Prima SP Anaesthetic

Machine Range

User Manual

Quality and Assurance in Anaesthesia

THE IMPORTANCE OF PATIENT MONITORING

WARNING

Anaesthetic systems have the capability

to deliver mixtures of gases and vapours

to the patient which could cause injury or

death unless controlled by a qualified

anaesthetist.

There can be considerable variation in

the effect of anaesthetic drugs on individual patients so that the setting and

observation of control levels on the

anaesthesia systems does not in itself

ensure total patient safety.

Anaesthesia system monitors and patient

monitors are very desirable aids for the

anaesthetist but are not true clinical monitors as the condition of the patient is

also dependent on his respiration and the

functioning of his cardio-vascular system.

IT IS ESSENTIAL THAT THESE ELEMENTS

ARE MONITORED FREQUENTLY AND

REGULARLY AND THAT ANY OBSERVATIONS ARE GIVEN PRECEDENCE OVER

MACHINE CONTROL PARAMETERS IN

JUDGING THE STATE OF A CLINICAL

PROCEDURE.

IMPORTANT

Servicing and Repairs

In order to ensure the full operational life of

this anaesthetic machine, servicing by a

Penlon-trained engineer should be

undertaken periodically.

The machine must be serviced to the

schedule detailed in section 8.

Details of these operations are given in this

Service Manual, available only for Penlon

trained engineers.

For any enquiry regarding the servicing or

repair of this machine, contact the nearest

accredited Penlon agent:

or communicate directly with:

Service Department

Penlon Limited

Radley Road

Abingdon

OX14 3PH

UK

Tel: +44 (0) 1235 547063

Fax: +44 (0) 1235 547062

E-mail: service@penlon.co.uk

Always give as much of the following

information as possible:

1. Type of equipment

2. Product name

3. Serial number

4. Approximate date of purchase

5. Apparent fault

(i)

FOREWORD

This manual has been produced to provide

authorised personnel with information on the

function, routine performance, maintenance

checks and repair procedures applicable to

the Prima SP anaesthetic machine range.

Information contained in this manual is

correct at the date of publication.

The policy of Penlon Limited is one of

continued improvement to its products.

Because of this policy, Penlon Limited

reserves the right to make any changes

which may affect instructions in this manual,

without giving prior notice.

Personnel must make themselves familiar

with the contents of this manual and the

machine’s function before using the

apparatus.

Copyright © Penlon Limited, 2002.

All rights reserved.

(ii)

CONTENTS

Page No.

USER RESPONSIBILITY 01

1. WARNINGS AND CAUTIONS 02

2. PURPOSE 05

3. DESCRIPTION 06

3.1 Framework and General Construction 06

3.2 Gas Circuit NON-AHD MACHINES 07

3.3 Gas Circuit Schematic 07

3.4 Gas Supply Safety Devices 10

3.5 Mechanical AHD 11

3.6 Pressure Gauges 12

3.7 Flowmeters and Controls 13

3.8 Vaporizers 14

3.9 Common Gas Outlet (CGO) Block 15

3.10 Electrical Power Supply 16

3.11 Third/Fourth Gas Options 17

3.12 Auxiliary Gas Outlets 17

3.13 Oxygen Monitor 18

3.14 A100 Absorber 23

3.15 Prima SP Anaesthetic System - MRI Compatibility 23

4. SPECIFICATION 24

4.1 Physical Dimensions 24

4.2 Gas Supplies 25

4.3 Flowmeters 25

4.4 Gas Pressures 26

4.5 Auxiliary Gas Outlets 27

4.6 Oxygen Failure Warning Devices 27

4.7 Oxygen Flush 27

4.8 Mechanical AHD Systems 27

4.9 Environmental 28

4.10 Third and Fourth Gas Options 28

4.11 Electrical Supply 28

4.12 Oxygen Monitor 29

5. PRE-USE CHECKS 31

5.1 Pre-use Check List 31

5.2 Pre-use Checks (Non-AHD Machines) 33

5.3 Pre-use Checks (Machines with Mechanical AHD) 35

5.4 Leak Rate Check 37

5.5 Electrical Supply 37

5.6 Patient Breathing System 38

5.7 Oxygen Flush 42

5.8 Anaesthetic Gas Scavenge System (AGSS) 42

5.9 Alarm System Testing 43

5.10 Vaporizers 44

5.11 Ventilator 44

5.12 Oxygen Monitor 45

(iii)

CONTENTS

6. FUNCTION TEST 49

6.1 Introduction 49

6.2 Machine Frame 50

6.3 Electrical Safety Tests 50

6.4 Pipeline Gas Supply and Non-Return Valve 51

6.5 Cylinder Gas Supply and Pressure Reducing Valves 52

6.6 Flowmeter Unit 54

6.7 Gas Safety Devices 56

6.8 Vaporizers and Back Bar Manifold Assembly 57

6.9 Reduced Pressure Gas Circuit Leakage 58

6.10 Emergency Oxygen Flush Control Test 58

7. FAULT FINDING 59

7.1 Introduction 59

7.2 Fault Diagnosis Table 60

8. SERVICE SCHEDULE 69

8.1 Service Schedule 69

8.2 Six Month Service Checks 69

8.3 Twelve Month Service Checks 72

8.4 Twenty-four Month Service Checks 75

8.5 Seventy-two Month Service Checks 78

9. SERVICING PROCEDURES 82

9.1 Servicing 82

9.2 Ancillary Equipment 82

9.3 Cleaning and Sterilisation 84

9.4 Gas System Components 85

9.5 Internal Gas Pipework 85

9.7 Front Cover - Remove and Refit 88

9.7 Flowmeter Cover 89

9.8 Gear Linkage - Reset 90

9.9 Control Valve Capsule Removal/Replacement 92

9.10 Oxygen Reservoir - Removal/Replacement 93

9.11 Secondary Regulators 94

9.12 Gas Block - Remove and Refit 95

9.13 Selectatec Compatible Manifold Block 96

9.14 Gas Delivery Switch 97

9.15 Air/N2O Interlock Switch 98

9.16 Oxygen Failure Visual Indicator 99

9.17 CGO - Clippard Valve Replacement 100

9.18 Flowmeter Tubes - Removal 101

9.19 Flowmeter Assembly - Removal 102

9.20 Flowmeter Lighting - Removal 103

9.21 Oxygen Monitor - Battery Replacement 104

9.22 Oxygen Monitor Sensor 105

9.23 A100 Circle System Absorber 106

10. SPARE PARTS LIST 107

11. APPENDIX 130

Care of Back-up Battery 130

Product Classification and Labelling Terminology 131

Wiring Diagram - Lighting 132

Wiring Diagram - General 133

(iv)

USER RESPONSIBILITY

This anaesthetic machine has been built to

conform with the specification and operating

procedures stated in this manual and/or

accompanying labels and notices when

checked, assembled, operated, maintained

and serviced in accordance with these

instructions.

To ensure the safety of this device it must be

checked and serviced to at least the

minimum standards laid out in this manual.

A defective, or suspected defective, product

must not under any circumstances be used.

The user must accept responsibility for any

malfunction which results from noncompliance with the servicing requirements

detailed in this manual.

Additionally, the user must accept

responsibility for any malfunction which may

result from misuse of any kind or noncompliance with other requirements detailed

in this manual.

Statements in this manual preceded by the

following words are of special significance:

WARNING means there is a

possibility of injury to

yourself or others.

CAUTION means there is a possibility

of damage to the apparatus

or other property.

NOTE indicates points of

particular interest for more

efficient and convenient

operation.

Always take particular notice of the

warnings, cautions and notes provided

throughout this manual.

Worn, broken, distorted, contaminated or

missing components must be replaced

immediately. Should such a repair become

necessary it is recommended that a request

for service advice be made to the nearest

Penlon accredited agent.

This device and any of its constituent parts

must be repaired only in accordance with

written instructions issued by Penlon

Limited and must not be altered or modified

in any way without the written approval of

Penlon Limited. The user of this equipment

shall have the sole responsibility for any

malfunction which results from improper

use, maintenance, repair, damage or

alteration by anyone other than Penlon or its

appointed agents.

USA and Canadian Federal Law restricts the

sale and use of this device to, or on the order

of, a licensed practitioner.

1

1. WARNINGS AND CAUTIONS

The following WARNINGS and

CAUTIONS must be read and

understood before using this

anaesthetic apparatus.

WARNINGS

1. This apparatus is designed for use

only with non flammable

anaesthetic agents. It must not be

used with or in close proximity to

flammable anaesthetic agents, due

to a possible fire or explosion

hazard.

2. Exterior panels must not be

removed by unauthorised

personnel and the apparatus must

not be operated with such panels

missing.

On machines with an electrical

power supply, there is a possible

electric shock hazard.

during test procedures as well as

during use with a patient.

6. Prima SP machines must only be

used with Sigma Delta vaporizers

(or other vaporizers approved by

Penlon Limited) installed by means

of the Cagemount or Selectatec

system.

Free-standing vaporizers may be

accidentally tipped, resulting in

excessive and uncalibrated

volumes of anaesthetic drug

entering the breathing system

Do not install or connect any

vaporizers of any description

between the Common Gas Outlet

(CGO) and the breathing system

unless they are specifically

designed for such use. (If this is

done, the oxygen flush flow will

pass through the vaporizer and

may result in gross overdosage

when the flush valve is operated.)

3. No oil, grease or other flammable

lubricant or sealant must be used

on any part of the machine in close

proximity to medical gas

distribution components.

There is a risk of fire or explosion.

4. When attaching cylinders of

medical gases ensure that the

machine yoke and cylinder faces

are dust free and clean and that the

sealing washer provided is in

position between the cylinder

valve and the yoke.

Tighten the yoke securely before

opening the cylinder valve. Dust

and dirt presents a fire hazard in

the presence of high pressure gas.

Leakage of high pressure gas can

cause serious injury.

5. Anaesthesia apparatus must be

connected to an anaesthetic gas

scavenging system (AGSS) to

dispose of waste gas and prevent

possible health hazards to

operating room staff.

This requirement must be observed

7. The breathing system which

conveys gases from the

anaesthetic machine to the patient

and disposes of expired gases is a

vital part of the anaesthetic delivery

system.

Because breathing systems require

frequent cleaning and disinfection

they are not a permanent part of the

anaesthetic machine and therefore

cannot be directly under the

control of the anaesthetic machine

manufacturer.

However, we strongly recommend

that only breathing systems which

have been approved and

authorised by Penlon for use with

the Prima SP range should be

employed.

This is particularly important when

mechanical ventilation is

employed.

8. When mechanical ventilation is

employed the patient breathing

system must be connected directly

to an over-pressure relief valve to

prevent the possibility of

barotrauma.

2

WARNINGS AND CAUTIONS

9. Always perform a pre-use check of

the machine, including vaporizers,

ventilator, circle absorber and

monitors before clinical use.

Follow the pre-use checklist (see

section 5) as a minimum

requirement.

Many clinical accidents occur

because of a failure to check for

correct function.

10. The machine must not be used if

any of the alarm, monitoring or

protection system devices are not

functioning correctly.

11. The machine must not be fitted with

more than four operator accessible

mains socket outlets. There is a

risk of an excessive leakage

current.

12. The use of antistatic or electrically

conductive breathing hoses is not

recommended when using high

frequency electrical surgery

equipment (e.g. : Diathermy).

Burns may be caused.

14. Before any electrically powered

machine is used clinically for the

first time, check that the hospital

engineering department has

carried out an earth continuity test.

15. Before using any additional

electrical equipment powered by

the auxiliary sockets on the

machine, check that the additional

equipment is correctly wired and is

earthed through its plug.

A missing or defective protective

earth conductor may increase earth

leakage currents to the patient to

values exceeding the allowable

limits, resulting in ventricular

fibrillation, or interference with the

pumping action of the heart.

Take care when moving a fully

loaded machine, particularly when

negotiating ramps.

Check that hoses or power leads

are not trailing on the floor.

CAUTIONS

1. Flowmeter needle valves are

designed to seal with light torque and

may be damaged if tightened

excessively.

Take particular care with the carbon

dioxide flowmeter control (if fitted); do

not force the control knob past either

the fully open or fully closed positions.

2. Open cylinder valves slowly to avoid

damage to pressure reducing valves.

Ensure that cylinder valves are at

least one full turn open when in use.

3. Under no circumstances should

anaesthetic agents be used for

cleaning purposes.

4. After use, always disconnect the

machine from the piped gas supply

and/or close the gas cylinder valves.

5. Mechanical AHD system - The oxygen

flow control is restricted to prevent the

needle valve from fully closing. This

ensures a minimum basal flow of

oxygen.

DO NOT attempt to close the flow to

zero.

Do not overtighten.

6. Compressed gas supplies must be

clean and dry.

16. Additional equipment placed on the

top shelf must be securely

attached.

3

WARNINGS AND CAUTIONS- O2 Monitor

Oxygen Monitor

WARNINGS

1. We recommend calibration of the

oxygen monitor every time the

system is turned on, as a safety

precaution.

2. Do not attempt to open the fuel

cell. The sensor contains a small

quantity of electrolyte, classified as

a harmful irritant which is

potentially hazardous.

3. ALWAYS check the integrity of the

sensor assembly before use. See

section 3.4.

4. Once exhausted, the sensor must

be disposed of according to

hospital, local, state and federal

regulations.

5. The sensor measures oxygen

partial pressure, and its output will

rise and fall due to pressure

change.

An increase in pressure of 10% at

he sensor inlet will produce a 10%

increase in sensor output.

Using the oxygen monitor

6. When the battery voltage has fallen to the minimum safe level, the

oxygen monitor will automatically

shut down to avoid permanent

damage to the battery.

7. If the internal battery is fully discharged, the oxygen monitor will

not function in the event of mains

power failures.

The battery must be recharged

before the oxygen monitor is used

clinically, otherwise back-up time

can not be guaranteed.

See section 3.13.

CAUTIONS

1. Do not sterilise the oxygen sensor or

control unit components.

These components are not

compatible with sterilisation

techniques and damage may result.

2. Do not autoclave or expose the

sensor to high temperatures.

3. If the sensor shows signs of being

affected by condensation, dry the

sensor with soft tissue.

Do not use heat to dry the sensor.

NOTES

1. The O2 SENSOR FAULT alarm

indicates that one of the following

conditions has occurred.

a) Internal electrical fault

b) Software/electronics fault

c) Oxygen sensor fault.

2. The concentration read-out may, in

certain conditions of excess pressure,

show a value above 100%.

To accommodate these conditions it is

possible to set the high alarm value up

to 105% (see section 5).

3. To maintain maximum sensor life,

always remove the unit from the

breathing circuit after use.

4

2. PURPOSE

The Prima anaesthesia workstation range is

intended to provide controlled

concentrations and flows of anaesthesia

gases into a patient breathing system, from

where the anaesthesia ventilator and

breathing circuit will then deliver this fresh

gas mixture to the patient

Use in conjunction with anaesthetic

vaporizers, breathing hoses and patient

connection fittings which comply with the

relevant ISO standard or equivalent.

Depending upon the patient circuit selected,

the machines can be used in open, semiopen, semi-closed or closed circuit

configurations.

The range has been designed to give a wide

choice of configurations and accessories, as

follows:

Machine size

Prima SP101 Induction machine with a

single vaporizer on the backbar manifold,

and up to three gas cylinders.

Anti-hypoxic Device (AHD)

Machines can be specified with a

mechanical AHD system, designed to

minimise the risk of a hypoxic mixture

reaching the patient, see section 3.

Oxygen monitor (optional)

The Oxygen Monitor is intended to continuously measure and display the concentration

of oxygen in breathing gas mixtures used in

anaesthesia, and is intended for adult, paediatric and neonatal patients.

The oxygen monitor is a module within an

anaesthesia machine.

The oxygen monitor is intended for use by

health care providers, i.e. Physicians,

Nurses and Technicians for use with patients

during general anaesthesia.

Prima SP102 Medium width machine with

capacity for two vaporizers on the backbar

manifold, and up to four gas cylinders.

Gas supplies

SP101 Up to three gases

SP102 Up to four gases (oxygen,

nitrous oxide, carbon

dioxide, and air, with pinindex cylinder yokes (see

above), and provision for up

to three pipeline supply

inlets.

Vaporizer mounting systems

Back bar manifold for Selectatec

Compatible, or Cagemount type vaporizers.

5

3. DESCRIPTION

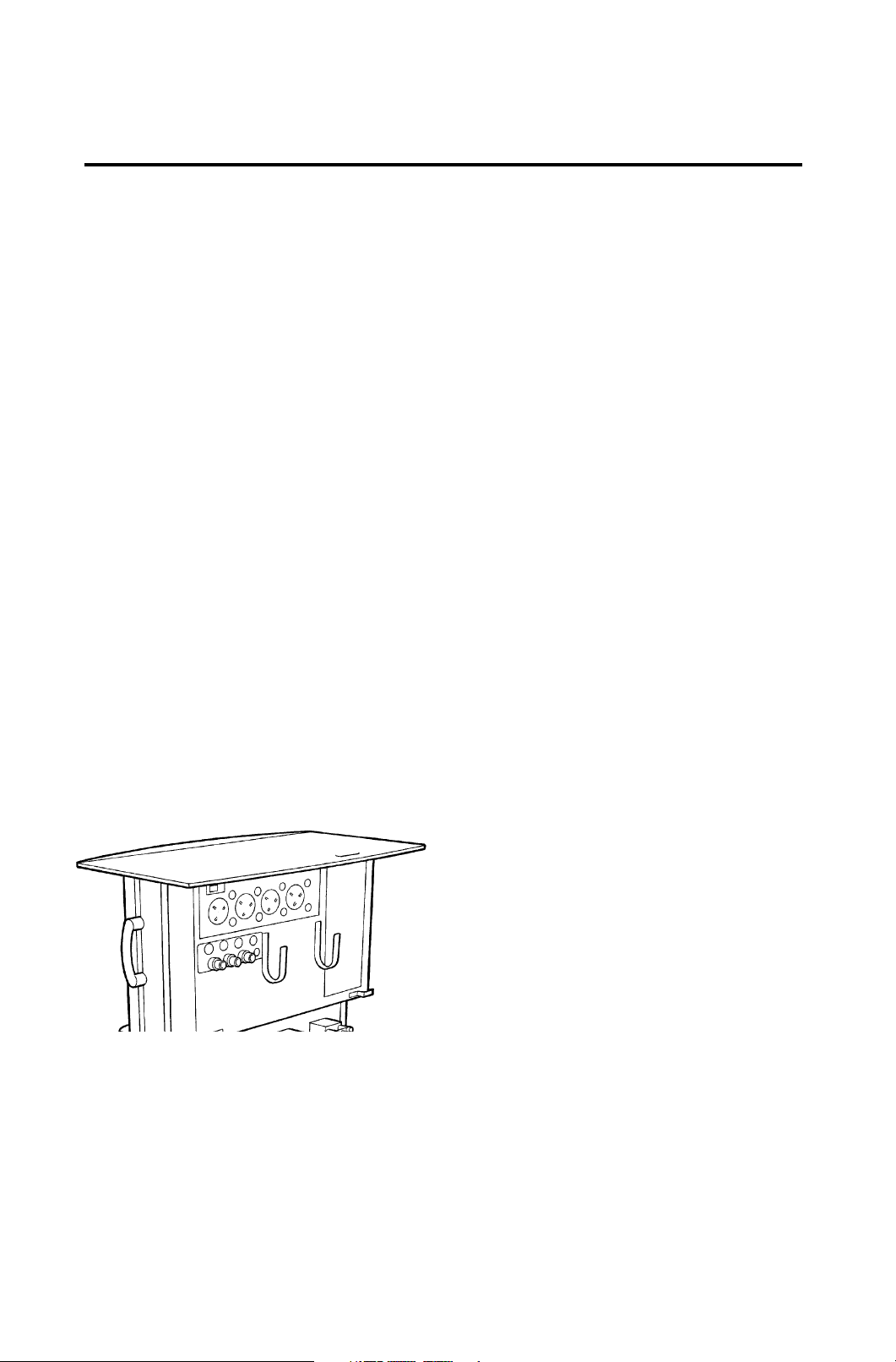

3.1 Framework and General

Construction

Frame

The machine has a cast base, extruded

aluminium uprights, and aluminium panels.

Mobility

Trolley models have four castors, with a

brake on each of the front castors. The

castors are five inches diameter with antistatic rubber.

A footrest is mounted on the front of the

machine.

To aid manoeuverability, two side handles

are provided.

Mounting posts and brackets

A ‘T-slot’ mounting system is built into each

side upright, to allow the use of pole-mount

brackets, V-brackets, and ventilator

mounting brackets.

The pole mount upright (see illustration) can

be used to mount a complete AV-series

Ventilator, or bellows unit only.

V brackets can be used to mount a gas

scavenging system, suction units, and

accessories.

Draw units and work surfaces

The machine can be fitted with a base

drawer unit (as illustrated) plus two

additional smaller drawers.

The work surface has has raised edges to

prevent instruments, vials etc. from rolling

off.

The Prima SP 102 illustrated is equipped

with a standard full-width top shelf unit

suitable for a large monitor, and a pull-out

writing tablet mounted under the work

surface.

Options available include a CPU tray

mounted above the drawer unit.

Prima SP 102 with

standard top shelf

and base drawer unit

Pole mount system

fitted to frame upright

6

DESCRIPTION

3.2 Gas Circuit

Gas Supplies

For each size machine, a variety of cylinder

and pipeline combinations can be added to

the basic specification of oxygen and nitrous

oxide cylinder and pipeline supply.

For example, the Prima SP102 can be supplied with an extra two gas cylinders (choose

from one additional oxygen, one additional

nitrous oxide, one carbon dioxide, one air),

and one extra pipeline supply - Air.

Note a) Kits are available for fitment to

existing machines - see section

9 (Ordering Information).

b) Carbon dioxide is not available

on US specification machines.

Cylinder Yokes

The cylinder yokes are rear mounted and

conform with ISO standards for pin-index

fitting.

To ensure that only cylinders of the

appropriate gas may be installed the yokes

are designed so that the retaining latch

cannot be closed unless the index pins are

fully engaged.

Pipeline Inlets

Machines can be fitted with up to three

pipeline gas inlets mounted on the rear of

the machine.

Pipeline supply hoses are connected by

non-interchangeable, threaded unions.

Filters

To prevent dirt entering the gas system,

cylinder yokes and pipeline inlets are fitted

with filters.

pressure gauge tapping for direct mounting

of a pressure gauge, and a non-return valve

to prevent back flow of gas.

In addition, gas blocks for cylinder supplies

have a diaphragm pressure regulator to

reduce the pressure of the compressed gas

supply, and a pressure relief valve, factory

set to prevent any pressure build up under

the diaphragm should any leakage develop

across the reducing valve seat.

Secondary Pressure Regulator

For oxygen, nitrous oxide, and air, a second

stage regulator reduces the pressure

supplied to the flowmeter controls (see

section 4.4).

The fitment of a secondary regulator for

oxygen and nitrous oxide enhances the

performance of the mechanical AHD system

fitted to some models.

Secondary regulation of the air supply is

utilised to allow connection to high pressure

air pipeline supplies.

Carbon Dioxide Flow Restrictor

On machines with a carbon dioxide supply,

an integral, factory set, flow valve is fitted to

restrict the flow of carbon dioxide to 500

ml/min.

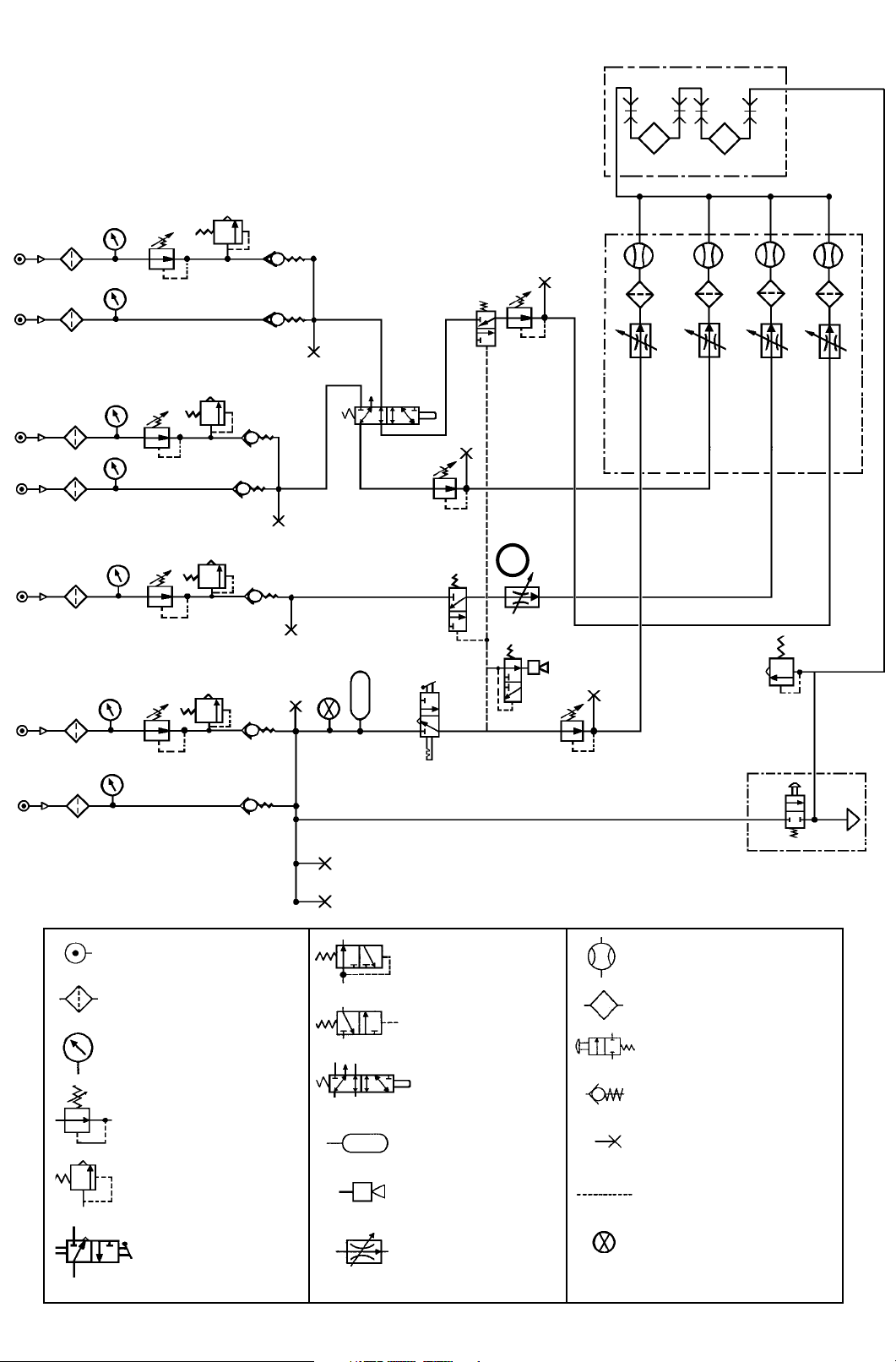

3.3 Gas Circuit Schematics

Gas circuit schematics for:

a) Non-AHD machines

b) Mechanical AHD machines

are shown on the following pages, and both

show a four-gas machine.

All available gas supply options are shown.

Gas Inlet Block

Each individual gas supply, from a cylinder

or pipeline, is routed through a separate gas

block.

Each gas block has an integral high

Note that carbon dioxide is not available for

US specification machines.

7

Prima SP Non-AHD Machine

UK specification four-gas machine

Note: US spec. machines are not fitted with CO

Air

N2O

facility

2

CO

O

2

2

Pneumatic pressure

source

Filter

Pressure gauge

Pressure regulator

Pressure relief valve

Pneumatic on/off

switch

Gas cut-off valve

(normally open)

Gas cut-off valve

(normally closed)

Gas cut-off valve

(open/closed)

Reservoir

Audible alarm

Flow control valve

(variable, but note

that valve 1 is not

user-adjustable)

1

Flowmeter

Vaporizer

Oxygen flush valve

Non-return valve

Power take-off point

(or test point)

Gas reference

connection

Visual indicator

8

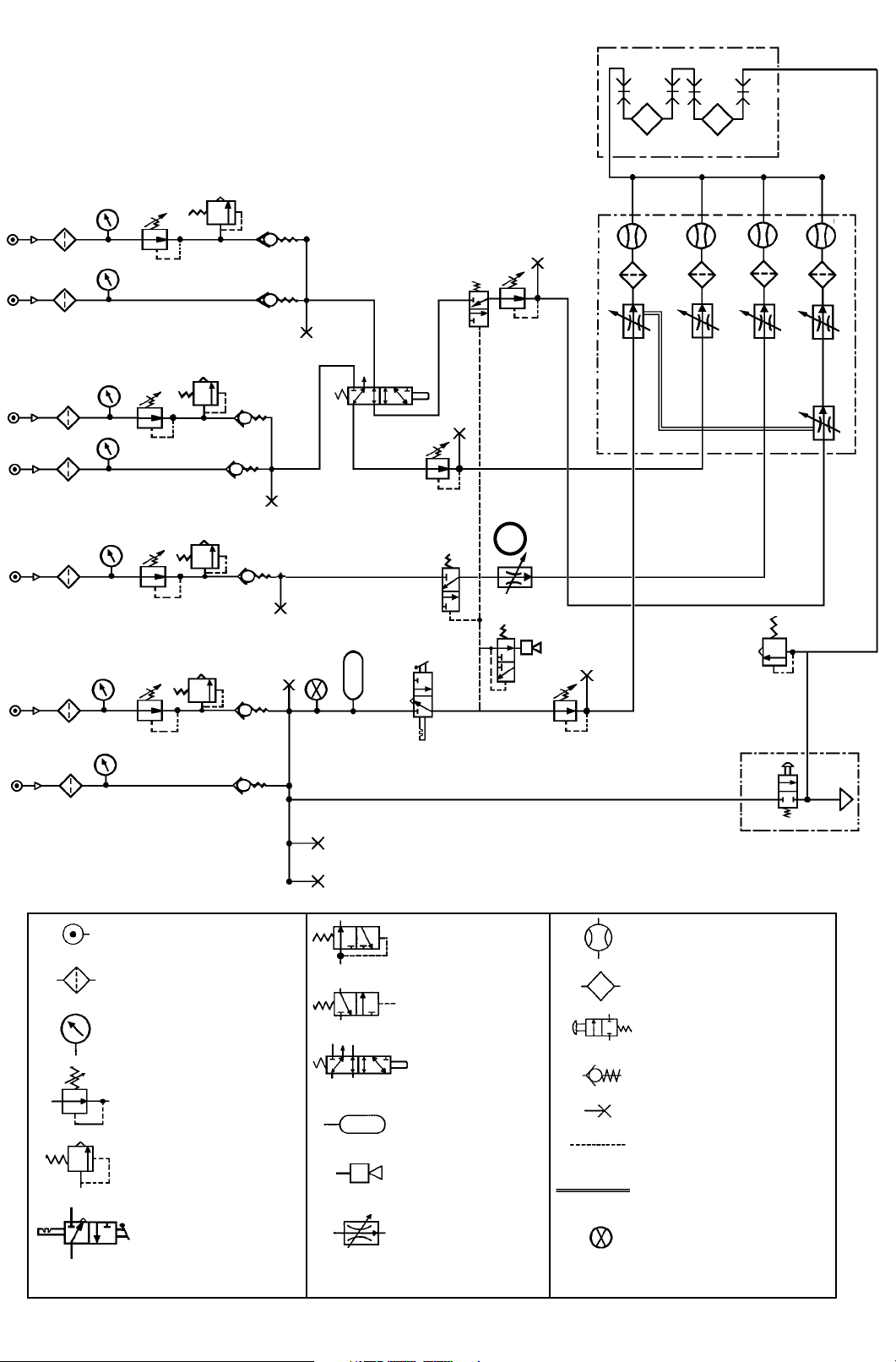

Prima SP Mechanical AHD Machine

UK specification four-gas machine

Note: US spec. machines are not fitted with CO

Air

N2O

facility

2

CO

O

2

1

2

Pneumatic pressure

source

Filter

Pressure gauge

Gas cut-off valve

(normally open)

Gas cut-off valve

(normally closed)

Gas cut-off valve

(open/closed)

Flowmeter

Vaporizer

Oxygen flush valve

Non-return valve

Pressure regulator

Pressure relief valve

Pneumatic on/off

switch

Reservoir

Audible alarm

Flow control valve

(variable, but note

that valve 1 is not

user-adjustable)

9

Power take-off point (or

test point)

Gas reference

connection

Mechanical connection

Visual indicator

DESCRIPTION

3.4 Gas Supply Safety

Devices

3.4.1 Gas Supply Cut-off Device

A gas cut-off device, triggered by low oxygen

supply pressure, cuts the supply of nitrous

oxide, and carbon dioxide (if fitted).

The cut-off operates when the oxygen

pressure falls below 172 kPa (25 psi).

Gas supplies are reinstated only when the

oxygen supply pressure rises above 227

kPa (33 psi).

3.4.2 Oxygen Supply Failure

Warning Whistle

A whistle gives an audible warning when

there is a reduction of oxygen supply

pressure.

Operated solely by the remaining oxygen in

the machine system, the warning whistle is

prolonged by an oxygen reservoir built into

the gas circuit, allowing a minimum warning

whistle of 7 seconds duration.

The whistle will start to sound when the

pressure falls to approximately 172 kPa (25

psi), and will continue to sound until the

pressure falls to approximately 70 kPa (10

psi).

3.4.4 Air/N

(Machines with Air option)

The user can switch

between Air and

Nitrous Oxide (A).

NOTE

a) The machine will

NOT deliver a

mixture of Air and

nitrous oxide.

b) On machines with

Mechanical AHD, the

2/N2O linkage

O

continues to operate.

2O Interlock

B

A

3.4.5 Oxygen Supply Visual

Indicator

The indicator (B) is operated from the

oxygen supply and shows GREEN when the

supply is at working pressure, and RED if

the pressure falls.

3.4.6 CO2 Flow Restriction

The maximum flow of carbon dioxide is

restricted to 500 ml/min by a pre-set flow

control valve.

This valve is not user-adjustable.

Note that carbon dioxide is not available for

US specification machines.

Oxygen consumption of the whistle is

approximately 2 L/min when sounding and

nil at other times.

3.4.3 Fresh Gas Pressure Relief

Valve

A pressure relief valve is mounted between

the vaporizer back bar and the common gas

outlet (CGO) on the inside face of the

machine right hand upright.

It is designed to prevent fresh gas being

delivered to the breathing system at

pressures exceeding 39 kPa (5.4 psi).

This valve also protects machine

components against excessive pressure in

the event of a total blockage of the CGO.

3.4.7 Mechanical AHD

A mechanical link between the oxygen

control valve and a needle valve in the

nitrous oxide flow ensures that the machine

delivers a fresh gas mixture with a minimum

oxygen concentration of 30% ±3%,

irrespective of the flow of nitrous oxide set by

the anaesthetist.

With the nitrous oxide control valve fully

open, the oxygen and nitrous oxide flows are

then both controlled by the oxygen control

valve.

See section 3.5 for a full description

3.4.8 Low Pressure Gas Tubing

Diameter-indexed tubing is used for the low

pressure gas system - see section 4.

10

DESCRIPTION

3.5 Mechanical AHD (Anti

Hypoxic Device)

3.5.1 Introduction

The Mechanical AHD is housed within the

flowmeter module and comprises a gear

linkage between the oxygen control valve

and a needle valve in the nitrous oxide flow.

The system is designed to control the

relative flow rates of oxygen and nitrous

oxide.

A predetermined minimum oxygen

concentration of 30% ±3% in the oxygen /

nitrous oxide mixture is maintained over the

flow range to ensure that a hypoxic mixture

is not supplied from the anaesthetic

machine.

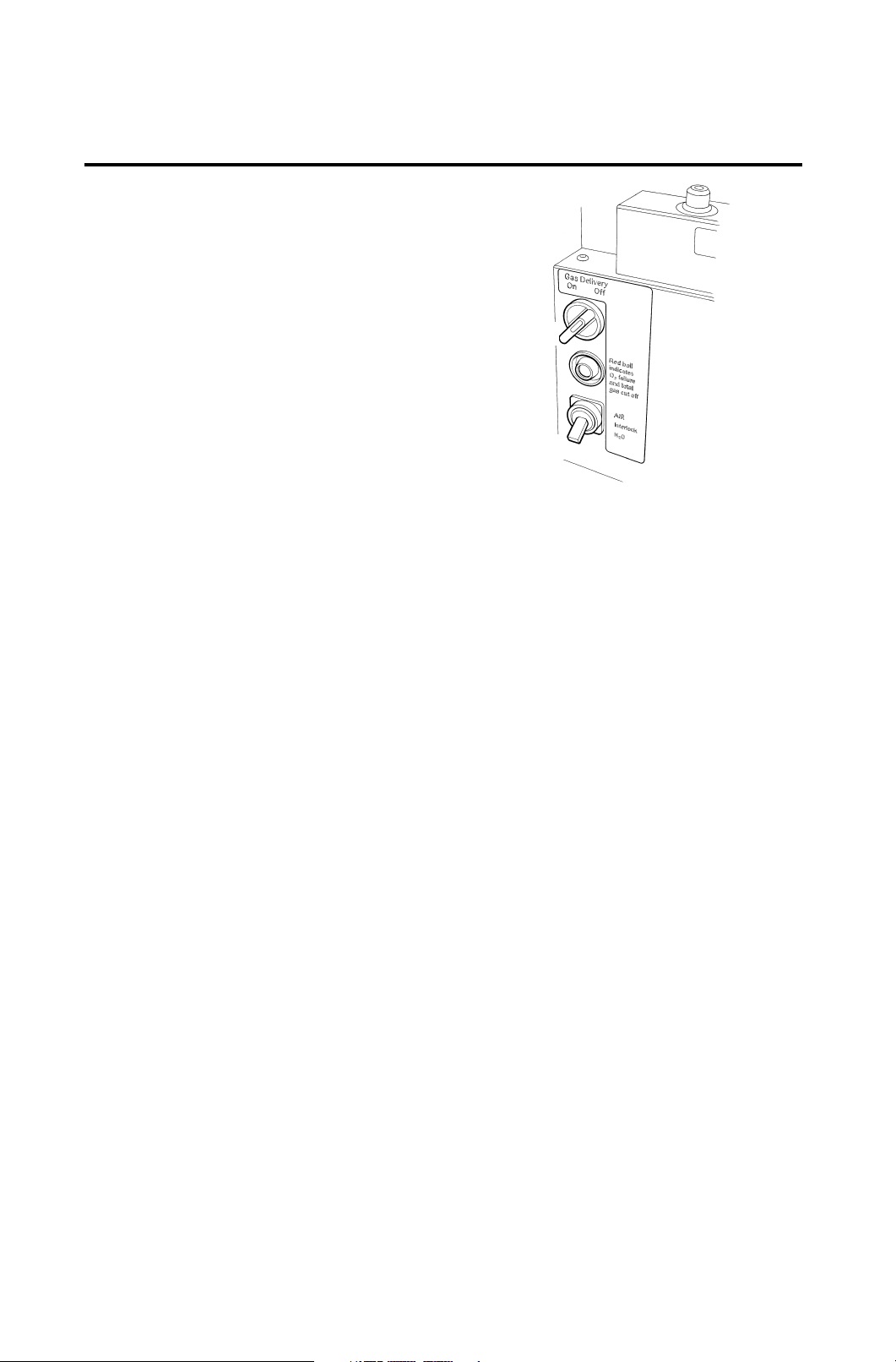

3.5.2 Gas Delivery Switch

The Gas Delivery Switch (A) operates on the

oxygen supply and must be in the ‘On’

position for normal operation of the

anaesthetic machine.

The switch consequently controls the supply

of all gases provided with a gas cut-off

triggered by a predetermined pressure level

within the oxygen supply (see section 3.4.1).

A whistle (oxygen failure warning whistle)

will sound briefly whenever the gas delivery

switch is turned on or off. Note that the

whistle functions normally if the oxygen

supply fails (see section 3.4.2).

The switch also controls the electrical supply

to the optional Flowmeter Lighting unit and

2 Monitor (see section 3.13.2).

O

A

B

NOTE

Machines with an Air supply option are fitted

with an Air/N2O Interlock switch (B).

The machine will NOT deliver a mixture of

Air and nitrous oxide - see section 3.4.4) .

This switch must be in the N

allow a flow of Nitrous Oxide.

The nitrous oxide control knob on the

flowmeter module operates a secondary

needle valve in the nitrous oxide flow. It is

positioned downstream of the primary valve

and therefore is used only to restrict the flow

already set by the primary valve, which itself

has been determined by the position of the

oxygen control knob.

Therefore for any oxygen flow set by the

user, the mixture delivered will still contain a

minimum 30% ±3% oxygen even with the

nitrous oxide control knob fully open. As the

nitrous oxide knob is progressively closed,

the oxygen content of the mixture increases

to 100%.

2O position to

3.5.3 Gear Linkage and Nitrous

Oxide Control Valves

A gear linkage connects the oxygen control

knob on the flowmeter module and a needle

valve in the nitrous oxide flow.

This linkage limits the flow of nitrous oxide

relative to the flow of oxygen set by the user.

Note that this needle valve acts as the

primary nitrous oxide valve, and is actuated

only by movement of the oxygen control.

3.5.4 Oxygen Basal Flow

To allow the system to function correctly, an

oxygen basal flow is continuously supplied

(see section 4.8). This basal flow can only

be turned on and off by using the Gas

Delivery Switch (A).

CAUTION The oxygen control is restricted

to prevent the needle valve from fully

closing. This ensures a minimum oxygen

basal flow.

DO NOT attempt to close the flow to zero.

Do not overtighten the knob.

11

DESCRIPTION

3.6 Pressure Gauges

Pressure gauges (50 mm diameter) are

located on the front panel below the

flowmeter bank.

The gauges for the third and fourth gases (if

fitted) are positioned between oxygen and

nitrous oxide. Unused gauge positions are

blanked out.

All pressure gauges are colour coded and

labelled for the gases whose pressures they

are indicating.

Cylinder contents are marked CYLINDER

and pipeline pressure gauges are marked

PIPELINE.

The gauges are calibrated in kPa x 100.

12

DESCRIPTION

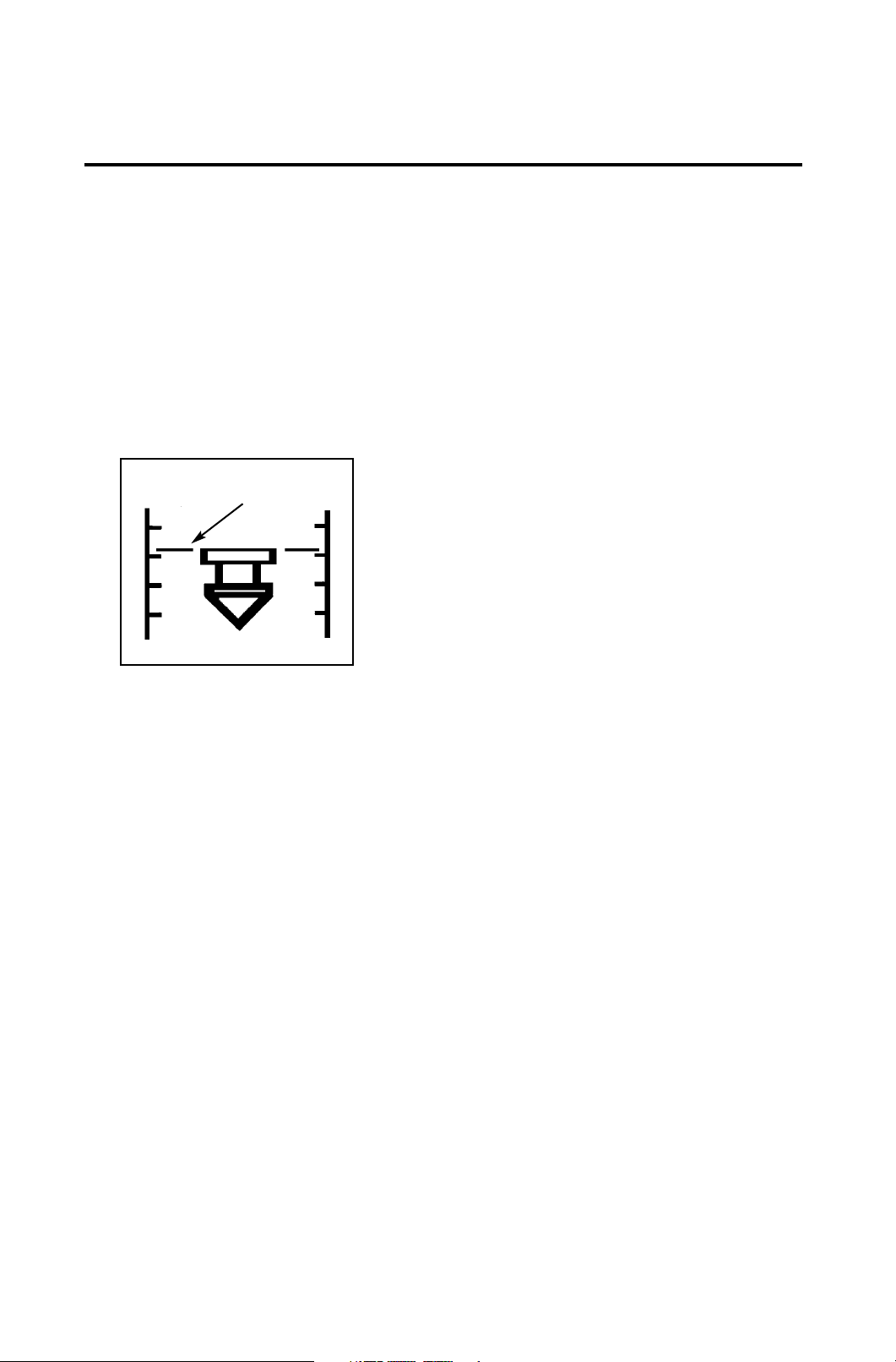

3.7 Flowmeters and

Controls

3.7.1 All models

The flowmeters, mounted behind the

perspex cover on the left hand side of the

machine, are length-indexed to prevent

inadvertent, incorrect installation.

All floats indicate flow rate in line with the

upper surface as shown below.

Read flow at

this level

Each flow control valve is positioned directly

underneath the flow tube assembly to which

it corresponds, and the control knob is

colour-coded for the gas which it controls.

supply of oxygen and must be in the ON

position for normal operation of the

machine.

Flow control of each gas is achieved by a

needle valve comprising a polished stainless

steel needle mounted concentrically in a

common manifold block. To minimise wear

and material pick-up the needle seat is

manufactured from silver. The flow control

knob is turned counter-clockwise to increase

the gas flow.

CAUTION

Needle valves are designed to seal with light

torque and may be damaged if tightened

excessively.

DO NOT USE EXCESSIVE FORCE.

3.7.2 Optional Dual Cascade

Flow Tubes

The flow of gas through dual cascade

system flow tubes always flows through the

low-flow tube first. The high-flow tube will not

show any flow until more than 1 L/min is set.

At flows above 1 L/min, the high-flow tube

reading indicates the rate of flow for that gas.

The oxygen flow control knob is made

physically distinguishable from the other flow

controls for identification by touch in

accordance with ISO standards.

When fitted, air and carbon dioxide

flowmeters are always installed in the inner

positions on the flowmeter assembly. These

positions are blanked out if air or carbon

dioxide are not specified for the machine.

NOTE

Machines with an Air supply option are fitted

with an Air/N

machine will NOT deliver a mixture of Air

and nitrous oxide - see section 3.4.4) .

This switch must be in the N

allow a flow of Nitrous Oxide.

The gas delivery switch, positioned to the

right of the flowmeter bank, controls the

2O Interlock switch (The

2O position to

3.7.3 Carbon Dioxide Flow

Restriction

The maximum flow of carbon dioxide (if

fitted) is restricted to 500 ml/min.

13

DESCRIPTION

3.8 Vaporizers

CAUTION

Read the instruction manual supplied with

the vaporizer before clinical use.

3.8.1 Vaporizer Mounting

Systems

Vaporizers for the administration of volatile

anaesthetic agents can be fitted to

customer’s requirements as follows:

(a) Up to two Penlon Sigma Delta

Selectatec compatible vaporizers

(interlock or non-interlock), mounted

on a Selectatec compatible backbar.

(b) One or two Penlon Sigma Delta

Cagemount vaporizers mounted on a

Modura rail (check that relevant

national standards for your country

allow fitment of more than one

cagemount type vaporizer).

WARNING

Vaporizers must always be securely

mounted, and never used free-standing.

Unmounted vaporizers may be

accidentally tipped resulting in

uncalibrated and excessive volumes of

liquid anaesthetic drug entering the

breathing system.

Vaporizers of any description must not be

installed or connected between the Common

Gas Outlet (CGO) and the Breathing

System, unless they are specifically

designed for such use. (If this is done, the

oxygen flush flow will pass through the

vaporizer, and severe overdosage may

result).

3.8.2 Selectatec Compatible

Vaporizers

Selectatec compatible vaporizers, e.g. the

Sigma Delta with the Selectatec

compatibility block, may be mounted on a

universal back bar manifold built onto the

Prima range as an option.

Single and two-station manifolds are

available, with each station fitted with two

valve capsule assemblies for vaporizer

connector block attachment.

When a vaporizer is installed on a station the

valves on that station open automatically to

allow gas flow into and out of the vaporizer.

Removal of the vaporizer from the station

closes the valves on that station.

Selectatec Compatible vaporizer interlock

systems are described in the literature

supplied with the vaporizer.

3.8.3 Cagemount Vaporizer

Vaporizers fitted with cagemount tapers

have the male taper (inlet port) on the left,

and the female taper on the right (viewing

the front of the vaporizer).

It is recommended that detachable

cagemount connectors are retained with a

safety clip (catalogue number 52275) to

prevent inadvertent disconnection.

14

DESCRIPTION

3.9 Common Gas Outlet

(CGO) Block

The CGO block is mounted on the rail on the

front of the machine, and can be moved

along the rail.

Slacken the securing screw under the block

and carefully slide the block along the rail to

the required position.

Tighten the screw to hold the block in place.

The fresh gas outlet is located on the front

face of the block, with 22 mm male taper and

concentric 15 mm female taper. The male

taper incorporates the Penlon Safelock

system designed to prevent accidental

disconnection of the breathing system.

A high mounting position for the CGO is

available as an option for induction

machines.

Oxygen Flush

An emergency oxygen flush valve button is

mounted on the top front of the CGO block

and is marked ‘O

Depressing the button provides a delivery of

between 35-75 litres/min of oxygen into the

common gas outlet.

Releasing the button allows the springloaded valve to return to its normal position.

2 FLUSH’.

15

DESCRIPTION

3.10 Electrical Power

Supply (if specified)

3.10.4 AV900 or AV800 Ventilator

(if fitted) Power Supply

3.10.1 Mains Power Supply

Power is fed to the machine via the mains

lead, to power an auxiliary output panel, and

optional flowmeter bank light.

NOTE

a) It is the user’s responsibility to ensure

that the total sum of leakage currents from

additional equipment plugged into the

auxiliary sockets plus the leakage current

from the machine does not exceed the

values specified in any relevant national

standards that may apply in the country

where the machine is in use.

b) Each socket is protected with a 5 Amp

fuse.

3.10.2 Auxiliary Power Supply

Sockets (if fitted)

An optional mains electricity auxiliary panel

with three or four sockets can be specified,

and fitted to the rear of the machine.

A

The mains lead for an AV-series ventilator

can be plugged into one of the auxiliary

power sockets on the rear of the machine.

Should the electrical power supply to the

ventilator fail, the ventilator has a battery

back up system to power the ventilator for 60

minutes, if the battery has been maintained

in a fully charged condition.

Reference must be made to the separate

user instruction manual supplied with the

ventilator

Charging of the back-up battery takes place

automatically when the ventilator mains lead

is connected to a ‘live’ mains supply.

The OFF indicator on the ventilator front

control panel will show a yellow light during

charging.

NOTE

The stated battery back-up period will only

be available if the battery is kept fully

charged. After the back-up power supply has

been run down, the ventilator will not

function until the battery is in a fully charged

state.

A fourteen hours recharge will be necessary

to bring the battery to full charge.

The supply to the sockets is controlled by an

ON/OFF switch (A).

3.10.3 Flowbank Lighting

(optional)

The lighting system is controlled by the

main ON/OFF switch (A).

3.10.5 Monitor and Other

Accessories (if fitted)

The mains lead (or adaptor) for a monitor

system or other accessories requiring an

electrical supply can be plugged into one of

the auxiliary sockets on the rear of the

machine.

See 3.13.17.

16

DESCRIPTION

3.11 Third/Fourth Gas

Options

3.11.1 Air

When air is requested as the third/fourth gas,

the machine specification is modified as stated

in 4.10.1.

NOTE

Machines with an Air supply option are fitted

with an Air/N

will NOT deliver a mixture of Air and nitrous

oxide - see section 3.4.4).

This switch must be in the N2O position to

allow a flow of Nitrous Oxide.

3.11.2 Carbon Dioxide

When carbon dioxide is requested as the

third/fourth gas, the machine specification is

modified as stated in 4.10.2.

2O Interlock switch (The machine

Gas supply cut-off devices operate on carbon

dioxide in all machines.

An integral, factory-set flow valve is fitted to

restrict the flow of carbon dioxide to 500

ml/min.

Note that carbon dioxide is not available on US

specification machines.

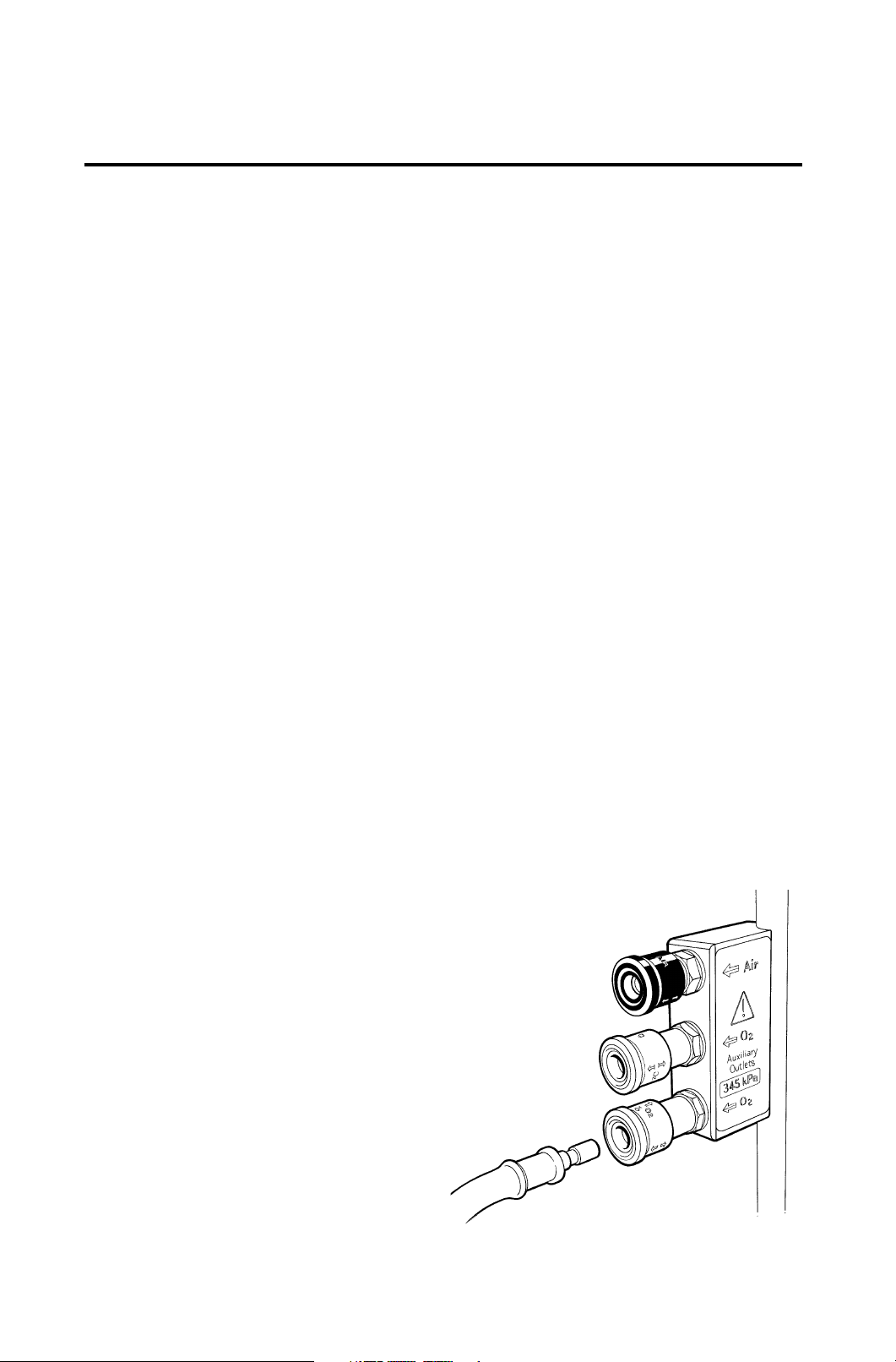

3.12 Auxiliary Gas Outlets

Oxygen

Auxiliary oxygen outlets are mounted on the

right hand side frame upright.

Air

On machines with an air cylinder/pipeline

supply, an auxiliary air outlet is fitted above the

oxygen outlets.

17

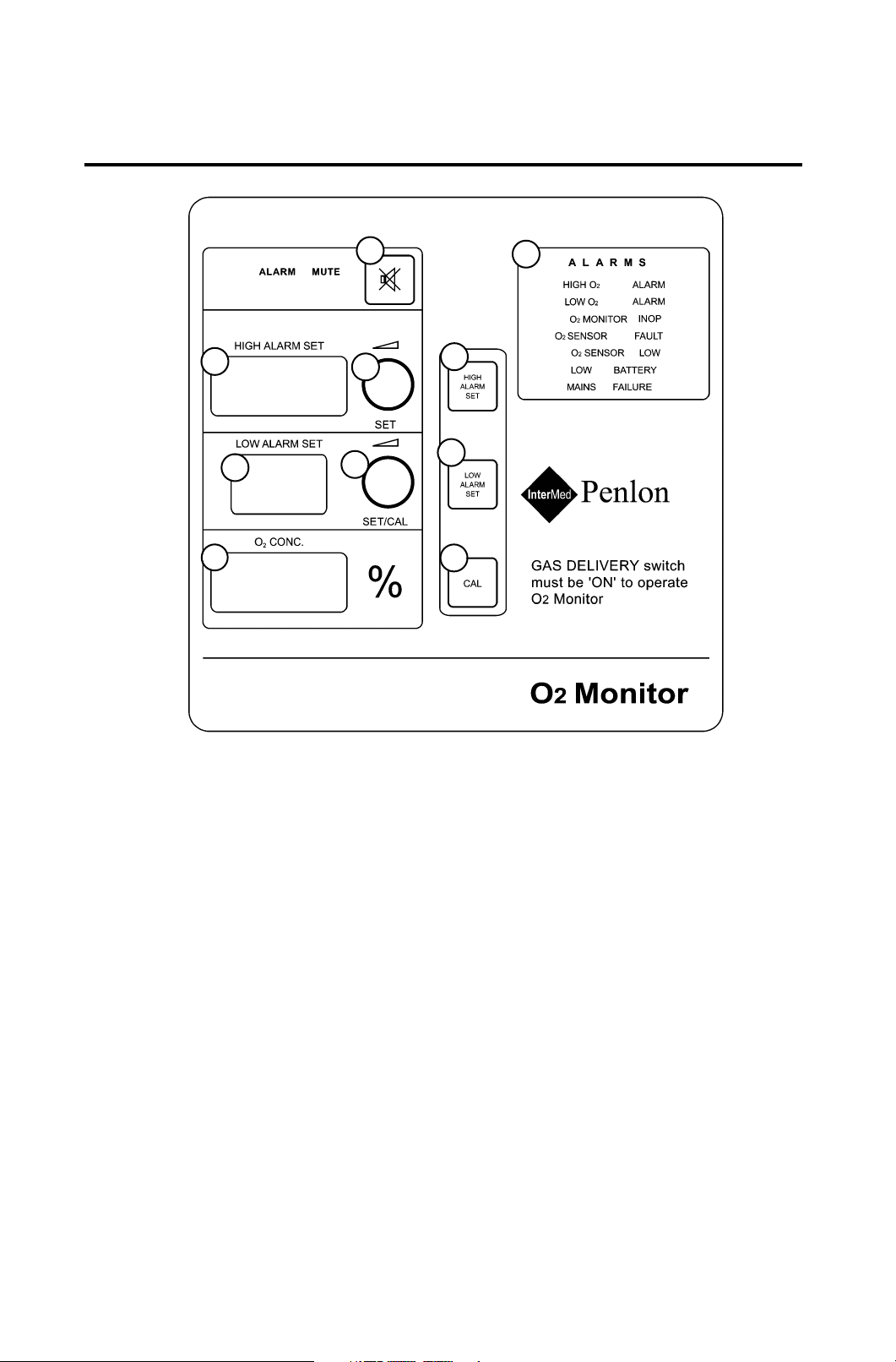

DESCRIPTION - O2 Monitor

3.13 Oxygen Monitor (Optional)

The oxygen monitor continuously measures and

indicates the concentration of oxygen in the breathing

system, and triggers an alarm when the concentration

varies from the set levels.

CAUTION

If your machine is fitted with an AV900 Ventilator with

a built-in Oxygen Monitor, please refer to the AV900

user manual for instructions on setting up and

operation.

3.13.1 System Description

The Oxygen Monitor uses a fast-responding, oxygenspecific, self powered sensor that achieves 90% of

final value in less than 10 seconds.

Sensor life:

approximately 1 500 000 O

20oC

(minimum one year in most normal applications).

2 percent hours at

An external probe is supplied with a 2 m (6 ft)

extendable cable and diverter fitting for a standard 15

mm Tee adaptor. The probe has a safety lock.

The system has user-adjustable high-level and lowlevel alarms with visual and audible indication of

alarm conditions.

Easy-to-read, seven segment LED display for highset, low-set, and oxygen concentration readings.

The monitor is controlled by the machine gas system

master On/Off switch (A).

A back-up battery provides a minimum of 60 minutes

operation in the event of mains failure.

The battery is charged when the machine is

connected to the mains supply.

3.13.2 System On/Off Switch

The switch controls gas delivery from the anaesthetic

machine, and electrical power to the oxygen monitor.

The switch must be in the On position to use the

oxygen monitor and anaesthetic machine.

A

When switched to On, the monitor will always default

to previous settings.

18

DESCRIPTION - O2 Monitor

5

3

2

10

9

1

6

7

8

4

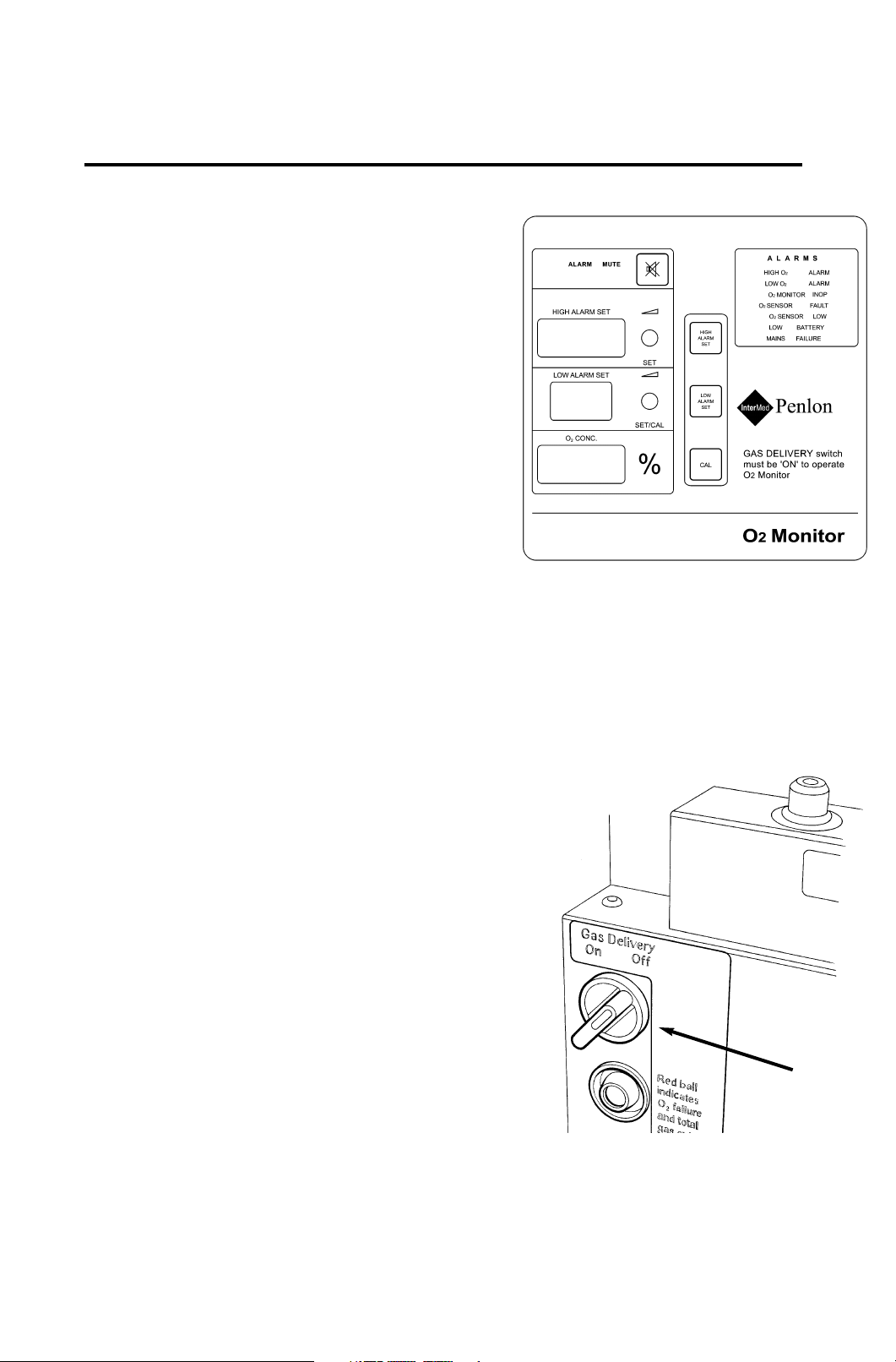

Oxygen monitor control panel

1. O2 Concentration display 6. High set key

2. Low alarm set display 7. Low set key

3. High alarm set display 8. Calibrate key

4. Alarm LEDs 9. Low alarm set / Calibration control

5. Alarm mute key 10. High alarm set control

3.13.3 Displays

Oxygen Percentage Readout

The display provides direct readout of oxygen concentrations in the range of 0-100%.

If the oxygen concentration exceeds 100%, the display will flash.

Low Alarm Set Readout

The indicated value represents the oxygen percentage at which the low alarm will be activated.

The low alarm set value is limited within 18-99%.

To set the low oxygen concentration alarm, see section 3.3.2.

High Alarm Set Readout

The indicated value represents the oxygen percentage at which the high alarm will be activated.

The high alarm set value is limited within 19-105% (Note that in certain conditions of excess pressure,

the readout may show a value above 100%.)

To set the high oxygen concentration alarm, see section 3.3.1.

19

DESCRIPTION - O2 Monitor

3.13.4 Alarm Conditions

HIGH O2 ALARM

The high O

oxygen concentration is 1% above the

setting.

In this alarm condition, a red HIGH O

ALARM LED will flash at a 0.5 second rate,

accompanied by a high priority sound.

To cancel this alarm, the high alarm setting

must be equal to, or above the oxygen

concentration.

LOW O

The low alarm is triggered when the oxygen

concentration is 1% below the setting.

In this alarm condition, a red LOW O

ALARM LED will flash at a 0.5 second rate,

accompanied by a high priority sound.

To cancel this alarm, the low alarm setting

must be equal to, or below the oxygen

concentration.

2 MONITOR INOP (inoperative)

O

This alarm indicates when the oxygen

monitor is in malfunction condition.

It could be triggered by electronic

components failure or software malfunction.

In this alarm condition, a red O

ALARM LED will flash at a 0.5 second rate,

accompanied by a high priority sound.

If this mode occurs you can reset the system

by pressing the ALARM MUTE and LOW

ALARM SET buttons simultaneously for 3

seconds.

2 alarm is triggered when the

2 ALARM

2 MONITOR

will fall very quickly to zero within two to

three weeks of normal usage.

See section 5 for sensor replacement.

NOTE

always remove from breathing circuit after use.

2

LOW BATTERY

To maintain maximum sensor life,

The low battery alarm indicates that the

battery is disconnected or the battery

voltage has dropped below acceptable

limits.

If the monitor is in use under battery power,

and the battery voltage is less than 11.5

volts, a low priority alarm is triggered, to

indicate that the battery has less than 20

2

minutes life left.

If the battery voltage falls to less than 10.8

volts a flashing medium priority alarm is

triggered to indicate there is less than 5

minutes power left in the battery.

To cancel this alarm, mains power must be

On.

NOTE

Penlon Service Centre, or Penlon Customer

Service Department in the UK.

At the end of the final 5 minute warning

period, the oxygen monitor will shut down, to

prevent damage to the battery.

If this condition persists, contact your

MAINS FAILURE

This alarm indicates mains power failure or

cut-off. The yellow MAINS FAILURE LED will

illuminate, and a low priority sound will be

triggered.

2 SENSOR FAULT

O

The alarm is triggered

a) when either the oxygen sensor is

disconnected or approaching the end of its

life.

b) if the the oxygen concentration exceeds

110%.

In the alarm condition, a red O

2 SENSOR

ALARM LED will flash at a 0.5 second rate,

accompanied by a high priority sound.

To cancel this alarm, check the sensor

connection or replace the sensor.

2 SENSOR LOW

O

This alarm indicates the sensor has

approached the end of its life.

The yellow O

2 SENSOR LOW LED will light

up, and a low priority sound will be triggered.

The sensor must be replaced as the output

3.13.5 Alarm Mute

In an alarm condition, pressing the ALARM

MUTE button will deactivate the alarm

sounder but the alarm LED will continue to

flash. The yellow MUTE ALARM LED will

illuminate, accompanied with a SINGLE

‘beep’ sound.

The alarm mute can not be operated:

a) until the mute time is over, or the alarm

condition has been rectified.

b) when the oxygen concentration drops

below 18%.

In high priority and medium alarm conditions

the alarm mute deactivates the sounder for

30 seconds and 120 seconds respectively.

20

DESCRIPTION - O2 Monitor

3.13.6 The MOX-3 Oxygen Sensor

The MOX-3 oxygen sensor offers quick

response, linear output over the entire 0-100%

oxygen range, and long service life.

The MOX-3 is a self-powered galvanic cell that

generates current, and the current is

proportional to the rate of oxygen consumption.

The cell has a highly stable output over its

operating life. Significant output loss is only

shown at the very end of its life.

Typical sensor drift rates are less than 1% per

month when the sensor is exposed to gas in

typical applications.

Sensor lifetime is governed by the mass of lead

available to react with the oxygen and its rate of

consumption. High oxygen partial pressure and

high temperature will increase the sensor

output current, thus shortening the operation

life.

Nevertheless, average sensor life will still

exceed one year.

At the point where all lead has been consumed,

the output will fall very quickly to zero over a

period of two to three weeks.

NOTE

To maintain maximum sensor life, always

remove from breathing circuit after use.

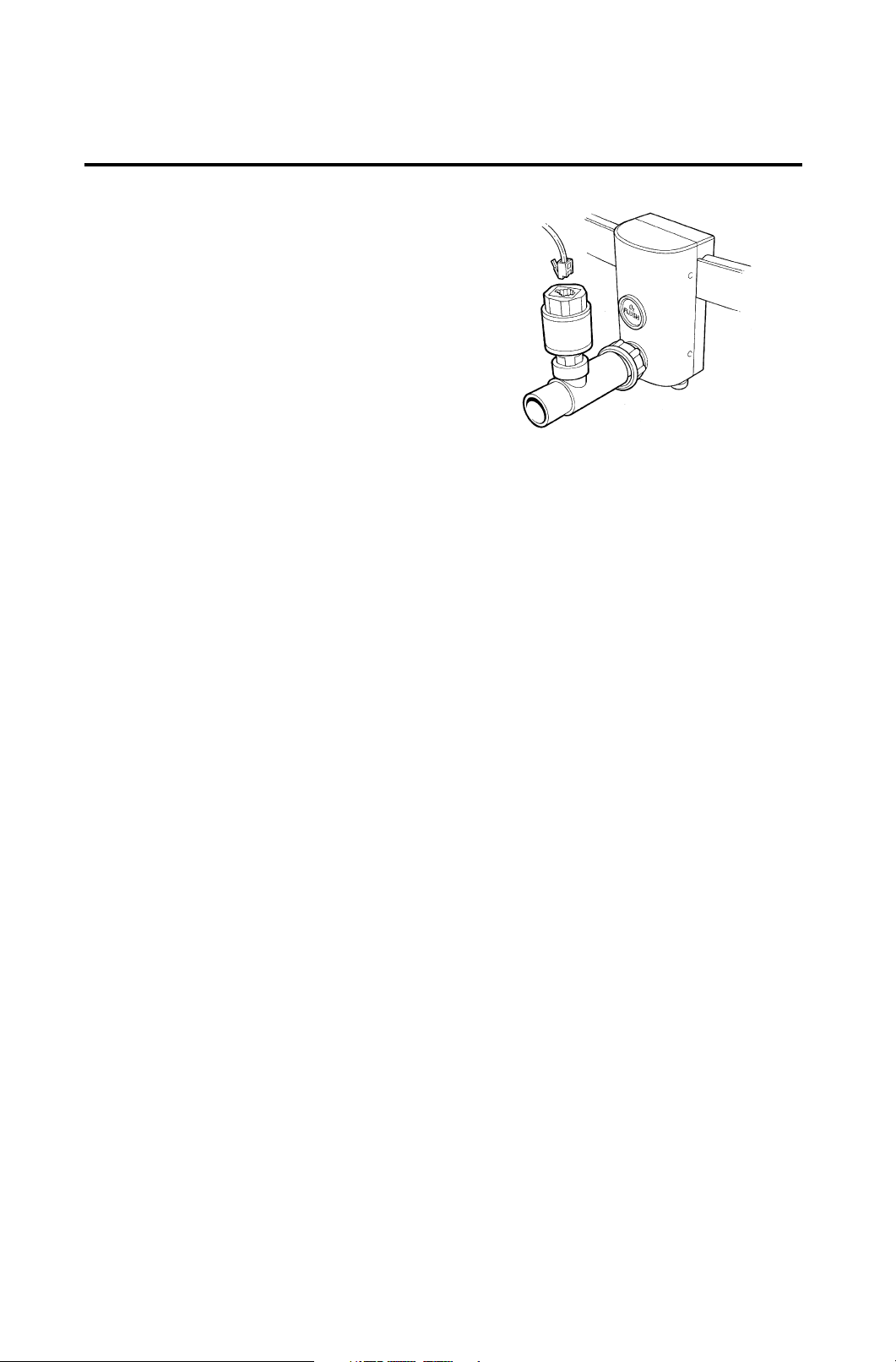

Typical Sensor Installation on

Machine CGO

The sensor assembly consists of an

external probe and 2 m (6 ft) cable and

diverter on a standard 15 mm Tee

adaptor.

On machines with an A100 Absorber,

the probe can also be mounted on the

dome of the inspiratory valve (see section 5).

21

DESCRIPTION - O2 Monitor

3.13.7 Power Supply

Mains Power Supply

Power is fed to the machine via the mains lead to a switching mode power

supply, and the oxygen monitor will be powered up by 14.2 v.

The monitor is controlled by the machine gas system master On/Off switch

(see 3.13.2).

Back-up Battery

Should the electrical power supply to the machine fail, the emergency battery

supply for the unit comes into action automatically.

This is indicated by the illuminated yellow ‘MAINS FAILURE’ LED alarm,

accompanied with a ‘beep’ sound.

The battery is maintained in a fully charged state during normal use (i.e. the

machine connected to the mains power supply).

A fully charged battery will power the unit for a minimum of 60 minutes.

Low Priority Battery Low Alarm

When the battery is discharged, and the mains power supply is not restored,

the ‘BATTERY LOW’ LED alarm will illuminate, accompanied with a low priority alarm sound.

Medium Priority Battery Low Alarm

When the battery is further discharged, and the mains power supply is not

restored, the ‘BATTERY LOW’ LED will flash at a two second rate and a

medium priority audible warning will be given when the minimum safe level of

voltage is reached.

Low Battery Shut Down

WARNING

When the battery voltage has fallen to the minimum safe level, the oxygen monitor will automatically shut down to avoid permanent damage

to the battery.

Recharging the Battery

Charging of the back-up battery takes place automatically when the mains

power supply is on, irrespective of the position of the machine gas system

On/Off switch position.

NOTE

The stated battery back-up period will only be available if the battery is kept

fully charged. After the back-up power supply has been run down, the oxygen monitor will not function until the battery is in a fully charged state. An

eight hours recharge will be necessary to bring the battery to full charge.

22

DESCRIPTION

3.14 A100 Absorber

In-board Mounting

The canister and valve block assemblies are

mounted under the work surface and can be

detached separately for cleaning (see section 7).

3.15 Prima SP Anaesthetic

System - MRI Compatibility

The following Prima SP system components are

MRI compatible:

Prima SP basic* machine

*A 'basic' machine includes any variant of

Back Bar

Flowmeter Bank

Drawers

Monitor Shelves

Additional Gases

A100 Absorber (In-board and pole-mounted)

Nuffield 200 Ventilator

Delta Vaporizer

The following components are currently not

MRI compatible:

Oxygen Monitor

Flowmeter lighting

Electrical power outlets

AV-series ventilator

NOTE

a) MRI Compatible Plastic Laryngoscopes -

see section 3.9 in the Price List.

b) The IDP Pressure Failure Alarm is MRI

compatible when used with appropriate batteries - see section 1.5.3 in the Price List.

23

4. SPECIFICATION

4.1 Physical Dimensions

Overall size: Height x Depth x Width (mm)

SP 101 1475 x 620 x 450

SP 102 1475 x 620 x 570

Work surface height: 890 mm

Work surface size: 690/570/450 x 370 mm

Loading: 30 kg (66 lb) - evenly distributed.

Writing tablet: 300 x 220 mm

Loading: 10 kg (66 lb) - evenly distributed.

Top shelf: 690/570/450 x 370 mm

Loading: 30 kg (66 lb) - evenly distributed.

Mid shelf: 690/570/450 x 370 mm

Loading: 25 kg (55 lb) - evenly distributed

Drawers: 150 x 325 x 500 mm.

Loading: 10 kg (22 lb) evenly distributed

Castors: Front pair braked

Absorber posts: Swivels on a 254 mm radius around the left

hand side frame upright:

Height adjustment 300 to 760 mm

Loading 30 kg (66 lb)

Ventilator bellows post Bushed to accept 25.4 mm (1 inch) or 22

mm (7/8 inch) poles.

Loading 30 kg (66 lb)

Gas scavenging fixing Dovetail clip on frame upright

Loading 30 kg (66 lb)

Common gas outlet: 22 mm male taper with coaxial 15 mm

female taper connections Safelock fitting

Weight:

SP 101 70 kg (154 lb)

SP 102 75 kg (165 lb)

24

SPECIFICATION

4.2 Gas Supplies

Cylinders: Oxygen, nitrous oxide, air, and carbon dioxide

cylinder fittings can be specified to the maximum

numbers given below.

All cylinder yokes are pin-indexed

SP 101 Maximum of three

SP 102 Maximum of four

Pipeline:

SP 101/102 Maximum of three (oxygen, nitrous oxide, air).

All to relevant national standards.

Medical gas colour codes:

Oxygen White* or Green

Nitrous Oxide Blue

Medical Air Black/White* or Yellow

Carbon Dioxide Grey

*To comply with relevant national standards.

Internal pipework is diameter indexed for each gas

Oxygen: 8 mm Carbon Dioxide: 4 mm

Nitrous Oxide 6 mm Air 5 mm

Mixed gas 10 mm

4.3 Flowmeters

Flow ranges:

Single flow tubes

Oxygen: 0 - 10 L/min

Nitrous Oxide: 0 - 10 L/min

Air 0 - 10 L/min

Carbon Dioxide 0 - 700 ml/min (flow limited to 500 ml/min)

Cascade flow tubes

Oxygen /Air /Nitrous Oxide (1) 0 - 1000 ml/min

(2) 0 - 10 L/min

25

SPECIFICATION

Flowmeter Accuracy

The accuracy of the flowmeter tubes is ± 2.5% of full scale reading

Flowmeter construction and dimensions

Tubes and floats are matched, and must not be interchanged.

Flowmeter tubes have antistatic coatings.

Tubes are length indexed:

Oxygen 260 mm (10.24 inch)

Nitrous oxide 250 mm (9.84 inch)

Other gases 240 mm (9.45 inch) (see 3.12)

Scale length 152 mm (6 in) minimum

(all flow tubes except carbon dioxide)

4.4 Gas Pressures

USA/ UK

Canada/

Japan

Pipeline supplies 340 kPa 400 kPa

(50 psi) (60 psi)

Cylinder supplies 310 kPa 380 kPa

(45 psi) (55 psi)

Supply pressure variation ±10% ± 10%

Reduced pressure from regulator 310 kPa

(at 5 L/min flow) (45 psi +2 psi / -5 psi) (55 psi +2 psi / -5 psi)

Regulator diaphragm 2800 kPa 2800 kPa

bursting pressure (410 psi) (410 psi)

Reduced pressure system 510 kPa 610 kPa

safety valve (75 psi) (90 psi)

Safety valve 39 kPa ±10% 39 kPa ±10%

(to protect flowmeter, (5.4 psi) ±10% 5.4 psi ±10%

vaporizer etc.)

Reduced pressure from secondary regulators(at 5 L/min flow)

Machines built from March 2002 onwards

Oxygen and Nitrous Oxide 152 - 241 kPa (22 - 35 psi)

Air 241 - 276 kPa (35 - 41 psi)

Machines built before March 2002

All gases 207 - 283 kPa (30 - 41 psi)

+15 kPa / -35 kPa 370 kPa +15 kPa / -35 kPa

26

SPECIFICATION

4.5 Auxiliary Gas Outlets

Oxygen

Two self sealing connections on side frame upright

Oxygen supply at pipeline pressure 340 kPa (50 psi)

Total flow rate: not less than 100 L/min to free air

80 L/min against 243 kPa (36 psi) resistance

70 L/min against 270 kPa (40 psi) resistance

50 L/min against 297 kPa (44 psi) resistance

Air

One self sealing connection on side frame upright.

4.6 Oxygen Failure Warning Devices

1. Gas system whistle

2. Visual indicator, direct pressure operated

4.7 Oxygen Flush

Button on CGO block

The system supplies 35 - 75 L/min when fully depressed.

4.8 Mechanical AHD System

Minimum oxygen concentration 30% ±3% of total O2 + N2O flow

Oxygen basal flow

All models - up to March 2002

Oxygen basal flow 100-200 ml/min

Cascade flowmeter models - March 2002 onwards

Oxygen basal flow 50-75 ml/min

Single flowmeter models - March 2002 onwards

Oxygen basal flow 100-200 ml/min

Reduced pressure from secondary regulators See section 4.4

27

SPECIFICATION

4.9 Environmental

Operating Conditions

Temperature

Storage and transport:

Basic machine -5 to 60oC (23 to 140oF)

Oxygen monitor option -5 to 50oC (23 to 122oF)

Operating ambient +10 to 38oC (50 to 100oF)

Atmospheric pressure range 70 kPa to 106 kPa

Altitude 2438 m (8000 ft) maximum

Humidity 10 - 95% R.H. non-condensing.

MRI Compatibility See section 3.15

Cleaning Wipe external surfaces with dry or damp cloth.

Use mild soap, or disinfectant solution if necessary.

4.10 Third and Fourth Gas Options

4.10.1 Air

Air flowmeter range: 0 - 10 L/min.

Cascade low flow tube: 0 - 1000 ml/min

Cylinder yoke pin-indexed for medical air.

Pipeline inlet for air.

Cylinder contents gauge.

Pipeline pressure gauge.

Air pipework is colour coded at each junction.

4.10.2 Carbon Dioxide

Carbon dioxide flowmeter range: 20 - 700 ml/min (flow restricted to 500 ml/min).

Cylinder yoke pin-indexed for carbon dioxide.

Cylinder contents gauge

Carbon dioxide pipework is colour coded at each junction.

4.11 Electrical Supply (if fitted)

Standard: 5.5 amp, 220-240 v, 50 Hz

Optional: 6 amp, 110-120 v, 60 Hz

Permanently attached 3 metre lead, with stowage hooks for cable on rear of machine.

Auxiliary electrical power outlets (if fitted):

SP102 4 outlets

SP101 3 outlets

Max. total current 5 amp

Battery back-up (oxygen monitor):

12v, 1.8-1.9 AH, rechargeable sealed lead acid battery.

Provides a minimum of 20 minutes operation.

28

SPECIFICATION - O2 Monitor

4.12 Oxygen Monitor

Measurement Range: 0-l00%

Resolution: ±1%

Accuracy and Linearity: ±2% of full scale (at constant temperature and pressure)

Response Time: 90% of final value in approx. 10 seconds (air to 100% O

Operating Temperature: +10 to 38oC(50 to 100oF)

Storage Temperature: -5°C to 50°C (23°F to 122°F )

Transport Temperature: -5°C to 50°C (23°F to 122°F )

Relative Humidity Range: 5%-95% (non-condensing)

Battery Back-up: See section 4.11

Sensor Type: MOX-3 galvanic fuel cell

High Priority Alarm: Flashing, 5 audio pulses with 6 seconds repeat time.

Medium Priority Alarm: Flashing, 3 audio pulses with 24 seconds repeat time

Low Priority Alarm: Static with single beep sound

Alarm Mute: 30 seconds for high priority alarm

120 seconds for medium priority alarm

Low Alarm Set Range: 18%-99% (+/- 1%)

High Alarm Set Range: 19%-105% (+/- 1%)

2)

Cable length: 2 m (6 ft), fully extended

Sensor

Type: Galvanic fuel cell sensor (0-100%)

Life: One year minimum in typical applications

Interference Gases and Vapours (in 30% Oxygen, 70% Nitrous Oxide)

Interference Volume % Dry Interference in O2%

Nitrous Oxide 80% <1%

Carbon Dioxide 5% <1%

Halothane 5% <1%

Enflurane 5% <1%

lsoflurane 5% <1%

Sevoflurane 5% <1%

Humidity Effects

Sensor output is relatively unaffected by prolonged operation in either high or very low relative

humidity.

If the sensor shows signs of being affected by condensation, dry the sensor with soft tissue.

CAUTION DO NOT use heat to dry the sensor.

29

SPECIFICATION - O2 Monitor

Oxygen Monitor - continued

Temperature Effects

The sensor has a built-in temperature compensation circuit, and is relatively unaffected by

temperature changes within the operating temperature range given above.

Pressure Effects

The sensor measures O2

change (e.g. changes in barometric pressure, or breathing system pressure).

An increase in pressure of 10% at the sensor inlet will produce a 10% increase in sensor

output.

MRI Compatibility

The oxygen monitor system is not MRI compatible (see section 3.15 for additional information).

partial pressure, and its output will rise and fall due to pressure

30

5. PRE-USE CHECKS

5.1 Pre-use Checklist

A pre-use checklist for the Prima SP range of

machines is printed on the next page.

This checklist is also supplied with the

machine.

Where necessary, subsequent sections in this

manual provide an explanation and procedure

for setting up the machine and ancillary

equipment and the various checks that must

be carried out before clinical use.

In addition, checks specific to non-AHD

machines, and mechanical AHD machines

are explained in separate sub-sections:

5.2 Non-AHD machines

5.3 Machines with mechanical AHD

Details of checks common to ALL types of

machine (e.g. Check correct connection and

functioning of vaporizers) are explained in

sections 5.4 onwards.

WARNING

Pre-use checks must be performed before

each period of clinical use.

These checks must be supplemented by

periodic Function Testing, and full Service

Testing by a Penlon-trained engineer to the

Service Schedule given in the Prima SP

Service Manual.

These checks will not in themselves ensure

the safe use of the apparatus, which remains

the responsibility of the qualified practitioner

in charge of it.

31

PRE-USE CHECKS

PRE-USE CHECKLIST

The machine must be carefully inspected and checked as follows.

An incorrectly functioning machine must be repaired by a suitably

qualified person before use.

1. Check for visible damage, machine stability, and condition of gas

supply hoses.

2. Check for labelling which may indicate status of machine, including

faults or recent servicing.

3. Check correct connection of electrical supply.

4. Check correct connections of gas supplies.

5. Check adequate pipeline supply and back-up cylinder supply.

6. Switch on gas delivery switch, and note special operating system:

Check functioning of flowmeters.

Check function of Mechanical AHD.

Check function of Air/N

7. Check correct connection and functioning of the vaporizers.

8. Check functioning of oxygen flush.

9. Check leak rate of low pressure gas system.

10. Check the integrity of the patient circuit.

11. Test the alarm system.

2O interlock switch.

Refer to Section 5 in the User Manual for further information.

Ancillary equipment

12. Check operation of the AGSS.

13. Check functioning of ventilator, including disconnect alarm.

14. Check that the oxygen analyser and other patient monitoring

equipment functions correctly.

Refer to the relevant user manual for further information.

32

PRE-USE CHECKS - (Non-AHD Machines)

5.2 Pre-use Checks - Gas Supply

(Non-AHD Machines)

5.2.1 Gas Pipeline Supplies

1. Connect the oxygen pipeline hose only.

Check that the warning whistle sounds briefly when the hose

is connected.

Check that the correct pressure gauge reading is obtained.

2. Switch the Gas Delivery Switch (A) to ON.

On machines with Air, set the Air/N

2O.

N

Open the oxygen and nitrous oxide flowmeter needle valves.

Check that flow is only shown in the oxygen flowmeter.

3. Close the flowmeter valves.

4. Connect the other pipeline hoses in turn.

Check the gauge reading for each gas.

For Air, set the interlock switch (B) to Air,

2O interlock switch (B) to

5.2.2 Gas Cylinder Supplies

CAUTION

Open the cylinder valves slowly to avoid damage to the pressure reducing

valve and pressure gauges. Ensure that valves are at least one full turn

open when in use.

A

B

1. Fit the gas cylinders to their respective yokes, open the

cylinder valves one at a time.

Check the contents on each pressure gauge.

NOTE

A) When two cylinders are provided for a single gas, test each separately,

clearing pressure after each test by opening the flowmeter valve.

B) Turn off the reserve cylinders during normal use.

2. Open the cylinder valve of the third and fourth gas cylinders (if

fitted).

Check the reading on the pressure gauge for each gas.

3. Ensure that all flowmeters are kept closed until gas supplies

are required.

5.2.3 Flowmeters

1. Operate each flowmeter control knob in turn.

Check that the full scale of flow can be obtained and that the

floats in all tubes move freely and rotate when at a steady

flow.

On machines with Air, use the interlock switch (B) to select Air

2O in turn.

and N

Check the supply for each gas.

2. Check that the flow can be turned off by gentle rotation of the

knob and that the floats reseat on the bottom stop.

3. On machines with optional dual cascade flow tubes, check

that gas flow is through the low flow tube initially, then through

the high flow tube.

33

PRE-USE CHECKS - All models

5.2.4 Air/N2O Interlock

(machines with Air supply option)

1. Switch the Gas Delivery Switch (A) to ON.

2. Set the Air/N

3. Open the Air flowmeter control and check that

Air is delivered.

4. On machines with mechanical AHD, turn on the

oxygen supply at the flowmeter.

5. Open the N

6. Check that N2O is NOT delivered.

7 Set the Air/N2O Interlock switch to N2O.

8. Check that the flow of Air has stopped.

9. Check that N

2O Interlock switch (B) to Air.

2O flowmeter control.

2O is now delivered.

A

B

For additional checks on non-AHD

machines, see sections 5.4 onwards

34

PRE-USE CHECKS - Machines with Mechanical AHD

5.3 Pre-use Checks - Gas Supply

(Machines with Mechanical AHD)

5.3.2 Gas Pipeline Supplies - Machines

1. Connect the oxygen pipeline hose only.

2. Turn on the Gas Delivery switch (A).

3. Open both oxygen and nitrous oxide flowmeter

4. Close both valves.

5. Connect the other pipeline hoses.

with Mechanical AHD

Check that the correct pressure gauge reading is

obtained.

Check that the warning whistle sounds briefly.

Check that a basal flow of oxygen is delivered, as

follows:

All models - up to March 2002 100-200 ml/min

Cascade O2 flowmeter

- March 2002 onwards 50-75 ml/min

Single O

- March 2002 onwards 100-200 ml/min

valves.

On machines with Air, set the Air/N

switch (B) to N2O.

Check that flow is only shown in the oxygen

flowmeter.

Turn off the Gas Delivery switch.

Check that the warning whistle sounds briefly, and

that the oxygen basal flow is stopped.

Check the gauge reading for those gases.

2 flowmeter

2O interlock

CAUTION

On machines fitted with a mechanical AHD, the

oxygen flowmeter control is restricted to prevent

the needle valve from fully closing.

This ensures a minimum oxygen basal flow.

DO NOT attempt to close the flow to zero.

Do not overtighten the knob.

A

B

5.3.3 Gas Cylinder Supplies

CAUTION

Open the cylinder valves slowly to avoid damage to the

pressure reducing valve and pressure gauges. Ensure

that valves are at least one full turn open when in use.

1. Fit the gas cylinders to their respective yokes,

open the cylinder valves one at a time and check

the contents on each pressure gauge.

NOTE

A) When two cylinders are provided for a single gas, test

each separately, clearing pressure after each test by

opening the flowmeter valve.

B) Turn off the reserve cylinders during normal use.

2. Check the third and fourth gas cylinders (if fitted),

open the cylinder valve and check the contents on

the pressure gauge.

3. Ensure that all flowmeters are kept closed until gas

supplies are required.

35

PRE-USE CHECKS - Machines with Mechanical AHD

5.3.4 Flowmeter - Machines with

Mechanical AHD

1. Turn on the Gas Delivery switch (A) .

Check that the warning whistle sounds briefly.

Check that a basal flow of oxygen is delivered, as

follows:

All models - up to March 2002 100-200 ml/min

Cascade O2 flowmeter

- March 2002 onwards 50-75 ml/min

Single O

- March 2002 onwards 100-200 ml/min

2. On machines with Air, set the Interlock switch

(B) to N2O.

3. Open the nitrous oxide needle valve and check that

there is no nitrous oxide flow.

4. Operate the oxygen flowmeter needle valve.

Check that full scale of flow of oxygen and nitrous

oxide can be achieved, and that the floats in both

tubes move freely and rotate when at a steady flow.

5. Check that the nitrous oxide flow can be turned off

by gentle rotation of the oxygen knob.

Check also that the nitrous oxide float reseats on

the bottom stop, and that the oxygen basal flow

resets to 150 ml/min.

6. Operate the other control knobs in turn to check:

the full scale of flow can be obtained;

the floats move freely and rotate at a steady flow;

the flow can be turned off by gentle rotation of the

knob; and that

the floats reseat on the bottom stop.

2 flowmeter

A

B

7. On machines with Air, set the interlock switch (B) to

Air, to check the supply for this gas.

8. On machines with optional dual cascade flow

tubes, check that gas flow is through the low flow

tube initially until full flow is achieved, then through

the high flow tube.

For additional checks on machines

with mechanical AHD, see sections 5.4

onwards.

36

PRE-USE CHECKS - All models

5.4 Leak Rate Check - Low

Pressure Gas System

1. Attach a side branch connector to the fresh

gas outlet on the CGO block outlet.

Connect the side branch tube to a

manometer.

2. Set a flow of 100 ml/min of oxygen.

Block the open port of the connector with a

finger.

The pressure in the low pressure gas

system will rise and be displayed on the

manometer.

3. Check that the pressure rises to at least

100 mmHg.

Release the finger seal immediately the

pressure is reached.

CAUTION

Do not maintain closure of the open port longer than

necessary to perform the test.

This test should be performed with each vaporizer in

turn set to 1%.

NOTE

This test is equivalent to, or more severe than the leakage rates quoted in national standards.

5.5 Electrical Supply

(if fitted)

1. Connect the machine power lead to a

suitable mains supply socket.

2. Set the switch (A) to On.

Check for correct function of all electrical

equipment powered by the auxiliary power

outlets on the rear of the machine.

3. Machines with optional O

Check for correct fitment of the mains lead

(B) into the rear of the monitor unit.

Switch the Gas Delivery Switch (C) to On.

Check that the monitor control panel LEDs

activate.

2 Monitor:

A

O2 Monitor

B

C

37

PRE-USE CHECKS - All models

5.6 Patient Breathing System

5.6.1 Hose Connections

Check that all hoses are correctly connected, as shown

in the illustrations on the next page.

5.6.2 A100 Absorber

Always follow the pre-use check procedures given

in the instruction manual supplied with the

absorber.

The use of an oxygen monitor (and a carbon dioxide

analyser) is highly recommended when using any

partial rebreathing anaesthetic system.

In-board A100 Absorber

Check the level of liquid in the condensate collection

system bottle (1).

1

WARNING

The condensate may be caustic:

a) Avoid skin contact.

b) Dilute the liquid with water before disposal.

c) Wear protective gloves if the bottle is full.

Carefully unscrew the bottle and dispose of the

contents.

5.6.3 Breathing System Hose, Reservoir

Bag, Ventilator

Connectors for the Inspiratory hose (A) and Expiratory

hose (B), and the reservoir bag connector (C) are 22

mm male.

All connectors comply with ISO 5356/1.

The ventilator connection point (D) is also 22 mm male.

Hose and bag connections are fitted with Penlon

Safelock high security fittings.

Check all connections for gas tightness.

5.6.4 Fresh Gas Supply

The fresh gas hose assembly (E) supplied with the

machine has a Penlon connector at the absorber inlet

and a 22 mm Safelock taper at the other end.

This should be connected to the common gas outlet (F)

of the anaesthetic machine.

Check all connections for gas tightness.

38

In-board A100 Absorber and AV900 Ventilator Bellows

(AV900 Control Unit mounted on side bracket or shelf)

For spirometer and

pressure monitor

connections, refer to

AV900 User Manual.

AV900 Control Unit

CGO

Block

F

D

E

C

A100

Canister

In-board A100 Absorber

AV900 Ventilator and Bellows Unit

mounted on side bracket or shelf

AV900 Bellows

AV900

A

B

For spirometer and

pressure monitor

connections, refer to

AV900 User Manual.

A100

Valve

Block

CGO

Block

F

A100

Canister

39

A100

Valve

Block

B

D

E

C

A

PRE-USE CHECKS - All models

AV900 VENTILATOR

Breathing System

Connections

EXHAUST TO

SCAVENGE

SYSTEM

VENTILATOR

DRIVE GAS

J

(REAR VIEW)

(AV900 with

built-in monitor)

O2 MONITOR SENSOR LINE

PRESSURE MONITOR

LINE

Monitor mounted on

anaesthetic machine

ANAESTHETIC

MACHINE

CGO

O2 MONITOR

REAR PANEL

FRESH

GAS

SUPPLY

DRIVE

GAS

(FROM MACHINE

AUXILIARY OUTLET)

HEAT AND

MOISTURE

EXCHANGER

(HME)

K

PATIENT

G

H

B