Page 1

-926/06

Supplement to the

Instruction Manual and

Parts List

for the PFAFF 1051, 1053

1181, 1183,

2481

296-12-18 396/002

Beiblatt zur Betriebsanleitung

und Teileliste engl. 02.2001

Page 2

The reprinting, copying or translation of PFAFF Instruction Manuals, whether in whole or in

part, is only permitted with our previous permission and with written reference to the

source.

G.M. PFAFF KAISERSLAUTERN

INDUSTRIEMASCHINEN AG

Postfach 3020

D-67653 Kaiserslautern

Königstr. 154

D-67655 Kaiserslautern

Editing/Illustrations

HAAS-Publikationen GmbH

D-53840 Troisdorf

Page 3

Contents

Contents ................................................................................. Chapter - Page

1 Safety ........................................................................................................................... 1 - 1

1.01 Directives...................................................................................................................... 1 - 1

1.02 General notes on safety................................................................................................ 1 - 1

1.03 Safety symbols ............................................................................................................. 1 -2

2 Control elements......................................................................................................... 2 - 1

2.01 Control device for remaining bobbin thread .................................................................. 2 - 1

2.02 Pedal ............................................................................................................................. 2 - 1

3 Setting up .................................................................................................................... 3 -1

3.01 Winding the bobbin thread / regulating the winder tension .......................................... 3 - 1

3.02 Inserting the bobbin in the bobbin case ........................................................................ 3 - 2

3.03 Inserting the thread in the bobbin case / regulating the bobbin thread tension ............ 3 - 2

4 Sewing ......................................................................................................................... 4- 1

4.01 Sewing with bobbin thread monitoring function ........................................................... 4 - 1

4.02 Sewing with bobbin thread counter function ................................................................ 4 - 2

5 Adjustments ................................................................................................................ 5 - 1

5.01 Parameter settings........................................................................................................ 5 - 1

6 Parts list ....................................................................................................................... 6 - 1

Page 4

Safety

1 Safety

1.01 Directives

1.02 General notes on safety

This machine is constructed in accordance with the European regulations contained in the

conformity and manufacturer’s declarations.

In addition to this Instruction Manual, also observe all generally accepted, statutory and other

regulations and legal requirements and all valid environmental protection regulations!

The regionally valid regulations of the social insurance society for occupational accidents or

other supervisory organizations are to be strictly adhered to!

● This machine may only be operated by adequately trained operators and only after having

completely read and understood the Instruction Manual!

● All Notes on Safety and Instruction Manuals of the motor manufacturer are to be read

before operating the machine!

● The danger and safety instructions on the machine itself are to be followed!

● This machine may only be used for the purpose for which it is intended and may not be

operated without its safety devices. All safety regulations relevant to its operation are to be

adhered to.

● When exchanging sewing tools (e.g. needle, roller presser, needle plate and bobbin), when

threading the machine, when leaving the machine unattended and during maintenance

work, the machine is to be separated from the power supply by switching off the On/Off

switch or by removing the plug from the mains!

● Everyday maintenance work is only to be carried out by appropriately trained personnel!

● Repairs and special maintenance work may only be carried out by qualified service staff or

appropriately trained personnel!

● Work on electrical equipment may only be carried out by appropriately trained personnel!

● Work is not permitted on parts and equipment which are connected to the power supply!

The only exceptions to this rule are found in the regulations EN 50110.

● Modifications and alterations to the machine may only be carried out under observance of

all the relevant safety regulations!

1 - 1

● Only spare parts which have been approved by us are to be used for repairs! We

expressly point out that any replacement parts or accessories which are not supplied by

us have not been tested and approved by us. The installation and/or use of any such

products can lead to negative changes in the structural characteristics of the machine. We

are not liable for any damage which may be caused by non-original parts.

Page 5

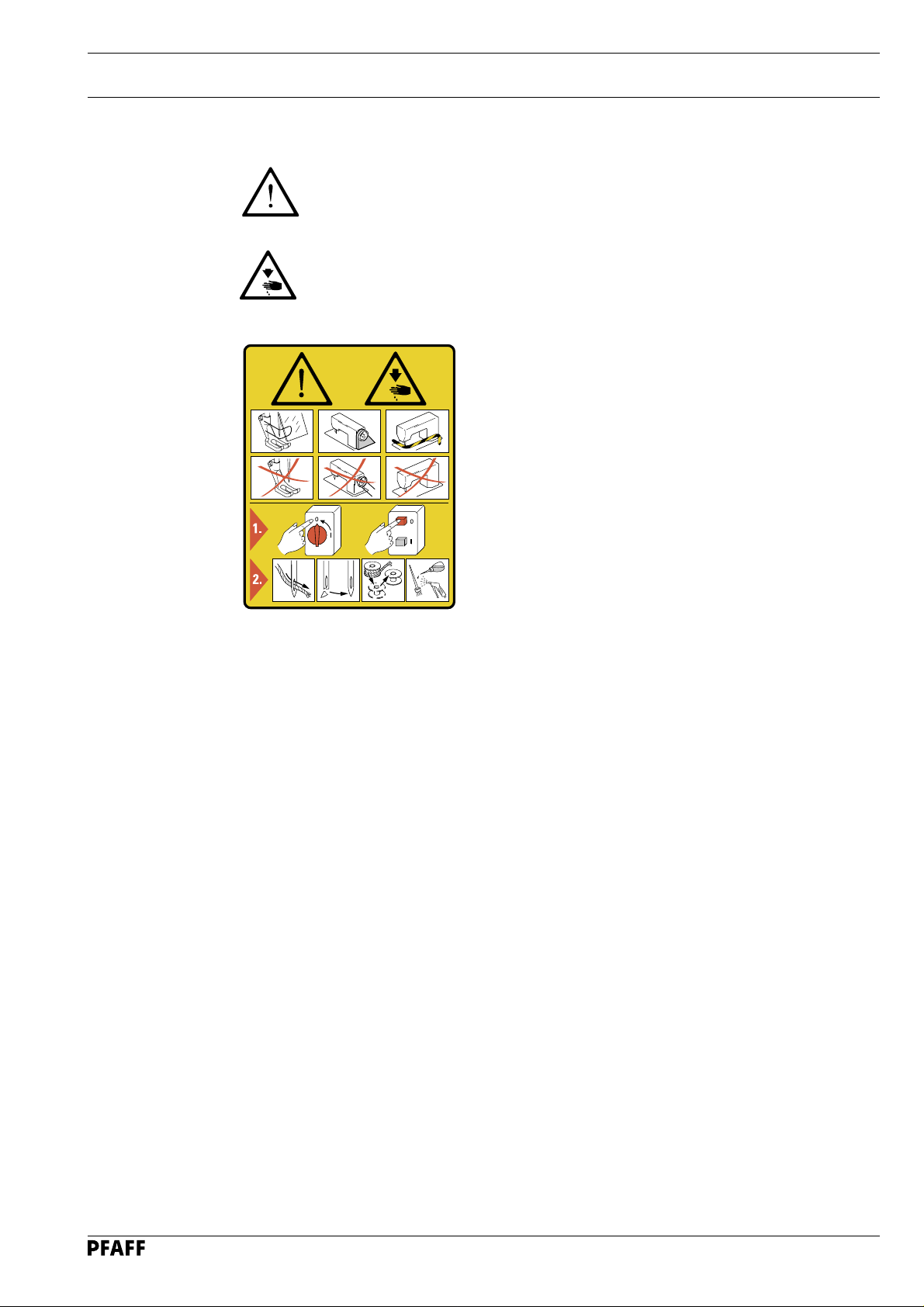

1.03 Safety symbols

Danger!

Points to be observed.

Danger of injury for operating and specialist personnel!

Safety

Caution

Do not operate without finger guard and safety devices.

Before threading, changing bobbin and needle, cleaning

etc. switch off main switch.

I

1 - 2

Page 6

Control elements

2 Control elements

2.01 Control device for remaining bobbin thread

Bobbin thread monitor

● When the use of the last amount of

the remaining thread supply begins, the

LED 1 starts flashing.

● When the remaining thread supply has

been used up, the LED 1 lights up

permanently until the bobbin has been

changed.

Bobbin thread counter

● When the thread counter reaches its

end, the LED 1 starts flashing.

● If sewing continues without the bobbin

being changed, the LED 1

1

permanently until the bobbin is changed.

remains on

Fig. 2 - 01

2.02 Pedal

To select thread monitoring or

thread counting see Chapter

5.01 Parameter settings

0 = Neutral position

1 = Sewing

2 = Raise presser foot

3 = Trim sewing threads / reset

0

1

bobbin thread monitor or bob

bin thread counter

..

.

..

2 - 1

2

3

Fig. 2 - 02

Page 7

3 Setting up

.01 Winding the bobbin thread / regulating the winder tension

3

Setting up

1

59_03

3

1

2

4

-

6

+

59_01

5

59_04

Fig. 3 - 01

● Place empty bobbin 1 on winder spindle 2 with the residual thread chamber pointing to

the outside.

● Insert the thread as shown in Fig. 3 - 01

around bobbin 1.

● Engage the bobbin winder by pressing spindle 2 and lever 3 simultaneously.

The bobbin fills during sewing.

If the machine is only operated in order to fill the bobbin (without sewing), a

bobbin case must be inserted in the hook!

If this is not done, a jammed thread may damage the hook!

● The tension of the thread wound onto bobbin 1 can be set with milled screw 4.

● The bobbin winder stops automatically when sufficient thread has been wound onto bobbin 1.

If the thread is wound unevenly:

● Loosen nut 5.

● Turn thread guide 6 as required.

● Tighten nut 5 again.

and wind the thread a few times clockwise

3 - 1

Page 8

Setting up

3.02 Inserting the bobbin in the bobbin case

● Insert bobbin 1 in the bobbin case 2 as

shown in Fig. 3 - 02.

2

1

Fig. 3 - 02

3.03 Inserting the thread in the bobbin case /

regulating the bobbin thread tension

● Guide the thread through the slit and

● Adjust the thread tension by turning

5 cm

-

below the spring as shown in Fig. 3 - 03.

screw 1.

When the thread is pulled, the

bobbin must move in the

direction of the arrow.

3 - 2

1

+

Fig. 3 - 03

Page 9

4 Sewing

4.01 Sewing with bobbin thread monitoring function

The bobbin thread monitoring function via sensor is activated, when parameter

"660" is set at value "1". The number of stitches, which can sewn with the

remaining thread, is entered under parameter "760", after the bobbin thread

monitoring function has responded.

You will find more information about parameter settings in Chapter 5.01

Parameter Settings.

● If, during sewing, the bobbin thread

monitor recognises that the residual

thread supply is being used, LED 1 starts

flashing.

Sewing can continue without a bobbin

change. From this point on the pre-set

number of stitches, which can be sewn

with the remaining thread, are counted.

● Once this number of stitches has been

sewn, the machine stops automatically

and LED 1 lights up permanently. The

bobbin must be changed.

1

2

● After the bobbin has been changed, the

bobbin thread monitoring function is

reset with pedal function "3", see

Chapter 2.02 Pedal.

Sewing

Fig. 4 - 01

By pressing key 2 and at the same time activating pedal function "3", the bobbin

thread monitoring function can be reset at any time.

4 - 1

Page 10

Sewing

4.02 Sewing with bobbin thread counter function

The bobbin thread monitoring function via counter is activated, when parameter

"660" is set at value "2". The total number of stitches, which can sewn with one

bobbin, is entered under parameter "760".

You will find more information about parameter settings in Chapter 5.01

Parameter Settings.

● Once the total number of stitches has

been sewn, the machine stops

automatically and LED 1

● If sewing continues without a bobbin

change, LED 1 lights up permanently.

● After the bobbin has been changed, the

bobbin thread counter function is reset

to the pre-set value with pedal function

"3", see Chapter 2.02 Pedal.

starts flashing.

Fig. 4 - 02

1

2

By pressing key 2 and at the same time activating pedal function "3", the bobbin

thread counter function can be reset at any time.

4 - 2

Page 11

5 Adjustments

.01 Parameter settings

5

5.01.01 Selecting and altering parameters

● Switch on the machine.

Adjustments

● Press the Parameter input

key (LED on).

100

● By pressing +/- on the P key select the desired group, e.g. "700".

700

● By pressing +/- on the S key select the desired parameter, e.g. "760".

760

● Set the desired value (e.g. number of stitches for bobbin thread monitor function) by

pressing +/- (L key).

● Save the input by ending the parameter input (LED off).

For further displays and information see the Motor Service Manual.

5 - 1

Page 12

Parts list

PFAFF 1051;1053

PFAFF 1181;1183

PFAFF 2481

95-734 419-91

95-734 377-05

11-108 093-25

91-004 181-05 (PFAFF 1051;1181;2481)

91-262 806-05 (PFAFF 1083;1183)

11-210 084-25 (2x)

95-734 378-91

95-774 361-05

95-774 366-25 (PFAFF 1051;

1181;

2481)

95-774 364-25 (PFAFF 1083;

1183)

6 - 1

71-710 000-57

95-774 365-91 (PFAFF 1051;1181;2481)

95-774 362-91 (PFAFF 1083;1183)

Page 13

PFAFF 1051;1053

PFAFF 1181;1183

95-784 322-91

Parts list

6 - 2

Page 14

Parts list

PFAFF 2481

95-784 314-91

91-291 973-91

6 - 3

Page 15

Notes

Page 16

Loading...

Loading...