Penlon AV-S Service manual (2005)

AV -S Ventilator

Remote Display Module and Interface

for use with A200SPAbsorber

Service Manual

Partnership for Life

Draft Copy

July 2005

No update will be given

THE IMPORTANCE OF PATIENT MONITORING

WARNING

Anaesthetic systems have the capability

to deliver mixtures of gases and vapours

to the patient which could cause injury or

death unless controlled by a qualified

anaesthetist.

There can be considerable variation in

the effect of anaesthetic drugs on

individual patients so that the setting and

observation of control levels on the

anaesthesia systems does not in itself

ensure total patient safety.

Anaesthesia system monitors and patient

monitors are very desirable aids for the

anaesthetist but are not true clinical

monitors as the condition of the patient is

also dependent on his respiration and the

functioning of his cardio-vascular system.

IT IS ESSENTIAL THAT THESE ELEMENTS

ARE MONITORED FREQUENTLY AND

REGULARLY AND THAT ANY

OBSERVATIONS ARE GIVEN

PRECEDENCE OVER MACHINE CONTROL

P ARAMETERS IN JUDGING THE STATE OF

A CLINICAL PROCEDURE.

Servicing and Repairs

In order to ensure the full operational life of this

ventilator, servicing by a Penlon-trained

engineer should be undertaken periodically.

The ventilator must be serviced to the following

schedule:

(a) Six monthly service - inspection and

function testing.

(b) Annual / 2 Year / four year service

including component replacement.

Details of these operations are given in this

Manual for the AV-S, available only for Penlon

trained engineers.

For any enquiry regarding the servicing or

repair of this product, contact the nearest

accredited Penlon agent:

or communicate directly with:

Technical Support

Penlon Limited

Abingdon Science Park

Barton Lane

Abingdon

OX14 3PH

UK

Tel: 44 (0) 1235 547076

Fax: 44 (0) 1235 547062

E-mail: technicalsupport@penlon.co.uk

Always give as much of the following

information as possible:

1. Type of equipment

2. Product name

3. Serial number

4. Approximate date of purchase

5. Apparent fault

IMPORTANT

(i)

This manual has been produced to provide

authorised personnel with information on the

function, routine performance, service and

maintenance applicable to the AV-S

Anaesthesia Ventilator.

Information contained in this manual is correct

at the date of publication.

The policy of Penlon Limited is one of continued

improvement to its products.

Because of this policy, Penlon Limited reserves

the right to make any changes which may affect

instructions in this manual, without giving prior

notice.

Personnel must make themselves familiar with

the contents of this manual and the machine’s

function before servicing the apparatus.

Copyright © Penlon Limited, 2005.

All rights reserved.

FOREWORD

(ii)

Page No.

USER RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1. WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2. PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. DESCRIPTION

3.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Ventilation Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3.1 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.4 Electrical System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.5 Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.5.1 Touchscreen Operation and Navigator wheel / push-button . . . . . . . . . . . . 16

3.5.2 User Adjustable Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5.3 Operational capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5.4 Output Compensation Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.6 Interface with Prima SP and A200SP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.7 Ventilation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7.1 Standby Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.7.2 Volume Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.7.3 Pressure Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.7.4 Spontaneous Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.7.5 Advanced Spontaneous Breathing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.7.5.1 SIMV (Synchronised Intermittent Mandatory Ventilation) . . . . . . . . . . . . . 24

3.7.5.2 SMMV (Synchronised Mandatory Minute Ventilation) . . . . . . . . . . . . 25

3.7.5.3 PSV (Pressure Supported Ventilation) . . . . . . . . . . . . . . . . . . . . . . 26

3.7.5.4 PEEP ( Positive End Expiratory Pressure) . . . . . . . . . . . . . . . . . . . . . . 27

3.8 On-screen Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.9 Spirometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.10 Display Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.11 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.12 Oxygen Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.13.1 System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.12.2 The MOX-3 Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

3.12.3 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.12.4 Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.12.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.12.6 Alarm Mute. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4. SPECIFICATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Oxygen Monitor . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CONTENTS

(iii)

CONTENTS

(iv)

5. PRE-OPERATION PROCEDURES

5.1 Ventilator Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.1 Mounting the Ventilator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.2 Electrical Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.3 Ventilator Gas Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.4 Breathing System Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.1.5 Bellows Drive Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.6 Anaesthetic Gas Scavenging System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.7 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.8 Breathing System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5.1.9 Spirometer Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5.1.10 Pressure Monitor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1.11 Bellows Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Pre-use Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.1 Daily Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5.2.2 Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2.3 Weekly Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

5.3 Oxygen Monitor Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3.1 Installation . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.3.3 Sensor Low Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.3.4 Setting the High and Low O

2 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6. SERVICE PROCEDURES

6.1 Service Intervals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2 Control Unit Patient Block Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7. SERVICE SCHEDULE

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8. PARTS LISTS

Preventive Maintenance Kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Assemblies 65

9. APPENDIX

1. Back-up Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

2. Menu System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

3. Ventilator Spirometry System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Outside Surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Bellows and Diaphragm Exhalation Valve . . . . . . . . . . . . . . . . . . . . . 86

Spirometer Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Patient Connector Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Sterilisation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Oxygen Monitor - Cleaning and Sterilisation . . . . . . . . . . . . . . . . . . 88

Oxygen Sensor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

This anaesthesia ventilator has been built to

conform with the specification and operating

procedures stated in this manual and/or

accompanying labels and notices when

checked, assembled, operated, maintained

and serviced in accordance with these

instructions.

To ensure the safety of this device it must be

checked and serviced to at least the

minimum standards laid out in this manual.

A defective, or suspected defective, product

must not under any circumstances be used.

The user must accept responsibility for any

malfunction which results from noncompliance with the servicing requirements

detailed in this manual.

Additionally, the user must accept

responsibility for any malfunction which may

result from misuse of any kind or noncompliance with other requirements detailed

in this manual.

Worn, broken, distorted, contaminated or

missing components must be replaced

immediately. Should such a repair become

necessary it is recommended that a request

for service advice be made to the nearest

Penlon accredited agent.

This device and any of its constituent parts

must be repaired only in accordance with

written instructions issued by Penlon

Limited and must not be altered or modified

in any way without the written approval of

Penlon Limited. The user of this equipment

shall have the sole responsibility for any

malfunction which results from improper

use, maintenance, repair, damage or

alteration by anyone other than Penlon or its

appointed agents.

USAand Canadian Federal Law restrict s the

sale and use of this device to, or on the order

of, a licensed practitioner.

Statements in this manual preceded by the

following words are of special significance:

WARNING means there is a

possibility of injury to the

user or others.

CAUTION means there is a possibility

of damage to the apparatus

or other property.

NOTE indicates points of

particular interest for more

efficient and convenient

operation.

Always take particular notice of the

warnings, cautions and notes provided

throughout this manual.

USER RESPONSIBILITY

1

1. WARNINGS AND CAUTIONS

The following WARNINGS and CAUTIONS

must be read and understood before using

this ventilator.

WARNINGS

General Information

1. Personnel must make themselves

familiar with the contents of this

manual and the machine’s function

before using the ventilator.

Before Using the Ventilator

2. Before the ventilator is used clinically

for the first time, verify that the hospital

engineering department has carried out

an earth continuity test.

3. Excessive electronic noise caused by

other poorly regulated devices, such as

an electrocautery unit, may adversely

interfere with the proper functioning of

the ventilator.

To avoid this problem, do not connect

the ventilator’s power cord into the

same electrical wall outlet or adaptor

strip into which an electrocautery unit

is connected.

4. If used with a mains extension cord, the

unit may be subject to electro-magnetic

interference.

5. The driving gas supply must be clean

and dry to prevent ventilator

malfunction.

6. This ventilator is designed to be driven

by oxygen or medical air only. It is

calibrated during manufacture for use

with either gas.

Before the ventilator is used clinically

for the first time, the commissioning

engineer must confirm that the internal

Air/Oxygen switch is set correctly for

the gas that is to be used.

The use of any other gas will cause

inaccurate operation and may damage

the ventilator, resulting in potential

injury to the patient.

7. The driving gas is discharged through

the opening in the back of the ventilator

control unit.

The discharged gas may contaminate

the environment, and should therefore

be extracted using a gas scavenging

system.

8. The bellows can only support

approximately 1 kPa (10 cmH

2

O)

differential positive pressure, above

which it may be dislodged from the

mounting ring, resulting in dangerous

malfunction of the ventilator.

Do not connect a positive end

expiratory pressure (PEEP) valve or

other restrictive device to the exhaust

port on the bellows base.

This would increase the pressure inside

the bellows and the bellows could

detach from the base, causing serious

malfunction.

9. Breathing System

The breathing system which conveys

gases from the anaesthetic machine to

the patient, and disposes of expired

gases, must conform to the

requirements of ISO 8835-2.

Because breathing systems require

frequent cleaning and disinfection they

are not a permanent part of the

anaesthetic ventilator and therefore

cannot be directly under the control of

the anaesthetic ventilator manufacturer.

However, we strongly recommend that

only breathing systems which have

been approved and authorised by

Penlon for use with AV-S should be

employed.

Do not use conductive breathing

system hoses.

When mechanical ventilation is

employed the patient breathing system

must be connected directly to a

pressure relief valve to prevent the

possibility of barotrauma.

10. Do not connect a spirometer to the

exhaust port on the bellows base.

The device will not measure exhaled

volumes in that position.

2

11. The operation of each alarm function

should be verified daily.

Periodically check the alarms at

clinically suitable intervals. If the

audible alarm or the visual indicator of

any alarm function fails to activate

during any alarm condition or fails to

reset after the alarm has been cleared,

refer the unit to an authorised service

technician.

12. Before using the ventilator check that

all connections are correct, and verify

that there are no leaks.

Patient circuit disconnects are a hazard

to the patient. Extreme care should be

taken to prevent such occurrences.

It is recommended that Penlon

Safelock fittings are used throughout

the breathing circuit.

Using the Ventilator

13. The AV-S ventilator is not intended for

use in intensive care applications.

14. This apparatus must not be used with,

or in close proximity to, flammable

anaesthetic agents.

There is a possible fire or explosion

hazard.

15. Anaesthesia apparatus must be

connected to an anaesthetic gas

scavenging system (AGSS) to dispose

of waste gas and prevent possible

health hazards to operating room staff.

This requirement must be observed

during test procedures as well as

during use with a patient.

The scavenging transfer and receiver

system must conform to ISO 8835-3.

Any problem arising from an

improperly functioning scavenging

system is solely the user’s

responsibility.

Do not use a scavenging system that

restricts drive gas flow when negative

pressure is exerted on it.

16. When the ventilator is connected to a

patient, it is recommended that a

qualified practitioner is in attendance

at all times to react to an alarm or other

indication of a problem.

17. In compliance with good anaesthesia

practice, an alternative means of

ventilation must be available whenever

the ventilator is in use.

18. It is recommended that the patient

oxygen concentration should be

monitored continuously.

19. If the drive gas supply pressure drops

below a nominal 241 kPa (35 psi), the

LOW DRIVE GAS SUPPLY alarm will

activate both audibly and visually.

Patient minute volume may be reduced

due to lowered flow rates

20. An audible alarm indicates an

anomalous condition and should never

go unheeded.

21. The characteristics of the breathing

circuit connected between the

ventilator and the patient can modify or

change patient ventilation.

To assist the maintenance of the

delivered patient tidal volume, the

ventilator control system software

includes:

A) a compliance compensation

algorithm,

B) a fresh gas compensation

algorithm.

However, patient ventilation must be

monitored independently from the

ventilator.

It is the responsibility of the user to

monitor patient ventilation.

22. Care must be taken to ensure that the

flow sensors are connected correctly

to the inspiratory and expiratory ports

of the absorber.

23. The Vent Inop (ventilator inoperative)

alarm indicates that one of the

following conditions has occurred:

a) The drive gas solenoid has failed.

b) The flow control valve has failed.

c) Internal electronic fault.

d) Internal electrical fault.

e) Software error.

Note that if a ventilator error is

detected, ‘Ventilator Inoperative’will be

displayed on the front control panel

display.

WARNINGS AND CAUTIONS

3

24. The High and Low Airway Pressure

Alarms are important for patient care.

It is important that the sensor is

properly located in the expiratory limb

of the circuit - refer to section 5.1.10.

25. The patient must be continuously

attended and monitored when

Advanced Breathing Modes are in use.

User Maintenance

Control Unit

26. Opening the control unit by

unauthorised personnel automatically

voids all warranties and specifications.

Prevention of tampering with the

control unit is exclusively the user’s

responsibility. If the control unit seal is

broken, the manufacturer assumes no

liability for any malfunction or failure of

the ventilator.

27. For continued protection against fire

hazards, replace the two fuses only

with the identical type and rating of

fuse.

See section 4 for fuse rating.

28. If the internal battery is fully

discharged, the ventilator will not

function in the event of mains power

failure. The battery must be recharged

before the ventilator is used clinically,

otherwise backup cannot be

guaranteed.

See Appendix for battery maintenance.

See also CAUTION No. 7.

Used or defective batteries must be

disposed of according to hospital,

local, state, and federal regulations.

29. No oil, grease or other flammable

lubricant or sealant must be used on

any part of the ventilator in close

proximity to medical gas distribution

components.

There is a risk of fire or explosion.

30. Exterior panels must not be removed

by unauthorised personnel and the

apparatus must not be operated with

such panels missing.

There is a possible electric shock

hazard.

31. Check that the cable between the

control unit and remote display screen

unit is connected before use.

Always use a cable type recommended

by the manufacturer.

Bellows Assembly

32. The valve seat on the patient gas

exhalation diaphragm valve in the base

of the bellows assembly must be

cleaned regularly - see section 6.2.

Failure to keep the valve seat clean

could result in the diaphragm sticking,

thus preventing exhalation.

Great care must be taken not to

damage the precision surface of the

valve seat on the patient gas exhalation

diaphragm valve in the base of the

bellows assembly.

Never use any hard object or abrasive

detergent to clean it; use only a soft

cloth.

If the valve seat is damaged, the valve

will leak and may cause serious

ventilator malfunction.

WARNINGS AND CAUTIONS

4

CAUTIONS

1. Do not sterilise the ventilator control unit.

The patient block assembly must be

removed from the control unit before

sterilisation ( see section 6.2.4).

All other internal components are not

compatible with sterilisation techniques

and damage may result.

2. For ventilator components which require

sterilisation, peak sterilisation

temperatures should not exceed 136oC

(275oF) to prevent possible damage.

(See section 6).

3. Those parts suitable for ethylene oxide

sterilisation should, following sterilisation,

be quarantined in a well ventilated area to

allow dissipation of residual gas absorbed

by the components.

Follow the steriliser manufacturer’s

recommendations for any special aeration

periods required.

4. The exhalation valve located in the

bellows base assembly and the paediatric

bellows adaptor must be cleaned and

sterilised separately. See section 6.

5. Care must be taken not to let any liquid

run into the control unit; serious damage

may result.

6. Always check for correct fitment, and carry

out a full function test before clinical use, if

the bellows has been removed and

refitted for any reason. See section 6.

7. Damage may occur to the battery if it is

allowed to remain in a discharged state.

Check the battery frequently if the

ventilator is in storage (see Appendix 1).

8. Fresh gas compensation is disabled if :

a) The spirometry system is turned OFF

through the menu system, or

b) The spirometry system is not functioning

correctly.

9. Fresh gas mixture compensation is disabled

if :

a) The spirometry system is turned OFF

through the menu system, or

b) The spirometry system is not functioning

correctly.

c) The O2 monitor is switched OFF.

10. Circuit compliance is not activated until

Fresh Gas Compensation is switched

OFF.

NOTES

1. The term ‘cycle’ is used to designate the

transition to the exhalation phase.

2. The term ‘trigger’ is used to indicate the

transition to the inhalation phase.

WARNINGS AND CAUTIONS

5

Oxygen Monitor

WARNINGS

1. We recommend calibration of the

oxygen monitor every time the system

is turned on, as a safety precaution.

2. Do not attempt to open the fuel cell.

The sensor contains small quantities

of :

a) electrolyte, classified as a harmful

irritant which is potentially hazardous,

and

b) lead.

Used or defective cells must be

disposed of according to hospital,

local, state, and federal regulations.

3. ALWAYS check the integrity of the

sensor assembly before use.

4. Once exhausted, the sensor must be

disposed of according to hospital,

local, state and federal regulations.

5. The sensor measures oxygen partial

pressure, and its output will rise and

fall due to pressure change.

An increase in pressure of 10% at the

sensor inlet will produce a 10%

increase in sensor output.

CAUTIONS

1. Only use low temperature ethylene oxide

sterilisation for the oxygen sensor.

The sensor is not compatible with other

sterilisation techniques - damage may

result.

Do not sterilise any other components.

2. Do not autoclave or expose the sensor to

high temperatures.

3. If the sensor shows signs of being affected

by condensation, dry the sensor with soft

tissue.

Do not use heat to dry the sensor.

6

NOTES

1. The O2 SENSOR FAULT alarm indicates

that one of the following conditions has

occurred.

a) Internal electrical fault

b) Software/electronics fault

c) Oxygen sensor fault.

2. The concentration read-out may, in

certain conditions of excess pressure,

show a value above 100%.

To accommodate these conditions it is

possible to set the high alarm value up to

105% (see section 5).

3. To maintain maximum sensor life:

i) always switch off the anaesthetic

machine after use, to ensure that the basal

flow ceases.

ii) disconnect the breathing circuit after

use.

4. The accuracy of flow and volume

measurements may be reduced if the

oxygen monitor is not in use.

5. Fresh gas mixture compensation is disabled

if the oxygen monitor is switched OFF.

WARNINGS AND CAUTIONS - Oxygen Monitor

The AV-S Ventilator is a software controlled,

multi-mode ventilator, designed for

mechanical ventilation of adult and

paediatric patients under general

anaesthesia.

In addition, in spontaneous mode, it can be

used to monitor spontaneously breathing

patients

It is designed for use in closed-circuit

anaesthesia and also to drive a Mapleson D

circuit.

Indications for use of the device:

The AV-S Ventilator is intended to provide

continuous mechanical ventilatory support

during anaesthesia. The ventilator is a

restricted medical device intended for use by

qualified trained personnel under the

direction of a physician. Specifically the

ventilator is applicable for adult and

paediatric patients.

The ventilator is intended for use by health

care providers, i.e. Physicians, Nurses and

Technicians with patients during general

anaesthesia.

The AV-S ventilator is not intended for use in

intensive care applications.

Oxygen Monitor

The Oxygen Monitor is intended to

continuously measure and display the

concentration of oxygen in breathing gas

mixtures used in anaesthesia, and is

intended for adult and paediatric patients.

The oxygen monitor is an integral part of the

ventilator.

The oxygen monitor is intended for use by

health care providers, i.e. Physicians,

Nurses and Technicians for use with patients

during general anaesthesia.

2. PURPOSE

7

3.1 General Description

The AV-S Ventilator is a pneumatically

driven, software controlled, multi-mode

ventilator.

The ventilator is a time-cycled,

volume/pressure controlled, and pressure

limited.

The ventilator has compliance compensation

and a user selectable option of an inspiratory

pause fixed at 25% of the inspiratory time.

In addition, fresh gas compensation and

user selectable gas mixture compensation is

a standard feature.

Ventilation Modes

Volume Mode - continuous mandatory

ventilation

Pressure Mode - pressure controlled

ventilation

Spontaneous, with advanced features SIMV, SMMV, PSV

PEEP

Patient Monitoring

Airway pressure, measured from the

expiratory limb of the breathing circuit.

Tidal volume and Minute Volume

measurement is provided by a dual

spirometry system

An integral oxygen monitor system

measures oxygen concentration in the

breathing circuit inspiratory limb.

The print function provides a permanent

record of function activity for up to eight

hours during a procedure, or can be used to

record waveforms.

Screen

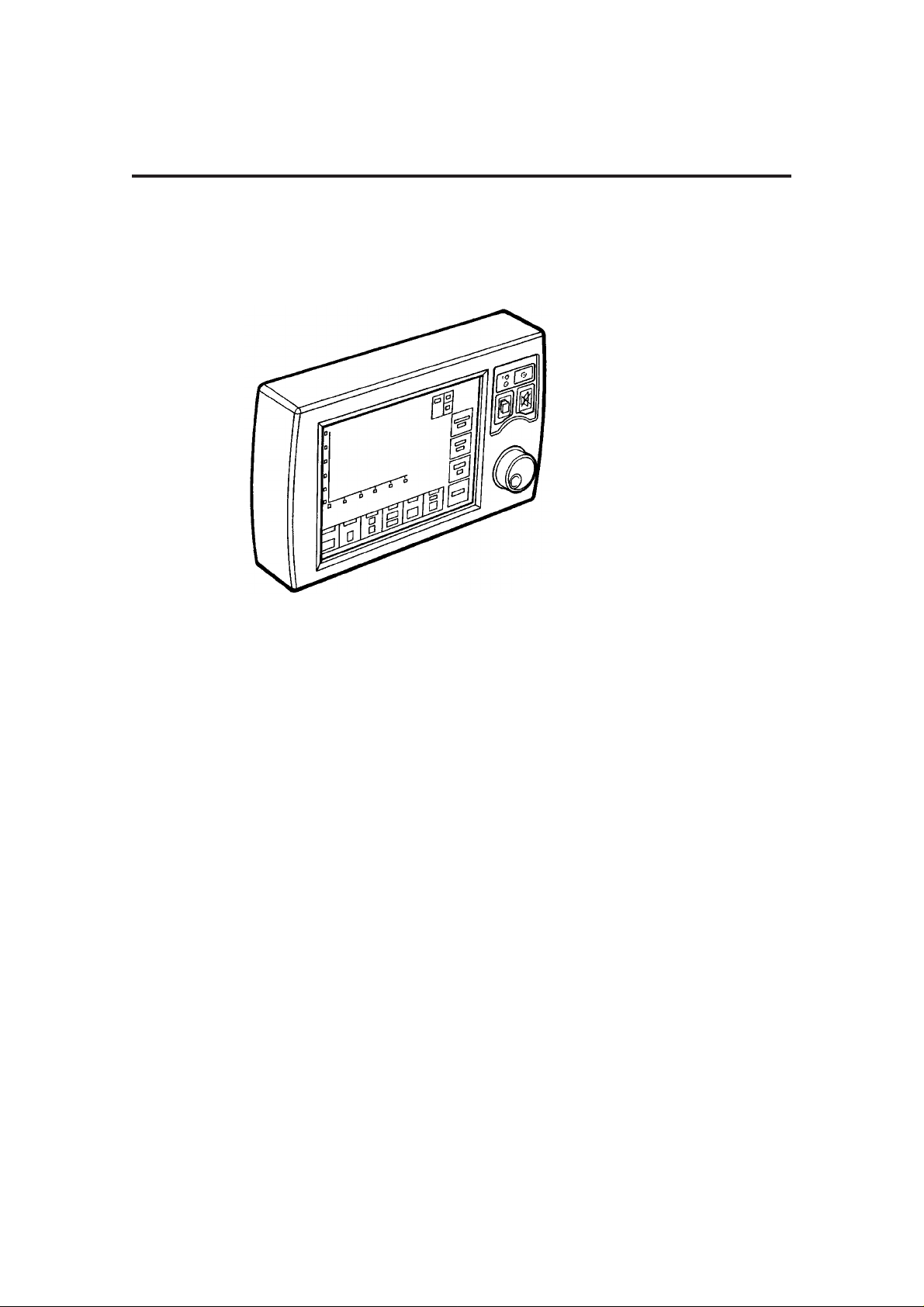

210 mm (8.4 inch) high definition, colour TFT

screen, with single/dual waveform display.

3. DESCRIPTION

8

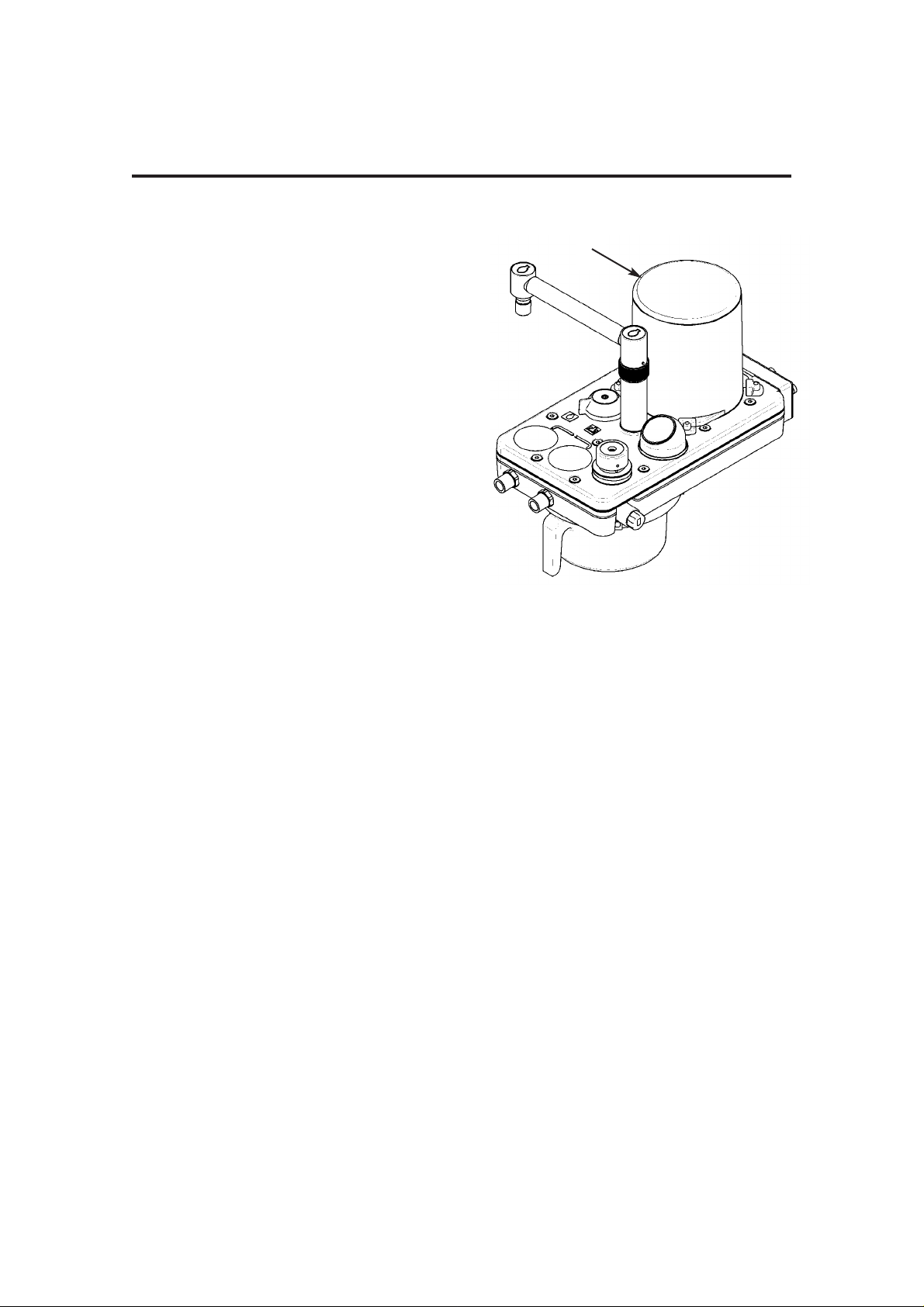

AV-S Ventilator

Bellows unit

The bellows unit (1) is built into the A200SP

absorber.

A paediatric bellows assembly is available as

an option

Mounting options

The AV-S integral screen and control unit can

be mounted securely on the anaesthetic

machine shelf or side bracket.

Drive gas supply

The supply must be at 310 to 689 kPa (45 to

100 psi ).

The ventilator drive gas supply can be oxygen

or air.

Note that the drive gas is specified by the

customer prior to delivery. Conversion from

one drive gas to another must be carried out by

a Penlon-trained service engineer.

DESCRIPTION

9

1

10

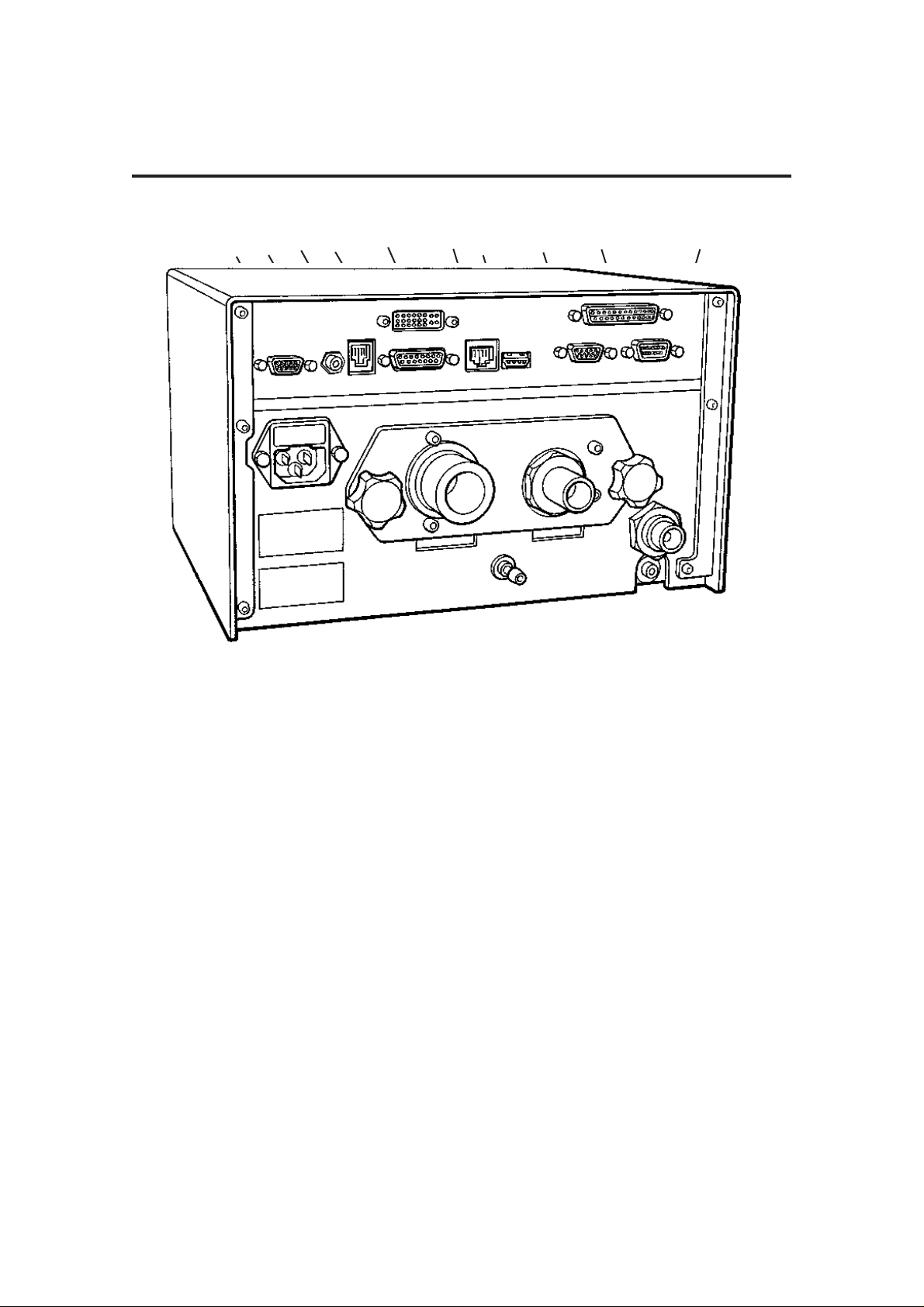

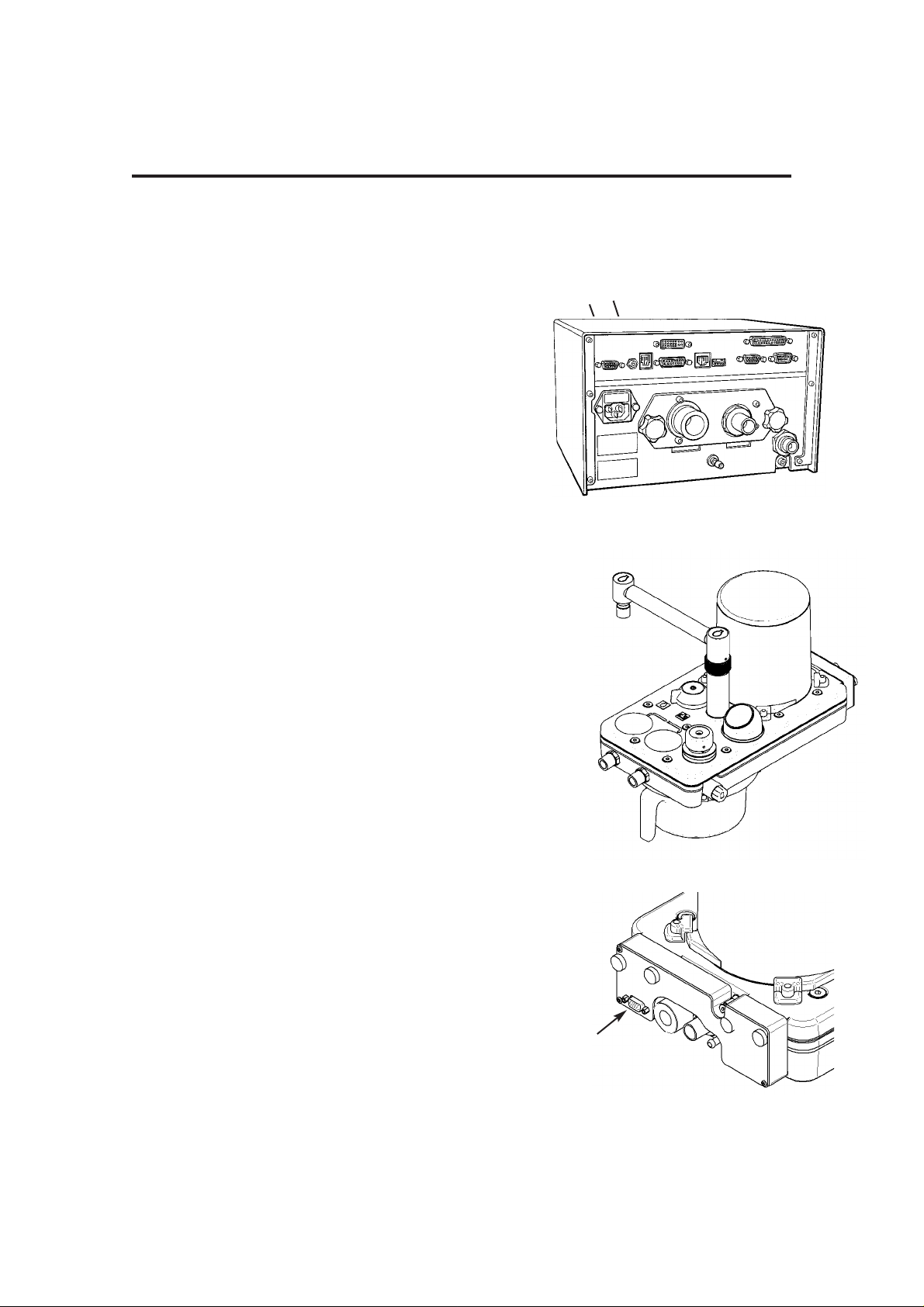

Control Unit

Rear Panel

Interface and Parameter inputs

5. A200SP Absorber Bag/Vent

switch interface

Spirometer connector

6. Prima SP Interface connector

7. Pressure Monitor Port

8. Input socket - Oxygen monitor

sensor

Data and Printer Ports

9. Data Output

10. Output to remote screen

11. Ethernet

12. USB

13. VGA

14. Printer port

15. RS232

NOTE

USB port is for use by Penlon-trained

engineers only.

All other data ports are read only.

For further information, please contact

Penlon Technical Support.

Gas Connections

1. Ventilator drive gas inlet

- connect to anaesthetic machine

auxiliary gas outlet

2. Bellows Drive Gas Output

- connect to bellows

( on Prima SP with A200SP absorber,

connect to absorber - see section 5.1.5)

3. Outlet - Exhaust Valve

Electrical Connection

4. Electrical mains input and fuse unit

DESCRIPTION

2

7

3

13 14 15

12

1110

9

8

6

5

4

1

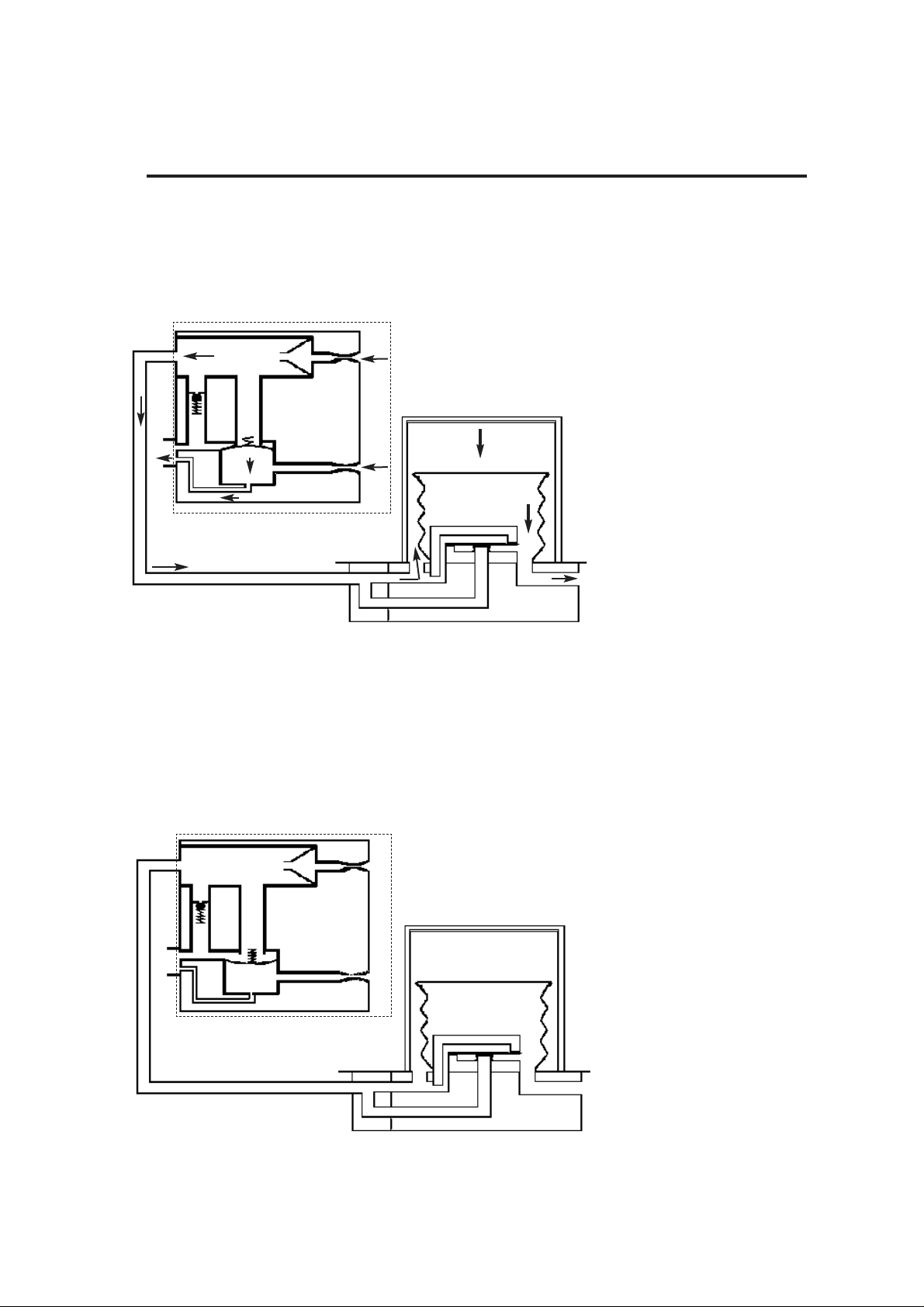

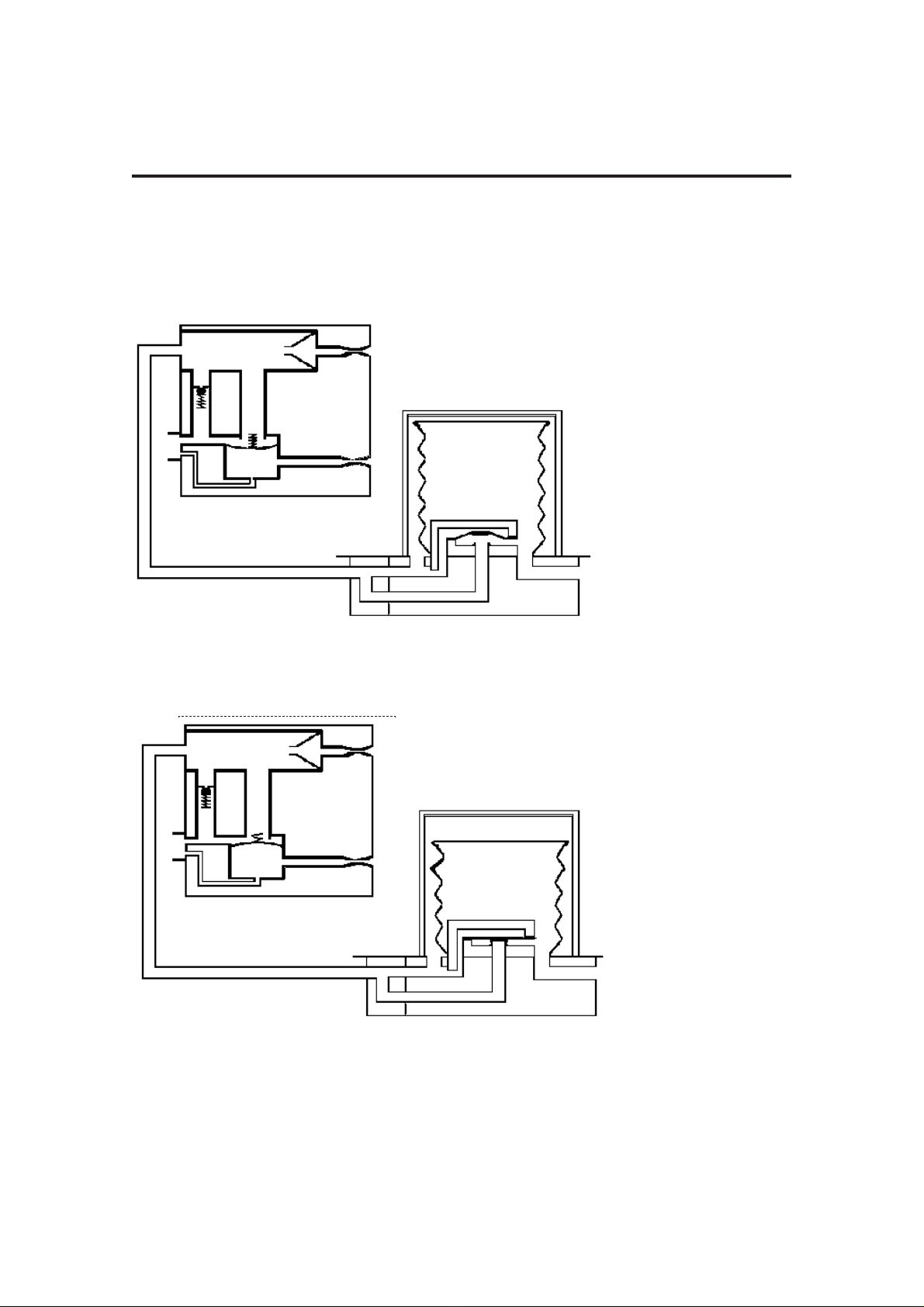

3.2 Ventilation Cycle

This section provides a simplified description of the ventilation cycle.

1. Inspiratory Phase

The inspiratory proportional

valve (1) in the control unit

opens, and bellows drive

gas is delivered to the

bellows housing (2).

The expiratory proportional

valve (3) opens and gas

flows through the bleed

valve. The back pressure

ensures that the exhaust

valve (4) is kept closed

Drive gas pressure builds

up above the bellows, which

starts to move down.

The diaphragm (5) in the

bellows assembly base is

held closed, and patient gas

is forced out of the bellows

base (6) into the breathing

system.

2. Beginning of

Expiratory Phase

The Inspiratory (1) and

Expiratory (3) proportional

valves close and the exhaust

valve (4) opens. Patient gas

returns to the bellows. As

the bellows rises, redundant

drive gas is pushed out

through the exhaust valve.

DESCRIPTION

11

1

4

4

5

6

2

3

3

1

3

1

4

DESCRIPTION

3. End of

Expiratory Phase

With the bellows at the top

of its housing fresh gas

continues to flow. To

prevent a high pressure

build up the exhalation

diaphragm (5) lifts and

allows gas to exit through

the exhaust valve (4).

4. PEEP

Positive End

Expiratory

Pressure

(user selectable)

During PEEP the Exhalation

Proportional valve (3)

applies PEEP pressure plus

20 cmH2O to the exhaust

valve, which remains closed

at this stage.

As fresh gas flows in the

patient circuit, any pressure

increase above PEEP

pressure in the bellows will

cause gas to bleed past the

exhaust valve (4).

A continuous flow from the

Inspiratory proportional

valve (1) ensures that any

fall in pressure is

compensated by driving the

bellows as required.

12

5

4

13

DESCRIPTION

A

Pneumatic Flow

Diagram

C

1817

5

8

14

9

12

6

16

13

15

11

7

1

2

10

4

3

B

0 - 80 cmH

2O

100 cmH

2O

0 - 90 cmH2O

241 kPa (35 psi)

3 to 7 bar

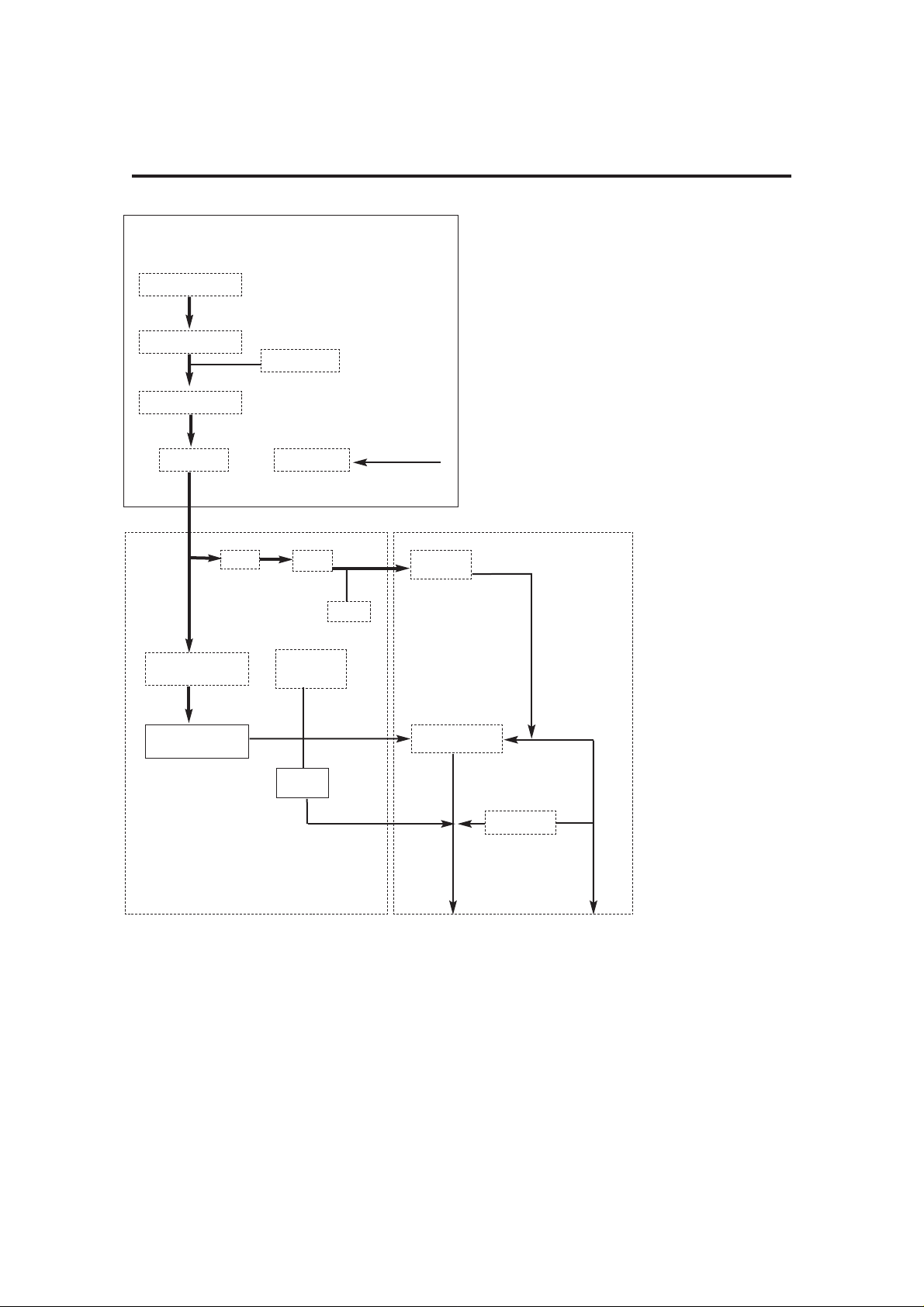

3.3 Pneumatic System

3.3.1 System Operation

Refer to the pneumatic system diagram on the

previous page.

A) Gas inlet manifold block

The AV-S Ventilator is designed to operate on a

310 - 689 kPa (45 -100 psi) drive gas supply

(oxygen or air - to customer’s requirement).

1. DISS Connector

The gas source is connected to the

DRIVE GAS SUPPLY fitting on the rear of

the ventilator control unit.

The gas supply should be capable of a

flow rate of 80 L/min while maintaining a

minimum pressure in excess of 310 kPa

(45 psi).

2. Filter

The drive gas is filtered with a 40-micron

Input Gas Filter which protects the

pneumatic components from incoming

particulate matter.

3. The Low Supply Pressure Detector

The pressure switch is set at a

predetermined level to detect a loss or

reduction of the input gas source

pressure.

When the pressure falls below 235 kPa

(35 psi ± 1 psi), the LOW SUPPLY

PRESSURE indicator will be displayed

and the high priority audible alarm will

activate.

4. Input Pressure Regulator

Regulates the input drive gas to 260 kPa

± 21 kPa (38 psi ± 3 psi).

5. Cut-off Valve

The valve isolates the the gas supply :

a) when the ventilator is switched off

b) when a fault condition occurs.

6. Airway Pressure Sensor

Connected to expiratory limb of breathing

circuit.

DESCRIPTION

14

B) Pneumatic Control Manifold Block

7. Inspiratory Proportional Valve

8.

Flow Sensor

9. Drive Gas pressure Sensor

10. Low Pressure Regulator

11. Expiratory Proportional Valve

12. PEEP pressure sensor

13. Restrictor

The restrictor allows a flow of up to 2 L/min

(<2 L/min bleeding)

C) Exhaust Manifold Block

14. Check Valve

15. Diaphragm Valve

16. Pressure Relief valve

Set to 100 cmH

2O

17. Exhaust Port ( to AGSS)

18. Bellows drive gas outlet (to bellows

assembly)

3.4 Electrical System

Mains Supply

The mains supply inlet is designed for

connection to any mains voltage from 100 to

240 VAC and a frequency of 50 to 60 Hz,

without any adjustment.

The connector is a standard IEC type.

Back-up Battery

In the event of mains electrical failure, the backup battery cuts in automatically.

A fully charged battery will power the ventilator

for approximately 30 minutes.

See Appendix 1 for battery care procedures.

DESCRIPTION

15

VmSET

Litres

3.6

VmMEAS

Litres

3.6

SET

BPM

6

Insp Time

Sec

2

PEEP

cmH2O

5

LIMIT

cmH2O

38

Spont

Mode

Pmean

cmH2O

10

Pmax

cmH2O

24

Standby

Freeze

Waveform

SMMV

%O2 100

33 20

Trigger

cmH2O

-1.0

cm H2O

secs

AV-S

Touchscreen control

1

4

3

5

2

Gas Mixture

O2 + air

.

.

IO

o

o

DESCRIPTION

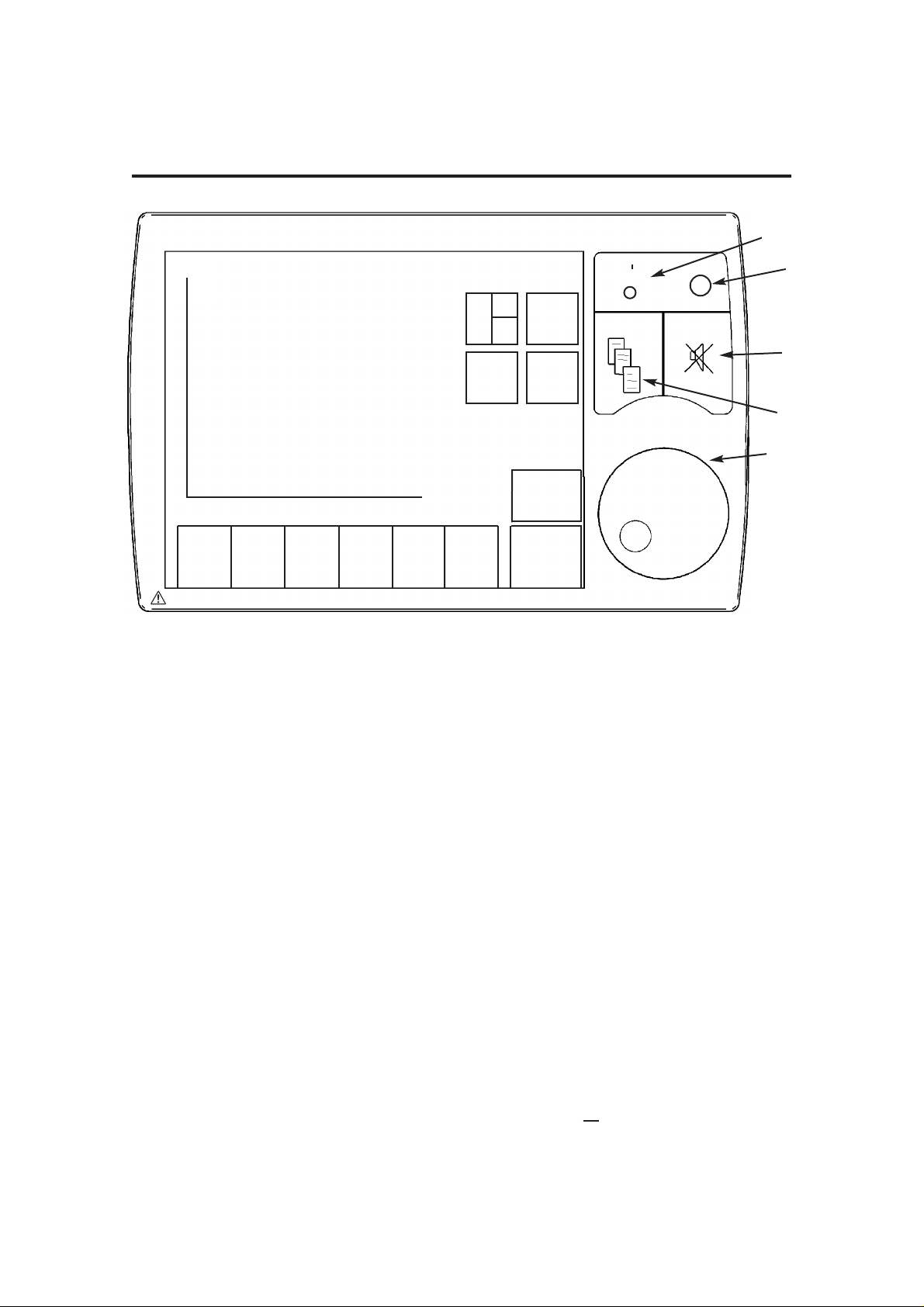

5. Navigator Wheel and Press Button

Turn the wheel to select a function or

parameter, or to alter the value of an

active parameter.

Press to confirm the setting.

3.5.1.2 Selecting Functions and

Parameters

The functions/parameters shown on the

screen can be activated as follows:

a) touch the screen at the appropriate tab

area.

b) rotate the navigator wheel and press it

when the indicator arrow is on the required

parameter tab

Note that parameters default to factory-set

values when the ventilator is switched on

and no further user selection is made.

3.5.1.3 User Adjustable Parameters

Variable parameters can be altered by

rotating the navigator wheel.

When the required value is displayed, press

the active tab or

the wheel to confirm the

setting.

3.5 Control Panel

3.5.1 Touchscreen and Navigator

Wheel / Push Button

3.5.1.1 Control Panel

1. On/Off control

Switch On:

Short internal test sequence

Switch Off:

5 second power down sequence with

audible tones

2. Status indicators for electrical power

(mains/battery supply)

Yellow indicator

- illuminated whenever power is

applied to the unit and internal battery

is being charged

Green indicator

- illuminates when the unit is switched

on, .

3. Menu switch

The menu function provides access to

user and service pages

4. Alarm mute switch

30 second or 120 second Alarm

silence, depending on alarm status.

Note also that some alarms are not

mutable (see 3.11).

16

3.5.2 User Adjustable Parameters

Tidal Volume Range 20 - 1600 ml

Rate 4 - 100 bpm

I:E Ratio 1:0.3 to 1:8

PEEP 4 - 30 cmH2O

Can be set to OFF

Pressure Limit

Volume mode: 10 - 80 cmH2O

Pressure mode: 10 - 70 cmH2O

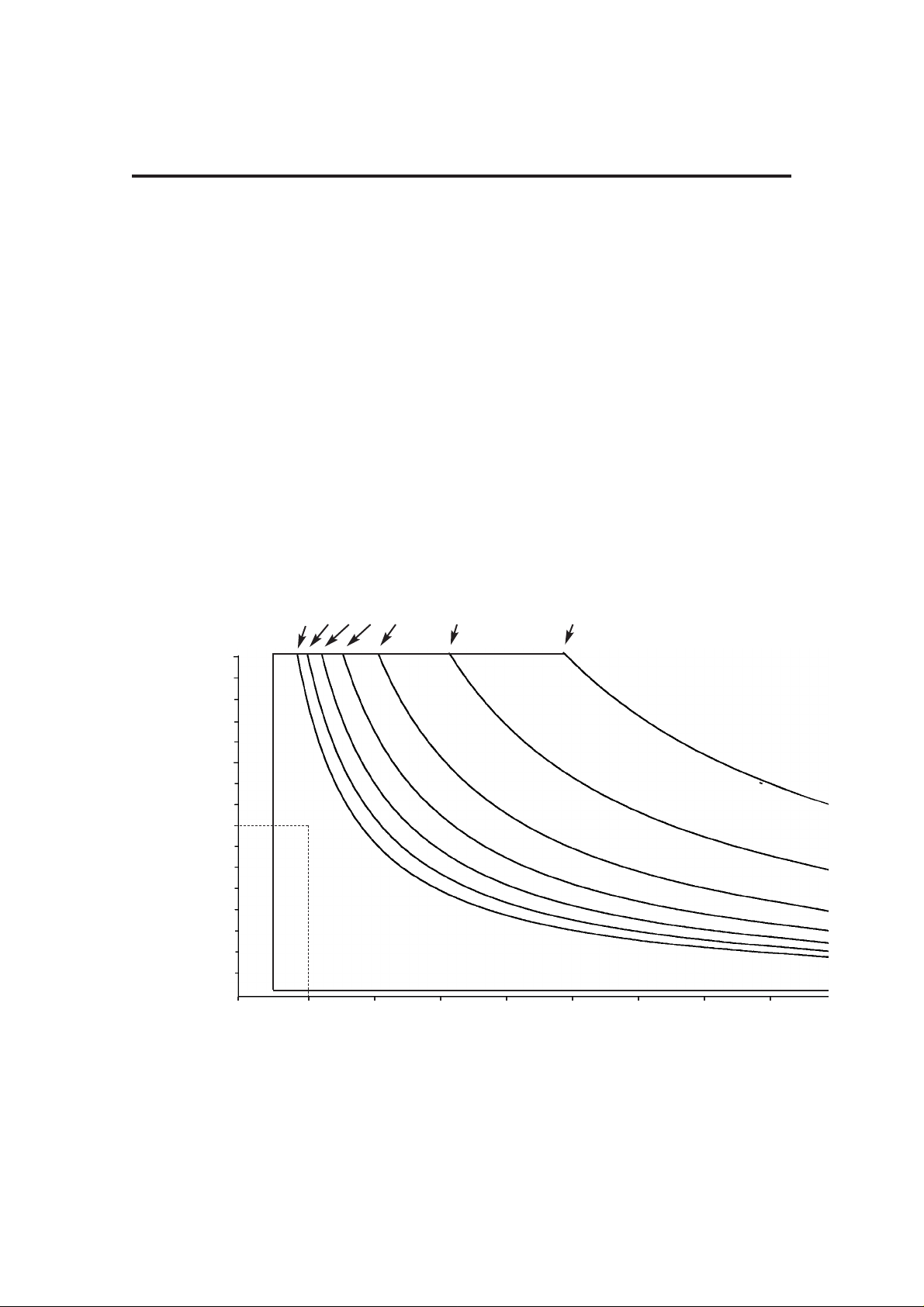

3.5.3 Operational Capability

Tidal Volume, Rate, and I:E ratio settings are all limited by a

maximum inspiratory flow of 75 L/min.

DESCRIPTION

17

0.1

0.2

0.4

0.3

0.6

0.5

1.6

1.5

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0 10 20 30 40 50 60 70 80

1:6 1:5 1:4 1:3 1:2 1:1 1:0.3

Rate (bpm)

Tidal

Volume

(litres)

(Vt)

I:E Ratio

The ventilator is capable of operating at the volumes and rates below each I:E ratio curve.

Example

1. Select required volume (Vt) (e.g. 0.8 L)

2. Select rate (e.g. 10 bpm).

3. Select I:E ratio of 1:2.

The point X on the graph lies beneath the 1:2 ratio curve, and is therefore within the

ventilator’s capability

.

X

3.5.4 Output Compensation

Functions

WARNING

The AV-S automatically compensates for fresh

gas (spirometry On), fresh gas mixture

(spirometry and oxygen monitor On), and

altitude.

However, the actual tidal volume delivered to the

patient may be different to the ventilation

parameters set by the user, due to:

A) an extreme compliance condition,

B) a substantial system leak,

C) patient circuit pressure effects, or

D) extreme fresh gas flows

In addition, high fresh gas flows will lead to an

increased Vt being delivered to the patient.

The patient must

be monitored independently

from the ventilator.

It is the responsibility of the user to monitor the

patient for adequate ventilation.

Fresh Gas Compensation

Adjusts delivered volume up to 60%

Alarms if measured volume is 50% different

than set volume

User adjustable

NOTE

Fresh gas compensation is disabled if :

a) The spirometry system is turned OFF through the

menu system, or

b) The spirometry system is not functioning correctly .

Fresh Gas Mixture Compensation

- models with Spirometry

The spirometry system compensates for fresh gas

mixture - the user must access the menu system and

select the gas mixture that will be used for each

clinical procedure.

NOTE

Fresh gas mixture compensation is disabled if :

a) The spirometry system is turned OFF through the

menu system, or

b) The spirometry system is not functioning correctly .

If the O2 monitor is switched OFF, a 40%/60%

mixture of O2/N2O is assumed.

Altitude Compensation

Monitors ambient pressure

Adjusts delivered volume accordingly

DESCRIPTION

18

A

B

3.6 Interface to Prima SP2/3 and A200SP

The AV-S is designed to interface with the Prima

SP Anaesthetic Machine and the A200SP

Absorber.

3.6.1 Prima SP Interface

The interface cable links the socket (A) on the

control panel to a socket on the rear panel of the

anaesthetic machine.

a) Turn the Prima Sp Gas Delivery Switch to

ON.

The ventilator will power-up.

b) While the Prima SP power is ON, the

Ventilator can be turned OFF and ON, using

the ventilator On/Off switch, as described in

section 3.5.1.

c) Turn the Prima SP Gas Delivery Switch to

OFF. The ventilator will power-down.

3.6.2 A200SP Absorber Interface

The interface cable links the socket (B) on the

control panel to a socket (C) at the rear of the

absorber.

a) The A200SP is fitted with fitted with a sensor

that detects the position of the absorber

bag/vent control (D).

The sensor signal cabling is routed internally

to connector (C) and a second cable runs to

the the rear of the AV-S control unit.

b) Operation of the Bag/Vent control will trigger

automatic Mode switching on the AV-S

ventilator, as follows:

i) If the Absorber Bag/Vent control is moved

from Vent to Bag, the ventilator will change

from Volume Mode, or Pressure Mode, into

Spontaneous Mode.

ii) Switching the absorber Bag/Vent control

from Bag to Vent:

The ventilator will reset from Spontaneous

Mode to the previously set active mode.

iii) If the ventilator is in any mode other than

those detailed above, operation of the

absorber Bag/Vent control will not affect the

ventilator.

NOTE This function can be enabled/disabled

through the AV-S on-screen menus (Service Submenu, see appendix).

19

DESCRIPTION

D

C

3.7 Ventilation Modes

3.7.1 Standby Mode

Allows parameters to be set.

Some patient alarms are active:

High airway pressure (at 80 cmH2O)

High/Low O2

Negative pressure

Incorrect Rate/Ratio

DESCRIPTION

20

3.7.2 Volume Mode

The ventilator delivers a mandatory set

volume of gas at preset, fixed breath

intervals.

The Patient is making no respiratory effort.

3.7.2.1 Fresh Gas Compensation

Adjusts delivered volume up to 60%

This delivered volume will consist of the

volume delivered from the ventilator bellows

plus the fresh gas flow from the anaesthetic

machine fresh gas supply, minus any

compliance loss and minus any leak.

This gives a total actual inspired tidal

volume.

An alarm is triggered if measured volume is

50% different than set volume

User adjustable

Altitude Compensation

Monitors ambient pressure

Adjusts delivered volume accordingly

3.7.2.2 Operating Functions

Inspiratory Pause function: Creates

25% plateau

Sigh function:

When the ventilator is in Volume Cycle

mode the "sigh" option is available. When

selected, this option provides extra volume

for 1 to 4 breaths in 50 (frequency is user

selectable).

The extra volume will be 50% above the

tidal volume set by the user.

Volumes measured if Spirometry function

selected

Auto High and Low volume alarms if

measured volume different by 50% of set

volume

User adjustable option

If max pressure limit achieved, ventilator

cycles to expiratory phase

3.7.2.3 Volume Type Selection

Use the menu to switch between Tidal

Volume and Minute Volume.

NOTE Minute Volume is derived from a rolling

average during a 30 second period.

Volume Mode Parameters

Tidal volume 20 – 1600 mL

Rate 4 – 100 bpm

I:E ratio 1:0.3 – 1:8

PEEP 'Off' or adjustable 4 – 30 cmH2O

Inspiratory pressure limit 10 to 80 cmH2O

Inspiratory pause 25%

(does not affect I:E ratio)

Sigh 1.5 x Set Vt is

delivered once, twice,

three times or four

times every 50

breaths (user selects

frequency)

DESCRIPTION

21

3.7.3 Pressure Mode

3.7.3.1 Parameters

The ventilator delivers a volume of gas to

achieve a set pressure at fixed breath

intervals.

The Patient is making no respiratory effort.

This is a common mode for the ventilation of

small paediatric patients.

Inspiratory pressure 10 - 70 cmH2O

Rate 4 – 100 bpm

I:E ratio 1:0.3 – 1:8

PEEP 'Off' or adjustable: 4 – 30 cmH2O

Inspiratory decelerating flow controlled by the

ventilator according to pressure setting

No Inspiratory pause function

3.7.3.2 Pressure Mode Operating Functions

Defaults to 10 cmH2O

Maximum Inspiratory Flow to achieve target

pressure

Sustaining flow maintains circuit pressure

Control achieved using exhaust valve

DESCRIPTION

22

3.7.4 Spontaneous Mode

3.7.4.1 Parameters

The ventilator monitors the following patient parameters:

Rate

I:E ratio

Pressure

Tidal volume

Provides waveform displays

Inspiratory oxygen is measured

3.7.4.2 Spontaneous mode operating functions

No mechanical ventilation

No Inspiratory Pause function

Patient Monitoring (Bag mode and Ventilator mode):

Airway pressures

FiO2,

Vt,

Rate

I:E ratio,

Supply pressures

Ventilation conditions

Advanced Spontaneous Breathing modes are selectable from

this mode - see below, and section 3.7.5.

3.7.4.3 Advanced Spontaneous Breathing Modes

Support modes available from 'Special Modes' (select from

main menu):

SIMV

SMMV

PSV

The A200SPAbsorber Bag/Vent control must be in 'Vent'

position for these modes to be selected.

Note that if the system fails to detect an absorber bag/vent

switch, a confirm message will be displayed.

DESCRIPTION

23

Loading...

Loading...