Page 1

Sales division

Technical network leadership

WORKSHOP MANUAL

-

Page 2

Workshop manual

Technical network leadership

Reproduction or transla tion, even partial, is for bidden without the written consent of Peugeot Motoc ycles

Page 3

TABLE OF CONTENTS.

TABLE OF CONTENTS.

TABLE OF CONTENTS. ...................................... ... ..........................................................................................1

PRODUCTS DANGER SYMBOLS USED......................................................................................................... 4

CHARACTERISTICS.........................................................................................................................................6

Engine........................................................................................................................................................6

Capacities..................................................................................................................................................6

Chassis......................................................................................................................................................7

Dimensions and weight............. ... .... ... .......................................................................................................7

Tyres..........................................................................................................................................................7

SERVICE SCHEDULE AND COMMISSIONING............................................................................................... 8

Check.........................................................................................................................................................8

Change ......................................................................................................................................................8

Check and lubricate ............... ... ... .... ...................................... .... ... ... ... .......................................................9

Reading the ECU fault codes.... ... .............................................................................. ... ... .... ... .. .................9

Test machine .............................................................................................................................................9

Time required for maintenance................................. .... ... ....................................... ... ... ... .... ......................9

Battery preparation (Except battery without maintenance)*.....................................................................10

Checks before handing over to the customer ..........................................................................................10

SPECIAL IMPORTANT POINTS..................................................................................................................... 11

Oil and fuel...............................................................................................................................................11

Starting up after overhauling the engine..................................................................................................11

Electricity..................................................................................................................................................11

Special features ..................................................... ... .... ... ... ....................................... ... ...........................11

TIGHTENING TORQUES. ....................... ... ... ... .... .......................................... .................................................12

Engine part...............................................................................................................................................12

Body panels .............................................................................................................................................13

Cycle part.................................................................................................................................................13

Standard ..................................................................................................................................................13

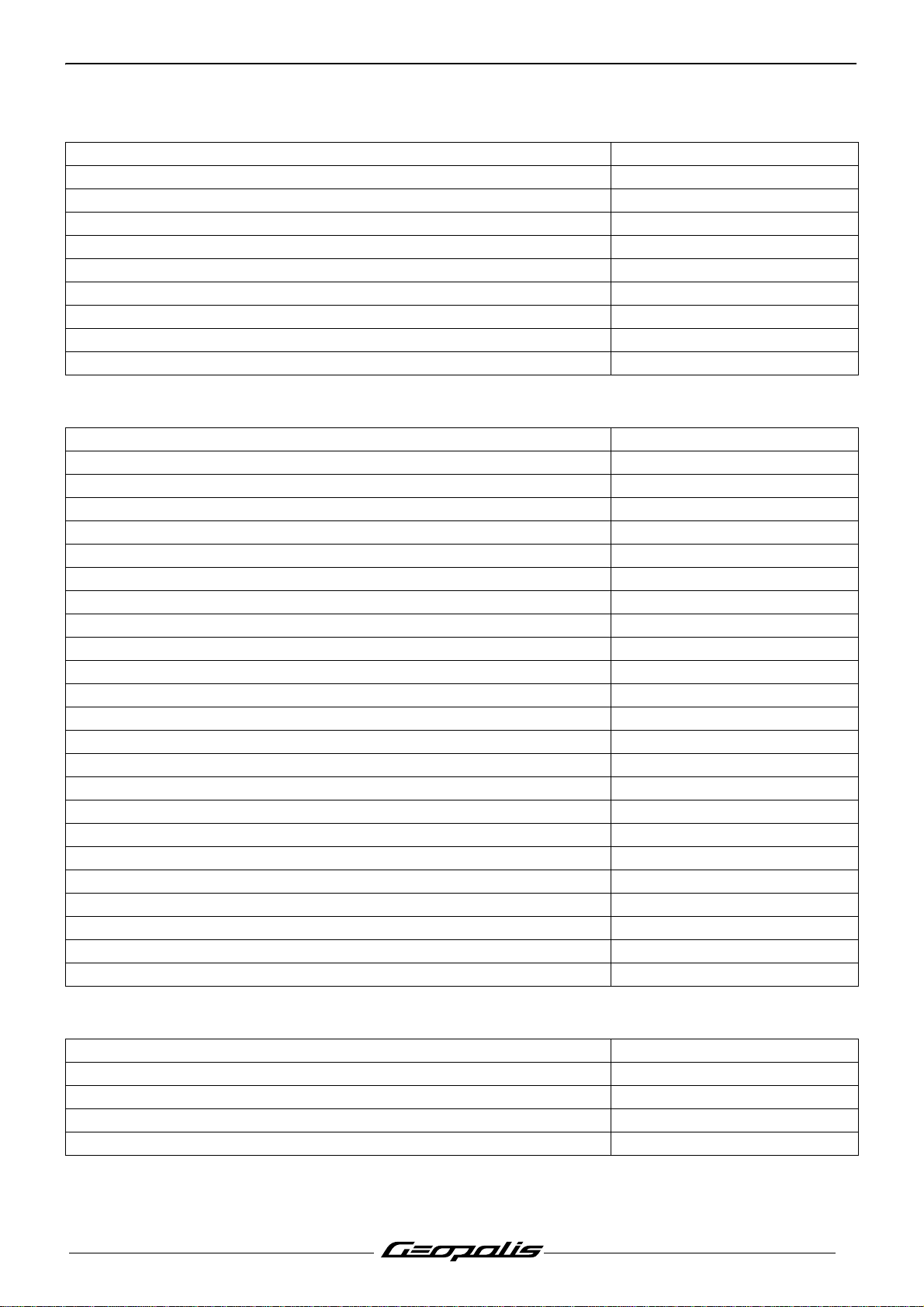

SPECIAL TOOLS ............................................................................................................................................ 14

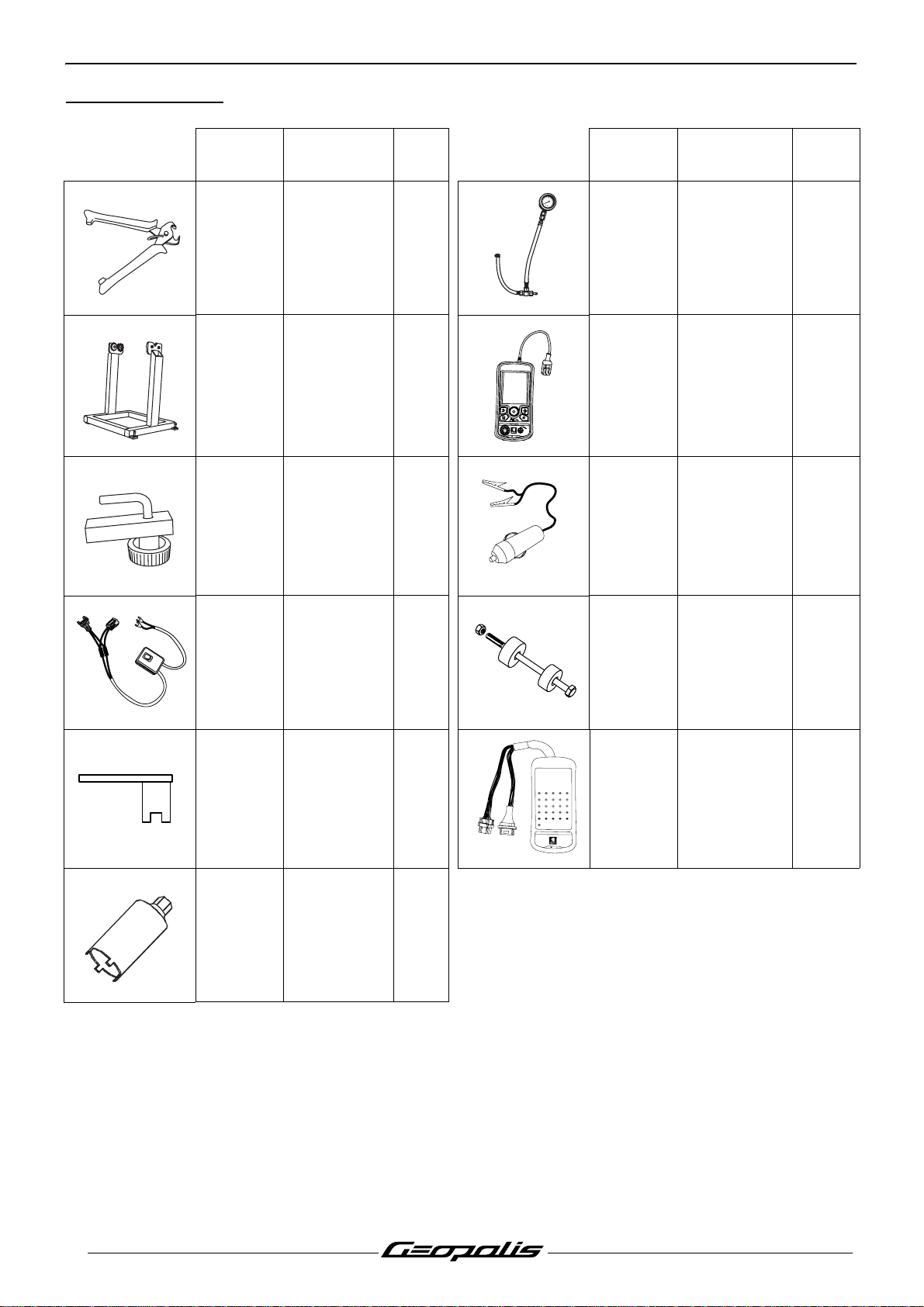

ELECTRICITY..................................................................................................................................................15

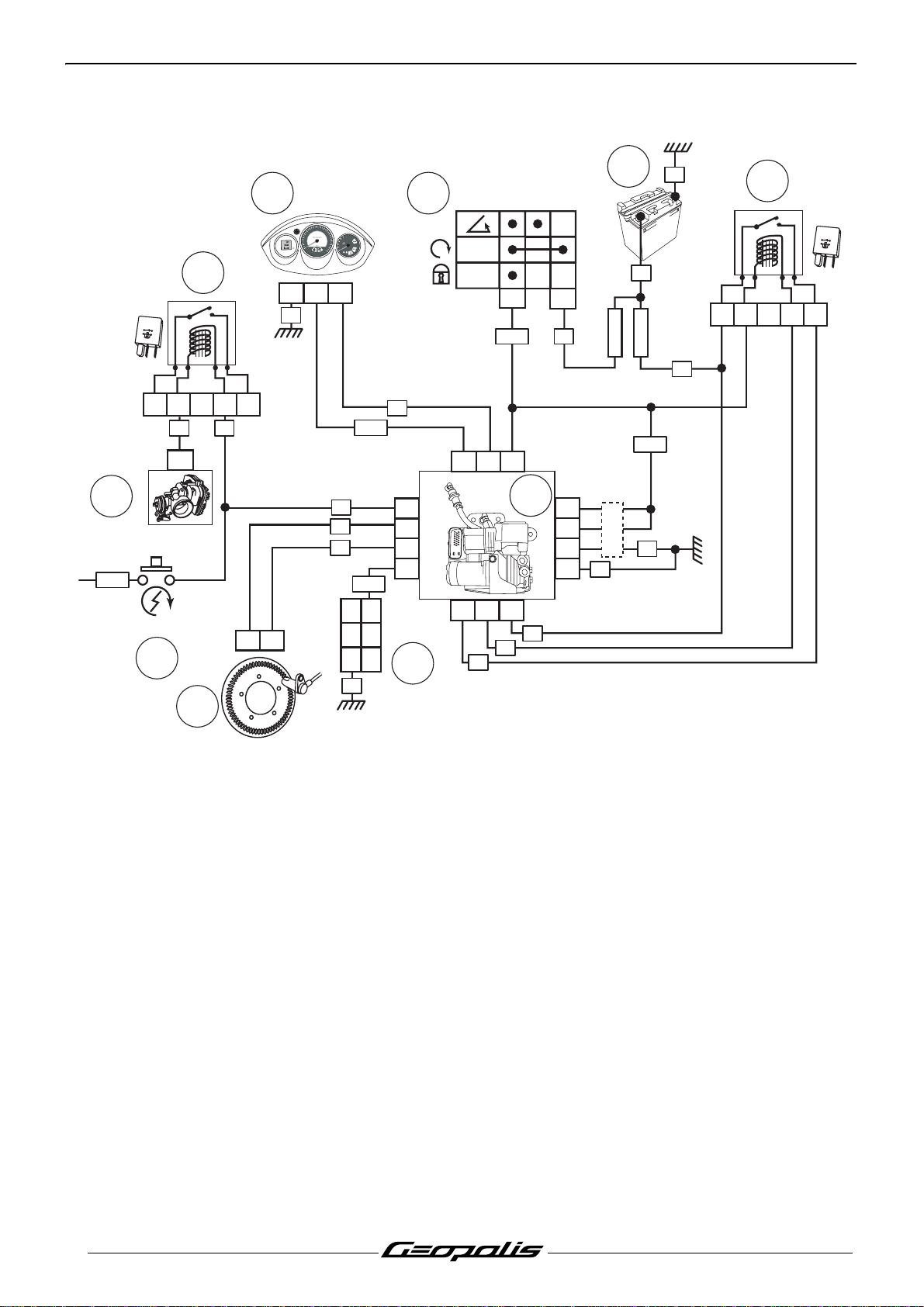

4 stroke indirect injection system functional diagram...............................................................................15

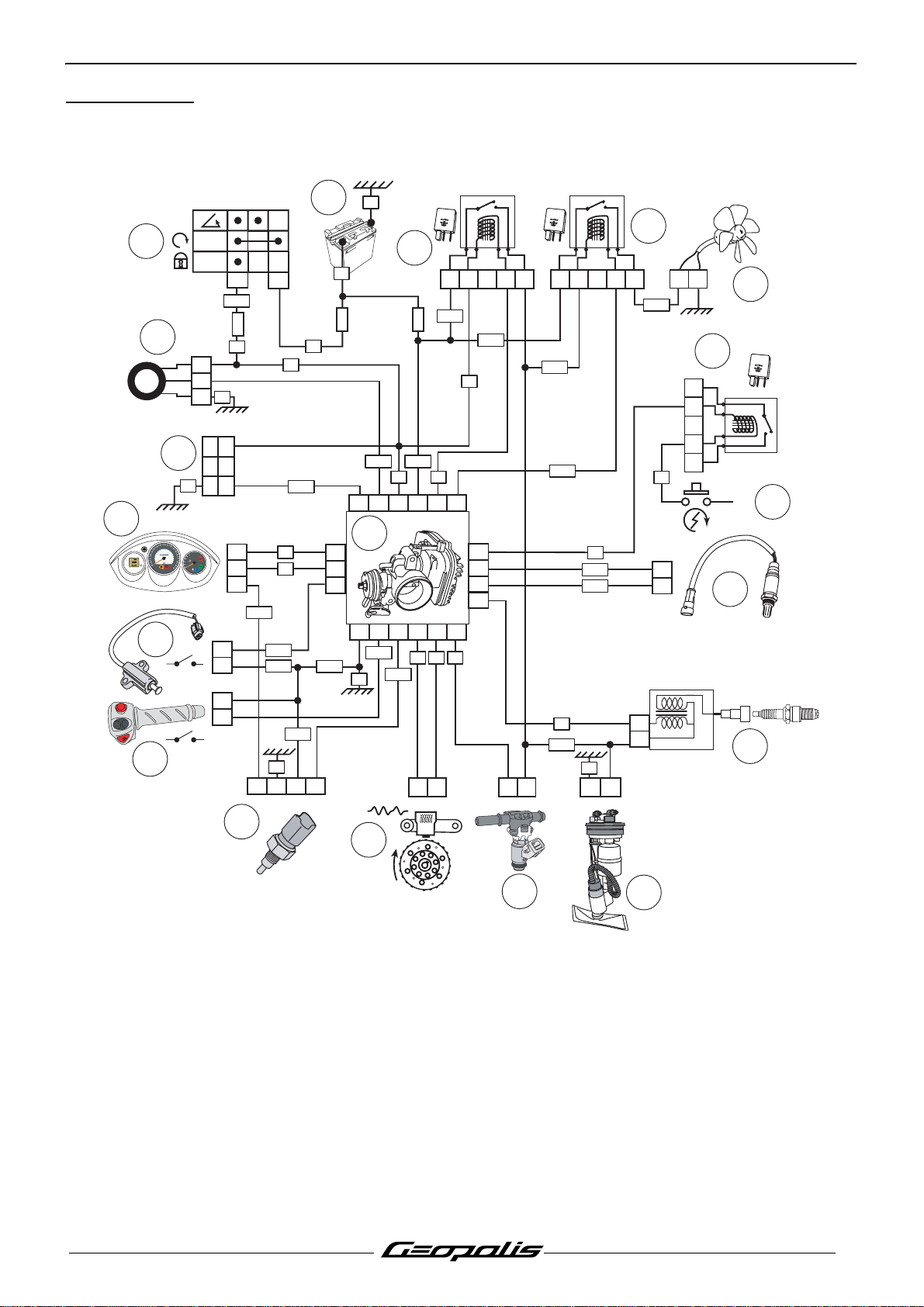

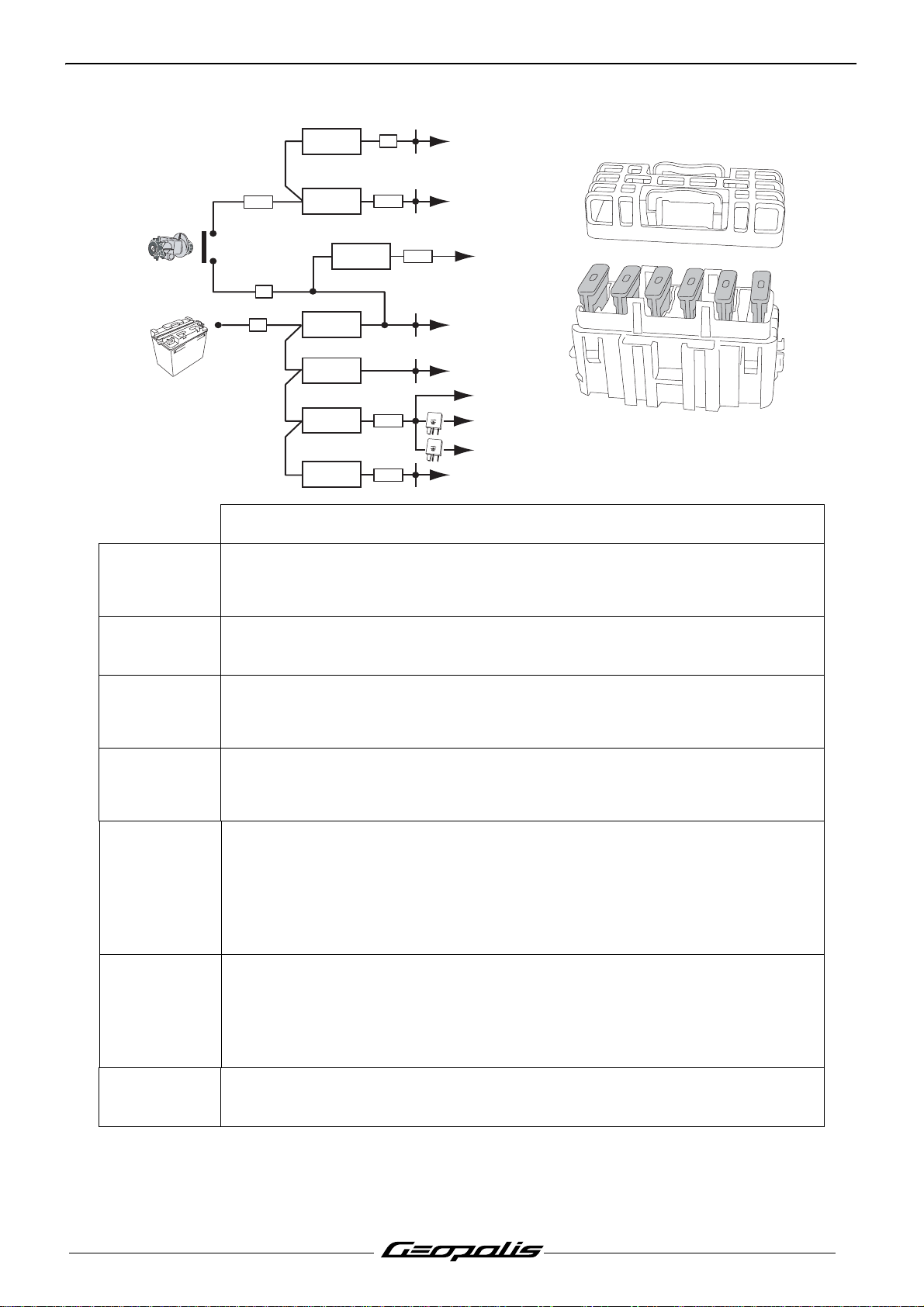

ABS/MBS system schematic diagram .....................................................................................................16

Fuses and energy distribution..................................................................................................................17

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

1

Page 4

TABLE OF CONTENTS.

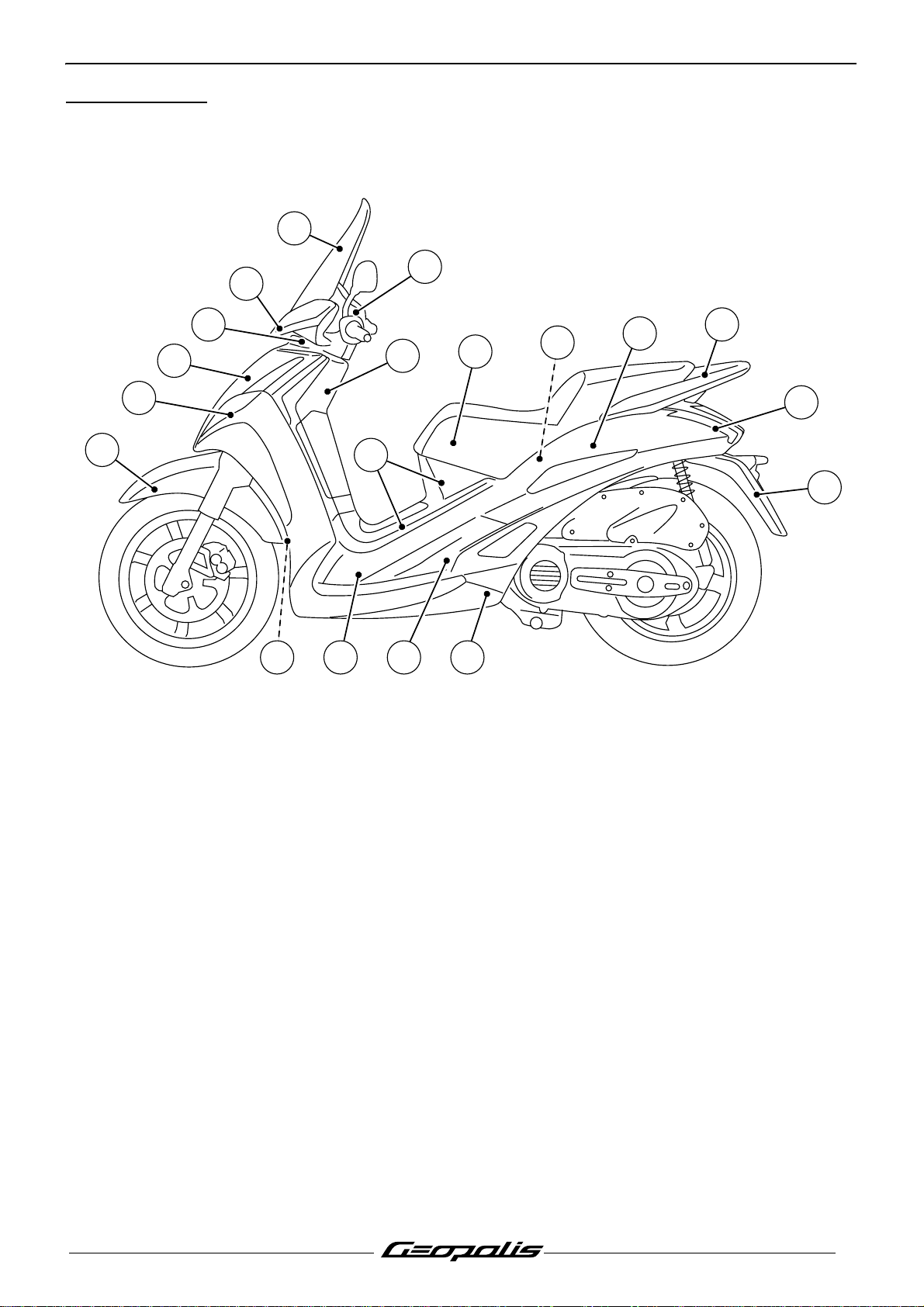

LOCATION OF COMPONENTS...................................................................................................................... 18

BODY PANELS ............................. .................................................................................................................. 19

Location of body components..................................................................................................................19

Body component sequence of disassembly.............................................................................................20

Removal of the storage compartment........................................................... ...........................................21

Removal of a RH or LH side cover ..........................................................................................................21

Removal of the tank covers .......................... ... ... ... ... ....................................... ... .... ... ... ...........................22

Removal of a RH or LH footboard.... ... ... ... .... ... ........................................................................................23

Removal of the front shield panel .......................... ....................................... ... ... .... ... ..............................24

Removal of the rear shield panel ..... ... ... ... .... ... ....................................... ... ... ... ........................................25

Removal of the dirt shield ................................ ... ... ....................................... ... ... .... ... ... ... ........................25

Removal of the instrument cluster ................... ... ....................................... ... ... ... .... .................................26

Removal of the battery holder.......................................... ... ... .... ... ....................................... ... .................26

SERVICE OPERATIONS............... ... .......................................... .......................................... ........................... 27

Changing the engine oil and replacing the oil filter ..................................................................................27

Draining the relay box............................................ ... .... ...................................... .... ... ... ... ... .....................29

Replacing the air filter ..............................................................................................................................30

Removal of the transmission air filter.......................................................................................................32

Changing the drive pulley bearings..........................................................................................................32

Removal of the spark plug ........... .... ... ... ... .... ...................................... .... ... ... ...........................................33

Draining the cooling circuit........ ... .... ... ....................................... ... ... ... .... ... ... ...........................................33

Installing the valve clearance........................... ........................................................................................34

Replacing the brake pads ........................................................................................................................36

Front brake........................................................................................................................................................36

Rear brake................. ... ....................................................................................................................................36

Checking the brake fluid level.......................................... ........................................................................40

SERVICING THE ABS/MBS SYSTEM............................................................................................................41

Reminder .................................................................................................................................................41

Removal of the brake modulator.. ....................................... ... .... ... ... ....................................... ... ..............41

Re-installing the modulator ......................................................................................................................42

Bleed procedure.......................................................................................................................................43

Draining the rear brake circuit...........................................................................................................................43

Bleeding the assistance circuit..........................................................................................................................45

Draining the front brake circuit..........................................................................................................................46

2

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 5

TABLE OF CONTENTS.

MISCELLANEOUS OPERATIONS ................................................................................................................. 49

Procedure for reducing the fuel circuit pr es su re ........................................ ...................................... ........49

Checking fuel pressure ............. ... .... ... ... ... ....................................... ... .... ... ... ...........................................50

Removal of the fuel pump................................................................................ ... .... ... ... ...........................51

Removal of the fuel gauge............................................................................... ... .... ... ... ...........................52

Removal of the throttle box.............................................................................. ... .... ... ... ...........................53

Removal of the lambda sensor ........ ...................................... .... ... ... ... ....................................... . .............53

Removal of the regulator. .... ...................................... .... ... ... ... ....................................... ... .... . ...................54

Removal of the radiator....... ...................................... .... ... ... ... ....................................... ... ........................55

Removal of the engine mounting assembly............................................................... ... ... .... ... ... ... ...........56

Removal of the engine........................................... ... .... ... ....................................... ... ... ... .... . ...................58

Removal of the fork................ ... ....................................... ... ... .... ... ...........................................................62

Replacing the bearings of the steering system........................................................................................62

Steering system tightening method........................... .... ...................................... .... ... ... ... ........................64

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

3

Page 6

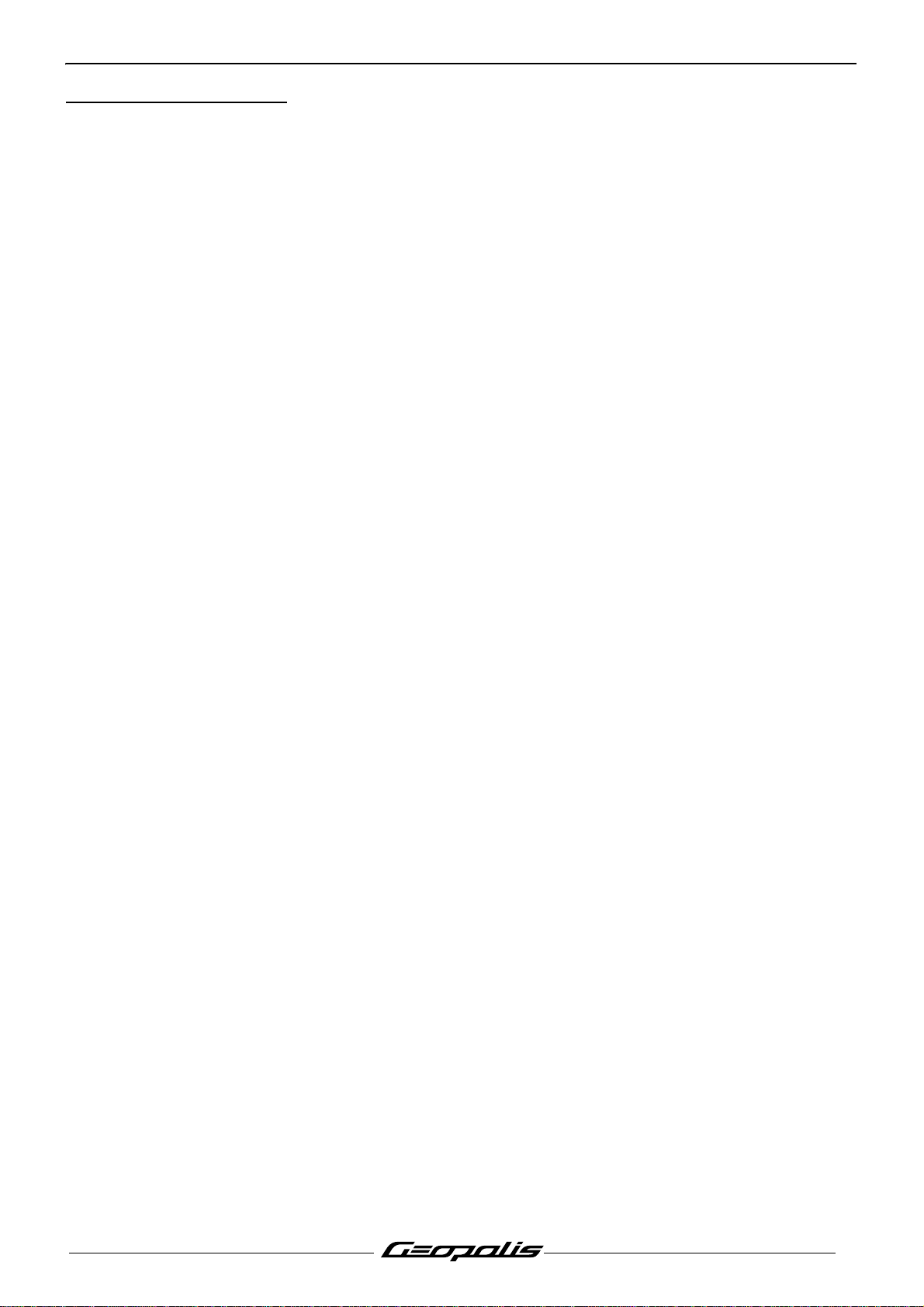

PRODUCTS DANGER SYMBOLS USED

PRODUCTS DANGER SYMBOLS USED

Protection of individuals and of the environment.

Möbius band Recyclable

The product can irritate the

Irritant

Flammable The product is flammable

Corrosive

skin, eyes and repiratory

organs

The product can damage living

tissues or other surfaces

Means that the product or the package

can be recycled. However, this does not

guarantee that the product will be

recycled.

Avoid contact with the skin and clothes.

Wear gloves, safety glasses and

appropriate clothes such as a cotton

overall. Do not breath fumes. If in contact,

wash thoroughly with water.

Keep it away from any flame or heat

source (barbecue, radiator, heating

device, etc.). . . . Do not leave the product

in the sun.

Avoid contact with the skin and clothes.

Wear gloves, safety glasses and

appropriate clothes such as a cotton

overall. Do not breath fumes.

Explosive

Hazardous to

the environment

Toxic

Do not throw

away into a

garbage can

Compulsory

gloves

The product can explode under

certain circumstances (flame,

heat, impact, friction)

The product affects fauna and

flora. Do not dump it in

garbage cans, sinks or nature.

The product can seriously

affect health if it is inhaled,

ingested or in contact with skin

One of the product's

component is toxic and can be

hazardous to environment. Ex.

Used batteries

Operation that can be

dangerous for people

Avoid impacts, friction, sparks and heat.

The ideal solution is to bring this product

to your nearest household waste recycling

centre.

Avoid direct contact with body even by

inhalation. If you feel unwell, seek medical

advice immediately.

This symbol informs the consumer that the

used product shall not be thrown away into

a garbage can, but shall be brought back

to the merchant or dropped at a specific

collection point

People's safety can be seriously affected if

the recommendations are not fully

respected.

4

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 7

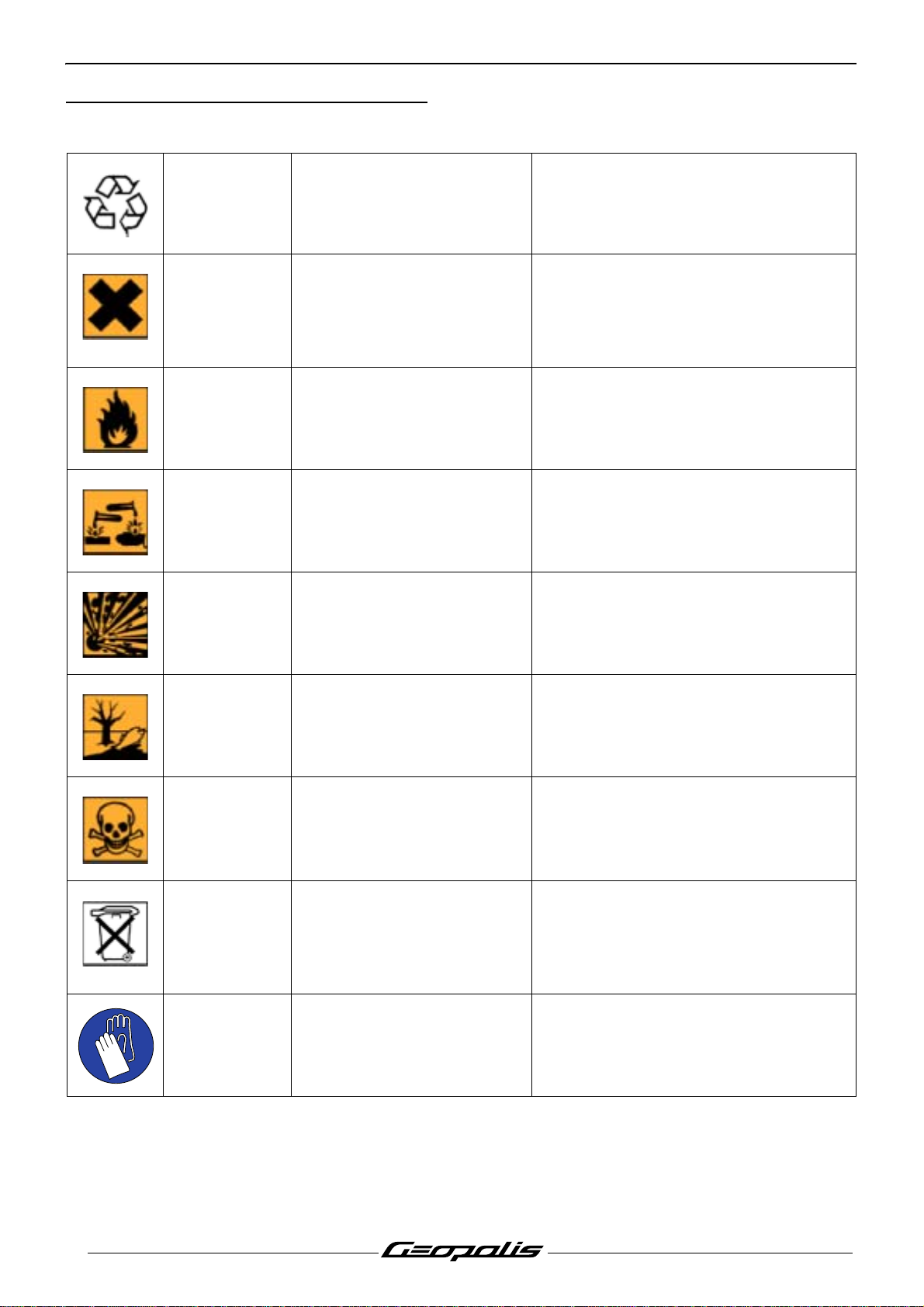

PRODUCTS DANGER SYMBOLS USED

N

People's safety

Important

Good operating

condition of the

vehicle

Note Operation that can be difficult

Lubricate

Grease

Operation that can be

dangerous for people

Operation that can be

hazardous to the vehicle

The operation must be carried

out in strict compliance with the

documents

Lubricate the parts to be

assembled

Grease the parts to be

assembled

People's safety can be seriously affected if

the recommendations are not fully

respected.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle

Serious damage to the vehicle and in

certain cases a cancellation of the

warranty can be involved if the

recommendations are not fully respected.

Indicate a note which gives key

information to make the procedure easier

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

GLUE

Glue Glue the parts to be assembled

New part Use a new part

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

Indicate the specific procedures that shall

be followed in order not to damage the

vehicle.

5

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 8

CHARACTERISTICS

CHARACTERISTICS

Engine

Marking M564M

400 cc

Type

4 valves per cylinder with chain driven overhead camshaft

4-stroke single-cylinder

Cooling Liquid

Bore x stroke 85.8 x 69 mm

Cubic capacity 399 cc

Max. power output 25 kW at 7500 rpm

Max. torque rating 5500 rpm

Lubrication Trochoidal pump

Transmission By 2 variable pulleys and V-type belt

Clutch Centrifugal automatic

Exhaust Catalytic

Starter motor Mitsuba 900 W

1 spark plug

Spark plug

NGK CR7EKB

Electrode gap

0.7-0.8 mm

Magneto flywheel Mitsuba 350 W

Fuel supply

Indirect electronic injection

Magneti-Marelli

Capacities

Engine oil

Relay box oil

Coolant 1.4 l Peugeot coolant part number 754614.

Fork oil 212 cc per tube (Esso Univis 46 or Agip HLift 46)

Fuel tank 13.2 l / Version ABS 10.5 l

1.7 l SAE 5W40.

Minimum grade: API SJ.

0.25 l SAE 80W90.

Minimum grade: API GL4.

6

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 9

CHARACTERISTICS

Chassis

Chassis Double cradle out of high-resistance steel tube

Front suspension Hydraulic telescopic fork. Ø37 mm

Travel 100 mm

Rear suspension 2 adjustable combined spring hydraulic shock absorbers

Travel 100 mm

Dimensions and weight

Overall length

Width at handlebar

Height.(without rear-view

2180 mm

755 mm

1486 mm

mirrors)

Wheelbase 1527 mm

Ground clearance

Saddle height

Unladen weight

Tyres

157 mm

805 mm

200 kg.

Front wheel rim 16 inch aluminium alloy

Front tyre 110/70 - 16

Front tyre pressure 2.2 bars

Rear wheel rim 14 inch aluminium alloy

Rear tyre 150/70 - 14

Rear tyre pressure 2.4 bars

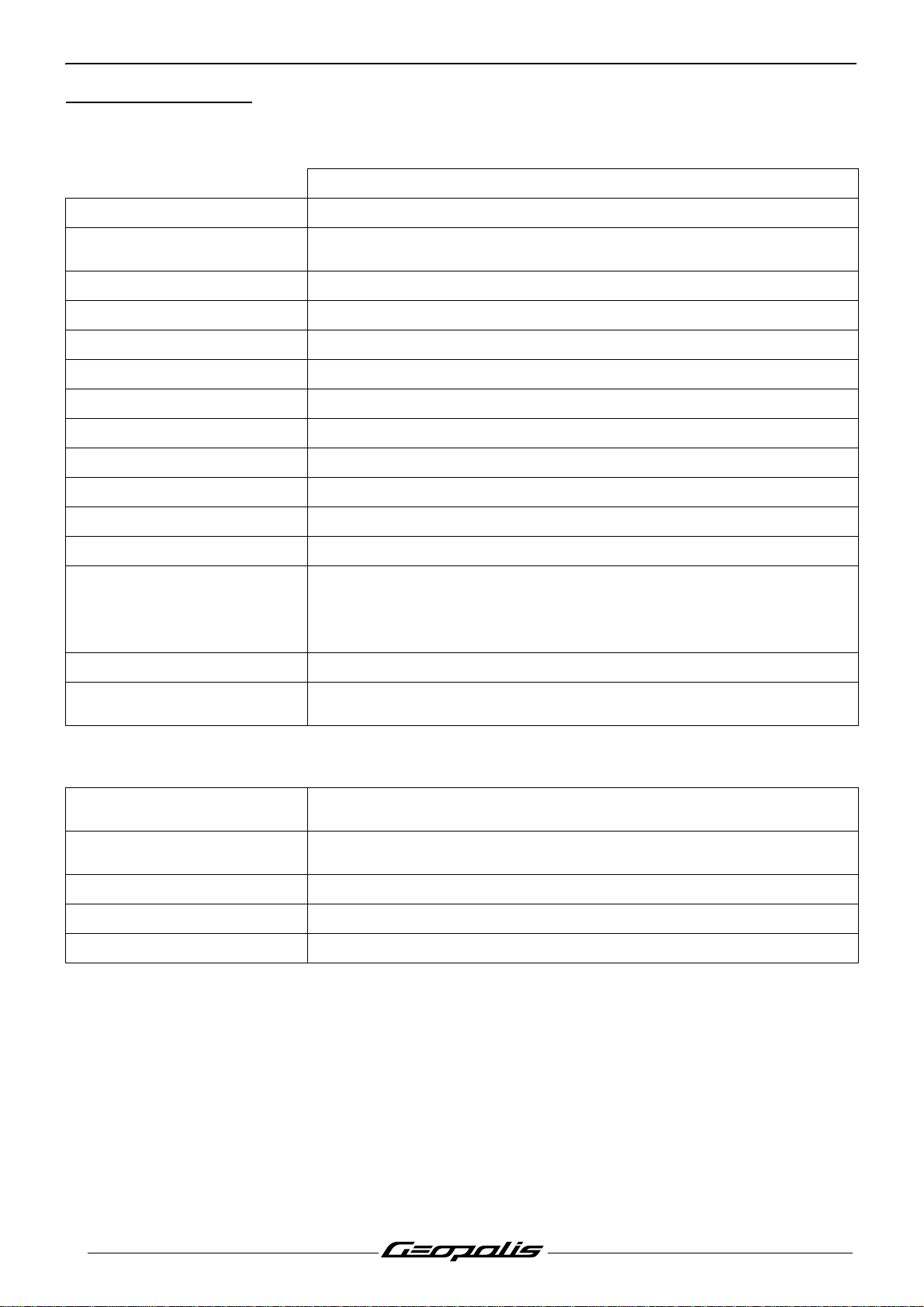

Chassis markings Engine marking

1

M461M

xxxxxxxxxx

2

1. Manufacturer's plate.(Left side)

- VIN number of the RH side of the vehicle

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

2. Engine number

7

Page 10

SERVICE SCHEDULE AND COMMISSIONING

SERVICE SCHEDULE AND COMMISSIONING

Heavy duty servicing applies to vehicles used under rugged operating conditions: door-to-door

deliveries, intensive urban use (courier), short journeys with engine cold, dusty areas, ambient

temperature over 30°C.

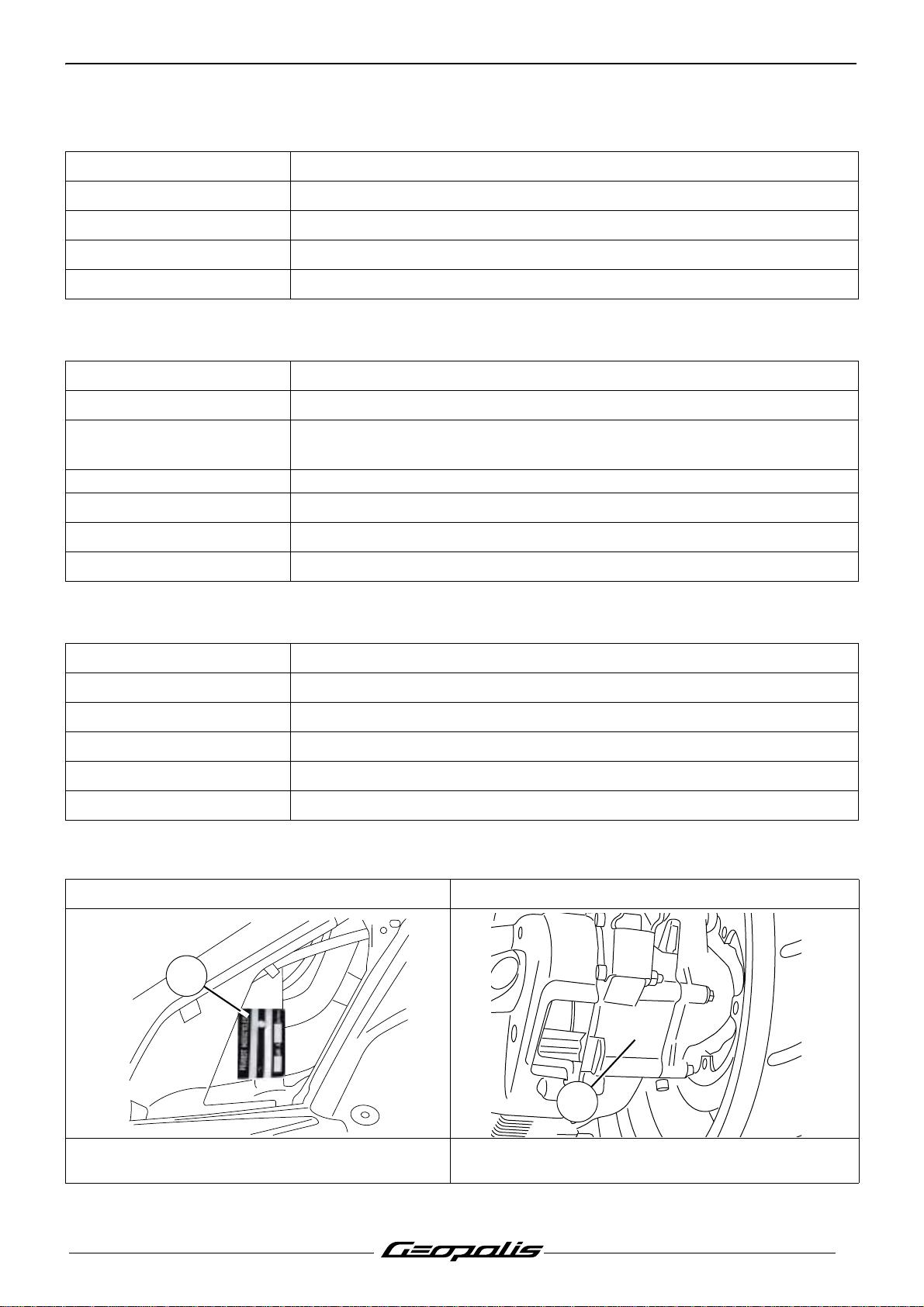

Service operations

Heavy duty servicing 500 kms

Check

1000 kms or

1 months

Every

5000 kms

Every

2500 kms

Every

10000 kms

Every

5000 kms

Every

20000 kms

Every

10000 kms

Throttle cable play C C C C

Steering column play C C C C

Operation of electrical equipment C C C C

Condition of front and rear brake

hydraulic controls

CCCC

Condition of petrol pipes C C C C

Condition of oil pipes C C C C

Tyre pressures C C C C

Tyre condition, pressure and wear C C C

Condition of the front suspension C C C C

Condition of the rear suspension C C C C

Brake fluid level C C C C

Battery electrolyte level * C C C C

Coolant level C C C C

Engine oil level C

Valve clearances C

Transmission air filter N N

Intake silencer drain N N N N

Tightening the engine mounting and

linkrod

CCC

Tightness of nuts and bolts C C C C

Change

Spark plug R R

Inlet silencer/air filter N N

Front brake pads C C C

Rear brake pads C C C

Drive pulley bearings and guides C C

Transmission belt R R

Belt anti-flapping roller C C

Engine oil R R R

Engine oil filter R R R

Relay box oil R C C

Brake fluid and coolant Once every 2 years

8

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 11

SERVICE SCHEDULE AND COMMISSIONING

Service operations

Heavy duty servicing 500 kms

Check and lubricate

1000 kms or

1 months

Every

5000 kms

Every

2500 kms

Every

10000 kms

Every

5000 kms

Every

20000 kms

Every

10000 kms

Drive pulley/Movable face C C

Driven pulley: Movable face C C

Driven pulley caged needle bearing G G

Reading the ECU fault codes

Injection and ABS/MBS system* C C C C

Test machine

On road (at least 2 km) C C C C

Time required for

maintenance

Code 9100 9300 9400 9600

Time required for maintenance 1.0 0.8 2.2 2.5

C: Check.

N: Clean.

R: Change.

G: Check and lubricate.

* Depending on equipment.

# Change if necessary.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

9

Page 12

SERVICE SCHEDULE AND COMMISSIONING

Battery preparation (Except battery without maintenance)*

Remove the battery.

Remove the 6 filler caps and the vent plug.

Fill all the battery cells with electrolyte to the upper level shown on the battery "UPPER LEVEL".

Electrolyte: (35% sulfuric acid = 1.28g/cm3). 1 litre can P/N 752740. 5 litre can P/N 752741.

Leave the battery to stand for around half an hour.

Top up if necessary.

Charge the battery for at least 2 hours with a current of 1.4 A.

Refit the battery and connect the vapour vent pipe.

Connect the red wire lug to the battery's + terminal, and the green wire lug to the battery's - termin al.

Then, the battery level should be topped up if necessary, after fully charging, using distilled water only.

Checks before handing over to the customer

Check the wheel nuts are tight.

Check nuts and bolts are tight.

Check brake adjustment and efficiency.

Check the tyre pressures cold.

Check operation of the lights, flashers, horn, and brake light.

Check the different warning lights work.

Carry out a road test.

Depending on equipment.

10

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 13

SPECIAL IMPORTANT POINTS

Oil and fuel

This engine is designed to run on 95 or 98 unleaded fuel only.

Fuel pipes must absolutely be changed if there are any signs of wear, cracks, etc.

The clips are specific, they must always be changed each time they are removed and replaced

with new genuine parts clips.

Petrol is highly inflammable, do not smoke in the working area and a void proximity to flames or

sparks.

Before carrying out any work, leave the engine to cool for at least 2 hours.

SPECIAL IMPORTANT POINTS

Starting up after overhauling the engine

When starting the engine hot or cold do not accelerate.

Check the coolant level in the header tank.

After road-testing the machine, check there are no fault codes left in the ECUs (using the diagnostic

tool).

Electricity

All components of the electrical system are powered with 12 volts DC.

The battery must not be disconnected while the engine is running and the voltage must be at least

7 volts for the ECU to function and enable engine starting.

Special features

An immobiliser built in the ECU provides the antitheft function by means of a transponder.

The ECU has a diagnostic function which via the instrument cluster LED or the diagnostic tool, enables

reading of the faults in the memory.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

11

Page 14

TIGHTENING TORQUES.

TIGHTENING TORQUES.

Engine part

Drive pulley 17 m.daN

Driven pulley 9.6 m.daN

Clutch plate and shoes 7 m.daN

Belt anti-flapping roller 1.8 m.daN

Transmission cover;

• 6 mm diameter screw

• 8 mm diameter screw

Relay box cover 2.5 m.daN

Relay box drain plug 1.5 m.daN

Flywheel magneto cover 1.2 m.daN

Stator 1 m.daN

Engine speed sensor 0.5 m.daN

Rotor 12 m.daN

Freewheel 1.4 m.daN

Starter motor 1.2 m.daN

Automatic tensioner 1.2 m.daN

Automatic tensioner plug 0.5 m.daN

Spark plug 1.2 m.daN

Camshaft gear 3.2 m.daN

Chain tensioner 1.2 m.daN

Camshaft stop plat 0.5 m.daN

Cylinder head. (Guide pins Procedure

Cylinder head bolts and nuts 1.2 m.daN

Cylinder head cover 0.8 m.daN

Inlet manifold 1.2 m.daN

Engine temperature sensor 1.1 m.daN

Injection ECU 1.2 m.daN

Injection rail 0.3 m.daN

Oil pressure switch 1.2 m.daN

Oil pump 0.6 m.daN

Oil filter 1.4 m.daN

Oil pump cover 0.9 m.daN

Crankcase 1.2 m.daN

Conrod and crankshaft assembly gear 1.1 m.daN

Balancing shaft 2.8 m.daN

Engine drain plug 2.5 m.daN

Water pump cap 0.4 m.daN

Water pump impeller 0.5 m.daN

Cooling system bleeder screw 0.3 m.daN

1.2 m.daN

2.4 m.daN

12

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 15

TIGHTENING TORQUES.

Body panels

Front mudguard 0.8 to 1.2 m.daN

Handlebar cover 0.2 to 0.4 m.daN

Front shield panels 0.2 to 0.4 m.daN

Rear shield 0.2 to 0.4 m.daN

Bottom panel 0.2 to 0.4 m.daN

Floor panel 0.4 to 0.6 m.daN

Saddle storage compartment 0.8 to 1.2 m.daN

Rear panels 0.2 to 0.4 m.daN

Grab handle 2 to 2.5 m.daN

Rear mudguard 0.4 to 0.6 m.daN

Cycle part

Front wheel spindle 6.5 m.daN

Rear wheel bolt 2.5 m.daN

Rear wheel spindle nut 13.5 m.daN

Linkrod to engine pivot 8 m.daN

Linkrod to frame pivot 8 m.daN

Linkrod connecting pin 8 m.daN

Linkage torque arms 3.8 m.daN

Shock absorber top mount 4.5 m.daN

Shock absorber bottom mount 4.5 m.daN

Exhaust to cylinder head mounting nut 2.2 m.daN

Exhaust to casing mounting bolt 2.2 m.daN

Exhaust system strap 1.8 m.daN

Exhaust clamp 1.8 m.daN

Centre stand holder 2.2 m.daN

Suspension arm 2.8 m.daN

Lambda sensor 4.5 m.daN

Upper cone (in 2 operations) 4/2.2 m.daN

Upper cone locknut Hand tightened

Steering locknut 7.5 m.daN

Front brake caliper 2.5 m.daN

Rear brake caliper 2.5 m.daN

Front brake disc 3 m.daN

Rear brake disc 3 m.daN

Handle bar 4 m.daN

Standard

Nut and bolt 5 mm diameter 0.6 m.daN

Nut and bolt 6 mm diameter 1 m.daN

Nut and bolt 8 mm diameter 2.2 m.daN

Nut and bolt 10 mm diameter 3.5 m.daN

Nut and bolt 12 mm diameter 5.5 m.daN

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

13

Page 16

SPECIAL TOOLS

SPECIAL TOOLS

Tool N° Designation

750539

Tie-wrap

pliers

Used

with

Tool N° Designation

4

6

2

8

0

1

0

b

a

r

757877

Balance

754278

support with

pins Ø15 and

Ø17 mm

OK

TEP 2005

test

xxo

by

758358 TEP 2005

755996 Hose clamp 758585

Used

with

Pressure

gauge

Power supply

cable tool

756017

756715

(*)

757860 Steering tool

(*) New or modified tool.

Fuel injector

power supply

harness

Tank gauge

spanner

Steeing head

758810

cup

installation

tool

432

1

9208197186

17516

24122311221021

26

BM 2005

t

e

s

t

xxo

b

y

151413

25

758924

24 way

terminal block

14

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 17

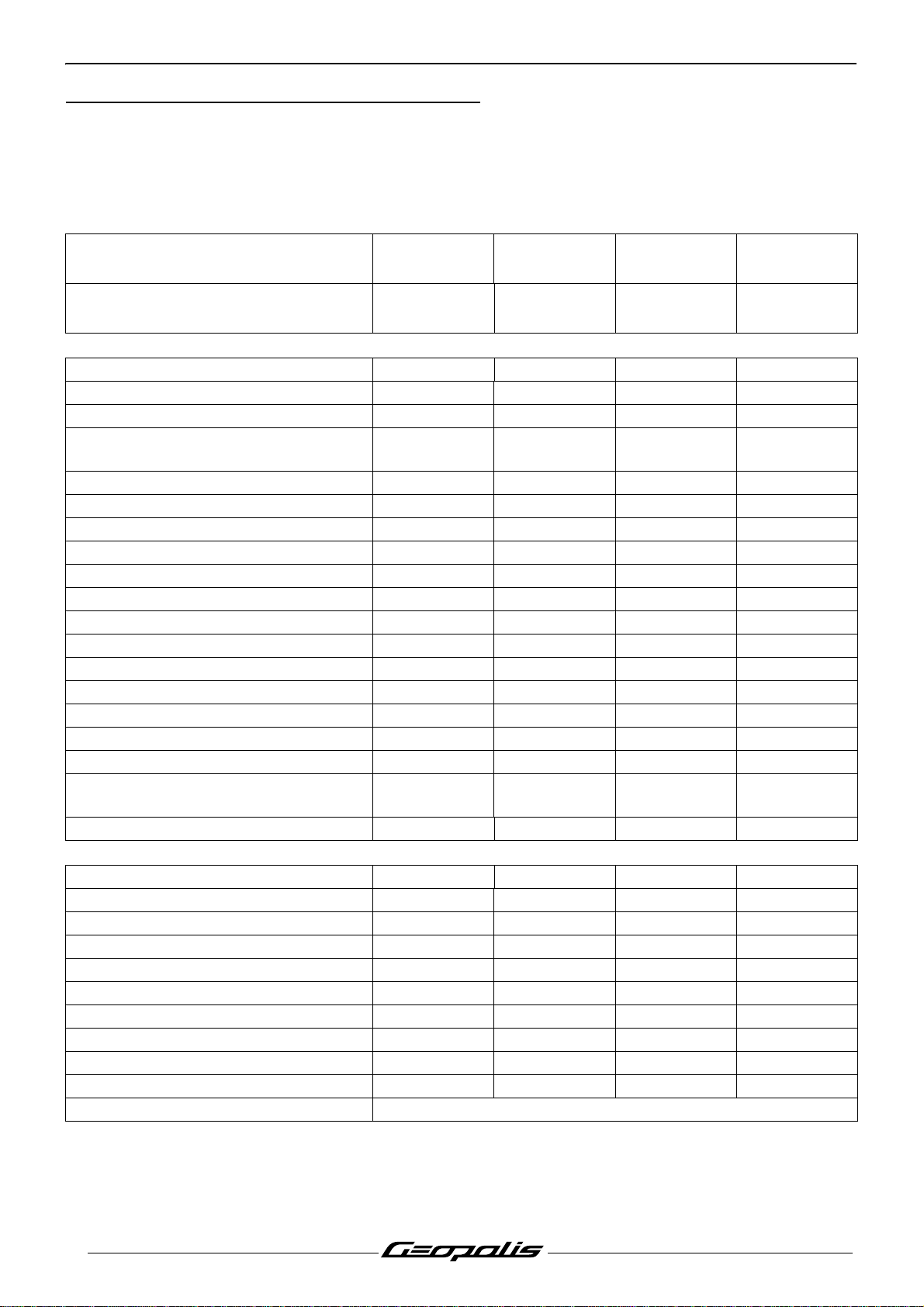

ELECTRICITY

4 stroke indirect injection system functional diagram

ELECTRICITY

16

PEUGEOT

13

K

m

M

H

rs

18

14

40

0

2

17

ON

OFF

7,5A

1

3

2

F5

VE

RG-NR

NR

12

6

3

30A

F1a

RG

NR

VE

L

E

V

L

E

E

L

V

R

E

E

P

R L

P

E

U

W

O

L

-

RG

15A

F2

11

1

2

V

2

5

A

12345

GR-RG

GR-RG

NR

1

2

V

25

A

21345

VE-NR

10

VI-BA

12

3

9

8

1

2

V

- 2

5A

2

4

15

A3

GR-RGMR-BA

VE

B1A1

BA-NR

BCNR

VI-NR

82420716 5 6

80

100

0

6

50

6

120

0

40

70

30

8

0

140

20

120

9

0

10

1

80

160

0

0

0

40

K

m

/

h

BE

8

BA

7

11

RG-BA

1

1

17

18

4

11

22

VI

BA-VE

BE-NR

1

5

VI

+

7

1

2

6

15 1413926 12

1

0

2

1

1

2

0

1

VE-NR

GR-VE

VE

GR-VE

GR-VE

GR-VE

RG MR OR

BA-BE

VE

JN

VE-NR

VE

1

2

2

1

21

2

1

R

5

19

2

1. Injection ECU.

2. Engine speed and position sensor.

3. Petrol injector.

4. Fuel pump.

5. Ignition coil.

6. Lambda sensor.

7. Starter motor switch.

8. Starter motor relay.

9. Cooling fan.

10. Fan relay.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

3

4

11. Injection relay.

12. Battery.

13. Ignition switch.

14. Transponder antenna.

15. Diagnostic plug.

16. Instrument panel.

17. Kickstand switch.

18. Emergency stop switch

19. Engine temperature sensor.

15

Page 18

ELECTRICITY

ABS/MBS system schematic diagram

8

JN/VE

1

2

V

2

5

A

START

6

24

3

10

80

100

60

5

0

60

120

0

4

70

0

3

40

80

140

20

120

9

Km

0

20

M

10

100

80

160

H

r

s

0

40

K

m/h

PEUGEOT

7

51417

VE

1

VI

2345

VI

MR/BA

GR

4

ON

OFF

6

RG/NR

RG

3

F1a 30A

-

RG

F1b 30A

RG/NR

VE

VEL

VEL

UPPER LE

OWER LE

L

5

1

2

V

2

5

A

12345

RG

13101

VI

BA

OR

A2

A3

A1 B1

VE

JN/BA

B3

14

17

3

5

9

RG

1

19

20

21

25

VE

PIN

VE

23911

RG

BE

2

1. Pressure control unit.

2. Speed sensor and pulse wheel.

3. Battery.

4. Ignition switch.

5. ABS/MBS relay.

6. Starter motor switch.

7. Starter motor relay.

8. Injection ECU.

9. Diagnostic plug.

10.Instrument panel (diagnostic lamp,

machine speed).

16

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 19

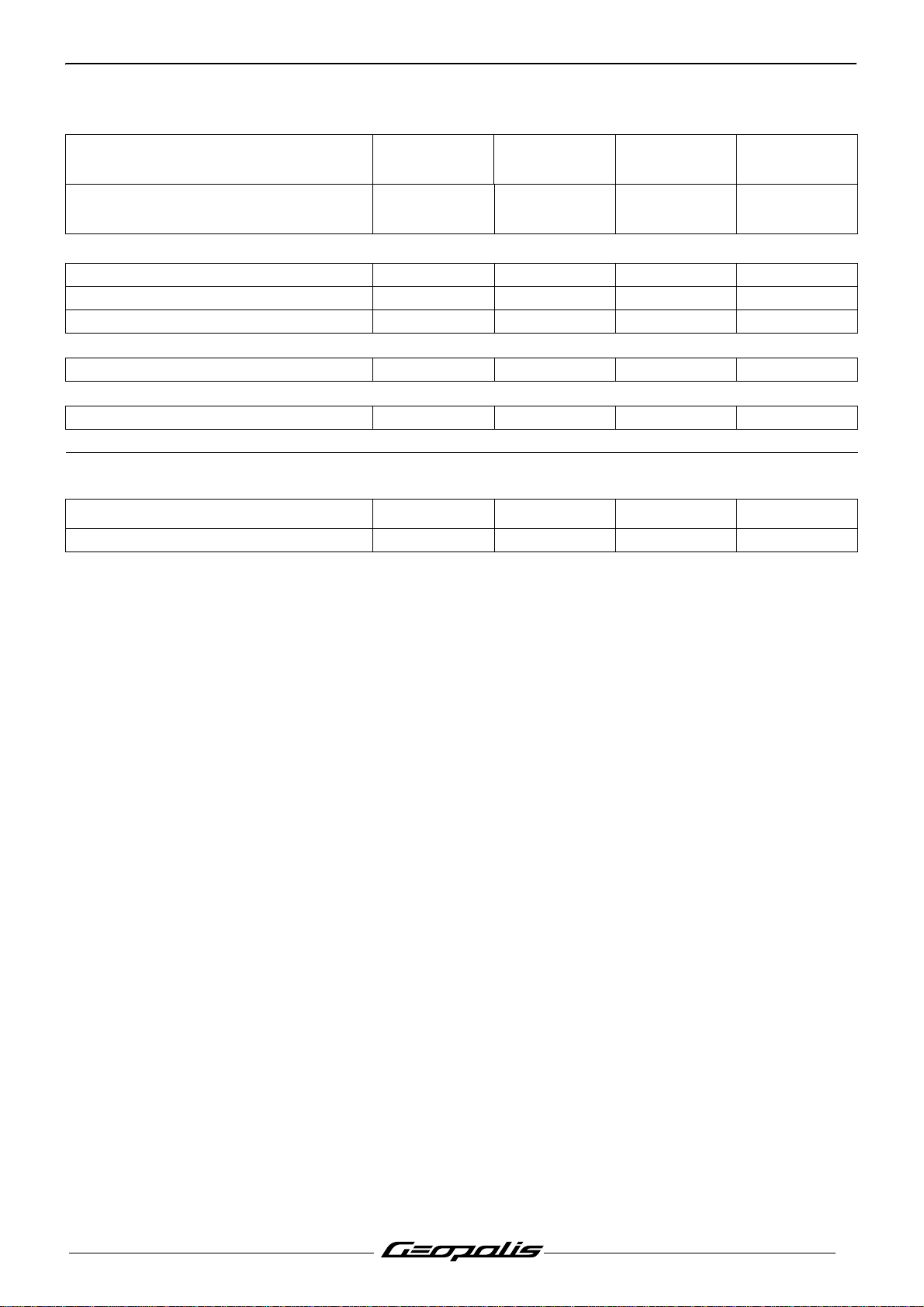

Fuses and energy distribution

ELECTRICITY

F1a

30A

F7-10A

NR

GR-NR

GR-RG

GR-BE

GR-RG

X

X

X

X

X

X

X

X

X

X

12V - 25A

12V - 25A

X

X

F5-7.5A

RG-NR

RG

RG

UPPER LEVEL

LOWER LEVEL

-

+B

F4-15A

F1a-30A

F1b-30A

F2-15A

F3-15A

Geopolis 400cc

Regulator

Ignition switch

F7

F1b

30A

F2

15A

F3

15A

F4

15A

F5

7.5A

ABS relay

Pressure control unit

Injection ECU.

Power supply relay

Fan relay

Instrument panel

Lighting relay

Starter motor relay control relay

Instrument panel

Dip switch (main/low headlight)

Horn

Number plate light

Sidelight

Stop light contact switch

Injection ECU

Transponder antenna

Diagnostic plug

Injection relay

Lighting relay

F7

10A

Accessory socket

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

17

Page 20

LOCATION OF COMPONENTS

LOCATION OF COMPONENTS

80

100

60

50

60

120

0

4

70

0

3

40

80

140

20

120

90

K

m

20

M

10

100

80

160

H

rs

0

40

K

m

/h

PEUGEOT

11

20

13

4

VEL

EL

V

ER LE

UPPER LE

W

O

L

-

12

OK

TEP 2005

test

xxo

by

7

6

17

24

19

14

1. Injection ECU.

2. Engine speed and position sensor.

3. Engine temperature sensor.

4. Battery.

5. Lambda sensor.

6. Petrol injector.

7. Ignition coil.

8. Transponder antenna.

9. Fuel pump.

10.Fuel gauge.

11.Diagnostic lights.

12.Diagnostic plug.

13.Starter motor relay.

21

16

1

23

10

8

22/02/

50395014

06 9 :

E63853

18

12V

- 2

5A

2

3

39 :

0101

07

4

CE 0051

e24

0064

15

5

14.Oil pressure switch.

15.10 A fuse.(Accessory socket. 12V.)

16.Fuses.

17.Motor-driven fan.

18.Lighting relay/Fan relay/Power supply

relay.

19.Voltage regulator.

20.Horn.

21.Saddle lock.

22.Machine speed sensor.

23.Emergency stop switch.

24.Kickstand switch.

9

22

18

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 21

BODY PANELS

Location of body components

2

1

BODY PANELS

3

4

5

6

19

1. Handlebar front fairing.

2. Wind protector.

3. Counter panel.

4. Lower handlebar cover.

5. Front top cover panel.

6. Front shield panels.

7. Mudguard.

8. Bottom panel.

9. Saddle.

10.Tank streamlining.

10

11

13 8127

9

15

11.Rear shield.

12.Footboard.

13.Access door.

14.Luggage carrier.

15.Helmet compartment.

16.Mudflap.

17.Rear cover.

18.Side panels.

19.Front mudguard.

18

14

17

16

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

19

Page 22

BODY PANELS

Body component sequence of disassembly

1* 5* 8* 9*

26 10

37 1112

4

19*

15*

14

16*

13*

17

*This item may be removed on its own.

20

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

18

Page 23

Removal of the storage compartment

Procedure 1.

- Remove the storage

compartment.(2 screws and 2 nuts).

Removal of a RH or LH side cover

Procedure 2.

- Remove the storage compartment. See:

Procedure 1. page 21.

- Remove the luggage carrier trim.(1)

- Remove the luggage carrier. (2 screws and

1 nuts).

BODY PANELS

1

- Remove the splash guard. (4 screw).

- Disconnect the license plate light.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

21

Page 24

BODY PANELS

- Remove the rear body cover. (4 screw).

- Remove the access door. (1 screw).

- Remove the 2 screws that secure the

footrest.(2)

- Remove the rear cover 3 fixing screws.(3)

- Unclip the support (A) and remove the side

panel together with the footrest.

3

A

2

Removal of the tank covers

Procedure 3.

- Remove the saddle. (2 screw).

- Remove the battery cover.(1)

- Open the tank filler cap door.

- Remove the upper fairing.(2)

3

1

2

22

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 25

- Remove the 2 fixing bolts.(3)

- Remove the fuel tank cover panel by sliding

it rearwards.

Removal of a RH or LH footboard

Procedure 4.

- Remove the tank cover panel. See:

Procedure 3. page 22.

BODY PANELS

3

2

3

- On each side remove:

• 2 washer head screws. Ø6 mm.(1)

• 1 washer head screws. Ø5 mm.(2)

• 5 plastic screws.(3)

- Remove the access door.

- Separate the front of the footboard which is

linked to the rear part of the leg shield panel.

- Remove the footboard.

3

1

3

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

23

Page 26

BODY PANELS

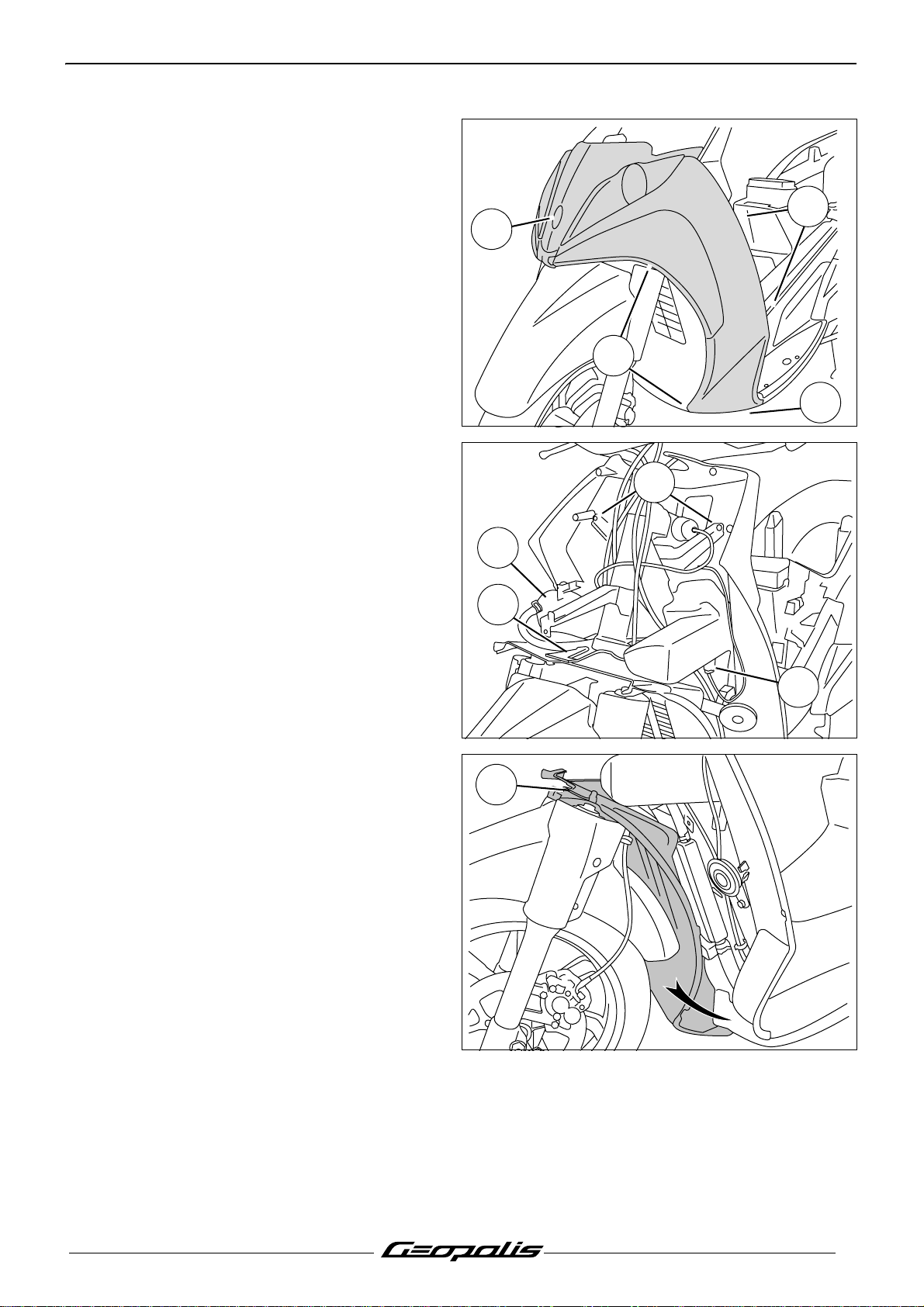

Removal of the front shield panel

Procedure 5.

- Remove the front top cover panel. (5 screw).

- Remove the footboard mat.

- On each side remove:

• 2 washer head screws. Ø6 mm.(1)

• 2 plastic screws.(2)

- Lift the footboard in order to reach the screw

that secures the shield panel.

1

2

24

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 27

- On each side remove:

• 5 plastic screws.(3)

BODY PANELS

- Remove the centre screw.(4)

- Remove the front legshield assembly.

- Disconnect the lighting and direction

indicator connections.

Removal of the rear shield panel

- Remove the footboards. See: Procedure 4.

page 23.

- Remove the front legshield assembly. See:

Procedure 5. page 24.

- Remove the header tank. (Right-hand

side (1))

- Remove the fuse holder. (Right-hand

side (2))

- Disconnect the accessory plug. Left side (3)

- Remove the 2 fixing bolts.(4)

- Remove the rear shield panel.

3

4

3

3

4

1

2

3

Removal of the dirt shield

- Remove the front legshield assembly. See:

Procedure 5. page 24.

- Remove the dirt shield (1) by unclipping it

from the upper bracket and by swivelling it to

the right or to the left.

Note: When removing the dirt cover make

sure it doesn't rub against the

radiator

1

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

25

Page 28

BODY PANELS

Removal of the instrument cluster

- Remove the handlebar front cover.

(2 screw).

- Remove the screen. (4 screw).

- Remove the handlebar rear cover and

instrument cluster assembly. (7 screw).

- Disconnect the instrument cluster.

Removal of the battery holder

Procedure 6.

- Remove the storage compartment. See:

Procedure 1. page 21

- Remove the tank cover panel. See:

Procedure 3. page 22.

- Disconnect and remove the battery.

- Unclip from the battery holder:

• The fuses.(1)

• The relays.(2)

- Remove the battery bracket. (3 screw).

1

2

26

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 29

SERVICE OPERATIONS

Changing the engine oil and replacing

the oil filter

- Remove the engine's oil filler cap.(1)

- Remove the cap and the filter to drain oil

from the engine.(2) (check the condition of

the O-ring and change it if necessary).

SERVICE OPERATIONS

1

- Using a facom D155 type oil filter notched

cap wrench, remove the oil filter.

2

Drain the engine when it is warm.

Wear gloves in order not to get burnt.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

27

Page 30

SERVICE OPERATIONS

- Lubricate the rubber seal of a new oil filter.

- Using a facom D155 type oil filter notched

cap wrench, install the oil filter.

Tightening torque: 1.4 m.daN.

- Fit the drain plug.

Tightening torque: 2.5 m.daN.

- Fill the engine with 1.7 L motor oil through

the filler hole.

- Fit the filler cap.

- Start the engine, let it run for a few minutes

and then stop it.

- Remove the filler cap and wipe up the oil.

- Fit and screw the cap home.

- Remove the engine's oil filler cap.

- Check the oil level by using the marks on the

filler cap.

A. Oil level high.

B. Oil level low.

A

- Add oil if necessaire.

Note: Check the level with the machine par-

ked on its centre stand, on level

ground.

B

28

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 31

Draining the relay box

500 4T 4V

- Remove the relay box filler cap.(1)

- Remove the screw (2) in order to drain the

relay box.

Note: Replace the copper seal every time

you change oil

SERVICE OPERATIONS

1

- Fit the drain plug.

Tightening torque: 1.5 m.daN.

- Fill the relay box with 0.25 L oil through the

filler hole.

- Fit and screw the cap home.

- Remove the relay box filler cap.

- Check the oil level by using the marks on the

filler cap.

A. Oil level high.

B. Oil level low.

- Add oil if necessaire.

Note: Check the level with the machine par-

ked on its centre stand, on level

ground.

2

A

B

29

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 32

SERVICE OPERATIONS

Replacing the air filter

- Remove the air filter cover (9 bolts) and its

seal.

- Remove the air filter.(1)

1

30

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 33

- Clean or change the filter according to the

maintenance recommendations.

- Clean the air filter with a cleaning and

degreasing agent for air filters.

Note: Do not use a flammable product to

clean the air filter.

- Lubricate the air filter with a special oil for air

filters and squeeze out the excess oil.

- Remove the inlet silencer drain plug to let

humidity and oil drip out.(2)

SERVICE OPERATIONS

2

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

31

Page 34

SERVICE OPERATIONS

Removal of the transmission air filter

Changing the drive pulley bearings

- Remove the 2 air filter box fixing bolts (1).

- Remove the transmission cover

trim.(2) (4 screw)

- Remove the transmission cover

hood.(1) (3 screw)

- Remove the transmission air filter.(2)

- Blow the air filter with compressed air.

1

2

1

- Remove the transmission cover. Refer to

the 400/500cc Engine workshop manual.

4 valves. Reference 759533.

2

32

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 35

Removal of the spark plug

- Remove the access door. (Left side)

- Disconnect the suppressor.

- Remove the spark plug.

Essential precautions: When re-installing,

srew in the spark plug (a few turns)

by hand. For torquing, use a spark

plug wrench equipped with a dial.

- Tighten the spark plug.

Tightening torque: 1.2 m.daN.

Draining the cooling circuit

SERVICE OPERATIONS

- Remove the storage compartment. See:

Procedure 1. page 21.

- Remove the header tank cap.

- Disconnect the lower pump from the coolant

pump to drain the cooling system.(1)

Note: The cooling system is drained when

the engine is cold.

- Connect the lower hose to the water pump.

- Fill the circuit with 1.4 L of coolant.

- Loosen the bleeder screw (2) to remove air

contained in the engine.

- Close the bleeder screw.

Tightening torque: 0.3 m.daN.

- Start the engine and accelerate in order to

warm it up.

- Stop the engine once it reaches its operating

temperature. (Approximately 90°C)

1

2

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

33

Page 36

SERVICE OPERATIONS

- Check the coolant level in the header tank.

- If necessary add coolant in the header tank.

A. Maximum level.

B. Minimum level.

Note: Check the level with the machine par-

ked on its centre stand, on level

ground.

Installing the valve clearance.

- Remove the storage compartment. See:

Procedure 1. page 21.

- Remove the battery bracket. See:

Procedure 6. page 26.

- Remove the access doors.

- Remove the rocker cover. (6 screw).

A

B

Tightening torque: 0.8 m.daN.

- Remove the 2 air filter box fixing bolts (1).

- Remove the transmission cover trim.(2)

(4 screw)

1

2

34

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 37

- Rotate the engine by hand in the operating

direction in order to align the (A) mark on the

pinion with the mark on the cylinder head.(B)

SERVICE OPERATIONS

- Loosen the lock nut of the rocker

adjustment screw.(3)

- By means of feeler gauges, adjust the

clearance of every valve by acting on the

rocker set screw.

Clearances:

• 15/100 at the intake.

• 15/100 at the exhaust.

B

A

3

- Immobilize the rocker set screw.

- Tighten the locknut without altering the

adjustment.

- Check the adjustment.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

35

Page 38

SERVICE OPERATIONS

Replacing the brake pads

Front brake

- Remove the 2 spindles (1).

- Remove the calliper. (2 screw).

Tightening torque: 2.5 m.daN.

- Remove the brake pads.

Mini. thickness: 1.5 mm.

- When refitting the brake pads, push the

pistons all the way into their housing.

Note: After refitting, actuate the brake

levers several times to bring the

brake pads against the brake disc.

Rear brake

- Remove the exhaust muffler trim. (3 screw)

1

- Remove the heat shield. (3 screw)

36

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 39

- Loosen the collars.(1)

- Remove the upper fixing bolts.(2)

- Remove the exhaust.

Tightening torque: 1 m.daN.

- Remove the collar retaining pin.(3)

- Remove the collar.

SERVICE OPERATIONS

2

1

- Remove the 2 lower fixing bolts (4) from the

mudflap.

3

4

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

37

Page 40

SERVICE OPERATIONS

- Remove the 2 screws that secure the stand

support.(5)

Tightening torque: 2.2 m.daN.

- Remove the 2 nuts that secure the arm.(6)

Tightening torque: 2.8 m.daN.

- Remove the shock absorber lower

mount (7).

Tightening torque: 4.5 m.daN.

- Remove the pin, the nut retainer and the

wheel nut.(8)

Tightening torque: 13.5 m.daN.

- Remove the suspension arm.

6

5

7

8

- Remove the spacer.(9)

- Remove the wheel. (5 screw)

Tightening torque: 2.5 m.daN.

9

38

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 41

- Remove the calliper. (2 screw).

Tightening torque: 2.5 m.daN.

- Remove the 2 spindles (10).

- Remove the brake pads.

Mini. thickness: 1.5 mm.

SERVICE OPERATIONS

10

- When refitting the brake pads, push the

pistons all the way into their housing.

Note: After refitting, actuate the brake

levers several times to bring the

brake pads against the brake disc.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

39

Page 42

SERVICE OPERATIONS

Checking the brake fluid level

- Position the handlebars so that the master

cylinder will be horizontal.

- Check the brake fluid level and if necessary

top up in the master cylinder.

A. Maximum brake fluid level.

B. Minimum brake fluid level.

- Remove the screen.

- Remove the handlebar rear cover and

instrument cluster assembly. (7 screw)

- Remove the cover and the diaphragm from

the master cylinder. (2 screw)

- Add brake fluid until it reaches the maximum

level.(A)

A

LOW

B

2

2

40

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 43

SERVICING THE ABS/MBS SYSTEM

SERVICING THE ABS/MBS SYSTEM

Reminder

The ABS/PBS system features 3 distinctive functions:

1. Combined front and rear braking system controlled by the LH brake lever.

2. Braking assistance system provided on the front wheel.

3. Anti-locking system provided on the front wheel.

Before servicing the system, carry out a diagnosis using the diagnostic tool and print out a parameter

report.

If fault codes appear, repair as required.

The diagnostic light of the system only goes off when the machine reaches 5 km/h.

The rider brakes with the left lever (integral braking), and the right lever (braking on the front wheel

only) becomes an emergency brake.

For diagnosing the ABS/MBS system, see document: ABS/MBS braking system functioning

principle. Reference: 759568.

Removal of the brake modulator

- Remove the front legshield assembly. See:

Procedure 5. page 24.

- Remove the screen.

- Remove the handlebar rear cover and

instrument cluster assembly. (7 screw)

- Remove the mudguard.

Plastic parts must be protected from brake fluid splashes.

Hold the brake levers at 20 mm from the rest position using plastic straps. This

operation allows you to close the circuits and to avoid emptying the

hydraulic controls when disconnecting the modulator.

20 mm

Do not remove the master cylinder covers.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

41

Page 44

SERVICING THE ABS/MBS SYSTEM

- Disconnect the modulator.

- Disconnect the hydraulic controls.

- Remove the brake modulator. (2 nuts)

Place a pan under the modulator so that the

brake fluid will drip into it.

The modulator shall not be open, the manufacturer is the only one allowed to service this

component.

Re-installing the modulator

- Place the modulator in its support.

Tightening torque: 2.2 m.daN.

- Position the hydraulic controls in the

indicated order:

• The hydraulic control coming from the LH

master cylinder.(1)

• The hydraulic control going to the rear brake

calliper.(2). Place it over the hydraulic

control.(1)

• The hydraulic control coming from the RH

master cylinder.(3)

• The hydraulic control going to the front

brake calliper.(4)

Tightening torque: 2.8 m.daN.

3

2

1

4

Change the copper seals each time they

are removed.

- Connect the modulator.

- Bleed the hydraulic system according to the

required procedure.

42

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 45

SERVICING THE ABS/MBS SYSTEM

Bleed procedure

Reminder:

- The rear brake hydraulic system is drained using the LH lever.

- The front brake hydraulic system is drained using the RH lever.

- The front and rear brake systems are drained the usual way.

- The brake assistance circuit is drained by actuating the modulator pump by means of the

diagnostic tool.

Note:

- Plastic parts must be protected from brake fluid splashes.

- Remove the hook or plastic strap in order to free the control lever.

Equipment required:

• 500 ml brake fluid of minimum grade: DOT4.

• Bleed syringe. P/N: 754306.

• Transparent pipe.

• 2 additional 100 ml reservoirs.

Draining the rear brake circuit

- Remove the cover from the LH master

cylinder.

- Using the syringe, empty the LH master

cylinder.

- Position the handlebars so that the master

cylinder is in its uppermost position, in order

to expell the air bubbles from the circuit.

- Fill the syringe with brake fluid.

- Connect the syringe to the bleed screw of

the rear calliper.

- Open the bleed screw by 1 to 2 turns.

- Inject the brake fluid slowly into the circuit

until the level inside the reservoir of the

master cylinder is halfway up.

- Close the caliper bleed screw.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

43

Page 46

SERVICING THE ABS/MBS SYSTEM

- Slowly actuate the brake control lever by

displacing it 2 cm (A) maximum from its rest

position until no more bubbles can be seen

coming up through the master cylinder.

- This operation can take a few minutes.

- Connect a reservoir containing brake fluid to

the rear brake calliper bleed screw using a

transparent pipe.. The reservoir must be

kept higher than the brake calliper to easily

check that the air bubbles are being

expelled.

- Open the bleed screw by 1 to 2 turns.

A

- Actuate the LH brake lever in an even way

and without undue haste while topping up

with brake fluid in the master cylinder.

Note: Don't lean over the master cylinder

when bleeding the circuit in order

not to get splashed by brake fluid.

- Stop the operation when no more bubbles

are expelled from the calliper bleeder screw.

- Close the caliper bleed screw.

- Check the firmness of the lever without

roughly squeezing the lever to avoid the

brake fluid from splashing out.

- Otherwise, repeat the operation from the

beginning.

- Check the brake fluid level and if necessary

top up in the master cylinder, and re-fit the

master cylinder cover.

44

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 47

Bleeding the assistance circuit

Note: Before servicing the assistance

system you must absolutely be sure

that the battery is perfectly charged,

as a considerable voltage drop

would immediately turn off the

assistance pump.

- Connect the additional reservoir equipped

with a transparent pipe to the modulator's

reservoir screw plug (1) and fill.

- Open the screw plug by 2 or 3 turns.

- Connect the reservoir containing brake fluid

to the front brake calliper bleed screw using

a transparent pipe. The reservoir must be

kept higher than the brake calliper to easily

check that the air bubbles are being

expelled.

- Open the bleed screw by 1 to 2 turns.

- Turn on the ignition.

- Connect the diagnostic tool and actuate the

modulator pump.

- Regularly add brake fluid in the additional

reservoir.

- Stop the operation when there are no more

bubbles in the transparent pipe.

- Close the caliper bleed screw.

SERVICING THE ABS/MBS SYSTEM

1

As a precautionary measure, the pump

shall not continuously operate for

more than 2 minutes.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

45

Page 48

SERVICING THE ABS/MBS SYSTEM

Draining the front brake circuit

- Remove the cover from the RH master

cylinder.

- Using the syringe, empty the RH master

cylinder.

- Position the handlebars so that the master

cylinder is in its uppermost position, in order

to expell the air bubbles from the circuit.

- Fill the syringe equippd with a transparent

pipe with brake fluid.

- Connect the syringe to the bleed screw of

the front calliper.

- Open the bleed screw by 1 to 2 turns.

- Inject the brake fluid slowly into the circuit

until the level inside the reservoir is halfway

up.

- Close the caliper bleed screw.

- Slowly actuate the brake control lever by

displacing it 2 cm (A) maximum from its rest

position until no more bubbles can be seen

coming up through the master cylinder.

- This operation can take a few minutes.

A

46

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 49

- Connect the reservoir containing brake fluid

to the modulator bleed screw (1) using a

transparent pipe. The reservoir must be kept

higher than the modulator to easily check

that the air bubbles are being expelled.

- Open the bleed screw by 1 to 2 turns.

- Actuate the RH brake lever in an even way

and without undue haste while topping up

with brake fluid in the master cylinder.

SERVICING THE ABS/MBS SYSTEM

1

Note: Don't lean over the master cylinder

when bleeding the circuit in order

not to get splashed by brake fluid.

- Stop the operation when no more bubbles

are expelled from the modulator.

- Close the bleeder screw.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

47

Page 50

SERVICING THE ABS/MBS SYSTEM

- Connect the reservoir containing brake fluid

to the front brake calliper bleed screw using

a transparent pipe. The reservoir must be

kept higher than the brake calliper to easily

check that the air bubbles are being

expelled.

- Open the bleed screw by 1 to 2 turns.

- Actuate the RH brake lever in an even way

and without undue haste while topping up

with brake fluid in the master cylinder.

- Stop the operation when no more bubbles

are expelled from the calliper bleeder screw.

- Close the caliper bleed screw.

- Check the firmness of the lever.

- Otherwise, repeat the operation from the

beginning.

- Check the brake fluid level and if necessary

top up in the master cylinder, and re-fit the

master cylinder cover.

Integral braking system static test.

- Wedge the machine frame so that the front wheel is not in contact with the floor.

- Turn on the ignition.

- Turn the front wheel at over 5 km/h, and operate one of the brake levers to check that

the high pressure pump operates with both levers.

- Check by actuating the LH control lever: the front wheel stops.

- If not, repeat the operation: Bleeding the assistance circuit.

48

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 51

MISCELLANEOUS OPERATIONS

Procedure for reducing the fuel circuit

pressure

Procedure 7.

- Remove the storage compartment. See:

Procedure 1. page 21.

- Disconnect the fuel injector.

- Remove the fuel injector without

disconnecting the supply hose.

- Connect the fuel injector power supply

harness tool P/N 756017 to the fuel injector

and the battery.

- Place the injector above a pan.

- Actuate the contact switch of the tool 3 times

for 5 seconds while respecting a released

time of 5 seconds between each action, in

order to drop the pressure inside the supply

hose of the fuel manifold.

756017

UPPER LEVEL

LOWER LEVEL

MISCELLANEOUS OPERATIONS

The pressurised jet of fuel may be dangerous for the skin, do not expose the hands to the jet of

fuel when opening the injector.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

49

Page 52

MISCELLANEOUS OPERATIONS

Checking fuel pressure

- Remove the tank cover panel. See:

Procedure 3. page 22.

- Carry out the procedure for lowering the

pressure in the fuel system. See:

Procedure 7. page 49.

- Disconnect the fuel supply hose. (1 "click"

collar).

- Insert the pressure gauge P/N 757877

between the gauge well and the supply

hose.

- Always use hose clamps that are in good

condition.

- Turn the ignition on 3 times to bleed the fuel

system.

- With the engine stopped, check the fuel

pressure which must be 2.5 bars when

switching on the fuel pump.

Before disconnecting the pressure gauges, lower the fuel pressure in the fuel system.

Always reinstall the hoses with new hose clamps.

4

2

6

0

8

bar

10

50

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 53

Removal of the fuel pump

- Remove the tank cover panel. See:

Procedure 3. page 22.

- Carry out the procedure for lowering the

pressure in the fuel system. See:

Procedure 7. page 49.

- Disconnect the fuel pump.(1)

- Disconnect the fuel pipe by pressing against

the ring (A) to remove the quick disconnect

coupler (2).

- Loosen by hand the pump locking ring.(3)

- Remove the fuel pump.

3

MISCELLANEOUS OPERATIONS

1

2

A

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

51

Page 54

MISCELLANEOUS OPERATIONS

Removal of the fuel gauge

- Remove the tank cover panel. See:

Procedure 3. page 22.

- Disconnect the fuel gauge.

Using tool P/N 756715, remove the fuel gauge.

Note: Modify the tool P/N 756715 as shown

in the sketch in order to use it with

the Geopolis.

756715

52

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 55

Removal of the throttle box

MISCELLANEOUS OPERATIONS

- Remove the storage compartment. See:

Procedure 1. page 21

- Disconnect the battery.

- Remove the intake silencer. (2 clips and

3screws).

- Remove the screw that secures the wiring

harness clamp and the fuel hose anchor

bracket.(A)

- Disconnect the throttle unit.(1)

- Remove the 3 screws that secure the

throttle box.(2)

- Remove the throttle box.

- Disconnect the throttle control cables.(3)

3

2

A

1

Removal of the lambda sensor

- Remove the storage compartment. See:

Procedure 1. page 21.

- Remove the RH fairing. See: Procedure 2.

page 21.

- Disconnect the lambda sensor.

- Using a box-end wrench, remove the

lambda sensor.

Tightening torque: 4.5 m.daN.

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

53

Page 56

MISCELLANEOUS OPERATIONS

Note: When reinstalling, lubricate the

threads (A) of the sensor with graphite grease.

In order not to damage the Lambda sensor, never lubricate or clean the end piece (B) which is

exposed to the exhaust gas.

A

B

- When re-installing, make absolutely sure

there is the fuel tank heat shield (1) and its

pin.(2)

Removal of the regulator

- Remove the storage compartment. See:

Procedure 1. page 21.

- Remove the RH fairing. See: Procedure 2.

page 21.

- Disconnect and remove the regulator.(1)

2

1

1

54

1

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 57

Removal of the radiator

MISCELLANEOUS OPERATIONS

- Remove the tank cover panel. See:

Procedure 3. page 22.

- Disconnect the fan.(1)

- Remove the front shield panel. See:

Procedure 5. page 24.

- Remove the mudguard.

- Remove the upper fixing bolts.(2)

- Drain the cooling circuit.

- Disconnect the 4 hoses of the radiator's

cooling circuit.

- Remove the radiator.

1

2

- Remove the fan.(3).(3 screw)

3

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

55

Page 58

MISCELLANEOUS OPERATIONS

Removal of the engine mounting

assembly

- Remove the side fairings. See:

Procedure 2. page 21.

- Suspend the rear of the machine.

- Remove the intake silencer. (1) (2 clips and

3screws).

- Remove the sheath holder.(A)

- Loosen the linkrod connecting pin nut.(1)

- Loosen the 2 nuts.(2)

A

Tightening torque: 9.5 m.daN.

- Remove the 2 nuts from the torque rods.(3)

Tightening torque: 3.6 m.daN.

1

2

3

3

56

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 59

- Remove the linkrod-to-engine connecting

pin.(1)

- Remove the linkrod-to-frame connecting

pin.(2)

MISCELLANEOUS OPERATIONS

2

- Remove the linkrod connecting pin.(3)

- Check the condition of the spacers and

needle bearings.(7)

- Make sure that the silent block is not

cracked.(8)

1

3

Note: We recommend greasing all needle

bearings when refitting these parts.

- When re-installing, fit the rubber bushings

with the colours shown:

A. Blue

B. Black

C. Grey

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

7

8

A

B

2

C

B

8

57

Page 60

MISCELLANEOUS OPERATIONS

Removal of the engine

Note: To remove the cylinder head, remove

the power propulsion unit.

For removal of the cylinder head, cylinder

and piston, see the workshop

manual: 4 stroke engine. 4 valves.

Reference: 758851

- Disconnect the battery.

- Remove the side fairings. See:

Procedure 2. page 21.

- Disconnect the lambda sensor.(1)

- Remove the exhaust assembly.

- Remove the intake silencer.(2)

- Remove the rear mudguard.(3)

1

3

- Remove the screw that secures the wiring

harness clamp and the fuel hose anchor

bracket.(A)

- Disconnect:

• The fuel injector.(4)

• The throttle box.(5)

• The temperature sensor.(6)

• The magneto.(7)

• The suppressor.

- Disconnect the injector fuel feed hose.(8)

4

2

6

8

7

A

5

58

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 61

- Disconnect:

- Oil pressure switch.(9)

- Disconnect:

• The engine ground.(10)

• The starter motor.(11)

MISCELLANEOUS OPERATIONS

9

10

- Disconnect the lower pump from the coolant

pump to drain the cooling system.

- Disconnect the cylinder head hose.(12)

11

12

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

59

Page 62

MISCELLANEOUS OPERATIONS

- Remove the suspension arm.

- Remove the wheel.

- Remove the calliper.(13)

- Re-install the wheel.

- Suspend the rear of the machine.

- Remove the shock absorber lower

mount (14).

13

- Remove the linkrod-to-engine connecting

pin.(15)

14

15

60

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 63

- Lift the rear of the machine.

- Disconnect the throttle control cables.(16)

- Remove the engine.

- Remove the 4 spacers.(17)

MISCELLANEOUS OPERATIONS

16

- When re-installing, make absolutely sure

there is the fuel tank heat shield (1) and its

pin.(2)

17

17

2

1

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

61

Page 64

MISCELLANEOUS OPERATIONS

Removal of the fork

Replacing the bearings of the steering

system

- Remove the front top cover panel.

- Remove the handlebar front and rear

covers.

- Remove the 2 upper screws that secure the

rear shield panel.

- Remove the braking units on the

handlebars.(1)

- Remove the handlebars from the fork tube.

- Remove the front mudguard.

- Remove the front brake caliper from the fork

tube.

- Remove the front wheel.

- Using tool P/N 757860 remove the steering

locknut.

- Remove:

• The lock washer.

• the adjustable cone locknut.

• the rubber washer.

• the adjustable cone.

757860

1

757860

- Remove the fork.

- Remove the balls.

- Using a drift, remove the steering head

cups.

62

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 65

- Using a chisel, pry the steering head cup off

by pressing the tool behind the dust cover.

- Install the following new parts:

• The plain washer.(1)

• The dust cover.(2)

• The fork cone.(3)

MISCELLANEOUS OPERATIONS

3

- Install new steering head cups using tool

P/N 758810.

758810

1

2

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

63

Page 66

MISCELLANEOUS OPERATIONS

Steering system tightening method

- Grease the cup bearing races.

- Fit the caged ball bearings. (1 and 2).

- Fit the fork into the steering column.

- Install the adjustable cone and tighten it.(3)

Tightening torque: 4 m.daN.

- Loosen and then retighten the adjustable

cone.

Tightening torque: 2.2 m.daN.

- Install the rubber washer.(4)

- Finger tighten the adjustable cone

locknut (5) so that its notches are aligned

with those of the adjustable cone.

- Fit the lock washer (6) in the notches of the

locknut and adjustable cone.

- Install the steering head locknut and tighten

it.(7)

Tightening torque: 7.5 m.daN.

7

5

6

2

3

4

1

64

Reproduction or translation, even partial, is forbidden without the written consent of Peugeot Motocycles

Page 67

Page 68

P/N. 759538

In our permanent concern to make improvements PEUGEOT MOTOCYCLES reserves the right to suppress,

modify, or add any reference mentioned.

DC/PS/APV Printed in the E.U. 07/2007 (non contractual pictures)

Loading...

Loading...