PR AQUA ROTOFILTER

DRUM FILTER

™

IMPORTANT SAFETY INSTRUCTIONS

READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE INSTRUCTIONS

INSTALLATION AND

OPERATION MANUAL

2

CUSTOMER SERVICE/TECHNICAL SUPPORT

If you have questions about ordering Pentair replacement parts and products, please contact:

Customer Service

8AM–5PM—Pacic Time

Canada & United States

Toll Free: +1 866 714 0141

International

Phone: +1 250 714 0141

Web site

PentairAES.com

© 2018 Pentair Aquatic Eco-Systems (Canada) Inc. All rights reserved.

This document is subject to change without notice.

2395 Apopka Blvd., Apopka, FL 32703, USA Phone: 407.886.3939 Web: PentairAES.com

All Pentair trademarks and logos are owned by Pentair or one of its global afliates. Pentair Aquatic Eco-Systems®,

PR Aqua™ and Rotolter™ are trademarks of Pentair Aquatic Eco-System, Inc. and/or its afliated companies in the

United States and/ or other countries. Unless expressly noted, names and brands of third parties that may be used in

this document are not used to indicate an afliation or endorsement between the owners of these names and brands

and Pentair Aquatic Eco-Systems (Canada), Inc. Those names and brands may be the trademarks or registered

trademarks of those third parties. Because we are continuously improving our products and services, Pentair reserves

the right to change specications without prior notice. Pentair is an equal opportunity employer.

P/N 450041 Rev. A 8/18

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

TABLE OF CONTENTS

3

Section 1: Foreword .................................................. 5

1.1 Scop e .......................................................... 5

1.2 Technical Specication Documents ......... 5

1.3 Serial Number Location ............................. 5

1.4 Support Contact ........................................ 5

Section 2: Safety ....................................................... 6

2.1 Safety Summary......................................... 6

2.2 Warning and Information Labels ............... 6

2.3 Protective Equipment ................................7

2.4 Electrical Safety ......................................... 7

2.5 Jewelry ....................................................... 7

2.6 Rotating Equipment ................................... 7

2.7 UV Radiation ..............................................7

Section 3: Shipping and Storage ............................8

3.1 Arrival on Site ............................................. 8

3.2 Lifting .......................................................... 8

3.3 Storage ..................................................... 10

Section 4: Introduction ........................................... 11

4.1 O ver v i ew ................................................... 11

4.2 Location of Major Components .............. 11

4.3 Operational Mechanics ........................... 12

Section 5: Pre-Installation ..................................... 13

5.1 Overview ................................................... 13

5.2 Site Requirements and Preparation ....... 13

5.3 Foundation and Service

Access Requirements .............................. 13

5.4 Sump Requirements ................................ 14

5.5 Hydraulic Controls ................................... 15

5.6 Backwash System Considerations ......... 16

5.7 Control Panel Considerations ................. 18

5.8 Electrical Power Requirements ............... 18

5.9 Flushing Plumbing ................................... 18

5.10 Pre-Installation Checklist .......................... 19

Section 6: Installation ............................................. 20

6.1 Tools Required ......................................... 20

6.2 Installing the Rotolter ............................20

6.3 Installing the Backwash System ............. 21

6.4 Connecting the Plumbing ........................ 22

6.5 Installing the Control Panel ..................... 22

6.6 Control Panel Installation Checklist ....... 22

6.7 UV Installation (RFUV Only) ..................... 23

Section 7: Pre-Operation .......................................24

7.1 O ver vi e w ................................................... 24

7.2 Checking Fasteners ................................. 24

7.3 Checking the Drum Seal .......................... 25

7.4 Checking Flow Levels .............................. 25

7.5 Adjusting Drive Tension

(Chain-Drive Models) ............................... 26

7.6 Checking the Housing and

Drum Enclosure ....................................... 27

7.7 Pre-Operation Checklist .......................... 27

7.8 Performing a Test Run ............................. 27

7.9 Performing a 24-Hour Run ...................... 28

7.10 Post 24-Hour Inspection .........................28

7.11 Calibrating Float Switches ......................29

Section 8: Startup and Shutdown ......................... 30

8.1 Filling the Rotolter .................................. 30

8.2 Startup Procedure ...................................30

8.3 Shutdown Procedure

(24 Hours or Less) .................................... 31

8.4 Shutdown Procedure

(24 Hours or More) ................................... 31

Section 9: Maintenance .........................................32

9.1 Maintenance Schedule ............................ 32

9.2 Maintenance Considerations .................. 32

9.3 Checking Flow and Water Levels ............ 32

9.4 Inspect Mechanical Parts .......................33

9.5 Combined Maintenance Procedure ........34

Section 10: Spray Bar Maintenance ..................... 39

10.1 Spray Bar Overview ................................. 39

10.2 Spray Bar Assembly ................................39

10.3 Removing the Nozzle Cap ....................... 39

10.4 Cleaning the Nozzle Tip ........................... 39

10.5 Removing the Nozzle Body ..................... 39

10.6 Gaskets and O-rings ................................ 39

10.7 Nozzle Reassembly .................................39

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

4

TABLE OF CONTENTS

Section 11: Screen Maintenance...........................40

11.1 Screen Damage ....................................... 40

11.2 Washing the Screens ............................... 41

11.3 Repairing Screen Panels ......................... 41

11.4 Removing Screen Panels and

Gasket Seals ............................................42

11.5 Replacing Screen Panels and

Gasket Seals ............................................43

Section 12: Drum Seal Maintenance ....................46

12.1 Ove r vi ew ................................................... 46

12.2 Removing the Drum Seal ......................... 46

12.3 Replacing the Drum Seal ......................... 47

Section 13: Support Wheel Maintenance ............. 49

13.1 Ove r vi ew ................................................... 49

13.2 Support Wheel Assembly Parts .............. 49

13.3 Greasing the Support Wheels ................. 49

13.4 Removing the Support Wheels ............... 50

13.5 Replacing the Support Wheels ............... 51

Section 14: Drive Assembly Maintenance ...........53

14.1 Ove r view ................................................... 53

14.2 Drive Assembly Parts

(Chain-Drive Models) ............................... 54

14.3 Maintaining Oil Bath Levels

(Chain-Drive Models) ............................... 54

14.4 Adjusting Chain Tension

(Chain-Drive Models) ............................... 54

14.5 Removing the Drive Assembly

(Chain-Drive Models) ............................... 55

14.6 Replacing the Drive Assembly

(Chain-Drive Models) ............................... 55

14.7 Removing the Drive Assembly

(Direct-Drive Models) ............................... 56

14.8 Positioning the Set Collar

(Direct-Drive Models) ............................... 58

14.9 Replacing the Drive Assembly

(Direct-Drive Models) ............................... 59

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

SECTION 1: FOREWORD

1.1 Scop e

This manual contains instructions for installation,

operation, and maintenance of the PR Aqua

Rotolter™ Dru m Fil ter.

Personnel should read the entire manual before

installation or operation of the Rotolter. The

manual contains vital information regarding proper

installation, operation, warranty conditions, and

personal safety. Disregarding this information may

cause irreversible damage to the unit or other

equipment, limit the operation, void the warranty,

or may cause bodily injury or death.

5

Figure 1. Product information location

1: Model Number

Due to the different congurations of Rotolter

models, some information provided in this manual

may not be applicable to your model. If you are

unsure whether certain information applies to your

model, please contact us before proceeding.

All safety information and warnings apply to all

Rotolter models.

A dedicated ultraviolet (UV) reactor manual is

provided with Ultraviolet (RFUV) models. Refer

to the UV reactor manual for operation and

maintenance of UV components.

1.2 Technical Specication Documents

Specication documents containing information

about the unique conguration and components of

your Rotolter are shipped prior to Rotolter arrival.

This information is useful for maintenance and

troubleshooting. You should keep these documents

near this manual and make copies for your records.

Contact us if your specication documents have

been lost or damaged.

2: Manufacture Date

3: Serial Number

If you have a technical question, need support, or

require parts, please have the information listed on

the product information plate available when you

contact a service representative at Pentair.

1.4 Support Contact

Additional copies of this manual are available

at no cost from your dealer. For manuals,

parts, service, warranty, or eld support,

please contact us:

Customer Service

8AM–5PM—Pacic Time

Canada & United States

Toll Free: +1 866 714 0141

International

Phone: +1 250 714 0141

1.3 Serial Number Location

The serial number for the Rotolter is stamped

on a product information plate, located to the

left of the drive system. The plate contains the

model number, manufacture date, and company

contact information.

Web site

PentairAES.com

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

6

SECTION 2: SAFETY

2.1 Safety Summary

This safety summary contains warnings that must

be understood and applied during operation and

maintenance of the Rotolter. Failure to obey these

precautions could result in damage to equipment,

serious injury, or death of personnel.

These are the icons used within the manual:

A Warning icon precedes an

essential operating or maintenance

procedure, practice, condition,

or statement, which, if not strictly observed, could

result in injury to or death of personnel or long-term

health issues

A Caution icon precedes an

essential operating or maintenance

procedure, practice, condition, or

statement, which, if not strictly observed, could

result in damage to or destruction of equipment.

NOTE

or statement that should be heeded for maximum

product benet.

Make sure you read all information in the Warnings,

Cautions, and Notes carefully. If any issues

are unclear, consult us. Additional safety

guidelines related to specic components of

the unit are described in the corresponding

component sections.

A Note icon precedes an essential

operating or maintenance

procedure, practice, condition,

2.2 Warning and Information Labels

Warning and information labels are posted on the

Rotolter. Read labels and note their locations

before operation, maintenance, or servicing of

the product. Ultraviolet (RFUV) models contain

additional labels. Refer to the UV manual for

applicable warnings and precautions.

Automated Machinery:

This unit may start at any time.

STAY CLEAR.Lockout/tagout

before servicing.

Located on individual lid

panels

Pinch Point:

Do not operate without guards

in place.

Located on drum support

wheel nger guards

Ultraviolet (UV)

Radiation Inside:

Exposure may cause eye

damage. Do not operate

without coverings. Do not look

into UV source. Wear UV eye

protection.

Located on UV chamber

(RFUV only)

Hot Surface:

Contact may cause burn.

Allow to cool before servicing.

Located on UV module light

block shield (RFUV only)

Rotation:

Located on drive assembly

end

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

SECTION 2: SAFETY

7

2.3 Protective Equipment

Protective equipment such

as safety glasses and hearing

protection may be appropriate

or required during installation, operation, and

maintenance of the Rotolter.

It is recommended that suitable personal protective

equipment be selected by a qualied entity prior

to installation and use of the unit. Personnel should

utilize such equipment to avoid bodily injury

or death.

2.4 Electrical Safety

Electrical hazards can cause injury

and death. Always use caution

when working near electricity.

Danger may still exist when the power is set to OFF.

All electrical work should be performed by a

qualied, professional electrician. This includes

installation, inspection, and repair of electrical

components.

A comprehensive lock-out, tag-out procedure

should be observed and followed for installation

and maintenance of the Rotolter. Lock-out/tagout procedures often exist as standard operating

procedures within company guidelines. If your

company does not employ a lock-out/tag-out

procedure, please contact your nearest workplace

safety and health administration to obtain one.

Never operate electrical equipment while you are

standing in water.

Remove power, discharge, and ground a circuit

before touching it.

2.6 Rotating Equipment

The Rotolter employs rotating

equipment, which can cause

severe injury or death. Be aware of

all rotating parts and keep body and objects away

from these areas.

Never attempt to service the unit while it is in

Automatic Mode. The drum may begin rotating

without warning when it is in Automatic Mode. The

unit should never be operated in Automatic

Mode without lids and access panels installed.

Some operation and service procedures require

rotating the moving parts. These procedures should

always be performed in Manual Mode.

Be aware of any personnel in the area when

attempting to service the unit in Manual Mode.

Do not attempt to manually rotate the drum without

rst observing the area for any personnel or objects

that may be caught in a rotating part.

Never attempt adjustments without powering off

the unit and locking out the control panel unless

otherwise specied by the service procedure.

2.7 UV Radiation

The RFUV emits ultraviolet light.

Never operate the unit without UV

module lids and covers installed.

Shut down the UV reactor prior to maintenance.

UV light can damage eyes and skin. Always wear

appropriate eye protection and protective clothing

when working on or around UV light.

When possible, work in pairs, preferably with basic

life support qualied personnel.

Personnel working with or near dangerous

voltage should be trained in modern methods

of resuscitation.

2.5 Jewelry

Remove rings, watches, chains,

and other metallic objects that

could result in shock, burns, or

may catch on equipment.

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

8

SECTION 3: SHIPPING AND STORAGE

3.1 Arrival on Site

The Rotolter is shipped fully enclosed and secured

in a wooden crate. It may be packaged as a single

unit or transferred with other system components.

UV modules for the Ultraviolet (RFUV) models

are always shipped separately because they are

extremely fragile.

There may be cardboard boxes on the oor of the

crate containing the backwash pump, plumbing kit,

or other items.

Inspect all crates for visible signs of damage before

acceptance from the shipping contractor. If damage

has occurred, the recipient should contact us

prior to acceptance in case an insurance claim

is required.

Verify the correct screen pore size from the

specication documents.

3.2 Lifting

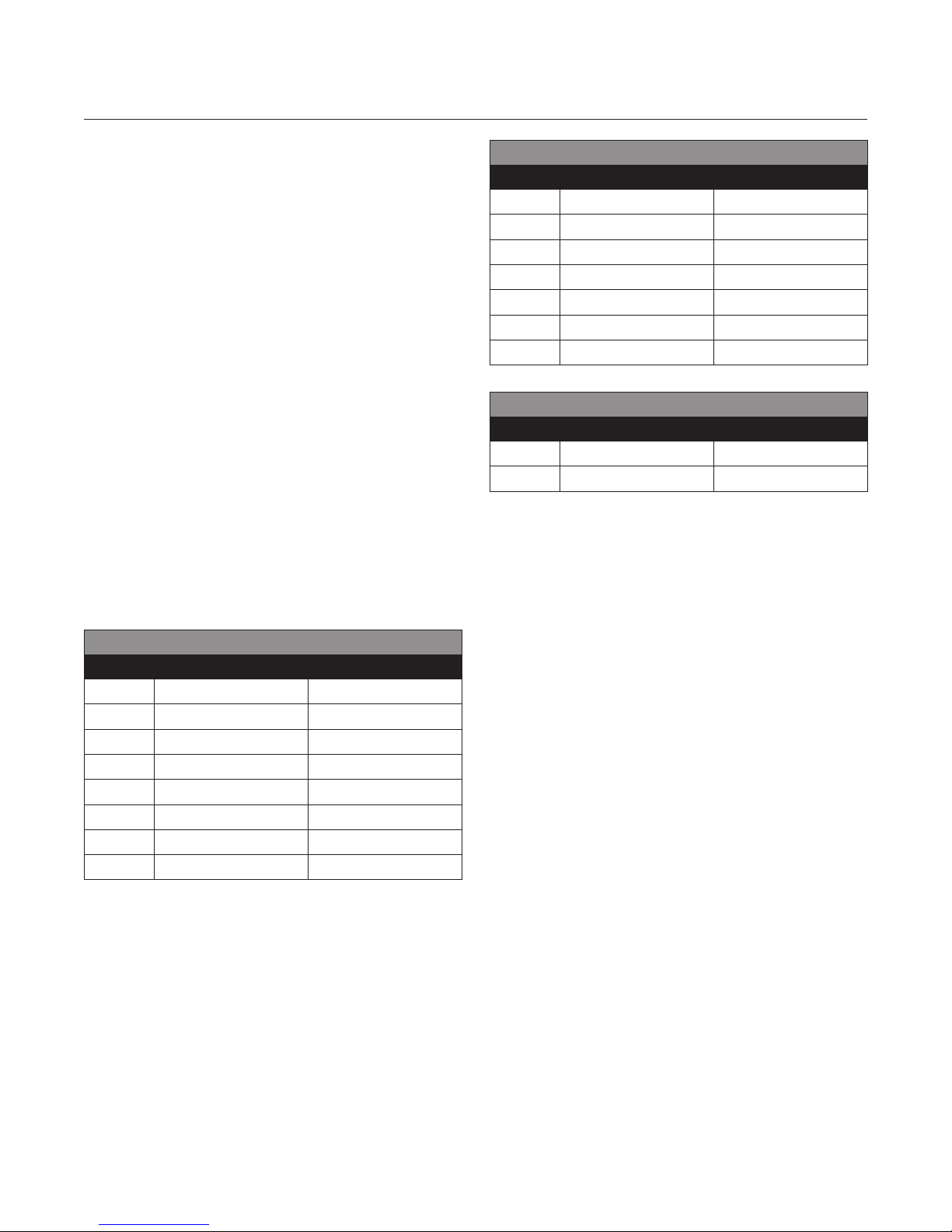

The approximate dry and wet weights of the

Rotolters are listed below:

Molded (RFM) Models

Size Weight Dry/Wet (kg) Weight Dry/Wet (lbs)

20014 90/200 kg 190/435 lbs

32018 185/670 kg 400/1,470 lbs

32036 295/1,225 kg 650/2,700 lbs

32054 355/1,470 kg 775/3,240 lbs

48048 545/2,495 kg 1,200/5,500 lbs

48072 820/3,585 kg 1,800/7,900 lbs

60096 1,13 6 /5,545 kg 2,500/12,200 lbs

Ultraviolet (RFUV) Models

Size Weight Dry/Wet (kg) Weight Dry/Wet (lbs)

32036 545/1,955 kg 1,200/4,300 lbs

48048 1,275/4,380 kg 2,800/9,650 lbs

The Rotolter can be extremely heavy. For

mechanically assisted lifting, use an appropriatelysized lifting device capable of safely lifting the unit.

Follow proper rigging procedures at all times. Never

allow the unit to swing out of control.

Frame (RFF) Models

Size Weight Dry/Wet (kg) Weight Dry/Wet (lbs)

32018 175 / 3 65 kg 385/800 lbs

32036 190/410 kg 415/9 0 0 lbs

32054 280/475 kg 615/1,040 lbs

48048 335/685 kg 730/1,500 lbs

48072 345/910 kg 760/2,000 lbs

60072 775/1,680 kg 1,700/3,700 lbs

60096 910/2,635 kg 2,000/5,800 lbs

6012 0 1135/3,290 kg 2,500/7,250 lbs

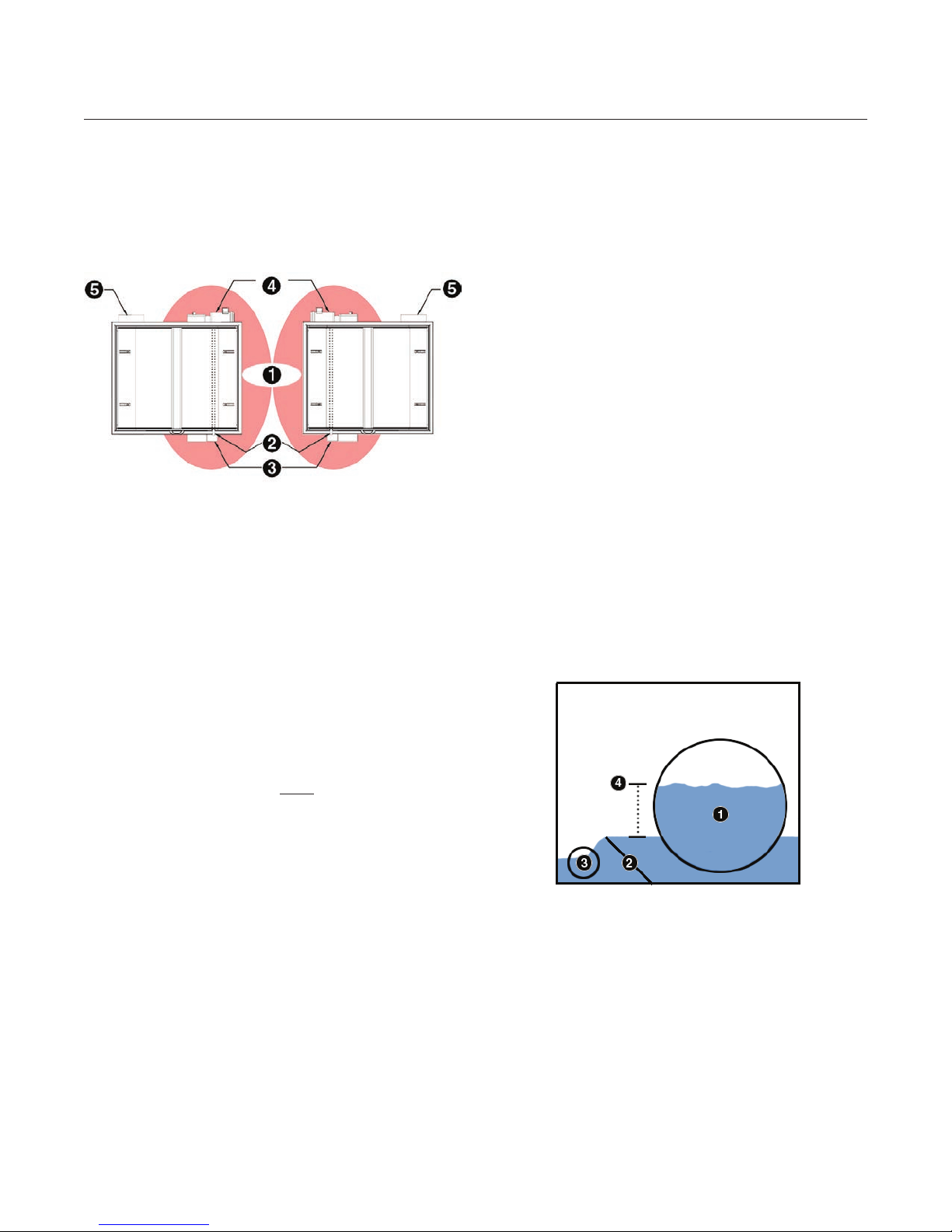

To safely lift the unit, you should use a spreader

bar accompanied with approved nylon slings. See

Figure 2.

External or internal lifting lugs may be provided

depending upon the unit.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

SECTION 3: SHIPPING AND STORAGE

The minimum length of the sling should allow

the distance between the spreader bar and the

Rotolter lifting points to be 1.5 times the distance

between the lifting points. See Figure 3.

9

Figure 2. Proper lifting procedure Figure 3. Proper sling length (not to scale)

1: Lifting Lug

2: Sling (Nylon or Canvas)

3: Spreader Bar

Slings should always be made of nylon or canvas,

and should be attached to the Rotolter in one of

three ways:

• Passed through a shackle securely connected to

the lifting lug

• Passed directly through the lifting lug

• If lugs are not present, passed beneath the

underside of the frame

1: Distance Between the Lifting Points (D)

2: 1.5 Times the Distance Between the Lifting

Points (1.5 x D)

Do not attempt to lift using slings around the drum

or any plumbing ttings. Doing so will damage the

Rotolter and void the warranty.

Use a pad between the sling and the Rotolter, as

pressure from the sling may mar the surface nish

of the unit.

Rotolter Frame (RFF) models have external lifting

lugs provided on each corner of the unit, each with

a hole to provide enough room to insert a shackle

or sling.

Molded (RFM) 48-series and 60-series models

should be lifted by the support bridge at the front

of the unit, and internally-mounted lifting lugs at the

back of the unit.

Molded (RFM) 32-series models should be lifted

using two 75mm (3 in) wide slings at a minimum,

looped underneath the housing and placed as close

to each end as possible.

Ultraviolet (RFUV) models: Do not install UV

Modules until the Rotolter has been installed and

properly anchored.

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

10

SECTION 3: SHIPPING AND STORAGE

3.3 Storage

The Rotolter should always be stored on a at and

level foundation.

The Rotolter should remain in its crate until time

of installation.

The unit should always be stored in a clean, heated,

and ventilated area.

If these conditions are not available, the Rotolter

should be fully covered by a UV-treated, waterproof

material such as a tarpaulin or plastic shroud.

Provide ventilation if the unit is covered. The

ventilation should not allow moisture in and should

not be located at the top of the unit.

Condensation can occur in the Rotolter, both

during shipping and storage. Ensure that the unit

is fully dry before applying power.

Perform a systematic inspection on the Rotolter

and implement a maintenance schedule during

longer storage periods.

Actions that should be performed every 40 days if

the unit is in storage:

Actions that should be performed every 90 days if

the unit is in storage include:

Visually inspect the storage area and storage

materials for potentially damaging issues, such as

leaks in the roof or tears in the covering.

Visually inspect the Rotolter for any damage.

Add oil to the chain bath of the drive assembly for

Frame (RFF) models. Add only Clarity® Synthetic

Hydraulic Oil AW. Oil should cover the bottom links

of the chain and lower sprocket.

Perform a megger test of the electrical system, and

keep a record of insulation values, temperature,

time, humidity, and length of voltage application to

show winding conditions prior to start up. The unit

must be fully dry before applying any power.

All electrical work should be

performed by a qualied,

professional electrician.

Please contact us with any questions concerning

proper storage of the Rotolter.

Visually inspect the storage area and storage

materials for potentially damaging issues, such as

leaks in the roof or tears in the covering.

Visually inspect the Rotolter for any damage.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

SECTION 4: INTRODUCTION

11

4.1 Overview

Microscreen Rotolters provide an efcient means

of solids removal from water. Drum lters are widely

accepted in the treatment of water in municipal,

aquaculture, and laboratory applications.

Rotolters are intended for in-line applications.

Internal components of the Rotolter are

constructed mainly from noncorrosive stainless

steel, increasing the longevity of the product when

operated under warranty conditions.

All Rotolters are housed in an enclosure.

The Rotolter Frame (RFF) model is installed into or

above a concrete or berglass sump, which acts as

the enclosure. A sump is a low space that collects

water. Water is fed into the drum, and once treated

occupies the bottom of the sump.

The Rotolter Molded (RFM) model is housed in

molded berglass-reinforced plastic. Water is

fed into the drum, and once treated ows out of

the enclosure.

The Rotolter Ultraviolet (RFUV) model is housed in

stainless steel. Water is fed into the drum, and once

treated, ows out of the enclosure.

4.2 Location of Major Components

Listed below are the major operating components

of the Rotolter. Note: Lid panels are not shown

for illustration purposes. Appearance may vary

according to model size.

Figure 4. Major component locations -

Frame (RFF) model

1: Support Wheel Assemblies

2: Solids (Waste) Outlet

3: Inlet

4: Drive Assembly

5: Spray Bar

6: Level Control Basin (optional)

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

12

SECTION 4: INTRODUCTION

4.3 Operational Mechanics

Microscreen drum lters operate under the principle

of a mechanical sieve. Untreated water is fed to the

inside of a drum housed in an enclosure. The drum

has ne screens mounted to its periphery. Gravity

causes the water to ow through the screens, while

suspended solids within the water adhere to the

screen surface. The ltered water then ows out of

the enclosure by gravity.

In Ultraviolet (RFUV) models, the ltered water

passes through a chamber containing a series of

UV modules, each sized to deliver a specic UV

dose for disinfection, prior to exiting the enclosure.

The water level inside the drum rises as solids

collect on the screen surface and obscure the

screen pores. When the water level reaches a

contact switch, the drum begins to rotate, and a

backwash spray system is started.

The backwash spray system washes the solids

from the screens into a separate trough inside the

drum. The solids ow from the trough by gravity for

disposal or recovery.

The potential treatment capacity of the Rotolter

depends on the ow rate, solids concentration of

the water, and the pore size of the microscreen.

UV transmittance of the water is also a factor for

Ultraviolet (RFUV) models.

The Rotolter operates in Automatic Mode or

Manual Mode. When in Automatic Mode, the

backwash system and drum rotation turn on

automatically when a high-level oat switch reaches

a predetermined position. Once the drum has been

sufciently cleaned, the backwash system and

drum rotation automatically shut off.

When in Manual Mode, the backwash system and

drum rotation are always on.

Clean screens are rotated into the water, and the

water level falls. The backwash spray system shuts

down once the screens are clean. In the event

of a backwash system failure, the Rotolter has

integrated overow protection that allows water

to bypass the screens and ow directly into the

enclosure, rather than backup into the waste trough

and inlet supply.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

SECTION 5: PRE-INSTALLATION

13

5.1 Overview

Rotolters require physical placement, electrical

connections, and plumbing upon arrival. It is

imperative to completely follow all preinstallation

and installation instructions sequentially to

maximize the efciency and longevity of the unit.

A site will need to be established for the Rotolter

and the backwash pump. These sites will need to

be prepared prior to installation.

A qualied electrician will need to be employed to

establish electrical connections for the backwash

system and the control panel. This manual does not

detail any electrical wiring of the backwash system

or control panel.

The site will require appropriate plumbing, and the

plumbing must have ow controls to limit potential

damage to the Rotolter.

5.2 Site Requirements and Preparation

The Rotolter requires a site that is prepared

prior to installation. The site requires a level,

solid concrete installation surface with adequate

service clearance.

Molded (RFM) and Ultraviolet (RFUV) models

require a solid, level concrete foundation. Section

5.3 of this chapter contains appropriate information.

Frame (RFF) models require a solid, level foundation

within a sump. Sumps should be composed of

solid concrete or berglass. Rotolters may

need to be installed inside the sump or directly

above it. Section 5.4 of this chapter contains

appropriate information.

Minimum service access is required for regular

maintenance of the Rotolter. Access is required on

the inlet, drive assembly, and spray bar assembly

sides of the unit.

Some maintenance procedures require the

Rotolter to be dry. To perform these procedures,

Frame (RFF) models will need to have sumps that

can be drained or pumped. Molded (RFM) and

Ultraviolet (RFUV) models have integrated drains in

their enclosures.

Inlet and outlet water levels coming to and going

from the site must be controlled for the Rotolter to

function properly, and to avoid damage to the unit.

The Rotolter does not supply external controls for

these levels.

External water source access, such as access

to a municipal water supply, may be needed if

the backwash system will not use the unit's

ltered discharge.

Electrical sources are required for the backwash

system and control panel.

5.3 Foundation and

Service Access Requirements

Rotolter Molded (RFM) and Ultraviolet (RFUV)

models must be placed on a solid, at, and level

concrete foundation with adequate service access

to the inlet, drive assembly, and spray bar assembly

sides of the unit. The technical specication

documents detail which side of the Rotolter is the

service access side (left or right, when facing the

inlet).

The location of the foundation should be

determined based on service access and stability.

Minimum recommended service access is 92

centimeters (36 inches).

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

14

SECTION 5: PRE-INSTALLATION

A layer of self-leveling concrete should be applied

to the foundation and the consistency of the level

should be conrmed prior to Rotolter installation.

Once this layer is applied, check that the foundation

surface does not differentiate more than 6.4

millimeters (0.25 inches) across the entire area.

Places that exceed this difference should be ground

down to prevent stress points from forming. The

berglass housing of Molded (RFM) models can

fracture from stress points. Stress points can also

cause damage to Ultraviolet (RFUV) units.

Figure 5. Minimum service clearance for right

(standard) and left service access units

1: Minimum Service Access (red area) - 96

centimeters (36 inches)

2: Spray Bar Assembly (can be connected at

opposite end)

3: Inlet (location may vary)

4: Drive Assembly and Motor

5: Outlet (location may vary)

Service access is required daily. The following are

some of the functions that require service access:

• Water level inspection

• Spray bar nozzle cleaning

• Inspection and maintenance of screen panels

• Inspection and maintenance of support wheels

5.4 Sump Requirements

Rotolter Frame (RFF) models should be installed in

or above concrete or berglass sumps, with service

access to the inlet, drive assembly, and spray bar

assembly sides of the unit.

Due to the high variation between Rotolter

congurations, this manual does not detail

sump creation. The following are guidelines for

consideration.

The sump should include (at a minimum) an inlet,

outlet, drain, and waste channel. An additional

channel may be required for overow protection.

Dimensions of required channels can be

determined from the technical specication

documents. Contact us with questions.

The Rotolter requires a minimum operating water

level, which can be controlled through a weir

integrated into the sump. Alternately, a level control

basin may be included on a Frame (RFF) unit, the

top edge of which acts as the level control.

• Inspection and maintenance of drum seal

• Inspection and maintenance of drive assembly

• Scheduled cleaning

The foundation must be sturdy, as the weight of

the Rotolter can be extremely heavy when in

operation. The weight of the unit is listed on the

technical specication documents, or see Rotolter

weights in Section 3.2

The area must be at and level. Operating the

Rotolter on an unleveled surface will cause

irreversible damage to the internal components,

will cause the unit to malfunction, and will void

the warranty.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

Inlet and outlet channels must have fully functional

ow controls located at or near the unit. These

controls will be described in the following section.

In the event of a backwash system failure, unltered

water will bypass the screens and ow directly into

the enclosure via the integrated overow weir of the

Rotolter. If unltered water can not be permitted to

enter the outlet water channel, an overow channel

upstream of the lter inlet should be included in the

sump design.

Some maintenance procedures require the

Rotolter to be dry. To perform these procedures,

Frame (RFF) models will need to have sumps that

can be drained or pumped.

SECTION 5: PRE-INSTALLATION

15

The bottom of the sump must be a solid, level

foundation. The location of the sump should be

determined based on service access and stability.

Minimum recommended service access is 92

centimeters (36 inches) on the inlet, drive assembly,

and spray bar assembly sides.

Figure 6. Minimum service clearance for right

(standard) and left service access units

1: Minimum Service Access (red area) - 96

centimeters (36 inches)

2: Spray Bar Assembly (can be connected at

opposite end)

The area must be at and level. Operating the

Rotolter on an unleveled surface will cause

irreversible damage to the internal components,

will cause the unit to malfunction, and will void

the warranty.

A layer of self-leveling concrete should be applied

to the foundation and the consistency of the level

should be conrmed prior to Rotolter installation.

Once this layer is applied, check that the foundation

surface does not differentiate more than 6.4

millimeters (0.25 inches) across the entire area.

5.5 Hydraulic Controls

The Rotolter has no external ow controls,

therefore the inlet and outlet channels connected

to the unit must have fully functional ow controls

located at or near the unit. These controls should

be installed prior to installation of the Rotolter. The

type of controls will depend on the inlet and outlet

channels at the installation site.

Control of the inlet and outlet water levels are

critically important to maintaining proper water

levels inside and outside of the Rotolter. These

water levels should never exceed the limits

identied by Pentair.

3: Inlet (location may vary)

4: Drive Assembly and Motor

5: Outlet (location may vary)

Service access is required daily. The following are

some of the functions that require service access:

• Water level inspection

• Spray bar nozzle cleaning

• Inspection and maintenance of screen panels

• Inspection and maintenance of support wheels

• Inspection and maintenance of drum seal

• Inspection and maintenance of drive assembly

• Scheduled cleaning

The foundation must be sturdy, as the weight of

the Rotolter can be extremely heavy when in

operation. The weight of the unit is listed on the

technical specication documents, or see Rotolter

weights in Section 3.2

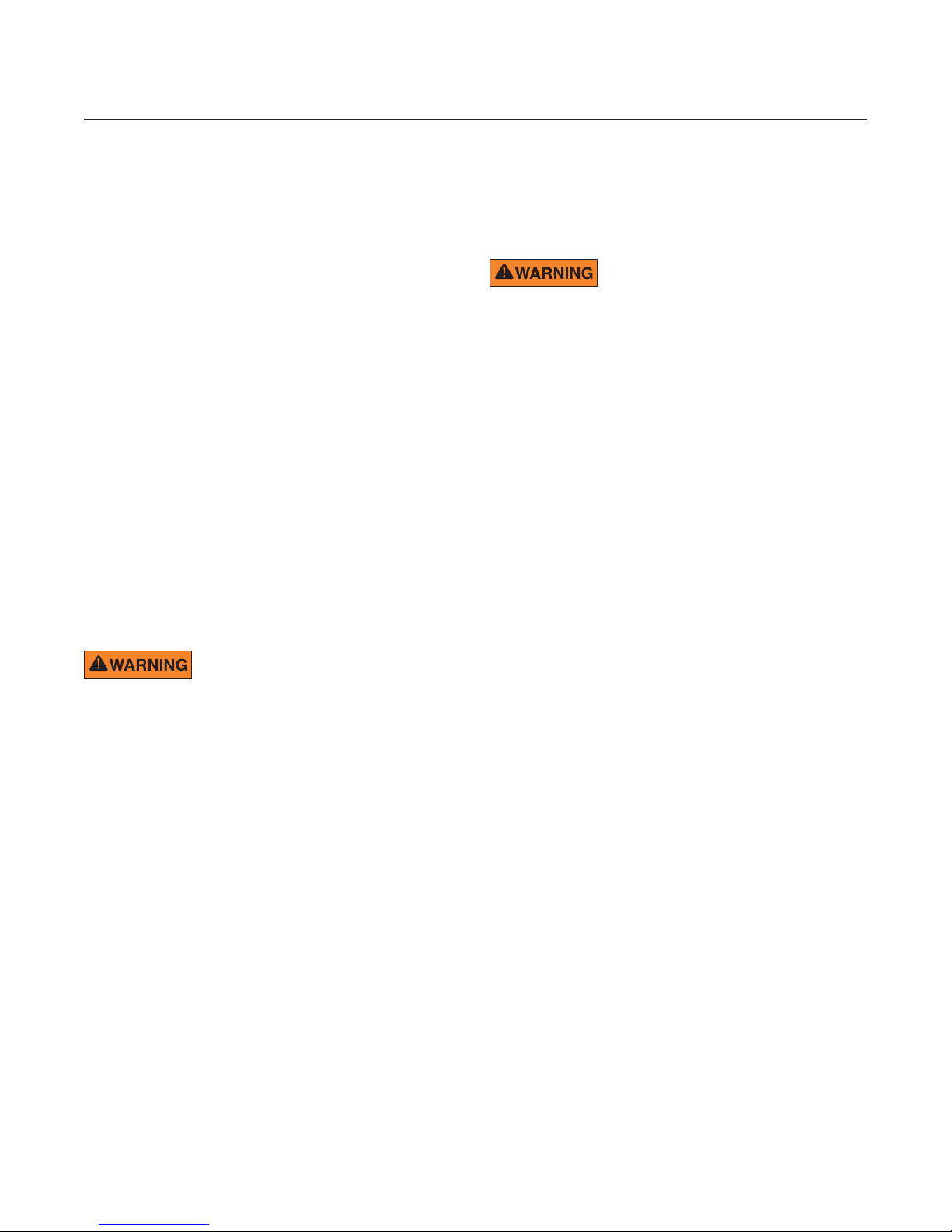

Figure 7. High water level differential inside

and outside of the drum

1: Water Level Inside Drum

2: Outlet (Level Control) Weir

3: Outlet

4: Water Level Differentia

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

16

SECTION 5: PRE-INSTALLATION

Problems that may occur if water levels are not

controlled include:

Damage to the Rotolter screens, drum shaft,

support wheels, and drum frame, due to excessive

weight caused by a high differential between water

levels inside and outside of the drum. The warranty

will be voided if the difference is greater than 30.5

centimeters (12 inches).

Reduced drum shaft bearing life, due to frequent

or constant submergence from a high outlet

water level.

Tray sludge may reenter the lter or may bypass the

lter and enter the outlet water, due to water owing

into the backwash tray of the lter from a high inlet

water level.

The above problems will result in reduced

operating range of the lter, which may cause

more frequent or continuous backwash, and will

reduce lter performance.

Continuous monitoring of the inlet and outlet

water levels (e.g., using a level transducer)

is recommended, but may not be suitable or

necessary in all applications.

• Inlet water levels should be continuously

monitored regardless of application if large

variations in ow are anticipated or could occur.

• Outlet water levels should be monitored if the

Rotolter does not have a low/high water level

alarm switch or automatic backwash system.

An outlet (level control) weir is necessary to

maintain a minimum water level inside the unit

to prevent damage. Rotolter Molded (RFM) and

Ultraviolet (RFUV) models contain integrated level

control weirs that help maintain the minimum water

level required inside of the drum. Frame (RFF)

models utilize one of two level control methods:

a weir integrated into the lter sump design, or a

level control basin installed on the underside of the

Roto lter.

A high overow weir is necessary to protect the

drum in the event of a backwash system failure.

The overow weir allows unltered water to bypass

the drum screens at critical levels and ow directly

into the outlet. Rotolters contain integrated

overow weirs. If overow directly into the outlet

is unacceptable, RFM and RFUV units will require

additional plumbing upstream of the lter. RFF units

will require an overow channel integrated into the

sump.

5.6 Backwash System Considerations

The backwash system requires a water supply, an

electrical supply, a xed pump location, and proper

plumbing.

5.6.1 Water Supply

The water supply may come directly from the

Rotolter or may need to come from an external

source. This depends predominantly on the water

quality requirements of the Rotolter application.

Some applications require highly ltered or puried

water. If water quality is not an issue, a source may

be selected based on the desired frequency of

maintenance.

The backwash system can be plumbed directly into

the ltered water supply of the Rotolter. Water

coming directly from the unit has been ltered, but

is not puried and contains dissolved nutrients that

will support bacterial growth.

This growth, combined with accumulations of ne

particles and deposition of dissolved minerals,

can cause the backwash system to foul over

time. Increased fouling will require more frequent

maintenance.

More stringent water quality requirements will

necessitate plumbing to an external water source.

Municipal water supplies generally do not contain

higher concentrations of dissolved nutrients and

ne particles, reducing the degree of fouling over

time.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

Check with the local water supplier for quality

parameters. Pressure and ow rates from external

water sources should meet the values required for

the Rotolter, as specied by Pentair.

SECTION 5: PRE-INSTALLATION

5.6.2 Electrical Supply

The electrical supply requirements depend on the

pump supplied with the Rotolter. The separate

pump manual will identify the supply requirements.

The backwash system electrical supply should be

diagrammed prior to lter installation.

All electrical work should

be performed by a

qualied electrician.

All dimensions and locations should be checked

for accuracy and changes should be made if any

part of the backwash system will interfere with the

service clearance required by the Rotolter.

5.6.3 Pump Location

The pump should be anchored near the Rotolter.

The pump can be placed above the lter, but a foot

valve (not included) may need to be installed to

prevent loss of prime due to back ow.

17

Figure 8. General backwash system assembly

1: Pressure Gauge

2: Connection Point (to Spray Bar Assembly)

3: Throttling Valve

The pump location should allow for the pump to be

securely attached, allow ample room for plumbing

and electrical xtures, and should not interfere with

the service clearance required by the Rotolter.

5.6.4 Proper Plumbing

The backwash system is shipped with ttings,

gauges, and valves. Plumbing xtures are

not included.

The backwash system plumbing should be

diagrammed prior to lter installation. All plumbing

dimensions and locations should be checked for

accuracy and changes should be made if any part

of the backwash system will interfere with the

service clearance required by the Rotolter.

If the backwash plumbing or pump will be

outside or partially outside, it must be insulated

to prevent freezing.

4: Solenoid (if Required)

5: Outlet Plumbing (Pump to Unit)

6: Backwash Pump

7: Inlet Plumbing (Source to Pump)

8: Connection Point (to Source)

A pressure gauge, throttling valve, and solenoid

valve (if required) will need to be connected to

the spray bar. This assembly can be connected

on either end of the spray bar. A solenoid valve is

required where the supply water is pressurized or

where the pump is located above the water supply

or discharge level.

The pressure assembly should be connected at the

Rotolter. See Figure 8.

The water supply should be connected to the

inlet of the pump. For Frame (RFF) models, the

pump inlet should be connected to a supply that is

completely submerged in the sump.

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

18

SECTION 5: PRE-INSTALLATION

5.7 Control Panel Considerations

Most Rotolters are purchased with a control panel.

This manual describes operation and maintenance

procedures for units that utilize a control panel. If

a control panel was not ordered with the Rotolter,

one may be ordered at any time.

The control panel allows toggling between

Automatic Mode, Manual Mode, and Off for the

drum rotation and backwash systems. The panel

also displays Power-On and Unit-Run conditions.

The control system is made from high-quality,

industrial-grade, CSA- and UL-approved

components. The control panel box is a waterproof,

corrosion-proof CSA- and UL-approved electrical

enclosure that can be secured with padlocks. The

control panel assembly is manufactured in a ULcertied facility, and should not be modied. Any

modication voids the UL rating.

The control panel should always be installed within

line of sight of the Rotolter. If this is not possible,

disconnects for the drum motor and backwash

pump system must be installed next to the

Rotolter as a safety precaution. The control panel

door should be able to open fully.

All electrical work should

be performed by a qualied

electrician. This manual does

not provide electrical installation procedures

or wiring diagrams.

The control panel installation location should

be outlined and diagrammed prior to Rotolter

installation. The location should allow ample room

for electrical xtures and should not interfere with

the service clearance required by the Rotolter.

5.8 Electrical Power Requirements

The electrical power requirements for the Rotolter

motor and backwash pump are listed in the

Technical Specication sheet sent prior to

Rotolter arrival.

All electrical work should

be performed by a qualied

electrician. This manual does

not provide electrical installation procedures

or wiring diagrams.

5.9 Flushing Plumbing

The plumbing that will be connected to the

Rotolter should be thoroughly ushed prior

to Rotolter installation. Flushing the plumbing

removes debris that could damage the screens and

internal components of the Rotolter.

All removed material should be collected and

disposed of properly.

To ush a system, the discharge valve should be

opened rst, then the charge valve. Flush for at

least 2 minutes. If there are multiple circuits within

a system, ush one full circuit at a time, each for at

least 2 minutes.

To prevent potentially dangerous pressure buildup,

open the next circuit discharge valve before closing

the preceding discharge valve. When all plumbing

has been ushed, shut off the charge valve rst and

then shut off discharge valves.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

SECTION 5: PRE-INSTALLATION

19

5.10 Pre-Installation Checklist

Be sure the following items are completed prior to

beginning installation.

Site foundation is at and level.

Sump is complete with all necessary channels

(RFF models only).

Rotolter will have at least 92 centimeters (36

inches) of service access on the inlet, spray bar

assembly, and drive assembly sides.

Inlet water channel has fully functioning ow

control capable of maintaining level identied

by Pe ntair.

Inlet water channel has monitoring system

installed (if necessary).

Appropriate connections are available and can

be made between the inlet water channel and the

Rotolter inlet.

Outlet water channel has fully functioning ow

control capable of maintaining level identied

by Pe ntair.

Appropriate connections are available and can be

made between the outlet water channel and the

Rotolter outlet.

Appropriate connections are available and can

be made between the overow channel and the

Rotolter overow weir (if necessary).

Backwash pump water source has

been identied.

Backwash pump electrical supply has

been identied.

Backwash electrical system has been outlined,

diagrammed, checked for accuracy, and will

not interfere with the service clearance of the

Roto lter.

Backwash plumbing system has been outlined,

diagrammed, checked for accuracy, and will not

interfere with the service clearance of

the Rotolter.

Control panel location has been identied,

outlined, diagrammed, and will not interfere with

the service clearance of the Rotolter.

Outlet water channel has monitoring system

installed (if necessary).

Existing plumbing has been thoroughly ushed.

PR Aqua Rotolter™ Drum Filter Installation and Operation Manual

20

SECTION 6: INSTALLATION

6.1 Tools Required

Flathead screwdriver

Phillips screwdriver

SAE hex key (Allen) wrench set

Socket wrench

SAE socket set

SAE open-end wrench set

Rubber and machinist hammer (deadblow

hammer)

Carpenter’s level

Measuring tape

Crescent wrench

Thread seal tape, or food-grade thread sealant

Anti-seize paste (food-grade or equivalent)

6. Measure the available service clearance on the

inlet, drive assembly, and spray bar assembly

sides of the Rotolter. Move the unit if clearance

is not adequate.

7. Use a carpenters level on all sides and top of the

Rotolter to ensure the unit is level. See Figure 9.

Figure 9. Leveling the Rotolter

6.2 Installing the Rotolter

Once the Pre-Installation Checklist (Section 5.10) is

complete, the Rotolter is ready to be installed.

1. Remove the top and sides of the shipping crate

from around the unit.

2. Remove the lag screws securing the unit anchor

brackets to the bottom of the pallet.

3. Remove lids from top of the unit.

4. Secure appropriate rigging to the Rotolter and

the lifting device. Refer to Section 3.2 for proper

lifting procedures. Lift the unit until the bottom

portion of the shipping pallet can be removed.

Rotolters can be extremely heavy.

For mechanically assisted lifting,

use an appropriately-sized lifting

device capable of safely lifting the unit. Follow

proper rigging procedures at all times. Never allow

the unit to swing out of control.

5. Lower the unit until it rests on the installation

location, but do not remove the lifting rigging.

Ensure the inlet, solids, and overow (if required)

channels align properly with the external

plumbing for Molded (RFM) and Ultraviolet

(RFUV) units, and sump channels align with

Frame (RFF) units.

1: Level the Rotolter from Side to Side

2: Level the Rotolter from Front to Back

If the unit cannot be leveled, another layer of

self-leveling concrete should be applied to the

installation location and allowed to set. Place the

Rotolter on the foundation and test for level again.

If a Frame (RFF) model remains unleveled, solid,

immobile stainless steel shims can be inserted

under the lower corner posts of the unit. Shims

should be used only if the installation location

cannot be leveled using the procedure listed above.

Do not attempt to use shims for Molded (RFM) or

Ultraviolet (RFUV) models.

Most models will need to be secured to the

installation location using the anchor brackets and

appropriate fasteners. The unit should be anchored

using sheer load-bearing hardware that is rated to

8 times the wetted weight of the Rotolter. Use a

hammer drill and always blow out the holes prior to

inserting hardware.

PR Aqua Rotolter™ Drum F ilter Installation and Operation Manual

Loading...

Loading...