Installation and Assembly - CRT Ceiling Mount Kit for 14" - 17" Monitors

IMPORTANT! Read entire instruction sheet before you

start installation and assembly.

IMPORT ANT! This kit includes all mounting hardware

for direct attachment to a wood joist ceiling. For

concrete ceiling installations order accessory kit ACC

210. Fixed Length and adjustable extension columns

are also available.

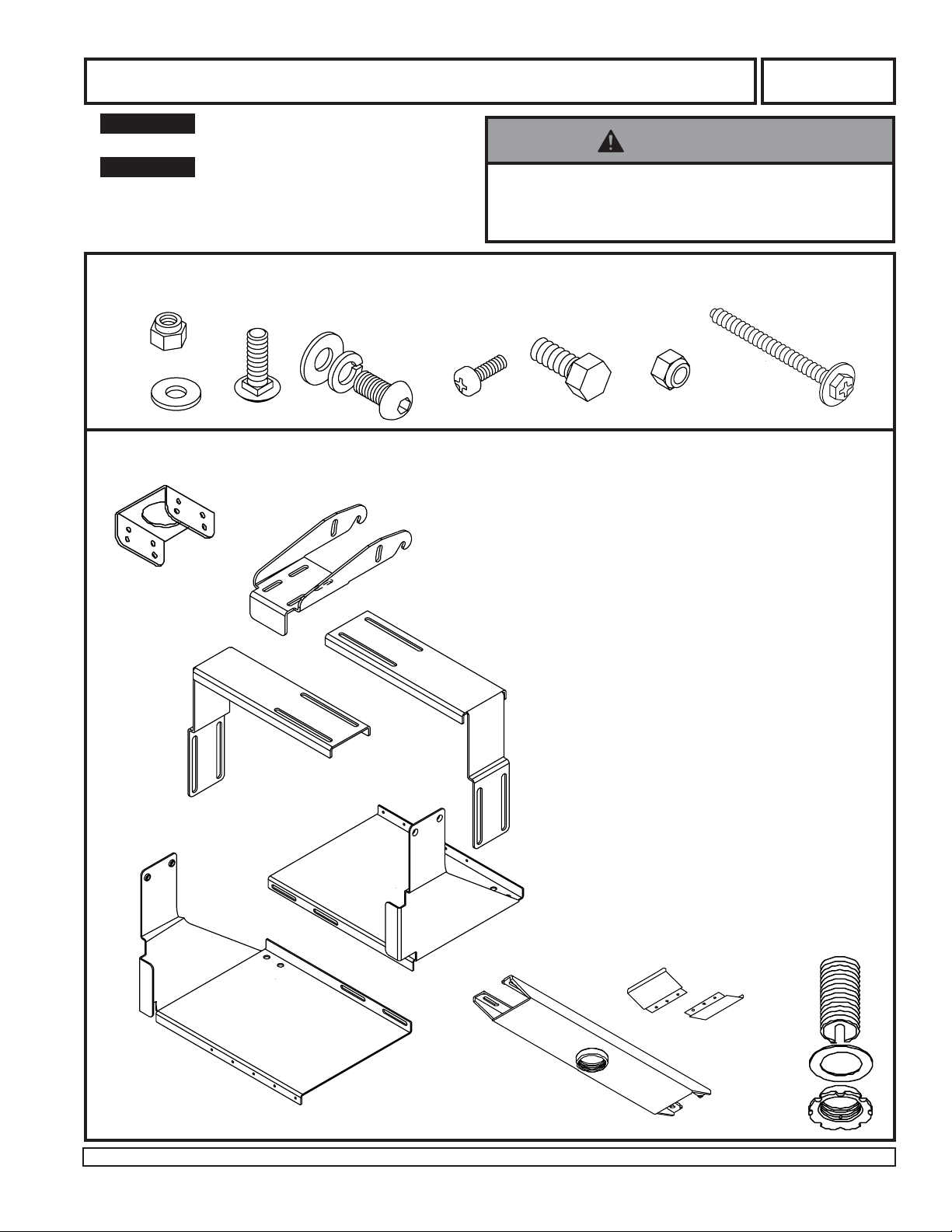

Before you start make sure all of the parts shown below are included with your product.

• Installer must verify that the ceiling will safely support

four times the combined weight of all attached equipment and hardware.

WARNING

Model: IMC 18

N

A

B

L

E

H

I

C

F

G

D

U

PARTS LIST

J

K

M

O

PART # QTY. DESCRIPTION

A 530-9413 4 1/4-20 nylock nut

B 540-9440 4 1/4 SAE flat washer

C 520-9513 4 1/4-20 x 3/4" carriage bolt

D 520-9549 6 5/16-18 socket head screw

E 540-9406 8 5/16 SAE flat washer

F 540-9405 6 5/16 lock washer

G 520-9250 5 M5 x .8 x 10 mm phillips screw

H 520-9210 2 5/16-18 x 3/4" hex head bolt

I 530-9306 2 5/16-18 nylock nut

J 073-1007 1 hanging bracket

K 073-1008 1 tilt bracket

L 073-1001 1 left adjuster

M 073-1002 1 right adjuster

N 073-1003 1 left tray

O 073-1004 1 right tray

P 128-1039 1 ceiling plate

Q 2PT-22CA01D 2 ceiling plate end cap

R 1446-014 1 flush mount tube

S 1800-375 1 retaining collar

T 540-9432 1 fiber washer

U 5S1-015-C03 4 #14 x 2.5" (6 mm x 65 mm)

wood screw

Note: Parts may not appear exactly as illustrated.

Visit the Peerless Web Site at www.peerlessindustries.com

1 of 5

Q

R

T

P

S

ISSUED: 2-19-98 SHEET #: 073-9003-1 08-26-04

For customer service call 1-800-729-0307 or 708-865-8870.

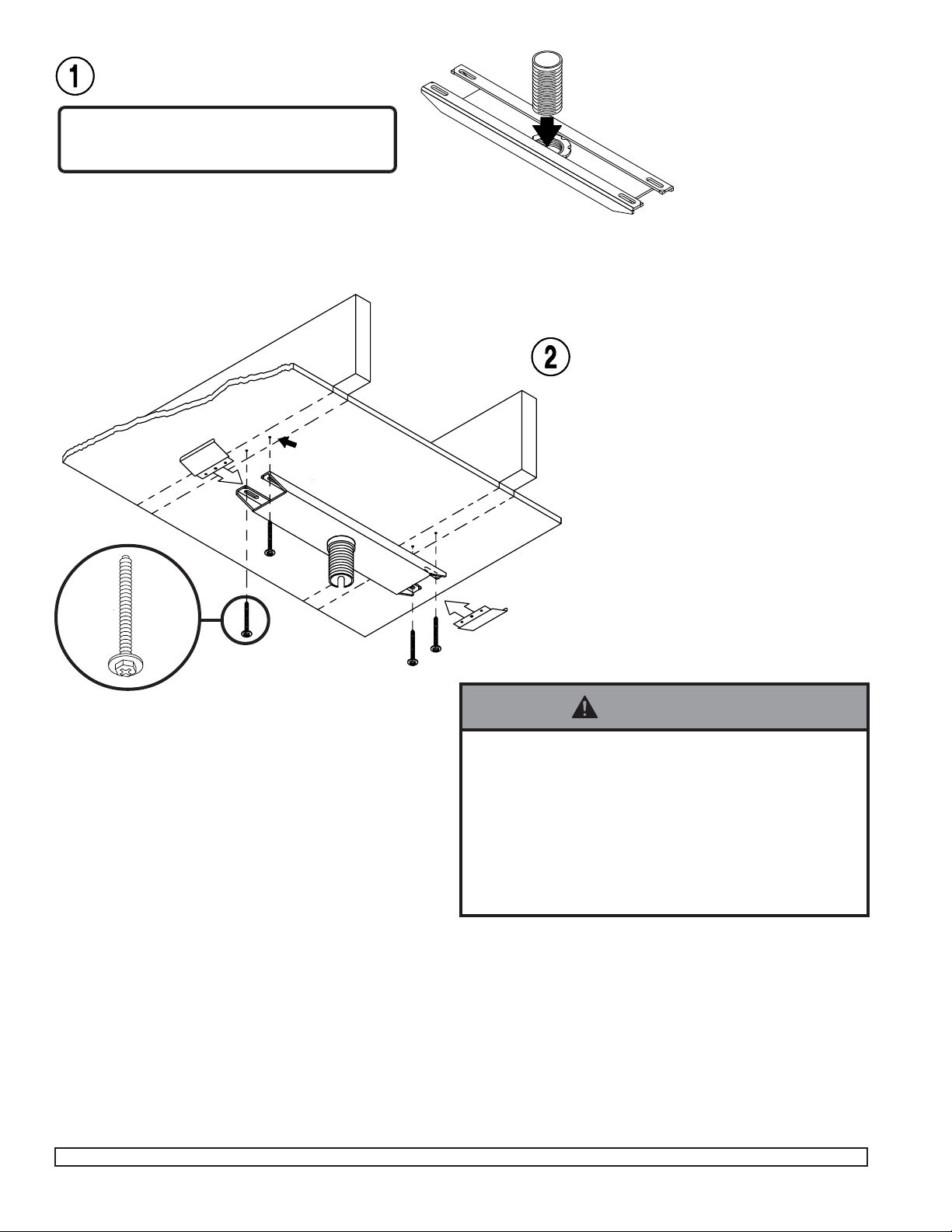

From the top thread flush mount tube (R)

through threaded fitting in ceiling plate (P).

IMPORTANT: If you will install an extension

column DO NOT INSTALL THE FLUSH

MOUNT TUBE.

Q

∅ 5/32" (4 mm)

P

R

P

For Wood Joist Finished Ceiling, Exposed Wood Joists, or Wood Beam

Ceiling. (See 3 for concrete ceilings). Drill

four 5/32" (4 mm) dia. holes to a minimum

depth of 2.5" (64 mm). Attach ceiling plate

(P) with four #14 x 2.5" (6 mm x 65 mm)

wood screws (U). Tighten wood screws so

ceiling plate is firmly attached. DO NOT

TIGHTEN WITH EXCESSIVE FORCE!

Overtightening can cause stress damage to

wood screws greatly reducing their holding

power! Tighten to 80 in • lb (9 N.M.) maximum torque.

Snap end caps (Q) into place.

U

Q

WARNING

• Tighten wood screws so that ceiling plate is firmly

attached, but do not overtighten. Overtightening can

damage the screws, greatly reducing their holding

power.

• Never tighten in excess of 80 in • lb (9 N.M.).

• Make sure that mounting screws are anchored into the

center of the joists. The use of an "edge to edge" stud

finder is highly recommended.

Visit the Peerless Web Site at www.peerlessindustries.com

2 of 5

ISSUED: 2-19-98 SHEET #: 073-9003-1 08-26-04

For customer service call 1-800-729-0307 or 708-865-8870.

WARNING

• Installer must verify that the ceiling will safely support

four times the combined weight of all attached equipment and hardware.

∅ 5/16" (8 mm)

Q

P

concrete

anchor

FOR PRODUCT SAFETY USE

ONL Y...

RAWLTM #5005 OR HIL TI

HL814 CONCRETE ANCHORS

[.312 x 1.625 (8 mm x 41 mm)].

ORDER ACCESSORY F ASTENER KIT #ACC 210

CONCRETE ANCHOR

INSTALLATION

Cross Section: Attachment

to a concrete ceiling.

TM

Q

For Concrete Ceilings drill four 5/16" (8 mm)

dia. holes to a minimum depth of 1 3/4" (45

mm). Attach ceiling plate (P) using concrete

expansion anchors as shown (left and next

page). Tighten to 80 in • lb (9 N.M.) maximum

torque.

Snap end caps (Q) into place.

WARNING

• Tighten concrete anchor bolt s firmly , but do not

overtighten. Overtightening can damage the bolts,

greatly reducing their holding power.

• Never tighten in excess of 80 in • lb (9 N.M.).

WARNING

• Always attach concrete expansion anchors directly to

load-bearing concrete.

• Never attach concrete expansion anchors to concrete

covered with plaster, drywall or other finishing material.

ceiling

STEP1: Hammer

in concrete

anchor.

Visit the Peerless Web Site at www.peerlessindustries.com

STEP2: Tighten to 80 in • lb (9

N.M.) maximum torque to

expand anchors.

3 of 5

CUT AW A Y VIEW

ISSUED: 2-19-98 SHEET #: 073-9003-1 08-26-04

For customer service call 1-800-729-0307 or 708-865-8870.

First: Assemble bracket as shown.

Leave all fasteners slightly loose to

allow for adjustment.

Second: From behind, insert

monitor into bracket. Face of

monitor should touch returns on

left and right trays (N & O). Adjust

height and width of bracket to fit

snugly around monitor.

Last: Tighten all fasteners!

A

B

K

monitor

C

L

M

N

E

F

return

D

O

G

return

Visit the Peerless Web Site at www.peerlessindustries.com

4 of 5

ISSUED: 2-19-98 SHEET #: 073-9003-1 08-26-04

For customer service call 1-800-729-0307 or 708-865-8870.

First: Choose tilt option (see "Tilt Options"

below).

P

J

R

H

R

S

J

H

G

Second: From inside, insert and tighten 5/16-

18 x 3/4" hex bolts (H) to hanger bracket (J).

Third: Attach hanger bracket using fiber

washer (T) and retaining collar (S). Tighten

retaining collar four or five complete turns.

Last: Align one hole in the side of the retaining collar with slot. From inside insert and

tighten one M5 x .8 x 10 mm phillips screw

(G) to lock retaining collar (S).

T

WARNING

S

• For safety retaining collar must be locked with screw!

Complete the assembly as shown.

WARNING

• Be sure to TIGHTEN ALL F ASTENERS SECUREL Y!

WARNING

• Always use an assistant or mechanical lifting equipment to safely lift and position the TV or monitor .

J

K

O

TILT OPTIONS - SIDE VIEW

0O to 20

Tilt Option One

Attach tilt bracket (K) to hanging

bracket (J) as shown for a tilt range

from 0O to 20O.

K

20

E

F

J

O

O

to 40

Tilt Option Two

Attach tilt bracket (K) to hanging

bracket (J) as shown for a tilt

range from 20O to 40O.

J

K

H

E

I

D

5 of 5

Visit the Peerless Web Site at www.peerlessindustries.com

© 2004 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademark of Peerless Industries, Inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.

ISSUED: 2-19-98 SHEET #: 073-9003-1 08-26-04

For customer service call 1-800-729-0307 or 708-865-8870.

Loading...

Loading...