PERMA PURE LLC

T

Baldwin™-Series

Model M8B

Tester’s Choice Portable

Sample Conditioning System

User’s Manual

PERMA PURE LLC

(732) 244-0010 ▪ (800) 337-3762 ▪ fax (732) 244-8140 ▪ www.permapure.com ▪ info@permapure.com

8 Executive Drive ▪ P.O. Box 2105 ▪

oms River, NJ 08754

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 2 of 22

PERMA PURE LLC

Contents

Introduction ...................................................................................................................... 3

General description ............................................................................................................ 4

Specifications .................................................................................................................... 6

Connections................................................................................................................... 6

Important Safety Warnings ................................................................................................. 7

Connection & Start-up ........................................................................................................ 8

Sample and Drain Connections ......................................................................................... 8

LED Summary.............................................................................................................. 10

Start-up ......................................................................................................................... 11

Set Points ....................................................................................................................... 12

Shutdown ....................................................................................................................... 12

Replacement Parts ........................................................................................................... 15

Appendix A: Installation of Peristaltic Pump ........................................................................ 16

Appendix B: Drawings ..................................................................................................... 17

B1: 4S-M8 flow diagram ............................................................................................... 17

B2: Impinger schematic ............................................................................................... 17

B3: Relay board contact state ....................................................................................... 17

B4: Relay board field connections .................................................................................. 17

B5: Interconnect diagram ............................................................................................. 17

Appendix C: Perma Pure Sample Pump Maintenance Instructions........................................... 18

Appendix D: Dual Stream Operation .................................................................................. 19

Appendix E: Conversion Tables ......................................................................................... 20

Appendix F: Warranty and Disclaimer ................................................................................ 22

PERMA PURE LLC

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 3 of 22

Unpacking

Perma Pure has made every effort to ship you a high quality product that has been thoroughly

inspected and tested. It has been carefully packed to ensure that it arrives at your facility in good

condition. Even though every effort has been made to prevent damage during the transportation

process, damage can occur by the carrier. This is out of control of Perma Pure and is the

responsibility of the carrier to ensure that your equipment arrives intact and undamaged.

Inspect outside packaging. If there is any visible damage, inform the carrier at the time of

deliver. This inspection is important! Once the package is signed for, responsibility for

any visible damage then transfers to the consignee.

Unpack your equipment. Visually inspect the outside of your equipment for any damage. If

there is any damage, contact the carrier immediately. Generally, a carrier must be notified

within 24 hours of the delivery to make a hidden damage claim.

Items in the carton include:

(1) Model M8B – Testers’ Choice Portable Sample Conditioning System

(1) Power cord

(1) User’s manual

If any of the above parts are missing or damaged, call the helpline at (800) 337-3762 ext-145.

Introduction

Thank you for purchasing this product from Perma Pure LLC. This manual has been assembled so

that it can answer all questions regarding operation. Please keep the operators manual near the

equipment for future reference. There may also be optional equipment available that was not

ordered at the time of original purchase, which may be described and/or illustrated in this manual.

If you still have any questions regarding your equipment’s operation, available options or technical

support, please contact your purchasing dealer or contact Perma Pure directly.

Perma Pure LLC Tel: 732-244-0010

P.O. Box 2105 Tel: 800-337-3762 (toll free US)

8 Executive Drive Fax: 732-244-8140

Toms River, NJ 08754 e-mail: info@permapure.com

website: www.permapure.com

The Testers Choice Portable Sample Conditioning System can be either used for intermittent or

continuous operation. It is designed for accurate, repeatable and precise gas sample conditioning

that can be effectively carried out nearly anyplace and at anytime. This unit is also designed to

require only a minimum amount of maintenance to maximize its operation.

3

COPYRIGHT 2008, ALL RIGHTS RESERVED

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 4 of 22

PERMA PURE LLC

General description

The Perma Pure/Baldwin Tester’s Choice Model M8 Thermo-Electric cooler features a complete gas

conditioning system in one easy to manage enclosure. The unique design leaves additional space to

install or access other sample conditioning system components. A unique drop-down door on the

M8 cooler section, provides easy access to electronic boards and the power supply. All electronic

boards (control, relay, and display) are mounted on the door of the cooler for easy access. Sample

pump and peristaltic drain pump(s) are also mounted within the enclosure.

The process of sampling combustion

product stack gas or exhaust from internal

combustion engines requires a method to

remove the moisture from the sample,

without removing the gas components of

interest. The Tester’s Choice M8 System is

an ideal way to decrease the dew point of

combustion gases to a repeatable, stable,

constant low dew point. The Tester’s Choice

M8 system prevents water condensation in

sample pre-filters, sample pumps, and gas

analyzers. For gas analyzers where water

vapor is an interferent, a stable, repeatable,

dew point, becomes a part of the gas

analyzer performance specification. The

Tester’s Choice system provides this

constant low water concentration, resulting

in an accurate component gas

measurement.

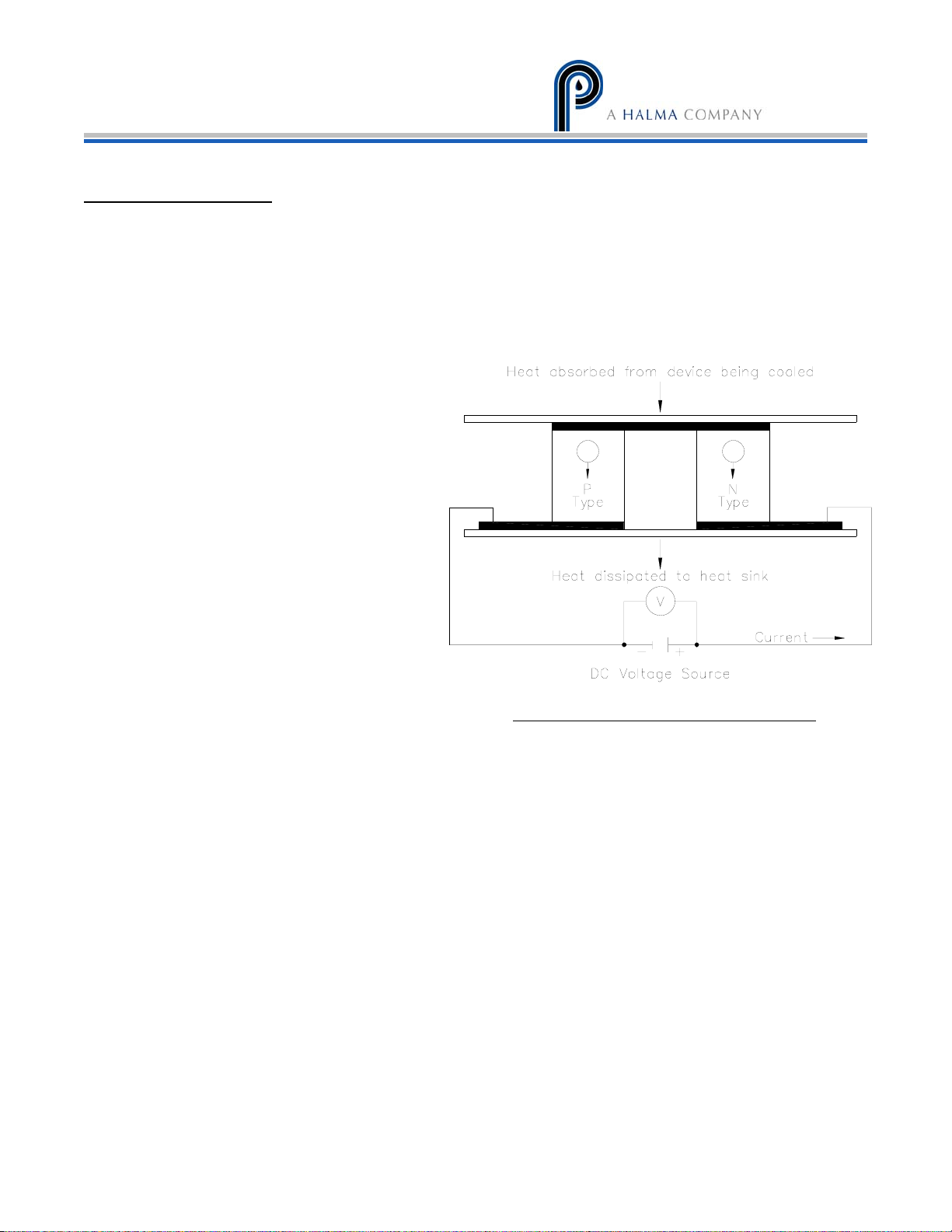

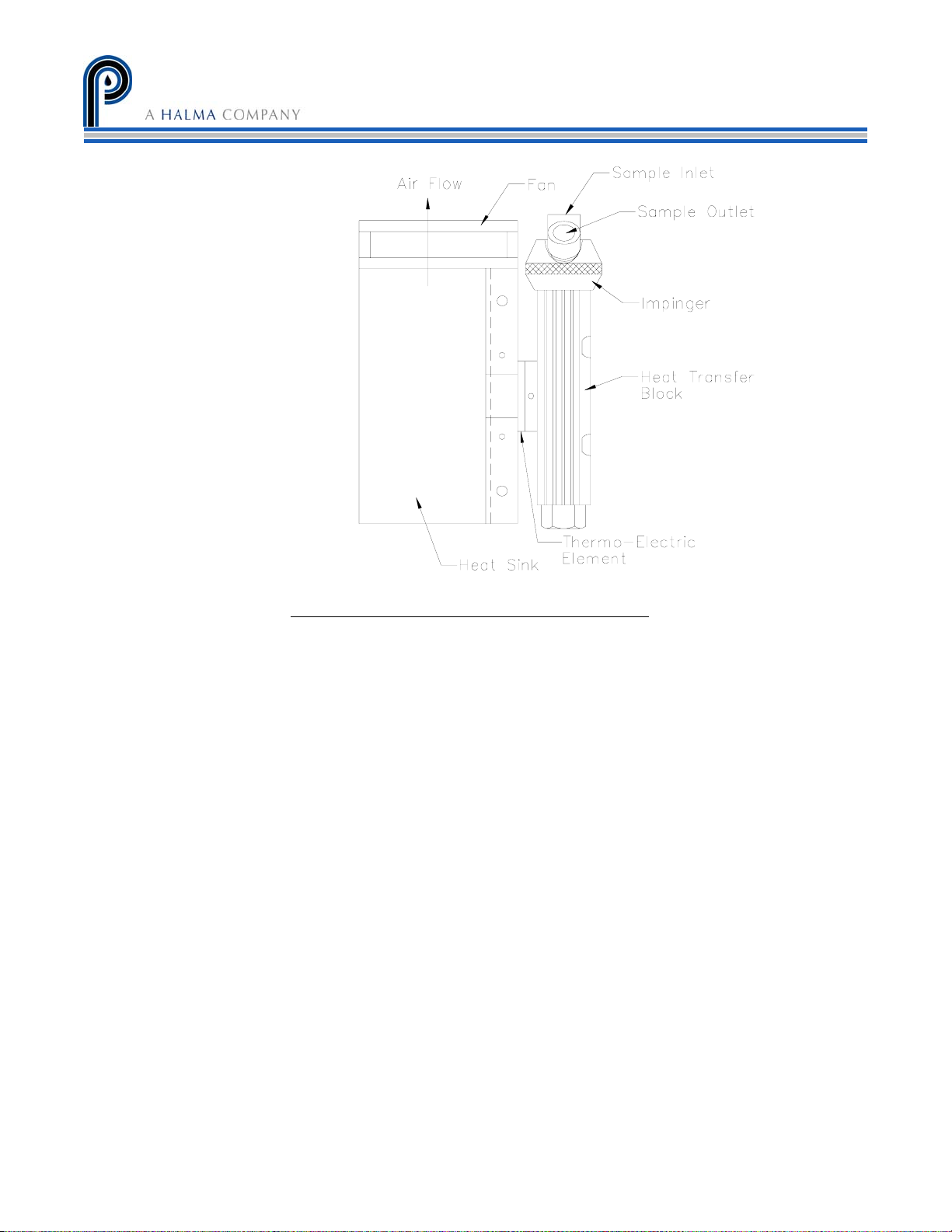

The Tester’s Choice M8 system removes the moisture from the sample gas by cooling the gas as it

passes through a laminar impinger (heat exchanger). A diagram showing the gas flow path through

an impinger is shown in the Appendix B2. The impinger, made of 316L stainless steel, Durinert

corrosion-resistant inert coating over 316L stainless steel), PVDF (Kynar®), or glass, is mounted

within a thermally insulated heat transfer block bored to receive the impinger without a mechanical

lock. This assembly allows the easy removal of any impinger simply by slipping it out of the cooling

block by hand. The heat transfer block cools the heat exchanger through the heat pumping action

of the Peltier element. The heat transfer block is on the cold side of the thermo-electric element

and the heat sink is on the hot side of the thermo-electric element. The desired temperature is

maintained by a closed loop control system, which is implemented through an analog proportional

controller. The controller uses a type K thermocouple as a sensor.

Figure 1: Thermo-electric element (Peltier)

®

(a

PERMA PURE LLC

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 5 of 22

The Tester’s Choice M8 system will reduce the sample gas dew point to 5

Liters Per Minute (LPM). This is slightly above the temperature that the condensate removed from

the gas stream will freeze. If the condensate freezes sample analysis and gas stream flow will be

compromised.

If a lower dew point is necessary, a Perma Pure LLC Supplemental Drying System (S.D.S.) may be

necessary. A sample gas stream that contains significant amounts of SO3 may also be

encountered. Perma Pure LLC/Baldwin can supply SO3 Aerosol Removal Systems, specifically for

this purpose.

Please contact Perma Pure LLC for suggestions on alternative devices. Perma Pure LLC has a

system and expertise that can handle nearly any sample conditioning application.

Figure 2: Heat Exchanger, Impinger and Heat Sink

°

C at a maximum flow of 8

5

COPYRIGHT 2008, ALL RIGHTS RESERVED

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 6 of 22

Physical Description

• Two channel system

• 2 x 10” heat exchangers connected in series or parallel

• 2 Active (cooled to 5°C) heat exchangers

• LCD temperature display and LED status indicators

• Dimensions: 14.5” x 11” x 10.5” HWD (37 x 28 x 26.5 cm)

• Weight: 53 lbs (24 kg)

Specifications

Sample gas flow range Up to 8 LPM (17 scfh)

PERMA PURE LLC

Water content 20% H

Maximum cooling rate 440 BTU/ht (464 kJ/hr)

Maximum inlet sample temp. 400°F (205°C) for SS or glass impingers

280°F (138°C) for Kynar™ impingers

Maximum inlet pressure 15 psig (1 bar)

Maximum pressure drop <+1 in H2O

Ambient temperature range 33-114°F (0.6-43°C)

Outlet sample gas dew point 41°F (5°C)

Voltage 115VAC (230VAC optional)

50/60 Hz

Power supply 1000W

Cooling down time Less than 10 minutes

O (60°C DP)

2

Connections

• Sample gas inlet: Kynar, 1/4” tube compression fitting

• Sample gas outlet: Kynar, 1/4” tube compression fitting

• Drain tubing connection: Kynar, 1/4” barbed tube fitting

PERMA PURE LLC

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 7 of 22

Important Safety Warnings

Please be sure to review the following basic safety procedures. These procedures

represent the MINIMUM requirements to operate the equipment safely. It is the ultimate

responsibility of the operator to ensure proper safety practices are utilized at the point

of operation.

• NEVER

• NEVER

ratings must be closely observed and not exceeded. Voltage rating of the equipment MUST

the rating on the data label. Please make sure that it matches before powering up the equipment.

• This equipment is NOT

• This equipment is NOT

• Condensate is potentially dangerous.

item that may have come in contact with the gas stream or any hazardous material, without

adequate personal protective equipment. ALWAYS

• Sample gas is potentially dangerous.

often as necessary to maintain a safe working environment around the equipment. The gas stream

exhaust must exit away from all personnel to prevent dangerous exposure.

• NEVER operate the equipment with any part of the enclosure unsecured.

doors and covers must be in place and secured prior to operation. Electrical current may be present

behind covers or doors, even if tools are not necessary to access these components.

• NEVER

Repair of this equipment should only be done by properly trained personnel that are familiar with

the potential risks involved with servicing of this equipment.

• NEVER

bypass this, or any, safety device.

• NEVER

been damaged.

• The use of components that have not been purchased through an authorized Perma Pure LLC

dealer or directly from Perma Pure LLC may compromise the safety of the operator. Additionally,

use of non-authorized components may change the operating characteristics of this equipment.

Any changes to the equipment, that modify its operation in any way, are dangerous, and are

strictly prohibited.

• Read the entire operating manual before attempting to set up or operate the equipment.

• Please heed all warning labels that are on the equipment. They are there to remind you of

possible hazardous conditions.

• Verify the integrity of any mechanical and/or electrical connections that are made to the Testers

Choice Portable Sample Conditioning System.

attempt to operate this equipment in an explosive or otherwise hazardous area.

exceed any specified rating for the equipment. Voltage, temperature and pressure

match

designed to be used in an explosive environment.

designed to operate in a wet environment.

Never handle drain lines, impingers or any other

assume that any liquid present is hazardous.

A leak test is recommended at initial startup and as

All operated

attempt service on this equipment without first disconnecting all energy sources.

replace fuses with types other then the same specification of type and current. Do not

operate this equipment if it is visibly damaged or the possibility exists that it may have

o Verify that the unit is connected to the proper rated power for the system

o Verify that the unit is plumbed properly to operate effectively

o Do not block either the cooling air inlet or outlet on the rear of the cabinet. The

efficiency of the unit will be compromised and long term use in this condition could

permanently damage the cooling system.

7

COPYRIGHT 2008, ALL RIGHTS RESERVED

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 8 of 22

PERMA PURE LLC

Connection & Start-up

The Classic Tester’s Choice portable sample conditioning system should be set up away from

any heat sources in a well vented area.

The system can only be operated in an upright position. The conditioning system must not be

set up at an angle greater than 30° from vertical.

NOTE: The operational stability of the cooler dew point is influenced by the

stability of the ambient temperature.

For proper operation, the ambient temperature cannot exceed 43°C (110°F). At, or close to the

maximum ambient temperature, the cooler will not be able to control the temperature to

reduce the dew point of the sample gas to the 5°C set point. This will result in compromised

operation and water slip or carryover, possibly into the analyzer.

The Tester’s Choice portable sample conditioning system can be either used for intermittent or

continuous operation. It is designed for accurate, repeatable and precise gas sample

conditioning that can be effectively carried out nearly anyplace and at anytime. This unit is also

designed to require only a minimum amount of maintenance to maximize its operation.

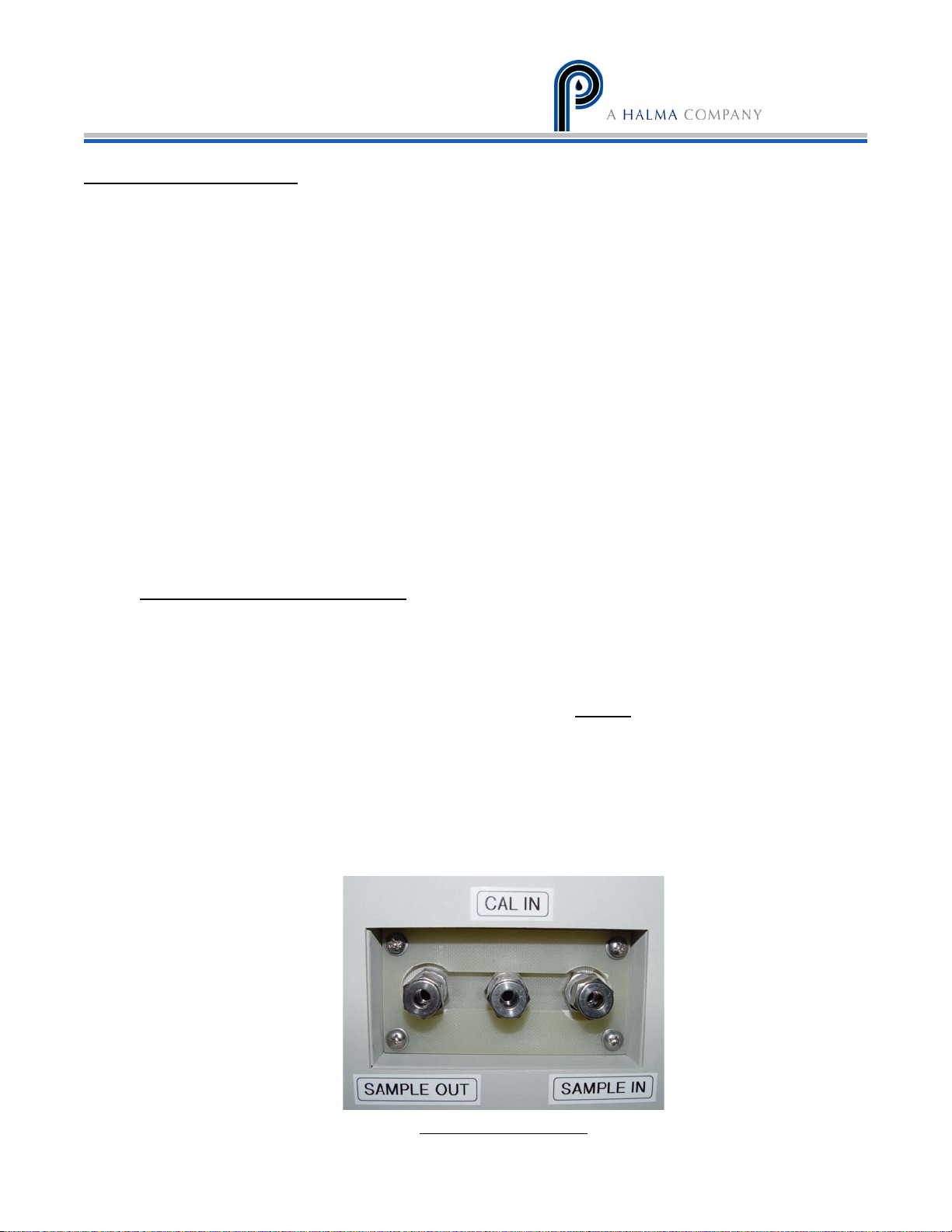

Sample and Drain Connections

1. Connect a suitable condensate drain line to the connector on bottom of unit.

NOTE: Do not reduce the size of the condensate tubing since doing so restricts water

flow resulting in water carryover into the sample.

2. Run the external drain line to appropriate drain receptacle.

Drain condensate can be potentially hazardous. Always make sure that proper

precautions are taken regarding personal protective equipment when handling

condensate.

3. Connect the sample line to the stainless steel sample inlet compression fittings on the

rear of the unit. See figure 3.

NOTE: If using stainless steel sample line, place 2 inches of Teflon tubing in between

the exchanger inlet fitting and the heated line. This prevents the sample cooler from

heat sinking the incoming heated line, which adds undue load to the cooler.

Figure 3 - Gas connections

PERMA PURE LLC

Model M8B User’s Manual

Doc. #580: Revision: 000

Page 9 of 22

The Tester’s Choice M8 will condition a single gas stream in its standard

configuration only. A second, parallel gas stream connection and the associated

hardware are available as an option. If this option was purchased, see Appendix D

for instructions.

4. Connect the conditioned sample outlet connector to the sample gas line leading to the

analyzer.

5. Connect the supplied power cord to the receptacle on the rear of the unit. See figure 4.

Figure 4 - Power connection

Do not power up the unit at this time. Verify that the proper supply voltage is available to

power the Tester’s Choice M8.

9

COPYRIGHT 2008, ALL RIGHTS RESERVED

Loading...

Loading...