Page 1

Projection Television

A

A

/

X

TX-51P950M

TX-51P950X

TX-43P950M

TX-43P950X

GP11N-VP

ORDER NO.PAVCSH200507005C3

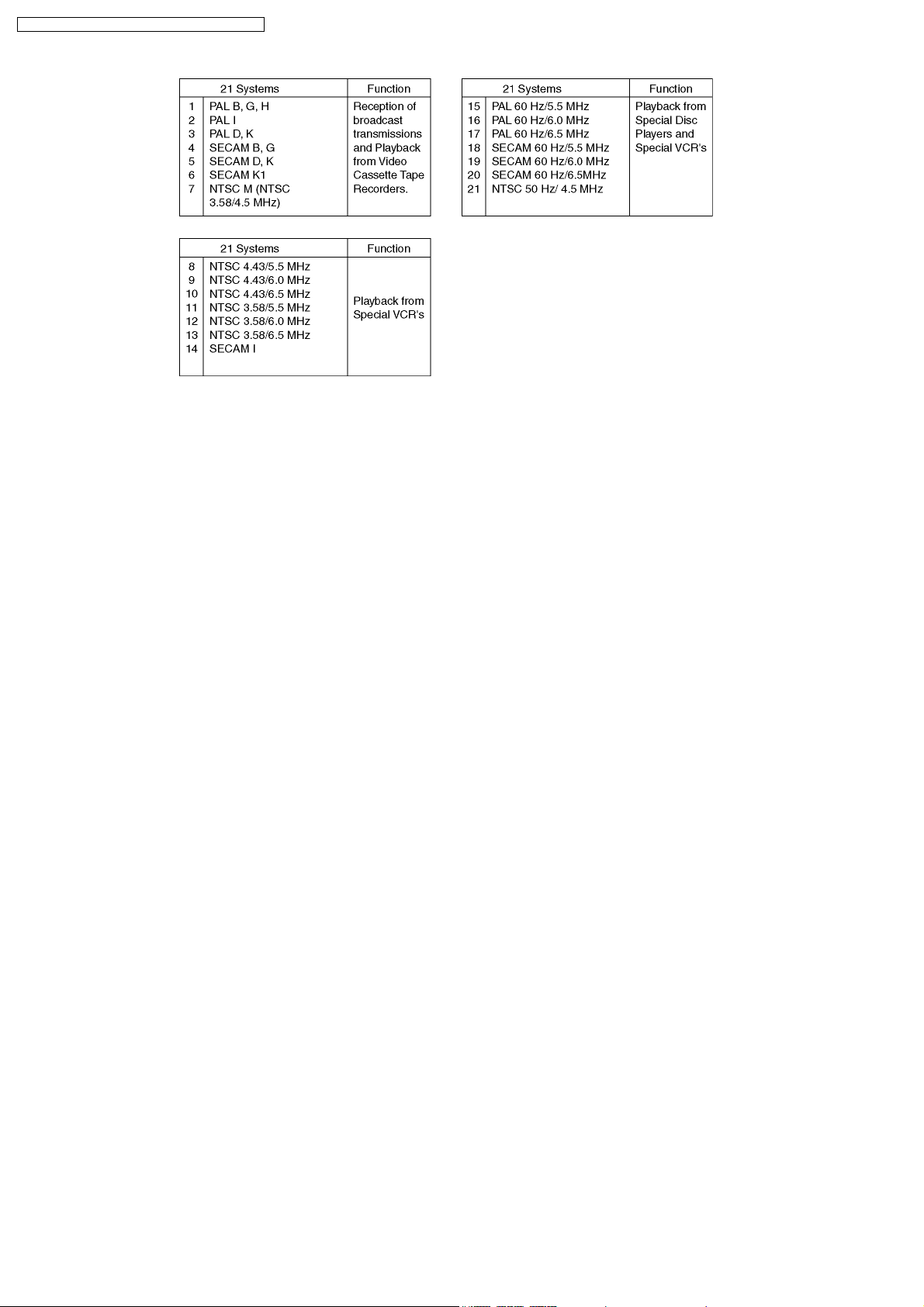

Specifications

TX-43P950M/TX-51P950M TX-43P950X/TX-51P950X

Power Source

Power Consumption Stand-bycondition: less than 1W

Dimensions (W×H×D) 1095 mm × 1267.5 mm × 518 mm 1298 mm × 1394 mm × 518 mm

Mass (Weight) 58 kg (Net) 68 kg (Net)

Remote control Transmitter N2QAJB000109

Receiving System

C 220 - 240 V, 50/60 Hz

Normal viewing: 165 W(43"),170W (51")

TX-43P950M

R6 (AA) Battery × 2

C 220 - 240 V, 50 / 60 Hz

Stand-bycondition: 0.5 W

Normal viewing : 165W(43"),170W(51")

TX-51P950M/X

© 2005 Matsushita Electric Industrial Co., Ltd. All

rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

V

V

r

A

t

V

o

/

A

A

A

A

A

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Receiving Channels Regular TV

Receiving Stereo System NICAM I, NICAM B/G, NICAM D,A2 (German)

Tuning System Frequencysynthesize

AudioOutpu

Speaker System Woofer × 2 + Squawker × 2

Headphones 3.5 mm Plug × 1

Aerial Impedance 75 Ω Unbalanced coaxial

ideo/Audi

Component Terminals

V1,2,3,4, S Video In Y: 1 V p-p, 75 Ω

Monitor Out Video Out 1 V p-p, 75 Ω

HF BAND

2-12 (PAL/SECAM B, K1)

0-12 (PAL BAUST.)

1-9 (PAL B N.Z)

1-12 (PAL/SECAM D)

1-12 (NTSC M Japan)

2-13 (NTSC M U.S.A)

UHF BAND

21-69 (PAL G, H, I/SECAM G, K, K1)

28-69 (PALAUST.)

13-57 (PAL D, K)

13-62 (NTSC M Japan)

14-69 (NTSC M U.S.A)

CAT

S1-S20 (OSCAR)

1-125 (U.S.ACATV)

C13-C49 (JAPAN)

S21-S41 (HYPER)

Z1-Z37 (CHINA)

5A, 9A (AUST.)

uto Search Tuning

POSITION: 100 Position

DIRECT: 125 Position

24W [12 W +12 W] (10 % THD)

C: 0.3 V p-p, 75 Ω

DVD (Y/PB/PR)

Video In 1 V p-p, 75 Ω

udio In

udio Out

pprox. 0.5 V 47 KΩ

pprox. 0.5 V, 1 KΩ

2

Page 3

A

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

V1 IN (Rear): S Video, Video,Audio L/R terminals

AV2 IN (Rear): Video or Y/ P

, Audio L/R terminals

B/PR

AV3 IN (Front): S Video, Video, Audio L/R terminals

AV4 IN (Rear): Video or Y/ P

Applicable signal to AV2, AV4 Y/ P

, Audio L/R terminals

B/PR

input terminals: 480i (525i), 576i (625i), 480P (525P) and 576P (625P)

B/PR

Notes: Design and Specifications are subject to change without notice. Weight and Dimensions shown are approximate .

CONTENTS

Page Page

1 Safety Precautions 5

1.1. General Guide Lines

1.2. Leakage Current Cold Check

1.3. Leakage Current Hot Check (See Fig.1)

1.4. X-Radiation

2 Chassis Board Layout

3 Disassembly for Service

3.1. Disassembly Flowchart

3.2. Cabinet Side (L, R)

3.3. Speaker Grille

3.4. Speaker Assエy

3.5. Cabinet (Top)

3.6. Speaker (Top Cabinet)

3.7. Screen

3.8. Mirror

3.9. Rear Cover (Top)

3.10. Rear Cover (Bottom)

3.11. Disassembly For CRT Removal

4 Service Hints

4.1. Service position for Main chassis

4.2. Service Position for DG-Board

4.3. Service Position for K-Board

4.4. Service Position for KA-Board

4.5. VOLTAGE CHART

5 Self Check

6 Service Mode Function

6.1. How to enter SERVICE 1

6.2. How to enter SERVICE 2

6.3. Option Descrition

7 CRT Set Up

7.1. Dynamic Focus Adjustment

7.2. Electrical Focus Adjustment

7.3. Optical Lens Focus Adjustment

7.4. Centering Magnet Adjustment

7.5. Alignment magnet Adjustment

8 Deflection Adjustment

8.1. PAL 100Hz mode (100i)

8.2. PAL 100Hz V Comp mode (100i)

10

10

10

11

12

12

12

12

13

13

14

15

15

15

17

20

20

20

20

21

22

23

23

24

8.3. PAL Progressive mode (50p)

5

5

5

5

6

7

7

8

8

8

9

9

9

8.4. NTSC Progressive mode (60p)

8.5. 525i/525p Deflection Adjustment / Confirmation

8.6. 625i/625p Deflection Adjustment / Confirmation

9 Adjustment Procedure

9.1. Cut off Adjustment

9.2. Sub Contrast Adjustment

9.3. Sub Color Adjustment

9.4. Blue Focus / Gamma Adjustment

9.5. White Balance Adjustment

9.6. Sub Bright Adjustment

9.7. Blue Limit Adjustment

10 Convergence Adjustment

10.1. Convergence Adjutment Sheet

10.2. Convergence Adjustment Procedure

10.3. Coarse Convergence Adjustment mode

10.4. Fine Convergence Adjustment

11 Location of Lead Wiring

11.1. Location of Lead Wiring (1)

11.2. Location of Lead Wiring (2)

12 Conductor Views

12.1. A-Board

12.2. D-Board

12.3. DG-Board

12.4. DC-Board

12.5. H-Board & KA-Board

12.6. GK-Board

12.7. LB-Board

12.8. LR-Board & LG-Board

13 Schematic Diagram

13.1. Schematic Diagram Notes

13.2. A-Board (1 of 4) Schematic Diagram

13.3. A-Board (2 of 4) Schematic Diagram

13.4. A-Board (3 of 4) Schematic Diagram

13.5. A-Board (4 of 4) Schematic Diagram

13.6. D-Board (1 of 2) Schematic Diagram

13.7. D-Board (2 of 2) Schematic Diagram

13.8. DC-Board Schematic Diagram

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

33

39

43

43

45

47

47

50

52

53

54

55

56

57

59

59

60

61

62

63

64

65

66

3

Page 4

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13.9. DG-Board (1 of 6) Schematic Diagram 67

13.10. DG-Board (2 of 6) Schematic Diagram

13.11. DG-Board (3 of 6) Schematic Diagram

13.12. DG-Board (4 of 6) Schematic Diagram

13.13. DG-Board (5 of 6) Schematic Diagram

13.14. DG-Board (6 of 6) Schematic Diagram

13.15. H and KA-Board Schematic Diagram

13.16. GK-Board Schematic Diagram

13.17. LB-Board Schematic Diagram

68

69

70

71

72

73

74

75

13.18. LG-Board Schematic Diagram

13.19. LR-Board Schematic Diagram

14 Parts Location

15 Packing Exploded View

16 Mechanical Replacemen t Parts List

17 Electrical Replacemen t Parts List

17.1. Replacement Parts List Notes

17.2. Electrical Replacemen t Parts List

76

77

79

81

83

85

85

86

4

Page 5

1 Safety Precautions

1.1. General Guide Lines

1. It is advisable to insert an isolation transformer in the AC

supply before servicing a hot chassis.

2. When servicing, observe the original lead dress, especially

the lead dress in the high voltage circuits.

If a short circuit is found, replace all parts which have been

overheated or damaged by the short circuit.

3. After servicing, see to it that all the protective devices such

as insulation barriers, insulation papers, shields, and

isolation R-C combinations, are properly installed.

4. When the receiver is not to be used for a long period of

time, unplug the power cord from the AC outlet.

5. Potential, as high as 30.0kV, is present when this monitor is

in operation. Operation of the Projection Monitor without the

rear cover involves the danger of a shock hazard from the

power supply. Servicing should not be attempted by anyone

who is not thoroughly familiar with the precautions

necessary when working on high voltage equipment.

Always discharge the anode of the projection tube to the

Projection Monitor chassis before handling the tube.

6. After servicing make the following leakage current checks to

prevent the customer from being exposed to shock

hazards.

1.2. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Turn on the Projection Monitor´s power switch.

3. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the projection monitor, such as screw heads,

connectors, control shafts, etc. When the exposed metallic

part has a return path to the chassis, the reading should be

between 4 MΩ and 20 MΩ.

When the exposed metal does not have a return path to the

chassis, the reading must be

.

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

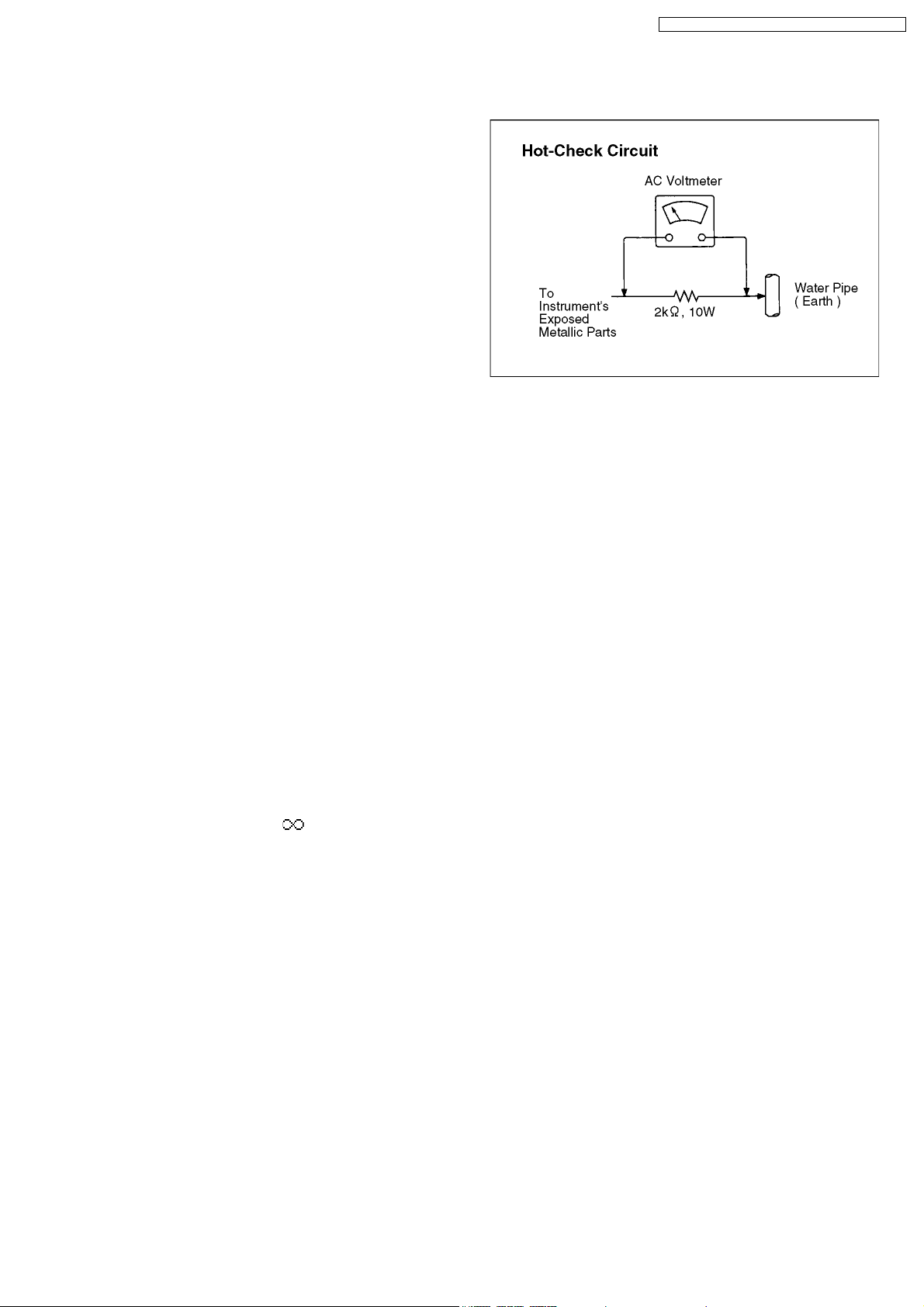

Fig. 1

1.4. X-Radiation

Warning :

1. The potential sources of X-Radiation in projection

monitor are the High Voltage section and the projection

tube.

2. When using a projection tube test jig for service, ensure

that jig is capable of handling 31.5kV without causing XRadiation.

Note:

It is important use an accurate periodically calibrated high

voltage meter.

1. Set the brightness to minimum.

2. Set the service switch to the service position.

3. Measure the High Voltage. The meter reading should

indicate 31.5(+1.0,-1.5kV). If the meter indication is out of

tolerance, immediate service and correction is required to

prevent the possibility of premature component failure.

4. To prevent an X-Radiation possibility, it is essential to use

the specified projection tube.

1.3. Leakage Current Hot Check

(See Fig.1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 2kΩ, 10W resistor, in series with an exposed

metallic part on the projection monitor and an earth such as

a water pipe.

3. Use an AC voltmeter, with high impedance type, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurement s.

6. The potential at any point should not exceed 1.0V rms. In

case a measurement is outside of the limits specified, there

is a possibility of a shock hazard, and the projection monitor

should be repaired and rechecked before it is returned to

the customer.

5

Page 6

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

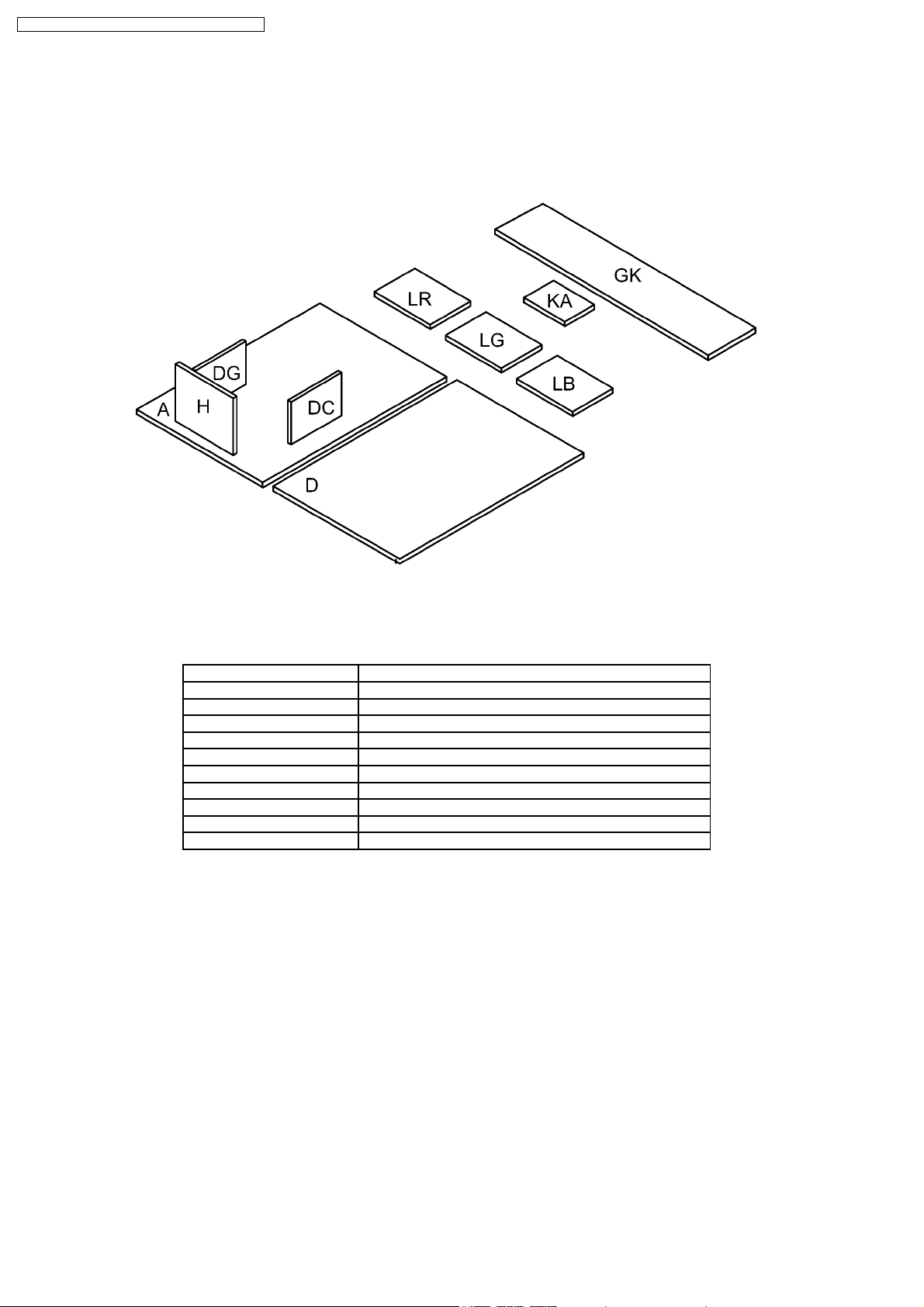

2 Chassis Board Layout

Board-Name Function

A-Board Main Signal, Digital Converter,Line Filter

D-Board Deflection, High Voltage

LR-Board CRT Drive (R)

LG-Board CRT Drive (G)

LB-Board CRT Drive (B)

H-Board Rear terminal

DG-Board Digital Core,MPU,AV Switch

DC-Board Convergence

GK-Board Front Terninal,Power Switch,Front Control panel

KA-Board Blue light

6

Page 7

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

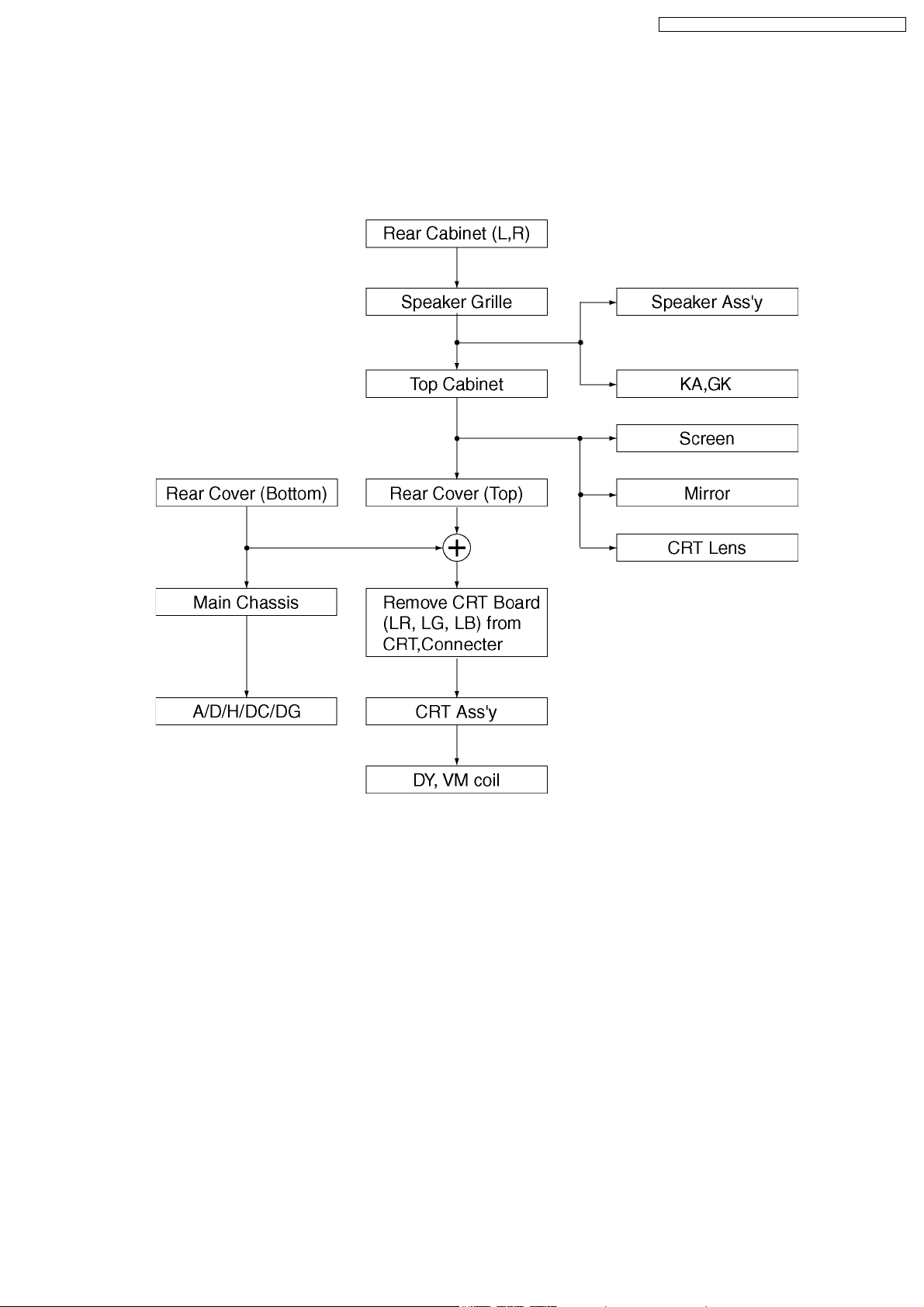

3 Disassembly for Service

This flowchart indicates disassembly items of the cabinet parts and circuit boards in order to find the items necessary for

servicing, when reassembling, perform the procedures in the reverse order.

3.1. Disassembly Flowchart

7

Page 8

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Note:

Board ground wires may have to be disconnected to disassemble some boards. All ground wires must be reconnected using

jumper leads if necessary before power is applied to Receiver for service.

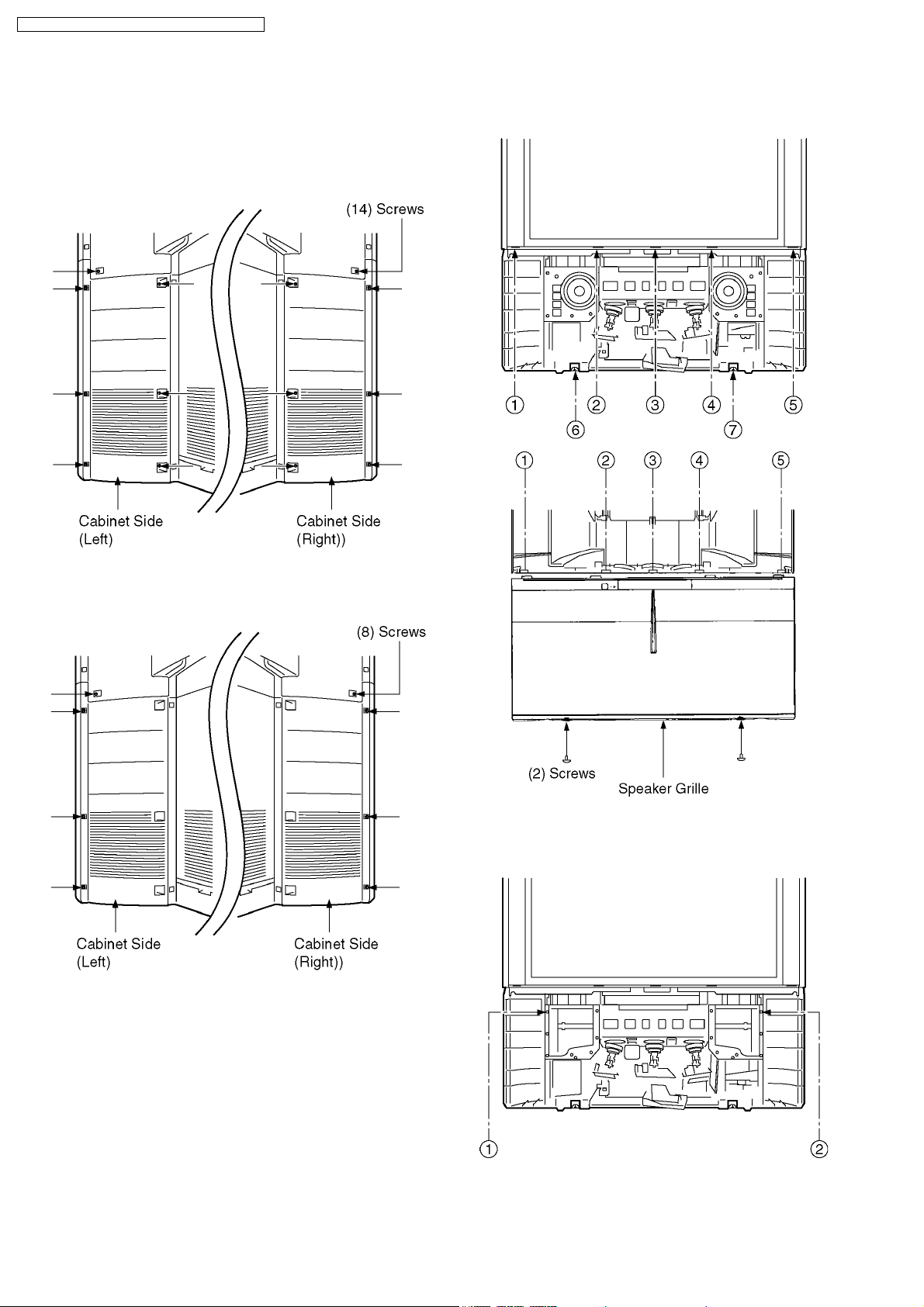

3.2. Cabinet Side (L, R)

1. Remove (14) screws.

3.3. Speaker Grille

1. Remove (8) screws.

2. Remove (2) screws.

3.4. Speaker Ass´y

1. Remove (10) screws.

8

Page 9

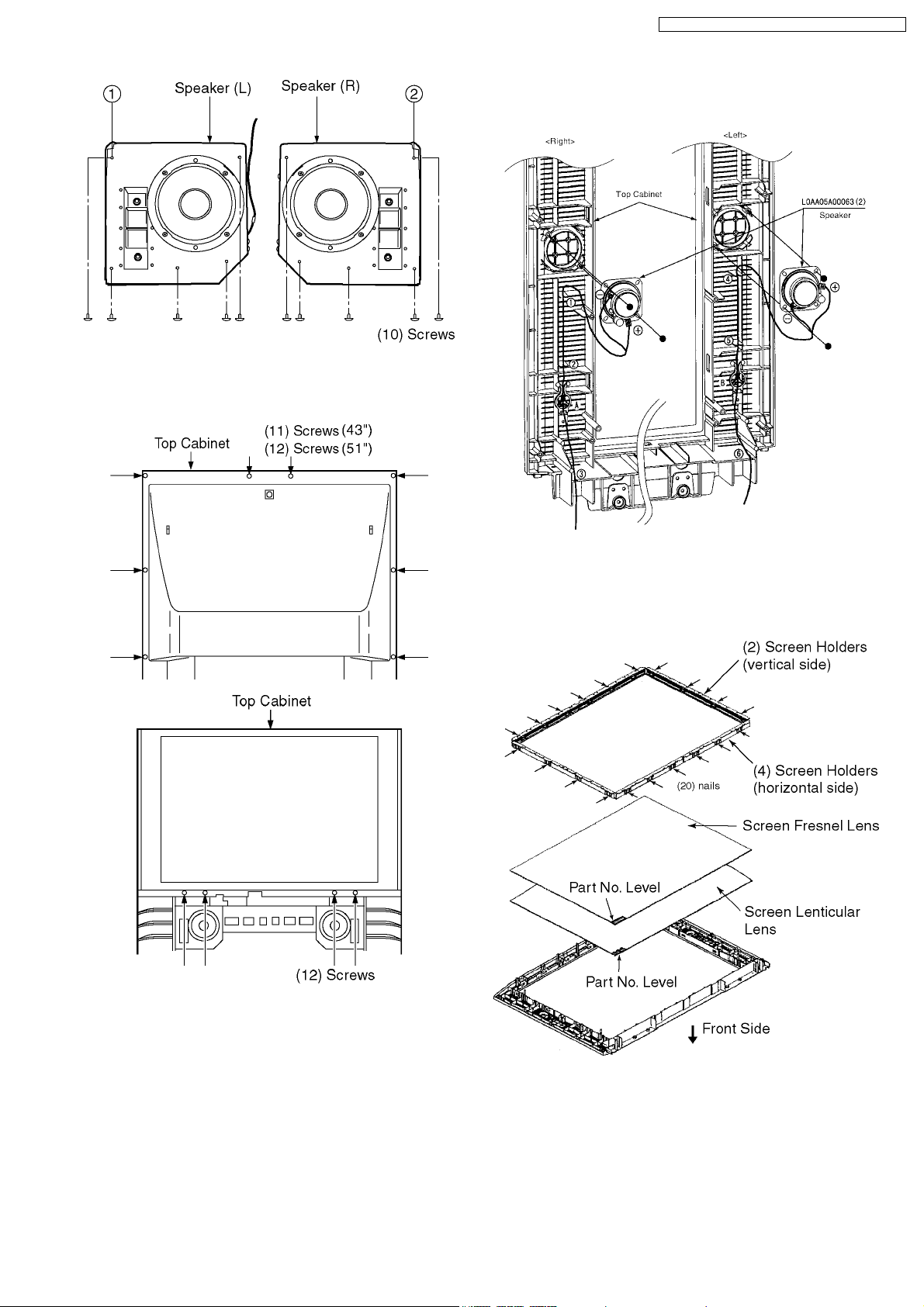

3.5. Cabinet (Top)

1. Remove (12) Screws.

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

3.6. Speaker (Top Cabinet)

3.7. Screen

1. Remove (20) nails, and remove (2) Screen Holders (vertical

side) and (4) Screen Holders (horizontal side).

9

Page 10

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

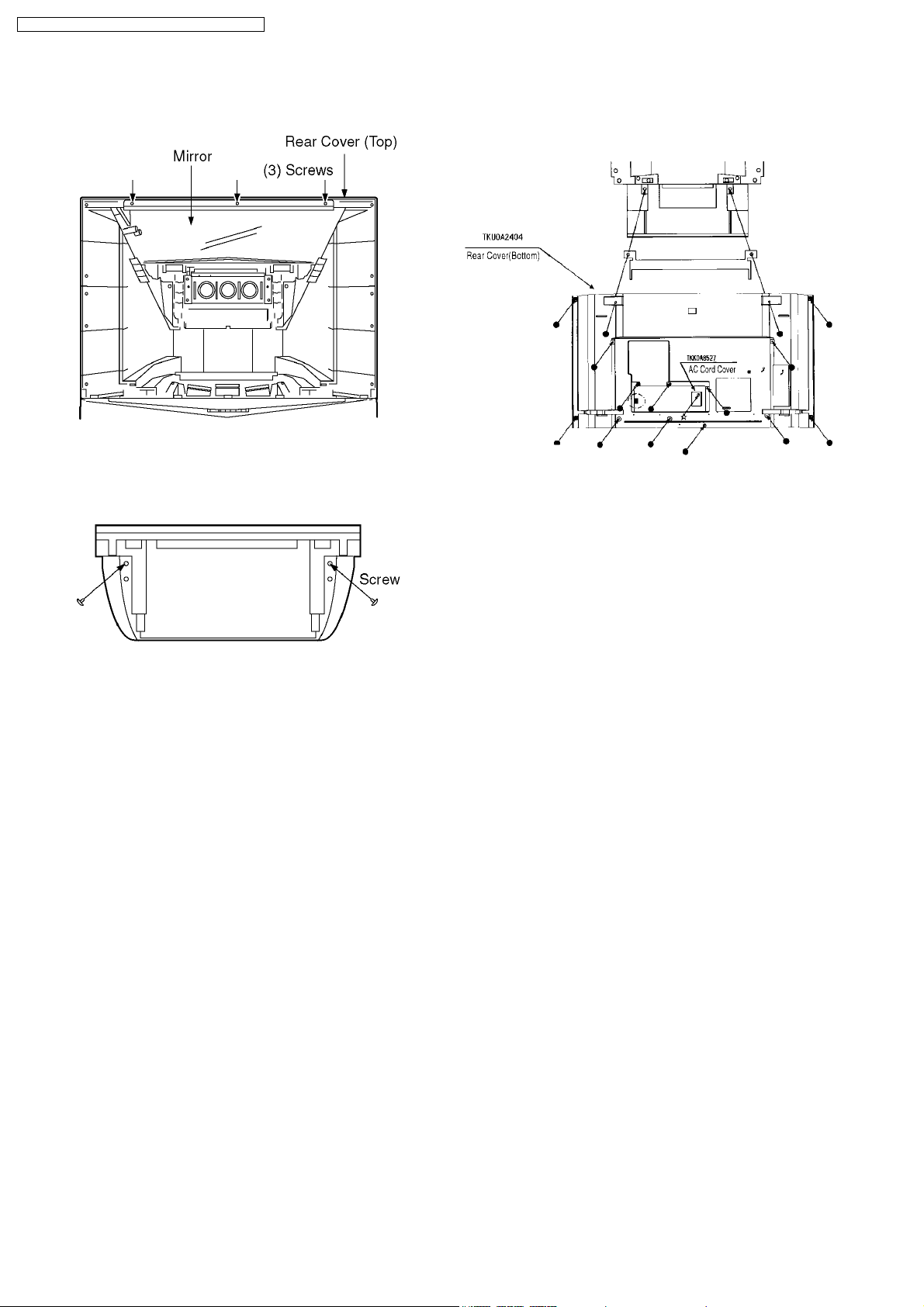

3.8. Mirror

1. Remove (3) screws.

3.9. Rear Cover (Top)

1. Remove the Top Cabinet.

2. Remove (2) screws.

3.10. Rear Cover (Bottom)

1. Remove (15) screws.

2. Remove (1) screw.

10

Page 11

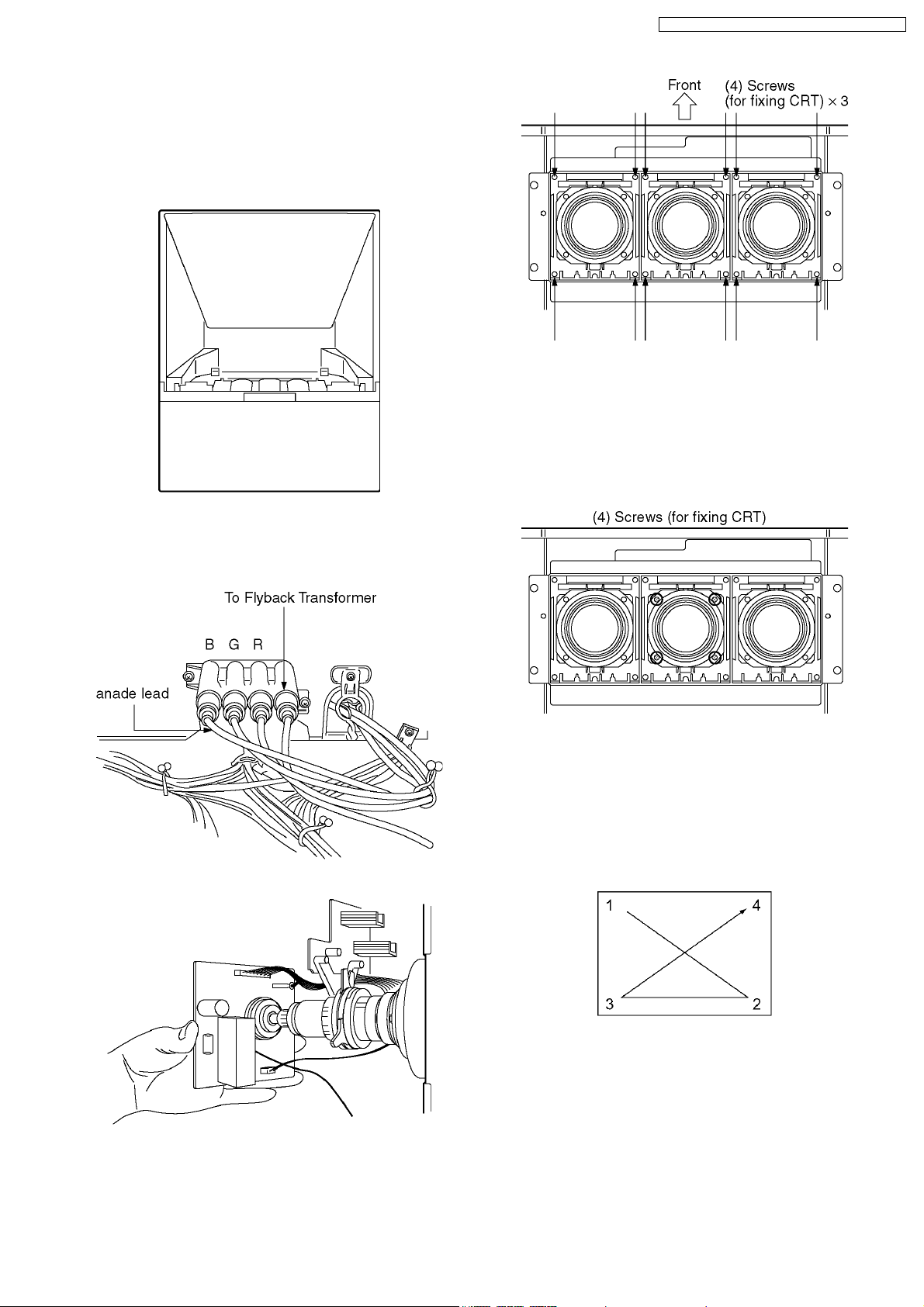

3.11. Disassembly For CRT Removal

To facilitate CRT replacement, the complete CRT mounting

chassis does not need to be removed.

1. Remove the Screen Frame Ass´y, Decorative Panel and

the Bottom Rear Cover Ass´y. ( See Disassemble for

Service ).

2. Unplug the defective CRT Dag ( GND ), from the CRT

Board, LBGND for LB, LGGND for LG, LRGND for LR.

3. Remove lead wires ( DY, VM coil ) and anode lead wire

from holders as necessary.

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

7. Release CRT anode lead from CRT chassis wire clamp and

all other wires from holders.

8. Wire the anode lead wire.

9. Lift out CRT assembly with lens assembly and other CRT

neck assemblies.

10. Lay CRT face down on a soft cloth.

11. Remove CRT lens by removing (4) screws.

4. Remove the CRT Board from the defective CRT neck.

5. Note position of yoke with centering tabs and remove from

defective CRT.

6. From the Top, remove (2) screws from the defective CRT.

12. Install yoke and VM coil with other CRT neck assemblies on

CRT neck in the same order and position as removed from

the defective CRT.

13. Push yoke against bell of CRT and tighten the clamp just

snug enough so it will not easily shift.

14. Assem ble CRT focus lens assembly to new CRT with (4)

screws. Make sure focus lens adjustment nut is in the same

location as on other CRT focus lens.

Note:

Please assemble with screws in the order shown in detail

and tighten with same torque.

11

Page 12

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

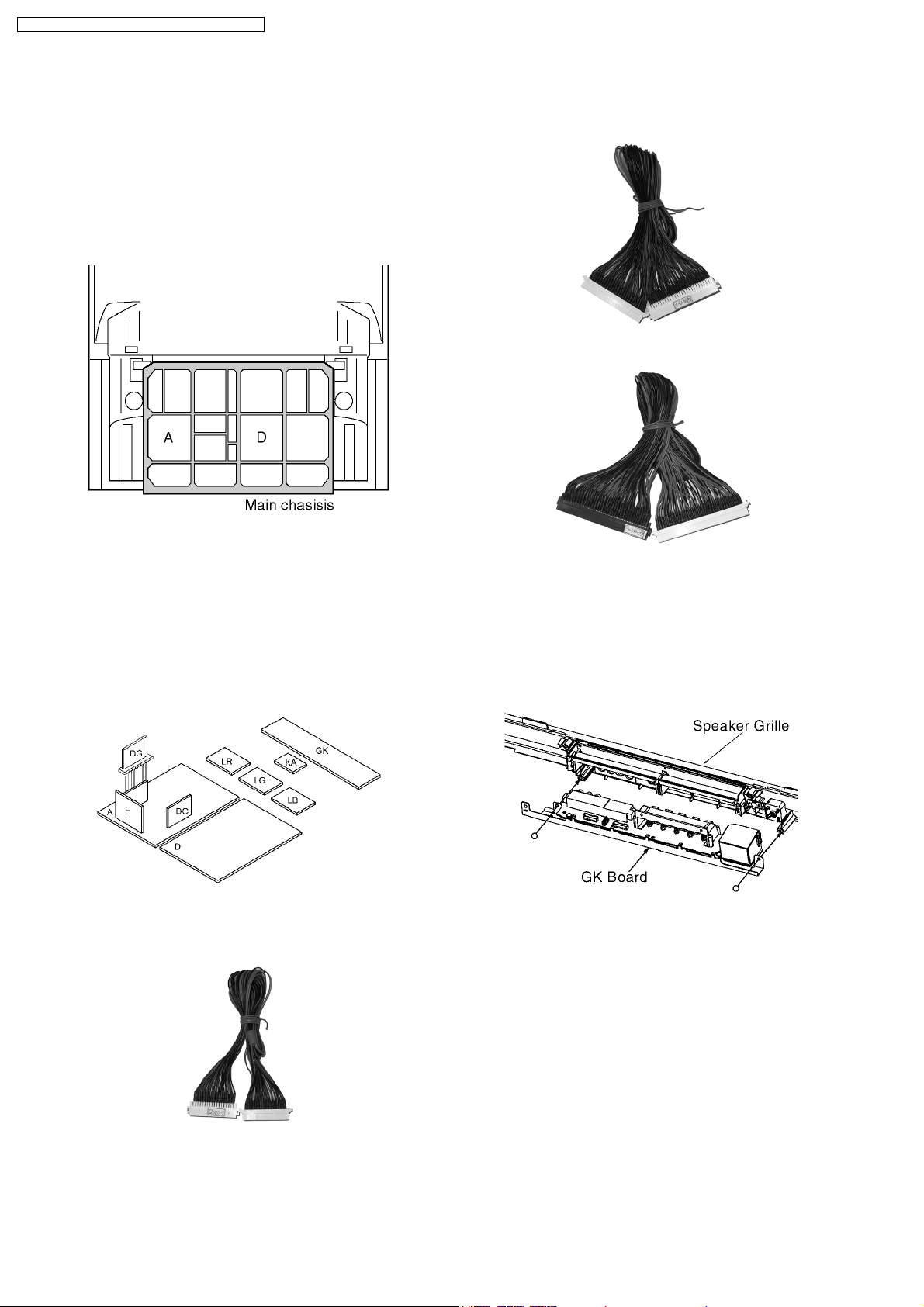

4 Service Hints

4.1. Service position for Main

chassis

1. Remove the Rear Cover (Bottom) by removing (15) screws

and (1) screws around its perimeter.

2. Remove lead wires and bundles from holders as necessary.

3. Pull out main chassis and stand it.

4.2. Service Position for DG-Board

PART No. :GP11(N)-2

PART No. :GP11(N)-3

1. Remove the each circuit board from A or D-Board.

2. Connect extension cables between individual circuit board

and A or D-Board.

Note:

Extension cable kit is supplied as service fixtures and tools.

PART No. :GP11(N)-1

4.3. Service Position for K-Board

1. Remove the Speaker Grille.

2. Remove the K-Board by (4) screws.

12

Page 13

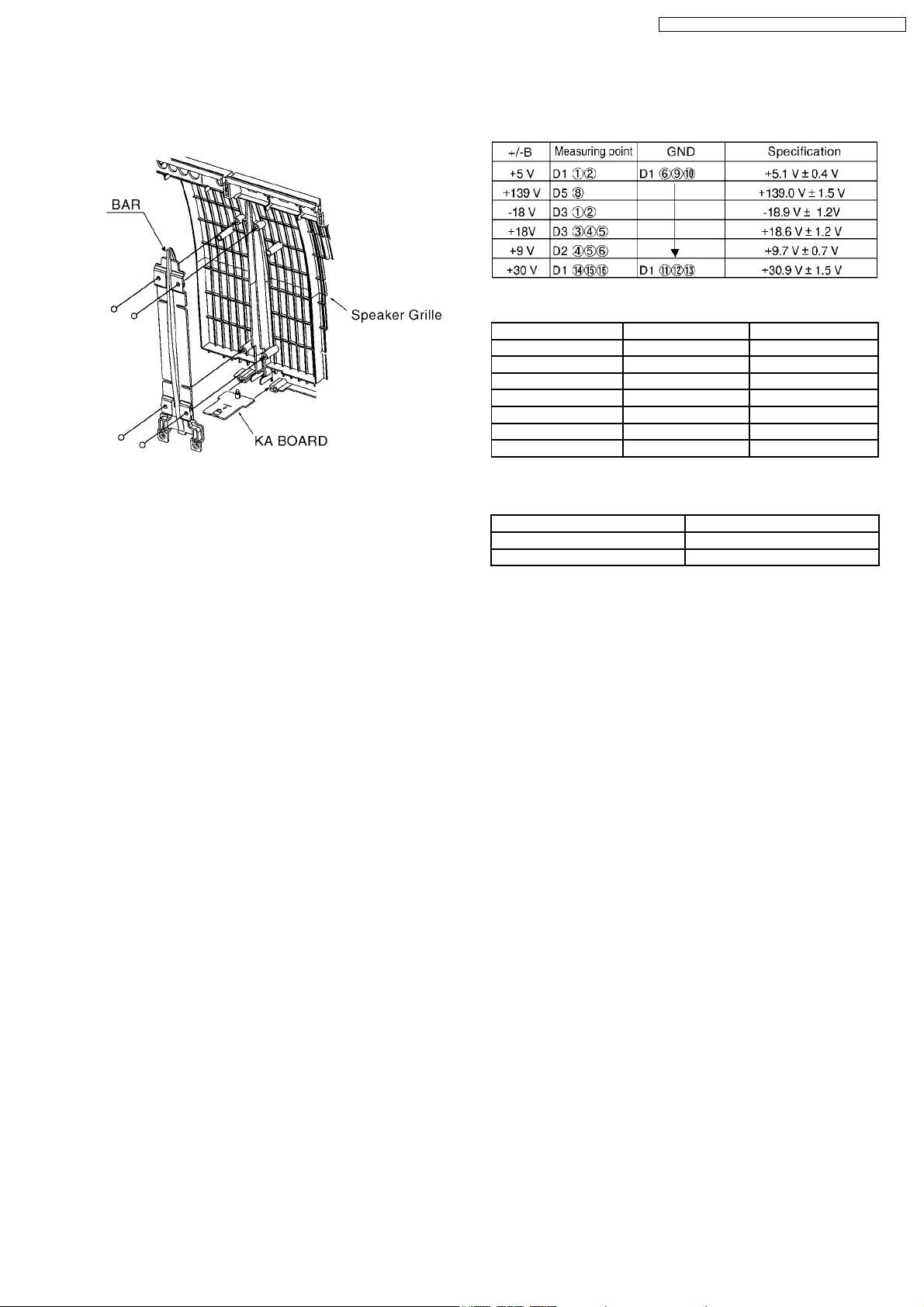

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

4.4. Service Position for KA-Board

1. Remove the Speaker Grille.

2. Remove the Terminal Door by (4) screws.

3. Remove the KA-Board.

4.5. VOLTAGE CHART

D-BOARD

A-BOARD

SUPPLY TEST POINT VOLTAGE

12V ~ GND A5 PIN9 11.9 ± 0.45V

TNR-5V ~ GND IC001 PIN3 5.0V ± 0.4V

9V ~ GND IC058 PIN3 9.0V ± 0.4V

8V ~ GND IC2000 PIN2 8.0V ± 0.4V

5V ~ GND IC2002 PIN3 5.0V ± 0.4V

3.3V ~ GND IC065 PIN2 3.2V ± 0.2V

2.5V ~ GND IC1402 PIN4 2.5V ± 0.25V

Heater Voltage And High Voltage

TPLB3(+) ~ TPLB2(-) 6.3 ± 0.24VRMS

High Voltage 31.5+1.0KV,-1.5KV

13

Page 14

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

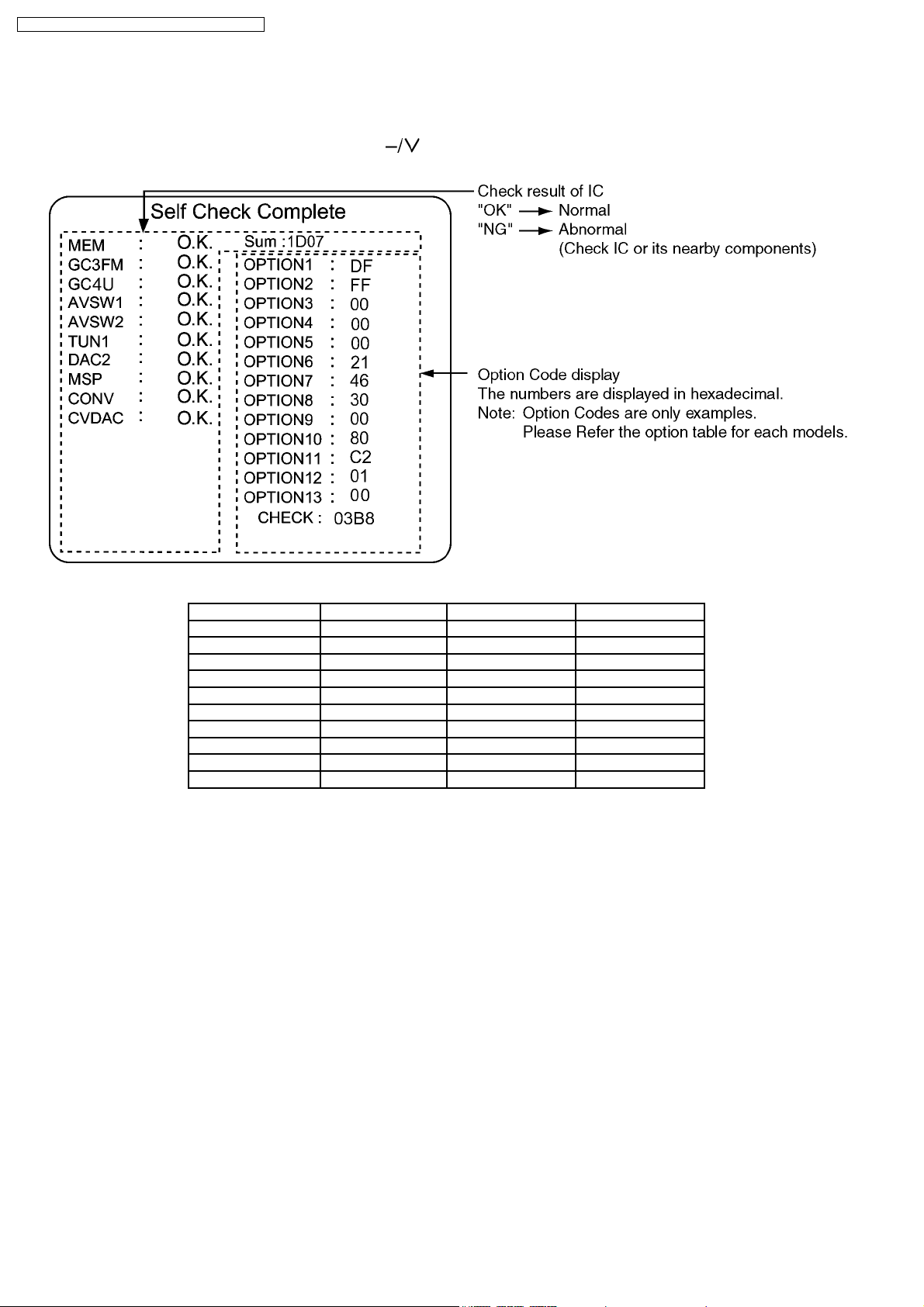

5 Self Check

1. Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

2. To get into the Self -Check mode press the down (

time pressing the OFF Timer button on the remote control, and the screen will show :

) button on the customer controls at the front of the set, at the same

If the CCU ports have been checked and found to be incorrect or not located then “--” will appear in place of “O.K.”.

Display Ref. No. Description P.C.B.

MEM IC1404 Memory A-Board

GC3FM IC4001 Grobal Core MAIN DG-Board

GC4U IC4401 Grobal Core SUB DG-Board

AVSW1 IC3001 AV Switch DG-Board

AVSW2 IC3002 AV Switch DG-Board

TNU1 TU1 Tuner A-Board

DAC2 IC1101 DAC Control2 DG-Board

MSP IC2001 Stereo Decoder A-Board

CONV IC7103 Convergence DC-Board

CVDAC IC7106 CONV. DAC DC-Board

14

Page 15

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

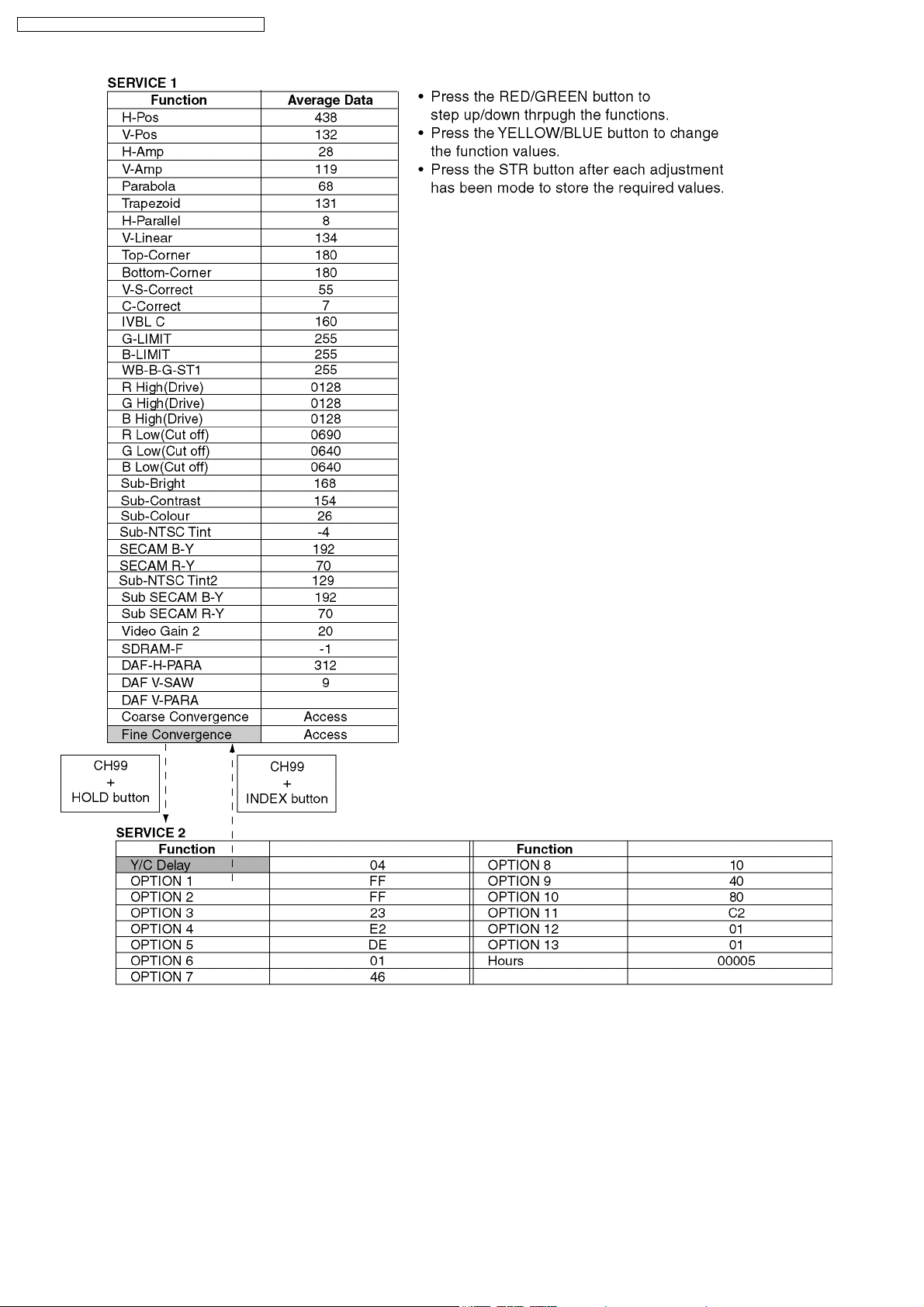

6 Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can be

adjusted by remote control in Service Mode.

6.1. How to enter SERVICE 1

1. In sound menu, set BASS to MAX, and set TREBLE to MINIMUM.

2. Simultaneously press RECALL button on remote control and VOLUME DOWN button [ - ] on the TV set.

6.2. How to enter SERVICE 2

1. Set the channel to CH99.

2. Press HOLD button on remote control.

Note:

To exit to Service mode, press N or Power button on remote control.

15

Page 16

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

16

Page 17

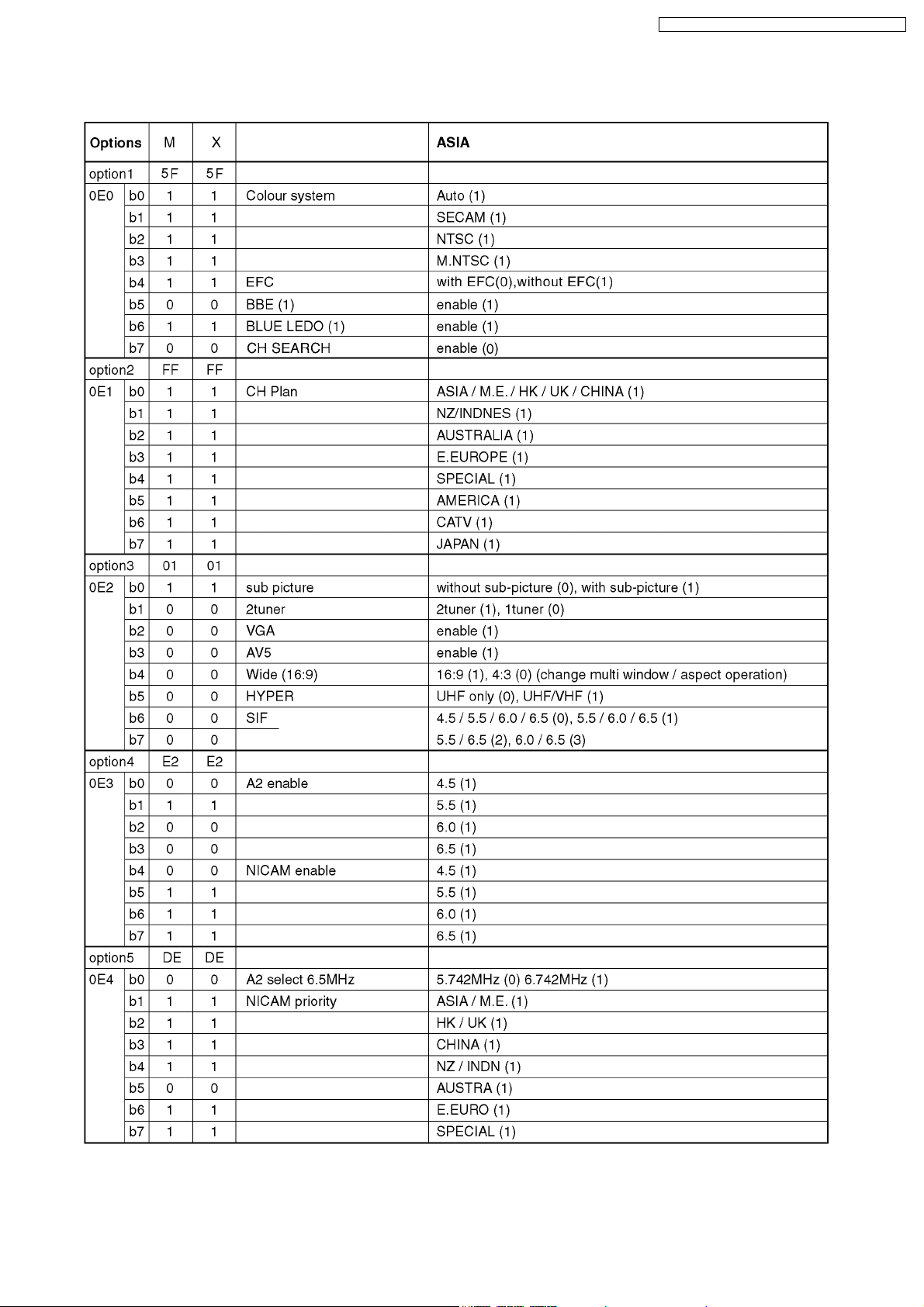

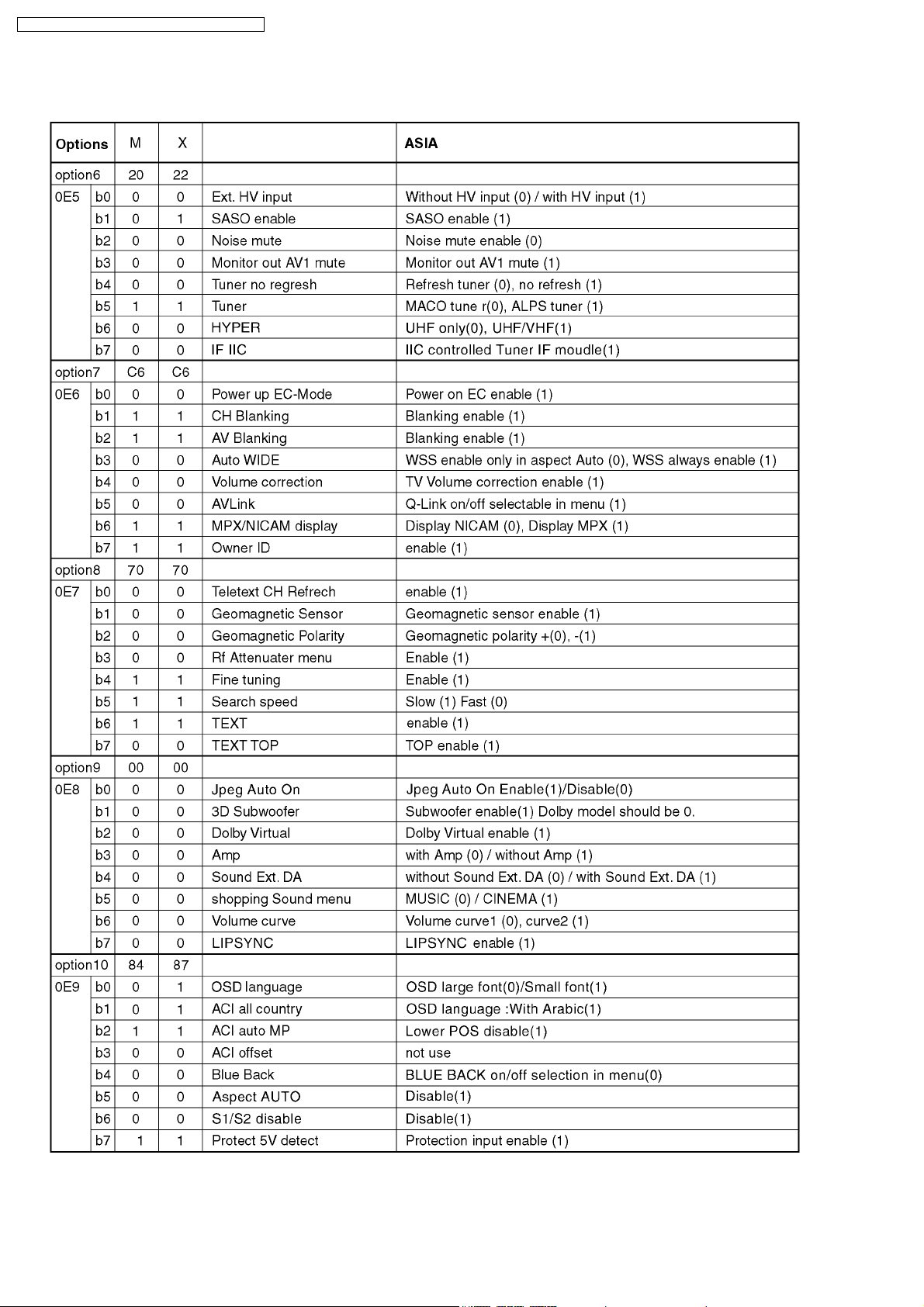

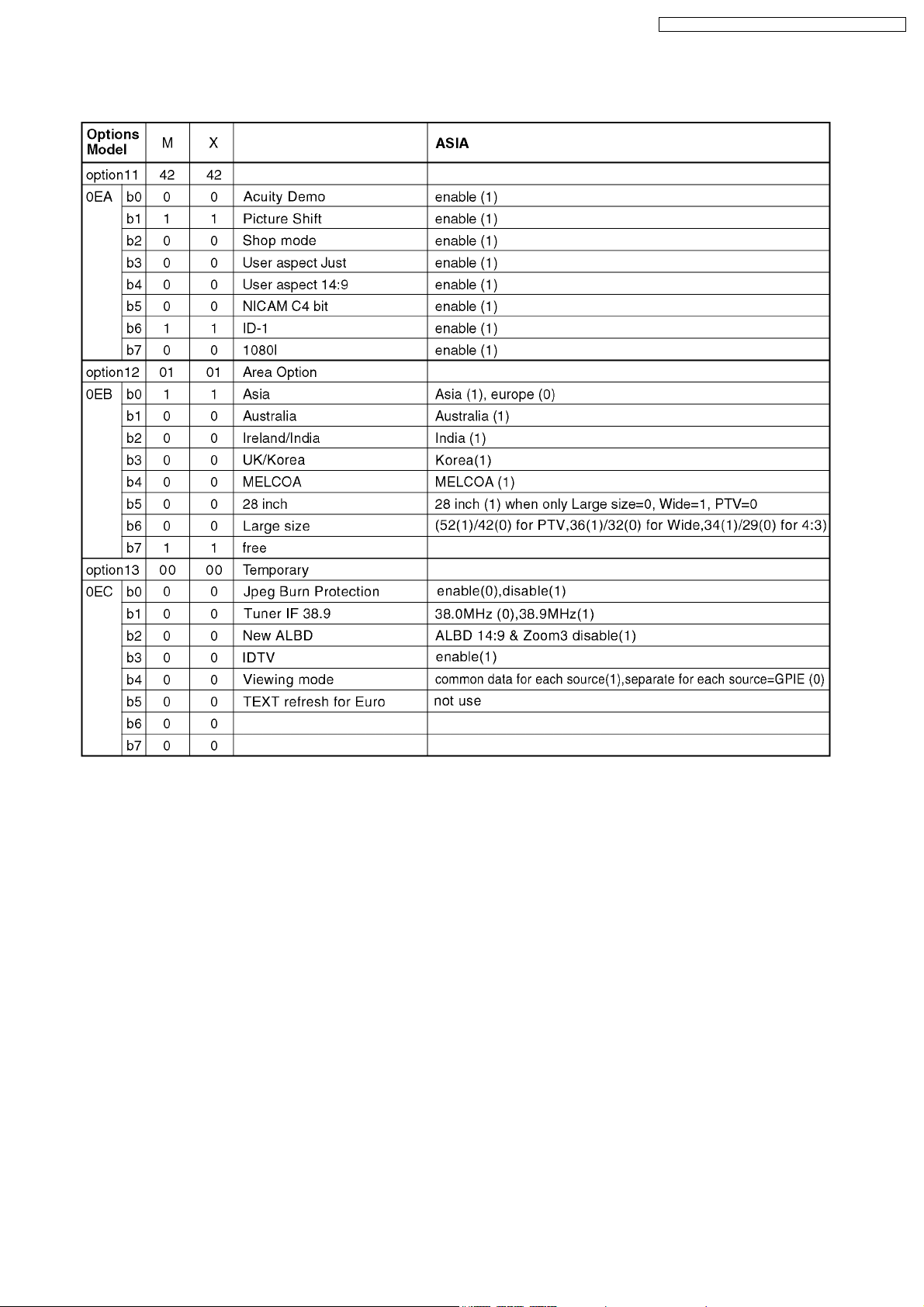

6.3. Option Descrition

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

17

Page 18

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

18

Page 19

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

19

Page 20

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

7 CRT Set Up

Caution:

Insure yoke plugs on the A-Board are reconnected before

turning the Receiver ON to prevent damage to the

horizontal output transistor and/or CRTs.

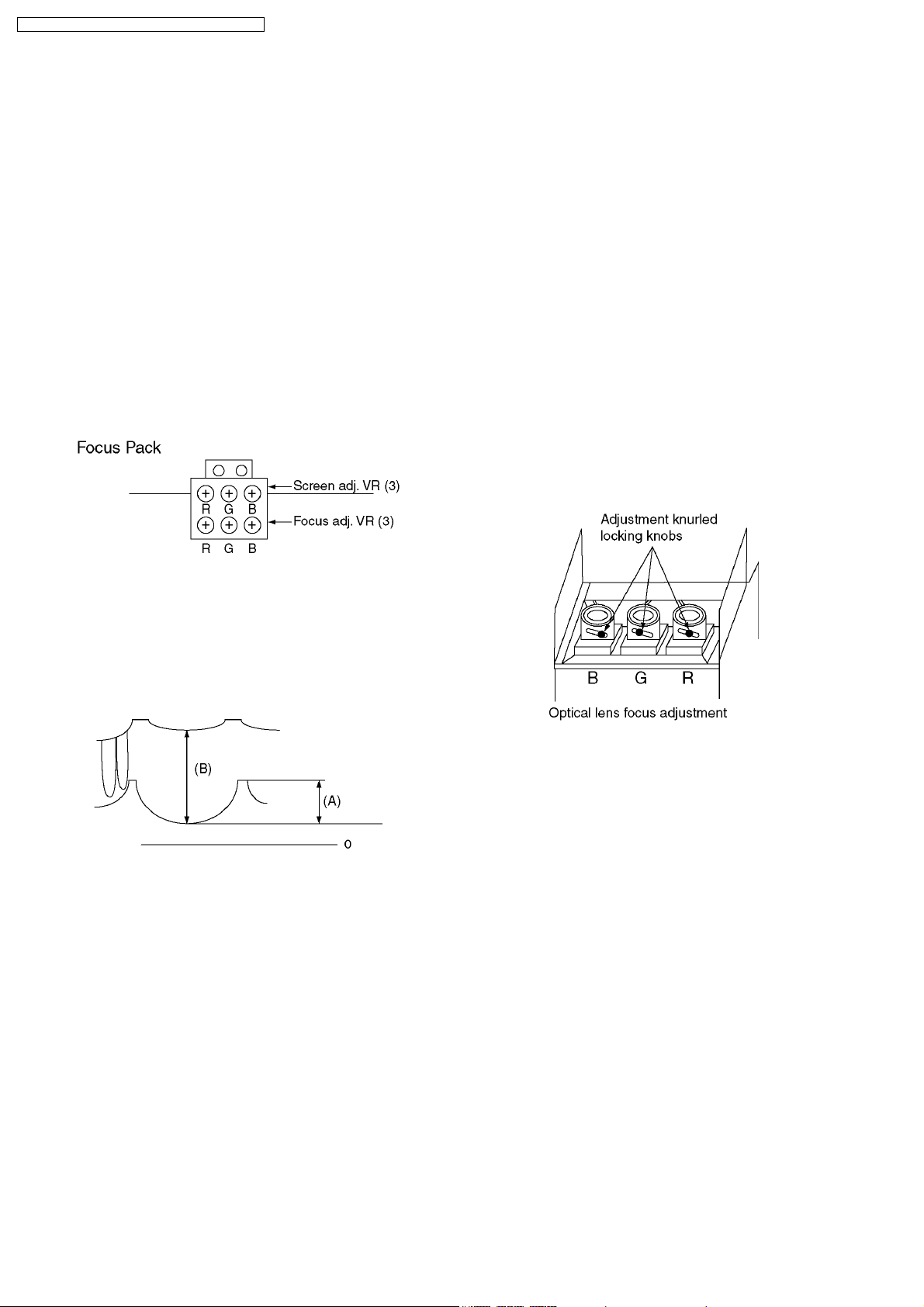

7.1. Dynamic Focus Adjustment

1. Focus adjustments should be performed after 1 hour of

aging.

2. Use oscilloscope with 100 : 1 probe.

3. Apply PAL monoscope pattern.

4. Set scan mode to 100Hz.

5. Set the picture menu to Dynamic.

6. Set the DAF V-SAW data: 7.

7. Adjust the Red, Blue and Green focus VR on the focus

block for best focus of overall picture of each CRT. (Fig. 2)

Fig. 2

7.2. Electrical Focus Adjustment

1. Receive a monoscope pattern.

2. Cover the Red and Blue CRT, projecting Green only.

The electrical focus controls are located on the front. Adjust

the Green Focus VR for best focus of overall picture. (Fig.

2)

3. Repeat for Red focus VR while projecting Red only.

4. Repeat for Blue. (Best focus at bottom left corner of screen)

7.3. Optical Lens Focus

Adjustment

Note:

This adjustment normally should not require resetting

unless the lens has been replaced or adjustment has

changed.

1. Optical focus adjustment is located on the top of each CRT

lens system. Loosen the adjustment knurls locking knob.

(Fig. 4)

8. Connect the scope probe to TPD20, GND to TPD21. Scope

set at 20V/div & 5m sec./div.

9. Adjust V-PARA (Service mode1) so that waveform (A) is

360V ± 20V. (Fig. 3)

10. Adjust H-PARA (Service mode1) so that waveform (B) is

560V + 40V,-60V. (Fig. 3)

Fig. 3

11. Set scan mode to PAL 100V Comp.

12. Set the picture menu to Dynamic.

13. Adjust V-PARA (Service model) so that waveform (A) is

260V ± 20V. (Fig. 3)

14. Adjust H-PARA (Service model) so that waveform (B) is

560V + 40V, -60V. (Fig. 3)

15. Set scan mode to Progressive.

16. Repeat step 7-10.

17. Apply NTSC monoscope pattern.

18. Set scan mode to Progressive.

19. Repeat step 7-10.

20. Set scan mode to 100Hz.

21. Repeat step 7-10.

22. Proceed with Focus Adjustments.

Fig. 4 (Rear view)

2. Turn the Receiver ON apply and view a monoscope pattern.

3. Adjust each lens focus for best focus while viewing each

CRT.

4. Cover the Red and Blue CRT, projecting green only.Rotate

the Green lens for best focus around screen center area.

5. Do the same for the Red focus lens while projecting Red

only.

6. Repeat for Blue.

20

Page 21

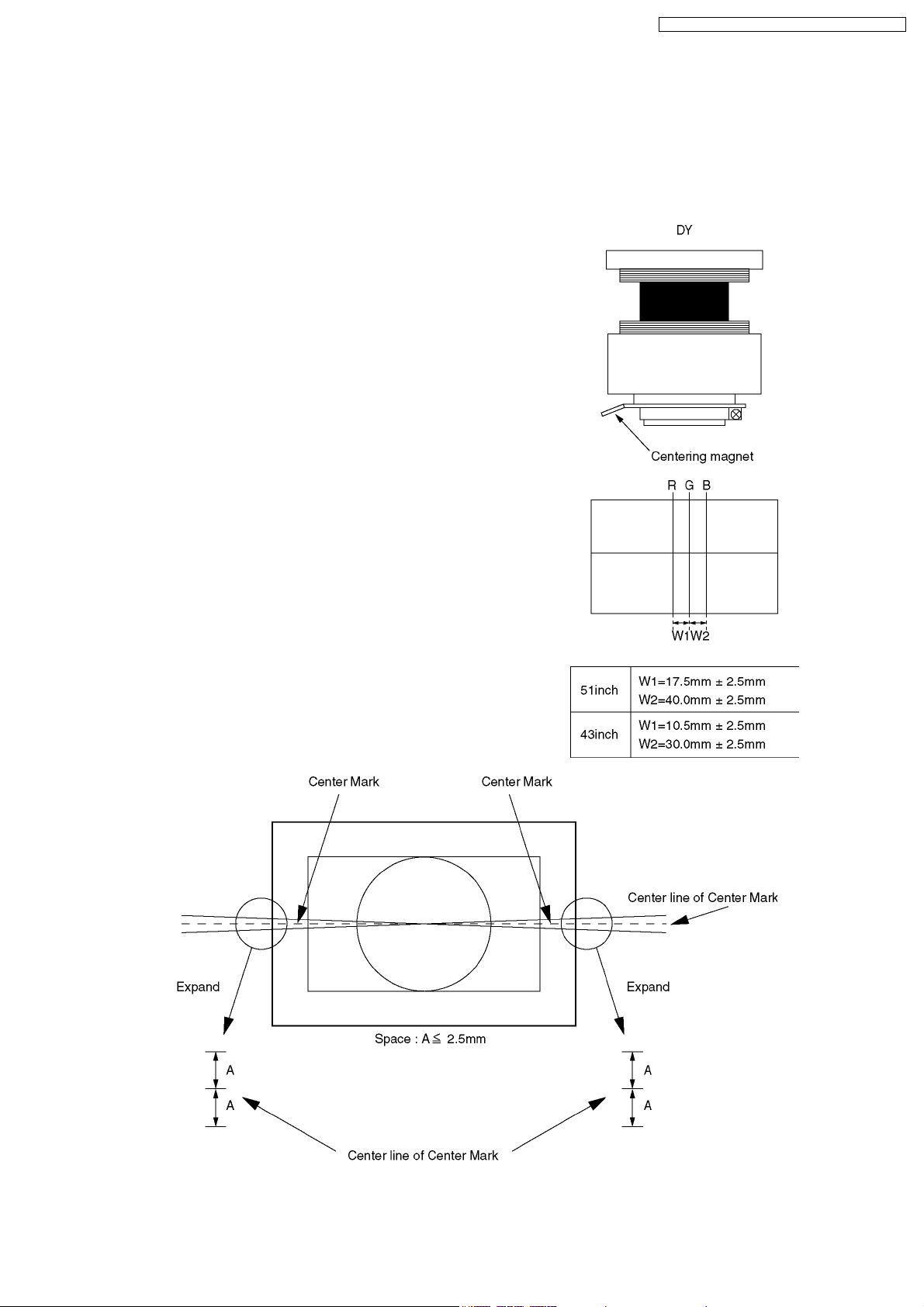

7.4. Centering Magnet Adjustment

1. Receive a monoscope pattern.

2. Set that Fine convergence data (Service mode1) is clear (no correction).

3. Set that V-Pos data (Service mode1) is [130].

4. Set that H-Pos data (Service mode1) is [954].

5. Set that H-Parallel data (Service mode1) is [16].

Procedure:

1. Cover the Red, Blue CRT lens, projecting Green only.

2. Adjust green centering magnet (DY) if the projected

green horizontal/vertical line does not line up with the

screen horizontal/vertical center line.

3. Cover the Green, Red CRT lens, projecting Blue only.

4. Repeat step 2. for blue.

5. Cover the Green, Blue CRT lens, projecting Red only.

6. Repeat step 2. for red.

7. Cover the Red, Blue CRT lens, projecting Green only.

8. Adjust green centering magnets until the center of the

monoscope pattern line up with the screen center line.

9. Cover the Green, Red CRT lens, projecting Blue only.

10. Adjust blue centering magnets to position the center of

the blue raster W2 away from the center of the green

raster.

11. Cover the Green, Blue CRT lens, projecting Red only.

12. Adjust red centering magnets to position the center of

the red raster W1 away from the center of the green

raster.

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

21

Page 22

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

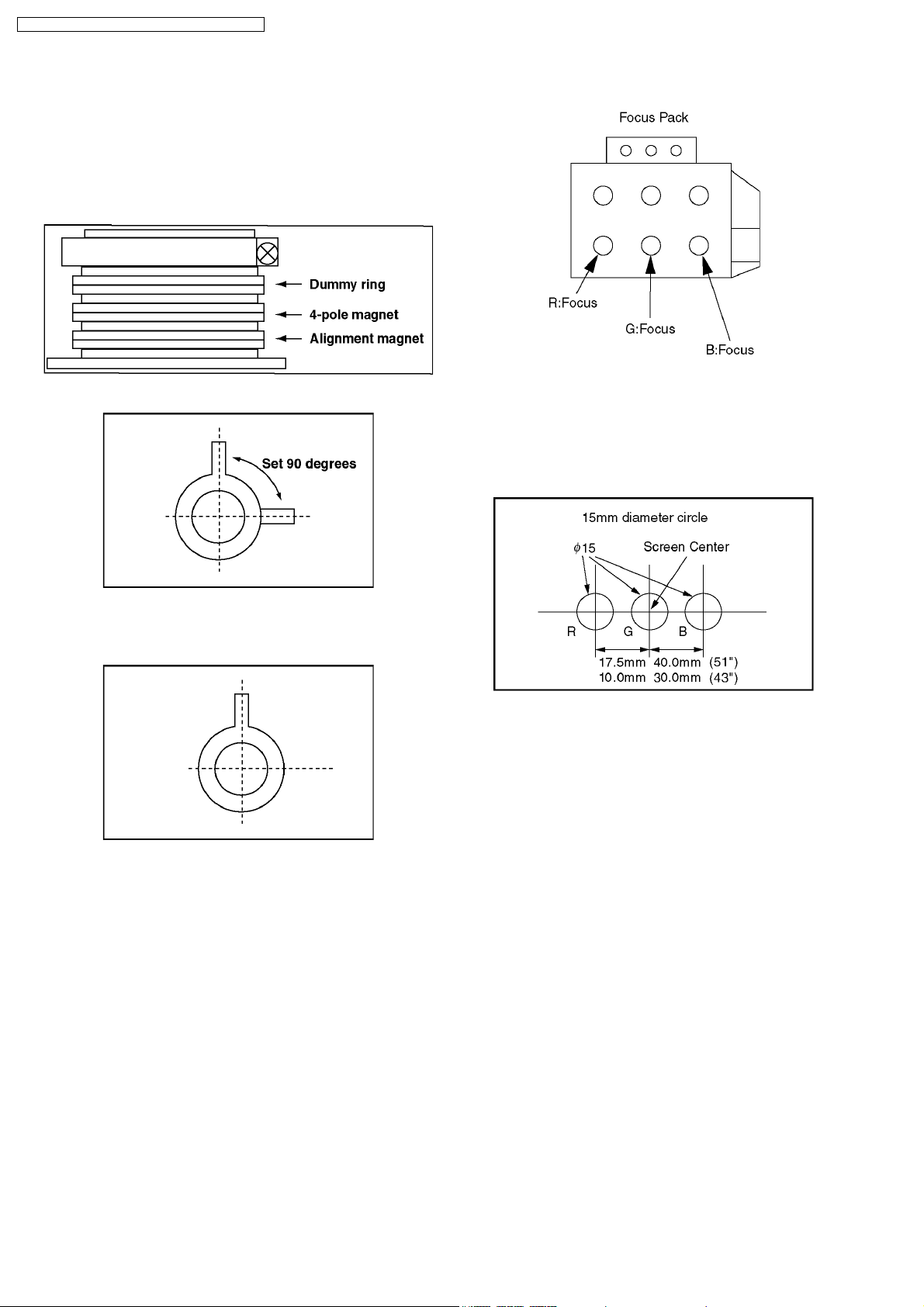

7.5. Alignment magnet Adjustment

Preparation:

1. Receive an cross hatch pattern with dots (pincushion).

2. Loosen the centering magnets screws.

3. Position the longer tab of the four-pole magnet to 90

degrees (uncorrected position).

VM Coil with focus correction magnet

4-pole magnet

4. Position the long tab of all alignment magnets and of the

dummy ring together in an uncorrected position.

Alignment magnet (or dummy ring)

Procedure:

1. Receive an cross hatch pattern with dots.

2. Cover the Red, Blue CRT lens, projecting Green only.

3. Turn the green electrical focus adjustment VR (on focus

pack) fully counterclockwise and note the position of the

dots at the center of the picture.

4. Turn the green electrical focus adjustment VR fully

clockwise.

5. Adjust the four pole magnets until the shape of the dot

at the center of the screen is circular.

6. Adjust for best green electrical focus with green

electrical focus adjustment VR.

7. Cover the Green, Red CRT lens, projecting Blue only.

8. Repeat step 4. ~ step 6. for blue electrical focus.

9. Cover the Green, Blue CRT lens, projecting Red only.

10. Repeat step 4. ~ step 6. for red electrical focus.

11. Receive an monoscope pattern.

12. Cover the Red, Blue CRT lens, projecting Green only.

13. If the center of the monoscope pattern is not inside the

15mm circle, shown in below, adjust the centering

magnets. Repeat the alignment magnet adjustments

and four pole magnet adjustments (step 1. ~ step 6.)

Centering magnet adjustment

14. Cover the Green, Blue CRT lens, projecting Red only.

15. Repeat step 13. for the red.

16. Cover the Green, Red CRT lens, projecting Blue only.

17. Repeat step 13. for the blue.

18. Following adjustments, fix the centering magnets of DY,

dummy rings of VM coil, four pole magnets of VM coil

and the alignment magnets of VM coil to prevent them

from moving.

22

Page 23

8 Deflection Adjustment

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Caution

1. The following adjustment have to be carried out one

with PAL signal (100i/50p) and with NTSC signal

(60p/120i).

2. Deflection adjustment need to set the Coarse/Fine

Convergence to Zero Correction some time.

3. Before Deflection Adjustment are attempted, CRT Set

up, Electrical Focus and Optical Lens Focus adjustment

must be completed.

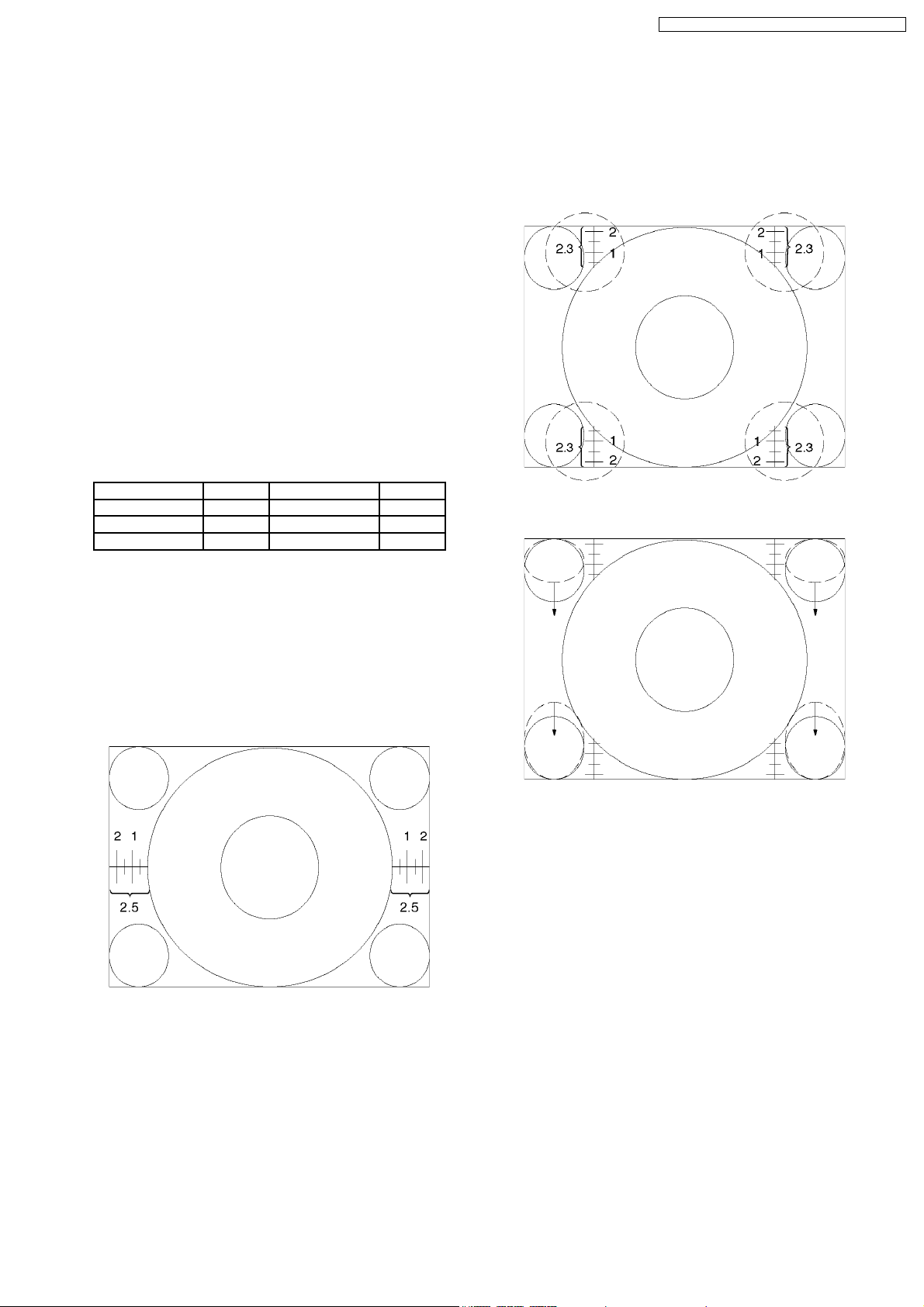

8.1. PAL 100Hz mode (100i)

8.1.1. Preparation

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz.

3. Set the Picture Menu to NORMAL.

4. Set the TV to Service Mode 1.

5. Set the Data of Service Mode 1 as follow

H-Pos 954 Top-Corner 186

V-Pos 130 Bottom-Corner 187

H-Parallel 16 V-S-Correct 62

IVBL C 52 C-Correct 16

6. Push [ 0 ] button so that set the Data of Coarse/Fine

Convergence to Zero Correction.

7. Push [ R-TUNE ] button so that projecting Green only.

8.1.3. V-Amp, V-Linear and V-Pos

Adjustment

1. Adjust Vertical amplitude for 2.3 ± 0.1 division of a scale by

V-Amp control.

2. Confirm Vertical Linear as to the balance of circle, if need

adjust V-Linear control.

8.1.2. H-Pos and H-Amp Adjustment

1. Adjust Monoscope pattern for center of the screen by HPos control.

2. Adjust Horizontal amplitude for 2.5 ±0.1 division of a scale

by H-Amp control.

3. Confirm Vertical Center , if it is not correct, adjust

Monoscope pattern for center of the screen by V-Pos

control.

8.1.4. Parabola and Trapezoid

Adjustment

1. Receive PAL cross hatch pattern.

2. Adjust the vertical line to straight line by Parabola control.

After adjustment,the Parabola data will descend 10 DAC.

3. Adjust the vertical line to straight line of both side Vertical

line by Trapezoid control.

23

Page 24

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

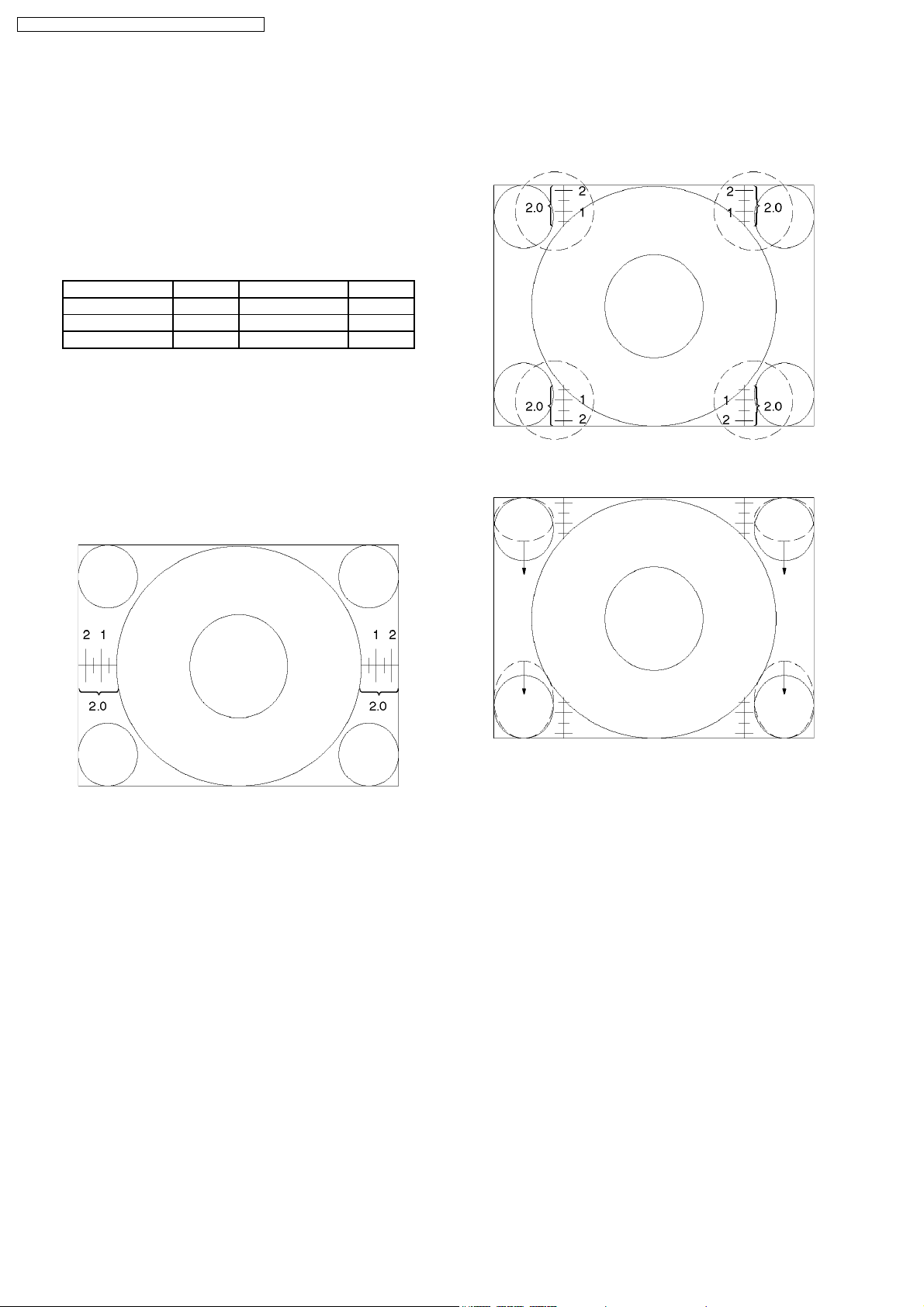

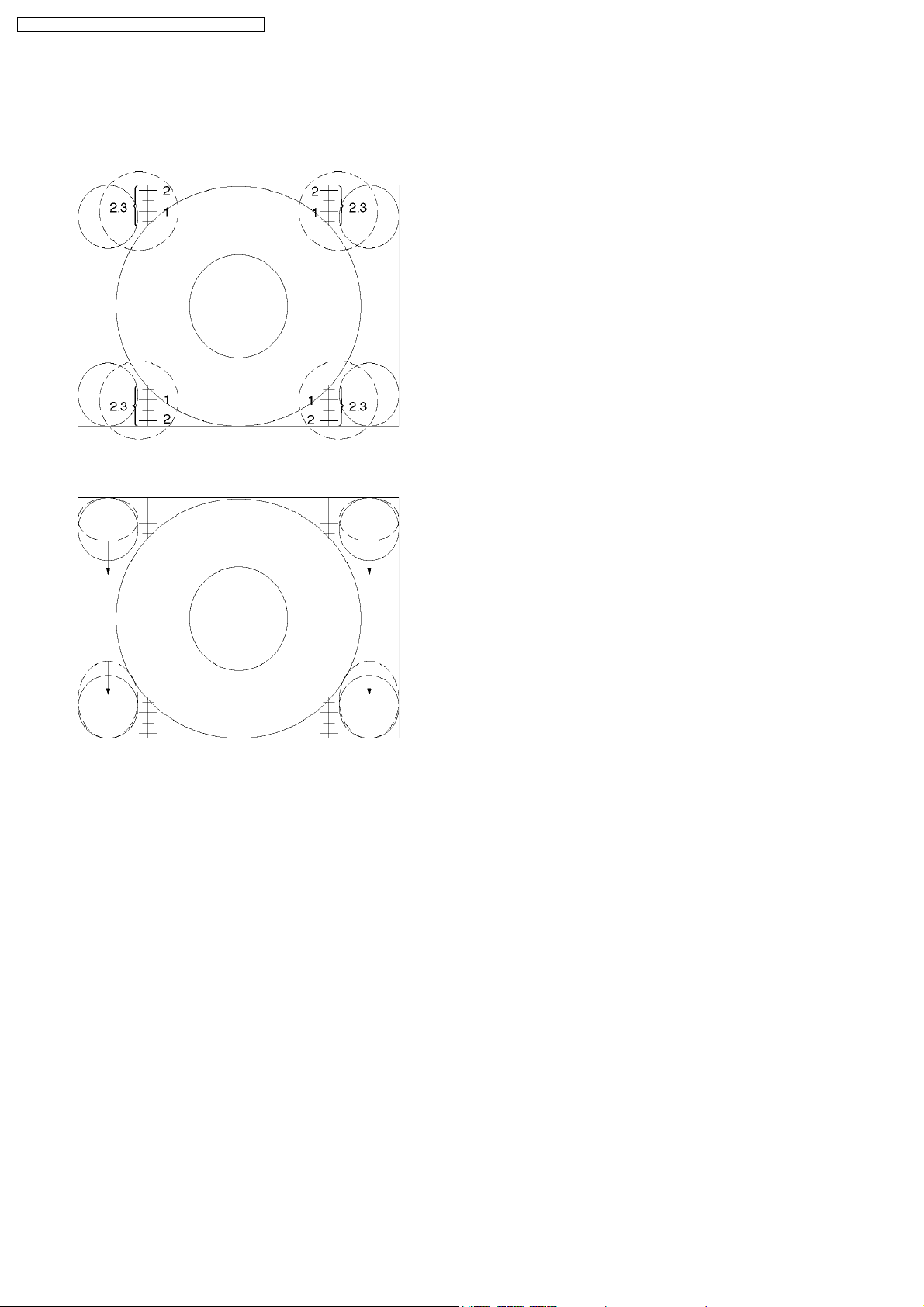

8.2. PAL 100Hz V Comp mode

(100i)

8.2.1. Preparation

1. Receive PAL monoscope pattern.

2. Set scan mode to 100Hz.

3. Set the Picture Menu to NORMAL.

4. Set the TV to Service Mode 1.

5. Set the Data of Service Mode 1 as follow

H-Pos 954 Top-Corner 185

Bottom-Corner 195

H-Parallel 16 V-S-Correct 73

IVBL C 26 C-Correct 16

6. Push [ 0 ] button so that set the Data of Coarse/Fine

Convergence to Zero Correction.

7. Push [ R-TUNE ] button so that projecting Green only.

8.2.2. H-Pos and H-Amp Adjustment

1. Adjust Monoscope pattern for center of the screen by HPos control.

2. Adjust Horizontal amplitude for 2.0 ±0.1 division of a scale

by H-Amp control.

8.2.3. V-Amp, V-Linear and V-Pos

Adjustment

1. Adjust Vertical amplitude for 2.0 ± 0.1 division of a scale by

V-Amp control.

2. Confirm Vertical Linear as to the balance of circle, if need

adjust V-Linear control.

3. Confirm Vertical Center , if it is not correct, adjust

Monoscope pattern for center of the screen by V-Pos

control.

8.2.4. Parabola and Trapezoid

Adjustment

1. Receive PAL cross hatch pattern.

2. Adjust the vertical line to straight line by Parabola control.

After adjustment,the Parabola data will descend 5 DAC.

3. Adjust the vertical line to straight line of both side Vertical

line by Trapezoid control.

24

Page 25

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

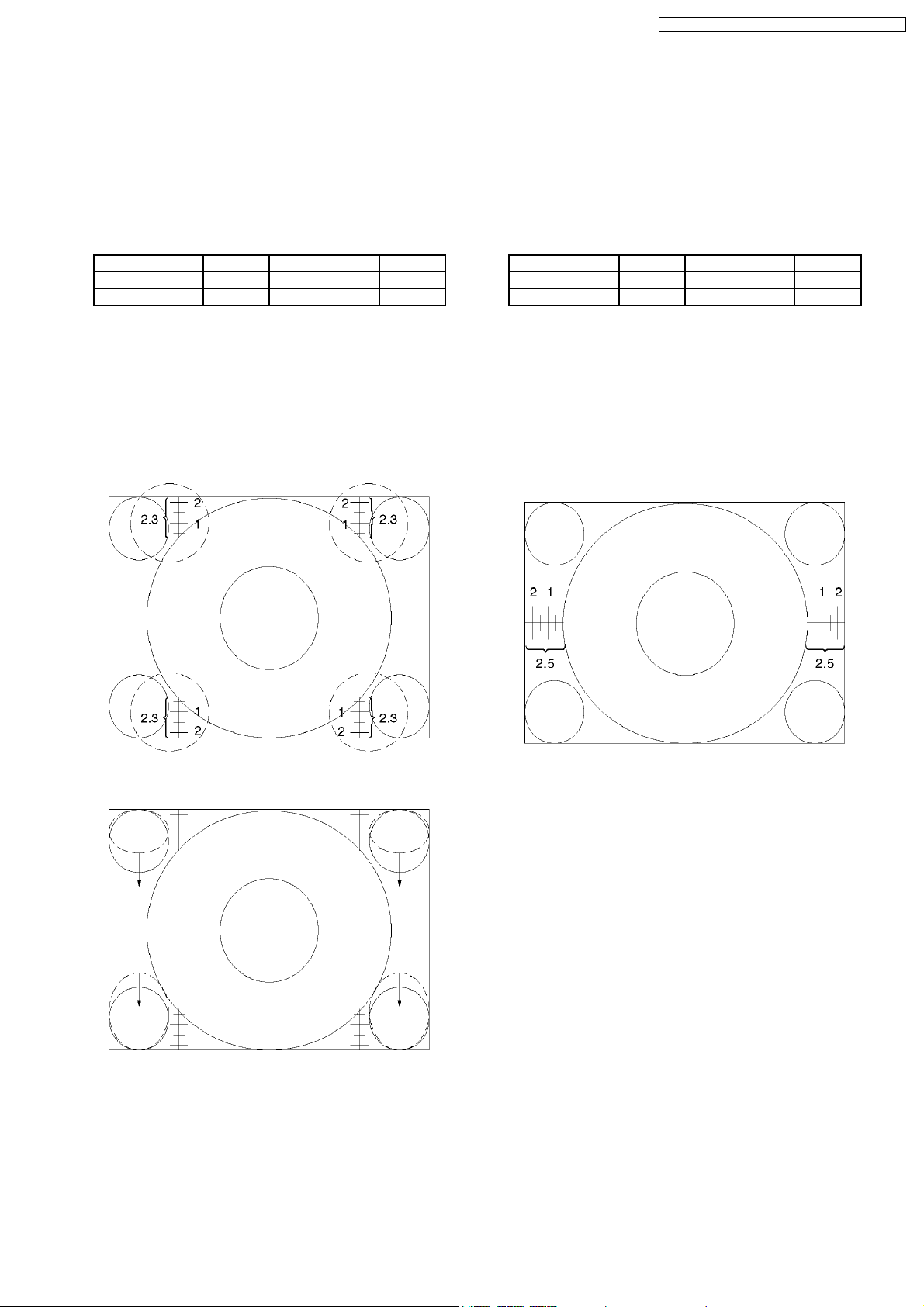

8.3. PAL Progressive mode (50p)

8.3.1. Preparation

1. Receive PAL monoscope pattern.

2. Set scan mode to progressive.

3. Set the Picture Menu to NORMAL.

4. Set the TV to Service Mode 1.

5. Set the Data of Service Mode 1 as follow

H-Parallel 16 Bottom-Corner 187

IVBL C 62 V-S-Correct 66

Top-Corner 186 C-Correct 16

6. Push [ 0 ] button so that set the Data of Coarse/Fine

Convergence to Zero Correction.

7. Push [ R-TUNE ] button so that projecting Green only.

8.3.2. V-Amp, V-Linear and V-Pos

Adjustment

1. Adjust Vertical amplitude for 2.3 ± 0.1 division of a scale by

V-Amp control.

8.4. NTSC Progressive mode (60p)

8.4.1. Preparation

1. Receive NTSC monoscope pattern.

2. Set scan mode to Progressive.

3. Set the Picture Menu to NORMAL.

4. Set the TV to Service Mode 1.

5. Set the Data of Service Mode 1 as follow

H-Parallel 16 Bottom-Corner 188

IVBL C 22 V-S-Correct 46

Top-Corner 188 C-Correct 16

6. Push [ 0 ] button so that set the Data of Coarse/Fine

Convergence to Zero Correction.

7. Push [ R-TUNE ] button so that projecting Green only.

8.4.2. H-Pos and H-Amp Adjustment

1. Adjust Monoscope pattern for center of the screen by HPos control.

2. Adjust Horizontal amplitude for 2.5 ± 0.1 division of a scale

by H-Amp control.

2. Confirm Vertical Linear as to the balance of circle, if need

adjust V-Linear control.

3. Confirm Vertical Center, if it is not correct, adjust

Monoscope pattern for center of the screen by V-Pos

control.

25

Page 26

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

8.4.3. V-Amp, V-Linear and V-Pos

Adjustment

1. Adjust Vertical amplitude for 2.3 ± 0.1 division of a scale by

V-Amp control.

2. Confirm Vertical Linear as to the balance of circle, if need

adjust V-Linear control.

8.5. 525i/525p Deflection

Adjustment / Confirmation

8.5.1. V / H-Deflection confirmation

1. Receive 525i or 525p signal.

2. Confirm V / H-Deflection is normal.

8.5.2. H-Pos confirmation / Adjustment

1. Receive 525i or 525p signal.

2. Confirm H-Pos and if need, adjust H-Pos.

8.6. 625i/625p Deflection

Adjustment / Confirmation

8.6.1. V / H-Deflection confirmation

1. Receive 625i or 625p signal.

2. Confirm V / H-Deflection is normal

8.6.2. H-Pos confirmation / Adjustment

1. Receive 625i/625p signal.

2. Confirm H-Pos and if need, adjust H-Pos.

3. Confirm Vertical Center, if it is not correct, adjust

Monoscope pattern for center of the screen by V-Pos

control.

8.4.4. Parabola and Trapezoid

Adjustment

1. Receive NTSC cross hatch pattern.

2. Adjust the vertical line to straight line by Parabola control.

3. Adjust the vertical line to straight line of both side Vertical

line by Trapezoid control.

26

Page 27

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

9 Adjustment Procedure

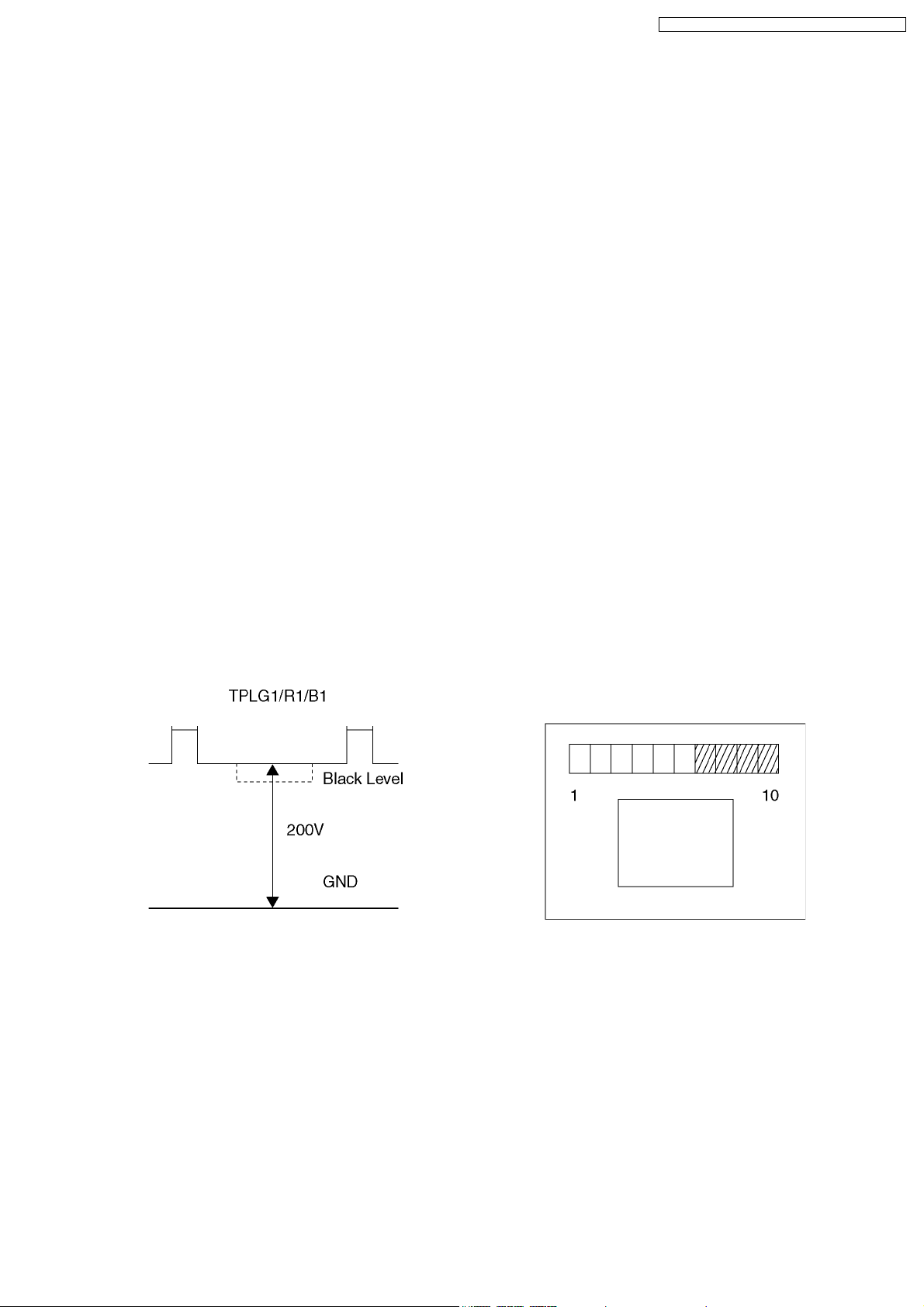

9.1. Cut off Adjustment

Preparation

Picture Menu : Dynamic WB-B-G-ST1 : 255

C Temp : Standard High-R/B : 128

AI : ON Low-RGB : 640

P-NR : AUTO

Scan Mode : 100Hz (PAL)

Screen VR : Full Counterclockwise B-Limit : 255

Adjustment

1. Receive a Black Level pattern.

2. Connect an oscilloscope to TPLG1 on LG-Board.

3. Adjust Sub Bright so that the waveform A is 200 ± 2V.

4. Connect an oscilloscope to TPLR1 on LR-Board.

5. Adjust Low-R so that the waveform A is 200 ± 2V.

6. Connect an oscilloscope to TPLB1 on LB-Board.

7. Adjust Low-B so that the waveform A is 200 ± 2V.

8. It pushes and it makes a [R-TUNE] key the project only of GREEN.

9. The 6th paragraph shines faintly with the screen VR of GREEN and the 7th paragraph does to the sinking style.

10. It pushes and it makes a [R-TUNE] key the project only of RED.

11. The 6th paragraph shines faintly with the screen VR of RED and the 7th paragraph does to the sinking style.

12. It pushes and it makes a [R-TUNE] key the project only of BLUE.

13. The 6th paragraph shines faintly with the screen VR of BLUE and the 7th paragraph does to the sinking style.

27

Page 28

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

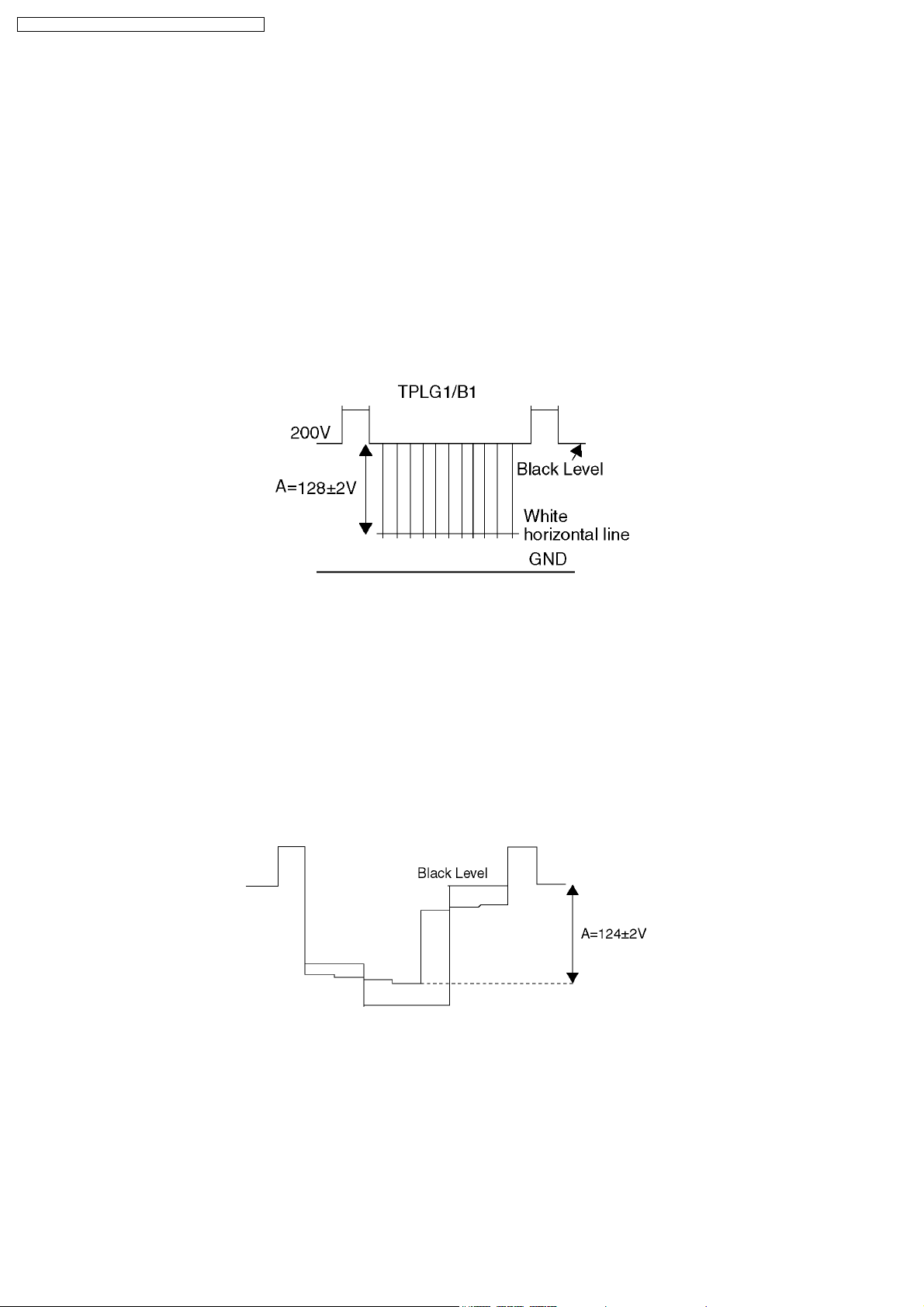

9.2. Sub Contrast Adjustment

Preparation

Picture Menu : Dynamic

C Temp : Standard High-R/B : 128

AI : ON Low-G : 640

P-NR : AUTO Low-R/B :***(Adjustment value)

Scan Mode : 100Hz (PAL)

Cut off Adjustment has been adjusted

Adjustment

1. Receive a Cross Hatch pattern.

2. Connect an oscilloscope to TPLG1 on LG-Board.

3. Adjust Sub Contrast so that the waveform A is 128 ± 2V.

9.3. Sub Color Adjustment

Preparation

Picture Menu : Dynamic P-NR : AUTO

C Temp : Standard Scan Mode : 100Hz (PAL)

AI : ON ACL : OFF

Adjustment

1. Receive a PAL Colour Bar pattern.

2. Connect an oscilloscope to TPLG1 on LG-Board.

3. Adjust Sub Color so that the waveform A is 124 ± 2V.

28

Page 29

9.4. Blue Focus / Gamma Adjustment

Preparation

Picture Menu : Dynamic WB-B-G-ST1 : 100

C Temp : Standard B-Limit : 255

AI : ON

P-NR : AUTO

Scan Mode : 100Hz (PAL)

Adjustment

1. Set the White Balance Meter on Screen center.

2. Receive a Window pattern.

3. Set the Sub Contrast and High-B to Max.

4. It pushes and it makes a [R-TUNE] key the project only of BLUE.

5. Adjust Blue Focus VR so that Y is 7.0 ± 0.1cd/m

2

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

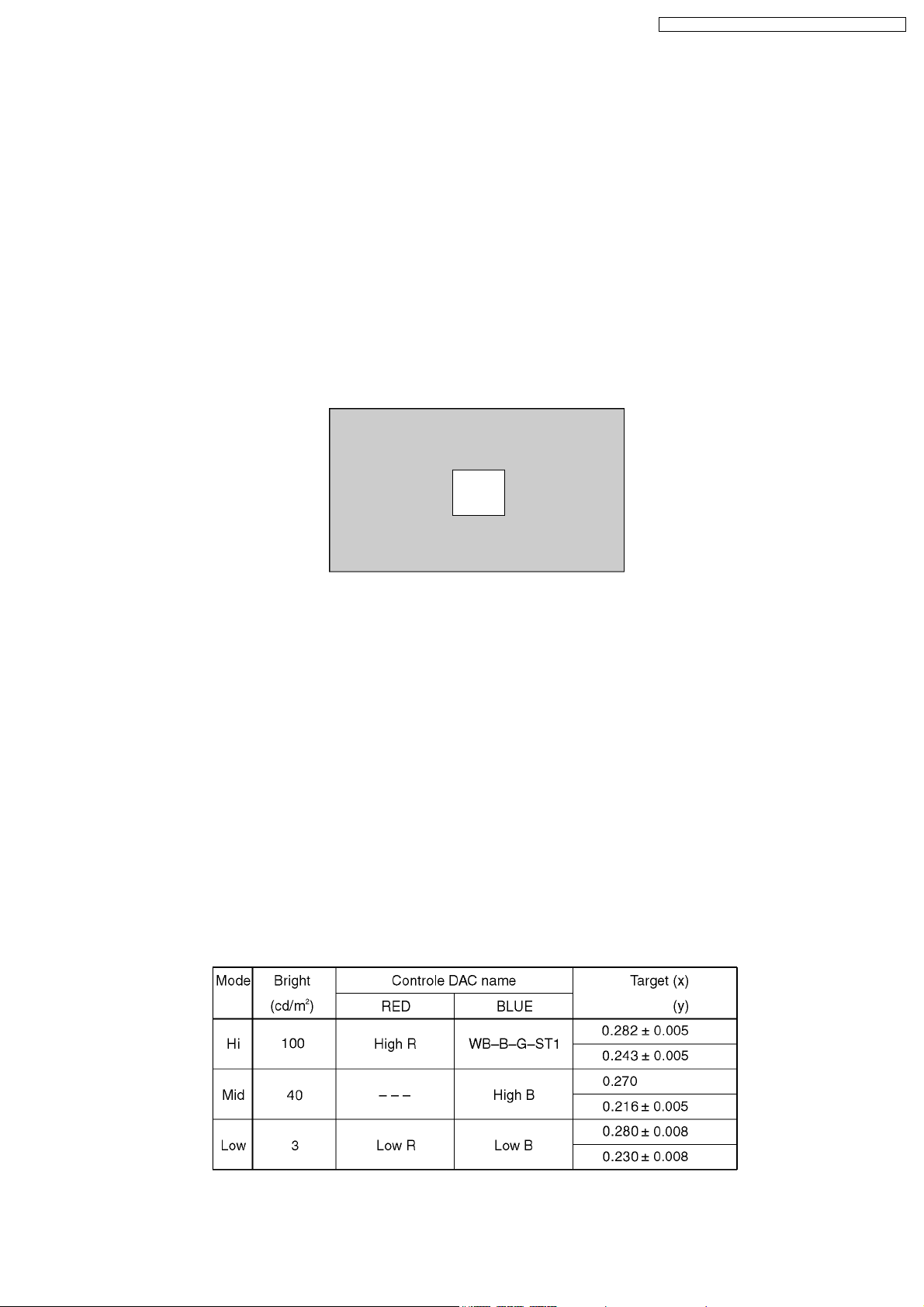

9.5. White Balance Adjustment

Preparation

Picture Menu : Dynamic Sub Bright :130

C Temp : Standard High R : 100

AI : ON

P-NR : ON High B : 128

Scan Mode : 100Hz (PAL) WB-B-G -ST1 : 170

Low G : 640

Adjustment

1. Set the White Balance Meter on Screen center.

2. Receive a Window pattern.

3. Adjust Sub Bright so that the 6th paragraph shines faintly and the 7th paragraph does to the sinking style.

4. Adjust High R, WB-B-G -ST1, High B, Low R, and Low B to the table value.

51 inch model

29

Page 30

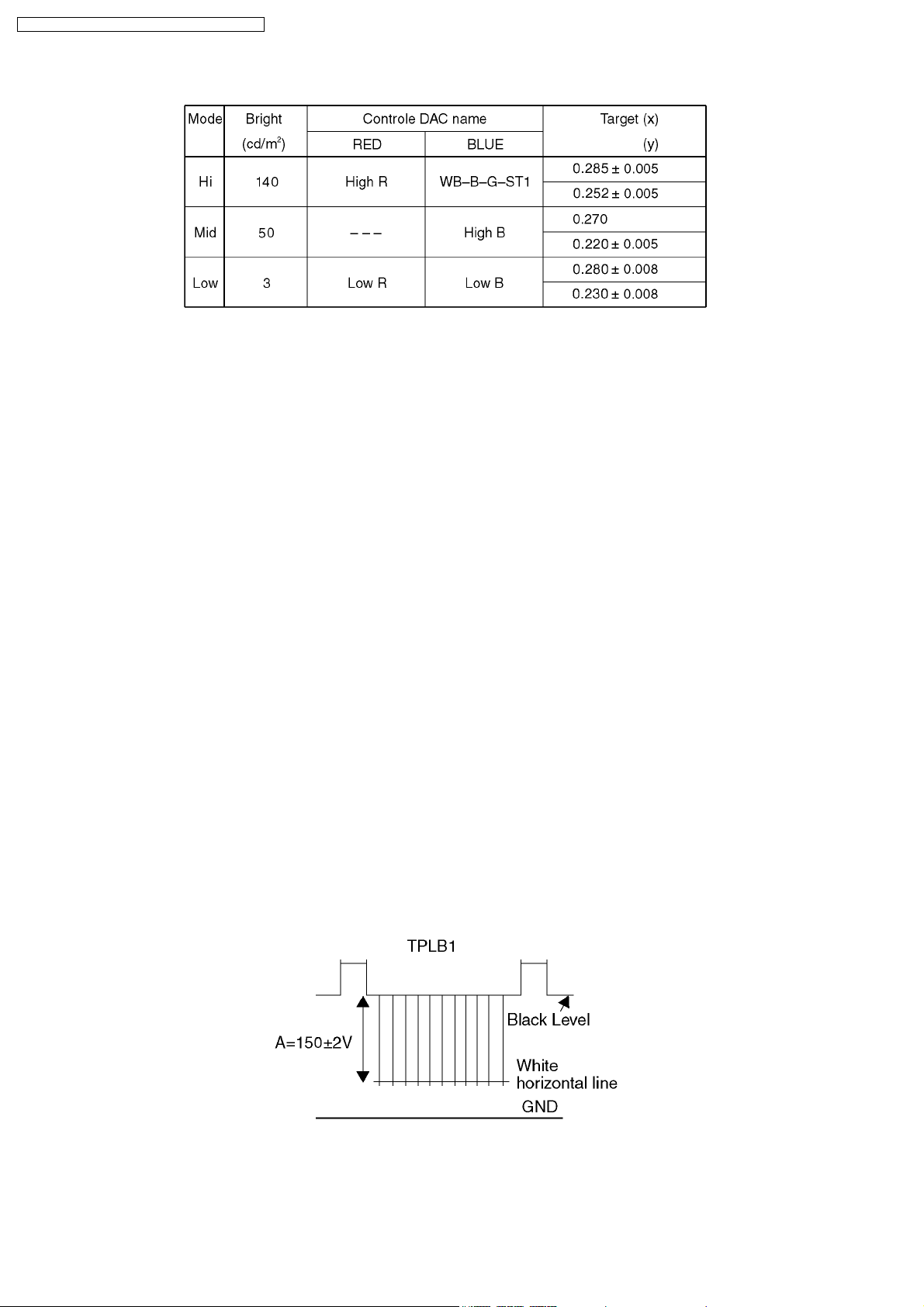

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

43 inch model

9.6. Sub Bright Adjustment

Preparation

Picture Menu : Dynamic P-NR : AUTO

C Temp : Dynamic Scan Mode : 100Hz (PAL)

AI : ON

Cut off and White Balance Adjustment has been adjusted

Adjustment

1. Set the White Balance Meter on Screen center.

2. Receive a PAL Window pattern.

3. Adjust Sub Bright so that the 6th paragraph shines faintly and the 7th paragraph does to the sinking style.

9.7. Blue Limit Adjustment

Preparation

Picture Menu : Dynamic

C Temp : Standard

AI : ON

P-NR : ON

Scan Mode : 100Hz (PAL)

White Balance Adjustment has been adjusted

Adjustment

1. Receive a Cross Hatch pattern.

2. Connect an oscilloscope to TPLB1 on LB-Board.

3. Adjust B-LIMIT so that the waveform A is 150 ± 2V.

30

Page 31

10 Convergence Adjustment

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

The convergence adjustment is set separately for each

50/100Hz/ 60/100Hz input (NTSC, PAL/ SECAM). The

following explanation uses the PAL mode as an example, since

the same procedure applies to the convergence adjustment for

NTSC mode.

When replacing the following Parts.

IC7104 (EEP-ROM in DC-Board)High Voltage Producing Parts

Other Parts (If change the convergence)

Create an Adjustment Sheet by tracing the following

specifications in their actual size on transparent film or tracing

paper.Then adjust the convergence.

When replacing one of the CRT´s.

10.1. Convergence Adjutment Sheet

Adjust the convergence for each of the 50/100Hz and

60/120Hz inputs so that they are aligned with the other colours.

Helpful Hint

All positions which have been adjusted are recorded within P-2

for NTSC data and P-3 for PAL data of the memory.This data

can be copied to P-4 memory area, allowing you to perform the

adjustment of P-2 (NTSC) and P-3 (PAL).To perform these

adjustments, push the “1“ button on the remote control, and

manipulate the position [

as instructed by the On Screen Display in Fine Convergence

adjustment.

All of the Convergence Control Charts have been listed for the

remote control buttons after the Convergence Adjustment

Procedure Please refer to these. (Page 29)

] and [ ] button and the "N" button

31

Page 32

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.2. Convergence Adjustment Procedure

1. Input a monoscope pattern of PAL.

2. Enter the Service Mode1.

3. Select the Coarse Convergence by pushing "RED" or

"GREEN" buttons. Then push "YELLOW" button, and push

Position and [N] buttons to set the data to zero.

4. Stick the Convergence Adjustment Sheet (PAL 50Hz) onto

the screen.

5. Push the “YELLOW” or “BLUE” on the remote control, and

enter the Coarse Convergence Adjustment mode.

6. Push the "0" of 10 key buttons, and then push the "N" of

position buttons on the remote control.

7. Enter to "TEST POS." mode.

8. Push the "5" button to display the monoscope pattern on

the screen.

9. Adjust the position buttons so that the cursor in the center

of the test pattern is aligned with the center of the

monoscope pattern.

10. Push the "TV/AV" button on the remote control, and enter

the "DATA POS." mode.

11. Push the "5" button and close the background image

(monoscope pattern).

12. Use the "+" and "-" of the position buttons so that the bump

in the screen center line is at the center of the cursor.

13. Push the "TV/AV " button twice, and enter the "OSD POS"

mode.

14. Adjust the position buttons so that the cross-cursor is

aligned near cross-bar.

15. Push the "MENU" button, and "N" button to store data.

16. Push the "0" of 10 key buttons, and return to Coarse

Convergence Adjustment mode.

32

Page 33

10.3. Coarse Convergence Adjustment mode

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.3.1. Green Coarse Convergence Adjustment

10.3.1.1. Reparation

Push the "SURROUND" button, and select the Green Adjustment mode.Push the "2" button, and select the "Border and Cross"

pattern.Push the "R-TUNE" button, and select the "Green" colour.

10.3.1.2. "G-SIZE (V)" adjustment

Push the "TV/AV" buttons, and select the "G-SIZE (V)".Push the "Channel up/down" buttons, and adjust the upper and lower

boarder line of test pattern is aligned with the edge of the screen frame.

33

Page 34

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.3.1.3. "G-SIZE (H)" adjustment

Push the "TV/AV " buttons, and select the "G-SIZE (H)".Push the "Volume up/down" buttons, and adjust the boarder line on either

side of test pattern is aligned with the edge of the screen frame.

10.3.1.4. "G-LINEAR" adjustment

Push the "TV/AV" buttons, and select the "G-LINEAR".Push the "Volume up/down" buttons, and adjust the "G-LINEAR" to become

the following figure.

10.3.1.5. "G-PIN (V)" adjustment

Push the "TV/AV" buttons, and select the "G-PIN".Push the "Channel up/down" buttons, and adjust the "G-PIN (V)" to become the

following figure.

10.3.1.6. "G-PIN (H)" adjustment

Push the "TV/AV" buttons, and select the "G-PIN".Push the "Volume up/down" buttons, and adjust the "G-PIN (H)" to become the

following figure.

34

Page 35

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.3.1.7. "G-CORNER" adjustment

Push the "TV/AV" buttons, and select the "G-CORNER".Push the "Volume up/down" buttons, and adjust the "G-CORNER" to

become the following figure.

10.3.1.8. "G-KEY" adjustment

Push the "TV/AV" buttons, and select the "G-KEY".Push the "Channel up/down" buttons, and adjust the "G-KEY" refer to following

figure.

10.3.1.9. "G-STATIC" adjustment

Push the "TV/AV" buttons, and select the "G-STATIC".Push the "Channel/Volume up/down" buttons, and adjust "G-STATIC" so

that Horizontal & Vertical center line is aligned with the bump in the screen center mark.

35

Page 36

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.3.2. Red Coarse Convergence Adjustment

10.3.2.1. Reparation

Push the "SURROUND" button, and select the Red Adjustment mode.Push the "2" button, and select the "Border and Cross"

pattern.Push the "R-TUNE" button, and select the "Yellow" colour.Push the "POSITION" button, and adjust the "R-STATIC " so that

the Red color of pattern is aligned with Green colour of pattern.

10.3.2.2. "R-SKEW (V)" adjustment

Push the "TV/AV" buttons, and select the "R-SKEW ".Push the "Volume up/down" buttons, and adjust the reference line become

a vertical line. (Refer to figure.)

10.3.2.3. "R-SKEW (H)" adjustment

Push the "TV/AV" buttons, and select the "R-SKEW".Push the "Channel up/down" buttons, and adjust reference line become a

horizontal line. (Refer to figure.)

10.3.2.4. "R-SIZE (V)" adjustment

Push the "TV/AV " buttons, and select the "R-SIZE".Push the "Channel up/down" buttons, and adjust the upper and lower boarder

line of test pattern is aligned with the edge of the screen frame. (Refer to Fig. A.)

10.3.2.5. "R-SIZE (H)" adjustment

Push the "TV/AV" buttons, and select the "R-SIZE".Push the "Volume up/down" buttons, and adjust the boarder line on either side

of test pattern is aligned with the edge of the screen frame. (Refer to Fig. B.)

36

Page 37

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.3.2.6. "R-LINEAR" adjustment

Push the "TV/AV " buttons, and select the "R-LINEAR".Push the "Volume up/down" buttons, and adjust the "R-LINEAR". (Refer to

Fig. C.)

10.3.2.7. "R-PIN (V)" adjustment

Push the "TV/AV " buttons, and select the "R-PIN".Push the "Channel up/down" buttons, and adjust the "R-PIN (V)". (Refer to Fig.

D.)

10.3.2.8. "R-PIN (H)" adjustment

Push the "TV/AV" buttons, and select the "R-PIN".Push the "Volume up/down" buttons, and adjust the "R-PIN (H)". (Refer to Fig.

E.)

10.3.2.9. "R-CORNER" adjustment

Push the "TV/AV" buttons, and select the "R-CORNER".Push the "Channel up/down" buttons, and adjust the "R-CORNER". (Refer

to Fig. F.)

10.3.2.10. "R-KEY" adjustment

Push the "TV/AV" buttons, and select the "R-KEY".Push the "Channel up/down" buttons, and adjust the "R-KEY". (Refer to Fig. G.)

10.3.2.11. "R-STATIC" adjustment

Push the "TV/AV" buttons, and select the "R-STATIC.Push the "Channel/Volume up/down" buttons, and adjust "R-STATIC" so that

Horizontal & Vertical Center line is aligned with the bump in the screen center mark. (Refer to Fig. H.)

10.3.3. Blue Coarse Convergence Adjustment

10.3.3.1. Reparation

Push the "SURROUND" button, and select the Blue Adjustment mode.Push the "2" button, and select the "Border and Cross"

pattern.Push the "R-TUNE" button, and select the "Cyan" colour.Push the "POSITION" button, and adjust the "B-STATIC" so that

the Blue color of pattern is aligned with Green colour of pattern.

10.3.3.2. "B-SKEW (V)" adjustment

Push the "TV/AV" buttons, and select the "B-SKEW".Push the "Volume up/down" buttons, and adjust the reference line become

a vertical line. (Refer to Fig. J.)

10.3.3.3. "B-SKEW (H)" adjustment

Push the "TV/AV" buttons, and select the "B-SKEW".Push the "Channel up/down" buttons, and adjust reference line become a

horizontal line. (Refer to Fig.K.)

10.3.3.4. "B-SIZE (V)" adjustment

Push the "TV/AV" buttons, and select the "B-SIZE".Push the "Channel up/down" buttons, and adjust the upper and lower boarder

line of test pattern is aligned with the edge of the screen frame. (Refer to Fig. A.)

10.3.3.5. "B-SIZE (H)" adjustment

Push the "TV/AV" buttons, and select the "B-SIZE".Push the "Volume up/down" buttons , and adjust the boarder line on either side

of test pattern is aligned with the edge of the screen frame. (Refer to Fig. B.)

37

Page 38

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.3.3.6. "B-LINEAR" adjustment

Push the "TV/AV" buttons, and select the "B-LINEAR".Push the "Volume up/down" buttons, and adjust the "B-LINEAR". (Refer to

Fig. C.)

10.3.3.7. "B-PIN (V)" adjustment

Push the "TV/AV" buttons, and select the "B-PIN".Push the "Channel up/down" buttons, and adjust the "B-PIN (V)" (Refer to Fig.

D.)

10.3.3.8. "B-PIN (H)" adjustment

Push the "TV/AV" buttons, and select the "B-PIN".Push the "Volume up/down" buttons, and adjust the "B-PIN (H)". (Refer to Fig.

E.)

10.3.3.9. "B-CORNER" adjustment

Push the "TV/AV " buttons, and select the "B-CORNER".Push the "Channel up/down" buttons, and adjust the "B-CORNER". (Refer

to Fig. F.)

10.3.3.10. "B-KEY" adjustment

Push the "TV/AV" buttons, and select the "B-KEY".Push the "Channel up/down" buttons, and adjust the "B-KEY". (Refer to Fig. G.)

10.3.3.11. "B-STATIC" adjustment

Push the "TV/AV" buttons, and select the "B-STATIC.Push the "Channel/Volume up/down" buttons, and adjust "B-STATIC" so that

Horizontal & Vertical Center line is aligned with the bump in the screen center mark. (Refer to Fig. H.)

38

Page 39

10.4. Fine Convergence Adjustment

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.4.1. Green Convergence Adjustment

1. Select the "G-LINE CURSOR" mode by pushing "TV/AV"

button on the remote control

8. Use the Position Buttons to adjust each point so that the

Green Crosshatch Pattern is aligned with the vertical and

horizontal lines of the Convergence Adjustment Sheet.

9. Push the "MULTI PIP" and with from "G-EASY DATA" to

"G-EASY CURSOR".

10. Repeat step 7~9 to adjust the 9 adjustment points.

2. Use the Position Buttons to move the cursor to the point

where you wish to change the data (adjustment lines). Then

use the "OK" to change from "G-LINE CURSOR" to "GLINE DATA".

3. Use the Position Buttons to adjust each point (line) so that

the Green Crosshatch Pattern is aligned with the vertical

and horizontal lines of the Convergence Adjustment Sheet.

4. Push the "OK" and switch from "G-LINE DATA" to "G-LINE

CURSOR".

5. Repeat step 1~3 to adjust the vertical lines (13) and the

horizontal lines (9).

6. Select the "G-EASY CURSOR" mode by pushing "TV/AV"

button on the remote control.

7. Use the Position Buttons to move the cursor to the point

where you wish to change the data (adjustment point). Then

use the "OK" to change from "G-EASY CURSOR" to "GEASY DATA".

11. Select the "G-POINT CURSOR" mode by pushing "TV/AV"

button on the remote control.

12. Use the Position Buttons to move the cursor to the point

where you wish to change the data (adjustment lines). Then

use the "OK" to change from "G-LINE CURSOR" to "GLINE DATA".

13. Use the Position Buttons to adjust each point so that the

Green Crosshatch Pattern is aligned with the vertical and

horizontal lines of the Convergence Adjustment Sheet.

14. Push the "OK" and switch from "G-POINT DATA" to "GPOINT CURSOR".

15. Repeat step 12-14 to adjust all of adjustm ent points.

39

Page 40

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

10.4.3. Blue Convergence Adjustment

1. Push the "R-TUNE" button twice and change to the Blue

Adjustment of cyan Colour.

2. Repeat the same steps described for the Green Conv.Adj.

in 1~16 to perform the Blue Convergence Adjustment.

3. To store the data after the Blue Convergence Adjustment

has been completed, push the "MENU" button and then

push the "N" button.

4. To switch from the Convergence Adjustment Mode to the

Service Mode, press the Power button and then push the

"N" button.

Repeat the same adjustment after inputting the 60Hz

(NTSC) signal.

16. Adjust the LINE, EASY and POINT DATA again viewing all

over the screen.

If need the adjustment at the around of screen, select the

"ORIGINAL" and adjust it.

17. To store the data after the Green Convergence Adjustment

has been completed, push the "MENU" button and then

push the "N" button (pushing the "N" button will store the

data in the E

2

PROM).

18. Remove the Convergence Adjustment Sheet from the

screen.

10.4.2. Red Convergence Adjustment

1. Push the "R-TUNE" button twice and change to the Red

Adjustment of Yellow Colour.

2. Repeat the same steps described for the Green Conv.Adj.

in 1~16 to perform the Red Convergence Adjustment.

3. To store the data after the Red Convergence Adjustment

has been completed, push the "MENU" button and then the

"N" button.

40

Page 41

Fine Convergence Control Chart

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

41

Page 42

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

42

Page 43

11 Location of Lead Wiring

11.1. Location of Lead Wiring (1)

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

43

Page 44

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

INSERTION OF CONNECTOR

LR1, LR2, LG1, LG2, LG3, LG4, LG5, LG6, LG7, LB1, LB2,

LR20, LG20, LB20

NOTICE FOR WORE DRESSING

1. Confirm that the lead line isn’t hitting the metallic part of the neck print after CRT neck print (R, G, B) insertion.

2. It decides to be permitted to insert the lead line (R, G, B) of the VM coil wherever of LG5, LG6, LG7 of the LG print.

3. It decides to be permitted to insert G, B of the DY lead in either.

4. Keep the Fo lead of B clear of components of the LB-Board and IC2301 heat sink of the A-Board.

44

Page 45

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

11.2. Location of Lead Wiring (2)

The Anode Lead

1. It inserts Anode lead tip in the back to FBT (the fly background transformer), and it makes turn on the right and it locks it.

(Three insertion positions are free).

2. Secure a safe space distance from the circumference part by equal to or more than 10 millimeters.

45

Page 46

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

INSERTION OF CONNECTOR

A6, A7, A21, A22, A23, A49, Anode distributor (R, G, B, FBT), D8, D5, DY (R, G, B),

CY (R, G, B), D30, P1, P2, P4, Focus Pack (R)

NOTICE FOR WIRE DRESSING

1. After insert R, G, B on CRT-print, confirm that wire should not touch to material parts of CRT-print.

46

Page 47

12 Conductor Views

12.1. A-Board

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

47

Page 48

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

A-Board(FOIL SIDE)

6

TNPH0625

5

4

3

2

1

TX-43P950M/X TX-51P950M/X

A-Board TNPH0625

ABC E F G H I

TX-43P950M/X TX-51P950M/X

A-Board TNPH0625

D

48

Page 49

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

TX-43P950M/X TX-51P950M/X

A-Board TNPH0625

49

A-Board(COMPONENT SIDE)

TNPH0625

6

D

ABC E F G H

TX-43P950M/X TX-51P950M/X

A-Board TNPH0625

5

4

3

2

1

Page 50

TX-43P950M/X TX-51P950M/X

D-Board TNPH0624

50

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

D-Board(FOIL SIDE)

TNPH0624

12.2. D-Board

D

ABC E F G H I

TX-43P950M/X TX-51P950M/X

D-Board TNPH0624

6

5

4

3

2

1

Page 51

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

TX-43P950M/X TX-51P950M/X

D-Board TNPH0624

51

D-Board(COMPONENT SIDE)

TNPH0624

6

D

ABC E F G H I

TX-43P950M/X TX-51P950M/X

D-Board TNPH0624

5

4

3

2

1

Page 52

TX-43P950M/X TX-51P950M/X

DG-Board TNPA3575

52

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

12.3. DG-Board

DG-Board(A SIDE)

TNPA3575

6

D

ABC E F G H I

DG-Board(B SIDE)

TNPA3575

5

4

3

2

TX-43P950M/X TX-51P950M/X

DG-Board TNPA3575

1

Page 53

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

DC-Board(B SIDE)

TNPA3616

TX-51P950M/X

TX-43P950M/X,

DC-BOARD TNPA3616

53

12.4. DC-Board

D

TX-51P950M/X

ABC E F G H I

DC-Board(A SIDE)

TNPA3616

6

5

4

3

2

1

TX-43P950M/X,

DC-BOARD TNPA3616

Page 54

KA-Board

TNPA3578

TX-51P950M/X

TX-43P950M/X,

H-Board TNPA3576

KA-Board TNPA3578

54

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

12.5. H-Board & KA-Board

D

TX-51P950M/X

H-Board

TNPA3576

6

5

4

3

2

1

ABC E F G H I

TX-43P950M/X,

H-Board TNPA3576

KA-Board TNPA3578

Page 55

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

TX-51P950M/X

TX-43P950M/X,

GK-Board TNPA3577

55

12.6. GK-Board

D

TX-51P950M/X

ABC E F G H I

GK-Board

TNPA3577

TX-43P950M/X,

GK-Board TNPA3577

6

5

4

3

2

1

Page 56

TX-43P950M/X TX-51P950M/X

LB-Board TNPA3392

56

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

12.7. LB-Board

LB-Board

TNPA3392

6

D

ABC E F G H I

TX-43P950M/X TX-51P950M/X

LB-Board TNPA3392

5

4

3

2

1

Page 57

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

LG-Board

TNPA3391

TX-43P950M/X, TX-51P950M/X

LR-Board TNPA3390

LG-Board TNPA3391

57

12.8. LR-Board & LG-Board

LR-Board

TNPA3390

6

D

ABC E F G H I

TX-43P950M/X, TX-51P950M/X

LR-Board TNPA3390

LG-Board TNPA3391

5

4

3

2

1

Page 58

58

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Page 59

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

59

13 Schematic Diagram

13.1. Schematic Diagram Notes

Page 60

4

1

2

3

5

6

7

8

9

10

11

12

A-Board Schematic Diagram(1/4)

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

60

A-Board Schematic Diagram(1/4)

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13.2. A-Board (1 of 4) Schematic Diagram

A-Board TNPH0625AH (1/4) For TX-43P950M

A-Board TNPH0625AJ (1/4) For TX-43P950X

A-Board TNPH0625AF (1/4) For TX-51P950M

A-Board TNPH0625AG (1/4) For TX-51P950X

!

A

1 234567 89

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

B

C

D

E

F

Page 61

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13

14

1516171819

2021222324

26

25

27

282930

A-Board Schematic Diagram(2/4)

A-Board TNPH0625AH (2/4) For TX-43P950M

A-Board TNPH0625AJ (2/4) For TX-43P950X

A-Board TNPH0625AF (2/4) For TX-51P950M

A-Board TNPH0625AG (2/4) For TX-51P950X

!

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

61

A-Board Schematic Diagram(2/4)

1

13.3. A-Board (2 of 4) Schematic Diagram

910 11 12 13 14 15 16 17

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

9

2

3

4

5

6

7

8

10

12

11

Page 62

33

31

32

34

35

36

37

38

39

40

A-Board Schematic Diagram(3/4)

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

62

A-Board Schematic Diagram(3/4)

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13

14

13.4. A-Board (3 of 4) Schematic Diagram

A-Board TNPH0625AH (3/4) For TX-43P950M

A-Board TNPH0625AJ (3/4) For TX-43P950X

A-Board TNPH0625AF (3/4) For TX-51P950M

A-Board TNPH0625AG (3/4) For TX-51P950X

25

212223

15

16

17

20

19

18

24

26

27

!

282930

17 18 19 20 21 22 23 24 25

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

Page 63

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

A-Board Schematic Diagram(4/4)

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

63

13.5. A-Board (4 of 4) Schematic Diagram

A-Board TNPH0625AH (4/4) For TX-43P950M

A-Board TNPH0625AJ (4/4) For TX-43P950X

A-Board TNPH0625AF (4/4) For TX-51P950M

A-Board TNPH0625AG (4/4) For TX-51P950X

!

31

A-Board Schematic Diagram(4/4)

25 26 27 28 29 30 31 32 33

TX-43P950M TX-43P950X TX-51P950M TX-51P950X

33

32

34

35

36

37

40

39

38

Page 64

0

5

6

2

1

4

3

7

8

1

9

1

1

121

3

TX-43P950M/X TX-51P950M/X D-Board Schematic Diagram (1/2)

D-Board TNPH0624AD (1/2) For TX-43P950M/X

D-Board THPH0624AE (1/2) For TX-51P950M/X

!

64

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13.6. D-Board (1 of 2) Schematic Diagram

1234567 89

TX-43P950M/X TX-51P950M/X D-Board Schematic Diagram (1/2)

B

C

D

E

F

Page 65

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

TX-43P950M/X TX-51P950M/X D-Board Schematic Diagram (2/2)

65

13.7. D-Board (2 of 2) Schematic Diagram

D-Board TNPH0624AD (2/2) For TX-43P950M/X

D-Board THPH0624AE (2/2) For TX-51P950M/X

!

2

4

1

3

910 11 12 13 14 15 16 17

TX-43P950M/X TX-51P950M/X D-Board Schematic Diagram (2/2)

0

5

6

7

8

1

9

1

1

121

3

Page 66

DC-BOARD TNPA3616

9

DC-Board Schematic Diagram

TX-51P950M/X, TX-43P950M/X

5

66

4

3 786

21

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13.8. DC-Board Schematic Diagram

TX-51P950M/X, TX-43P950M/X DC-Board Schematic Diagram

A

B

C

D

E

F

Page 67

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

4

2

1

3

6

5

DG-Board TNPA3575AB(1/6) For TX-43/51P950X

DG-Board TNPA3575AE(1/6) For TX-43/51P950M

9

11

7

8

10

67

13.9. DG-Board (1 of 6) Schematic Diagram

1 234567 89

TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(1/6) TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(1/6)

A

B

C

D

E

F

Page 68

24

13

15

12

14

16

DG-Board TNPA3575AB(2/6) For TX-43/51P950X

DG-Board TNPA3575AE(2/6) For TX-43/51P950M

17

18

19

22

20

23

21

68

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

1

3

2

4

13.10. DG-Board (2 of 6) Schematic Diagram

910 11 12131415 1617

TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(2/6) TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(2/6)

5

6

9

11

8

7

10

Page 69

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

2526272829

30

31

323334

35

36

37

38

39

4041424344

45

DG-Board TNPA3575AB(3/6) For TX-43/51P950X

DG-Board TNPA3575AE(3/6) For TX-43/51P950M

69

15

13

12

14

13.11. DG-Board (3 of 6) Schematic Diagram

17 18 19 20 21 22 23 24 25

TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(3/6) TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(3/6)

16

17

18

19

24

22

20

23

21

Page 70

4647484950

52

51

5354555657585960616263

6465666768

DG-Board TNPA3575AB(4/6) For TX-43/51P950X

DG-Board TNPA3575AE(4/6) For TX-43/51P950M

70

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

2526272829

13.12. DG-Board (4 of 6) Schematic Diagram

25 26 27 28 29 30 31 32 33

TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(4/6) TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(4/6)

30

31

323334

35

36

37

38

39

4041424344

45

Page 71

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

6970717273

74

75

76

77

787980

81

828384

858687

88

71

4647484950

13.13. DG-Board (5 of 6) Schematic Diagram

33 34 35 36 37 38 39 40 41

TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(5/6) TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(5/6)

DG-Board TNPA3575AB(5/6) For TX-43/51P950X

51

DG-Board TNPA3575AE(5/6) For TX-43/51P950M

52

5354555657585960616263

6465666768

Page 72

72

DG-Board TNPA3575AB(6/6) For TX-43/51P950X

DG-Board TNPA3575AE(6/6) For TX-43/51P950M

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

6970717273

13.14. DG-Board (6 of 6) Schematic Diagram

41 42 43 44 45 46 47 48 49

TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(6/6) TX-43/51P950X, TX-43/51P950M DG-Board Schematic Diagram(6/6)

74

75

76

77

787980

81

828384

858687

88

Page 73

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

KA-BOARD TNPA3578

9

TX-51P950M/X, TX-43P950M/X

KA-Board Schematic Diagram

TX-51P950M/X, TX-43P950M/X

H-Board Schematic Diagram

5

73

4

3 786

21

TX-51P950M/X, TX-43P950M/X

KA-Board Schematic Diagram

13.15. H and KA-Board Schematic Diagram

H-BOARD TNPA3576AB

A

TX-51P950M/X, TX-43P950M/X

H-Board Schematic Diagram

B

C

D

E

F

Page 74

9

GK-Board Schematic Diagram

TX-51P950M/X, TX-43P950M/X

5

74

4

3 786

21

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13.16. GK-Board Schematic Diagram

GK-BOARD TNPA3577

A

TX-51P950M/X, TX-43P950M/X GK-Board Schematic Diagram

B

C

D

E

F

Page 75

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

9

TX-43P950M/X LB-Board Schematic DiagramTX-51P950M/X,

5

75

4

3 786

21

13.17. LB-Board Schematic Diagram

LB-Board TNPA3392AE For TX-43P950M/X

LB-Board TNPA3392AF For TX-51P950M/X

A

B

TX-43P950M/X LB-Board Schematic DiagramTX-51P950M/X,

C

D

E

F

Page 76

9

LG-Board Schematic Diagram

coil

coil

TX-51P950M/X, TX-43P950M/X

5

76

4

3 786

21

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

13.18. LG-Board Schematic Diagram

LG-BOARD TNPA3391AD

A

TX-51P950M/X, TX-43P950M/X LG-Board Schematic Diagram

B

C

D

E

F

Page 77

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

9

LR-Board Schematic Diagram

TX-51P950M/X, TX-43P950M/X

5

77

4

3 786

21

13.19. LR-Board Schematic Diagram

LR-BOARD TNPA3390AD

A

TX-51P950M/X, TX-43P950M/X LR-Board Schematic Diagram

B

C

D

E

F

Page 78

78

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Page 79

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

79

14 Parts Location

Note: The numb er on mech anical parts indicates Ref. No.Me chanical Replaceme nt Parts List.

Page 80

80

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Page 81

15 Packing Exploded View

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

81

Page 82

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

82

Page 83

16 Mechanical Replacement Parts List

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

51" mechanical replacement parts list

Ref. No. Part No. Part Name & Description Remarks

1 D9ZZ00000106 VR or D9ZZ00000079

2 G0F100000006 DY

19 K2CR2DZ00001 AC CORD(TX-51P950M/XB)

19 K2CT3DZ00006 AC CORD(TX-51P950XA)

3 L0AA05A00063 SPEAKER

4 L0AA10A00022 SPEAKER

5 N2QAJB000109 REMOTE CONTROLLER

6 TBL0A8407 LEG-CASTER

7 TBM0A0270 MODEL NAME PLATE(TX-

7 TBM0A0271 MODEL NAME PLATE(TX-

7 TBM0A0281-1 MODEL NAME PLATE(TX-

8 TKG0A9526 LENS

11 TKG0A9542 MIRROR

9 TKGH5077 SCREEN

10 TKGH5078 SCREEN

12 TKK0A8401 LED PANEL

13 TKK0A8527 REAR COVER

14 TKP0AB1604 REAR AV BRACKET

15 TKU0A2404A BACK COVER

16 TKU0A3401-1 BACK COVER

17 TKX0A1501-1 CABINER(RIGHT)

18 TKX0A1601-1 CABINER(RIGHT)

3800A PROTECT TAPE

KFT7CP336F HIGH VOLTAGE DISTRIBUTE

DCA9015 VM COIL

J0KF00000018 FERRITE CORE

K2DR53D00001 TRANSFORM SOCKET(TX-

NO.720 PAPER TAPE

R6(DW)/2STA BATTERY

SC102HSC SILICA GEL

T4FM2515J TAPE

T5E7756 TAPE

T8C1710201H SILICA GEL

TBM0A0257 OPERATE PANEL

TBM0A0258 AV PANEL

TBM0A3005 PANASONIC BADGE

TBX0A83701 POWER BUTTON

TBX0A83801 5-KEY BUTTON

TES0A203 SPRING

TKK0A8531 LED PANEL

TKP0AB2201 BAR

TKP0AB2301 DOOR

TKZ0A8808 SOLEPLATE

TKZ0A8811 BAR

TKZ0A8812 BAR

TMK0A013 FELT

TMK0A082 FELT

TMK0A086 FELT

TMK0A087 FELT

TMK0A090 FELT

TMK0A091 FELT

TMK0A098 FELT

TMK0A122 FELT

TMK0A123 FELT

TMK0A131 FELT

TMK0A136 FELT

TMK0A137 FELT

TMK0A153 FELT

TMK0A734 SPONGE

TMK0A756 SPONGE

TMK0A767 RUBBER MAT

TMM0A448 CLAMPER

TMZ0A9101 BAR

TMZ0A9501 BAR

TPC0A48601 CARTON BOX

TPC0A48702 CARTON BOX(TX-51P950M)

51P950XA)

51P950M)

51P950XA)

51P950XB)

Ref. No. Part No. Part Name & Description Remarks

20 TXCB1KZV PICTURE TUBE

21 TXCG1KYV PICTURE TUBE

22 TXCR1KZV PICTURE TUBE

23 TXFKJ01KYV SPEAKER BRACKET

24 TXFKJ11KYV SPEAKER BRACKET

25 TXFKP01HGC5 SPEAKER BOARD

26 TXFKY04HFC5 CABINET(BOTTOM)

27 TXFKY011KZV CABINET(TOP)

TPC0A48703 CARTON BOX(TX-51P950XA)

TPC0A48704 CARTON BOX(TX-51P950XB)

TPD0A1064 CUSHION

TPD0A2059 CUSHION

TPD0A5023 CUSHION

TPD0A5024 CUSHION

TPD0A5025 CUSHION

TPD0A9002L HANDLE

TPD0A9022 ROUND PAPER PIPE

TPD0A9031 MAT

TPD0A9034 BRACKET

TPE0A4020 PROTECT COVER

TPE0A4024 BAG

TQB0A1151 FAN BAG(TX-51P950M)

TQB0A1152 FAN BAG(TX-51P950XA)

TQB0A1156 FAN BAG(TX-51P950XB)

TQD0A12002 CHECK OUT TICKET

TUA0A0500-3 BRACKET

TUX0A132 OPERATE PANEL

XTB4+20AFJK SCREW

KFT7CM356F FBT CORD 43cm(Anode Lead)

KFT7CM357F FBT CORD 60cm(Anode Lead)

43" mechanical replacement parts list

Ref. No. ITEM ITEM DESCRIPTION Remarks

1 D9ZZ00000106 VR or D9ZZ00000079

2 G0F100000006 DY

19 K2CR2DZ00001 AC CORD(TX-43P950M/XB)

19 K2CT3DZ00006 AC CORD(TX-43P951XA)

3 L0AA05A00063 SPEAKER

4 L0AA10A00022 SPEAKER

5 N2QAJB000109 REMOTE CONTROLLER

6 TBL0A8407 LEG-CASTER

7 TBM0A0266 MODEL NAME PLATE(TX-

7 TBM0A0267 MODEL NAME PLATE(TX-

7 TBM0A0280-1 MODEL NAME PLATE(TX-

8 TKG0A9525 DRAWTUBE

9 TKG0A9534 SCREEN

10 TKG0A9535 SCREEN

11 TKG0A9536 MIRROR

12 TKK0A8401 LED PANEL

3800A PROTECT TAPE

KFT7CP336F HIGH VOLTAGE DISTRIBUTE

DCA9015 VM COIL

J0KF00000018 FERRITE CORE

K2DR53D00001 TRANSFORM SOCKET(TX-

NO.720 PAPER TAPE

R6(DW)/2STA BATTERY

SC102HSC SILICA GEL

T4FM2515J TAPE

T5E7756 TAPE

T8C1710201H SILICA GEL

TBM0A0257 OPERATE PANEL

TBM0A0258 AV PANEL

TBM0A3005 PANASONIC BADGE

TBX0A83701 POWER BUTTON

TBX0A83801 5-KEY BUTTON

TES0A203 SPRING

43P950XA)

43P950M)

43P950XA)

43P950XB)

83

Page 84

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Ref. No. ITEM ITEM DESCRIPTION Remarks

13 TKK0A8527 REAR COVER

14 TKP0AB1604 REAR AV BRACKET

15 TKU0A2404A BACK COVER (BOTTOM)

16 TKU0A3701 BACK COVER

17 TKX0A1701-1 CABINET(LEFT)

18 TKX0A1801-1 CABINET(RIGHT)

20 TXCB1KYV PICTURE TUBE

21 TXCG1KYV PICTURE TUBE

22 TXCR1KYV PICTURE TUBE

23 TXFKJ01KYV SPEAKER BRACKET

24 TXFKJ11KYV SPEAKER BRACKET

25 TXFKP01HDC5 SPEAKER BOARD

27 TXFKY011KYV CABINET(TOP)

26 TXFKY04HFC5 CABINET(BOTTOM)

TKK0A8531 LED PANEL

TKP0AB2201 BAR

TKP0AB2301 DOOR

TKZ0A8808 SOLEPLATE

TKZ0A8813 PRESS BAR

TKZ0A8814 BAR

TMK0A082 FELT

TMK0A086 FELT

TMK0A090 FELT

TMK0A091 FELT

TMK0A093 FELT

TMK0A096 FELT

TMK0A098 FELT

TMK0A129 FELT

TMK0A131 FELT

TMK0A137 FELT

TMK0A138 FELT

TMK0A139 FELT

TMK0A734 SPONGE

TMK0A757 SPONGE

TMK0A767 RUBBER MAT

TMM0A448 CLAMPER

TMZ0A9101 BAR

TMZ0A9401 BAR

TPC0A48401 CARTON BOX

TPC0A48502 CARTON BOX(TX-43P950M)

TPC0A48503 CARTON BOX(TX-43P950XA)

TPC0A48504 CARTON BOX(TX-43P950XB)

TPD0A1062 CUSHION

TPD0A2057 CUSHION

TPD0A5017 CUSHION

TPD0A5018 CUSHION

TPD0A5019 CUSHION

TPD0A9002L HANDLE

TPD0A9021 PAPER PIPE

TPD0A9033 MAT

TPD0A9034 BRACKET

TPE0A4021 PROTECT COVER

TPE0A4025 BAG

TQB0A1151 FAN BAG(TX-43P950M)

TQB0A1152 FAN BAG(TX-43P950XA)

TQB0A1156 FAN BAG(TX-43P950XB)

TQD0A12002 CHECK OUT TICKET

TUA0A0500-3 BRACKET

TUX0A132 OPERATE PANEL

XTB4+20AFJK SCREW

KFT7CM356F FBT CORD 43cm(Anode Lead)

KFT7CM357F FBT CORD 60cm(Anode Lead)

84

Page 85

17 Electrical Replacement Parts List

17.1. Replacement Parts List Notes

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

85

Page 86

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

17.2. Electrical Replacement Parts List

Ref. No. Part No. Part Name &

IC001 AN78M05LB IC

IC054 C0DAAZG00014 IC

IC055 C0DAAZG00014 IC

IC057 C0DAAZG00014 IC

IC058 AN78M09LB IC

IC065 C0DAEHG00006 IC

IC701 AN6914 IC

IC801 C5HABZZ00123 IC

IC804 SE139N IC

IC805 C5HABZZ00165 IC

IC807 C0DAAMA00003 IC

IC1101 C1AB00000441 IC

IC1102 C0CBCBD00043 IC

IC1103 C2CBYF000032 IC

IC1105 C0EBE0000436 IC

IC1106 C0JBAZ001839 IC

IC1107 C0DBEZG00013 IC

IC1108 TVRN553 IC C3FBMD000182

IC1110 C3ABPG000133 IC

IC1403 C0EAH0000139 IC

IC1404 TVRN551 IC(TX-43P950M) C3EAHC000008

IC1404 TVRN552 IC(TX-43P950X) C3EAHC000008

IC1404 TVRN548 IC(TX-51P950M) C3EAHC000008

IC1404 TVRN549 IC(TX-51P950X) C3EAHC000008

IC2000 AN78L08-TA IC

IC2001 C1AB00002133 IC

IC2404 C1AA00000677 IC

IC3001 C1AB00002123 IC

IC3002 AN15861A-VT IC

IC4001 C1AB00002165 IC

IC4011 C0CBCAC00095 IC

IC4012 C0CBCAD00012 IC

IC4201 C1AB00002202 IC

IC4202 C0CBCAC00095 IC

IC4203 C0CBCAD00012 IC

IC4401 C1AB00002186 IC

IC4402 C3ABPJ000063 IC

IC4404 C0JBAM000129 IC

IC4405 C0ABBA000025 IC

IC4406 C0ABBA000025 IC

IC4407 AN15935A-VF IC

IC4408 C0CBCBC00062 IC

IC4411 C0CBCBC00062 IC

IC4412 C0CBCAC00096 IC

IC4413 C0CBCBC00062 IC

IC4415 C0CBCAF00007 IC

IC7001 C5AA00000204 IC

IC7002 C5AA00000204 IC

IC7101 C0DBFGD00002 IC

IC7103 C1AB00001940 IC

IC7104 C0ABFB000016 IC

IC7105 C0ABFB000016 IC

IC7106 C1AB00000454 IC

IC7109 AN79L12M-E1 IC

IC7110 AN78L12M-E1 IC

IC7300 TVRN550 IC(TX-43P950M/X) C3EBJC000059

IC7300 TVRN547 IC(TX-51P950M/X) C3EBJC000059

IC7701 C1AB00001394 IC

IC9601 AN6562 IC

IC400-A C1AA00000688 IC

D001 MAZ31500HL DIODE

D002 MAZ31500HL DIODE

D003 MA3X152K0L DIODE

D010 MA3X152K0L DIODE

D055 B0BA01000070 DIODE

D056 B0JAME000091 DIODE

D062 B0JAME000091 DIODE

D069 B0JAME000091 DIODE

D353 MA2C165001VT DIODE

D354 MA2C165001VT DIODE

Description

Remarks

Ref. No. Part No. Part Name &

D357 MA2C165001VT DIODE

D360 MA2C18800E DIODE

D361 MA2C18800E DIODE

D362 MA2C18800E DIODE

D363 MA2C18800E DIODE

D366 B0EAKC000003 DIODE

D367 MA2C18800E DIODE

D368 MA2C18800E DIODE

D369 MA2C18800E DIODE

D370 MA2C18800E DIODE

D373 MA2C165001VT DIODE

D374 MA2C165001VT DIODE

D377 MA2C165001VT DIODE

D387 MA2C18800E DIODE

D388 MA2C18800E DIODE

D389 MA2C18800E DIODE

D390 MA2C18800E DIODE

D393 MA2C165001VT DIODE

D394 MA2C165001VT DIODE

D397 MA2C165001VT DIODE

D400 B0EAKC000003 DIODE

D401 B0EAKC000003 DIODE

D402 B0HAMR000048 DIODE

D403 B0EAKC000003 DIODE

D404 B0EAKC000003 DIODE

D406 MA3X152K0L DIODE

D407 B0EAKC000003 DIODE

D408 B0EAKC000003 DIODE

D409 MA2C72300F DIODE

D458 MAZ30330LL DIODE

D501 B0HALP000007 DIODE

D502 B0HALP000007 DIODE

D503 B0HALP000007 DIODE

D504 B0HALP000007 DIODE

D505 MA2C165001VT DIODE

D506 MA2C165001VT DIODE

D507 MA2C165001VT DIODE

D509 B0HAMC000013 DIODE

D510 B0HAKM000005 DIODE

D511 B0KZ00000001 DIODE

D513 MAZ41500MF DIODE

D514 MAZ42700MF DIODE

D515 MAZ40680LF DIODE

D701 B0HALP000007 DIODE

D702 MAZ41200MF DIODE

D801 B0HANR000014 DIODE or FMGG26S

D802 B0HAGP000003 DIODE

D803 B0HAGP000003 DIODE

D804 B0HAGP000003 DIODE

D805 MAZ20820A0LS DIODE

D806 MAZ20820A0LS DIODE

D807 B0HAPV000009 DIODE

D808 MA2C165001VT DIODE

D809 MA2C165001VT DIODE

D813 MA2C165001VT DIODE

D814 MA2C165001VT DIODE

D815 MAZ22400B0LS DIODE

D816 ERZV10V621P2 DIODE

D818 B0HBRM000012 DIODE

D819 B0JANE000009 DIODE

D821 ERA22-10 DIODE

D822 MA2C16700E DIODE

D823 B0HBRM000012 DIODE

D824 MA2C165001VT DIODE

D825 B0BA01000070 DIODE

D826 B0FBAT000008 DIODE

D827 ERA22-10 DIODE

D830 TVSC0510 DIODE

D831 TVSC0510 DIODE

D832 B0ZAZ0000045 DIODE

D833 B0BA42500001 DIODE

Description

Remarks

86

Page 87

TX-51P950M / TX-51P950X / TX-43P950M / TX-43P950X

Ref. No. Part No. Part Name &

D834 ERA22-10 DIODE

D835 B0JANG000003 DIODE

D837 B0JAMG000025 DIODE

D838 B0JAMG000025 DIODE

D839 ERZV10V621P2 DIODE

D875 ERZV10V621P2 DIODE

D876 ERZV10V621P2 DIODE

D953 B0ZAZ0000054 DIODE

D962 MA2C18800E DIODE

D1011 LNG201RFC DIODE

D1013 MAZ40560MF DIODE

D1015 B3AEA0000033 DIODE

D1016 MAZ40680MF DIODE

D1101 MAZ30560ML DIODE

D1408 MA3X152K0L DIODE

D1416 MAZ30560ML DIODE

D2000 MA3X152K0L DIODE

D2001 MA3X152K0L DIODE

D2407 MAZ33600ML DIODE

D2408 MAZ33600ML DIODE

D2409 MAZ33600ML DIODE

D2410 MAZ33600ML DIODE

D2411 MAZ33600ML DIODE

D2412 MAZ33600ML DIODE

D2413 MAZ43600MF DIODE

D3001 MAZ30510ML DIODE

D3201 MA2C165001VT DIODE

D3202 MA2C165001VT DIODE

D3205 MA2C165001VT DIODE

D3206 MA2C165001VT DIODE

D3351 MA2C165001VT DIODE

D3352 MA2C165001VT DIODE

D3361 MA2C165001VT DIODE

D3362 MA2C165001VT DIODE

D3371 MA2C165001VT DIODE

D3372 MA2C165001VT DIODE

D4401 MA3X152K0L DIODE

D4402 MA3X152E0L DIODE

D4403 MA3X152K0L DIODE

D4407 MA2J11100L DIODE

D4410 MA3X152E0L DIODE

D4411 MA3X152E0L DIODE

D7102 MA3X152E0L DIODE

D7103 MAZ30620ML DIODE

D7300 MAZ30300HL DIODE

D7701 MA3X152E0L DIODE

D7702 MA3X152E0L DIODE

D7703 MA3X152K0L DIODE

D7706 MAZ30330LL DIODE

D9601 MA2C165001VT DIODE

D9602 MA2C0290BF DIODE

D9603 B0HACW000001 DIODE

D9604 MAZ40620L3TV DIODE

D9605 MAZ40300HF DIODE

D9606 MAZ40300HF DIODE

D9607 MAZ40750HF DIODE

PC803 ON3171R DIODE or B3PAA0000012

PC806 ON3171R DIODE or B3PAA0000012

Q006 2SB0709A0L TRANSISTOR

Q353 2SC3942000LB TRANSISTOR

Q354 B1BAAN000025 TRANSISTOR

Q355 B1BCAN000004 TRANSISTOR

Q356 B1BCAN000004 TRANSISTOR

Q373 2SC3942000LB TRANSISTOR

Q374 B1BAAN000025 TRANSISTOR

Q375 B1BCAN000004 TRANSISTOR

Q376 B1BCAN000004 TRANSISTOR

Q393 2SC3942000LB TRANSISTOR

Q394 B1BAAN000025 TRANSISTOR

Q395 B1BCAN000004 TRANSISTOR

Q396 B1BCAN000004 TRANSISTOR