Panasonic TX-55DX650B Schematic

ORDER No. PCZ1604118CE

Service Manual

LED TV

TX-55DX650B

LA64 Chassis

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potencial dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

product or products deal within this service information by anyone else could result in serious injury or death.

There are special components used in this equipment which are important for safety. These parts are marked in the

Schematic Diagrams, Circuit Board Diagrams, Explorer Views and Replacement Parts List. It is essential that these

critical parts should be replaced with manufacturer´s specified parts to prevent shock, fire or other hazards. Do not

modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Warning

© Panasonic Corporation 2016.

Unauthorized copying

distribution is a violation of law.

and

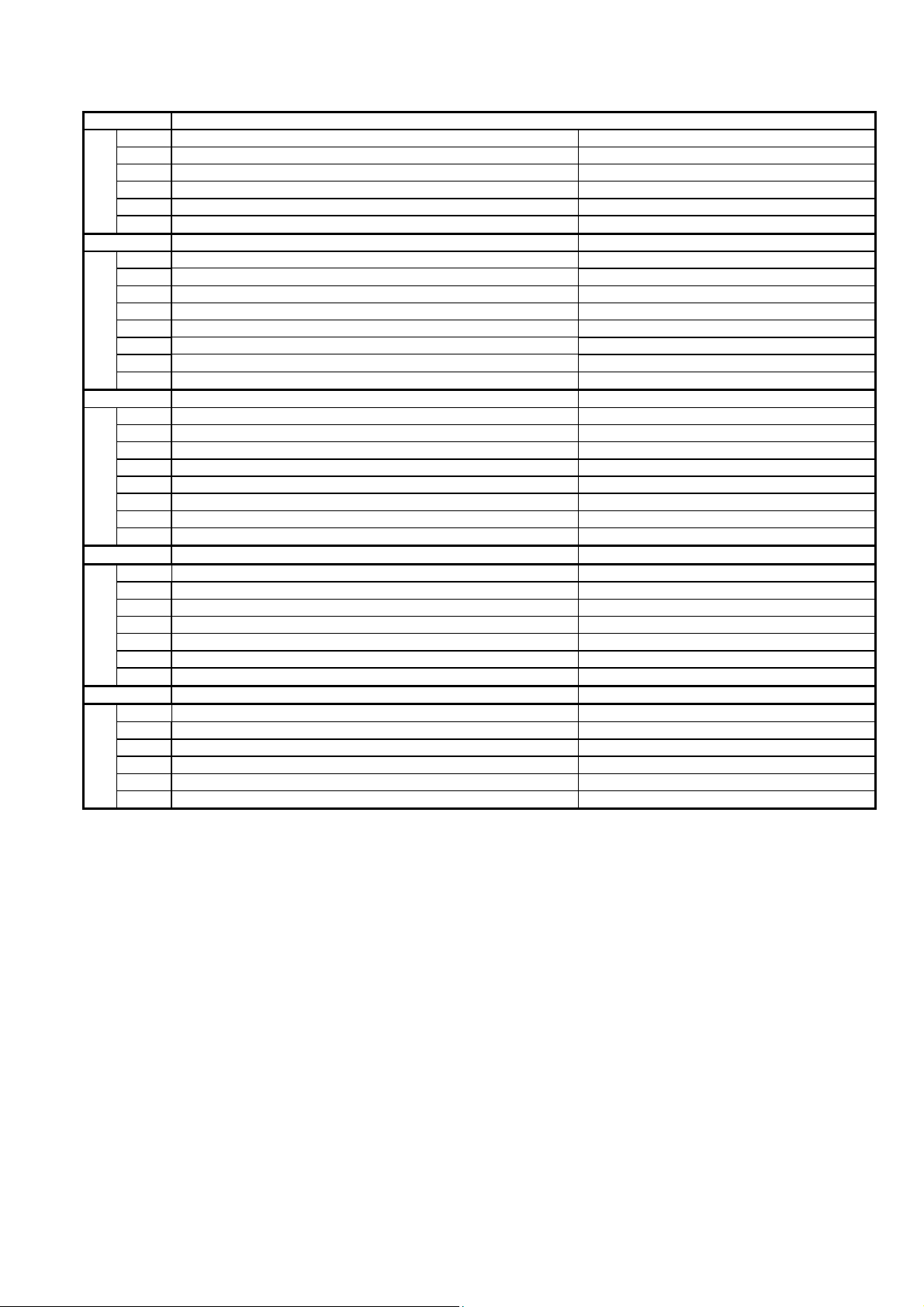

CONTENTS

2

SAFETY PRECAUTIONS ........................................... 3

GENERAL GUIDE LINES ...................................... 3

TOUCH – CURRENT CHECK ............................... 3

PREVENTION OF ELECTROSTATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES .................................................................... 4

ABOUT LEAD FREE SOLDER (PBF) ......................... 5

SUGGESTED PB FREE SOLDER ........................ 5

SERVICE NAVIGATION ............................................. 6

CHASSIS BOARD LAYOUT .................................. 6

SERVICE HINTS ........................................................ 7

APPLICABLE SIGNALS ............................................ 10

SPECIFICATIONS .................................................... 11

TECHNICAL DESCRIPTION ................................ ….13

SPECIFICATION OF KEY FOR DTCP-IP,

C2MOD, CI PLUS, DIMORA, HDCP2.2,

NETFLIX, WIDEVINE, FREETIME, HDCP1.4 ..... 13

GENERAL INFORMATION ................................. 13

REPLACEMENT OF ICS ..................................... 13

MODEL AND KEYS ............................................ 13

USB HDD RECORDING ..................................... 13

SETTING INSPECTION ............................................ 14

CS MAINTENANCE MENU ...................................... 15

SYSTEM INFORMATION ......................................... 17

HOTEL MODE .......................................................... 18

DATA COPY BY USB MEMORY .............................. 19

DATA COPY FROM TV SET TO USB MEMORY ..... 20

DATA COPY FROM USB MEMORY TO TV SET ..... 21

OPTION BYTES DESCRIPTION .............................. 22

SELF CHECK ........................................................... 23

POWER LED BLINKING TIMING CHART ................ 24

LCD PANEL TEST MODE ........................................ 24

WIRING DIAGRAM ................................................... 25

BLOCK DIAGRAM (1 OF 2) ...................................... 26

PARTS LOCATION ................................................... 28

LOCATION OF LEAD WIRING ................................. 31

LOCATION OF HEAT RUBBERS AND GASKETS .. 32

PACKING STRUCTURE ........................................... 33

REPLACEMENT PARTS LIST NOTE ....................... 34

REPLACEMENT PARTS LIST .................................. 35

SCHEMATIC DIAGRAMS NOTE .............................. 60

A-BOARD (1 OF 16) SCHEMATIC DIAGRAM .......... 61

P-BOARD (1 OF 3) SCHEMATIC DIAGRAM ............ 77

K-BOARD SCHEMATIC DIAGRAM .......................... 80

CONDUCTOR VIEWS .............................................. 81

CONDUCTOR VIEWS .............................................. 87

Safety Precautions

3

General Guide Lines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated

or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following touch current checks to prevent the customer from being exposed to shock hazards.

4. Always ensure cover label TBM4GU113 is correctly replaced before returning to customer (see Fig.1).

Touch-Current Check

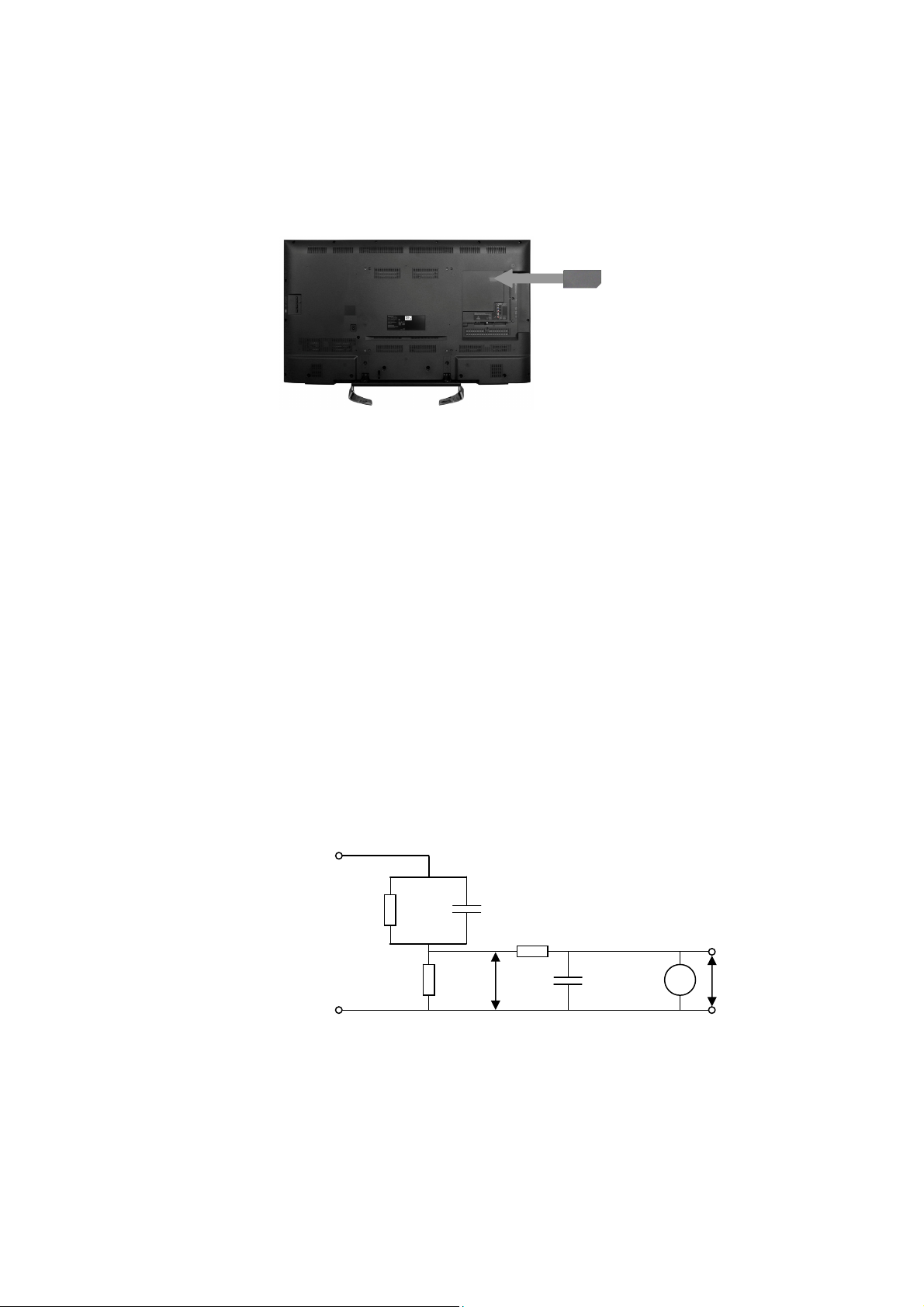

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth

ground such as a water pipe, as shown in Fig. 2.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential acr oss the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U1 and U2, does not exceed the following values:

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U1 = 1.0 V,

Note:

The limit value of U2 = 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and

2.0 mA d. c.

The limit value U1 = 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100

kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment shoul d

be repaired and rechecked before it is returned to the customer.

COLD

WATER PIPE

(EARTH GROUND)

TO

APPLIANCES

EXPOSED

METAL PARTS

Resistance values in ohms ()

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Measuring network for TOUCH CURRENTS

Fig. 1

C

=1500

R

S

R0=500

Input resistance: 1M

Input capacitance:200pF

Frequency range: 15Hz to 1MHz and d.c.respectively

Fig. 2

=0.22F

S

10k

U

(V)

1

0.022F

V

U2 (V)

4

Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of

component damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD

wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by cond uctive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as th e

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity

(ESD) sufficient to damage an ES device).

There are special components used in this equipment which are important for safety.

These parts are marked by in schematic diagrams, exploded views and replacement parts list. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire, or other hazards. Do

not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

5

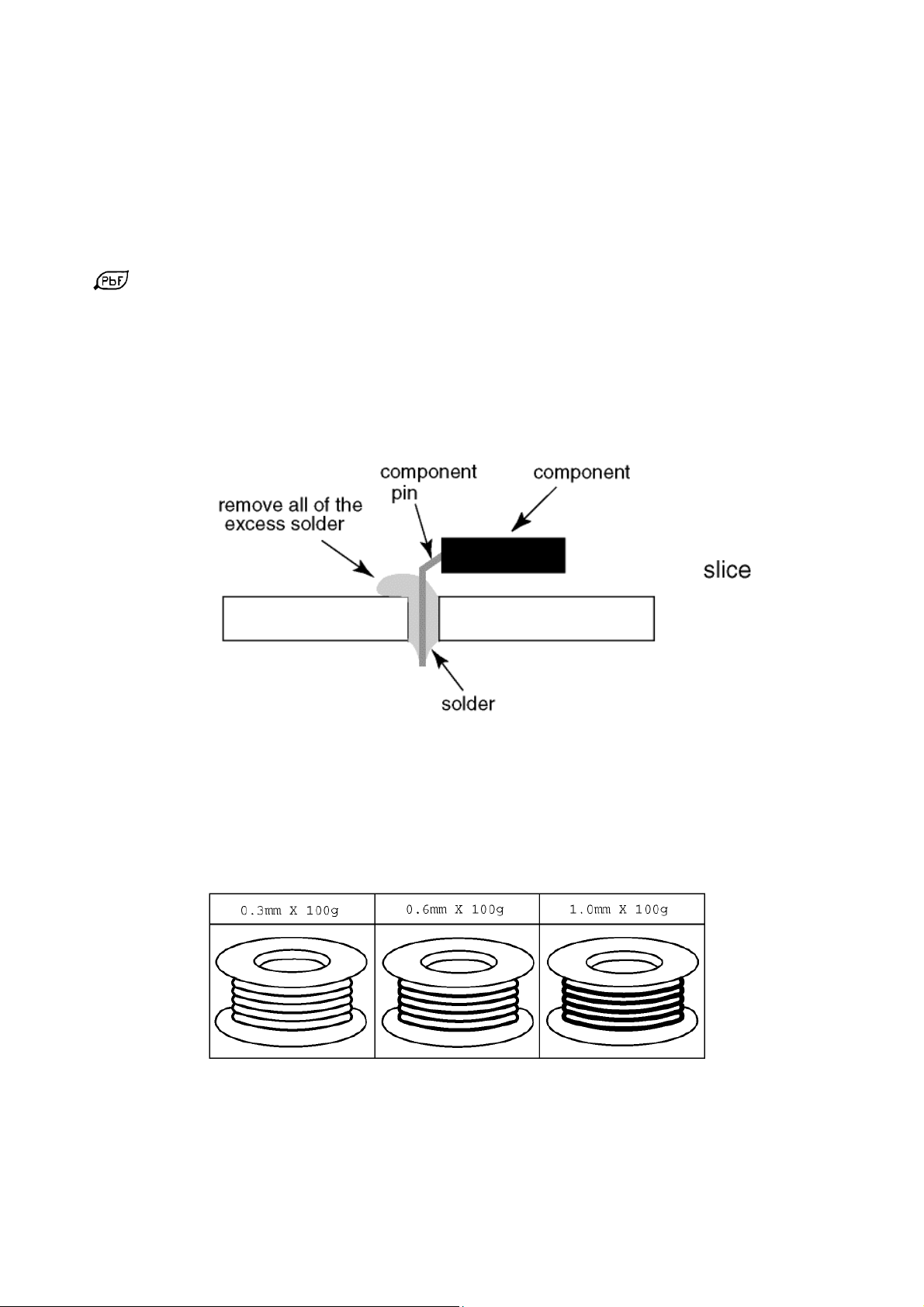

About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work,

we’d suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

stamped on the back of PCB.

Caution

Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C)

higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before

applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

After applying PbF solder to double layered boards, please check the component side for excess solder which may

flow onto the opposite side. (see Fig.3)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used. (see Fig.4)

Fig.3

Fig.4

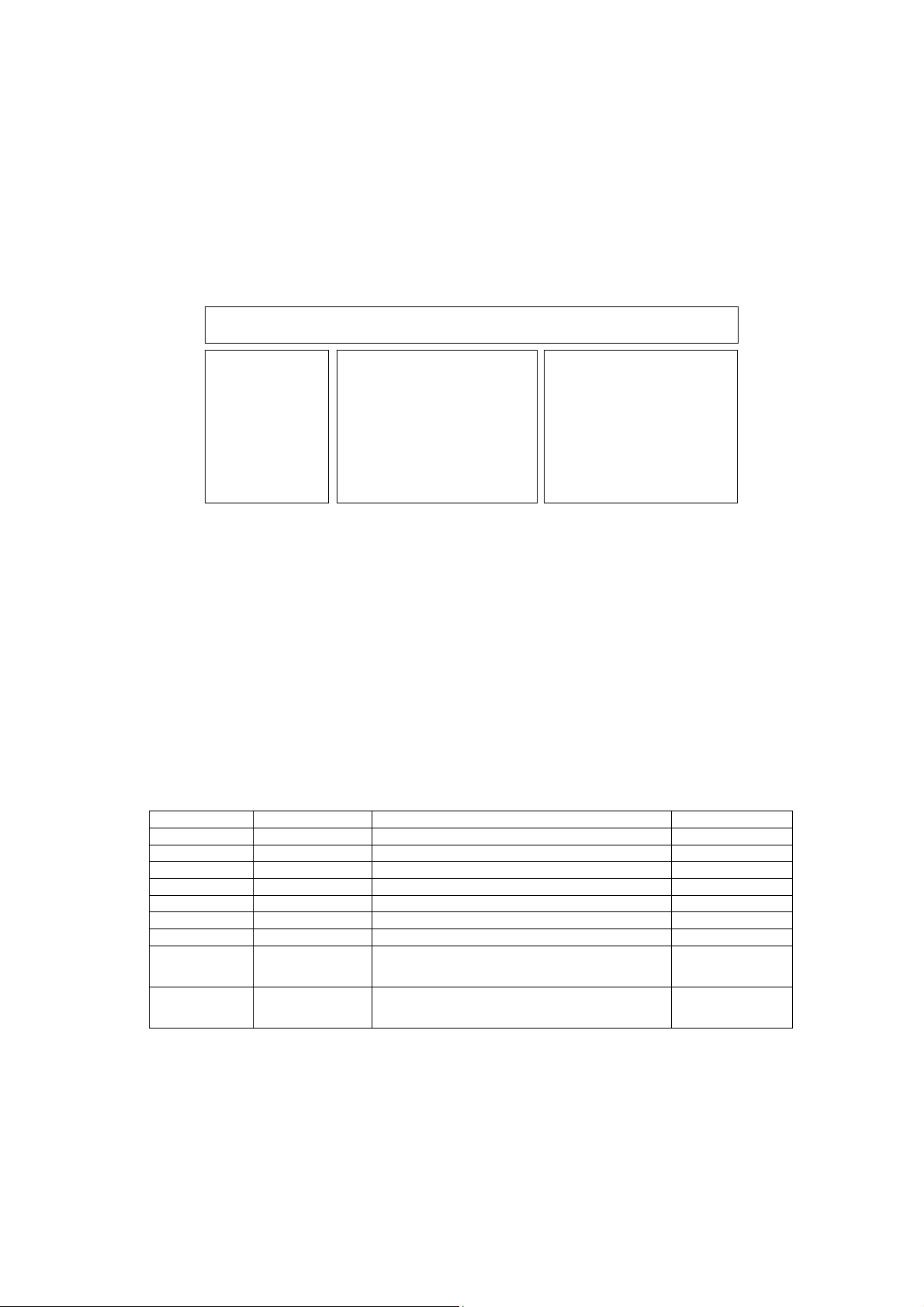

Service Navigation

6

Chassis Board Layout

P-BOARD

Board Name Function

A-Board AV Terminal, HDMI, USB, WIFI, Ethernet, Digital Audio Out, CI Slot,

INTEGRATED TUNER A/DVB-T2/T/C, DVB-T2/T/C Dem, Peaks IC_MTK,

P-Board Main Input, Power Supply, LED Driver, KEY Control, Power Switch

K-Board Remote Receiver, Power and Timer LED, C.A.T.S

A-BOARD

K-BOARD

Speaker out, HP, eMMc Memory, DDR SDRAM

Service Hints

7

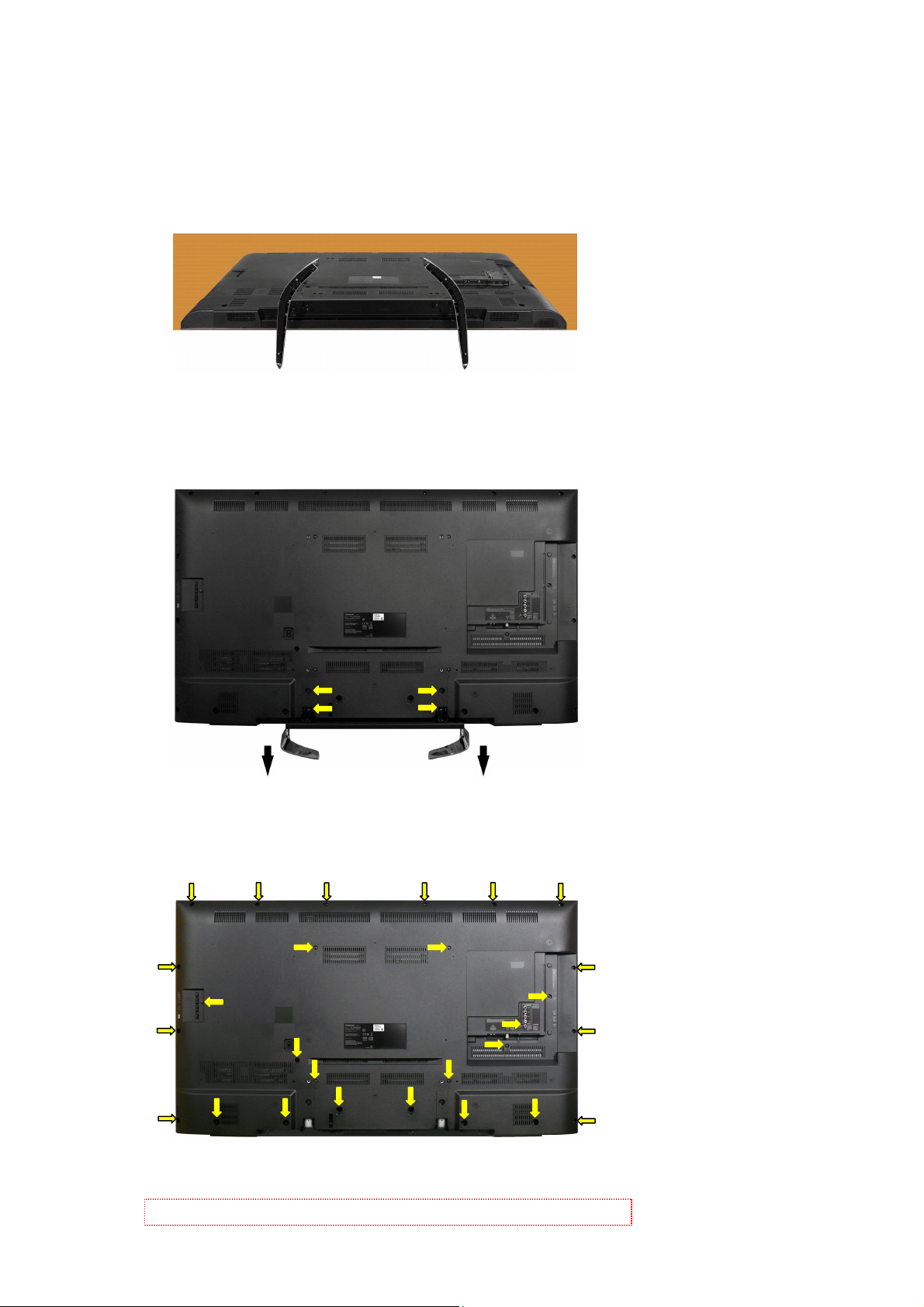

How to remove the pedestal assembly

How to remove the backcover

Lay the main unit face down. (see Fig.5)

Remove the 4 fixing screws and Pedestal assembly. (see Fig.6)

Remove the 27 fixing screws and the back cover. (see Fig.7)

(2)

(2)

(2)

(2)

(3)

(2)

(2)

(2)

(3)

(3)

Caution: Before removing cover, receiver must be disconnect from mains.

Fig.5

(1)

(1)

Fig.6

(2)

(2) (2)

Fig.7

(1)

(1)

(2)

(2)(2)

(2)

(3)

(2)

(2)

(3)

SCREWS

(1) THE5ZL002N /4pcs/

(2)

SCREWS

(2) THEC1509 /21pcs/

(3) THTD037J /6pcs/

(2)

(2)

(2)

(3)

(2)

Service Hints

8

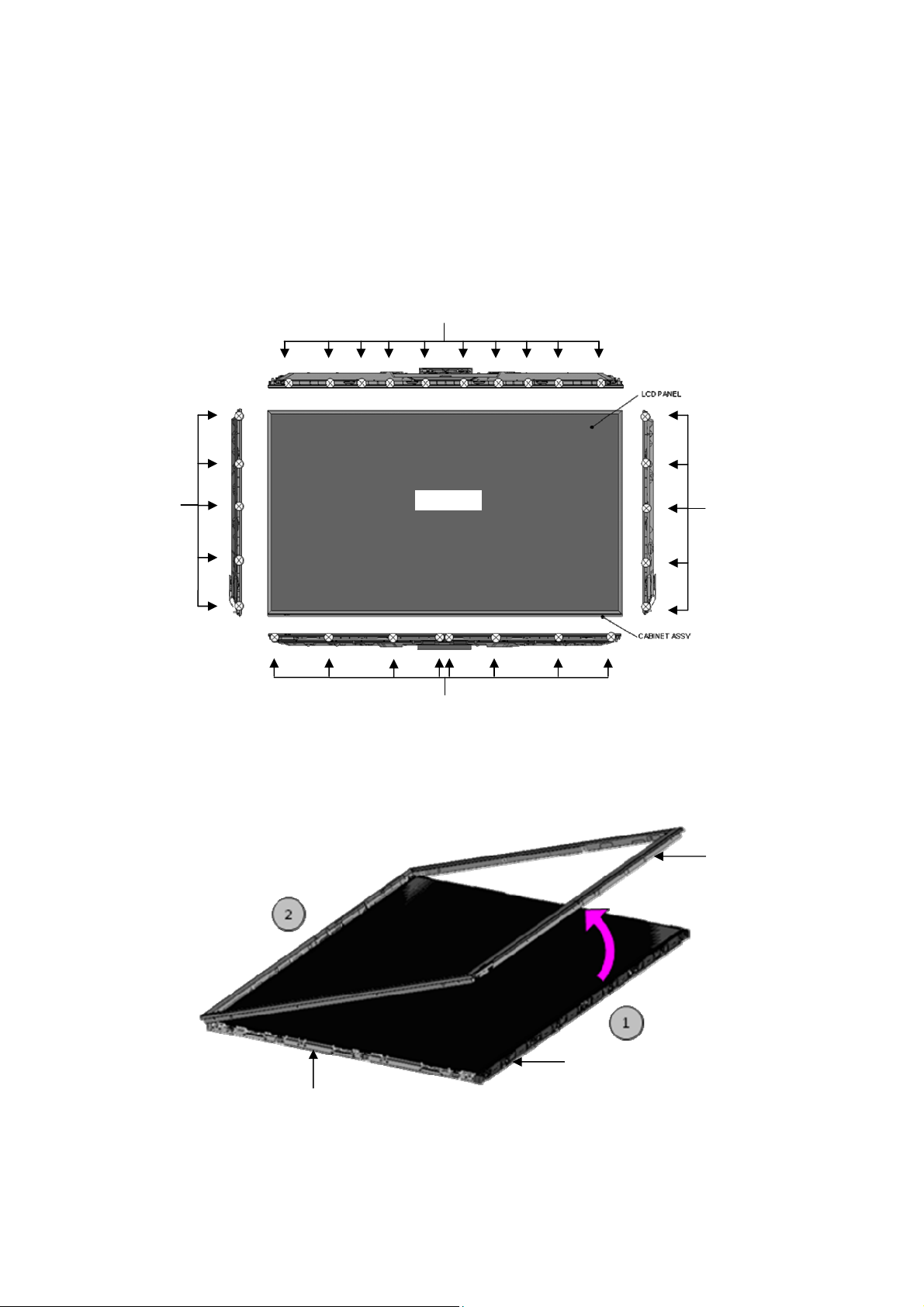

Preparation of replacement of LCD panel

Remove screws and Metal Bezel out of replacement panel according to specifications bellow.

Unscrew and remove Metal Bezel from LCD panel (see Fig.8,Fig.9)

Note:

Be careful to damage edge of LCD panel by remove of Metal Bezel!

Screws and Metal Bezel not to use for further.

10pcs

5pcs

Front View

5pcs

8pcs

Fig.8

Metal Bezel

LCD panel

Bottom side of

LCD panel

Fig.9

Service Hints

9

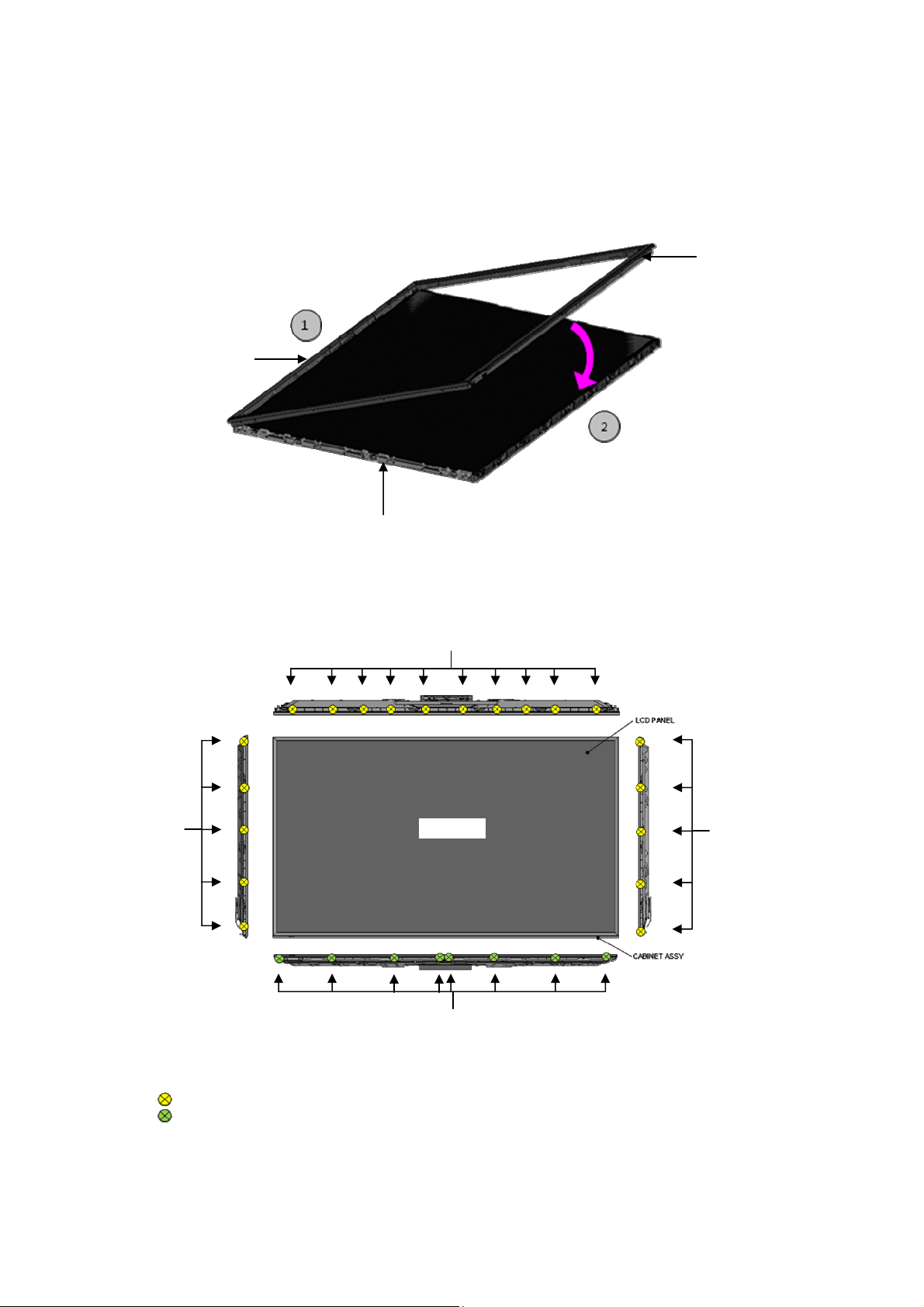

Assembly of LCD panel and cabinet assy

Insert and screw cabinet assy to LCD panel in order according to specification bellow. (see Fig.10,Fig.11)

Cabinet Assy

Top side of

LCD panel

LCD panel

Fig.10

10pcs

5pcs

Front View

5pcs

8pcs

NOTE: Be careful to damage edge of LCD Panel by insertion of cabinet assy!

Press on the cabinet assy /back side of LCD/ Panel during screwing!

SCREWS

THE5ZC021J /20pcs/

THE5ZC022J /8psc/

Fig.11

Applicable Signals

10

Component (Y, Pb, Pr) (from AV terminal), HDMI

525 (480) / 60i,60p

625 (576) / 50i, 50p

750 (720) / 60p, 50p

1,125 (1,080) / 60i, 50i

1,125 (1,080) / 60p, 50p, 24p

3,840 x 2,160 / 60p, 50p, 30p, 25p, 24p

4,096 x 2,160 / 60p, 50p, 30p, 25p, 24p

Note:

Signal name COMPONENT HDMI

* *

* *

* *

* *

*

*

*

Signals other than above may not be displayed properly.

The above signals are reformatted for optimal viewing on your display.

Specifications

11

Power Source: 220-240V AC, 50 / 60Hz

Rated Power Consumption: 170W

Stand-by Power Consumption: 0.50W

Aerial Impedance: 75 unbalanced, Coaxial Type

Receiving System: TX-55DX650B (UK)

DVB-T/T2 Digital terrestrial services

PAL I UHF E21-E68

PAL 525/60 (AV only)

M.NTSC (AV only)

NTSC (AV only)

TX-55DX650B (Ireland)

DVB-T/T2 Digital terrestrial services

PAL I VHF A-J

UHF E21-E69

CATV S1-S20

CATV S21-S41(Hyperband)

PAL 525/60 (AV only)

M.NTSC (AV only)

NTSC (AV only)

Aerial - Rear:

UHF VHF/UHF

Operating Conditions: Temperature: 0°C 35°C

Humidity: 20% 80% RH (non condensing)

Terminals:

AV IN (COMPONENT/VIDEO)

VIDEO Video (RCAx1) 1V p-p 75

Video (RCAx3) Y:1V p-p 75 (including synchronisation)

Pb/Cb, Pr/Cr: ±0.35V p-p 75

AUDIO IN Audio (RCAx2) 500mV rms 10k (used for HDMI analogue audio IN)

HDMI1/2/3 Type A Connectors

HDMI

HDMI 2 : 4K/60p, Content Type, Audio Return Channel, Deep Colour, x.v.Colour

HDMI

This TV supports “HDAVI Control 5” function.

DIGITAL AUDIO OUT PCM / Dolby digital, Fibre optic

USB 1/2 USB1 :DC 5V, Max 500mA [Hi-Speed USB (USB 2.0)]

USB2 :DC 5V, Max 900mA [SuperSpeed USB (USB 3.0)]

ETHERNET RJ45, IEEE802.3 10BASE-T / 100BASE-TX

CARD SLOT Common interface slot (Complies with CI+) x 1

Wireless LAN:

Standard Compliance IEEE802.11a/n , IEEE802.11b/g/n

Frequency Range IEEE802.11a/n: 5.180 GHz – 5.320 GHz

5.500 GHz – 5.580 GHz

5.660 GHz – 5.700 GHz

IEEE802.11b/g/n: 2.412 GHz – 2.472 GHz

Security WPA2-PSK (TKIP/AES)

WPA-PSK (TKIP/AES)

WEP(64 bit/128 bit)

LCD screen: L5EDDYY00872

3840 x 2160, 16:9

Visible Diagonal 1390mm

TX-55DX650B (UK) TX-55DX650B (Ireland)

1 : 4K/60p, Content Type, Deep Colour, x.v.ColourTM

3 : 4K/30p, Content Type, Deep Colour, x.v.ColourTM

TM

12

Audio Output: 20W (10W + 10W)

Headphones: 3.5mm, 8 Impedance

Accessories supplied : Remote Control

2 x R6 Batteries

Dimensions: Width: Height: Depth:

Including TV stand 1,244mm 776mm 364mm

TV set only 1,244mm 723mm 69mm

Mass:

Including TV stand 21.0kg

TV set only 18.0kg

Design and Specifications are subject to change without notice.

Mass and dimensions shown are approximate.

Technical Description

13

Specification of KEY for DTCP-IP, C2MOD, CI Plus, DIMORA, HDCP2.2, Netflix,

Widevine, Freetime, HDCP1.4

General information:

1. eMMc Memory(IC8920) for spare parts has the seed of KEY for each.

2. The final KEY data will be generated by MTK IC (IC8000) when SELF CHECK was done and are stored in both

MTK IC (IC8000) and eMMc (IC8920).

All KEYs are not generated for all models.

The necessary KEY are only generated and stored depend on the feature of models.

Replacement of ICs:

When MTK IC (IC8000) is replaced, eMMc (IC8920) should be also replaced with new one the same time.

When eMMc Memory(IC8920) is replaced, MTK IC (IC8000) is not necessary to be replaced the same time.

After the replacement of IC, SELF CHECK should be done to generate the final KEY data.

Note:

Keys HDCP1.4 (SINK) for MTK and HDCP2.2 (SINK) for MTK HDMI are not displayed in SELF CHECK.

Connect the 4K60Hz with HDCP2.2 compatible equipment to HDMI1/2 for verification of key [HDCP2.2 (SINK)

for MTK HDMI].

Connect the 4K30Hz compatible equipment to HDMI1/2/3 for verification of key [HDCP1.4 (SINK) for MTK HDMI].

How to SELF CHECK: While pressing [VOLUME ( - )] button on the main unit, press the MENU button on the remote

control for more than 3 seconds.

TV will be forced to the factory shipment setting after this SELF CHECK.

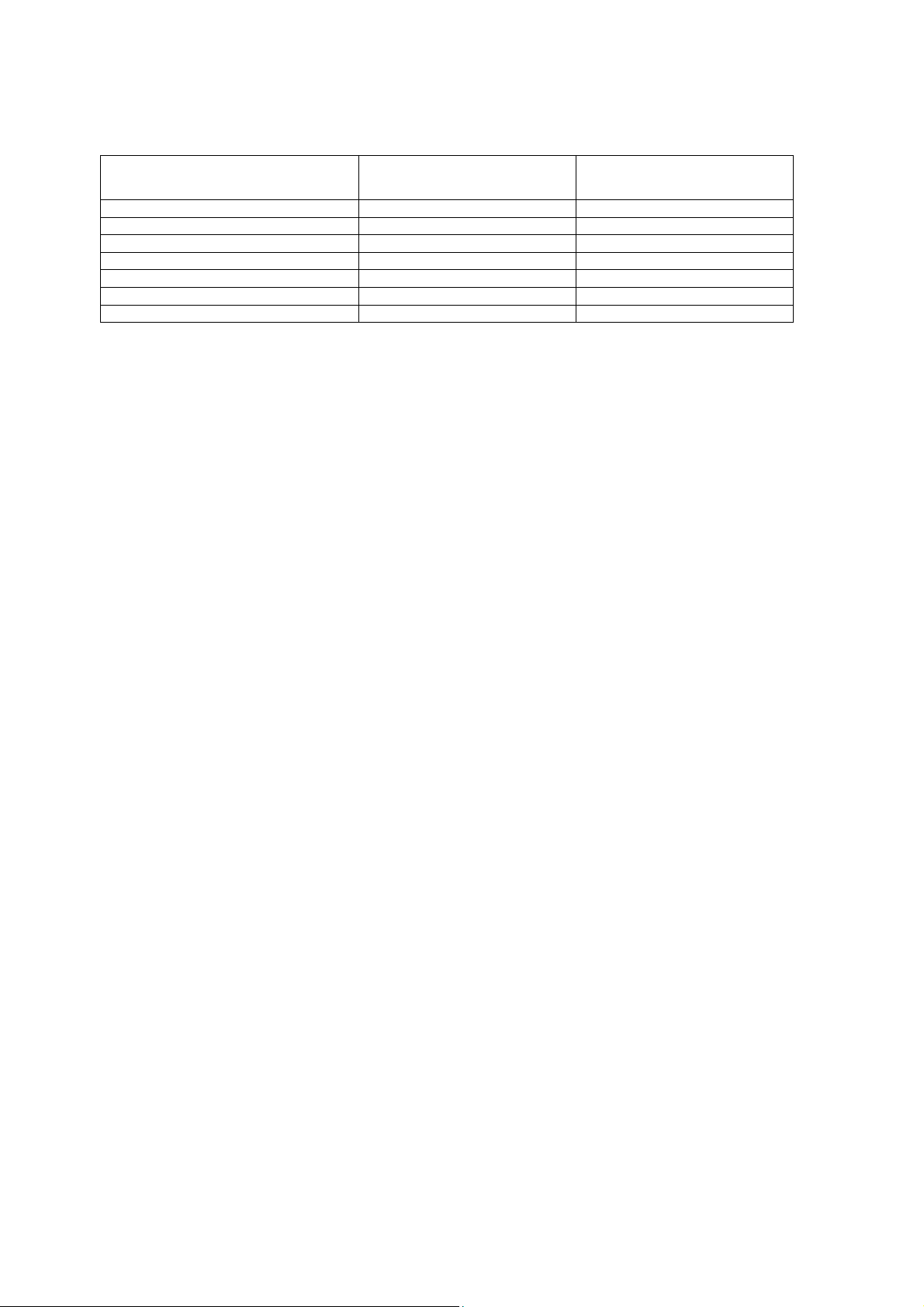

Model and Keys:

Keys

Model No.

TX-55DX650B Yes Yes Yes Yes Yes Yes Yes Yes Yes

DTCP-IP

for MTK

C2MOD

CI+

for MTK

DIMORA

HDCP2.2

(SINK)

for MTK

Netflix

Widevine

MAC

FREETIME

for MTK

HDCP1.4

(SINK)

for MTK

HDMI

HDCP2.2

(SINK)

for MTK

HDMI

USB HDD Recording:

General information:

Digital TV programmes can be recorded in USB HDD.

C2MOD key generated in A-board by SELF CHECK binds TV and USB-HDD for communication.

That key is only one key for them. If the key is different, TV can not access USB-HDD.

Caution:

New key will be generated by following SELF CHECK and previous TV programmes recorde d in USB HDD will not be

viewed.

SELF CHECK: While pressing [VOLUME ( - )] button on the main unit, press the MENU button on the remote control for more

then 3 seconds.

Setting Inspection

V

V

V

14

Voltage Confirmation

A board

Description Test point

PNL12V TP4059 12V ± 1.2V

USB5V TP5241 5.17V ± 0.25V

USB1 TP8705 5.00V ± 0.25V

USB2 TP8711 5.00V ± 0.25V

USB-WiFi TP8718 5.14V ± 0.20V

SUB3.3V TP5201 3.33V ± 0.15V

HDMISW3.3V TP4514 3.35V ± 0.17V

SUB_AI_3.3V TP2206 3.30V ± 0.17V

STB_1.5V TP8101 1.52V ± 0.07V

SUB1.0V TP8100 1.02V ± 0.05V

AVDD1.0V TP8102 1.06V ± 0.05V

WOL3.3V/PHY3.3V TP8606 3.30V ± 0.17V

EU_TU_1.8V TP5704 1.84V ± 0.10V

T2_1.1V TP5705 1.15V ± 0.11V

SUB9V TP5004 9.00V ± 0.40V

SUB_CI_5V TP6406 5.00V ± 0.50V

P board

Description Test point

64V TP7407/08/09

16V TP7410/11/12

5V TP7405/20 5.24V ± 0.2V 5.24V ± 0.2V

PFC TP7201/02 and GND TP7203*** <340V 390V ± 15V

* Connect AC 230V to P1 connector of P-PCB (Main switch is OFF).

** Set main switch is ON.

*** Beware, for testing of PFC use the GND (TP7203) in Hot area of P board – risk of electric shock.

oltage

oltage*

<1V

<1V

oltage**

65V ± 5V

16V ± 0.6V

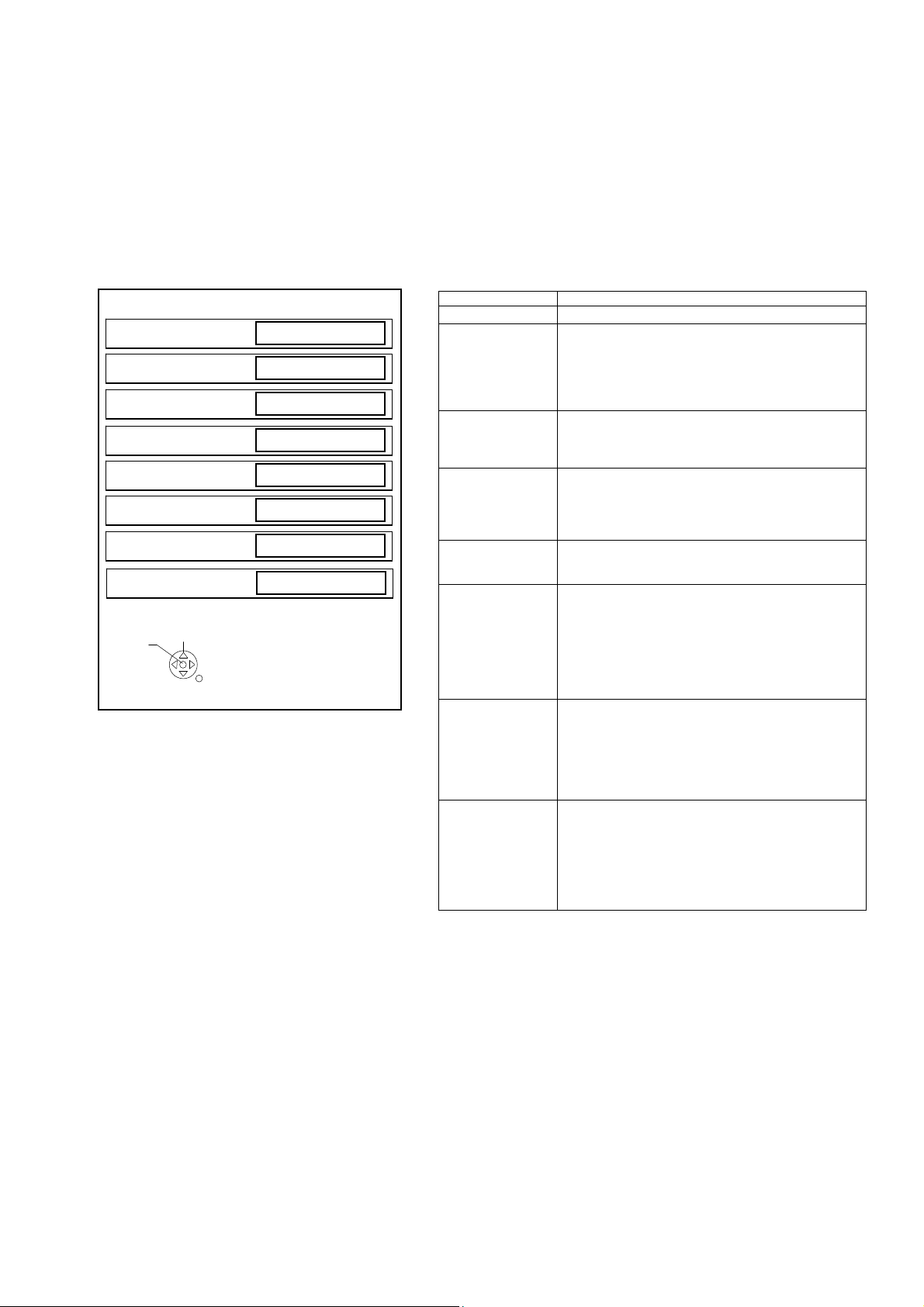

CS Maintenance Menu

15

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can

be adjusted by remote control in Service Menu

How to enter into CS Maintenance Menu

Purpose

After exchange parts, check and adjust the contents of adjustment mode.

While pressing [VOLUME ( - )] button on the main unit, press the [RED] button on the remote control for 3 times within

2 seconds.

Note:

Input 2D signal to enter CS Maintenance Menu.

How to exit

Press the [EXIT] button on the remote control.

CS Maintenance Menu

OPT

EDID CLK

DRV CHECK

WB-ADJ

Key Command

Press the ( / / / ) button to step up/down/right/left through the functions and adjustments

Press the OK button to change the adjustment values.

Press the RETURN button for return to the main menu.

OPT

1.Select [OPT] in CS Maintenance Menu.

2.Press [OK] button or Cursor key [Right] on the remote control.

CS Maintenance Menu

OPT

EDID CLK

DRV CHECK

WB-ADJ

7 6 5 4 3 2 1 0

OPT1 0 0 0 0 0 1 0 0

OPT2 1 1 1 0 1 1 1 0

OPT3 0 0 0 0 0 0 0 1

OPT4 0 0 0 0 0 0 0 0

Exit:

Press the [EXIT] button or the [RETURN] button on the remote control.

EDID Clock

16

1.Select [EDID CLK] in CS Maintenance Menu.

2.Press [OK] button or Cursor key [Right] on the remote control.

CS Maintenance Menu

OPT

EDID CLK

DRV CHECK

EDID-CLK S-HIGH

HDMI 1

WB-ADJ

Exit:

Press the [EXIT] button or the [RETURN] button on the remote control.

DRV Check (USB HDD Drive Check)

1.Select [DRV CHECK] in CS Maintenance Menu.

2.Press [OK] button or Cursor key [Right] on the remote control.

CS Maintenance Menu

OPT ******** ***-**-OK

EDID CLK

DRV CHECK OK

ERROR-NG

******** ***-**-OK

WB-ADJ

Press [OK] button (3sec)

BUSY

Performing (Max 3minutes)

NG OK

OK NG

OK: HDD is normal

NG: HDD is failure or mismatch

USBHDD check History

******** *** -** OK…………This time :OK

ERROR-NG………………. Last time : NG

******** *** -** OK…………Before last time:OK

Exit:

Press the [EXIT] button or the [RETURN] button on the remote control.

WB-ADJ

1.Select [WB-ADJ] in CS Maintenance Menu.

2.Press [OK] button or Cursor key [Right] on the remote control.

CS Maintenance Menu

OPT

EDID CLK

DRV CHECK

WB-ADJ

WB-ADJ

R-GAIN 73

COLOR TEMP NORMAL

WB-ADJ

B-GAIN 78

COLOR TEMP NORMAL

WB-ADJ

G-GAIN 80

COLOR TEMP NORMAL

COLOR TEMP:COOL

NORMAL

WARM

TUNING

Note:for change press [OPTION] button on Remote Control.

Exit:

Press the [EXIT] button or the [RETURN] button on the remote control.

Clock speed

HDMI Number

System Information

17

How to access

1. While pressing [MENU] button on the remote control.

2. To select [ Help] and then to select [System Information].(see Fig.12, Fig.13)

Fig.12 Fig.13

System Information

SW version 3200-10000 3200

Status1 0d 7301-0003 0000-0100 0d

Status2 001e-020-0016ff 001e

Status3 00-000000-F000 00

Status4 A00000-0000001-00000 A

Status5 00000-10000 16d080ff 0

Status6 0115573-1000035 01015573

Status7 00000-0750 00000

HDAVI

Control

5 5 VIERA Link version is displayed

10000

7301-0003

0000-0100

020

0016ff

00

00

00

F

00000

0000001

00000

0

0

0

0

1

0000

16d0800ff

1000035

0750

How to exit

Press the [RETURN] button on the remote control.

*Sample only

Peaks SW

STBY SW

Outer model ID

Inner model ID

Panel inch size

LSI Package

LSI Release

Model data version

Number of bad block in NAND Flash (dec)

Peaks reboot counter

System crash counter

Emergency (SOS) counter

Peaks NAND Maker ID

Power-On period (A<=100hrs, B<=200hrs, C>200hrs)

Total Power-On time (dec, max is 65535)

Power-On timer (dec, max is 1048575)

Fixed (always)

SOS history (latest)

SOS history (last time)

SOS history (last but one)

SOS history (2

SOS history (1

Self-check _0-never selfcheck

1-production selfcheck by “FF” or USCM

2-user selfcheck by pressing “OK”

Fixed (always)

Panel ID

Peaks EEPROM version

STM EEPROM version

STM ROMCOR version

AJAX_CE version

nd

time after shipping)

st

time after shipping)

Hotel Mode

18

1. Purpose

Restrict a function for hotels.

2. Access command to the Hotel mode setup menu.

In order to display the Hotel mode setup menu,

please enter the following command (within 2 second).

[TV] : Vol.[Down] + [REMOTE] : AV (3 times)

Then, the Hotel mode setup menu is displayed.

Hotel mode

Hotel mode

Initial INPUT

Initial POS

Off

Off

Off

Initial VOL Level

Maximum VOL Level

Button Lock

Remote Lock

Off

100

Off

Off

Private Information

Change

Select

RETURN

Keep

3. To exit the “Hotel mode”:

Switch off the power with the [POWER] button

on the main unit or the [POWER] button

on the remote control or pressing [EXIT] button

on the remote control.

4. Explain the Hotel mode setup menu.

ITEM Function

Hotel Mode Select hotel mode ON/OFF

Initial INPUT Select input signal modes.

Initial POS Select programme number.

Initial VOL Level Adjust the volume when each time power is

Maximum VOL

Level

Button Lock Select local key conditions.

Remote Lock Select remote control key conditions.

Private

Information

Set the input, when each time power is switched on.

Selection:

Off/DVB/AV/HDMI1/HDMI2/HDMI3

*Off: give priority to the last memory. However, Euro

Model is compulsorily set to TV.

Selection:

Off/0 to 99

*Off: give priority to the last memory

switched on.

Selection/Range:

Off/0 to 100

*Off: give priority to the last memory

Adjust maximum volume.

Range:

0 to 100

Selection:

Off/SETUP/MENU

*Off: altogether valid

*Setup: only F-key is invalid

(Tuning guide (menu) can not be selected.)

*MENU: only F-key is invalid

(only Volume/Mute can be selected.)

Selected”

Off/SETUP/MENU/VOD

*Off: altogether valid

*Setup: only Setup menu is invalid

MENU: Picture/Sound/Setup menu are invalid

VOD:NETFLIX service is invalid

Select private information for VIERA Cast is Keep or

Reset if Hotel mode is set to [On] when TV power

on.

Selection :

Keep/Reset

•Keep: private information for VIERA Cast is keep

•Reset: private information for VIERA Cast is reset

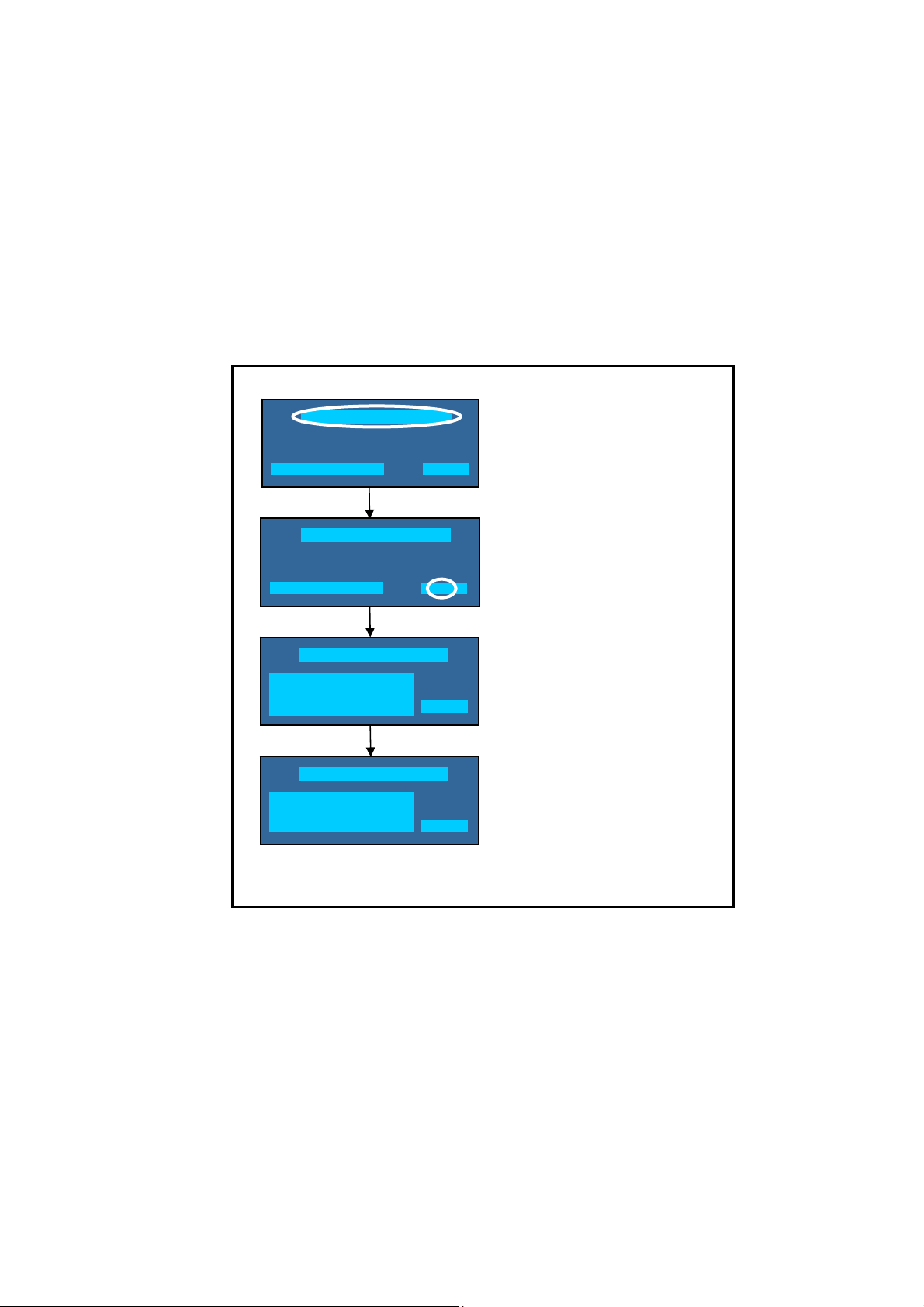

Data Copy by USB Memory

19

Purpose

a) Board replacement (Copy the data when exchanging A-board):

When e xchanging A-board, the data in original A-board can be copied to USB Memory and then copy to new A-board.

TV

A-board

(Before exchanging)

Copy to USB Memory

(After exchanging)

Copy back from USB Memory

USB

Following data can be copied.

User setting data

(inc. Hotel mode setting data)

Channel scan data

Adjustment and factory preset data

b) Hotel (Copy the data when installing a number of units in hotel or any facility):

When insta lling a number of units in hotel or any facility, the data in master TV can be copied to USB Memory and the

copy to other TVs.

Master TV

Copy to USB Memory

USB

Memory

Other TV

Copy from USB Memory

Other TV

Other TV

Following data can be copied.

User setting data

(inc. Hotel mode setting data)

Channel scan data

Preparation

Make pwd file as startup file for (a) or (b) in an empty USB Memory.

1. Insert an empty USB Memory to your PC.

2. Right-click a blank area in a USB Memory window, point to New, and then click text document. A new file is created

by default (New Text Document.txt).

3. Right-click the new text document that you just created and select rename, and then change the name and

extension of the file to the following file name (a) or (b) and press ENTER.

File name:

(a) For Board replacement: boardreplace.pwd

(b) For Hotel: hotel.pwd

Note:

Please make only one file to prevent the operation error.

No any other file should be in USB Memory.

Data Copy from TV set to USB Memory

20

1. Turn on the TV set.

2. Insert USB Memory with a startup file (pwd file) to USB Terminal.

On-screen Display will be appeared according to the startu p file automatically.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement: 2770

(b) For Hotel: 4850

Data will be copied from TV set to USB Memory.

It takes around 1 to 2 minutes maximum for copying.

4. After the completion of copying to USB Memory, remove USB Memory from TV set.

5. Turn off the TV set.

Note:

Following new folder will be created in USB Memory for data from TV set.

(a) For Board replacement: user_setup

(b) For Hotel: hotel

Data Copy(Board replacement )

Input password

Data copy

(Board replacement) or (Hotel)

-----

Data Copy(Board replacement )

Input password

Input Password

2770 or 4850

-----

Data Copy(Board replacement )

Copy TV to Media

Please wait for a while

Please do not remove the Media

Performing

GETTING

Data Copy(Board replacement )

Performing

Data copy has been successful

Please remove Media

Completion

FINISH

Data Copy from USB Memory to TV set

21

1. Turn on the TV set.

2. Insert USB Memory with Data to USB Terminal.

On-screen Display will be appeared according to the Data folder automaticall y.

3. Input a following password for (a) or (b) by using remote control.

(a) For Board replacement: 2771

(b) For Hotel: 4851

Data will be copied from USB Memory to TV set.

4. After the completion of copying to USB Memory, remove USB Memory from TV set.

(a) For Board replacement: Data will be deleted after copying (Limited one copy).

(b) For Hotel: Data will not be deleted and can be used for other TVs.

5. Turn off the TV set.

Note:

1. Depending on the failure of boards, function of Data for board replacement does not work.

2. This function can be effective among the same model numbers.

Data Copy(Board replacement )

Input password

Performing

Input Password

2771 or 4851

-----

Data Copy(Board replacement )

Copy Media to TV

Please wait for a while

Please do not remove the Media

Performing

WRITING

Data Copy(Board replacement )

Performing

Data copy has been successful

Please turn off the TV for system

initializing

FINISH

Option Bytes Description

22

OPTION1

b1 TEXT Ch Refresh ON (1) / OFF (0)

b2 ID-1 ON (1) / OFF (0)

b3 Macrovision Auto-judge ON (1) / OFF (0)

b5 Reserved b6 Enable HDMI force reset ON (1) / OFF (0)

b7 Reserved OPTION2

b0 Adjust Igain enable ON (1) / OFF (0)

b1 A2 BG enable (5.5MHz) ON (1) / OFF (0)

b2 A2 DK1 enable (6.26MHz) ON (1) / OFF (0)

b3 A2 DK3 enable (5.742MHz) ON (1) / OFF (0)

b4 NICAM scan ON (1) / OFF (0)

b5 NICAM BG enable (5.5MHz) ON (1) / OFF (0)

b6 NICAM I enable (6.0MHz) ON (1) / OFF (0)

b7 NICAM DK enable (6.5MHz) ON (1) / OFF (0)

OPTION3

b0 NICAM priority ON (1) / OFF (0)

b1 Reserved -

b2 Reserved -

b3 A2 DK2 enable ON (1) / OFF (0)

b4 Inhibition of countermeasure for SIF signal drop ON (1) / OFF (0)

b5 Get onid from physical CH (CHINA) ON (1) / OFF (0)

b6 SSU search enable for HOTEL model ON (1) / OFF (0)

b7 SASO mute (ASIA) ON (1) / OFF (0)

OPTION4

b0 Countermeasure for Taiwan NTSC noise sound ON (1) / OFF (0)

b2 3DYC color motion detect ON (1) / OFF (0)

b3 RF Clamp Current minimum (TAIWAN) ON (1) / OFF (0)

b4 Reserved -

b5 Reserved -

b6 Reserved -

b7 Enable workaround for Polsat CAM problem (POLAND) ON (1) / OFF (0)

OPTION16

b0 PIP/MW (derivate models) ON (1) / OFF (0)

b2 Digital Remaster sound menu enable (derivate models) ON (1) / OFF (0)

b4 Ambience sound menu enable (derivate models) ON (1) / OFF (0)

b5 Control4 function enable ON (1) / OFF (0)

b6 Reserved -

b7 Reserved -

Self Check

p

23

How to access

Self-check indication only:

While pressing [VOLUME ( - )] button on the main unit, press [BLUE] button on the remote control.

Self-check indication and forced to factory shipment setting:

While pressing [VOLUME ( - )] button on the main unit, press [MENU] button on the remote control for more than 3 seconds.

How to exit

Switch off the power with the [POWER] button on the main unit.

TX-55DX650B

H14TUN IC6950 INTEGRATED TUNER A/DVB-T2/T/C A-Board

H38FRC IC8000 IC Peaks-MTK A-Board

H07TEMP IC5911 Temperature Sensor A-Board

H17LAN IC8000/IC8920 Ethernet/MAC A-Board/LAN

H00FE IC6800 DVB-T2/T/C Demodulator A-Board

H96ID IC8920 CI+,HDCP2.2, DTCP-IP, C2MOD A-Board

H97ID2 IC8920 Dimora, Netflix, Widevine, Freetime A-Board

H42WIFI

H71TCON T-CON on Panel

Self Check Com

H14TUN O.K.

H38FRC O.K.

H07TEMP O.K.

H17LAN O.K.

H00FE O.K.

H96ID O.K.

H97ID2 O.K.

H42WIFI O.K.

H71TCON O.K.

PEAKS-SOFT *.***

PEAKS-EEP **.**.****

LSI-PACKAGE *.***

LSI-RELEASE *.**

STBY-SOFT *.**.**

STBY-EEP *.**.****

TCON SOFT ********

TCON DATA ********

lete

MODEL ID 0D

03000170

00010000

Display Ref. No. Description P.C.B.

IC8000

N5HBZ0000114

IC Peaks-MTK

Wifi Dongle

A-Board

Wifi Dongle

T-CON Board

on Panel

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

Power LED blinking timing chart

24

1. Subject

Information of LED Flashing timing chart.

2. Contents

When abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by number of blinking of the Power LED on the front panel of the unit.

Blinking

times

Once

1 BL_SOS

7

Blinking timing Contents Check point

4 sec

Light

No Light

SUB3.3V_SOS

LCD PANEL

P BOARD

A BOARD

P BOARD

9

10

13

SOUND_SOS

FRC_SOS A BOARD

EMERGENCY A BOARD

A BOARD

SPEAKERS

LCD Panel Test Mode

Purpose:

To find the possible failure point where in LCD Panel or Printed Circuit Board when the abnormal picture is displaye d.

How to Enter:

While pressing [VOLUME ( - )] button of the main unit, press [YELLOW] button of the remote control three times.

How to Exit:

Switch off the power with the [POWER] button on the main unit or the [POWER] button on the remote control.

How to confirm:

If the abnormal picture is displayed, go into LCD Panel test mode to display the several test patterns.

And then, judge by the following method.

Still abnormal picture is displayed: The cause must be in LCD Panel.

Normal picture is displayed: The cause must be in A board.

Remarks:

The test pattern is created by the circuit in LCD Panel.

In LCD Panel test mode, this test pattern is displayed unaffected by signal processing for RF or input signal.

If the normal picture is displayed, LCD Panel must be okay and the cause of failure must be in A board.

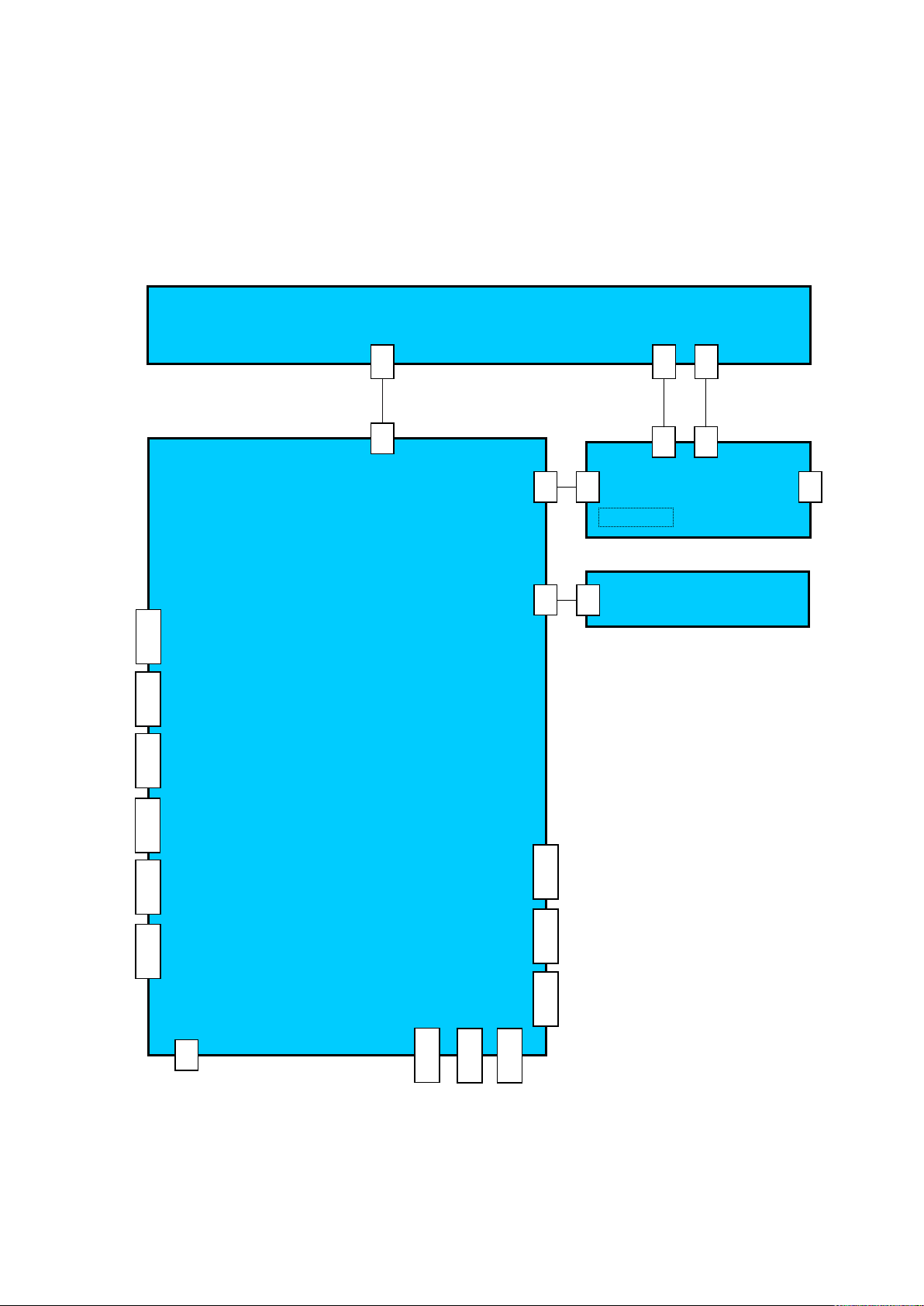

Wiring Diagram

25

CN1

A16A

LCD PANEL

P6

P5

WIFI

JK8705

JK8703

USB2(3.0)

USB1

JK8702

HDMI1

JK4703

HDMI2

JK4702

A-BOARD

A02A

A10

HP

JK3104A

P2

KEY CONTROL

K10

P-BOARD

K-BOARD

P1

MAIN IN

HDMI3

JK4701

A12

SP

D3200

DIGITAL

AUDIO OUT

JK6400

CI SLOT

JK8600

JK3101

JK6951

INPUT

ANTENNA

ETHERNET

RCA

YUV, V IN

AUDIO IN

SP_L

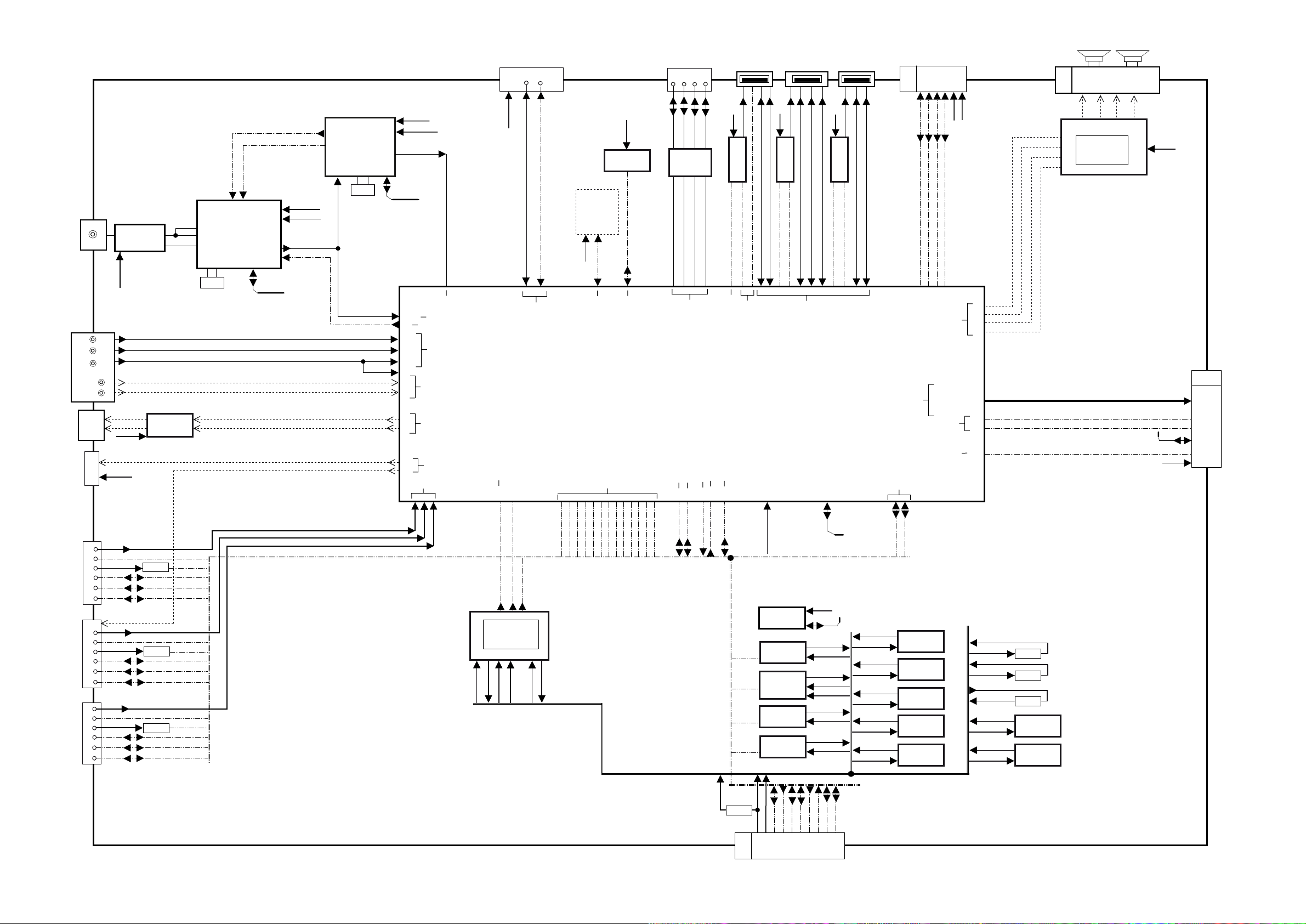

Block Diagram (1/2)

26

RF_IP

20

[C1AB00004337]

9

11

R4521

3

6

IC3201

Stereo HP

Driver

RF_IN

13

15

3_HPD

3_PWR5V

HDMI_3_SDA

HDMI_3_SCL

CEC

2_HPD

2_PWR5V

HDMI_2_SDA

HDMI_2_SCL

CEC

1_HPD

1_PWR5V

HDMI_1_SDA

HDMI_1_SCL

CEC

22

Digital and Analog

24

14

13

X6950

JK6951

Y/Vin,PB,PR

JK3101

JK3104A

Digital

Audio Out

JK4703

JK4702

JK4701

IN

AUDIO

HP-OUT

D3200

HDMI1

HDMI2

HDMI3

L

R

HP_L

HP_R

ASPDIFO0

SUB3.3V

P3_RX

HPD3

5VDET3

DDCSDA3

DDCSCL3

CEC

CEC

P2_RX

HPD2

5VDET2

DDCSDA2

DDCSCL2

CEC

P1_RX

HPD1

5VDET1

DDCSDA1

DDCSCL1

CEC

4

1

SUB3.3V

COMP_D_PR

COMP_D_PB

COMP_D_Y

SUB3.3V

IC6952

LNA

LIN_TERMINAL

RIN_TERMINAL

R4545

ASPDIFO1

R4515

AGC1

5

IC6950

TV Tuner

FEF_FLAG

1

2,3

9,15,17,23

10,11

DMD_0_T

SP_R

3

USB5V

1

4

USB_DM_P3(P)

OCP2

STB3.3V

PHY3.3V

SUB1.0V

AVDD1.0V

STB_1.5V

SUB3.3V

HDMI3.3V

SD3.3_1.8V

IC5911

Temp.Sensor

IC5200

DC/DC

1

IC8100

DC/DC

14

IC4506

Reg

5

IC5240

DC/DC

7

1

6

SW

IC8703

3

VBUS2

12,23,26

2,3 5,6

10,15

JK8703

USB2

USB_DM(DP)_P2(P,N)

USB+GPI0

6

8

17

1

8

3

2

Power

AD38

BL_SOS

1

3

LED_PWM3

PWM

AL36

BL_ECO

JK8705

WIFI

1

4

STB5V

6

SW

IC8706

4

OPCTRL18

Other

DCDCEN-2

DCDCEN

DCDCEN-2

DCDCEN

2

USB_DM_P3(N)

OPCTRL12

Power

HDMI_CEC

HDMI_2_SCL

HDMI_2_SDA

ETHERNET

JK8600

1

2

3

TX-

TX+

RX+

14

16

11

T8600

1 3 6

TX-

TX+

RX+

ETHERNET

IC8000

[MT5810PEHJ]

SERVO ADC input

SERVO ADC input

L35

P35

KEY1

BL_ ON

POWER ON

6

RX-

9

8

RX-

Power

Y34

JK6400

CI SLOT

17,18

51,52

SUB3.3V

AGC1

FEF_FLAG

IC6800

[C1AB00004028]

48

DVB-T/T2/C DEM

47

38,37

34

35

X6800

SUB3.3V

TU_1.8V

7

IF2_N,P

AGC2

4

IF2_N,P

COMP_D_PR

COMP_D_PB

COMP_D_Y

CVBS3P

LIN_TERMINAL

RIN_TERMINAL

ASPDIFO0

ASPDIFO1

3,4,5,8

20,21

45,46

IF2_N,P

AGC2

HP_L

HP_R

P2_RX

P3_RX

P1_RX

DMD_0_T

IIC_2

F37,F38

J37

K36

L36,L37

K37

D37

B36

C35

D36

AB34

DMD_1.2/1.1V

TSVAL

TSSYNC

TSCLK

TSDATA0

Demod

B14

J38

G27

HDMI

Receiver

P2_RX

DEMOD

Demod

Analog Video input

Audio Line in ADC

Audio DAC

Audio

P1_RX

P3_RX

1

16V

TV_SUB_ON

[AN34043AAVF]

ANALOG ASIC

6 2

STB5V

SUB9V

SUB_CI_5V

TS Paraller Input_Output

GPI0, DEMOD

Power

M34,R36

AB38

EASTERRST2

DCDCEN

TV_SUB_ON

EASTERRST2

8

11

13

IC5000

31

14

STB5V

SUB5V

CI DATA

32

STB3.3V

3_HPD

1_HPD

DDR3 _ 5X4GB

IC8200

IC8201

IC8202

IC8203

IC8204

STB1.5V

DDR

HDMI

2_PWR5V

3_PWR5V

2_HPD

1_PWR5V

SUB3.3V

IC8920

eMMC 4GB

HDMI_3_SDA

HDMI_3_SCL

HDMI_1_SDA

eMMC

HDMI_1_SCL

8,9

SSUSB_TX(P,N)

SSUSB_RX(P,N)

SUB3.3V

IIC_1

SUB3.3V

16V

SUB1.0V

DCDCIN

SUB5V

HDMISW3.3V

SUB5V

SUB5V

16V

USB5V

1

3

VBUS1

IIC_0

IIC_1

IIC_2

JK8702

USB1

1

2

6

SW

IC8702

4

USB_DM_P1(N)

OCP1

3

USB_DP_P1(P)

PHY3.3V

STB5V

SUB_CI_5V

SUB5V

DMD_1.2/1.1V

SUB5V

STB_1.5V

STB5V

PNL12V

16V

PWM

BL_PWM1

LVDS

BL_PWM2

5

4

5

1

3

2

6

5

11,12

4,5,6

TO K10

7

A10

REMOTE

Y35

IC8601

Reg

IC6405

Reg

IC5705

DC/DC

IC8101

DC/DC

IC5260

DC/DC

AI_SENSOR

4

2

5

1

3

SUB3.3V

STB3.3V

R_LED_ON

G_LED_ON

U37

AA33

AA34

AUDIO

AT32,AR32,AV33,AU33

AT33,AR33,AT34,AR34

AV35,AU35, AT35,AR35

AT36,AR36,AV37,AU37

TCON

LVDS/EPI/VBI

AN30

AM31

AN31

AP36

AL25

AN25

AR25

SD3.3_1.8V

SUB5V

HDMISW3.3V

HDMI3.3V

EU_TU_1.8V

AVDD1.0V

LRCLK

BCLK

SDATA0

MCLK

SUB3.3V

USB5V

SUB3.3V

SUB3.3V

VJ5002

VJ8700

VJ4600

2,4

3

1

8

IC5704

Reg

IC8102

Reg

A12

8

7

6

5

V-By-One

1

R+

10,11

2 3

L- L+

R-

14,15 26,27

IC3800

[C1AB00003984]

AUDIO AMP

30,31

9,16

25,32

4

16V

IIC_0

PANEL_TEST_ON

LOCK

HTPD

PNL12V

A16A

2,3,5,6

8,9,11,12

14,15,17,18

20,21,23,24

26

27

33,34

29

44-51

TO PANEL

(CNV1)

DCDCIN

F2000

16V

A02A

1-4

STB5V

7

TV_SUB_ON

KEY1

3

8

POWER ON

9

10

BL_ECO

7

12

BL_ON

14

9-10

BL_SOS

15

12

BL_PWM2

BL_PWM2

BL_PWM1

BL_PWM1

16

13

A-BOARD

[EXCHANGE UNIT]

TO P2

Loading...

Loading...