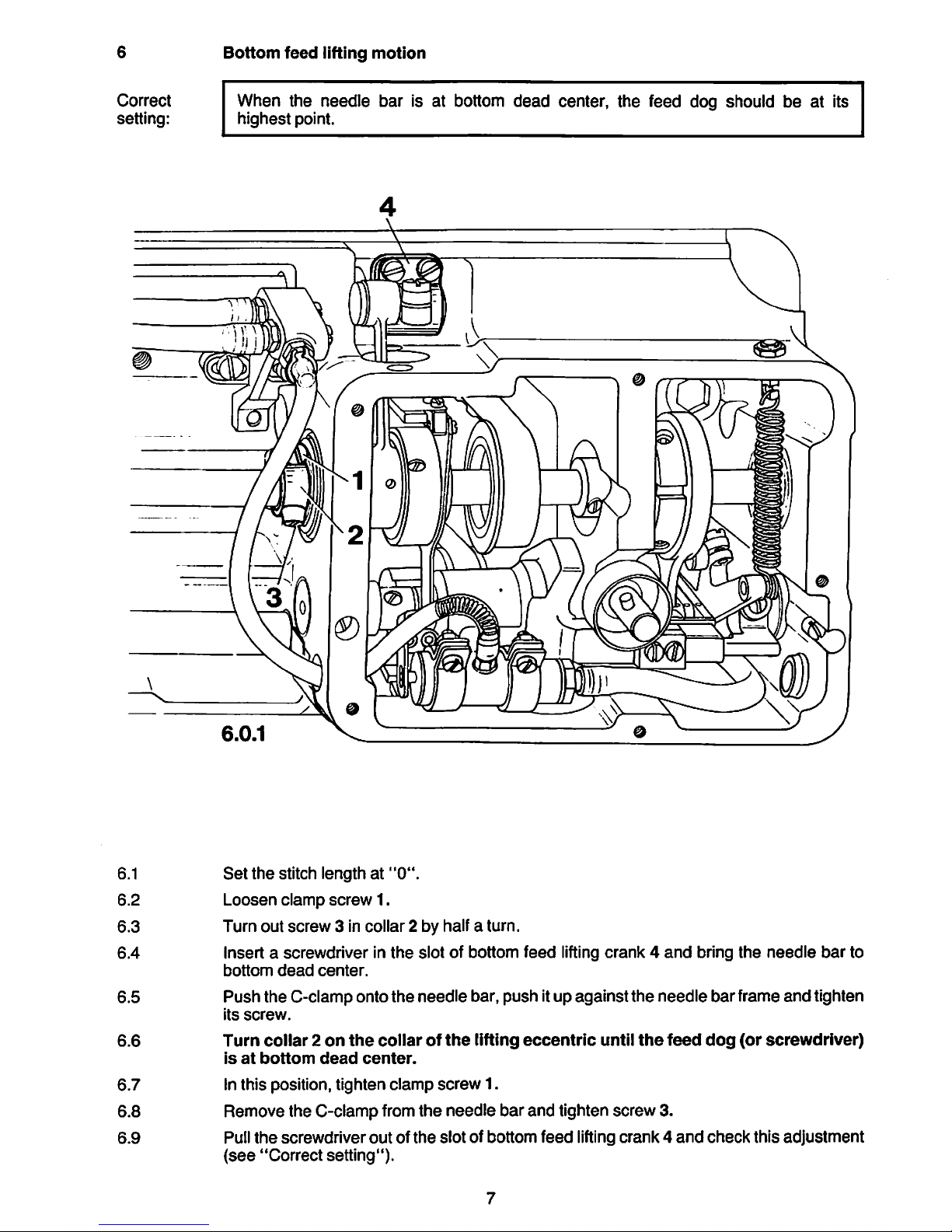

Correct

setting:

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

Bottom

feed

lifting

motion

When the needle bar is at bottom

dead

center, the feed dog should be at its

highest

point.

n

W

Set

the

stitch length at

"0".

Loosen

clamp

screw

1.

Turn out

screw

3 incollar 2 by half a turn.

Insert a screwdriver in

the

slot of bottom

feed

lifting

crank4and

bring

the

needle

bar

to

bottom

dead

center.

Push

the C-clamponto

the

needle

bar, push itup

against

the

needle

bar

frame

and

tighten

its

screw.

Turn

coiiar2on

the

collarofthe

lifting

eccentric

until

the

feed

dog

(or

screwdriver)

isatbottom

dead

center.

Inthis position, tighten clamp

screw

1.

Remove the C-clamp from

the

needle

bar

and

tighten

screw

3.

Pull

the

screwdriver

outofthe

slot

of bottom

feed

lifting

crank4and

check

this

adjustment

(see

"Correct

setting").

Page 10

Correct

setting:

7.1

7.2

7.3

7.4

7.5

7.6

7.7

Note:

Clearance

between

presser

foot

and

needle

plate

Withpresser bar lifter1 raised, there shouid be a ciearance of7.0 mm (needie system

134) or 9.0 mm (needle system 134-35) between presserfootand needle plate.

7mm(9mm)

f

Take

out

the

two

screwsofthe

face

cover

and

remove

the

latter.

Unscrew

the

cover

on

the

backofthe

machine

arm.

Raise

presser

bar lifter1 and screw on the

presser

foot.

Loosen both

screws

2 in the

presser

bar collar.

Push the 7-mm (or9-mm) thickpart ofthe gauge under the presserfootso that itsrecess

faces downwards (Fig. 7.0.1).

Push the presser foot downonto the gauge and adjustItlaterallysothat its

sides

are

parallel to

the

edgesofthe

needle

plate

slot.

Inthis position, tighten both screws 2.

Adjust

the presser footpressure by

turning

regulating

screw4

(Fig.

9.0.1)inoroutwhen

you

make

a sewing test.

Page 11

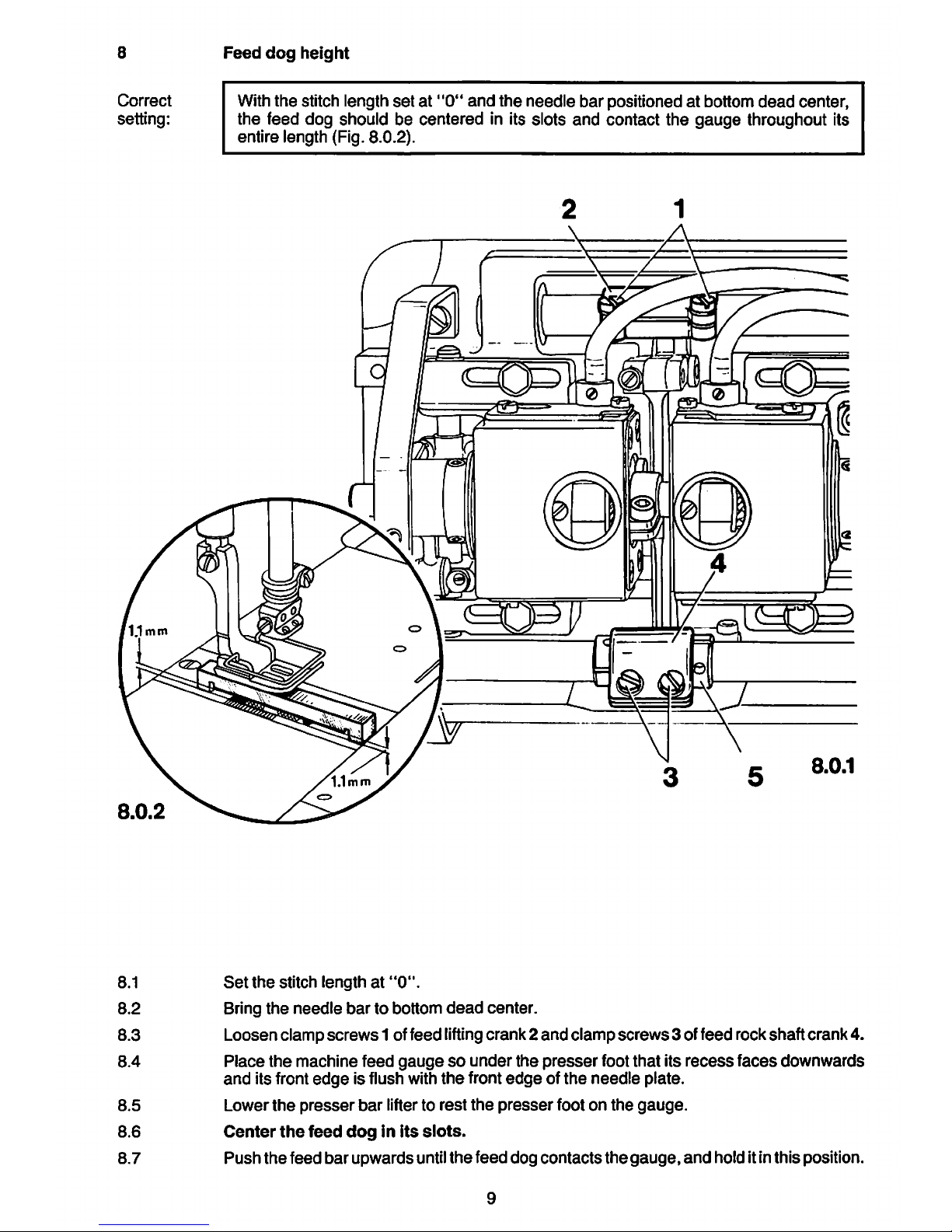

Correct

setting:

Feed

dog

height

Withthe stitch length

setat"0"

and

the

needle

bar

positioned at bottom

dead

center,

the feed dog should be centered in its slots and contact the gauge throughout its

entire length (Fig. 8.0.2).

2

8.1

Set

the

stitch length at

"0".

8.2

Bring

the

needle

bar

to bottom

dead

center.

8.3 Loosenclamp

screws

1 offeed liftingcrank2

and

clamp

screws

3 offeed rock shaftcrank4.

8.4

Place

the

machine feed

gaugesounder

the

presser

foot that its

recess

faces

downwards

and

its front

edge

is flush with

the

front

edgeofthe

needle

plate.

8.5

Lower

the

presser

bar

lifterto

rest

the

presser

foot on

the

gauge.

8.6

Center

the

feed

doginits

slots.

8.7

Push

the

feed

bar

upwardsuntil

the

feed dog

contacts

the

gauge,

and

hold itinthis position.

Page 12

8.8 Turn

eccentric

bushing5located

under

feed

rock

shaft

crank

4 until

the

feed

dog

is

in

contact

with

the

gauge

throughout

its

entire

length

(Fig. 8.0.2);

the

feed

dog

now

protrudes

1.1

mm

from

the

needle

plate

surface.

8.9 inthis position, tightenclamp

screws1and

3, making

sure

that

the

feed dog isstill

centered

in

its

slots.

8.10

Check

this adjustment

(see

"Correctsetting").

8.11

Raise

the

presser

bar

lifter and remove the

gauge

from under

the

presser

foot.

10

Page 13

Correct

setting:

Centering the

needlesinthe

needle holes

With

the stitch length set at "0", the needles should be centered exactly Inthe re

spective needle holes. (ItIs recommended to Inserttwonew needles)

9.0.2

9.1 Unscrew the coveron the back ofthe machine arm

near

the balancewheel.

9.2

Unscrew

the presser footandthe thread tensionbase plate.

9.3 Set the stitchlengthat"0", and

bring

the needlebartotopdead center.

9.4 inserttwoneedles

Into

the needleholdersothattheir

long

groovesfaceeach other(note

the

needle

system).

9.5 Loosenscrew11ncollar2 onthe needle bar

driving

shaft

which

isaccessiblethroughthe

aperture (see arrowinFig.9.0.1).

9.6

Aiso

loosen

clamp

screw3 intheneedlebar

driving

crank

(Fig.

9.0.3).

11

Page 14

9.7

Turn

the

balance

wheel

to position

the

needles

above

the

needle

holes.

9.8

Turn

the

balance

wheel

while

moving

the

needle

bar

frame

sideways

until

both

needles

are

centeredintheir

needle

holes

both

lengthwise

and

crosswise

(Fig. 9.0.2).

9.9 Inthis position, push coilar 2 to the rightasfarasit

wiii

go and tighten screw 1.

9.10 Also tighten clamp screw 3, making

sure

the needle bar drivingshaft

has

no end play.

9.11

Check

this

adjustment

(see

"Correct

setting").

9.0.3

12

Page 15

10

Preliminary

adjustmentofneedle

bar

height

Correct When the needle bar Isat top

dead

center, there should be a clearance of 17 mm be

setting: tweenneedle pointand needle plateon

Model

S machines,and a clearanceof22mm

on

ModelLmachines.

Model

S =33mm

needle

bar

stroke

Model

L =38mm

needle

bar

stroke

17mm(22mm)

10.0.1

10.0.2

10.1 Bringthe needle bar to top

dead

center.

10.2 Loosen hexagon screw 1 inthe needle bar connecting stud.

10.3

Adjust

the needlebarvertically untilthereis a clearanceof17mmbetweenneedle

pointand needle plate on

Model

S machines, or a ciearance of 22 mmon

Model

L

machines.

Make

sure

the

needie

barisnot

turnedinthe

process.

10.4 Inthis position,tighten hexagon screw 1.

13

Page 16

11

Correct

setting:

Hook timing,

hook-to-needle

clearance

and

needle

bar

height

Withthe stitch length

setat"0"

and the needle bar positioned 1.8 mm

past

bottom

dead

center(needle rise position) each hook pointshould be exactly opposite the centerline

of the respective needle, the lateral clearance between hook point and needle being

0.1 mm. Also, Inthis position, the hook points should be positioned 0.8 mm above the

top

edge

of the respective

needle

eye.

\

11.0.1

11.0.2

11.0.3

11.1

Set

the stitch length at

"0".

11.2 Unscrewthe needle plateand the feed dog.

11.3

Loosen

alien

screw1,

which

Isaccessible

through

the holeinthe

bevel

gearcase

cover,

and alien screw 2 between both bevel gearcases.

11.4

Loosen

both

screws3,which

areaccessible

through

the

holes

inthe

bevel

gearcases.

14

Page 17

11.5

Loosen

screws

4 of

the

bobbin

case

opener

eccentrics.

11.6 Also loosen hexagon screws 5 ofthe hook bearing brackets.

11.7 Bringthe needle bar to bottom

dead

center.

11.8

Push

the 1.8-mm-thick blade of

the

gauge

onto

the

needle

bar immediately below its

lower bearing, push the C-clamp up againstthe blade and tighten itsscrew.

11.9 Pull out the gauge and turn the balance wheel in its normal direction

until

the C-clamp

contacts

the

needle

bar

bearing.

11.10 Turn

both

hooksontheir

shafts

so

that

their

points

are

opposite

the

center

iine of

the

respective needle. Inthis position(needle rise position), the hook points should be

positioned0.8 mm above the top edge ofthe respective needle eye. Ifnecessary, adjust

the

needle

bar height.

11.11

Adjust the hook bearing brackets laterally untilthere is a clearance of 0.1 mm be

tween

the

hook

points

and

the

needles.

11.12 Inthis position, securelytighten hexagon screws 5.

11.13 Adjustthe leftpart ofthe maindriveshaft so that the clutch has a playof0.5 mm.

11.14 Inthis

position,

tightenalienscrews 1 and 2, makingsure thatthe bevelgears are neither

set

too

close

nor

have

too much play.

11.15 Tightenone each ofscrews 4 of the bobbin

case

opener eccentric.

11.16 Push the bushings up against the bevel gears and tightenbothscrews 3 on each.

11.17 Remove the C-clamp from the needle bar.

11.18 Check this adjustment

(see

"Correct setting").

11.19 Do not tighten the second screws 4

as

yet.

Note: In

case

the hooks have to be exchanged, make surethe marks on hook bearing and hook

are

on the

same

side

(see

Fig. 11.0.4)

15

Page 18

12

12.1

Correct

setting:

12.0.1

12.1.1

12.1.2

12.1.3

12.1.4

12.1.5

12.1.6

Bobbin

case

openers

Right bobbin

case

opener

eccentric

When

thetake-upleverisat

bottom

deadcenter,shaft3ofthe

right

bobbin

caseopener

shouldbeexactly

atitsrear

point

ofreversal,asseeninthe

direction

offeed(see

arrow).

a

Screwon the feed dog.

Also

screwontheneedle

plate,

making

surethatthelugsof

both

bobbin

case bases enter

the

appropriate

slotsonthe

underside

oftheneedle

plate.

Loosen

screw1in

the

right

bobbin

case

opener

eccentric,

which

was

tightened

previously.

Turnthe balancewheelto

bring

the take-up leverto

bottom

dead center.

Turn

the

right

bobbin

case openereccentric 2onitsshaft

until

shaft3 is

exactly

at

its rearpointof reversal

(see

arrow).

Inthis

position,

tighten

screws1 securely.

16

Page 19

12.2

Left

bobbin

case

opener

eccentric

Correct

setting:

When

the

take-up lever Isat bottom

dead

center,shaft6 of

the

left bobbin

case

opener

shouldbe exactlyat itsfront point ofreversal,asseen

inthe direction offeed

(see

arrow).

12.2.1

Loosen

screw

4 in

the

left bobbin

case

opener

eccentric, which

was

tightened previously.

12.2.2

Turn

the

balance

wheel

to bring

the

take-up

leverto bottom

dead

center.

12.2.3

Turn

the

left

bobbin

case

opener

eccentric5on

its

shaft

until

shaft6is

exactly

at

its

front

pointofreversal

(see

arrow).

Inthis position, tighten

screw

4 securely.

17

Page 20

12.3

Right

bobbin

case

opener

Correct Whenshaft 1ofthe rightbobbin

case

opener isat itsrear pointofreversal (see arrow),

setting:

as

seen

inthe direction of feed,

there

should be a

clearance

of 0.3 to 0.5 mm

between

the lugofthe rightbobbin

case

base

and the rear

edge

ofthe needie plate slot.

12.3.1

12.3.2

12.3.3

12.3.4

12.3.5

12.3.6

12.0.2

12.0.3.

Bring

the

needle

bar

to bottom

dead

center.

Turn

the

balance

wheel

inits

normal

direction

until

shaft1ofthe

right

bobbin

case

opener

is at itsrear pointof reversal (see arrow).

Loosenclampscrew2 ofthe connecting crankon the

right

shaft1.

Reposition

the

connecting

crank

on its

shaftsothat

there

is a

clearance

of 0.3 to

0.5mmbetweenthelugofthe rightbobbincase base andthe rearedgeofthe needle

plate

slot.

In

this

position,

tighten

clamp

screw2,making

surethatthe

connecting

crank

isnot

tilted.

Checkthis adjustment(see "Correctsetting").

18

Page 21

12.4

Left

bobbin

case

opener

Correct

setting:

When shaft 3 of

the

left bobbin

case

opener

is at its front point of reversal

(see

arrow),

as

seeninthe

direction of

feed,

there

shouldbea

clearanceof0.3to0.5

mm

between

the lugofthe leftbobbin

case

base

and the frontedge ofthe needle plateslot.

12.4.1 Bringthe needle bar to bottom

dead

center.

12.4.2 Continue turningthe balance wheel inits normaldirection

until

shaft 3 ofthe leftbobbin

case

openerIsat itsfront pointof reversal

(see

arrow).

12.4.3 Loosen clamp screw 4 of the connecting crank on the leftshaft 3.

12.4.4 Reposition the connecting crank on its shaft

so

that there Is a clearance of 0.3 to

0.5 mm between

the

lug of

the

left bobbin

case

base

and

the

front

edgeofthe

needle

plate

slot.

12.4.5 Inthis

position,

tightenclampscrew4,

making

sure thattheconnecting crankisnot

tilted.

12.4.6 Check this adjustment

(see

"Correct setting").

19

Page 22

13

Correct

setting;

13.0.1

13.1

13.2

13.3

13.4

13.5

Oil

check

valve

When the machine is initsinoperativepositionthere should be a clearanceof0.3 mm

betweenactuating lever4 and

lifting

eccentric5 at the

point

wherethey are closest

together

(Fig.

13.0.2).

Also,

there

should

bea clearanceof2.0mm

between

actuating

lever

4and

circlip6.Furthermore,

operating

pin8shouldbecenteredinthe

elongated

holeand its

circlip

should

lightly

contactthe actuatinglever.

13.0.3

13.0.2

Loosen

both

clamp

screws

1and

push

oil

check

valve

2tothe

right.

Also

loosen

screw

3.

Adjust

actuating lever4so thatthereisa clearanceofabt.0.3

mm

between

it,when

at

rest,

and

lifting

eccentric

5.

in this position,tighten screw3.

Repositioncirclip6 so that, when the machine is at rest,there isa clearance ofabt.

2.0mmbetweenactuating lever4and circlip6.

20

Page 23

13.6

Loosen

screws

7.

13.7 Push operating pin8 toward the right until

pressure

is felt. Adjust bracket 9 so that

opera

ting pin 8 is centered in its elongated hole.

13.8

In this position, tighten

screws

7.

13.9

Reposition

oil

check

valve2so

that

the

circiiponoperating

pin 8 lightly

contacts

actuating

lever

4. Make

sure

operating pin 8 is stillat the point where pressure is felt.

13.10 In this position, tighten clamp

screws

1.

13.11

Screw

on the lateral

gearcase

cover.

13.12 Carefully

clean

the

gasket

face on

the

gearcase

and

the

gasketofthe

gearcase

cover.

13.13 Replace the

gearcase

cover and screw itdown, tightening its fivescrews crosswise.

21

Page 24

14

Correct

setting:

Tension

release

mechanism

When

the

presser

bar

lifter is raised, both

tension

discs

shouldbeat

least

0.5

mm

apart.

® J ©

14.0.1

14.0.2

14.1

14.2

14.3

14.4

14.5

14.6

Raise the presser bar

lifter,

then screw on the presser

foot.

Screw tension

base

plate 1.

Checktomake

sure

both

tension

discsareatieast0.5

mm

apart.

ifthe

tension

discsare

either

toofarapartor tooclose

together,

remove

tension

base

piate1againandbend

tension

release

lever2accordingly.

After

the adjustment,replacetension base piate 1.

Checkthisadjustment (see "Correctsetting").

22

Page 25

15

Correct

setting:

Knee

lever

play

When operated,

the

knee

lever should have a small amount of play before

the

presser

foot

starts

rising.

15.0.1

15.1 Push the knee leverjointontothe vertical knee lever shaft, push itupwards and turn itto

the rightasfarasitwillgo.

15.2

Insert

the

knee

lever

Into

the

knee

lever

joint.

15.3 Lowerthe presserfootontothe needle plate by means ofthe presserfoot

lifter.

15.4 Loosen locknut 1 of the rightstop screw 2 and turn the stop screwout a few turns.

15.5 Then turnstop screw 2 inagain

until

the presserfootstarts to

lift

clear ofthe needle plate.

15.6 Inthis position, turn

stop

screw2out byone turn and lockitInposition bytightening

nutl.

15.7 Check this adjustment

(see

"Correctsetting").

23

Page 26

16

Correct

setting:

16.1

16.2

16.3

16.4

16.5

16.6

Knee

lever

stroke

limitation

When the knee lever is

fully

operated, the presser bar

lifter

should drop by Itsown

weightand the presserfootshould be

lifted

fromthe needle plate by a

little

more than

7.0

mm (or 9.0 mm).

16.0.1

Loosen locknut1 ofstop screw 2.

Turn

stop

screw2out

a few turns.

Raise

the

presser

bar

lifter,

place

the

7-mm-(or

9-mm)

thick

blade

ofthe

gauge

under

the

presser footand lowerthe presser bar

lifter

again.

Move

the knee lever to the right until a noticeable resistance is felt;howeverthe

presser

foot

must

not be lifted off

the

gauge.

Hold

the

knee

lever

atthis

position

andturnstopscrew2inasfaras it

will

go,then

back out by one turn, and lock it in place with locknut 1.

Checkthis adjustment (see "Correctsetting").

24

Page 27

17

Correct

setting:

17.0.2

Most

favourable

knee

lever

position

When

in its

rest

position,

knee

iever connecting rod 4 shouid be at abt. 15° to

the

ieft

of an imaginary line extending at right angles to the front

edge

of the bedplate.

17.0.1

17.1

Lower

thepresser

foot

ontothe needleplatebymeansofthe presserbar

lifter.

17.2 Loosenbothclampscrews1 just

sufficientlytopermit

the

vertical

kneeievershaft2 to be

tumed

in crank 3

against

resistance.

17.3 Adjustthe kneeleverso that kneeleverconnecting rod4,whenat rest, Ispositioned

at abt. 15° to

the

left of an imaginary line extending at right

anglestothe

front

edge

of

the

bedplate.

17.4

In

this

position,

securely

tighten

clamp

screws1 incrank3,

making

surethatthe

vertical

knee

lever

shaft2has

no vertical play.

17.5

Check

this

adjustment

(see "Correct setting") and

pull

thekneeieveroutofits

joint.

25

Page 28

18

Correct

setting:

18.0.2

18.1

18.2

18.3

18.4

18.5

18.6

Hook

lubrication

Afterthe machine has run at

full

speed

forabout ten seconds, a finetrace ofoilshould

appearopposite each hookon a piece of paper placed vertically behind them.

18.0.1

Checkthe

oil

level

at the

oil

sightglass and, ifnecessary, top upthe reservoir

until

the

oil

level

Isin line

with

the upper mark. Use

oil

withaviscosity

of16.0

mm^/s

at 50°Cand a

density

of 0.87

kg/dm^.

We

recommend

Pfaff

sewing

machine

oil

No.

280-1-120

144.

Turninregulating

screws

1and2ofthe

oil

check

valveasfarasthey

will

go,

and

then

back

out by half a turn.

Turn on the master switch and let the machine run about one minute.

Placea pieceof paper

vertically

behindthe hooks.Thencheckto see ifa finetraceof

oil

hasappeared onthepaper

opposite

each

hook

raceway.

Iftoomuchoilis

emitted,

turnin

regulating

screw1fortherighthookor2forthe left

hooksomewhat.Iftoo

little

oilIsemitted, turn outthe respectivescrewa

little.

Checkthisadjustment(see "Correctsetting").

26

Page 29

19

Correct

setting:

19.0.1

Bobbin

winders

When the bobbin winders are

engaged,

the winder spindlesshould be driven reliably;

when

the

bobbin

winders

are

disengaged,

however, friction

wheels3must

not

contact

drive

wheels

2.

Furthermore,

each

bobbin winder should

stop

automatically

when

the

thread

wound

on

the

bobbin

has

reached

a point abt. 1.0 mm below Its rim.

19.0.2

19.1 Engage both bobbin winders.

19.2 Loosen

screws

1 of both drive wheelswhich

are

accessiblefrom the back of the machine

arm.

19.3

Adjust

the

positionofdrive

wheels

2onthearmshaftso that

both

winder

spindles

will

be

driven

reliably

whenthe

bobbin

winders

areengaged,butthat

friction

wheels3

will

notbe

in

contact

withdrive

wheels2when

the

bobbin winders

are

disengaged.

19.4

Inthis position, tighten

screws

1.

19.5

Loosen

screw

4 of

the

right

stop

latch.

19.6 If

the

bobbinis

too

full,

push

regulating

stud

5toward

the

right; ifit is not full

enough,

pushittoward

the

left.

19.7 Afterthe adjustment, tightenscrew 4 again.

19.8 Repeat the sameadjustment forthe leftbobbinwinder.

19.9 Check this adjustment (see "Correct setting").

27

Page 30

20

Correct

setting:

Thread

check

spring

The

thread

check

spring should

have

completed its stroke

when

the

needle

points

enter

the

material (which

amounts

to a

stroke

abt.

7 mm long).

20.0.1

20.0.2

Note: Actual sewing conditions may make it necessary to increase or decrease the stroke

ofthe threadcheck spring.

20.1 Thread the needles and place a piece offabricunder the presserfoot.

20.2 Operatethe presser bar liftertolowerthe

presser

footonto the material.

20.3 Loosen screw1 inthe elongatedhole ofstop 2.

20.4 Turnthebalancewheeltosewa fewstitchesand

bring

thetake-uplevertoitshighest

point.

20.5

Continue

turning

the

baiance

wheelinits

normal

directiontocause

the

thread

check

springtomakeareturn

strokeof7

mm.

20.6 Inthis

position,

bring

stop2incontact

with

thethreadcheckspringand

tighten

screw1.

20.7 Checkthis adjustment (see "Correctsetting").

28

Page 31

Only

on

1442

Correct

setting:

1.1'

1.2

1.3

l.'t

1.5

1.6

1.7

Note;

Thread

check

springs

The movement

of

the

thread

check

springs

must be

completed

when

the

needle point penetrates the material (roughly 7

mm

stroke).

Thread

th«»

machine

and

place

a

piece

of

waste

fabric

under

the

presses

foot.

Lower

the

presser

foot

onto

the

needle

plate.

Loosen

screws

and 2

of

stops

3 and

Make a number of

stitches

b>'

turning

the

balance

wheel,

then

set

the

take-up

lever

at

top

dead

centre.

Continue turning

the

balance wheel in

rotating

direction

and allow the

thread

check

springs

to

move

back by 7

m.

In

this

position

move

stops

2 and £ up

against

the

thread

check springs

and

tighten

screws

and 2.

Carry

out

a check

(see

"Correct

setting").

When

the

thread

is

passed

around

the

sewing hook

the

check

spring

should

just

make a

brief

movement.

This is

adjusted

by

re-setting

the

position

of

thread

regulators

b and 6.

Hove

towards

for

more

thread

and

towards

for

less

thread.

Page 32

Page 33

21

Final

worksteps

21.1

Screw

on

the

two

covers

on

the

backofthe

machine

arm.

21.2

Replace the left upper plastic plug on

the

back of

the

arm

standard.

21.3

Screw

on

the

face

cover.

21.4 Make a sewing

test

and

at the

same

time turn regulating screw 4 (Fig.9.0.1) to adjust the

presser

foot

pressuresothat

the

fabric is fed properly

even

at top

speed.

CONTENTS

1

Scale

ringinreverse-feedcontrol

2 Zeroingthe bottomfeed

3 Bottom

feed

driving motion

4 Lower

needle

bar

driving

crank

5

Counter-balance

6 Bottom

feed

liftingmotion

7 Clearancebetween presserfootand needle plate

8

Feed

dog height

9 Centering the needlesinthe needle holes

10 Preliminary adjustmentof

needle

bar

height

11 Hook

timing,

hook-to-needleclearanceand needle barheight

12 Bobbin

case

openers

13

Oil

check

valve

14

Tension

release

mechanism

15

Knee

leverplay

16

Knee

lever

stroke

limitation

17 Most favourable

knee

lever position

18

Hook

lubrication

19

Bobbin

winders

20

Thread

check

spring

Page

1

2

4

5

6

7

8

9

11

13

14

16

20

22

23

24

25

26

27

28

Page 34

(EBEE)

Nr.296-12-14003 WormserVerlagsdruckerei, D-6520Worms

PrintedinWest Germany ^ 7/81

Loading...

Loading...