Page 1

Maintenance

Manual

`````````````````````````````````````````````````````````````````````````````````````````````````````````````

Page 2

Maintenance Manual of Pantum

Multi-functional Laser Printer

Product model: M6700-M6800-M7100-M7200 Series

I

Page 3

Legal Notice

Trademark

Pantum and Pantum logos are registered trademarks of Zhuhai Pantum Electronics Co., Ltd.

Microsoft®, Windows®, Windows server® and Windows Vista® are trademarks registered by

Microsoft Corporation in the United States or other countries.

The ownership of the names of the software in this manual belongs to their respective companies

in accordance with corresponding license agreement.

All other products and brand names in this manual may be the registered trademarks, trademarks

or service marks of their respective owners.

Copyright

The copyright of this manual is owned by Zhuhai Pantum Electronics Co., Ltd

Any copy, translation, modification and transmission of this manual by any means or in any form

without the prior written consent of Zhuhai Pantum Electronics Co., Ltd is prohibited.

Version: V 1.0

Disclaimer

For a better user experience, Zhuhai Pantum Electronics Co., Ltd. reserves the right to make

changes to the User Guide without notice.

Users are responsible for any damage arising from failing to follow this User Guide. Meanwhile,

except the express warranty made in the product maintenance manual or service commitment,

Zhuhai Pantum Electronics Co., Ltd. does not make any express or implied warranty or guarantee

to this User Guide (including composing or words).

Using this product to copy, print, scan certain documents or images or make other forms of

operations may be prohibited by the local laws. If you are uncertain about the legality of using this

product, you should consult your legal advisor in advance.

The product can only be used safely in the non-tropical areas at an altitude no higher than 2,000

meters.

Safety Information

Please carefully read and understand the following safety and precautions prior to maintenance.

Key Precautions

As the product may be damaged by the maintenance of non-professionals, the Company

strongly recommends the maintenance by technical staff trained by the company. The user

must bear the risks of personal injury and damage to the product while repairing the product or

parts in this manual. Please carefully read this manual prior to maintenance, to ensure correct

operation and maintenance.

Please keep this manual properly for future maintenance.

Warnings, notes and explanations:

*Please follow the warnings to avoid personal injury.

* Please follow the warnings for proper maintenance of the printer, in order to avoid damage.

* Please pay attention to relevant prompts in maintenance of the printer.

* “Warnings” are listed below:

II

Page 4

There is high-voltage electrode inside the printer.

Before cleaning the printer. make sure the power is

turned off!

Plugging and unplugging the power cord plug with a

wet hand can result in an electric shock.

£

The fuser unit is hot when and after printing .

Touching the fuser unit (the shaded area as

shown) may cause bums!

The fuser unit is attached with a high temperature

warning label. Please do not remove or damage

this label.

III

Page 5

Where to Install

Install the printer on a flat and secure surface where vibration and impact does not occur

easily, such as the tabletop. Keep the printer near the standard and grounded power socket. In

addition, the temperature of the installation location should be 10°C to 35°C, and the relative

humidity should be 20% to 80%.

Note:

Do not install the printer in a place of large pedestrian volume.

Do not put the equipment near the heater, refrigerator, air conditioner, fluid or chemical

product.

Do not make the printer exposed to the sunlight or install it in a too hot, humid or dusty

place.

Do not connect the printer to the socket with a wall-mounted switch or automatic timer.

The information in the memory of the printer may be lost in the case of power failure.

Do not connect the printer to the socket in the circuit with high-power household appliances

or other devices that may result in power failure.

Keep the printer away from interference sources such as the loudspeaker or cordless

telephone base.

Pay attention to indoor air circulation in the case of long-time operation or printing of a

large number of documents in the poorly ventilated room.

Laser Safety

Laser radiation is harmful to the human body. To avoid laser radiation, please do not randomly

disassemble the printer!

The printer follows the provisions of Class 1 laser products under CFR standard. It has a Class IIIb

laser diode, which has no laser radiation leakage among laser components.

The following label is attached to the laser components inside the printer:

IV

Page 6

Laser Safety

Laser radiation is harmful to the human body. To avoid laser radiation, please do not randomly

disassemble the printer!

The printer follows the provisions of Class 1 laser products under CFR standard. It has a Class IIIb

laser diode, which has no laser radiation leakage among laser components.

The following label is attached to the laser components inside the printer:

V

Page 7

This symbol indicates that the product cannot be discarded with other wastes.

Instead, you should dispose of the used equipment at a designated collection point

for the recycling of waste electrical and electronic equipment.

This product is suitable for indoor use only.

European Community (EC) Directive Compliance

This product complies with the Member State Approximation and Coordination

Act of the EC Council Directive 2014/35/EU and 2014/30/EU.

These directives cover the protection requirements of the Paper Feed Solenoidic

compatibility and electrical equipment safety (used within the specific voltage

range).

Manufacturer: Zhuhai Pantum Electronics Co., Ltd., Central Zone A, 3rdFloor,

Building 01, 3883#, Zhuhai Road, Zhuhai City, P.R.C.

For the statements compliance with these directives, please contact the authorized

representative.

This product complies with the Class B requirements of EN 55032 and the safety

requirements of EN 60950.

This product is fully compliant with the ROHS Directive 2009/95/EC and the

requirements of the revised Directive 2011/65/EU for managing toxic and

hazardous substances.

This product can only be used safely in the non-tropical areas.

This product can only be used safely in the areas at an altitude no higher than

2,000 meters.

Legal Information

VI

Page 8

Table of Contents

1. Product Introduction ................................................................................................................. 1

2. Driver Installation and Uninstallation ....................................................................................... 2

2.1 One-click Installation ..................................................................................................... 2

2.1.1 Method I: Connect the printer via USB cable .................................................... 2

2.1.2 Method II: Connect the printer via wired network ........................................... 3

2.1.3 Method III: Connect the printer via wireless network ...................................... 6

2.1.3.1 Configure wireless network via USB cable and install driver .................... 6

2.1.3.2 Connect computer to router via Wi-Fi ...................................................... 6

2.1.3.3 Connect computer to router via network cable ........................................ 9

2.1.3.4 Connect computer to printer via Wi-Fi direct and install the driver ....... 11

2.1.3.5 The printer is already connected to wireless network ............................ 13

2.2 Manual installation ..................................................................................................... 16

2.2.1 Installation via USB connection ....................................................................... 16

2.2.2 Installation via wired network connection ...................................................... 17

2.2.3 Installation by wireless network connection mode ........................................ 18

2.2.3.1 Installation in basic structure mode ........................................................ 19

2.2.3.2 Installation in Wi-Fi Direct mode ............................................................. 21

2.2.3.3 Method of driver uninstallation .............................................................. 23

2.3 Mac system driver installation .................................................................................... 24

2.4 Add printer to Mac system ........................................................................................ 24

2.4.1 Driver installation ............................................................................................ 24

2.4.2 Add up the printer via USB .............................................................................. 26

2.4.3 Add up the printer via wireline connection..................................................... 26

2.4.4 Add up the printer via wireless connection .................................................... 26

2.4.5 Add AirPrint printer ......................................................................................... 27

3. Printer Information Report ...................................................................................................... 28

3.1 Information Report Printing ........................................................................................ 28

3.2 Information Page ......................................................................................................... 28

4. Restoration of Factory Settings ............................................................................................... 31

4.1 Restore factory settings with menu ............................................................................. 31

4.2 Restoration of Factory Settings via Embedded Web Server ........................................ 31

5. Operating Principle ................................................................................................................. 32

5.1 Overall Structural Diagram ......................................................................................... 32

5.2 Component Structure Diagrams .................................................................................. 33

5.3 Mechanical Devices .................................................................................................... 34

5.4 Paper Path ................................................................................................................... 35

5.4.1 ADF Paper Routine Diagram .......................................................................... 35

5.4.2 Paper Routine Diagram of Printer ................................................................... 35

VII

Page 9

6. Disassembly and Installation .................................................................................................. 36

6.1 Disassembly Flowchart ............................................................................................... 36

6.2 Disassembly Steps ....................................................................................................... 36

6.2.1 Before disassembly ......................................................................................... 36

6.2.2 Front cover ...................................................................................................... 38

6.2.3 Rear cover ....................................................................................................... 38

6.2.4 Left cover ........................................................................................................ 39

6.2.5 Right cover ...................................................................................................... 39

6.2.6 ADF Pick-UP Assembly and separation assembly ............................................ 39

6.2.7 ADF/scanner assembly .................................................................................... 40

6.2.8 ADF motor ...................................................................................................... 41

6.2.9 Scanner cover assembly .................................................................................. 42

6.2.10 CIS .................................................................................................................. 43

6.2.11 Scanner motor ................................................................................................. 43

6.2.12 Control panel assembly ................................................................................... 44

6.2.13 Fax Board ........................................................................................................ 45

6.2.14 Upper cover component .................................................................................. 45

6.2.15 Transfer roll ..................................................................................................... 46

6.2.16 Pick-UP Assembly ........................................................................................... 46

6.2.17 Paper sensor .................................................................................................... 47

6.2.18 Chip adapter Board ......................................................................................... 47

6.2.19 Paper Feed Sensor ........................................................................................... 47

6.2.20 Data Board ...................................................................................................... 47

6.2.21 Engine Board ................................................................................................... 48

6.2.22 Power Board .................................................................................................... 49

6.2.23 LSU ................................................................................................................. 49

6.2.24 Fuser ................................................................................................................ 50

6.2.25 Driver unit ....................................................................................................... 50

6.2.26 Fan ................................................................................................................... 51

6.2.27 Paper Feed Solenoid ........................................................................................ 51

6.2.28 Motor ............................................................................................................... 51

6.2.29 Clutch assembly .............................................................................................. 52

7. Maintenance ............................................................................................................................ 53

7.1 Printer cleaning ........................................................................................................... 53

7.2 Use and Maintenance of Consumables ....................................................................... 56

7.2.1 About toner cartridge and drum component .................................................... 56

7.2.2 Replacement of toner cartridge and drum component .................................... 56

8. Error Message and Troubleshooting ....................................................................................... 59

8.1 Check before maintenance .......................................................................................... 59

8.2 Error Status Prompts ................................................................................................... 60

8.3 Warning and Prompt Status ......................................................................................... 61

8.4 Error Code ................................................................................................................... 68

8.5 Removal of Jammed Paper .......................................................................................... 73

VIII

Page 10

8.5.1 Middle jamming .............................................................................................. 73

8.5.2 Jammed paper in fuser unit ............................................................................. 75

8.5.3 . Jammed paper in duplex printing unit ........................................................... 76

8.5.4 Jammed paper of document feeder (ADF) ...................................................... 77

8.6 Troubleshooting .......................................................................................................... 79

8.6.1 Paper feeding problem .................................................................................... 79

8.6.2 Common faults ................................................................................................ 80

8.6.2.1 Printing fault ........................................................................................... 80

8.6.2.2 Scanning failure ...................................................................................... 84

8.6.2.3 Copy failure............................................................................................. 84

8.7 Image Defects ............................................................................................................. 85

8.7.1 Printing ............................................................................................................ 85

8.7.2 Scanning and copying ..................................................................................... 88

Appendix 1 Perimeters of Printer Rolls ..................................................................................... 89

Appendix 2 Description of Product Series Number ................................................................... 90

Appendix 3 Explanation of Special Terms in the Manual ......................................................... 90

IX

Page 11

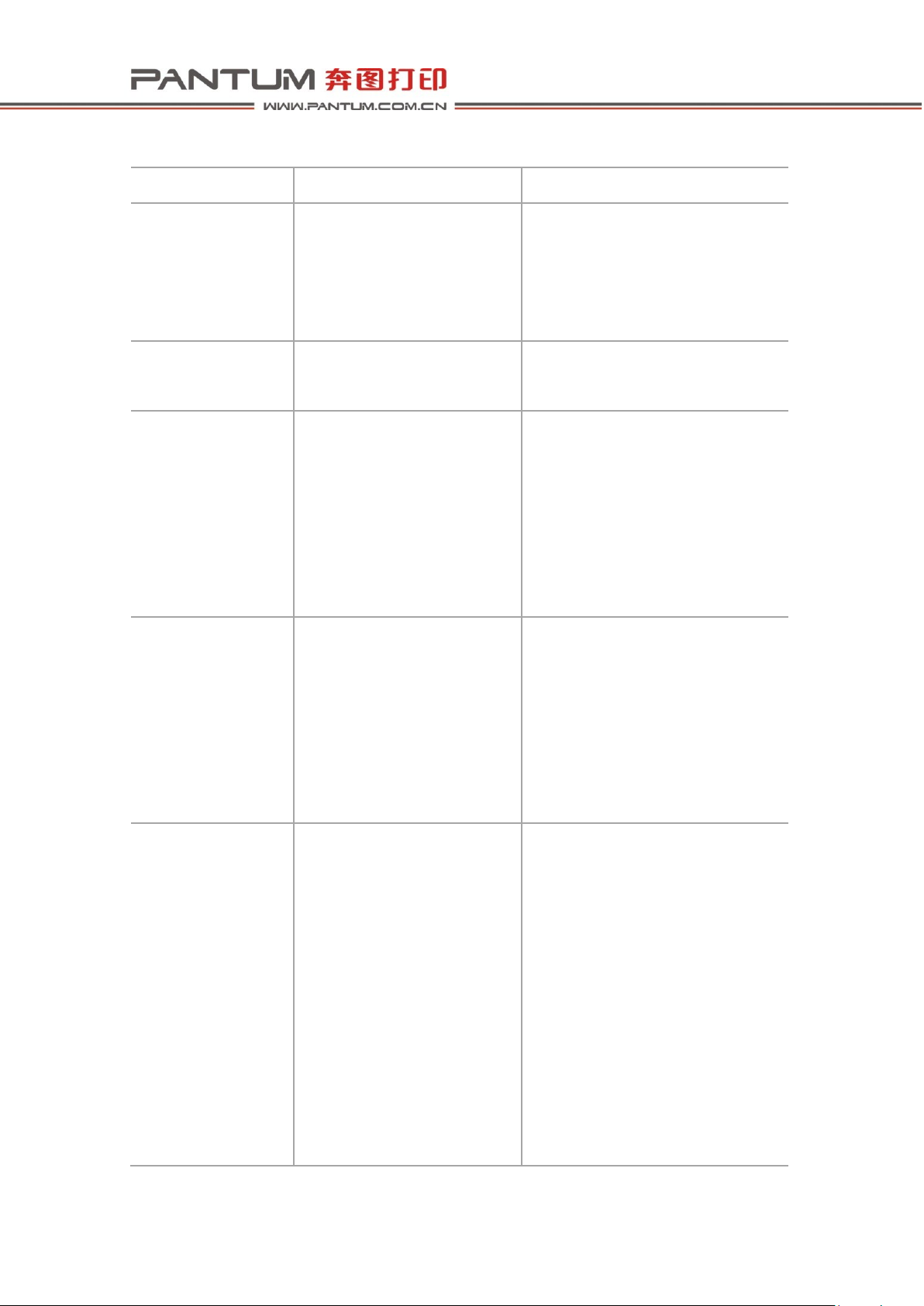

Product Parameters

M6700D

series

M6700D

W /

M6760D

W series

M7100DN

series

M7100DW

series

M6800FDW /

M6860FDW

series

M7200FD

series

M7200FDN

series

M7200FDW

series

Interface

type

USB

● ● ● ● ● ● ●

●

NET

● ● ● ● ●

●

Wi-Fi

● ● ●

●

Print

Language

GDI

● ● ●

PDL

● ● ● ●

●

Control

panel

LCD

● ● ● ● ● ● ●

●

Print speed

A4

30ppm

● ● ●

33ppm

● ● ● ●

●

Letter

32ppm

● ● ●

35ppm

● ● ● ●

●

Automatic two-sided printing

● ● ● ● ● ● ●

●

NFC function

● ● ●

●

Mute printing

● ● ● ● ● ● ●

●

Copy function

● ● ● ● ● ● ●

●

Scanning function

● ● ● ● ● ● ●

●

Fax function

● ● ●

●

Scan to USB flash disk

● ● ● ● ●

●

ADF

● ● ● ●

●

1. Product Introduction

(●: support; Blank: unsupport)

Note: The product series will be increased or changed without prior notice.

If the printer has the fax function, conduct language setting, system setting and fax setting as per the prompts on the panel after initial

startup or restoration of default settings.

In this manual, “ADF” is short for the document feeder.

1

Page 12

2. Driver Installation and Uninstallation

2.1 One-click Installation

One-click installation provides three methods of installation: connect the printer via USB cable, connect

the printer via wired network, and connect the printer via wireless network. You can choose one of

them according to your habit.

2.1.1 Method I: Connect the printer via USB cable

1. Connect the printer to computer via USB cable, power the printer and computer on.

2. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of computer

desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note: • Some computers may be unable to auto play the CD because of system configuration.

Please double click "Computer" icon, find "DVD RW driver", then double click "DVD RW

driver" to run the installation procedure.

3. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

4. Click on the “One-click installation” button in Method I and enter into the installation process.

The process may need some time, and the duration is related to your computer configuration, please

wait patiently.

2

Page 13

5. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.1.2 Method II: Connect the printer via wired network

1. Turn the power of printer and computer on.

2. Connect the computer to wired network.

3. Connect network cable to the network interface of printer, to make sure the printer is

connected to computer network.

4. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

3

Page 14

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note: • Some computers may be unable to auto play the CD because of system

configuration. Please double click "Computer" icon, find "DVD RW driver", then

double click "DVD RW driver" to run the installation procedure.

5. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

6. Please click on the “One-click installation” button in Method II and install driver software.

Note :• You can put your mouse cursor in the “One-click installation” button to check the popup

information in order to confirm if the current printer is the one you need to install through IP

address before you click the button.

• You can check the printer IP address through “Network configuration page”

• Click on the “One-click installation” button to enter installation process if your software has searched

only one printer. The process may need some time, and the duration is related to your computer

configuration. Please wait patiently.

4

Page 15

• If your software has searched several printers, click on the One-click installation” button, and the printer

list interface will pop up. Please select the printer that you need according to your printer wired network

IP address or host ID.

5

Page 16

Note:• If the printer you need is not shown in the list, please click “Refresh” button to search

again. If it is not found, please check if the printer and computer are in the same network.

• When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option “Install the printer in the list with host ID”.

7. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.1.3 Method III: Connect the printer via wireless network

Please check if the printer is connected with wireless network when installing the printer driver

software.

Note: • You can print "Network configuration page" to confirm printer network connection status

to see if printer is connected with network.

2.1.3.1 Configure wireless network via USB cable and install driver

Since some computers are not provided with wireless network function, this section is divided into

“Connect computer to router via Wi-Fi” and “Connect computer to router via wired connection” to

introduce installation process.

2.1.3.2 Connect computer to router via Wi -Fi

1. Computer is already connected to router via Wi-Fi.

2. Connect the printer to computer via USB cable, then power the printer on.

3. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of computer

desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note: • Some computers may be unable to auto play the CD because of system configuration.

Please double click "Computer" icon, find "DVD RW driver", then double click "DVD RW

driver" to run the installation procedure.

6

Page 17

4. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

5. Click the “One-click installation” button in Method III to install driver software.

Note: • You can put your mouse cursor in the “One-click installation” button to check the popup

information in order to confirm if the current printer is the one you need to install through

IP address before you click the button.

• You can check the printer IP address through “Network configuration page”

• Click “One-click installation” button if your software has searched only one printer, and enter into

installation process to complete automatic network configuration and driver installation

7

Page 18

• If your software has searched several printers, click “One-click installation” button, and the printer

list interface will pop up. Please select “Configure printer with Wi-Fi via USB an install” and select USB

printer, click “Confirm” button and enter into installation process complete automatic network

configuration and driver installation

Note: • When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option "Install the printer in the list with host ID".

6. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

8

Page 19

2.1.3.3 Connect computer to router via network cable

1. Connect computer to router via network cable.

2. Connect the printer to computer via USB cable, then power the printer on.

3. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of computer

desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click "Computer" icon, find "DVD RW driver", then double click "DVD RW

4.

Click on the “I agree” button on the right button corner after reading the license agreement and

enter into driver installation interface.

driver" to run the installation procedure.

5.

Please click on the “One-click installation” button in Method III and install driver software.

Note:• You can put your mouse cursor in the “One-click installation” button to check the popup

information in order to confirm if the current printer is the one you need to install through

IP address before you click the button.

• You can check the printer IP address through “Network configuration page”.

9

Page 20

• Click on the “One-click installation” button if your software has only searched only one printer, and the

wireless network configuration interface will pop up, input the SSID an password that you need, then

click “Confirm” button, and enter into installation process. The process may need some time, and the

duration is related to your computer configuration please wait patiently.

• If your software has searched more than one printers, the printer list interface will pop up. You need to

configure the current printer which is connected via USB cable to wireless network and install driver.

Please select “Configure the print via USB and install” on the printer list interface and check the USB

printer option. Click the “Confirm” button, and the wireless network configuration interface will pop up.

Input the wireless SSID and password that you need, then click “Confirm” button, and enter into

installation process. The process may need some time, and the duration is related to your computer

configuration, please wait patiently.

10

Page 21

Note:• When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option "Install the printer in the list with host ID".

6.

After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.1.3.4 Connect computer to printer via Wi-Fi direct and install the driver

Connect the computer to printer via a direct Wi-Fi connection. It is applicable to wireless network

without infrastructure mode, but it still needs scenario of temporary use of printer via wireless network.

You can directly connect the computer that has wireless function to the printer to realize printing

function.

1. Turn the power of printer and computer on.

11

Page 22

2. Connect computer to the Wi-Fi Direct network of the printer.

3. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click "Computer" icon, find "DVD RW driver", then double click "DVD RW

driver" to run the installation procedure.

4. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

5. Click on the “One-click installation” button in Method III, and enter into installation process. The

process may need some time, and the duration is related to your computer configuration please wait

patiently.

12

Page 23

6. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.1.3.5 The printer is already connected to wireless network

1. The printer is already connected to wireless network, you can print the “Network

configuration page” to check.

2. Connect the computer to printer network.

3. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click "Computer" icon, find "DVD RW driver", then double click "DVD RW

driver" to run the installation procedure.

4. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

5. Click the “One-click installation” button in Method III to install driver software.

13

Page 24

Note:• You can put your mouse cursor in the “One-click installation” button to check the popup

information in order to confirm if the current printer is the one you need to install through

IP address before you click the button.

• You can check the printer IP address through “Network configuration page”.

• Click on the “One-click installation” button to enter installation process if your software has searched

only one printer. The process may need some time, and the duration is related to your computer

configuration. Please wait patiently.

14

Page 25

• If the software has searched several printers, the printer list interface will pop up. Please select the

printer you need according to your printer wired network IP address or host ID.

Note:• If the printer you need is not shown in the list, please click “Refresh” button to search

again. If it is not found, please check if the printer and computer are in the same

network.

• When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option “Install the printer in the list with host ID”.

15

Page 26

6. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.2 Manual installation

• Before installing the drive, you need to learn about printer model by printing printer

information page out and check the product name.

2.2.1 Installation via USB connection

1. Connect the printer to computer via USB cable, power the printer and computer on.

2. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click “Computer” icon, find “DVD RW driver”, then double click “DVD RW

driver” to run the installation procedure.

3. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

4. Click on the “Manual installation” at the bottom of driver installation interface, and enter into

manual installation interface.

5. Please select installation language and printer model.

6. Select “Connect via USB” and click on “Install”.

16

Page 27

7. The software installs the driver automatically and the installation process may need some time. The

duration is related to your computer configuration, please wait patiently.

8. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.2.2 Installation via wired network connection

1. Turn the power of printer and computer on.

2. Connect the computer to wired network.

3. Connect network cable to the network interface of printer, to make sure the printer is

connected to computer network.

4. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click “Computer” icon, find “DVD RW driver”, then double click “DVD RW

driver” to run the installation procedure.

5. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

6. Click on the “Manual installation” at the bottom of driver installation interface, and enter into

manual installation interface.

7. Please select installation language and printer model.

8. Select “Wireless network connection” and click on “Install”.

17

Page 28

9. The installation software will search the printer automatically and the searching process may need

some time.

10. After finishing searching, select the printer that needs to be connected and click “Next”

Note: • If the printer you need to connect is not in the list of printers searched, please click

“Refresh” to search again.

• When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option "Install the printer in the list with host ID".

• If IP address or host name is added manually, you need to know the IP address of the

printer connected or host name. If they are not made clear, please print the

11. The software installs the driver automatically and the installation process may need some time.

The duration is related to your computer configuration, please wait patiently.

12. After the installation, click “Print &Test Page” button. If your printer prints the test

page successfully, it means that you have installed the driver correctly.

2.2.3 Installation by wireless network connection mode

Wireless network connection type is divided into basic structure mode and Wi-Fi Direct mode

18

Page 29

2.2.3.1 Installation in basic structure mode

1. Connect computer to access point (wireless router).

2. Connect the printer to computer via USB cable, then power the printer on.

3. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click "Computer" icon, find "DVD RW driver", then double click "DVD RW

driver" to run the installation procedure.

4. Click on the "I agree" button on the right button corner after reading the license agreement and enter

into driver installation interface.

5. Click on the "Manual installation" at the bottom of driver installation interface, and enter into

manual installation interface.

6. Please select installation language and printer model.

7. Select "Wireless network connection" and click on "Install".

19

Page 30

8. Select “Yes, I want to configurate the printer’s wireless network” on the wireless setup window

popped out, and operate according to the prompts to set up the printer to wireless network.

9. The installation software will search the printer automatically after wireless network is

configured successful. The search process may need some time.

10. Select the printer needs to be connected and click “Next”.

Note: • If the printer you need to connect is not in the list of printers searched, please click

“Refresh” to search again.

• When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option "Install the printer in the list with host ID".

• If IP address or host name is added manually, you need to know the IP address of the

printer connected or host name. If they are not made clear, please print the

20

Page 31

11. The software installs the driver automatically and the installation process may need some time. The

duration is related to your computer configuration, please wait patiently.

12. After the installation, click “Print &Test Page” button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.2.3.2 Installation in Wi-Fi Direct mode

1. Turn the power of printer and computer on.

2. Connect computer to the Wi-Fi Direct network of the printer.

3. Place the attached installation CD in the computer CD-ROM:

• Windows XP system: automatically run the installation procedure.

• Windows 7/Vista/Server 2008 system: Pop up “Autoplay” interface, click “Autorun.exe” to run the

installation procedure.

• Windows 8 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the pop-up window, then click “Autorun.exe” to run the

installation procedure.

• Windows 10 system: When the “DVD RW driver” window pops up from the right top corner of

computer desktop, click anywhere in the window, then click “Autorun.exe” to run the installation

procedure.

Note:• Some computers may be unable to auto play the CD because of system configuration.

Please double click “Computer” icon, find “DVD RW driver”, then double click “DVD RW

driver” to run the installation procedure.

4. Click on the “I agree” button on the right button corner after reading the license agreement and enter

into driver installation interface.

5. Click on the “Manual installation” at the bottom of driver installation interface, and enter into manual

installation interface.

6. Please select installation language and printer model.

7. Select “Wireless network connection” and click on “Install”.

21

Page 32

8. Select “No, the printer has been connected to wireless network” on the wireless setup window

popping out, and then click “Next”.

9. The installation software will search the printer automatically and the searching process may need

some time.

10. Select the printer needs to be connected and click “Next”.

Note: • If the printer you need to connect is not in the list of printers searched, please click

“Refresh” to search again.

• When the printer IP address changes under printer driver installed with host ID, you can

also directly print without re-installing the driver. If you need to install the printer driver with

the host ID, please check the option "Install the printer in the list with host ID".

• If IP address or host name is added manually, you need to know the IP address

22

Page 33

11. The software installs the driver automatically and the installation process may need some time. The

duration is related to your computer configuration, please wait patiently.

12. After the installation, click "Print &Test Page" button. If your printer prints the test page

successfully, it means that you have installed the driver correctly.

2.2.3.3 Method of driver uninstallation

Windows 7 is taken as the example in the following operation. The information on your computer

screen may differ because of multiple operating systems.

1. Click the Start menu of computer and then click All programs.

2. Click Pantum, and then Click Pantum XXX Series. Pantum XXX

Series where XXX represents product model.

3. Click uninstall to delete the driver according to instructions on uninstall window.

4. Restart computer after finishing unloading

23

Page 34

2.3 Mac system driver installation

• Driver installation under Mac system is divided into 2 steps, driver installation and adding a printer. If

you are going to print in AirPrint mode, there is no need to install a driver and you just need to add a

printer directly.

• When you are installing a driver with wired or wireless network, you may need to know the Bonjour

name of printer. Please print the “Network setup page” to view it.

2.4 Add printer to Mac system

2.4.1 Driver installation

Mac 10.11 is taken as the example in the following operation. The information on your computer

screen may differ because of multiple operating systems.

1. Turn the power of printer and computer on.

2. Insert the CD companying with printer in the CD driver of your computer, and double click Pantum XXX

Series installation package. (XXX in Pantum XXX Series represents product model.)

3. Click “Continue”.

4. Read licensing agreement and then click “Continue”.

24

Page 35

5. Click “Agree” on the prompt window popping out to accept the licensing agreement.

6. Click “Install”.

7. Input computer password and click “Install Software”.

8. Click “Continue Installation” on the prompt window popping out.

9. The system will finish driver installation automatically.

• If using a USB cable to connect a computer with a Wi-Fi model printer, a wireless network configuration

prompt window will pop up during driver installation, as shown in following picture.

Note: • Click “Yes”, you can configure printer’s wireless network via wireless network

configuration tool. When configuration is completed, unplug USB cable, and then on the

pop-up “Add Printer” interface, you may add the network-connected printer.

• Click “No”, you can add a USB-connected printer on the pop-up “Add Printer” interface.

If using a USB cable to connect a computer with a non-Wi-Fi model printer, “Add Printer”

interface will pop up during the driver installation and you can add a printer here.

25

Page 36

2.4.2 Add up the printer via USB

1. Connect the printer to computer with USB cable and then turn power on.

2. Enter the “System Preferences” – “Printers & Scanners” of computer.

3. Click button to select “Add Printer or Scanner”.

4. Select printer and then select the corresponding printer mode from the “Use” menu popping out.

5. Click “Add”.

2.4.3 Add up the printer via wireline connection

1. Turn the power of printer and computer on.

2. Connect the computer to wired network.

3. Connect the network cable to the network interface of printer, and make sure the printer is connected

to the computer network.

4. Enter the “System Preferences” – “Printers & Scanners” of computer.

5. Click button to select “Add Printer or Scanner”.

6. Select printer and then select the corresponding printer mode from the “Use” menu popping out.

7. Click “Add”.

2.4.4 Add up the printer via wireless connection

1. Turn the power of printer and computer on.

2. Make sure the wireless network connection between computer and printer is set up.

Note: • In case of basic structure mode, connect wireless network printer to the access

point (wireless router).

• In case of Wi-Fi Direct mode, connect wireless client to wireless network printer directly.

26

Page 37

3. Enter the “System Preferences” – “Printers & Scanners” of computer.

Click button to select “Add Printer or Scanner”.

4.

5. Select printer and then select the corresponding printer mode from the “Use” menu

popping out.

6. Click “Add”.

2.4.5 Add AirPrint printer

1. Turn the power of printer and computer on.

2. Make sure the connection between printer and computer is set up (USB connection

or network connection).

3. Enter the “System Preferences” – “Printers & Scanners” of computer.

4. Click button to select “Add Printer or Scanner”.

5. Select printer and select “Secure AirPrint” (data encryption) or “AirPrint” (no

encryption) in the “Use” option box.

6. Click “Add”.

Note: • When the printer is connected to computer with USB cable, the system will

recognize and add AirPrint automatically.

• If AirPrint printer of network connection is added, then the connecting

USB cable should be disconnected first before adding the printer.

• AirPrint printer is named after the ending of “AirPrint”.

27

Page 38

Note: The product report above is the most complete version, and may be different from that

of the model you actually use.

3. Printer Information Report

3.1 Information Report Printing

1. Enter the menu setting interface by pressing “Menu”.

2. Select “Information Report” by pressing “▲” or “▼”.

3. Enable the information report printing function by pressing “OK”. Thus, you can print the

report according to the needs.

The following options can be printed: Demo page, information page, menu structure page,

network configuration, Email address, group Email, FTP address and WiFi hotspot.

3.2 Information Page

1. Printer Information Page

28

Page 39

Toner cartridge and drum unit information (the printed

pages are the actually printed pages instead of

theoretical pages within the calculated service life)

Total pages printed

actually

2. Network Configuration Information Page

29

Page 40

IP information

30

Page 41

4. Restoration of Factory Settings

“Restore default settings” is applied to restore the default settings of the printer. After the default

settings are restored, the printer will be automatically restarted.

4.1 Restore factory settings with menu

1) Press “Menu” to enter the menu setting interface.

2) Press “▲” or “▼”, select “System Settings” and then press “OK”.

3) Press “▲” or “▼”, select “Restore Default Settings” and then press “OK”.

4.2 Restoration of Factory Settings via Embedded Web Server

For the network type printer, the factory settings can be restored via the embedded Web server.

1. Connect the printer with the network. Enter the IP address of the printer in the address bar of

the Web browser for access to the embedded Web server of the printer.

2. Click “User Management” and “Restore Factory Settings”. The printer will be restarted

automatically after factory settings are restored.

Note: After the factory settings of the printer are restored, the username of the administrator

will be restored into admin, and the login password into 000000.

31

Page 42

5. Operating Principle

5.1 Overall Structural Diagram

32

Page 43

Top cover

assembly

Right

cover

Fan

Drive

assembly

Rear cover

Feed-out assembly

Fuser Unit

Duplex Unit

LSU

Engine Board

Power Board

Left cover

Data Board

Paper tray

stopper

Paper tray

Toner cartridge (toner cartridge

and drum component)

Front

cover

ADF assembly

Glass Platen Component

Control Panel Board

5.2 Component Structure Diagrams

33

Page 44

S/N

Name

1

Paper Feed Solenoid

2

Separator Roller

3

Pick-up Assembly

4

Secondary conveying roll

5

Guide roll

6

Toner-feeding roll

7

Developing roll

8

OPC photosensitive drum

9

Charging roll

10

LSU

11

Duplex Unit

12

Transfer roll

13

Motor

14

Pressing roll

15

Heating roll

16

Feed-out roll

17

ADF Pick-UP Assembly

18

ADF feed-out guide wheel

5.3 Mechanical Devices

34

Page 45

5.4 Paper Path

5.4.1 ADF Paper Routine Diagram

5.4.2 Paper Routine Diagram of Printer

35

Page 46

Before disassembly

(preparation)

ADF Pick-

UP

Assembly

and

Separation

assembly

Paper-

feeding roll

assembly

Transfer

roller

Front cover

Back cover

Left and right cover

Data

Board

Power

board

Engine

Board

ADF/scan

ner

assembly

Control panel

Upper

scanner cover

Scanner

motor

CIS

ADF motor Fax board

Upper cover

component

Chip adapter

board

Laser Motor Clutch

Fuser Fan

Drive

assembly

Paper

Feed

Solenoid

Paper

sensing

board

Front-end

sensing

board

6. Disassembly and Installation

6.1 Disassembly Flowchart

6.2 Disassembly Steps

6.2.1 Before disassembly

1. Before disassembly, shut down the power of the printer, and pull out the power cord, USB

cable and network cable.

36

Page 47

2. Remove the toner cartridge.

Note: Package the toner cartridge with black tapes to prevent the photosensitive drum from

being damage as a result of exposure.

3. Remove the paper tray.

4. Remove the duplex printing unit.

37

Page 48

Connecting rod

6.2.2 Front cover

Remove the front cover connecting rod with forceps, and push the front cover

out of the buckle, using the palm.

6.2.3 Rear cover

Open the rear cover, and push it out of the buckle, using the palm.

38

Page 49

6.2.4 Left cover

Remove the front cover and rear cover, pry four buckles of the left cover, and remove the

left cover.

6.2.5 Right cover

Remove the front cover and rear cover, pry four buckles of the right cover, and remove the

right cover.

6.2.6 ADF Pick-UP Assembly and separation assembly

1. Open the upper ADF cover, press the buckler of the separation assembly with the

tweezers, and take out the separation assembly.

2. Open the upper ADF cover, take the paper-feeding assembly from the area between two

baffles, remove the snap spring and gear shaft, and pull out the bearing buckle and

bearing.

39

Page 50

Snap

Bearing

3. Push the paper-feeding roll sleeve right with the slotted screwdriver and take out the

paper-feeding roll assembly.

6.2.7 ADF/scanner assembly

1. Remove the front cover, back cover, left cover and right cover, pull out five harnesses of

the left data Board connected to the scanner assembly, and remove one ground screw.

2. Remove two screws of the hinge support rod and then the hinge support rod (hold the

scanner assembly by hand).

3. Hold the scanner/ADF assembly by hand, remove three screws of the upper side cover, and

40

Page 51

pry out the upper side cover with the slotted screwdriver.

4. Hold the scanner/ADF assembly by hand, remove the scanner harness, and vertically pull

out the scanning assembly.

6.2.8 ADF motor

1. Remove the ADF/scanner assembly and four screws at the bottom of ADF. Then remove the

ADF tray assembly by means of pulling it up.

2. Remove four sheet metal screws, sheet metal assembly and then ADF motor.

41

Page 52

6.2.9 Scanner cover assembly

1. Remove the ADF/scanner assembly, two bottom screws of the scanner assembly, and then the

iron baffles.

5. Remove ADF by pulling it up.

6. Pry out the bucklers (just into the corresponding holes of the jaws, and keep the tweezers in

the first position while conduct prying in other positions) with two slotted screwdrivers or

tweezers, and remove the scanner cover assembly.

42

Page 53

①

②

③

④

⑤

⑥

⑦

⑧

6.2.10 CIS

1. Remove the scanner cover assembly. Then pull out the CIS friction pads (one respectively on

the left and right).

2. Pull out the CIS harness. Make CIS upright and take it out through the right side (do not

directly touch the CIS luminous tube while replacing CIS, in order to avoid abnormality of the

scanned image).

6.2.11 Scanner motor

1. Remove the scanner cover assembly, pry out the gear cap, and then remove the scanner belt.

43

Page 54

2. Remove the screws and the conductive sheet of the steel shaft. Then pry out the left end of the

steel shaft.

3. Remove the two screws and take out the motor assembly. Then remove two motor screws and

scanner motor.

6.2.12 Control panel assembly

Remove the upper side cover of the scanner. Unplug the control panel harness, remove two

screws, and take out the control panel.

44

Page 55

Shake the sheet metal to this side

6.2.13 Fax Board

1. Remove the ADF/scanner assembly, five screws and left boss.

2. Make the left boss inverted, remove the two screws, and take out the fax Board assembly.

6.2.14 Upper cover component

Pull out the left and right harnesses in Figure I. Remove two screws in Figure II and take

out the upper cover component.

Figure I:

45

Page 56

Figure II:

6.2.15 Transfer roll

Open the front cover, pull out the clamping jaw at the right end of the transfer roll, remove

the bushing at the right end of the transfer roll, and then remove the transfer roll.

Note: Do not directly touch the sponge of the transfer roll by handle while removing the transfer

roll, in order to avoid printing abnormality.

6.2.16 Pick-UP Assembly

Pry up 2 clamping jaws, rotate the shaft pins via the clamping jaws until the pins are located

in holes, and remove the paper-feeding roll assembly.

46

Page 57

6.2.17 Paper sensor

Pull out the paper tray and duplex printing unit, remove the screw and plug of the sensor,

and then remove the paper sensor.

6.2.18 Chip adapter Board

After removing the top cover, remove the Board screw and plug, and take out the chip

adapter Board.

6.2.19 Paper Feed Sensor

Pull out the paper tray and duplex printing unit, remove two screws of the cover (at the

bottom of the printer), and take out the cover. Remove the screw and plug of the sensor

Board, and take out the Paper Feed Sensor.

6.2.20 Data Board

1. Remove the front cover and back cover, and pull out the harness plug on the data Board.

47

Page 58

Note: For the WiFi type printer, remove the top cover, lift the buckle of WiFi antenna, and take

out the WiFi antenna.

2. Remove the four screws and data Board.

6.2.21 Engine Board

Remove the front cover and rear cover, and pull out six harness plugs of the high-voltage

Board (Figure 1). Remove the five screws (Figure 2) and then high-voltage Board.

48

Page 59

Plug

Note: You can see four conductive springs (easy to fall) after removing the engine Board.

Keep them properly, and install them in the correct positions. Among the four conductive

springs, the one at the bottom is different from the other three.

6.2.22 Power Board

Remove the front cover and rear cover, and pull out two plugs of the power Board. Remove

the four screws and then power Board.

Note:

The large capacitor of the Board is still energized immediately after shutdown of the printer.

It should be discharged before disassembly, to avoid electric shock.

6.2.23 LSU

Remove the front cover, rear cover, left cover, right cover and top cover, and pull out two

plugs of the laser unit. Remove the three screws and then laser unit.

49

Page 60

Harness plug

6.2.24 Fuser

1. Remove the front cover, rear cover, left cover and right cover. Then remove two screws

of the feed-out assembly, and take out the feed-out assembly.

2. Remove the three plugs of the data Board and power Board, and five screws of the fuser.

Then remove the fuser.

6.2.25 Driver unit

Remove the right cover and five screws of the driver unit. Then remove the driver unit

(Note: pay attention to gear protection in the disassembly process, in order to prevent the

gear from damage caused by falling down).

50

Page 61

6.2.26 Fan

Remove the front cover, rear cover, left cover, right cover and top cover, and pull out the fan

plug from the Engine Board. Remove the three screws of fan assembly. Then remove the fan

assembly and take out the fan (Note: pay attention to gear protection in the disassembly

process, in order to prevent the gear from damage caused by falling down).

6.2.27 Paper Feed Solenoid

Remove the right cover, and pull out the Paper Feed Solenoid plug. Remove one screw of the

Paper Feed Solenoid, and take out the Paper Feed Solenoid.

6.2.28 Motor

1. Remove the driver unit, two screws of the right frame and two buckles of the slide rail

of the paper tray. Take out the slide rail of the paper tray, and pull out the harness plug

of the motor.

51

Page 62

2 screws and 2 buckles

Gear 1

Clutch assembly

2. Remove the five screws of the right frame, the right frame and the three screws of the

motor in sequence. Then remove the motor.

6.2.29 Clutch assembly

1. Remove the right frame and gear 1, and take out the clutch assembly.

52

Page 63

7. Maintenance

Note: The printer appearance varies depending on the model and function. The schematic diameter

is for reference only.

7.1 Printer cleaning

Note: Please use mild detergents.

Some parts are still hot in a short time after the printer is shut down. After opening the front cover

or back cover, do not directly touch the internal parts with high temperature warning labels, in order to

avoid scalding.

1. Turn off the main power switch, and unplug the power cord and other connecting wires.

2. Use soft cloth to wipe the outside of the printer, to remove dust.

3. Lift the scanner cover and gently wipe the glass platen with soft cloth.

4. Open the front cover, and take out the laser toner cartridge out along the guide rail.

Note:

53

Page 64

Remove metal articles such as the watch and bracelet before removing the toner cartridge, as

internal components may be damaged in the case of contact.

After removing the toner cartridge, put it into a protective bag or wrap it with thick paper, to

prevent damage caused by direct light.

5. As shown below, clean the inside of the printer by gently wiping the shaded area with dry and

lint-free cloth.

6. Wipe the LSU lens of the printer gently with dry and lint-free cloth.

7. Open the automatic feeder tray of the printer, and gently wipe the paper-feeding roll with dry

lint-free cloth.

54

Page 65

Note:

If the printer is provided with the document feeder, the document feeder cover should be

cleaned regularly by means of wiping with soft cloth.

Wipe the part shown in the figure.

55

Page 66

7.2 Use and Maintenance of Consumables

7.2.1 About toner cartridge and drum component

1. Use and maintenance of toner cartridge.

Use the original toner cartridge for better printing quality. Pay attention to the following items

while using the toner cartridge.

·Do not take the toner cartridge out of the package, unless required immediately.

·Do not refill the toner cartridge without permission; otherwise, the damages caused will be

excluded in the scope of warranty of the printer.

·Keep the toner cartridge in a cool and dry place.

·Keep the toner cartridge away from ignition sources, as the toner inside is flammable and may

cause fire.

·Pay attention to toner leakage while taking out or removing the toner cartridge. In case of skin

contact with toner or spattering into the eyes or mouth as a result of toner leakage, immediately

wash them with clean water, or see a doctor if feeling unwell.

·Keep the toner cartridge away from the area accessible to children.

2. Service life of toner cartridge.

·· The service life of the toner cartridge depends on the toner quantity needed for printing.

· If the LCD screen displays “The Toner Cartridge Life Expired”, it means that the service life of

the toner cartridge is expired. Replace the toner cartridge.

3. Service life of drum component

·If the LCD screen displays “The Drum Component Life Expired”, it means that the service life of

the drum component is expired. Replace the drum component.

7.2.2 Replacement of toner cartridge and drum component

Note: Before replacing the toner cartridge, pay attention to the following items:

· There may be toner on the surface of the toner cartridge. Be careful to take out the toner

cartridge in order to avoid spillage.

· Place the toner cartridge onto paper, to avoid toner spillage within a large area.

· Do not touch the drum surface during installation in order to prevent the drum from

scratching.

1. Turn off the power of the printer. Open the front cover, and take out the laser toner cartridge

along the guide rail.

56

Page 67

2. Press the blue button on the left side of the drum component with the left hand, lift the

toner cartridge handle with the right hand, and take out the toner cartridge.

3. Open the package of new drum component, remove the protective device, and place the

drum component onto a horizontal table.

4. Open the new cartridge package, hold the cartridge handle, and gently shake the cartridge

right and left 5-6 times to make toner dispersed evenly.

5. Pull out the seal and remove the protective cover of the toner cartridge.

6. Install the toner cartridge into the drum component along the guide rail of the drum

component.

57

Page 68

7. Install the drum component with toner cartridge along the guide rail of the printer, and close

the front cover.

58

Page 69

8. Error Message and Troubleshooting

8.1 Check before maintenance

I. Operating environment

d) Keep the power voltage at the rated voltage AC220-240V on the nameplate.

e) Install the printer on the secure and horizontal surface.

f) Keep the indoor temperature of 10°C to 35°C and relative humidity of 20% to 80%.

g) Do not install the printer in a dusty place.

h) Do not expose the printer to ammonia or other harmful gases.

i) Do not install the printer in a hot or humid area (such as beside the water or humidifier).

j) Do not make the printer exposed to the direct sunlight.

k) Keep good ventilation of the room where the printer is installed.

l) Do not install the printer in a place where the vent may be blocked.

II. Print paper

m) Check whether the print paper type complies with the specifications. [If the paper is too thick

or thin or easy to roll, jamming or feeding problems may occur or the printed image may be

blurring.]

n) Check whether the print paper is wet. [If the paper is wet, use dry paper and check whether

the printing quality is improved.]

o) Check whether the print paper is short-texture or acidic. [In this case, the printing quality

problem may be caused.]

III. Consumables

p) If the indicator on the control panel of the printer flickers in yellow or the LCD screen

displays that toner is used up, replace the toner cartridge promptly.

q) Check whether the applied toner cartridge is designated by Pantum.

59

Page 70

Error Message

Cause

Solution

The printer is not

connected.

1. The USB cable or power

cord is not connected.

2. The main control Board

fails.

1. Properly connect the USB cable

and power cord.

2. Replace the main control Board.

The front cover is

open.

The front cover is not fully

closed.

Close the front cover.

No paper is provided

or paper feeding fails.

1. Check whether there is

paper.

2. The print paper is not

installed properly.

3. The pickup roll is dirty or

aged.

1. Make sure that there is paper in

the paper tray.

2. Properly install the print paper.

3. Clean or replace the pickup roll.

Paper is jammed.

1. The print paper is not

installed properly.

2. The paper is damp.

3. The pickup roll is dirty.

4. The front-end sensor fails.

5. The fuser unit is damaged.

1. Install the print paper properly.

2. Use dry paper.

3. Clean the pickup roll.

4. Check or replace the front-end

sensor.

5. Replace the fuser unit.

The drum component

and carbon cartridge

are not detected.

1. The drum component and

toner cartridge are not

installed or installed

improperly.

2. The chip contact of the

drum component or toner

cartridge is dirty or

damaged.

3. The chip of the drum

component or toner

1. Install the drum component and

toner cartridge properly.

2. Replace the Engine Board.

3. Use new drum component and

toner cartridge.

8.2 Error Status Prompts

60

Page 71

cartridge is damaged.

The drum component

and toner cartridge

are not matching.

The models of the drum

component and toner cartridge

are not matching.

Replace the drum component and

toner cartridge.

The life of the drum

component and toner

cartridge is expired.

The print pages of the drum

component and toner cartridge

are used up.

Replace the drum component and

toner cartridge.

Please close the ADF

cover.

The ADF cover is not installed

in place.

Close the ADF cover.

ADF jamming

1. The original is not installed

properly or the original size

or medium does not meet

the requirements.

2. ADF paper-feeding roll is

dirty.

1. Replace the original.

2. Clean the paper-feeding roll.

Function

Prompt Status

Notes

Warning

The status indicator is

ON in orange.

Little toner (LED does not shown the status of little toner during operation) and no

display on LCD.

After the sleep mode is disabled, the status indicator will not turn orange and the LED

will be normally green as the status of little toner is not detected in the wake-up action

(such as sweeping and ADF cover opening) with the engine not working.

Sleep

The power indicator is

in the breathing

indicator mode.

The light intensity gradually decrease (tentatively 2s, to be adjusted according to the test

results) and then increase (with the same time as above) in a cyclic manner.

Tip

Communication error

xx

Cancel: OK

This is the scanning communication error prompt. Once this error occurs, the current

scanning will be automatically terminated by the system. This will not affect the

subsequent functions of the printer. Scanning, sweeping and fax reception or low voltage

enabling can be performed normally in this status.

You can exit this status in three ways: enabling the automatic sleep, update the scanning

status or press “OK” on the panel.

xx: Error code

21 Communication failed (WSD communication error [the wired network connection

and WiFi connection cannot be distinguished in this communication error])

8.3 Warning and Prompt Status

61

Page 72

22 Invalid instruction (reserved)

23 Invalid parameter (reserved)

24 (Reserved)

25 USB connection error

26 Network connection error

27 WiFi connection error

The status LED indicator is normally ON in red.

The memory does not

have enough capacity.

Press OK.

Cancel the operation!

This is the prompt of insufficient capacity of the email and ftp memory. Once this error

occurs, the current scanning will be automatically terminated by the system. This will not

affect the subsequent functions of the printer. Printing, sweeping or low voltage enabling

can be performed normally in this status.

The current status of LED will not change.

Insufficient memory

capacity

This is the prompt of insufficient capacity of the ADF copy memory. Once this error

occurs, scanning of the current copying process will be suspended. Press “Cancel” to

cancel copying. The other keys are invalid in this status. If the memory has the enough

capacity in the follow-up waiting process, the scanning job will continue. Printing,

sweeping or low voltage enabling will be invalid in this status.

The current status of LED will not change.

Insufficient memory

capacity

Cancel: OK

This is the prompt of insufficient capacity of the memory for ADF duplex-to-duplex

copying. As the matching duplex scanning data are not available, the memory will not be