Penlon Sigma Delta Service manual

Sigma Delta Vaporizer

Service Manual

Quality and Assurance in Anaesthesia

Servicing and Repairs

In order to ensure the full operational life of

the Sigma Delta vaporizer, we recommend

that a periodic service check should be

performed by a Penlon trained engineer.

This check comprises a vaporizer LEAK

TEST and CALIBRATION CHECK.

Note:

(a) The calibration check must be performed

using a suitable agent analyser, e.g. a Riken

refractometer or infrared analyser.

(b) The service check is part of the

recommended pre-use check for your

Anaesthesia System.

Should the calibration checks show the unit

to be outside the specified performance

requirement, then an overhaul service must

be performed.

This may be done on site by:

(a) A trained user.

(b) An authorised Penlon agent.

(c) A Penlon service engineer.

A calibration and service record section is

provided in the user instruction manual to

maintain a record of the vaporizer's

performance.

For any enquiry regarding the service or

repair of this vaporizer, contact the nearest

accredited Penlon agent* or contact the

Service Department at Penlon Limited.

Service and Repair Department

Penlon Ltd

Abingdon

OX14 3PH

UK

Tel: +44 (0) 1235 547063

Fax: +44 (0) 1235 547062

E-mail: service@penlon.co.uk

Always give as much of the following

information as possible:

1. Type of equipment

2. Product name

3. Serial number

4. Approximate date of purchase

5. Apparent fault

IMPORTANT

(i)

This manual has been produced to provide

authorised personnel with information on the

function, routine performance, maintenance

checks and repairs, applicable to the Penlon

Sigma Delta vaporizer.

Information contained in the manual is correct at the date of publication. The policy of

Penlon Limited is one of continued improvement to its products. Because of this policy

Penlon Limited reserves the right to make

any changes, which may affect instructions

in this manual, without giving prior notice.

Personnel must make themselves familiar

with the contents of this manual before using

the vaporizer.

Terminology

This manual complies with ISO 4135,

Anaesthetic Apparatus Terminology.

The following additional definitions should be

noted:

Vol.% - shortened form of volumetric per-

centage.

The commonly used method of expressing

vapour concentrations so that they can be

compared with concentrations of true gases.

100 Vol.% is equivalent to 100% partial pressure in a mixture.

Copyright © Penlon Ltd, 2002

FOREWORD

(ii)

CONTENTS

User Responsibility 1

1. Warnings and Cautions 2

2. Purpose 4

3. Description 7

4. Specification 11

5 Service Procedures 12

5.1 Service Policy 12

5.2 Workplace and Equipment 14

5.3 Pre-Service Checks 18

5.3.1 Leak Test, Bypass Resistance Check (before servicing) 18

5.3.2 Fault Finding (before servicing) 19

5.4 Service Overhaul 21

5.4.1 General Information 21

5.4.2 Health and Safety 21

5.4.3 Service Overhaul Procedure 22

5.4.4 Leak Test, Bypass Resistance, and Calibration Check (after servicing) 64

6 Parts List 68

(iii)

(iv)

This vaporizer has been built to conform with

the specification and operating procedures

stated in this manual and/or accompanying

labels and notices when checked. assembled, operated, maintained and serviced in

accordance with these instructions provided.

To ensure the safety of this vaporizer it must

be checked and serviced to at least the minimum standards laid out in this manual.

A defective or suspected defective, product

must not, under any circumstances be used.

The user must accept responsibility for any

malfunction which results from non-compliance with the servicing requirements

detailed in section 8.1.

Worn, broken, distorted, contaminated or

missing components must be replaced

immediately. Should such a repair become

necessary it is recommended that a request

for service advice is made to the nearest

Penlon service centre,

This vaporizer and any of its constituent

parts must be repaired only in accordance

with written instructions issued by Penlon

Limited, and must not be altered or modified

in any way without the written approval of

Penlon Limited.

The user of this equipment shall have the

responsibility for any malfunction which

results from improper use, maintenance,

repair, damage or alteration by anyone other

than Penlon Limited or its appointed agents.

This vaporizer must only be supplied to, and

used by, suitably qualified medical practitioners.

Caution: USA and Canadian Federal Law

restricts the sale and use of this device by or

on the order of a physician.

Statements in this manual preceded by the

following words are of special significance.

WARNING - means there is a possibility

of personal injury to yourself or others.

CAUTION - means there is a possibility of

damage to the instrument or other property.

NOTE - indicates points of particular interest

for more efficient and convenient operation.

The reader must take particular notice of the

warnings, cautions,. and notes printed

throughout the manual.

USER RESPONSIBILITY

1

WARNINGS

1. The Sigma Delta vaporizer is to be

sold to, and used on the order of, a

medically qualified practitioner

only.

2. Anaesthetic agents are poisonous,

and inhaling their vapours, even in

low (sub-anaesthetic)

concentrations may present a

health hazard.

Care must be taken to avoid

spillage of anaesthetic drugs when

filling or draining the vaporizer.

3. The procedures described herein

which involve dismantling the

vaporizer must only be performed

after the instrument has been

drained and dried out.

4. Calibration procedures must only

be performed with the vaporizer

outlet connected to an anaesthetic

gas scavenging system designed

in accordance with national

standards or regulations.

5. No oil or grease should be

permitted in the vaporizer service

area.

This applies equally to silicone

based lubricants, flammable oil,

and grease.

6. The Sigma Delta vaporizer is

designed for use only with one

anaesthetic agent - that which is

named on the filler block.

Misdosage will occur if the

vaporizer is filled with the wrong

drug.

Keyed filler devices are provided

on certain models to meet national

and international standards.

7. The Sigma Delta vaporizer must not

be modified or disassembled by

any unauthorised person. It should

be regularly serviced by a Penlon

authorised service agent, trained

technician or engineer and by no

other person (see section 6).

8. The pharmacopoeia name of the

drug is used on the label according

to BP, USP or Ph EUR.

The user is responsible for

confirming that any trade name of a

drug is equivalent to the registered

name.

9. Violent movement or tipping of a

filled vaporizer may cause liquid

agent to leak into the control

mechanism and subsequently

deliver uncontrolled doses of

vapour.

The vaporizer must be empty, and

the control must be in the zero

position during transport.

The vaporizer must be purged at

maximum output with 5 L/min flow

of oxygen for 2 minutes, and the

output checked with an analyser

prior to use.

10. The vaporizer control must be in

the zero position during the filling

or draining process. Delivered

concentrations are inaccurate

while the standard filler port is

open or the key filler shoe loose.

The vaporizer must be upright

during filling, to prevent overfilling.

11. Vaporizers may malfunction if

exposed to excessively high

temperatures, e.g. by storage

above a radiator. This may

permanently damage the vaporizer.

Maximum storage temperature:

50oC (122oF)

Minimum storage temperature:

-20oC (-5oF).

12. Vaporizer outputs are sensitive to

barometric pressure and a

correction factor may be necessary

when assessing the output using

an analyser, for example at high

altitude. Barometric pressure

effect are not usually of clinical

importance. (See user manual).

1. WARNINGS AND CAUTIONS

2

13. Anaesthetic drugs must be treated

as a pharmaceutical product.

Liquid should never be drained

from a vaporizer into an open

container and then reused.

Contamination is likely.

Always dispose of such drained

liquid as a hazardous chemical.

CAUTIONS

1. The instructions given in this manual

assume that the service engineer has

received adequate training in the

practice of servicing anaesthetic

apparatus and is familiar with the use

of flowmeters, pressure gauges and

other laboratory equipment.

Details of such procedures are

therefore not

included.

2. Each Sigma Delta vaporizer is a

tested and calibrated unit. It is most

important that components are not

transferred from one unit to another.

In particular, the service engineer

must accept responsibility for

ensuring that agent specific items

such as labelling, keyed fillers, and

control needles are treated as critical

devices and that full records of

vaporizer servicing are kept.

Following any service procedure, a

label to indicate to clinical staff that

the vaporizer has been serviced must

be attached to each unit.

WARNINGS AND CAUTIONS

3

2. PURPOSE

The Sigma Delta vaporizer is designed for

incorporation in the fresh gas supply system

of continuous flow anaesthetic machines,

directly connected between the flowmeter

unit and the common gas outlet of the

machine.

The vaporizer is unsuitable for use within a

breathing system 'in circuit' because of the

relatively high internal resistance.

Its purpose is the provision of accurate

concentrations of anaesthetic drugs in the

fresh gas supply, in accordance with the

setting of the control dial, when the fresh gas

supply flow is between 0.2 and 15 litres/min.

Factors affecting output accuracy are listed

in the user instruction manual (Section 7,

Performance Characteristics), which shows

the extent of modifications to the control calibration.

4

5

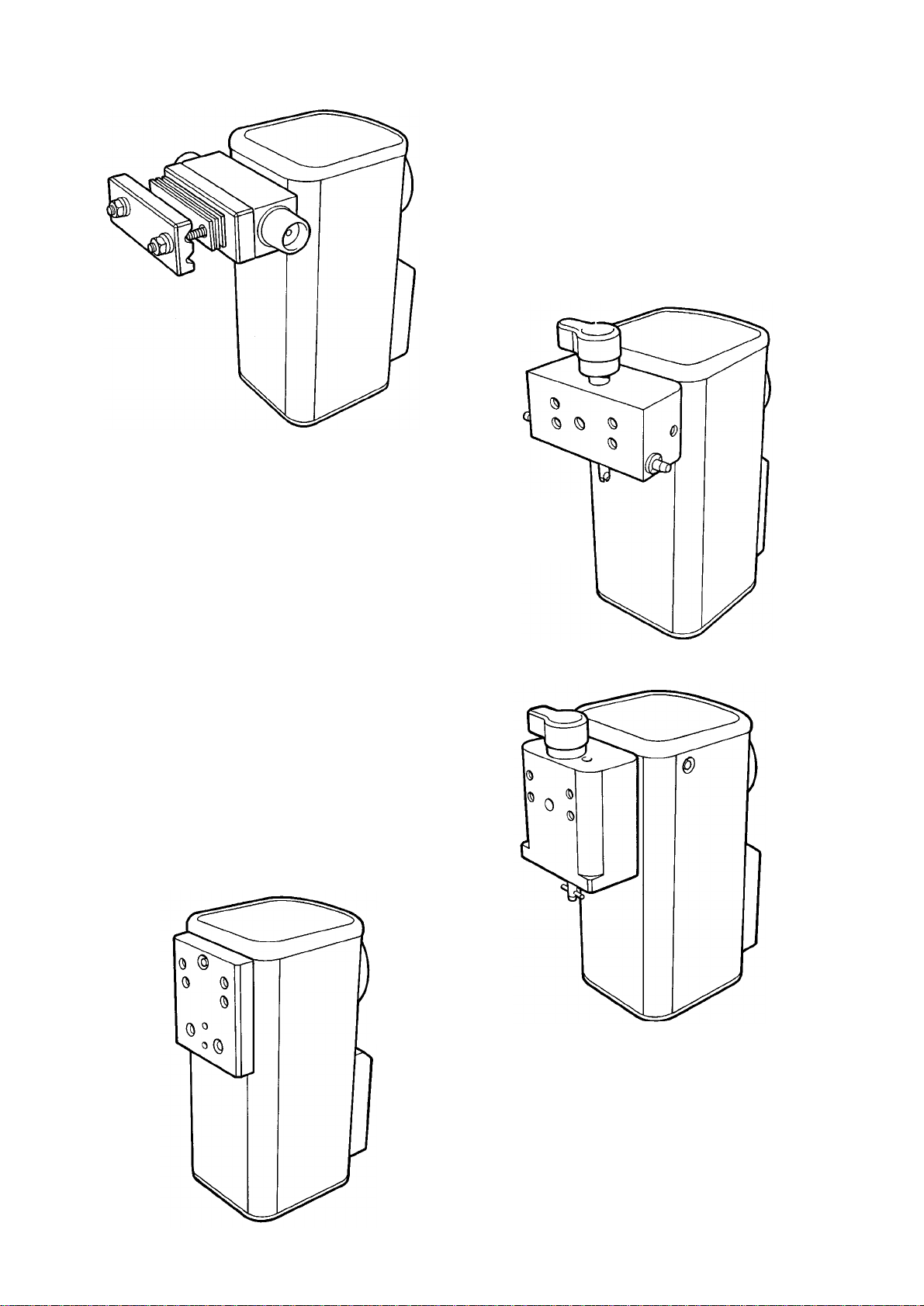

Cagemount

Selectatec

Drager

North

American

Drager

Delta Vaporizer

Connector Block Types

6

Figure 1

Gas Flow Path

Closing

mechanism

(On/off control)

Vapour

concentration

control needle

Temperature

compensator chamber

Spiral

passage

Vapour

chamber

Mixing

chamber

Gas

Flow

Out

Bypass

Flow

Saturated

vapour

Gas

Flow

In

3.1 General Description

The Delta User Manual provides additional

information on the operation of the vaporizer. The

service engineer should have a copy for

reference, in addition to this service manual.

Introduction

The Sigma Delta vaporizer enables the

anaesthetist to add a predetermined amount

of vapour of a volatile drug to the fresh gas

stream supplied to the patient’s breathing

system.

All anaesthetic agents of a volatile nature

have relatively high vapour pressures at

normal room temperature so that this

saturated vapour must be diluted

considerably to produce the concentrations

required clinically.

Gas Flow Path

Figures 1 and 2 show that the vaporizer

contains two paths for gas flow. One is

always open, through the bypass system.

The second, which is open only when the

control knob is moved from zero, is routed

via the closing mechanism vapour chamber,

and, vapour control orifice, and joins up with

the bypass flow in a mixing chamber, and

then on to the vaporizer outlet.

Vapour Chamber

The vapour chamber contains the liquid

anaesthetic drug, and is filled through the

filler unit to a level shown on the level

indicator. The chamber contains a spiral

wick assembly.

Gas which enters the chamber has to pass

through the narrow passages between the

wicks, becoming saturated with vapour

before emerging through the vapour control

orifice.

The proportion of the total flow which passes

through the vapour chamber is determined

by the relative resistances of the bypass

orifice (which does not vary with control knob

setting, but does vary with temperature) and

the vapour control orifice (which varies only

with control knob setting).

Compensation for total flow variation is

achieved by the design of the orifice

elements which are precision parts.

Temperature Compensation

Compensation for temperature variation

(and therefore changes in vapour pressure,

viscosity etc.) is achieved by the movement

of a bypass control plate (in the form of a

bimetallic strip) against the bypass orifice,

thus changing the area of the orifice. This

device is mounted within the vapour

chamber so that it is exposed to both gas

and liquid temperatures within the vaporizer.

Back-pressure Compensation

Compensation for fluctuating back-pressure

on the vaporizer, as produced by the use of

IPPV in the breathing system, is provided by:

A) the inclusion of a long gas flow path

prior to the closing mechanism system, and

B) a spiral passage after the closing

mechanism,

which prevents reverse flow of vapour from

the chamber into the bypass gas flow.

3. DESCRIPTION

Figure 2

Gas Flow

Block Diagram

7

3.2 Concentration Control

and Cut-off Mechanism

3.2.1 Control Knob Assembly

The laser engraved dial is etched to match the

performance characteristics of the components

of the individual vaporizer using its allotted

agent.

A self-adhesive label, colour coded for the

agent to be used with the vaporizer, is fixed to

the knob.

3.2.2 Dial Stop Plate Assembly

and Vapour Control Valve

When the control knob is pushed in, the dial

drive plate disengages from the zero position

dial stop (which prevents knob rotation in the

zero (off) position), and opens the closing

mechanism by pushing on the shaft assembly

(see 3.2.4).

The stop plate is now disengaged from the dial

stop and it is free to turn anti-clockwise. A drive

screw produces movement of the vapour

control needle valve within the needle housing,

altering the size of the orifice available for the

passage of vapour.

3.2.3 Dial Stops

The dial stop (zero position) prevents rotation

of the knob assembly in the zero position.

3.2.4 Cut-off Mechanism

When the control knob assembly is in the zero

position, the spring-loaded cut-off valve is

closed. This prevents gas flowing into the

vapour chamber.

When the control knob assembly is pushed in,

the closing mechanism shaft pushes a spring

loaded seal off its seat on a spool assembly.

Gas is then able to flow into the vapour

chamber.

3.2.5 Interlock Mechanism

With two or three interlocked vaporizers on the

anaesthetic machine back bar, initial operation

of the concentration control dial, by pushing on,

activates the interlock system. The interlock

push rods move outwards, ensuring that only

that vaporizer can be in use at any time.

The interlock deactivates as soon as the control

dial is returned to the zero position.

DESCRIPTION

8

Selectatec

Interlock

3.3 Temperature

Compensator (TC)

This device alters the resistance to the flow of

gas passing through a bypass valve.

The temperature sensitive element comprises a

bimetallic assembly that expands/contracts with

increase/decrease in temperature, causing the

bypass plate to move away from, or towards the

TC base.

At low temperature the bypass resistance is

increased, forcing more gas through the vapour

chamber to compensate for the lower vapour

pressure of the liquid. At high temperatures the

reverse is effected.

3.4 Wick Assembly

The large wick assembly consists of a long strip

of wick material attached to a metal backing

strip, and rolled into a spiral. This forms a single unit cartridge assembly for ease of replacement.

9

DESCRIPTION

3.5 Filler Systems and

Agent Level Indicator

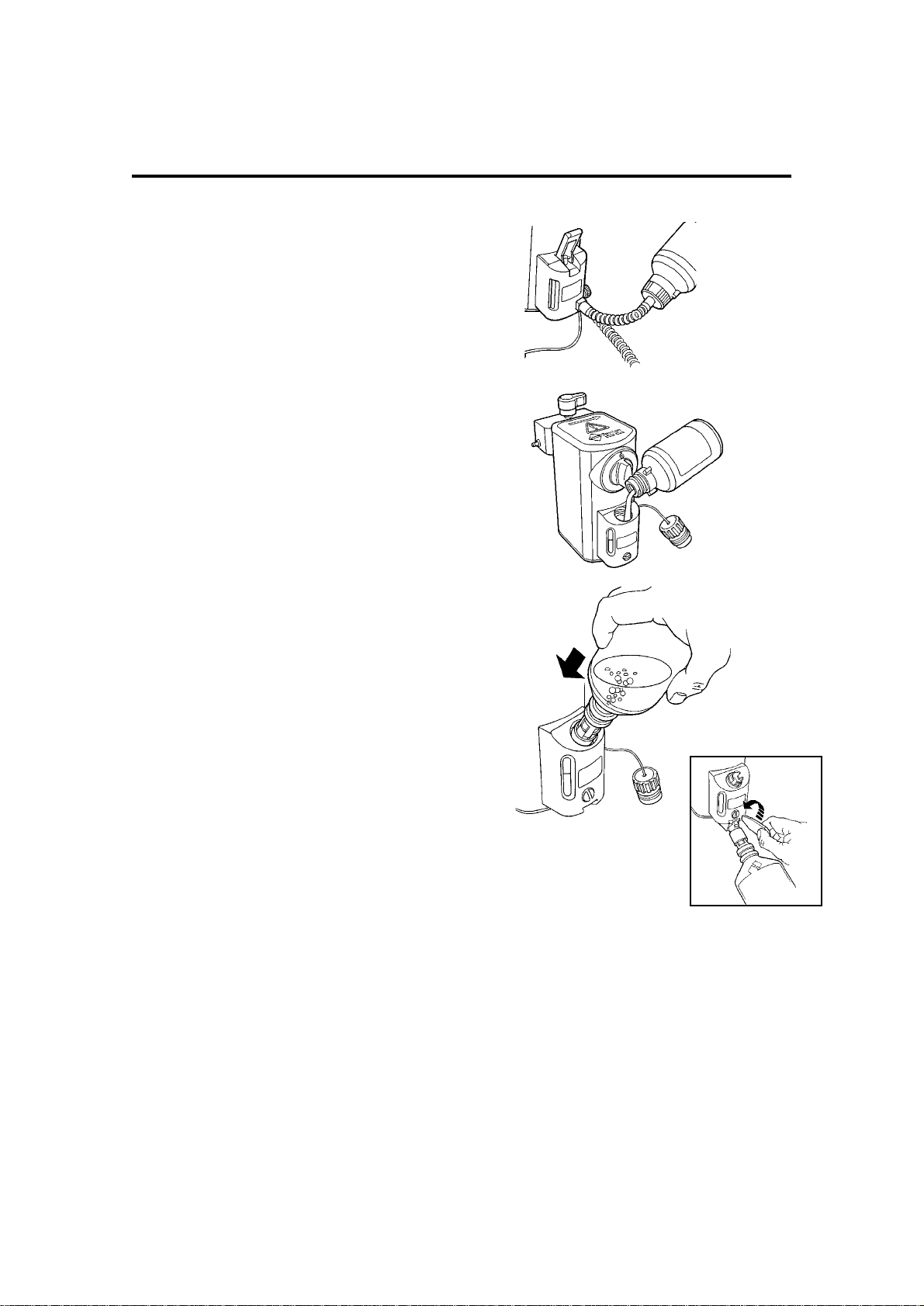

3.5.1 Agent Specific (Keyed) Filler

This unit is designed to be used with a bottle

adaptor only - refer to the vaporizer user

manual.

Bottle adaptors for each agent type are

available - see section 10, in the user instruction

manual.

3.5.2 Screw Cap Pour Filler

This unit has a screw-plug, sealed filler opening.

3.5.3 Quik-Fil Filler

This unit is designed to be used with an agentspecific nozzle, permanently attached to the

agent bottle.

When the nozzle is inserted into the filler block,

a valve opens inside the filler block.

When the nozzle is pressed further into the filler

block, a valve in the nozzle opens and agent

flows into the vaporizer.

The filler block utilises an air lock which

automatically stops the filling process at the

maximum fill position.

The vaporizer is drained through a separate

valve in the base of the filler block.

3.5.4 Agent Level Indicator

The level indicator is a glass tube with

maximum and minimum fill level marks printed

on the glass.

Provided the vaporizer is upright, with the

control knob set at zero, the chamber cannot be

overfilled as the design of the air escape ports

facilitates air trapping at the maximum safe

level.

On agent specific (keyed) filler models, an

overfill hole drains excess agent from the filler

system.

On screw cap filler models, a drain hole is

included in the side of the filler block to drain the

filler funnel level should excess agent be tipped

into the filler block during filling.

10

DESCRIPTION

4. SPECIFICATION

11

4.1 Physical Dimensions

Width Height Depth

Cagemount 133 219 158

Selectatec Compatible with Interlock 120 242 190

Drager 'plug in' Compatible 100 242 190

Dimensions given above are in millimetres

NOTE

The figures for Depth relate to Key Filler (Agent Specific) and Quik Fil models.

To calculate the depth dimension for Screw Cap Filler models, subtract 11 mm from the figures given above.

4.2 Weight

Approximate weight: 4.8 kg.

4.3 Capacity

Volume at MAX mark 250 ml (nominal)

Volume at MIN mark 35 ml (nominal)

NOTE After draining, approximately 60 ± 10 ml of liquid is retained by the wick.

4.4 Filling System

Key Filler (Agent Specific)- Use with corresponding agent specific filler adaptor, see section 10 (USER

Manual), Ordering Information.

Pour Fill (Screw Cap)

Quik Fil - Sevoflurane only -

Use with corresponding agent specific bottle.

4.5 Control Dial Scale

The control dial is marked as follows:

From 0 to 2% vol, by intervals of 0.2% vol

From 2% to maximum, by intervals of 0.5% vol

The control dial is marked '0' at zero

4.6 Patents

The Sigma Delta is protected by UK and foreign patents.

4.7 Temperature Range

Operating Temperature Range 15 to 35oC (58 to 95oF)

Storage Temperature Range -20 to 50oC (-5 to 122oF)

Storage in Transit (up to 7 days) -40 to 60oC (-40 to 149oF)

4.8 Flow Range

Operating Flow Range: 0.2 to 15 litres/min.

See section 7.4.1 (User Manual) for output accuracies at extreme conditions.

4.9 Pressure Range

Operating Pressure Range 0 to 5 kPa (0 to 0.7 psi)

Maximum Manifold Pressure 38 kPa (5.5 psi)

Maximum Test Pressure 38 kPa (5.5 psi)

5. SERVICE PROCEDURES

5.1 Service Policy

The Sigma Delta must only be serviced at an authorised

service centre or by Penlon-trained technicians in

accordance with the following procedure.

(a) The calibration should be checked periodically under

controlled conditions and a leak test performed.

Detailed information on the use of the Riken

Analyser is given in the following pages.

Record the measured values in section 11 in the

vaporizer user manual.

(b) Successive sets of figures should be compared to

determine if performance is deteriorating.

Should deterioration be detected, a service should

be carried out to restore normal operation.

(c) A major overhaul must be performed every ten years

(Halothane models - 5 years) to maintain

performance within the specification.

(d) The Selectatec compatible vaporizer locking system

should be inspected during the vaporizer calibration

test, and if damage to the locking shaft is suspected,

the device must be referred to a Penlon certified

engineer.

(e) Interlock system vaporizers -

function test the interlock system during the

vaporizer calibration test.

(d) Quik-Fil system - at regular intervals (3 monthly

minimum, 6 monthly maximum), filling and draining

must be checked under controlled conditions

NOTE

The user must accept responsibility for any malfunction which

results from non-compliance with the above requirements.

Returning the Vaporizer for Service / Repair

The vaporizer must be drained and allowed to dry out

before packing.

Always use the original packaging, to prevent damage

during transit.

12

Checking Vaporizer Output

Calibration Procedure using the

Riken Analyser

The Riken Model 1F-18 is normally calibrated by

the manufacturer for measuring up to 8% vol.

Halothane or up to 9% vol. Sevoflurane, either in

air or in oxygen.

Service checks on the vaporizer must be

performed with oxygen if the vaporizer is checked

on an anaesthetic machine.

Use air or oxygen if the vaporizer is checked in a

test laboratory.

CAUTION

A) It is essential that the gas used during service

checks is recorded,

B) The reference cell of the Riken must be

purged with the appropriate gas before

measurements are made.

Agents

The Riken gas analyser measures the refractive

index of the gases and vapours and, although

normally calibrated for measuring halothane, the

instrument can also measure other vapours if an

appropriate correction factor is applied.

To obtain the true concentration of gases other

than halothane multiply the reading shown on the

Riken by the correction factors given below.

Carrier Gas

The refractive index of oxygen is higher than that

of air so that,

(a) the unit must be re-zeroed if the carrier gas is

changed, and

(b) the scale must be adjusted by a correction

factor, applied by multiplying the Riken scale

reading to obtain the true concentration.

Correction Factors

Halothane in Air Riken:

Factor (using air) Factor (using O2)

Halothane 1 1.06

Enflurane 1.05 1.11

Isoflurane 1.06 1.12

Sevoflurane 1.05 1.10

Halothane in Oxygen Riken:

Factor (using air) Factor (using O2)

Halothane 0.95 1

Enflurane 0.99 1.05

Isoflurane 1 1.06

Sevoflurane 0.99 1.05

Temperature and Barometric Pressure

Calibration checks must be performed at a

temperature between 19 and 21oC.

13

SERVICE PROCEDURES

The correction factor is ± 1.5% of readings, which

is negligible in view of the accuracy of the

instrument.

Temperature correction is therefore not required,

but the temperature should be measured and

recorded to ensure that the test is carried out

within the specified range.

Changes of barometric pressure due to weather

are not normally of significance and can be

ignored.

Altitude can, however, have significant effects

and the following correction factors should be

applied when appropriate.

The Riken reading multiplied by the stated

correction factor gives the true concentration

corrected to Standard Temperature and Pressure

(STP).

Altitude Factor Barometric

pressure

(for reference)

600 m 0.9 910 mb

(2000 ft)

1200 m 0.85 850 mb

(4000 ft)

1800 m 0.8 813 mb

(6000 ft)

Method of reading the Riken

Analyser

1. Readings may be taken from a tee-piece

connected to the common gas outlet of the

anaesthetic machine.

An AGS system must be connected.

2. The sampling tube must be nylon or PTFE

(which do not absorb vapours).

Rubber sleeves may be used to make end

connections but there must be minimal

length of rubber exposed to the gases

being sampled.

3. Sample by 2 or 3 squeezes of the hand

bulb. Wait for fringe movement to cease

before taking the reading.

4. After each resetting of the vapour control,

time must be allowed for the output to

stabilise.

Suggested timescale:

2 L/min flow - wait 4 minutes

4 L/min flow - wait 2 minutes

8 L/min flow - wait 1 minute

5. a) The vaporizer must be half full, and

rigidly supported in its correct operating

position.

b) Temperatures must be stabilised for

approximately 4 hours before checking

c) The temperature must be in the range

19 to 21oC.

14

SERVICE PROCEDURES

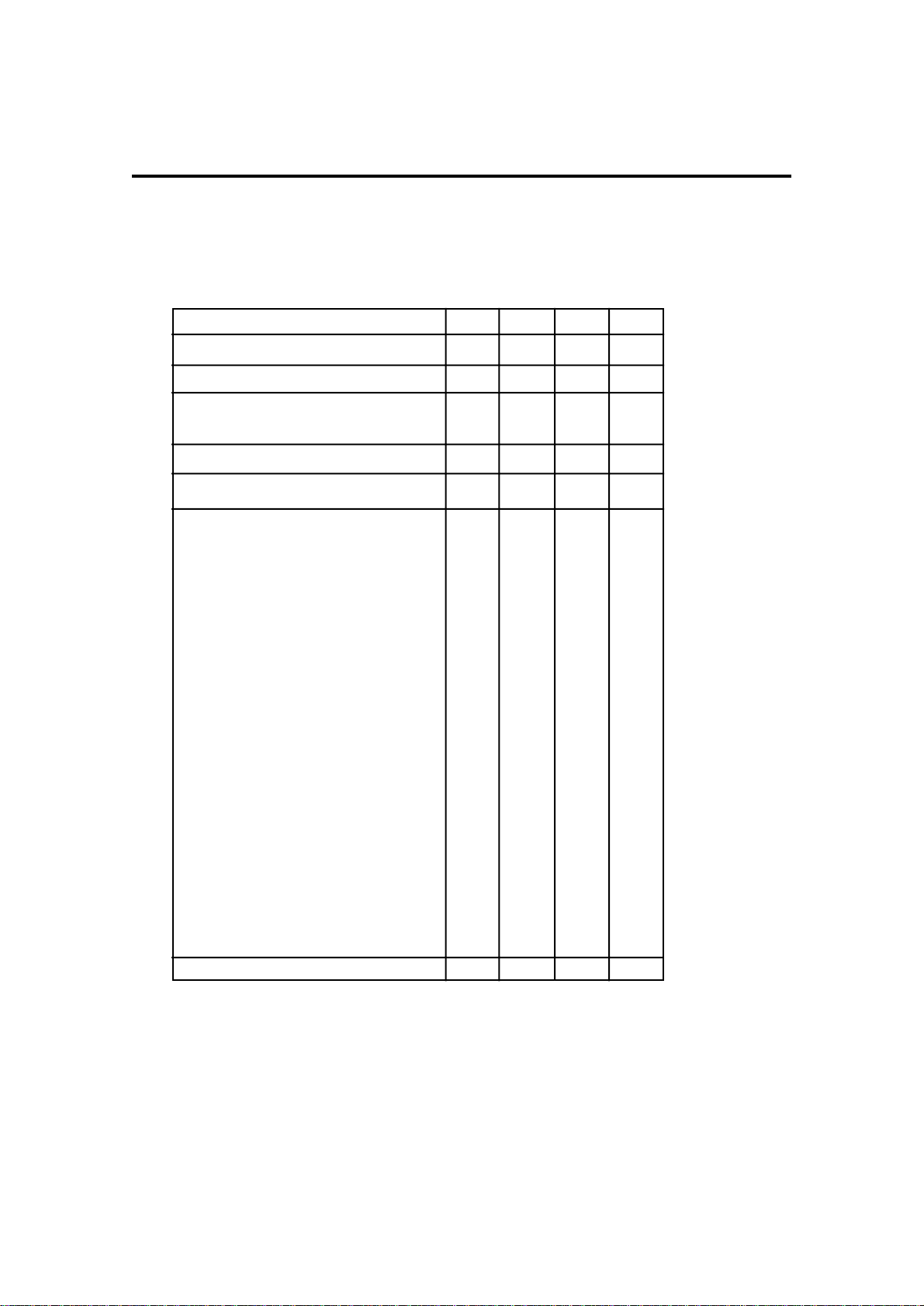

Sample of Service Record Page

(see section 11 in the Delta User Manual)

Test Period 1 2 3 4

Vaporizer serial number:

Date:

Signature:

Print name:

Carrier Gas

Leak Test

(at 200 mmHg for minimum 60 secs)

Pressure must not drop below 180 mm Hg

Set Tolerance

0.0 0 - 0.1

0.2 0.14 - 0.26

0.6 0.45 - 0.75

1.0 0.8 - 1.2

3.0 2.4 - 3.6

*4.0 3.2 - 4.8

5.0 4.0 - 6.0

**7.0 5.6 - 8.4

**8.0 6.4 - 9.6

**7.0 5.6 - 8.4

5.0 4.0 - 6.0

3.0 2.4 - 3.6

1.0 0.8 - 1.2

0.6 0.45 - 0.75

0.2 0.14 - 0.26

0.0 0 - 0.1

*

4% Halothane vaporizer only

**

7% and 8% vaporizers only

Bypass resistance at 4 L/min

5.2 Workplace and Equipment

NOTE

For complete safety when servicing this device,

full reference must be made to the WARNINGS

and CAUTIONS listed in section 1.

WARNING

Adequate ventilation of the work area must be

provided. During calibration procedures,

connect the outlet of the vaporizer to an

anaesthetic gas scavenging system that

conforms to your national standards or

regulations.

Environment - servicing must be carried out

in a stable temperature environment,

preferably with thermostatic control or air

conditioning, to maintain the temperature

within 22°C ±1°C.

Gas Supply - flow check for bypass

resistance measurement must be carried out

using air. Calibration after servicing must be

carried out using oxygen.

Small tools - as listed throughout the

service procedures listed in this manual, and

in the following pages.

Gauges, etc. - as listed in the following

pages.

Test Rigs - layouts and components are

listed in the following pages.

5.2.1 Standard Equipment

Pressure regulator 0 - 400 kPa (0 - 60 psig)

Pressure gauge 0 - 400 kPa (0 - 60 psig)

Pressure gauge 0 - 40 kPa (0 - 3000 mmHg)

Pressure gauge or

water column 0 - 10 kPa (0 - 100 cm H

2O)

Flow meter unit 0 - 10 L/min

Pressure isolating valve

Leak detection fluid

Torque driver 0 - 10 Nm

Gas analyser - The preferred form of

analysis apparatus is an interferometer.

However, if used carefully, the following

instruments are also suitable for a calibration

check:

Infrared analyser

Mass spectrometer

Molecular absorption meter

The selected analyser should have a

sensitivity better than ± 0.1%.

5.2.2 Test connectors and

equipment

(available from Penlon)

Pressure gauge tee connector 53196

Flexible hose with cagemount female

connector end 37019

Blanking plug with pressure gauge connector

(Cagemount male) 37018

Nylon Catheter 52605

Exhaust tubing

(22 mm diameter breathing hose) 57004

5.2.3 Special Purpose Service Tools

and Equipment

(available from Penlon)

Test Connection Block 410579

Sample Tee Connector 53196

Blanking Plug with Pressure Gauge

Connector 37018

Needle Housing Locknut Tool 410644

Small Wick Assembly Tool 410659

Needle Bal Seal Tool 410660

Interlock Checking Tool 410582

TC Assembly Tool (includes Bi-metallic

Strip Assembly Tool) 410647

TC Hinge Assembly Tool 410694

Dial Stop Setting Tool 410695

Closing Mechanism Removal Tool 410650

Interlock Bush Tool 408889

Needle Setting Tool 410602

NAD Interlock Tool 410772

5.2.4 Test Apparatus

Leak Test

- 5.2.4.1 (Test Apparatus A)

Flow Check for Bypass Resistance Measurement

- 5.2.4.2 (Test Apparatus B )

Calibration Check

- 5.2.4.3 (Test Apparatus B adapted for

calibration)

A schematic layout for each apparatus is

given in the following pages.

15

SERVICE PROCEDURES

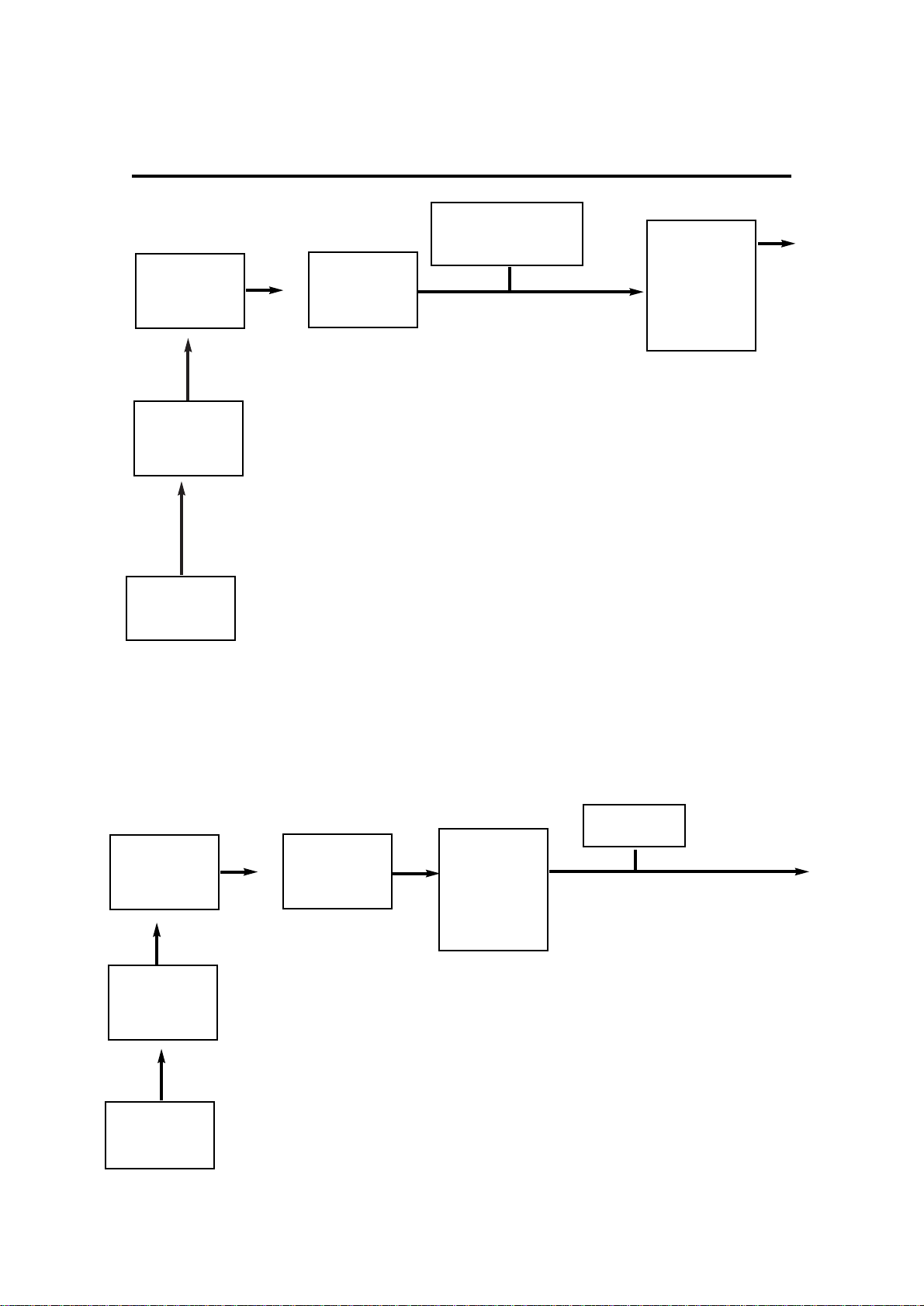

5.2.4.1 Test apparatus A

For leak testing

A - Air or Oxygen supply

B - Pressure regulator 0 - 400 kPa (0 - 60 psig)

C - Pressure gauge 0 - 400 kPa (0 - 60 psig)

D - Flowmeter unit 0 - 10 L/min

E - Vaporizer on Test connection block (410579)

F - Blanking plug with pressure gauge connector (cagemount male) (37018)

G - Pressure Gauge 0 - 40 kPa (0 - 300 mmHg)

Air or

Oxygen

Supply

Regulator

Pressure

Gauge

Flowmeter

Unit

Pressure

Gauge

Vaporizer

A

B

C

D

G

E

Blanking

Plug

F

16

SERVICE PROCEDURES

5.2.4.2 Test Apparatus B

Flow check for measurement and adjustment of

bypass resistance

A - Air supply

B - Pressure regulator 0 - 400 kPa (0 - 60 psig)

C - Pressure gauge 0 - 400 kPa (0 - 60 psig)

D - Flow meter unit 0 - 10 L/min

E - Pressure gauge or water column 0 - 100 cm H

2O

- Sample connector tee (53196)

- Vaporizer mounted on Test connection block (410579)

NOTE While the bypass resistance is being measured, nothing must be

attached to the outlet of the vaporizer.

Air

Supply

Regulator

Pressure

Gauge

Flowmeter

Module

Pressure gauge

or Water Column

Vaporizer

(mounted on

test connection

block 410579)

Vaporizer must be in

the OFF position

A

B

C

D

E

In Out

Sample connector

tee (53196)

17

SERVICE PROCEDURES

5.2.4.3 Test Apparatus B

Adapted for calibration test

A - Oxygen supply

B - Pressure regulator 0 - 400 kPa (0 - 60 psig)

C - Pressure gauge 0 - 400 kPa (0 - 60 psig)

D - Flowmeter unit 0 - 10 L/min

E - Vaporizer mounted on Test connection block (410579)

G - Exhaust tubing (22 mm diameter breathing hose)

- Sample connector tee (53196)

Oxygen

Supply

Regulator

Pressure

Gauge

Flowmeter

Module

Vaporizer

A

B

C

D

Analyser

F

G

E

Flow to

scavenge

system

Sample connector

tee (53196)

5.3 Pre-Service Checks

5.3.1 Leak Test and Bypass Resistance Measurement

(Before servicing)

NOTE:

Anaesthetic gas scavenging equipment must be connected during these

tests.

1. Drain the vaporizer and discard the contents - see section

5 in the vaporizer user Manual.

Do NOT reuse the anaesthetic agent.

Close the filler system.

2. Check for leaks from the vaporizer:

Use Test Apparatus A (5.2.4.1),and set a pressure of 200

mmHg.

Measure, and record the pressure drop after a minimum of

60 seconds.

3. Measure the Bypass Resistance:

Allow 4 hours for temperature stabilisation.

Use Test Apparatus B (5.2.4.2) to measure, and record the

vaporizer Bypass Resistance, using a flow of Air at 4 L/min.

18

SERVICE PROCEDURES

19

SERVICE PROCEDURES

5.3.2 Fault Finding (Before servicing)

Fault Possible Cause Treatment Reference

1.

Low or zero (a) Insufficient liquid in chamber (a) Refill / check level User Manual

output at all indicator

settings

(b) Leak to atmosphere from (b) Service 5.4

(c) Cut-off mechanism not (c) Check operation 5.4

operating of closing mechanism

shaft

(d) Incorrect needle setting (d) Service 5.4

(e) Bypass resistance out of (e) Adjust 5.4

adjustment

(f) Wrong agent (f) Drain and dry User Manual

WARNING

If Halothane has been used in a non-Halothane vaporizer, DO NOT USE that vaporizer

until all traces of Halothane have been removed.

To prevent the possibility of malignant hypothermia, the vaporizer must be completely

disassembled.

(g) Leaking sight glass seals (g) Fit new seal 5.4 (complete service

not necessary)

(h) Damaged sealing counterbores (h) Fit new block 5.4

on Selectatec block

(j) Worn or damaged claws on (j) Fit new locking 5.4 (complete service

Selectatec block locking shaft shaft not necessary)

2.

Low output at (a) Contaminated wick (a) Renew wick as part 5.4

high setting of Service

only

(b) Leaking wick sealing (b) Renew wick as part 5.4

washer of Service

3.

Excessive (a) Worn, or broken vapour control (a) Return unit to Penlon

variation in needle valve spring or authorised distributor/agent

output,

when the set (b) Jamming needle (b) Service 5.4

value required

is selected (c) Loose needle drive (c) Service 5.4

(i) clockwise,

and then

(ii) anti-clockwise.

20

Fault Possible Cause Treatment Reference

4.

Zero not obtained (a) Cut-off mechanism (a) Service 5.4

O-seals leaking

(b) Leak between seal (b) Service 5.4

assembly and spool

(c) Leaks through TC (c) Service 5.4

assembly

(d) Worn needle or seat (d) Service 5.4

(e) Jamming needle (b) Service 5.4

(f) Incorrectly adjusted needle (b) Service 5.4

and seat

5.

High output (a) Bypass out of adjustment (b) Service 5.4

(b) Bypass control plate (b) Return unit to

contamination Penlon, or authorised

distributor/agent

(c) Bypass exit port partially (b) Service 5.4

blocked

6.

Agent leaking (a) Leak between TC cover and (b) Service 5.4

from base chamber

7.

Air leaking (a) Leak between TC base and (b) Service 5.4

from base body

during test

8.

Air or vapour (a) Leak between valve block (b) Service 5.4

leak around and body

valve block

SERVICE PROCEDURES

5.4 Service Overhaul

5.4.1 General Information

If the vaporizer fails the calibration test a Service

Overhaul must be carried out.

NOTE

A service overhaul must be carried out at a maximum 10

year interval even if performance appears satisfactory.

This is a mandatory preventive maintenance

requirement.

Preparation

The vaporizer must be removed from the

anaesthetic machine for this service.

The vaporizer must be drained of anaesthetic

agent and then dried - pass an air flow of 10 L/min

through it with the control at maximum setting until

all trace of vapour at the output port is eliminated.

Check using an agent analyser.

Bypass Resistance Measurement

Measure and record the bypass resistance before

and after servicing - see 5.3.1.

Service Area

These procedures should be carried out in a

laboratory room at a temperature

of 22°C ± 1°C, not varying by ± 1°C over the test

period.

Approximately 1 metre of bench space is required.

A scavenge system for anaesthetic vaporizers

should be in operation.

A supply compressed air, dry and clean, at 0.6 bar

(8.7 psi) should be available.

O seal Lubrication

Lightly lubricate O-seals / O-rings with PTFE

based, oxygen compatible, lubricant.

APPLY SPARINGLY.

5.4.2 Health and Safety

Cleaning - always comply with the local health and

safety regulations when using solvents to clean

components.

Loctite Superlube - use sparingly.

Prolonged skin contact may cause irritation.

Always follow the manufacturer's instructions

when using this product.

21

SERVICE PROCEDURES

SERVICE PROCEDURES

22

5.4.3 Service Overhaul

Procedure

CAUTION

Before servicing, always drain the vaporizer follow the instructions given in the User Manual.

Do not invert the vaporizer until the wicks are

removed.

Leak Test and Bypass Resistance

(See section 5.3.1)

Before dismantling the vaporizer:

a) Leak test the vaporizer.

b) Measure the bypass resistance.

Dismantling the vaporizer

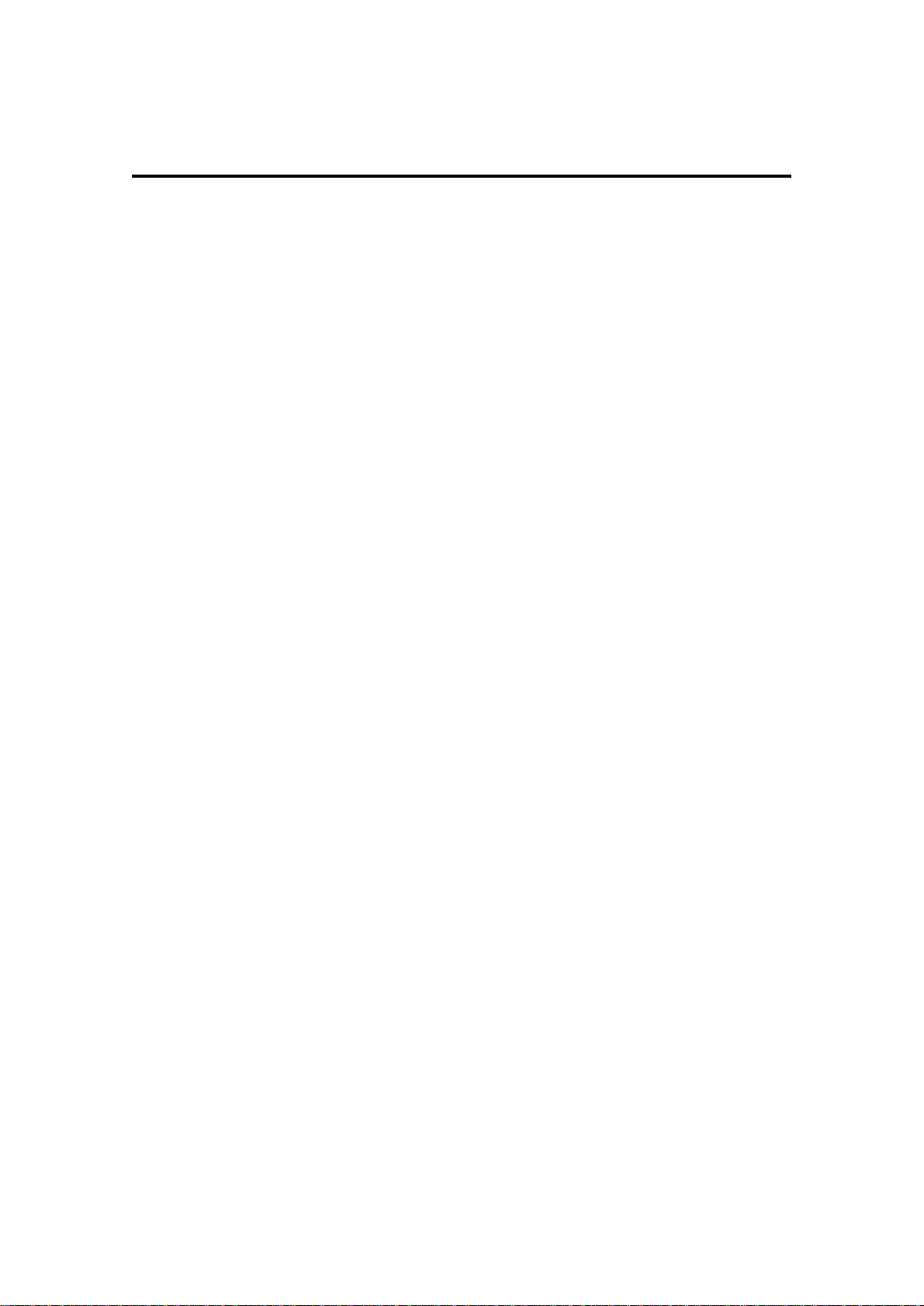

Connector Block

1. Remove the four M4 cap-head screws

(1) and the connector block (2).

2. Remove the O-seals (3) (connector

block to valve block).

3. Remove the top label (4) and lid (5)

(M6 countersunk screw).

Dial Assembly

4. Remove the dial label (6), and

discard.

5. Remove the two M3 cap head screws

and dial assembly (7).

6. Remove the circlip (8) from the shaft,

and remove the dial drive (9).

7. Remove the dial bezel (10) - two M3

cap-head screws.

23

2

10

1

4

5

3

1

1

Selectatec

North American Drager

Drager

2

2

4

4

5

5

3

3

Cagemount

Dial Assembly

Connector Blocks

1

3

2

4

5

6

7

8

9

Interlock - Selectatec

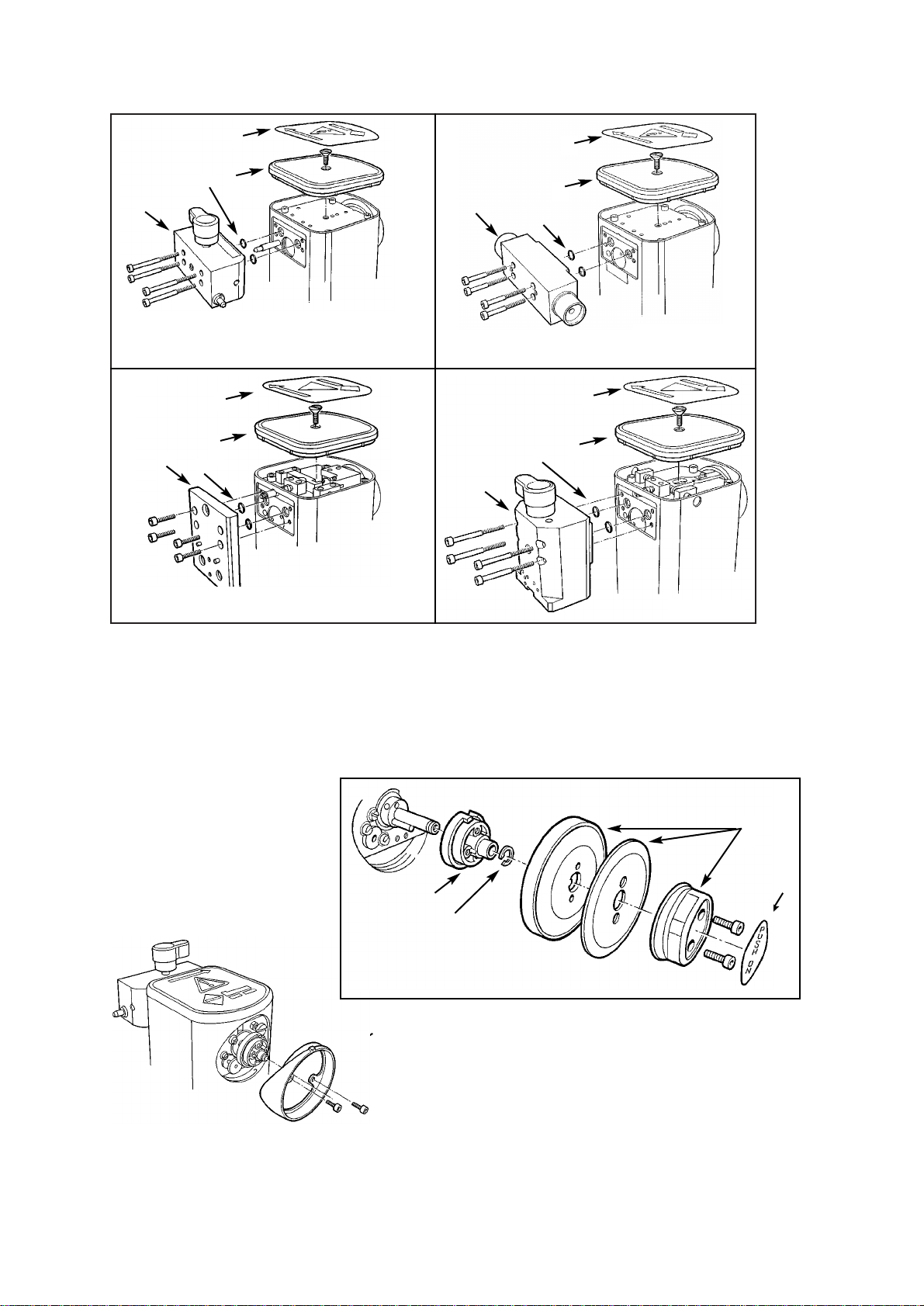

8. Remove the interlock shaft (11) and spring

(12).

Note - on Cagemount, Drager and North

American Drager models a dial return shaft

(plus spring) is fitted.

Interlock - Drager and North American

Drager

9. Remove the interlock system components

(13).

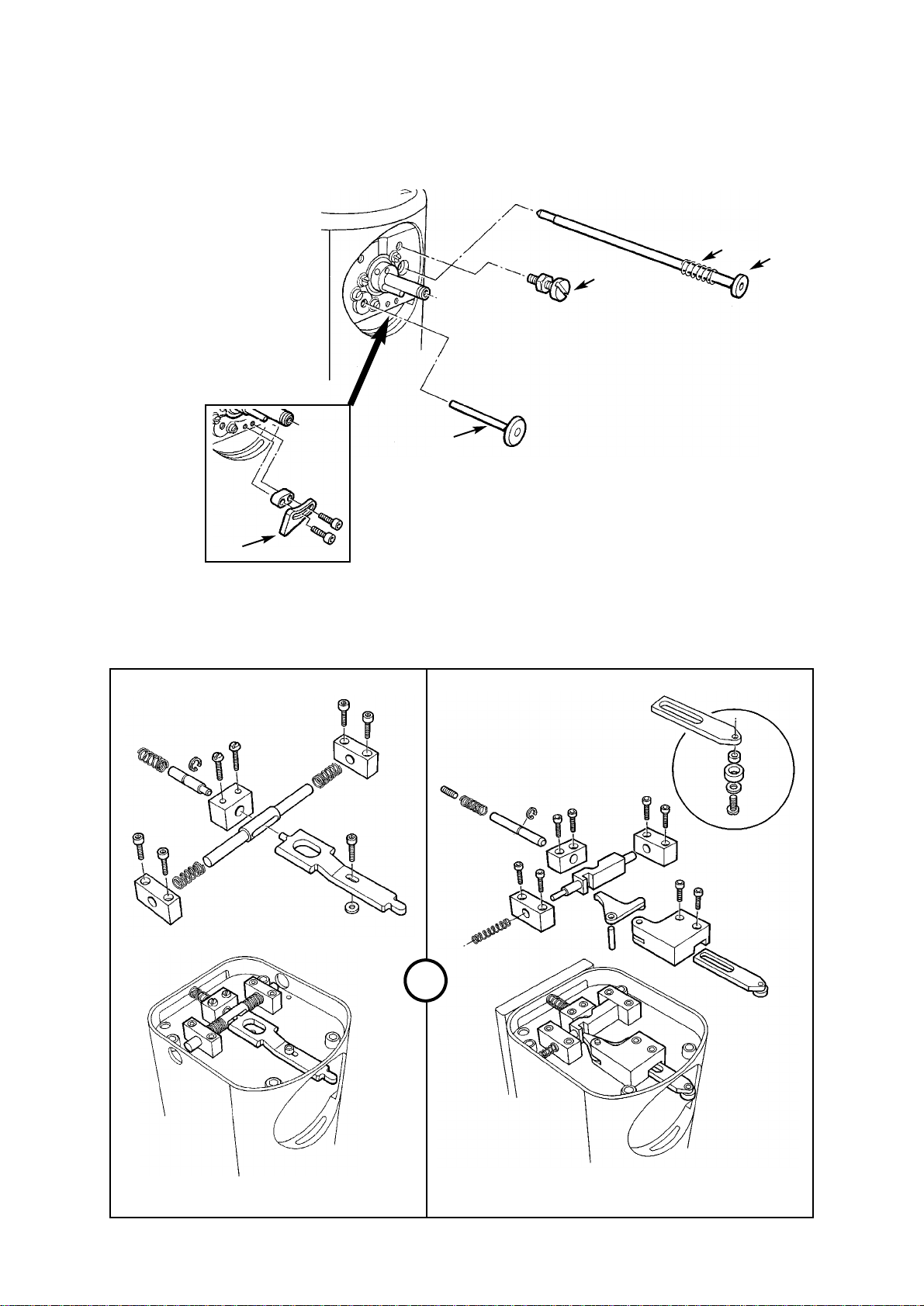

Dial Stops and Closing Mechanism

Shaft - All models

10. Remove the dial ‘zero’ lock screw (14)

11. Remove the closing mechanism shaft (15).

12. Remove the dial ‘max’ stop (16).

24

SERVICE PROCEDURES

Drager Interlock

15

14

12

11

25

16

North American

Drager Interlock

13

Selectatec Interlock Shaft,

Dial Stops and Closing

Mechanism Shaft

Loading...

Loading...