FILTRATION & PROCESS

5730 NORTH GLEN PARK ROAD, MILWAUKEE, WI 53209

P: 262.238.4400 | 800.279.9404

www.pentairaqua.com

PRF26K, PRF34K, and PRF40K

Water Softening System

INSTALLATION INSTRUCTIONS

English .............................. Pages 2-19

Repair Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 14

Manual de Sistema ablandador

de agua

INSTRUCCIONES DE INSTALACIÓN

Español .......................... Páginas 20-37

Piezas de repuesto ..................... Página 32

Manuel

Adoucisseur d'eau

INSTRUCTIONS D’INSTALLATION

Français ............................ Pages 38-55

Piéces de Rechange ..................... Page 50

Tools and Fittings Required

• Pipe Cutter

• Tubing Cutter

• File

• Pliers

• Tape Measure

• Soldering Tools

• Lead Free Solder

• Bucket

• Towel

• PTFE Pipe Tape

• Adjustable Wrench

• Tube 100% Silicone Grease

Tested and Certied by WQA to NSF/

ANSI Standard 44 & 372 for softener

performance & lead free compliance and

CSA B483.1.

Herramientas y accesorios

necesarios

• Sierra para cortar tuberías

• Cortatubos

• Lima

• Pinzas

• Cinta métrica

• Herramientas para soldar

• Soldador libre de plomo

• Cubeta

• Toalla

• Cinta de PTFE para tubería

• Llave ajustable

• Tubo de grasa 100% de silicona

Probado y certicado por la WQA

según la norma 44 y 372 de NSF/ANSI

por el desempeño del suavizador y el

cumplimiento del no contenido de plomo

y CSA B483.1.

Outils et accessoires requis

• Coupe-tuyau

• Coupe-tube

• Lime

• Pince

• Mètre ruban

• Outillage de brasage

• Brasure sans plomb

• Seau

• Serviette

• Ruban pour tuyau en PTFE

• Clé ajustable

• Graisse de silicone à 100 %

pour tube

Testé et certié par WQA conforme

à la norme 44 et à la norme 372 de

NSF/ANSI pour la perfomance des

adoucisseurs et pour la conformité à

l'exemption de plomb et CSA B483.1.

For further operating, installation, maintenance,

parts or assistance:

Call Technical Service at:

800.297.9404

Para obtener más información sobre el

funcionamiento, la instalación, el mantenimiento,

las piezas o para obtener asistencia:

Comuníquese con el Servicio de atención

al cliente al: 800.297.9404

Pour de tout autre renseignement concernant

le fonctionnement, l’installation ou l’entretien:

Appelez le service à la clientèle en composant le : 800.297.9404

WARNING:

1

TABLE OF CONTENTS

Contents

MANUAL OVERVIEW ............................................................2

PARTS INCLUDED ................................................................2

EQUIPMENT INSTALLATION ................................................2

CONTROL OPERATION & LAYOUT ......................................9

PROGRAMMING ....................................................................10

AUTOMATIC RECHARGE .....................................................11

MANUAL REGENERATION ...................................................11

QUICK CYCLING THE CONTROL .........................................11

CYCLE DEFAULTS TABLE ....................................................11

START-UP ..............................................................................12

INSTALLATION CHECKLIST .................................................12

CARE AND USE OF YOUR BRINE TANK .............................13

SYSTEM DISINFECTION ......................................................13

ACCESSING HISTORY VALUES ...........................................13

TANK ASSEMBLY ..................................................................14

VALVE ASSEMBLY .................................................................15

BRINE WELL ASSEMBLY CH15675 ......................................16

TROUBLESHOOTING ...........................................................17

PERFORMANCE DATA SHEET .............................................19

MANUAL OVERVIEW

2

3

4

9

Manual

10

How To Use This Manual

This installation manual is designed to guide the installer

through the process of installing and starting the system.

This manual is a reference and will not include every system

installation situation. The person installing this equipment

should have:

• Knowledge in the water softener installation

• Basic plumbing skills

Icons That Appear In This Manual

Failure to follow this instruction can result in

personal injury or damage to the equipment.

NOTE: This will make the process easier if followed.

Inspection

Inspect the unit for damage or missing parts. Contact your

supplier if any discrepancies exist.

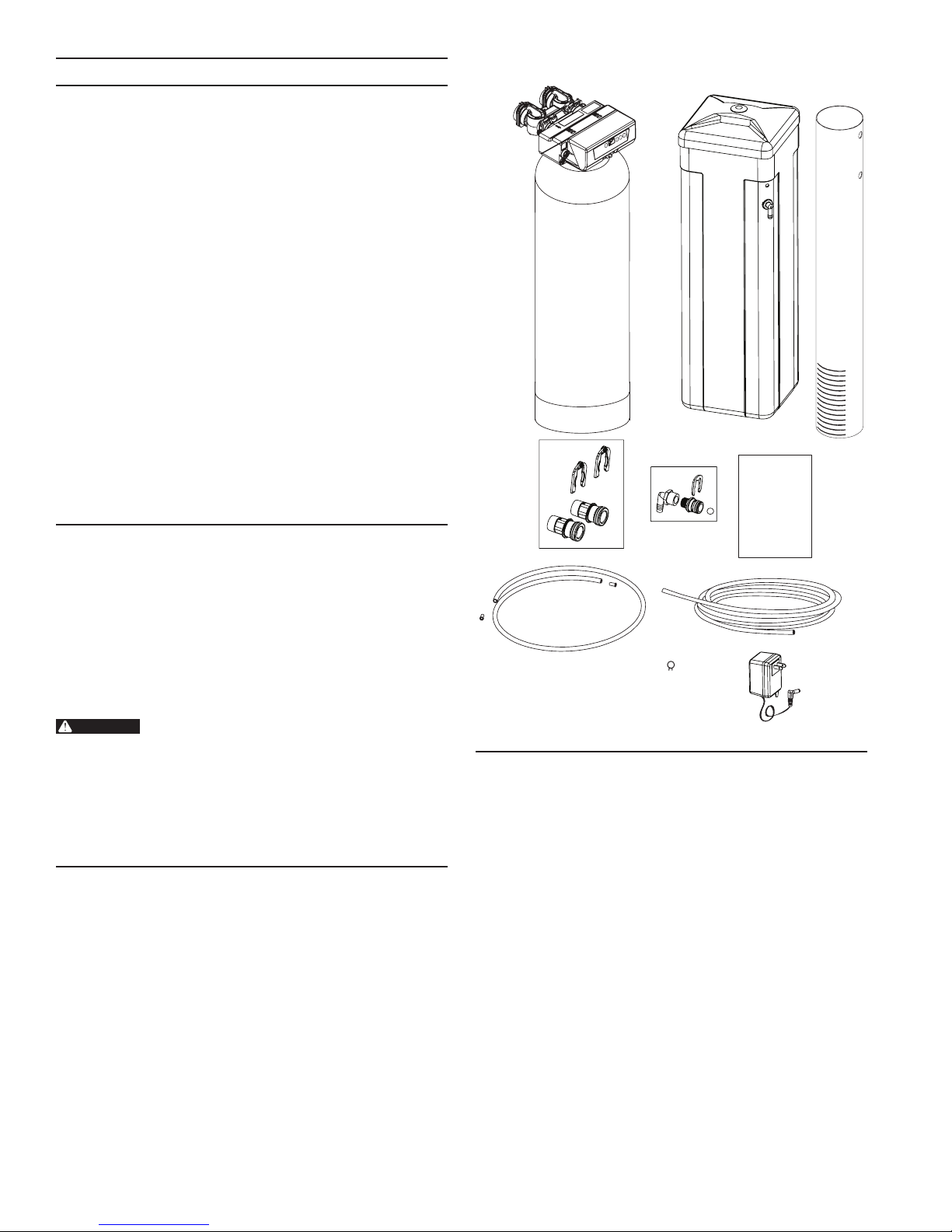

PARTS INCLUDED

The PRF Water Softening System should have the following

parts:

1. Softener Tank with Valve and Bypass

2. Salt Tank with Cover

3. Connector Kit

4. Drain Line Flow Control and Drain Fitting

5. Brine Line Tubing with End Inserts

(shipped inside the Brine Well #10)

6. Drain Line Tubing

7. Tubing Clamp

8. Wall Transformer

9. Instruction Manual

10. Brine Well

5

7

6

8

EQUIPMENT INSTALLATION

General Warnings And Safety Information

Electrical

There are no user-serviceable parts in the AC adapter, motor,

or controller. In the event of a failure, these should be replaced.

• All electrical connections must be completed according to

local codes.

• Use only the power AC adapter that is supplied. If the AC

adapter is replaced use a Class II, 12 volt, 150 mA supply.

• The power outlet must be grounded and always on.

• To disconnect power, unplug the AC adapter from its

power source.

• Install an appropriate grounding strap across the inlet

and outlet piping of the water system to ensure proper

grounding is maintained.

2 • PRF26K, PRF34K, and PRF40K

Mechanical

• Do not use petroleum based lubricants such as vaseline,

oils, or hydrocarbon based lubricants. Use only 100%

silicone lubricants.

• All plastic connections should be hand tightened.

Plumber's tape should be used on connections that do not

use an O-ring seal. Do not use pliers or pipe wrenches.

• All plumbing must be completed according to local codes.

• Soldering of the plumbing should be done before

connecting to the valve. Excessive heat will cause interior

damage to the valve.

• Observe drain line requirements.

• Do not use lead-based solder for sweat solder

connections.

• The drain line must be a minimum of 1/2-inch diameter.

Use 3/4-inch pipe if the pipe length is greater than

20 feet (6 m).

• Do not support the weight of the system on the control

valve ttings, plumbing, or the bypass.

• It is not recommended to use sealants on the threads.

Use Plumber's tape on all NPT threads.

General

• Observe all warnings that appear in this manual.

• This system is not intended to be used for treating water

that is microbiologically unsafe or of unknown quality

without adequate disinfection before or after the system.

• Keep the unit in the upright position. Do not turn on side,

upside down, or drop. Turning the tank upside down will

cause media to enter the valve.

• Operating ambient temperature is between 34°F (1°C)

and 120°F (49°C).

• Operating water temperature is between 35°F (1°F) and

100°F (38°C).

• Working water pressure range is 20 to 125 psi

(1.38 to 8.61 bar). In Canada the acceptable working

water pressure range is 20 to 100 psi (1.38 to 6.89 bar).

• Use only salts designed for water softening. Acceptable

salt type is sodium chloride pellet salt.

• Follow state and local codes for water testing. Do not

use water that is micro biologically unsafe or of unknown

quality.

• When lling media tank, do not open water valve

completely. Fill tank slowly to prevent media from exiting

the tank.

• Always make modications to house plumbing rst.

Connect to valve last.

• Plastic parts and O-rings may be damaged by heat and

solvents. When constructing plumbing connections allow

heated parts to cool and protect parts from solvents.

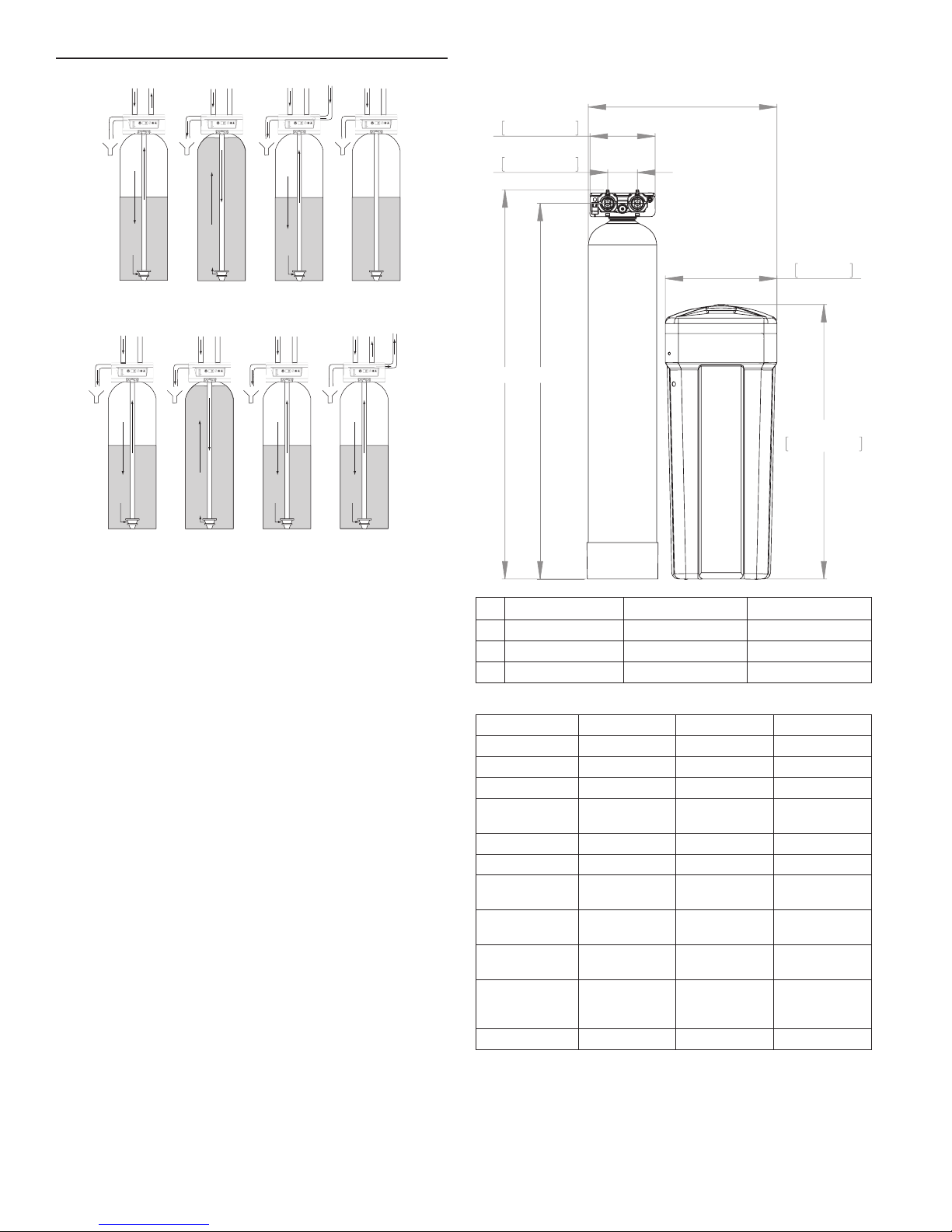

System Recharge Cycles

Service (Downow):

Untreated water is directed down through the resin bed and up

through the riser tube. The hardness ions attach themselves

to the resin and are removed from the water. The water is

conditioned as it passes through the resin bed.

When a recharge cycle starts, the softener goes through

seven cycles. During the recharge cycle the softener will allow

untreated water to bypass into the building.

1. Backwash 1 (Upow):

The ow of water is reversed by the control valve and

directed down the riser tube and up through the resin bed.

During the backwash cycle, the bed is expanded and debris

is ushed to the drain.

2. Brine Draw (Downow):

The brine draw cycle takes place during the slow rinse

cycle. The control directs water through the brine injector

and brine is drawn from the salt tank. Brine draw is

completed when the air check in the salt tank closes.

Slow Rinse (Downow):

The brine is directed down through the resin bed and up

through the riser tube to the drain. The hardness ions are

displaced by sodium ions and are sent to the drain. The

resin is recharged during the brine cycle.

3. Repressurize Cycle (Hard Water Bypass Flapper Open):

This cycle closes the appers for a short time to allow the

air and water to hydraulically balance in the valve before

continuing the recharge.

4. Fast Rinse 1 (Downow):

The control directs water down through the resin bed and

up through the riser tube to the drain. Any remaining brine

residual is rinsed from the resin bed.

5. Backwash 2 (Upow):

The ow of water is reversed by the control valve and

directed down the riser tube and up through the resin bed.

During the backwash cycle, the bed is expanded and debris

is ushed to the drain.

6. Fast Rinse 2 (Downow):

The control directs water down through the resin bed and

up through the riser tube to the drain. Any remaining brine

residual is rinsed from the resin bed.

7. Brine Rell:

Water is directed to the salt tank at a controlled rate, to

create brine for the next recharge.

PRF26K, PRF34K, and PRF40K • 3

EQUIPMENT INSTALLATION continued

From Regenerant

Tank

SERVICE

BACKWASH

Cycle 1

BRINE/SLOW RINSE

Cycle 2

REPRESSURIZE

Cycle 3

To Regenerant

Tank

8.75in

222.25mm

4.00in

101.60mm

A

B

C

15.00in

381mm

36.91in

937.55mm

FAST RINSE

Cycle 4

BACKWASH

Cycle 5

FAST RINSE

Cycle 6

BRINE REFILL

Cycle 7

Figure 1 Flow Patterns

Location Selection

Location of a water treatment system is important. The

following conditions are required:

• Level platform or oor.

• Ambient temperatures over 34°F (1°C) and below 120°F

(49°C).

• Water pressure below 125 psi (8.61 bar) and above

20 psi (1.4 bar).

• In Canada the water pressure must be below 100 psi

(6.89 bar).

• Constant electrical supply to operate the controller.

• Total minimum pipe run to water heater of ten feet (three

meters) to prevent backup of hot water into system.

• Local drain or tub for discharge as close as possible.

• Water line connections with shutoff or bypass valves.

• Must meet any local and state codes for site of

installation.

• Valve is designed for minor plumbing misalignments. Do

not support weight of system on the plumbing.

• Be sure all soldered pipes are fully cooled before

attaching plastic valve to the plumbing.

• Room to access equipment for maintenance and adding

salt to tank.

PRF26K PRF34K PRF40K

A 48.3 in (1266.8 mm) 52.33 in (1329.2 mm) 48.4 in (1229.4 mm)

B 46.5 in (1181.1 mm) 50.51 in (1282.9 mm) 46.6 in (1183.6 mm)

C 24.36 in (618.7 mm) 25.36 in (644.23 mm) 26.36 in (669.54 mm)

System Specications

Model PRF26K PRF34K PRF40K

Recharge Style Meter - Demand Meter - Demand Meter - Demand

Media Tank Size 8" x 44" 9" x 48" 10" x 44"

Resin Volume 0.80 Ft

Recharge (Salt)

Tank Size

Salt Storage 240 lbs 240 lbs 240 lbs

Drain Water Rate 2.1 GPM 2.1 GPM 2.7 GPM

Service

Connection Size

Drain Connection

Size

Recharge (Brine)

Connection Size

Installation

Space

Requirements

Shipping Weight 78 lbs 95 lbs 110 lbs

25" W x 15" D 25" W x 15" D 26" W x 15" D

3

14" x 34" 14" x 34" 14" x 34"

1" NPT 1" NPT 1" NPT

1/2" NPT 1/2" NPT 1/2" NPT

3/8" NPT 3/8" NPT 3/8" NPT

1.04 Ft

3

1.25 Ft

3

4 • PRF26K, PRF34K, and PRF40K

WARNING:

EQUIPMENT INSTALLATION continued

CAUTION!

REMOVE BRINE T

WARNING:

WARNING:

Outdoor Locations

It is recommended that the system be installed indoors. When

the water conditioning system must be installed outdoors,

several items must be considered.

• Moisture — The valve and controller are rated for NEMA

3 locations. Falling water should not affect performance.

The system is not designed to withstand extreme humidity

or water spray from below. Examples are: constant heavy

mist, near corrosive environment, upwards spray from

sprinkler.

• Direct Sunlight — The materials used will fade or discolor

over time in direct sunlight. The integrity of the materials

will not degrade to cause system failures.

• Temperature — Extreme hot or cold temperatures may

cause damage to the valve or controller.

Freezing temperatures will freeze the water in the valve.

This will cause physical damage to the internal parts as

well as the plumbing.

• Insects — The controller and valve have been designed

to keep all but the smallest insects out of the critical

areas.

Things You Need to Know

• When the controller is rst plugged in, it may display

an Err 3, this means that the controller is rotating the

camshaft to the home position.

• The preset default time of recharge is 2:00 AM.

• The controller is programmed to recharge if a recharge

has not taken place in the last 7 days. This setting cannot

be changed.

• Make sure control power source is plugged in. The

transformer should be connected to a non-switched

power source.

• Unless changed, the settings for a newly installed system

are:

Hardness - 25 grains per gallon

Salt Setting - HC (High Capacity)

Internal System clock starts at 0 hours (midnight)

The rst recharge will occur when the system clock

reaches 2:00 AM

• Test your water. Take a 4-5 oz sample of your water to

someone who can test for hardness. This information will

be used to setup the control.

Inspection

The system is shipped with several parts unassembled. When

parts are removed from the packing, they should be inspected

for damage. If any parts are damaged or missing, contact your

supplier.

When handling the media tank do not turn it

upside down or drop on its side.

When the carton is rst opened, the softener will be standing

upright.

ANK SLOWLY

3

5

1

2

Figure 2

The brine tank ts tightly over the valve.

When removing the brine tank tip it forward

and rotate slightly to pull off. Take care not

to damage valve cover or control.

To assemble the system, remove the salt tank components

(cover, tank and brine tube assembly) from the shipping

container.

1. Remove the brine well, parts box and brine line.

2. Lift the brine tank off unit

3. Tilt the brine tank forward and slowly lift free.

The media tank can now be removed.

To Assemble the Salt Tank:

1. Stand the salt tank up and in position. Level as needed.

The tank has two ports that will be connected. One to a

drain and one to the valve.

2. Remove the overow tting from the brine tube. Place the

brine tube in position. Align the large hole in the brine well

with the hole in the brine tank. Install the overow tting in

this hole to secure well to tank. Lay cover aside for now.

To Assemble the Media Tank:

1. Stand the tank up and in position.

2. If the oor under the media tank is uneven, level as needed.

The media tank contains loose particles that

will shift. If the tank is turned upside down or

laid back quickly, the particles may enter the

valve. If this happens, the valve may need to

be disassembled and cleaned.

4

PRF26K, PRF34K, and PRF40K • 5

EQUIPMENT INSTALLATION continued

Outside

Outside

Bath Tub Lavatory Toilet Kitchen

Outside

Faucet

Faucet

Hot Water

Pump

or

Meter

Hot Water

Outlet

Outlet

Water

Heater

Laundry Tubs

Floor Drain

Figure 3 Standard Basement Before Installation. Cold Water Lines Shown

Bath TubLavatoryToilet Kitchen

Grounding

Strap

Outside

Faucet

Faucet

Soft Water

Hard Water

Pump

or

Meter

Water

Heater

Bypass

Drain Line

Softener

Figure 4 Softened Water Flow

Laundry Tubs

Brine Tank Overow Drain

Floor Drain

6 • PRF26K, PRF34K, and PRF40K

Loading...

Loading...