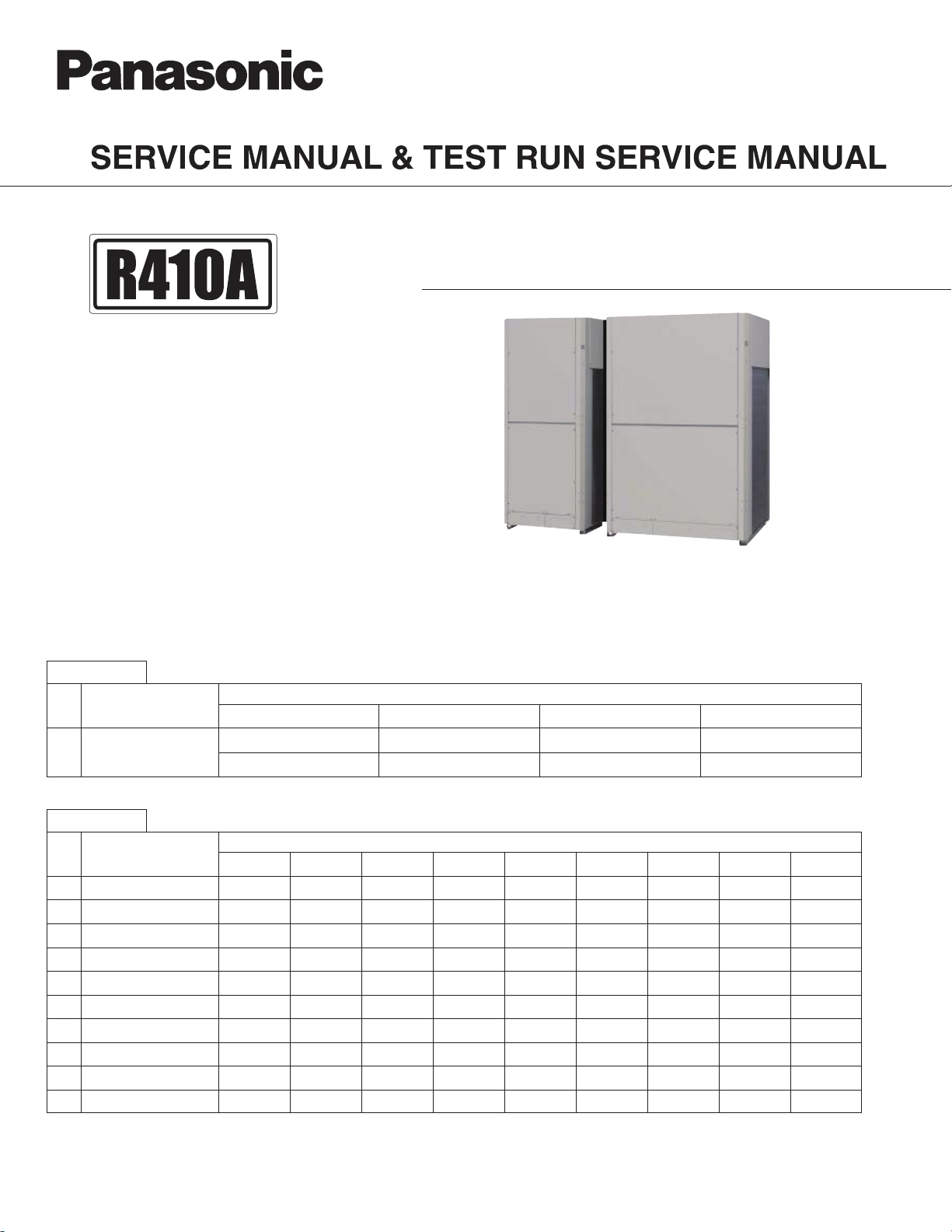

Panasonic U-72ME2U9, U-120ME2U9, U-96ME2U9, U-144ME2U9, U-72ME2U94 service manual

...

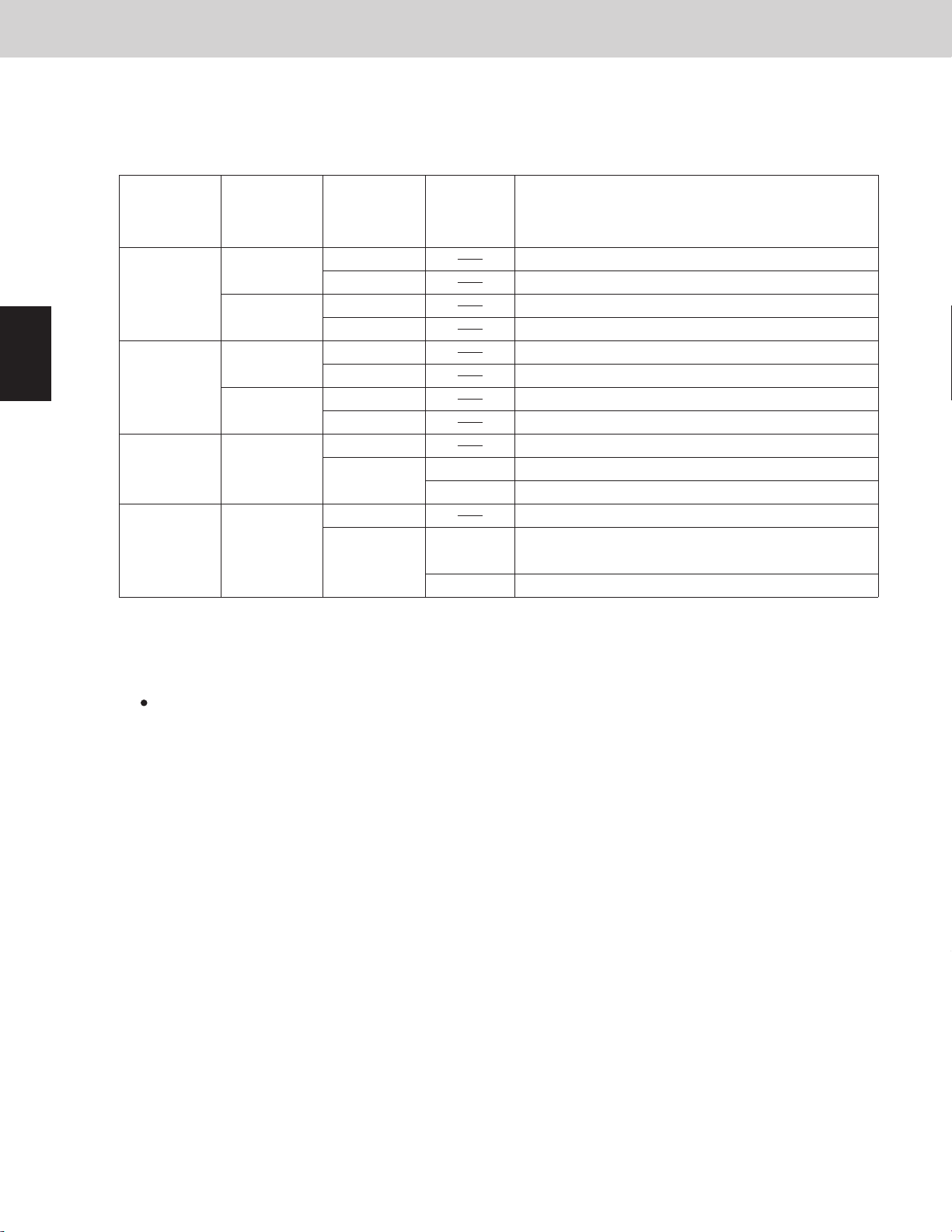

U-72ME2U9

U-96ME2U9

U-120ME2U9

U-144ME2U9

U-72ME2U94

Order No. SBPAC1404012CE

2WAY VRF System

U-96ME2U94

U-120ME2U94

U-144ME2U94

Model No.

Outdoor Unit

Outdoor Unit TypeType

ME2 2WAY VRF System

To be connecting Indoor Units

Indoor Units

Indoor Unit TypeType

U2 4-Way Cassette 36"x36"

4-Way Cassette 24"x24"

Y2

D1

1-Way Cassette

Concealed Duct

F2

-Medium Static

Concealed Duct

M2

-Low Static

Concealed Duct

E1

-High Static

T2

Ceiling

K2

Wall Mounted

P1

Floor Standing

R1

Concealed Floor Standing

S-07MD1U6

S-07MF2U6

S-07MM2U6

S-07MK2U6

S-07MP1U6

S-07MR1U6

Nominal Capacity

72 96 120 144

U-72ME2U9

U-72ME2U94

7 9 12 15 18 24 36 48 54

S-12MU2U6S-09MU2U6S-07MU2U6

S-09MY2U6S-07MY2U6

S-09MD1U6

S-09MF2U6

S-09MM2U6

S-09MK2U6

S-09MP1U6

S-09MR1U6

S-12MY2U6

S-12MD1U6

S-12MF2U6

S-12MM2U6

S-12MT2U6

S-12MK2U6

S-12MP1U6

S-12MR1U6

U-96ME2U9 U-120ME2U9 U-144ME2U9

U-96ME2U94 U-120ME2U94 U-144ME2U94

Nominal Capacity

S-15MF2U6

S-15MM2U6

S-15MP1U6

S-15MR1U6

S-18MY2U6

S-18MF2U6

S-18MM2U6

S-18MT2U6

S-18MK2U6

S-18MP1U6

S-18MR1U6

S-24MU2U6

S-24MF2U6

S-24MT2U6

S-24MK2U6

S-24MP1U6

S-24MR1U6

S-36MU2U6

S-36MF2U6

S-36ME1U6

S-48MF2U6 S-54MF2U6

S-48ME1U6

85464849337007

This air conditioner uses the refrigerant R410A.

REFERENCE NO.

SM830237-07

IMPORTANT!

• Do not leak refrigerant while piping work for an

installation or re-installation, and while repairing

refrigeration parts.

Handle liquid refrigerant carefully as it may cause

frostbite.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit.

WARNING

• This product must not be modified or

disassembled under any circumstances.

Modified or disassembled unit may cause fire,

electric shock or injury.

• Do not clean inside the indoor and outdoor

units by users. Engage authorized dealer or

specialist for cleaning.

• In case of malfunction of this appliance, do

not repair by yourself. Contact to the sales

dealer or service dealer for a repair.

CAUTION

• Do not touch the air inlet or the sharp

aluminum fins of the outdoor unit. You

may get injured.

• Ventilate any enclosed areas when installing or

testing the refrigeration system. Leaked

refrigerant gas, on contact with fire or heat, can

produce dangerously toxic gas.

• Confirm after installation that no refrigerant gas

is leaking. If the gas comes in contact with a

burning stove, gas water heater, electric room

heater or other heat source, it can cause the

generation of toxic gas.

Others

CAUTION

• Do not sit or step on the unit, you may

fall down accidentally.

• Do not touch the air inlet or the sharp

aluminum fins of the outdoor unit.

You may get injured.

• Do not stick any object into the FAN

CASE.

You may be injured and the unit may

be damaged.

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not exceed

a set limit.

The refrigerant (R410A), which is used in the air

conditioner, is safe, without the toxicity or combustibility of

ammonia, and is not restricted by laws imposed to protect

the ozone layer. However, since it contains more than air,

it poses the risk of suffocation if its density should rise

excessively. Suffocation from leakage of refrigerant is

almost non-existent. With the recent increase in the

number of high density buildings, however, the installation

of multi air conditioner systems is on the increase

because of the need for effective use of floor space,

individual control, energy conservation by curtailing heat

and carrying power, etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners.

If a single unit of the multi air conditioner system is to be

installed in a

small room, select a suitable model and

installation procedure so that if the refrigerant

accidentally leaks out, its density does not reach the limit

(and in the event of an emergency, measures can be

made before injury can occur).

ASHRAE and the International Mechanical Code of the

ICC as well as CSA provide guidance and define

safeguards related to the use of refrigerants, all of which

define a Refrigerant Concentration Level (RCL) of

refrigerant.

For additional guidance and precautions related to

refrigerant safety, please refer to the following documents:

International Mechanical Code 2012 (IMC-2012)

(or more recently revised)

ASHRAE 15

ASHRAE 34

400 oz (11.3 kg) per 1,000 ft3 (28.3 m3) for R410A

Please Read Before Starting

This air conditioning system meets strict safety and

operating standards. As the installer or service person, it is

an important part of your job to install or service the

system so it operates safely and efficiently.

For safe installation and trouble-free operation, you

must:

● Carefully read this instruction booklet before beginning.

● Follow each installation or repair step exactly as shown.

● This air conditioner shall be installed in accordance with

National Wiring Regulations.

● Pay close attention to all warning and caution notices

given in this manual.

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

•Do not supply power to the unit until all wiring and tubing

are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system.

Carefully refer to the wiring diagram and these instructions

when wiring. Improper connections and inadequate

grounding can cause accidental injury or death.

•Ground the unit following local electrical codes.

•Connect all wiring tightly. Loose wiring may cause over-

heating at connection points and a possible fire hazard.

•To prevent possible hazards from insulation failure,

the unit must be grounded.

•This equipment is strongly recommended to be installed

with Earth Leakage Circuit Breaker (ELCB) or Residual

Current Device (RCD). Otherwise, it may cause electrical

shock and fire in case of equipment breakdown or

insulation breakdown.

WARNING

CAUTION

WARNING

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

This symbol refers to a hazard or

unsafe practice which can result

in severe personal injury or death.

This symbol refers to a hazard or

unsafe practice which can result

in personal injury or product or

property damage.

When Wiring

When Transporting

Be careful when picking up and moving the indoor and

outdoor units. Get a partner to help, and bend your knees

when lifting to reduce strain on your back. Sharp edges or

thin aluminum fins on the air conditioner can cut your

fingers.

When Installing…

Select an installation location which is rigid and strong

enough to support or hold the unit, and select a location for

easy maintenance.

…In a Room

Properly insulate any tubing run inside a room to prevent

“sweating” that can cause dripping and water damage to

walls and floors.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a

solid, level foundation for the outdoor unit. This prevents

water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a

metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher

than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

• Pay particular attention to refrigerant leakages.

•Ventilate the room immediately, in the event that is

refrigerant gas leaks during the installation. Be careful not

to allow contact of the refrigerant gas with a flame as this

will cause the generation of toxic gas.

•Keep all tubing runs as short as possible.

•Apply refrigerant lubricant to the matching surfaces of the

flare and union tubes before connecting them, then tighten

the nut with a torque wrench for a leak-free connection.

•Check carefully for leaks before starting the test run.

i

CAUTION

Keep the fire alarm and the air

outlet at least 5 ft. (1.5 m) away

from the unit.

WARNING

•When performing piping work, do not mix air

except for specified refrigerant (R410A) in

refrigeration cycle. It causes capacity down, and

risk of explosion and injury due to high tension

inside the refrigerant cycle.

•If the refrigerant comes in contact with a flame,

it produces a toxic gas.

•Do not add or replace refrigerant other than

specified type. It may cause product damage,

burst and injury, etc.

• Do not leak refrigerant while piping work for an

installation or re-installation, and while repairing

refrigeration parts.

Handle liquid refrigerant carefully as it may cause

frostbite.

When Servicing

• Turn the power OFF at the main power box (mains)

before opening the unit to check or repair electrical

parts and wiring.

• Keep your fingers and clothing away from any moving

parts.

• Clean up the site after you finish, remembering to

check that no metal scraps or bits of wiring have been

left inside the unit.

CAUTION

• Do not touch the air inlet or the sharp

aluminum fins of the outdoor unit. You

may get injured.

• Ventilate any enclosed areas when installing or

testing the refrigeration system. Leaked

refrigerant gas, on contact with fire or heat, can

produce dangerously toxic gas.

• Confirm after installation that no refrigerant gas

is leaking. If the gas comes in contact with a

burning stove, gas water heater, electric room

heater or other heat source, it can cause the

generation of toxic gas.

WARNING

• This product must not be modified or

disassembled under any circumstances.

Modified or disassembled unit may cause fire,

electric shock or injury.

• Do not clean inside the indoor and outdoor

units by users. Engage authorized dealer or

specialist for cleaning.

• In case of malfunction of this appliance, do

not repair by yourself. Contact to the sales

dealer or service dealer for a repair.

Check of Density Limit

The room in which the air conditioner is to be

installed requires a design that in the event of

refrigerant gas leaking out, its density will not exceed

a set limit.

The refrigerant (R410A), which is used in the air

conditioner, is safe, without the toxicity or combustibility of

ammonia, and is not restricted by laws imposed to protect

the ozone layer. However, since it contains more than air,

it poses the risk of suffocation if its density should rise

excessively. Suffocation from leakage of refrigerant is

almost non-existent. With the recent increase in the

number of high density buildings, however, the installation

of multi air conditioner systems is on the increase

because of the need for effective use of floor space,

individual control, energy conservation by curtailing heat

and carrying power, etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners.

Others

CAUTION

• Do not sit or step on the unit, you may

fall down accidentally.

• Do not touch the air inlet or the sharp

aluminum fins of the outdoor unit.

You may get injured.

• Do not stick any object into the FAN

CASE.

You may be injured and the unit may

be damaged.

If a single unit of the multi air conditioner system is to be

installed in a

installation procedure so that if the refrigerant

accidentally leaks out, its density does not reach the limit

(and in the event of an emergency, measures can be

made before injury can occur).

ASHRAE and the International Mechanical Code of the

ICC as well as CSA provide guidance and define

safeguards related to the use of refrigerants, all of which

define a Refrigerant Concentration Level (RCL) of

400 oz (11.3 kg) per 1,000 ft3 (28.3 m3) for R410A

For additional guidance and precautions related to

refrigerant safety, please refer to the following documents:

International Mechanical Code 2012 (IMC-2012)

(or more recently revised)

ASHRAE 15

ASHRAE 34

small room, select a suitable model and

refrigerant.

ii

Precautions for Installation Using New Refrigerant

3-2. Use R410A exclusive cylinder only.

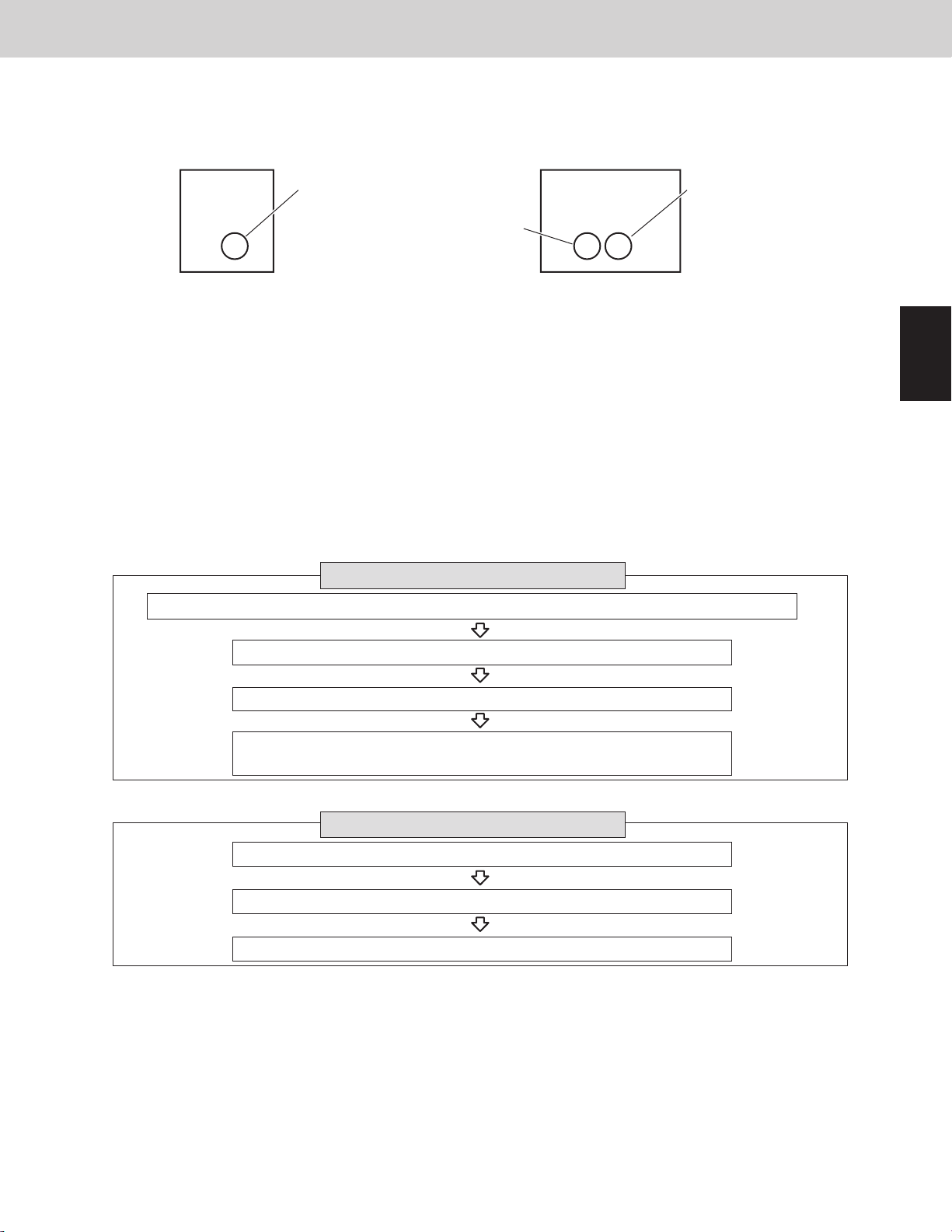

Single-outlet valve

(with siphon tube)

Liquid refrigerant should be recharged

with the cylinder standing on end as

shown.

New refrigerant R410A cannot be used for

earlier models

1. Compressor specifications are different.

If recharging a R22 or R407C compressor with

R410A, durability will significantly decrease since

some of the materials used for compressor parts are

different.

2. Existing tubing cannot be used (especially R22).

Completely cleaning out residual refrigerating

machine oil is impossible, even by flushing.

3. Refrigerating machine oil differs (R22).

Since R22 refrigerating machine oil is mineral oil, it

does not dissolve in R410A. Therefore, refrigerating

machine oil discharged from the compressor can

cause compressor damage.

R22 refrigerating machine oil Mineral oil (Suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R410A refrigerating machine oil Synthetic fluid (ether oil)

Valve

Liquid

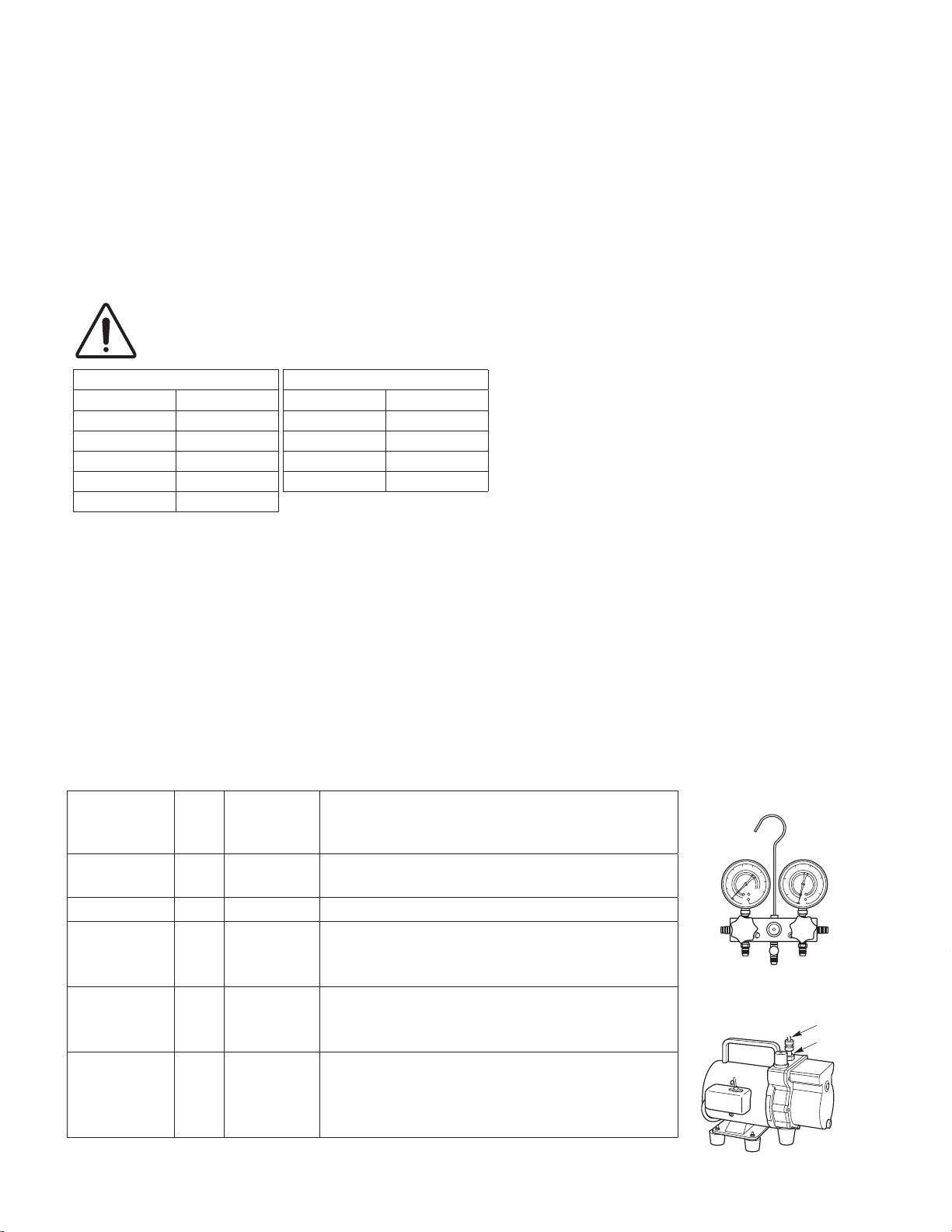

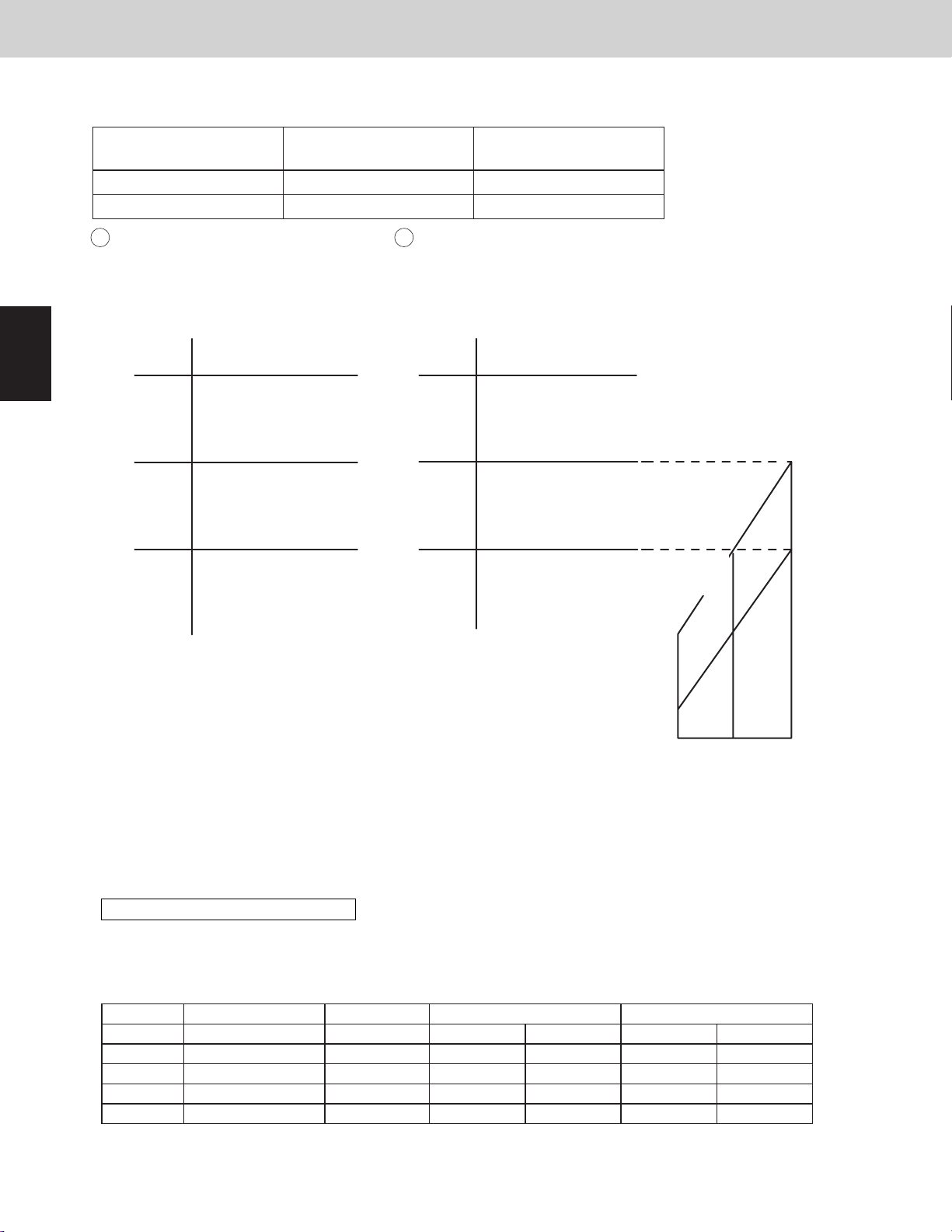

1. Care regarding tubing

1-1. Process tubing

l

Material: Use clean, dry, free of oil, refrigeration grade, seamless, phosphorous deoxidized copper tube rated for

R410A only. Wall thickness shall comply with the applicable legislation. The minimal wall thickness must be in

accordance with the table below.

l

Tubing size: Be sure to use the sizes indicated in the table below.

l

Use a tube cutter when cutting the tubing, and be sure to remove any flash. This also applies to distribution joints

(optional).

l

When bending tubing, use a bending radius that is 4 times the outer diameter of the tubing or larger.

Use sufficient care in handling the tubing. Seal the tubing ends with caps or tape to

CAUTION

prevent dirt, moisture, or other foreign substances from entering.

These substances can result in system malfunction.

Outer diameter Wall thickness Outer diameter Wall thickness

5/8" (15.88) 0.040 (1.016) 1-5/8" (41.28) 0.060 (1.524)

3/4" (19.05) 0.042 (1.0668) Unit: in. (mm)

Material: O Material: O

1/4" (6.35) 0.025 (0.635) 7/8" (22.22) 0.045 (1.143)

3/8" (9.52) 0.030 (0.762) 1-1/8" (28.58) 0.050 (1.27)

1/2" (12.7) 0.035 (0.889) 1-3/8" (34.92) 0.055 (1.397)

1-2. Prevent impurities including water, dust and oxide from entering the tubing. Impurities can cause R410A

refrigerant deterioration and compressor defects. Due to the features of the refrigerant and refrigerating machine

oil, the prevention of water and other impurities becomes more important than ever.

2. Be sure to recharge the refrigerant only in liquid form.

2-1. Since R410A is a non-azeotrope, recharging the refrigerant in gas form can lower performance and cause defects

in the unit.

2-2. Since refrigerant composition changes and performance decreases when gas leaks, collect the remaining

refrigerant and recharge the required total amount of new refrigerant after fixing the leak.

3. Different tools required

3-1. Tool specifications have been changed due to the characteristics of R410A.

Some tools for R22- and R407C-type refrigerant systems cannot be used.

Item

Manifold gauge Yes No

Charge hose Yes No To resist higher pressure, material must be changed.

Vacuum pump Yes Yes

Leak detector Yes No

Flaring oil Yes No

* Using tools for R22 and R407C and new tools for R410A together can cause defects.

tools?

New

R407C tools

compatible

with R410A?

Remarks

Types of refrigerant, refrigerating machine oil, and

pressure gauge are different.

Use a conventional vacuum pump if it is equipped with

a check valve. If it has no check valve, purchase and

attach a vacuum pump adapter.

Leak detectors for CFC and HCFC that react to chlorine

do not function because R410A contains no chlorine.

Leak detector for HFC134a can be used for R410A.

For systems that use R22, apply mineral oil (Suniso

oil) to the flare nuts on the tubing to prevent refrigerant

leakage. For machines that use R407C or R410A, apply

synthetic oil (ether oil) to the flare nuts.

Manifold gauge

Vacuum pump

Outlet

Inlet

iii

3-2. Use R410A exclusive cylinder only.

New refrigerant R410A cannot be used for

earlier models

1. Compressor specifications are different.

If recharging a R22 or R407C compressor with

R410A, durability will significantly decrease since

some of the materials used for compressor parts are

different.

Valve

Single-outlet valve

(with siphon tube)

Liquid refrigerant should be recharged

with the cylinder standing on end as

shown.

Liquid

2. Existing tubing cannot be used (especially R22).

Completely cleaning out residual refrigerating

machine oil is impossible, even by flushing.

3. Refrigerating machine oil differs (R22).

Since R22 refrigerating machine oil is mineral oil, it

does not dissolve in R410A. Therefore, refrigerating

machine oil discharged from the compressor can

cause compressor damage.

R22 refrigerating machine oil Mineral oil (Suniso oil)

R407C refrigerating machine oil Synthetic fluid (ether oil)

R410A refrigerating machine oil Synthetic fluid (ether oil)

iv

—

CONTENTS

—

Section 1: CONTROL FUNCTIONS .......................................... 1-1

1. Introduction .............................................................1-2

2. Selecting Outdoor Unit for Operation .......................................... 1-3

3. Compressor Control .......................................................1-5

4. Output of PCB ..........................................................1-12

5. Outdoor Unit Fan Control .................................................. 1-18

6. Outdoor Unit CCU (command controller unit) Control ............................1-22

7. Oil Control .............................................................1-27

8. 4-Way Valve Adjustment Control ............................................1-30

9. Defrost Control ..........................................................1-31

10. Upper Current Limitation Mode (Demand control) ............................... 1-34

11. Backup Operation ....................................................... 1-36

12. Other Functions .........................................................1-40

13. Detailed Settings in EEPROM of Outdoor Unit .................................1-42

14. Outdoor Unit Control PCB .................................................1-44

Section 2: OUTDOOR UNIT REPAIR PROCEDURES ........................... 2-1

1. Removing Panels ......................................................... 2-2

2. Discharging Compressor Oil ................................................ 2-4

3. Backup Operation ........................................................ 2-7

4. Recovering Refrigerant .................................................... 2-9

5. Checking for Leakage After Repair .......................................... 2-14

6. Evacuating System ...................................................... 2-15

7. Charging Compressor Oil ................................................. 2-16

8. Pumping Out Refrigerant from Outdoot Unit ................................... 2-22

9. Compressor ........................................................... 2-26

10. Replacing Peripheral Parts of Fusible Plug .................................... 2-36

11. High and Low Pressure Sensors ............................................ 2-37

Section 3: OUTDOOR UNIT MAINTENANCE REMOTE CONTROLLER ............. 3-1

1. Overview ............................................................... 3-2

2. Functions ...............................................................3-3

3. Ordinary Display Controls and Functions ...................................... 3-4

4. Monitoring Operations .....................................................3-9

5. Outdoor Unit Alarm History Monitor .......................................... 3-11

6. Mode Settings ..........................................................3-12

Section 4: REMOTE CONTROLLER FUNCTIONS ............................. 4-1

1. Simple Settings Function ................................................... 4-2

2. Detailed Settings Function .................................................. 4-8

3. Remote Controller Servicing Functions ....................................... 4-28

v

Section 5: TROUBLE DIAGNOSIS .......................................... 5-1

1. Contents of Remote Controller Switch Alarm Display .............................5-2

2. Outdoor Unit Control Panel LED Display .......................................5-4

3. 2WAY Alarm Codes .......................................................5-5

4. Blinking Inspection Display on the Remote Controller ............................5-30

5. Inspection and Characteristics of Parts .......................................5-31

6. Test Pin ...............................................................5-35

7. Symptom: Thermostat in OFF continues or cycles OFF & ON too Frequently .........5-36

Section 6: TEST RUN .................................................... 6-1

1. Preparing for Test Run ..................................................... 6-2

2. Test Run Procedure ....................................................... 6-3

3. Main Outdoor Unit PCB Setting ..............................................6-4

4. Function Switches on P. C. Board ............................................6-7

5. Auto Address Setting ......................................................6-9

6. Setting Test Run Remote Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17

7. Caution for Pump Down ................................................... 6-18

8. Self-Diagnosis Function Table and Contents of Alarm Display ..................... 6-18

vi

– MEMO –

vii

2WAY VRF SYSTEM

2WAY VRF SYSTEM

Control Functions

Contents

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. 1-2

Selecting Outdoor Unit for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.

Compressor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

Output of PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

Outdoor Unit Fan Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.

Outdoor Unit CCU (command controller unit) Control . . . . . . . . . . . . . . . . . . . . . . .

6.

1. CONTROL FUNCTIONS

Control Functions

1-3

1-5

1-12

1-18

1-22

7. Oil Control

4-Way Valve Adjustment Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.

Defrost Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.

Upper Current Limitation Mode (Demand control) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

10.

Backup Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11.

Other Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-27

1-30

1-31

1-34

1-36

1-40

1-4213. Detailed Settings in EEPROM of Outdoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-4414. Outdoor Unit Control PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

2

3

4

5

1 - 1

6

7

8

9

1

2WAY VRF SYSTEM

Control Functions

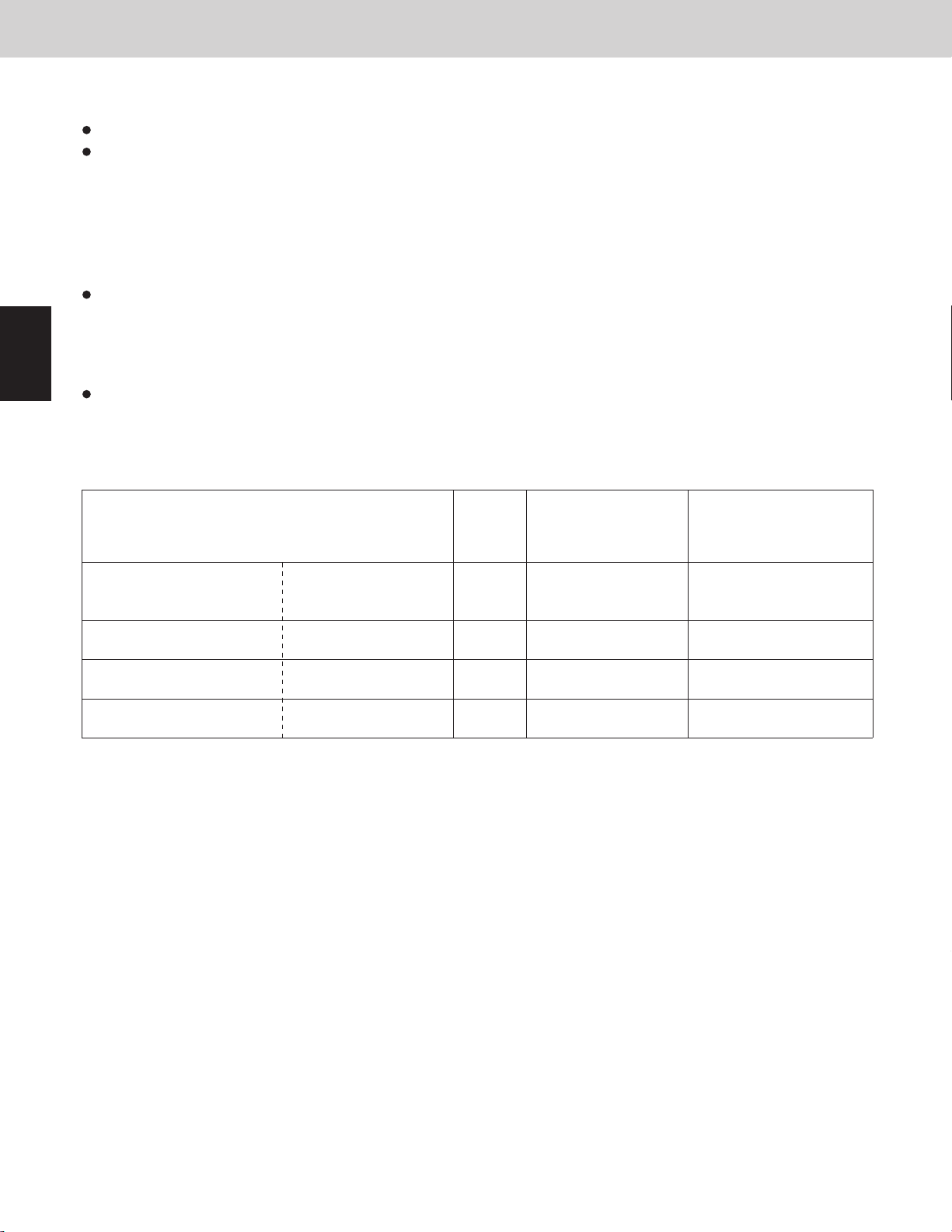

1. Introduction

2. Selecting Outdoor Unit for Operation

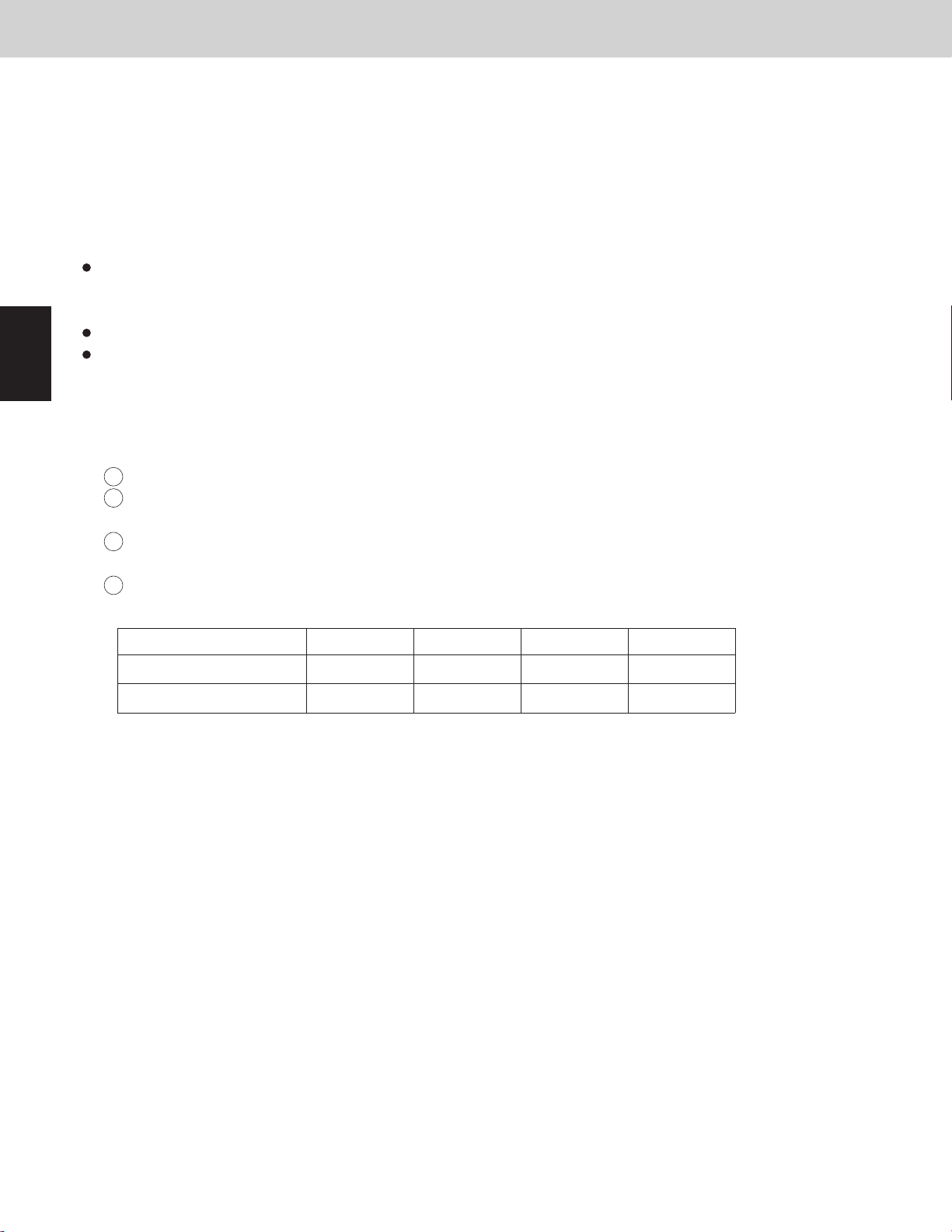

Outdoor Unit Operating Rules

(1) Outdoor Unit Operating Rules

As a result of setting the main outdoor and sub outdoor units due to the O/U.ADD setting, the order of priority for

the outdoor units is determined in small values of O/U.ADD sequence. Because in this system all outdoor units

contain an inverter compressor, ordinarily there is no absolute order of priority for compressor operation.

(2) Delayed Start of Outdoor Units

1. Delayed start of outdoor unit in the same system

If it is necessary to operate the compressors simultaneously at multiple outdoor units, each outdoor unit will

start in order of unit No. every one second, beginning with unit No. 1.

*

Operation starts

Main outdoor unit Sub outdoor unit Sub outdoor unit

O/U.ADD = 1 O/U.ADD = 2 O/U.ADD = 3

Starts after 1 second Starts after 2 seconds Starts after 3 seconds

This is in order to reduce the load on the power supply equipment.

2. Delayed start for each system

When systems are linked with one communication cable and multiple systems are required to operate

simultaneously by the central control device, all main outdoor units will begin operating simultaneously.

In this situation, the load of the power supply equipment increases temporarily.

To prevent the overload, the start timing of each system can be delayed.

In order to enable this delay time, it must be set in the EEPROM for each system (Main outdoor unit).

Those systems (Main outdoor units) where this setting has been made will start after a delay according to

their system addresses.

To activate this delay start function, it is necessary to set it to EEPROM on main outdoor PCB.

EEPROM setting in main outdoor unit

CODE: 3E

2WAY VRF SYSTEM

Control Functions

Delay timeSetting No.

0

(factory preset mode)

No delay start for each system

1 (System address × 1 × 8) seconds delay

2 (System address × 2 × 8) seconds delay

3 (System address × 3 × 8) seconds delay

2

2WAY VRF SYSTEM

1. Introduction

1. Introduction

The ME2U series outdoor units for USA is a system that allows multiple outdoor units to be connected.

All the outdoor units do not utilize the sub units that were used in earlier systems.

The O/U.ADD of outdoor unit PCB where the unit is set to “1” becomes the main unit and activates

as the CCU (command controller unit) functions that controls the entire system.

PCB Setting of Outdoor Unit

In order to determine the outdoor unit to be the main or sub unit, it is necessary to make settings at each PCB.

Main outdoor unit

The outdoor unit where the O/U.ADD is set to “1” activates the CCU (command controller unit) functions that

controls the entire system. This outdoor unit is the main outdoor unit.

* For the main outdoor unit, perform all the settings in the table (PCB setting of outdoor unit) below.

Sub outdoor unit

The outdoor unit where the unit No. is set to other than “1” is a sub outdoor unit.

* The system will not operate if outdoor units have been set other than unit No. “1”.

PCB Setting of Outdoor Unit

Control Functions

3

4

5

6

7

Factory

O/U.ADD [SW5] 11Outdoor units address

R.C.ADD [SW1, SW2] 1 Not necessarySystem 1 ~ 30System address

NO.OF I/U [SW3, SW4] 1 Not necessarySystem 1 ~ 64 unitsNo. of indoor units

NO.OF O/U 1 Not necessarySystem 1 ~ 3 unitsNo. of outdoor units[SW6]

* This system can be exteded to connect a maximum of 3 outdoor units.

preset

mode

Main outdoor unit

On-site setting

Sub outdoor unit

On-site setting

Setting other than 1

(Duplication prohibited)

8

9

1 - 2

2WAY VRF SYSTEM

2. Selecting Outdoor Unit for Operation

2WAY VRF SYSTEM

Control Functions

2. Selecting Outdoor Unit for Operation

Outdoor Unit Operating Rules

(1) Outdoor Unit Operating Rules

As a result of setting the main outdoor and sub outdoor units due to the O/U.ADD setting, the order of priority for

the outdoor units is determined in small values of O/U.ADD sequence. Because in this system all outdoor units

contain an inverter compressor, ordinarily there is no absolute order of priority for compressor operation.

(2) Delayed Start of Outdoor Units

1. Delayed start of outdoor unit in the same system

If it is necessary to operate the compressors simultaneously at multiple outdoor units, each outdoor unit will

start in order of unit No. every one second, beginning with unit No. 1.

*

This is in order to reduce the load on the power supply equipment.

Operation starts

Control Functions

1

2

Main outdoor unit Sub outdoor unit Sub outdoor unit

O/U.ADD = 1 O/U.ADD = 2 O/U.ADD = 3

Starts after 1 second Starts after 2 seconds Starts after 3 seconds

2. Delayed start for each system

When systems are linked with one communication cable and multiple systems are required to operate

simultaneously by the central control device, all main outdoor units will begin operating simultaneously.

In this situation, the load of the power supply equipment increases temporarily.

To prevent the overload, the start timing of each system can be delayed.

In order to enable this delay time, it must be set in the EEPROM for each system (Main outdoor unit).

Those systems (Main outdoor units) where this setting has been made will start after a delay according to

their system addresses.

To activate this delay start function, it is necessary to set it to EEPROM on main outdoor PCB.

EEPROM setting in main outdoor unit

CODE: 3E

Delay timeSetting No.

0

(factory preset mode)

No delay start for each system

3

4

5

6

7

1 (System address × 1 × 8) seconds delay

2 (System address × 2 × 8) seconds delay

3 (System address × 3 × 8) seconds delay

1 - 3

8

9

1

2WAY VRF SYSTEM

Control Functions

2. Selecting Outdoor Unit for Operation

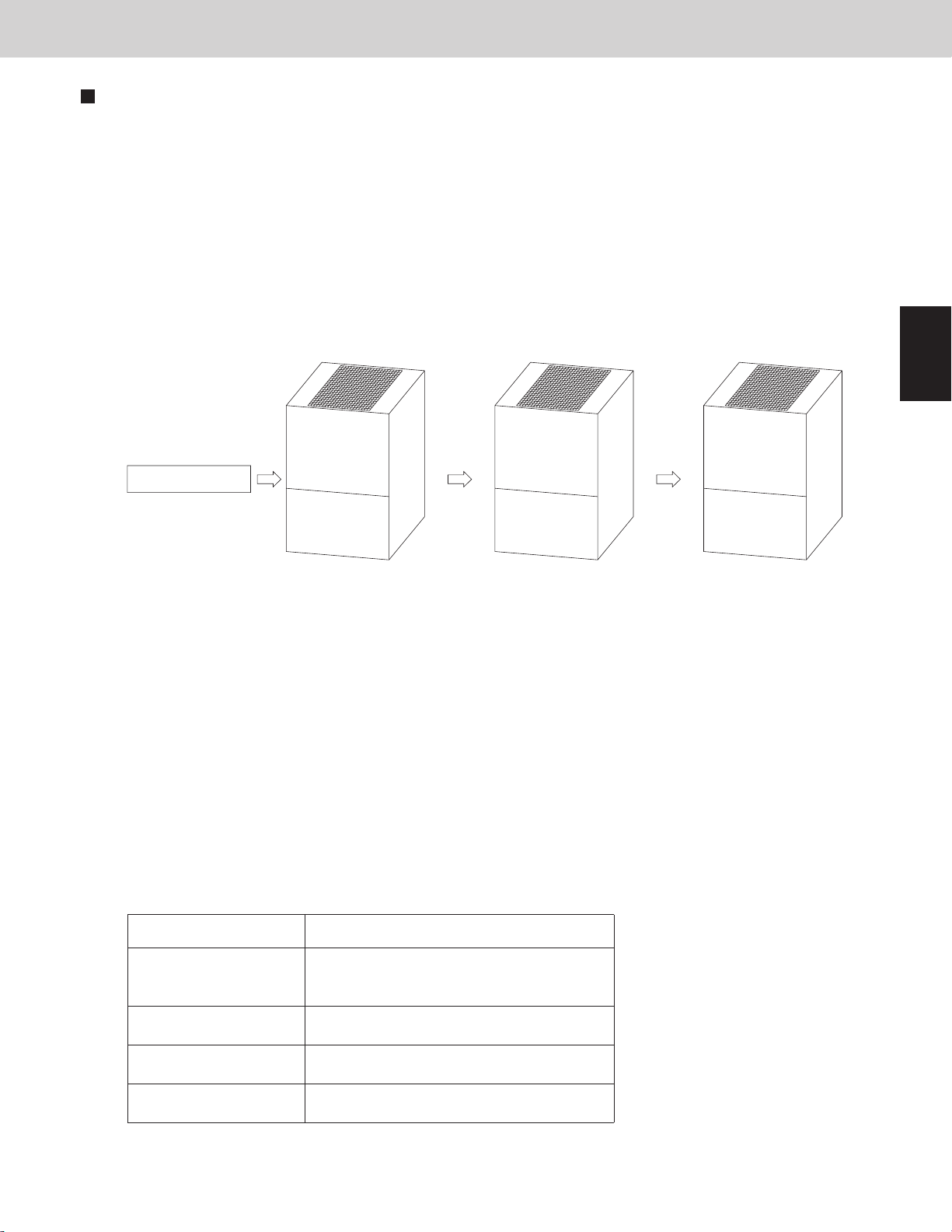

3. Compressor Control

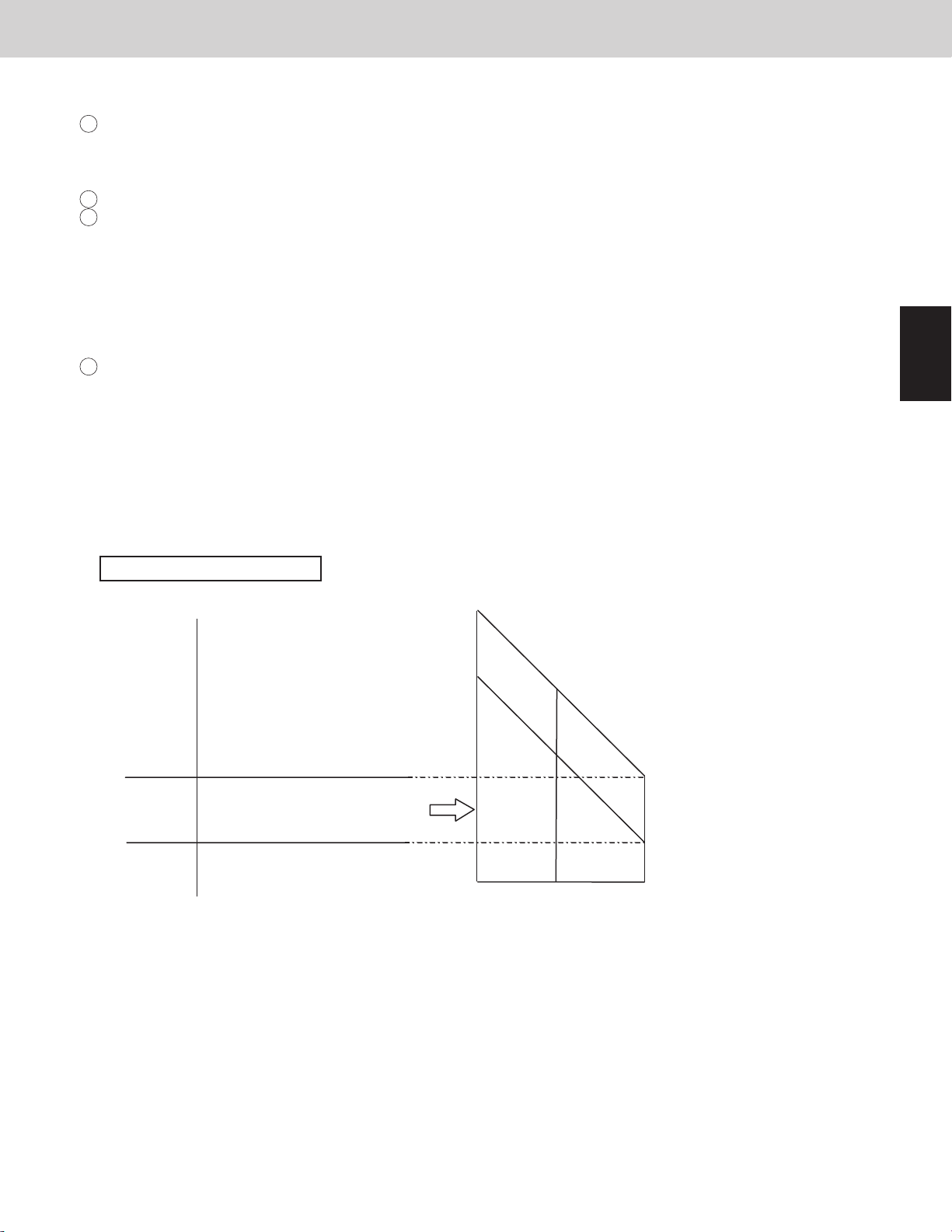

(1) Compressors Mounted in the Outdoor Units

(2) Compressor Selection Rules

Placement of compressor seen from the top

1. Priority order of compressors

A.

A

B

C

D

Decide first priority order of compressor in each outdoor unit.

B. Priority order of compressor trip counter = 0 is higher than that of compressor trip counter = 1.

C. Inverter compressor: Shorter operating time > Longer operating time

D. Compressor that “outdoor unit small address”

installed in outdoor unit

Compressor that “outdoor unit large address”

installed in outdoor unit

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

“Outdoor unit small address”

installed in outdoor unit

“Outdoor unit large address”

installed in outdoor unit

>

>

*1

*1 Select first priority order of compressor in each outdoor unit by following method.

The compressor that has no trip counter, shorter operating time and smaller number of compressor will be

taken first priority.

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

2WAY VRF SYSTEM

Control Functions

Type 72, 96 Type 120, 144

Front side

1st compressor

2nd compressor

1st compressor

Front side

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

1st compressor > 2nd compressor

Priority order flow of all compressors

Priority order flow of each outdoor unit

2. Selecting Outdoor Unit for Operation

(3) Outdoor Unit Stop Rules

1. Stopping of all outdoor units

When all outdoor units must stop, all units will stop in order of unit No. every one second.

2. Stopping of individual outdoor units

When it is necessary to reduce the number of operating compressors due to load reduction of indoor units,

the outdoor units will stop in order of priority for the compressors. All outdoor units stop when all compressors

installed in the outdoor units stop.

The outdoor unit which operates continuously until the end installs the highest priority order of compressor in it.

Cooling operation

There are two patterns of operation.

One is that the operation continues to run until the last one outdoor unit runs due to the detected outdoor

temperature and the other is that all outdoor units stop simultaneously.

2WAY VRF SYSTEM

Control Functions

2

3

4

5

All outdoor units stop simultaneously in the operating range of all outdoor units.

Outdoor

temperature

118.4°F (48°C)

109.4°F (43°C)

59°F (15°C)

50°F (10°C)

The inverter compressor mounted in the outdoor unit which continues to run until the end is short operating

time. The priority order of this inverter compressor is higher than that of other outdoor unit.

Operating range in

all outdoor units

*1

Operating range in each

inverter compressor

*2

Operating range in

all outdoor units

When starting at 109.4°F (43°C) - 118.4°F (48°C),

*1

operation starts from all outdoor operating

ranges.

*2

When starting at 50°F (10°C) - 59°F (15°C),

operation starts from all outdoor operating

ranges.

6

7

8

9

Heating operation

Operation continues to run until the last outdoor unit remains in the operating mode.

1 - 4

3. Compressor Control

3. Compressor Control

2WAY VRF SYSTEM

Control Functions

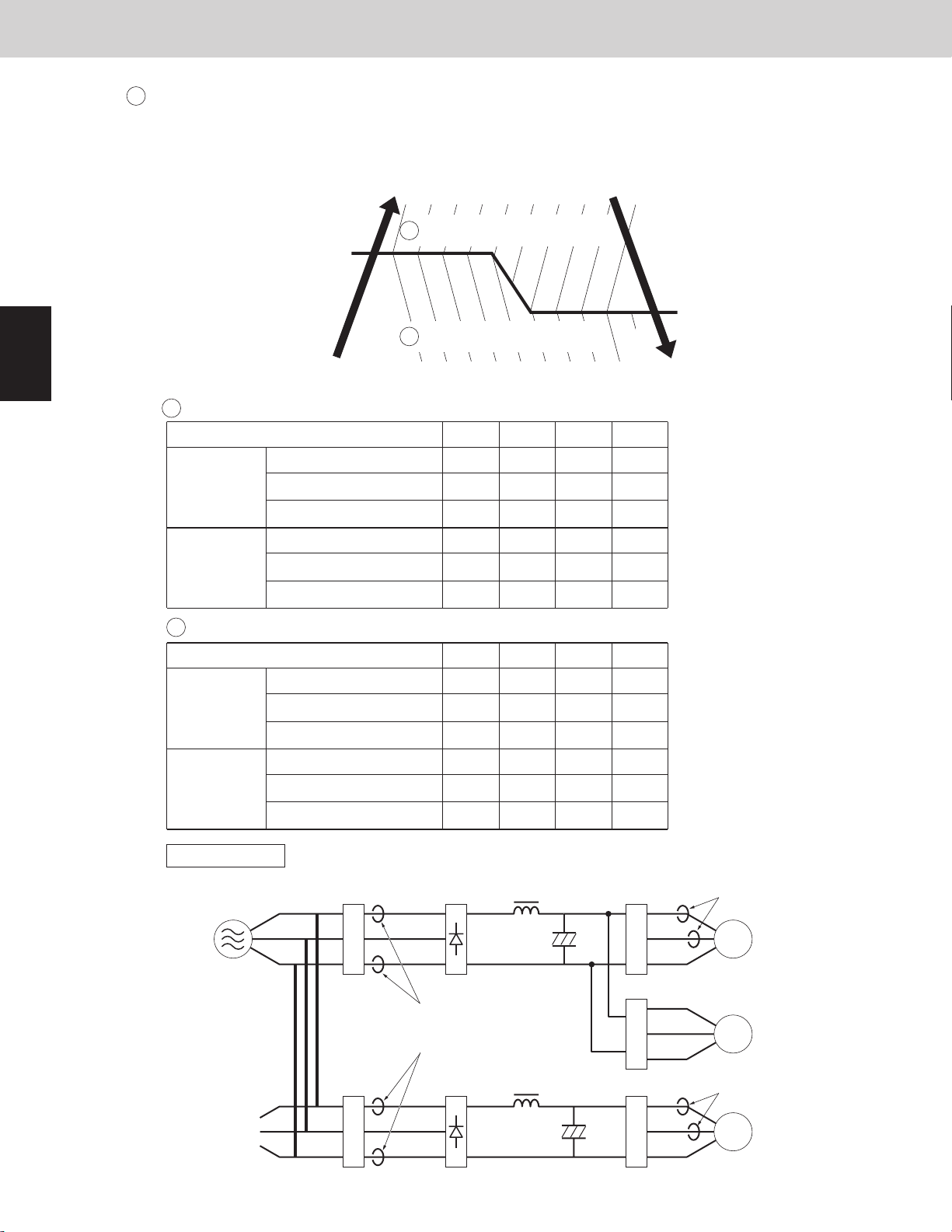

(1) Compressors Mounted in the Outdoor Units

Placement of compressor seen from the top

Type 72, 96 Type 120, 144

2WAY VRF SYSTEM

Control Functions

1st compressor

2nd compressor

Front side

(2) Compressor Selection Rules

1. Priority order of compressors

A.

Decide first priority order of compressor in each outdoor unit.

The compressor that has no trip counter, shorter operating time and smaller number of compressor will be

taken first priority.

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

B. Priority order of compressor trip counter = 0 is higher than that of compressor trip counter = 1.

C. Inverter compressor: Shorter operating time > Longer operating time

D. Compressor that “outdoor unit small address”

installed in outdoor unit

Priority order flow of all compressors

A

First priority order of inverter compressor in each outdoor unit > Other inverter compressor

Compressor that “outdoor unit large address”

>

installed in outdoor unit

Front side

1st compressor

1

2

3

*1

B

C

D

*1 Select first priority order of compressor in each outdoor unit by following method.

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

“Outdoor unit small address”

installed in outdoor unit

Priority order flow of each outdoor unit

Compressor trip counter =0 > Compressor trip counter =1

Shorter operating time > Longer operating time

1st compressor > 2nd compressor

“Outdoor unit large address”

>

installed in outdoor unit

4

5

6

7

8

1 - 5

9

1

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

2

3

2WAY VRF SYSTEM

3. Compressor Control

2. Operating compressors

The compressor with higher priority order starts according to the priority orders described on previous page.

3. Stopping compressors

The compressor with lower priority order stops according to the priority orders described on previous page.

(3) Operation When Starting 2 Compressors Mounted in Outdoor Unit

When necessary capacity gradually increases and one more inverter compressor is additionally started under

the present operating compressor, reduce the compressor frequency to 25Hz temporarily and then start an additional

compressor.

The operation noted above is performed when 1st compressor or 2nd compressor is additionally started.

If necessary capacity is initially higher and two compressors are started simultaneously, the operation noted above

is not performed and both of them are regarded as the target frequency.

(4) Operating Frequency Range of Inverter Compressor

The inverter compressor can operate within the range in the table below.

1

When the high pressure is over 435psi (3.0MPa), the upper limit frequency is 90Hz.

If the high pressure is over 450psi (3.1MPa) and the minimum frequency operation is in progress, the system

2

is stopped. (P25: Pre-trip)

If the low pressure is over 213psi (1.47MPa) during operation of the inverter compressor, the system is stopped.

3

(P27: Pre-trip)

If 2 inverter compressors are simultaneously operating in the same outdoor unit, the frequency of 1st

4

compressor becomes 5Hz lower than that of the 2nd compressor.

Control Functions

4

5

6

7

8

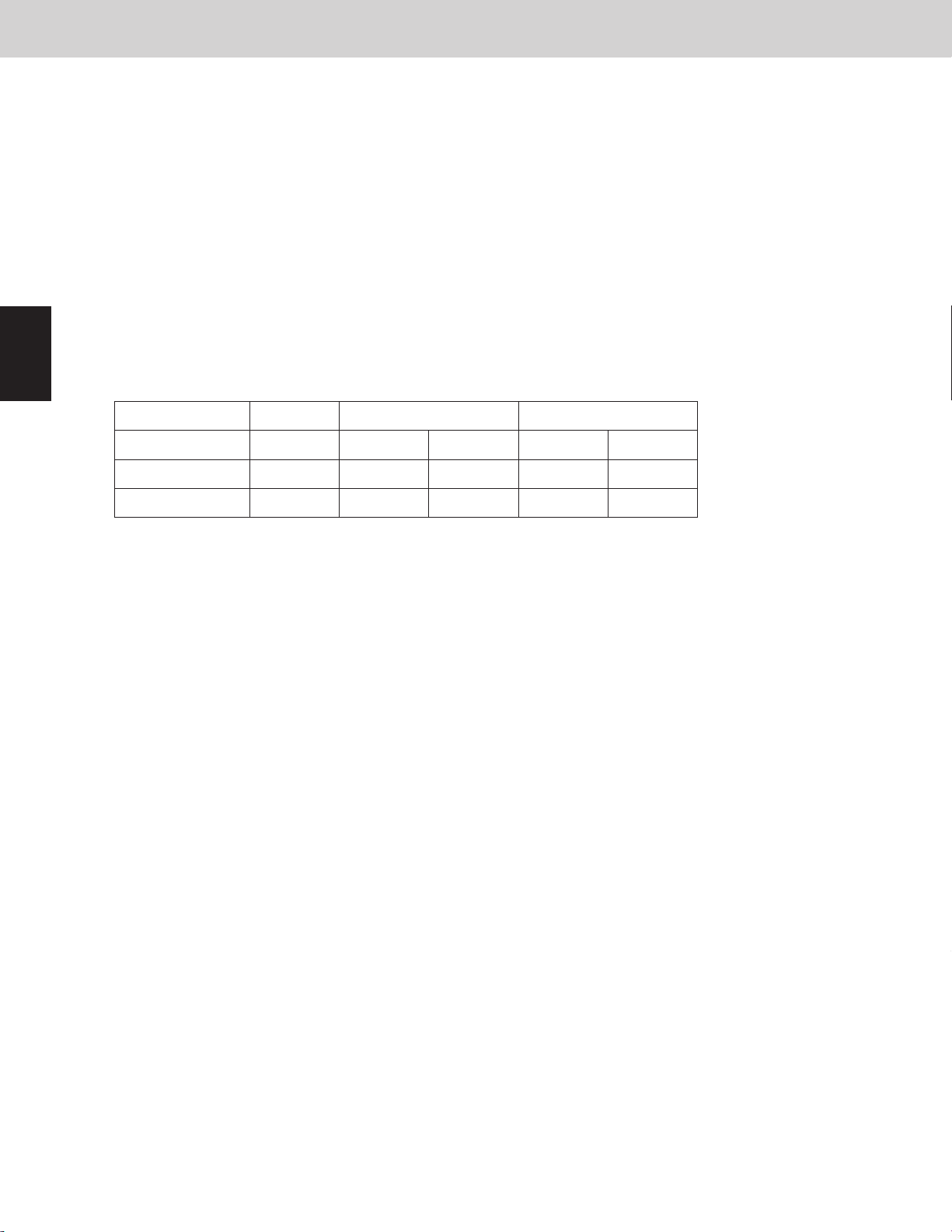

Type of outdoor unit

Minimum frequency (Hz)

Maximum frequency (Hz) 80

The frequency range in the table above is subject to change without notice.*

(5) Forced Stopping of Compressor

Once a compressor stops, it will not start for a period of 3 minutes (3-minute forced OFF).

However, this does not apply when the compressor was forced to stop as the result of a special control operation.

(start control, defrost control, refrigerant oil recovery control, etc.)

72 96 120 144

15 15 15

100

15

80

80

9

1 - 6

2WAY VRF SYSTEM

3. Compressor Control

(6) Capacity Control (Roadmap control)

1 The capacity control by the compressors is performed according to the pressure sensor attached to the outdoor

unit and temperature thermistor attached to the indoor / outdoor unit heat exchanger.

* With roadmap control, the pressure detected by the pressure sensor is converted to saturation temperature

before it is used by microcomputer. This converted temperature is called “pressure sensor temperature”.

2 This control is performed every 30 seconds.

3 Required level of each indoor unit

Required level of indoor unit is calculated by difference between preset temperature in remote controller and

intake temperature of indoor unit (TA), difference between preset discharge air temperature in EEPROM on

indoor unit PCB and discharge air temperature of indoor unit (TF).

Required level has “0” to “30” phases. This level becomes “31” at the test run.

The target temperature of indoor unit heat exchanger is decided according to the maximum required level.

* Target temperature of all indoor units heat exchanger is same value because all indoor units are connected

with the same pressure piping.

4 Denition of evaporation temperature and condensation temperature

● Evaporation temperature (Te):

Shows the lowest temperature among the temperature sensors (E1 or E3) when the indoor unit heat exchanger

is functioning as an evaporator.

● Condensation temperature (Tc):

Shows the highest temperature among the high-pressure saturated temperature in the system.

Control Functions

1

2

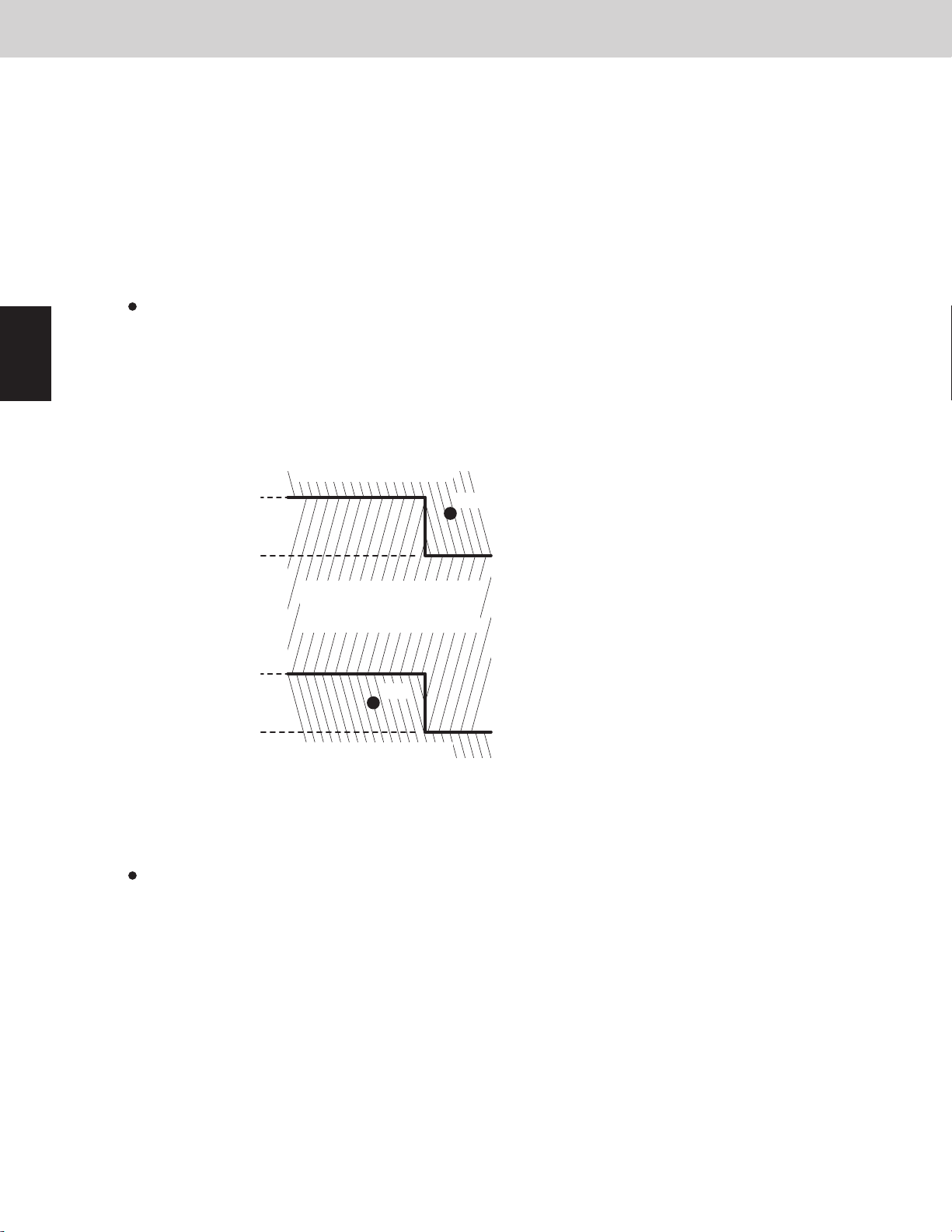

6-1. Evaporation temperature adjustment by roadmap control

The cooling capacity is adjusted with this control. It prevents freezing of the indoor unit's heat exchanger and the

dew to the outside panel of the indoor unit. The capacity is adjusted according to the following gure.

Evaporation temperature area

deg

Compressor capacity increase possible

43.0 (6.1)

42.8 (6.0)

37.4 (3.0)

37.2 (2.9)

* The evaporation temperature area changes depending on the maximum required level of each indoor unit as

shown above.

* Area C is regarded as area B for 6 minutes after compressor starts.

* When the system operates in a minimum capacity, the system will continue operating for at least 6 minutes if the

evaporation temperature area is area C.

* The evaporation temperature is not adjusted while specially controlling defrosting and the oil recovery, etc.

* The evaporation temperature is not adjusted when there are one or more indoor units that select the test run.

If one or more indoor units are selected into test run, the system doesn't stop in all states except alarm appearing.

* The test run will nish automatically in about one hour.

Compressor capacity

increase prohibited

Compressor capacity decrease

60.8 (16.0)

55.4 (13.0)

Area A

Area B

Area C

46.4 (8.0)

0

Max. required level

15

51.8 (11.0)

unit: °F (°C)

42.8 (6.0)

37.4 (3.0)

30

3

4

5

6

7

8

1 - 7

9

1

2

3

4

3. Compressor Control

6-2. Condensation temperature adjustment by roadmap control

The area B target temperature is different due to cooling and heating operation.

Target lower temperature

Cooling 127.4°F (53.0°C) 131.0°F (55.0°C)

Heating 118.4°F (48.0°C) 123.8°F (51.0°C)

Cooling mode

1

The purpose of this control at cooling

is to prevent abnormal high-pressure.

・Standard setting (at the shipment)

°F (°C) °F (°C)

PX=136.4

(58.0)

136.2

(57.9)

131.2

(55.1)

131.0

(55.0)

127.4

(53.0)

127.2

(52.9)

Thermostat

OFF

Compressor

capacity

decrease

Compressor

capacity

increase

prohibited

Compressor

capacity

increase

possible

Area D

Area C

Area B

Area A

(Tc_tgt_min)

2

PX=136.4

Heating mode

Heating capacity is adjusted with this control.

It also prevents abnormal high-pressure simultaneously.

The capacity is controlled in the following diagram.

(58.0)

136.2

(57.9)

124.0

(51.1)

123.8

(51.0)

118.4

(48.0)

118.2

(47.9)

Target upper temperature

(Tc_tgt_max)

Thermostat

OFF

Compressor

capacity

decrease

Compressor

capacity

increase

prohibited

Compressor

capacity

increase

possible

Area D

Area C

Area B

Area A

95.0

(35.0)

2WAY VRF SYSTEM

Control Functions

°F (°C)

123.8

(51.0)

118.4

109.4

(43.0)

104.9

(40.5)

(48.0)

5

6

7

8

91.4

(33.0)

15 300

Max. required level

* PX is usually xed to 136.4°F (58°C). If the high pressure goes up rapidly after the compressor starts, the

system experiences urgent stop. The next time the system will start with lower PX.

* In the area B, the compressor capacity changes depending on the refrigerant condition.

* When the system operates in a minimum capacity, the system will continue operating for at least 6 minutes

if the condensation temperature area is area C.

* The condensation temperature is not adjusted when there are one or more indoor units that select the test run.

Limit pressure adjustment function

Operation pressure is able to be adjusted for existing old piping.

If area shift function is set, values below shift.

EEPROM setting in main outdoor unit

CODE : 4B

Setting No. Limited pressure PX °F (°C) Cooling mode Heating mode

Tc_tgt_min Tc_tgt_max Tc_tgt_min Tc_tgt_max

0 478.5psi (3.3MPa) 126.5 (52.5) 116.6 (47.0) 120.2 (49.0) 116.6 (47.0) 118.4 (48.0)

1 No use - - - - 2 551.1psi (3.8MPa) 136.4 (58.0) 127.4 (53.0) 131.0 (55.0) 118.4 (48.0) 123.8 (51.0)

3 No use - - - - -

9

1 - 8

2WAY VRF SYSTEM

3. Compressor Control

6-3. Protection Control

1

Compressor discharge temperature protection

The compressor capacity is controlled according to the table below.

*Discharge temperature that is used for this control is the highest temperature among all compressors.

Discharge temp.

°F (°C)

222.8

(106)

221.0 (105)

219.2 (104)

217.4 (103)

213.8 (101)

2

Abnormal low pressure protection

The compressor capacity is controlled according to the table below.

Low pressure

psi (MPa)

36.3 (0.25)

29.0 (0.20)

24.7 (0.17)

Stop

If this temperature is detected at regular intervals, alarm appears.

Compressor

capacity

decrease

Compressor capacity increase prohibited

Compressor capacity increase possible

No restriction

Capacity goes up slowly

Capacity increase prohibited

Capacity goes down

Capacity goes down 2.0 hp

Capacity goes down 1.0 hp

Capacity goes down 0.5 hp

Control Functions

hp = horsepower

1

2

3

4

5

6

7

8

1 - 9

9

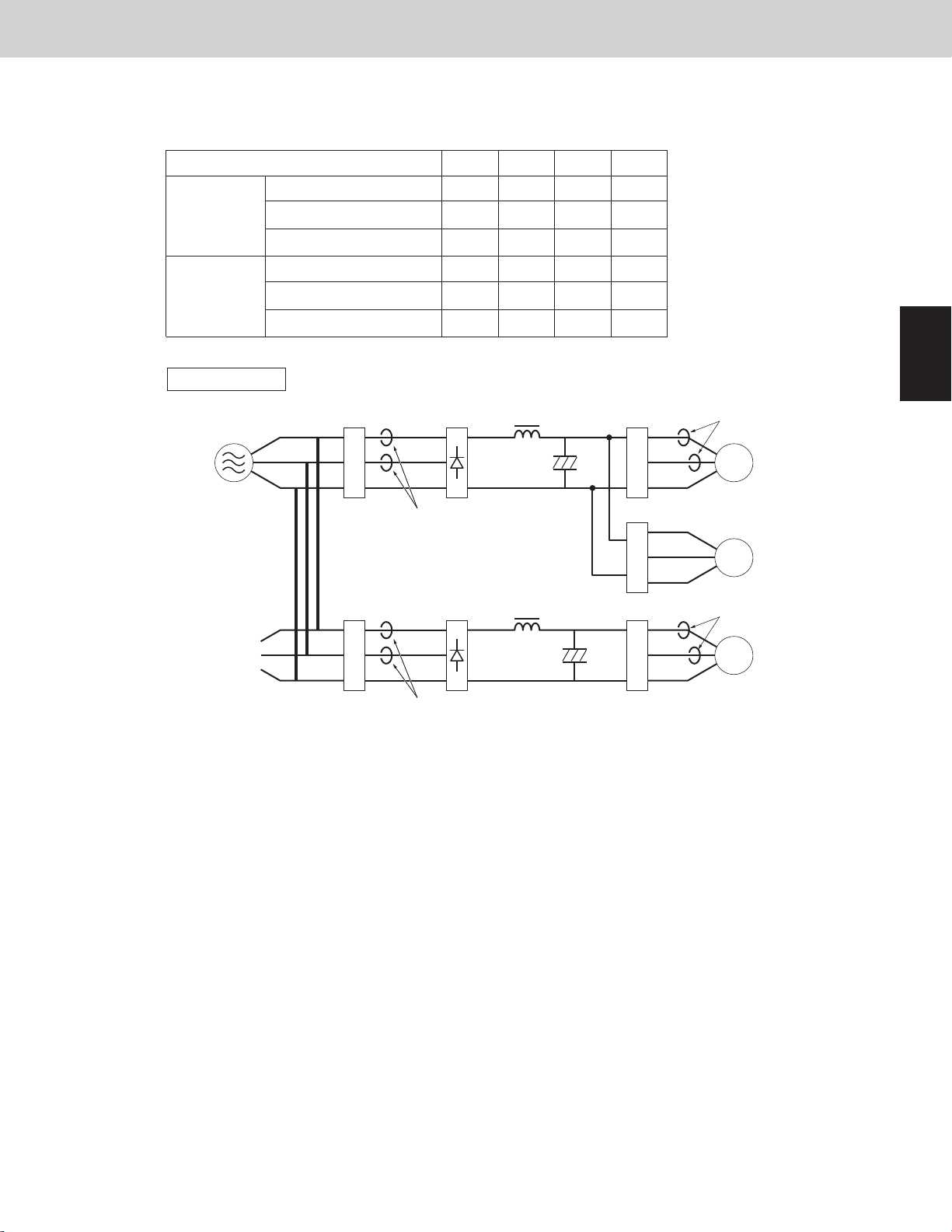

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

Inverter layout

Noise

filter

R

S

T

U

V

W

U

V

W

U

V

W

R

S

T

Power

supply

Primary CT1

Primary CT2

Secondary CT1

Secondary CT2

Diode

bridge

IPM (CM)

1st compressor

Fan motor

U-72ME2U94 / U-96ME2U94 / U-120ME2U94 / U-144ME2U94

Use the same values of 1st compressor and 2nd compressor.

unit: Ampere

Current limit 1

Maximum current 1 H

Primary

Maximum current 1 L 15.5

19.5 19.5 19.5 19.5

72 96 120 144

15.5

16.5

15.5

16.5 16.5 16.5

15.5

Current limit 2

Maximum current 2 H

Secondary

Maximum current 2 L 13.1

16.6 23.0 16.6 16.6

19.5

14.1

13.1

14.1 20.5 14.1

13.1

Type of outdoor unit

Noise

filter

Diode

bridge

IPM (CM)

IPM (FN)

2nd compressor

3. Compressor Control

3

Current protection

This restriction protects the compressor and controls the compressor electric current simultaneously.

The current limitation value changes to “normal status” and “overload status” according to the outdoor

temperature.

The primary and secondary current values of 1st compressor or 2nd compressor are measured.

2WAY VRF SYSTEM

Control Functions

1

2

3

4

Outdoor temperature

U-72ME2U9 / U-96ME2U9 / U-120ME2U9 / U-144ME2U9

A Normal status: Use the same values of 1st compressor and 2nd compressor.

Primary

Secondary

Overload status: Use the same values of 1st compressor and 2nd compressor.

B

114.8°F (46°C)

Type of outdoor unit

Type of outdoor unit

Current limit 1

Maximum current 1 H

Maximum current 1 L24

Current limit 2

Maximum current 2 H

Maximum current 2 L24

Current limit 1

B

A

Current table <Overload>

Current table <Normal>

72 96 120 144

30 43 30 30

25 38 22.5

30 44 30 30

25 40 25

72 96 120 144

30 43 30 30

37

39

22.5

21.5

25

24

21.5

24

Outdoor temperature

109.4°F (43°C)

unit: Ampere

unit: Ampere

5

6

7

8

Primary

Secondary

Inverter layout

Power

supply

R

S

T

Maximum current 1 H

Maximum current 1 L24

Current limit 2

Maximum current 2 H

Maximum current 2 L24

Noise

R

S

T

Noise

filter

Primary CT1

Primary CT2

filter

25 38 21

30 44 30 30

25 40 23

Diode

bridge

Diode

bridge

37

39

21

20

23

22

20

22

IPM (CM)

U

V

W

IPM (FN)

U

V

W

IPM (CM)

U

V

W

Secondary CT1

1st compressor

Fan motor

Secondary CT2

2nd compressor

9

1 - 10

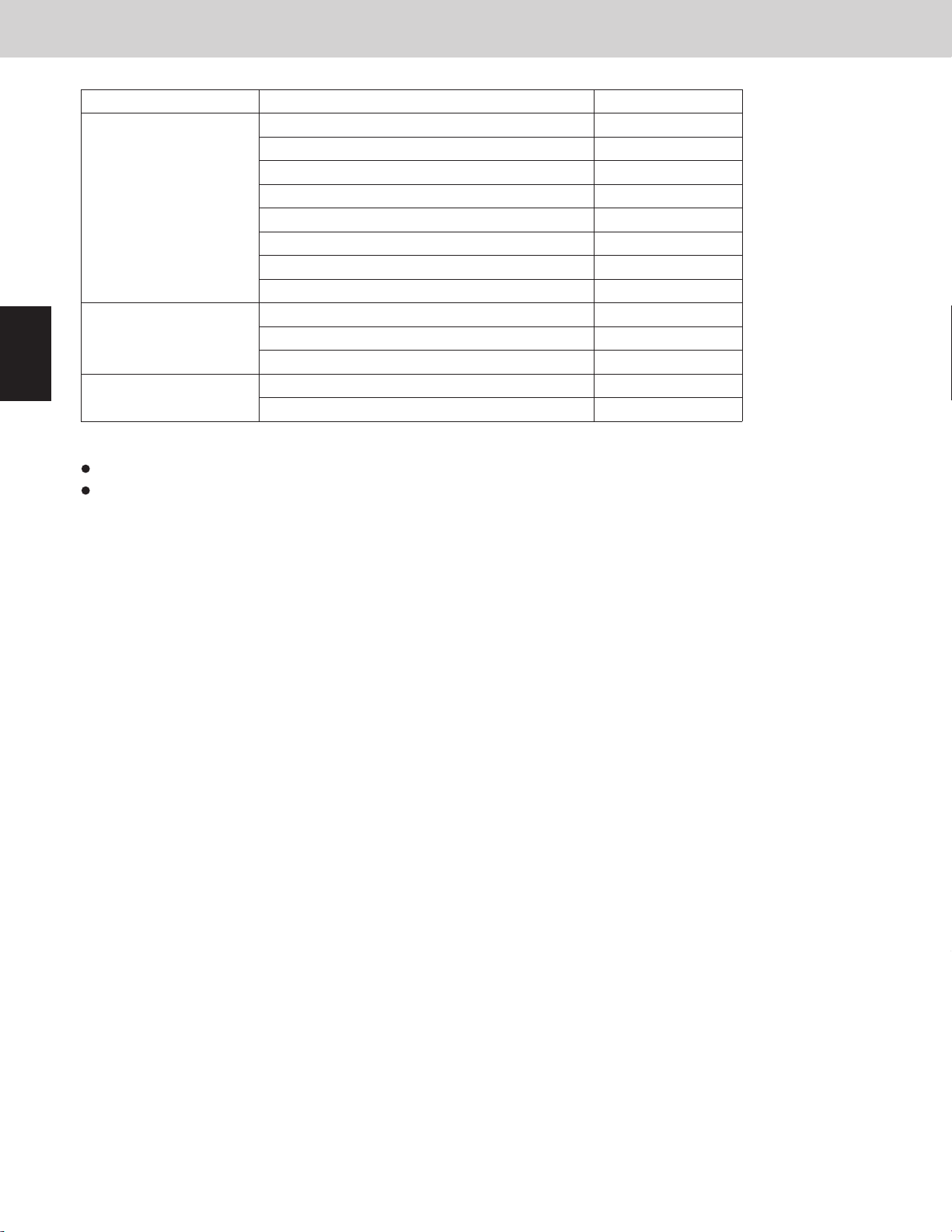

2WAY VRF SYSTEM

Control Functions

3. Compressor Control

3. Compressor Control

U-72ME2U94 / U-96ME2U94 / U-120ME2U94 / U-144ME2U94

Use the same values of 1st compressor and 2nd compressor.

Type of outdoor unit

Current limit 1

72 96 120 144

19.5 19.5 19.5 19.5

2WAY VRF SYSTEM

Control Functions

unit: Ampere

Primary

Secondary

Inverter layout

Power

supply

R

S

T

Maximum current 1 H

Maximum current 1 L 15.5

Current limit 2

Maximum current 2 H

Maximum current 2 L 13.1

Noise

filter

R

S

T

Primary CT1

Noise

filter

16.5 16.5 16.5

16.6 23.0 16.6 16.6

14.1 20.5 14.1

Diode

bridge

Diode

bridge

15.5

19.5

16.5

15.5

14.1

13.1

15.5

13.1

IPM (CM)

U

V

W

IPM (FN)

U

V

W

IPM (CM)

U

V

W

Secondary CT1

1st compressor

Fan motor

Secondary CT2

2nd compressor

1

2

3

4

Primary CT2

5

6

7

8

1 - 11

9

1

4. Special Control

2WAY VRF SYSTEM

Control Functions

2WAY VRF SYSTEM

Control Functions

4. Special Control

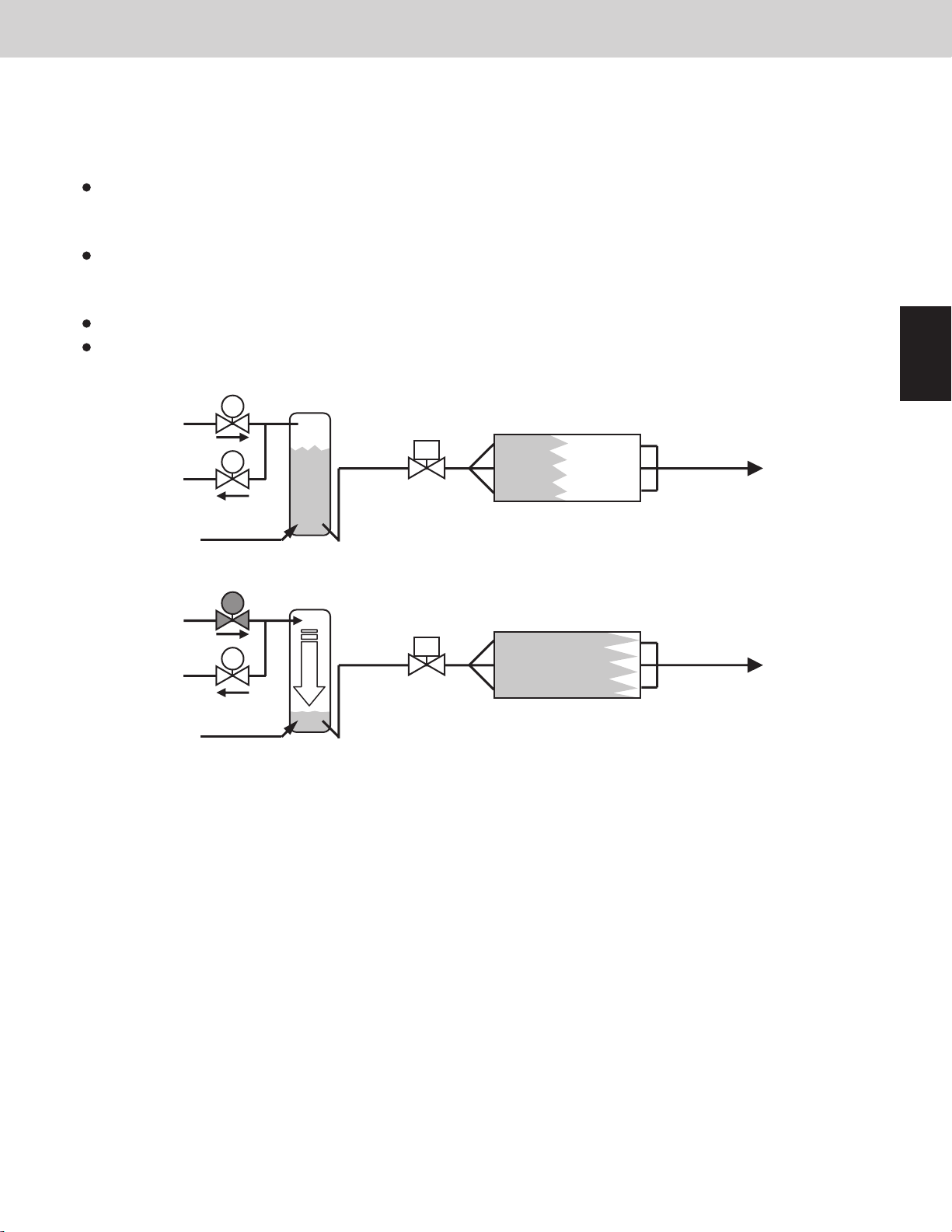

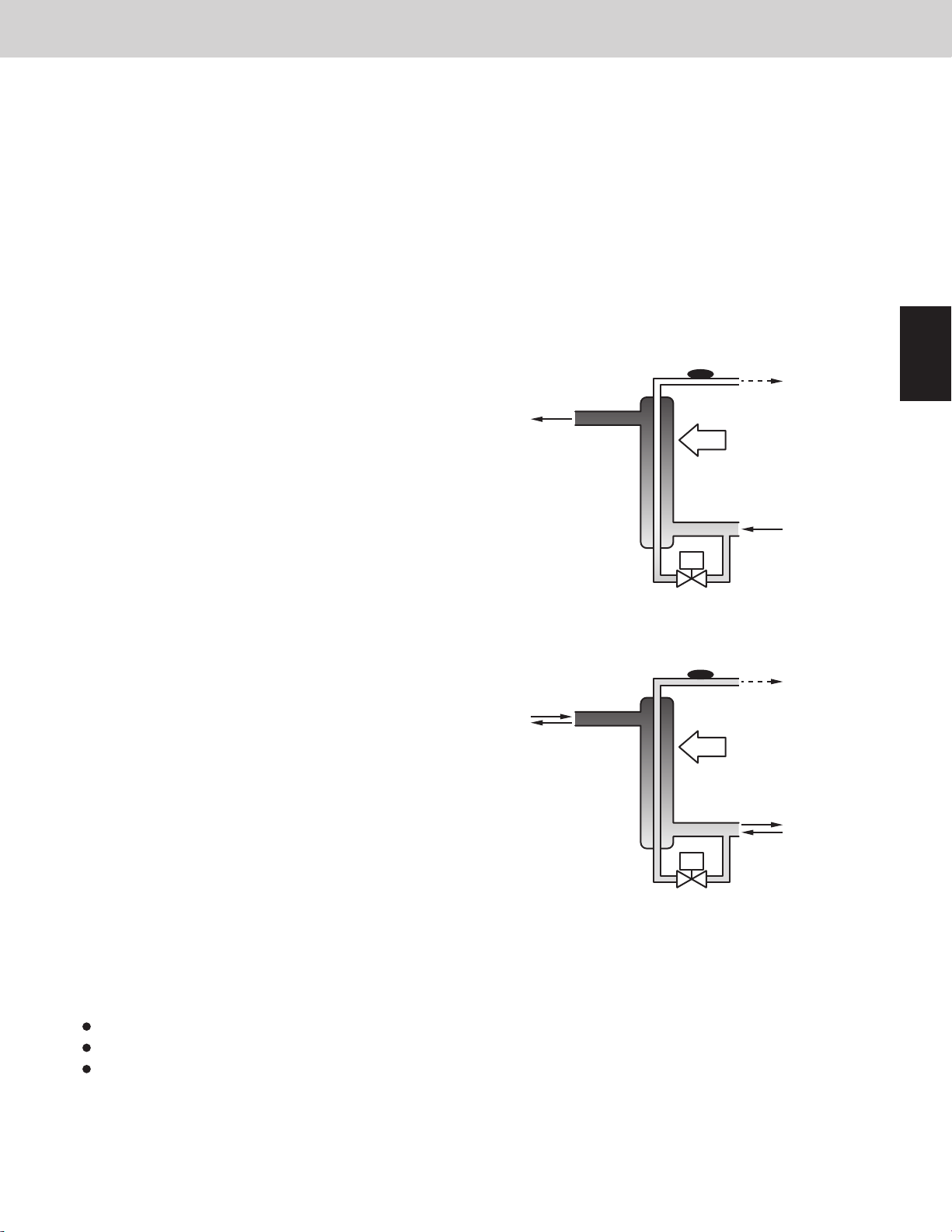

(3) Refrigerant Control Valve [RCV]

The main purpose of this valve is to adjust the flow of refrigerant (refrigerant volume).

When the outdoor unit receives a sign of refrigerant shortage, the valve opens and refrigerant is supplied from the

receiver tank to the system.

This valve turns ON when the evaporator is refrigerant shortage.

The heat exchanger of indoor unit is the evaporator in cooling mode.

The heat exchanger of outdoor unit is the evaporator in heating mode.

This valve turns OFF when the excessive amount of refrigerant is in the condenser.

The heat exchanger of indoor unit is the condenser in heating operation.

The heat exchanger of outdoor unit is the condenser in cooling operation.

This valve turns OFF when the outdoor unit is stopped.

This valve might turn ON when a special control is in progress.

Evaporator

RBV

RCV

LP

HP

Refrigerant shortage in evaporator.

Receiver tank holds refrigerant.

Two-phase

flow

Evaporator

RBV

RCV

LP

HP

Sufficient refrigerant is supplied to evaporator.

High pressure from RCV pushes the liquid refrigerant out of the receiver tank.

ON

Two-phase flow

2

3

4

5

2WAY VRF SYSTEM

4. Output of PCB

Control Functions

Solenoid valve

Expansion valve

Crankcase heater

(1) 4-way Valve [20S]

This valve turns OFF at cooling mode, and turns ON at heating mode.

This valve turns OFF at defrosting control.

* When the outdoor unit stops, the 4-way valve maintains in the same state as before.

(2) SAVE Valve [SAVE]

● This valve turns ON for 5 seconds before the inverter compressor starts.

After the inverter compressor starts, the valve turns ON for 10 seconds. Then it turns OFF.

● This valve turns ON for 30 seconds after the outdoor unit stops. Then it turns OFF.

● This valve turns ON when high pressure sensor detects 496psi (3.42MPa) to prevent abnormal pressure.

This valve turns OFF when the high pressure goes down below 481.5psi (3.32MPa).

● This valve might turn ON when the system capacity is excessive although the inverter compressor operates at

Min. frequency.

● This valve turns ON in the following status :

(Compressor discharge temperature - High pressure saturation temperature) < 9deg F (5deg C)

● Under control of 4-way valve adjustment control

● This valve turns ON when low pressure sensor goes down 24.7psi (0.17MPa) to prevent abnormal pressure.

This valve turns OFF when low pressure sensor increase 29psi (0.20MPa) or over.

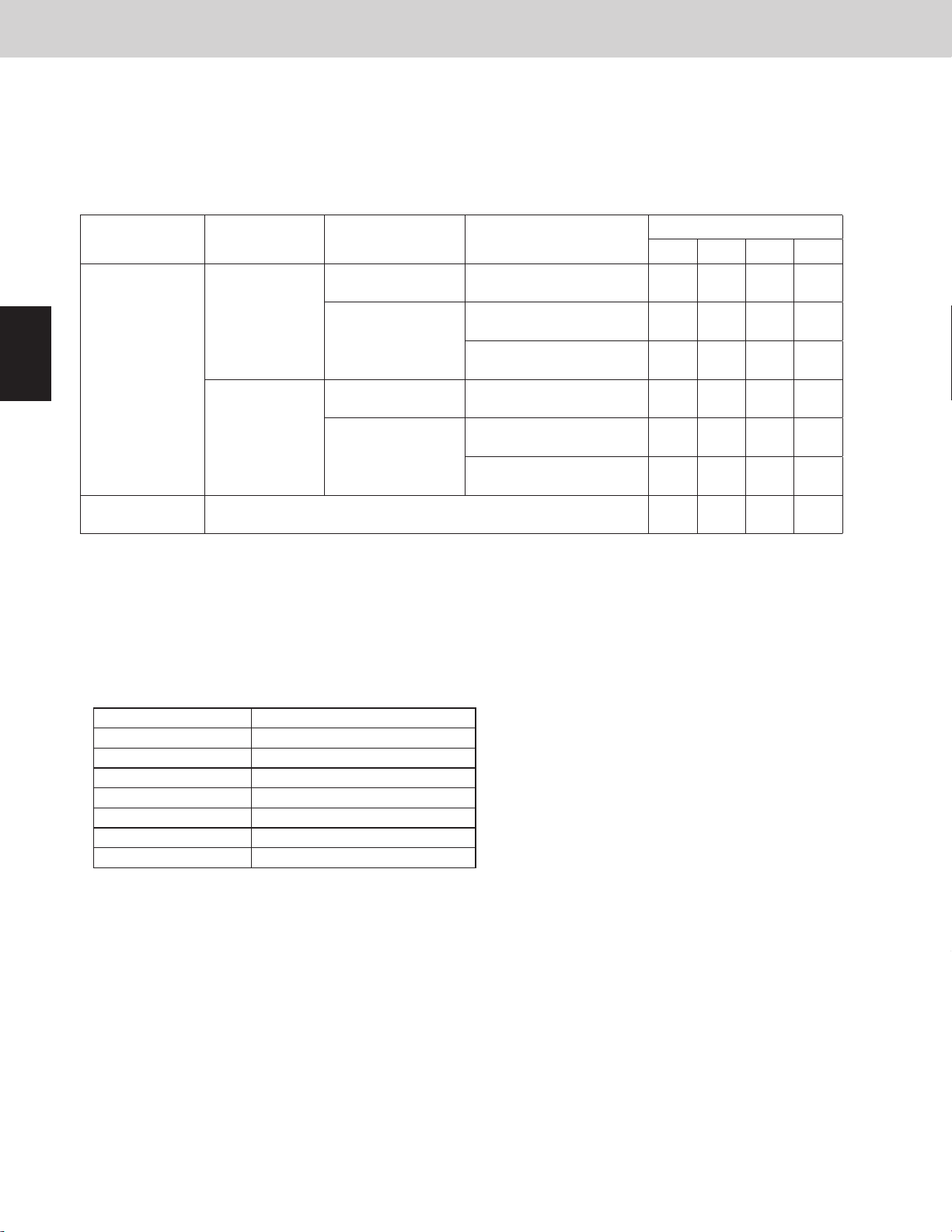

Items Remarks Indication on PCB

20S

SAVE

RCV

RBV

ORVR

BPV

ACV

O

2

MOV1

MOV2

MOV4

CH1

CH2

4-way valve

Save valve

Refrigerant control valve

Refrigerant balance valve

Oil recovery valve

By-pass valve

Accumulator valve

O

2 valve

MOV for heat exchanger 1

MOV for heat exchanger 2

SC circuit expansion valve

Crankcase heater for 1st compressor

Crankcase heater for 2nd compressor

6

7

8

9

1 - 12

2WAY VRF SYSTEM

2WAY VRF SYSTEM

Control Functions

4. Special Control

4. Output of PCB

(3) Refrigerant Control Valve [RCV]

The main purpose of this valve is to adjust the flow of refrigerant (refrigerant volume).

When the outdoor unit receives a sign of refrigerant shortage, the valve opens and refrigerant is supplied from the

receiver tank to the system.

This valve turns ON when the evaporator is refrigerant shortage.

The heat exchanger of indoor unit is the evaporator in cooling mode.

The heat exchanger of outdoor unit is the evaporator in heating mode.

This valve turns OFF when the excessive amount of refrigerant is in the condenser.

The heat exchanger of indoor unit is the condenser in heating operation.

The heat exchanger of outdoor unit is the condenser in cooling operation.

This valve turns OFF when the outdoor unit is stopped.

This valve might turn ON when a special control is in progress.

RCV

HP

Evaporator

Control Functions

1

LP

HP

LP

RBV

RCV

RBV

Two-phase

flow

Refrigerant shortage in evaporator.

Receiver tank holds refrigerant.

ON

Evaporator

Two-phase flow

Sufficient refrigerant is supplied to evaporator.

High pressure from RCV pushes the liquid refrigerant out of the receiver tank.

2

3

4

5

6

1 - 13

7

8

9

1

4. Special Control

2WAY VRF SYSTEM

Control Functions

2WAY VRF SYSTEM

Control Functions

4. Special Control

(5) Oil Recovery Valve [ORVR]

The purpose of this valve is to recover oil from the oil separator of its own outdoor unit or balance tube to the

compressor.

This valve turns ON when the oil level of the compressor is “0” or “1”.

This valve turns ON for 2 minutes after the compressor starts.

This valve is always OFF when outdoor unit is stopped.

* For oil level of compressor, see “7. Oil Control”.

This valve turns ON when recovering refrigerant from the stopped outdoor unit.

(6) By-pass Valve [BPV]

This valve is for pushing the oil in the balance piping into other outdoor units.

When the compressor oil level of its own outdoor unit is in the “2” or “1”, this valve turns ON when the oil level “0”

is detected in other outdoor units.

When the compressor itself is stopped with a full of refrigerant, this valve turns ON.

Then the refrigerant is supplied to the other operating outdoor units.

* This valve turns ON for 10 seconds and turns OFF for 20 seconds.

This operation is repeated while oil is supplied to others.

* For more information on oil level of compressor, see “7. Oil Control”.

(7) Accumulator Valve [ACV]

The purpose of this valve is to recover oil and refrigerant from the accumulator

to the compressor.

This valve turns OFF when the compressor operation just started.

This valve turns ON when the compressor is warmed up.

This valve turns ON while the oil recovery among the systems and defrost

control are in progress.

This valve turns ON while the MOV4 is operating.

(8) O2 Valve [O2*]

ACV

Accumulator

This valve works when the outdoor unit receives signal of the refrigerant leakage from the indoor unit.

*O

2

valve is the field supply parts.

The indoor unit that transmits the signal of the refrigerant leakage gives “P14”alarm.

To activate this function, it is necessary to set it to EEPROM on the main outdoor PCB and indoor PCB.

EEPROM setting in main outdoor unit

CODE: C1

Setting No

Setting No

0

0

1

1

2

This function invalid (factory preset mode)

This valve is turned OFF when the system is normal.

This valve is turned ON when the outdoor unit receives signal from the indoor unit

This valve is turned ON when the system is normal.

This valve is turned OFF when the outdoor unit receives signal from the indoor unit

EEPROM setting in indoor unit

CODE: 0B

Function of EXCT plug short-circuit

Indoor unit does thermostat OFF

(factory preset mode)

Indoor unit gives “P14”alarm and transmits the refrigerant leakage signal.

2

3

4

5

2WAY VRF SYSTEM

4. Output of PCB

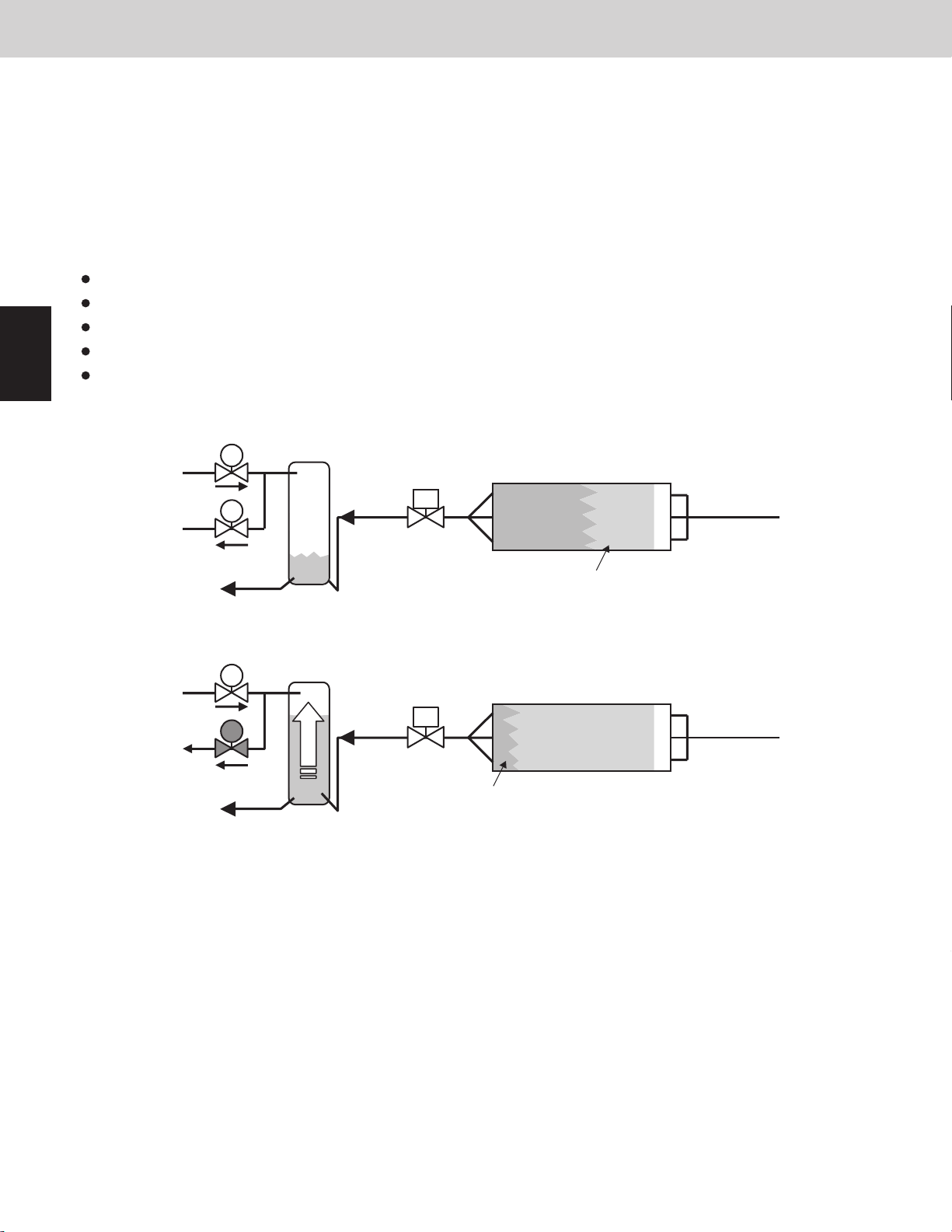

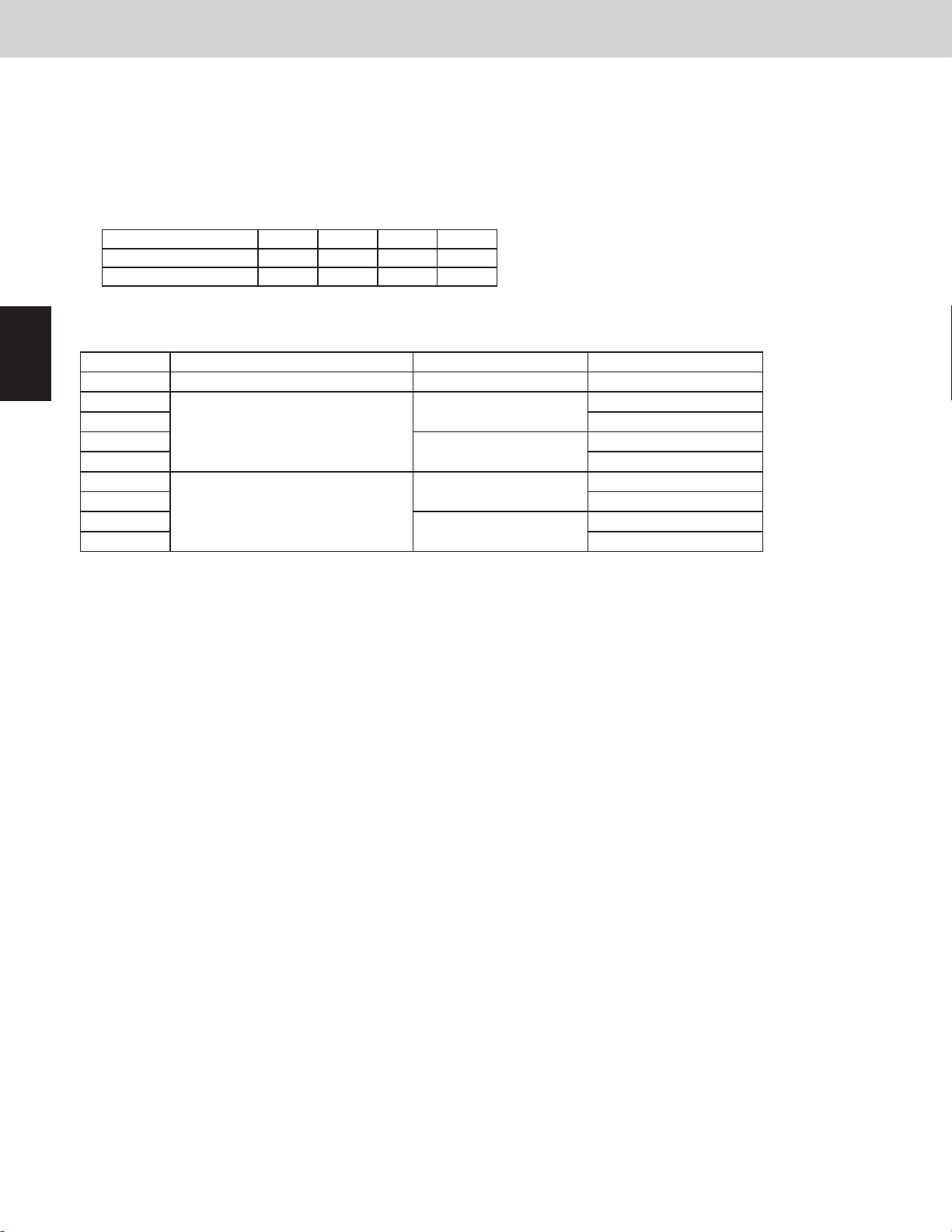

(4) Refrigerant Balance Valve [RBV]

The main purpose of this valve is to adjust the flow of refrigerant (refrigerant volume) in the evaporator.

When the outdoor unit receives a sign of overcharged refrigerant, the valve opens and refrigerant is recovered at the

receiver tank.

This valve also turns ON in order to recover refrigerant at the outdoor unit after heating operation is stopped.

* It is possible to set the RBV to valid or invalid by the outdoor unit EEPROM settings.

Initial setting is invalid.

* This valve is never turned ON with the RCV at the same time.

This valve turns ON for 20 seconds after heating operation is stopped, and then turns OFF.

This valve turns OFF when an abnormal drop in compressor discharge gas temperature is detected.

This valve turns OFF when an abnormal drop in compressor suction gas temperature is detected.

After the valve turns from ON to OFF, it will not turn ON again for 15 minutes.

This valve turns ON when low pressure sensor decreases 24.7psi (0.17MPa) at stopped system.

This valve turns OFF when low pressure sensor increases 29psi (0.20MPa).

RCV

HP

RBV

LP

Receiver tank holds a low refrigerant volume.

RCV

HP

RBV

LP

ON

Condenser

Liquid flow

Two-phase flow

Over charge condition

Condenser

Two-phase flow

Liquid flow

Control Functions

6

7

8

9

Appropriate condition

Refrigerant gas in the top of receiver tank is absorbed into low pressure side.

1 - 14

2WAY VRF SYSTEM

2WAY VRF SYSTEM

Control Functions

4. Special Control

4. Output of PCB

Control Functions

(5) Oil Recovery Valve [ORVR]

The purpose of this valve is to recover oil from the oil separator of its own outdoor unit or balance tube to the

compressor.

This valve turns ON when the oil level of the compressor is “0” or “1”.

This valve turns ON for 2 minutes after the compressor starts.

This valve is always OFF when outdoor unit is stopped.

* For oil level of compressor, see “7. Oil Control”.

This valve turns ON when recovering refrigerant from the stopped outdoor unit.

(6) By-pass Valve [BPV]

This valve is for pushing the oil in the balance piping into other outdoor units.

When the compressor oil level of its own outdoor unit is in the “2” or “1”, this valve turns ON when the oil level “0”

is detected in other outdoor units.

* This valve turns ON for 10 seconds and turns OFF for 20 seconds.

This operation is repeated while oil is supplied to others.

* For more information on oil level of compressor, see “7. Oil Control”.

When the compressor itself is stopped with a full of refrigerant, this valve turns ON.

Then the refrigerant is supplied to the other operating outdoor units.

1

2

(7) Accumulator Valve [ACV]

The purpose of this valve is to recover oil and refrigerant from the accumulator

to the compressor.

This valve turns OFF when the compressor operation just started.

This valve turns ON when the compressor is warmed up.

This valve turns ON while the oil recovery among the systems and defrost

control are in progress.

This valve turns ON while the MOV4 is operating.

(8) O2 Valve [O2*]

This valve works when the outdoor unit receives signal of the refrigerant leakage from the indoor unit.

The indoor unit that transmits the signal of the refrigerant leakage gives “P14”alarm.

To activate this function, it is necessary to set it to EEPROM on the main outdoor PCB and indoor PCB.

EEPROM setting in main outdoor unit

CODE: C1

Setting No

0

1

2

EEPROM setting in indoor unit

CODE: 0B

Setting No

0

1

This function invalid (factory preset mode)

This valve is turned OFF when the system is normal.

This valve is turned ON when the outdoor unit receives signal from the indoor unit

This valve is turned ON when the system is normal.

This valve is turned OFF when the outdoor unit receives signal from the indoor unit

Function of EXCT plug short-circuit

Indoor unit does thermostat OFF

Indoor unit gives “P14”alarm and transmits the refrigerant leakage signal.

valve is the field supply parts.

*O

2

(factory preset mode)

Accumulator

ACV

3

4

5

6

7

8

1 - 15

9

1

4. Special Control

2WAY VRF SYSTEM

Control Functions

2WAY VRF SYSTEM

Control Functions

4. Special Control

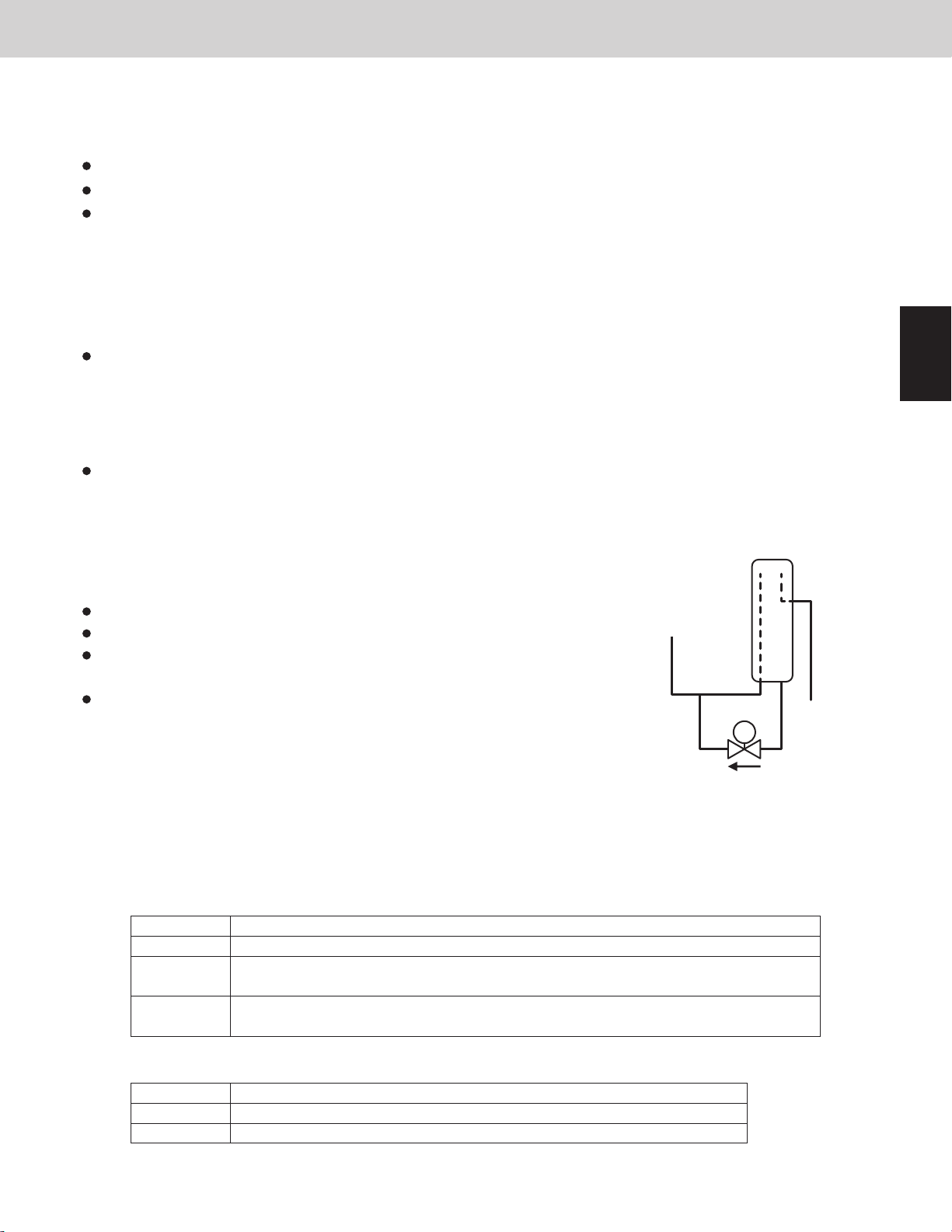

(10) SC Circuit Expansion Valve [MOV4]

During cooling operation, the liquid refrigerant which condenses at the outdoor unit heat exchanger flows into

the receiver tank, and SC (sub-cooling) approaches 32°F (0°C).

When SC is small and the length of the tubing connecting the indoor and outdoor units is long, the refrigerant

flow in the indoor unit will be reduced significantly.

To prevent this trouble from occurring, MOV4 operates so as to increase super-cooling in the double tube coil.

10-1.

(11) Crankcase Heater Control [CH1, CH2]

When the compressor stops, the crankcase heater of its own compressor is turned ON in the following conditions.

Cooling SC Control

During heating operation, MOV4 operates so as to

improve the refrigerant flow of the outdoor unit heat

exchanger and the system.

MOV4 controls refrigerant flow volume so that it will

not flow back to the compressor in the liquid state.

MOV4 controls the difference of temperature

between the SCG thermistor and low pressure

saturated temperature to 5.4deg F (3deg C).

10-2. Heating SC Control

When the discharge temperature increases to

194°F (90°C) or more, MOV 4 opens to 100 pulses

to cool down the compressor.

Then, the MOV 4 operates according to the state of

the discharge temperature between 20 ~ 480 pulses.

This operation takes priority over SC control.

This operation is continued until discharge

temperature decreases to 176°F (80°C) or less.

10-3. Discharge Temperature Control of Compressor

MOV4 controls the difference of temperature between the SCG thermistor and low pressure saturated temperature

to 5.4deg F ~ 9deg F (3deg C ~ 5deg C).

Thermistor (SCG)

MOV4 (SH control)

Gas refrigerant

returns to accumulator.

Liquid refrigerant

Refrigerant on the inner side

evaporates, cooling the liquid

refrigerant on the outer side.

Liquid refrigerant

Thermistor (SCG)

MOV4 (Discharge temperature control of compressor)

Liquid refrigerant

returns to accumulator.

Liquid refrigerant

Does not fully evaporate,

resulting in liquid back-up.

Liquid refrigerant

When the discharge temperature ≤ the outdoor air temperature + 27deg F (+15deg C)

When the outdoor air temperature ≤ 68°F (20°C)

When the compressor stops and 30 minutes later.

2WAY VRF SYSTEM

4. Output of PCB

(9) MOV for Heat Exchanger [MOV1, MOV2]

9-1. Type of expansion valves

MOV1 : For upper side heat exchanger

MOV2 : For lower side heat exchanger

9-2. Power Initialization

If no indoor units have started (even once) after the power supply to the outdoor unit, the MOV holds the 480

pulses (fully open).

*When the indoor unit receives the signal for operation request from the control equipment, the pulse turns

other than the 480 pulses (regardless of the thermostat ON/OFF or operating ON/OFF).

It is necessary to switch ON the power supply again if the 480 pulses are required.

9-3. Control of expansion valves

Expansion valves for heat exchanger control according to the operation mode.

Control Functions

2

3

4

5

6

Stop

0

0

Cooling HeatingMode of system

Operation

480

480

Stop

0

0

Operation

0 ~ 480

0 ~ 480

Compressor

MOV1 (pulse)

MOV2 (pulse)

* If any one compressor in the outdoor unit is operating at heating mode, expansion valves perform SH

control.

SH control adjusts the difference of temperature between the liquid and gas temperature to

-1.8deg F ~ 9deg F (-1deg C ~ 5deg C).

Stop

Stop

0

0

7

8

9

1 - 16

2WAY VRF SYSTEM

2WAY VRF SYSTEM

Control Functions

4. Special Control

4. Output of PCB

Control Functions

(10) SC Circuit Expansion Valve [MOV4]

10-1.

Cooling SC Control

During cooling operation, the liquid refrigerant which condenses at the outdoor unit heat exchanger flows into

the receiver tank, and SC (sub-cooling) approaches 32°F (0°C).

When SC is small and the length of the tubing connecting the indoor and outdoor units is long, the refrigerant

flow in the indoor unit will be reduced significantly.

To prevent this trouble from occurring, MOV4 operates so as to increase super-cooling in the double tube coil.

MOV4 controls the difference of temperature between the SCG thermistor and low pressure saturated temperature

to 5.4deg F ~ 9deg F (3deg C ~ 5deg C).

10-2. Heating SC Control

During heating operation, MOV4 operates so as to

improve the refrigerant flow of the outdoor unit heat

exchanger and the system.

MOV4 controls refrigerant flow volume so that it will

not flow back to the compressor in the liquid state.

MOV4 controls the difference of temperature

between the SCG thermistor and low pressure

saturated temperature to 5.4deg F (3deg C).

10-3. Discharge Temperature Control of Compressor

When the discharge temperature increases to

194°F (90°C) or more, MOV 4 opens to 100 pulses

to cool down the compressor.

Then, the MOV 4 operates according to the state of

the discharge temperature between 20 ~ 480 pulses.

This operation takes priority over SC control.

This operation is continued until discharge

temperature decreases to 176°F (80°C) or less.

Liquid refrigerant

Liquid refrigerant

Thermistor (SCG)

Refrigerant on the inner side

evaporates, cooling the liquid

refrigerant on the outer side.

MOV4 (SH control)

Thermistor (SCG)

Does not fully evaporate,

resulting in liquid back-up.

1

Gas refrigerant

returns to accumulator.

2

Liquid refrigerant

3

4

Liquid refrigerant

returns to accumulator.

5

Liquid refrigerant

MOV4 (Discharge temperature control of compressor)

(11) Crankcase Heater Control [CH1, CH2]

When the compressor stops, the crankcase heater of its own compressor is turned ON in the following conditions.

When the discharge temperature ≤ the outdoor air temperature + 27deg F (+15deg C)

When the outdoor air temperature ≤ 68°F (20°C)

When the compressor stops and 30 minutes later.

1 - 17

6

7

8

9

1

2WAY VRF SYSTEM

Control Functions

5. Outdoor Unit Fan Control

Independent control of outdoor unit

This control is intended to prevent snow from accumulating on stopped fans.

The fan motor rotates at 500rpm in the below conditions even if the outdoor unit stops.

(1)

Control with snow detection sensor (field supply)

If a snow detection sensor (field supply) is available and this function is set in validity, the fan motor of the outdoor

unit rotates at 600 rpm when the snow detection sensor detects snow.

The judgment of this control performs at 10 minutes interval.

One snow detection sensor can control all outdoor units on the communications wiring.

The snow detection sensor is only possible to connect to the main outdoor unit (unit No.1) and it can control all

outdoor units in communication wiring.

(2)

Fan motor operates for 45 seconds and stops for 2 hours when ambient temperature is 41.18°F (5.1°C) or

more.

Fan motor operates for 45 seconds and stops for 1.5 hours when ambient temperature is 32.2 - 41.0°F

(0.1 - 5.0°C).

Fan motor operates for 45 seconds and stops for 1 hour when ambient temperature is 32.0°F (0.0°C) or less.

EEPROM setting in each main outdoor unit

* All outdoor units are connected with same communication wiring.

To activate this function, it is necessary to set it to the EEPROM on each system’s main outdoor unit PCB.

CODE: 04

System address 1

Snow detection sensor installed

Unit No.1

Unit No.1

Unit No.1

Unit No.2

Unit No.2

Unit No.2

Unit No.3

Unit No.3

Unit No.3

System address 2 System address 3

Function

No snow detection sensor is connected but control is available. (at factory shipment)

Snow detection sensor is connected and control is available.

Setting No.

0

1

No snow detection sensor is connected and control is not available.2

Snow detection sensor is connected but control is not available.3

Setting No.

Fan motor

status during

snowfall

100000222

ON ON ON ON ON ON OFF OFF OFF

1-2. Snow removal control

2

3

2WAY VRF SYSTEM

5. Outdoor Unit Fan Control

Control Functions

(1) Fan Mode

These outdoor units utilize a DC fan motor that can be controlled in a maximum of 15 steps (15 modes).

However, fan modes 14 and 15 can only be used if high static pressure mode has been set.

* For information concerning EEPROM settings, refer to the eld application functions.

The following table shows the maximum and minimum fan mode and fan forced mode for each unit.

Maximum value

Minimum value * 1 1 1 1

* For the sake of protecting temperature of the electrical parts, the minimum values of the fan mode may

sometimes increase in accordance with the ambient temperature or the amount of secondary current.

1-1. High static pressure mode

The outdoor unit allows a high static pressure changing the settings.

The maximum permissible static pressure is 0.01psi (80Pa).

Standard

High static

pressure mode

setting

Status of

heat exchanger

Condenser 13 13 12 12

Ambient

Evaporator

Condenser 15 15 12 12

Evaporator

temperature

Ambient

temperature

Ambient

temperature

Ambient

temperature

>

≤

>

≤

50°F

(10°C)

50°F

(10°C)

50°F

(10°C)

50°F

(10°C)

72 96 120 144

13 13 12 12

13 13 13 13

15 15 12 12

15 15 13 13

Type of outdoor unit

4

5

6

7

8

EEPROM setting in each outdoor unit

CODE : 8F

However, maximum fan mode is upper limit.

Setting No.

0 Invalid (factory preset mode)

1 High static pressure mode

2 Never use

3 Never use

4 Never use

5 Never use

6 Never use

9

1 - 18

2WAY VRF SYSTEM

2WAY VRF SYSTEM

Control Functions

5. Outdoor Unit Fan Control

5. Outdoor Unit Fan Control

Control Functions

1-2. Snow removal control

Independent control of outdoor unit

(1)

This control is intended to prevent snow from accumulating on stopped fans.

The fan motor rotates at 500rpm in the below conditions even if the outdoor unit stops.

Fan motor operates for 45 seconds and stops for 2 hours when ambient temperature is 41.18°F (5.1°C) or

more.

Fan motor operates for 45 seconds and stops for 1.5 hours when ambient temperature is 32.2 - 41.0°F

(0.1 - 5.0°C).

Fan motor operates for 45 seconds and stops for 1 hour when ambient temperature is 32.0°F (0.0°C) or less.