Table of contents:

- Special Tools

- Disassembling Mixing Chamber

- Assembling Mixing Chamber

- Adjustment Rotor / Level Indicator Unit

- Temperature Compensating Unit

- Filler Unit

- Leakage Test

- Closing Mechanism (Release Valve)

EMO

Service Instruction

created by Frank Weithöner

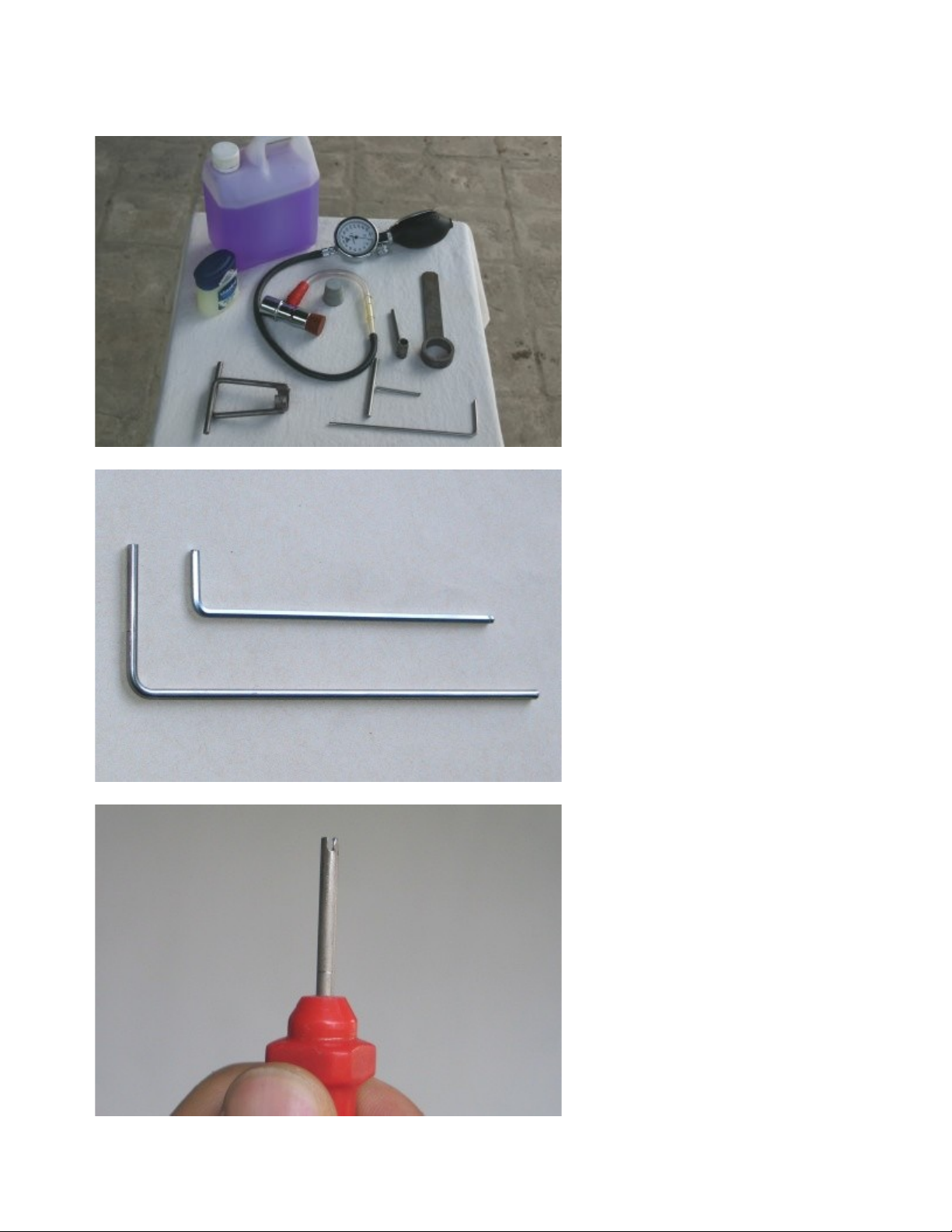

Special Tools

Before starting make sure that all

tools are available. Besides a set of

normal blade screw drivers you will

need some special tools.

1. For opening the EMO:

Allen key 3/32'' (or 2.3mm)

2. For leakage test:

Pressure gauge with plugs

3. Special EMO tools:

- Setting gauge

- Tool for taking out springs

- Tool for taking out the rotor

- Tool for taking out the filler

- Tool for rotor counter nut

- Tool for taking out the filler

4. Alcohol, Vaseline

Here the special EMO tools:

For calibration a setting gauge is

needed. It is a simple piece of bent

metal with a diameter of 2.5mm.

An allen key of the same size also

works fine.

(down the original tool)

For turning the springs out of the

pointer such a tool helps you a lot.

It is an old screw driver (diameter

3mm) with a slit.

If you are experienced you can try

to turn out the springs with strong

forceps. In my opinion it is faster

and easier to build such a tool than

getting out the springs with

forceps.

For holding the counter nut of the

rotor while adjusting you need a

socket with a handle. It's a nice tool

but not really necessary. You also

can hold a simple 8mm socket with

pliers.

This tool helps you to lift out the

rotor. Unfortunately it is difficult to

make and does not work so well.

By now I have no idea how to

create a better tool. Maybe you

have an idea...

The inner diameter is 28mm.

To grab into the notches of the

rotor shaft there must be at least

one nose. In this case it is a 5mm

bolt placed half in the ring.

This a tool for taking out the filler

unit.

It is difficult to make (and to

describe) but you will need it only if

you really want to take out the

filler...

Do you really want to take out the

filler and build it?

Here are the measurements:

Take a 1" pipe (4 mm strong) and

saw a 9mm cut. Now you need 2

little noses with a hight of

approximately 1.5mm. The easiest

way to take material from the pipe

is with a file and leaving the two

noses blank.

The handle is not important but of

course it must be higher than the

filler.

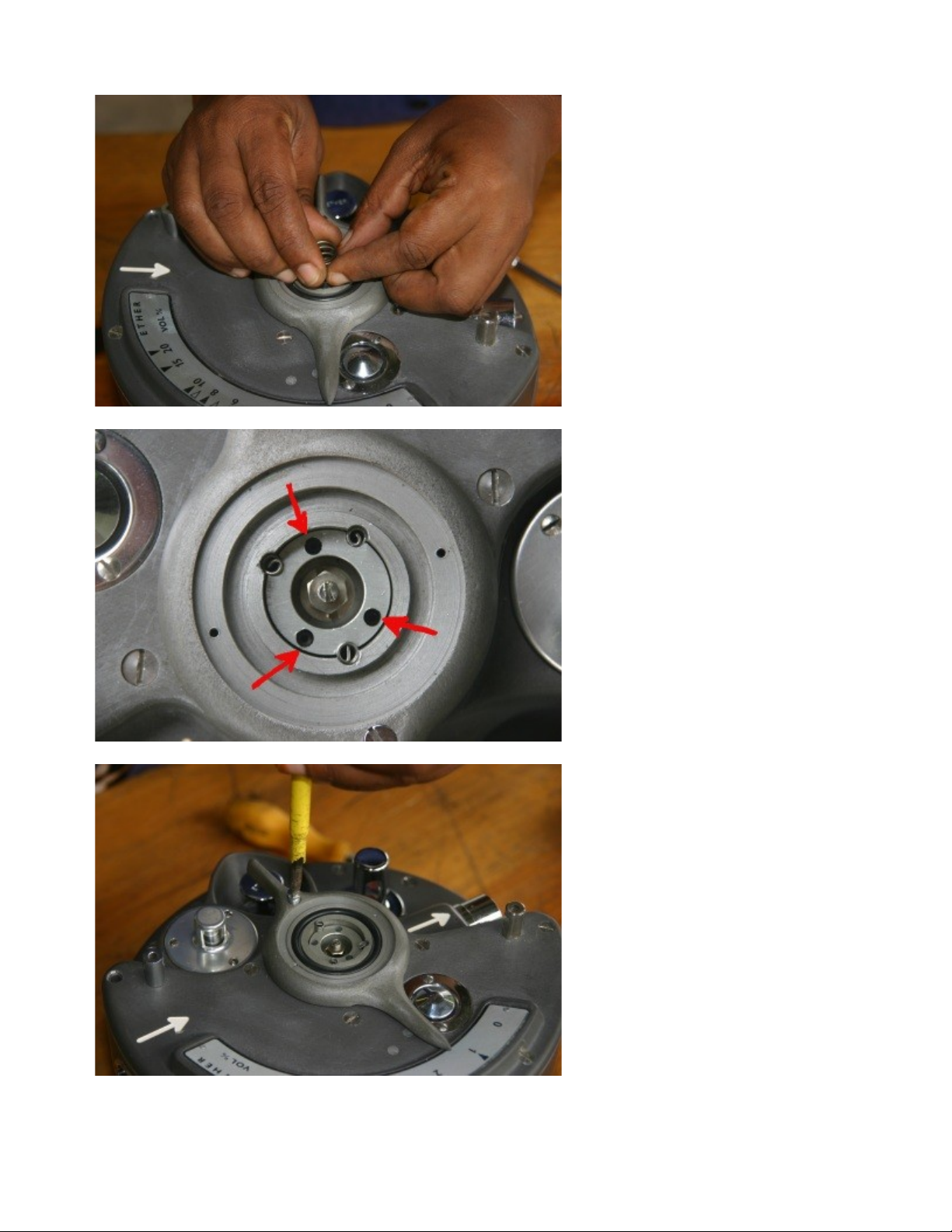

Disassembling Mixing Chamber

Step 1

Clean the whole unit to make sure

that no dirt gets inside while

working with the open unit.

Ether would be perfect, but alcohol

also works.

Step 2

Remove the handle on top.

(2 screws)

Step 3

Remove cover.

(2 screws)

Step 4

Lift out the spring.

Step 5

DO NOT TOUCH THE 3 SCREWS.

Step 6

Remove the screw of the pointer.

It is only a cover screw and hides

an allen key screw which you have

to remove later.

Step 7

Remove the 3 springs. A special

tool is needed.

See Tool Section.

Even with the special tool it is a

very tricky procedure.

Because there is no thread you

have to turn the springs anti-

clockwise to reduce their

diameters while pulling them out.

That sounds easier than it is...

Step 8

Now the pointer turns free, but the

rotor is still attached.

Turn the lever now to 6%.

Now through the hole of the lever

an allen key screw appears (3/32'').

Remove the screw.

Step 9

Remove the lid.

(8 screws)

Don't forget the screw in the centre

under the lever.

Step 10

Now you have to lift out the rotor.

Loosen the nut with the socket key

until the end.

Don't take out the screw

completely.

Step 11

Now screw the axle in the centre

clockwise.

The rotor must come out slowly.

If the rotor is stuck lubrication

around the rotor helps a lot.

Give the oil time to penetrate.

The perfect lubrication is a mixture

oil and ether.

Step12

The rest you have to do with the

special wrench.

Put on the wrench and move the

rotor from side to side and lift it

simultaneously.

Use the wrench only. Do not take a

pair of pliers. You will destroy the

shaft.

Step 13

Clean the rotor and the wall with

ether.

For heavy dirt and particles use

metal polish and a cloth. NEVER

use sand paper or a file. You will

create massive leaks!

Step 14

Now clean the mixing box chamber

and the gasket with ether or

alcohol.

Check gasket for damages.

Step 15

Check the closing mechanism of

proper functionality.

Warning: Do not press the button

too deep. If you do so the gasket

will come out of the button and you

have to dismantle the whole

mechanism to bring it back in

place.

If this already has happened see

the Closing Mechanism section.

Step 16

Lubricate the rotor very slightly

with vaseline.

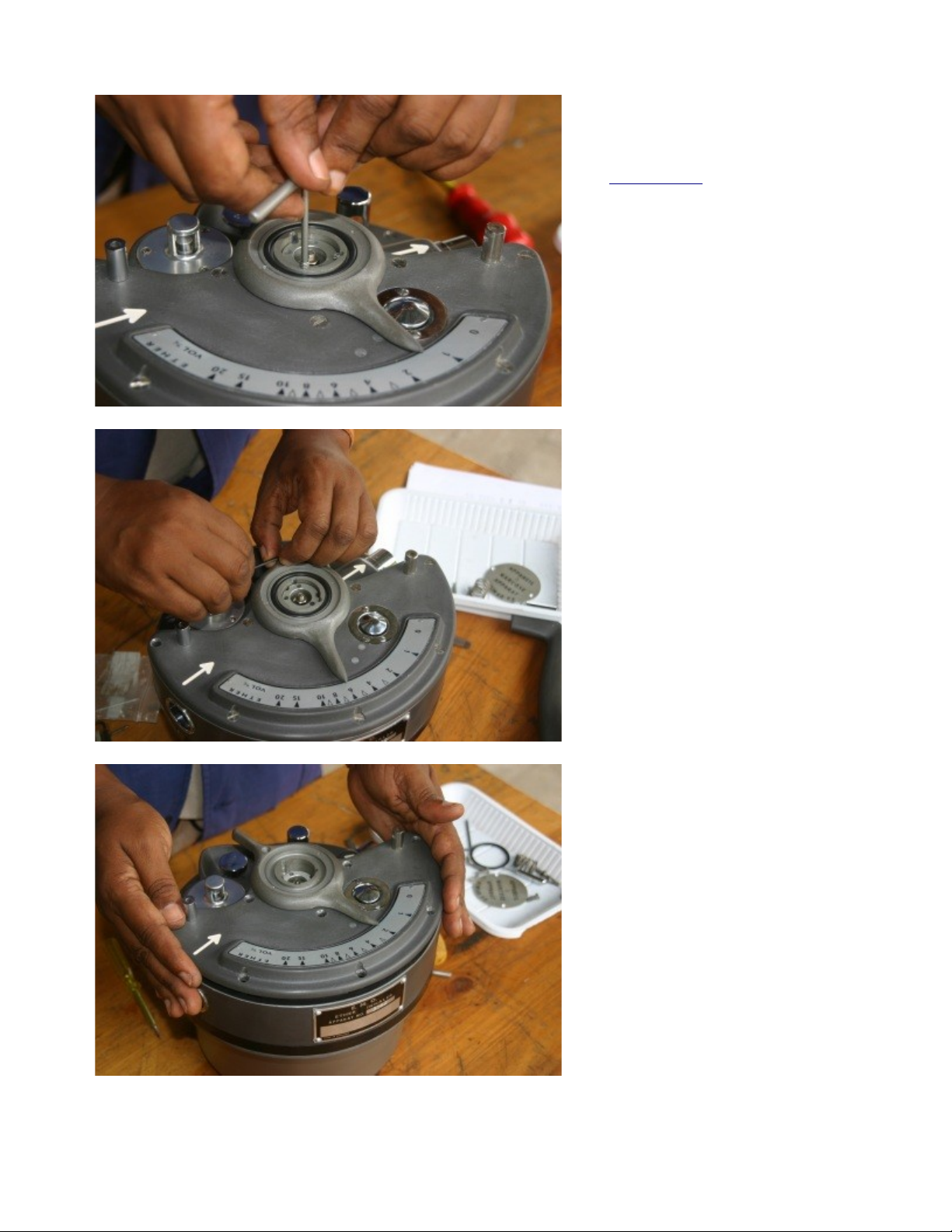

Assembling Mixing Chamber

Step 17

Set the rotor back in place.

If this is difficult even with vaseline

turn the rotor and try another

position. Note the cuttings of the

rotor and the inlet and outlet of the

chamber and take the original

position.

Step 18

Screw out the screw (anticlockwise) and push the rotor

down.

The exact positioning of the rotor

comes later.

Step 19

Clean the mixing chamber.

Inspect the vaporizer chamber.

If it is very dirty inside fill in ether,

stir up and wash it out through the

filler unit.

Replace the seal.

Step 20

Replace the lid.

(8 screws and

1 allen key screw with

1 cover screw of the pointer)

Step 21

And now the tricky part: Replacing

the springs.

Turn the pointer and rotor into the

correct position so that the holes

for the springs appear.

Now put the springs in. Use the

special tool, turn anti-clockwise

to reduce the diameter of the

springs and press them down.

Step 22

Remember, there are no threads so

do not turn clockwise! You will open

the springs and then the springs

get damaged.

If you already have a damaged

spring with a little luck and skill you

may repair it.

Adjustment Rotor / Level Indicator Unit

Step 23a

For adjusting the rotor you first

have to take out the level indicator.

Therefore you have two options.

First the correct one:

Just loose the 3 screws

(2-4 turns)

and pull the whole unit out.

That is probably difficult because

the unit usually is stuck. So turn it

right and left and rock it slightly.

Use your hands only - no tools.

Step 23b

If it is not possible to take out the

whole unit turn out the screws

completely and lift only the upper

part of the unit out of the EMO.

But watch out for the thin plastic

washer.

The washers hold the distant tubes

in place. They are not so important

but must not fall into the main

chamber.

Clean and check everything,

especially the gasket.

Continue with the rotor adjustment.

Step 24

The adjustment is made by setting

the vertical height of the rotor.

Turn the pointer to approximately

'4'. Insert the setting gauge in the

slit between the rotor and housing.

The rotor is correct adjusted when

the setting gauge fits without

backlash.

To reduce the slit turn the

adjustment screw clockwise. To

open the slit loose the screw and

press the rotor down.

Step 25

After the adjustment secure the

screw and pointer by screwing the

counter nut tighter. Make sure that

the screw is not turning.

Replace the cover of the pointer.

(2 screw)

Temperature Compensating Unit

Step 26

Remove the Temperature

Compensating Unit.

(3 screws)

Be careful. The glass ball is fragile.

Look for dirt and check gasket.

If possible do only a visual

inspection - you can destroy more

than you can repair.

Put it back into its place carefully.

Filler Unit

Step 27

Take out the Filler Unit with the

special tool.

Step 28

Clean everything and check the

function.

The valve should move easily.

Check the gasket.

Put the unit back into the EMO.

Leakage Test

Step 29

For the leakage test you need a

pressure gauge and 2 rubber plugs.

Note: Before using the test

equipment check the pressure

gauge itself for leakage.

Step 30

Connect pressure gauge on one

side and lock the other side with a

plug. Set the pointer between 1

and 20. Do not leave the pointer on

the release valve.

Pump up the system with

approximately 150 mmHg. The

pressure must be stable, but a

pressure loss of up to 10 mmHg in

10 sec. is acceptable.

If the test is OK press the release

valve down. Air must be released

now.

Step 31

But most likely you will have

leakage problems

Do the following:

1. Check your test equipment

2. Screw all screws tight

3. Is the filler closed?

4. Take a closer look to the

release valve. It is always a

source of problems.

Tip: A soap solution spread out with

a brush on all the gaskets is a very

good indicator for leakages. Even

the smallest leakages will

immediately create bubbles.

For the solution just take some

drops of dish washing liquid.

Closing Mechanism (Release Valve)

Step 32

The closing mechanism is the most

sensitive part of The EMO. If

possible leave it in the lid.

But if you have problems (probably

leakages) here are images that

helps you to dismantle and mantle.

Step 33

For removing the closing

mechanism turn the two screws for

2 or 3 turns only.

The third screw is for adjusting.

Do not turn.

Step 33

Two little hooks inside will swing in

and leave the unit free.

Step 34

Clean everything carefully and

watch for damages.

The major problems are the

gaskets. Clean it with alcohol and

put some vaseline on it.

Start with reassembling the silver

knob. First put the gasket around

the knob and insert the knob into

the frame from the inside.

Step 35

As I mentioned above the biggest

problems are the gaskets - the

rubber gaskets as well as the little

plastic washers under the heads of

the crews. They are definitely

damaged. If tightening the screws

with force does not help you may

try liquid gasket maker - but not

too much.

Work carefully that no gasket

maker gets into the chamber.

Step 36

If you use gasket maker don't

forget to seal the screw heads.

Step 37

Remove excessive gasket maker

immediately after assembling and

wait until rubber has dried before

doing another leakage test.

Don't forget to adjust the closing

mechanism after reassembling. You

do this with the adjustment screw.

Check in close and open position.

Loading...

Loading...