PRINCIPLE OF OPERA TION

PERFORMANCE

MH™-Series Humidifiers are shell and tube

moisture exchangers that allow the transfer of

water vapor between a liquid water supply and a

flowing gas stream. Water is absorbed into the

walls of the Nafion® tube and transferred to the

dry gas stream. This transfer is driven by the

difference in partial pressures of water vapor on

the opposing sides.

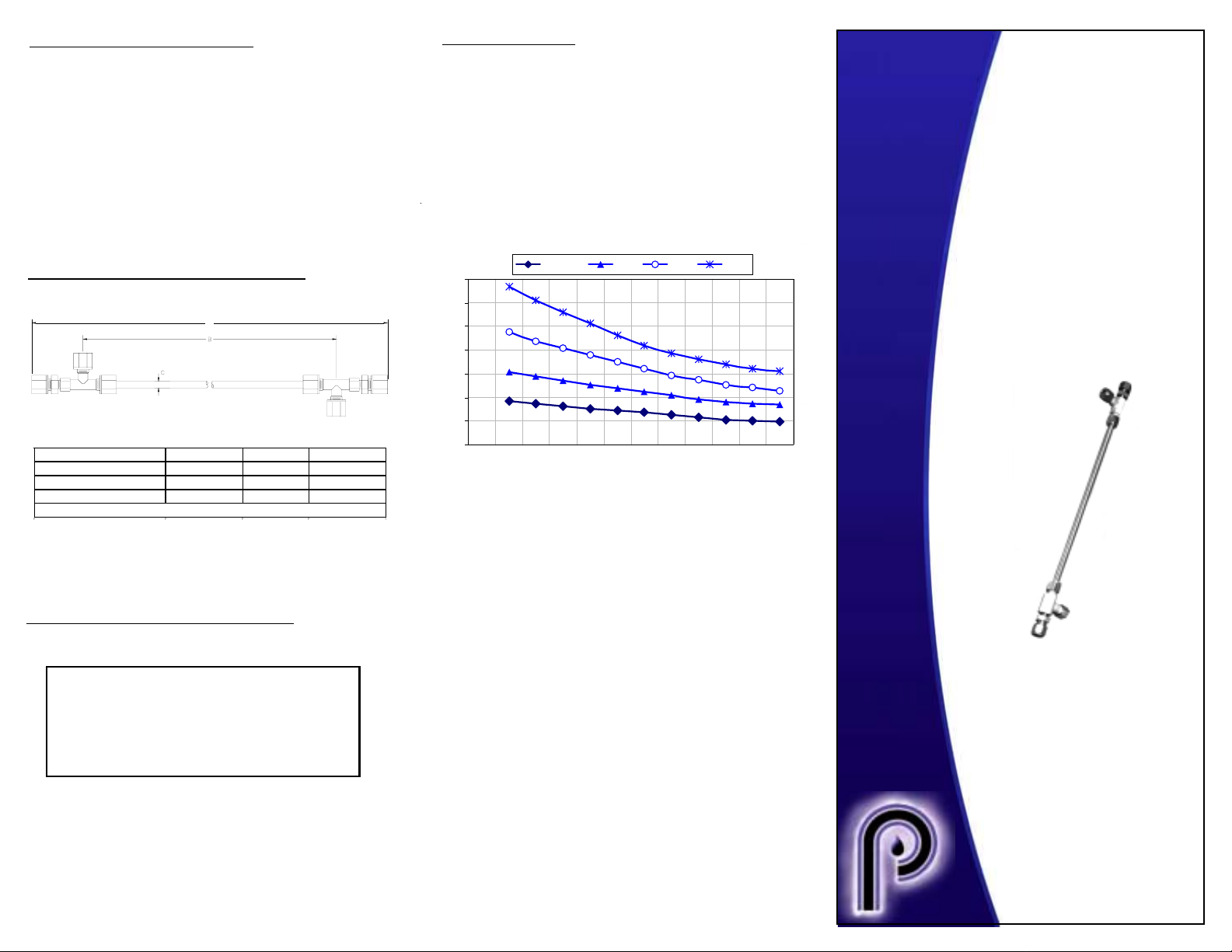

MH HUMIDIFIER SPECIFICA TIONS

A

Model Number A B C

MH-(070 or 110)-12 14+/ -1 /4" 10" 1/4"

MH-(070 or 110)-24 26+/ -1/4" 22" 1/4"

MH-(070 or 110)-48 50+/ -1/4" 46" 1/4"

Sampl e F i ttings 1/8" or 1/4" , Purge Fi t ting 1/ 4" Compression.

MH-070 humidifier’s performance is shown in

the chart below. The MH-110 which has a

slightly larger ID shows about a 3 degree higher

outlet dew point. MH-110 should be chosen

when a lower pressure drop is desired.

MH-070 Humidi fi er Performa n ce

70

60

50

40

30

Dew point (C)

20

10

0

12"0.512345678910

24"1 2 4 6 8 101214161820

48" 2 4 8 12 16 20 24 28 32 36 40

Ambient 30 C 50 C 70 C

MH™- Series

Humidifier

User Manual

INSTALLATION SPECIFICA TIONS

Warning!

Do not allow Nafion tube to dry out.

Nafion will shrink up to 125% and pull

out of the end fittings or break. Should

the element dry, soak it in DI water for

5 minutes before re-assembly.

1. Use only de-ionized water.

2. Controlled temperature water.

3. Do not allow unit to dry out. If element dries

completely, soak in DI water for 1 hour.

Flow Rate (l/min.)

MH-070 Performance Chart

Nafion® is a registered trademark of DuPont.

MH™ is a tradmark of Perma Pure LLC.

Bulletin# 206

PERMA PURE

8 Executive Drive

Toms River, N.J. 08755

Phone: 800-337-3762

732-244-0010

Fax: 732-244-8140

e-mail: info@permapure.com

Web Site: www.permapure.com

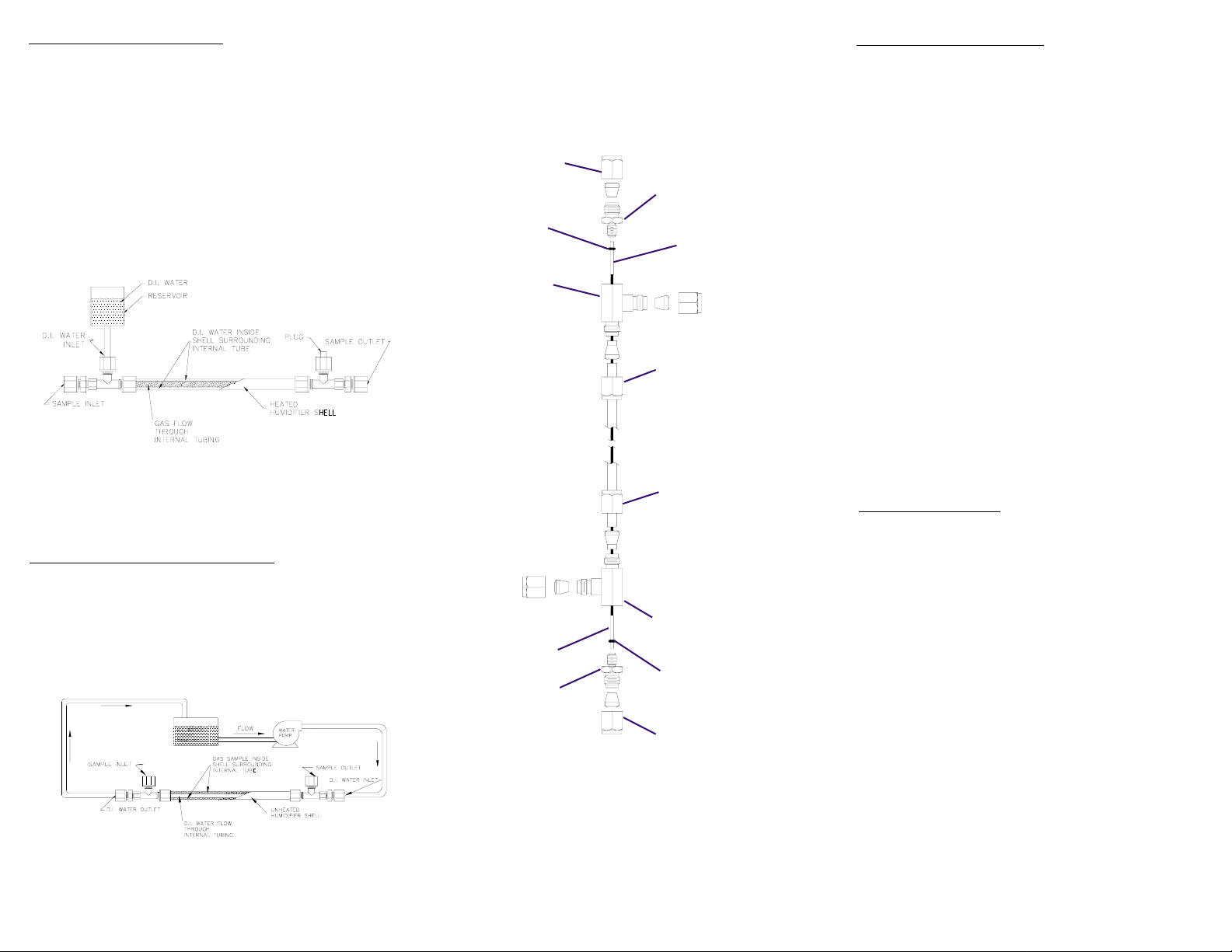

SIPHON FEED METHOD

ROTATE TEE FITTINGS

In the Siphon feed setup (shown in Figure 1),

temperature at which the air will be fully saturated

(“dew point”) must be determined. The humidifier

must be heated or insulated to this temperature and

kept constant. A reservoir of de-ionized water is

pulled through to fill the shell side and cap off at the

outlet. A positive pressure sample gas is pushed

through the inner tubes and is humidified.

Figure 1

Nut

O-Ring

Tee Fitting

Union Fitting

Element

Inside Nut

Inside Nut

Tools Needed:

- Two wrenches- 5/8 and 7/16

- Tweezers

1. Hold tee fitting with 7/16 wrench and loosen

union connector fitting with 5/8 wrench (refer

to Figure 3).

2. Remove fitting.

3. Rotate dryer element 10 degrees each way

with tweezers or fingertips.

4. With two wrenches, loosen inside nut

connecting tee fitting to shell tube.

5. Rotate tee fitting to desired location and

tighten into place.

6. Install union into tee fitting while making sure

element is not pushed back out of o-ring seal.

Take caution to ensure element does not

rotate inside shell.

7. Tighten union fitting by hand and then tighten

1/4 turn with wrench.

DISASSEMBLING

CIRCULATION FEED METHOD

The circulation method (shown in Figure 2) requires

heated water to be continuously circulated. The flow

with greater pressure needs to be flowing inside the

tubes to prevent tubing collapse.

Figure 2

Element

Union Fitting

Figure 3

Tee Fitting

O-Ring

Nut

Tools Needed:

- Two wrenches - 5/8 and 7/16

- Pair of lightweight gloves

1. Repeat steps 1-4 for other end.

2. Put on lightweight gloves to protect membrane

tubing (skin oils can contaminate surface).

3. Gently push one end of element out of o-ring

while pulling other end out of tee fitting.

4. Gently pull element out of housing from

opposite end.

5. Reverse for reassembly.

6. Element ends should extend equally from

each end of shell housing before installing

union fittings. Soak element for 5 minutes in

DI water if it is too short.

Loading...

Loading...