Page 1

Installation Manual

NORITZ AMERICA

CORPORATION

Canada

TANKLESS GAS WATER HEATER

N-0751M (Indoor/Outdoor Installation)

N-0751M-OD (Outdoor Installation)

Potential dangers from accidents during installation and use are divided into the following three

categories. Closely observe these warnings, they are critical to your safety.

DANGER indicates an imminently hazardous situation which,

DANGER

if not avoided, will result in death or serious injury.

WARNING

CAUTION

WARNING: If the information in this manual is not followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

Prohibited

WARNING indicates a potentially hazardous situation which,

if not avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which,

if not avoided, may result in minor or moderate injury.

Disconnect

Power

Ground

Be sure to do

CAUTION

Requests to Installers

• In order to use the water heater safely, read this installation manual carefully, and follow the

installation instructions.

• Failures and damage caused by erroneous work or work not as instructed in this manual are not

covered by the warranty.

• Check that the installation was done properly in accordance with this Installation Manual upon

completion.

•

After completing installation, please either place this Installation Manual in a plastic pouch and

attach it to the side of the water heater (or the inside of the pipe cover or recess box if applicable),

or hand it to the customer to retain for future reference. Also, be sure to fill in all of the required

items on the warranty and to hand the warranty to the customer along with the Owner's Guide.

CERTIFIED

WS-06-9012

Rev. 01/07

R

Low NOx

Approved by

SCAQMD

Installation must conform with local codes, or in the absence of local

codes, the National Fuel Gas Code, ANSI Z223.1/NFPA 54- latest edition and/or CSA B149.1, Natural Gas and Propane Installation Code

(NSCNGPIC).

Noritz America reserves the right to discontinue, or change at any time,

the designs and/or specifications of its products without notice.

Page 2

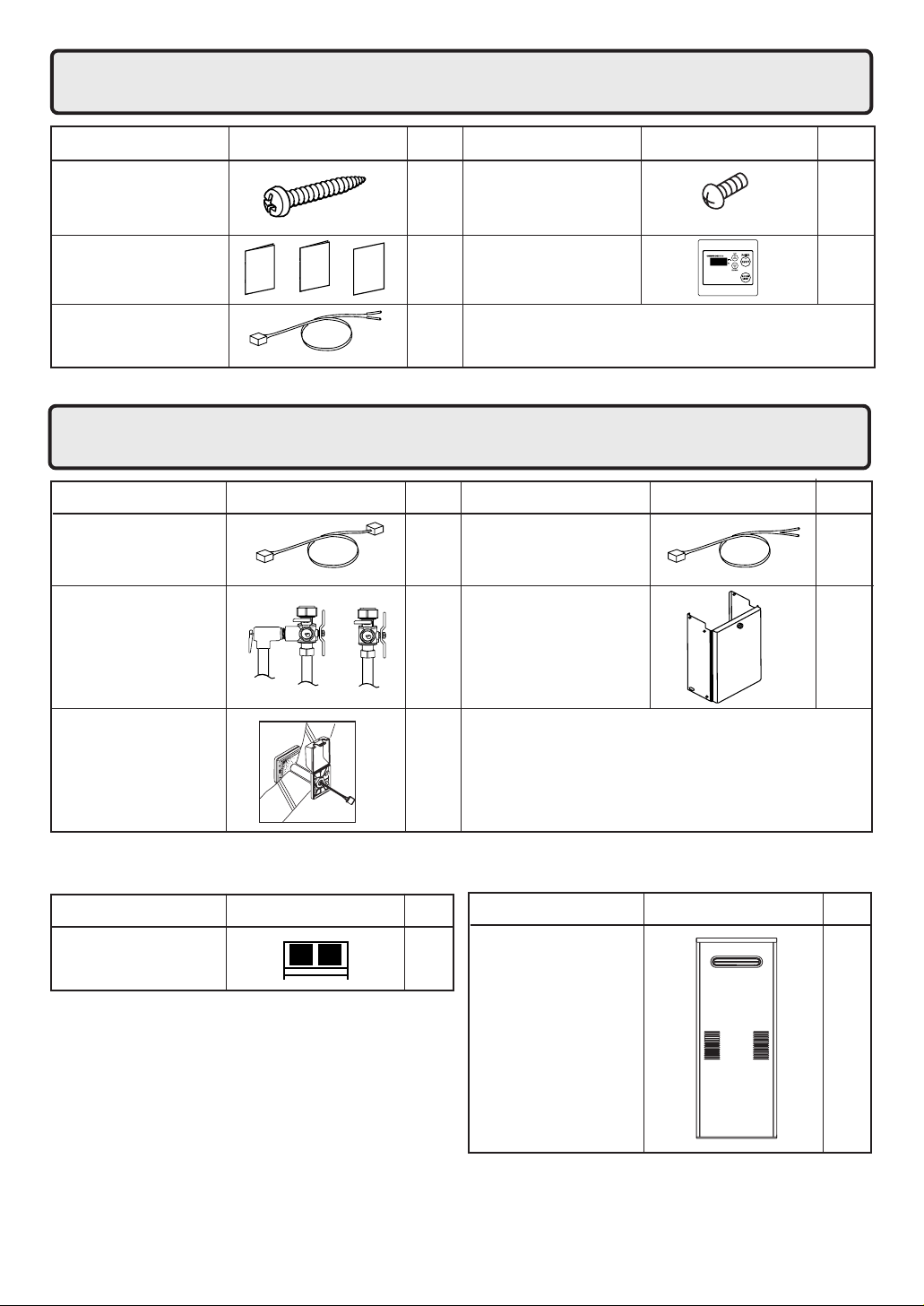

1.

Included Accessories

The following accessories are included with the unit.

Check for any missing items before starting installation.

Part Shape Q’ty

Tapping Screw

(N-0751M only)

Owner's Guide, Warranty,

Installation Manual

(this document)

Remote Controller

Cord (3m(10'))

2.

Optional Accessories

Quick Connect Cord

Isolator Exp

(includes pressure

relief valve)

5

1

each

1

1

1

Cross Recessed

Head Screw

(N-0751M-OD only)

Remote Controller

(See p. 21)

The accessories listed below are not

included with the units, but may be necessary

for installation.

Remote Controller

Cord (8m(26'))

Pipe Cover

Q’tyShapePart

3

1

Q’tyShapePartPart Shape Q’ty

1

1

[Outdoor installation only]

Remote Controller

Outdoor

Junction Box

[ N-0751M only ]

Part Shape Q’ty

Outdoor Vent Cap

(VC4(-1))

1

[ N-0751M-OD only ]

Part Shape Q’ty

1

Recess Box

(RB-4)

1

2

Page 3

3.

Quick Connect Multi System Installation

• The Quick Connect Multi System allows the installation of two units together utilizing only the Quick

Connect Cord.

The Quick Connect Cord is 2m (6'). long. Install the units 50 - 450mm (2-18") apart from each

other to ensure the cord will be able to reach between the units. (See Typical Plumbing diagram).

(If the distance between the two units is too great, not only will the cord not be able to reach,

but the water temperature may also become unstable because of the difference in pipe length

between the two units).

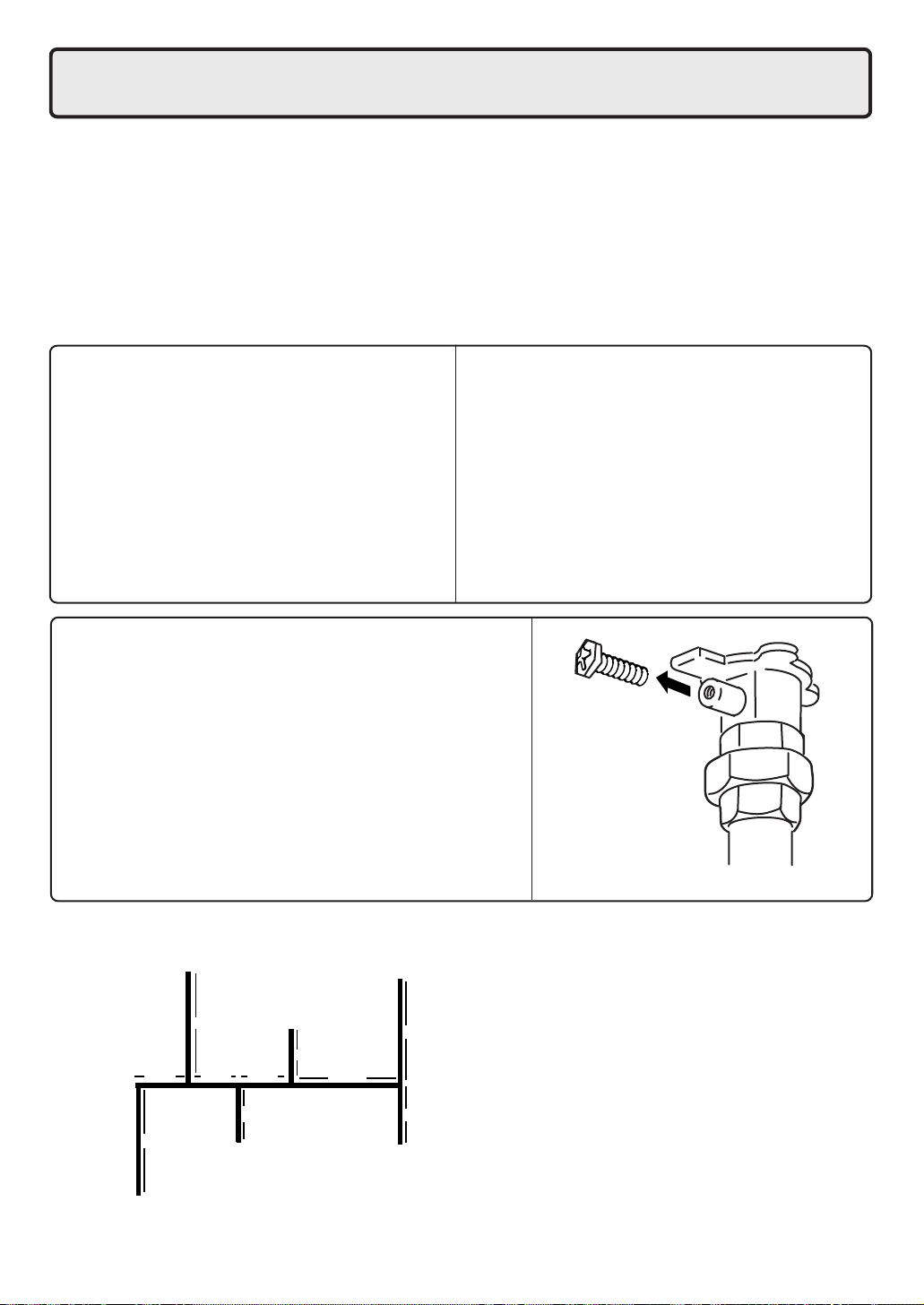

System Diagram

Quick Connect

Cord

Cord

Connector

Typical Plumbing

Cord

Connector

Terminal Block

Remote Controller

Remote Controller Cord

G

Distance at center

400 - 800mm (16-32")

Distance on sides

50 - 450mm (2-18")

* When connecting two units, use only

a single remote controller.

Note: Connect the remote

controller to only one

of the units.

Gas Supply Piping

Cold Water Supply

Hot Water

Union

Union

Gas Valve

Shutoff Valve

Shutoff

Valve

Hot Water

Cold Water

Size the piping to allow for the maximum

flow rates of the units.

Make this distance as short as possible.

* The hot water temperature will

become unstable as the pipe

length increases.

Union

Quick Connect

cord

Pressure

Relief

Valve

Shutoff

Valve

Leave enough clearance around the plumbing to

apply insulation. It will be necessary to add

bends to the piping to ensure that this clearance

is available.

• Insulate the hot water piping to prevent heat loss. Insulate and apply heating materials to the cold

water supply piping to prevent heat loss and freezing of pipes when exposed to excessively cold

temperatures.

3

Page 4

0 - 2,000 Ft.

168,000

2.0

162,800

2,000 - 4,500 Ft.

610 - 1,370 m

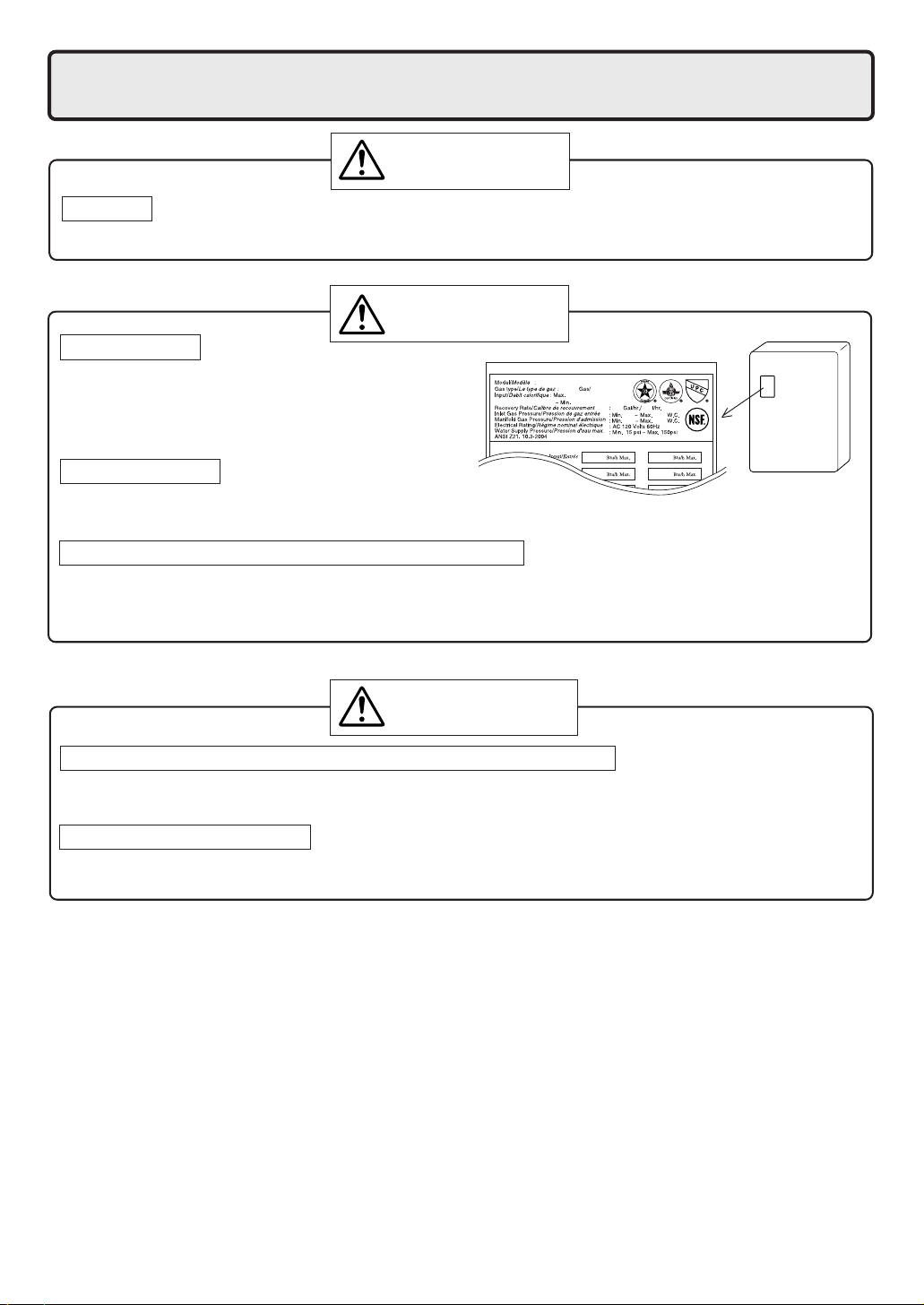

Before Installation

4.

DANGER

Checkup

[For indoor installation only]

• Check the fixing brackets and vent pipe yearly for damage or wear. Replace if necessary.

WARNING

Check the Gas

• Check that the rating plate indicates the

correct type of gas.

• Check that the gas supply line is sized for

199,900 Btuh for this unit.

Check the Power

• The power supply required is 120V AC, at 60Hz.

N-0751M

Natural

199,900 BTU

12,000 BTU

0 - 2,000 Ft.

Gaz Naturel

199,900

168,000

2.0

202

(

0 - 610 m

4.0

0.65

765

)

2,000 - 4,500 Ft.

10.5"

2.55"

192,800

162,800

*

(610 - 1,370 m

2.0

)

*

Using the incorrect voltage may result in fire or electric shock.

Use Extreme Caution if Using With a Solar Pre-Heater

• Using this unit with a solar pre-heater can lead to unpredictable output temperatures and

possibly scalding. If absolutely necessary, use mixing valves to ensure output temperatures do

not get to scalding levels. Do not use a solar pre-heater with the quick-connect multi-system.

CAUTION

Do Not Use Equipment for Purposes Other Than Those Specified

• Do not use for other than increasing the temperature of the water supply, as unexpected accidents

may occur as a result.

Check Water Supply Quality

• If the water supply is hard, acidic or otherwise impure, treat the water with approved methods in

order to ensure full warranty coverage.

4

Page 5

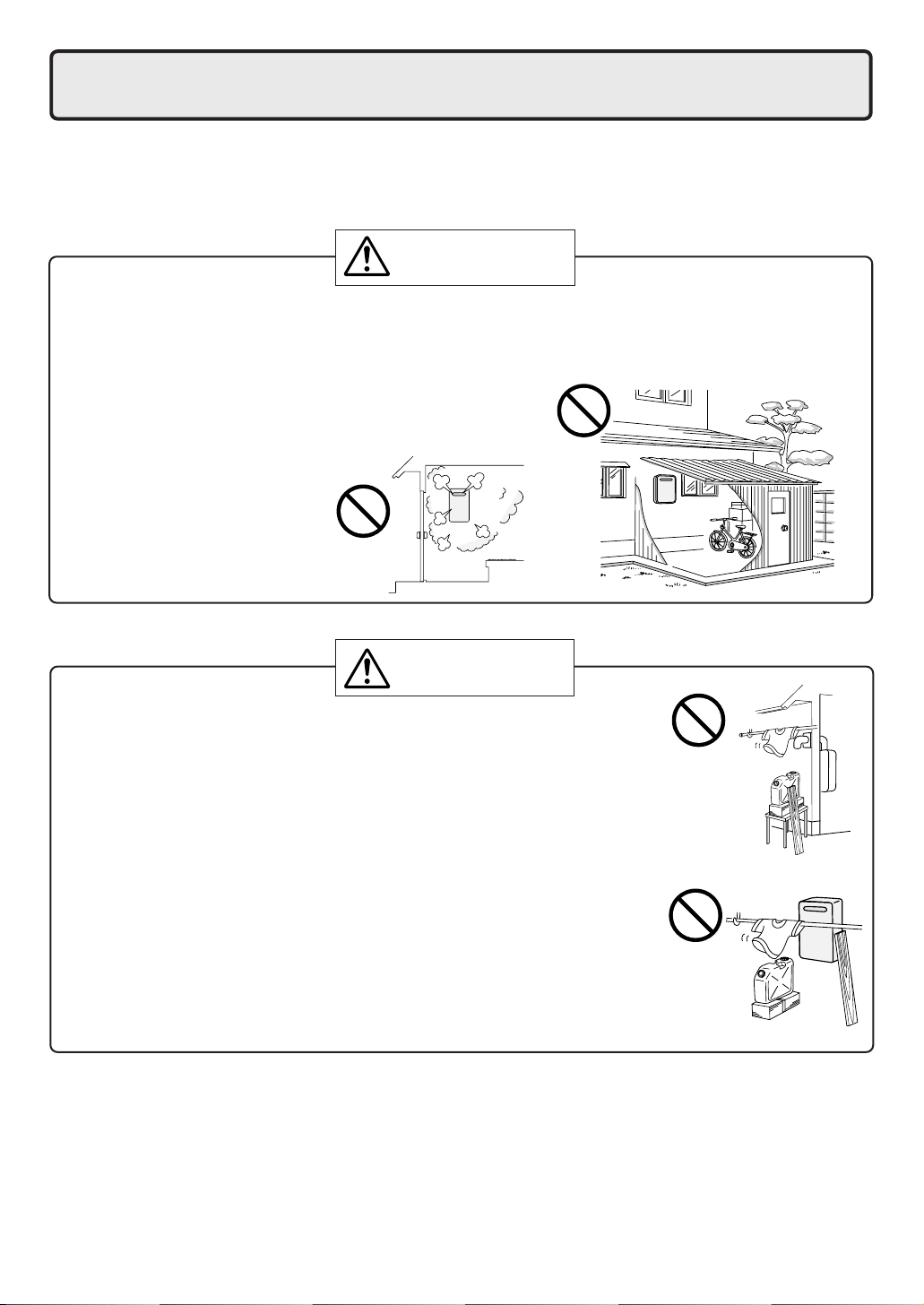

Choosing Installation Site

5.

* Locate the appliance in an area where leakage from the unit or connections will not result in damage

to the area adjacent to the appliance or to the lower floors of the structure. When such locations

cannot be avoided, it is recommended that a suitable drain pan, adequately drained, be installed

under the appliance. The pan must not restrict combustion air flow.

DANGER

[For indoor installation only]

• Install the exhaust vent so that there are no obstacles around the termination and so that

exhaust can't accumulate. Do not enclose the termination with corrugated metal or other

materials.

[For outdoor installation only]

• Do not enclose the termination with corrugated

metal or other materials.

This will cause carbon monoxide

poisoning and a potential fire

hazard.

Indoor

WARNING

• Avoid places where fires are common, such as those where gasoline,

benzene and adhesives are handled, or places in which corrosive gases

(ammonia, chlorine, sulfur, ethylene compounds, acids) are present.

Using the incorrect voltage may result in fire or cracking.

• Avoid installation in places where dust or debris will accumulate.

Dust may block the air-supply opening, causing the performance of the

device fan to drop and incomplete combustion to occur as a result.

• Avoid installation in places where special chemical agents

(e.g., hair spray or spray detergent) are used.

Ignition failures and malfunction may occur as a result.

• Carbon Monoxide Poisoning Hazard. Do not install this water heater in a

mobile home, recreation vehicle or on a boat.

Prohibited

[Indoor installation]

Prohibited

[Outdoor installation]

5

Page 6

CAUTION

• Consult with the customer concerning the location of installation.

• Do not install the water heater where the exhaust will blow on outer walls or material not resistant

to heat. Also consider the surrounding trees and animals.

The heat and moisture from the water heater may cause discoloration of walls and resinous

materials, or corrosion of aluminum materials.

• Install in a location where the exhaust gas flow will not be affected by fans or range hoods.

• Take care that noise and exhaust gas will not affect neighbors.

• Before installing, make sure that the vent termination (or the vent

cap in an outdoor installation) will have the proper clearances

according to the National Fuel Gas Code (ANSI Z223.1).

[For outdoor installation only]

• Install the water heater in a location where it is free from obstacles and stagnant air.

• Do not install the water heater near staircases or emergency exits.

•

Do not locate the vent termination directed towards a window or any

other structure which has glass or wired glass facing the termination.

•

Avoid installation where the unit will be exposed to excessive winds.

[For indoor installation only]

• Avoid installation above gas ranges or stoves.

• Avoid installation between the kitchen fan and stove.

If oily fumes or a large amount of steam are present in the

installation location, take measures to prevent the fumes and

steam from entering in the equipment.

Prohibited

Prohibited

Be sure to do

[For N-0751M only]

• Make sure that the location allows installation of the exhaust

vent as specified.

• For outdoor installation, use the outdoor vent cap.

If it is necessary to vent above the roof line in an outdoor

installation, also use the base of the vent cap for rain protection.

State of California: The water heater must be braced, anchored or strapped to avoid moving during an

earthquake. Contact local utilities for code requirements in your area or call: 1-800-456-9805 and request

instructions.

6

Page 7

6. Installation Clearances

WARNING

Before installing, check for the following:

Install in accordance with relevant building and mechanical codes, as well as any local, state or

national regulations, or in the absence of local and state codes, to the National Fuel Gas Code ANSI

Z223.1/NFPA 54 – latest edition. In Canada, see NSCNGPIC for detailed requirements.

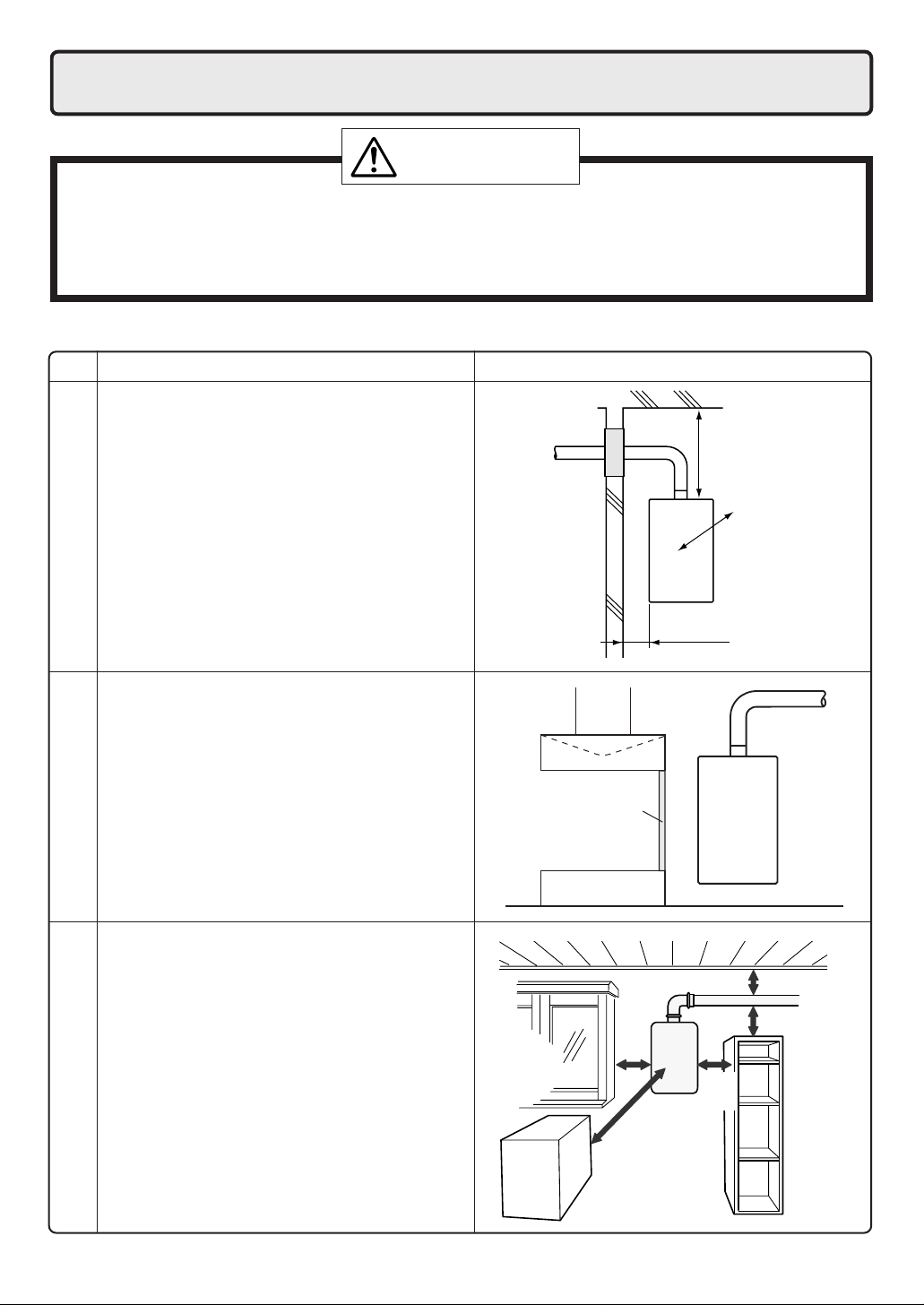

[ For N-0751M ]

Item

• Maintain the following clearance from

both combustible and non-combustible

materials.

From Heater

Required Clearances

• If the unit will be installed in the vicinity of a

permanent kitchen range or stove that has

the possibility of generating steam that

contains fats or oils, use a dividing plate or

other measure to ensure that the unit is not

exposed to air containing such impurities.

* The dividing plate should be of noncombust-

ible material of a width greater than the

Cooking Equipment

water heater.

Check Illustration

Exhaust hood

Dividing plate

Range

300mm (12") Indoor

900mm (36") Outdoor

600mm (24") Outdoor

100mm (4") Indoor

50mm (2") Indoor

600mm (24") Outdoor

Water

heater

• If possible, leave 200mm (8") or more on

either side of the unit to facilitate inspection.

• If possible, leave 600mm (24") or more in

front of the unit to facilitate maintenance

and service if necessary.

repair/inspection

Securing of space for

200mm

(8") or

more

600mm

(24") or

more

Min: 75mm (3")

Min: 75mm (3")

200mm

(8") or

more

7

Page 8

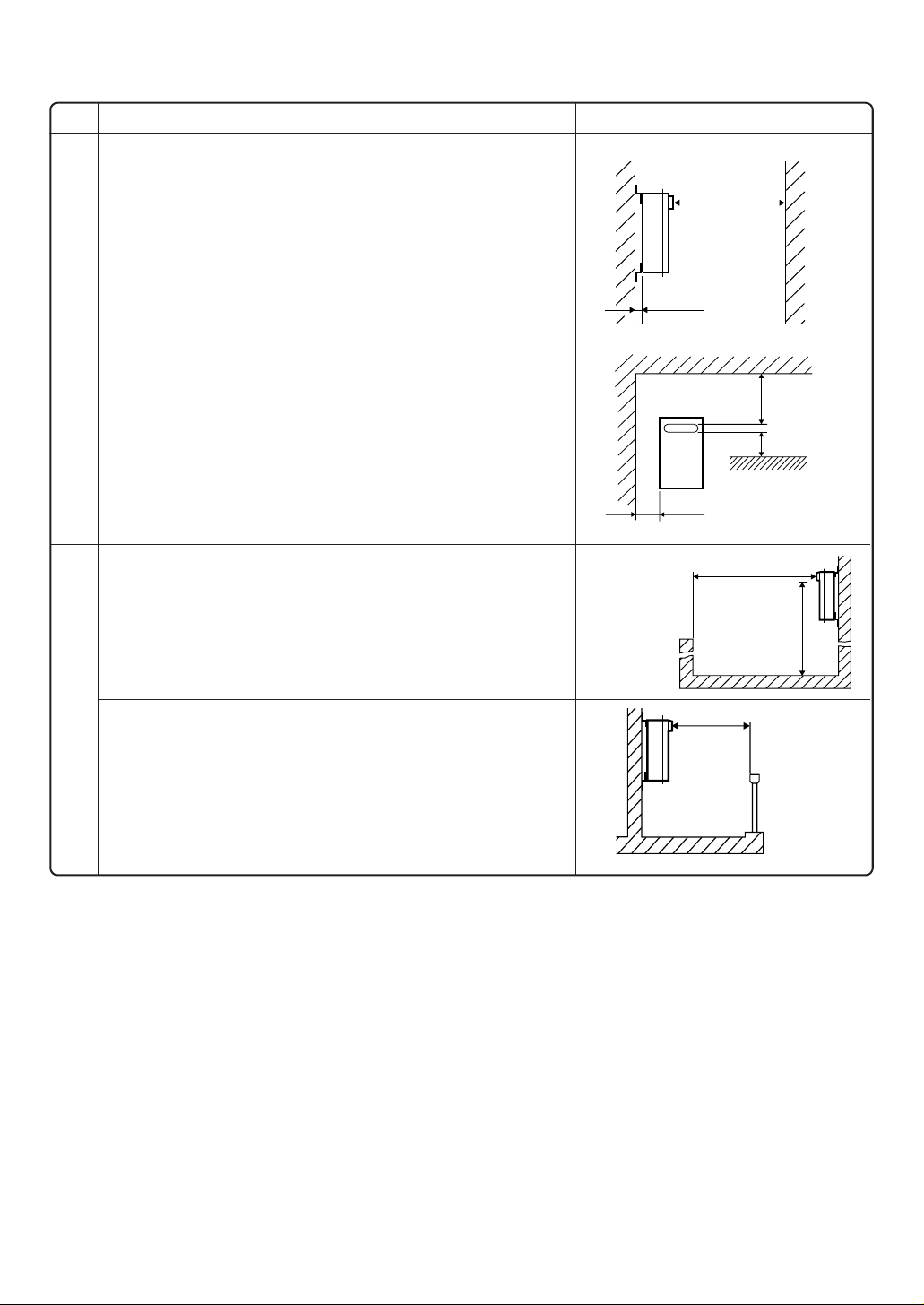

[ For N-0751M -OD]

Item Check

• Maintain the following clearance from both combustible

and non-combustible materials.

*( ) indicates the distance when installing a heat insulat-

ing board (incombustible material other than metal, with

thickness of 2.5mm (0.1") or more) or "section of building effectively finished with incombustible material."

Note, however, that combustion failure may occur to the

unit as exhaust gas reflects from the wall. Provide clearance of 600mm (24") or more in the front of the unit to

facilitate inspection and repair.

Required Clearances From Heater

•

When installing the unit in a common side corridor, provide

a clearance of 1175mm (47") or more in front of the unit.

• Set the bottom edge of the exhaust port about 2100mm

(84") from the corridor floor.

600mm (24")

(300mm (12"))

or more

combustible

10mm (0.4")

or more

combustible

combustible

150mm

(6") or more

Handrail

combustible

900mm

(36") or more

150mm

(6") or more

combustible

1175mm (47")

or more

about

2100mm (84")

common side

corridor

• When installing the unit on a balcony, etc., secure an

evacuation route of 600mm (24") or more in width.

• Provide clearance of 600mm (24") or more in front of the

unit to facilitate inspection and repair. Do install the unit

such as the wall of the second floor where the unit is out

Surrounding the area of installation

of reach.

600mm (24")

or more

Handrail

balcony, etc.

8

Page 9

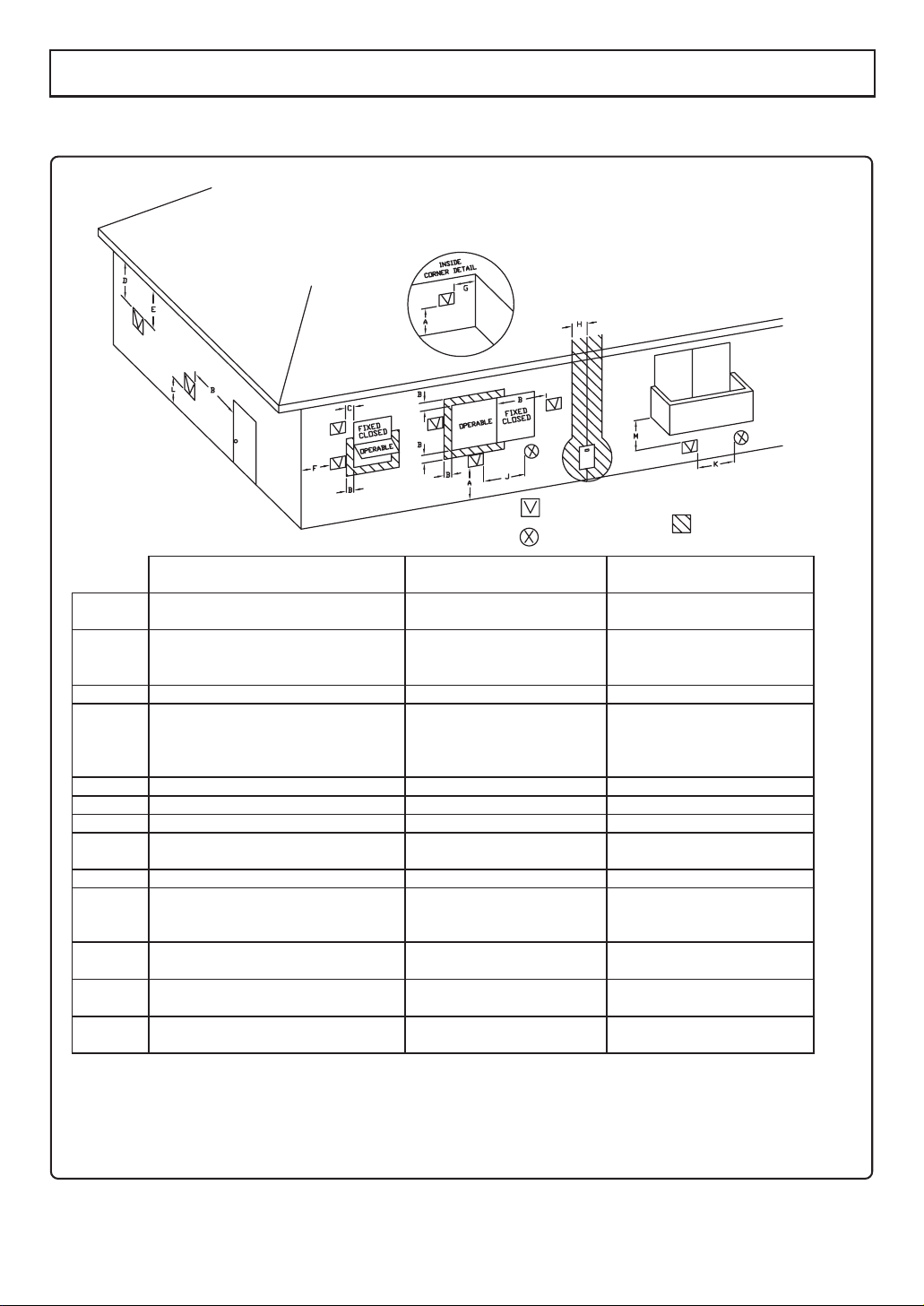

Clearance Requirements from Vent Terminations to Building Openings

* All clearance requirements are in accordance with ANSI Z21.10.3 and the National Fuel Gas Code,

ANSI Z223.1 and in Canada, in accordance with NSCNGPIC.

A=

B=

C=

D=

E=

F=

G=

H=

I=

J=

K=

L=

M=

Clearance

Above grade, veranda, porch, deck,

or balcony

Window or door that may be opened

Permanently closed window

Vertical clearance to ventilated soffit

located above the terminal within a

horizontal distance of 0.6m

the center of the terminal

Unventilated soffit

Outside corner

Inside corner

Each side of center line extended

above meter/regulator assembly

Service regulator vent outlet

Nonmechanical air supply inlet or

combustion air inlet to any other

appliance

Mechanical air supply inlet

Above paved sidewalk or paved

driveway located on public property

Under veranda, porch, deck, or

balcony

(2')

from

Vent Terminal

Air Supply Inlet

Indoor Installation

(See p.10)

1.2m (4') below or to the side of

opening, or 0.3m (1') above

opening [900mm (36")]

*

*

*

*

*

0.9m (3') within a height 4.5m (15')

above meter/regulator assembly

0.9m (3')

1.2m (4') below or to the side of

opening, or 0.3m (1') above

opening [900mm (36")]

0.9m (3') above if within

3m (10') [1.8m (6')]

[2.1m *** (7' ***)]

*[300mm (12") - Canada Only****] *[300mm (12") - Canada Only****]

Outdoor Installation

300mm (12") [300mm (12")]300mm (12") [300mm (12")]

300mm (12") [900mm (36")]

0.9m (3') within a height 4.5m (15')

above meter/regulator assembly

300mm (12") [900mm (36")]

0.9m (3') above if within

3m (10') [1.8m (6')]

Area Where Terminal

is Not Permitted

(See p.10, 11)

*

*

*

*

*

0.9m (3')

[2.1m *** (7' ***)]

[ ]= indicates clearances required in Canada

* Maintain clearances in accordance with local installation codes and the requirements of the gas supplier

*** A vent shall not terminate directly above a sidewalk or paved driveway that is located between two

single family dwellings and serves both dwellings.

**** Permitted only if veranda,porch,deck,or balcony is fully open on a minimum of two sides beneath the floor.

9

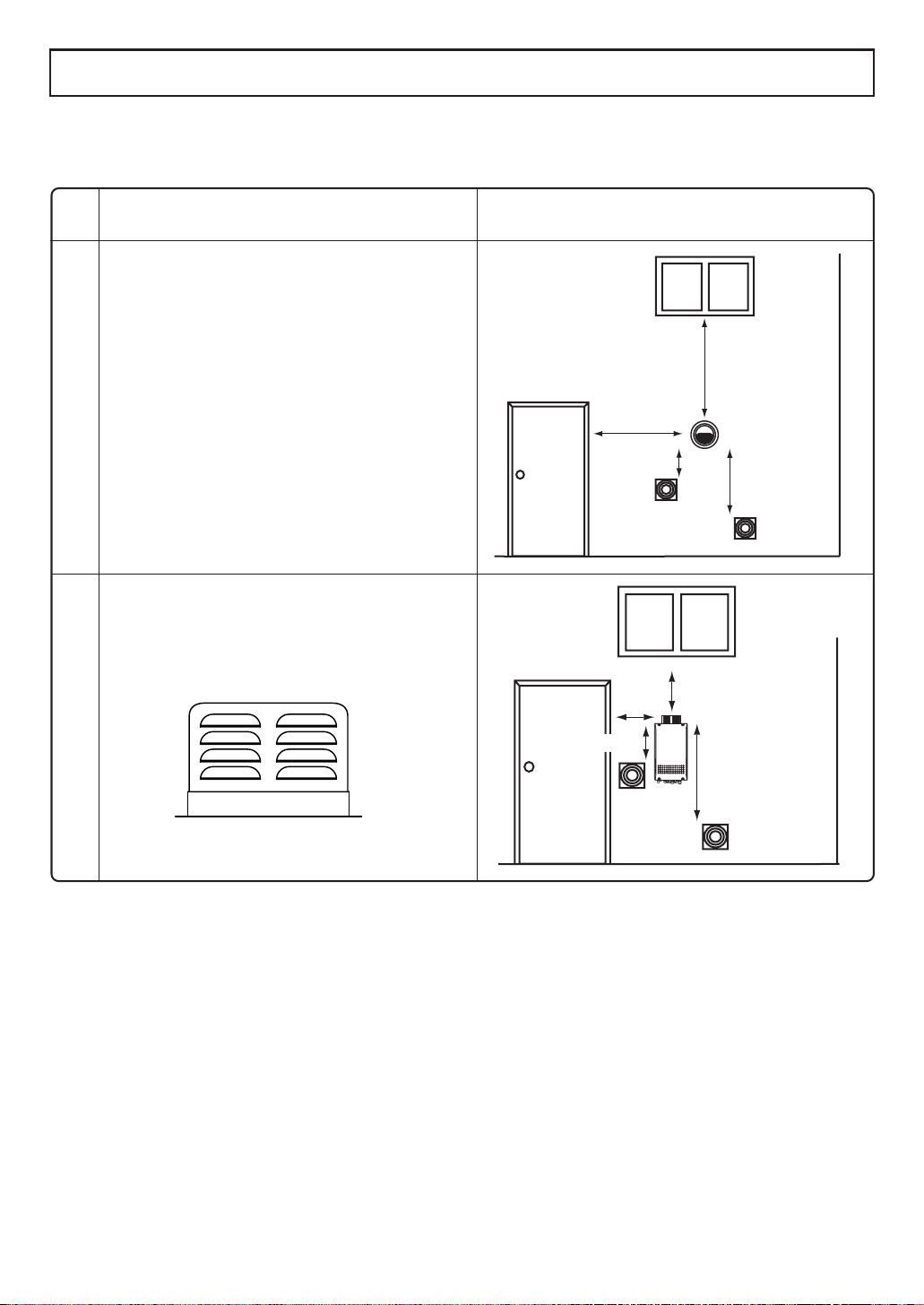

Page 10

Clearance Requirements from Vent Terminations to Building Openings

* All clearance requirements are in accordance with ANSI Z21.10.3 and the National Fuel Gas Code,

ANSI Z223.1 and in Canada, in accordance with NSCNGPIC.

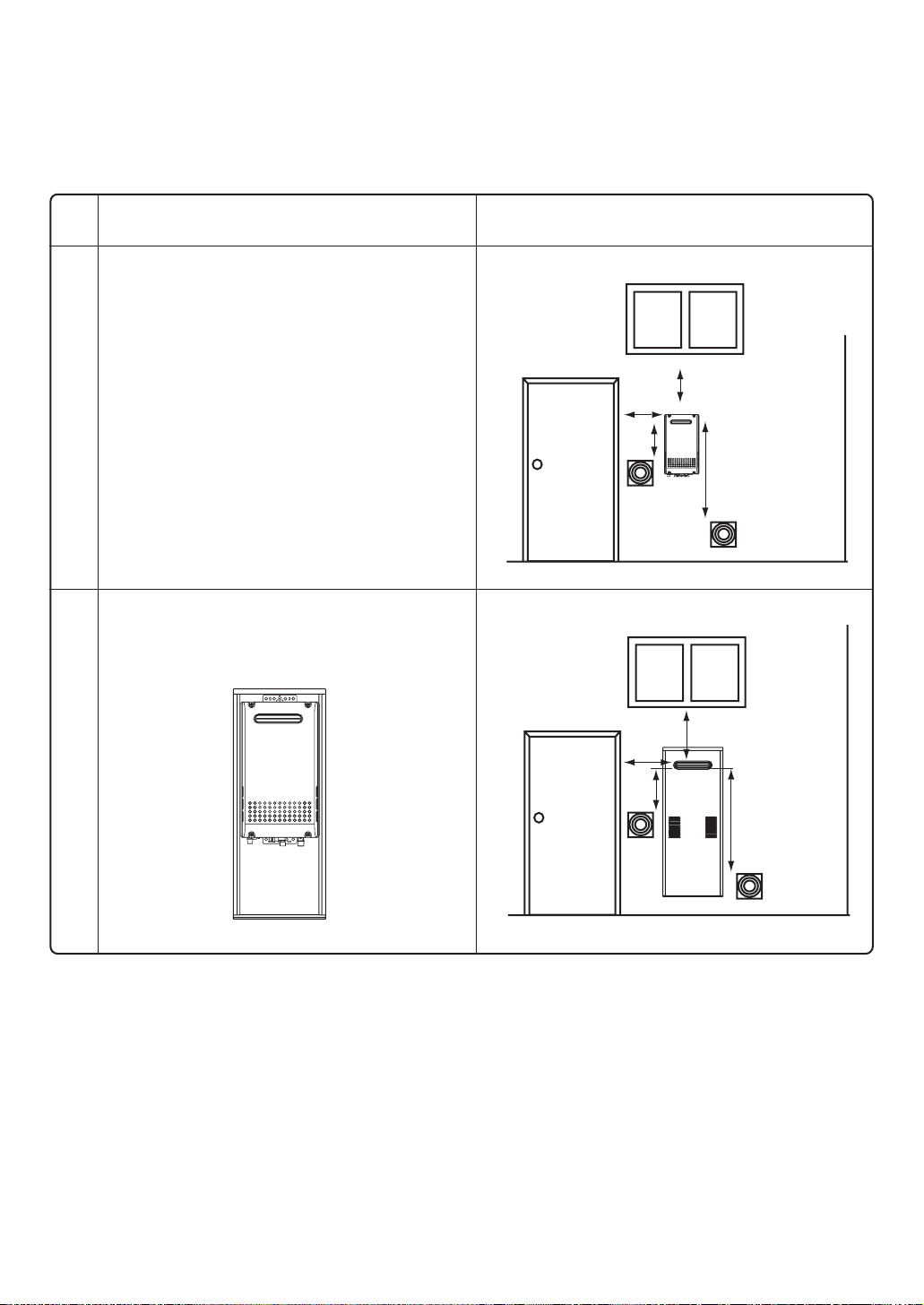

[ For N-0751M]

Maintain the following clearances to any

opening in any building:

• 1.2m (4') below, 1.2m (4') horizontally from,

or 0.3m (1') above any door, operable window, or gravity air inlet into any building.

0.9m (3') above any forced air inlet within

3m (10').

stalled Indoors

Vent Clearances When Heater is In-

• 0.3m (1') below, 0.3m (1') horizontally from,

or 0.3m (1') above any door, operable

window, or gravity air inlet into any building.

0.9m (3') above any forced air inlet within

3m (10').

Illustration

1.2m (4')

1.2m (4')

0.3m (1')

0.3m (1')

0.9m (3')

0.3m (1')

0.3m (1')

0.9m (3')

stalled Outdoors With a Vent Cap

Vent Clearances When Heater is In-

*

For Installations in Canada, clearances are as follows: To windows, doors, & gravity air inlets: 900mm (36").

To forced air inlets: 1.8m (6'). These clearance requirements hold true for all of the above situations: Indoor,

Outdoor w/vent cap.

(Noritz vent cap)

10

Page 11

[ For N-0751M- OD]

Maintain the following clearances to any

opening in any building:

• 0.3m (1') below, 0.3m (1') horizontally from,

or 0.3m (1') above any door, operable

window, or gravity air inlet into any building.

0.9m (3') above any forced air inlet within

3m (10').

into Any Building

Outdoor Clearances to Opening

• 0.3m (1') below, 0.3m (1') horizontally from,

or 0.3m (1') above any door, operable

window, or gravity air inlet into any building.

0.9m (3') above any forced air inlet within

3m (10').

Illustration

0.3m (1')

0.3m

(1')

0.3m

(1')

0.3m (1')

0.9m (3')

0.3m (1')

0.3m

(1')

0.9m (3')

Installed in a Recess Box

Vent Clearances When Heater is

(recess box installation with cover removed)

*

For Installations in Canada, clearances are as follows: To windows, doors, & gravity air inlets: 900mm (36").

To forced air inlets: 1.8m (6').

11

Page 12

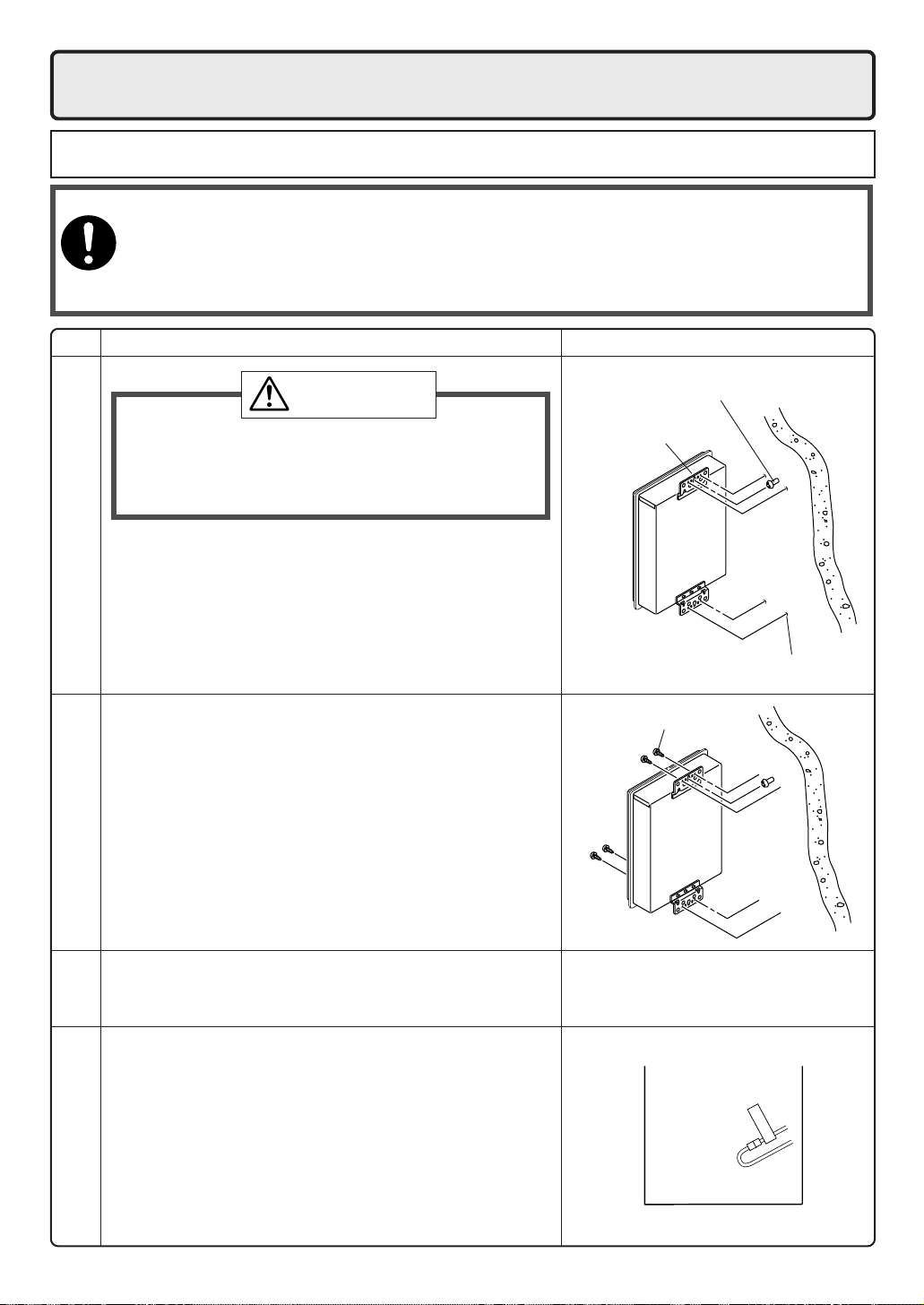

7. Installation

Securing to the wall

• The weight of the device will be applied to the wall. If the strength of the wall is not sufficient, reinforcement must be done to prevent the transfer of vibration.

• Do not drop or apply unnecessary force to the device when installing. Internal parts may

Be sure to do

be damaged and may become highly dangerous.

• Install the unit on a vertical wall and ensure that it is level.

Item

Check

CAUTION

• When installing with bare hands, take caution to

not inflict injury.

• Be careful not to hit electrical wiring, gas, or water

piping while drilling holes.

1. Drill a single screw hole, making sure to hit a stud.

2. Insert and tighten the screw and hang the unit by

the upper wall mounting bracket.

Locating Screw Holes

3. Determine the positions for the remaining four screws

(two for the top bracket and two for the bottom), and

remove the unit.

4. Drill holes for the remaining four screws.

5. Hang the unit again by the first screw, and then

insert and tighten the remaining four screws.

6. Take waterproofing measures so that water does

not enter the building from screws mounting the

Mounting

device.

Illustration

Location of Screw Hole

Mounting Bracket

(upper)

Locating Screw Holes

Tapping Screw

• Make sure the unit is installed securely so that it will

not fall or move due to vibrations or earthquakes.

Structure

• If this water heater is being installed at an elevation of

610m (2,000') or higher, disconnect the connector labeled "High Elevation Disconnect" as illustrated on the

right. This connector is located inside the unit.

•Disconnect power to the water heater before discon-

necting this connector. Failure to perform this step will

result in a "73" code displayed on the remote controller

and a cease in operation. If this occurs, disconnect,

then reconnect power to the water heater to reset the

Above 610m (2,000').

system.

Installations at Elevations

12

DISCONNECT

HIGH ELEVATION

Page 13

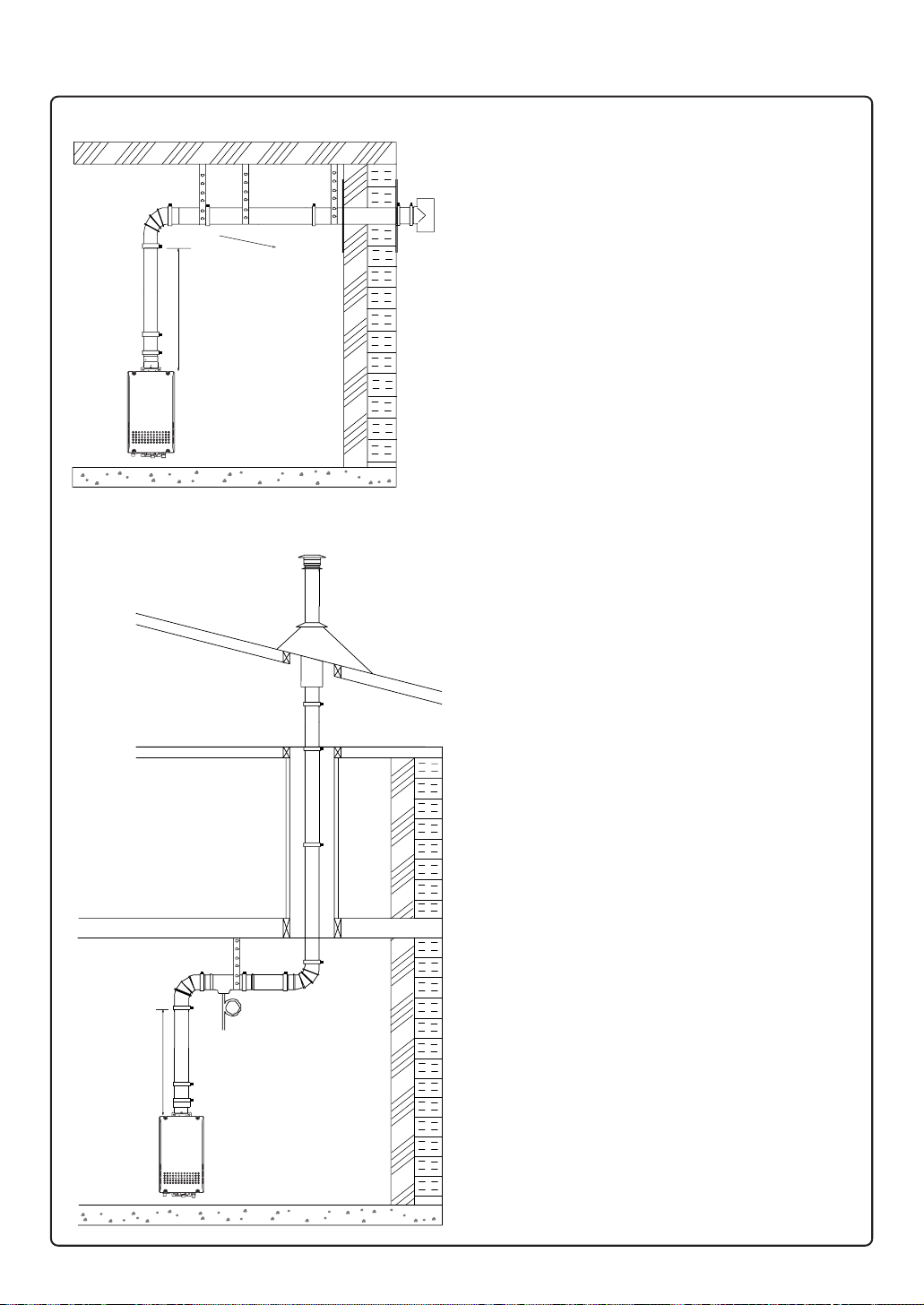

Vent Pipe Installation

8.

[ For N-0751M]

CARBON MONOXIDE POISONING

Follow all vent system requirements in accordance with relevant local or state regulation,

Be sure to do

or, in the absence of local or state code, in the U.S. to the National Fuel Gas Code ANSI

Z233.1/NFPA 54 – latest edition, and in Canada, in accordance with NSCNGPI.

(Indoor Installation Only)

WARNING

Vent Piping

•Use only UL listed category III vent materials.

• Follow the vent pipe manufacturer's installation

instructions.

Pipe diameter 100mm (4")

No. of Elbows Max. Straight Vent Length

34.6m (15')

28.2m (27')

1 11.7m (39')

• Make the vertical section of the exhaust vent

as short as possible.

• Maintain the same vent pipe diameter from the

heater flue to the vent termination.

Clearances

Manufacturer and Enclosed Unenclosed

Product Hor. Vert. Hor. Vert.

Noritz N-Vent

Protech FasNSeal

Protech FasNSeal W2

HeatFab SafTVent

Z-Flex Z-Vent

Flex-L-StaR-34

250mm (10") (sides)

375mm (15") (top)

150mm (6") (bottom)

200mm (8") (sides)

300mm (12") (top)

100mm (4") (bottom)

150mm

(6")

150mm

(6")

200mm

(8")

200mm

(8")

100mm

(4")

100mm

(4")

100mm

(4")

150mm

(6")

100mm

(4")

100mm

(4")

75mm

(3")

75mm

(3")

75mm

(3")

50mm

(2")

25mm

(1")

25mm

(1")

75mm

(3")

75mm

(3")

75mm

(3")

50mm

(2")

25mm

(1")

25mm

(1")

These clearances are subject to change.

Refer to the UL listing for the proper clearances.

• The first vertical run from the top of the heater

should be no longer than 0.9m (3').

• Make sure vent pipe is gas tight and will not

leak. Use silicon sealant wherever necessary.

• Do not common vent or connect more than

one appliance to this venting system.

•

The total vent length including horizontal & verti-

cal vent runs should be no less than 0.9m (3').

• Do not place any dangerous objects at the end

of the exhaust vent and check that vent pipe is

not blocked in any way.

• Steam (smoke) or water drops may come out

from the end of the exhaust pipe. Select the

location for the end of the vent so that steam is

not visible, and the vent is not wet with dripping water.

• If snow is expected to accumulate, take care

the end of the pipe is not covered with snow or

hit by falling lumps of snow.

• Consult the vent pipe manufacturer's installation instructions for chimney connections.

Appliance Adapters

• Use the following adapters to connect the

unit to the venting system.

Manufacturer and

Product

Part No.

Protech FasNSeal FSAA4

HeatFab SafTVent 9401RYPK

Z-Flex Z-Vent 2SVWA04

Flex-L Star-34 SRASPSA4

13

Page 14

Horizontal Vent Termination

Hanger

Straps

Elbow

Slope vent

Downwards

**0.3m (1') Min. -

Appliance

Adapter*

0.9m (3') Max.

* Adapter not required when

using Noritz N-Vent.

** 0.3m (1') minimum recommended,

but not required. Avoid installing

elbow directly on flue.

Vertical Vent Termination

Storm

Collar

Roof

Jack

Hanger

Elbow

**0.3m (1') Min. -

0.9m (3') Max.

Appliance

Strap

Condensation

Drain (Install

According to

Local Codes)

Adapter*

* Adapter not required when

using Noritz N-Vent.

** 0.3m (1') minimum recommended,

but not required. Avoid installing

elbow directly on flue.

Wall

Thimble

Rain

Cap

Flashing

Firestop/

Support

Firestop

Roof

Te r mination

• Terminate at least 300mm (12") above

grade or above snow line.

• Terminate at least 2.1m (7') above a public

walkway, 1.8m (6') from the combustion air

intake of any appliance, and 0.9m (3') from

any other building opening, gas utility meter,

service regulator etc.

• Terminate at least 0.9m (3') above any

forced air inlet within 3m (10'), 1.2m (4') below, 1.2m (4') horizontally from or 0.3m (1')

above any door, window, or gravity air inlet

into any building per National Fuel Gas Code

ANSI Z223.1/NFPA 54.

• Slope the horizontal vent 1/4" downwards

for every 300m (12").

• Use a condensation drain if necessary.

•In the Commonwealth of Massachusetts a

carbon monoxide detector is required for all

side wall horizontally vented gas fuel equipment. Please refer to Technical Bulletin TB

010606 for full installation instructions.

• Terminate at least 1.8m (6') from the combustion air intake of any appliance, and 0.9m (3')

from any other building opening, gas utility

meter, service regulator etc.

• Enclose exterior vent systems below the roof

line to limit condensation and protect against

mechanical failure.

• When the vent penetrates a floor or ceiling and

is not running in a fire rated shaft, a firestop and

support is required.

• Terminate the vent system at least 0.6m (2')

above, but not more than 1.8m (6') above the

roof line, or according to the vent pipe

manufacturer's instructions.

• Terminate the vent system at least 0.6m (2')

above any portion of a building located within

3m (10') horizontally.

• Provide vertical support every 3.6m (12') or as

required by the vent pipe manufacturer's instructions.

• Slope the horizontal vent 1/4" for every 300m

(12") towards the drain tee.

• Do not vent straight upwards.

Always have a horizontal section of venting.

• Install a condensation drain in the horizontal

section of the venting.

14

Page 15

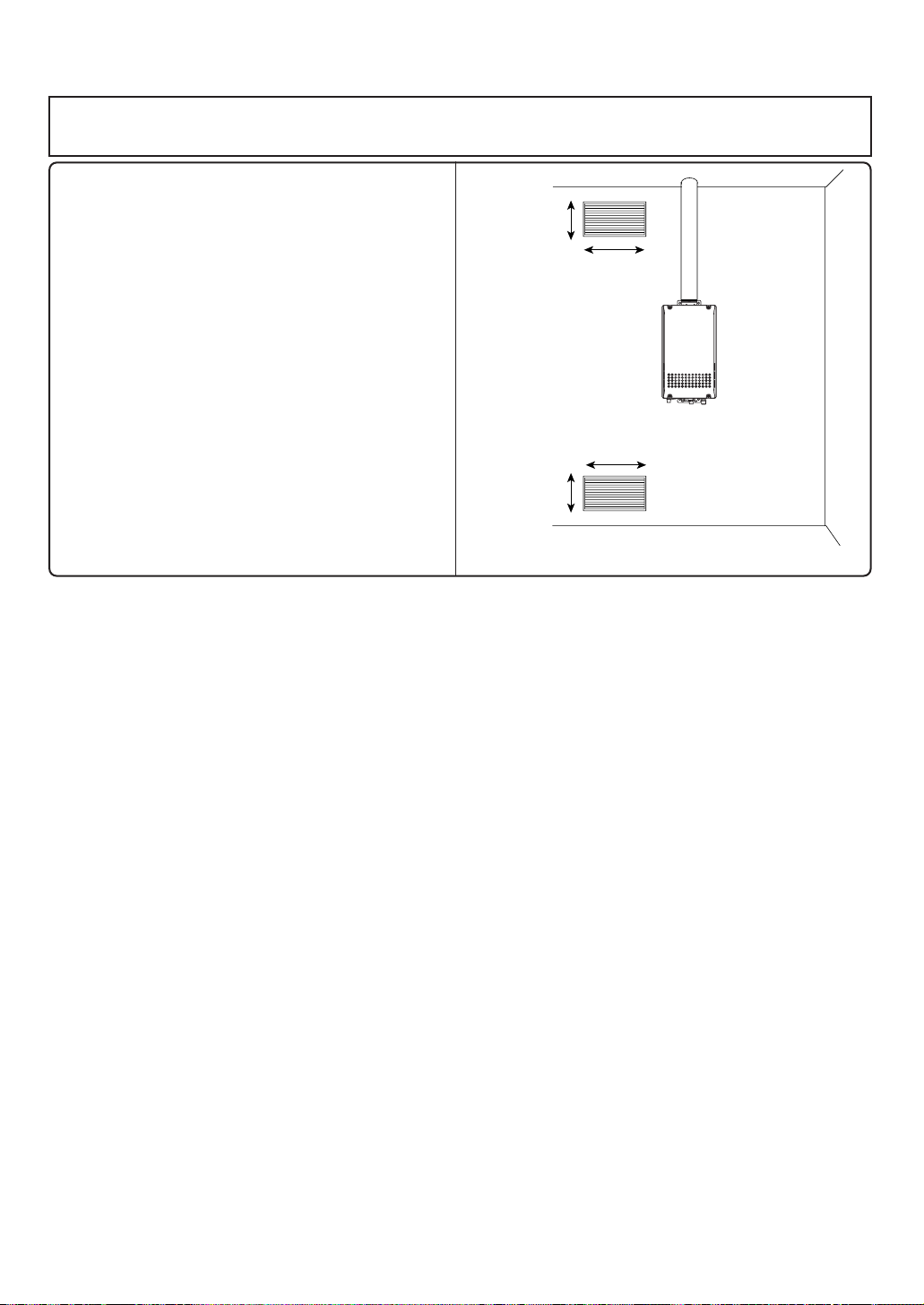

Combustion Air

Supply combustion air to the units as per the National Fuel Gas Code, ANSI Z223.1 and

in Canada, in accordance with NSCNGPIC.

• Provide two permanent openings to allow

circulation of combustion air.

• Make each opening 199 square inches if they

provide indoor air, and 100 square inches for

outdoor air.

• If the unit is installed in a mechanical closet,

provide a 600mm (24") clearance in front of

the unit to the door.

• If combustion air will be provided through a

duct, size the duct to provide 60 cubic feet of

fresh air per minute.

250mm (10")

500mm (20")

500mm (20")

250mm (10")

Openings supplying indoor air

15

Page 16

Gas Piping

9.

Follow the instructions from the gas supplier.

The appliance and its individual shutoff valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1⁄2 psi (3.5 kPa).

The Appliance must be isolated from the gas supply piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1⁄2

psi (3.5 kPa).

The appliance and its gas connections must be leak tested before placing the appliance in operation.

The inlet gas pressure must be within the range specified. This is for the purposes of input adjustment.

In order to choose the proper size for the gas line, consult local codes or the National Fuel Gas Code ANSI

Z223.1.

Gas Pressure

Size the gas line according to total btuh demand

of the building and length from the meter or

Gas Meter

Select a gas meter capable of supplying the entire

btuh demand of all gas appliances in the building.

regulator so that the following supply pressures

are available even at maximum demand:

Natural Gas Supply Pressure

Min. 4" WC

Max. 10.5" WC

LP Gas Supply Pressure

Min. 8" WC

Max. 14" WC

Gas Connection

•Do not use piping with a diameter smaller than

the inlet diameter of the water heater.

• Gas flex lines are not recommended unless they

are rated for 199,900 btuh.

• Install a gas shutoff valve on the supply line.

• Use only approved gas piping materials.

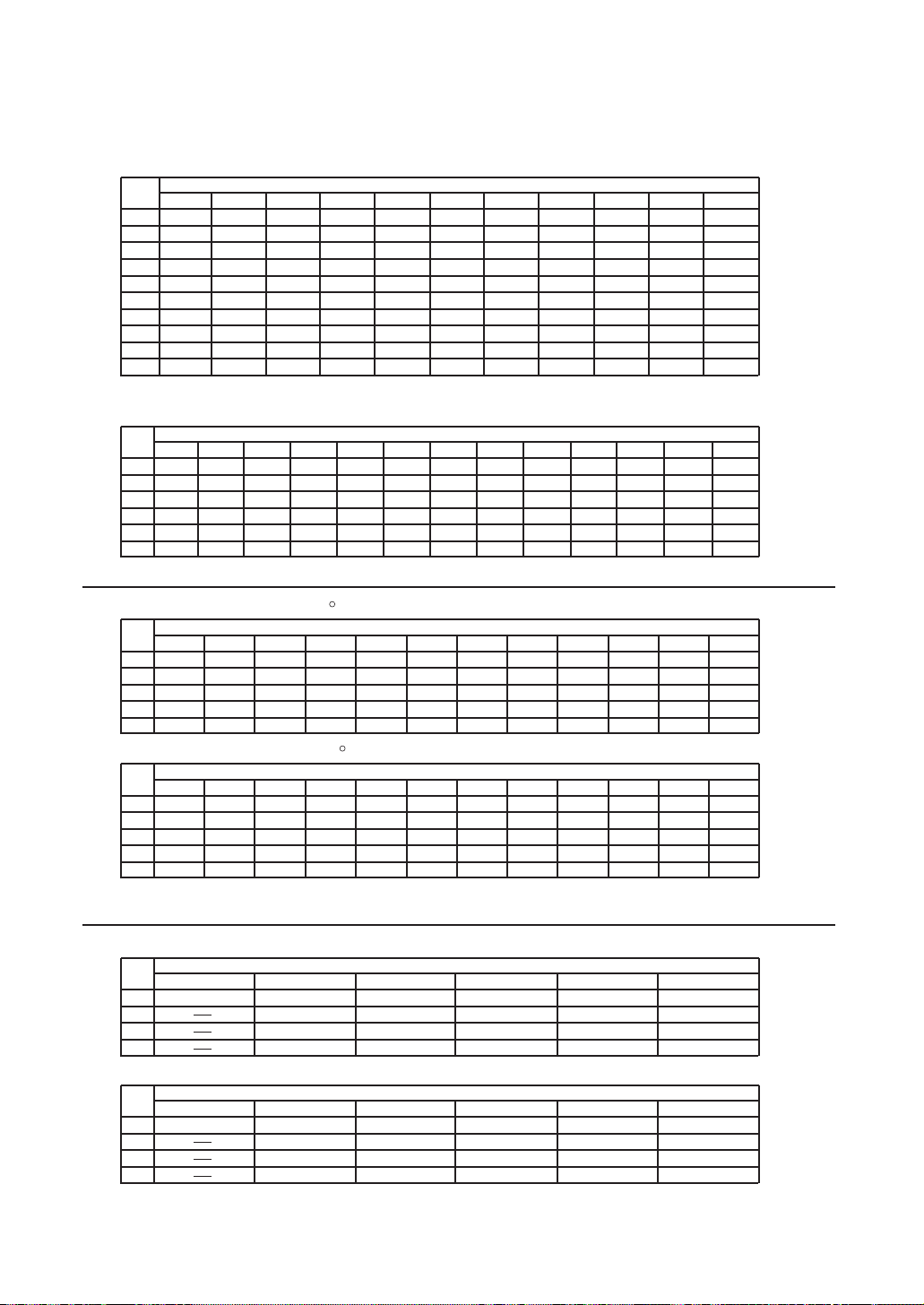

Measuring Gas Pressure

In order to check the gas supply pressure to the unit, a

tap is provided on the gas inlet. Remove the hex head

philips screw from the tap, and connect a manometer

using a silicon tube.

In order to check the gas manifold pressure, a pair of

taps are provided on the gas valve inside the unit.

The pressure can be checked either by removing the hex

head philips screw and connecting a manometer with a

silicon tube, or by removing the 1/8" NPT screw with an

allen wrench and connecting the appropriate pressure

gauge.

16

Noritz Gas Water Heater

(199,900 Btuh)

Outlet E

Section 4

1.5m (5') 1.5m (5')

3m (10')

Natural Gas

Meter

Sample Gas Line

Clothes Dryer

3m (10')

Section 3 Section 2

Outlet D

Gas Fireplace

(25,000 Btuh)

**See next page for the pipe capacity charts.

(35,000 Btuh)

Outlet C

1.5m (5')

1.5m (5')

1.5m (5')

Section 1

3m (10')

Barbecue

(50,000 Btuh)

Outlet A

Outlet B

Gas Range Stove

(65,000 Btuh)

3m (10')

1.5m (5')

Instructions

1. Size each outlet branch starting from the furthest

using the Btuh required and the length from the

meter.

2. Size each section of the main line using the

length to the furthest outlet and the Btuh

required by everything after that section.

Sample Calculation

Outlet A: 13.5m (45') (Use 15m (50')), 50,000 Btuh requires 1/2"

Outlet B: 12m (40'), 65,000 Btuh requires 1/2"

Section 1: 13.5m (45') (Use 15m (50')), 115,000 Btuh requires 3/4"

Outlet C: 9m (30'), 35,000 Btuh requires 1/2"

Section 2: 13.5m (45') (Use 15m (50')), 150,000 Btuh requires 3/4"

Outlet D: 7.5m (25') (Use 9m (30')), 25,000 Btuh requires 1/2"

Section 3: 13.5m (45') (Use 15m (50')), 175,000 Btuh requires 1"

Outlet E: 7.5m (25') (Use 9m (30')), 199,900 Btuh requires 3/4"

Section 4: 13.5m (45') (Use 15m (50')), 374,900 Btuh requires 1-1/4"

Page 17

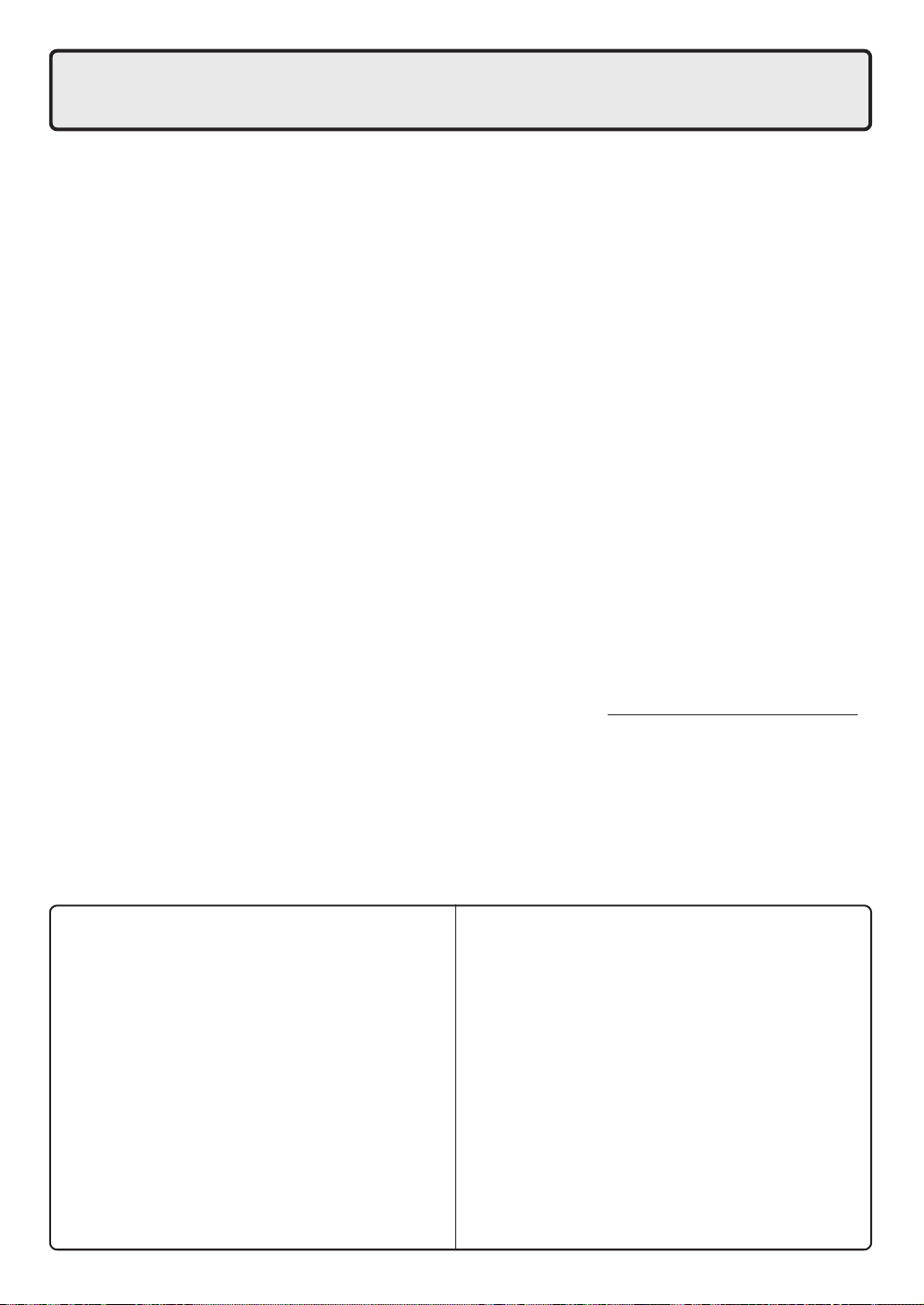

Gas Line Sizing for a Noritz Gas Water Heater

Natur

Liquified P

Maximum Natur

Pipe

3m (10')

Size

1/2"

3/4"

1"

1 1/4"

1 1/2"

2"

2 1/2"

3"

3 1/2"

4"

Adapted from UPC 1997

al Gas Delivery Capacity in Cubic Feet per Hour (0.60 Specific Gravity, 0.5" WC Pressure Drop)

6m (20') 9m (30')

174

119

249

363

470

684

1404

2103

4050

6455

11,412

16,709

23,277

Contact the Gas Supplier for Btu/Cubic Ft. of the Supplied Gas. 1000 BTU/Cubic Ft. is a Typical Value

965

1445

2784

4437

7843

11,484

15,998

12m (40') 15m (50') 18m (60') 21m (70') 24m (80') 27m (90')

96

200

377

775

1161

2235

3563

6299

9222

12,847

82

171

323

663

993

1913

3049

5391

7893

10,995

Length in Feet

73

152

286

588

880

1696

2703

4778

6995

9745

66

138

259

532

798

1536

2449

4329

6338

8830

61

127

239

490

734

1413

2253

3983

5831

8123

404

605

1165

1857

3284

4808

6698

37.5m (125')

1033

1646

2910

4261

5936

56 53 50 44

118 111 104 93

222 208 197 174

456

683

1315

2096

3705

5425

7557

30m (100')

428

641

1234

1966

3476

5090

7091

358

536

Maximum Liquified P

Pipe

3m (10')

Size

1/2"

275

3/4"

567

1071

1"

2205

1 1/4"

3307

1 1/2"

2"

6221

** For reference only. Please consult gas pipe manufacturer for actual pipe capacities.

Maximum Capacity of Flex TracPipe in Cubic Feet per Hour of Natural Gas

Pipe

Size

3m (10')

206

3/4"

1"

383

1 1/4"

614

1 1/2"

1261

2"

2934

Maximum Capacity of Flex TracPipe in Thousands of Btuh Liquified Petroleum

Pipe

Size

3m (10')

325

3/4"

1"

605

1 1/4"

971

1 1/2"

1993

2"

4638

** For reference only. Please consult gas pipe manufacturer for actual pipe capacities.

TracPipe® is a registered trademark of Omega Flex.

etroleum (Undiluted) Delivery Capacity in Thousands of Btuh (0.5" WC Pressure Drop)

94

168

251

559

1317

149

265

397

884

2082

Length in Feet

103

217

409

834

1275

2394

Length in Feet

86

153

227

509

1203

Length in Feet

136

241

359

805

1902

96

196

378

771

1181

2205

80

141

209

471

1114

126

222

330

745

1761

89

185

346

724

1086

2047

75

132

194

440

1042

118

208

307

696

1647

83

173

322

677

1023

1921

78

162

307

630

976

1811

(0.60 Specific Gravity, 0.5" WC Pressure Drop)

71

125

181

415

983

112

197

286

656

1554

6m (20') 9m (30')

189

152

393

315

732

590

1496

1212

2299

1858

4331

3465

6m (20') 9m (30')

6m (20') 9m (30')

147

269

418

888

2078

232

425

661

1404

3285

121

218

334

723

1698

191

344

528

1143

2684

12m (40') 15m (50') 18m (60') 21m (70') 24m (80') 27m (90') 30m (100') 60m (200')

129

114

267

237

504

448

1039

913

1559

1417

2992

2646

R

12m (40') 15m (50') 18m (60') 21m (70') 24m (80') 27m (90') 30m (100') 45m (150')

105

188

284

625

1472

R

12m (40') 15m (50') 18m (60') 21m (70') 24m (80') 27m (90') 30m (100') 45m (150')

166

297

449

988

2327

37.5m (125') 45m (150')

1606

67

118

171

393

933

106

186

270

621

1475

63

69

132

146

275

252

567

511

866

787

1496

55

94

137

320

762

( 0.5" WC Pressure Drop)

87

143

217

506

1205

55

112

213

440

675

1260

60m (200')

48

82

116

277

661

60m (200')

76

129

183

438

1045

Maximum Capacity for Gas Flex Connectors in Cubic Feet per Hour of Natural Gas

Pipe

Size

300mm (12") 600mm (24") 900mm (36") 1200mm (48") 1500mm (60") 1800mm (72")

1/2"

3/4"

1"

1 1/4"

180 150

290

581

1470

Length in Inches

125

255

512

1200

106

215

442

1130

(0.60 Specific Gravity, 0.5" WC Pressure Drop)

197

397

960

Maximum Capacity for Gas Flex Connectors in Thousands of Btuh Liquified Petroleum

Pipe

300mm (12") 600mm (24") 900mm (36") 1200mm (48") 1500mm (60") 1800mm (72")

Size

1/2"

3/4"

1"

1 1/4"

** For reference only. Please consult gas pipe manufacturer for actual pipe capacities.

288 240

465

930

2352

Length in Inches

200

409

825

1920

169

344

708

1808

149

315

638

1536

93

173

347

930

( 0.5" WC Pressure Drop)

137

278

556

1488

86

17

Page 18

Installation and service must be performed by a qualified plumber. In the

Commonwealth of Massachusetts, this product must be installed by a licensed

10.

This appliance suitable for potable water and space heating applications. Do not use this appliance if any part has

been underwater. Immediately call a qualified service technician to inspect the appliance and replace any part of the

control system and gas control which has been under water.

If the water heater is installed in a closed water supply system, such as one having a backflow preventer in the cold

water supply line, means shall be provided to control thermal expansion. Contact the water supplier or a local plumbing inspector on how to control this situation.

A pressure relief valve must be installed near the hot water outlet that is rated in accordance with and complying with

either The Standard for Relief Valves and Automatic Shutoff Devices for Hot Water Supply Systems, ANSI Z21.22, or

The ANSI/ASME Boiler and Pressure Vessel Code, Section IV ( Heating Boilers ). This pressure relief valve must

be capable of an hourly Btu rated temperature steam discharge of 199,900 Btuh. Multiple valves may be used. The

pressure relief capacity must not exceed 150 psig. No valve shall be placed between the relief valve and the water

heater. The relief valve must be installed such that the discharge will be conducted to a suitable place for disposal

when relief occurs. No reducing coupling or other restriction may be installed in the discharge line. The discharge line

must be installed to allow complete drainage of both the valve and the line. If this unit is installed with a separate

storage vessel, the separate vessel must have its own temperature and pressure relief valve. This valve must also

comply with The Standard for Relief Valves and Automatic Gas Shutoff Devices for Hot Water Supply Systems, ANSI

Z21.22. (in the U.S. only). A temperature relief valve is not required, but if one is used, do not install the valve with the

probe directly in the flow of water. This may cause unwarranted discharge of the valve.

Piping and components connected to the water heater shall be suitable for use with potable water.

Toxic chemicals, such as those used for boiler treatment, shall not be introduced into the potable water.

A water heater used to supply potable water may not be connected to any heating system or components previously

used with a nonpotable water heating appliance.

When water is required in one part of the system at a higher temperature than in the rest of the system, means such

as a mixing valve shall be installed to temper the water to reduce the scald hazard.

• Flush water through the pipe to clean out metal powder, sand and dirt before connecting it.

• Take appropriate heat insulation measures (e.g., wrapping with heat insulation materials, using electric heaters)

according to the climate of the region to prevent the pipe from freezing.

•

Use a union coupling or flexible pipe for connecting the pipes to reduce the force applied to the piping.

• Do not use piping with a diameter smaller than the coupling.

• When feed water pressure is too high, insert a depressurizing valve, or take

• Avoid using joints as much as possible to keep the piping simple.

• Avoid piping in which an air holdup can occur.

• If installing the unit on a roof:

• About lower-level hot water supply

If the unit is installed on a roof to supply water to the levels below, make sure that the water pressure supplied to

the unit does not drop below 29 psi. It may be necessary to install a pump system to ensure that the water pressure

is maintained at this level.

Check the pressure before putting the unit into operation.

Failure to supply the proper pressure to the unit may result in noisy operation, shorter lifetime of the unit, and may

cause the unit to shut down frequently.

Water Piping

plumber or gas fitter in accordance with the Massachusetts Plumbing and Fuel

Gas Code 248 CMR Sections 2.00 and 5.00. Observe all applicable codes.

water hammer prevention measure.

Supply water piping

•

Do not use PVC, iron, or any piping which has been

treated with chromates, boiler seal or other chemicals.

•

Mount a check valve and a shut off valve (near the inlet).

• In order for the client to use the water heater

comfortably, 98.1 to 491 kPa (14 to 70 PSI) of

pressure is needed from the water supply.

Be sure to check the water pressure. If the water

pressure is low, the water heater cannot perform

to its full capability, and may become a source of

trouble for the client.

Drain piping

• Expansion water may drop from the pressure

prevention device and wet the floor. If necessary, provide drain piping or use a drain hose to

remove the water.

18

Hot water piping

• Do not use lead, PVC, iron or any piping which

has been treated with chromates, boiler seal or

other chemicals.

• The longer the piping, the greater the heat loss.

Try to make the piping as short as possible.

• Use mixing valves with low water resistance. Use

shower heads with low pressure loss.

• If necessary, use a pump or other means to ensure that the supply water pressure to the inlet of

the heater does not fall below 29 PSI when the

maximum amount of water is being demanded.

Also install a pressure meter on the inlet. If this is

not done, local boiling will occur inside the water

heater causing abnormal sounds and decreasing

the durability of the heat exchanger.

Page 19

11. Plumbing Applications

Recirculation System

Hot Water Return

Pump

(See notes for Sizing)

Optional 30 - 38L

(8-10 Gal.)

Storage Tank

(To Alleviate Cold

Water Sandwich)

Backflow

Preventer

(Optional)

Pressure

Reducing

Valve

(Optional)

Fixtures

* Size the pump to provide at least 6L/min. (1.58 GPM) through the system at 30kPa (10')

of Head plus piping losses. Check the maintenance monitors on the unit to make sure the

pump is providing that much flow.

** Adjust the flow using a gate valve and verify the flow rate with the maintenance monitors.

Pressure

Relief

Valve

Drain

Cold Water Supply

NORITZ

Gas Water

Heater

Shutoff Valve

Hot Water

(Relay for

Pump

> 85 W)

(See p. 23)

Cold Water Supply

Check

Valve

Expansion Tank

(Install According

to Local Codes)

Pump Control Signal

(See p. 23)

Check Valve

Aquastat

(Use Aquastat if Unit Isn't

Controlling Pump)

Heating System

Aquastat Wiring

Use Honeywell Aquastat

(Model L6006A or L6006C)

Pump

AC120

Neutral

Ground

Live

Hot Water Return

105

R

B

5

W

Pressure

Relief Valve

Gas

Water

Heater

NORITZ

Gas Water

Drain

Mixing Valve

Heater

Shutoff

Valve

(Relay for

> 85 W)

(See p. 23)

Shutoff Valve

Hot Water

Pump

Expansion

Tank

(Install According

to Local Codes)

Boiler Drain Valve

Tempered Potable Hot Water

Check

Valve

Pump Control signal

(See p. 23)

Check Valve

Aquastat

(Use Aquastat if

Unit Isn't Controlling

Pump)

Temp. &

Press. Gauge

(Optional)

* Size the pump to provide at least 6L/min. (1.58 GPM) through the system at 30kPa (10') of

Head plus piping losses. Check the maintenance monitors on the unit to make sure the

pump is providing that much flow.

** Adjust the flow using a gate valve and verify the flow rate with the maintenance monitors.

Cold Water Supply

Hot Water for Heating

Pump

(See notes for Sizing)

Air Scoop

(Optional)

Heating

Controls

For Space Heating Purposes:

Hydronic Heat

Exchanger or

Radiant Heat

Piping

For Baseboard

Applications:

Please contact

Noritz for

compatibility.

If the system requires water

for space heating at a higher

temperature than for other

uses, means such as a mixing

valve shall be provided to

temper the water for the other

uses to help prevent scalding.

19

Page 20

Consult a qualified electrician

12.

Disconnect Power

This appliance must be electrically grounded in accordance with local codes, or in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70. In Canada, the latest CSA C22.1 Electrical Code.

Caution: Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper

and dangerous operation.

Verify proper operation after servicing.

Field wiring to be performed at time of appliance installation.

Electrical Wiring

Do not connect electrical power to the unit until all electrical wiring has been completed.

for the electrical work.

WARNING

Electrical Shock Hazard

Do not turn power on until electrical wiring is finished. Disconnect power before servicing.

Failure to do so may result in death or serious injury from electrical shock.

• The electrical supply required by the water heater is 120V

AC at 60 Hz.

The power consumption may be up to 125W or higher if

using optional accessories.

Use an appropriate circuit.

• Do not disconnect the power supply when not in use. When

the power is off, the freeze prevention in the water heater

will not activate, resulting in possible freezing damage.

Ground

• To prevent electrical shock, provide a ground

with resistance less than 100 . An electrician

should do this work.

•A grounding screw is provided on the back in

the junction box.

Do not connect the ground to the city water

or gas piping. Do not tie the ground to a telephone line.

Ground

Breaker Installation

• Mount a device which shuts off the electrical

path automatically (leakage breaker) when

electrical leakage is detected.

1.Unscrew the junction box and slide it out of the unit..

2.Push the power cord through the bottom of the unit.

3.Connect the live and neutral wires to the black and

white wire in the junction box.

Screw the ground wire to the ground screw on the

4.

back in the junction box and replace the junction box.

•Do not let the power cord contact the

gas piping.

Tie the redundant power cord outside the water heater. Putting the

redundant length of cord inside the

water heater may cause electrical

interference and faulty operation.

Junction Box

Power Cord

CAUTION

Electrostatic discharge can affect electronic components. Take precautions to prevent electrostatic discharges from

personnel or hand tools during the water heater installation and servicing to protect product’s electronic control.

20

Page 21

Remote Controller

• Applicable Model

N-0751M,OD

Remote controller

RC-7650M

Install the remote controller according to the instructions in the Installation Guide (p. 28).

* The water heater has been factory set to allow a maximum temperature setting of 50°C (122°F).

To access higher temperature settings through the remote controller, follow the below steps.

<When setting the maximum temperature to 55-60°C (130-140°F)>

1. Turn the water heater off by pressing the ON/OFF button on the remote controller.

2. Press and hold the FLOW METER ALARM SET button until a sound is heard (2 sec.) and 50°C

(122°F) appears on the display.

3. Set the upper limit of the hot-water supply temperature to 55°C(130°F) or 60°C (140°F) using the

UP and DOWN setting buttons.

4. To put the water heater back into operation, press the ON/OFF button on the remote controller.

To keep the water heater off, let the unit sit for 30 sec. to return to the original display.

<When setting the maximum temperature to 55-83°C (130-180°F)>

1. Turn the water heater off by pressing the ON/OFF button on the remote

controller.

2. Disconnect electrical power to the water heater.

3. Remove the front cover of the water heater (4 screws).

4. Connect "WATER TEMPERATURE ADJUSTMENT CONNECTOR" tag

connector to "180°F" tag connector as shown on the right.

5. Replace the front cover of the water heater (4 screws).

6. Reconnect electrical power to the water heater, but do not turn it on.

7. Press and hold the FLOW METER ALARM SET button until a sound is

heard (2 sec.) and 50°C (122°F) appears on the display.

(the back : 55 C) (the back : 60 C)

(the back : 83 C)

WATER TEMPERATURE

ADJUSTMENT CONNECTOR

8. Set the upper limit of the hot-water supply temperature to

55°C (130°F), 60°C, 65°C, 70°C, 75°C (140°F, 149°F, 158°F, 167°F) or 83°C (180°F)

using the UP and DOWN setting buttons.

9. To put the water heater back into operation, press the ON/OFF button on the remote controller.

To keep the water heater off, let the unit sit for 30 sec. to return to the original display.

TOR

NNEC

STMENT CO

TER TEMPERATURE

ADJU

WA

• The N-0751M, OD can be programmed so that it will default to one of four temperatures if the remote

controller is removed (80°C, 60°C, 55°C, 50°C (176°F, 140°F, 130°F, 122°F)). To change the default

temperature, connect the temperature selection wire as shown in the above diagram. The default temperature is 50°C (122°F) when the temperature selection wire is not connected.

WARNING

• When changing the temperature, make sure to confirm with the customer that the temperature of

the hot water will be very high and that there is a risk of scalding.

• Water temperatures above 52°C (125°F) can cause severe burns or death from scalding.

21

Page 22

Connecting Remote Controller Cord to Unit

• Keep the remote controller cord away from the freeze prevention heaters in the unit.

•Tie the redundant cord outside the water heater. Do not put the extra length inside the equipment.

• The remote controller cord can be extended up to 90m (300') with 18AWG wire.

• Use a Y type terminal with a resin sleeve. (Without the sleeve, the copper wire may corrode and

cause problems).

• Be sure to hand tighten when screwing to the terminal block. Power tools may cause damage to the

terminal block.

Remote controller cord

• For extensions, a 7.8m (26') cord can be purchased (Part # RC-CORD26) or use 18AWG wire.

• Install according to the National Electrical Code and all applicable local codes.

1. Leave enough slack so that the remote controller

cord will not be damaged if the unit is removed from

the wall.

2. Remove the front cover of the heater (4 screws).

3. Pass the remote controller cord through the wiring

throughway and into the unit.

4. Connect the Y terminals at the end of the remote

controller cord to the terminal block.

5. Secure the remote controller cord with a clamp.

6. Replace the front cover.

Wiring

Throughways

18AWG Wire

Terminal

Block

Clamp

22

Page 23

Pump Wiring

* This feature is not available when using the Quick Con-

nect Multi System feature.

Connecting the pump control wire

1. Leave enough slack so that the pump control

wires will stay connected if the unit is removed

from the wall.

2. Remove the front cover of the heater (4 screws).

3. Cut off the connector at the end of the pump

control wires.

4. Wire the pump control wires through the wiring

throughway and connect them to the wiring inside

the pump (this will be the power supply for the pump,

do not also connect 120 V to the pump).

If a large pump is being used (greater than 85W)

use the voltage from these wires as the signal to

close a normally open relay through which 120 V will

be supplied directly from a wall circuit to the pump.

5. Replace the front cover.

Crimping Terminal

Wiring

Throughway

PUMP

Pump Control

Wire Tag

Supplies Power for

Circulating Pump

(Use a Relay for

Larger Pumps)

Relay connection with larger pumps (>85 W)

1. Locate and prepare the pump control wires as described above.

2. Choose a suitable installation location for the relay where it will be protected from moisture.

3. Connect the pump control wires from the heater to the signal input on the relay.

4. Cut one of the electrical supply leads and wire it across the open terminals of the relay.

5. Secure all connections and replace the front cover of the heater.

AC120V

Connect to Pump Control

Wires in Unit

Circulation Pump

012

4

Relay (ex. Omron G7L2ABUBJCBAC120)

23

Page 24

Connecting Quick Connect Cord

Caution

The wire coloring on the Quick Connect Cord will

not be the same as the wire coloring of the

connection plug inside the unit.

* The remote controller can be connected to either

unit A or B.

For Quick Connect Multi System Installation

use a Quick Connect Cord (sold separately).

1.Red

2.Black

3.White

4.Green

5.Blue

6.Blue

1.Red

2.Black

3.White

4.Green

5.Blue

6.Blue

1.White

2.Green

3.Red

4.Black

5.Blue

6.Blue

1.Red

2.Black

3.White

4.Green

5.Blue

6.Blue

Quick Connect

Cord

Connecting the Quick Connect Cord to the two

units.

1. Turn off the power.

2. Remove the front cover of the heater (4 screws).

3. Pass the Quick Connect Cord through the wiring

throughway and into the unit.

4. Plug the connector on the Quick Connect Cord to

the receptacle inside the unit.

5. Attach the ground wire of the Quick Connect

Cord to the terminal block fixing plate.

(If the ground wire is not attached, electrical

noise may cause problems).

6. Secure the Quick Connect Cord with a clamp.

7. Replace the front cover.

AB

"Quick Connect Cord" tag

Connector

Ground wire

Connector

Clamp

Wiring Throughway

Coupling Cord

24

Page 25

Periodically check the following to ensure proper

13.

• The venting system must be examined periodically by a qualified service technician to check for

any leaks or corrosion.

• The burner flame must be checked periodically for a proper blue color and consistency.

• If the flame does not appear normal, the burner may need to be cleaned.

• If the burner needs to be cleaned, it must be performed by a qualified service technician.

• Do not obstruct the flow of combustion and ventilation air.

• The pressure relief valve must be operated once a year to ensure that it is functioning properly

and there is no obstruction. Turn the power off to the unit before opening the relief valve, and

make sure that water draining out of the valve will not cause any damage.

• If the relief valve discharges periodically, it may be due to thermal expansion in a closed water

system. Contact the water supplier or a local plumbing inspector on how to correct this situation.

Do not plug the relief valve.

• See Operation Manual for further maintenance.

Warning:

14.

Maintenance

There is a scald potential if the output temperature is set too high.

Should overheating occur, or the gas supply fail to shut off, turn off the manual gas control valve to the appliance.

Do not use this appliance if any part has been under water. Immediately call a qualified service

technician to inspect the appliance and to replace any part of the control system and any gas control

which has been under water.

Periodically check and clean the filter inside the cold water inlet of the unit.

Trial Operation

operation of the water heater.

The installer should test operate the unit, explain to

the customer how to use the unit, and give the owner

this manual before leaving the installation.

•Preparation ........... (1) Open a hot water fixture to confirm that water is available, and then close

the fixture.

(2) Open the gas supply valve.

(3) Turn on the power supply. Using the remote controller, turn on the Power

On/Off button (the Operation lamp will turn on).

(1) Open a hot water fixture and confirm that the Burner On lamp comes on, and that hot water is

being produced. (If necessary, repeat until the air in the gas piping is bled out).

* White smoke may be noticed from the exhaust vent during cold weather. However, this is not a

malfunction of the unit.

* If an “11” error code appears on the remote controller, turn the unit off and then back on again,

and then open a hot water fixture again.

(2) Change the temperature setting on the remote controller and check that the water temperature changes.

• If the water heater does not operate normally, refer to “Troubleshooting” in the Operation Manual.

* After the trial operation, clean the filter in the cold water inlet.

<If installed with a quick connect multi-system>

• Turn the system power ON with the remote controller.

• Slowly open a hot water fixture and check that the units ignite sequentially. Check to see that the

hot water temperature is the same as the temperature displayed on the remote controller (*1)

* If both units do not ignite, switch which unit will ignite first by pressing the Max. or Min. Mani-fold

Pressure Set Button on the circuit board. (*2)

Unit A Ignites

Unit B Doesn't Ignite

Press Max. or Min. Manifold

Pressure Set Button on Unit B

Unit A Doesn't Ignite

Unit B Ignites

* If an 11 or F11 error code flashes on the remote controller, hit the Power Button on the remote

controller off and on 2 -3 times.

* If (*1) and (*2) cannot be done, the Quick Connect Cord may not be properly connected.

Check that the cord is properly connected.

25

Page 26

CAUTION

Handling after trial operation

• If the unit will not be used immediately, close off all gas and water shutoff valves, drain all of

the water out of the unit and the plumbing system to prevent the unit and system from freezing,

and bleed the gas out of the gas line.

Freezing is not covered by the warranty.

WARNING

A fire or explosion may result if these instructions are not followed, which may cause lose of

life, personal injury or property damage.

Lighting Instructions

This water heater does not have a pilot. It is equipped with an ignition device that automatically lights

the burner.

Do not try to light the burner by hand.

1. Read the safety information in the installation manual or on the front of the water heater.

2. Turn off all electrical power to the unit.

3. Do not attempt to light the burner by hand.

4. Turn the gas control manual valve (external to the unit) clockwise to the off position.

5. Wait five minutes to clear out any gas. If the smell of gas remains, stop, and follow the instructions

on page 3 of Owner's Guide.

6. Turn the gas control manual valve counterclockwise to the on position.

7. Turn on electric power to the unit.

8. The unit will now operate whenever hot water is called for. If the unit will not operate, follow the

shutdown instructions and call a service technician.

Shutdown Instructions

1. Stop any water demand.

2. Turn off electric power.

3. Turn the gas control manual valve clockwise to the off position.

Should overheating occur, or the gas supply fail to shut off, turn off the manual control valve to the appliance.

26

Page 27

15.

Dimensions

N-0751M

HOT WATER OUTLET (3/4")

WIRING THROUGHWAYS

UPPER WALL

MOUNT BRACKETS

LOWER WALL

MOUNT BRACKETS

N-0751M-OD

HOT WATER OUTLET (3/4")

70mm (2.8")

115mm (4.5")

178mm (7")

119mm (4.7")

61mm (2.4")

84mm (3.3

")

(VIEW FROM TOP)

261mm (10.3")

186mm (7.3")

181mm (7.1")

62mm (2.4")

(VIEW FROM TOP)

261mm (10.3")

186mm (7.3")

181mm (7.1")

62mm (2.4")

36mm (1.4")

120mm(4.7")

10mm (0.4")10mm (0.4")

622mm (24.5")

36mm (1.4")

122mm (4.8")

180mm (7.1")

GAS INLET (3/4")

COLD WATER INLET (3/4")

240mm (9.5")

11mm (0.4")

95mm (3.7

1.2")

31mm (

567mm (22.3")

10mm (0.4")

")

2.7")

70mm (

AIR INLET

COLD WATER INLET

WATER DRAIN VALVE

(WATER FILTER)

HOT WATER OUTLET

600mm (23,6")

BOTTOM OF CASE

55mm (2.1")

45mm (1.8")

WATER DRAIN VALVE

336mm (13.2")

350mm (13.8")

( 4")100.8mm

336mm (13.2")

FLUE COLLAR

AIR INLET

BOTTOM OF CASE

56mm (2.2")

WIRING THROUGHWAYS

GAS INLET

178mm (7")

WIRING THROUGHWAYS

120mm(4.7")

UPPER WALL

MOUNT BRACKETS

119mm (4.7")

61mm (2.4")

LOWER WALL

MOUNT BRACKETS

70mm (2.8")

15mm (4.5")

84mm

(3.3")

10mm (0.4")

622mm (24.5")

10mm (0.4")

122mm (4.8")

180mm (7.1")

GAS INLET (3/4")

COLD WATER INLET (3/4")

11mm (0.4")

240mm (9.4")

1.2")

31mm (

567mm (22.3")

10mm (0.4")

10mm (0.4")

AIR INLET

FLUE COLLAR

600mm (23,6")

BOTTOM OF CASE

55mm (2.1")

45mm (1.8")

COLD WATER INLET

WATER DRAIN VALVE

(WATER FILTER)

HOT WATER OUTLET

WATER DRAIN VALVE

350mm (13.8")

219mm (8.6")

73mm (2.9")

54mm

( 2.1")

42mm (1.7")

AIR INLET

BOTTOM OF CASE

56mm

WIRING THROUGHWAYS

GAS INLET

(2.2")

27

Page 28

For Installers:

Remote Controller RC-7650M

Read this installation guide

carefully before carrying out

installation.

Installation Guide

NORITZ AMERICA CORPORATION

Note

Do not connect power to the water heater before the remote controller has been properly installed.

Recommended installation location of the remote controller is in a bathroom.

Included Parts List

Part Name

Remote Controller

Wall Packing

Phillips Roundhead Wood Screw

Wall Anchor

Do not disassemble the remote controller.

Quantity

1

1

2

2

Notes on the Installation Location

• The remote should be installed in an easily

accessible location.

• Avoid installing in a place where water or

steam can come into contact with the

controller.

• Avoid locations where special chemical

agents (e.g., benzene, fatty and oily detergents) are used.

•Avoid outdoor installation, or installation in an

indoor location where it will be exposed to

direct sunlight.

Wall Packing

Remote Controller

Connecting Wire

Phillips Roundhead

Wood Screw

Wall Anchor

Connection of Remote Controller Cord

White Connector

Y-shaped terminals To Water heater

(two-core)

* Confirm the connection with the labels at

both ends of the remote controller cord.

•A 7.8m (26') cord can be purchased

separately (Part # RC-CORD26).

•The remote controller cord can be extended up to

and using 18 gauge wire to extend the

cord to the appropriate length.

90m (300')

To Remote controller

by splicing the cord

28

Page 29

Installation

1. Apply Wall Packing to the rear side of the

remote controller.

2. Connect the remote controller wires to the

separate remote controller cord.

Remote

Control

Wires

Wall Packing

(take off the paper)

Remote Controller Cord

Rear Side of

Remote Controller

3. Remove the cover of the remote control,

mark the location of the screw holes, and

drill holes for the wall anchors.

4. Insert the wall anchors, screw the remote

control to the wall and replace the cover.

Wall Anchor

Phillips Roundhead

Wood Screw

29

Page 30

[For outdoor installation only]

Installing the Remote Controller Outdoor Junction Box

1. Insert the remote controller wires through the

wall pipe and secure the wall pipe to the

remote controller. Locate the remote controller

wall packing, slide it over the pipe and wires,

and apply it to the rear side of the remote.

Rear side of remote controller

Wall Packing

Secure the wall pipe

firmly into the remote

controller.

Take off the

paper.

2. Drill a 32mm ( 1-1/4") hole in the wall

where the remote controller will be installed.

* Do not install the remote controller in a

location that is exposed to moisture, direct

sunlight, or chemical agents. These can

damage the remote controller.

5. Slide the box nut over the remote controller

wires and screw it onto the wall pipe.

Wall Pipe

Box Nut

Remote

Controller

Wires

6. Connect the remote controller wires to the

separate remote controller cord inside the box.

Wind the excess remote controller wire on the

provided hooks as illustrated below.

(Wind the

excess wire

here.)

3. Insert the wall pipe containing the remote

controller wires through the hole.

4. Slide the junction box packing and the junction

box over the remote controller wires and wall

pipe protruding from the outside wall.

Wall packing

Take off the paper.

Wall pipe

Take out the pipe about

18.75mm (3/4") from

the wall.

Junction Box

Box Nut

Remote

Controller

Wires

Junction Box Packing

Remote Controller

Wires

Junction Box

Remote Controller

Cord

Tie the redundant length of the remote

controller cord outside the junction box.

7. Close the junction box.

30

Page 31

Manuel d’installation

NORITZ AMERICA

CORPORATION

Canada

CHAUFFE-EAU À GAZ SANS CUVE

N-0751M (Installation intérieure/extérieure)

N-0751M-OD (Installation extérieure)

Les dangers potentiels provenant d’accidents pendant l’installation et l’utilisation sont classés dans les

trois catégories suivantes. Observez bien ces avertissements, ils sont indispensables à votre sécurité.

DANGER indique une situation dangereuse imminente qui, si elle n'est

DANGER

pas évitée, entraînera des blessures graves ou mortelles.

AVERTISSEMENT

ATTENTION

AVERTISSEMENT : Si les informations présentées dans ce manuel ne sont pas respectées à

la lettre, il peut en résulter un incendie ou une explosion pouvant entraîner des dégâts matériels,

blessures corporelles ou mortelles.

Interdit

AVERTISSEMENT indique une situation potentiellement dangereuse qui, si

elle n'est pas évitée, pourrait entraîner des blessures graves ou mortelles.

ATTENTION indique une situation potentiellement dangereuse qui, si elle

n'est pas évitée, pourrait entraîner des blessures minimes ou modérées.

Couper

l’alimentation

électrique

Terre

Veillez à

l’exécuter

ATTENTION

Requêtes auprès des installateurs

•

Pour assurer une utilisation en toute sécurité de chauffe-eau, lisez attentivement le manuel

d’installation et suivez les instructions pour l’installation.

• Les défaillances et dégâts provoqués par un travail erroné ou différent des instructions de ce

manuel ne sont pas couverts par la garantie.

• Vérifiez que l’installation a été correctement effectuée en accord avec ce manuel d’installation

une fois terminée.

•

Après avoir effectué l'installation, placez ce manuel d'installation dans une pochette plastique et attachezla sur le côté du chauffe-eau (ou à l'intérieur du couvre-tuyau ou du boîtier encastré, le cas échéant) ou

bien remettez-le au client pour qu'il le conserve soigneusement. Veillez également à remplir tous les

éléments requis sur la carte de garantie et à remettre cette dernière au client avec le guide de l'utilisateur.

CERTIFIED

R

Low NOx

Approved by

SCAQMD

L'installation doit être conforme aux réglementations locales ou en

l'absence de réglementation locale, au National Fuel Gas Code, à la

norme ANSI Z223.1/NFPA 54- dernière édition et/ou CSA B149.1, au

Natural Gas and Propane Installation Code (NSCNGPIC).

Noritz America se réserve le droit d'arrêter ou de modifier à tout moment et sans préavis la conception et/ou les spécifications de ses

produits.

Page 32

1.

Accessoires inclus

Les accessoires suivants sont inclus avec l’unité.

Vérifiez qu’il ne manque aucun élément avant de

commencer l’installation.

QtéFormePiècePièce Forme Qté

Vis autotaraudeuse

(N-0751M uniquement)

Guide de l’utilisateur,

Garantie,

Manuel d’installation

(ce document)

Cordon de

télécommande

3m (10')

2.

Accessoires optionnels

Cordon de

raccordement rapide

Clapets d’isolement

(comprenant une soupape de

sûreté de la pression)

1 de

chaque

Vis autotaraudeuse

5

(N-0751M-OD uniquement)

1

1

1

Télécommande

(Voir p.21)

Les accessoires présentés ci-dessous ne

sont pas inclus avec l’unité, mais peuvent

être nécessaires à l’installation.

Cordon de

télécommande

8m (26')

Couvre-tuyau

3

1

QtéFormePiècePièce Forme Qté

1

1

Boîte de dérivation

extérieure de la

télécommande

[ N-0751M uniquement ]

Pièce Forme Qté

Bouchon d’évent

extérieur

(VC4(-1))

2

1

[ N-0751M-OD uniquement ]

Pièce Forme Qté

1

Boîtier encastr

(RB-4)

1

Page 33

3.

Installation du multisystème par raccordement rapide

• Le multisystème à raccordement rapide permet d’installer deux unités ensemble en utilisant uniquement

le cordon à raccordement rapide.

Le cordon de raccordement rapide mesure 2m (6') de long. Installez les deux unités entre 50mm 450mm (2-18") d’écart chacune pour garantir que le cordon puisse relier les deux unités.

(Si la distance entre les deux unités est trop grande, non seulement le cordon ne pourra pas

les relier, mais la température de l’eau fluctuera également à cause de la différence de

longueur des tuyaux entre les deux unités.)

Schéma du système

Cordon de

raccordement

rapide

Connecteur

du cordon

Plomberie type

Connecteur

du cordon

* Lors du raccordement de deux appareils,

n’utilisez qu’une seule télécommande.

Bornier de raccordement

Télécommande

Cordon de télécommande

G

Distance au centre : 400 - 800mm (16-32")

Distance sur les côtés

50 - 450mm

(2-18")

Tuyauterie de distribution en gaz

Alimentation en eau froide

Eau chaude

Remarque: Raccordez la

télécommande à

un seul des

appareils.

Union

Union

Soupape du gaz

Valve d’arrêt

Valve d’arrêt

Eau chaude

Eau froide

Calibrez la tuyauterie pour permettre les

vitesses d’écoulement maximales des unités.

Raccourcissez autant que possible

cette distance.

* La température de l’eau chaude

fluctuera à mesure que la longueur

de la conduite augmentera.

Union

Cordon de

raccordement rapide

Soupape de

sûrté de

la pression

Valve

d’arrêt

Laissez suffisamment d’espace autour de la

plomberie pour mettre l’isolant. Il sera nécessaire

d’ajouter des coudes à la tuyauterie pour garantir

le dégagement.

• Isolez les conduites d’eau chaude pour empêcher la perte de chaleur. Isolez et appliquez des

matériaux chauffant à la tuyauterie de distribution d’eau froide pour empêcher la perte de chaleur

en cas d’exposition à des températures excessivement froides.

3

Page 34

4.

Avant l’installation

DANGER

Check-up

• Vérifiez les dégâts ou usures des appliques de fixation et du tuyau d’évent chaque année.

Remplacez-les au besoin.

AVERTISSEMENT

Vérifiez le gaz

• Vérifiez que la plaque signalétique indique le

type de gaz correct.

• Vérifiez que la conduite d’alimentation de gaz est

calibrée pour 199,900 Btuh pour cette unité.

Vérifiez l’alimentation

• L’alimentation requise est de 120V CA, à 60Hz.

Une tension incorrecte pourrait provoquer un incendie ou une électrocution.

Prenez des précautions extrêmes en cas d’utilisation avec un réchauffeur solaire

• L’utilisation de cette unité avec un réchauffeur solaire peut entraîner des températures émises

imprévisibles et de possibles brûlures. En cas d’absolue nécessité, utilisez des mitigeurs pour

s’assurer que les températures émises n’atteignent pas des niveaux bouillants. N’utilisez pas un

réchauffeur solaire avec le multisystème à raccordement rapide.

N-0751M

199,900 BTU

12,000 BTU

0 - 2,000 Ft. (0 - 610 m

199,900

168,000

376

892

8.0

14.0"

1.0

4.4"