Panasonic TX-37LZD80, TX-37LZD80F, TX-32LZD80, TX-32LZD80F Service manual

ORDER No. PCZ0802006CE

Service Manual

Colour LCD Television

TX-37LZD80

TX-37LZD80F

TX-32LZD80

TX-32LZD80F

LH69 Chassis

Specifications

(Informations in brackets [ ] refers to model 32”)

Power Source: 220-240V AC, 50/60Hz

Power Consumption 190W [150W]

Stand-by Power Consumption: 0.3W (Without monitor out recording)

19W (With monitor out recording)

Aerial Impedance: 75Ω unbalanced, Coaxial Type

Receiving System: LZD80 LZD80F

PAL-I, PAL-I/H, B/G, D/K,

PAL-525/60 (AV only) SECAM B/G, D/K, L/L’

DVB (via UHF aerial input) PAL-525/60 (AV only)

M.NTSC (AV only) DVB (via VHF/UHF aerial input)

NTSC (AV only) M.NTSC (AV only)

NTSC (AV only)

Receiving Channels: LZD80 LZD80F

UHF E21-E68 VHF E2-E12 VHF H1-H2 (ITALY)

VHF A-H (ITALY) VHF R1-R2

VHF R3-R5 VHF R6-R12

UHF E21-E69 CATV (S01-S05)

CATV S1-S10 (M1-M10) CATV S11-S20 (U1-U10)

CATV S21-S41 (Hyperband)

Operating Conditions: Temperature: 0°C ÷ 35°C

Humidity: 20% ÷ 80% RH (non condensing)

Scanning format: 480i(60Hz), 480p(60Hz), 576i(50Hz), 576p(50Hz), 720p(60Hz), 720p(50Hz), 1.080i(60Hz),

1.080i(50Hz), 1.080p(60Hz), 1.080p(50Hz), 1080p(24Hz)

PC signals: VGA, SVGA, XGA, SXGA(compressed)

Horizontal scanning frequency 31 – 69 kHz

Vertical scanning frequency 59 – 86 Hz

Panasonic CS ( U.K. ) Ltd.

WILLOUGHBY ROAD,

BRACKNELL,

BERKS.,

RG12 8FT.

Intermediate Frequency:

Video/Audio LZD80 LZD80F

Video 38,9MHz 38,9MHz, 33,9MHz

Audio 32.90MHz 33,4MHz (B/G), 33,16MHz (A2)

32.35MHz(NICAM) 33,05MHz (NICAM B/G, D/K, L)

32,4MHz (D/K), 32,66MHz (CZ STEREO)

40,4MHz (L

Colour 34,47MHz 34,47MHz (PAL)

’), 39,75MHz (L’NICAM)

34,5MHz, 34,65MHz (SECAM)

38,3MHz, 38,15MHz (SECAM L

Terminals:

’)

AV1 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin) 0,7V p-p 75Ω

AV1 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV2 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin) 0,7V p-p 75Ω

S-video IN (21-pin) Y: 1V p-p 75Ω

C:0,3V p-p 75Ω

AV2 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV3 IN S-Video IN (4-pin) Y: 1V p-p 75Ω

C:0,3V p-p 75Ω

Audio (RCAx2) 500mV rms 10kΩ (used for HDMI3 AUDIO)

Video (RCAx1) 1V p-p 75Ω

HDMI1, HDMI2, HDMI3 Type A Connector

COMPONENT Video (RCAx3) Y:1V p-p 75Ω (inc luding synchronization)

Pb, Pr: ±0,35V p-p 75Ω

AUDIO IN Audio (RCAx2) 500mV rms 10kΩ (for HDMI1, COMPONENT-AUDIO)

AUDIO OUT Audio (RCAx2) 500mV rms 1kΩ (high impedance)

DIGITAL AUDIO OUT PCM, Fiber optic

CARD SLOT SD CARD slot x1

PC HIGH-DENSITY D_SUB 15PIN R,G,B: 700mV p-p 75Ω

HD,VD/TTL Level 2-5V p-p (high impedance)

LCD screen: L5EDD9T00003 [L5EDD8T00001]

1920 x 1080 XGA, 16:9

Visible Diagonal 940mm [800mm]

Audio Output: 20W (2x10W)

Headphones: 3,5mm, 8Ω Impedance

Accessories supplied : Remote Control 2 x R6 (UM3) Batteries

Dimensions:

Height: Width: Depth:

Including TV stand 648mm 943mm 295mm

[579mm 831mm 225mm]

TV set only 606mm 943mm 108mm

[538mm 831mm 103mm]

Net weight:

Including TV stand 22.5kg [18.0kg]

TV set only 19.5kg [15.5kg]

Specifications are subject to change without notice.

Weights and dimensions shown are approximate.

Warning

This service information is designed for experienced repair technicians only and is not designed for use by the general public. It does not

contain warnings or cautions to advise non-technical individuals of potencial dangers in attempting to service a product. Products

powered by electricity should be serviced or repaired only by experienced professional technicians. Any attempt to service or repair the

product or products deal within this service information by anyone else could result in serious injury or death.

2

CONTENTS

SAFETY PRECAUTIONS...........................................4

GENERAL GUIDE LINES...................................... 4

TOUCH – CURRENT CHECK............................... 4

PREVENTION OF ELECTROSTATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES.................................................................... 5

ABOUT LEAD FREE SOLDER (PBF)......................... 6

SUGGESTED PB FREE SOLDER........................ 6

APPLICABLE SIGNALS.............................................. 7

SERVICE HINTS ........................................................ 8

CHASSIS BOARD LAYOUT....................................... 9

LOCATION OF LEAD WIRING………………………….9

SETTING INSPECTION............................................ 10

SELF-CHECK ........................................................... 11

POWER LED BLINKING TIMING CHART................ 13

SERVICE MODE FUNCTION................................... 14

SERVICE ................................................................. 15

OPTION BYTES DESCRIPTION..............................16

ADJUSTMENT METHOD.......................................... 17

WIRING DIAGRAM................................................... 18

BLOCK DIAGRAMS.................................................. 19

PARTS LOCATION................................................... 22

REPLACEMENT PARTS LIST.................................. 24

SCHEMATIC DIAGRAMS......................................... 42

A-BOARD (1 OF 16) SCHEMATIC DIAGRAM....43

P-BOARD (1 OF 3) SCHEMATIC DIAGRAM......59

M-BOARD SCHEMATIC DIAGRAM ................... 62

V-BOARD SCHEMATIC DIAGRAM ................... 63

G-BOARD SCHEMATIC DIAGRAM………………64

CONDUCTOR VIEWS………………………………….65

3

Safety Precautions

Ω

μ

Ω

General Guide Lines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated

or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such a s insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following touch current checks to prevent the customer from being exposed to shock hazards.

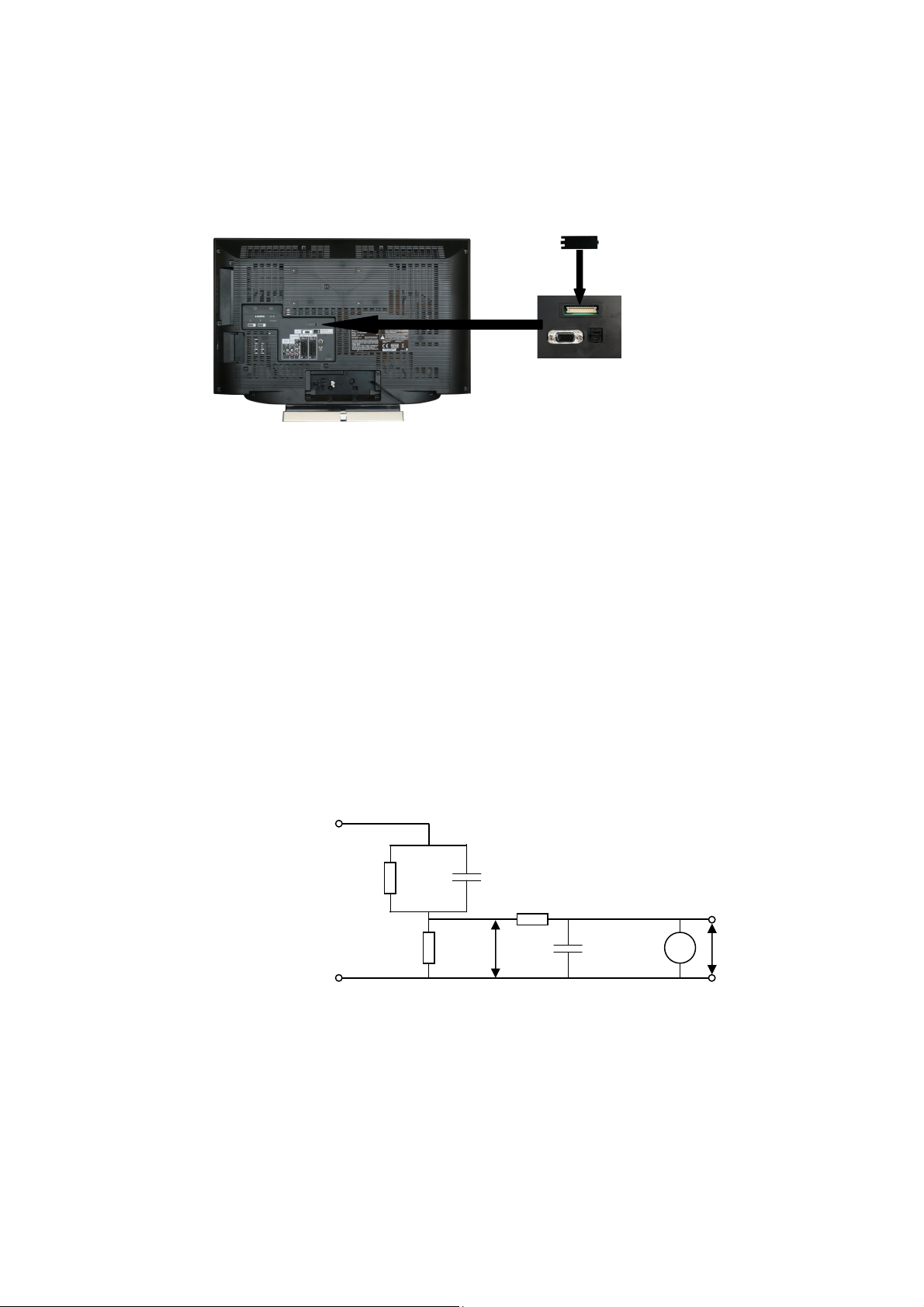

4. Always ensure panel TKP0E16001 is correctly replaced before returning to customer (see Fig.1).

Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transfor mer for this check.

2. Connect a measuring network for touch currents between each exposed metallic part on the set and a good earth

ground such as a water pipe, as shown in Fig. 2.

3. Use Leakage Current Tester (Simpson 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reserve the AC plug in the AC outlet and repeat each of the above measure.

6. The potential at any point (TOUCH CURRENT) expressed as voltage U1 and U2, does not exceed the follo wing values:

For a. c.: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For d. c.: U1 = 1.0 V,

Note:

The limit value of U2 = 0.35 V (peak) for a. c. and U1 = 1.0 V for d. c. correspond to the values 0.7 mA (peak) a. c. and

2.0 mA d. c.

The limit value U1 = 35 V (peak) for a. c. correspond to the value 70 mA (peak) a. c. for frequencies greater than 100

kHz.

7. In case a measurement is out of the limits specified, there is a possibility of a shock hazard, and the equipment should

be repaired and rechecked before it is returned to the customer.

COLD

WATER PIPE

(EARTH GROUND)

TO

APPLIANCES

EXPOSED

METAL PARTS

Resistance values in ohms (Ω)

V: Voltmetr or oscilloscope

(r.m.s. or peak reading)

NOTE – Appropriate measures should be taken to obtain the correct value in case of non-sinusoidal waveforms

Measuring network for TOUCH CURRENTS

=1500Ω

R

S

Input resistance: ≥ 1M

Input capacitance: ≤ 200pF

Frequency range: 15Hz to 1MHz and d.c.respectively

R0=500Ω

Fig. 2

Fig. 1

C

=0.22μF

S

10k

F

0.022

V

U2 (V)

4

Prevention of Electrostatic Discharge (ESD) to Electrostatically

Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect

transistors and semiconductor "chip" components. The following techniques should be used to help reduce the incidence of

component damage caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on

your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD

wrist strap, which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge build up or exposure of the assembly.

3. Use only a grounded-tip s oldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD

protected)" can generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelle d chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by cond uctive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protectiv e material from the le ads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity

(ESD) sufficient to damage an ES device).

There are special components used in this equipment which are important for safety.

These parts are marked by in schematic diagrams, exploded views and replacement parts list. It is essential that

these critical parts should be replaced with manufacturer’s specified parts to prevent shock, fire, or other hazards. Do

not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

5

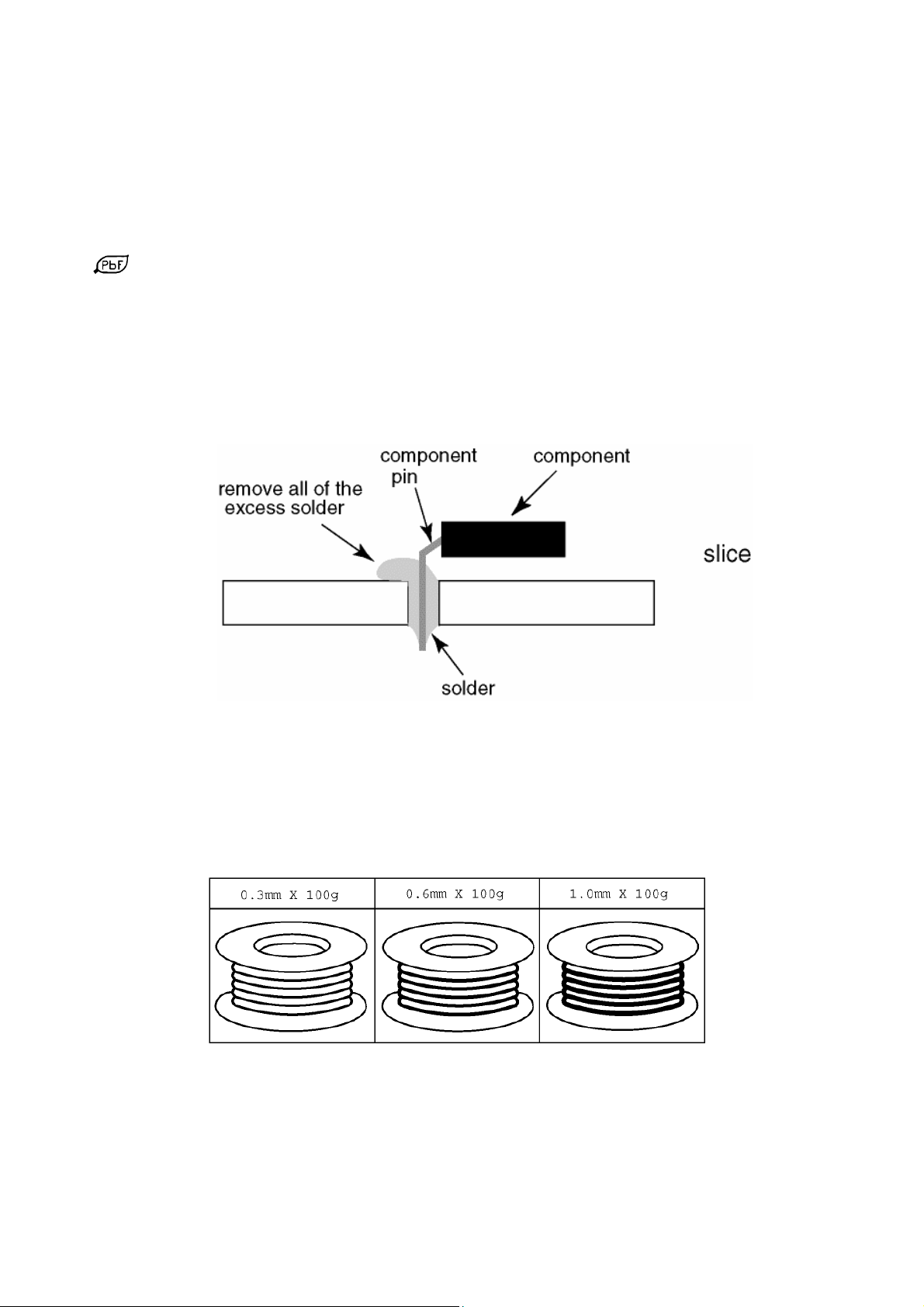

About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work,

we’d suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

stamped on the back of PCB.

Caution

• Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40°C)

higher. Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

• Pb free solder will tend to splash when heated too hi gh (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before

applying Pb solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

• After applying PbF solder to double layered boards, please check the component side for excess solder which may

flow onto the opposite side. (see Fig.3)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used. (see Fig.4)

Fig.3

Fig.4

6

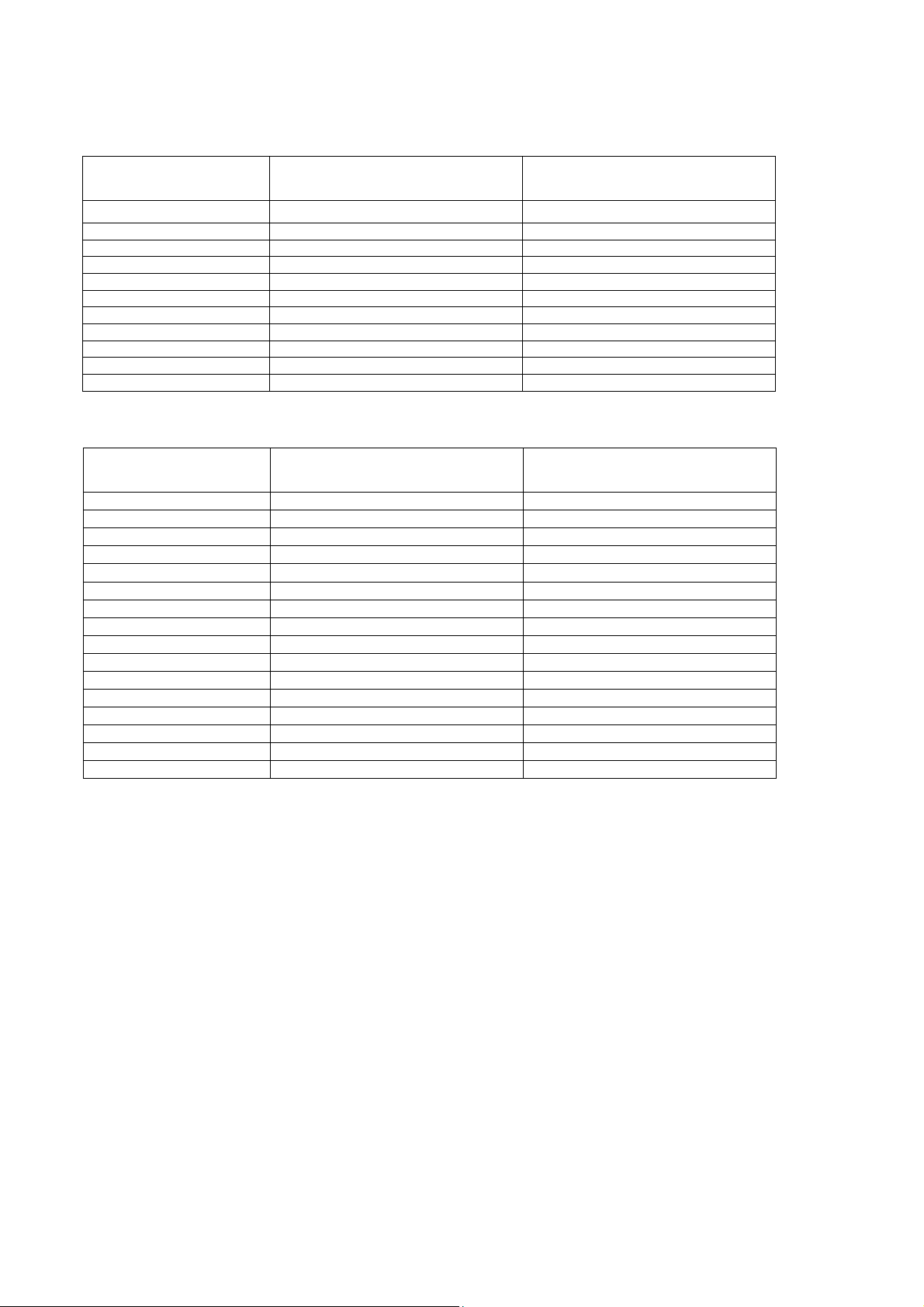

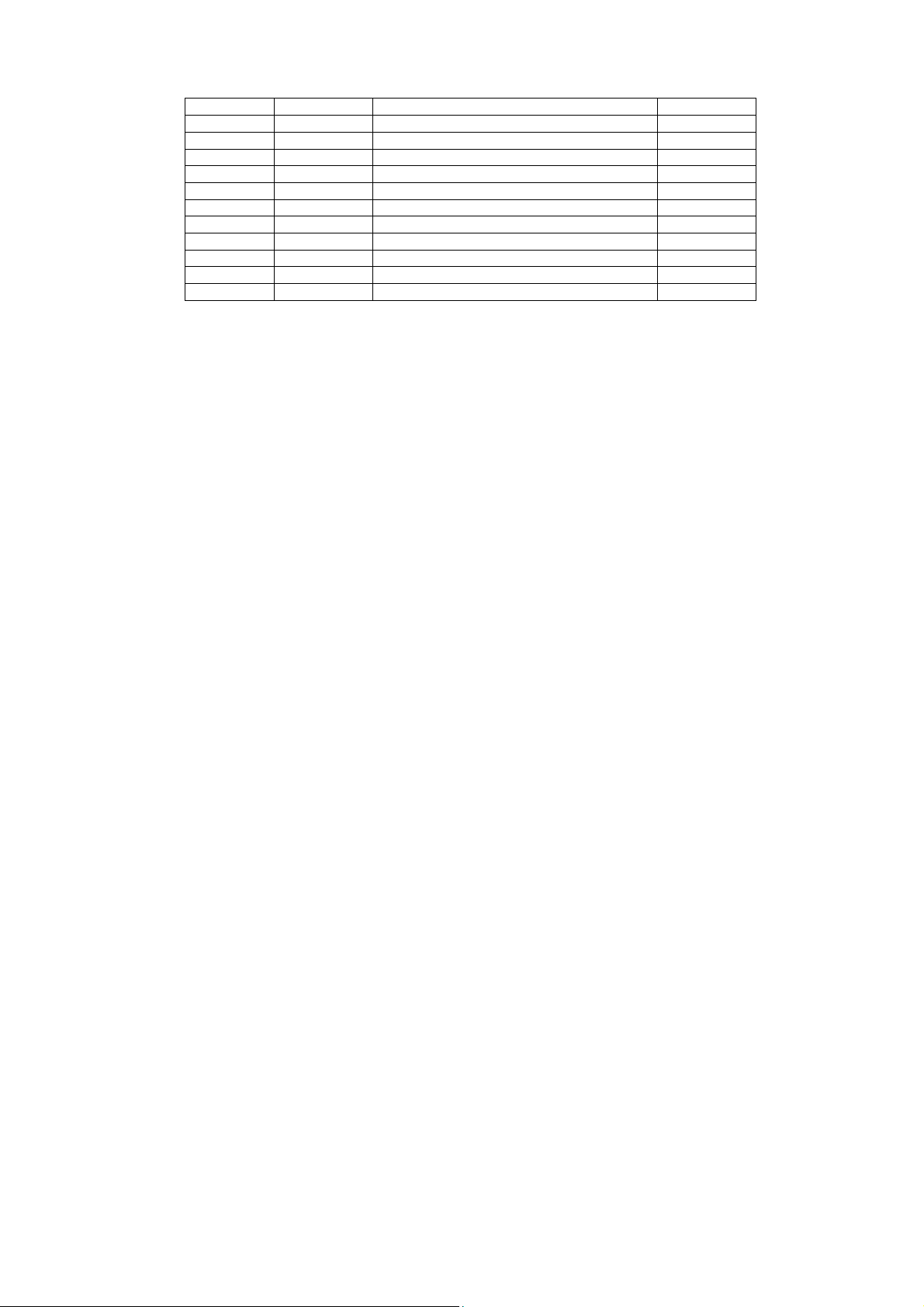

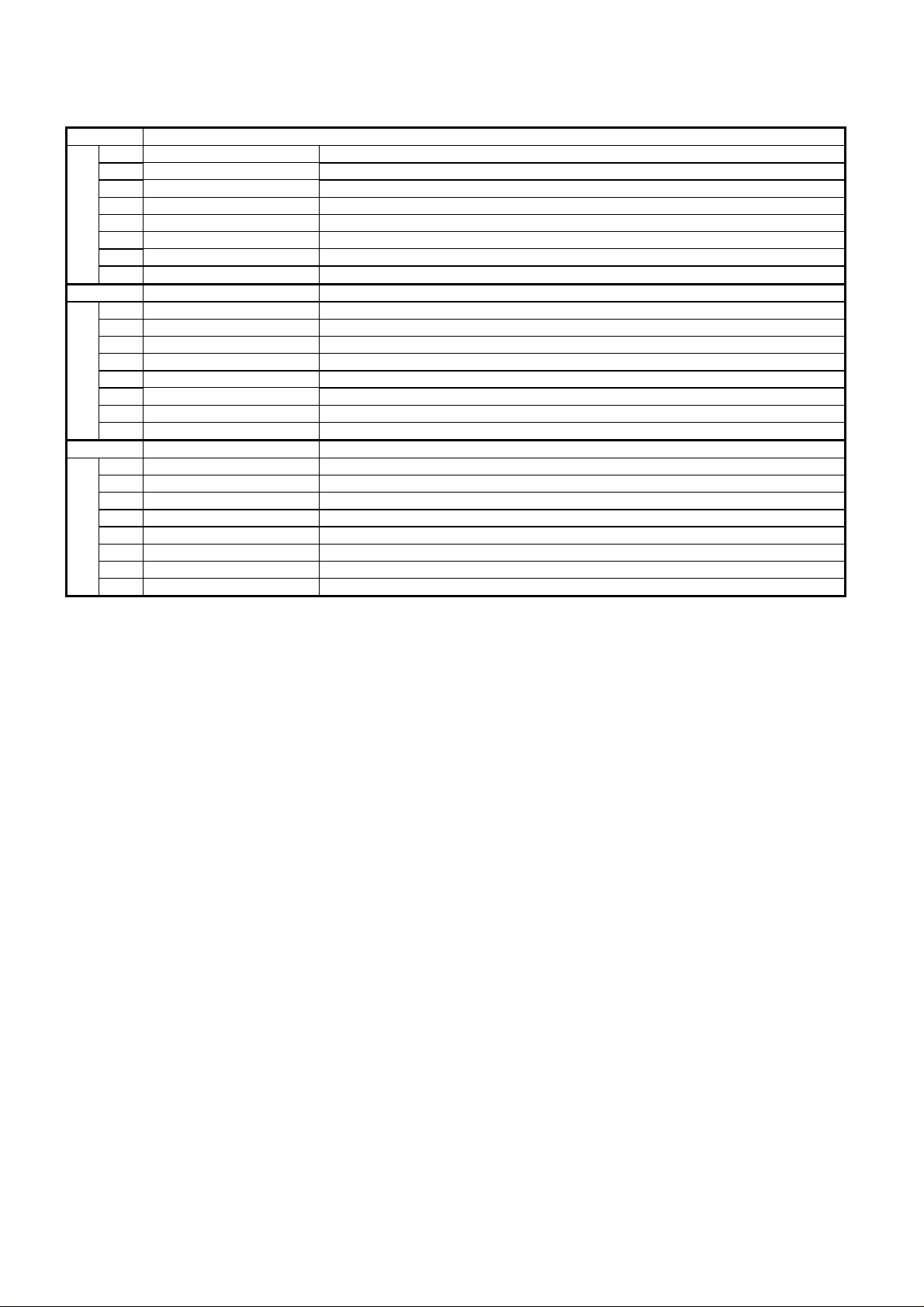

Applicable Signals

Component (Y, Pb, Pr), HDMI

Signal name COMPONENT HDMI

525 (480) / 60i * *

525 (480) / 60p * *

625 (576) / 50i * *

625 (576) / 50p * *

750 (720) / 60p * *

750 (720) / 50p * *

1,125 (1,080) / 60i * *

1,125 (1,080) / 50i * *

1,125 (1,080) / 60p *

1,125 (1,080) / 50p *

1,125 (1,080) / 24p *

PC (D-sub 15P)

Signal name Horizontal frequency (kHz) Vertical frequency (Hz)

640 × 400 @70 Hz

640 × 480 @60 Hz

640 × 480 @75 Hz

800 × 600 @60 Hz

800 × 600 @75 Hz

800 × 600 @85 Hz

852 × 480 @60Hz

1,024 × 768 @60Hz

1,024 × 768 @70Hz

1,024 × 768 @75Hz

1,024 × 768 @85Hz

1,280 × 1,024 @60Hz

1,366 × 768 @60Hz

Macintosh 13“ (640 × 480)

Macintosh 16“ (832 × 624)

Macintosh 21“ (1,152 × 870)

Note:

• Signals other than above may not be displayed properly.

• The above signals are reform atted for optimal viewing on your display.

• Applicable input signal for PC is basicall y com patible to VESA standard timing.

• PC signal is magnified or compresse d for display, so that it may not be possible to show fine detail

with sufficient clarity.

31.47 70.07

31.47 59.94

37.50 75.00

37.88 60.32

46.88 75.00

53.67 85.06

31.44 59.89

48.36 60.00

56.48 70.07

60.02 75.03

68.68 85.00

63.98 60.02

48.39 60.04

35.00 66.67

49.73 74.55

68.68 75.06

7

Service Hints

How to remove the backcover

Remove the 20 [21] fixing screws. (see Fig.5)

SCREWS

How to remove the Pedestal assembly

Lay the main unit face down. (see Fig.6)

Remove the 4 fixing screws and the pedestal assembly. (see Fig.7)

Remotion of a Protection Cover

Remove a protection cover from new LCD Panel when replacing the LCD Panel.(see Fig.8)

This cover is for transportation LCD panel use only.

Fig.6

Fig.5

Fig.7

Fig.8

SCREWS

SCREWS

8

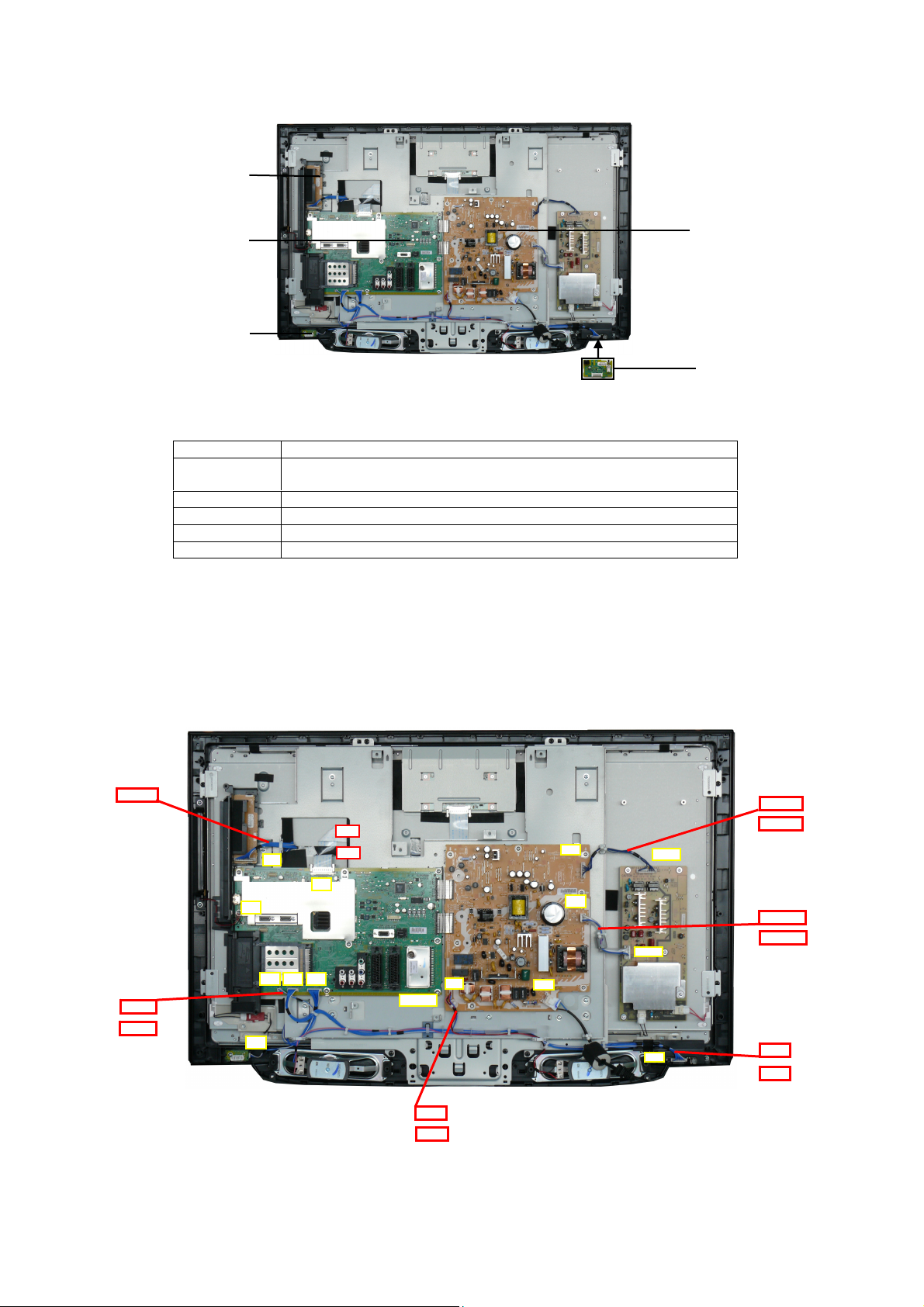

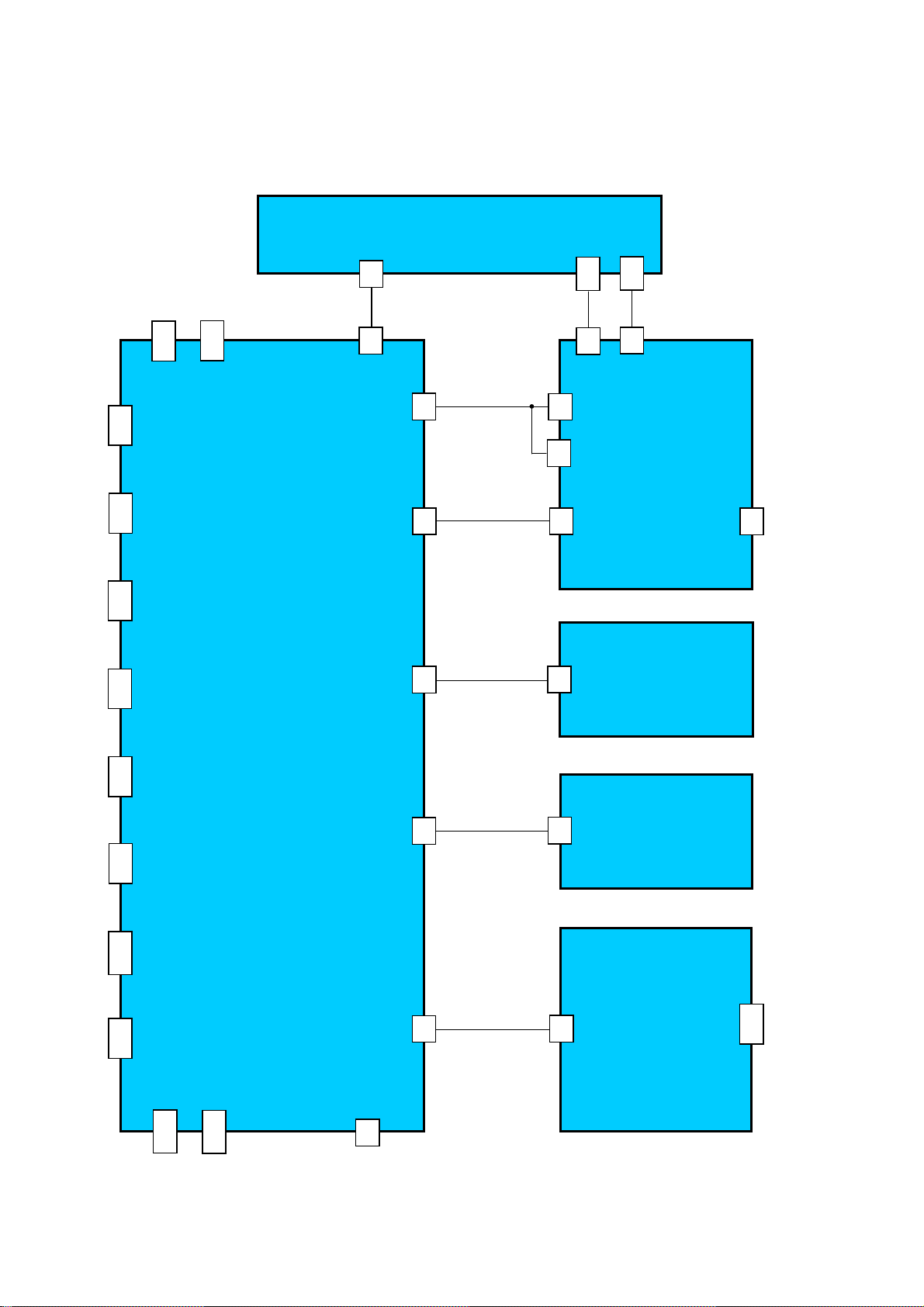

Chassis Board Layout

G-BOARD

A-BOARD

M-BOARD

Board Name Function

A-Board AV Terminal, AV Switch, Sound Processor, Speaker out, TV tuner, PC,

SD,Global Core, HDMI, IDTV Processor, D/A Converter, Peaks Lite 2

P-Board Main Input, Power Supply, Power Supply Regulator, Speaker out

G-Board Side AV Terminal

V-Board Remote Receiver, R&G LED,Timer Rec LED,Main Switch

M-Board C.A.T.S.

P-BOARD

V-BOARD

Location of Lead Wiring

To find the Part Number of required wire in Replacement Parts List click on the wire name in red box.

G51-A51

LVDS

LVDS

(32’’)

(37’’)

TU2901

P2

P5

P3

P1

CN501

CN1

V1

(32’’)

(37’’)

A11-M11

A11-M11

A10

M11

G51

A11

A5

A51

A1

P3-SP

P3-SP

(32’’)

(37’’)

P2-CN501

P2-CN501

P5-CN1

P5-CN1

A1-V1

A1-V1

(32’’)

(37’’)

(32’’)

(37’’)

(32’’)

(37’’)

9

Setting Inspection

Voltage Confirmation

Confirm the following voltages:

P board

Description Test point Position Normal mode Stand by mode Active stand by mode

Sound_Vcc TP7050 P7, pin 1,2 18V +/- 1V Max 3V Max 3V

BT_30V TP7060 P7, pin 5 31V +/- 1V Max 3V 31V +/- 1V

SUB_5V T P7059 P7, pin 12,13,14 5,1V +/- 0,2V Max 1V 5,1V +/- 0,2V

SUB_9V TP 7055 P7, pin 17 9,1V +/- 0,3V Max 1V 9,1V +/- 0,3V

DTV_12V TP7057 P7, pin 20,21 12V +/- 0,4V Max 1V 12V +/- 0,4V

PANEL_12V TP7058 P7, pin 22,23 12V +/- 0,4V Max 2V Max 2V

5VS TP7061 P6, pin 11 5V +/- 0,2V 5V +/- 0,2V 5V +/- 0,2V

STB_5V TP7062 P6, pin 13 5V +/- 0,2V 5V +/- 0,2V 5V +/- 0,2V

SUB_6V TP 7064 P6, pin 23 6,1V +/- 0,4V Max 1V 6,1V +/- 0,4V

V+ - V- TP7025-26 P5, pin 1,3 370V - 395V Max 1V 370V - 395V

12V TP7070 P2, pin 1 12V +/- 0,4V Max 3V 12V +/- 0,4V

A board

5VS TP1037 A1, pin 10 5V +/- 2%

DTV12V TP1016 A7, pin 20,21 12V +/- 2%

SUB9V TP1015 A7, pin 17 9V +/- 2%

SUB5V TP1011 A7, pin 12,13,14 5V +/- 2%

BT30V TP1010 A7, pin 5 30V +/- 2%

SUB6V TP1014 A6, pin 23 6V +/- 2%

PNL12V TP1012 A7, pin 22,23 12V +/- 2%

S_17V TP1013 A7, pin 1,2 17 +/- 2%

10

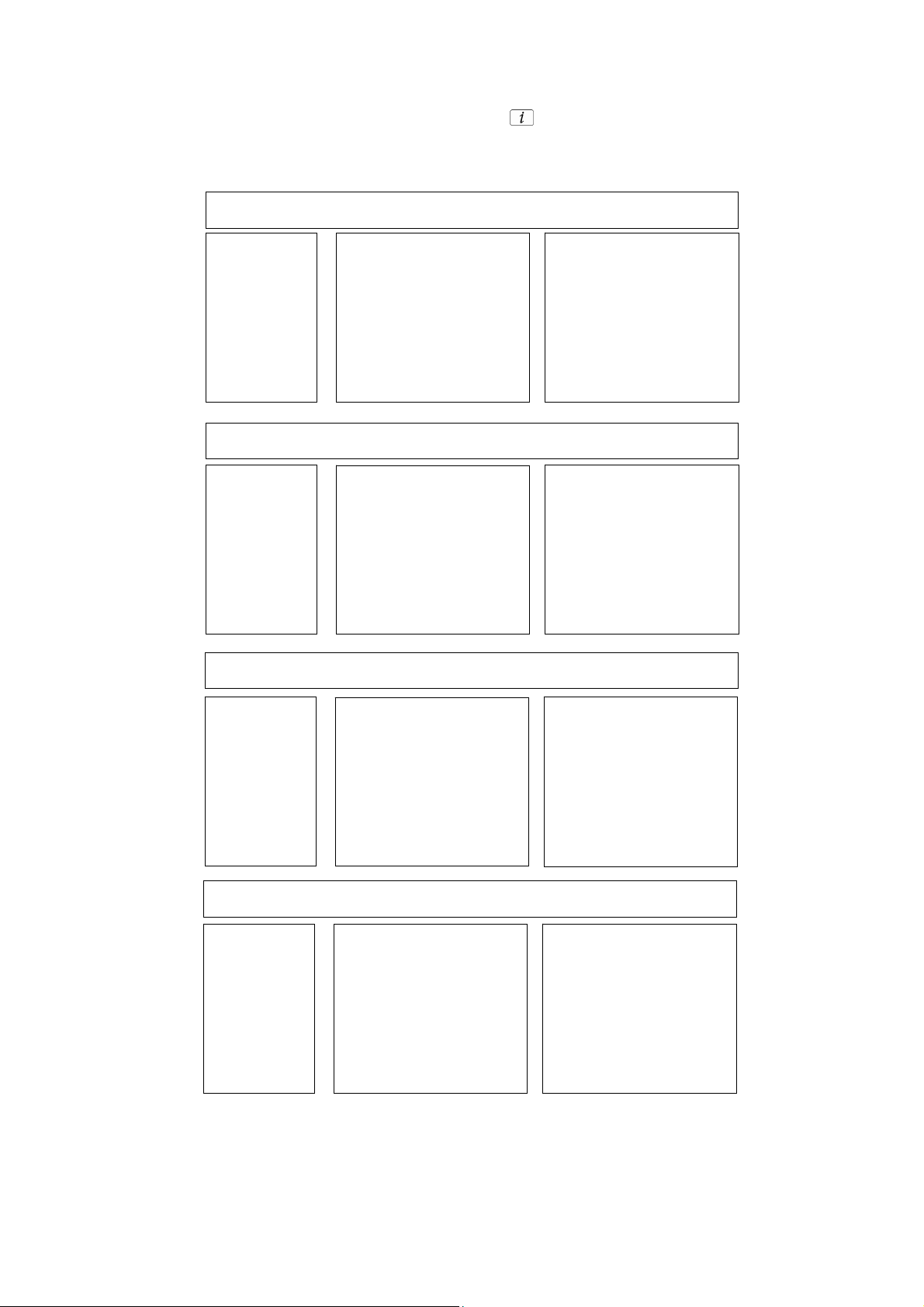

Self Check

p

p

p

p

Self-check is used to automatically check the bus lines and hexadecimal code of the TV set. To enter Self-Check mode, keep

pressing the down (-/v) button on the TV set and press the STATUS button on the remote control. To exit Self Check,

switch off the TV set at the power button.

TX-37LZD80

TX-37LZD80F

TX-32LZD80

TX-32LZD80F

37FHD Panasonic 2008LCD

Self Check Com

ADV O.K.

ADAV O.K.

TUN O.K.

GENX O.K..

MEM1 O.K.

MEM2 O.K.

AVSW O.K.

OFDM O.K.

TEMP O.K.

MIHO O.K.

VIF O.K.

37FHD Panasonic 2008LCD

Self Check Com

ADV O.K.

ADAV O.K.

TUN O.K.

GENX O.K..

MEM1 O.K.

MEM2 O.K.

AVSW O.K.

OFDM O.K.

TEMP O.K.

MIHO O.K.

VIF O.K.

32FHD Panasonic 2008LCD

Self Check Com

ADV O.K.

ADAV O.K.

TUN O.K.

GENX O.K..

MEM1 O.K.

MEM2 O.K.

AVSW O.K.

OFDM O.K.

TEMP O.K.

MIHO O.K.

VIF O.K.

32FHD Panasonic 2008LCD

Self Check Com

ADV O.K.

ADAV O.K.

TUN O.K.

GENX O.K..

MEM1 O.K.

MEM2 O.K.

AVSW O.K.

OFDM O.K.

TEMP O.K.

MIHO O.K.

VIF O.K.

PEAKS-SOFT 1.011

PEAKS-EEP 01.03.0030

GenX-SOFT 1.01.00

GenX-EEP 1.03.01

GenX-ROMCORR 1.01.00

PEAKS-SOFT 1.011

PEAKS-EEP 01.03.0005

GenX-SOFT 1.01.00

GenX-EEP 1.03.01

GenX-ROMCORR 1.01.00

PEAKS-SOFT 1.011

PEAKS-EEP 01.03.0031

GenX-SOFT 1.01.00

GenX-EEP 1.03.01

GenX-ROMCORR 1.01.00

PEAKS-SOFT 1.011

PEAKS-EEP 01.03.0006

GenX-SOFT 1.01.00

GenX-EEP 1.03.01

GenX-ROMCORR 1.01.00

lete

lete

lete

lete

SUM 1d34

OPTION 1 2c

OPTION 2 00

OPTION 3 00

CHECK 2c

MODEL ID 05

03101100

00000010

EDID1 2d.2b

EDID2 2d.1b

SUM 1d08

OPTION 1 2c

OPTION 2 00

OPTION 3 00

CHECK 2c

MODEL ID 05

03111100

00000010

EDID1 2d.2b

EDID2 2d.1b

SUM 1d35

OPTION 1 2c

OPTION 2 00

OPTION 3 00

CHECK 2c

MODEL ID 05

03101100

00000004

EDID1 2d.2b

EDID2 2d.1b

SUM 1d09

OPTION 1 2c

OPTION 2 00

OPTION 3 00

CHECK 2c

MODEL ID 05

03111100

00000004

EDID1 2d.2b

EDID2 2d.1b

11

Display Ref. No. Description P.C.B.

ADV IC4510 A/D CONVERTER A-Board

ADAV IC2106 AUDIO PROCESSOR A-Board

TUN TU2901 TUNER A-Board

GENX IC1100 MICROPROCESSOR A-Board

MEM1 IC1101 EEPROM /GenX/ A-Board

MEM2 IC8601 EEPROM /PeaksLite/ A-Board

AVSW IC3001 AUDIO VIDEO SWITCH A-Board

OFDM IC8301 COFDM DEMODULATOR A-Board

TEMP IC1000 TEMP SENSOR A-Board

MIHO IC4200 MIHO A-Board

VIF TU2901 TUNER A-Board

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

12

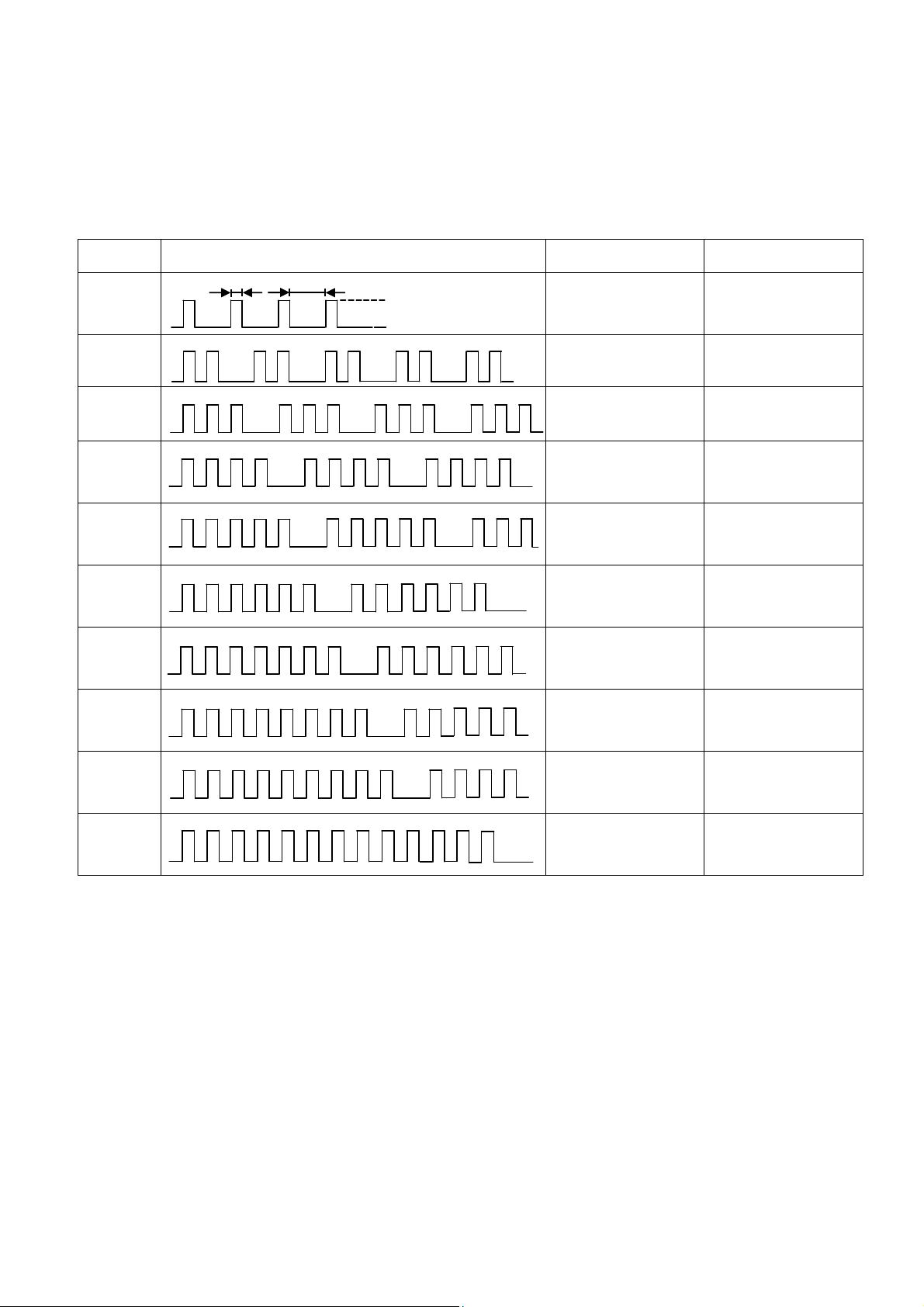

Power LED blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by number of blinking of the Power LED on the front panel of the unit.

Blinking

times

Once

1 INVERTER_SOS

2

3

Blinking timing Contents Check point

4 sec

Light

No Light

FAN_SOS

SOS

A BOARD, P BOARD

LCD PANEL

A BOARD

A BOARD

P BOARD

4

5

6

7

8

9

13

DTV_12V

MAIN_9V

SUB_5V

SUB_3.3V A BOARD

MAIN_3.3V A BOARD

SOUND_SOS

Emergency SOS A BOARD

P BOARD

A BOARD

A BOARD

P BOARD

A BOARD, M BOARD

A BOARD

13

Service Mode Function

MPU controls the functions switching for each IICs through IIC bus in this chassis. The following setting and adjustment can

be adjusted by remote control in Service Menu

How to enter SERVICE

While pressing (-/v) button on the TV unit, press on the remote control for 3 times within 2 seconds.

Note:

To exit from Service mode, press the exit button on remote control.

0

14

SERVICE

A

A

A

A

A

SERVICE

ADJUST

WB-ADJ

OPTION

SRV-TOOL

Peaks SOFT 1.011 OPTION 1 2c

Peaks EEP 01.03.0006 OPTION 2 00

S e r v i c e 1

LSI DATA 11.22.33 OPTION 3 00

STBY SOFT 1.01.00 Model ID 05

STBY EEP 1.03.01 03111100

STBY ROMCOR 1.01.00 00000004

RB Cnt 000

Time 00010:15

0004515

1

ADJUST DYNAMIC

CONTRAST

YMAX

1,2:MAIN SELECT

3,4:SUB SELECT

9 :PICTURE MENU SELECT

YELLOW:AUTO ADJUST

VOL:ADJUST

OK :WRITE

1

WB-ADJ DYNAMIC

R-GAIN

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

7 :COLOR TEMP SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

1

OPTION DYNAMIC

Boot

1,2:MAIN SELECT

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

1

SRV-TOOL DYNAMIC

1,2:MAIN SELECT

9 :PICTURE MENU SELECT

OK :ENTER

204

FF

ROM

00

2

3

4

2

3

4

2

3

4

2

ADJUST DYNAMIC

COLOR

1,2:MAIN SELECT

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

WB-ADJ DYNAMIC

G-GAIN

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

7 :COLOR TEMP SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

OPTION DYNAMIC

STBY-SET

1,2:MAIN SELECT

3,4:SUB SELECT

9 :PICTURE MENU SELECT

OK :POWER OFF

3F

F5

00

216

DJUST DYNAMIC

3

TINT

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

WB-ADJ DYNAMIC

B-GAIN

3

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7 :COLOR TEMP SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

OPTION DYNAMIC

Emergency

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

Key Command

• Press the 3/4 button to change the adjustment values or function.

• Press the 1/2 button to step up/down through the functions and adjustments

• Press the numerical button VOLUME (+/-) to change of e ach option item.

• Press the OK button after each adjustment has been made to store the required values.

ON

00

EC

ADJUST DYNAMIC

3

SUB-BRT

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

WB-ADJ DYNAMIC

R-CENT

3

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4

7 :COLOR TEMP SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

OPTION DYNAMIC

Y/C Delay

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

808

8B

O

DJUST DYNAMIC

3

BACKLGT

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

WB-ADJ DYNAMIC

G-CENT

3

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

7 :COLOR TEMP SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

OPTION DYNAMIC

OPT 1

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

5,6:BIT SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

29F

80

00101100

DJUST DYNAMIC

H-POS

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

WB-ADJ DYNAMIC

B-CENT

3

COLOR TEMP NORMAL

1,2:MAIN SELECT

3,4:SUB SELECT

4 4

7 :COLOR TEMP SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

OPTION DYNAMIC

OPT 2

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

5,6:BIT SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

00000000

80

DJUST DYNAMIC

0

H-AMP

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

OPTION DYNAMIC

OPT 3

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

5,6:BIT SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

0

00000000

ADJUST DYNAMIC

V-POS

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

DJUST DYNAMIC

0

V-AMP

3

1,2:MAIN SELECT

4

3,4:SUB SELECT

9 :PICTURE MENU SELECT

VOL:ADJUST

OK :WRITE

0

15

Option Bytes Description

OPTION1

0 Speed ATP Slow (1) / Fast (0)

1 TXT Ch ON (1) / OFF (0)

2 ID-1 ON (1) / OFF (0)

3 Macrovision Auto evaluate ON (1) / OFF (0)

4 SRS Surround ON (1) / OFF (0)

5 Teletext Top OFF (1) / ON (0)

6 Equalizer

7 Not use Not use

OPTION2

0 Not use Not use

1 A2 Stereo (5,5MHz) ON (1) / OFF (0)

2 A2 Stereo (6,0MHz) ON (1) / OFF (0)

3 A2 Stereo (6,5MHz) ON (1) / OFF (0)

4 Not use Not use

5 NICAM (5,5MHz) ON (1) / OFF (0)

6 NICAM (6,0MHz) ON (1) / OFF (0)

7 NICAM (6,5MHz) ON (1) / OFF (0)

OPTION3

0 NICAM priority (ASIA/M.E) ON (1) / OFF (0)

1 NICAM priority (K/UK) ON (1) / OFF (0)

2 NICAM priority (China) ON (1) / OFF (0)

3 NICAM priority (NZ/INDN) ON (1) / OFF (0)

4 NICAM priority (AUS) ON (1) / OFF (0)

5 NICAM priority (E.Evropa) ON (1) / OFF (0)

6 NICAM priority (Special) ON (1) / OFF (0)

7 Not use Not use

16

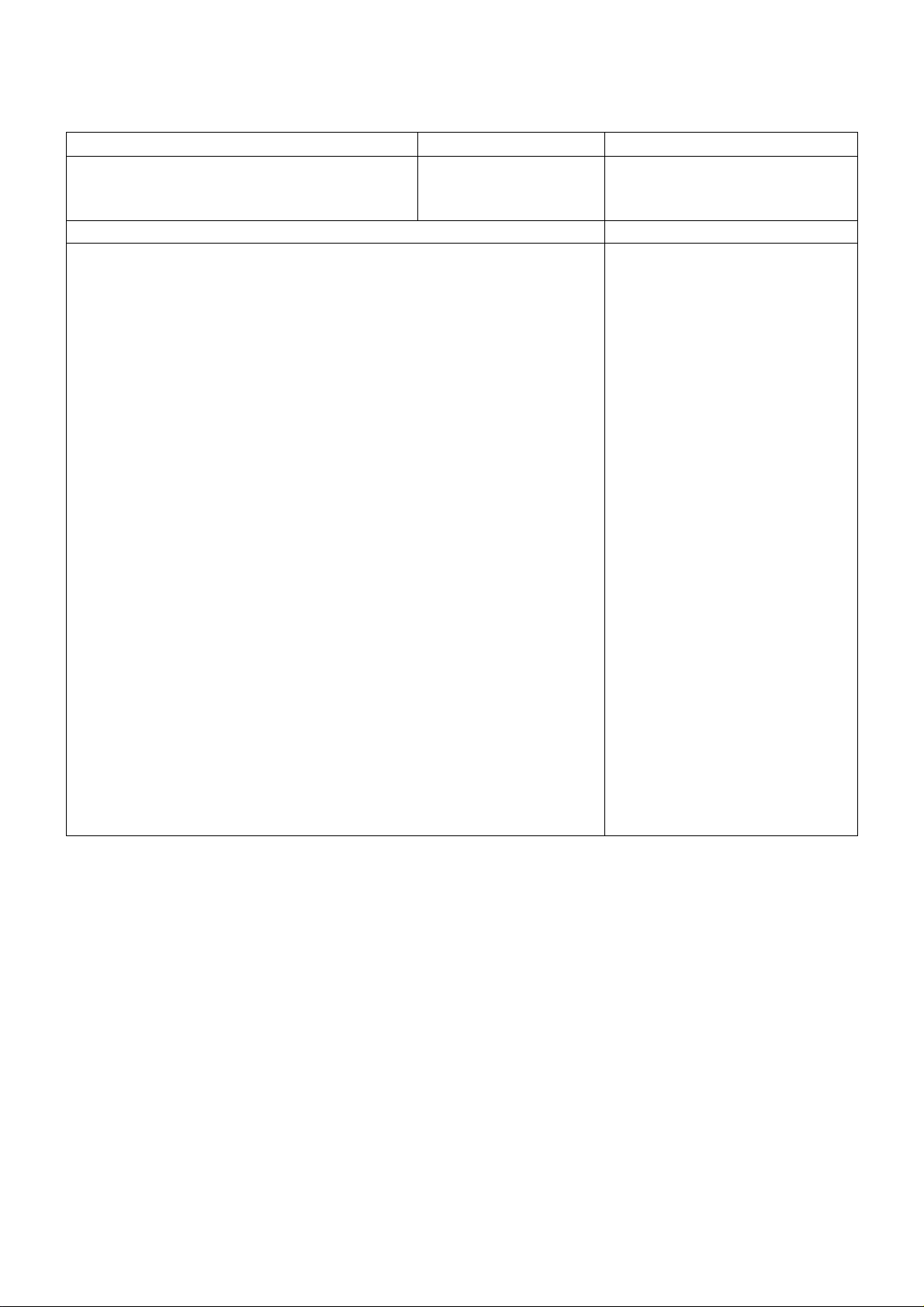

Adjustment Method

Sub-Contrast/White Balance Adjustment

Instrument Name Connect to Remarks

1. Remote controller

2. LCD WB meter (Minolta CA-210 or eq uivalent)

3. Comunication jig

4. Computer for external control

Procedure Remarks

Subcontrast adjustment

1. Receive PAL colour bar (10 0% white) RF signal.

2. Enter “Contrast” adj. In SERVICE mode.

3. Start adjusting by using Yellow Key.

4. If the adjustment finished normally, the letter of Contrast will change from red

to black.

White Balance adjustment

1. Procedure basically performs checking using the production software and

make automatic adjustment using external computer.

2. It adjusts in the mode of: Colour balance Normal

Viewing Mode Dynamic

LZD80 LZD80F

WHITE Normal WHITE Normal

x: 0,2880 ± 0,010 x: 0,2850 ± 0,010

y: 0,3100 ± 0,010 y: 0,3010 ± 0,010

GRAY Normal GRAY Normal

x: 0,2880 ± 0,010 x: 0,2850 ± 0,010

y: 0,3100 ± 0,010 y: 0,3010 ± 0,010

Correlation can be also taken by

CS-1000A or equivalent

Let the panel standfor more than 3

hours at more than 20 °C.

Basically perform adjustment in the

ambient environment of room

temperature more than 20 °C.

The aging time is more than20 min

at above room temperature.

Applied signal

100% full colour bar

0,7V p-p white peak

85% modulation

100% WHITE

50% GRAY

17

Wiring diagram

3003

3

00A

DIGITAL AUDIO OUT

TU2901

D3015

LCD PANEL

CN1

CN501

P2

A5

P5

SERVICE

SD SLOT

HDMI3

A6

CN0100

P6

P3

SP

P-BOARD

M11

P7

P1

MAIN IN

M-BOARD

JK8801

JK4700

JK4500

A7

A11

A-BOARD

JK4501

A1

V1

JK8401

CI SLOT HDMI1 HDMI2

1

K

AUDIO OUT

YUV,AUDIO IN,

PC

JK3001

A51

G51

AV3

JK3700

G-BOARD

V-BOARD

B

JK3002B

AV1

K

AV2

A10

KEY

18

JK3002B

V

Y

_

_

,

K

A

K

A

V

R

JK3003B

YPBPR, AUDIO / IN,OUT/

PC

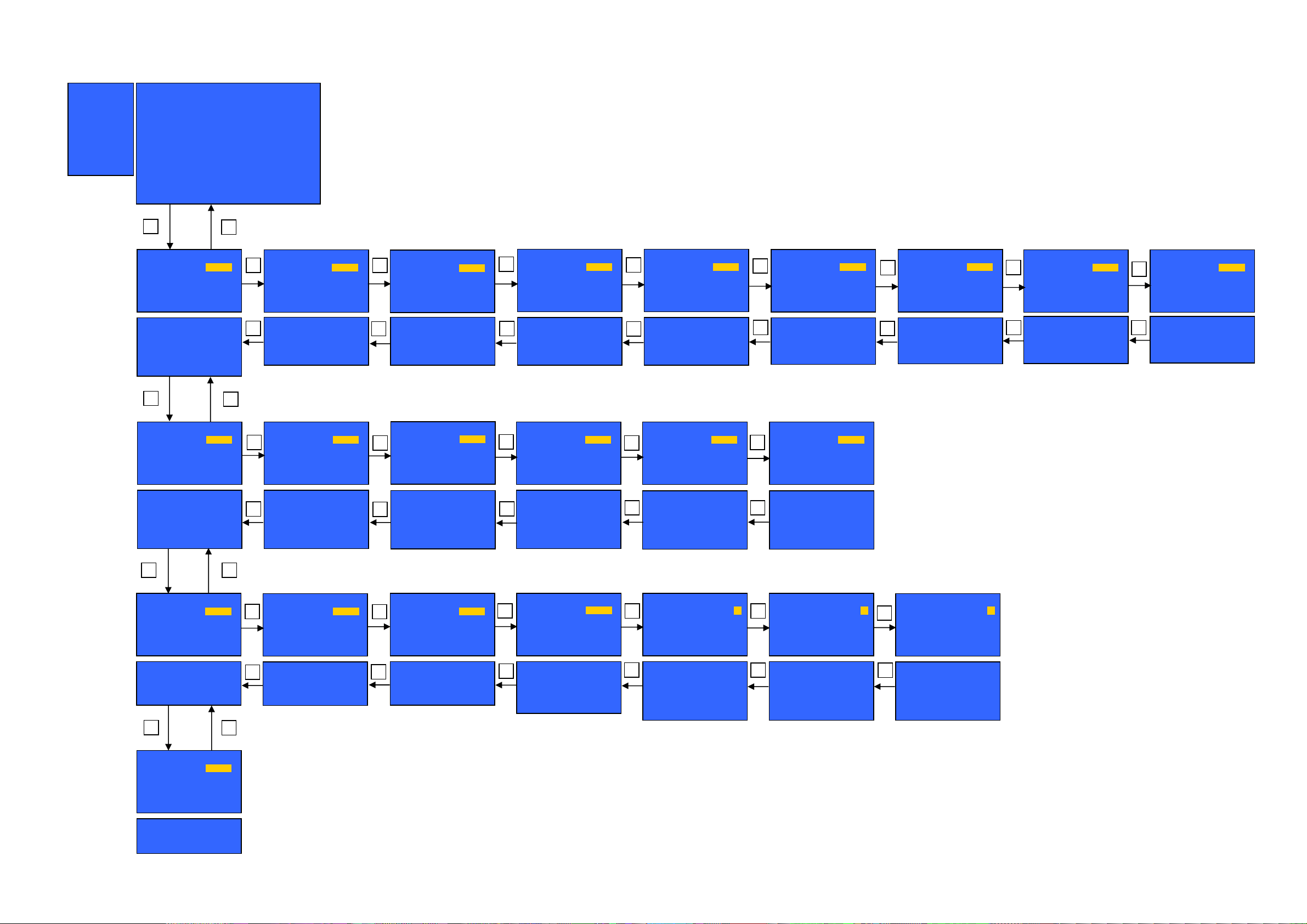

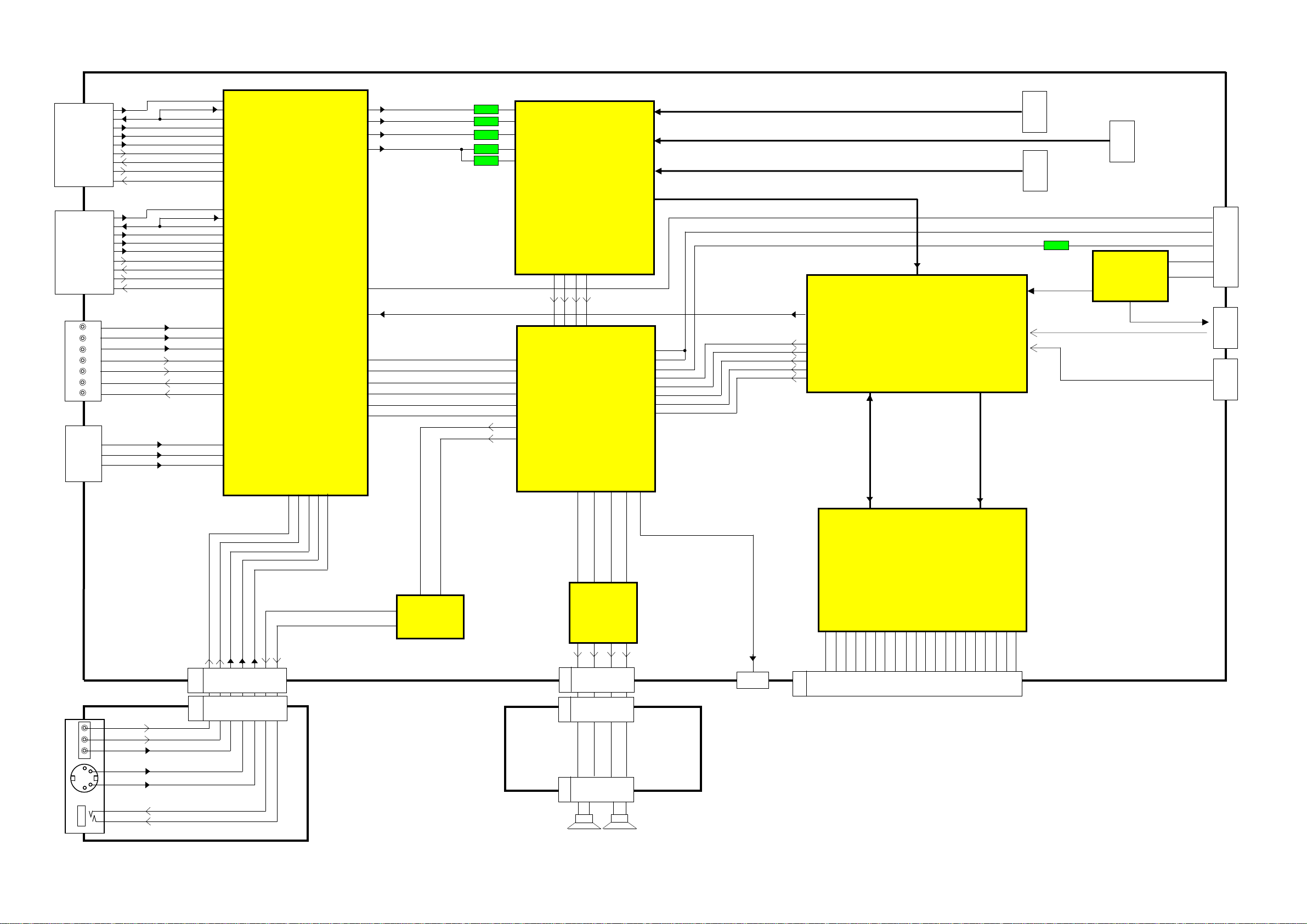

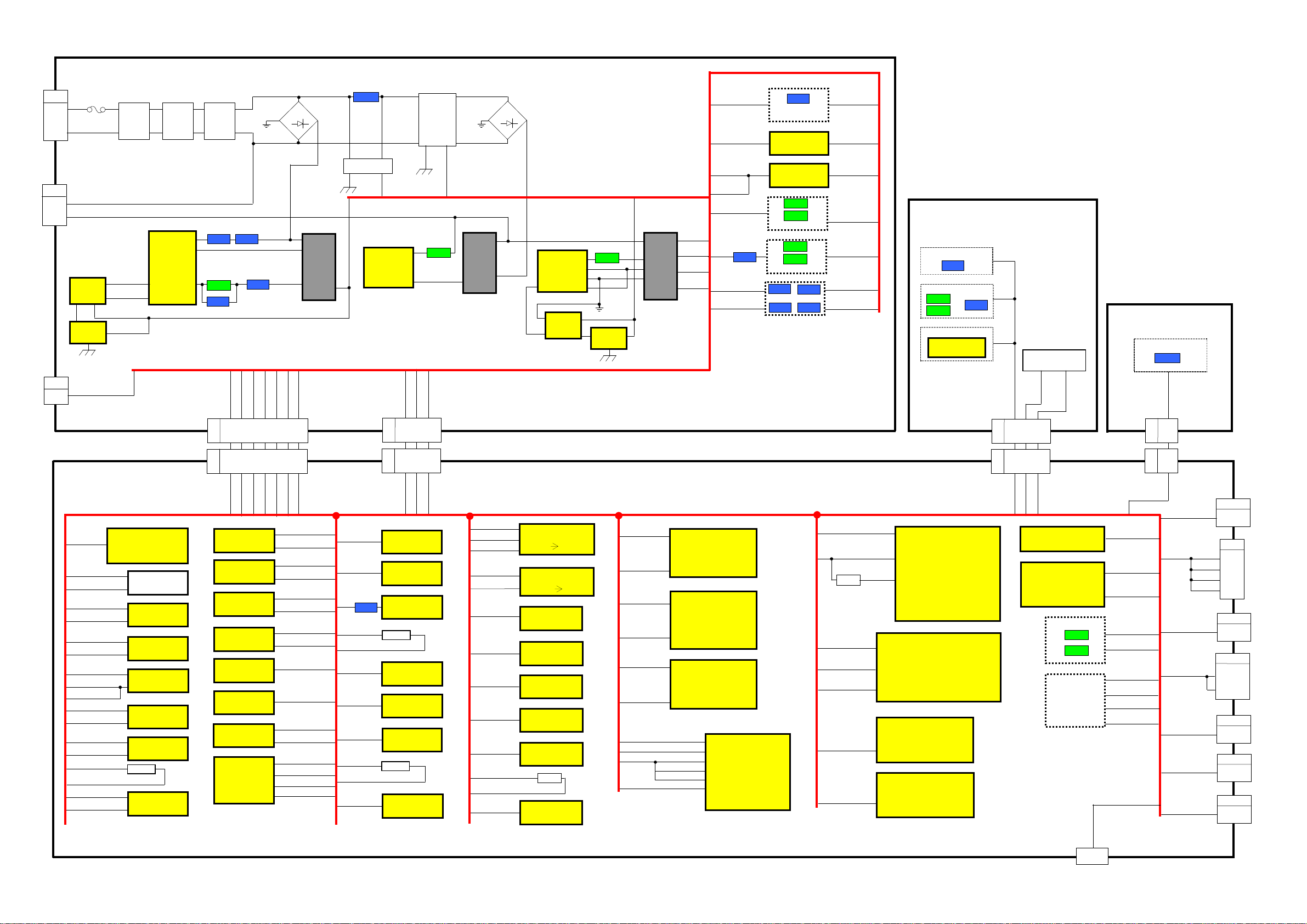

Video & Stereo Audio Block Diagram

AV1_V 20

AV1_VOUT 19

AV1_RED 15

AV1_GREEN 11

AV1_BLUE 7

AV1_L 6

AV1_LOUT

AV1_R 2

AV1 21PIN SCART

AV1_ROUT 1

AV2_V 20

AV2_VOUT 19

AV2_RED/C 15

AV2_GREEN 11

AV2_BLUE 7

AV2_L 6

AV2_LOUT

AV2_R 2

AV2 21PIN SCART

AV2_ROUT 1

Y

PB

PR

L

JK3100A

R

L

R

1

2

JK3001

3

3

3

YPBPR_Y

YPBPR_PB

YPBPR_PR

PC_LIN

PC_RIN

RCA_AUDIOOUT_L

RCA_AUDIOOUT_R

PC_R

PC_G

PC_B

79 AV1_V

43 AV1_FEED_B

44 AV1_VO

91 AV1_RED

89 AV1_GREEN

87 AV1_BLUE

62 AV1_L

56 AV1_LO

63 AV1_R

55 AV1_RO

19,23 AV2_V_Y

37 AV2_FEED_B

38 AV2_VO

11,21 AV2_RED_C

13 AV2_GREEN

15 AV2_BLUE

64 AV2_L

54 AV2_LO

65 AV2_R

53 AV2_RO

95 YPBPR_Y

93 YPBPR_PB

97 YPBPR_PR

70 PC_LIN

71 PC_RIN

52 RCA_AUDIOOUT_L

51 RCA_AUDIOOUT_R

3 PC_R

1 PC_G

99 PC_B

MAIN_Y/CVBS

MAIN_PB 33

MAIN_PR/C 35

RGB _CVBS 46

IC3001

[C1AB00002855]

AUDIO VIDEO SWITCH

MAIN_RF_CVBS

DVB _CVBS 17

AV_R 50

AV_L 49

TV_R

TV_L 60

AUDIOOUT_R 59

AUDIOOUT_L 58

68 FRONT_AV_LIN

69 FRONT_AV_RIN

83 FRONT_AVS_

81 FRONT_AV_V

85,88 FRONT_AVS_C

RXB_2P,2N,1P,1N,0P,0N,CP,CN

RXC_2P,2N,1P,1N,0P,0N,CP,CN

RXA_2P,2N,1P,1N,0P,0N,CP,CN

I1P0,VI1P2-VI1P19,VI1P21-VI1P29,VI1CLK,CLK0A,VS,HS,VI1ENB,VI1CLK2

AM

77

18

38 SPDIF_OUT

DVB_CVBS

DTV_LRCK

DTV2_BCLK

DTV2_SDIN

DTV_SDIN

IECOUT0

D12 ANALOG

VIDEO I/F

F14

B13

AUDIO IF

D15

A13

C14,E15,B14,A14,B15,A15,

E11,E10,F10,E9,F9,E8,F8,

A10

E7,F7,D6,D5,F5,E4,D3,F4

8,C9,G6,F2,E1,F3,A9,B9,B8,C8,A7,C6,C5,A4,

D2,D1,B4,C4,A3,B3,A2,B1,C2,C1,E3,E2,B10,C10,

B7,C7,A6,B6,A5,B5

IC8001-PeksLite2

MN2WS0047

A23,C22,E20,E18,B18,F16,F17,A18,

C17,B17,A17,E17,B20,E19,A20,C19,

F18,B19,A19,C18,B22,D20,A22,C21,

F19,B21,A21,C20

LOSD0-LOSD15

O-HSO,CLK0,

VSI,HSI,CLKI

14,15,20-31,34-45,

48-50,53-55,59,60

6 HDMI_BCLK

7 HDMI_LRC

114,115,117,118,

120,121,123,124

130,131,133,134,

136,137,139,140

95,96,98,99,101,

102,104,105

31

Q4516

Q4515

Q4514

Q4519

Q4517

71 MAIN_Y/CVBS

73 MAIN_PB

72 MAIN_PR/C

78 RGB_CVBS

69 SOY

IC4510

[C1AB00002901]

8 HDMI_SDIN

4 HDMI_SPDIF

5

61

79 AV_R

78 AV

L

75 TV

R

73 AUDIOOUT_R

72 AUDIOOUT_L

58 HPOUT1R

57 HPOUT1L

35

HDMI_SDIN 22

HDMI_BCLK

HDMI_SPDIF 25

IC2106

[C1AB00002909]

AUDIO PROCESSOR

43 SQ_L-

HDMI_LRCK 36

42 SQ_L+

AUXIN2R

AUXIN2L 76

SIF_IN1 8

DTV_LRCK

DTV_BCLK 19

DTV2_SDIN 23

DTV_SDIN 24

IECOUT0 27

44 SQ_R+

45 SQ_R-

(1,3,4,6,7,9,10,12)

(1,3,4,6,7,9,10,12)

CH.IS IF

POD. CI I/F

SD CARD I/F

VS,HS,CL

RIN2-RIN9,GIN1-GIN9,BIN2-BIN9

HDMI1

HDMI3

JK4501

JK4700

Q2001

(1,3,4,6,7,9,10,12)

TS SERIAL

BUS

DATA

DATA

HDMI2

JK4500

IC8301

[C1AB00002710]

COFDM

DEMODULATO

30

31

VIDEO_OUT

AUDIO_OUT

SIF_OUT

IFD1

IFD2

21

10

11

TUNER

17

TU2901

19

CI SLOT

JK8401

JK8801

SD SLOT

R

L

JK3700

3-6,9-13,192,194,195,199,

119

203,206-212

121 122

120

IC4200

[C1AB00002886]

126

130

128

127

129

FRONT_AV_RIN

FRONT_AV_LIN

FRONT_AV_V

FRONT_AVS_Y

FRONT_AVS_C

HP_LOUT

HP_ROUT

3 5

IC2012

[C1BB00000947]

1

HP AMP

14

12

IC2301

[C1AB00002875]

AUDIO AMPLIFIER

21

25

5

7

30

34

TD2-

TD2+

TCLK2-

TCLK2+

3

7

5

A51

15

AV4_R

AV4_L

AV4_V

AV4_Y

Y

AV4_C

C

L

HP_LOUT

HP_ROUT

G51

13

14

11

12

7

R

1

10

3

1

5

G-BOARD

A6

P6

P3

SP_L

7,8

1,2

1,2

SP_L-

4

5,6

3,4

6

5

7,8

3,4

SP_R-

SP_L+

SP_R+

P-BOARD

3

2

1

SP_R

D3015

DIGITAL

UDIO OUT

A5

13

14

17

16

TB2-

TA2+

TC2-

TB2+

TC2+

20

22

21

19

TO LCD PANEL

131 143

TA2-

23

MIHO

24

144

TD1+

TD1-

29

30

53,54,57-63,65,67-70,72-76,

81-84,87-90,94

145

150

146

154

152

153

151

TCLK1-

TCLK1+

32

33

TB1-

TC1+

TC1-

TB1+

37

35

38

36

155

A-BOARD

TA1-

TA1+

40

39

[EXCHANGE UNIT]

19

P1

050

V

V

,

,

V

V

V

V

V

V

V

V

V

,

,

V

V

V

V

V

V

V

GU

V

V

V

out

V

out

5

A

A

V

8

V

8

V

8

V

8

V

V

000

V

V

V

V

V

A

V

A

A

V

V

V

V

V

A

1

MAINS IN

2

Power Supply Block Diagram

P - BOARD

F7001

LF7001

3

Line

Filter

2

4

1

LF7002

3

Line

Filter

2

4

1

LF7003

2

Line

Filter

3

4

1

-

~

D7001

~

IC7009

4

REGULATOR

D7031

BT-30V

~

D7003

+

RL7030

-

+

~

33V

12V

BT30V

SUB_9V

5

P5

V-

3

TO INV

1

V+

PC7000

PHOTO

COUPLER

IC7001

P2

12V

1

TO INV

A - BOARD

EXCHANGE UNIT

SOUND17V

TUNER5V

BT30V

SUB6V

TUNER5V

SUB5V

FHD3.3V

SUB5V

DVDDIO3.3V

TVDD3.3V

SUB5V

AUD3.3V

SUB_M9V

5V

SUB9V

SUB_M9V

SUB3.3V

DVDD1.8V

REG

19,20,35,36

5,16

3

4 Vin

5 Vout

2 Vcc

4 Vout

7 Vin

1 Vout

7 Vin

1 Vout

4 Vin

5

L5692

4 Vin

5 Vout

IC7000

MAINS PS

CONTROL

3

4

IC2301

AUD AMP

TU2901

IC2902

REGULATOR

IC4201

REGULATOR

IC4511

REGULATOR

IC2008

REGULATOR

IC2013

RE

out

IC4512

REGULATOR

LATOR

7,8

RL7001

Q7005

SUB_6

23

23

SUB6

STB_5V

11

T7001

3

6

DTV12V

SUB1.8V

SUB1.2V

DTV12V

SUB3.3V

SUB5V

SUB5

SUB3.3V

SUB3.3V

SUB3.3V

SUB1.8V

1.8V_DDRI/F

SUB3.3V

IC7003

MAINS PS

CONTROL

2

PC7001

PHOTO

COUPLER

23

IC5601

DC-DC CONVERTER

3

12V 1.2-1.8V

12

IC5600

17

DC-DC CONVERTER

12V 3.3V

23

IC8404

20

TS BUF

IC8405

20

TS BUF

IC8004

5,13,15

CLOCK GEN

IC8408

20

BUS BUF

IC8409

20

BUS BUF

L8003

IC8554

29,43,53

FLASH

5

1

4

6

Q7006

IC7005

REG

12V

T7002

6

4

1

2,11

DVDD1.8V

UD3.3V

SUB5V

SUB9V

SUB5V

SUB3.3

DVDDIO3.3V

TVDD3.3V

1.8V

DVDD1.8

7

8,9

10

12

14,21,31,40,51

4,53,59,68,71,12,29

4,6,18,22,24,36,82,

86,90,92

80,45,

2,17,33

49

CVDD1.8V

PVDD1.8V

AVDD1.8V

DTV12V

5VS

DTV12

21

17

20

21

17

20

DTV12VPNL12V

T7000

8

6

3

PANEL_12

22,23

22,23

SUB3.3V

SUB1.8V

SUB3.3V

1.8V

SUB3.3V

DVDD1.8V

FHD3.3V

FHD1.2V

FHD3.3V

SUB5V

5VCARD

SUB5V

STB5V

STB3.3V

5VS

9

5V

STB3.3

SUB3.3

SUB_M5

D4713

SUB5V

SUB_M5V

STB5

STB5

DTV12V

SUB3.3V

SUB_M3.3

SUB_M3.3V

IC7002

MAINS PS

CONTROL

P6

A6

L5690

2

L5691

4,5

7

5

5VS

STB_5

11

13

11

13

5VS

STB5

IC1101

EEPROM

IC8601

EEPROM

IC4700

EEPROM EDID

IC4514

IC SWITCH

IC4515

IC SWITCH

IC5660

RESET IC

IC1

TEMP SENSOR

D7007

Q7000

D7008

P7

A7

IC8302

REGULATOR

IC4513

REGULATOR

IC2107

REGULATOR

IC4202

REGULATOR

IC4203

LOGIC IC

IC2012

HP AMP

IC8403

IC SWITCH

IC7601

RESET IC

SOUND_17

1,2

SOUND17

D7010

BT_30

1,2

BT30

D7013

SUB_5

5

5

SUB5

Vout 5

V

V

13

12

13

12

4,5

out 1

Vdd

in 7

in 4

12

10,11

15

SUB_5

SUB5

4

1

8

8

1

5

9

SUB_9

14

14

SUB9

5

2

6V

SUB_6V

12V

33V

17V

6V

12V

17V

AUD PROCESSOR

D7075

BT30V

17V

IC2106

IC3001

UDIO& VIDEO

SWITCH

IC8401

LEVEL SHIFT

12,33,52

94,108,113,125,129,141

1,92,109,127

87,90

75,81,85

3,19,57

IC4510

DV7495ABSTZ-170

IC7

2

REGULATOR

Q7008

Q7009

PANEL 12V

Q7025

Q7026

SOUND 17

D7062

D7060

SOS

D7066 D7069

SUB_5V

4

PANEL_12V

SOUND_17V

SUB_5

SUB_9V

FHD1.2V

FHD3.3V

FL4206

SUB3.3V

SUB1.2V

SUB1.8V

1.8V_DDRI/F

1.8V_DDRI/F

8,30,32,37,38,41,42,43,79,86,93,97,106,

110,112,114,137,158,159,162,

166,170,177,183,190,197,204,214,216

2,16,25,28,34,46,47,50,52,71,96,108,

163,174,179,193,196

VDDLVDS

116,123,125,132,134,140,147,149,156

IC8001-PeksLite2

1,E1,M9,J9,R1,J1, A9,C1,

C3,C7,C9,E9,G1,G3,G7,G9

1,E1,M9,J9,R1,J1, A9,C1,

C3,C7,C9,E9,G1,G3,G7,G9

V - BOARD

TIMER REC LED

Q2501

Q2502

REMOTE CONTROL

RM2501

LED RECEIVER

IC4200

C1AB00002886

MIHO

MN2WS0047

IC8002

DDR SDRAM

IC8003

DDR SDRAM

D2503

R&G LED

D2501

V1

A1

STB3.3

STB3.3V

3

3

STB5

SW2501

STB5

8

10

8

10

5VS

IC1100

GENX5

IC8301

COFDM DEM

5VS

24,39,62,64,68,

73,83,88

2,13,15,16,17,

18,33,45,54

7,19,21,28,37,

39,59,64

MUTE SW

Q2063

Q2065

POWER DET

M - BOARD

STB3.3

SUB3.3

SUB1.8

DTV12V

STB5V

DTV12V

SUB3.3V

SUB5V

FHD3.3V

SUB3.3V

SN2551

SUB5

M11

A11

SUB5

STB5V

SUB3.3V

5VCARD

+5V

+5V

+5V

I

1

1

CN0100

1

SERVICE

PNL12V

PNL12V

PNL12V

PNL12V

A5

1

2

3

4

TO LCD PANEL

JK8801

4

SD SLOT

JK8401

17, 18

51, 52

CI SLOT

JK4501

18

HDMI 1

JK4500

18

HDMI 2

JK4700

18

HDMI 3

D3015

DIGITAL

20

AUDIO OUT

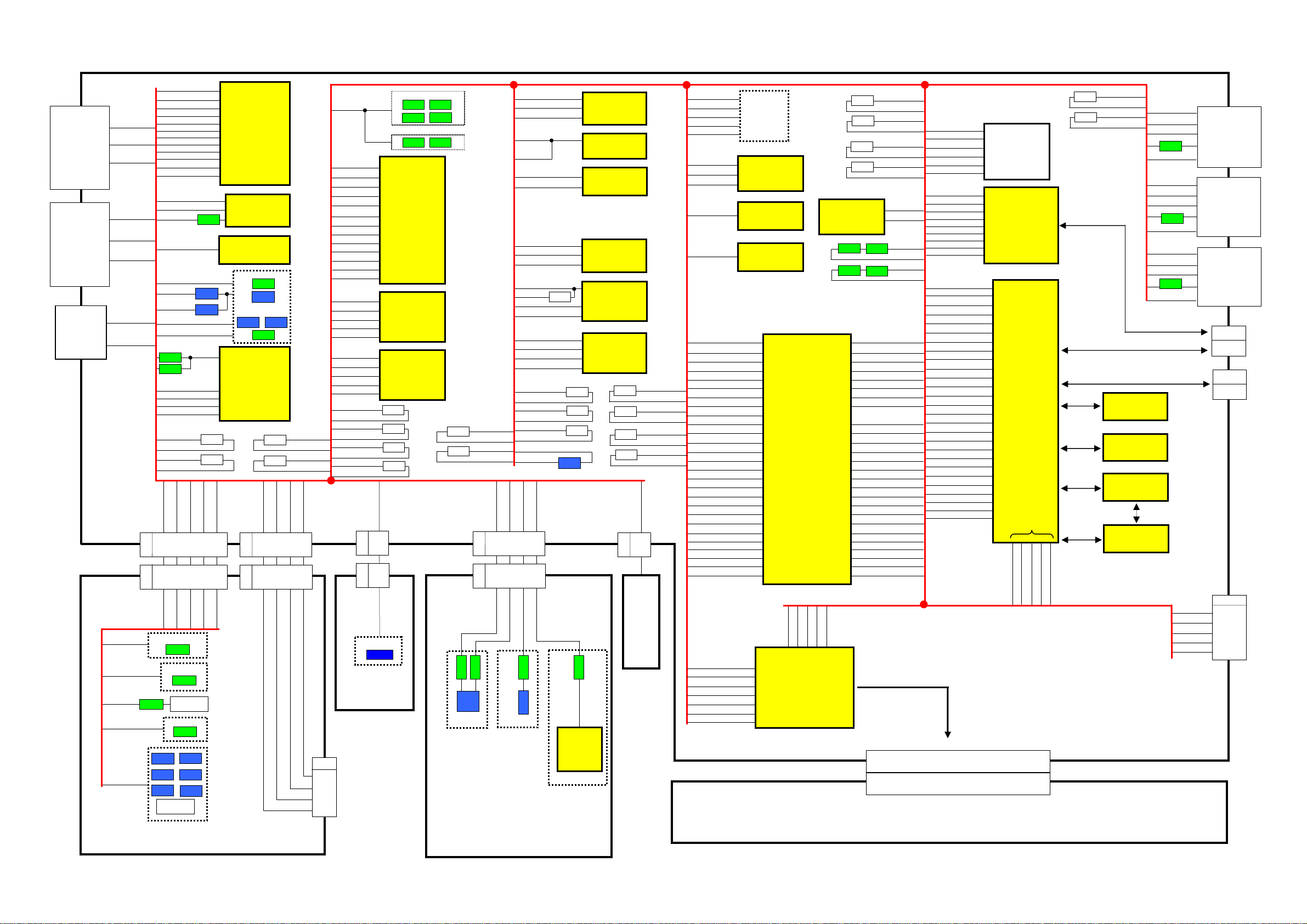

Control Block Diagram

A

_

A

A

V

_

_

V

_

SUB5VSENS

JK3002B

JK3003B

PC

A - BOARD

8

AV1_SLOW

AV1_QLINK 10

AV1_FB 16

AV1 21PIN SCART

AV2_SLOW 8

AV2_QLINK 10

AV2_FB 16

AV2 21PIN SCART

13

14

JK3001

PC_H_IN

PC_V_IN

A7

P7

PC_H_IN

AV1_SLOW

AV2_SLOW

RGB_FB

AV-SW_SDA

AV-SW_SCL

PC_HS

PC_VS

AV1_FB

AV2_FB

ADV_XRST

PC_V_IN

AMUTE

PWM_READY

SOUND_SOS

AMUTE

AUDIO_MUTE

SP_MUTE

MON_MUTE

MONITOROUT_MUTE

AMUTE

AUDIO_MUTE

Q2021

Q2020

SOUND_SOS

ADAV_SDA

ADAV_SCL

PWM_READY

AUDIO_XRST

SDA2

ADAV_SDA

SCL2

ADAV_SCL

TV_MAIN_ON

6

6

Q2022

D2024

D2025

MUTE

R2000

R2001

TV_SUB_ON

PANEL_STBY_ON

SOS

9

8

10

8

9

10

OVP

11

11

2

14

20

27, 94

28

29

32

34

76

78

96

100

1

3

16

2

15

16

17

39

50

IC3001

AUDIO VIDEO

SWITCH

IC2301

AUDIO AMP

IC2012

HP AMP

MUTE SW

Q2061

D2070

D2068 D2069

Q2066

IC2106

AUDIO

PROCESSOR

R4658

R4657

INVERTER_SOS

INVERTER_ON

18

17

A6

17

18

P6

INV_ADIM

19

ADV_SDA

ADV_SCL

PWM

INV

19

SDA1

SCL1

20

20

MONITOROUT_MUTE

ADV_SDA

ADV_SCL

XIRQ3

ADV_XRS

PC_HS

PC_VS

RGB_FB

DDCA_SCL

DDCA_SDA

DDCB_SCL_AD

DDCB_SDA_AD

DDCC_SCL_AD

DDCC_SDA_AD

DDCC_SCL_AD

DDCC_SDA_AD

DDCC_SDA

DDCC_SCL

STB_RST

DDCB_SCL_AD

DDCB_SDA_AD

DDCB_SDA

DDCB_SCL

STB_RST

SDA2

AV-SW_SDA

SCL2

AV-SW_SCL

SDA3

LITE2-EEP_SDA

SCL3

LITE2-EEP_SCL

AI_SENSOR

A11

M11

9

10

16

64

65

66

67

106

107

111

112

142

143

2

5

3

6

1,7

2

5

3

6

1,7

R3130

R3131

R8601

R8602

3

3

V1-2 OUT MUTE

Q3005

Q3004

Q3003

Q3002

Q3000 Q3001

IC4510

C1AB00002901

IC4515

IC SWITCH

IC4514

IC SWITCH

R8314

R8315

FE-OUT_SCL

TUNER_SCL

FE-OUT_SDA

TUNER_SDA

G_LED_ON

1

A1

1

V1

LITE2-EEP_SD

LITE2-EEP_SCL

EEPROM_WP

XRST

DTV_XRST

TMP-SENS_SCL

TMP-SENS_SDA

DDCA_SD

DDCA_SCL

EDID_WP

STB_RST

G72_NRST

OVP

TV_SUB_ON

IN

CLK74

CK27

CLKGEN_S2

SDA2

FE_SDA

SCL2

FE_SCL

XNFWE

FE_XRST

HDMI_CEC_PU_ON

HDMI_CEC

STBY_LED_ON

R_LED_ON

RMIN

2

7

5

7

5

2

R1146

D1107

R8311

R8310

R8947

5

6

7

1

1

6

5

6

7

7

17

18

4

7

9

14

IC8601

EEPROM

IC5660

RESET IC

IC1000

TEMP SENSOR

IC4700

EEPROM

IC7601

RESET IC

IC8004

CLOCK GEN

R1206

R1205

R1184

R1183

A10

GENX_EEP_SDA

SDA

GENX_EEP_SCL

SCL

GENX_SDA1

SDA

GENX_SCL1

SCL

KEY

1

MAIN3.3V_SENSE

MAIN9V_SENSE

SUB5V_SENSE

SUB3.3V_SENSE

DTV9V_SENSE

GENX_EEP_SDA

GENX_EEP_SCL

GENX_EEP_WP

FRCLKIN

TV_MAIN_ON

SP_MUTE

AUDIO_MUTE

R_LED_ON

G_LED_ON

STBY_LED_ON

DDCB_SDA

DDCB_SCL

DDCC_SDA

DDCC_SCL

HPD1

HPD2

SBI2

SBO2

HDMI_5V_DET1

GENX_SDA0

GENX_SCL0

HDMI_5V_DET2

SRQ_GENX

SOS

TV_MAIN_ON

PANEL_STBY_ON

INVERTER_ON

RMIN

MAIN3.3V_SENSE

SUB3.3V_SENSE

MAIN9V_SENSE

HDMI_5V_DET4

POWER DET

5

IC1101

6

EEPROM

7

IC4203

5

LOGIC IC

IC4201

1

REGULATOR

2

3

5

MICROPROCESOR

6

7

10

11

12

13

14

15

17

18

19

20

21

23

26,71

28

29

30

31

32

34

35

36

37

IC1100

IC8403

IC SWITCH

Q4204

Q4205

43

44

45

47

49

50

51

52

54

55

27

57

58

59

60

70

72

84

85

87

92

93

94

95

99

100

R4282

R4281

R1003

R1004

Q4206

Q4203

BACK_VOUTENB

HDMI_CEC_PU_ON

MIHO_SCL

SCL0

MIHO_SDA

SDA0

TMP_SENS_SCL

SCL

TMP_SENS_SDA

SDA1

SMTCLK0

3

IS1CLK

4

INV_ADIM

PWM2

INV_PWM

PWM1

AUDIO_XRST

ADV_XRST

HQ_XRST

GENX_SDA1

GENX_SCL1

GENX_EEP_WP

TV_SUB_ON

DTV9V_SENSE

DTV_XRST

VI2ENB

VOUTENB

EDID_WP

HPD4

SOUND_SOS

G72_NRST

AI_SENSOR

KEY

RF_AFT1

AV1_QLINK

AV2_QLINK

HDMI_CEC

INVERTER_SOS

CLKGEN_S2

IFAGC

TUNER_SCL

TUNER_SDA

IFD1

IFD2

RF_AFT1

FE_SCL

FE_SDA

XIRQ2

FE_XRST

IFD1

IFD2

FE_OUT_SCL

FE_UUT_SDA

IFAGC

IS1CLK

SCL0

SDA0

SCL1

SDA1

SCL2

SDA2

SCL3

XRST

IS1CLK

SMTCLK0

VI2CLK2

VIN

CLK74

SBI2

E

SBO2

VOUTENB

PWM2

PWM1

AUDIO_MUTE

MON_MUTE

V_DISPEN

OSD_FLAG

P - BOARD

R_LED_ON

STBY_LED_ON

TIMER REC

Q2503 D2503

RMIN

Q2504

OUT

RM2501

REMOTE

RM

KEY CONTROL

MIHO_SCL

MIHO_SDA

FRCLKIN

BACK_VOUTENB

HQ_XRST

V_DISPEN

OSD_FLAG

EXCHANGE UNIT

175

176

172

180

181

189

202

MIHO_TDI

MIHO_TCK

MIHO_TMS

18 19

17

14

IC4200

C1AB00002886

MIHO

TDO

MIHO

TRST

MIHO

20

TV_MAIN_ON

PANEL_ON

TV_SUB_ON

TV_SOS

OVP_DET

TV_MAIN_ON

SOUND17V

Q7026

PANEL 12V

Q7001

D7085

D7043 D7040

D7042

T7002

PANEL_ON

TV_SUB_ON

Q7009

RL7030

SOS

Q7022

D7084

D7039

ADIM

TV_SOS

OVP_DET

INV_ON

INV_SOS

INV_PWM

AI_SENSOR

AI

G_LED_ON

SN2551

Q2502

Q2501

M - BOARD

LED

P2

5

3

2

TO INVERTER

LCD PANEL

SDA3

XIRQ3

CK27

I2ENB

12

13

14

TU2901

17

19

20

4

5

6

9

COFDM DEM

30

31

35

36

42

AD5

M2

M1

N5

N3

AD6

AB8

AC4

AD1

P1

D21

AD5

AD9

J1

J22

H25

K21,AD24

A24

B23

G3

H26

AD10

AE10

AB7

AF3

K3

L6

TUNER

IC8301

PeaksLite2

IC8001

JTAG

MIHO_TDI

MIHO_TCK

MIHO_TMS

TRST

MIHO

MIHO_TDO

R1175

R1174

DATA BUS

DATA

DATA BUS

DATA BUS

DATA BUS

GENX_SDA0

SDA3

GENX_SCL0

SCL3

IC8002

DDR2-0 SDRAM

IC8003

DDR2-1 SDRAM

IC8554

NOR FLASH

IC8401

LEVEL SHIFT

HDMI_CEC

DDCB_SCL_AD

DDCB_SDA_AD

Q4503

HPD1

HDMI_CEC

DDCC_SCL_AD

DDCC_SDA_AD

Q4502

HPD2

HDMI_CEC

DDCA_SCL

DDCA_SDA

Q4701

HPD4

SRQ_GENX

SCL

SDA

SCL3

SDA3

13 HDMI_CEC

15 SCL

16 SDA

18 HDMI_5V_DET1

19 HPD1

13 HDMI_CEC

15 SCL

16 SDA

18 HDMI_5V_DET2

19 HPD2

13 HDMI_CEC

15 SCL

16 SDA

18 HDMI_5V_DET4

19 HPD4

JK8401

CI SLOT

JK8801

SD SLOT

CN0100

2

4

5

6

7

HDMI1 HDMI3

JK4501

HDMI2

JK4500

JK4700

SERVICE

V - BOARD

21

Loading...

Loading...