Penlon Prima SP2 User Manual

Prima SP2

Anaesthetic Machine Range

User Manual

Partnership for Life

Servicing and Repairs

In order to ensure the full operational life of

this anaesthetic machine, servicing by a

Penlon-trained engineer should be

undertaken periodically.

The machine must be serviced to the

schedule detailed in section 6.4.

Details of these service operations are given

in the Prima SP2 Service Manual, available

only for Penlon trained engineers.

For any enquiry regarding the servicing or

repair of this machine, contact the nearest

accredited Penlon agent:

or communicate directly with:

Technical Support

Penlon Limited

Abingdon Science Park

Abingdon

OX14 3PH

UK

Tel: +44 (0) 1235 547076

Fax: +44 (0) 1235 547062

E-mail: technicalsupport@penlon.co.uk

Always give as much of the following

information as possible:

1. Type of equipment

2. Product name

3. Serial number

4. Approximate date of purchase

5. Apparent fault

IMPORTANT

(i)

This manual has been produced to provide

authorised personnel with information on the

function, routine performance and

maintenance checks applicable to the Prima

SP anaesthetic machine range.

Information contained in this manual is

correct at the date of publication.

The policy of Penlon Limited is one of

continued improvement to its products.

Because of this policy, Penlon Limited

reserves the right to make any changes

which may affect instructions in this manual,

without giving prior notice.

Personnel must make themselves familiar

with the contents of this manual and the

machine’s function before using the

apparatus.

Copyright © Penlon Limited, 2008

All rights reserved.

FOREWORD

(ii)

The Importance of

Patient Monitoring

WARNING

Anaesthetic systems have the capability to

deliver mixtures of gases and vapours to the

patient which could cause injury or death

unless controlled by a qualified anaesthetist.

There can be considerable variation in the

effect of anaesthetic drugs on individual

patients so that the setting and observation

of control levels on the anaesthesia systems

does not in itself ensure total patient safety.

Anaesthesia system monitors and patient

monitors are very desirable aids for the

anaesthetist but are not true clinical

monitors as the condition of the patient is

also dependent on his respiration and the

functioning of his cardio-vascular system.

IT IS ESSENTIAL THAT THESE ELEMENTS

ARE MONITORED FREQUENTLY AND

REGULARLY AND THAT ANY

OBSERVATIONS ARE GIVEN PRECEDENCE

OVER MACHINE CONTROL PARAMETERS

IN JUDGING THE STATE OF A CLINICAL

PROCEDURE.

Before using any monitoring system or

device with the anaesthetic machine, the

user must check that it conforms to the

relevant standard, as listed in the table

below.

Parameter / Device Relevant Standard

Pressure Measuring ISO 8835-2

Pressure Limitation Device EN 60601-2-13:2006 - 51.101.1

Exhaled Volume Monitor EN 60601-2-13:2006 - 51.101.4

Breathing System Integrity Alarm System EN 60601-2-13:2006 - 51.101.5

Continuing Pressure Alarm EN 60601-2-13:2006 - 51.101.6

Oxygen Monitor ISO 7767

Carbon Dioxide Monitor ISO 9918

Breathing Circuit ISO 8835-2

Gas Scavenging ISO 8835-3

Vaporizers ISO 8835-4

Ventilators ISO 8835-5

Agent Monitor ISO 11196

For information on installing and connection of any of these systems or devices, please refer to the relevant manufacturer’s instructions.

Page No.

USER RESPONSIBILITY 1

1. WARNINGS AND CAUTIONS 2

2. PURPOSE 4

3.

DESCRIPTION 5

3.1 Framework and General Construction 5

3.2 Gas Circuit 5

Gas Circuit Schematic 6

3.3 Gas Supply Safety Devices 7

3.4 Mechanical Anti Hypoxic Device (AHD) 8

3.5 Pressure Gauges 8

3.6 Flowmeters and Controls 9

3.7 Vaporizers 10

3.8 Common Gas Outlet (CGO) 10

3.9 Electrical Power Supply 11

3.10 Auxiliary Gas Outlets 13

3.11 A200SP Absorber 13

3.12 AV-S Ventilator 13

4.

SPECIFICATION 14

4.1 Physical Dimensions 14

4.2 Gas Supplies 15

4.3 Flowmeters 15

4.4 Gas Pressures 16

4.5 Auxiliary Gas Outlets 16

4.6 Oxygen Failure Warning Devices 16

4.7 Oxygen Flush 16

4.8 Mechanical AHD System 17

4.9 Environmental 17

4.10 Electrical Supply 17

4.11 Device Classification and Labelling 18

5.

PRE-USE CHECKS 19

5.1 Pre-use Check List 19

5.2 Pre-use Checks - Gas Supply 21

5.2.1 Gas Pipeline Supplies 21

5.2.2 Gas Cylinder Supplies 21

5.2.3 Flowmeters 22

5.3 Vaporizers 23

5.4 Electrical Supply 24

CONTENTS

(iii)

5.5 Patient Breathing System 25

5.6 Leak Rate Check - Low pressure gas System 28

5.7 Oxygen Flush 28

5.8 Anaesthetic Gas Scavenge System (AGSS) 28

5.9 Ventilator 29

5.10 Alarm System Testing 30

6.

USER MAINTENANCE

6.1 Cleaning and Sterilisation 31

6.2 A200SP Absorber 32

6.3 Service Schedule 33

APPENDIX

Disposal at end of useful life: risk assessment 34

Accessories 35

CONTENTS

(iv)

USER RESPONSIBILITY

This anaesthetic machine has been built to

conform with the specification and operating

procedures stated in this manual and/or

accompanying labels and notices when

checked, assembled, operated, maintained

and serviced in accordance with these

instructions.

To ensure the safety of this device it must be

checked and serviced to at least the

minimum standards laid out in this manual.

A defective, or suspected defective, product

must not under any circumstances be used.

The user must accept responsibility for any

malfunction which results from noncompliance with the servicing requirements

detailed in this manual.

Additionally, the user must accept

responsibility for any malfunction which may

result from misuse of any kind or noncompliance with other requirements detailed

in this manual.

Worn, broken, distorted, contaminated or

missing components must be replaced

immediately. Should such a repair become

necessary it is recommended that a request

for service advice be made to the nearest

Penlon accredited agent.

This device and any of its constituent parts

must be repaired only in accordance with

written instructions issued by Penlon

Limited and must not be altered or modified

in any way without the written approval of

Penlon Limited. The user of this equipment

shall have the sole responsibility for any

malfunction which results from improper

use, maintenance, repair, damage or

alteration by anyone other than Penlon or its

appointed agents.

USA and Canadian Federal Law restricts the

sale and use of this device to, or on the order

of, a licensed practitioner.

Statements in this manual preceded by the

following words are of special significance:

WARNING means there is a

possibility of injury to

yourself or others.

CAUTION means there is a possibility

of damage to the apparatus

or other property.

NOTE indicates points of

particular interest for more

efficient and convenient

operation.

Always take particular notice of the

warnings, cautions and notes provided

throughout this manual.

1

The following WARNINGS and

CAUTIONS must be read and

understood before using this anaesthetic

apparatus.

WARNINGS

1. This apparatus is designed for use only

with non flammable anaesthetic agents.

It must not be used with or in close

proximity to flammable anaesthetic

agents, due to a possible fire or

explosion hazard.

2. Exterior panels must not be removed by

unauthorised personnel and the

apparatus must not be operated with

such panels missing.

On machines with an electrical power

supply, unauthorised personnel must

not attempt to access fuses or other

electrical components. There is a

possible electric shock hazard.

3. No oil, grease or other flammable

lubricant or sealant must be used on any

part of the machine in close

proximity to medical gas distribution

components.

There is a risk of fire or explosion.

4. When attaching cylinders of medical

gases ensure that the machine yoke and

cylinder faces are dust free and clean

and that the sealing washer provided is

in position between the cylinder valve

and the yoke.

Tighten the yoke securely before

opening the cylinder valve. Dust and dirt

presents a fire hazard in the presence of

high pressure gas.

Leakage of high pressure gas can

cause serious injury.

5. Anaesthesia apparatus must be

connected to an anaesthetic gas

scavenging system (AGSS) to dispose of

waste gas and prevent possible health

hazards to operating room staff.

This requirement must be observed

during test procedures as well as

during use with a patient.

6. Prima SP series machines must only be

used with Sigma Delta vaporizers (or

other vaporizers approved by Penlon

Limited) installed by means of the

Cagemount or Selectatec system.

Free-standing vaporizers may be

accidentally tipped, resulting in

excessive and uncalibrated volumes of

anaesthetic drug entering the breathing

system

Do not install or connect any vaporizers

of any description between the Common

Gas Outlet (CGO) and the breathing

system unless they are specifically

designed for such use.

(If this is done, the oxygen flush flow will

pass through the vaporizer and may

result in gross overdosage when the

flush valve is operated.)

7. The breathing system which conveys

gases from the anaesthetic machine to

the patient and disposes of expired

gases is a vital part of the anaesthetic

delivery system.

Because breathing systems require

frequent cleaning and disinfection they

are not a permanent part of the

anaesthetic machine and therefore

cannot be directly under the control of

the anaesthetic machine manufacturer.

However, we strongly recommend that

only breathing systems which have been

approved and authorised by Penlon for

use with the Prima SP range should be

employed.

This is particularly important when

mechanical ventilation is employed.

8. When mechanical ventilation is

employed the patient breathing system

must be connected directly to an overpressure relief valve to prevent the

possibility of barotrauma.

9. Always perform a pre-use check of the

machine, including vaporizers,

ventilator, circle absorber and monitors

before clinical use. Follow the pre-use

checklist (see section 5) as a minimum

requirement.

Many clinical incidents occur because of

a failure to check for correct function.

10. The machine must not be used if any of

the alarm, monitoring or protection

system devices are not functioning

correctly.

11. The gas supply failure systems within

the anaesthetic machine will not

necessarily operate as indicated in the

user manual during any procedures that

are outside the scope of the indications

for use of the machine:

2

1. WARNINGS AND CAUTIONS

(A) Machine set to deliver Air only

When the machine is operated with an Air

flow only, note that there may still be

retained oxygen in the system, and that the

visual O2 alarm will continue to indicate

green, even though oxygen is not being

delivered.

(B) Machine set to deliver Oxygen only

through Auxiliary Outlets

The oxygen failure alarm is designed to

operate during normal use of the machine,

i.e. when providing controlled

concentrations and flows of gases to a

patient breathing system, as described in

Section 2 (Purpose).

Do not use the machine solely to provide

large flows of oxygen, via the anaesthetic

machine auxiliary outlets, to external

devices which may not be equipped with a

supply failure alarm.

12. The machine must not be fitted with

more than four operator accessible

mains socket outlets. There is a risk of

an excessive leakage current.

13. The use of antistatic or electrically

conductive breathing hoses is not

recommended when using high

frequency electrical surgery equipment

(e.g. : Diathermy). Burns may be

caused.

14. Before any electrically powered machine

is used clinically for the first time,

check that the hospital engineering

department has carried out an earth

continuity test.

15. Before using any additional electrical

equipment powered by the auxiliary

sockets on the machine, check that the

additional equipment is correctly wired

and is earthed through its plug.

A missing or defective protective earth

conductor may increase earth leakage

currents to the patient to values

exceeding the allowable limits,

resulting in ventricular fibrillation, or

interference with the pumping action of

the heart.

16. Additional equipment placed on the top

shelf must be securely attached.

Take care when moving a fully loaded

machine, particularly when negotiating

ramps.

Check that hoses or power leads are not

trailing on the floor.

3

WARNINGS AND CAUTIONS

17. Prima SP2 series anaesthetic machines

are not MRI compatible.

CAUTIONS

1. Flowmeter needle valves are designed to

seal with light torque and may be damaged

if tightened excessively.

Do not force the control knob past either the

fully open or fully closed positions.

2. Open cylinder valves slowly to avoid

damage to pressure reducing valves.

Ensure that cylinder valves are at least one

full turn open when in use.

3. Under no circumstances should anaesthetic

agents be used for cleaning purposes.

4. After use, always disconnect the machine

from the piped gas supply and/or close the

gas cylinder valves.

5. Mechanical AHD system - The oxygen flow

control is restricted to prevent the needle

valve from fully closing. This ensures a

minimum basal flow of oxygen.

DO NOT attempt to close the flow to zero.

Do not overtighten.

6. Compressed gas supplies must be clean

and dry.

7. When the auxiliary gas outlets are in use on

a machine with cylinder supply only, or if

the pipeline supply is not in use, check flow

rate requirements, and ensure that

adequate back-up cylinders are available.

8. The requirements of IEC 60601-1-1 apply to

any device connected to the auxillary

sockets. Users must be aware of the risks of

increased leakage currents when

equipment is connected to the auxillary

power sockets

9. In the event of malfunction of any device

powered by the auxiliary sockets, check if

the circuit breaker has tripped.

10. On machines with pipeline connections,

note that a malfunction of the central gas

supply within your facility may cause

immediate cessation of gas delivery and

total anaesthesia system failure.

The Prima SP2 anaesthesia workstation

range is intended to provide controlled

concentrations and flows of anaesthesia

gases into a patient breathing system, from

where the anaesthesia ventilator and

breathing circuit will then deliver this fresh

gas mixture to the patient

Use the Prima SP2 in conjunction with

anaesthetic vaporizers, breathing hoses and

patient connection fittings which comply with

the relevant ISO standard or equivalent.

Depending upon the patient circuit selected,

the machines can be used in open, semiopen, semi-closed or closed circuit

configurations.

The range has been designed to give a wide

choice of configurations and accessories,

including:

Gas supplies

Up to four gases - oxygen, nitrous oxide, and

air, with optional fourth gas (see section 4).

Pin-index cylinder yokes, and provision for

up to three pipeline supply inlets.

Vaporizer mounting systems

Backbar manifold for Selectatec Compatible,

or Cagemount type vaporizers.

Anti-hypoxic Device (AHD)

The mechanical AHD system is designed to

minimise the risk of a hypoxic mixture

reaching the patient (see section 3).

4

2. PURPOSE

3.1 General Construction

Frame

The machine has a cast aluminium base,

extruded aluminium uprights, with aluminium

and plastic panels.

Mobility

Four castors are fitted, with a brake on each

of the front castors. The castors are five

inches diameter.

A footrest is built into the front of the

machine and, to aid manoeuvrability, two

handles are provided.

Mounting posts and brackets

A mounting system is built into each side

upright, to allow the use of pole-mount

brackets, V-brackets, and ventilator

mounting brackets.

The pole mount upright can be used to

mount an A200SP Absorber assembly.

Work surfaces

The work surface has raised edges to retain

instruments, vials etc.

A pull-out writing tablet is mounted under the

work surface.

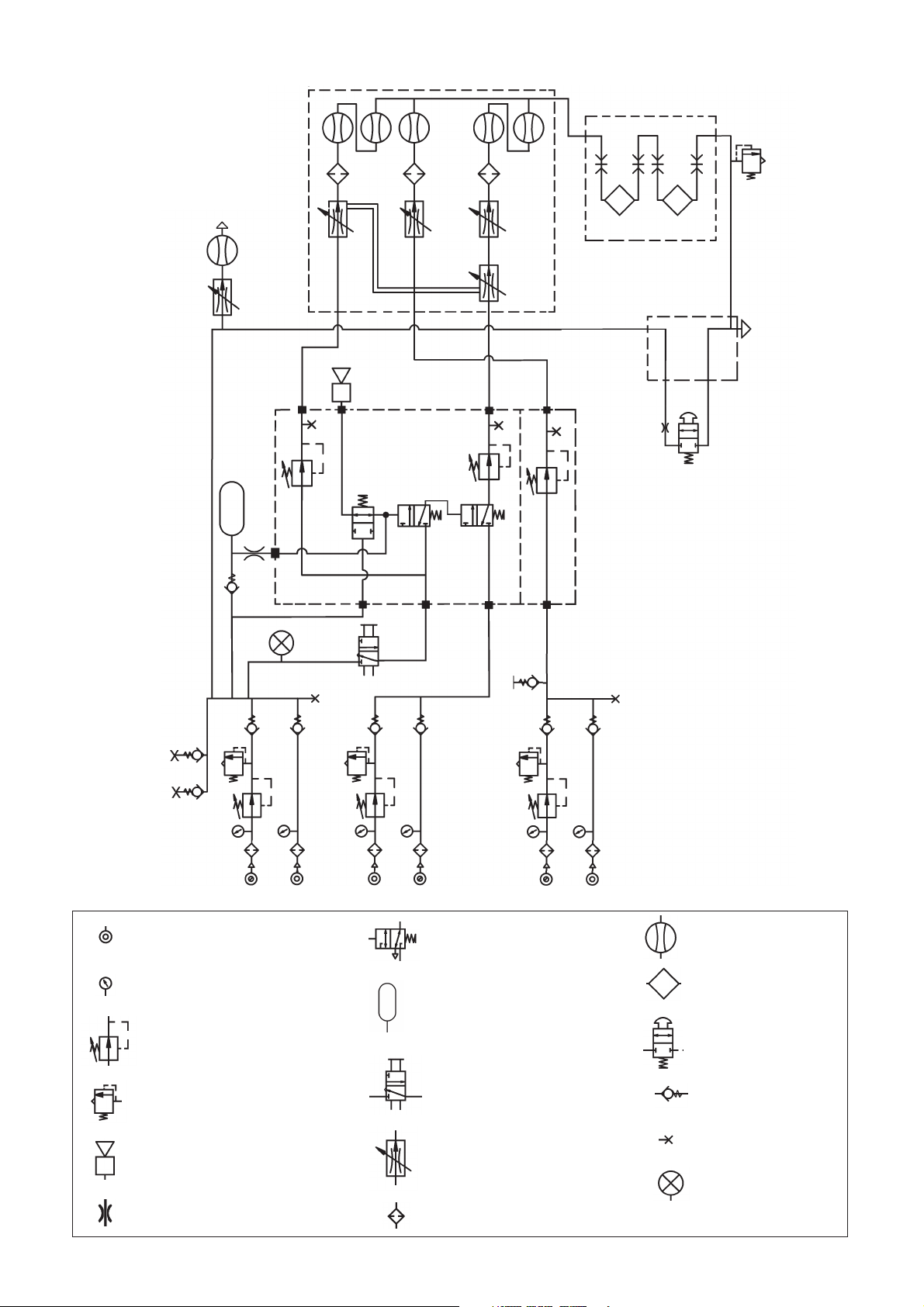

3.2 Gas Circuit

Gas Circuit Schematic

A gas circuit schematic is shown on the

following page.

Gas Supplies

A variety of cylinder and pipeline

combinations can be added to the basic

specification of oxygen and nitrous oxide

cylinder and pipeline supply.

For example, two extra gas cylinders

(choose from one additional oxygen, one

additional nitrous oxide, one air), and one

extra pipeline supply - Air.

Cylinder Yokes

The yokes are rear mounted and conform

with ISO standards for pin-index fitting.

To ensure that only cylinders of the

appropriate gas may be installed the yokes

are designed so that the retaining latch

cannot be closed unless the index pins are

fully engaged.

5

3. DESCRIPTION

Pipeline Inlets (1)

Up to three, rear mounted pipeline gas inlets

can be fitted.

Pipeline supply hoses are connected by

non-interchangeable, screw threaded

unions.

CAUTION

A malfunction of the central gas supply within

your facility may cause immediate cessation of

gas delivery and total anaesthesia system failure.

Filters

To prevent dirt entering the gas system,

cylinder yokes and pipeline inlets are fitted

with filters.

Gas Inlet Block

Each individual cylinder or pipeline supply,

is routed through a separate gas block.

Each gas block has an integral high

pressure gauge tapping for direct mounting

of a pressure gauge, and a non-return valve

to prevent back flow of gas.

In addition, cylinder gas blocks have a

diaphragm pressure regulator to reduce the

pressure of the compressed gas supply, and

a pressure relief valve, factory set to 517

kPa (75 psi). This prevents pressure build up

under the diaphragm should any leakage

develop across the reducing valve seat.

Secondary Pressure Regulator

A second stage regulator reduces the

pressure supplied to each flowmeter control

(see section 4).

The fitment of a secondary regulator for

oxygen and nitrous oxide enhances the

performance of the mechanical AHD system.

Secondary regulation of the air supply aids

the stabilisation of the output at the

flowmeter.

1

6

Prima SP2

USA specification three-

gas machine with dual

cascade oxygen and

nitrous oxide flowmeters.

O2 N2O Air

O

2 Air N2O

Gas Tray

Flowmeter

Assembly

Pneumatic pressure

source

Pressure gauge

Pressure regulator

Pressure relief valve

Audible alarm

Restrictor

Gas cut-off valve

(normally open)

Reservoir

Pneumatic on/off

switch

Flow control valve

(variable)

Filter

Flowmeter

Vaporizer

Oxygen flush valve

Non-return valve

Power take-off point

(or test point)

Visual indicator

3.3 Gas Supply Safety Devices

3.3.1 Gas Supply Cut-off Device

A gas cut-off device, triggered by low oxygen

supply pressure, cuts the supply of nitrous

oxide, and carbon dioxide or other fourth gas

(if fitted).

The cut-off operates when the oxygen

pressure falls to 200 ± 14 kPa (29 ± 2 psig).

Gas supplies are reinstated only when the

oxygen supply pressure rises above 227

kPa (33 psig).

3.3.2 Oxygen Supply Failure Warning

Whistle

WARNING: Refer to WARNING 11 (section 1).

A whistle gives an audible warning when

there is a reduction of oxygen supply

pressure.

Operated solely by the remaining oxygen in

the machine system, the warning whistle is

prolonged by an oxygen reservoir built into

the gas circuit, allowing a minimum warning

whistle of 7 seconds duration.

The whistle will start to sound when the

pressure falls to 200 ± 21 kPa (29 ± 3 psig),

and will continue to sound until the pressure

falls to approximately 70 kPa (10 psig).

Oxygen consumption of the whistle is

approximately 2 L/min when sounding and

nil at other times.

3.3.3 Fresh Gas Pressure Relief Valve

A pressure relief valve is mounted between

the vaporizer back bar and the common gas

outlet (CGO) on the inside face of the

machine right hand upright.

It is designed to prevent fresh gas being

delivered to the breathing system at

pressures exceeding 41 kPa (6 psi).

This valve also protects machine

components against excessive pressure in

the event of a total blockage of the CGO.

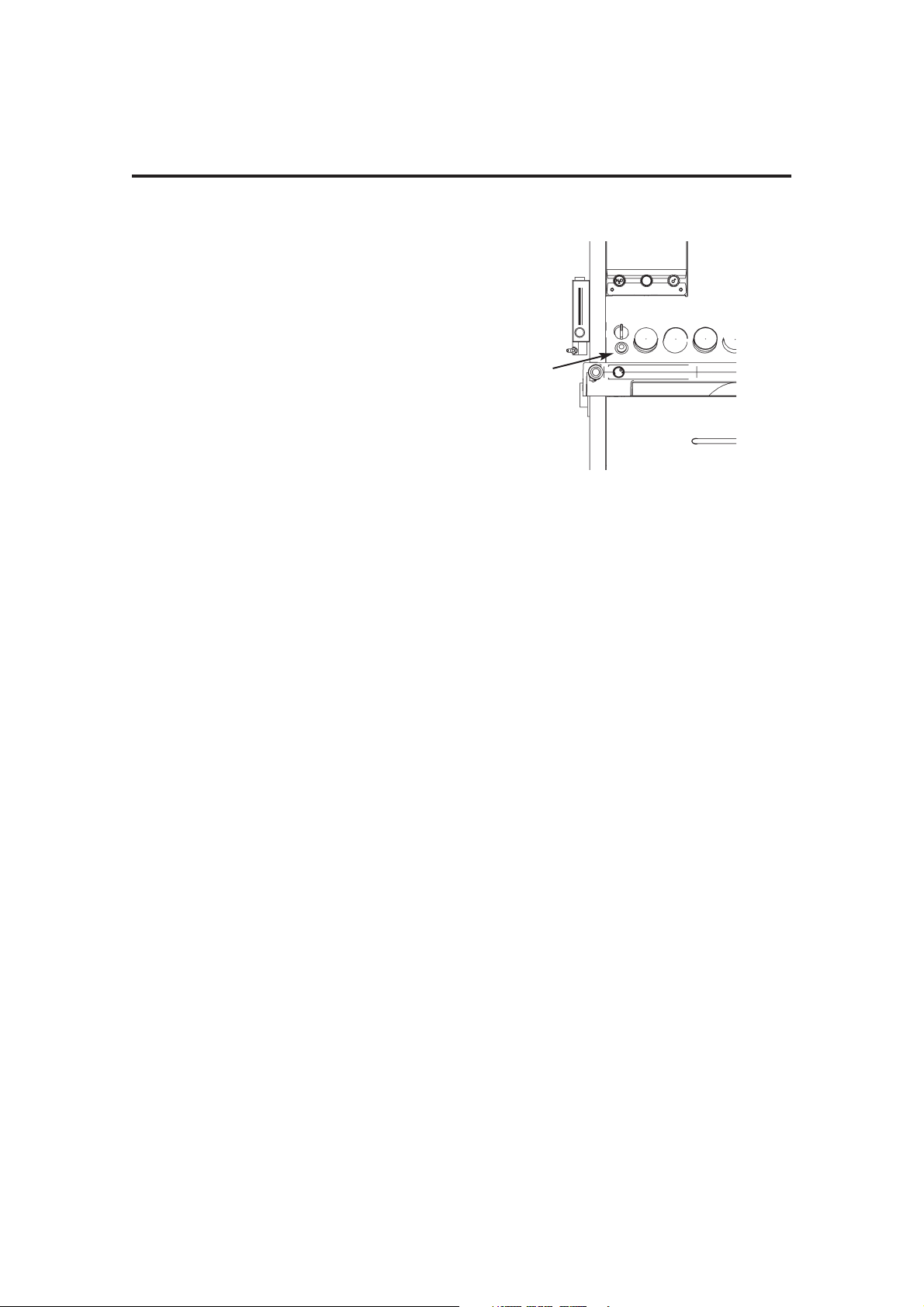

3.3.4 Oxygen Supply Visual Indicator

WARNING: Refer to WARNING 11 (section 1).

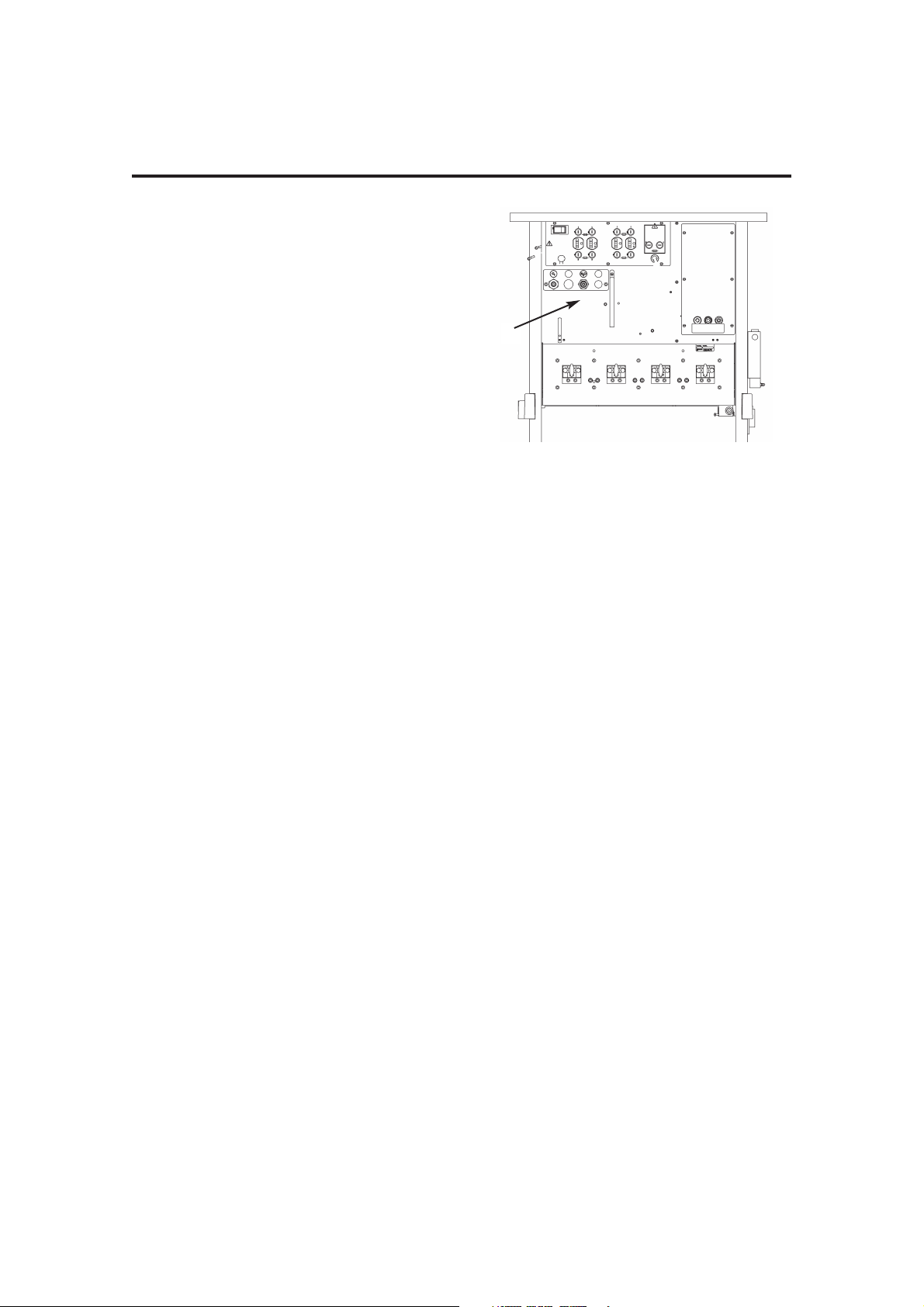

The indicator (1) is mounted on the front of

the machine and is operated from the

oxygen supply and shows GREEN when the

supply is at working pressure, and RED if the

pressure falls.

3.3.5 Mechanical AHD

A mechanical link between the oxygen

control valve and a needle valve in the

nitrous oxide flow ensures that the machine

delivers a fresh gas mixture with a minimum

30% (±3%) oxygen, irrespective of the flow

of nitrous oxide set by the anaesthetist.

With the nitrous oxide control valve fully

open, the oxygen and nitrous oxide flows are

then both controlled by the oxygen control

valve.

See section 3.4 for a full description

3.3.6 Low Pressure Gas Tubing

Diameter-indexed tubing is used for the low

pressure gas system - see section 4.

7

DESCRIPTION

1

3.4 Mechanical AHD

(Anti Hypoxic Device)

3.4.1 Introduction

The Mechanical AHD is housed within the

flowmeter module and comprises a gear

linkage between the oxygen control valve

and a needle valve in the nitrous oxide flow.

The system controls the relative flow rates of

oxygen and nitrous oxide.

A predetermined minimum oxygen

concentration of 30%

±3% in the oxygen /

nitrous oxide mixture is maintained over the

flow range to prevent delivery of a hypoxic

mixture.

3.4.2 Gas Delivery Switch (1)

The Gas Delivery Switch (1) operates on the

oxygen supply and must be in the ‘On’

position for normal operation of the

anaesthetic machine.

The switch consequently controls the supply

of all gases provided with a gas cut-off

triggered by a predetermined pressure level

within the oxygen supply (see section 3.3.1).

A whistle (oxygen failure warning whistle)

will sound briefly whenever the gas delivery

switch is turned on or off. Note that the

whistle functions continuously if the oxygen

supply fails (see section 3.3.2).

NOTE

The switch also controls the electrical supply to

the optional flowmeter lighting unit.

3.4.3 Gear Linkage and Nitrous Oxide

Control Valves

A gear linkage connects the oxygen control

knob on the flowmeter module and a needle

valve in the nitrous oxide flow. This linkage

limits the flow of nitrous oxide relative to the

flow of oxygen set by the user.

Note that this needle valve acts as the

primary nitrous oxide valve, and is actuated

only by movement of the oxygen control.

The nitrous oxide control knob on the

flowmeter module operates a secondary

needle valve in the nitrous oxide flow. It is

positioned downstream of the primary valve

and therefore is used only to restrict the flow

already set by the primary valve, which itself

has been determined by the position of the

oxygen control knob.

Therefore, for any oxygen flow set by the

user, the mixture delivered will still contain a

minimum 30%

±3% oxygen even with the

nitrous oxide control knob fully open.

As the nitrous oxide knob is progressively

closed, the oxygen content of the mixture

increases to 100%.

3.4.4 Oxygen Basal Flow

To allow the system to function correctly, an

oxygen basal flow is continuously supplied.

Single Flow Tubes: 100 - 200 ml/min

Dual Cascade System Flow Tubes:

50 - 75 ml/min

This basal flow can only be turned on and off

by using the Gas Delivery Switch.

CAUTION

The oxygen control is restricted to prevent the

needle valve from fully closing. This ensures a

minimum oxygen basal flow.

DO NOT attempt to close the flow to zero. Do not

overtighten the knob.

3.5 Pressure Gauges

Pressure gauges (50 mm diameter) are

located on the front panel below the

flowmeter bank.

The gauge for Air is positioned between

oxygen and nitrous oxide. Unused gauge

positions are blanked out.

All pressure gauges are colour coded and

labelled for the gases whose pressures they

are indicating.

Cylinder gauges are marked: CYLINDER.

Pipeline gauges are marked: PIPELINE.

The gauges are calibrated in kPa x 100.

8

DESCRIPTION

1

Loading...

Loading...