Page 1

SPECIFICATIONS

General

Power requirement : AC 120 V 60 Hz

Power consumption : 105 W (with options)

Frequency response : 20 Hz - 20 kHz, +1 dB - –2 dB

T.H.D. (total harmonic distortion) : Less than 0.1 % (input = +10 dB/1 kHz, output = +4 dB/RL 600 Ω)

Equivalent input noise : –128 dB (Rs = 150 Ω Input sensitivity = –60 dB typical)

Residual noise : –93 dB typical

Maximum voltage gain : 84 dB: MIC/LINE(1-16) in to BUS out

84 dB: MIC/LINE(1-16) in to MASTER out

84 dB: MIC/LINE(1-16) in to AUX out

Common Mode Rejection Ratio : More than 80 dB (1kHz)

Crosstalk : 90 dB typical (1kHz)

Dynamic Range (Fs = 48kHz, DIN audio filter) :

113 dB typical : DA converter (digital in to analog out)

112 dB typical : AD converter (analog in to digital out)

110 dB typical : AD + DA (analog in to analog out)

AD Converter : 24 bit, 64 times oversampling (input 1 to 16)

20 bit, 64 times oversampling (aux returns 3 to 6)

DA Converter : 24 bit, 64 times oversampling (MASTER, MONITOR A)

24 bit, 128 times oversampling (MONITOR B)

20 bit, 128 times oversampling (aux returns 3 to 6)

Internal signal processing : 32 bit (Dynamic range 192 dB)

Sampling Frequency (Fs) : Internal: 44.1 kHz and 48 kHz

External: 44.1 kHz ± 6 % and 48 kHz ±6 %

Signal delay : Less than 2.5 ms, MIC/LINE input to MASTER out

Audio Mixer

WR-DA7

ORDER NO. AVS9805093C1

D29

C 1998 Matsushita Communication Industrial Co., Ltd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

The Meter Bridge shown in photo is one of the optional accessories.

R

Page 2

This service information is designed for experienced repair technicians only and is not designed for use by the

general public.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to

service a product.

Products powered by electricity should be serviced or repaired only by experienced professional technicians. Any

attempt to service or repair the product or products dealt with in this service information by anyone else could

result in serious injury or death.

!

WARNING

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

CAUTION:

TO REDUCE THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE.

REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

This symbol warns the user that uninsulated voltage within

the unit may have sufficient magnitude to cause electric

shock. Therefore, it is dangerous to make any kind of contact

with any inside part of this unit.

This symbol alerts the user that impotant literature concerning

the operation and maintenance of this has been included.

Therefore, it should be read carefully in order to avoid

any problems.

There are special components used in this equipment which are important for safety. These parts are indicated

by the ” Y ” mark on the schematic diagram and the replacement parts list. It is essential that these critical

parts should be replaced with manufacturer's specified parts to prevent shock, fire, or other hazards.

Do not modify the original design without permission of manufacture.

IMPORTANT SAFETY NOTICE

Dynamics

Compressor

Threshold : –40 dB - 0 dB (1 dB/step)

Ratio : 1.0, 1.1, 1.3, 1.5, 1.7, 2.0, 2.5, 3.0, 3.5, 4.0, 5.0, 6.0, 8.0, 10, 20, ∞ (16 points)

Attack time : 0 ms - 250 ms (1 ms/step)

Release time : 5 ms - 2000 ms (5 ms/step)

Gain : 0 dB - +12 dB (0.5 dB/step)

Gate

Threshold : –80 dB - –15 dB (1 dB/step)

Attack Time : 0 ms - 250 ms (1 ms/step)

Release time : 5 ms - 2000 ms (5 ms/step)

Expander

Threshold : –80dB - –15dB (1dB/step)

Ratio : 1.0, 2.0, 3.0, 4.0, 5.0, 6.0, ∞

Attack time : 0 ms - 250 ms (1 ms/step)

Release time : 5 ms - 2000 ms (5 ms/step)

Range : 0 dB - +40 dB (0.5 dB/step)

Equalizer

LOW band PEQ (parametric equalizer) type: Q = 0.5 - 50 (41 steps)

F = 20 Hz - 20 kHz (1/12 oct step)

G = ± 15 dB (0.5 dB/step)

LOW band SHL (shelving low) type : F = 20 Hz - 1.6 kHz (1/12 oct step)

G = ± 15 dB (0.5dB/step)

LOW band HPF (high-pass) type : F = 20 Hz - 1.6 kHz (1/12 oct step)

LOW-MID band PEQ type : Q = 0.5 - 50 (41 steps)

F = 20 Hz - 20 kHz (1/12 oct step)

G = ± 15dB (0.5dB/step)

HIGH-MID band PEQ type : Q = 0.5 - 50 (41 steps)

F = 50 Hz - 20 kHz (1/12 oct step)

G = ± 15 dB (0.5 dB/step)

HIGH band PEQ type : Q = 0.5 - 50 (41 steps)

F = 50 Hz - 20 kHz (1/12 oct step)

G = ± 15 dB (0.5 dB/step)

HIGH band SHH (shelving high) type : F = 1 kHz - 20 kHz (1/12 oct step)

G = ± 15 dB (0.5 dB/step)

HIGH band LPF (low-pass) type: 1 kHz - 20 kHz (1/12 oct step)

Page 3

Delay : 0 - 14,400 samples/0 - 300 ms (Fs = 48 kHz), 0 - 326 ms (Fs = 44.1 kHz)

Phase : normal/reverse (switchable)

Stereo meter : Bar graph type LED, Left and Right, 20 points for each

VU or PPM (selectable), Peak hold on/off, ∞

Fader : 100 mm motor fader ( x 21), +10 db - –90 dB –∞ dB

Display : LCD, 320 x 240 dot, with backlight

Memory : SCENE MEMORY (Snapshot) 50 registers

CHANNEL library 50 registers

EQUALIZER library 50 registers

DYNAMICS library 50 registers

AUTOMATION 4 mix

Ambient operating temperature : 0 °C - 40 °C (32 °F - 104 °F)

Dimensions (mm) : 698 (W) x 244 (H) x 549.5 (D)

Weight (without options) : 23kg (51lbs)

Finish : ABS resin (Top Panel), Blue black

Standard Accessories : Power Cord, Users’ Guide, Warranty Card, Registration Card

Dimensions and weights indicated are approximate.

Specifications are subject to change without notice.

Digital In and Out

2TR IN (INPUT 15,16) :

In/Out : In

Format : IEC 958 Professional (AES/EBU) or Consumer (S/PDIF) switchable

Level : RS-422 (AES/EBU) or 0.5 V [pp]/75 Ω (S/PDIF)

Connector : XLR 3-31

REC OUT :

In/Out : Out

Format : IEC 958 Professional (AES/EBU) or Consumer (S/PDIF) switchable

Level: RS-422 (AES/EBU) or 0.5 V[pp]/75 Ω (S/PDIF)

Connector : XLR 3-32

AUX RETURN 1/2 :

In/Out : In

Format : IEC 958 Consumer (S/PDIF)

Level : 0.5 V [pp]/75 Ω

Connector : RCA pin jack

Input Type Source Impedance Signal Level (Nominal-before clipping) Connector Type

CH input 1-8 5 kΩ mics, 50 Ω - 600 Ω –60 dB - –46 dB XLR 3-31 (bal)

lines, 600 Ω +10 dB - +24 dB XLR 3-31 (bal)

CH input 9-16 5 kΩ mics, 50 W - 600 Ω –60 dB - –46 dB TRS phone jack (bal)

lines, 600 Ω +10 dB - +24 dB TRS phone jack (bal)

CH Insertion Returns

1-16 10 kΩ lines, 600 Ω +4 dB - +18 dB TRS phone jack (unbal)

2TR B IN (analog) 10 kΩ lines, 600 Ω +4 dB - +18 dB TRS phone jack (bal)

AUX returns 3-6 10 kΩ lines, 600 Ω +4 dB - +18 dB TRS phone jack (unbal)

Input Type Output Impedance Adapted Load Impedance Signal Level (Nominal-before clipping) Connector Type

MASTER L/R 5 kΩ 150 Ω lines 600 Ω +4 dB - +18 dB XLR 3-32 (bal)

AUX sends 3 - 6 75 Ω lines 10 kΩ +4 dB - +18 dB TRS phone jack (unbal)

INSERTION 1 - 16 10 Ω lines 10 kΩ +4 dB - +18 dB TRS phone jack (unbal)

REC OUT L/R (analog) 150 Ω lines 10 kΩ +4 dB - +18 dB TRS phone jack (bal)

MONITOR A out L/R 150 Ω lines 600 Ω +4 dB - +18 dB TRS phone jack (bal)

MONITOR B out L/R 150 Ω lines 600 Ω +4 dB - +18 dB TRS phone jack (bal)

Headphones 8 Ω phones 40 Ω/8 Ω 400 mW/100mW Stereo phone jack (unbal)

Analog Inputs (0 dB = 0.775 Vrms, 0 dBV = 1 Vrms)

Analog Outputs (0 dB = 0.775 Vrms, 0 dBV = 1 Vrms)

Page 4

AUX SEND 1/2 :

In/Out : Out

Format : IEC 958 Consumer (S/PDIF)

Level : 0.5 V [pp]/75 Ω

Connector : RCA pin jack

WORD CLOCK IN :

In/Out : In

Level : TTL/75Ω switchable

Connector : BNC

WORD CLOCK OUT/THROUGH :

In/Out : Out

Level : TTL/75 Ω, Pass-through (75 Ω OFF) or termination (75 Ω ON)

Connector : BNC

MIDI IN :

In/Out : In

Format : MIDI

Connector : DIN Connector 5P

MIDI OUT :

In/Out : Out

Format : MIDI

Connector : DIN Connector 5P

TO PC :

In/Out : In and Out

Connector : Mini-DIN Connector 8P

RS422/485 :

In/Out : In and Out

Connector : D-sub 9P

FOOT SWITCH :

In/Out : In

Level : TTL level, Normally Open (Unlatch type)

Connector : Phone jack

Optional Accessories

Meter Bridge :

Type : Bargraph LED, 26 channels, 15 points for each

Format : RAMSA original Level NET II

Power : DC 7 V

Connector : D-sub 15P

WR-ADTA (ADAT Interface card (8 in / 8 out))

Type : ADAT (DIRECT OUT / BUS / AUX / MASTER, Input 9-32)

In/Out : In and Out

Connector : Optical

WR-TDIF (TDIF Card (8 in / 8 out))

Type : TDIF (DIRECT OUT / BUS / AUX / MASTER, Input 9-32)

In/Out : In and Out

Format : TDIF-1

Connector : D-sub 25P (in and out)

WR-AESS (AES/EBU Card (8 in / 8 out))

Type : AES/EBU/SPDIF

Signal type : RS422

Connector : D-sub 25P (in and out)

Page 5

WR-ADDA (A-D/D-A Card (8 in / 8 out))

Input 1 - 8 (balanced)

Indicated impedance : 10kΩ

Nominal source impedance : 50Ω ~ 600Ω

Nominal input level : +4dB (1.23V)

Maximum input level before clipping : +18dB (6.15V)

Connector type : D-sub 25P

Output 1 - 8 (balanced)

Indicated impedance : 10kΩ

Nominal source impedance : 150Ω

Nominal input level : +4dB (1.23V)

Maximum input level before clipping : +18dB (6.15V)

Connector type : D-sub 25P

WR-SMPT (SMPTE/V SYNC Card)

SMPTE IN

In/Out : In

Format : SMPTE (LTC)

Signal type : nominal -10dBV / 10kΩ

Connector : XLR

V SYNC

In/Out : In

Format : NTSC (B/W or color) / PAL

Signal type : 75Ω , termination

Connector : BNC

WR-TNDM (TANDEM Card (for running two

DA7

mixers simultaneously))

Type : TANDEM connection

In/Out : In and Out

Format : RAMSA SSA

Signal type : RS422

Connector : D-sub 25P

Page 6

PRODUCT COMPLIES WITH DHHS RULES 21 CFR SUBCHAPTER J

APPLICABLE AT DATE OF MANUFACTURE

SAFETY PRECAUTIONS

GENERAL GUIDELINE

1. When service is required, observe the original lead dress.

Components, wires or cables that indicate evidence of

overheating or other electrical or mechanical damage

should be replaced.

2. After servicing see to that all the protective devices, such

as insulation tape, shields must be properly installed.

3. After servicing, make the following leakage current

checks to prevent the customer from being exposed to

shock hazards.

LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the

two prongs on the plug.

2. Measure the resistance value, with an ohmmeter,

between the jumpered AC plug and each exposed

metallic cabinet part on the equipment such as

screwheads, connectors, control shafts, etc.

When the exposed metallic part has a return path to the

chassis, the reading should be between 1M Ω and 5.2M

Ω. When the exposed metal does not have a return path

to the chassis, the reading must be ∞ (infinity).

Any resistance value below this range indicates an

abnormality which requires corrective action.

3. Repeat the test with the AC switch in the "OFF" position.

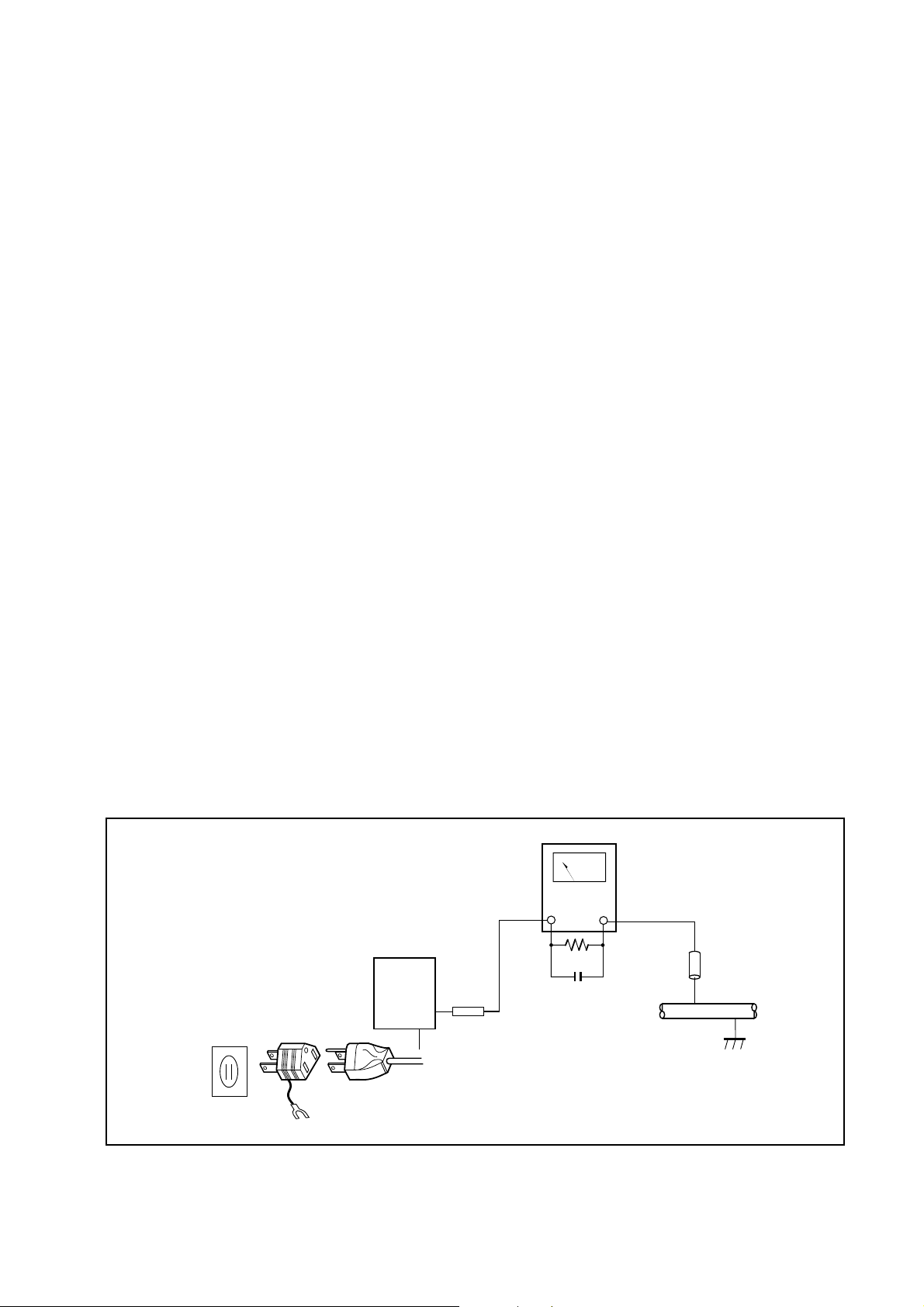

LEAKAGE CURRENT HOT CHECK

1. Plug the AC cord directly into adaptor socket and plug

adaptor into the AC outlet. Do not use an isolation

transformer for this check.

2. Connect a 1.5k Ω/10W resistor, paralleled by 0.15 µF

capacitor, between each exposed metallic part on the unit

and a good earth ground such as a water pipe, as shown

in Figure 1.

3. Use an AC voltmeter, with 1000Ω/volt or more sensitivity,

to measure the potential across the resistor.

4. Check all exposed metallic parts of the cover (BNC

connector, Handle bracket, Metallic cabinet, Screwheads,

Metallic overlays, etc.), and measure the voltage at each

point.

5. Reverse the AC plug in the AC plug adaptor and re-peat

each of the above measurements.

6. The potential at any point should not exceed 0.75 V RMS.

A leakage current tester (SIMPSON MODEL 229 or

equivalent) may be used to make the hot checks.

Leakage current must not exceed 0.5 milliampere.

In case a measurement is outside of the limits specified,

there is a possibility of a shock hazard, and corrective

action must be taken before returning the instrument to

the customer.

AC VOLTMETER

1.5 kΩ

0.15 µF

Water Pipe

(Earth Ground)

Test all exposed

metal parts

DEVICE

UNDER

TEST

AC PLUG

ADAPTOR

AC OUTLET

Ground Lead Disconnected during safety check.

Fig. 1 Leakage Current Hot Check

Page 7

CONTENTS

Major Operating Controls and Their Functions...................................................................................................... 1

Self Check Procedure................................................................................................................................................ 15

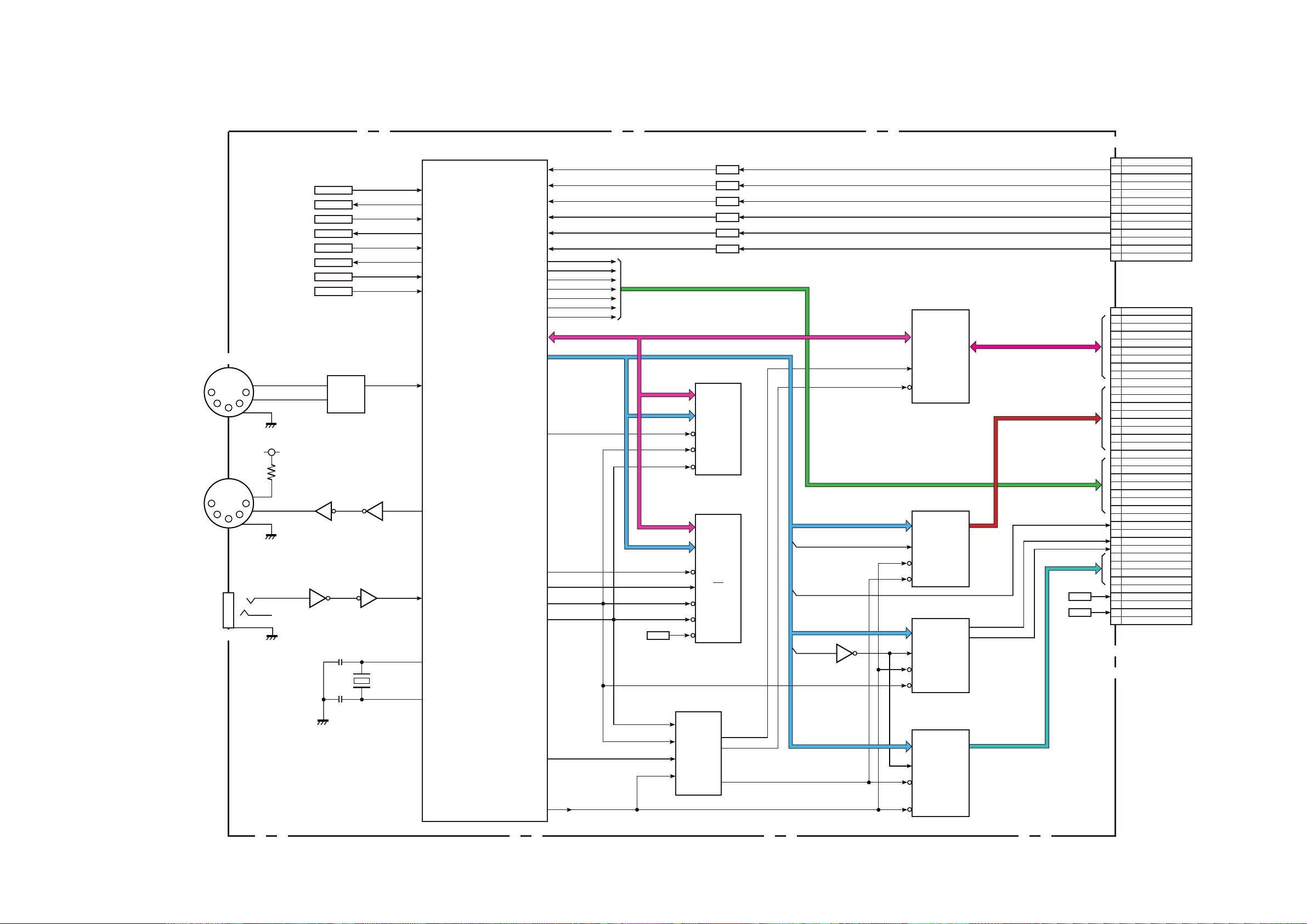

Wiring Diagram .......................................................................................................................................................... 22

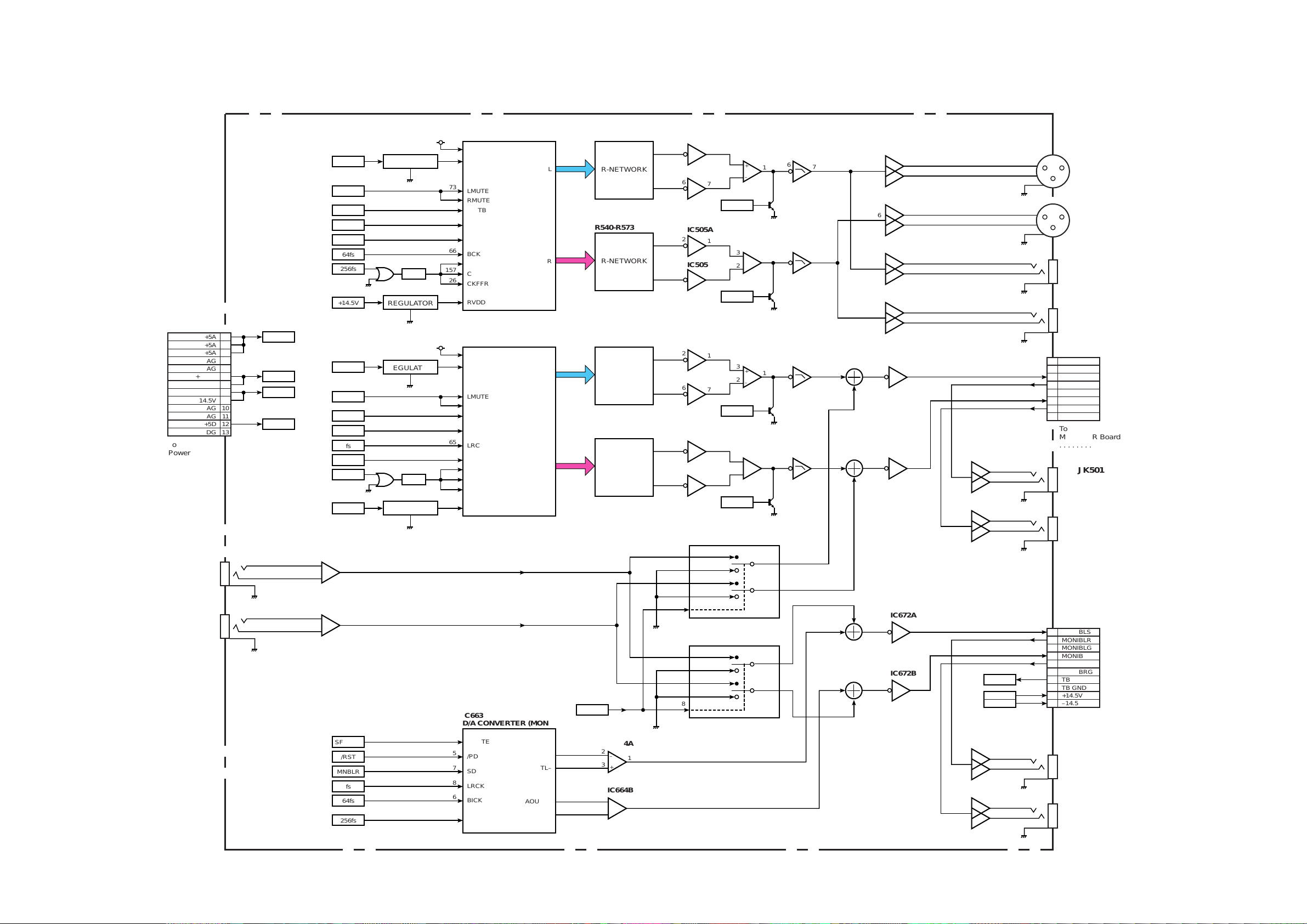

Block Diagram

Overall Block Diagram.............................................................................................................................................. 23

Main Board (CPU Section) ....................................................................................................................................... 24

Main Board (Panel Control CPU Section)................................................................................................................. 25

Main Board (DSP Section-1) .................................................................................................................................... 26

Main Board (DSP Section-2) .................................................................................................................................... 27

Main Board (Audio Interface Section)....................................................................................................................... 28

AD/DA Board (1/2).................................................................................................................................................... 29

AD/DA Board (2/2).................................................................................................................................................... 30

Fader Drive Board (1/2)............................................................................................................................................ 31

Input Switch Board/Fader Drive Board (2/2)............................................................................................................. 32

HA Board and INS Board.......................................................................................................................................... 33

Monitor VR/HP/TB Boards........................................................................................................................................ 34

EFX Board ................................................................................................................................................................ 35

Block Diagram .......................................................................................................................................................... 36

Level Diagram........................................................................................................................................................... 37

Schematic Diagram

Monitor VR/HP/TB Boards........................................................................................................................................ 39

Bus Relay Board....................................................................................................................................................... 40

Power-1/Power-2 Boards.......................................................................................................................................... 42

HA Board and INS Board.......................................................................................................................................... 45

EFX/Meter Board...................................................................................................................................................... 46

Fader Drive Board .................................................................................................................................................... 48

Input Switch Board.................................................................................................................................................... 51

AD/DA Board (2/3).................................................................................................................................................... 53

AD/DA Board (3/3).................................................................................................................................................... 54

AD/DA Board (1/3).................................................................................................................................................... 55

Main Board (1/4)....................................................................................................................................................... 56

Main Board (2/4)....................................................................................................................................................... 57

Main Board (3/4)....................................................................................................................................................... 58

Main Board (4/4)....................................................................................................................................................... 59

WR-MTBR ................................................................................................................................................................ 60

WR-TNDM ................................................................................................................................................................ 63

WR-TDIF................................................................................................................................................................... 64

WR-SMPT................................................................................................................................................................. 67

WR-AESS................................................................................................................................................................. 68

WR-ADAT................................................................................................................................................................. 71

Conductor View

Monitor VR/HP/TB Boards........................................................................................................................................ 38

Bus Relay Board....................................................................................................................................................... 41

Power-1/Power-2 Boards.......................................................................................................................................... 43

HA Board and INS Board.......................................................................................................................................... 44

EFX/Meter Board...................................................................................................................................................... 47

Fader Drive Board .................................................................................................................................................... 49

Input Switch Board.................................................................................................................................................... 50

AD/DA Board ............................................................................................................................................................ 52

Main Board ............................................................................................................................................................... 58

WR-MTBR ................................................................................................................................................................ 61

WR-TNDM ................................................................................................................................................................ 62

WR-TDIF................................................................................................................................................................... 65

WR-SMPT................................................................................................................................................................. 66

WR-AESS................................................................................................................................................................. 69

WR-ADAT................................................................................................................................................................. 70

Exploded View

WR-DA7.................................................................................................................................................................... 72

WR-MTBR ................................................................................................................................................................ 73

WR-TNDM ................................................................................................................................................................ 74

WR-TDIF................................................................................................................................................................... 75

WR-SMPT................................................................................................................................................................. 76

WR-AESS................................................................................................................................................................. 77

WR-ADAT................................................................................................................................................................. 78

Replacement Parts List............................................................................................................................................. 79

Page 8

1

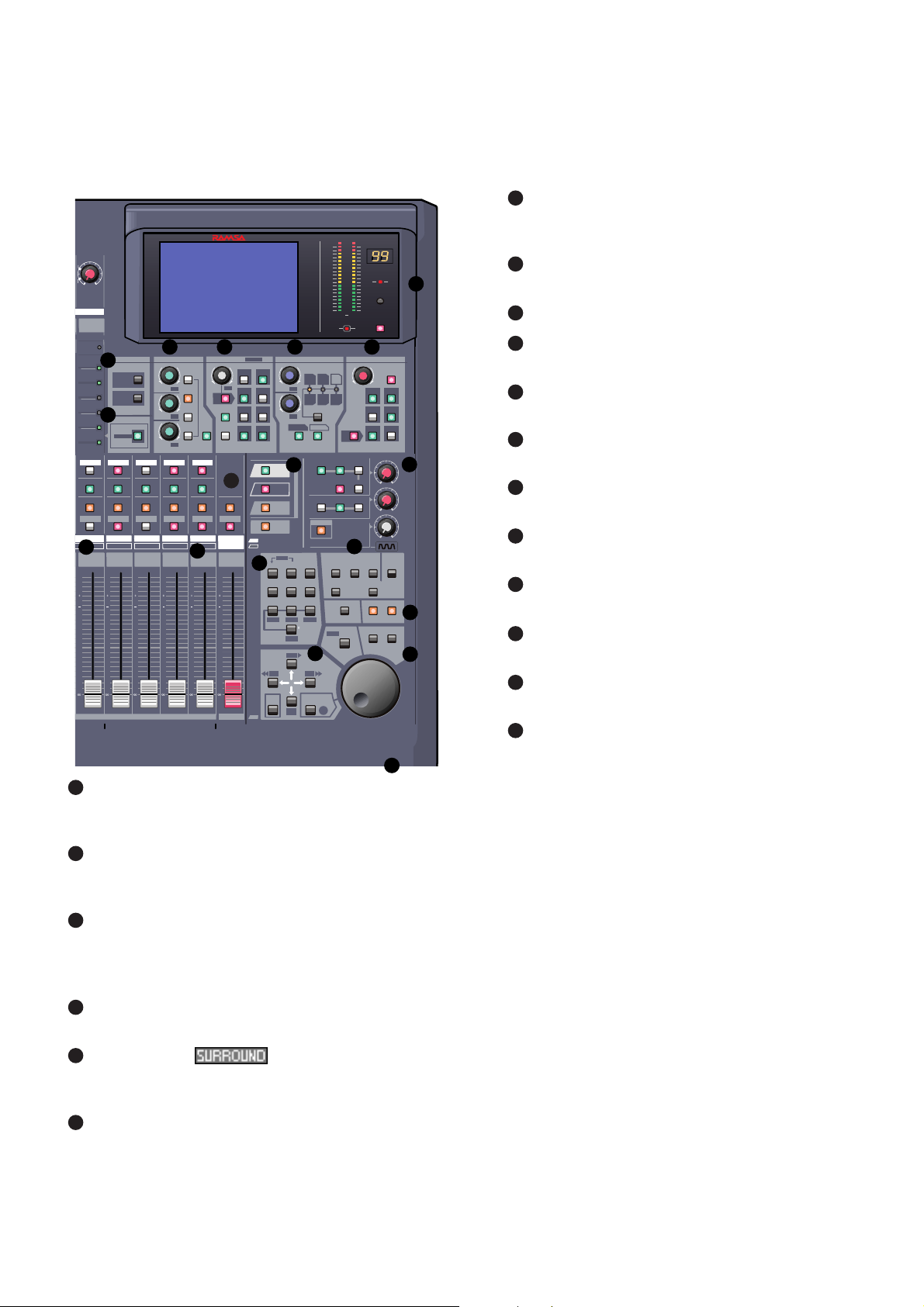

MAJOR OPERATING CONTROLS AND THEIR FUNCTIONS

10

1

2

3

4 5 7

8

6

9

11

12

13

14

15

16

17

18

Illustrated Guide

Channel Strip – input gain controls with channel

control and status indicators. Also called a Channel

Fader Strip.

AUTOMATION/AUX LED button – selects the display

mode of the Channel Strip LED field indicators, and

arms the AUTOMATION system.

MASTER DISPLAY section – the METER and

CHANNEL buttons are direct buttons to the respective

LCD screen windows. These should be considered as

"home base" for the LCD display.

EQUALIZER section – controls for setting the

equalization parameters for a selected channel.

PAN/ASSIGN/ , BUS ASSIGN section –

controls for setting the pan and bus assignments for a

selected channel.

DYNAMICS/DELAY section – controls for setting the

onboard dynamics processing parameters for a

selected channel.

AUX section – controls for routing channels to outboard

sources and for defining the signal path as either prefader or post-fader.

Display Bridge – contains the LCD screen, L/R meter

display, and primary mixer display status indicators.

BUS Fader Strip – controls for output BUSes.

MASTER L/R Fader Strip – controls for L/R MASTER

output.

Fader Layer Controls section – selects the current

fader layer to be displayed.

MONITOR section – volume and selection controls for

monitoring.

SETUP section – mixer function, or display control

buttons.

SCENE MEMORY section – buttons for writing and

reading the 50 mixer scene memories.

LIBRARY section – buttons for storing and recalling

Channel, EQ and Dynamics libraries.

Keypad – alphanumeric keys for entering numbers or

text.

Cursor Control section – buttons and controls for

defining the cursor actions.

Headset Control section – the location of the headset

connector and level control of the DA7 is immediately

below the right front edge of the Top Panel.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Digital Mixer

WR - DA7

OL

MEMORY

2

THL

+-

RATIO

PARAMETER SELECT

+-

DELAY

MONITOR A

MONITOR A

MONITOR B

TALK BACK

3

6

9

LOOP

0

FF

CURSOR

MODE

ATK

RLS

ON

L/R

ON

REC

10

15

20

25

35

50

L

SOLO

DLY

GAIN

CONTROL

ON

2TR A

MONO

L/R

UTILITY MIDI

GROUP

UNDO/REDO

/CURSOR

MMC

4

6

8

FADER

LEVEL

ON / OFF

R

2TR B

AUX

AUX

CONSOLE

LOCK

CONTRAST

MULTI-

CH VIEW

AUX

+-

12

3

56

010

010

010

D-I/O

AUTOMATION

WRITE

SCENE MEMORY

STORE

PRE

SOLO

MONITOR

SET UP

READ

RECALL

LIBRARY

PARAMETER

MIC/LINE

-10

+4

+10

-60

INPUT

16

PEAK /

SIGNAL

FADER

AUX 1

CH

AUX 2

EQ

AUX 3

PAN/SURR

AUX 4

LIBRARY

AUX 5

SEL/MAN

AUX 6

SOLO SOLO SOLO SOLO SOLO

FLIP FLIP FLIP FLIP FLIP

SELECT SELECT SELECT SELECT SELECT SELECT

ON ON ON ON ON ON

16

32

10

10

0

0

10

10

20

20

30

30

40

40

BUS 4 BUS 6 BUS 7 BUS 8BUS 5

EQUALIZERMASTER DISPLAY

METER

CHANNEL

RED

AUTOMATION

AUX

GREEN

BUS 1 BUS 3 BUS 5 BUS 7

BUS 2 BUS 4

H

+-

L

Q

HM

LM

+-

FREQ

SL

L

+-

SUB

GAIN

BUS 6

BUS 8

10

10

10

0

0

0

10

10

10

20

20

20

30

30

40

30

40

40

SURROUND

12

4

3

6

5

8

7

PQRS WXYZ

LOCATE

ENTER

SET

INPUT

1-16

INPUT

17-32

AUX

/ BUS

CUSTOM

/ MIDI

REW

1

4

7

LOOP

DYNAMICS / DELAY

R

SR

DYNAMICS

ON

ABC DEF

2

JKLGHI MNO

5

TUV

8

REPLAY

SHIFT

PLAY

STOP

PAN /ASSIGN /

R

L

C

PAN

ON

L/R

DIRECT

EQ

ON

BUS ASSIGN

MASTER

L/R

10

0

10

20

30

40

MASTER L/R

4

MONITOR

A LEVEL

MONITOR

B LEVEL

T. B.

LEVEL

MIC

Page 9

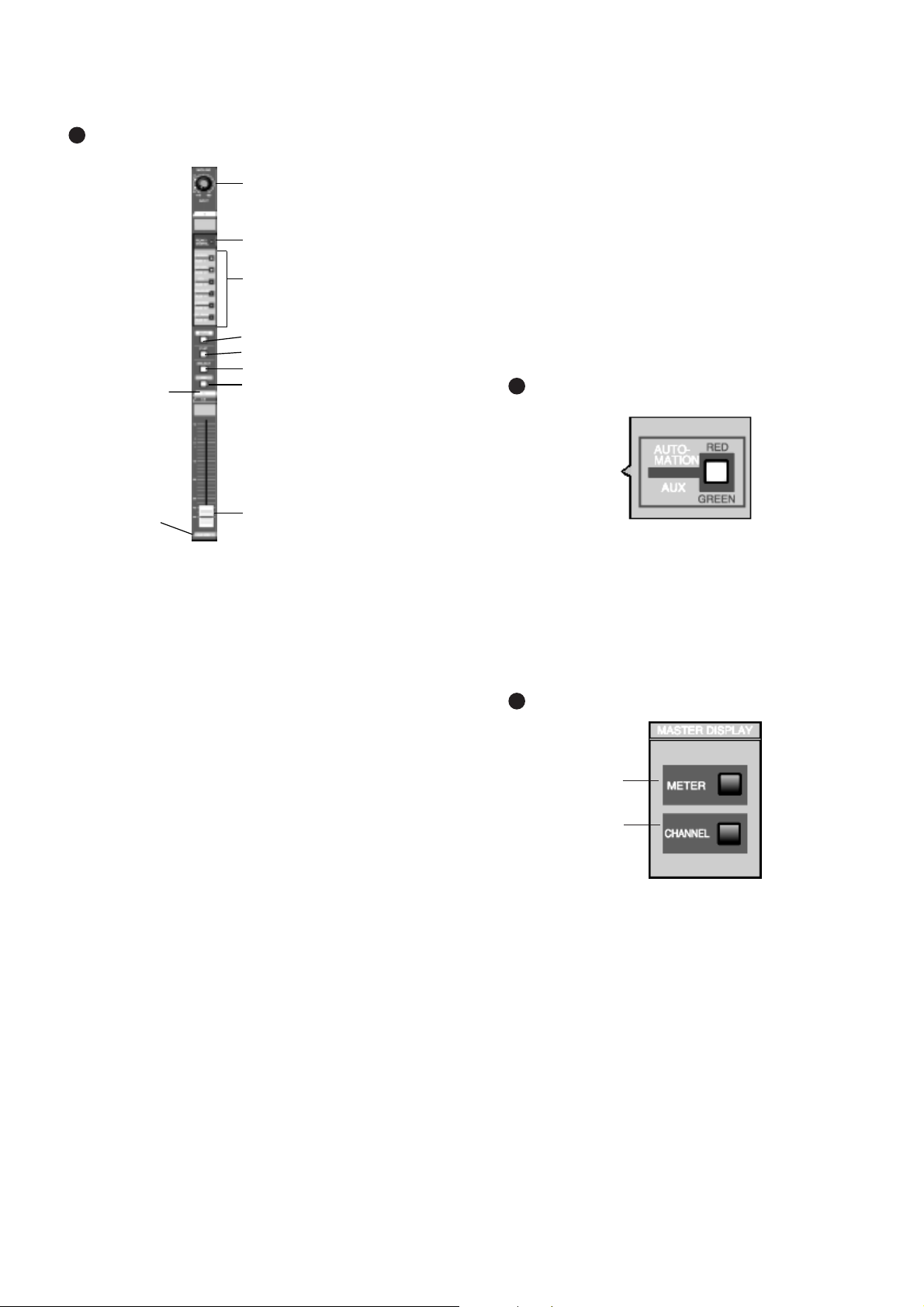

2

Fader

MIC/LINE INPUT knob

PEAK/SIGNAL LED

LED field indicators for AUX 1-6,

and automation parameters, CH,

EQ, PANASSIGN/SURR, LIBRARY

and SEL/MAN

SOLO LED button

FLIP LED button

SELECT LED button

On LED button

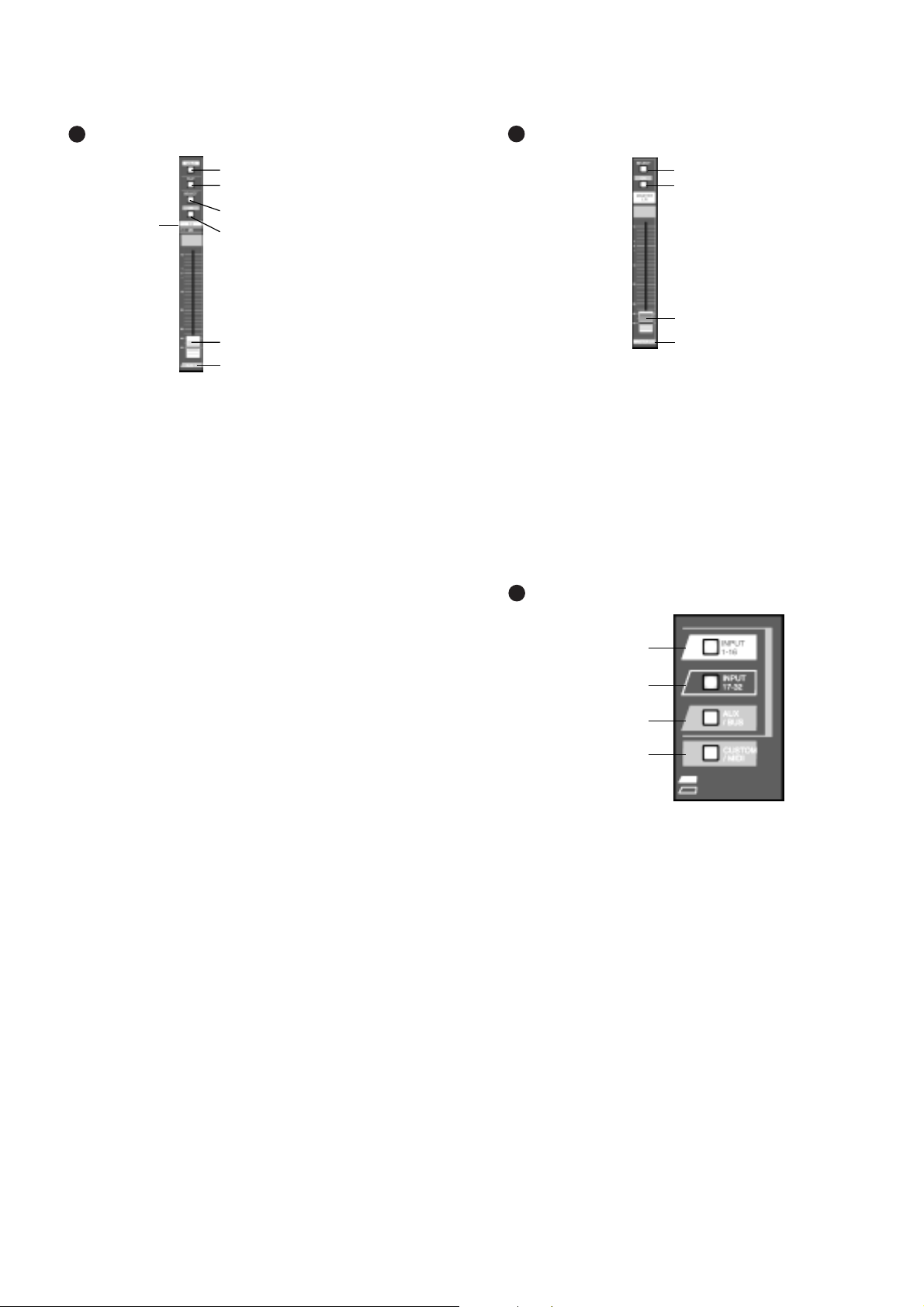

Channel Fader Strip

AUX/BUS Layer

function

Channel Fader Strip

1

Channel numbers

There are sixteen Channel Fader Strips on the

DA7

.

Depending on the selection of the four Fader Layer

controls, each strip directly controls (1) INPUT 1-16, (2)

INPUT 17-32, (3) AUX/BUS (indicated on the bottom of the

strip), and (4) a user CUSTOM/MIDI function.

The MIC/LINE INPUT knob varies the channel input gain

volume and adjusts for either a mic or line-level input. Due to

the high quality design of this circuit, there is no pad switch

necessary; the input knob range sets the input level. This

knob only affects the analog inputs 1-16.

The

PEAK/SIGNAL LED

indicates when an input signal is

present (

green

), and when the input signal level is too high

(

red

).

The LED field indicators reflect the auxiliary (AUX) routing

assignments and automation parameters. The LED color

signifies the AUTOMATION/AUX button selection; AUX

(

green

), AUTOMATION (

red

).

The SOLO LED button toggles on (

red

) or off. When on, the

channel output will be routed to the MONITOR A speakers

(overriding the MONITOR A input), and to the headphones.

The FLIP LED button flips the control of the Channel Fader

Strip from one input layer to the other. The LED color

indicates the current input selection and matches the Fader

Layer control LED button colors, INPUTS 1-16 (

green

) or

INPUTS 17-32 (

red

).

The SELECT LED button, when on (

orange

), identifies the

channel as the current channel selected. Only one Fader

Strip can be selected at a time (unless it’s in stereo or link

mode).

For more detail, see Chapter 5, Channel, Library, and

Meter Windows in the Users' Guide.

The ON LED button toggles on (

red

) and off. When on, the

channel output is active.

There are two channel numbers for each strip, indicating the

INPUT connections on the Rear Panel of the

DA7

.

The AUX/BUS label at the bottom of a Channel Fader Strip

indicates its function when the AUX/BUS Fader Layer

control is selected.

See Chapter 6, Fader Layers and Channel Strips in the

Users' Guide for additional information.

AUTOMATION/AUX LED Button

The AUTOMATION/AUX LED button toggles the display of

the Channel Fader Strips LED field indicators. The LED

color indicates the current selection.

See Chapter 14, Automation and Chapter 10, AUX in the

Users' Guide for additional information.

MASTER DISPLAY Section

Pressing the METER button will display the [METER]

window group on the LCD screen in the Display Bridge.

Pressing the METER button again will cycle the three

window selections: [METER INPUTS 1-32], [BUS/AUX],

[SLOT].

Pressing the CHANNEL button will display the [CHANNEL]

window group on the LCD screen in the Display Bridge.

The window displayed will show the current mixer strip

selected.

See Chapter 5, Channel, Library, and Meter Windows in

the Users' Guide for additional information.

AUTOMATION/AUX LED Button

2

METER button

CHANNEL button

MASTER DISPLAY Section

3

Page 10

3

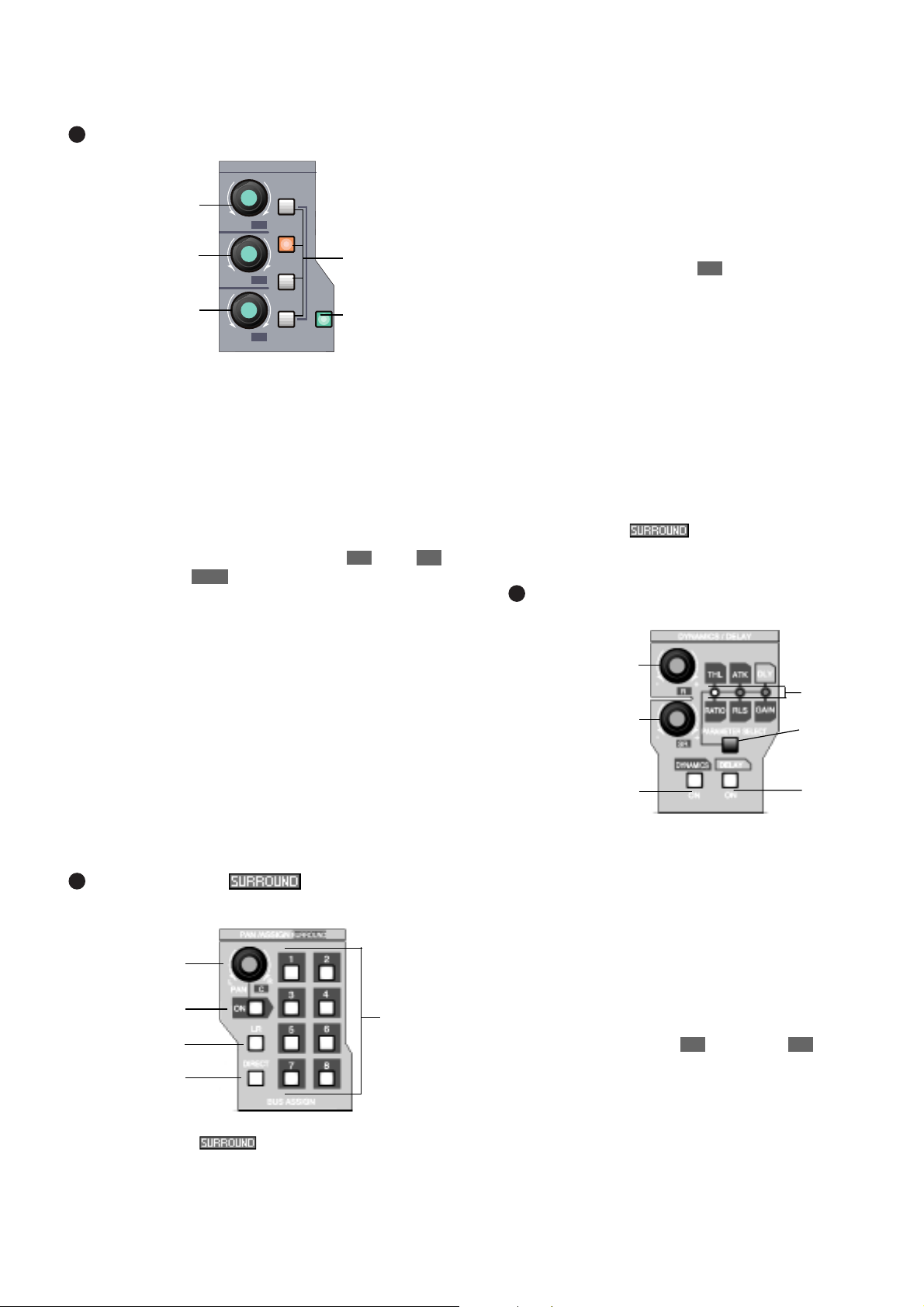

EQUALIZER Section

EQUALIZER Section

There are three parameter knobs and four frequency range

LED buttons in the EQUALIZER section, which are used to

change the EQ settings of the currently selected channel.

The EQ ON LED button toggles the EQUALIZER on (green)

and off. When the controls are active, adjustments can be

made to the currently selected channel.

The three knobs are labeled Q (quality), FREQ (frequency),

and GAIN (gain). The additional labeling of (left),

(surround left), and (surround subwoofer) indicate the

surround sound parameters that are controlled by the knobs

when the [SURROUND] mixing area is activated. Surround

sound capabilities are discussed in Chapter 8.

The four frequency band LED buttons can be selected one

at a time, and turn on (

orange

) to show which band is

operating. They are labeled H (high), HM (high-mid), LM

(low-mid), and L (low).

Pressing the GAIN knob displays the [EQUALIZER] window

on the LCD screen. Once the [EQUALIZER] is displayed in

the LCD window, these buttons perform other shortcut

functions.

The EQUALIZER section is detailed in Chapter 7 in the

Users' Guide.

PAN/ASSIGN/ , BUS ASSIGN

Section

PAN/ASSIGN/ , BUS ASSIGN Section

SUB

SL

L

Pan, bus assignment, and surround sound parameters for

the selected channel is set within this area. The pan control

is always active for the L/R bus, so you do not need to

activate the ON button to pan across the Master L/R out.

However, if you wish to pan between odd/even buses, you

must push the ON button. Assignment to the DIRECT output

is not affected by the pan control.

The additional labeling of (center) indicates the

surround sound parameter that is controlled by the knob

when the [SURROUND] mixing area is activated.

The L/R, the DIRECT, and the BUS ASSIGN LED buttons

toggle on (

green

) and off. In addition to the eight bus

selections, labeled 1 - 8, selections for L/R (master L/R)

output and DIRECT output are available. The DIRECT

output works in conjunction with the option cards installed in

the

DA7

Rear Panel, routing signals directly to the cards.

The DIRECT output is detailed in Chapter 12, D-I/O (Digital

Input/Output) in the Users' Guide.

Pressing the PAN knob displays the [SURROUND] window

on the LCD screen.

The PAN/ASSIGN/ , BUS ASSIGN section of the

Top Panel is detailed in Chapter 8 in the Users' Guide.

DYNAMICS/DELAY Section

DYNAMICS/DELAY Section

DYNAMICS and/or DELAY processing can be added to

each of the

DA7

Channels. Pressing the PARAMETER

SELECT button cycles the current parameter selections,

which are grouped in pairs. The top knob adjusts the top

parameter selection in the pair, and the bottom knob adjusts

the bottom parameter selection in the pair. The DYNAMICS

ON LED button toggles the dynamics processing on (

green

)

and off for the selected channel, and the DELAY ON LED

button toggles the delay on (

green

) and off.

The additional labeling of (right) and (surround

right) indicates the surround sound parameters that are

controlled by the knobs when the [SURROUND SOUND]

mixing area is activated. The surround sound function is

activated in the [SURROUND] window of the [SURROUND]

window group.

SR

R

C

EQUALIZER

H

HM

LM

ON

L

EQ

Q

FREQ

GAIN

+-

+-

+-

SUB

SL

L

Q (quality) parameter

knob or left surround

sound attenuator

FREQ (frequency)

parameter knob or

surround left surround

sound attenuator

GAIN parameter knob

or subwoofer surround

sound attenuator

Frequency band

LED buttons

EQ ON LED

button

4

PAN parameter

knob or center

surround sound

attenuator

PAN ON LED button

MASTER L/R LED

button

DIRECT LED button

BUS

ASSIGN

LED

buttons

5

THL (threshold),

ATK(attack), DLY

(delay) parameter knob

or right surround sound

attenuator

RATIO, RLS (release),

GAIN parameter knob

or surround right

surround sound

attenuator

DYNAMICS ON LED

button

PARAMETER

SELECT

LEDs

PARAMETER

SELECT

button

DELAY ON

LED button

6

Page 11

4

See Chapter 8 in the Users' Guide for more information on

surround sound.

Pressing the bottom knob displays the [DYNAMICS] window

group on the LCD screen.

For more information on the DYNAMICS/DELAY section of

the Top Panel, see Chapter 9 in the Users' Guide.

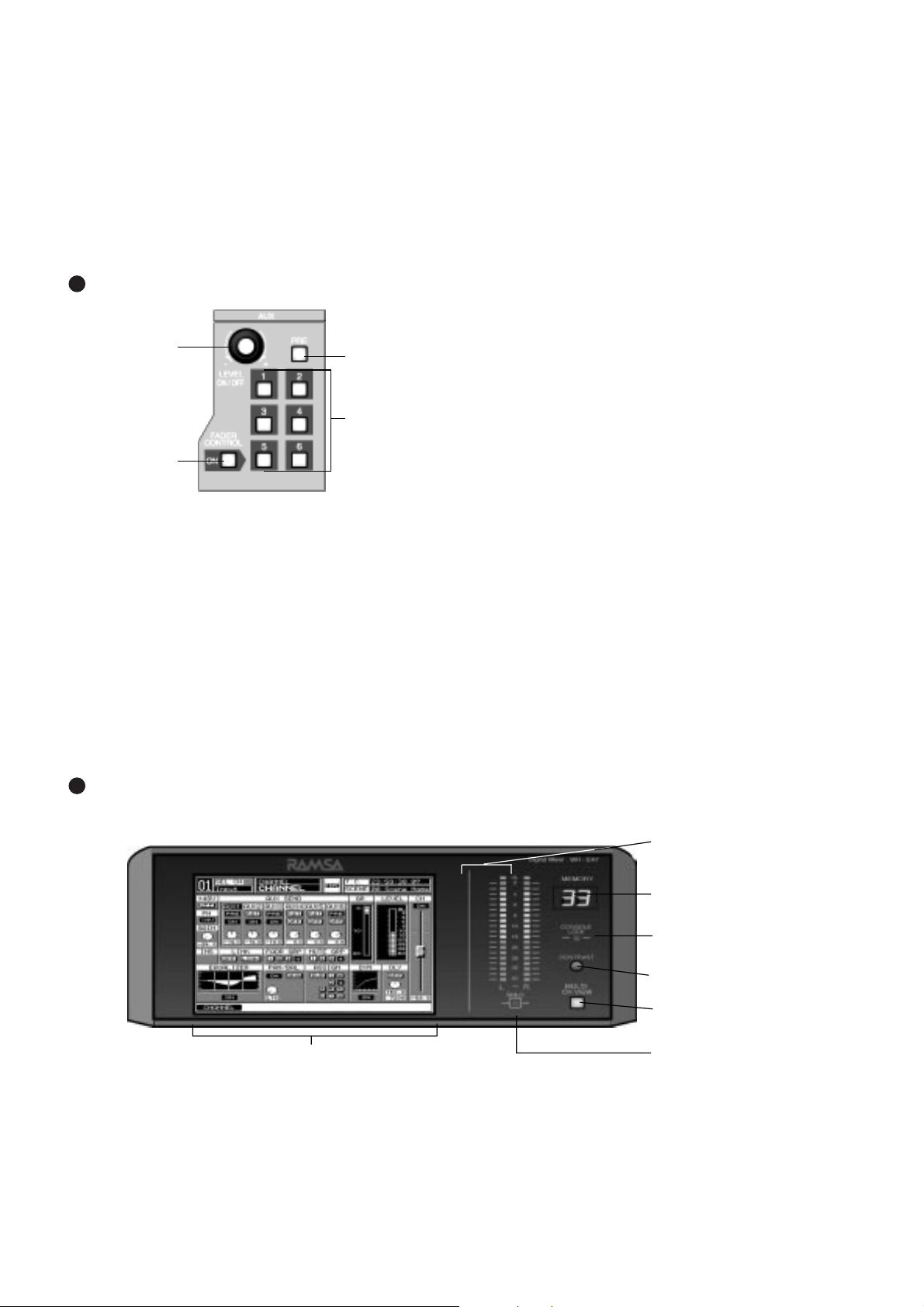

AUX Section

AUX Section

This section of the Top Panel contains controls for routing

selected channels from/to outboard sources. These six aux

routes are independent of the channel input connecters on

the Rear Panel of the

DA7

and greatly expand the flexibility

of the mixer. They can be used as six mono sends, or in

stereo pairs (such as 1&2, 3&4, 5&6), and six mono returns

or stereo pairs. There are two digital aux routes, AUX 1/2,

and four analog aux routes, AUX 3/4 and AUX 5/6. These

are paired for convenience on the Rear Panel connectors. If

you wish to use them as Mono channels, connect a standard

audio “Y” cable (available at your dealer) to split the audio

channels.

Display Bridge

With a channel selected, press an AUX 1-6 LED button

(green) to select which aux route you wish to assign for the

channel. The LEVEL knob performs two functions. By

pressing the knob, you will assign the channel to the

selected aux route, and by turning the knob, you can adjust

the individual channel output to the aux selection. The LED

field of the Channel Fader Strips will reflect the aux

assignments for the channels.

Aux routing is defaulted to a post-fader condition for the

selected channel. Press the PRE LED button to select it

(

red

) and change the aux routing function to a pre-fader

condition.

Press the FADER CONTROL LED button to select it (red)

and display the [FADER CONTROL] window group on the

LCD screen. The window displayed will be determined by

the current AUX 1-6 LED button selection. The channel

fader status of the 32 input channels for the aux selected will

be reflected in the [FADER CONTROL] window, and the

Channel Faders will reset to their respective level positions

for the aux selected.

The AUX/BUS designations at the bottom of the Channel

Fader Strips identify the strip functions when the Fader

Layer AUX/BUS LED button is pressed.

For more information on the AUX section of the Top Panel

see Chapter 10 in the Users' Guide.

7

Send LEVEL

volume and assign

ON/OFF knob

FADER CONTROL

mode LED button

PRE LED button

AUX 1-6 select

LED buttons

LCD screen

L/R Meter display

MEMORY numeric readout

CONSOLE LOCK LED status indicator

LCD CONTRAST control knob

MULTI-CH VIEW LED button

SOLO LED status indicator

Display Bridge Section

The Display Bridge contains the information for the current status of the

DA7

and the LCD screen. The various windows for the

functions and features of the mixer are displayed on the LCD screen.

8

Page 12

5

BUS Fader Strip

BUS Fader Strip

There are four BUS Fader Strips on the

DA7

. In

conjunction with the Fader Layer controls, each strip directly

controls the BUS outputs, or the AUX/BUS functions which

are indicated on the bottom of the strip or a user

CUSTOM/MIDI function.

The SOLO LED button toggles on

(red)

or off. When on, the

selected bus output will be routed to the MONITOR A

speakers and headphones, overriding the previous input.

There are two bus numbers for each strip, indicating the

BUS ASSIGN selections that can be controlled by the strip.

The FLIP LED button flips the BUS Fader Strip from

controlling one bus to controlling the other bus for the strip.

The LED color

(red orgreen)

indicates the current bus

selection.

The SELECT LED button, when on

(orange)

, identifies the

bus strip as the current bus strip selected. Only one BUS

Fader Strip can be selected at a time unless they are paired

for LINK or STEREO operation.

The ON LED button toggles on

(red)

and off. When on, the

bus output is active.

The AUX/BUS indication at the bottom of the BUS Fader

Strip indicates the strip function when the AUX/BUS Fader

Layer control is selected.

See Chapter 6, Fader Layers and Channel Strips in the

Users' Guide for additional information.

MASTER L/R Fader Strip

MASTER L/R Fader Strip

The MASTER L/R Fader Strip controls the

DA7

master L/R

output.

The SELECT LED button, when on

(orange)

, identifies the

strip as the current fader strip selection.

The ON LED button toggles on

(red)

and off. When on, the

master output is active.

See Chapter 6, Fader Layers and Channel Strips in the

Users' Guide for additional information.

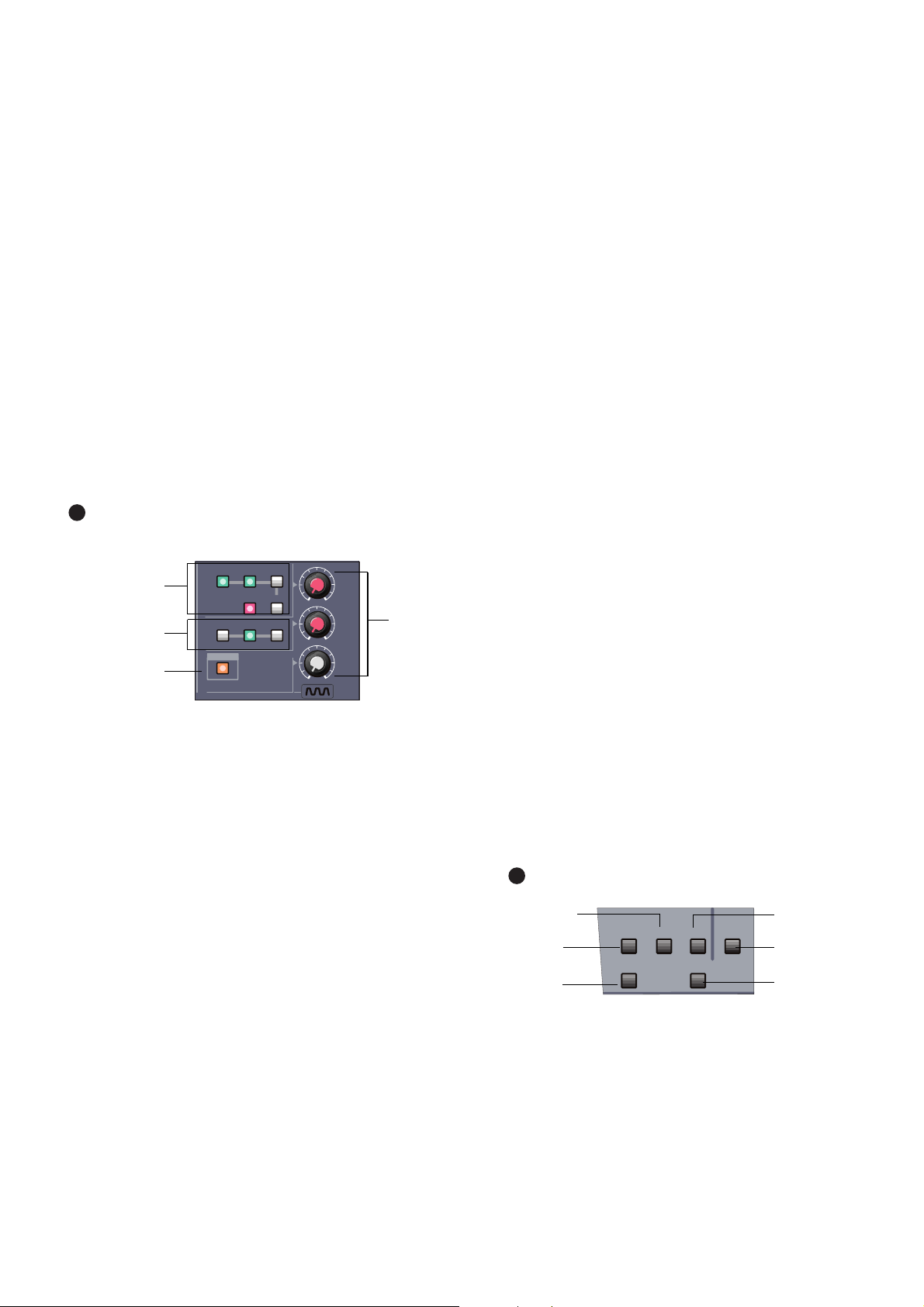

Fader Layer Controls Section

Fader Layer Controls Section

The Fader Layer controls significantly expand the flexibility

of the

DA7

mixer. The LED button selections define the

current function for the fader strips.

LED buttons for the Fader Layer controls assist you in

determining or checking the current channel and bus fader

settings on the mixer.

INPUT 1-16, when selected

(green)

, resets the fader strips

to control channel inputs 1 through 16, and buses 1, 3, 5,

and 7. When selected, the faders move to the positions

reflecting the current settings for the layer, unless previously

flipped. To reset a flipped Channel Fader Strip, press the

FLIP button. To reset all the currently flipped Channel

Fader Strips, press the INPUT 1-16 Fader Layer control

button and hold it or two seconds. This will set all faders to

the selected layer.

Fader

AUX/BUS Layer function

SOLO LED button

FLIP LED button

SELECT LED button

ON LED button

Bus Assign

numbers

9

Fader

AUX/BUS Layer function

SELECT LED button

ON LED button

10

11

INPUT 1-16 LED

button

(green)

INPUT 17-32 LED

button

(red)

AUX/BUS LED button

(orange)

CUSTOM/MIDI LED

button

(orange)

Page 13

6

INPUT 17-32, when selected

(red)

, resets the fader strips to

control channel inputs 17 through 32, and buses 2, 4, 6, and

8. When selected, the faders move to the positions reflecting

the current settings for the layer, unless previously flipped.

To reset a flipped Channel Fader Strip, press the FLIP

button. To reset all the currently flipped Channel Fader

Strips, press the INPUT 17-32 Fader Layer control button

and hold it for two seconds. This will set all faders to the

selected layer.

AUX/BUS, when selected

(orange)

, resets the fader strips to

control the aux sends, aux returns, and bus outputs, while

the faders move to the positions reflecting the current fader

settings for the layer.

CUSTOM/MIDI is a user-definable Fader Layer control,

where the functions are selectable.

See Chapter 11, MIDI for more information on the

DA7

MIDI

feature, and Chapter 6, Fader Layers and Channel Strips

in the Users' Guide for additional information.

MONITOR Section

MONITOR Section

The

DA7

provides controls for two monitor outputs and a

talkback circuit. There are source selection LED buttons for

the MONITOR A and MONITOR B outputs, and LEVEL

knobs for both of the monitor outputs and the talkback

circuit.

MONITOR A Controls

The MONITOR A selection LED buttons route the input

selected

(green)

to the MONITOR A OUTPUT (CR) (Control

Room) connections on the Rear Panel of the mixer and to

the headphones. The selections are:

8

L/R routes the MASTER L/R output to the monitors.

8

2TR A routes the device that is connected to 2TR A IN

on the Rear Panel to the monitors.

8

2TR B routes the device that is connected to 2TR B IN

on the Rear Panel to the monitors.

8

AUX routes the AUX SEND outputs to the monitors.

Press the AUX LED button to monitor the selections,

beginning with AUX SEND 1/2, followed by AUX SEND

3/4, and AUX SEND 5/6. The MEMORY numeric

readout on the Display Bridge will momentarily display

the AUX SEND selections.

The MONO button, when on

(red)

, sums the selected input

and sends a monaural signal to the monitors. This will not

affect the 2TR B output stereo signal.

MONITOR B Controls

The MONITOR B selection LED buttons route the input

selected

(green)

to the MONITOR B OUTPUT (STUDIO)

connections on the Rear Panel of the mixer. The selections

are:

8

MONITOR A routes the current MONITOR A selection

to the studio monitors.

8

AUX routes the AUX SEND outputs to the monitors.

Press the AUX LED button to monitor the selections

beginning with AUX SEND 1/2, followed by AUX SEND

3/4, and AUX SEND 5/6. The MEMORY numeric

readout on the Display Bridge will momentarily display

the AUX SEND selections.

TALKBACK

The TALKBACK ON button controls the talkback

microphone installed in the Top Panel of the

DA7

. When on

(orange)

, the MIC is active and the MONITOR A speakers

will be dimmed. This can be either a “push-to-talk”

momentary interrupt type button, or a “push on/push off”

type button. This is selected in the [UTILITY] window.

Talkback routing is selected in the [SOLO MONITOR]

window. There is also a phone jack on the Rear Panel that

allows for remote Talk back operation.

For additional information on the talkback, see Chapter 16,

Utility and Solo monitor in the Users' Guide.

SETUP Section

SETUP Section

These are direct-action buttons that will display the selected

windows in the LCD screen of the Display Bridge.

12

MONITOR A

source selection

buttons

MONITOR B

source selection

buttons

Talkback ON LED

button

LEVEL

knobs

SOLO

MONITOR

UTILITY MIDI

D-I/O

GROUP

AUTOMATION

SET UP

MIDI button

UTILITY

button

GROUP

button

D-I/O button

SOLO MONITOR

button

AUTOMATION

button

13

2TR A

MONO

L/R

2TR B

AUX

AUX

MONITOR

010

A LEVEL

MONITOR

010

B LEVEL

T. B.

LEVEL

010

MIC

L/R

MONITOR A

MONITOR A

MONITOR B

ON

TALK BACK

Page 14

7

UTILITY Button

Pressing the UTILITY button will display the [UTILITY]

window group on the LCD screen in the Display Bridge.

The window displayed will be determined by the window

selection buttons at the bottom of the window. Pressing the

UTILITY button again will cycle the window selections:

[OSC_BATT], [CONFIGuration], [USER CuSToM].

See Chapter 16, Utility and Solo Monitor in the Users'

Guide for additional information.

MIDI Button

Pressing the MIDI button will display the [MIDI] window

group on the LCD screen in the Display Bridge. Pressing

the MIDI button again will cycle the window selections:

[SETUP], [PRoGram ASsiGN], [ConTRoL ASsiGN],

[BULK], [REMOTE].

See Chapter 11, MIDI in the Users' Guide for additional

information.

D-I/O Button

Pressing the D-I/O button will display the [D-I/O] (Digital

Input/Output) window group on the LCD screen in the

Display Bridge. Pressing the D-I/O button again will cycle

the window selections: [INPUT SET], [TO SLOT],

[DITHER].

See Chapter 12, D-I/O in the Users' Guide for additional

information.

GROUP Button

Pressing the GROUP button will display the [GROUP]

window selections on the LCD screen in the Display

Bridge. Pressing the GROUP button again will cycle the

window selections: [FADER GRouP], [MUTE GRouP],

[LINK/STR].

See Chapter 13, Group in the Users' Guide for additional

information.

AUTOMATION Button

Pressing the AUTOMATION button will display the

[AUTOMATION] window group on the LCD screen in the

Display Bridge. Pressing the AUTOMATION button again

will cycle the window selections: [SETUP], [EXECUTE],

[EVenT EDIT] .

See Chapter 14, Automation in the Users' Guide for more

information.

SOLO MONITOR Button

This button displays Solo Monitor mode, Talk back

assignment and Surround Monitor.

See Chapter 16, Utility and Solo Monitor in the Users'

Guide for additional information.

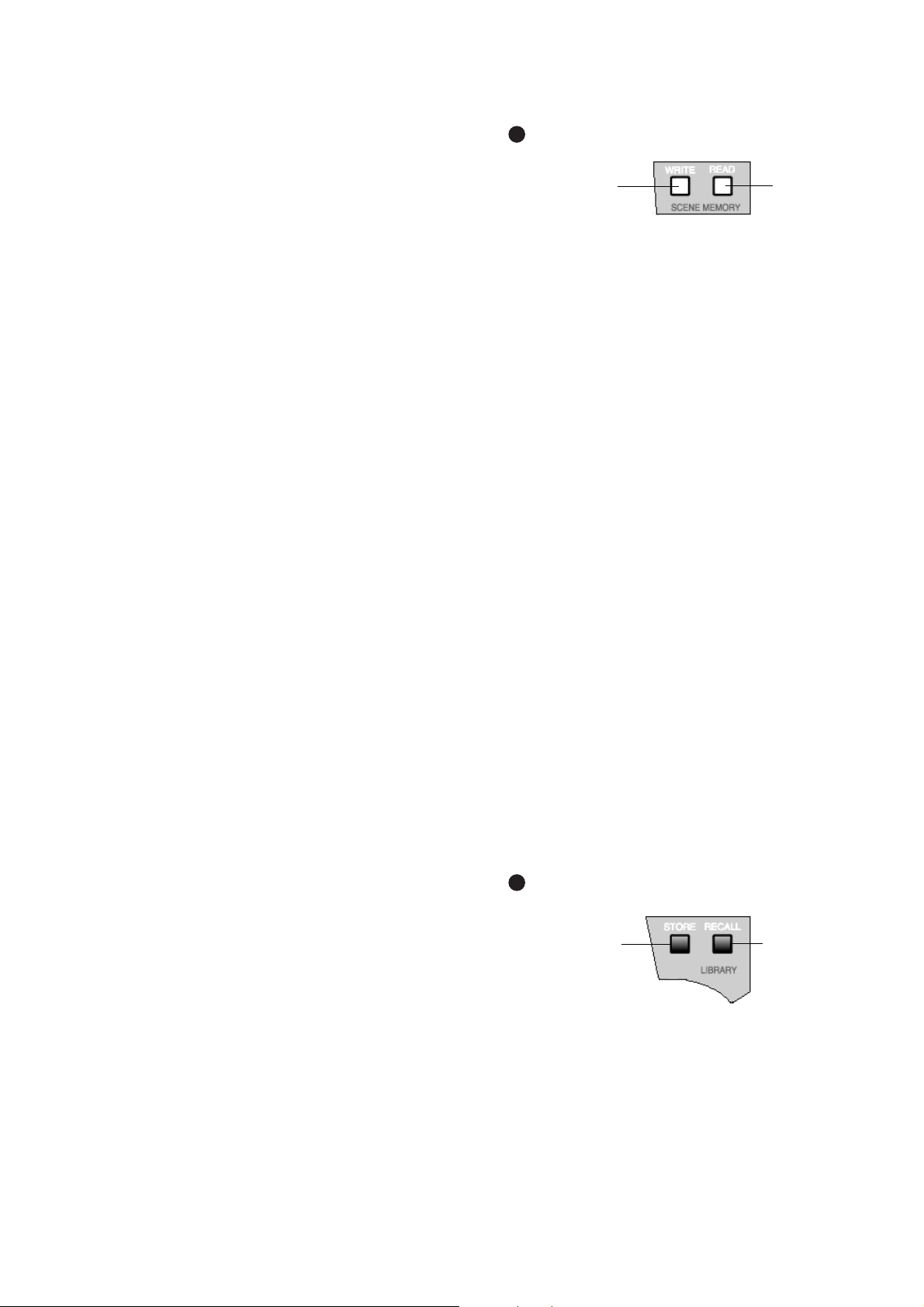

SCENE MEMORY Section

SCENE MEMORY Section

SCENE MEMORY allows you to store and recall complete

mixer setups and functions. There are fifty registers,

numbered 01 through 50, available for storage of mixer

settings. Memory 00 is reserved for Automation.

Press either the WRITE LED button or the READ LED

button

(orange)

to select it and display the [ReaD/WriTe]

window of the [SCENE MEMORY] window group on the

LCD screen of the Display Bridge.

There are two windows in the group: [RD/WT], [XFADE].

The [RD/WT] window is always the initial window displayed

when either button is selected. To change to the [XFADE]

window, use the ARROW buttons to navigate to the

respective window selection button and then press the

ENTER button, or press either the WRITE or READ LED

buttons a second time.

When the [RD/WT] window is displayed, the JogDial is

enabled to scroll the [SCENE MEMORY] list area of the

window. This allows you to quickly access a previously

stored scene, locate an empty scene memory, or locate a

scene memory to be overwritten. By pressing the ENTER

button after a scene has been located, the mixer will

immediately assume the setting for the stored scene.

The MEMORY readout display will flash the memory number

that is selected until it is recalled. The selected memory will

be displayed without flashing once it has been recalled.

While the [RD/WT] window is displayed, pressing the

ENTER button will immediately overwrite the current scene

memory with the settings on the mixer at the moment the

ENTER button is pressed, unless the register is writeprotected. See Chapter 15, Scene Memory in the Users'

Guide for additional information.

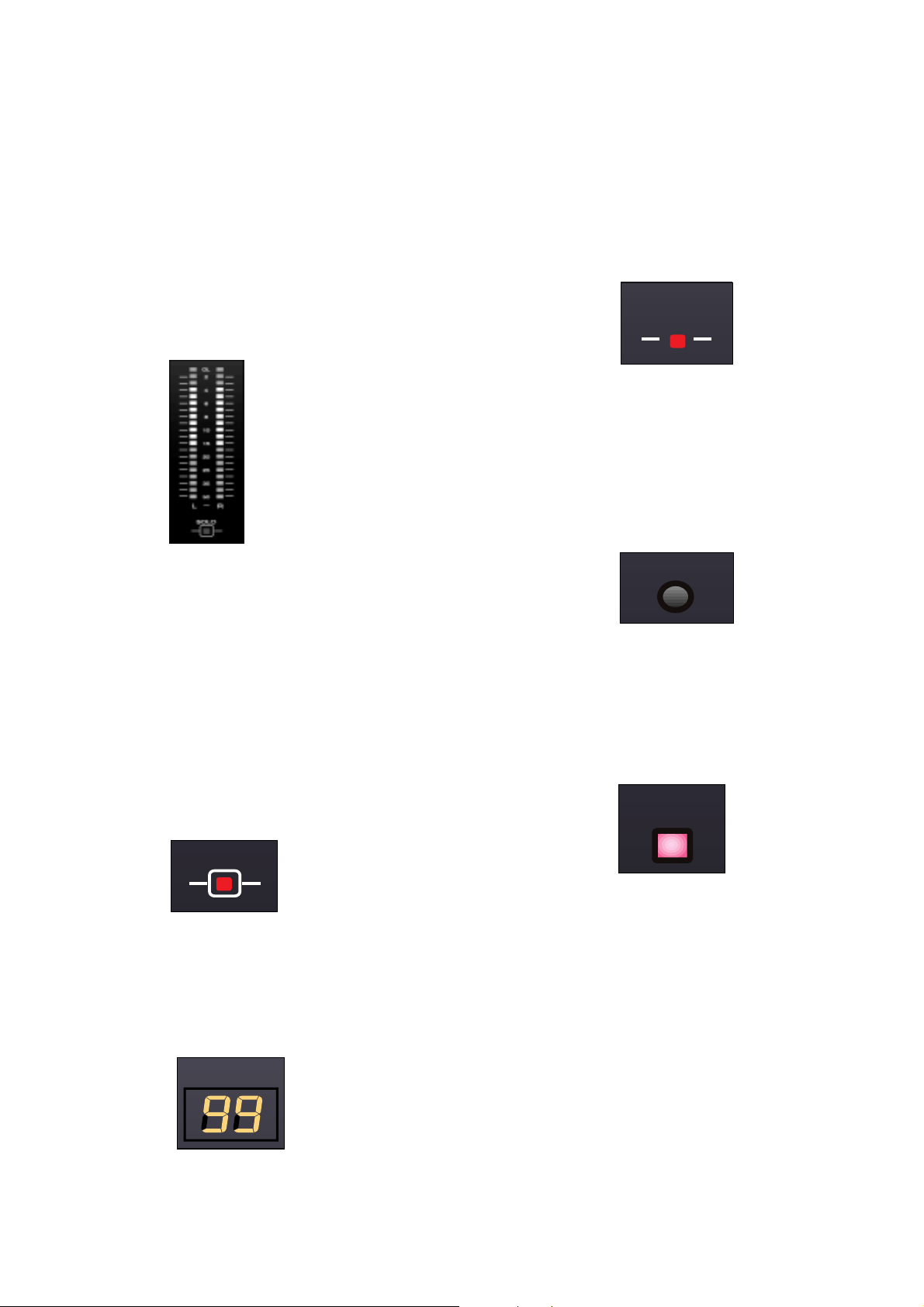

LIBRARY Section

LIBRARY Section

There are three mixer functions with associated libraries:

CHANNEL, EQUALIZER, DYNAMICS/DELAY. The library

feature allows you to store and recall individual function

parameters to a separate library. There are fifty registers for

each library, numbered 01 through 50.

WRITE LED button READ LED button

14

15

STORE LED button

RECALL LED button

Page 15

8

The RECALL button opens the library window for the

selected function. What this means is that if the [CHANNEL]

window was displayed when you pressed the RECALL

button, the CHANNEL library will be displayed. The same

goes for the EQUALIZER AND DYNAMICS/DELAY

libraries. Once selected, the parameter knob will allow you

to scroll through the stored memories. After you have

chosen a memory, press the RECALL button again and the

selected memory will be recalled to the currently selected

function. You will also automatically return to the main

screen for the selected function.

While the library is displayed, pressing the STORE button

will immediately store the current function settings to the

current memory location, unless the memory location is

write-protected.

See Chapter 5, Library in the Users' Guide for additional

information.

Keypad and Cursor Control Section

Keypad

Display Bridge

Cursor Control Section

Details on the Keypad, UNDO/REDO button,

MMC/CURSOR button, ARROW buttons, ENTER button,

CURSOR MODE button, and JogDial elements of the

DA7

Top Panel are provided in Chapter 4 in the Users' Guide.

Headset Control Section

A stereo headset connector and headset volume control are

located under the right front edge of the Top Panel of the

DA7

. The current MONITOR A selection is always routed to

the headset connector.

16

17

1

2

4

5

7

8

0

3

6

9

ABC DEF

JKLGHI MNO

TUV

PQRS WXYZ

SHIFT

LOCATE

SET

REPLAY

LOOP

LOOP

ARROW buttons

ENTER button

CURSOR

MODE button

JogDial

UNDO/REDO button

MMC/CURSOR button

18

Display Bridge Section

The Display Bridge for the

DA7

is your “window” to the mixer functions and features. The elements comprising the Display Bridge

are the LCD screen, the L/R meter display, the MEMORY numeric readout, the CONSOLE LOCK LED status indicator, the

CONTRAST control knob, the MULTI-CH VIEW (multi-channel) LED button, and the SOLO LED status indicator.

LCD screen

L/R meter display

MEMORY numeric readout

CONSOLE LOCK LED status

indicator

LCD CONTRAST control knob

MULTI-CH VIEW LED button

SOLO LED status indicator

Page 16

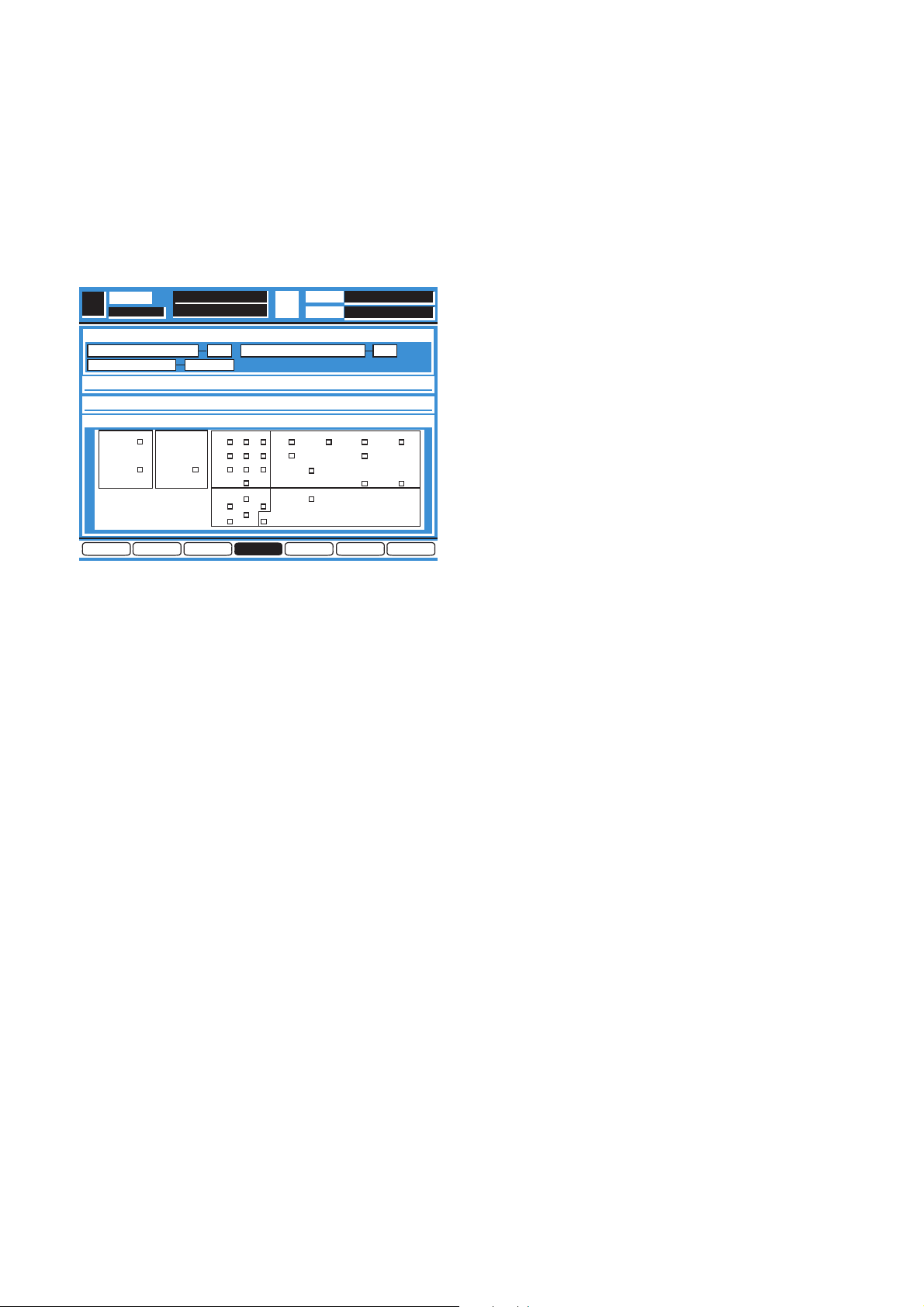

9

LCD Screen

Taskbar

Sample Window Display (CHANNEL window displayed)

Function area

Window selection buttons

The LCD screen is the 320x240 backlit liquid-crystal display (LCD) element of the Display Bridge. The screen displays the various

windows that show the functions and status of the

DA7

. The windows contain areas and items that can be accessed with the cursor

control or JogDial.

There are three general areas for the windows displayed on the LCD screen: the [taskbar] area, the [function] area, the [windows

selection buttons] area.

Taskbar Area

Channel type field Current window SCENE MEMORY field

name

Channel selection field Window group name Communication Timecode field

status indicator

Taskbar Area

The [taskbar] area of a window contains information about

the current window and the most recent mixer selections.

Several of the items in the [taskbar] will remain unaffected

when you change to another window, depending on the new

window selection.

Channel Selection Field

This field shows the currently selected Channel, BUS, or

MASTER L/R strip selection. When channels or buses are

paired, the field will display both numbers. The field will

change when you press a different SELECT LED button on

the Top Panel.

Channel Type Field

This field shows the most recently selected channel type.

The field will change when you press a SELECT LED button

on the Top Panel.

Window Group Name

The current window group name is displayed in this field.

Current Window Name

The name of the current window is displayed in this field.

Communication Status Indicator

This area of the [taskbar] displays the current

communication status as configured in the [MIDI>SETUP]

window. The selections are either [TO PC], [S I/O], or

[MIDI].

Timecode Field

This field displays the most recent time code value received

by the mixer, as defined by the settings in the

[AUTOMATION>EXECUTE] window.

SCENE Field

This field displays the most recently read SCENE MEMORY

number and name.

Page 17

10

Function Area

The [function] area of a window contains the various

controls, buttons, settings, and values for the current

window.

Window Selection Buttons Area

This area of a window contains the buttons for the windows

that comprise the current window group. The button for the

current window will be highlighted.

L/R Meter Display

This meter reflects the current MASTER L/R (left/right)

output of the

DA7

, unless SOLO has been activated for a

channel. If a SOLO LED button is selected on the mixer, the

meter reflects the level of the solo’d channel(s) only.

In the [METER>SLOT] window, the [RESPONSE] area lets

you select between [VU] (Volume Units) and [PPM] (Pulse

Position Modulation). When [VU] is selected, the L/R Meter

Display will show the mixer output in Volume Units, and

when [PPM] is selected, the Meter reflects the mixer output

as Pulse Position Modulation.

SOLO LED Status Indicator

Located below the L/R meter display, the SOLO LED status

indicator will light and flash

(red)

when SOLO has been

activated for any channel on the mixer.

MEMORY Numeric Readout

The two-digit numeric readout displays the most recently

accessed SCENE MEMORY. Whenever an AUX monitoring

selection button is activated for either MONITOR A or

MONITOR B, the numeric display will momentarily display

the AUX selections.

CONSOLE LOCK LED Status Indicator

CONSOLE LOCK LED Status Indicator

When illuminated

(red)

, the password protection for an area

or function of the mixer is engaged, and selected mixer

operations cannot be performed.

See Section 16-3, [UTILITY>CONFIG] Window for more

information.

CONTRAST Control Knob

CONTRAST Control Knob

This knob controls the contrast value of the LCD screen.

Rotate the knob to adjust the contrast value of the LCD

screen for optimum viewing and to suit the operating

environment.

MULTI-CH VIEW LED Button

MULTI-CH VIEW LED Button

Press this LED button to activate the multi-channel viewing

mode for the LCD screen. When on (red), the LCD screen

will display the currently selected Channel Fader and one of

other sources that can be used to compare or copy

information from the current selection.

See Chapter 5, Channel, Library, and Meter Windows in

the Users' Guide for more information.

L/R Meter Display

SOLO LED status indicator

SOLO LED Status Indicator

MEMORY Numeric Readout

CONSOLE

LOCK

SOLO

MEMORY

CONTRAST

MULTI-

CH VIEW

Page 18

11

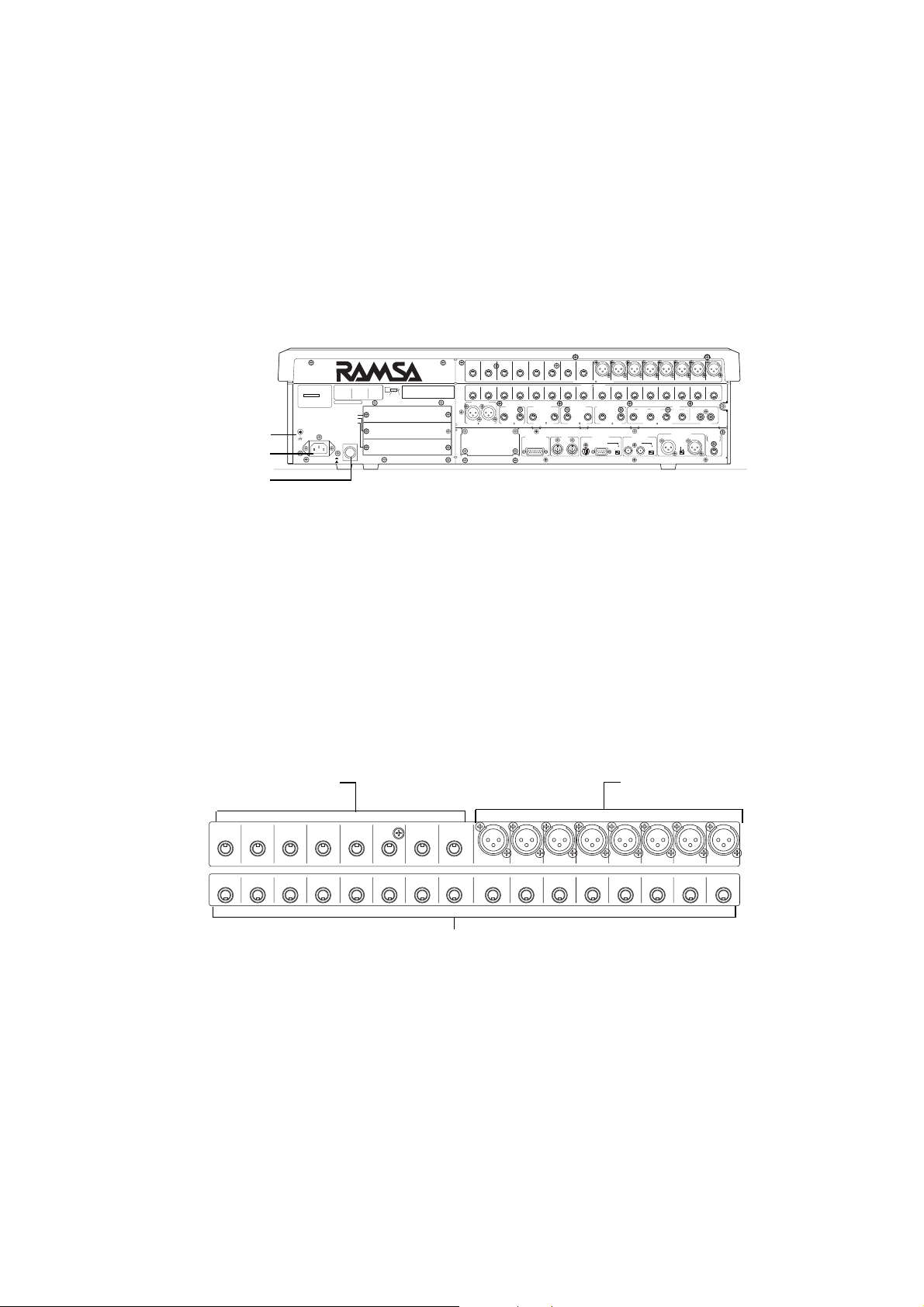

Rear Panel

Everything that goes in, out, and through the

DA7

happens

on the Rear Panel, with the exception of the headphone

connector. The

DA7

provides multiple ways for doing many

things, so let your creativity be your guide.

The rear of the

DA7

is configured in four rows. The top row

contains analog INPUTS 1-16 (inputs 1-8 are balanced XLR

connectors and inputs 9-16 are balanced TRS (tip-ringsleeve) phone plug connectors).

Row 2 contains analog INS 1-16 (inserts) with (TRS) phone

plug connectors. Row 3 contains outputs for MASTER OUT,

REC OUT analog, MONITORS A&B, and AUX returns and

sends 1 through 6. The bottom row contains the METER

BRIDGE connection, MIDI IN/OUT, SERIAL PORT (for

direct connection to a PC or a Macintosh computer), WORD

CLOCK IN/OUT, DIGITAL IN/OUT, and a REMOTE SW

connector.

THIS EQUIPMENT COMPLIES WITH THE REQUIREMENTS FOR

A CLASS A COMPUTING DEVICE IN FCC RULES PART 15

SUBPART J. OPERATION OF THIS DEVICE IN A RESIDENTIAL

AREA MAY CAUSE HARMFULL INTERFERENCE REQUIRING THE

USER TO TAKE WHATEVER STEPS MAY BE NECESSARY TO

CORRECT THE INTERFERNCE.

WARNIG

- TO REDUCE THE RISK

OF FIRE OR ELECTRIC

SHOCK. DO NOT EXPOSE

THIS APPLIANCE TO

RAIN OR MOISTURE.

CAUTION

- TO REDUCE

THE RISK OF ELECTRIC SHOCK,

DO NOT REMOVE COVER. NO USER SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED SERVICE

PERSONNEL.

CAUTION

- MAKE SURE THE POWER OF THE UNIT IS TURNED OFF

WHEN INSERTING OPTION CARDS INTO THE SLOTS OF THE UNIT.

OTHERWISE THE UNIT MAY BE DAMAGED.

RING

SLEEVE

METER BRIDGE I/F MIDI SERIAL PORT WORD CLOCK

AC IN

POWER

SIGNAL

GND

TIP

CONNECTION

INPUT/OUTPUT

NO 1:GND

NO 2:HOT

NO 3:COLD

INS

TIP:SEND

RING:RETURN

SLEEVE:GND

AUX

TIP:ODD

RING:EVEN

SLEEVE:GND

OdB is referenced to 0.775Vrms

CH17–24/SLOT 1

CH25–32/SLOT 2

TANDEM/

CH9-16

/BUS & AUX INSERT/SLOT3

ON

OFF

OUT

TO PC

OUT

/THRU

REC OUT 2TR A IN / INPUT15.16

IN

IN

RS422 / 485

110

OFF ON75OFF ON

DIGITAL IN / OUT

AUX2TR B IN (ANALOG)

MONITOR A OUT

(CR)

MONITOR B OUT

(STUDIO)

REC OUT

(ANALOG)

MASTER OUT

RETURN

5/6RL

R

LRLRL

R

L

3/4 5/6 3/4 1/2 1/2

RETURN SEND

SEND

+4dB 10k (UNBAL) (S/PDIF)

+4dB 10k (BAL)

–60dB to +10dB 5k (BAL/UNBAL)

+4dB 10k (UNBAL)

+4dB 10k (BAL)

+4dB 600 (BAL/UNBAL)

SMPTE & V SYNC

+4dB 600

(BAL)

+4dB 600

(BAL)

REMOTE SW

AES/EBU

S/PDIF

Talk on/off

Rec on/off

INS16 INS15 INS14 INS13 INS12 INS11 INS10 INS9

INPUT16 INPUT15 INPUT14 INPUT13 INPUT12 INPUT11 INPUT10 INPUT9 INPUT8 INPUT7 INPUT6 INPUT5 INPUT4 INPUT3 INPUT2 INPUT1

INS8 INS7 INS6 INS5 INS4 INS3 INS2 INS1

DA7 Rear Panel

Signal Gnd (signal ground)

AC Inlet

Power switch

Power Switch

Turns the power on and off to the

DA7

.

AC Inlet

Plug the AC power cord here.

Signal Ground [SIGNAL GND]

Connect to a grounded source to stabilize the voltage levels of the connected devices, and to prevent hum and buzz created by

ungrounded sources.

Rows 1 & 2 Connectors

Inputs 9-16 (TRS). Use these for

balanced -60 to +10 signals

Inputs 1-8 (XLR). Use these for balanced

-60 to +10 signals. Phantom powered

Channel 1-16 Inserts. These are TRS send and return connectors.

Cutaway of DA7 Rear Panel (Rows 1 and 2) Input and Insert Connectors

INPUTS 1-8

These inputs are designed for XLR connectors. The input

range is from -60dB to +10dB, 5k Ω BAL. Use the MIC/LINE

INPUT knobs on the Channel Strips for adjustment of the

incoming level. From the [CHANNEL] window, the +48V

phantom power can be individually turned on or off for each

channel via the screen.

INPUTS 9-16

Use these inputs with a 1/4” TRS (tip-ring-sleeve) phone

plug connector. Use the MIC/LINE INPUT knob to adjust the

input level. The input range is from -60dB to +10dB, 5k Ω

BAL. There is no +48V phantom power. Microphones used

on these inputs must be externally powered if required.

Page 19

12

INSERTS 1-16

These inserts are used for creating an effects loop. A 1/4”

TRS phone plug, with a level of +4 dB, 10k Ω UNBAL,

provides an output (tip) send to effects, or an input (ring) return

from an outboard effects device.

Monitor B Out

These terminals are 1/4” TRS dual phono plugs at a level of

+4dB, 600Ω BAL, and connect the output of the MONITOR

B source selection to an external amplifier for monitoring in

the studio.

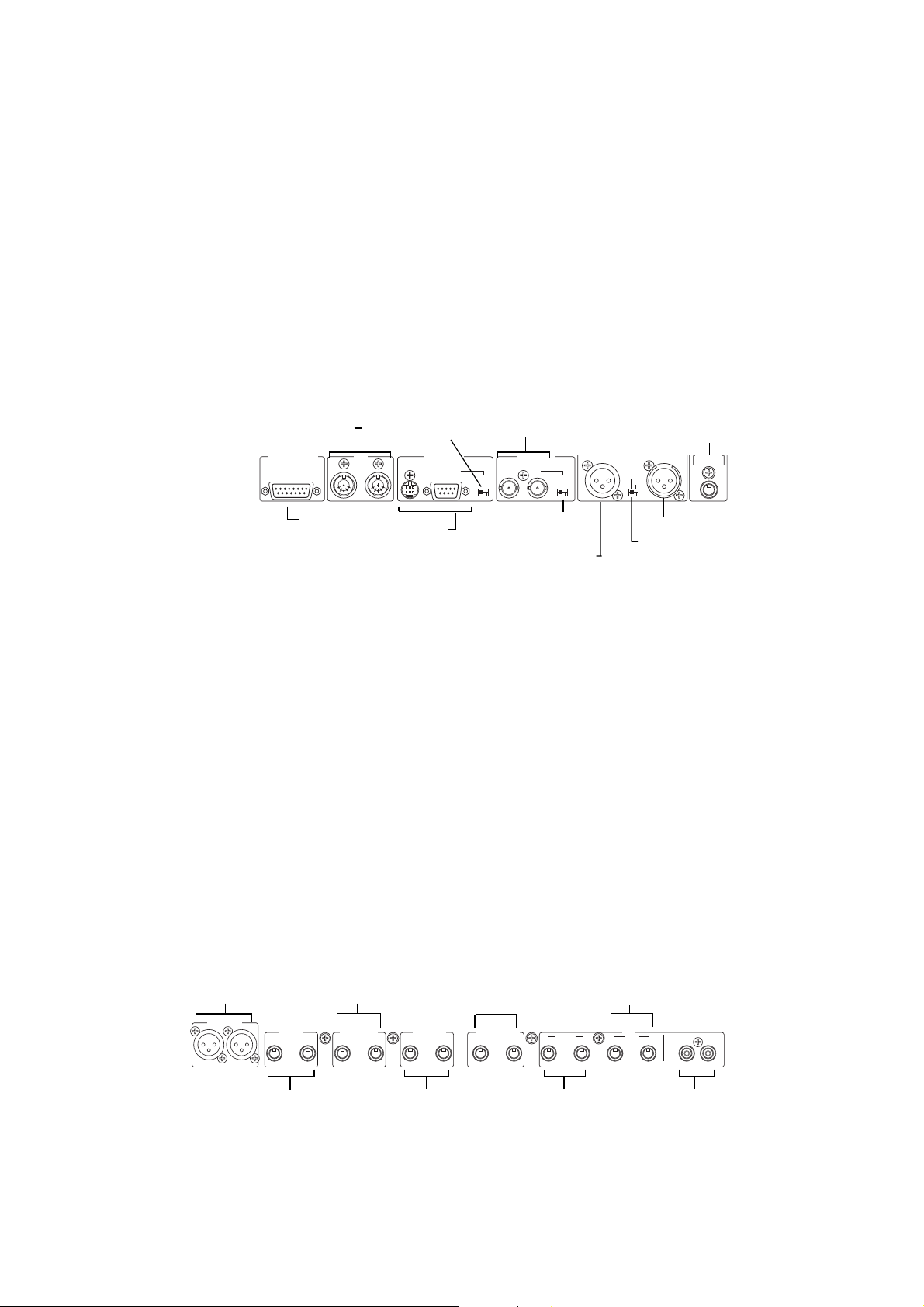

Row 4 Connectors

[REC OUT] Record Output

Use 1/4” TRS phone plugs, at a level of +4dB, 10kΩ BAL, to

output signals for recording.

Master Output

Female XLR connectors send the MASTER L/R analog

program output to external speakers and/or a recording

device of +4 dB, 600Ω BAL.

Meter Bridge

connector

(Option).

MIDI In and Out connectors

Serial I/O

connectors

Wordclock In and Out /

Thru connectors

2TR Input Digital (XLR)

Format select switch

Remote switch connector for Talkback

ON/OFF and automation REC ON/OFF

Cutaway of DA7 Rear Panel Row (4) Digital and Serial Connectors

Record Out Digital(XLR)

RS terminating

switch

Clock terminating &

OUT / Thru switch

Remote SW [Switch]

Connect a momentary or press-to-talk switch with a 1/4” TS

phone plug for Talk Back or automation record functions.

Parameters are assignable in the [UTILITY>CONFIG]

window.

Digital Input [AES/EBU]

An XLR connector inputs an audio signal from a DAT or

other digital source. Assignments can be made from the [D-

I/O>INPUT SET] window.

Row 3 Connectors

This incoming source can be monitored by selecting the 2TR

A LED button as the MONITOR A source selection, or, on

Channel Faders 15 and 16, when 2TR A is assigned in the

[D-I/O>INPUT SET] window. The signal can also be directly

assigned to the MASTER L/R program output.

Digital Record Output [AES/EBU]

XLR connections of the MASTER L/R digital output are for

use in recording by a digital device with AES/EBU digital

input capabilities.

Master L/R outputs

(Analog XLR balanced)

Record L/R outputs

(Analog TRS balanced)

Monitor B outputs

(Analog TRS balanced)

Monitor A outputs

(Analog TRS balanced)

2TR B input connectors

(Analog TRS balanced)

Aux Returns 3/4 and

5/6 (Analog TRS)

Aux Sends 3/4 and 5/6

(Analog TRS)

Aux 1/2 send and return

(Digital RCA, S/PDIF)

Cutaway of DA7 Rear Panel (Row 3) Output Connectors

Page 20

13

AUX SEND 1/2

Use RCA connectors to attach a digital effects device or

another S/PDIF device to the AUX SEND 1/2 and AUX

RETURN 1/2 digital terminals. AUX/BUS Fader Layer

faders control the AUX 1/2 SEND and RETURN. These

connections are not analog signals.

AUX SEND 3/4, 5/6

These terminals are 1/4” TRS phone plug connectors, at a

level of +4dB, 10kΩ UNBAL. They can be used for

connecting outboard signal processing devices, or for a

studio headphone feed, or as part of a multitrack output

setup. The possibilities are limited only by your imagination.

The AUX/BUS Fader Layer is the fader control for these

connections.

AUX RETURN 3/4, 5/6

These terminals are 1/4” TRS phone plug connectors, at a

level of +4dB, 10kΩ UNBAL. The AUX/BUS Fader Layer is

the fader control for these feeds.

2-Track B Input

This is used to connect an analog source strictly for

monitoring purposes, as it does not appear as an input to

the mixer. Connect a 1/4” TRS phone plug to the output

signal from a cassette deck, for example. The input signals

are sent to the 2 TR B IN LED button in the monitor section.

The level is +4dB, 10kΩ BAL.

Monitor A Out

These terminals are 1/4” TRS dual phone plugs at a level of

+4dB, 600Ω BAL, and connect the output of the MONITOR

A to an external amplifier (or powered speaker) for

monitoring in the control room (CR).

Format Select Switch

This switch is used to select the signal format of the

connected device, either AES/EBU or S/PDIF. The digital

input and output are both switched. For S/PDIF usage, an

optional adapter is required. You must make certain that the

adapter connects pin #1 and #3 together.

Clock Terminating 75 Ω ON/OFF & Out / Thru

Switch

Next to the WORD CLOCK IN BNC connection, this switch

should be set to 75 Ω OFF and Thru position if the

DA7

is

being used to pass the wordclock signal to other devices in

the chain.

Set the switch to 75 Ω ON and OUT for terminating the

wordclock, if the

DA7

is slaved and located at the end of the

wordclock chain. The 75 Ω ON and OUT position should

also be selected when the

DA7

is being used to slave other

devices to the

DA7’s

wordclock. See Chapter 12, D-I/O in

the Users' Guide for more information.

Clock Input

This is used to synchronize the

DA7

to an external word

clock source. This allows the

DA7

’s internal clock to slave to

another reference, such as a digital multi-track deck or other

device. Use a BNC connection to attach an external

wordclock source.

Clock Output

This is used to slave an external device, such as a digital

multi-track machine, to the

DA7

internal clock. It can also be

used to relay an external wordclock that is being used to

synchronize the

DA7

to an external device. Using a BNC

connector, other devices can synchronize to the

DA7

wordclock.

Serial Terminating Switch

Set the switch to ON if the

DA7

is the termination point of

the RS-422/485 serial transmission path. The 110Ω switch

turns this function OFF/ON.

Serial Port [RS-422/485]

Use this serial port to connect an IBM compatible computer

having an RS-422/485 port. Connect to the

DA7

with a DSUB 9-pin connector. Optional remote control software for

your computer can be used to control the

DA7

, thus

expanding the features and capabilities of the mixer.

Serial Port [TO PC]

Use this serial port to connect with a Macintosh computer. If

the computer is an IBM compatible, you may need a

conversion cable that changes a Mini-DIN 8 pin (for TO PC)

to a D-sub 9 pin(for RS-232C), available at nearest dealer.

Optional remote control software for your computer can be

used to control the

DA7

, thus expanding the features and

capabilities of the mixer.

MIDI IN

This connector is used to receive signals from peripheral

MIDI devices.

MIDI OUT

This connector is used to send signals to peripheral MIDI

devices. The

DA7

can be used as a MIDI controller. See

Chapter 11, MIDI for details.

METER BRIDGE Connector

This is used to connect the optional Meter Bridge for the

DA7

.

See Chapter 17, Options in the Users' Guide for more

details.

Page 21

14

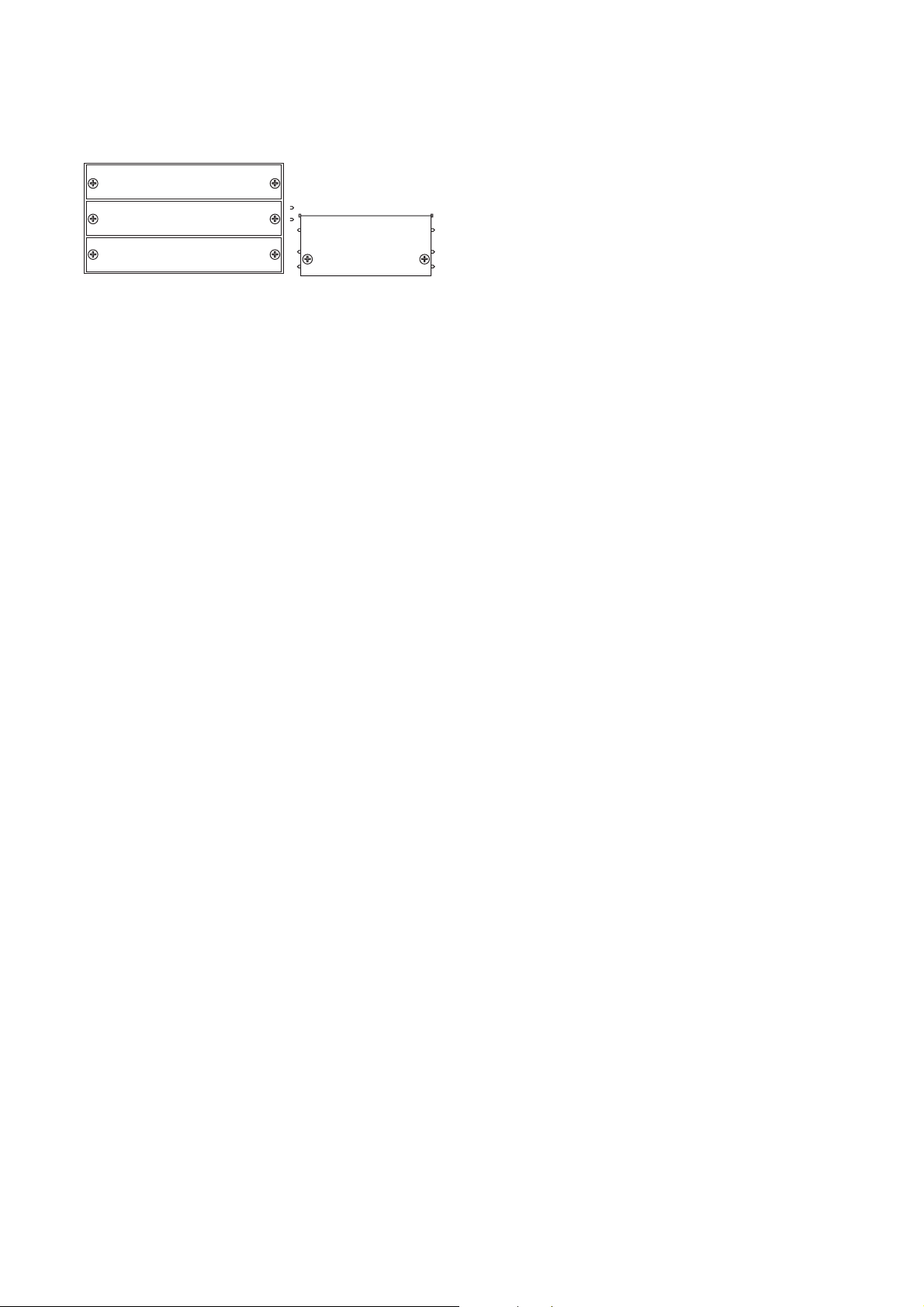

Option Card Slots

There are three slots for the optional audio Input/Output

cards, plus one dedicated slot for the SMPTE/V SYNC card.

The space for the SMPTE/V SYNC card is located directly

under the MASTER OUT XLR connectors. Audio option

cards are next to the power switch. The audio option cards

can be used in any of the audio slots, but for TANDEM

operation, the TANDEM card MUST be used in Slot 3.

Video Sync Input [V SYNC]

This is used to connect a vertical synchronizing signal from

a video device.

See Chapter 17, Options in the Users' Guide for more

about SMPTE/V SYNC.

Digital I/O Slot 1 [CH17-24/SLOT 1]

When an option card is inserted into Slot 1, the output of the

connected device appears on Channel Faders 17 through

24, and is controlled by the Fader Layer Inputs 17-32.

Digital I/O Slot 2 [CH25-32/SLOT 2]

When an option card is inserted into Slot 2, the output of the

connected device appears on Channel Faders 25 through

32, and is controlled by the Fader Layer Inputs 17-32.

Digital I/O Slot 3 [CH9-16/SLOT 3]

When an option card is inserted into Slot 3, the output of the

connected device appears on Channel Faders 9 through

16, and is controlled by the Fader Layer Inputs 1-16. This

connection REPLACES the analog inputs 1-16 with

whatever is connected to the option card in Slot 3.

For more information regarding optional slots, see Chapter

12, D-I/O and Chapter 17, Options in the Users' Guide.

Slot 1

Slot 2

Slot 3

SMPTE/V SYNC

card slot

Option Card Slots

Page 22

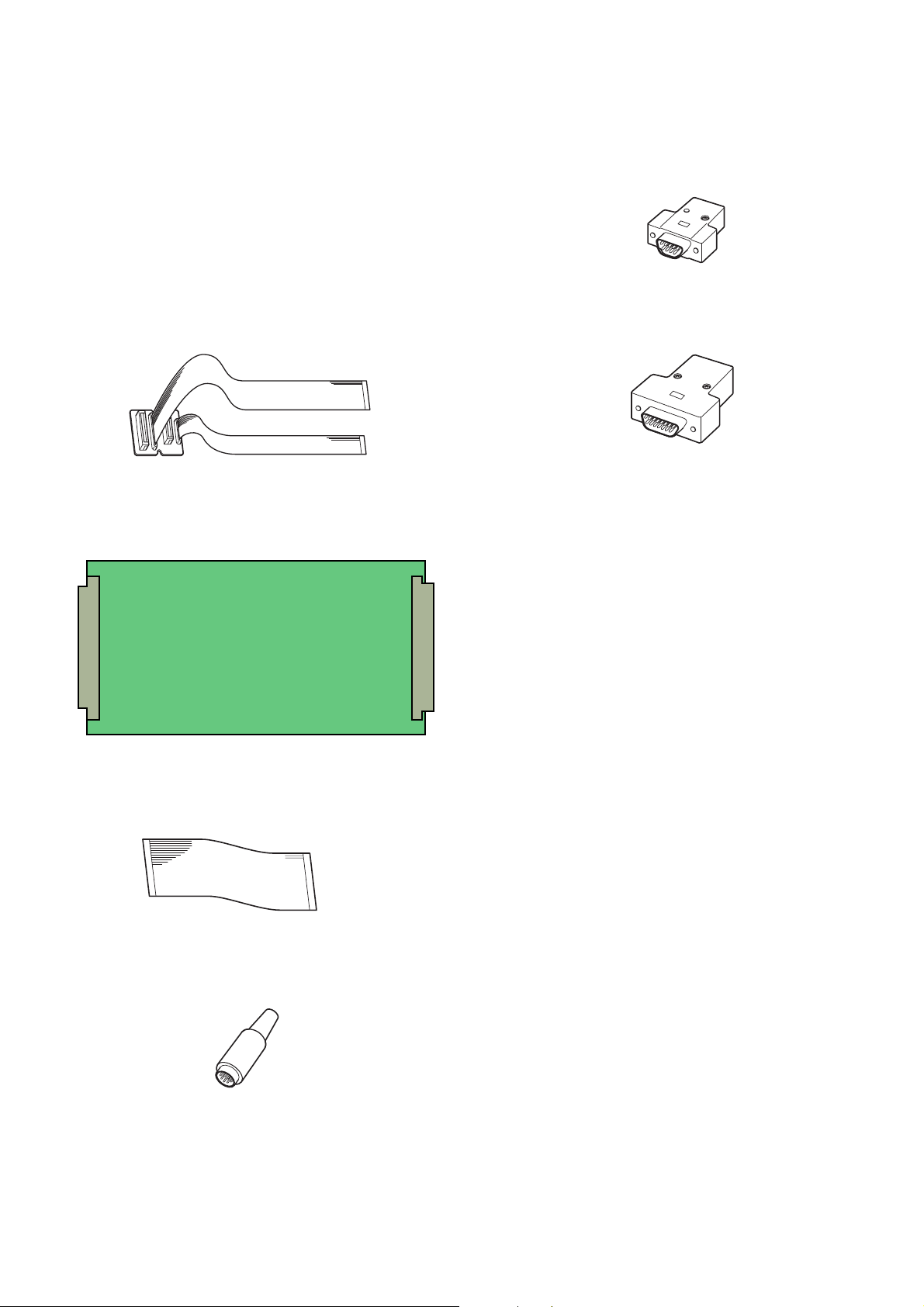

15

8

The Self Check Function is incorporated in the Digital

Audio Mixer WR-DA7.

1. Test Equipment Required

8

The following Test Jigs are required for Self Check and

Service of the WR-DA7.

8

AD EXTD-1 (Part Number : YWA0EA1196AN) between

the Power-2 Board and AD/DA Board as shown in fig. 1-1.

Fig. 1-1

8

SLOT EXTD (Part Number : YWA0EA1198AN) for the

optional Board as shown in fig. 1-2.

Fig. 1-2

8

AD EXTD-2 (Part Number : YWA0EA1199AN) between

the Main Board and AD/DA Board as shown in fig. 1-3.

Fig. 1-3

8

PC RTN (Part Number : YWA0EA1200AN) for the PC

Connector as shown in fig. 1-4.

Fig. 1-4

8

RS232/485 RTN (Part Number : YWA0EA1202AN) for

RS232C/485 Connector as shown in fig. 1-5.

Fig. 1-5

8

MTBR RTN (Part Number : YWA0EA1203AN) for the

Meter Bridge Connector as shown in fig. 1-6.

Fig. 1-6

SELF CHECK FUNCTION

Page 23

16

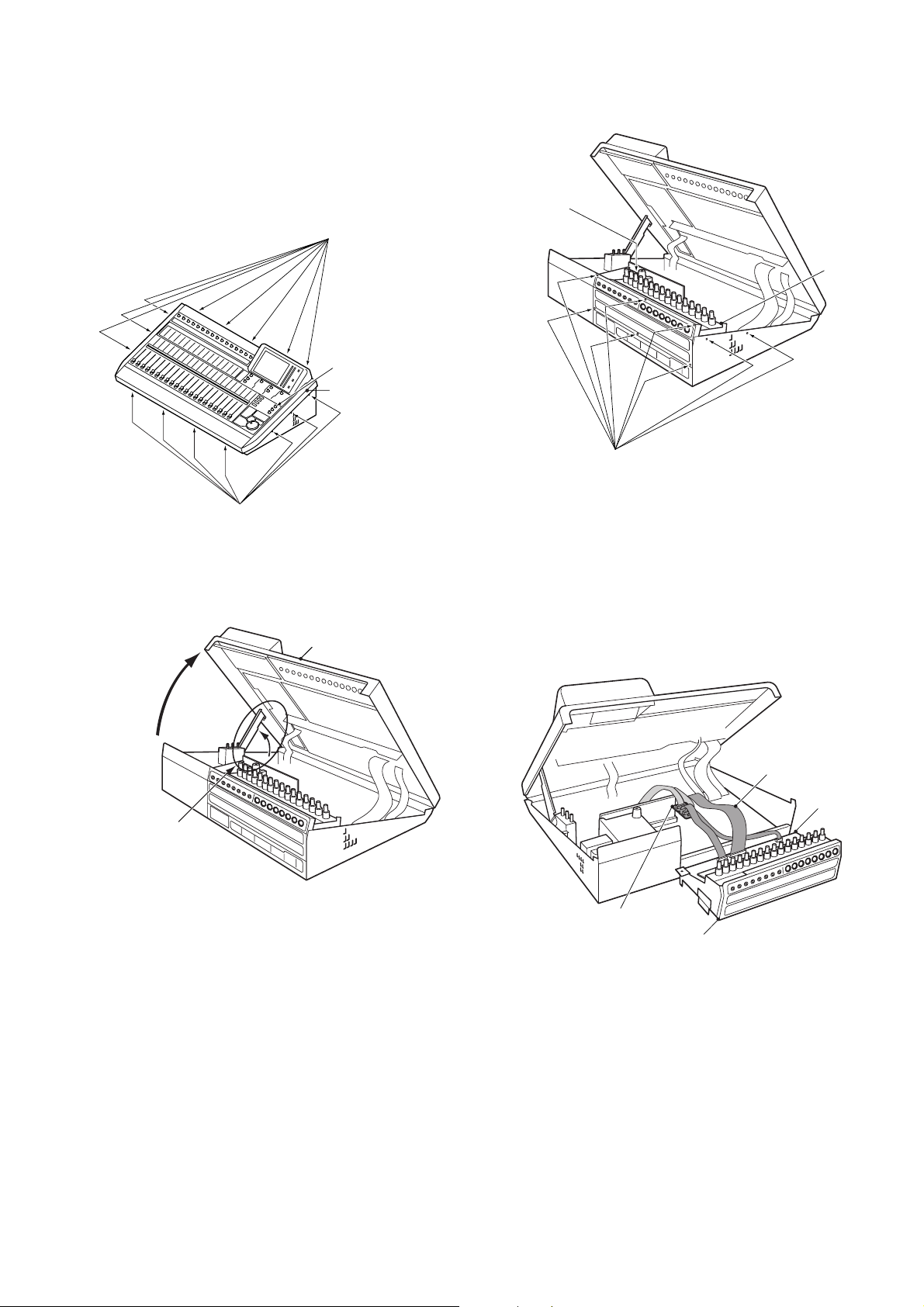

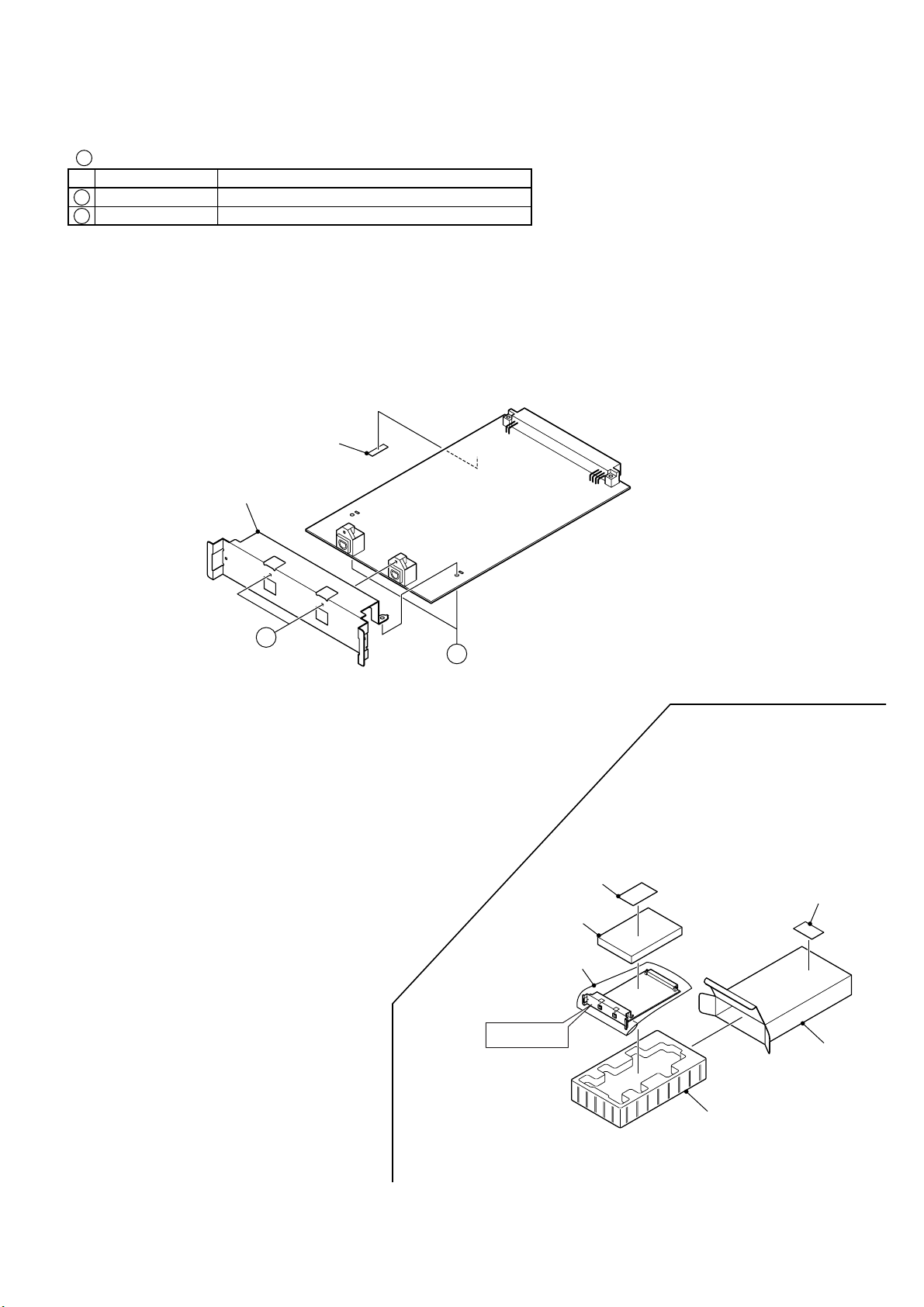

2. Disassembling Procedure

8

Referring to Fig. 2-1, remove three knobs and fifteen

screws that secure the Upper Cover Ass'y.

Fig. 2-1

8

Referring to Fig. 2-2, pull up the Upper Cover Ass'y and

hock to the slot of the Right Side Chassis of the Upper

Cover Ass'y.

Fig. 2-2

8

Referring to Fig. 2-3, pull up the Upper Cover Ass'y and

remove nine screws that secure the HA Block and remove

the HA Block.

8

Cut one Wire Binder that secure the Ground Cable and

others.

8

Remove one screw that secure the Ground Cable (Brown

Wire) at the Power-2 Board and tighten this screw.

8

Connect this Ground Cable (Brown Cable) to the Chassis.

Fig. 2-3

8

Referring to Fig. 2-4, disconnect three Cables from the

Connectors CN33, CN52 and CN 53 of the AD/DA Board.

8

Insert two Cables from the Power-2 Board to the AD

EXTD-1.

8

Insert two Cables of the AD EXTD to two Connectors

CN52 and CN53 of the AD/DA Board.

8

Insert the AD EXTD-2 between CN33 of the Main Board

and CN33 on the AD/DA Board.

Fig. 2-4

Remove eight screws.

Remove seven screws.

Remove three knobs.

Upper Cover Ass'y

Pull up the Upper

Cover Ass'y.

Release the Angle and

hock to the Slot of the

Right Side Chassis of

the Upper Cover Ass'y.

Upper Cover Ass'y

Remove eight screws.

Remove one

screw.

HA Block

AD/DA Board

AD EXTD-2

AD EXTD-1

HA Block

Page 24

17

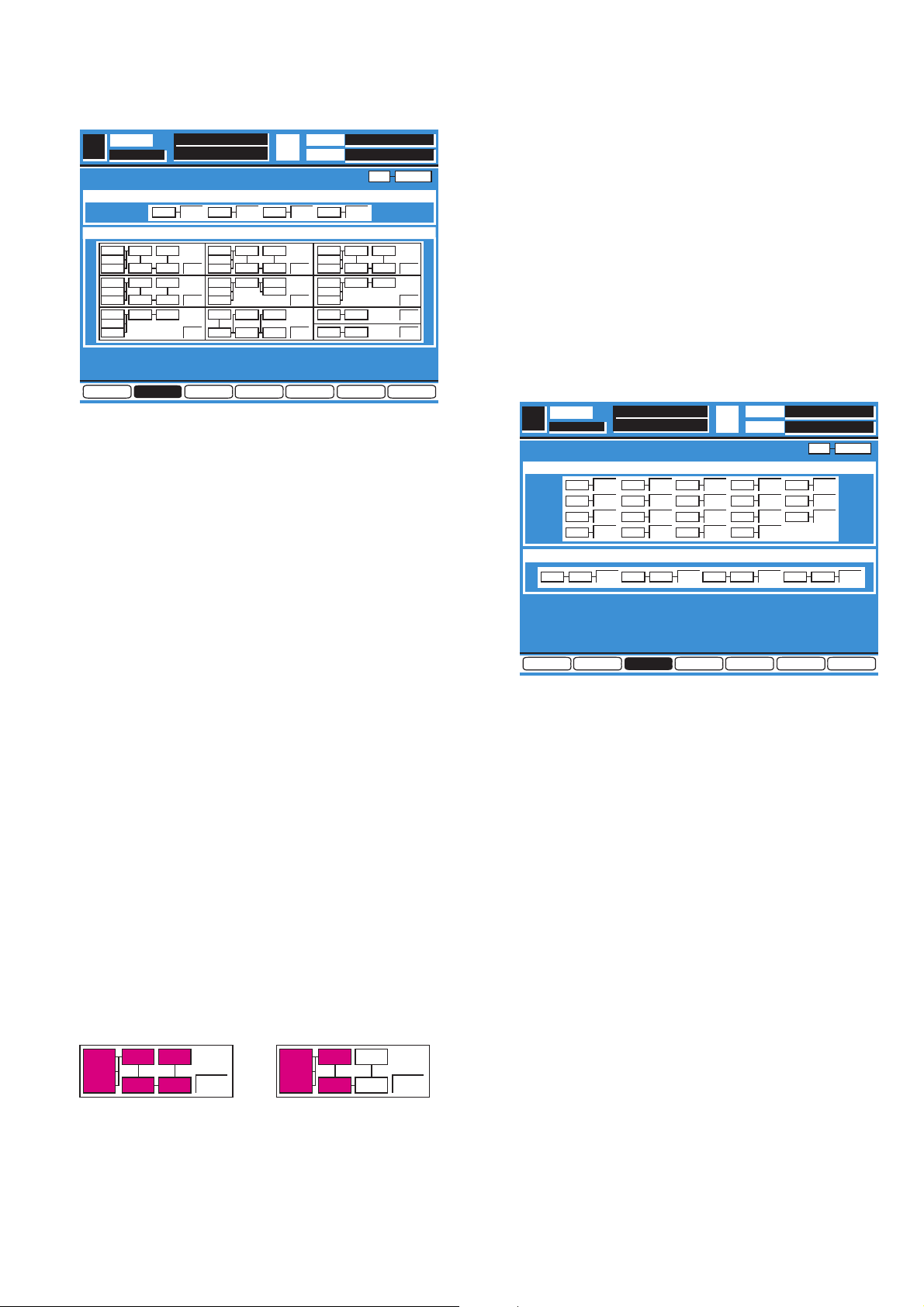

3. Execution of the Self Check Function

8

Turn the Power On while pressing the [SELECT] Key,

[ON] Key of the MASTER LR and [3] Key of the TEN KEY

simultaneously, the Self Check Function has been

executed and the Diagnostic Menu 1 as shown in Fig. 3-1

is displayed on the LCD Display of the WR-DA7.

Fig. 3-1

4. Fundamental Operation

4.1. Selection and Execution of the Check

Item

8

Select the Check Item by either UP or DOWN Cursor Key

on the Upper Cover Ass'y.

8

Execute the Check Item by pressing the Enter Key on the

Upper Cover Ass'y.

4.2. Switching of the Diagnostic Menu

8

Move the Cursor to most bottom position by either UP or

DOWN Cursor Key.

8

Select the Diagnostic Item by either LEFT or RIGHT

Cursor Key on the Upper Cover Ass'y.

8

Execute the Diagnostic Item by pressing the Enter Key.

5. Check Each Item

5.1. Version Indication (VERSION)

8

Referring to Fig. 3-1, the Product Description and the

Version of the Control Program will be displayed.

8