Pelton Crane OCM, OCR Service manual

REMEDY

A. RECALIBRATE FROM COLD START.

B. RESISTANCE SHOULD BE 1 MEG Ω @ 77˚F 20%.

C. MEASURE VOLTAGE FROMCOMMON TERMINALOF POWER

SWITCH NO.2 TO COMMON TERMINAL OF FUNCTION SWITCH

IF 120 VOLTS, BOARD IS OPEN. IF 0 VAC, BOARD IS GOOD.

D. POSSIBILITY OF SHORT IN HOT SIDE OF LINE. TRACE OUT HOT

SIDE OF LINE FROM POWER CORD TO SWITCHES FOR A SHORT.

CHECK CENTER ELEMENT FIRST.

A. CHECK DOOR TO MAKE SURE IT IS IN THE LOCKED POSITION

AND NOT LEAKING.

B. CHECK SWITCH POSITION AND READJUST IF NECESSARY.

C. USE LEVEL AND ADJUST FEET IF NECESSARY.

D. WHEN PROPERLY FILLED, WATER SHOULD

COVER FILL PLATE.

E. TURN CLOCKWISE TO CALL FOR MORE HEAT.

F. CHECK RESISTANCE OF ELEMENT, IT SHOULD BE:

• ~ 10Ω FOR OCM

• ~ 8Ω FOR OCR OR OCR

+

G.RECALIBRATE FROM COLD START,

OR REPLACE AND CALIBRATE. (PCT042).

H.CHECK RESISTANCE. SHOULD BE 1 MEG Ω @ 77˚F 20%.

I. CHECK RESISTANCE 20K Ω 10%.

J. MEASURE VOLTAGE FROM TOP TERMINAL

OF NO. 1 POWER SWITCH TO COMMON TERMINAL

OF FUNCTION SWITCH. (IF 120 VAC BOARD IS

PROBABLY OPEN; IF 0 VAC, BOARD IS PROBABLY GOOD). THIS

IS PROVIDED THERE IS CONTINUITY THROUGH FUNCTION

SWITCH, OT SWITCH AND HEATING ELEMENT.

K. CHECK TEFLON SEATS FOR SCORING OR TRASH

LODGED AROUND SEATS. IF SCORED, REPLACE.

IF TRASH OR DEBRIS, CLEAN AND RE-ASSEMBLE.

L. CHECK FOR ACTIVATION OF SWITCH BY MAIN VALVE CAM.

ADJUST POSITION OF SWITCH ARM SO IT IS DEPRESSED

AND SWITCH IS CLOSED IN THE STERILIZER MODE.

M.VISUALLY CHECK FOR ROCKER ARM DEPRESSING PUSH ROD

IN STERILIZE MODE. CHECK FOR CLEARANCE AND ADJUST

(FLATTEN) CAM SHAFT IF NECESSARY.

A. REPLACE BELLOWS, IF NECESSARY (PCB001).

B. REPLACE TEMPERATURE GAUGE,

IF NECESSARY (PCG050).

C.REPLACE PRESSURE GAUGE, IF NECESSARY (PCG040).

D. CLEAN AIR VALVE HOUSING AND/OR REPLACE.

A.REPLACE TEMPERATURE GAUGE, IF NECESSARY.

B.REPLACE PRESSURE GAUGE, IF NECESSARY.

A. CHECK LINE VOLTAGE.

B. REPLACE BULB (PCL027).

A. REPLACE TIMER, IF NECESSARY (PCT049).

B. LOOSEN NUT ON BACKSIDE OF BELL AND RECENTER.

C.LOOSEN NUT ON TIMER SHAFT, ROTATE

TIMER UNTIL TOP MARK IS AT 12:00 POSITION.

ANALYZE

A. OVERTEMP SWITCH

B. THERMISTOR ASSEMBLY

C. SOLID STATE CONTROLLER

D. CENTER HEATING ELEMENT

A. DOOR

B. DOOR SWITCH (OCR+ ONLY)

C. UNIT LEVEL

D. AMOUNT OF WATER ADMITTED

DURING FILL CYCLE

E. POTENTIOMETER ON

CONTROLLER

F. CENTER HEATING ELEMENT

G.OVERTEMP SWITCH

H. THERMISTOR

I. FRONT POTENTIOMETER

J. SOLID STATE CONTROLLER

K. MAIN VALVE (FILL/VENT VALVE)

L. FUNCTION SWITCH

M.ROCKER ARM

A. BELLOWS

B. TEMPERATURE GAUGE

C. PRESSURE GAUGE

D. AIR VALVE HOUSING

A. TEMPERATURE GAUGE

B. PRESSURE GAUGE

A. LINE VOLTAGE

B. BULB

A. TIMER

B. TIMER BELL OFF-CENTER

C. TIMER POSITION

SYMPTOM

NO CONTROL OF

PRESSURE/TEMPERATURE

WILL NOT BUILD UP TO

STERILIZING PRESSURE/

TEMPERATURE

THERMOMETER READS

MORE THAN 4˚F BELOW

REQUIRED TEMPERATURE

AT GIVEN PRESSURE

THERMOMETER READS

MORE THAN 4˚F ABOVE

REQUIRED TEMPERATURE

AT GIVEN PRESSURE

PILOT LIGHT BULBS SLOW

TO LIGHT WHEN AUTOCLAVE

IS TURNED ON

TIMER BELL WILL NOT RING

AT END OF TIMING CYCLE

_

+

YOUR GUIDE TO MAINTAINING

THE PELTON & CRANE OCM, OCR & OCR

+

STERILIZERS

Replacement Parts Industries, Inc. is pleased to present this valuable work tool that can help save you and your

customers time and money. Take a look, you will find a Trouble Shooting Guide, schematics, exploded views and a

complete listing of all RPI parts that fit the Pelton & Crane OCM, OCR and OCR

+

sterilizers. It’s all here, in one easy-

to-use tool. Keep it close by– in your RPI catalog or at your workbench.

_

+

_

+

TROUBLE SHOOTING GUIDE

TROUBLE SHOOTING GUIDE

CALL (800) 221-9723 or (818) 882-8611 • FAX (818) 882-7028 • EMAIL order@rpiparts.com • WEBSITE www.rpiparts.com

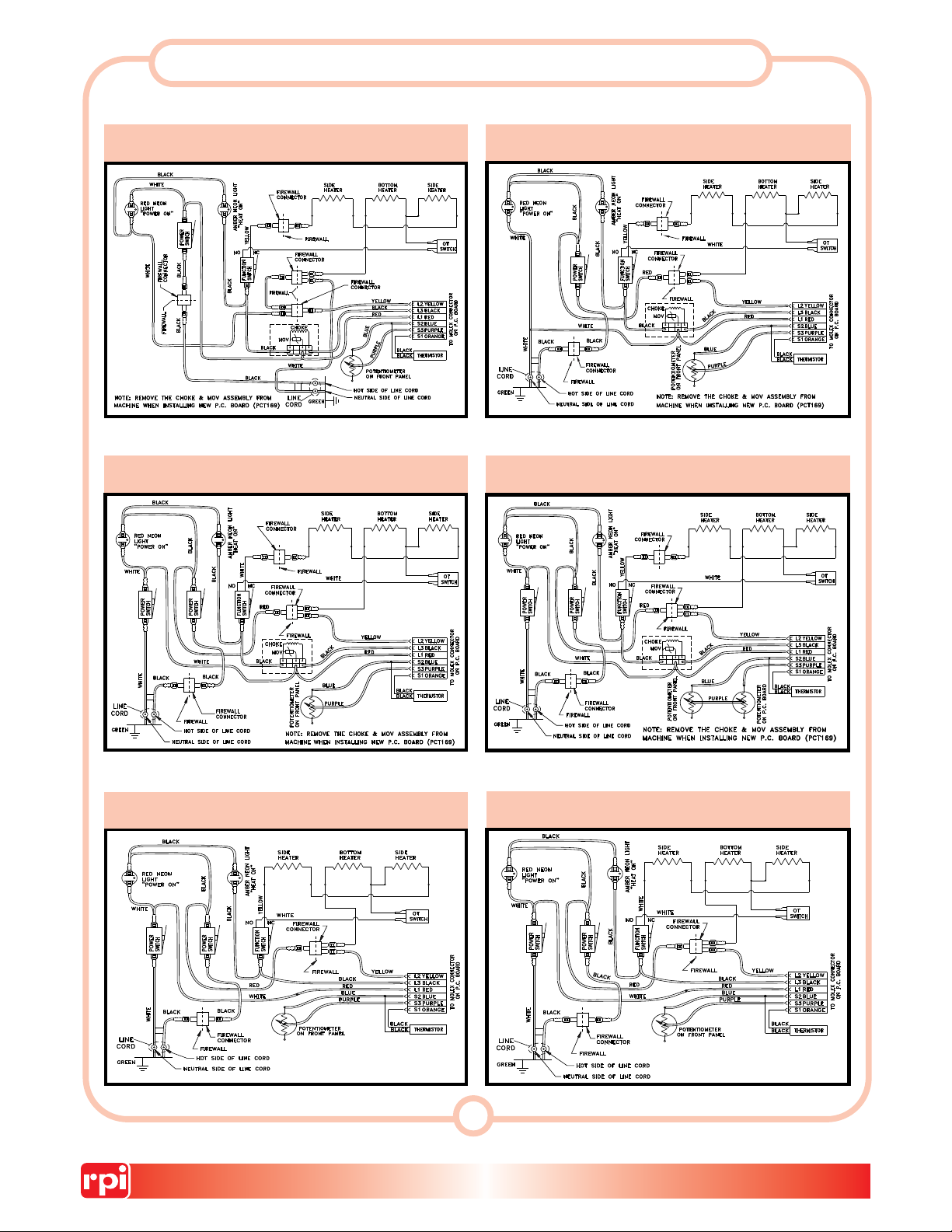

OCM & OCR SCHEMATICS

OCM

Serial #38817-41587

OCM

Serial #41588-58397

OCM

Serial #41588-51260

OCM

Serial #58398-61878

OCM

Serial #61879-69563

OCM

Serial #34350-38816

CALL (800) 221-9723 or (818) 882-8611 • FAX (818) 882-7028 • EMAIL order@rpiparts.com • WEBSITE www.rpiparts.com

2

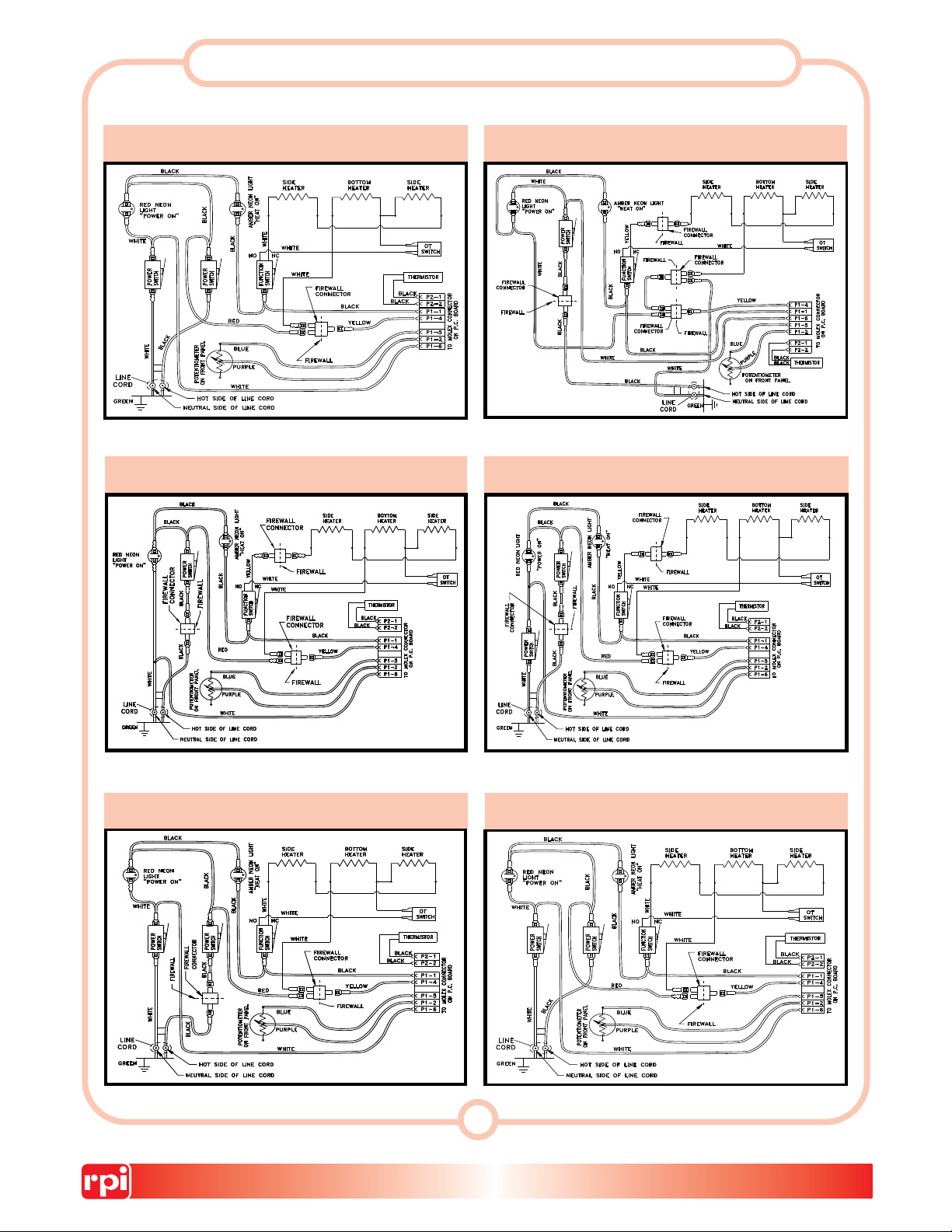

OCM & OCR SCHEMATICS

OCR

Serial #15050-17492

OCR

Serial #17493-18900

OCR

Serial #18901-33399

OCR

Serial #33400-38388

OCR

Serial #38389 AND ABOVE

OCM

Serial #69564 AND ABOVE

CALL (800) 221-9723 or (818) 882-8611 • FAX (818) 882-7028 • EMAIL order@rpiparts.com • WEBSITE www.rpiparts.com

3

Loading...

Loading...