Page 1

PRODUCT SPECIFICATION

EXSITE ENHANCED FIXED SERIES

camera solutions

ExSite® Enhanced Explosionproof Camera System

HIGH RELIABILITY, FULL HD FIXED IP SYSTEMS

Product Features

• Up to 1920 x 1080p Resolution Wide Dynamic Range (WDR),

30x zoom lens, and Superb Low light Performance

• Dual Stream H.264 IP Video with Smart Compression

• Rated to Operate from -60 to +60° C while in Compliance to T6

Surface Temperature (<85

• 316L Billet Stainless Steel Electro Polished Construction

• Standard IP Ethernet Connection and Integrated Transmission

Options including Fiber, Ethernet over Coax, and UTP Extension

• Full Suite of Built-In Analytics including AutoTracker, Adaptive

Motion Detection, Abandoned Object, and More

• Electronic Image Stabilization

• ONVIF Profiles S, G, and Q Conformant

• Efficient Installation with a Safety Attach Point, and Simple Wire

Termination Methods.

• Dual Entry Ports to Separate Data and Power Cables

° C) Hazardous Location Regulations

• Certifications: FCC Part 15, CE, UL/cUL, ICES-003, RCM, S-Mark, KC

• Hazardous Location Certifications: IECEx, ATEX, INMETRO, EAC Ex,

CCOE, UL/cUL, NTRL

• Marine Certification: DNV

ExSite Enhanced Series camera systems are designed to meet

demanding explosionproof requirements, providing high reliability,

ease of installation, and best-in-class imaging and technology.

The ExSite Enhanced Series is designed for rugged environmental

applications including oil and LNG facilities, refineries, on and

offshore drilling rigs, and on-board marine applications. Featuring

rugged 316L stainless steel construction that has been subjected to

extensive vibration and environmental testing make it ideal for use in

the most extreme conditions of temperature, moisture, ice, and dust.

The system can operate from –60° to 60°C (–76° to 140°F) while

maintaining compliance to the T6 (<85°C) surface temperature

specifications.

ExSite Enhanced Series cameras are easy to install and adaptable to

most operational needs. The camera has dual-entry ports, allowing

for separate transmission and power cables, and it is adaptable to

most transmission methods via SFSP modules. ExSite Enhanced

cameras support a range of input power options with a new 48 VDC

option that enables installation in DC-only facilities. ExSite

Enhanced cameras also come standard with wipers and sun shrouds,

capturing desired video regardless of the weather.

The ExSite Enhanced Series provides industry-leading image quality

using a Full HD 1080p camera with 30x zoom producing up to 60

images per second. The ExSite Enhanced system has Surevision 3.0

technology, providing excellent picture quality in the challenging

lighting conditions common to hazardous areas with 130db wide

dynamic range (WDR), and low-light imaging performance down to

.03 lux. The camera’s image defog capability increases video quality

in poor visibility conditions. And with anti-bloom, 3D noise filtering,

and enhanced tone mapping, ExSite Enhanced with Surevision 3.0

technology offers the finest video quality in the explosionproof

market.

International Standards

Organization Registered Firm;

ISO 9001 Quality System

C4041 / PRELIMINARY 2-2-17

Page 2

TECHNICAL SPECIFICATIONS

Additional Features

• Integrated Wiper

• Sun Shroud, and Heater/Window Defroster

• Configurable On-Screen Displays

• 4 Alarm Inputs

• 2 Relay Outputs (1 is dedicated for the washer)

• Autofocus with Manual Override

• Auto Iris with Manual Override

• Dual cable entries for multiple data and power configurations

• Easily accessible internal microSD storage for local recording (ONVIF

Profile G)

• 1000Base-T / 100Base-T ethernet or SFSP connection

• FSFP modules to support fiber, ethernet-over-coax (EoC), or UTP

• Compatible with Third Party Explosionproof Wash Systems

• Manual 360° Pan and 180° Tilt Adjustments with optional accessory

mount

• Remote hard-reset capability allows for maintenance without physical

access to the camera

PELCO ANALYTICS BEHAVIORS

ExSite Enhanced includes nine user-configurable behaviors, with up to three

analytics behavior active at any one time.

• Abandoned Object: Detects objects placed within a defined zone and

triggers an alarm if the object remains in the zone longer than the userdefined time allows.

• Adaptive Motion Detection: Detects and tracks objects that enter a

scene and then triggers an alarm when the objects enter a user-defined

zone.

• Camera Sabotage: Detects contrast changes in the field of view. This

behavior triggers an alarm if the lens is obstructed by spray paint, a cloth,

or lens cap or if there is any unauthorized repositioning of the camera.

• Directional Motion: Generates an alarm when a person or object

moves in a specified direction over a user defined “trip wire” location.

This behavior is often used where personnel or vehicles are supposed to

enter or exit a scene going a specific direction; subjects coming from the

disallowed direction will trigger the analytic alarm.

• Loitering Detection: Identifies when people or vehicles remain in a

defined zone longer than the user-defined time allows. This behavior is

effective in real-time notification of suspicious behavior in sensitive

areas.

• Object Counting: Counts the number of objects that enter or pass

through a user defined zone.

• Object Removal: Triggers an alarm if an object is removed from a

user-defined zone.

• Stopped Vehicle: Detects vehicles stopped near a sensitive area longer

than the user-defined time allows.

SOFTWARE FEATURES

• 256 presets

• 16 tours

• Multilingual menus

• Password protection

• 32 window blanks, configurable in size

• Configurable park

• Proportional pan/tilt continually decreases pan/tilt speeds in proportion

to depth of zoom

• Pelco analytics including nine user-configurable behaviors

• Smart Compression, reducing bandwidth consumption while still

providing high quality imaging

CAMERA/OPTICS

Sensor Type 1/2.8-inch Type Exmor CMOS Sensor

Optical Zoom 30X

Digital Zoom 12X

Maximum Resolution 1920 x 1080

Aspect Ratio 16:9

Lens f/1.6 ~ f/4.7, focal length 4.3 mm (wide) ~

129.0 mm (tele)

Horizontal Angle of View 63.7° wide - 2.3° tele

Light Sensitivity*

Color (33 ms) 0.03 lux

Color (250 ms) 0.008 lux

Mono (33 ms) 0.004 lux

Mono (250 ms) 0.001 lux

Day/Night Capabilities Yes

Shutter Range 1/1 ~ 1/10,000 sec

Signal-to-Noise Ratio >50dB

IR Cut Filter Yes

Wide Dynamic Range 130 db

Iris Control Auto iris with manual override

Backlight Compensation Yes

Automatic Gain Control Yes

Active Noise Filtering Yes; 3D Noise Filtering

Electronic Image

Stabilization (EIS) Yes

*Sensitivity in lux for 90% reflectance, f/1.6 (wide angle), 50 dB gain

at 30 IRE (30% of signal level) with Sensitivity Boost OFF; 4X

improvement to sensitivity with Sensitivity Boost ON

Page 3

TECHNICAL SPECIFICATIONS

VIDEO

Video Encoding H.264 High, Main, or Base profiles and

Video Streams Up to 2 simultaneous streams; the second

Frame Rate Up to 60, 30, 25, 15, 12.5, 10, 8.333, 7.5, 6, 5,

Available Resolutions

Resolution

MPx Width Height

2.07 1920 1080 16:9 30 6.05

0.92 1280 720 16:9 30 3.00

0.36 800 448 16:9 30 2.00

0.23 640 352 16:9 30 1.80

MJPEG

stream is variable based on the configuration

of the primary stream

3, 2.5, 2, 1 (depending on the coding,

resolution, and stream configuration)

H.264 High Profile

(IP GOP structure)

Aspect

Ratio

Maximum

IPS

Recommended

Bit Rate (Mbps)

NETWORK

Ethernet Interface Ethernet (1000Base-TX or100Base-TX)

Ethernet Cabling Type Cat5e or better

FSFP Interface Supports Pelco FSFP Series Transceivers

Supported Protocols TCP/IP, UDP/IP (Unicast, Multicast IGMP),

Users

Unicast Up to 20 simultaneous users depending on

Multicast Unlimited users H.264

Security Access Password protected

Software Interface Web browser view and setup

Pelco System Integration Endura 2.0, Digital Sentry 7.3 and

Auto MDI/MDI-X

Auto-negotiate/manual setting

(input models)

UPnP, DNS, DHCP, RTP, RTSP, NTP, IPv4, IPv6,

SNMP v2c/v3, QoS, HTTP, HTTPS, SSH, SSL,

SMTP, FTP, and 802.1x (EAP)

resolution settings (2 guaranteed streams)

Pelco VideoXpert 1.9 (or later)

OPERATING TEMPERATURE*

Operating Humidity 10% to 100% RH (condensing)

Storage Humidity 10% to 100% RH (condensing)

Temperature

Sustaining Maximum 60°C (140°F) 60°C (140°F)

Minimum –60°C (-76°F) –60°C (-76°F)

Ice Free Windows –40°C (-40°F) –40°C (-40°F)

Cold Start* –40°C (-40°F) –40°C (-40°F)

Storage 60°C (140°F) 60°C (140°F)

*Cold starts within 240 minutes at specified temperature

48 VDC 110-240 V

Power

GENERAL

Construction 316L billet electropolished stainless steel

Window High transmissivity, low iron soda lime glass

Sun Shroud 316L stainless steel with laser etched logo

Weight EXF1230-4N: 37.0 lb (16.8 kg)

Effective Projected Area 191 in

(EPA)

Reset Capabilities Internal reset button for servicability; remote

with robotic guided laser welding and 100%

hydrostatic pressure testing

(passivated for environmental protection)

EXF1230-7N: 37.0 lb (16.8 kg)

2

hard-wire reset; remote software restart

ELECTRICAL

Alarm

Unsupervised Detects open or closed alarm state

Supervised Detects open and short alarm state with

Input 3.5 VDC maximum, 3.5 mA maximum

Relay Output 30 VDC, 500 mA maximum

Input Power Options 48 VDC or 110-240 VAC @ 50/60 Hz

Input Voltage Range ±10%

Power Consumption (VA / W)*

Model Description

EXF1230-4N Fixed–48 VDC 17 / 17 26 / 26 48 / 48 74 / 74

EXF1230-7N Fixed–110-240 V 29 / 18 33 / 27 58 / 50 85 / 77

*To determine power consumption, take the “Min” power and add the

appropriate values under Heating that apply to your installation and

environment. For worst-case calculations, use the “Max” values,

which include wiper activation.

external 1-kohm resistor to detect alarm

tampering

Add Heating (VA / W)

Min

(VA / W)

Max

(VA / W)@5° C @-55° C

MECHANICAL

Cable Entry Dual 1.91 cm (0.75-inch NPT) threaded

openings; two explosionproof sealable plugs

supplied

One plug supplied for installations requiring

only one cable entry

Page 4

RELATED PRODUCTS

RECOMMENDED MOUNTS

WXM100 Wall mount designed to mount the

PXM200 Pedestal mount designed to mount an ExSite

CMXM100 Corner adapter for use with the WXM100 to

PAXM100 Pole adapter for use with the WXM100 to

AXM100 Adjustable mount for ExSite Enhanced

Mounting Method

WXM100, CMXM100*,

and PXM200

PAXM100* Steel pole with a diameter of 4 to 9

AXM100

ExSite Series system directly to a

load-bearing vertical surface

Enhanced Series system directly to a

horizontal surface in either an upright or

inverted position

mount an ExSite Series system to the corner

of a structure

mount a system to a vertical pole or with a

PXM200 to mount a system to a horizontal

pole; recommended pole diameter is 10.16 to

22.86 cm (4 to 9 inches)

Models; enables manual pan/tilt adjustment

Recommended

Mounting Surface

Solid concrete with recommended

strength of 3,600 psi or 25 Mpa

Steel I beam with a minimum of 1/

8-inch wall

inches (10.16 to 22.86 cm)

Five 3/8-16 x 1-9/16-inch long stainless steel drop-in anchors and five 3/8-16 x 1.0-inch thread

length, stainless steel hex head bolts with stainless steel lock washers (not supplied)

Five 3/8-16 x 1.0-inch, stainless steel hex head bolts with lock washers are supplied with the

CMXM100 and PAXM100 for use with the WXM100 wall mount or PXM200 pedestal mount.

Five 3/8-16 x 1.0-inch thread length, stainless steel hex head bolts with stainless steel lock washers

and 3/8-16 stainless steel nuts (not supplied)

Four 5/8-inch wide x 40-inch (101.6 cm) long stainless steel straps to attach the adapter to a pole

(supplied)

GENERAL

Construction

Mounts Electropolished 304 stainless steel

PAXM100 Mounting Straps 316 stainless steel

Maximum Load

WXM100 33.00 kg (72.8 lb)

CMXM100 38.50 kg (84.9 lb)

PAXM100 40.00 kg (88.2 lb)

PXM200 35.83 kg (79.0 lb)

AXM100

Unit Weight

WXM100 5.62 kg (12.4 lb)

CMXM100 3.45 kg (7.6 lb)

PAXM100 4.17 kg (9.2 lb)

PXM200 0.60 kg (1.3 lb)

AXM100

Shipping Weight (approximate)

WXM100 7.71 kg (17.0 lb)

CMXM100 5.89 kg (13.0 lb)

PAXM100 6.35 kg (14.0 lb)

PXM200 1.81 kg (4.0 lb)

AXM100

Recommended Hardware

Page 5

RELATED PRODUCTS

5X THREADED HOLES

FOR 3/8-16 SS BOLTS (SUPPLIED)

(14.9)

37.8

20.7

(8.15)

14.1

(5.5)

23.5

(9.25)

THRU EQ SP ON A Ø 8.00 B.C.

T

22.85

(9.00)

17.78

(Ø7.00)

16.18

(Ø6.37)

1.66

0.25

(0.098)

CMXM100 CORNER ADAPTER

PAXM100 POLE ADAPTER

PXM200 PEDESTAL MOUNT

Note: Designed for use with a WXM100 wall mount.

Note: Designed for use with a WXM100 to mount a system to a vertical pole or a

PXM200 to mount the system to a horizontal pole. Recommended pole diameter is

10.16 to 22.86 cm (4 to 9 inches).

4X Ø 0.433 INCHES

HRU EQ SP ON A Ø 4.75 B.C

8X Ø 0.433 INCHES

(0.65)

11 X THREADED HOLES

FOR 3/8-16 SS BOLTS (SUPPLIED)

25.4

(10.00)

8.33

(3.28)

8.9

(3.5)

21.6

(8.50)

Page 6

RELATED PRODUCTS

(7.46)

19.62

(7.72)

7.18

(2.83)

13.56

3/4” NPT

46.36

(18.25)

43.18

7.18

(2.83)

15.24

(6.00)

8.75

(3.44)

MODELS

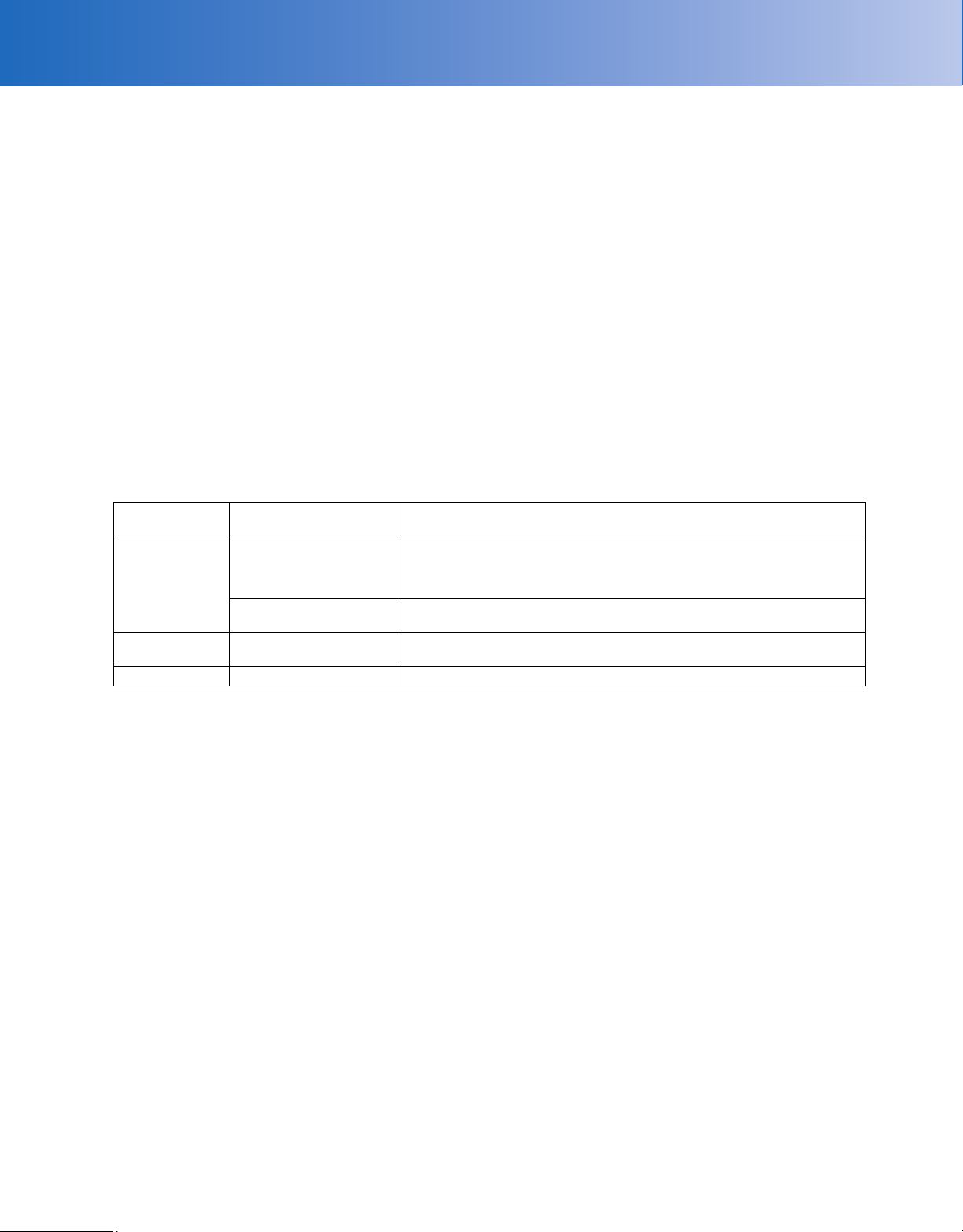

Model Number PTZ/Fixed

EXF1230-4N

EXF1230-7N 110-240 VAC

Fixed 1080p 30x

Camera /

Lens

CERTIFICATIONS/RATINGS

• FCC Part 15

•CE

• UL/cUL Listed

• ICES-003

•RCM

• IP66 and Type 4X

• S Mark for Argentina

Power

48 VDC

HAZARDOUS CERTIFICATIONS

• Tamb -60° C to +60° C

• UL/cUL Hazardous Locations Listed per NEC Division and

Zone requirement

Class I, Groups A, B, C, and D

Class II, Groups E, F, G, and T6

Class I, Zone 1, and AEx d IIC

AEx tb IIIC T85°C IP66

• IECEx

Ex db IIC T6 Gb

Ex tb IIIC T85°C Db IP66

• ATEX Ex tb IIIC T85°C Db IP66 INMETRO*

BR-Ex d IIC T6 IP66

•EAC Ex*

•CCOE*

•NTRL

*At the time of this publication, certifications are pending. Consult the

factory or www.pelco.com for the current status of certifications.

MARINE CERTIFICATION

•DNV

18.94

(17.00)

Note: Please contact Pelco for information on the dimensions of the

flameproof joints.

VALUES IN PARENTHESES ARE INCHES; ALL OTHERS ARE CENTIMETERS.

Pelco by Schneider Electric

3500 Pelco Way, Clovis, California 93612-5699 United States

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

www.pelco.com www.pelco.com/community

(5.34)

Pelco, the Pelco logo, and other tradema rks associated with Pelco products referred to in this

publication are trademarks of Pelco, Inc. or its affili ates. ONVIF and the ONVIF logo are trademarks of

ONVIF Inc. All other product names and services are the property of their respective companies.

Product specifications and availability are subject to change without notice.

©Copyright 2017, Pelco, Inc. All rights reserved.

Loading...

Loading...