Pelton Crane DeltaQ User manual

USE & CARE

Model AE (8")

Model AF (10")

Dear Customer

Congratulations on the purchase of your new Delta-Q Autoclave. The technical documentation provided is designed as a part of

this product. Always keep this documentation handy. The Use & Care Manual describes the 8” and 10” models. Please read the

instructions and get to know the autoclave. Please carryout maintenance according to relevent instructions.

Pelton & Crane

TABLE OF CONTENTS

Important Safety Instructions ..................................................................................................................................................... 3

Familiarization ............................................................................................................................................................................. 6

Operating Features ............................................................................................................................................................. 6

Safety Features .................................................................................................................................................................. 6

Visual Displays ................................................................................................................................................................... 4

Switch Functions ................................................................................................................................................................ 6

Audible Signals ................................................................................................................................................................... 8

Program Parameters ........................................................................................................................................................... 8

Installation .................................................................................................................................................................................... 9

Programming ............................................................................................................................................................................. 10

Operation ................................................................................................................................................................................... 11

Important Sterilization Practices ........................................................................................................................................ 11

Preparation and Loading ................................................................................................................................................... 12

Operating Steps ................................................................................................................................................................ 13

Maintenance ............................................................................................................................................................................... 14

Maintenance and Performance Schedule .......................................................................................................................... 14

Cleaning Procedure .................................................................................................................................................... 15 -16

Tr o ub l e Shooting Guide ..................................................................................................................................................... 17

Self-Diagnostic Check ...................................................................................................................................................... 19

Operating Alarms .............................................................................................................................................................. 20

Options ....................................................................................................................................................................................... 21

Installation and Servicing Checklist ......................................................................................................................................... 22

-2-

! IMPORTANT SAFETY INSTRUCTIONS !

Caution! Personal Safety

•To avoid electrical shock, never insert plug into outlet with

wet hands.

•Do not attempt to open door unless pressure gauge reads

“0” or injury may result.

•Do not operate Autoclave in area containing combustible

gases.

•Do not place Autoclave within 6 feet of patient.

•Routinely inspect power cord for cuts and abrasions.

Discontinue use and have authorized service representative replace cord if damaged.

•Protect your hands from contact with soiled instruments to

prevent serious infections. Wear heavy rubber gloves when

handling instruments.

Warning! T o A v o i d S e r i o us B u r n s:

Do not open door during sterilization cycle.

Stand to one side when opening door after

sterilization cycle and do not place hands or

face over door.

-Use a tool or hot pad to remove trays and avoid

touching chamber walls.

-Stand away from door after the sterilization cycle is

completed. Liquids may still be in the chamber and

can cause serious burns.

-Ensure unit is properly leveled. Follow the Installa-

tion Instructions on page 9.

-When performing safety valve maintenance (pg. 14)

stand clear of discharge area (lower right corner at

rear of unit).

Caution! Check weekly for proper

door switch operation (see pg. 14).

Product Safety

•This unit requires a dedicated circuit (separate branch circuit

only).

•Always use distilled quality water. Tap water will cause

corrosion of chamber and clog valves and filters with mineral

deposits.

•Never operate unit outside the specified voltage range (see

data plate on back of unit).

•Do not use steel wool or steel brushes on stainless steel.

Metal pads will damage chamber.

•Use only manufacturer’s replacement parts/accessories.

Failure to do so may cause poor performanc e.

•Refer servicing to authorized service representative.

•Do not position the unit so that it is difficult to reach the

circuit breaker on the power plug.

WARNING: If unit is operating in high altitude,

adjustments to time, temperature or pressure

may be required. Also, leaking of safety valve

may indicate need for adjustment.

Do not remove cover: Electrical shock

hazard. Refer servicing to authorized

service representative . Disconnect power

before servicing.

DANGER: Do Not attempt to open door with

pressure in the chamber. Avoid direct contact with hot chamber walls or sterilized load.

Use metal handle (8” model only) and gloves.

Warning! —To avoid serious burns —

If used for liquid sterilization, the liquid

must be allowed to cool or the liquid may

boil when exposed to atmospheric pressure. Pelton & Crane does not recommend use of

this device for liquid sterilization.

Product Disposal

Caution!

Contact your local authorized

dealer for proper disposal of the

device or the components of the

device to ensure compliance with

your local environmental regulations.

CAUTION: ANY LIQUIDS THAT ARE STERILIZED

IN THIS UNIT ARE FOR LABORATORY USE

ONLY AND NOT FOR USE IN DIRECT PATIENT

CONTACT.

Interference with electromedical devices:

To g u a r a nt e e t h e o p e r a t io n a l s a f e ty o f e l ec t r o m e d ic a l d e v i c e s,

it is recommended that the operation of mobile radio telephones in the medical practice or hospital be prohibited.

Strong EMI sources such as electro surgery units or x-ray

units may effect performance. If performance problems occur,

move the unit to another electrical circuit or physical location.

-3-

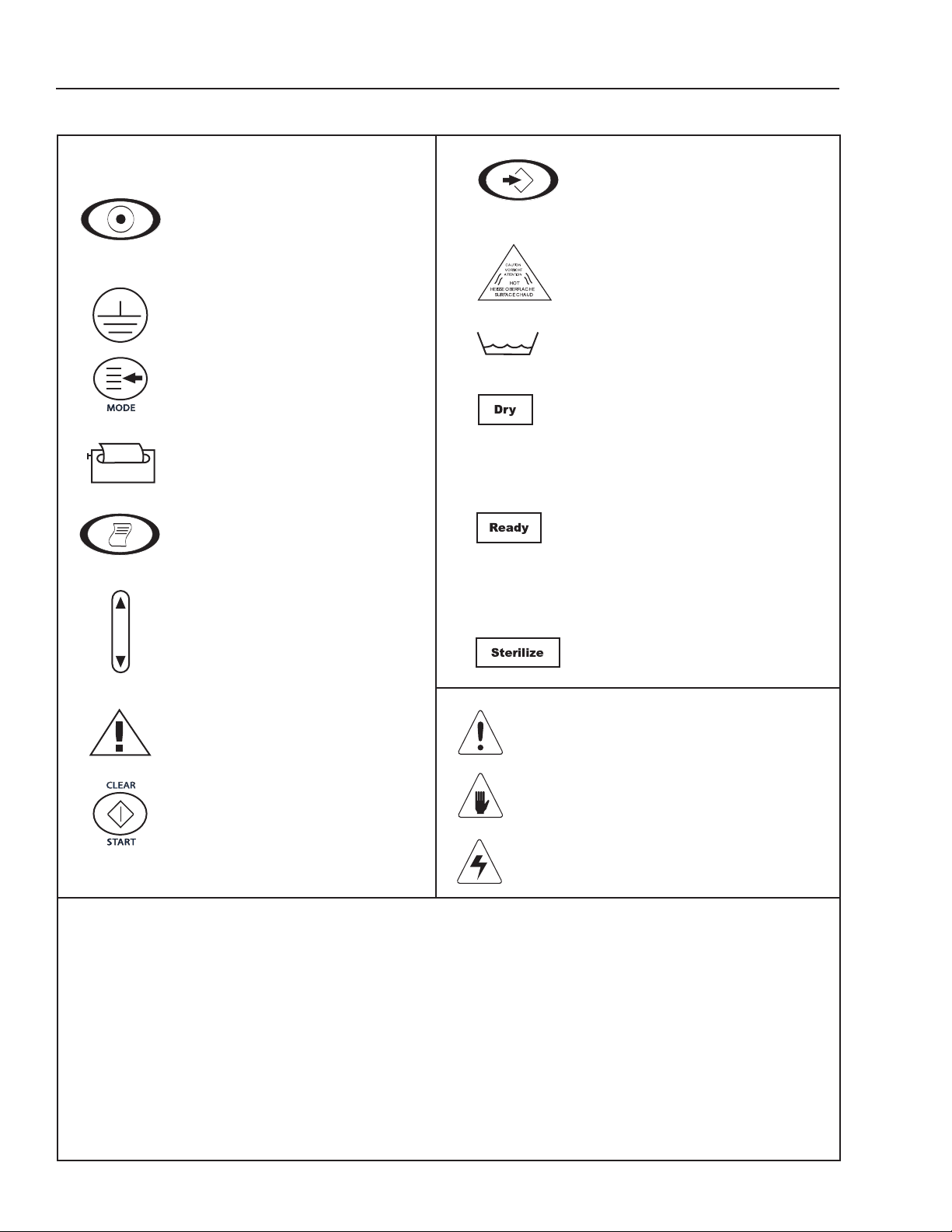

Power

Ground

Mode

Printer Connection

PRODUCT INFORMATION

Table of Sym b ols

Program

Hot Surface

Low Water

Dry

Printer On/Off

Arrows

Attention: Printer Connection Only

Clear/Start

The conformity of the quality management system is certified with Certificate No. 369CE, dated April 8, 1999 by:

AMTAC Certification Services, LTD

Norman Road, Broadheath, Altrincham

Cheshire WA 14 4EP, United Kingdom

CAUTION. Failure to carefully follow the

described procedure may result in damage

to the equipment.

WAR NING . Fail ure to care fully fo llow the

described procedure may result in damage

to the equipment and the operator.

Risk of electrical shock present. Make sure

power is disconnected before attempting this

procedure.

Ready

Sterilize

-4-

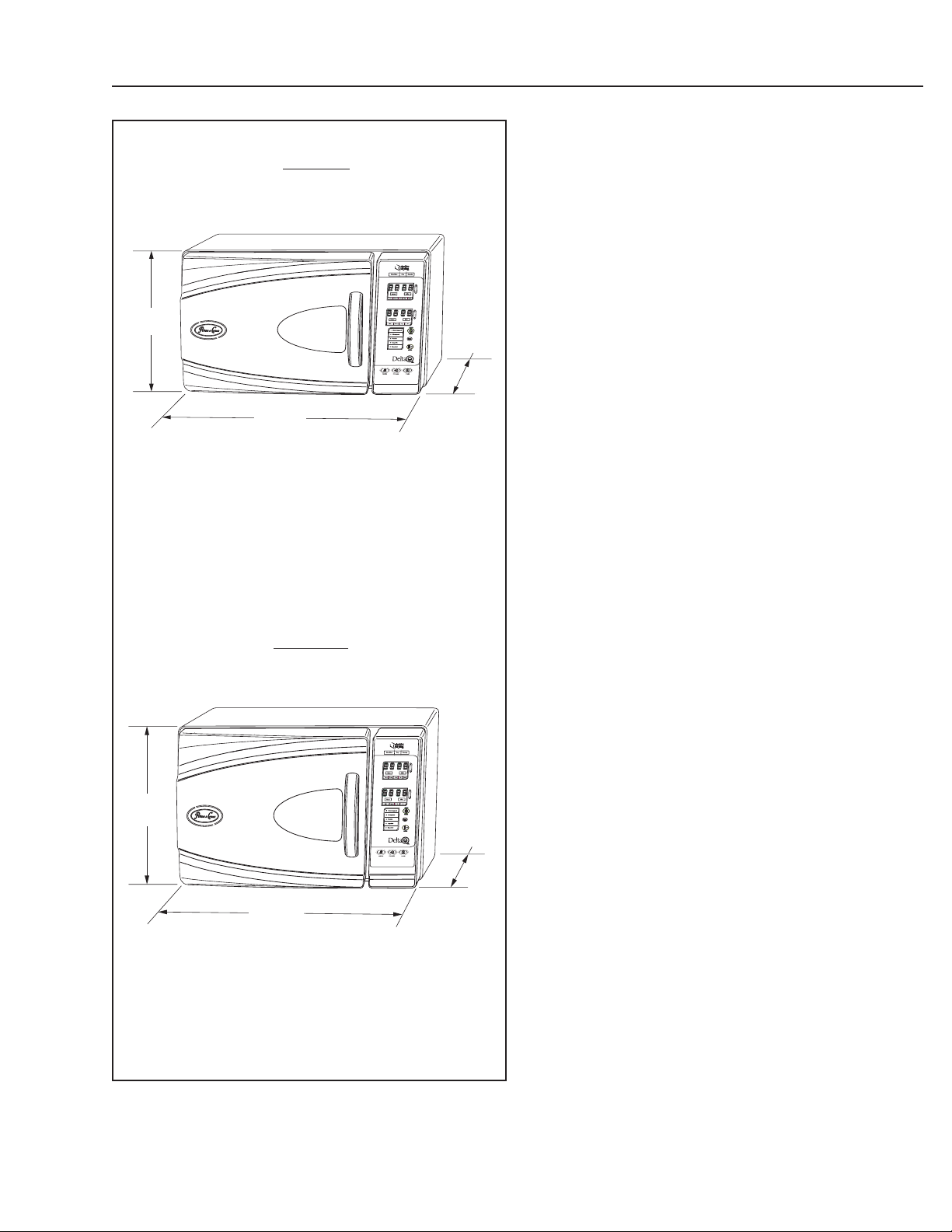

12 1/4”

(31.1cm)

14”

(35.6cm)

8” Model

17 ½”

(44.5cm)

10” Model

19 1/4”

(48.9cm)

PRODUCT INFORMATION

Specifications

Exterior Dimensions

8” Model12 1/4” high x 20 1/4” deep x 17 1/2” wide

(31.1 cm high x 51.4 cm deep x 44.5 cm wide)

10” Model14” high x 24 5/8” deep x 19 1/4” wide

(35.6 cm high x 62.5 cm deep x 48.9 cm wide)

Chamber Dimensions

8” Model8 7/32” inside diameter x 14” useable depth

(21 cm inside diameter x 35.6 cm deep)

20 1/4”

(44.5cm)

24 5/8”

(62.5cm)

10” Model9 7/8” inside diameter x 17 7/16” useable depth

(25.1 cm inside diameter x 44.3 cm deep)

Weight Without Water in Reservoir

8” Model61 lbs. (28 kg)

10” Model84 lbs. (38 kg)

Measurement Accuracy

Pressure: +/- 8 kPa (1.16 PSI or .08 bars)

Te m p e ra t u r e : + / - 3 . 6 ° F ( 2 ° C )

Time: +/- 1 second

Power Supply

Both Models110 - 120 Volts, 50/60 Hz or

220 - 240 Volts, 50/60 Hz

Nominal Current Consumption

8” Model12 Amperes @115 Volts

6 Amperes @230 Volts

10” Model10 Amperes @115 Volts

8 Amperes @230 Volts

Environmental and Storage Limitations

Both ModelsOptimum Operating Temperature Range:

50°F to 104°F

(10°C to 40°C)

Relative Humidity Range:

30% to 75%

Unit is designed for normal dental/medical office environ-

ment.

NOTE: If printer is used, its operating temperature is 41°F

to 95°F (5°C to 35°C).

Mode of Operation:

Both Models- Continuous

NOTICE: Manu facture r wi ll m ake available all information

which will assist the authorized service representative to

repair equipment. Calibration of the power board is to be

done only at the factory.

-5-

FAMILI ARIZATION

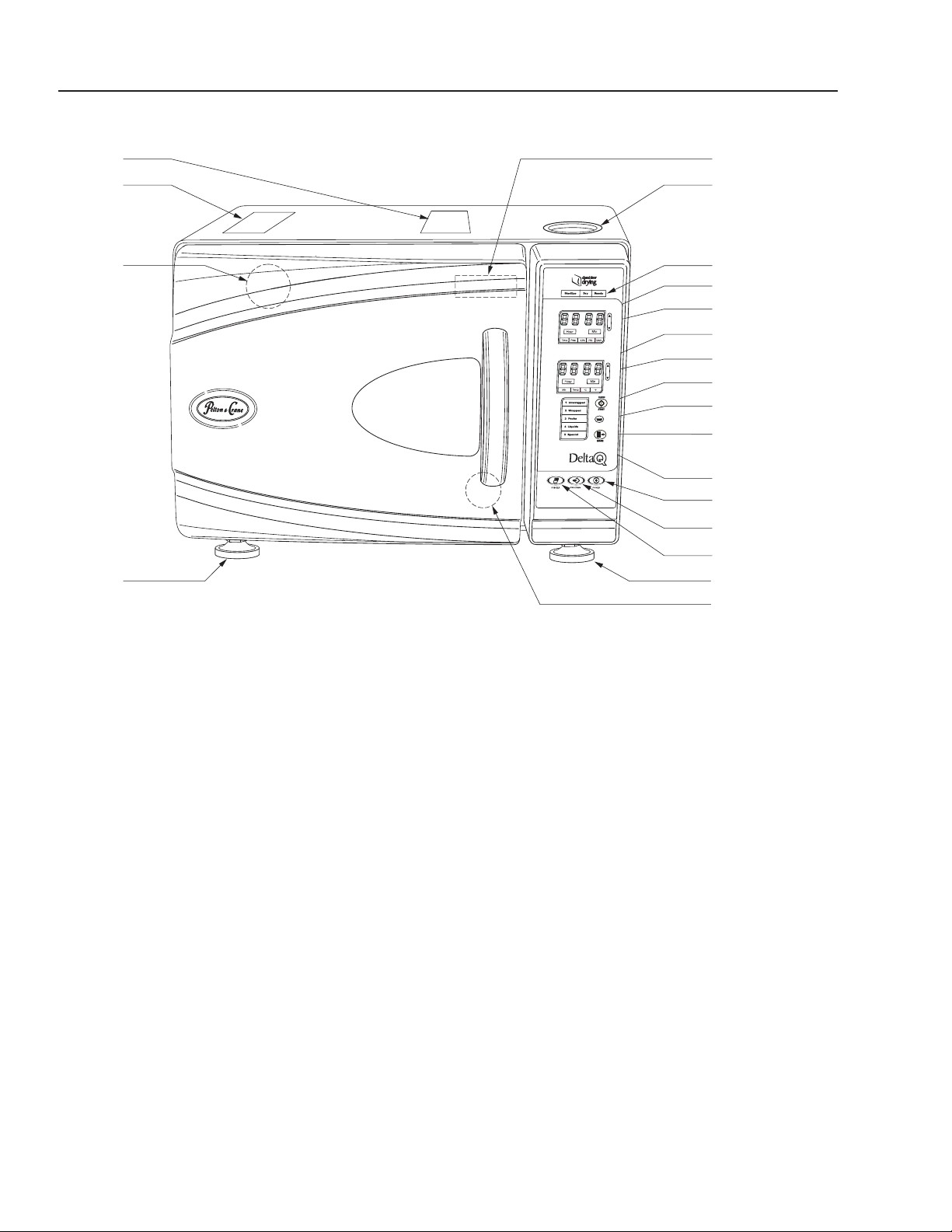

19

18

17

15

20

2

3

4

5

6

5

7

8

9

10

11

12

13

15

14

OPERATING FEATURES

1. Power Switch/Circuit Breaker (rear of unit)

2. Reservoir Fill

3. Operation Indicator Light

4. Display Window (Pressure) kPa

5. Arrow Switches

6. Display Window (Temp/Time) C/F / Minutes

7. Clear/Start Switch

8. Low Water Light

9. Mode Selection Switch

10. Mode/Program Display

11. Power On Switch

12. Programming Switch

13. Printer On/Off Switch

14. Quick Drain Connection (inside door)

15. Leveling Feet

16. Door Lock

17. Safety Valve (rear corner of unit)

18. Operating Instructions Label

19. Caution Label

20. Serial Number Plate (inside door)

.

SAFETY FEATURES

The design of the autoclave has these safety features for

your protection:

Door Lock

Door can be opened only when internal pressure is at

atmospheric pressure.

Vent Valve

The vent valve will open and the P-2 alarm will display should

the chamber pressure exceed 240 kPa.

Safety Valve

The safety valve opens as backup protection should the

chamber pressure exceed 262 kPa.

Overheat Protection

Chamber temperature is protected with a surface sensor so

the temperature will not exceed 159°C. It has additional

overheat protection should the temperature of the heating

elements reach 180°C.

Electrical Power Interruption

In case of a power failure during the sterilization cycle,

pressure in the chamber is automatically vented to the

atmosphere and display is blank

-6-

FAMILI ARIZATION

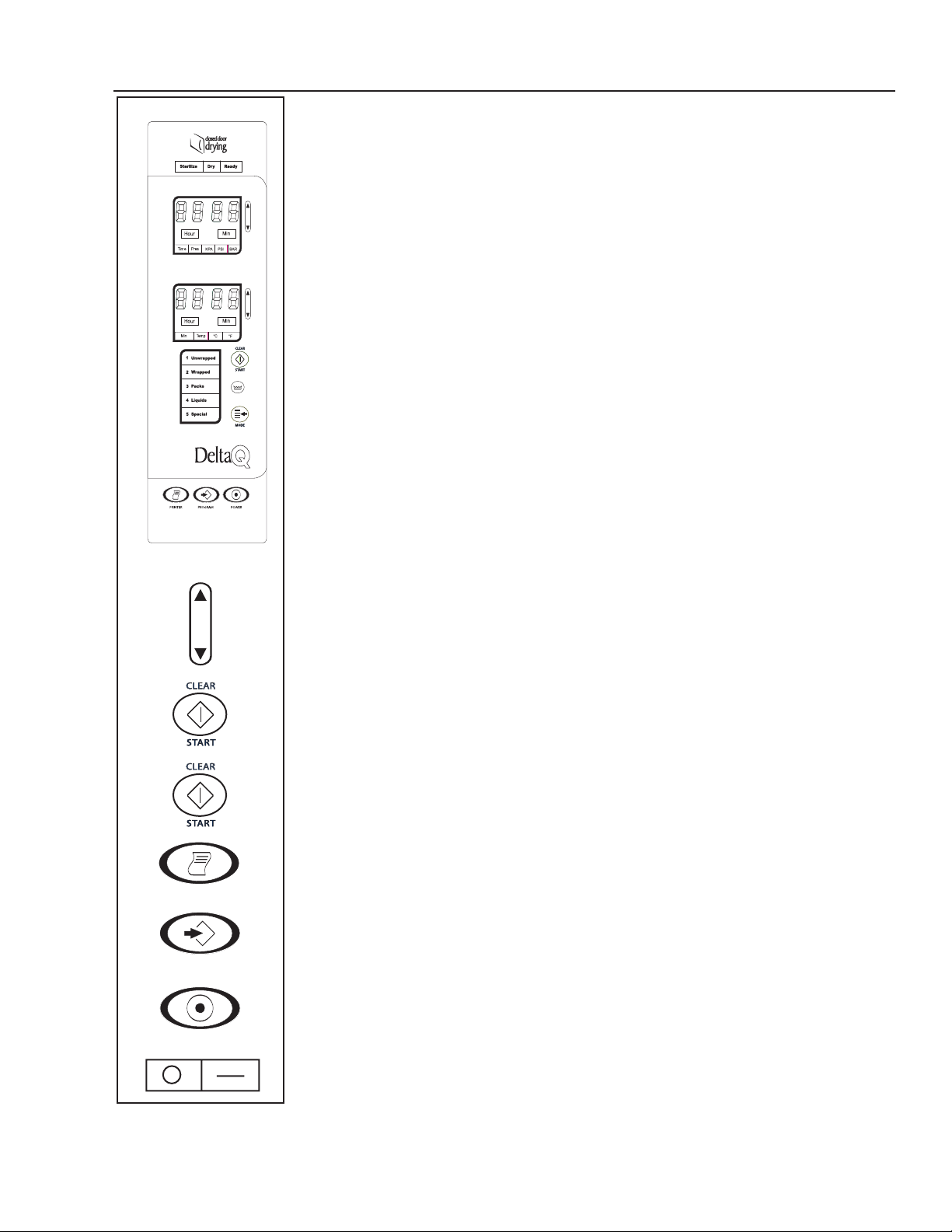

VISUAL DISPLAYS

Indicator Lights

“Sterilize” light illuminates to indicate sterilization cycle in progress.

“Dry” light indicates the heater and pump are on for the drying cycle.

“Ready” light illuminates when instruments may be removed from chamber.

Upper Window

Displays Time, Pressure, Clock and Year.

Lower Window

Displays Temperature, Date, Operational Timer, Failure Codes, Power colon “:” (

power button is not activated when main power is ON) and End.

Mode/Program

See Program Parameters, pg. 10.

Low Water

When the water level in the reservoir is too low, the “Low Water” light illuminates.

SWITCH FUNCTIONS

Arrows

Increases or decreases values of digits flashing when programming the system

parameter.

Clear/Start

Controls the start of a sterilizing cycle when unit is in stand-by. Also, used to clear

a cycle and returns unit to stand-by. If depressed with “Power” switch, self-diagnostic check is performed.

Mode Selection

Press to select one of the five sterilization mode programs. (See page 14 for

special mode)

Printer On/Off

Use to switch the printer on or off.

Program

Sets the minutes, hour, day, month and year. Chooses units of temperature and

pressure. Changes the drying time. Also, chooses the Special mode to the parameter desired. It initiates selected display mode during sterilization.

Power

Powers on operating contro ls. LCD will be visible. If depres sed wi th “Clea r/Star t”

switch, self-diagnostic check is performed.

Main Power (back of unit)

Depress “I” side of switch to turn unit on. A colon “:” illuminates in the lower

display indicating power is on. Leave switch in the On position.

-7-

FAMI LIAR IZAT ION

AUDIBLE SIGNALS

Switches

One beep occurs when depressing switches, except when depressing Power Switch and Arrow switches. When pressing

Arrow or Power Switch, no beep occurs.

Sterilization/Dry Cycle

Five beeps indicate the Sterilization or Drying cycles are complete.

Operational Alarm

Sixty beeps indicates an operational error or alarm. Depress Clear/Start to put unit in standby mode.

Door Open

Continuous beeping indicates the door has been opened during or prior to start of cycle.

PROGRAM PARAMETERS*

Program/Temp**, Pres,

Time**

1Unwrapped/

134°C, 216 kPa for 3

minutes

2Wrapped/

134°C, 216 kPa for 12

minutes

3Packs/

121°C, 115 kPa for 30

minutes

4Liquids/

121°C, 115 kPa for 30

minutes

Items to be Sterilized

Instruments loose on a tray. Open glass or metal canisters. Heat-resistant rubber tubing

which will not be used in surgical procedure. Any items where 134°C-137°C for 3 minutes

is appropriate.

Loosely wrapped individual instruments.

Wrapped dental handpieces***. Multiple layers of instruments separated by fabric. Instruments in pouches. Wrapped tray of loose instruments. Heat-resistant rubber tubing. Any

items where 134°C-137°C for 12 minutes is appropriate.

Common groups of surgical instruments in commercially prepared packs. Surgical instruments subject to prolonged storage. Any items, other than liquids, where 121°C for 30

minutes is appropriate.

Liquids or gels that could boil or spill out of container. At end of sterilizing cycle, venting is

slowed to allow heat in liquid to dissipate

slowly and eliminate boilovers. Venting occurs at 20 kPa to complete the cycle. There is

NO drying cycle in the “Liquids” mode.

!CAUTION: ANY LIQUIDS THAT ARE STERILIZED IN THIS UNIT ARE FOR

LABORATORY USE ONLY AND NOT FOR USE IN DIRECT PATIENT CONTACT.

Warning! —To avoid serious burns —

If used for liquid sterilization, the liquid must be allowed to cool or the liquid

may boil when exposed to atmospheric pressure. Pelton & Crane does not

recommend use of this device for liquid sterilization.

5Special/

Programmable to

101°C to 135°C, for 1

to 90 minutes.

* For mixed loads, use the longer or lower temperature program (i.e., for loose instruments and surgical dressings in packs, use

“3 Packs”).

** Time and temperatures are minimums.

*** When sterilizing handpieces, check handpiece manufacturer’s recommendations for appropriate sterilization conditions. Use “2

Wrapped” program only if handpieces are able to withstand 134°C-137°C temperature.

The names of the various modes of operation are general categories.

When selecting the mode of operation, take into consideration the density of the individual load and the ability of the steam to

circulate and penetrate wraps. Then determine the correct programmed values to assure sterilization.

Dependent upon parameters user has programmed. Operator is responsible for correct

time and temperature settings for load.

-8-

Loading...

Loading...