Page 1

Tel: 732-244-0010

Tel: 800-337-3762(toll free US)

Fax: 732-244-8140

Email: info@permapure.com

Web: www.permapure.com

Version 5.01

eCOOL™ 5000XP Series

Digital Thermo-Electric Cooler

Instruction Manual

Page 2

TABLE OF CONTENTS

A: SPECIFICATIONS .......................................................................................................... 3

B: LIMITED WARRANTY .................................................................................................... 4

C: PRINCIPLE OF OPERATION ......................................................................................... 5

D: INSTALLATION .............................................................................................................. 8

E: START-UP PROCEDURE ............................................................................................... 9

F: LEDS & LCD ..................................................................................................................10

G: BOARDS .......................................................................................................................11

H: DEFAULT SETPOINTS ..................................................................................................16

I: “NEW JERSEY” THERMOCOUPLE OPTION ................................................................17

J: MAINTENANCE..............................................................................................................18

K: TROUBLESHOOTING ...................................................................................................19

L: SPARE PARTS: eCOOL™ 5000XP ...............................................................................20

APPENDIX: eCOOL™ 5000XP ..........................................................................................22

Table of Contents 2

Page 3

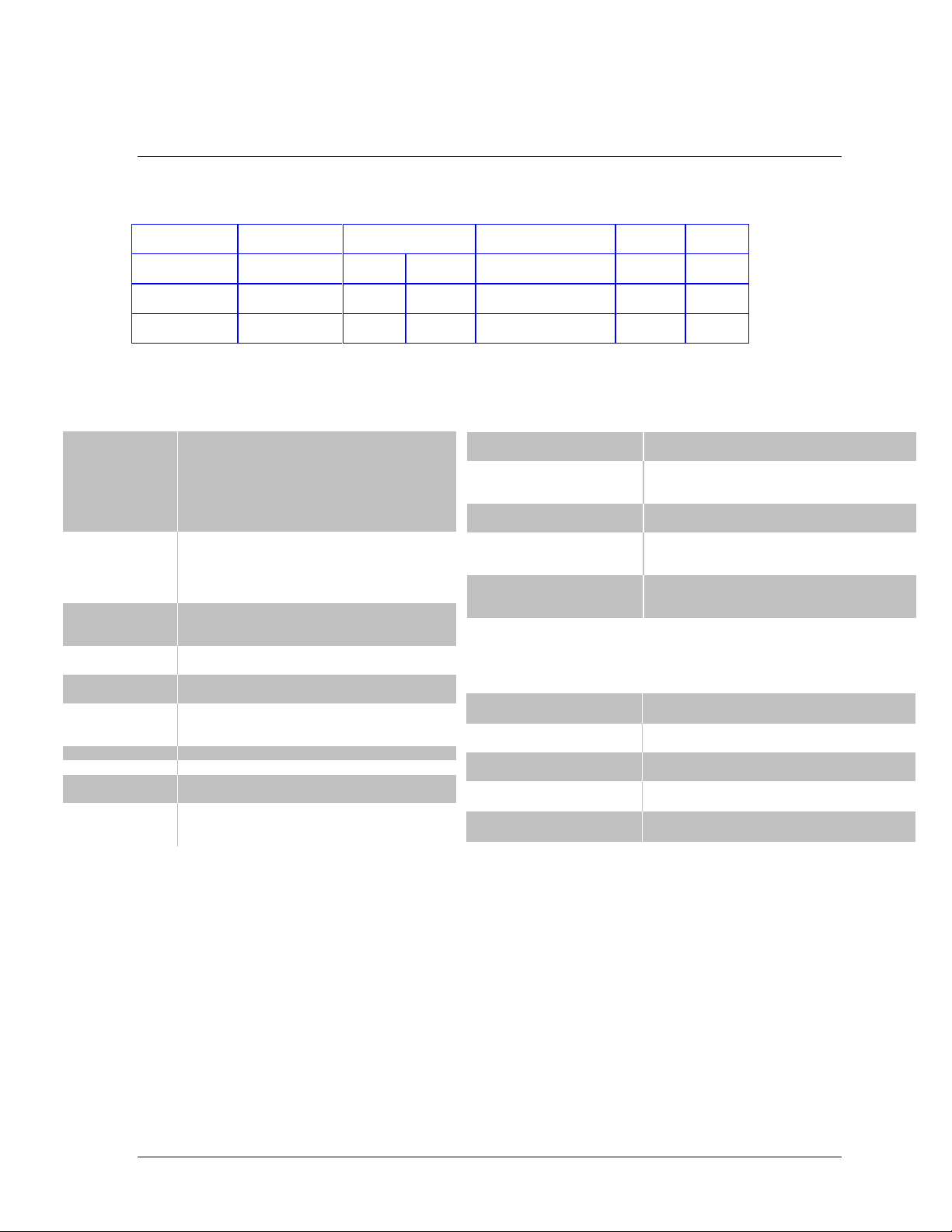

Model

Standard

Capacity

Heat Exchangers

Passive Active

Dimensions

Weight

Power

Supply

e5500XP

4-7 LPM

8-15 SCFH

1x10 in.

1x10 in.

14 x 13 x 13 in. HWD

36 x 33 x 33 cm HWD

39 lbs

18 kg

240W

e5800XP

7-10 LPM

15-21 SCFH

2x10 in.

14 x 13 x 13 in. HWD

36 x 33 x 33 cm HWD

39 lbs

18 kg

500W

e5900XP

10-20 LPM

21-42 SCFH

2x10 in.

2x10 in.

14 x 13 x 13 in. HWD

36 x 33 x 33 cm HWD

41 lbs

19 kg

500W

Digital Boards

Main control board

Water slip alarm relay board

LAN card (optional)

Filter probe & heated sample line accessory

board (optional)

Heat exchanger thermocouple isolated output

board (optional)

Alarms

Probe over / under temperature

Heated sample line over / under temperature

Cooler over temperature

Cooler thermocouple failure

Water slip (moisture carryover)

Display

Jumbo dual-line LCD

LED red, amber, green heat exchanger status

indicators

Heat Exchanger

Type

EZ-Clean™ twist apart

Heat Exchanger

Material

Stainless steel (standard); Durinert® treated

stainless steel, Kynar®, Glass (optional)

Heat Exchanger

Connections

1/4” FNTP Inlet (first heat exchanger)

1/8” FNTP Outlet

3/8” FNTP Drain

Heat Sink

High heat transfer aluminum

Voltage

120VAC, 50/60Hz, 4.60 Amps

Sample Pump

(Optional)

Model 2PAD-006R dual-head

115VAC, 50/60Hz, 1.03 Amps, 1/14Hp

Drain Pump

(Optional)

Model 3KPB-001 single head peristaltic

Model 3KPB-003 dual head peristaltic

120VAC, 60Hz, 0.52 Amps

Digital Board Specifications

Main Control Board

4 thermocouple inputs

4 analog outputs

Water Slip Alarm Relay

Board

2 water slip (moisture carryover) inputs

2 high current digital contact outputs

2 digital PLC outputs

LAN card (optional)

Modbus or TCP/IP

RJ45 / CAT 5 cable

Filter Probe & Heated

Sample Line Accessory

Board (optional)

2 thermocouple inputs

Pulse width modulated digital output

Heat Exchanger

Thermocouple Isolated

Output Board (optional)

2 thermocouple inputs

2 x 4-20mA outputs

2 x 0-10VDC outputs

Operating Specifications

Maximum Inlet Sample

Temperature

400F (205C) SS, Durinert®, Glass Impingers

280F (138C) Kynar® Impingers

Maximum Inlet Pressure

45 psig

3 bar / 2250 mmHg

Maximum Heat Exchanger

Pressure Drop

<+1 in. H2O

Ambient Temperature

Range

33-104F

0.6-40C

Outlet Sample Gas Dew

Point

41F

5C

A: SPECIFICATIONS

Model Specifications

General Specifications

Section A: Specifications 3

Page 4

B: LIMITED WARRANTY

Perma Pure LLC

WARRANTY and DISCLAIMERS

Perma Pure (Seller) warrants that product supplied hereunder shall, at the time of delivery to Buyer,

conform to the published specifications of Seller and be free from defects in material and

workmanship under normal use and service. Seller’s sole obligation and liability under this warranty is

limited to the repair or replacement at its factory, at Seller’s option, of any such product which proves

defective within one year after the date of original shipment from seller’s factory (or for a normal

usable lifetime if the product is a disposable or expendable item) and is found to be defective in

material or workmanship by Seller’s inspection.

Buyer agrees that (1) any technical advice, information, suggestions, or recommendations given to

Buyer by Seller or any representative of Seller with respect to the product or the suitability or

desirability of the product for an particular use or application are based solely on the general

knowledge of Seller, are intended for information guidance only, and do not constitute any

representation or warranty by Seller that the product shall in fact be suitable or desirable for any

particular use or application; (2) Buyer takes sole responsibility for the use and applications to which

the product is put and Buyer shall conduct all testing and analysis necessary to validate the use and

application to which Buyer puts the product for which Buyer may recommend the use or application of

the product by others; and (3) the characteristics, specifications, and/or properties of the product may

be affected by the processing, treatment, handling, and/or manufacturing of the product by Buyer or

others and Seller takes no responsibility for he nature or consequence of such operations or as to the

suitability of the product for the purposes intended to be used by Buyer or others after being

subjected to such operations.

SELLER MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, OF THE PRODUCT

SUPPLIED HEREUNDER, INCLUDING, WITHOUT LIMITATION, IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR PARTICULAR PURPOSE, AND ALL SUCH

WARRANTIES ARE HEREBY EXPRESSLY EXCLUDED. SELLER SHALL HAVE NO LIABILITY

FOR LOSS OF PROFITS, OR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES UNDER

ANY CIRCUMSTANCES OR LEGAL THEORY, WHETHER BASED ON NEGLIGENCE, BREACH

OF WARRANTY, STRICT LIABILITY, TORT, CONTRACT, OR OTHERWISE. SELLER SHALL IN

NO EVENT BE LIABLE IN RESPECT OF THIS ORDER AND OR PRODUCT DELIVERED ON

ACCOUNT OF THIS ORDER FOR ANY AMOUNT GREATER THAN THAT PAID TO SELLER ON

ACCOUNT OF THIS ORDER.

Section B: Limited Warranty 4

Page 5

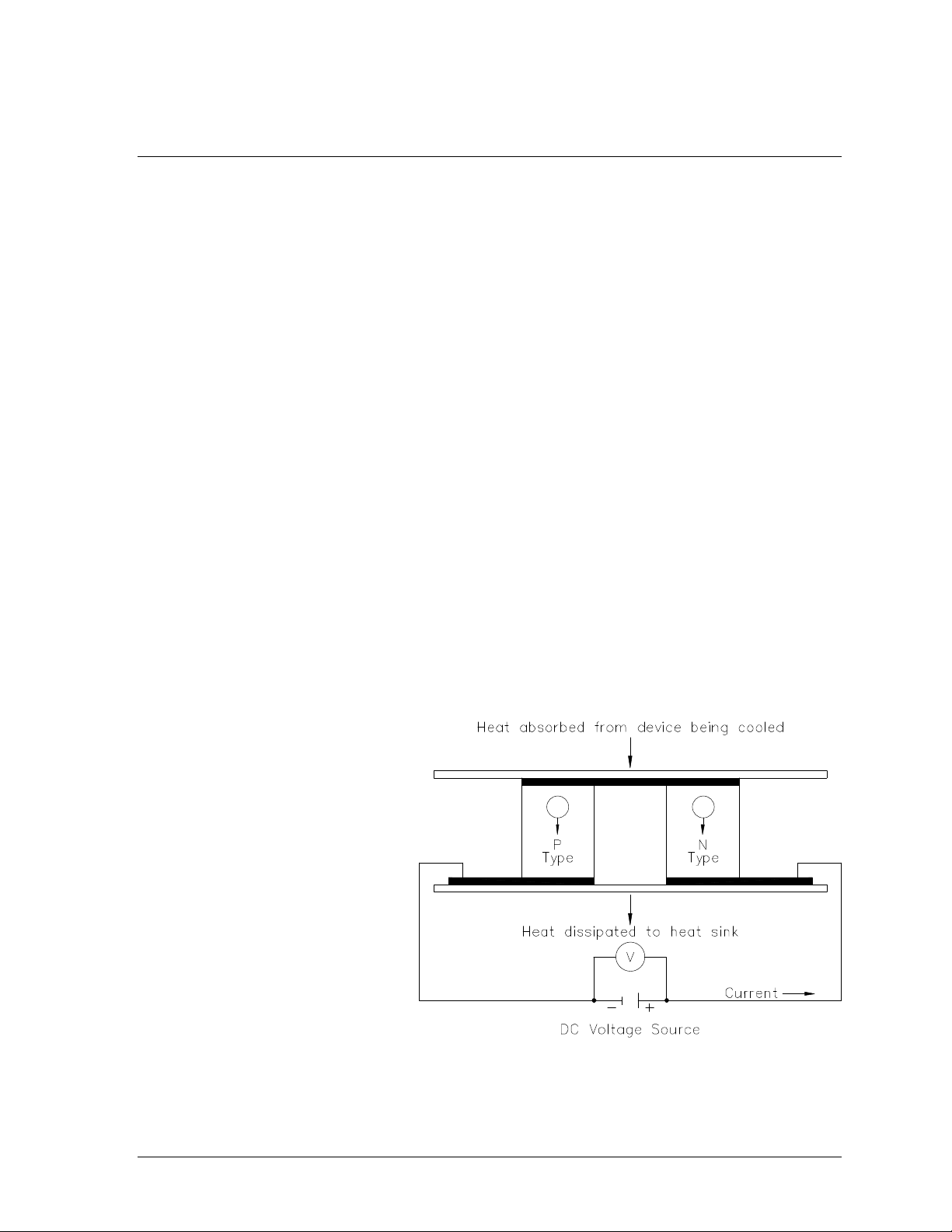

Figure 1: Thermo-electric element (Peltier)

C: PRINCIPLE OF OPERATION

Thank you for purchasing a Perma Pure Baldwin™-Series eCOOL™ 5000XP Series

Digital Thermo-Electric Cooler CSA-C and CSA-US certified for Class I Division 2

Groups A,B,C,D hazardous locations. The eCOOL™ 5000XP Series has numerous

features including:

Remote monitoring and control of heated filter probe, heated sample line, and sample

conditioning system.

eCOOL

Local Area Network.

A jumbo 2-line LCD display with multi-colored LED’s provides easy local monitoring and

control of your sample handling system.

Alarm notification of over / under temperature, thermocouple failure, and water slip

(moisture carryover).

Alarm relay shuts off the sample pump to protect expensive analyzers from water slip

(moisture carryover).

Eliminates the cost and complexity of separate temperature controllers such as for a

heated sample line and filter probe.

Extra thermocouple inputs and outputs available.

Operates with 110/120VAC, 220/240VAC, 12VDC, 15VDC, or 24VDC.

Field friendly, requires virtually no maintenance, and is backed by our 1-year limited

warranty.

All Baldwin-Series coolers use thermo-electric elements (Peltiers) to cool the sample

gas to the desired dew point temperature. A thermo-electric cooler is best illustrated

as a small heat pump with no

moving parts. The Peltiers

operate on direct current and

may be used for heating or

cooling by reversing the

direction of current flow. This is

achieved by moving heat from

one side of the module to the

other with current flow and the

laws of thermodynamics. A

typical single stage Peltier

(figure 1) consists of two

ceramic plates with p- and ntype semiconductor material

(bismuth telluride) between the

™

interface software included for monitoring and control over the Internet or a

plates. The elements of

semiconductor material are

connected electrically in series and thermally in parallel.

Section C: Principle of Operation 5

Page 6

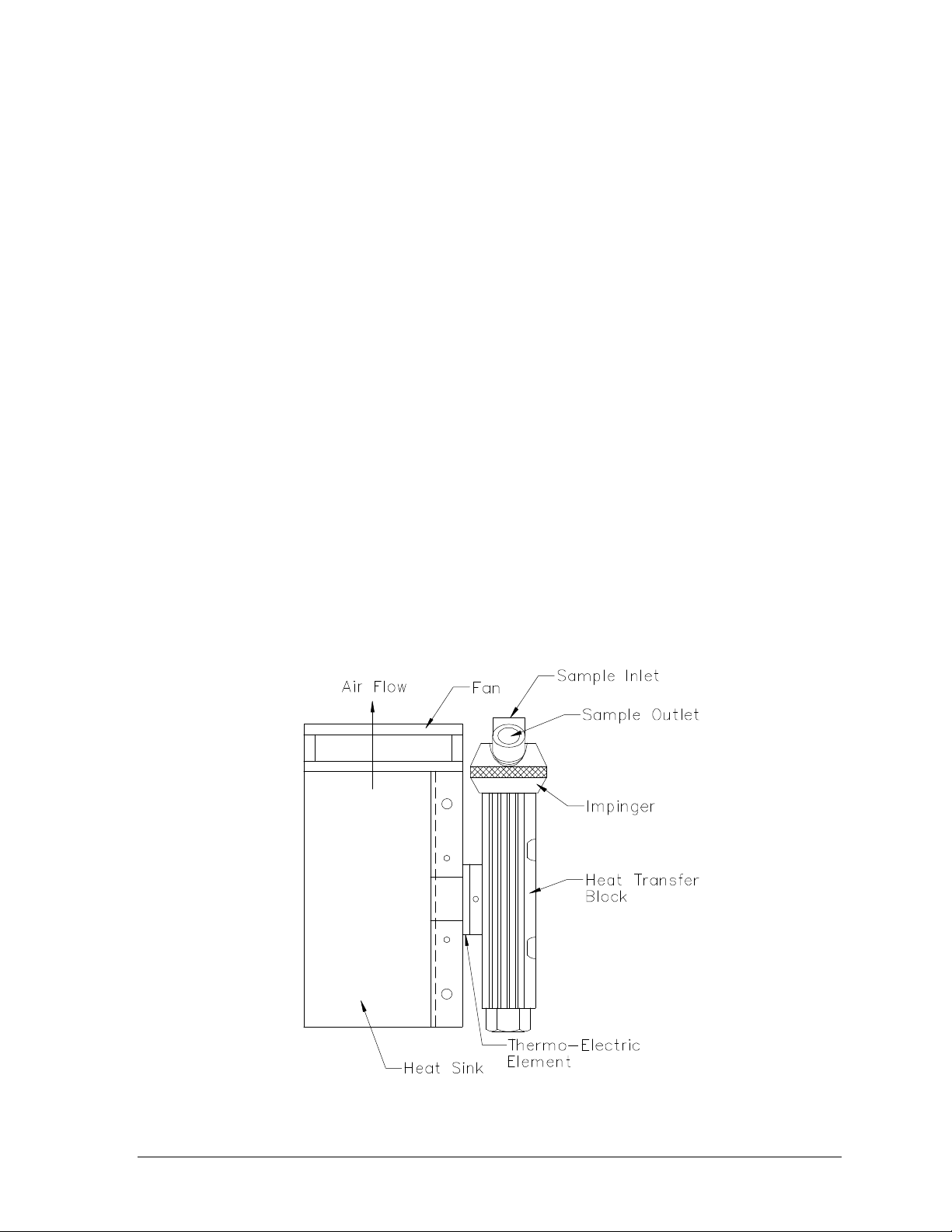

Figure 2: Heat Exchanger, Impinger and Heat Sink Assembly

When a positive DC voltage is applied to the n-type thermo-electric element,

electrons pass from the p- to the n-type thermo-electric element and the cold side

temperature will decrease as heat is absorbed. The heat absorption (cooling) is

proportional to the current and the number of thermo-electric couples. This heat is

transferred to the hot side of the Peltier element where it is dissipated into the heat

sink and surrounding environment.

Baldwin™-Series Thermo-Electric Coolers remove the moisture from the sample gas

by cooling the gas as it passes through a laminar impinger (heat exchanger). A

diagram showing the gas flow path through an impinger is shown in the Appendix.

The heat exchanger, made of 316L stainless steel, Durinert® (a corrosion-resistant

inert coating over 316L stainless steel), PVDF (Kynar®), or glass, is mounted within

a thermally insulated heat transfer block bored to receive the heat exchanger without

a mechanical lock. This assembly allows the easy removal of any heat exchanger

simply by slipping it out of the cooling block by hand. The heat transfer block cools

the heat exchanger through the heat pumping action of the peltier element. The

heat transfer block is on the cold side of the thermo-electric element and the heat

sink is on the hot side of the thermo-electric element. The heat from the heat

transfer block is pumped to the heat sink where it is then dissipated into the air by

the heat sink fan. See figure 2. The desired temperature is maintained by a closed

loop control system, which is implemented through a proportional controller. The

controller uses a type K thermocouple in the heat transfer block located very close to

the cold side of the peltier element as the input sensor.

Section C: Principle of Operation 6

Page 7

The sample gas is passed to the thermo-electric cooler via the heated filter sample

probe and heated sample line. The thermo-electric cooler lowers the sample dew

point to 5°C (41°F). As the gas cools and the moisture vapor condenses, the

condensate exits the heat exchanger through the bottom drain connection.

Particulate matter which passes through the sample cooler is removed by an

optional Perma Pure pre-filter, located downstream from the cooler along with an

optional water slip sensor. The conditioned sample gas can then be directed to the

gas analyzers.

Section C: Principle of Operation 7

Page 8

D: INSTALLATION

WARNING! eCOOL™ 5000XP Digital Thermo-Electric Coolers and related

components must be installed with appropriate conduit and connections for area

classification subject to the local inspection authority having jurisdiction.

eCOOL™ 5000XP Digital Thermo-Electric Coolers should be installed away from

heat sources in a well ventilated area of an instrument rack or enclosure.

Sample tubing connections to the eCOOL™ 5000XP Coolers depend on the heat

exchanger material of construction. A cooler with stainless steel heat exchangers

uses a stainless steel inlet fitting on the first heat exchanger. All other inlets and

outlets are Kynar® standard compression type tube fittings with Teflon® ferrules.

PVDF (Kynar®) heat exchangers use all Kynar® standard compression type tube

fittings with Teflon® ferrules. Perma Pure cannot warrantee against damage to the

Peltier elements or heat exchangers if our supplied Kynar® tube fittings are not used.

CAUTION: If using a stainless steel sample line, place 2 inches of Teflon® tubing in

between the exchanger inlet fitting and the heated line. This prevents the sample

cooler from heat sinking the incoming heated line, which adds undue load to the

cooler.

The inlet and outlet tubing of all metal or Kynar® heat exchangers is 1/4" NPT. The

operator should use the compression type fittings. The inlet of the first1 heat

exchanger uses a 3/8” tube x ¼” MNPT, tube connector fitting to mate with most

standard 3/8” sample lines.

For eCOOL™ 5000XP models that utilize passive/active heat exchangers (i.e.,

e5500XP), the sample pump should be installed after the cooler to protect the pump

head from moisture and ensure longer diaphragm life. The sample pump should be

installed between the heat exchangers in active/active models (e5800XP, e5900XP).

This will assist in water removal by pressurizing the downstream heat exchanger.

There will be minimal sacrifice in pump diaphragm life since the majority of water will

be removed by the first active heat exchanger. It is also acceptable for the sample

pump to be installed after active/active coolers.

The condensate drain connections are Kynar® elbows, 3/8” MNPT x 1/4” barbed

tube fittings. A Perma Pure peristaltic drain pump is recommended for water

removal. This pump uses size 17 tubing.

CAUTION: Do not reduce the size of the condensate tubing since doing so restricts

water flow which may result in water slip (moisture carryover) in the sample.

Section D: Installation 8

Page 9

E: START-UP PROCEDURE

WARNING! eCOOL™ 5000XP Digital Thermo-Electric Coolers and related

components must be installed with appropriate conduit for power cords and

connections for area classification subject to the local inspection authority having

jurisdiction.

Plug in the power cord to a properly grounded main circuit. The LCD should display

the actual temperature. The temperature of each channel should fall until it reaches

5C.

If there are no alarms (an alarm condition consists of water slip detection after the

cooler, thermocouple failure, or actual temperature > 10°C), then the LED(s) should

turn to an amber color. This indicates that the alarms are cleared and the user can

press the reset button to begin operation. Once the reset button is pressed, the

LED(s) should turn green indicating that there are no alarms and sample flow can

begin. If the sample pump is wired through the relay board alarm contacts and all

alarms are cleared, the sample pump will start. The sample pump will stop if any

alarms are detected.

Note: Current alarm conditions are displayed on the second line of the LCD.

eCOOL™ 5000XP Thermo-Electric Coolers are virtually maintenance free.

However, in the event of electrical problems, refer to the Troubleshooting section in

this manual.

Section E: Start-up Procedure 9

Page 10

F: LEDS & LCD

Every eCOOL™ 5000XP Series Digital Thermo-Electric Cooler has a jumbo 2-line

LCD display and 2 LED indicators.

Each of the two LED indicators corresponds to an active heat exchanger and will be

colored Green, Amber, or Red:

LED Summary

GREEN: Status OK, Sampling can begin. Sample pump will run.

AMBER: Alarm is no longer present. User must press the reset button to

acknowledge the alarm and return to normal operation.

Sample pump off.

RED: Alarm - see message on LCD screen. Sample pump off.

The top line of the LCD screen displays the temperature of each active heat

exchanger in degrees Celsius (e.g., 5°C). The scrolling bottom line of the LCD

screen displays cooler status, such as alarm messages.

Alarm Summary

Thermocouple failure

Channel over-temperature alarm

Water slip (water detect) alarm

Please refer to the Troubleshooting section of this manual if your cooler displays any

of the alarms above.

.

Section F: LEDs & LCD 10

Page 11

G: BOARDS

Control Board

The control board is the motherboard for the eCOOL system. The control board

handles the majority of the functions for the cooler module. It contains the micro

processor that controls all of the functional areas of the design, as well as the

temperature measurement of the controlled vapor flow as well as the Pulse Width

Modulation (PWM) control of the Peltier elements to cool the vapor.

Inputs:

4 Thermocouple Inputs (Channel 1, Channel 2, and two Spare)

12-24VDC Power Inputs

12-24VDC Control Board Power Inputs

1 Analog Input

Input/Outputs:

Relay Board 1 Input/Output

Relay Board 2 Input/Output

LAN Card Input/Output

Accessory Board Input/Output

Isolator Board Input/Output

Outputs:

4 Analog Outputs (scaled 0 to 4.5VDC matching the Thermocouple Inputs)

Peltier Power Outputs (spade terminals)

DC Fan Power Output 1

DC Fan Power Output 2

Power Connections

The board is powered in two locations by a DC power supply rated to handle the

current required by the Peltier elements present in the system. The Peltier power is

supplied via the E1 and E2 lugs, where E2 is connected to the positive terminal and

E1 is connected to ground. The rest of the board is powered by the JP1 power

connector. This connector has two terminals on it with number 1 connected to the

positive DC voltage coming from the power supply and number 2 connected to

ground. The wires that are used to connect to the power supply should be

individually routed back to the power supply to minimize the noise created by the

peltiers.

Fuses

The fuses are labeled as F1, F2, F3. They are self-resetting fuses. If one of the

fuses trips, disconnect all power, identify and correct the problem that caused the

Section G: Boards 11

Page 12

high current draw, and reconnect power. It could take up to 5 minutes for a fuse to

self-reset in a power off state.

Main Control Board Overview

Configuration Switches

The configuration switches identify which components are connected to the system.

They are used by the control firmware to determine how the board is going to

operate in the system. The switches are read at power-up, or when the external

reset switch is activated. The table below identifies the switch positions and their

functions.

Section G: Boards 12

Page 13

SW3

Function

OFF

ON

1

Heated Line Control

OFF

ON

2

Probe Control

OFF

ON

3

Peltiers

1 per channel

2 per channel

4

Channels 1 2

5

Peltier Power Share

Full Power

Power Sharing

6

ISO Channels

Inactive

Displayed

SW2

Function

ON

OFF

1

ICE VCC

Enabled

Disabled

2

JTAG ICE ResetN

Enabled

Disabled

3

Calibration

Enabled

Normal Operation

4

Dflash Res

Enabled

Normal Operation

5

Init Clr

Enabled

Normal Operation

Button Control

The buttons are used to control the calibration settings. Follow the bottom line on

the display to determine the functions in the different modes. The three

combinations that are available are left only, right only, or both. To select the center

option on the bottom line of the display, press both buttons together.

Calibration Menus

The calibration mode allows the board to be setup with min and span points as well

as all of the other configuration information applicable depending on the

configuration switch settings.

Ch1, Ch2, TC1, TC2

Min = 0

Span = 5 degrees C

Max = 8*Span Temp (360°C limit)

The calibration is performed by first calculating the expected settings for the

calibration resistors before entering the calibration operation to get a good starting

point. Then the 0 point is adjusted to the minimum point in the ADCC (memory

chip). The span temperature is then set and the span gain is adjusted to make the

span point 1/8 of the entire range for the temperature measurements.

ChX: MIN = xxC

ChX: SPAN = xxC

Section G: Boards 13

Page 14

ChX:RDY TMP= xxC

ChX:SET TMP= xxC

ChX GAIN=%3u

Probe, Heated Line

Min = 0°C

Span =

Max = 360°C

Calibration is performed by setting the gain of the span circuit to minimal gain then

adjusting the 0 point to the minimum reading from the ADCC. The span temperature

is used to measure the ADCC value and calculate the step size of the ADCC.

ChX: MIN = xxC

ChX: SPAN = xxC

ChX:MIN TMP= xxC

ChX:MAX TMP= xxC

ChX:SET TMP= xxC

ChX: GAIN=%3u

Isolation Channels

Min = 0°C

Max = 25°C

The temperature range for the isolation circuit is 0 to 25°C. The calibration is

performed by first calculating a good starting point for the offset and span resistors.

Then adjust the 0 point to the minimum point in the ADCC. The last step is to set

the input to 25°C and adjust the span gain to achieve the max value in the ADCC.

ChX: MIN = xxC

ChX: MAX = xxC

ChX:MIN TMP= xxC

ChX:MAX TMP= xxC

ChX:SET TMP= xxC

ChX: GAIN=%3u

Water Slip (Moisture Carryover) Relay Board

Note: For the following instructions, typical applications run each of the relays in

series through the Common and Normally Open (NO) contacts.

A: Computer Status Alarms (External PLC monitoring).

Wire computer status alarms to JP4 & JP2. Wire the Common and Normally

Open Contacts in series to a PLC. If an alarm occurs, one or both of these

contacts will open.

Section G: Boards 14

Page 15

B: Sample Pump Control – Water slip, over-temperature, thermocouple failure

alarms.

Wire the Line (hot) power for the sample pump through terminals through JP3

and JP1. Wire the Common and Normally Open (NO) contacts in series. If

an alarm occurs, one or both of these contacts will open.

The sample pump is now in series with the Water Slip (Moisture Carryover) Sensor

and the Ready/Slip/power failure relay, which will only allow the sample pump to

start if conditions are satisfactory (i.e., no water slip, and safe operating temperature

of the sampling system, and no thermocouple failure).

LAN Card

To use the LAN Card, connect the 5 VDC power from the LAN card terminal JP1, to

the Power Out terminal on the Control Board terminal JP29 (+5VDC and GND).

Connect a ribbon cable between JP15 on the Control Board to JP16 on the LAN

Card. Then, connect a Cat 5 Ethernet cable with an RJ45 connector to the LAN

Card. The Ethernet cable should connect to a switch or router on a Local Area

Network (LAN) to run the TCP/IP executive software or connected to a Modbus

server.

Accessory Board

To use the Accessory boards make sure that the shorting jumpers on HDR1 and

HDR2 are shorting pins 3-5, 4-6 on both headers.

The Accessory board connects to JP23 on the cooler board.

Isolated Output Board

To use the ISO boards make sure that the shorting jumpers on HDR1 and HDR2 are

shorting pins 3-5, 4-6 on both headers.

The ISO board connects to JP20 on the cooler board.

Section G: Boards 15

Page 16

H: DEFAULT SETPOINTS

eCOOL™ 5000XP Heat Exchangers:

Setpoint Temperature = 5°C

Run Temperature = 10°C

Cooler must operate below the Run Temperature to avoid the over temperature

alarm condition.

Heated Sample Probe:

Setpoint Temperature = 190°C

High Temperature Alarm = 210°C

Low Temperature Alarm = 120°C

Heated Sample Line:

Setpoint Temperature = 190°C

High Temperature Alarm = 210°C

Low Temperature Alarm = 120°C

LAN Card:

Static IP Addressing: 192.168.45.140

DHCP Disabled.

Relay Card:

Relay contacts are in their Normal state (de-energized state) during an alarm

condition.

Analog output 0-4.5 VDC equates to 0-10°C corresponding to each thermocouple.

Section H: Default Setpoints 16

Page 17

Part No.

Description

3KTC-001

Kit, Thermocouple, NJ Option, Type K, w/Fitting & Sleeve

3KTC-002

Kit, Thermocouple, NJ Option, Type J, w/Fitting & Sleeve

3CCB-026

Circuit Board, eCOOL, Isolator Board

I: “NEW JERSEY” THERMOCOUPLE OPTION

Some air quality management districts (e.g., those in New Jersey and Southern

California) require temperature measurement of the gas stream at the outlet of the

last heat exchanger on the cooler. Perma Pure offers a 1/32-inch diameter

hypodermic-style type K thermocouple that can be inserted into a special heat

exchanger (i.e., it has a small port for insertion of the thermocouple) so the actual

sample dew point temperature can be measured. This is sometimes referred to as

the New Jersey thermocouple outlet temperature option.

If the cooler is run as a single stream, the final heat exchanger will have a New

Jersey thermocouple to sense the temperature inside the heat exchanger. A

quantity of two (2) NJ thermocouples are required when the cooler is used for dualstream simultaneous conditioning.

In the Baldwin™-Series eCOOL™ 5000XP, this New Jersey Thermocouple can be

connected to one of the extra thermocouple inputs for readout. Alternately, for a 420mA output, the optional isolator board should be purchased.

eCOOL™ 5000 Series New Jersey Thermocouple Option

Section I: “New Jersey” Thermocouple Option 17

Page 18

J: MAINTENANCE

Note: Please refer to the Spare Parts section of this manual for part numbers and

descriptions.

Daily

Verify each channel is running at 5°C (+/- 1.5°C).

LED’s should be Green.

Verify cooling fans are running.

Verify that the peristaltic pump is running and water is draining out.

Verify that the sample pump is drawing full flow.

Quarterly

Verify power supply voltage is above 14.5 VDC.

Inspect and clean the EZ-Clean Twist-Apart heat exchangers with de-ionized water.

Depending on the composition of the sample stream, heat exchangers may need to

be cleaned more often.

Inspect and replace the sample pump diaphragm when needed.

Inspect and replace the peristaltic pump tubing.

Inspect the water slip sensor and verify that there is no corrosion or restrictions to

the sensing pins.

Annually

Check and replace the Peltier cooling elements. At room temperature, a Peltier

should have a resistance of 5-10 Ohms. Higher resistance signifies the Peltier is

stressed and could fail soon.

Using a K-type thermocouple simulator, disconnect each thermocouple and simulate

a temperature between 0°C and 10°C. Verify that the readout on the display

matches the temperature to within 0.5°C. If it does not, the cooler needs to be

recalibrated. Contact Perma Pure for the calibration procedure and assistance.

Section J: Maintenance 18

Page 19

Alarm Message

Symptom

Action(s)

Thermocouple

Failure Channel #

Thermocouple is failing or

disconnected

Ensure proper connection to TB6 for Channel 1, TB7 for

Channel 2.

Replace K-type thermocouple.

Water Slip Alarm

Water has slipped passed the

thermo-electric cooler and tripped

the water slip sensor.

Ensure system loading (gas flow and water %) does not

exceed cooler capacity.

Verify that the cooler last impinger is holding a constant

temperature near 5°C.

If a dry sensor still trips the alarm, clean the sensor or

replace if necessary.

Overtemp Alarm

Cooler channel does not maintain a

temperature below 10 degrees C.

Verify that the system loading (gas flow and water %) does

not exceed the cooler capacity.

Verify that each Peltier element is drawing approximately 6

Amps. Replace the Peltier element if the current draw is

low.

Calibrate the temperature inputs using a thermocouple

simulator.

Probe Overtemp

Alarm

Probe temperature has exceeded

the Max Set temperature for the

probe.

Max temp is set too low. Adjust accordingly.

Inlet gas sample temp is too high. Consider installing a

cooling spool piece before the probe.

Inspect for wiring problem that is not allowing the controller

to properly maintain temperature.

Probe Undertemp

Alarm

Probe temperature is below the

Minimum Set temperature for the

probe.

Minimum set temperature is too low. Adjust accordingly.

On initial startup, the Heated Probe was initially below the

minimum temp, but now is above minimum. Press reset to

clear the alarm.

The isolated power source for the heater is disconnected

or off.

The heater is failing, causing the probe to not hold

temperature.

Inspect for wiring problem that is not allowing the controller

to properly maintain temperature.

Heated Line

Overtemp Alarm

Heated Line temperature has

exceeded the Max Set temperature

for the line.

Max set temperature is too low. Adjust accordingly.

Inlet gas sample temp is too high. Consider installing a

gas cooling spool piece before the probe.

Inspect for wiring problem that is not allowing the controller

to properly maintain temperature.

Heated Line

Undertemp Alarm

Heated Line temperature is below

the Minimum Set temperature for

the line.

Min set temperature is too low. Adjust accordingly.

On initial startup, the Heated Line was initially below the

minimum temp, but now is above minimum. Press reset to

clear the alarm.

The heater is failing causing the Heated Line to not hold

temperature.

The isolated power source for the heater is disconnected

or off.

Inspect for wiring problem that is not allowing the controller

to properly maintain temperature.

K: TROUBLESHOOTING

Section J: Troubleshooting 19

Page 20

Problem

Check

Action(s)

No LCD or LED(s)

and no fan.

AC power input.

DC 3A fuse (F1) on control board.

AC 15A fuse on power supply.

Check for +15VDC at P1 & P11 of

control board.

Ensure that AC power is connected.

Replace fuse as necessary.

Replace fuse as necessary.

If low reading, remove wires from P1 & P11, measure at

power supply and replace supply if voltage still is low.

Heat exchanger

remains at Peltier current draw. Should be Replace peltier.

ambient

temperature.

Peltier element current draw.

(Should be above 6 amps.)

Replace Peltier element.

Heat exchanger

frozen and cooler

indicates ambient

temperature.

Thermocouple placement in heat

exchanger block.

Peltier current draw (>6A) for both

elements on that channel.

Ensure proper placement.

Replace Peltier element.

Impinger does not

reach set

temperature, but is

below ready

temperature.

System loading.

Calibration and set temperature

adjustment.

Ensure system loading is not exceeding cooler capacity.

Adjust as necessary.

Heat exchanger

temperature cycles

up and down.

Peltier element connections on

control board.

Ferrite beads on thermocouples

going into terminal TB1 & TB2

Ensure a firm connection on flag connectors on control

board. Ensure system loading is not exceeding cooler

capacity.

Wrap a Ferrite bead around thermocouple wires.

Water carryover in

system.

Heat exchanger temperature.

(Should be below 6°C.)

Ensure system loading is not exceeding cooler capacity.

Pump does not

start. LCD(s) are

green.

Pump electrical connections.

Ensure proper connections.

Replace relay board.

For further service assistance, contact:

Perma Pure LLC

P.O. Box 2105

8 Executive Drive (08755)

Toms River, NJ 08754

Tel: 800-337-3762 (toll free U.S.)

Tel: 732-244-0010

Fax: 732-244-8140

Email: info@permapure.com

or your local representative

Section J: Troubleshooting 20

Page 21

Part No.

Description

3CCB-022

Circuit Board, eCool® 5000, Control Board

2FAN-005

Fan: Muffin, 4” x 1”, 12 VDC

2FAN-007

Fan: Muffin, 6” x 1½”, 12 VDC

3CXD-022

Heat Exchanger, SS, EZ-Clean™ Twist-Apart, 10", Durinert® Coated

3CXG-006

Heat Exchanger: 10” Glass, threaded w/ fittings

3CXK-003

Heat Exchanger: 10” Kynar

3CXS-022

Heat Exchanger, SS, Twist-Apart, 10"

3KPE-004

Peltier Element Kit, 40 mm

1PSD-028

Power Supply, 300W, 24VDC, 12A, Explosion Proof, Class 1, Div 2

3CCB-023

Circuit Board, eCOOL, Relay Board

3CCB-024

Circuit Board, eCOOL, LAN Card

3CCB-025

Circuit Board, eCOOL, Accessory Board

3CCB-026

Circuit Board, eCOOL, Isolator Board

1TTC-001

Thermocouple: Temperature, Control, Type K, 24”

Part No.

Description

3CCB-022

Circuit Board, eCool® 5000, Control Board

2FAN-005

Fan: Muffin, 4” x 1”, 12 VDC

2FAN-007

Fan: Muffin, 6” x 1½”, 12 VDC

3CXD-022

Heat Exchanger, SS, EZ-Clean™ Twist-Apart, 10", Durinert® Coated

3CXG-006

Heat Exchanger: 10” Glass, threaded w/ fittings

3CXK-003

Heat Exchanger: 10” Kynar

3CXS-022

Heat Exchanger, SS, Twist-Apart, 10"

3KPE-004

Peltier Element Kit, 40 mm

1PSD-028

Power Supply, 300W, 24VDC, 12A, Explosion Proof, Class 1, Div 2

3CCB-023

Circuit Board, eCOOL, Relay Board

3CCB-024

Circuit Board, eCOOL, LAN Card

3CCB-025

Circuit Board, eCOOL, Accessory Board

3CCB-026

Circuit Board, eCOOL, Isolator Board

1TTC-001

Thermocouple: Temperature, Control, Type K, 24”

Part No.

Description

3CCB-022

Circuit Board, eCool® 5000, Control Board

2FAN-005

Fan: Muffin, 4” x 1”, 12 VDC

2FAN-007

Fan: Muffin, 6” x 1½”, 12 VDC

3CXD-022

Heat Exchanger, SS, EZ-Clean™ Twist-Apart, 10", Durinert® Coated

3CXG-006

Heat Exchanger: 10” Glass, threaded w/ fittings

3CXK-003

Heat Exchanger: 10” Kynar

3CXS-022

Heat Exchanger, SS, Twist-Apart, 10"

3KPE-004

Peltier Element Kit, 40 mm

1PSD-028

Power Supply, 300W, 24VDC, 12A, Explosion Proof, Class 1, Div 2

3CCB-023

Circuit Board, eCOOL, Relay Board

3CCB-024

Circuit Board, eCOOL, LAN Card

3CCB-025

Circuit Board, eCOOL, Accessory Board

3CCB-026

Circuit Board, eCOOL, Isolator Board

1TTC-001

Thermocouple: Temperature, Control, Type K, 24”

L: SPARE PARTS: eCOOL™ 5000XP

Model e5500XP

Model e5800XP

Model e5900XP

Section L: Spare Parts – Thermo-Electric Coolers 21

Page 22

APPENDIX: eCOOL™ 5000XP

E Cool LAN Card Setup and Configuration

Setup:

1. Start a Hyperterminal session or similar terminal emulation software and configure it to

operate at 57600,8 data bits, No Parity, and 1 Stop Bit.

2. Disconnect power from the E Cool cooler card

3. Connect the E Cool LAN card that is to be configured with the following connectors:

a. JP15 - 10 pin connector to DB9 adapter to serial cable connected to PC.

b. JP16 - 10 pin ribbon cable to JP15 on the E Cool cooler board

c. P1 - Connected to Ethernet Cable

d. JP1 - Connected to +5V power and GND coming from the E Cool cooler board JP29.

4. Apply power to the E Cool cooler card

5. Press the reset button on the E Cool LAN card (SW1)

a. The Hyperterminal window should now have configuration information from the card.

b. The last line should show "ATMEL ok."

6. Add a shorting jumper to JP12 to allow EEPROM configuration

Configuration via terminal program:

1. Type bootinfo to get a list of the current settings for the card

2. Choose to Enable/Disable DHCP

If DHCP is enable, the DHCP server can be setup to assign a specific IP address to the

unique MAC address for the LAN card. The address is found printed on a label on the card.

The MAC address can also be obtained by holding down SW5 on the main control board an

monitoring the LCD display. By assigning the address in the DHCP server the card will get

the same address each time it is powered up.

a. To Enable DHCP enter dhcp enable

b. b.To Disable DHCP enter dhcp disable (factory default)

3. If DHCP is disabled: (factory default values shown)

a. Assign a static IP address

ip 192.168.45.145

b. Assign a DNSserver (if required; no value factory set)

dns xxx.xxx.xxx.xxx

c. Assign a default gateway

gw 192.168.45.100

d. Assign a subnet mask

subnetmask 255.255.255.0

4. Press the reset button on the E Cool LAN card (SW1)

Verify that the card gets either gets an IP address from the DHCP server or contains the

statically assigned IP address by monitoring the terminal program.

5. Remove the shorting jumper from JP12

6. Power down the E Cool controller card

22

Loading...

Loading...