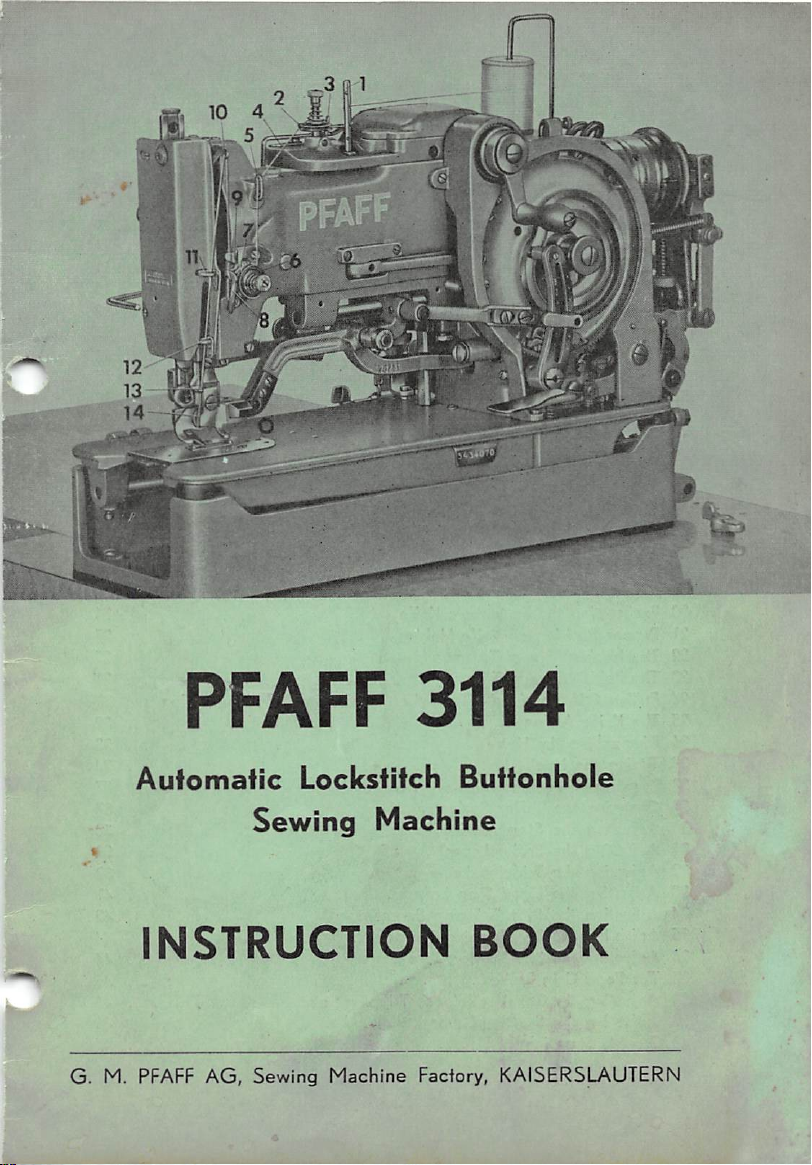

Page 1

PFAFF

3114

Auiomatic

r.

INSTRUCTION

G. M.

PFAFF

AG, Sewing Machine Factory, KAISERSLAUTERN

Locksfifch

Sewing

Buttonhole

Machine

•Jf/Zv-'

a )

BOOK

Page 2

Inde

X

Section

1. Setting Up

2. Cleaning

3.

Needle

4. Inserting the

5. Threading

6. Winding the Bobbin 12

the

Machine 5

and

Lubricating 7

and

Thread

Needle

the

Needle

Page

10

11

11

7. Changing the Bobbin 13

8. Threading the Bobbin Cose 13

9. Regulating

the

Bobbin

Thread

Tension 15

10. Regulating the Needle Threod Tension 16

11.

Placement

of

the

Work

18

12. Starting the Mochine 18

13. Stopping the Machine 19

14.

Stopping the Machine

15. Regulating the Length of Buttonhole

16.

Changing the Number of Stitches per Buttonhole 24

17. Changing the Width of

While

Sewing 19

Bcur

and

Parallel 25

.22

18. Adjusting the Position of the Buttonhole in Relation to the

Cutting

Space

26

19. Regulating the Distonce Between Parallels 26

20. Exchanging the Buttonhole Knife 26

21.

22.

23.

24.

25.

Proper

The

The

Pulling

The

Position of Knife Holder 27

Needle

Bobbin

Thread

Thread

Trimmer

Trimmer

Off the Needle Thread and Releasing the Top Tension . .

Knife

Action

27

29

31

32

26. Dismantling the Hook 33

27. Timing the Hook 34

28. Regulating the Pressure on the Material 37

29. Changing the Buffer Spring 37

30. Adjusting the Stop Motion Lever 38

31. Adjusting the Brake Lever 39

32. Adjusting the Tripping Lever 39

33.

Adjusting the Hand Stop Lever

34.

Adjusting the Stop

35. Adjusting the Bar

Tripping

Tripping

Segment 42

Segment 44

41

36. Adjusting the Needle Bar Zero Lug 44

37. The

38. Adjusting the Tension Release

Feed

Cam

Broke 46

Tripping

Point 46

39. Adjusting the Starting Lever 46

40. Trouble Shooting 47

Page 3

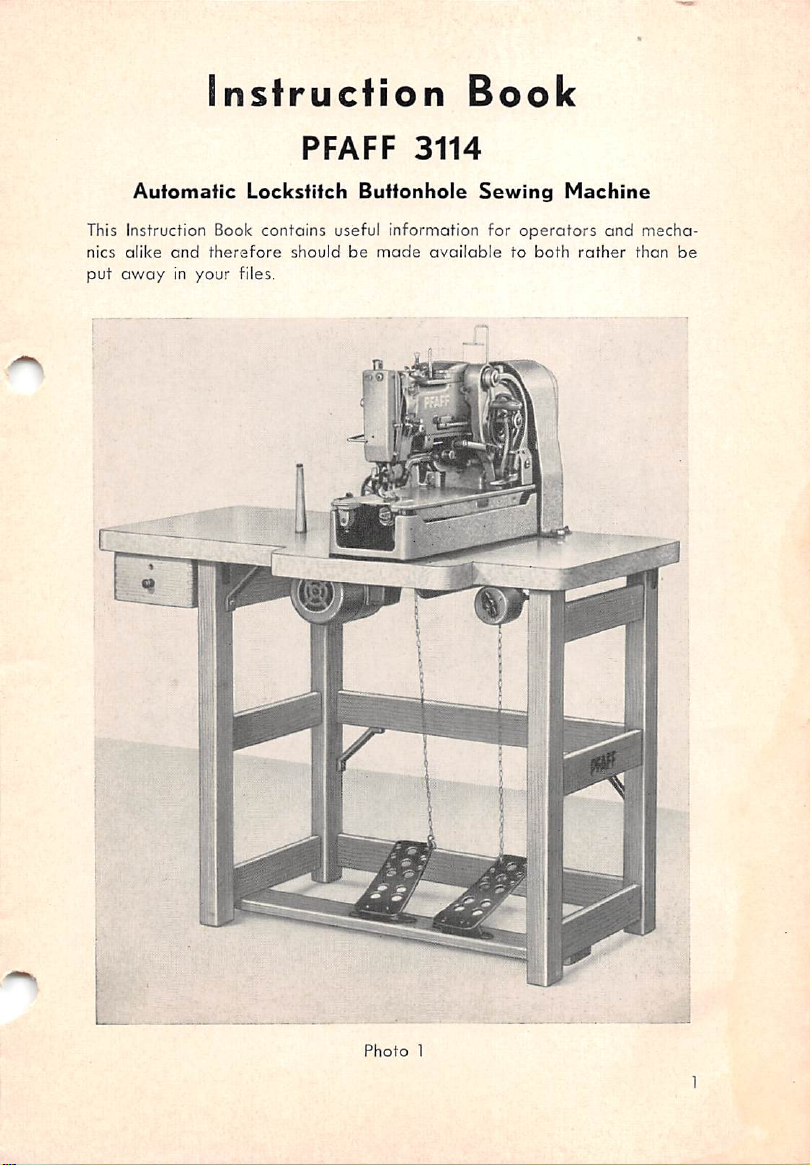

Instruction

Book

Automatic

This Instruction Book

nics

alike

and

therefore

put

av/ayinyour

PFAFF

Lockstitch

contains

should

files.

3114

Buttonhole

useful informoHon for

be

made

Sewing

available

operators

to

both

Machine

and

rather

mecha

than

be

Photo

1

Page 4

Photo

2

Page 5

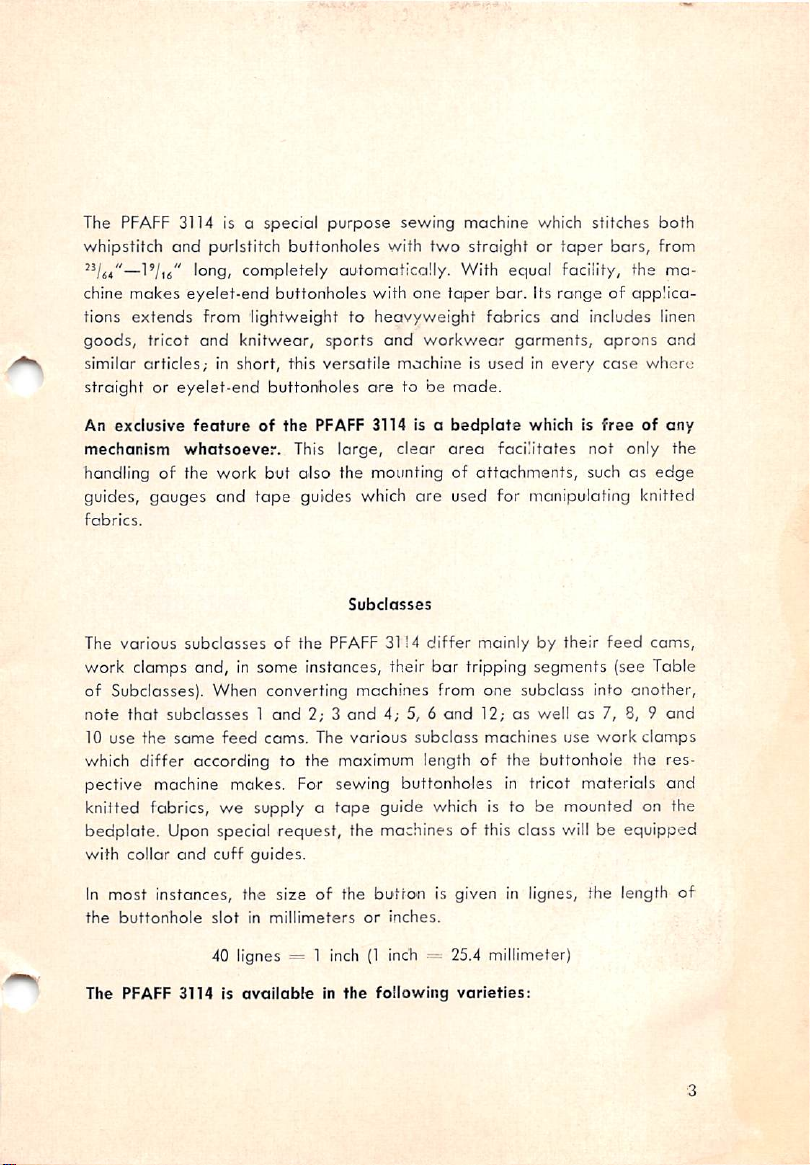

The PFAFF 3114 is a special

whipstitch

and

purlstitch

purpose

buttonholes

sewing

with

machine which stitches

two

straightortaper

bars,

both

from

—I'/ifi" long/ completely automatically. With equal facility, the ma

chine

makes

eyelet-end

tions

extends

goods,

similar

from lightweight to

tricot

and

articles;inshort,

straightoreyelet-end

An

exclusive

mechanism

featureofthe

whatsoever.

handling of the work but

guides,

fobrics.

The

work clamps

gauges

various

subclassesofthe

and,

of Subclasses). When converting machines from one subclass into

note

that

subclasses1and

10

use

the

same

which

differ

according to the maximum lengthofthe buttonhole tiie

pective machine mokes. For sewing buttonholes in tricot materials

buttonholes

knitwear,

this

sports

versatile

buttonholes

PFAFF 3114 Is a

This large, clear

also

the mounting of

and

tape

guides which

Subclasses

PFAFF 31!4

in some instances, their

2; 3

and

feed

cams.

The

various

with

one

taper

bar.

heavyweight

and

workwear

machineisusedInevery

are

to be

fabrics

garments,

made.

bedplate

area

facilitates not only the

attachments,

are

used for manipulating knitted

differ

mainlybytheir

bar

tripping segments (see Table

4; 5, 6

and

12;aswellas7, 8, 9

subclass

machines

Its

rangeofapplica

and

includes linen

aprons

case

which is

freeofany

such as

feed

use

work

and

where

edge

cams,

another,

and

clamps

res

and

knitted fabrics, we supply a tape guide which is to be mounted on the

bedplate. Upon special request, the machines of this class will be equipped

with collar

and

cuff guides.

In most instances, the size of the

the

buttonhole

slotinmillimeters

40 lignes = 1 inch(1inch 25.4 millimeter)

The PFAFF 3114 is

availableInthe

button

or

inches.

following

is given in lignes, the length

varieties:

of

Page 6

Lenghf

Buttonhole

'/4"-l"

Inside

of

Model

Dimensions

of

Feed

WIdfh

"/S4

-•'Ui

Work

Frame

Length

IVs.'

ClassofWork

Lingerie

Blouses

Corsetry

Stitch

with 2

Diagram

straight

bars

V/'-l"

"2"-lV4"

'//'-T/4"

V2"-l'/4'

Vs"

1"

^'4"-V

15/

'i/

^-1.

1"/

]19j

2"/,

1"/s

li

It*

]*9I

It*

l"/44"

Tricot

Knit

Goods

Ladies'

Wear

Sport

and

Work

Clothes

Extra

long

belt

and

slashes

flies

flaps

Clothing

Goods

button

slots

and

in

work

button

and

trouser

holes,

aprons

clothes

Ornamental

holesInlapels

sleeve

Buttonholesintrouser

front

pocket

Work

Staple

with2straight

with2straight

with 2

with2taper

with1taper

and

withttaper

and1conceoled

pear-shaped

with1straight

and

pear-shaped

l"/4

Work

Staple

Clothing

Goods

bars

bars

straight

bars

bar

bars

eye

and1conceoled

eye

bar

bar

V4"-l'/4"

1^744"

Work

Staple

Clothing

Goods

with1taper

and

and1concealed

pear-shaped

bar

eye

Page 7

10

Lenght

Buttonhole

^/4"-T/4'

Inside

of

Model

Dimensions

of

Feed

Width

Work

Frame

Length

ClassofWork

Work

Clothing

Staple

Goods

with 1

Stitch

straight

and

Diagram

and1concealed

pear-shabed

bar

eye

Tricot

30

V/'-V

12

30

14

As shown in

operator.

When

and

ready-assembled.

the felt

the

front

732

l"/64

Jl/..

1''/S4

1.

Setting

photo

1, the

PFAFF

supplied with individual

has to be mounted on the

For this purpose,

pads

on the

of the

tablesothat

table

projection

edge

(with

Tricot,

(with

Up

3114 is

power

power

Knitwear

gimp

guide)

Knitwear

gimp

guide)

the

table,

table

place

the front

and

that

ly in the middle of this projection. Now the machine

mounted

Make

Mount

hinges.

Make

direction,asindicated

on the

base

sure

that

the machine

both

driving

particularly sure

and

belts,

by

connected

rests

properly

attach

that

the

the machine pulley

the

arrowinphoto

with its hinges.

belt

TheVaHP electric motor performsata constant

is provided with a

in

two-speed

diameter

pulley No. 99057, with

with the machine

When in

permanent

r.p.m. for the first six weeks.

two-speed

and

permitsasewing

and

allows

operation, the

pulley No. 99056 which

diameters

for a

sewing

PFAFF

After

3114 should be

this time the

to 2,000 r.p.m. by exchanging the mofor pulley.

with1taper

with 1

taper

bar

bar

Machine

set

up with its

the

headispacked

which comes from the factor/i

the cast-iron machine

edge

of the

the

baseispositioned

on the

rubber

guard

and

always

23.

speed

speedof1,800 s.p.m. A second

of ond P'/a:"* comes

speedof2,000 s.p.m.

speed

head

facing the

separately

base

base

is flush with

head

is carefully

blocks.

screwitdown

rotates

in the right

of 1,400 r.p.m.

measures

S^/g"

operatedat1,800

may

be increased

and

exact

on its

and

and

-5

Page 8

When using first-rate thread, the sewing

2,200 r.p.m. For this purpose, mqtor pulley No.

4^/32"

and

When ordering motor pulleys,

shaft.

In

those

cases

has to be used, a

set

up on individual

is avoi-lobleatextra

whereamotor

speed

reducer will be furnished for the

power

table. The

please

withahigher

should be specified on the order. High-speed motors

because

ratios.

the small pulleys

they

require

speed

may

cost.

specify the

speedisalready

typeofspeed

have

very

even be increased to

99058,

diameter

are

unfavorable

To facilitote mounting the PFAFF 3114 on an existing

system,

and with the

is

speed

With a line

is

When

diameter

sewing

it is

advisabletoprocure

conveyedtoihe

necessary

pulley.

shaft

cutouts

machinebymeansoftwo

speedof300 r.p.m., a line

requiredtoobtainasewing

using

thread

may

speedof2,200 s.p.m.

ofasuperior

be

used

after

from us a

and

holes. From the line

table

jockey

shaft

pulleyof9^'/32"

speedof1,800 s.p.m.

quality,

the breaking-in

a line

period

fop in the

pulleys

shaft

with diameters

of the motor

on

PFAFF

reducer

hand

3114 when

required

not recommended

transmission

power

shaft

pulley

so

astoobtain

proper

pulley,

and

of

benching

length

power

one

diameter

11

of

end

two-

,a

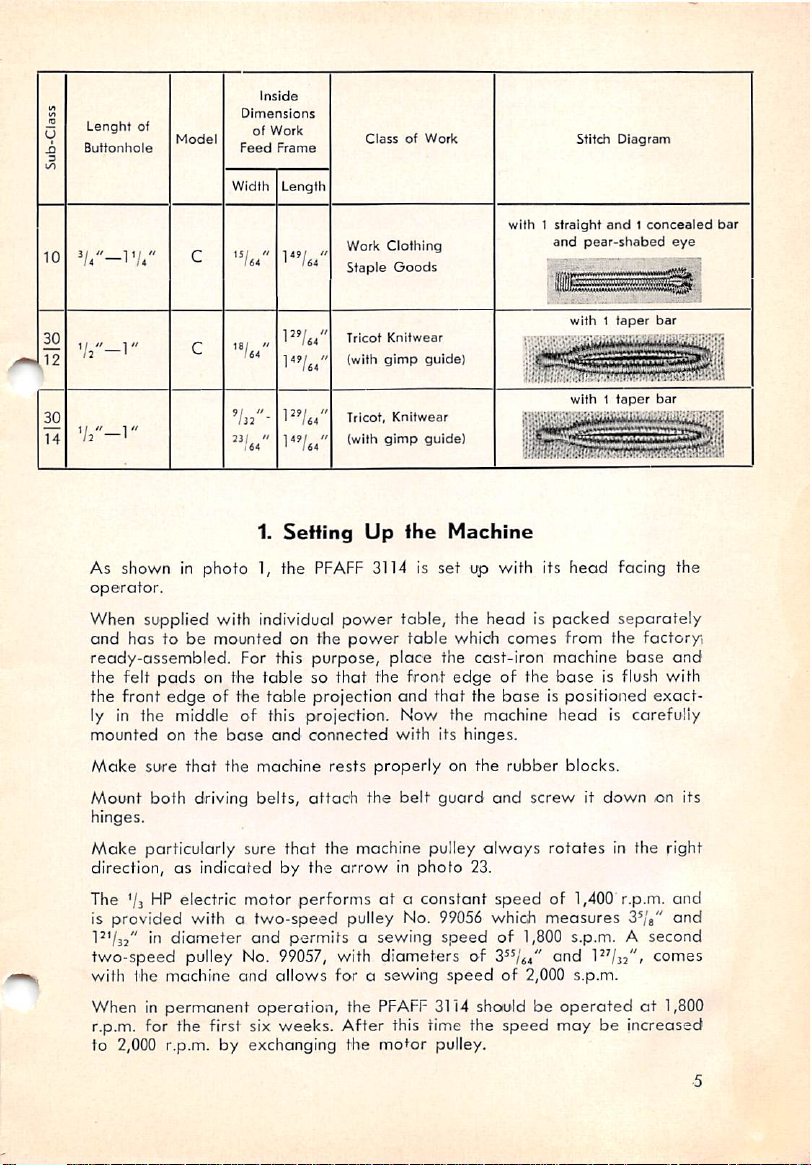

Photo

3

Page 9

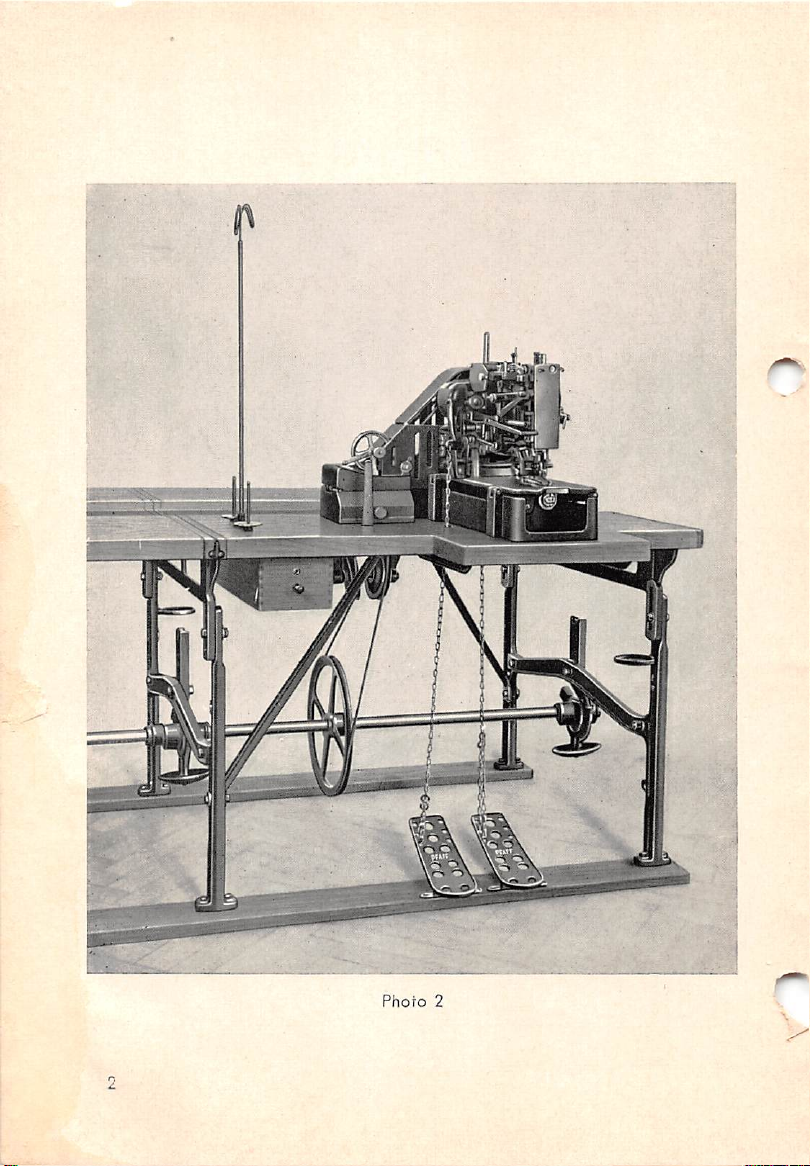

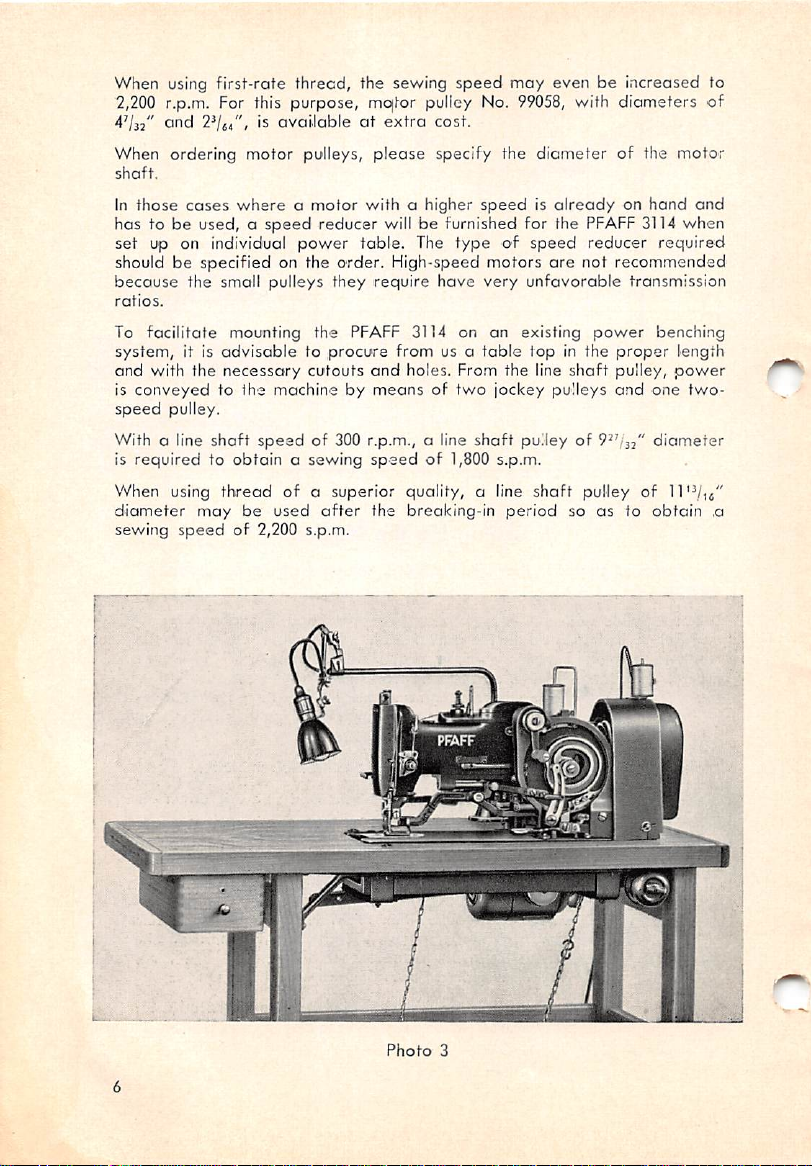

Photo2depicts

the belt guard. The

on within

The long chain which

lifting lever L on the

the

toble

depending

the

dispositionofthe

easy

treadles

reachofthe

top,

on the angleofinclination

left

and

connectedtothe

for

operator.

serves

to lift the

sideofthe machine,

two-speed

operating

work

second

desired.

and

jockey

pu'Ileys

the macNine should be

clampissuspended

passed

or third hole in the

through the

left

and

screwed

from

hole

treadle,

the

The short chain is suspended from the starting lever inside of the machine

base

endisconnectedtothe

Whereas

shown in

mounted

the

PFAFF 3114 is

photos1and2,when

lengthwise of the

right

treadle.

exclusively

usedingarment

toble

(Photo 3)

setupcrosswiseofthe

when

manufacture,

used

in the

table,

it is

manufacture

as

often

of linen and tricot goods. Since the buttonholes in these articles, e.g. men's

shirts,

extend

the machine

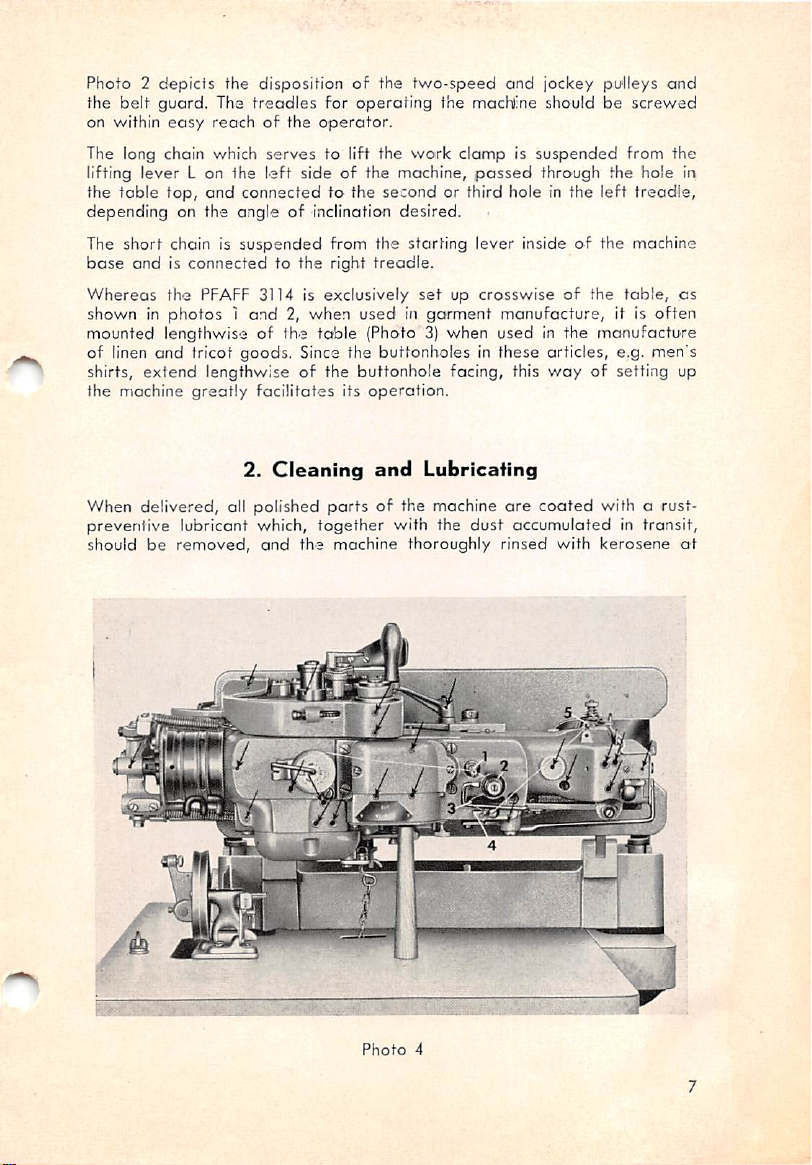

When

delivered,

prevenlive

should be

lengthwise of the buttonhole facing, this

greatly

lubricant which,

removed,

facilitates

2.

all

polished

its

operotion.

Cleaning

and

the machine thoroughly rinsed with

and

Lubricating

partsofthe machine

together

with the

are

dust

way

of setting up

coated

accumulated

with a rust-

in transit,

kerosene

ir>

ot

Photo

4

Page 10

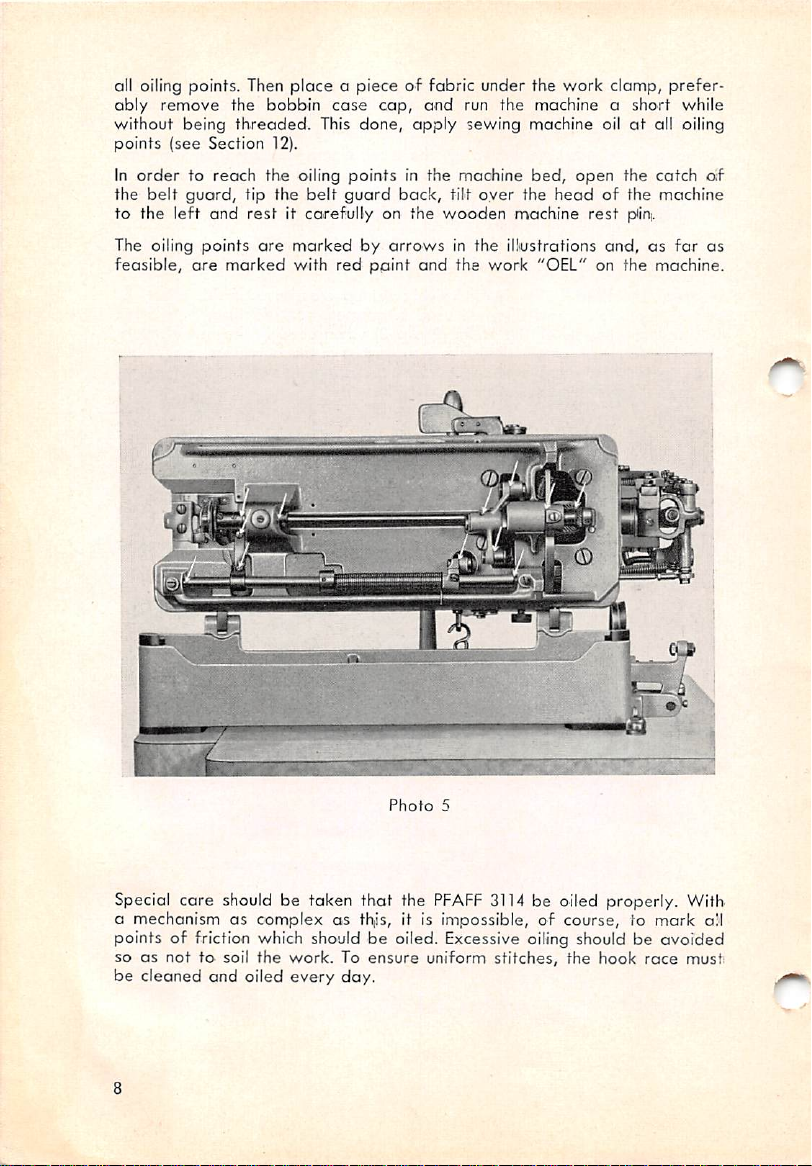

all oiling points. Then

ably

remove

without

being

the bobbin

threaded.

points (see Section 12).

In

ordertoreach

the

belt

to the

guord,

left

The oiling

feasible,

are

points

and

marked

the

tip the

rest

ore

place

a piece of fabric under the work clamp,

cose

cap,

and

This

done,

oiling

pointsinthe

belt

guard

back,

it carefully on the

markedbyarrows

with

red

pqint

UlUUIBBSf

run the machine a short while

apply

sewing machine oilatall oiling

machine

tilt

wooden

over

bed,

the

machine

in the illustrations

and

the

work

open

the

headofthe

rest

pfini.

and,asfar

"OEL"onthe

prefer

catch

machine

machine.

o;f

as

Photo

5

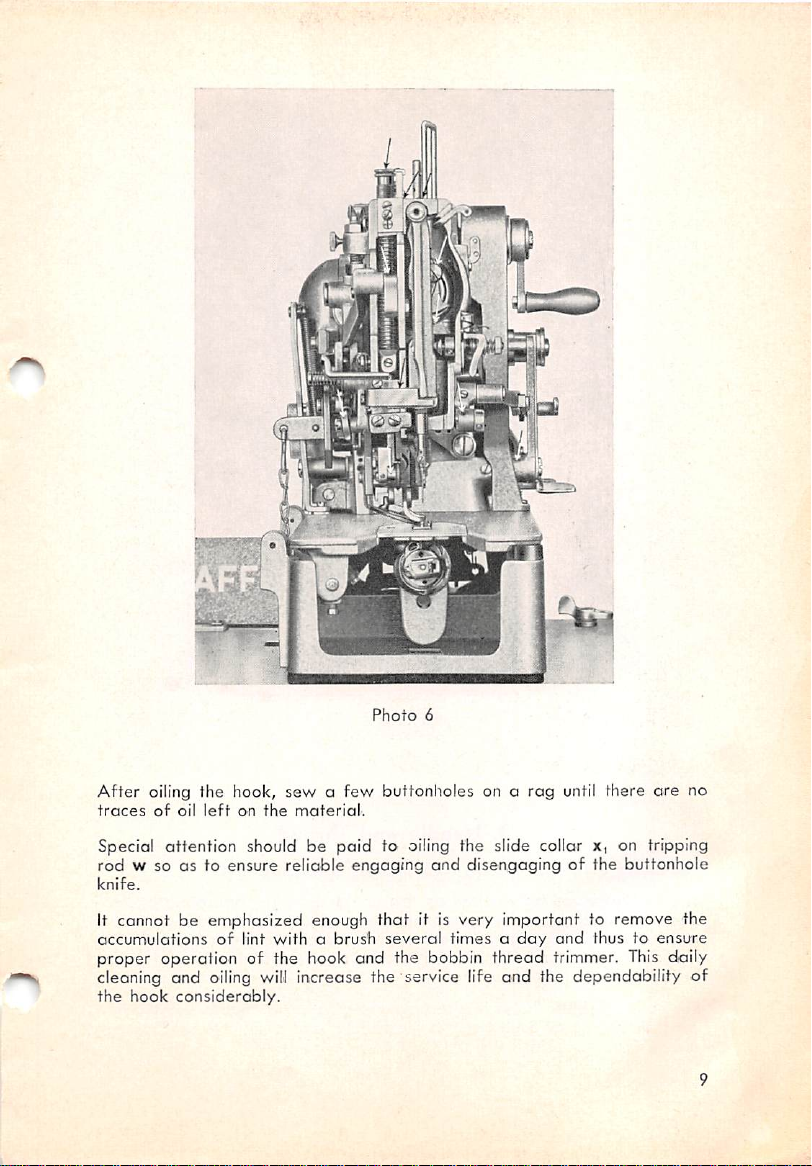

Special

a mechanismascomplexasth,is, it is impossible,ofcourse,tomark

care

should be taken

that

the

PFAFF

3114 be oiled properly. With

all

points of friction which should be oiled. Excessive oiling should be avoided

soasnottosoil

be

cleaned

and

the

work.Toensure

oiled

every

day.

uniform

stitches,

the

hook

race

must

Page 11

After

oiling the hook,

traces

of

oil

•.V"t

left

on

sewafew

the

material.

n

Photo

6

butfonlioles on a

rag

until there

are

no

Special attention should be

paid

to oiling the slide collar x, on tripping

rod w so as to ensure reliable engaging and disengaging of the buttonhole

knife.

It cannot be emphasized enough

accumulationsoflint

withabrush

that

it is very important to remove the

several

timesaday

and

thus to

ensure

proper operation of the hook and the bobbin thread trimmer. This daily

and

cleoning and oiling witl increase the service life

the

hook

considerably.

the dependability of

Page 12

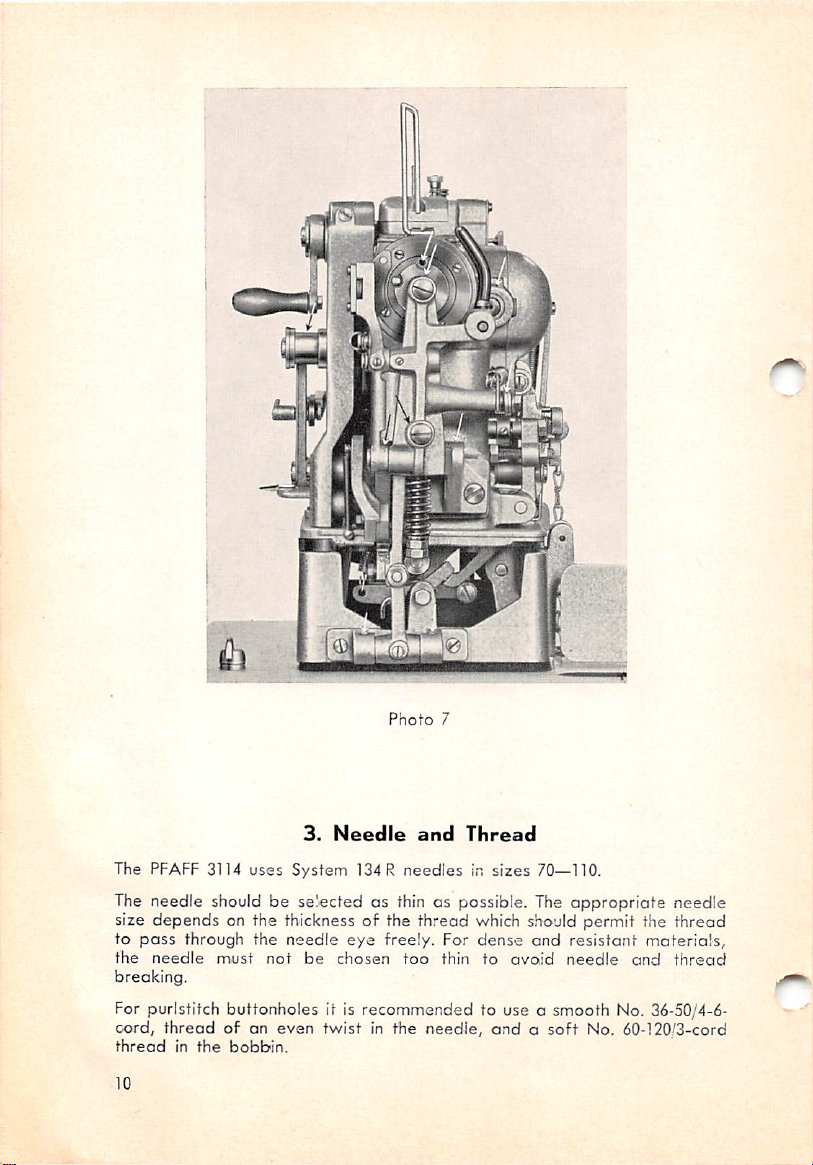

Phot-o

7

3.

The PFAFF 3114

uses

Needle

System

and

134R

neediesinsizes

Thread

70—110.

The needle should be selected as thin as possible. The appropriate needle

size

to

the

depends

pass

needle

on the thickness of the

through the

must

not

needle

be

eye

chosen

thread

freely. For

too

thin

which should permit the

dense

and

to

resistant

avoid

needle

materials,

and

thread

thread

breaking.

For purlstitch buttonholes it is recommended to use a smooth No. 36-50/4-6-

cord,

thread

10

threadofan

in

the

bobbin.

even

twistinthe

needle,

andosoft

No.

60-120'3-cord

Page 13

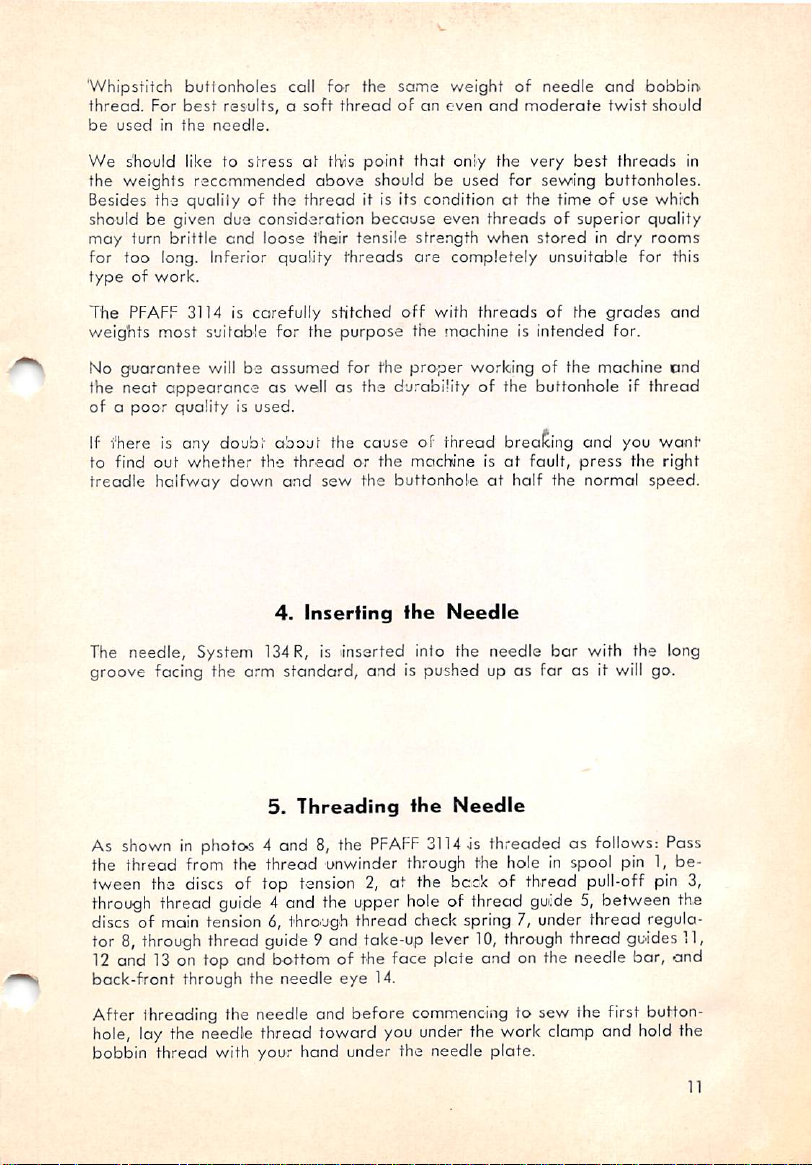

'Whipstitch

thread.

be

usedinthe

We

weights

the

Besides the quality of the

should be given due consideration

may

for

too

typeofwork.

The

weights most suitoble for the purpose the machine is intended for.

No

guarantee

the

neat

ofopoor

If

thereisany

to find

treadle

buttonholes

For

best

results, o

needle.

should like to

turn brittle

PFAFF 3114 is corefully stitched

recommended

end

long. Inferior

will be

appearance

qualityisused.

doubt

out

whether

halfway

call for the

soft

thread

stressatttvis

loose

quality

assumed

as well as the durability of the buttonhole if

about

the

down

threadorthe

and

4.

point

above

thread

it is its conditionatthe time of use whrch

their tensile

threads

for the

the

causeofthread

sew

the

Inserting

some

weightofneedle

oF an

even

and

that

strength

are

off

proper

with

only the very

for sewing buttonholes.

even

threads

when

completely

threads

working of the machine

shouldbeused

because

breaking

machineisat

buttonholeathalf the

the

Needle

moderate

storedindry

and

twist

best

threads

of superior quality

unsuitable for this

of the

grades

and

fault,

press

normal

you

the

bobbin

should

in

rooms

and

end

thread

want

right

speed.

The needle. System 134R, is linserted inio the needle

bar

with the long

groove facing the arm standard, and is pushed up as far as it will go.

5.

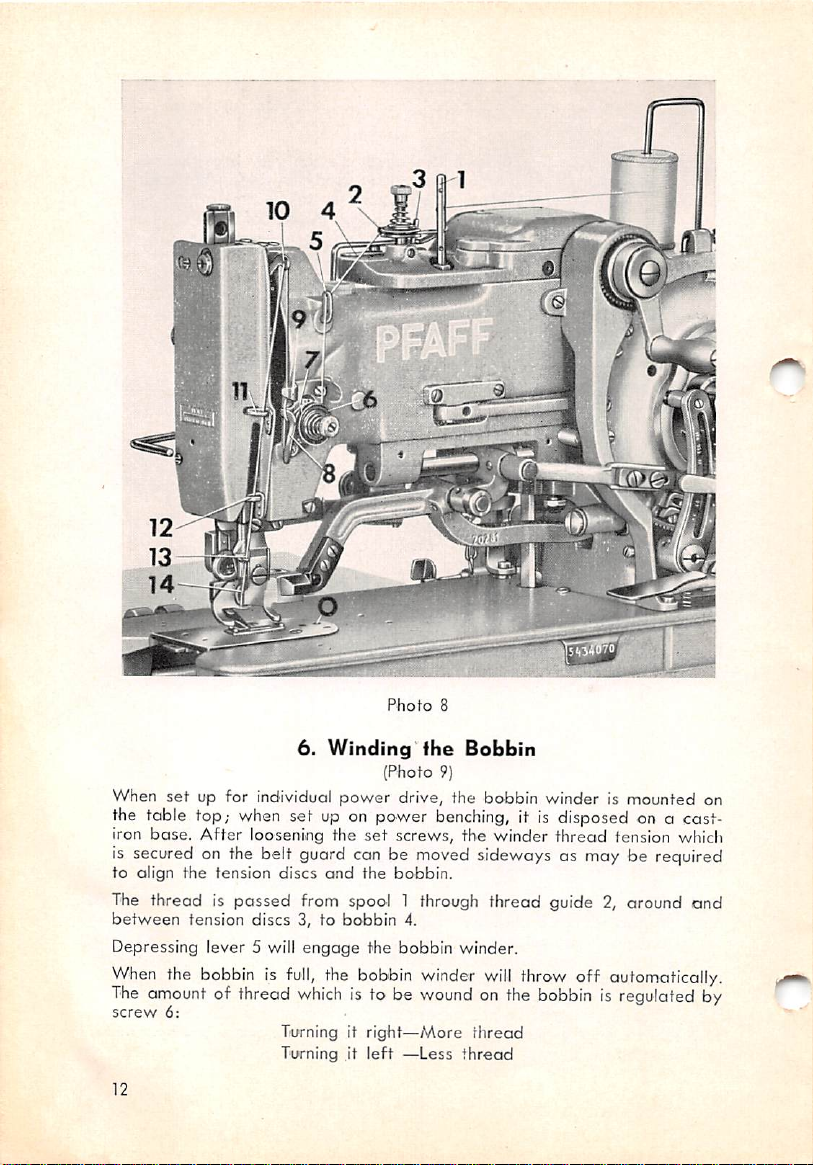

As shown in

the

thread

Threading

photc»s

from the threod unwinder through the hole in spool pin 1,

4 and 8, the

PFAFF

the

Needle

3114

Js threaded as follows: Pass

be

tween the discs of top tension 2, at the beck of threod pull-off pin 3,

through

thread guide 4 and the upper hole of thread guide 5, between the

discs of main tension 6, through thread check spring 7, under thread regula

tor 8,

through

thread guide9 and take-up lever

10,

through

thread guides

12 and 13 on top and bottom of the face plote and on the needle bar, ond

back-front through the needle

eye

14.

After threading the needle and before commencing to sew the first button

hole, lay the needle thread toward you

bobbin

thread

with your

hand

under the

under

the work clamp and hold the

needle

plate.

11,

11

Page 14

a

Phofo

8

6.

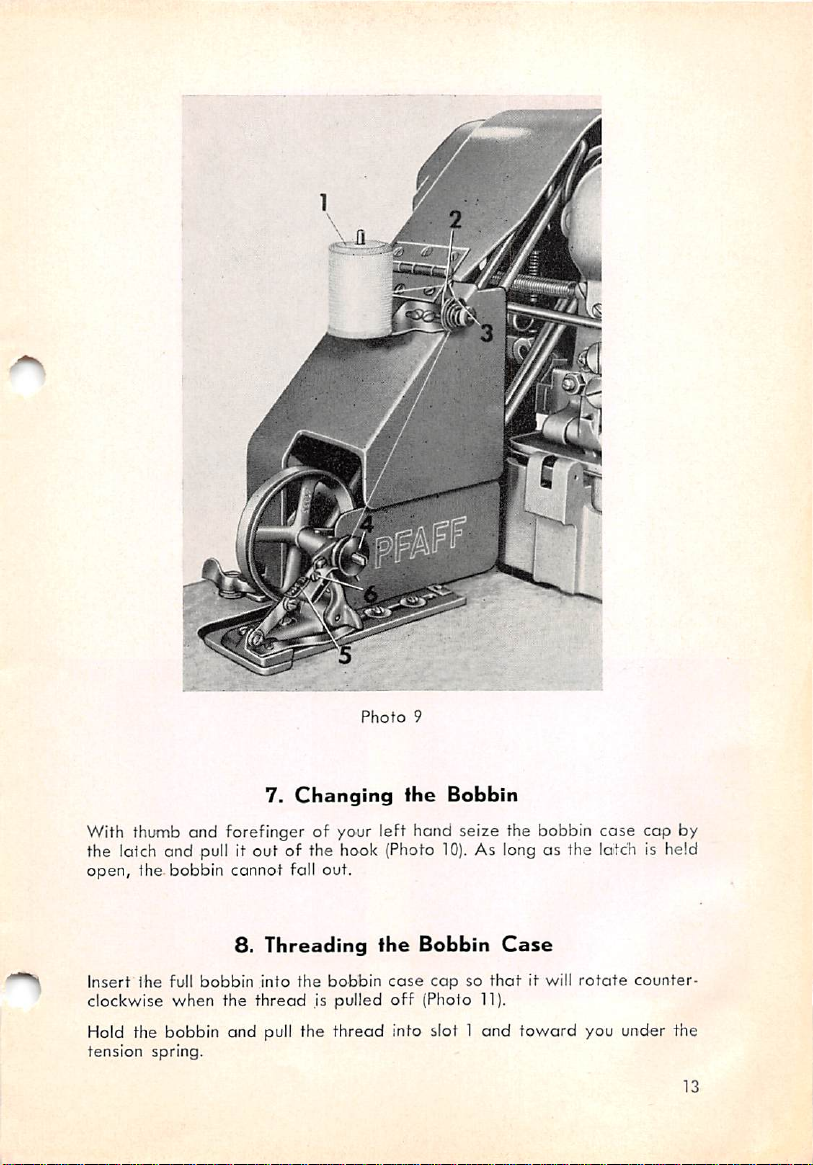

Winding

When

set

the table top; when set up on power benching, it is disposed on c cast-

up for individual

iron

base.

After

loosening the

is secured on the belt guard can be moved sideways as may be required

to

align

the

tension

The thread is

between

Depressing lever 5 will

When

The

screw

tension

the bobbin is

amount

of thread

6:

discs

passed

discs3,to

power

and

from spool 1 through thread guide 2, oround

bobbin

engage

full,

the bobbin winder

which

is to be

Turning it right—More

Turning it

fhe

Bobbin

(Photo

9)

drive, the bobbin winder is mounted on

set

screws,

the

bobbin.

the bobbin winder.

left

4.

wound

—Less

the

winder

will

on the

thread

thread

thread

throw off automatically.

bobbin

tension which

is regulated by

and

12

Page 15

7.

Changing

Photo

9

the

Bobbin

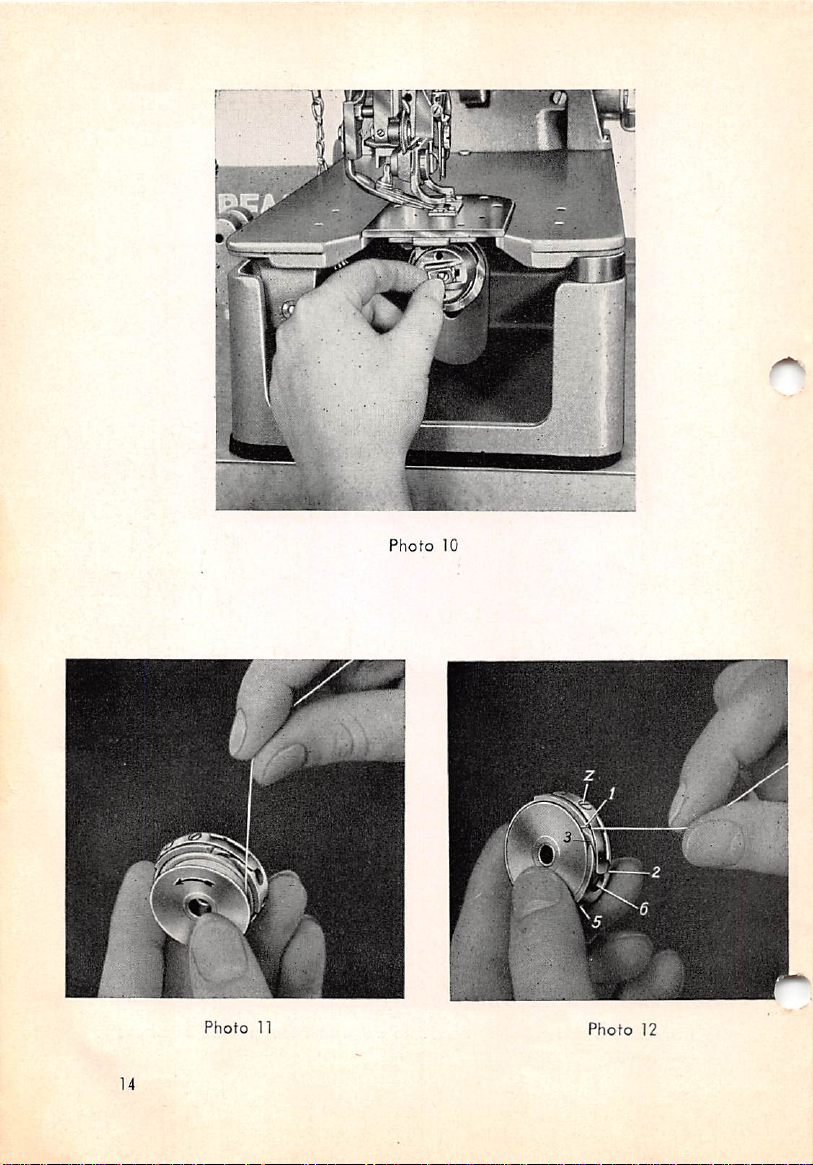

With thumb and forefinger of your left hand seize the bobbin

10).

the latch and pull it out of the hook (Photo

As long as the lotch is held

open, the. bobbin cannot fall out.

8.

Threading

Insert

the

full

clockwise

bobbin

when

Hold the bobbin and pull the

tension

spring.

the

into

thread

the

,is

bobbin

pulled

thread

the

Bobbin

case

off

(Pholo 11).

info slot 1

Case

capsothat

and

it will

toward

case

cap by

rotate

counter

you under the

13

Page 16

Photo

10

Photo

11

14

Photo

12

Page 17

Then

retain

the

forefinger of

through the

4

into

the

When letting go of the

threadinfront

yo-ur

gap

delivery

left hand until the thread is pulled back into slot 3,

between the bobbin case and the bobbin, and through slot

eye

5.

thread

will properly snap under the tension spring and be visible through

ture6(Photo

4).

While holding the latch open, the bobbin

ed

onto

the

center

studinthe

of the tipofthe tension spring with the

and

pulling it through the delivery

case

cap

and

bobbin

case

base

and

the bobbin

the

latchisclosed.

ore

eye,

aper

push

A slight pressure exerted with the thumb will make the cap snap into posi

tion audibly. This is very important since an improperly inserted bobbin icase

may cause

damage

to the hook, the bobbin

case

or the needle.

it

Photo

Photo

13

14

9. Regulating the Bobbin Thread Tension

The bobbin thread tension is regulated by means of screw z (Photo

Tightening

decrease

this

screw

will

it.

increase

the

tension,-

and

looseningitwi-Ii

Purlstitch buttonholes of any description require a very weak bobbin thread

tension.

The

tension

by its own weight when letting it hang on the threod.

account

is properly regulated if the bobbin case

should the

bobbin

thread

tension be

will

slowly

(Photo

increasedinexcess

15).

slide down

16).

On no

of

the

15

Page 18

Photo

15

Photo

16

amount given above since this would necessitate increasing the needle

thread

tension

The

PFAFF

when the machine is inoperative.

When

startingthe

It is set for a

tobelocked

and

10.

Regulating

3114

normal

insideofthe

m.ight

resultinthread breaking.

has

two

needle

machine,

amountoftension

material.

the

the top

Needle

thread

tension

Thread

tensions which

Sp 1

(Photo

and causes the

Tension

are

both

17)

is engaged

knotting

released

first.

stitches,-

After some stitches, the lateral tension Sp 2 is engaged and increases the

needle thread tension so that the bobbin thread

threads

purl-line

To

will

interlace on the top surface of the

along

either

parallelofthe buttonhole.

prevent breaking of the needle threaa, the tension Sp 2

willbepulled

fabric

and

up and both

form

a straight

should

not be

set tighter than is absolutely necessary for obtaining a raised seam coti-

struction without risking thread breaking.

16

Page 19

Sp

Phofo

17

For

best

It cannot be emphasized enough

results, cotton No.

that

so

the high sewing

Toprevent ravellingof the buttonhole, tension Sp 2 is automatically released

when making the last

the

threads

to

formadurable

Sp 1 is released when the machine has stopped.

36-50/4

speed

of the

two

or three stitches

concatenation

or 6-cord is used as needle threod.

that

only first-class thread should be .used

PFAFF

3114 can fully be utilized.

and

tension Sp 1 will cause

insideofthe

fabric.

Tension

To

ensure

that

the

needle

thread

will be pulled into the

tension Sp 1 is released by means of lever A (Photo

is

cut

open.

In

case

sewn

inferior quality

on the PFAFF 3114. For this

Sp 2 so

that

only tension Sp 1 will remain active.

thread

is used, only whipstitch buttonholes can be

purpose,

loosen

material

18)

while the buttonhole

the

thumb nutoftension

securely,

17

Page 20

11.

1

Placement

Photo

18

ol

the

Work

When depressing the left

is

placed

under the needle. In

into

the

machine

order

treadle,

the work clamp is raised. Then the work

with

the

front

to ovoid crooked buttonholes, the buttonhole

endofthe

marked

buttonhole

marking should be placed exactly in the middle under the work clamp.

When the left treadle is released, the work clamp is again lowered onto

the

work.

Upon lifting the work clamp, lifting lever L is pulled between the vertical

guide

and

the

lower

started

accidentally while the work clamp is

endoflocking lever S so

12.

Slariing

ihe

that

raised

Machine

the machine

(Photo 18).

cannot

be

Don't run the machine unless you have thoroughly familiarized yourself with

its operation. Make particularly sure that you know how to stop the mo-

chine

during

mechanism (see Section

18

o sewing

cycle

and practise actuating the

14).

Only when the operator is fully acquainted with

knife

interlocking

Page 21

these

manipulations

know

the machine is to turn the machine pulley by

can

she

commence

sewing. The

best

hand

waytoget

andtostudy

all

phases of the performance of the machine. Then, preferably without

threading the machine

motor

and

run

the

and

machine,

with the bobbin

but

don't

let

the

case

removed, switch on the

knife

cut.

to

By pressing down the right

driving

driving pulley, thus driving the machineathalf

right treadle all the

the

the

stage,

lever S

accidentally while sewing (Photo 18).

The

belt

(low

speed)isshifted

way

rear

driving belt (high speed) is shifted from the

rear

driving pulley, thus bringing

the front driving

arrests

two-belt

lifting lever L so

drive

ensures

not only faster but also at a lesser

slippage and excessive

13.

treadle,

the

brakeisreleased

from the

front

loose pulley to the

speed.

and

the front

When pressing the

down (and then taking the foot off the treadile),

rear

loose pulley to

speed.

At this

and

locking

raised

to

top

speed

belt

is shifted to the

that

wear

are

Stopping

the

machinetofull

rear

that

the work clamp cannot be

the

machiiieisaccelerated

power

greatly

eliminated.

the

loose pulley,

consumption and that

Machine

front

belt

After completion of the buttonhole the machine stops automatically. Shortly

before making the bartacking stitches, the machine is automatically slowed

down to half speed in order to effect a soft impact of the buttonhole knife.

the

advantage

machine

Another

of

buffer springs when the machine stops instantaneously.

eliminate the

of this reduction in speed is the fact that the momentum

is much

less

and

can

be

easily

absorbed

by

This

breakageofparts

and

trouble in the machine.

the

will

double

greatly

14.

Stopping

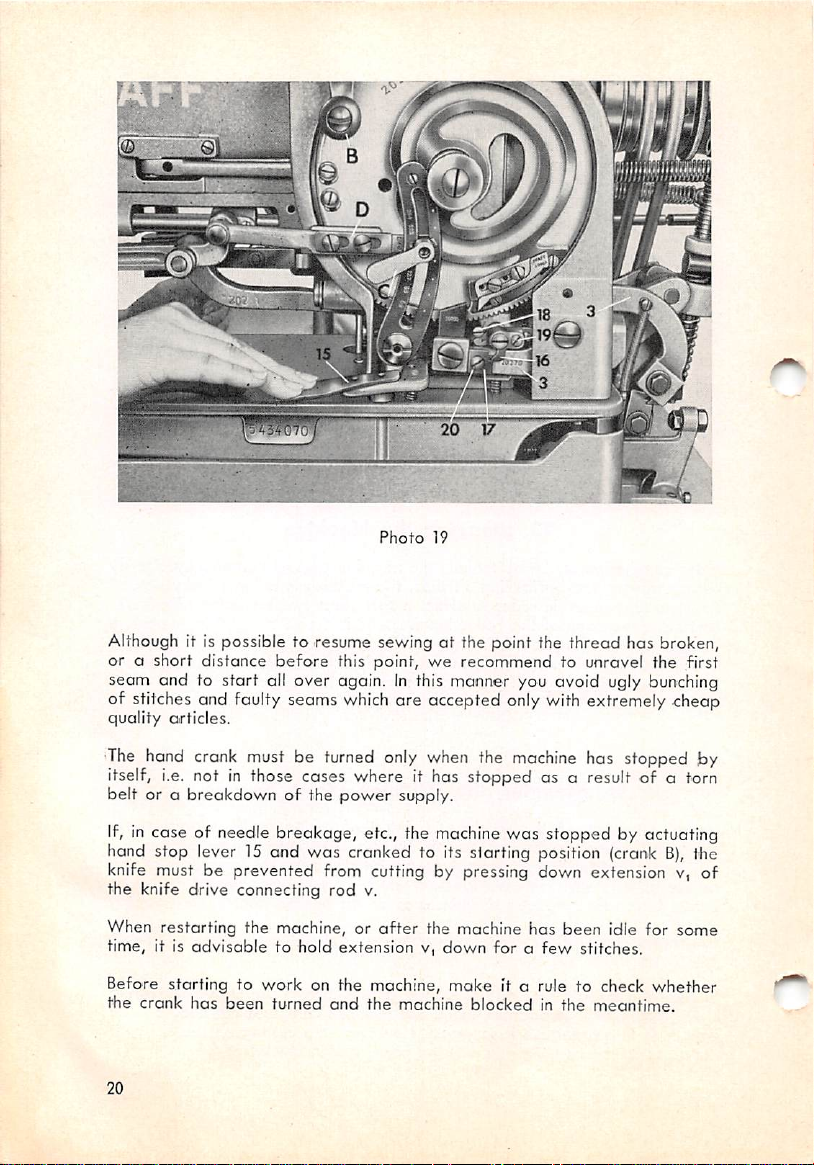

Instant stopping of the

Important when thread jams

the

machine

in

Machine

during

While

Sewing

the sewing cycle is particularly

the hook race or the needle breaks

ios,

otherwise, the fabric or the hook would be damaged by fragments of the

needle or its

would be easily

stump.

damaged

This

is especially essential with delicate fabrics

by punctures of the needle stub.

which

The machine is stopped by quickly pressing down hand stop lever 15 twice

(Photo

19).

case

the

In

bobbin

runs

outofthread

or

the

thread

breaks

while

sewing

the buttonhole, it is possible to let the machine complete the needle cycle

until it is in starting position again. However, the cutting of the knife

the close of the needle cycle must be

prevented

in any case.

at

19

Page 22

Photo

19

Although it is possible to resume sewing at the point the thread has broken,

or a short distance

before

this point,

we

recommend to unravel the first

seem and to start all over again.Inthis manner you avoid ugly bunching

of stitches and faulty seams which are accepted only with extremely cheap

quality

•The

articles.

hand crank must be turned only when the

machine

has stopped by

itself, i.e. not in those cases where it has stopped as a resultofa torn

belt

or a

breakdown

of the

power

supply.

If, in cose of needle breakage, etc., the machine was stopped by actuating

hand stop lever 15 and was cranked to Its sfarting position (crank

B),

the

knife must be prevented from cutting by pressing down extension v, of

the knife drive connecting rod v.

When

restarting

time, it is

the machine, or

advisable

to hold

after

extensionv,down

the machine

for a

has

few

been

stitches.

idle for

some

Before storting to

the

crank

has

been

20

work

on the machine,

turned

and

the

machine

make

It a rule to check

blockedinthe

whether

meantime.

Page 23

Photo

Photo

20

21

Blocking of the machine

the

crank

was

of

connecting

lever Hj by

turned which

rodvnot

set

collar x (Photo 28).

may

occur when it did not

caused

being

the knife to cut

locked, it is

pressed

stop

automatically

prematurely.

against

and

As a

result

knife driving

21

Page 24

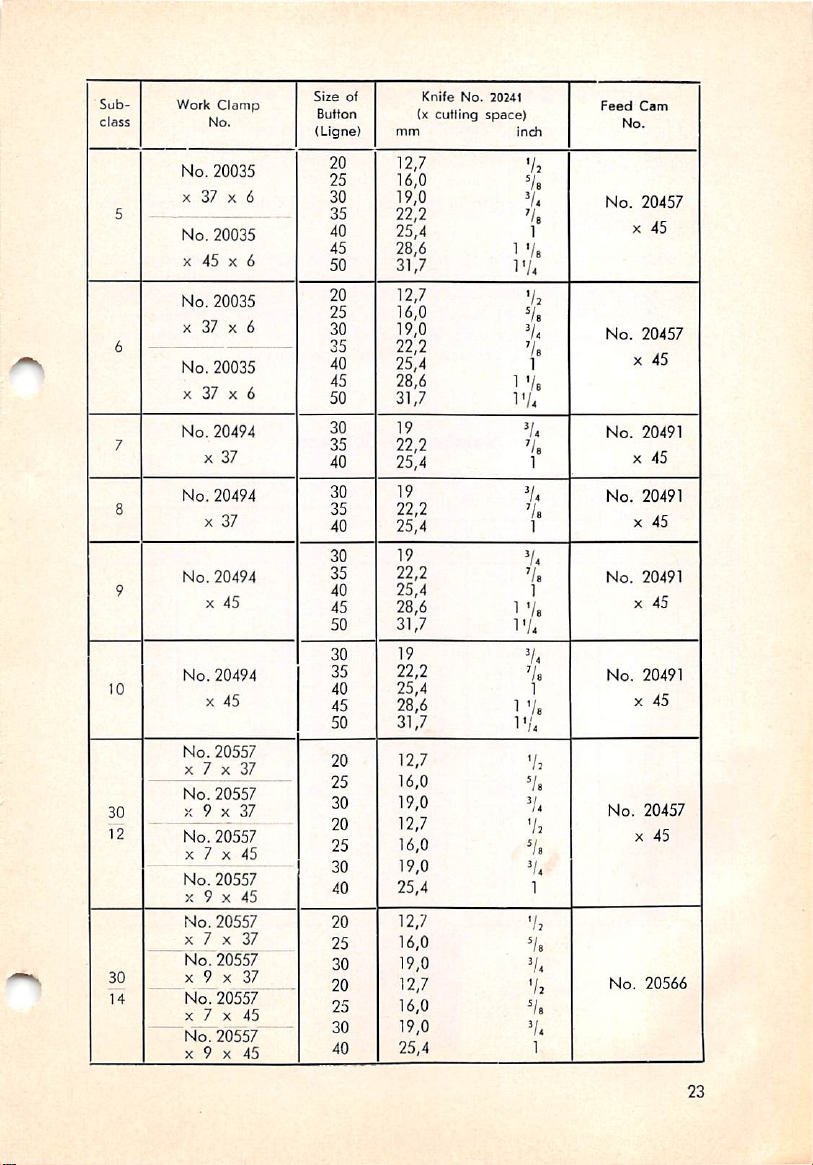

15.

Regulating

the

Length

of

Buttonhole

To regulate the length of the buttonhole, loosen locking lever C (Photo 21)

and

move

feed

required.

creases;

When

when

driving

moving

moving it

rod

D in the slot of

rod

D up, lengthwise

down,

the lengthofbuttonhole

feed

regulatorEas

travelofthe

may

work

clamp

decreases.

be,

in

To facilitate this setting, feed regulator E is provided with a graduatfon

whose

numbers Indicate the length of the cut in inches

buttonhole knives

are

marked occordingly.

and

millimeters. The

The length of buttonhole (length of buttonhole knife blade) in relation to

the

sizeofthe

Sub

class

Work

No.

button

usedisshowninthe

Clamp

Size

Button

(Ligne)

table

below:

of

mm

(x

Knife

cutting

No.

20241

space)

incti

Feed

Cam

No.

10

No.

20401

X28 X

1

2

3

4

4,5

No.

20035

X37X 5

No.

20035

X37X 5

No.

20035

X37X 6

No.

20035

X37X 6

No.

20035

X45X 6

No.

20035

X45X 6

No.

20035

X55X 6

15

20

25

30

35

40

10

15

20

25

30

35

40

20

25

30

35

40

45

50

35

40

45

50

55

60

62

6,4

9,6

12,7

V«

Va

1/2

16,0 V,

19,0 V-

22,2 Va

25,4 1

6,4

9,6

12,7 V:

Va

Va

16,0

19,0 ^4

22,2 '/e

25,4 1

12,7

V2

16.0

19,0

22,2 7a

25,4 1

28.6 1

Va

31.7 IV,

22,2

25,4 1

28.6 1

Va

Va

31.7 IV.

35.0 1 Va

38.1 1 Vi

39,7 1 V.a

No.

No.

No.

No.

20226

X

20226

X

20226

X

20226

X

40

40

53

53

22

Page 25

Sub

class

Size

Work

Clamp

No.

No.

20035

5

6

7

8

9

10

30

12

30

14

X37X 6

No.

20035

X45X 6

No.

20035

X37X 6

No.

20035

X37X 6

No.

20494

X

37

No.

20494

X 37

No.

20494

X

45

No.

20494

X

45

No.

20557

X 7 X

No.

20557

X 9 X

No.

20557

X 7 X

No.

20557

X 9 X

No.

20557

X 7 X

No.

20557

X 9 X 37

No.

20557

X 7 X

37

37

45

45

37

45

N^20557

X 9 X

45

of

Button

(Ligne)

20

25

30

35

40

45

50

20

25

30

35

40

45

50

30

35

40

30

35

40

30

35

40

45

50

30

35

40

45

50

20

25

30

20

25

30

40

20

25

30

20

25

30

40

Knife

No.

(x cutting

mm

2024t

space]

Indi

12,7 V:

16,0

19,0

22,2

25,4 1

28.6 1

5/8

5/8

'/.

Vb

31.7 VU

12,7

'/,

16,0 5/

19,0 5/

22,2

25,4

^/8

28.6 1

31.7 IV.

19

V4

22,2 V,

25,4 1

19 V.

22,2

25,4 1

19 V.

22,2

25,4 1

Vb

28.6 1

31.7 IV.

19 V.

22,2

25,4 1

28.6 1

31.7 IV.

12,7 %

16,0

19,0 V.

12,7 V:

16,0 V.

19,0 V.

25,4

12,7 V,

16,0

19,0 V.

12,7

16,0

19,0 V.

25,4 1

1

Ve

Vb

Vb

Vb

Vb

Vb

Va

Feed

Cam

No.

No.

20457

X

45

No.

20457

45

X

No.

20491

X

45

No.

20491

X

45

No.

20491

X

45

No.

20491

X

45

No.

20457

X

45

1

No.

20566

23

Page 26

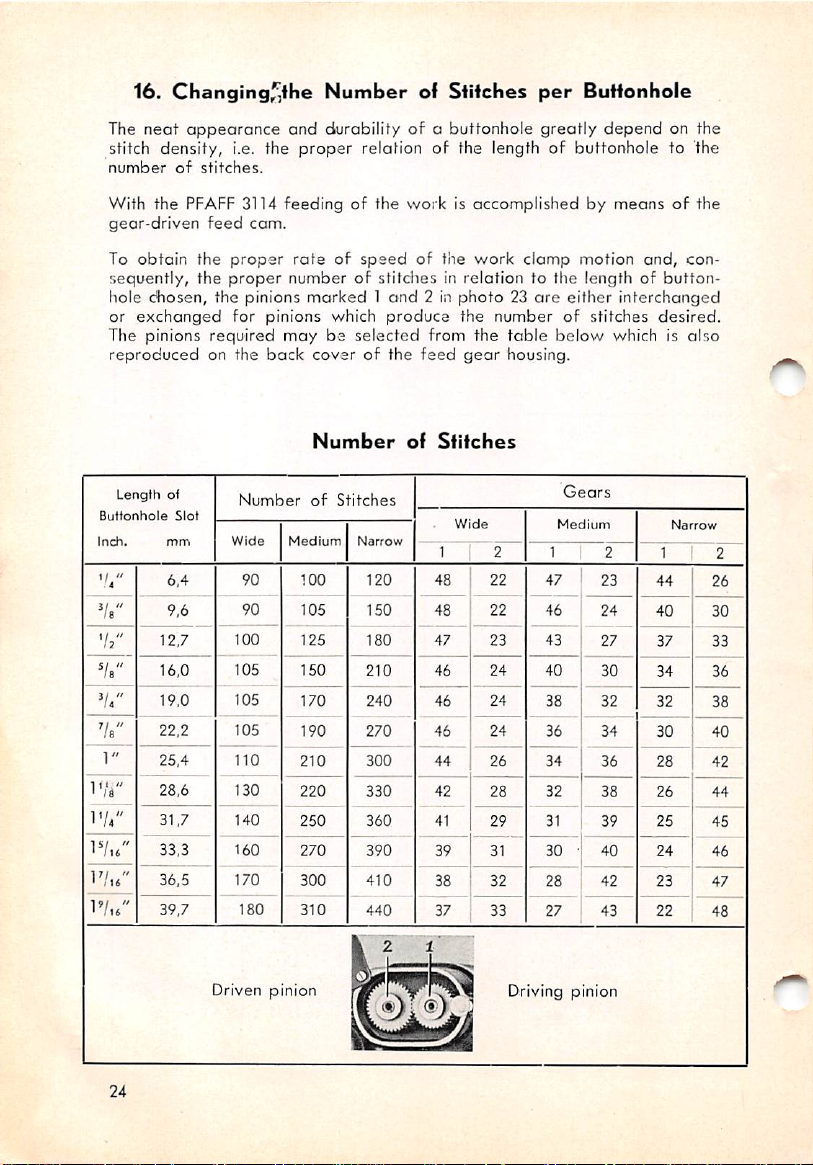

16. Changingf^the

The

neat

stitch density, i.e. the

number

With

gear-driven

To

sequently, the

hole chosen, the pinions

or

The pinions

reproduced

appearance

of

stitches.

the

PFAFF 3114

obtain

the

exchanged

feed

cam.

proper

proper

for pinions which

required

on the

back

Number

and

durability of a buttonhole

proper

feedingofthe

rateofspeed

number of

marked1and

ol

relation of the length of buttonhole to 'the

workisaccomplishedbymeansofthe

of tlie

stitches

2 in

produce

maybeselected

cover

of the

from the

feed

Stifches

work

per

greatly

clamp

Buttonhole

depend

motion

in relation to the length of

photo23are

the

number

table

gear

housing.

either

of stitches

below

which is

interchanged

on the

and,

button

desired.

con

also

Inch.

V'/'

'/?"

Vs"

V/'

Vb"

1"

1'/^"

1'//'

IV,b"

1'/ib"

IV,b"

Length

ot

mm

6.4

9,6

12,7

16,0

19,0

22,2

25.4

28,6

31,7

33,3

36.5

39,7

Number

Wide

Medium

90

90

100

105

105

105

110

130

140

160

170

180

Driven pinion

Number

of

100

105

125

150

170

190

210

220

250

270

300

310

Stitches

Narrow

120

150

180

210

240

270

300

330

360

390

410

440

If

of

Sfitches

1

48

48

47

46

46

46

44

42

41

39

38

37 33

J

Gears

Medium

2 1 2

22

47

22

46

23

43

24

40

24

38

24

36

34

26

32

28

29

31

31

30

-

32

28

27

Driving pinion

Narrow

2

1

23

44

26

24

40

30

27

37

33

30

34

36

32

32

38

34

30

40

36

28

42

38

26

44

39

25

45

40

24

46

42

23

47

22

43

48

24

Page 27

The number of teeth given in any two of the adjoining columns must

up to 70. The driving

the

operator

(Photo 23).

pinion

No. 1 should be mounted on the stud close to

add

After swinging up the cover, the pinions can be easily pulled

and

interchangeable

holds the

feed

feed

gears

geors in position on their studs should be

mounted without tools. The cover which

off

kept

the studs

closed while

sewing so that the pinions cannot fall out.

17.

Changing

The stitch

regulatedatlever H (Photo

width

for the

ihe

Widfh of

bartocking

22).

The upper thumb screw J serves to regulate

and

Bar

and

buttonhole

Parallel

stitches (parallels) is

the width of bight for the buttonhole parallel, and the lower thumb screw K

for

the

bar.

Turn

them

Turn them

inwardly

outwardly

for

wider

for

stitch

norrower

width

stitch

width

\

N,^.WVf

Photo

j'

22

25

Page 28

18.

Adjusting

The position of the buttonhole in relation to the cutting space is adjusted

as

follows:

The

zero

vibrates

When the amount of needle vibration is reduced to zero by turning screw J

out, i.e. when the needle

either parallel of the buttonhole on its right.

The knife must cut the slash exactly in the middle of the buttonhole.

In

the knife is bent. If not, the position of the parollels must be corrected.

This

line of the needle

from

case

the cut is

is done by means of screw N and N, on lever M (Photo

right to

somewhat

the

Position

to

left

olways.

does

of

the

Buttonhole

the

Cutting

bar

vibration lies on the right, i.e. the needlef

not

off

center,

Space

vibrateatall, the needle

first check

whether

in

the

22).Byturning

Relation

penetrates

needle

or

the lower screw N inwardly, the right parallel is moved to the left; by

turning it outwardly, to the right. Turninginwardly the upper screw N, wili

move the left parallel to the left; turning it outwardly, to the right.

19.

Regulating

fhe

Distance

(Photo

22)

Between

Parallels

As follows from the preceding section, the distance between the parallels

of the buttonhole can be regulated by means of screws N and N,. After

the regulation tighten the nuts of both screws x securely.

The distance

resultinan

When

inserting

the knife up in the knife holder as far as it

When

cutting

between

ugly

20.

a new

the fabric, the

the poralleis must not be

appearance of the buttonhole after

Exchanging

buttonhole

knife

the

knife,

should

Buttonhole

loosen

too

screw b

will

go.

descend far

wideasthis would

cutting

open.

Knife

(Photo

17)

end

enough

so that its

push

lowest point (front edge) is .04" below the needle plate. If the knife is

worn by grinding, it must be

26

set

lower accordingly.

Page 29

I

Photo

23

21.

Proper

The

knife

holderissetinsuchamonner

between

hole, and

If, in spite of the above, the knife should injure a bar, the knife holder must

be adjusted

the knife

that

the buttonhole will be cut open all the

after

loosening set screws c and d (Photo

and

Position

the

needle

ol

Knife

that

irregardlessofthe lengthofbutton

there

Holder

willbea

way

clearance

to the bars.

17).

of

22.

The

Needle

When depressing the left treadle after

Thread

finishing

Trimmer

the buttonhole, the needle

thread Is automatically trapped by the trapper spring, which is mounted

on the needle

hole

before

thread

the

trimmer,

work

clampisraised.

and

is cut on the top surface of the button

When re-starting the machine for the next buttonhole, the needle thread

trimmer

stitch

firstismoved

across

the

loose

back

and

endofthread.

thentothe

leftsothat

the

needle

can

After tacking the end, both the trimmer and the trapper spring open and

release

parallel of the next buttonhole.

the

thread

so

thatitmay

be completely covered by the first

27

Page 30

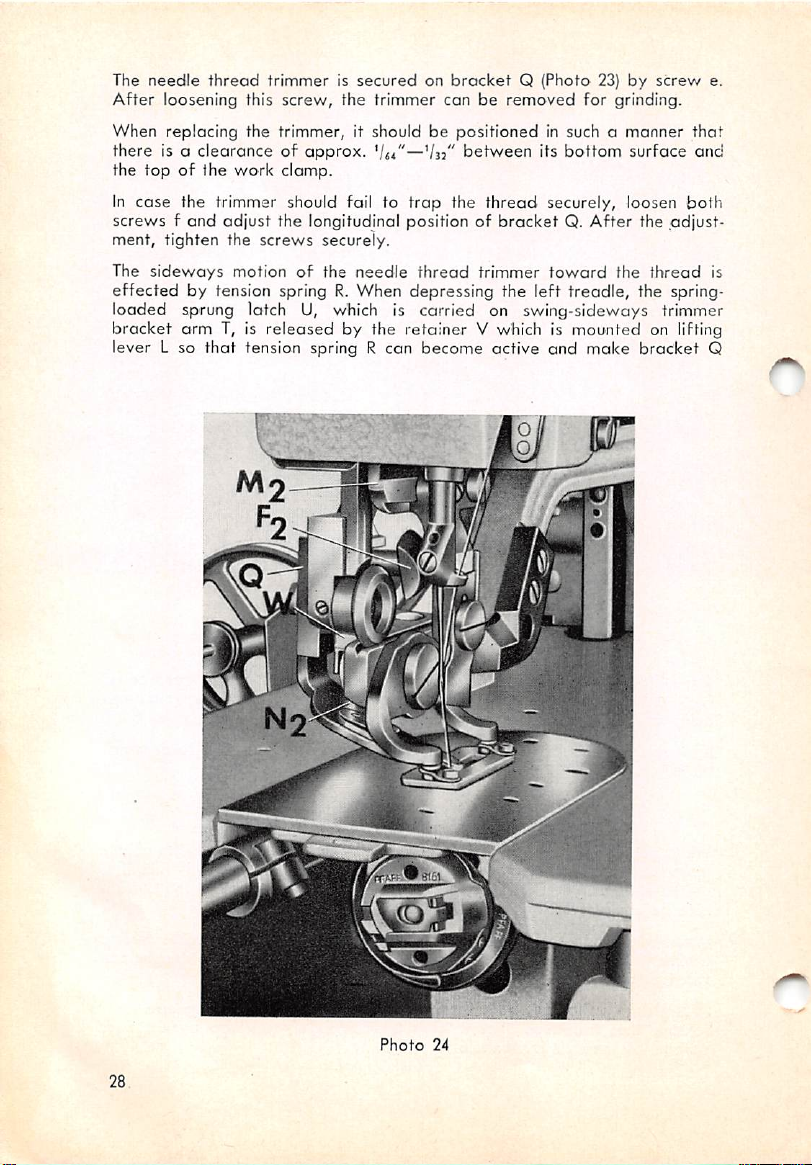

The

needle

After

When replacing the trimmer, it should be

there

the

top

case

In

screwsfand

thread

loosening this

is a

clearanceofapprox.

of the

the trimmer should fail to

trimmerissecuredonbrocketQ(Photo

screw,

work

clomp.

adjust

the longitudinal position of

the trimmer conberemoved

'lit

—'/jz

trap

positioned

between

the

in such o

its

thread

securely, loosen

bracketQ.After

23)byscrew

for grinding.

bottom

manner

surface

that

and

both

the .adjust

ment, tighten the screws securely.

The

sideways

effected

motionofthe

needle

thread

trimmer

by tension spring R. When depressing the left

toward

treadle,

the

thread

the spring-

loaded sprung latch U, which is carried on swing-sideways trimmer

bracket

lever L so

arm

T, is

that

released

tension spring R can

by the retainer V which is mounted on lifting

become

active

and

make

bracket

e.

is

Q

Photo

24

28

Page 31

and

the

trimmer

vertical

trimmer

the

cam

strikes

trimmer

When re-storting the machine, the trimmer

pushed sufficiently

guide W, so

Sprung latch U which yields

Vj"

below

Retainer V must be

between

sprung latch U

adjustmentisrequired,

N2 (Photo

the

closes

that

the

top

snap

back

and

far

forword

24}

sideWof

the

over

toward

on the

threadistrapped

movable

cam

to the left by the

the sprung lotch U will

downwardly

surface

set

of the

in such a

and

loosen

retainerbyangle

way

retainer

that

V when the trimmer is

set

screwOiand

the

needle

bladeofthe

guide

and

bracket

again

thread.

Thereby

needle

W, (Photo 23). As a

cut.

Q is pulled

slanted

be caught by

side

of

retainer

should be held in position

X (Photo 23).

there will be a

clearanceof.04"

retracted.

move

the

retainerVas

thread

result,

back

the .cam

about

the

ond

mayberequired.

To avoid

early, guide screw Fj (Photo 24)of

andisdisposed

bar

striking

Mj will

the

damage

force

trimmer.

to the needle

in such a

the trimmer

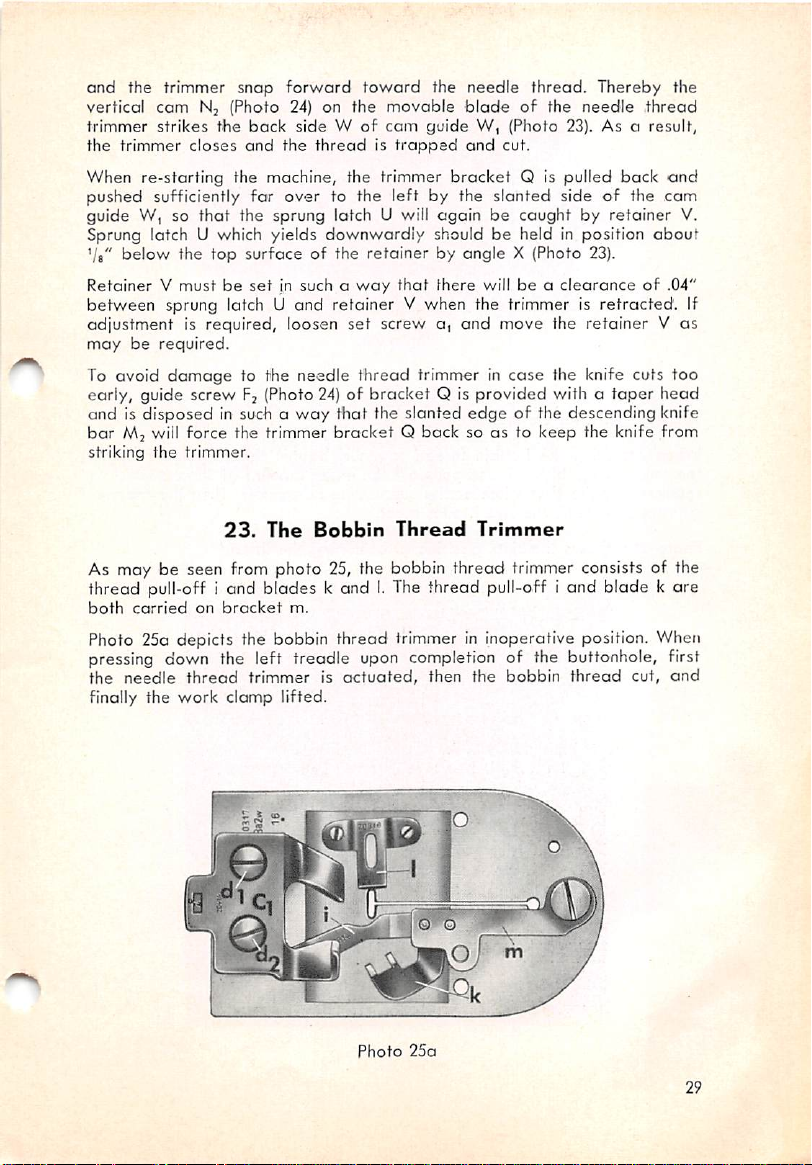

23.

The

way

Bobbin

thread

bracket

that

the slanted

bracket

trimmer in

Q is

provided

edge

Q bock soasto

Thread

Trimmer

case

the knife cuts

with a

taper

head

of the descending knife

keep

the knife from

too

As may be seen from photo 25, the bobbin thread trimmer consists of the

thread pull-off i and blades k andI.The thread pull-off i and blade k ore

both

carried

on

bracket

m.

Photo 25a depicts the bobbin thread trimmer in inoperative position. When

pressing down the left treadle upon completion of the buttonhole, first

the

needle

finally the work clamp lifted.

thread

trimmerisactuated,

then

the

bobbin

thread

cut,

and

V.

If

Photo

25a

29

Page 32

Photo

25b

This

arrangement causes the short end of needle thread to be pulled down

which is left

after

cutting.

When actuating the bobbin thread trimmer, bobbin thread pull-off i pulls

the thread over blade 1 and pulls off the exact amount of thread which is

required for the first stitch of the succeeding buttonhole. Then the trimmer

cuts

the

thread

os

the

two

blades

meet.

Photo 25b shows the final position

30

Photo

after

cutting the thread.

26

Page 33

For

properly

blades

screw

When

bladeisapprox.

injury to

The

compact

needle

loosen

the

mechanism,

enters

24.

To

avoid

first stitchofthe

setting

the

should

n (Photo 26)

exchanging

the

overlap

needle

bobbin

about

and

turn the

blade1,make

—Vu"

thread.

thread

.04" in their final position. To

away

trimmer it should be

crankasmaybeappropriate.

sure

that

the

the cutting

needle

from

disposition of the trimmer mechanism on the underside of the

plate

facilitates removal in

screw

o (Photo 26)

the

make

slotofthe

Pulling

unthreadingofthe

next

sure

bobbin

OK

buttonhole

and

the

the

the

that

case

Needle

Top

needle,

case

the knives need grinding. Simply

needle

the

bobbin

position

plate

bracket.

set

case

Thread

Tension

the

amountofthread

must

be

pulled

Sp, prior to cutting the needle thread. This action is

pin p which is

(Photo

27).

mounted

on lug q,

and

carried

on tension

edge

hole in

screw.

position

and

off

by

performed

Releasing

noted

that

of

the

replacing

properly

top

both

loosen

new

for the

tension

adjust,

ordertoprevent

When

lug

needed

the

by pull-off

release

lever q

Photo

27

Upon

stop

starting the

motion

lever 1

machine

(Photo

by pressing down the right treadle, the

28)

actuates connecting rod s and

tension

hinged

release

lever q whose upper end moves forward to release the pulled-off thread.

Simultaneously, the

top

tension Spi is

engaged.

31

Page 34

Photo

28

Shortly

returned

required

release

tension.

"While the machine is

raised

drive

meansofcrank B,

There should be a

rodVand

32

before

the

machine

to its initial position so

from

top

leverqmoves

tension

q,.Atthe

under

25.

inoperative,

position by locking lever S (Photo 23)

lever

assembly

cannotbeblocked

and

tripping

clearanceof.02"—.04"

slide

collar

x,.

stops,

tension

that

pin p

the

The

same

tension

Knife

(Photo 28)

knife drive connecting

rod

w with

release

can

pull

time

release

Action

and

angleX.Thereby

v/hen the

set

collar x

between

lever

q is

automatically

amountofthread

topoftension

releases

rod

v is held in

camisturned

can

move

the

pin

off

the

lug on

and

feed

knife drive connecting

the

top

the knife

by

freely.

Page 35

When

starling

rod Vwhich falls

buttonhole,

the

machine, locking lever S

and

tripping

pushes slide collar x,

be

pulled

onto

the

rod w

leverHjand

and

somewhat

set

collar x return, driving block z can

actuate

rests

on slide collar Shortly

rod

w is

tripped

away

from the machine until connecting rod v can

smaller

the

knife.

by the

set

collarxby

releases

feed

cam

knife drive connecting

before

completing the

and

with

set

collar x

springy.When

engage

tripping

knife driving

26.

Dismantling

The

PFAFF

3114

hook

hasadivided

To

dismantle

follows:

rest

pin. Remove the bobbin case

two

hook gib screws a, and 02 on the

with the

Igib can be

(Photo 30)

is in line with

the

hook

out.

for

overtothe

Seize

the

Tilt

the

machine

screw

driver (Photo 29).

swung

and

turn the driving pulley until

pointGof

Photo

29

the

Hook

bobbin

cleaningorremoving

cap

After

the

bobbin

left

case.

and

restiton

and

turn the driving pulley until the

back

of the hook can be reached

removing

case

base

pointSof

hook.

of

thread,

the

both

screws,

by its

the bobbin

wooden

center

proceed

machine

the hook

stud A,

case

as

base

33

Page 36

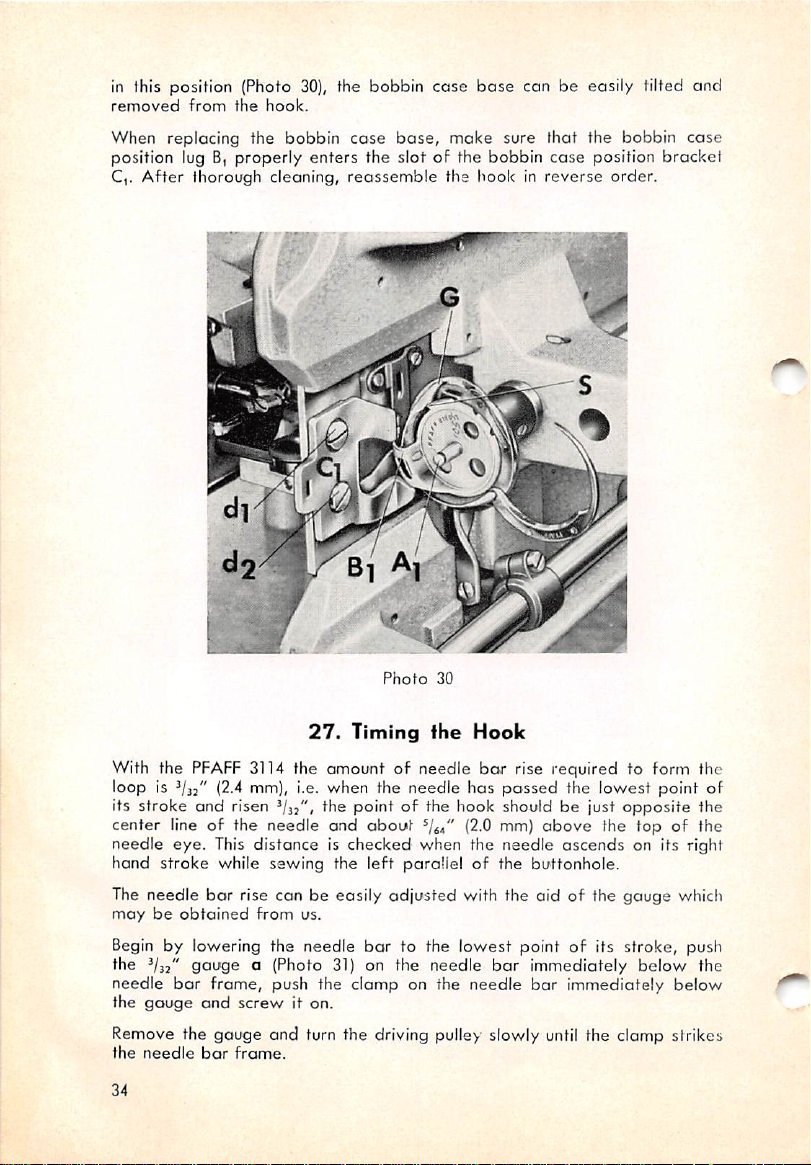

in this position {Photo 30), the bobbin

removed

When

from

the

replacing the

hook.

bobbin

case

base,

case

make

base

con be easily tilted

sure

that

the

bobbin

and

cose

position lug B, properly enters the slot of the bobbin case position bracket

C,.

After

thorough cleaning,

reassemble

the hook in

reverse

order.

Photo

30

27.

Timing

With the

loop is (2,4 mm), i.e. when the needle has

its

center line of the needle

needle eye. This distance is checked when the needle

hand

The needle

maybeobtained

Begin by lowering the needle

the

needle

the

stroke

stroke

gauge

PFAFF

3114 the amount of needle

end

risen the

while

sewing

bor

rise can be easily

from

pointofthe hook shouldbejust

and

about

the

left

us.

bar

gauge

bar

a (Photo 31) on the needle

frame, push the clamp on the needle

and

screw

it on.

the

Hook

(2.0 mm)

parollel of the

adjusted

to the

with the aid of the

lowest

bor

rise required to form the

passed

the lowest point of

above

opposite

the top of the

ascends

buttonhole.

gauge

point of its stroke, push

bar

immediately

bar

immediately

the

on its right

which

below

the

below

Remove the gauge and turn the driving pulley slowly until the clamp strikes

the

needle

bar

frame.

34

Page 37

Photo

31

To turn the

above (point of hook about

screwsb(and

The

needle

hook

on- the hook

bj (Photo 26).

barissetatthe

shaft

^44"

correct

until it is in the position

above top of needle eye), loosen both set

height

when

the

bottomofthe

described

eye is flush with the top edge of the needle guard while the needle

isatthe

The

ensure

point of the hook

In

hook

pull

readjustment of the position

together

lowest

sideways

that

pointofits

adjustment should be

there

is a

and

stroke.

clearance

the needle.

of

made

about

with particular

.004"

(0.1

mm)

care

between

so as to

order to exchange the hook, loosen both set screws c, andCjon the

shaft

collor (Photo 26), remove bobbin

case

position

brackerC,and

the hook forward out of its mount on the shaft. To save lengthwise

with its

base

bracket,

by loosening screws d,

it is

advisable

and

dj.

to remove

needle

bar

the

same

35

Page 38

i

Photo

32

36

Page 39

28.

Regulating

The

amountofpressuretobe

occordcnce

thumb

such a

fabric

with

sorewontopofthe machine

mannerasto

puckeraswellaspoor

the

ensure

29.

To

absorb

stop

of

the

The

position and the needle

highest

the

motion, a

machine.

machineisblocked

pointofits

momentum

powerful

stroke.

the

material

perfect

Changing

of

buffer

when

bar

has

Pressure

exerted

to

be

sewn.Bytightening

arm,

feeding

buttonhole

the

the

machine

spring is

the

take-up

descended

by

the

the

seams.

Butter

provided

on

the

Material

work

clomp

pressure

of the

canberegulated

material

Spring

ond

has

about

reduce

almost

the

in the

rear

reached

.118" (3.0 mm) from the

shouldbeset

the

presser

andtoprevent

impact

on

driving pulley

its

highest

in

bar

in

the

The buffer spring is

after

some

causes

take-upinvarying

low

needle

In

ordertoreplace

Dj

and

take

After

ring G,

timeasa

irregular stopping of the machine, leaving the needle

when

the machine

thread

Ei (Photo 32),

off

the hinged

removing the four

and

stop

The new spring is inserted

compressed

To

facilitate

sufficiently to permit inserting the

exposed

resultoffair

positions. Thus it

trimmer.

exchanging the

stops

the

remove

stop

cam H,

broken

motion

set

and

to excessive stress

wear

that

screws

between

may

the

needleisdamagedorbroken

buffer

and

brake

f,,

spring, loosen

f2,,

the

screwsJiand

remove

the

buffer

spring, it is

special wrench which we will furnish on

buffer

spring. As shown in

the rim of the

against

rear

the bearing

stud of the wrench

wrenchinyour

left

the buffer spring, until the Novotex

that

the straight side of the spring

land

screwonstop

and

brake

lever

assembly.

photo

driving pulley

bracket

and

push the wrench on the

hand

33,

and

0|.

Then slide the loose spring

and

pressitstraight

segment

rest

cam

and

cap

ring

insert

turn Ihe pulley until punch M,

faces

and

and

and

tear.Abrokenorworn

occur

e,,

lever

fj and (Photo 32),

broken

two

spring

may

that

the

both

pull

out

assembly.

buffer

rests

Novotex

recommended

order,

a punch info hole L,

together with the new

top

shaft

down,

can be inserted.

the

Novotex

mount the hinged

slacken or

needle

tension springs

hinge

spring.

Kt (Photo 33)

bar

pin F,,

take

bar

break

spring

and

by the

off

Ihc

is so

end

cap

and

segment Jj.

to use a

located

rest

on

on

resl^

ihe

hub. Take the

thus compressir^g

Make

sure

segment. Replace

stop

motion

37

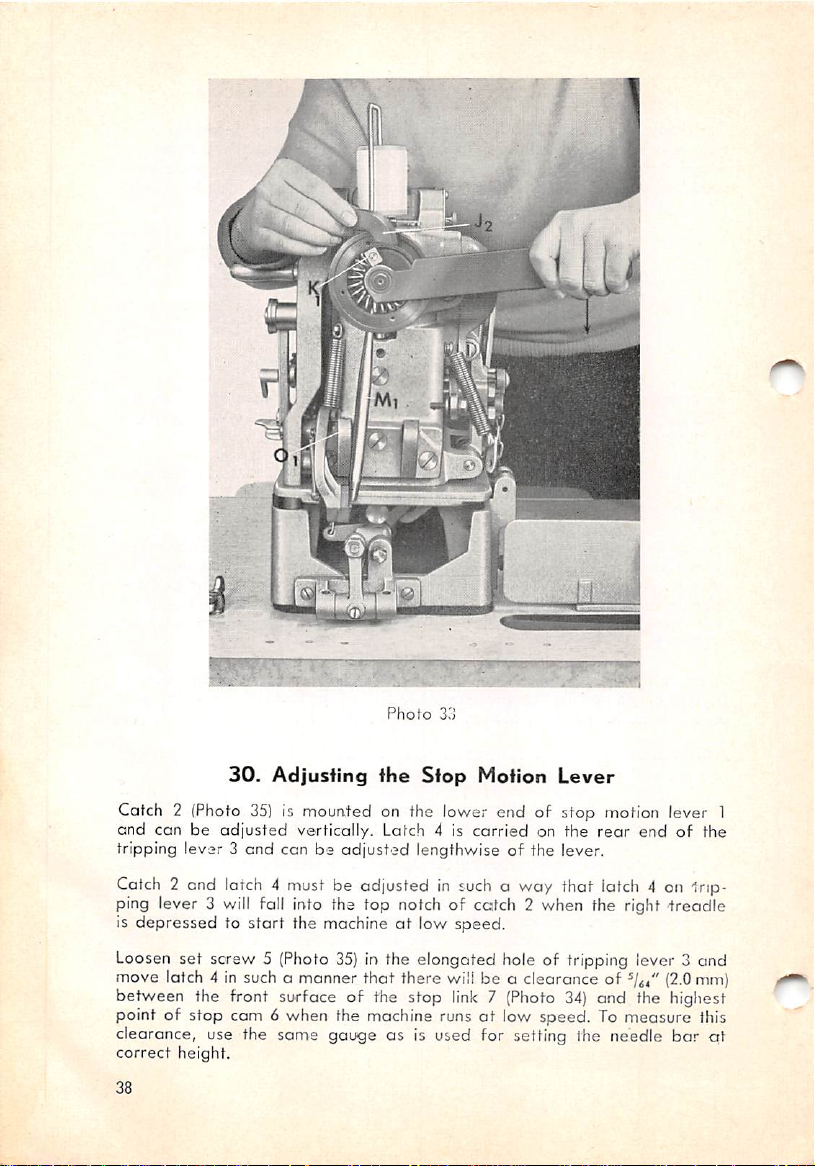

Page 40

Photo

33

30.

Adjusting

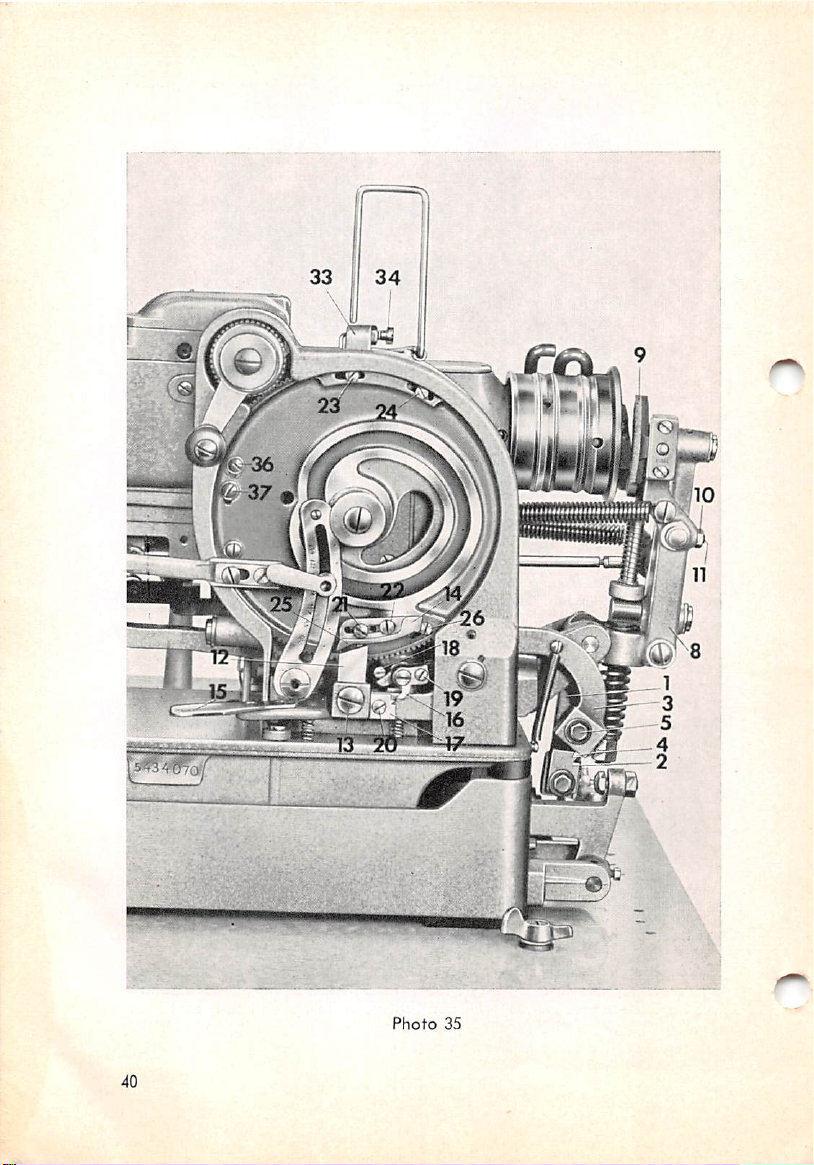

Catch 2 (Photo

and con be

tripping lever 3 end can be

35)

odjusted

is mounted on the lower end of stop motion lever 1

vertically. Latch 4 is

fhe

adjusted

Stop

Motion

carried

lengthwise of the lever.

Lever

on the

rear

endofthe

Catch 2 and latch 4 must be adjusted in such a way that latch 4 on trip

ping lever 3 will fall into the top notch of catch 2 when the right

is

depressedtostart

the machineatlow speed.

treadle

Loosen

move latch 4 in such a manner that there will be a clearance of

between the front surface of the stop link 7 (Photo

point of

set

screw 5 (Photo

stop

cam 6 when the machine runsatlow

35)

in the elongated hole of tripping lever 3 and

34)

^1^,"

and the highest

speed.Tomeasure

clearance, use the same gauge as is used for setting the needle

correct

38

height.

(2.0

bar

mm)

this

at

Page 41

In

case

the

stop

yield sufficiently when falling into

31.

Brake

lever

(inxisssf

facesofbrake

when

and

regulate

8 (Photo 35)

the machine runsatlow

shoe9and

set

screw

too

Adjusting

mustbeadjusted

the

driving

11 in the middleofbrake

Phofo

34

dose

to the

the

stop

the

Brake

pulley

speed.Toset

1

stop

ccm, the former connot

cam

and

may

break.

Lever

in such a

ore

about

this

manner

.275" (7.0 mm)

distance,

lever 8.

that

itie

sur

loosen nut 10

aport

Brake lever 8 is in the

driving pulley

Tripping lever 3 (Photo 35) should be

has

been

another

properly

proper

32.

Adjusting

setasinstructed in Section 30.

position if it can be pulled

(2.0 mm)

when

the

adjusted

Tripping

the machine is

Lever

only

after

inoperative.

stop

Tripping dog 12 is carried on the front end of tripping lever 3.

ing screw 13, this tripping

willbea

clearanceof.04" (1.0 mm)

segment 14 when the machine

dog

should be

between

has

stopped

adjusted

in height so

its tip

and

that

In this position, latch 4 of

tripping lever 3 should rest on catch 2

away

from the

motion lever 1

After

loosen

that

of tripping

there

39

Page 42

w

Photo

35

40

Page 43

When running the machine of low speed, latch 4 must enter the top notch

of catch 2;athigh

To

adjust

switch

position

the

off

the

showninphoto

speed,

distance

machine

33.

Adjusting

it must fall into the lower notch.

between

40.

and

the tripping

turn

the

the

crank

Hand

dog

until

Stop

and

the tripping

the

Lever

feed

cam

segment,

is in

the

Hand stop lever 15 (Photo

35)

carries a spring-loaded latch 16 which

p>ust

engage the vertically adjustable catch 17 mounted on the tripping lever 3.

Stud 18 is

ways

For adjustment, loosen

sideways as may be required to ensure

selyontime.

After loosening screw 20, catch 17 can be adjusted in height so

disposed

motionofthe

on the left of latch 16 which serves to limit the side

latch.

set

screw 19 In the

elongated

that

slot and move latch 16

it will engage catch 17 preci

that

latch 16

wilt engage in the lower notch of catch 17 and the speed of the machine

will be reduced to half upon pressing down hand stop lever 15 once (while

machine is switched on). When in this position, latch 4 of tripping lever 3

is engaged in the top notch of catch 2 (Photo

35).

Upon depressing hand

i

Photo

m

36

41

Page 44

stop

(ever 15 the

tripping lever 3 is tripped

stops

the

machine.

34.

second

time, latch 16 falls into the

Adjusting

and

the

the

stop

Stop

motion

Tripping

and

top

notch of

brake

lever assembly '/a

Segment

catch

17,

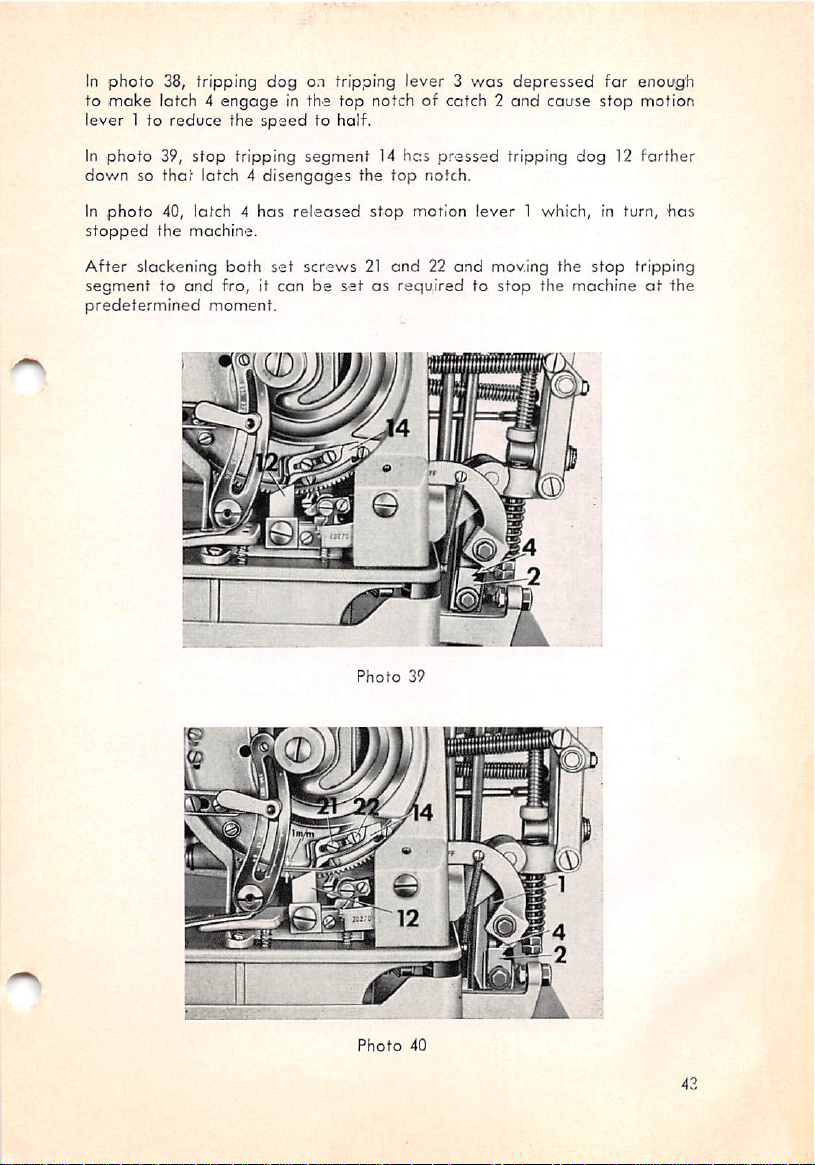

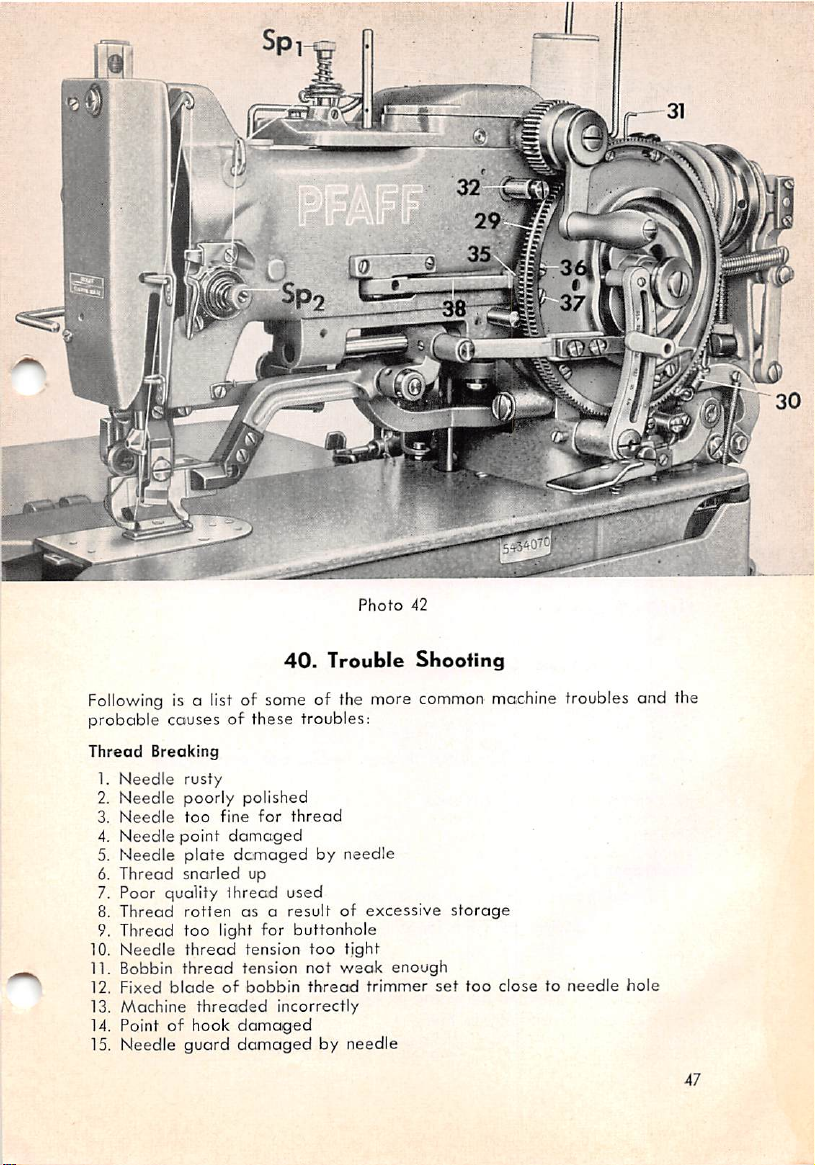

The function of the stop tripping segment may be seen from photos 37,

38, 39

and

40.

In photo 37, the front edge of stop tripping segment 14 on the feed cam,

which

moves counter-clockwise, has reached tripping dog

12.

Photo

3/

Photo

33

42

Page 45

In

photo

to moke iotch 4

lever 1 to

In

downsothat

In

stopped

After

segmenttoand

predetermined

38, tripping dog on tripping lever 3

reduce

photo

39,

stop

photo

40, latch 4

the machine.

slackening

engage

latch4disengages

fro, it conbesetasrequiredtostop

moment.

in the top notch of catch 2

the

speed

to half.

tripping

both

segment14has

the

has

released

set

screws21and22and

top

stop

was

pressed

notch.

motion

n.

depressed

and

tripping

lever

1 which, in turn,

moving

the machineatthe

for enoi/g'h

cause

stop

dog12farther

the

stop

nnotion

has

tripping

Photo

39

w

CD

m.

Photo

40

43

Page 46

The

final

bar

stitchofthe

always (see Section

machine has stopped too early

to the left accordingly. Conversely, if the

second

bartack

36).

If the last stitch lies too far to the right, the

must

be

modeinthe

and

tripping segment 14 must be moved

last

stitch lies too far to the left,

middleofthe

the tripping segment must be moved to the right in order to make the

machine

Note

narrow

the

you check first

will

This

would

the machine to

speed

stop

earlier.

that

stop tripping segment 14 must be

limits

as,

feed

cam

sufficetomake

adjustment

cause

first.

may

the

35.

otherwise,

become

whether

calls for

rear

be

necessary. For this reason,werecommend

raising or lowering the position of tripping dog 12

the

machine

great

endoftripping fever 3 tobeswung up too

stopped

Adjusting

retimingofall

stop

soonerorlater.

care

since

abruptly

the

Bar

rather

Tripping

adjusted

other

setting

only within certain

motions controlled by

tripping

than

being

dog12too

shifted

Segment

that

high

far

and

to low

The tripping

control

be

adjustedasrequired.

by

screws23and

After

so

that

segments

the

widthofthe

24,

slackening

these

the sewingofthe

which

bartacking

The tripping

that

for

screws,

bars

are

the

mounted

both

will

conformity with the feeding motion.

The

tripping

that

the

ordertoavoid

in

The tripping

enough to ensure

tely

covered

Lug 27

motion

first

36.

(Photo

of

the

segment

bar

for

will

notbesewn

displacing the first

segment

and

for the

that

the first stitches of the first parallel will be comple

thataneat

Adjusting

22) on

the

needle

barinrelcjtion

the

first

second

appearance

the

topofleverHpermitstoadjust

for making the tying stitches in the

In

ordertoenhance

mustbemade

there

must be

ways

motion of the

by lug 27

of

the

whenithas

buttonhole.

the

in the

appearance

centerofthe

absolutelynosideways

guide

roller for the

reachedaposition

on the

stitches

segment

end

barbyscrews25and

bar

tripping

back

have

for the

commenceatthe

bar

shouldbeadjusted

until

after,

bartacking

bar

Needle

to

end

of

the

end

bartack.

the first

stitches to the left.

should trip the machine

of

the

buttonhole

Bar

the

center

bcwtack.

buttonhole,

When

motionofthe

needle

bctf vibration is thus

conforming to the

of the

elongated

first

segments

proper

Zero

line

the

making

needle

feed

cam

slots

and

barissecured

26 [Photo 35).

canbeadjusted

time

in such a

parallel

willbeobtained.

manner

is finished

Lug

the

the

tying

these

bar.

zero

sideways

buttonhole

stitches

stitches

The side

checked

(center) line

of

last

and

and

can

in

early

44

Page 47

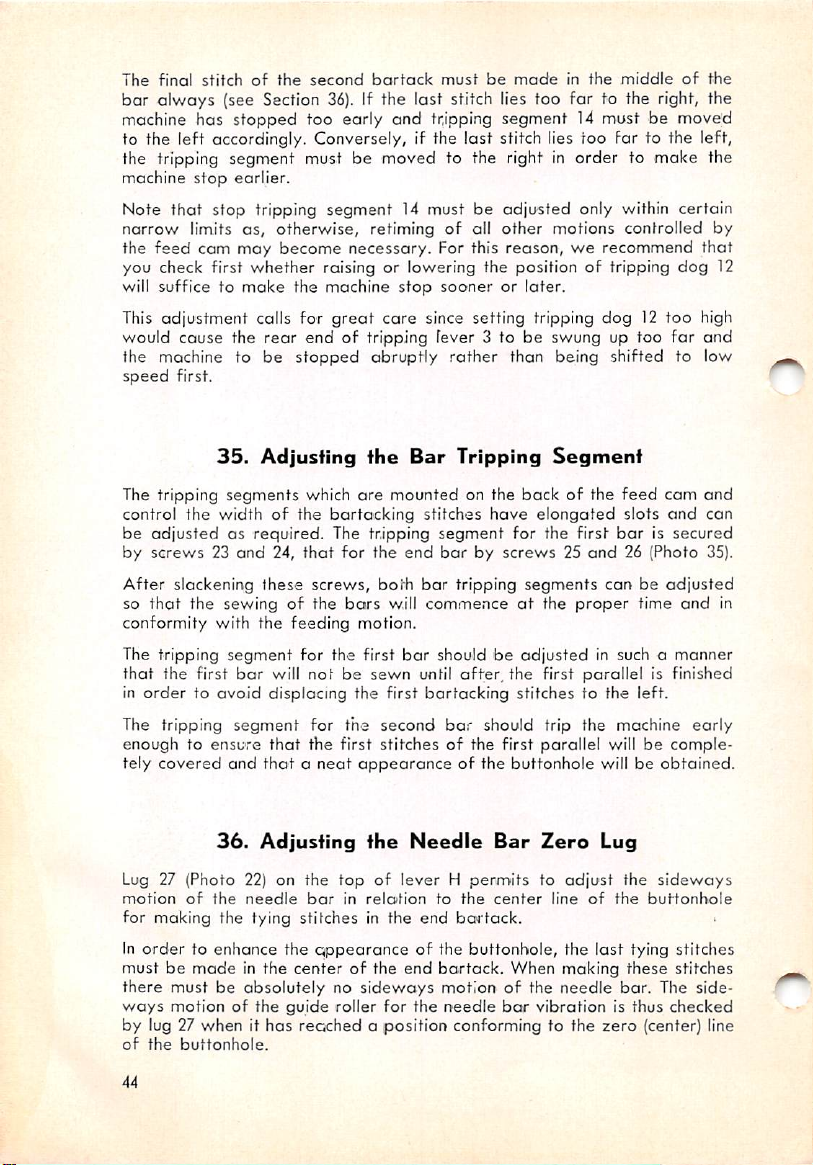

Photo

41

45

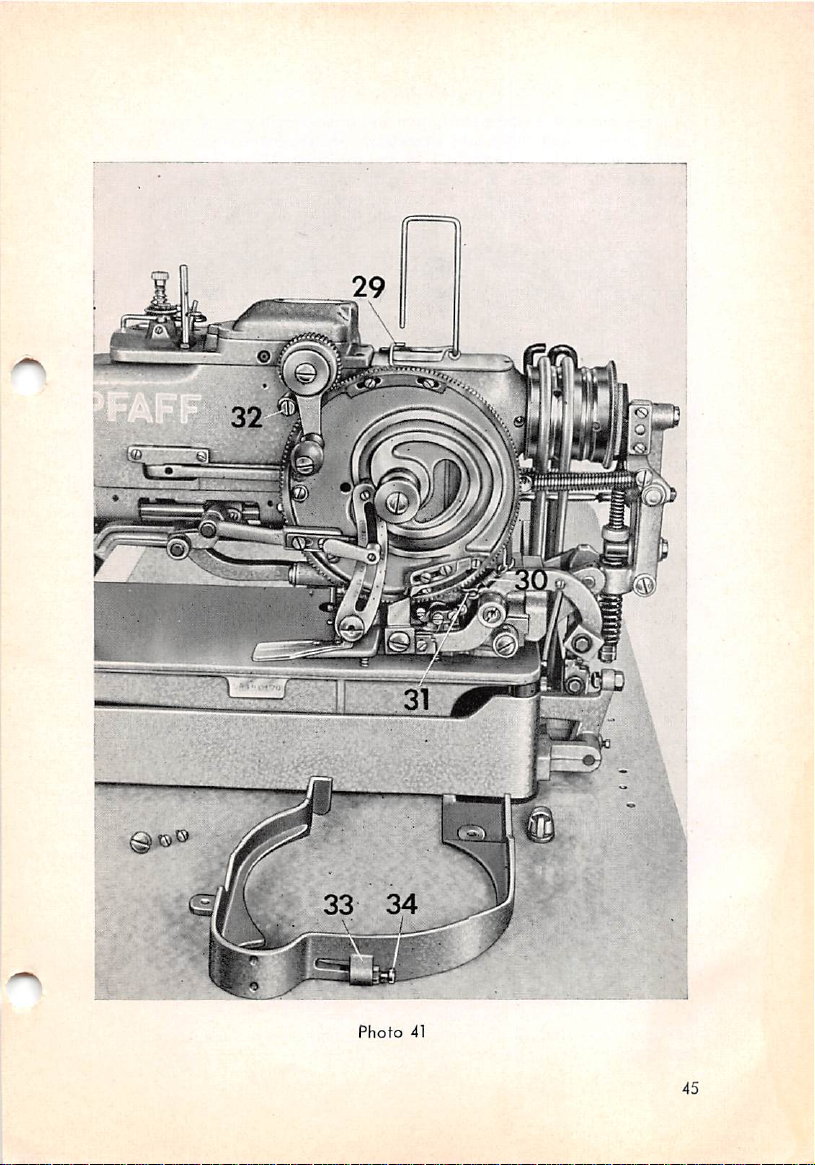

Page 48

To

adjust

the

positionoflug 27,

proceedasfollows:

With the machine switched off, turn the driving pulley bock

hand, let the

of

the

not

affect

until the

the

materialinone

needle

needle

marks.

the position of

needle

stitch into a

bar

vibration is

and

Loosen

the

pieceofstiff

nut 28

lever

H. With nut 28

reducedtozero

same

point.

and

move

Tighten nut 28

paper

lug 27

slackened,

and

and

check the position

backsothatitdoes

the

needle

securely.

and

tap

forth by

on the lug

penetrates

The careful

the

stop

important

In

ordertoretain

be

caused

adjustable

This

connected

toothed

retainer

To

regulate

adjustmentofthe

tripping

prerequisites

segment

37.

the

feed

for

The

zero

and

their

obtaining

Feed

cam

against

lug, the

proper

durable

Cam

any

bartack

reverse

tripping

timing relationships

and

neat

buttonholes.

Brake

movement

by the buffer spring when stopping the machine abruptly, an

brakeisprovidedonthe

brakeismade

by

rimofthe

33

with

the tensionofthe spring, turn

of two wire hooks 29

tension

feed

the

other.

spring

30. This spring is

cam

andisfastened

feed

cam.

and

set

31 (Photo 41) which

contained

to

screw

in a

stud32with

34 of

segments

are

which

and

very

may

are

grooveinthe

one

end

and

retainer

33 on

the cam guard inwardly so that the cam will still turn easily without apply

ing

excessive

38.

Tension Sp^ mustbeautomatically

first tying stitch

the top tension Spi

will

cause

force.

Adjusting

after

the

threads

the

Tension

Release

released

campleting the end bartack.

engaged

which is

to

lock

within

set

for a normal

the

material.

when

Tripping

the machine

This

will leave only

thread

Point

makes

tension

the

and

To-time the release of the tension, loosen screws 36 and 37 and move trip

ping point 35 as moy be

correctly if its tip is

tension

release

lever 38 when the machine stops.

appropriate.

opposite

The tripping point 35 is

adjusted

the center of the straight vertical side of

39.

Adjusting

the

StartinglLever

After starting the machine by depressing the right treadle, starting lever 39

is returned to its initial position by pressure spring 40. Its return motion

is checked by stop screw41which,

in such a manner

that

there will be a clearance of .04"

after

loosening nut 42, should be

(1.0

mm) between

set