Panasonic TX-28PB50, TX-32PB50, TX-36PB50 Schematic

Colour Television

SPECIFICATIONS

Power Source: 220-240V a.c., 50Hz

ORDER No. SM-01022

TX-28PB50

TX-32PB50/PB50N

TX-36PB50/PB50N

EURO-7 Chassis

Power Consumption: 145W (28”) , 149W (32”) , 175W (36”)

Stand-by Power

Consumption: 2.8W

Aerial Impedance: 75Ω unbalanced, Coaxial Type

Receiving System: PAL I, PAL-525/60 UHF

M.NTSC

NTSC (AV only)

Receiving Channels: UHF E21-E69

Intermediate Frequency:

Video/Audio

Video 39.5MHz

Audio 33.5MHz

32.95MHz (NICAM)

Colour 35.07MHz (PAL)

Terminals:

AV1 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

RGB (21 pin)

AV1 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

AV2 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

S-Video IN Y: 1V p-p 75Ω

(21-pin) C: 0.3V p-p 75Ω

AV4 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10kΩ

S-Video IN Y: 1V p-p 75Ω

(21-pin) C: 0.3V p-p 75Ω

RGB (21 pin)

AV4 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

High Voltage: 30.5kV ± 1kV (28”) , 32kV ± 1Kv (32/36”)

Picture Tube: W66EKT10X71 66cm (28”)

W76EKW10X72 76cm (32”)

W86LPX955X07 86cm (36”)

Audio Output: Front Left/Right 2 x 20W

(Music Power) 8Ω Impedance

Digital Audio Input Coaxial / Optical

Headphones: 8Ω Impedance

3.5mm

Accessories

supplied : Remote Control

2 x R6 (UM3) Batteries

Dimensions: 28” 32” 36”

Height: 509mm 558mm 623m m

Width: 763mm 850mm 950mm

Depth: 512mm 549mm 582mm

Net weight: 45kg 58.5kg 79.5kg

Specifications are subject to change without notice.

Weights and dimensions shown are approximate.

AV2 OUT Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 1kΩ

Selectable output (21 pin)

AV3 IN S-Video IN Y: 1V p-p 75Ω

(4-pin) C: 0.3V p-p 75Ω

Audio (RCAx2) 500mV rms 1Video

Video (RCAx2) 1V p-p 75Ω

NOTE: This Service Manual should be used in conjunction with

the EURO-7 Technical guide.

CONTENTS

SAFETY PRECAUTIONS..........................................................................................................................................................2

SERVICE HINTS.......................................................................................................................................................................3

ADJUSTMENT PROCEDURE AND FACTORY SETTINGS.....................................................................................................4

WAVEFORM PATTERN TABLE...............................................................................................................................................5

ALIGNMENT SETTINGS...........................................................................................................................................................6

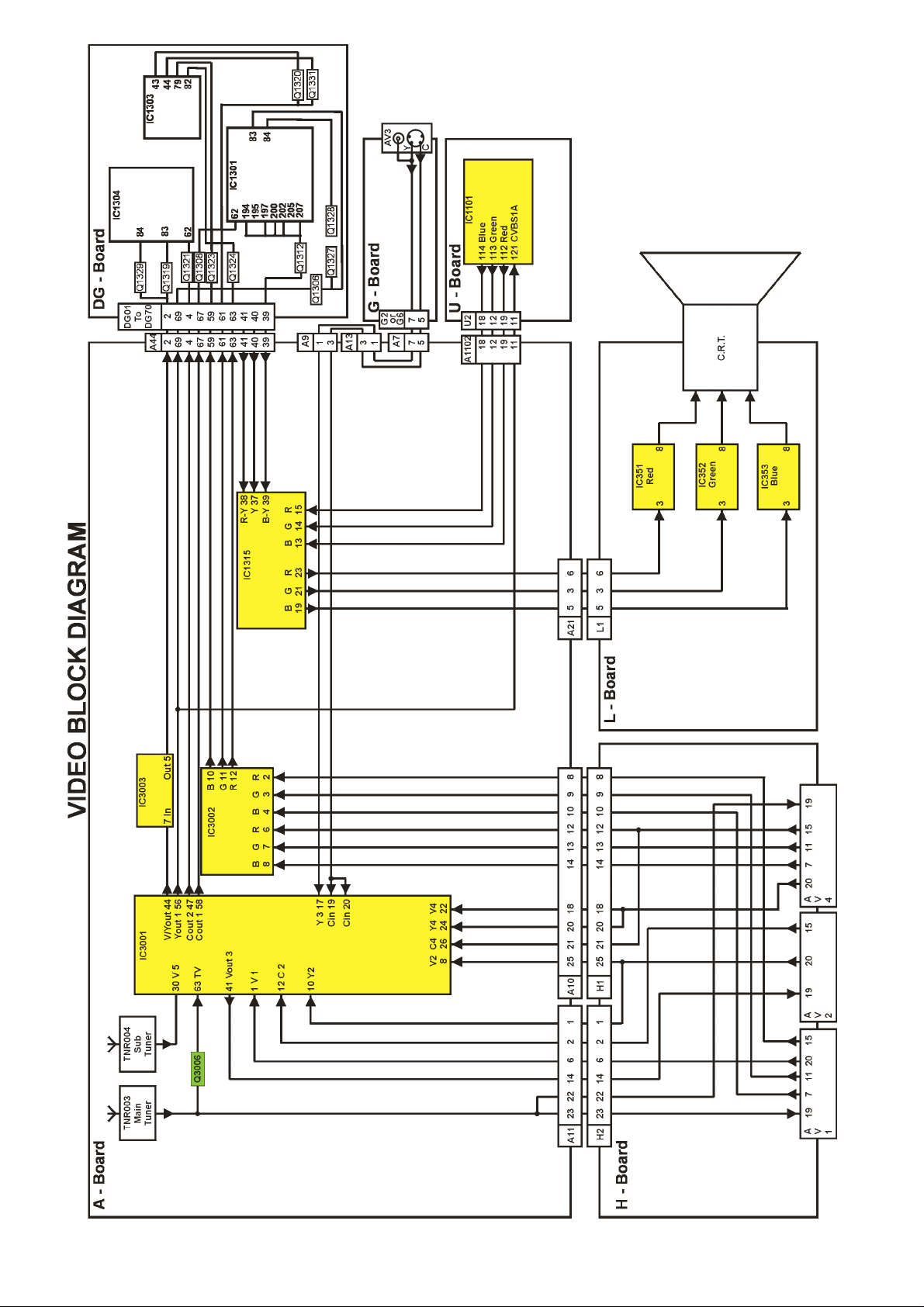

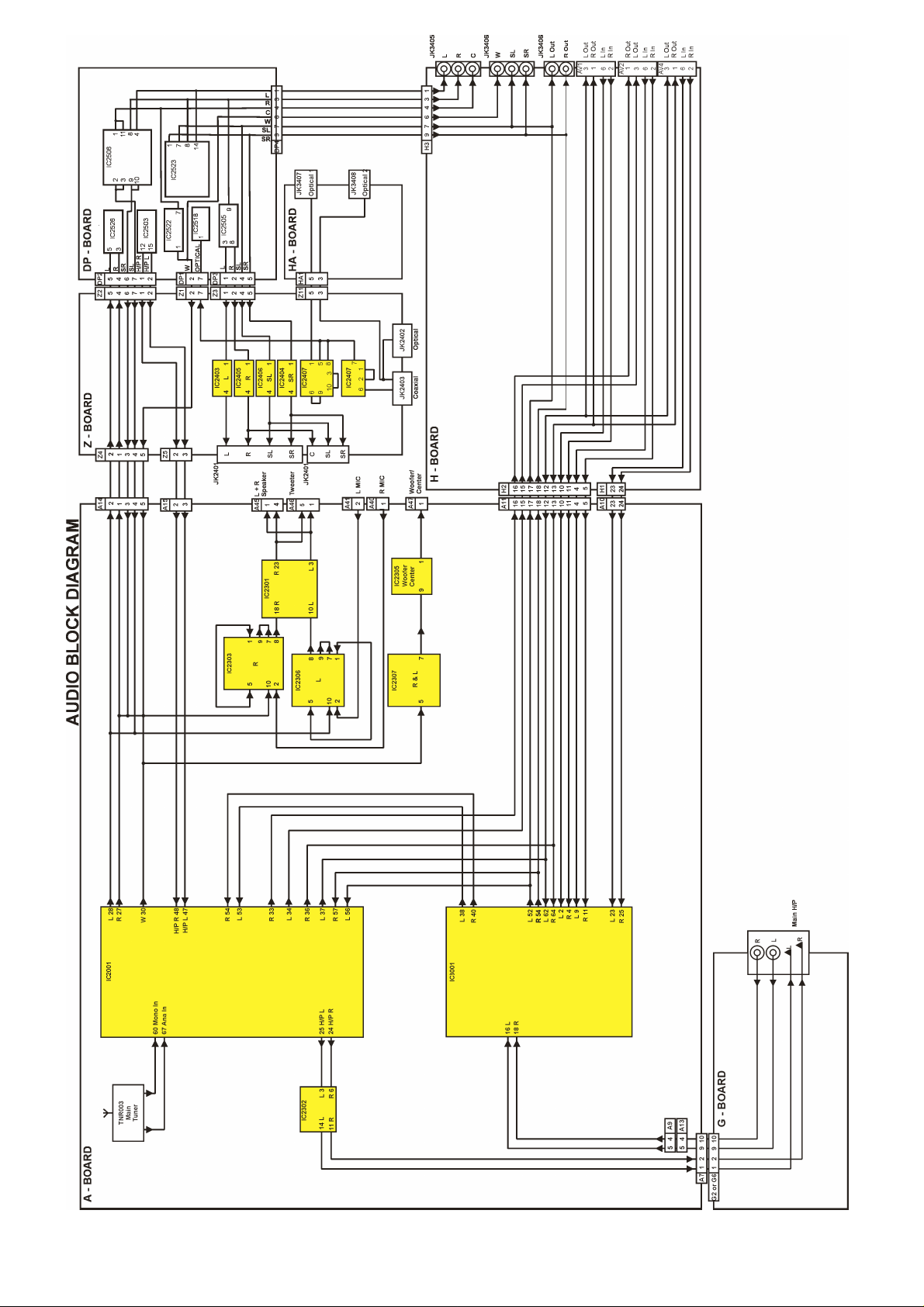

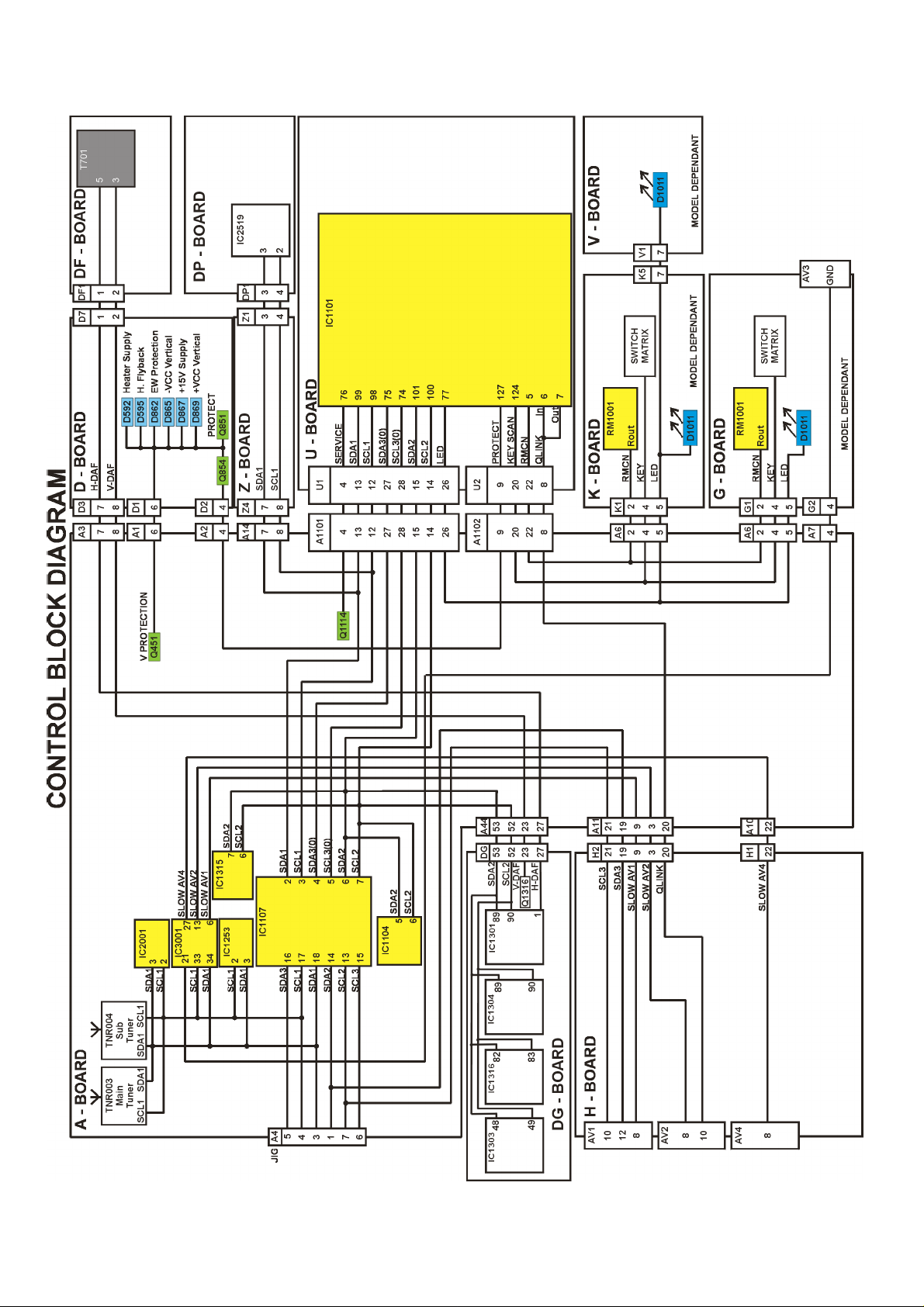

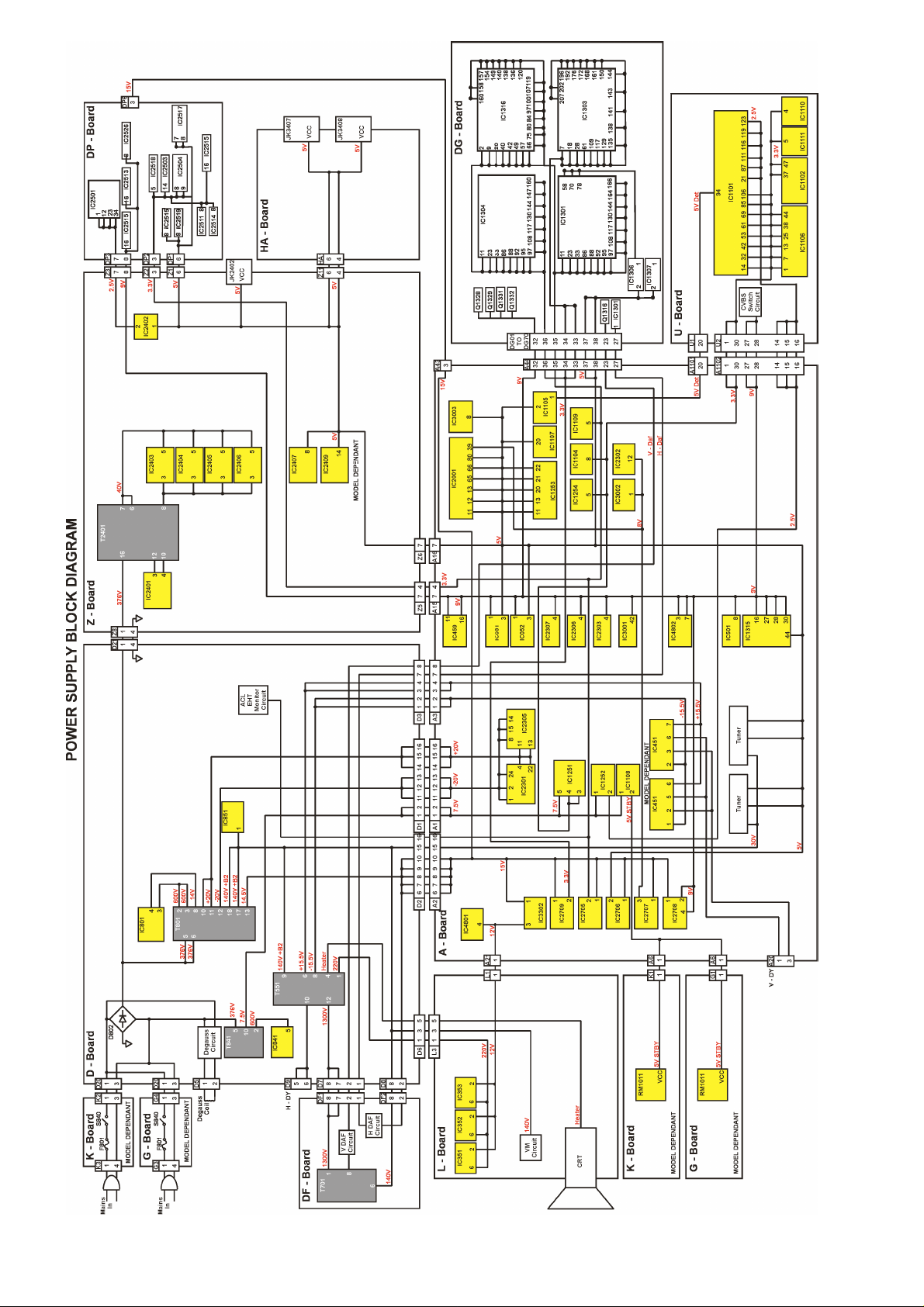

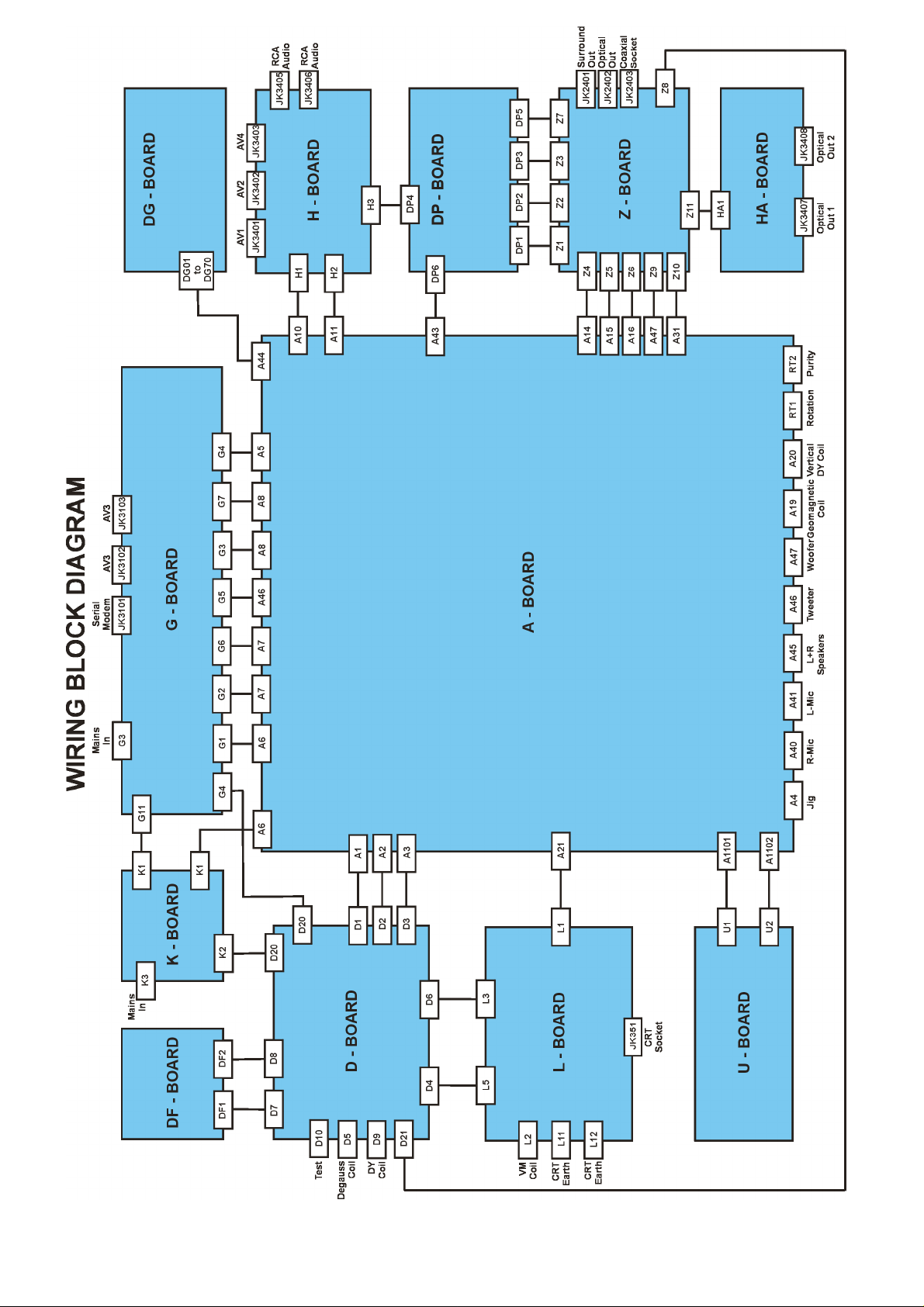

BLOCK DIAGRAMS..................................................................................................................................................................7

PARTS LOCATION.................................................................................................................................................................13

REPLACEMENT PARTS LIST................................................................................................................................................14

SCHEMATIC DIAGRAMS.......................................................................................................................................................38

CONDUCTOR VIEWS.............................................................................................................................................................49

SAFETY PRECAUTIONS

GENERAL GUIDE LINES

1. It is advisable to insert an isolation transformer in the

a.c. supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3. After servicing, see that all the protective devices

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4. When the receiver is not being used for a long period

of time, unplug the power cord from the a.c. outlet.

5. Potentials as high as 33kV are present when this

receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6. After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the a.c. cord and connect a jumper between

the two prongs of the plug.

2. Turn on the receiver’s power switch.

3. Measure the resistance value with an ohmmeter,

between the jumpered a.c. plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the a.c. cord directly into the a.c. outlet. Do not

use an isolation transformer for this check.

2. Connect a 2kΩ 10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3. Use an a.c. voltmeter with high impedance to

measure the potential across the resistor.

4. Check each exposed metallic part and check the

voltage at each point.

5. Reverse the a.c. plug at the outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed

1.4V rms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

X-RADIATION WARNING

1. The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that the jig is capable of handling 33kV without

causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

HOT CHECK CIRCUIT

a.c. VOLTMETER

2kΩ 10 Watts

TO INSTRUMENT’S EXPOSED

METALLIC PARTS

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should indicate.

30.5kV ± 1kV (28”) , 32kV ± 1kV (32”/36”).

If the meter indication is out of tolerance, immediate

service and correction is required to prevent the

possibility of premature component failure.

3. To prevent any X-Radiation possibility, it is essential

to use the specified tube.

Fig. 1.

WATER PIPE

(

EARTH)

2

SERVICE HINTS

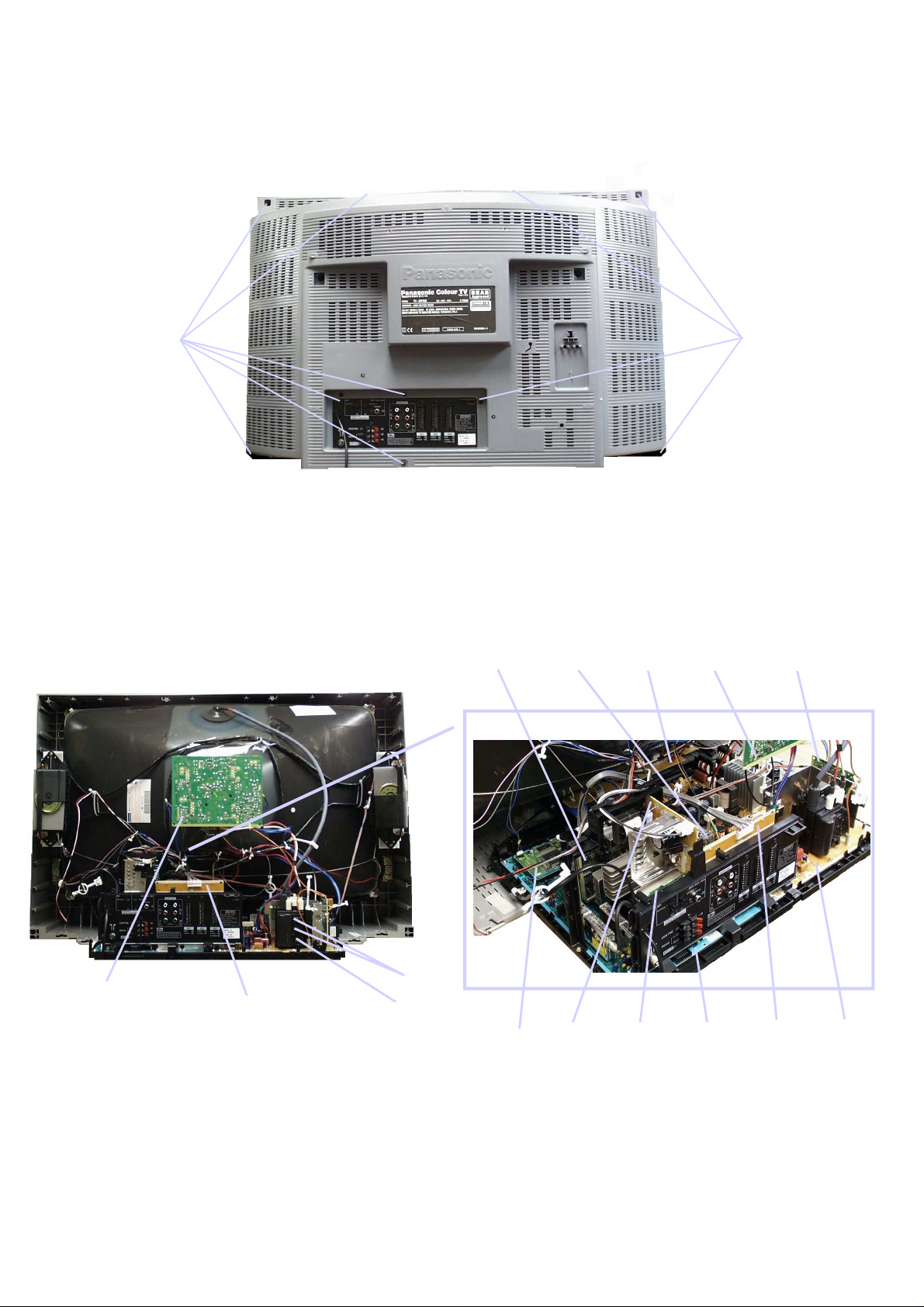

How to remove the rear cover

1. Remove the 10 screws as shown in Fig.2.

SCREWS

LOCATION OF CONTROLS

Fig.2.

DP-Board

DG-Board

G-Board

L-Board

SCREWS

DF-Board

L-Board

H-Board

Focus

Screen

Fig.3.

U-Board

3

Z-Board

HA-Board

A-Board

H-Board

D-Board

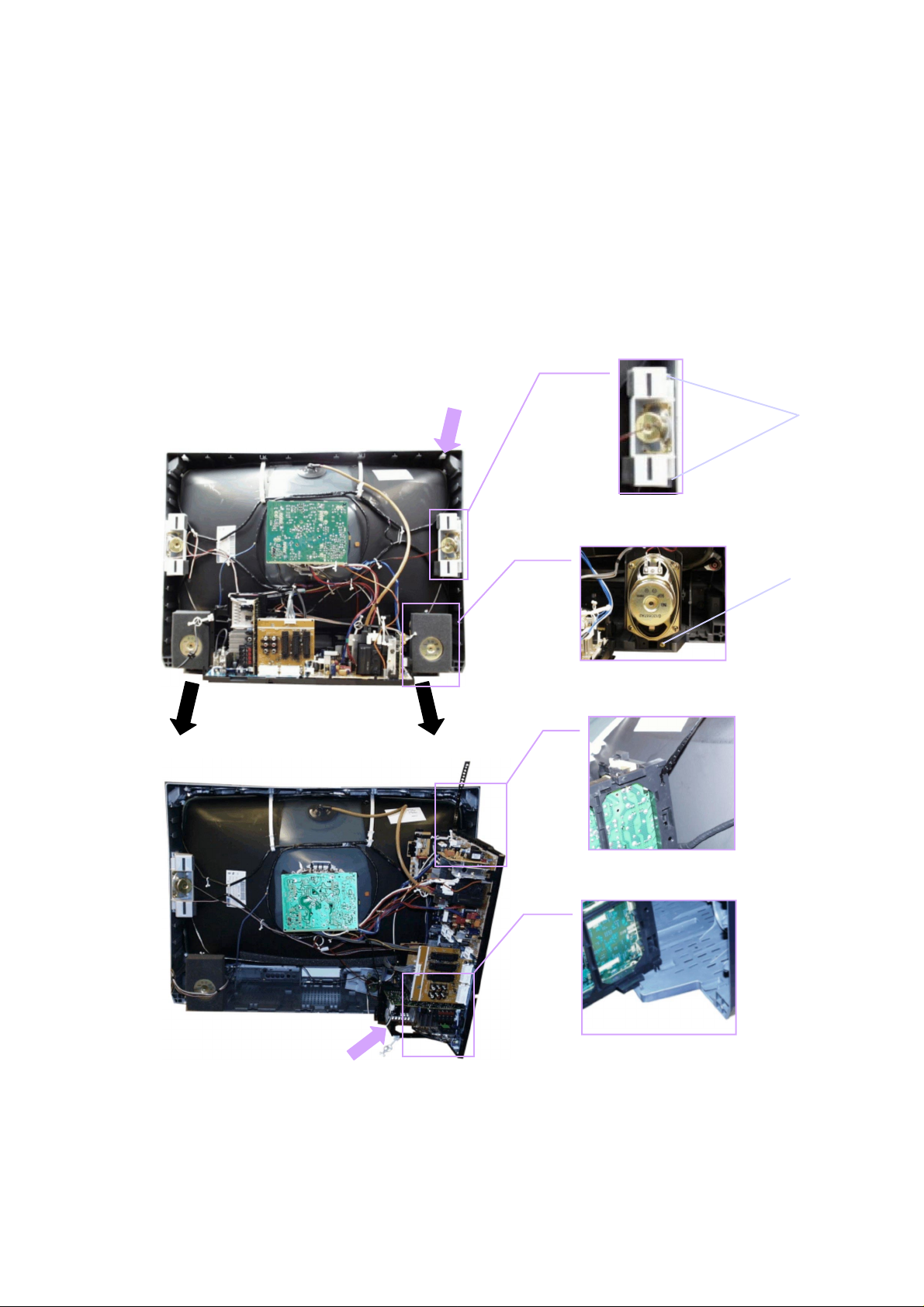

HOW TO MOVE THE CHASSIS INTO SERVICE POSITION

(C)

(D)

(A)

(B)

1. Remove the 3 screws (B) and (C) shown in Fig.5. / Fig.6., and remove the 2 speakers from the cabinet.

2. Affix the support strap supplied in the service pack (TZS1EK002) using a back cover screw, into the top right-hand

cabinet rib (A) shown in Fig.4.

3. Hold and lift the rear of the chassis and gently pull toward you, as shown in Fig.4.

4. Release the respective wiring clips and rotate the chassis vertically through 90°, anti-clockwise.

5. Locate the base of the chassis frame into location (D), shown in Fig.7. / Fig.9.

6. Clip the chassis frame onto the support strap, shown in Fig.7. / Fig.8.

7. After servicing replace the speakers, and ensure all wiring is returned to it’s original position before returning the receiver

to the customer.

Fig.5.

Fig.4.

Fig.7.

Fig.6.

Fig.8.

Fig.9.

4

ADJUSTMENT PROCEDURE

Item / Preparation Adjustment/Confirmation

+B SET-UP

4. Receive a Window pattern.

5. Set the controls :Brightness Minimum

Contrast Minimum

Volume Minimum

CUT OFF

1. Receive a Window pattern.

2. Degauss the tube externally.

3. Set the TV into Service Mode 1.

4. Select Sub brightness mode.

Confirm the following voltages.

A - Board

A1 Pin2 7.5 ± 0.5V IC1252 Pin2 2.5 ± 0.25V

A1 Pin12 -20 ± 0.5V IC1251 Pin3 3.3 +0.3 / -0.2V

A1 Pin16 20 ± 0.5V IC3302 Pin3 12 ± 0.6V

A2 Pin15 30 ± 0.5V IC2707 Pin3 8 ± 0.4V

A2 Pin6 15 ± 0.5V L2707 (IC2708) 9 ± 0.4V

A3 Pin4 15 ± 0.5V L2704 (IC2706) 5 ± 0.2V

A3 Pin2 -15 ± 0.5V L2716 (IC2705) 3.3 ± 0.2V

D – Board

TPD8-GND 7.5 ±0.5V

TPD9-TPD11 38.5 ± 2V

TPD10-GND 15.5 ± 1V

TPD13-GND 14.5 ± 1V

TPD15-GND 144.8 ± 1V

TPD32-GND 209 ± 10V

C864-GND -15.5 ± 1V

D2 Pin15-GND 31 ± 1V

To adjust Cutoff connect an oscilloscope to the Blue cathode. Adjust "Cutoff"

value using the "Yellow" and "Blue" buttons until the black level is 170V ± 5V,

press "STR" to store the value. Remove the oscilloscope.

Select Highlight/Lowlight mode press "5" to collapse the screen and adjust the

screen “VR” until the display is just visible, press "5" to return to service mode.

Using the "Yellow" and "Blue" buttons adjust until optimum picture white

balance is achieved, press "STR " to store the value. Select Sub Brightness

mode and adjust until optimum picture brightness is achieved.

L2717 (IC2709) 3.3 ± 0.2V

SELF CHECK

Self-Check is used to automatically check the bus lines and hexadecimal code of the TV set.

To get into Self-Check mode press the down (-/v) button on the customer controls at the front of the TV set, at the same time

pressing the STATUS button on the remote control, and the screen will show: -

Factory use only

MEM : O.K.

GC1 : O.K.

GC2 : O.K.

VDU : O.K.

CIP : O.K.

RGB : O.K.

AVSW : O.K.

TUN1 : O.K.

TUN2 : O.K.

DAC1 : O.K.

MSP : O.K.

DOLBY : O.K.

CODEC : O.K.

DAC2 : O.K.

DAC3 : O.K.

OPTION 1:

OPTION 2:

OPTION 3:

OPTION 4:

OPTION 5:

OPTION 6:

OPTION 7:

OPTION 8:

OPTION 9:

OPTION 10:

OPTION 11:

OPTION 12:

OPTION 13:

Check:

Sum : ****

TX-28PB50

0D

00

13

10

00

50

00

41

85

80

19

28

FA

01

TX-32PB50/PB50N

0D

00

13

10

00

50

00

41

85

80

19

08

FA

E1

TX-36PB50/PB50N

0D

00

13

10

00

50

00

41

85

80

19

48

FA

21

To exit Self-Check, switch off the TV set at the power button.

If the CCU ports have been checked and found to be incorrect or not located then " - - " will appear in place of "O.K.".

5

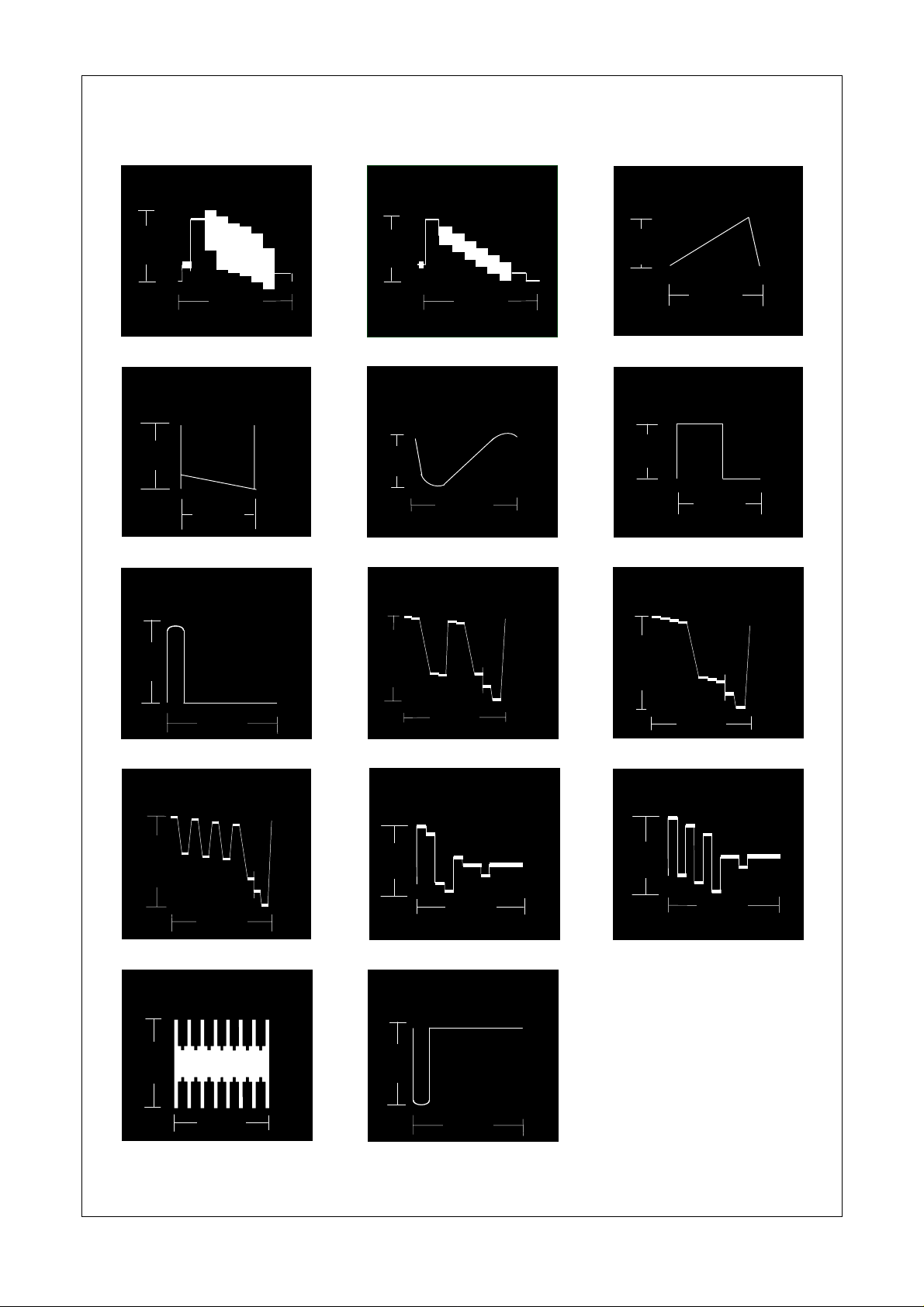

WAVEFORM PATTERN TABLE

Note: All waveforms have been taken using a standard colour bar pattern.

Video Out

IC3001 Pin 56

2.2V

Vert Out

IC451 Pin 3

88V

HFLB

A3 Pin 11

10mS

64µS

Luminance In

IC1315 Pin 37

0.9V

VFLB

IC451 Pin 6

1V

R - Out

IC1315 Pin 23

20mS

32µS

Vert Drive

A44 Pin 24

0.9V

10mS

H - Drive

A3 Pin 10

4V

32µS

G - Out

IC1315 Pin 21

4V

B - Out

IC1315 Pin 19

4V

SVM Out

A44 Pin 43

1V

32µS

32µS

4V

R - Y

IC1315 Pin 38

0.8V

E/W Out

IC501 Pin 1

8V

32µS

32µS

4V

32µS

B - Y

IC1315 Pin 39

0.8V

32µS

32µS

32µS

6

ALIGNMENT SETTINGS

(The figures below are nominal and used for representative purposes only.)

1. Set the Bass to maximum position, set the Treble to minimum position, press the down button (- / v) on the customer

controls at the front of the TV and at the same time press the INDEX button on the remote control, this will place the TV

into the Service Mode.

2. Press the RED / GREEN buttons to step up / down through the functions.

3. Press the YELLOW / BLUE buttons to alter the function values.

4. Press the STR button after each adjustment has been made to store the required values.

5. To exit the Service Mode, press the "N" button.

Alignment Function Settings / Special features

Horizontal Position

Vertical Position

Horizontal Amplitude

Vertical Amplitude

Parabola

Trapezoid

Horizontal Parallel

Vertical Linearity

Top Corner

Bottom Corner

Vertical Symmetry Correction

H – Pos

97

V – Pos

111

H – Amp

86

V – Amp

134

Parabola

26

Trapezoid

124

H – Parallel

13

V – Linear

34

Top – Corner

20

Bottom – Corner

20

V – S – Correct

9

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Center Correction

DAF - Phase

Highlight

Lowlight

Sub-Brightness

Video Gain 2

Splitter Gain (Tuner)

C – Correct

10

DAF – Phase

205

High 0144 0126 0128

Low 0331 0340 0384

Sub-Brightness

144

Video Gain 2

157

SPL. Gain

0

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

Optimum setting.

7

8

9

10

11

12

16

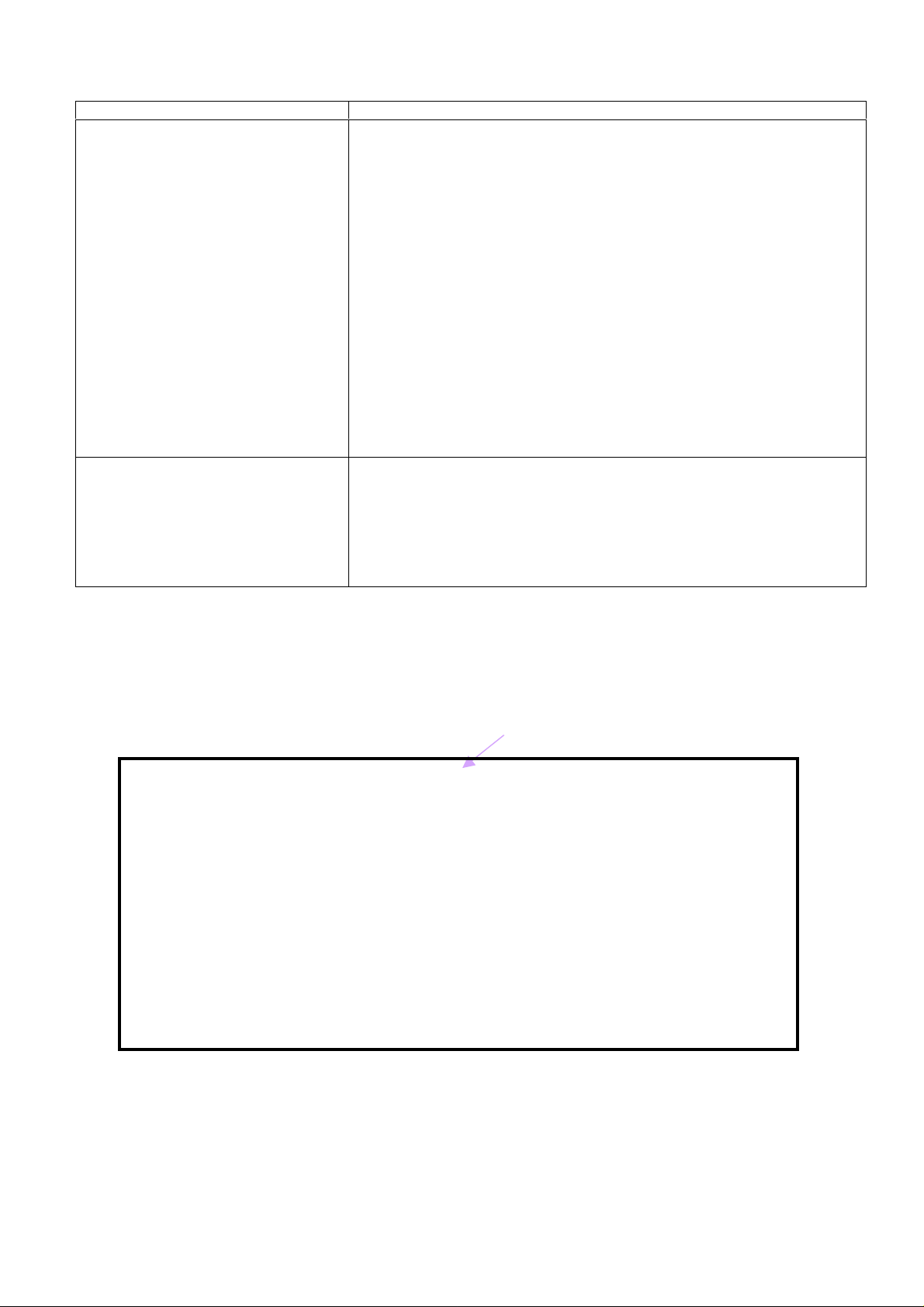

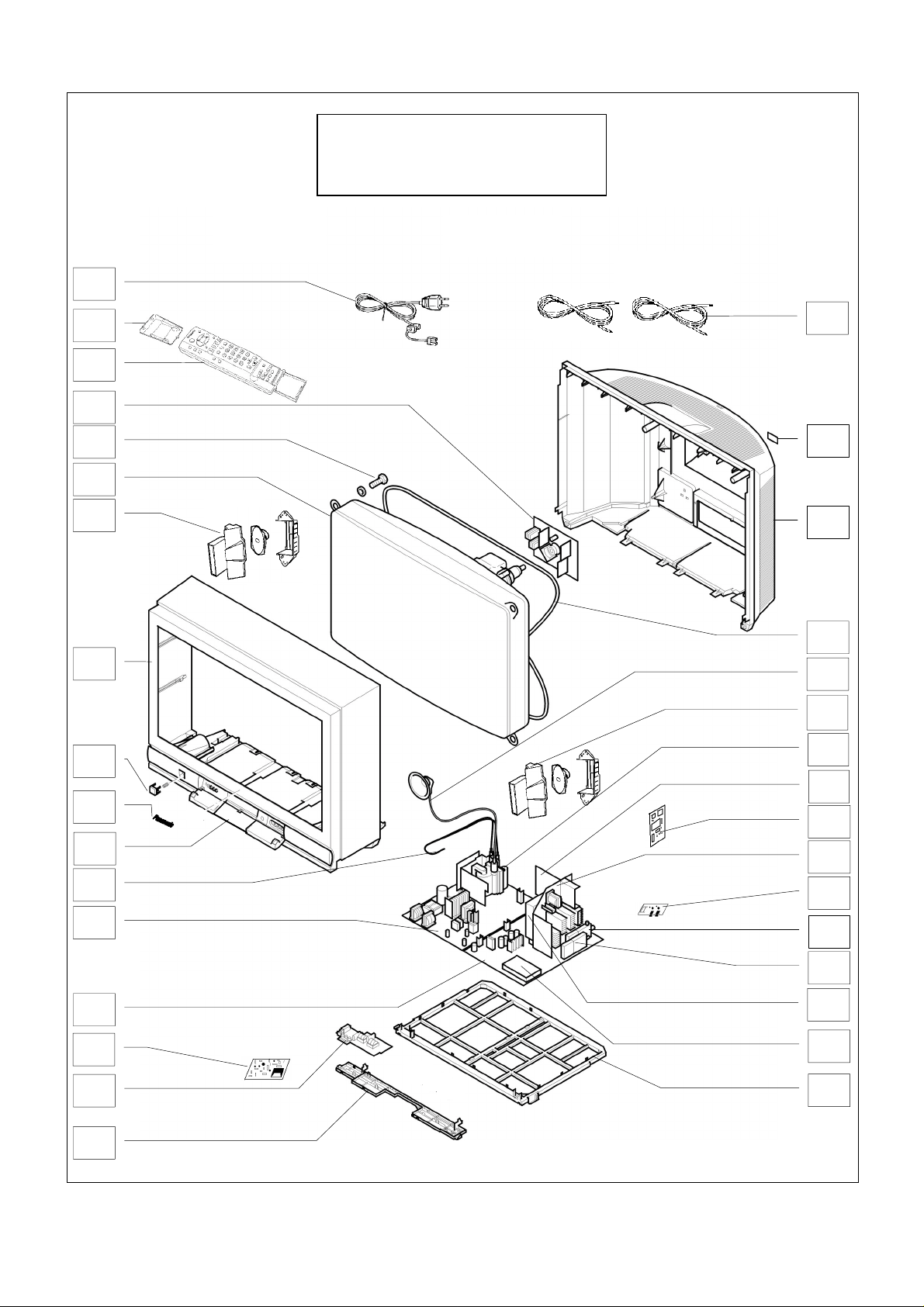

PARTS LOCATION

NOTE:

The numbers on the exploded view below

refer to the mechanical section of the

Replacement Parts List.

18

31

22

23

33

17

5

7

1

6

32

21

26

20

2

28

12

13

29

25

19

27

30

24

8

DF BOARD ONLY USED

ON 32” & 36” MODELS.

11

10

3

4

14

15

9

13

Components Identifie d by mark have special charac t eris t ics important for safety.

* When replacing any of these components, us e only manufacturers specified parts.

In case of ordering these spare parts, please always add the c omplete Model-Type

number to your order.

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

COMMON PARTS

EXPLODED VIEW

SPEAKER 1 EAB10108B2

SPEAKER 2 EABG12506C2

TUNER 3 ENG27510G

TUNER 4 ENG27C01G

REMOTE CONTROL 5 EUR511224

POWER BUTTON 6 TBX8E089

CRT FIXING SCREW 7 THT1062

DOOR LID 8 TKP8E1430

CHASSIS FRAME 9 TMX8E050

HA P.C.B. 10 TNP8EHA02AA

Z P.C.B. 11 TNP8EZ007AA

H P.C.B. 12 TNPA1724

DP P.C.B. 13 TNPA1727AH

DG P.C.B. 14 TNPA1965AB

U P.C.B. 15 TNPA2042AT

AC POWER CORD 16 TXASX01CRKG

SPEAKER WIRE 17 TXJ/E50CQKG

BATTERY COVER (REMOTE) 18 UR51EC904A

MISCELLANEOUS COMPONENTS

SPEAKER TWEETER . EASG7D506B2

PRESET LABEL . TBM8E2137

AV LABEL . TBM8E2192

SPEAKER REFLECTOR. TKK8E026

AV PANEL . TKP8E1324

LED WINDOW . TKP8E1431

BATTERY PACK . UM-3DJ-2P

ROTATION COIL ROT TLK8E05177

I.C.s

REGULATOR D354 TL431CLPM

5V REGULATOR IC051 AN7805FLB

RGB OUTPUT IC351 TDA6111Q-N4

RGB OUTPUT IC352 TDA6111Q-N4

RGB OUTPUT IC353 TDA6111Q-N4

MULTIVIBRATOR IC459 TC74HC221AF

AUDIO AMPLIFIER IC501 NJM2903MTE1

POWER SUPPLY IC801 STRF6656LF53

POWER SUPPLY SWITCHINGIC841 MIP0254SPSCF

ERROR AMPLIFIER IC851 SE140N

MICRO PROCESSOR IC1101 SDA6000-A23

EEPROM * IC1102 E2F6/010/05

5V REGULATOR IC1105 S-80843ALY-Z

SDRAM IC1106 TVSA0500

CONVERTER IC1107 TC7MBD3245FK

5V REGULATOR IC1108 AN78L05TA

REPLACEMENT PARTS LIST

Important Safety Notice

SYSTEM RESET IC1109 PST9119NR

3.5V REGULATOR IC1251 SI-3033C

D/A CONVERTER IC1253 M62392FP70BC

RESET IC1254 PST9128NR

VIDEO PROCESSOR IC1303 C1AB00001282

SCAN RATE CONVERTOR IC1305 SDA9415

3.3V REGULATOR IC1306 MM1065ZMR

3.3V REGULATOR IC1307 MM1065ZMR

3.3V REGULATOR IC1309 MM1065ZMR

VIDEO LOGIC IC1310 TC7WH241FUEL

3.3V REGULATOR IC1311 MM1065ZMR

AUDIO AMPLIFIER IC1312 NJM2904VTE1

AUDIO AMPLIFIER IC1314 NJM2904MTE1

R.G.B. PROCESSOR IC1315 AN5394FB

CIP IC1316 MB87F1720

M.S.P. IC2001 MSP3410DQAC5

AUDIO AMPLIFIER IC2301 TDA7490

H.P. AMPLIFIER IC2302 AN7108

QUAD AMPLIFIER IC2303 NJM2059MTE1

AUDIO AMPLIFIER IC2305 TDA7481

QUAD AMPLIFIER IC2306 NJM2059MTE1

QUAD AMPLIFIER IC2307 NJM2059MTE1

POWER SUPPLY IC2401 STR10006-N

AUDIO AMPLIFIER IC2404 TDA2030AV

AUDIO AMPLIFIER IC2405 TDA2030AV

AUDIO AMPLIFIER IC2406 TDA2030AV

INVERTER BUFFER IC2407 TC7WU04FEL

VIDEO LOGIC IC2409 TC74HC00AFEL

AUDIO DECODER IC2501 CS493002-CLR

DIGITAL AUDIO RECEIVERIC2502 CS8414-CSR

STEREO D/A CONVERTER IC2503 CS4340-KSR

AUDIO D/A & A/D IC2504 CS4228-KSRB

ADDRESS BUFFER IC2508 TC74LCX574FL

ADDRESS BUFFER IC2509 TC74LCX574FL

4MBIT FLASH EPROM IC2510 C3ZBK0000011

INVERTER BUFFER IC2511 TC7WU04FEL

CONVERTER IC2512 TC7MBD3245FK

D/A CONVERTER IC2513 CXA1315M-T4

D/A CONVERTER IC2515 CXA1315M-T4

D TYPE F.F. LOGIC IC2516 TC7WH74FUEL

VIDEO LOGIC IC2517 TC7WH241FUEL

2 INPUT NAND GATE IC2518 TC7SH00FEL

CONVERTER IC2519 TC7MBD3245FK

AMPLIFIER IC2520 BA15218F-E2

OPERATIONAL AMPLIFIER IC2521 AN6554NSF-E2

OPERATIONAL AMPLIFIER IC2522 C0ABBB000102

OPERATIONAL AMPLIFIER IC2523 AN6554NSF-E2

12V REGULATOR IC2524 AN78L12M-E1

OPERATIONAL AMPLIFIER IC2526 C0ABBB000102

DUAL VCA (AMPLIFIER) IC2527 M5222FP-E 2

DUAL VCA (AMPLIFIER) IC2528 M5222FP-E 2

DUAL VCA (AMPLIFIER) IC2529 M5222FP-E 2

REGULATOR IC2705 PQ1CG21H2RZ

14

FUSES

DIODES

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

REGULATOR IC2706 PQ1CG21H2RZ

8V REGULATOR IC2707 AN7808LB

POWER SUPPLY IC2708 SI-8090K

REGULATOR IC2709 PQ1CG21H2RZ

SWITCHING IC3001 CXA2069Q-TL

12V REGULATOR IC3002 TDA8601T/C1

VIDEO AMPLIFIER IC3003 CXA1211M-T4

12V REGULATOR IC3302 L78M12MRB

OPERATIONAL AMPLIFIER IC4801 AN6564NS-E1

GEOMAGNETIC CORRECTIONIC4802 PUB4301

LED RECEIVER RM1001 RPM6937

FUSE HOLDER F801-1 EYF52BC

FUSE HOLDER F801-2 EYF52BC

FUSE F801 XBA2C50T H15

DIODE D003 MA3150HTX

DIODE D004 MA3150HTX

DIODE D010 MA152KTX

DIODE D053 MA152KTX

DIODE D351 ERA15-04V3

DIODE D352 ERA15-04V3

DIODE D353 MA3110LTX

DIODE D355 ERA15-04V3

DIODE D356 ERA15-04V3

DIODE D358 MA151ATX

DIODE D360 ERA15-02V3

DIODE D361 MA151ATX

DIODE D362 MA151ATX

DIODE D363 MA151ATX

DIODE D364 MA3130MTX

DIODE D365 MA3130MTX

DIODE D366 MA3130MTX

DIODE D367 MA3051HTX

DIODE D368 MA3051HTX

DIODE D369 MA3051HTX

DIODE D383 ERA15-04V3

DIODE D385 ERA22-04V3

DIODE D386 ERA15-04V3

DIODE D389 ERA15-04V3

DIODE D452 MA152KTX

DIODE D453 EU02AV1

DIODE D454 MA152KTX

DIODE D455 MA152KTX

DIODE D456 ERA22-02V3

DIODE D465 MA3039HTX

DIODE D502 MA4150TA

DIODE D503 ERA81004V3

DIODE D504 D1NL40V70

DIODE D553 MA167TA5

DIODE D554 EU02

DIODE D555 RH3GLF102

DIODE D557 MA1033MTA

DIODE D558 AU02V0

DIODE D559 FMV-3GULF730

DIODE D560 MA165TA5

DIODE D562 MA182TA

DIODE D570 RU3ANV1

DIODE D580 MA4360

DIODE D591 MA165TA5

DIODE D592 MA4104

DIODE D593 ERA15-02V3

DIODE D594 MA165TA5

DIODE D595 MA4360MTA

DIODE D701 D1NL40V70

DIODE D802 D6SB80LF-B

DIODE D805 MA2240-BLFS

DIODE D809 MA2082-ALFS

DIODE D811 MA2082-ALFS

DIODE D819 ERA22-04V3

DIODE D820 ERA22-04V3

DIODE D821 ERA22-04V3

DIODE D823 PC123FY2

THERMISTOR D825 232266296706

THERMISTOR D826 232266296706

DIODE D843 ERC0510V1

DIODE D844 TVSSR2KL

DIODE D845 RY24V1

DIODE D847 ERA22-10

DIODE D848 PC123FY2

DIODE D851 FMGG26S

DIODE D852 MA4030LTA

DIODE D853 RU2AMLFA1

DIODE D854 RU2AMLFA1

DIODE D855 FMGG2CS

DIODE D856 EU02

DIODE D857 FMGG26S

DIODE D858 MA165TA5

DIODE D859 MA165TA5

DIODE D861 MA165TA5

DIODE D862 MA4360MTA

DIODE D865 MA165TA5

DIODE D867 MA165TA5

DIODE D869 MA165TA5

DIODE D881 MA165TA5

DIODE D885 MA4056HTA

DIODE D886 MA165TA5

DIODE D887 MA165TA5

DIODE D888 EU02

DIODE D891 ERC0510V1

DIODE D953 R2KNLFA1

DIODE D961 MA152KTX

LED D1011 LNH201RFCF6

DIODE D1012 MTZJT-775.1C

DIODE D1152 MA152KTX

DIODE D1153 MA152KTX

DIODE D1302 MA152KTX

DIODE D1305 MA704ATX

DIODE D1306 MA3062MTX

DIODE D1307 MA3091MTX

DIODE D1308 MA152KTX

DIODE D1309 MA152KTX

DIODE D1310 MA3062MTX

DIODE D1311 MA3062MTX

DIODE D1312 MA3062MTX

DIODE D1313 MA3043MTX

DIODE D1315 MA3043MTX

DIODE D2040 MA152KTX

DIODE D2041 MA152KTX

DIODE D2048 MA152KTX

DIODE D2301 TVSRM26V1

DIODE D2302 MTZJT-775.6B

DIODE D2305 MA3047MTX

DIODE D2306 MA29TA5

DIODE D2311 MA1180HTA

DIODE D2312 MA3130MTX

DIODE D2313 MA152KTX

DIODE D2314 MA152KTX

DIODE D2316 MA152KTX

DIODE D2401 MA4200MTA

DIODE D2402 D5L60F4015

DIODE D2403 TVSEH1LF-F7

15

TRANSISTORS

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

DIODE D2404 MTZJT-778.2A

DIODE D2405 EU02

DIODE D2406 EU02

DIODE D2407 EG01CV0

DIODE D2410 EU02

DIODE D2411 FMGG26S

DIODE D2432 MA167TA5

DIODE D2433 MA167TA5

DIODE D2434 MA167TA5

DIODE D2436 MA167TA5

DIODE D2437 MA167TA5

DIODE D2438 MA167TA5

DIODE D2501 MA152KTX

DIODE D2509 MA152KTX

DIODE D2510 MA152KTX

DIODE D2520 MA152KTX

DIODE D2521 MA152KTX

DIODE D2711 RK34LFC4

DIODE D2712 AK04V0

DIODE D2713 RK34LFC4

DIODE D2714 RK34LFC4

DIODE D2715 MA29TA5

DIODE D3003 MA3091LTX

DIODE D3004 MA3091LTX

DIODE D3103 MA165TA5

DIODE D3104 MA165TA5

DIODE D3401 MA165TA5

DIODE D3402 MA165TA5

TRANSISTOR IC2514 TC7WH157FUEL

TRANSISTOR Q002 BC857B

TRANSISTOR Q052 BC857B

TRANSISTOR Q369 BC857B

TRANSISTOR Q451 BC847B

TRANSISTOR Q460 BC847B

TRANSISTOR Q461 BC847B

TRANSISTOR Q462 BC847B

TRANSISTOR Q501 2SK2962TPE6

TRANSISTOR Q551 2SC5591000RK

TRANSISTOR Q552 2SC1473ATA

TRANSISTOR Q703 2SK2538000LB

TRANSISTOR Q805 2SK2123000LB

TRANSISTOR Q851 2SA1018QTA

TRANSISTOR Q854 2SC3311ATA

TRANSISTOR Q874 2SA684R

TRANSISTOR Q875 2SA720-RS

TRANSISTOR Q881 2SC3311ATA

TRANSISTOR Q882 2SC3311ATA

TRANSISTOR Q883 2SC1317-TA

TRANSISTOR Q902 BC847B

TRANSISTOR Q903 BC847B

TRANSISTOR Q908 BC847B

TRANSISTOR Q951 BC857B

TRANSISTOR Q952 BC847B

TRANSISTOR Q953 BC847B

TRANSISTOR Q954 BC857B

TRANSISTOR Q955 2SA1535ARLB

TRANSISTOR Q956 2SC3944ARLB

TRANSISTOR Q1003 2SC3311ATA

TRANSISTOR Q1107 BC847B

TRANSISTOR Q1108 BC847B

TRANSISTOR Q1109 BC847B

TRANSISTOR Q1110 BC847B

TRANSISTOR Q1111 BC847B

TRANSISTOR Q1112 BC847B

TRANSISTOR Q1113 BC847B

TRANSISTOR Q1114 BC847B

TRANSISTOR Q1115 BC847B

TRANSISTOR Q1121 BC847B

TRANSISTOR Q1122 BC847B

TRANSISTOR Q1125 BC847B

TRANSISTOR Q1301 BC847B

TRANSISTOR Q1302 BC847B

TRANSISTOR Q1303 BC847B

TRANSISTOR Q1305 BC847B

TRANSISTOR Q1306 BC857B

TRANSISTOR Q1307 XN5601TX

TRANSISTOR Q1308 BC857B

TRANSISTOR Q1309 BC857B

TRANSISTOR Q1311 BC857B

TRANSISTOR Q1312 BC857B

TRANSISTOR Q1313 BC857B

TRANSISTOR Q1314 BC857B

TRANSISTOR Q1315 BC857B

TRANSISTOR Q1316 BC857B

TRANSISTOR Q1318 BC857B

TRANSISTOR Q1319 BC857B

TRANSISTOR Q1320 BC857B

TRANSISTOR Q1321 BC857B

TRANSISTOR Q1322 BC857B

TRANSISTOR Q1323 BC857B

TRANSISTOR Q1324 BC857B

TRANSISTOR Q1326 BC857B

TRANSISTOR Q1327 2SK198RTX

TRANSISTOR Q1328 BC847B

TRANSISTOR Q1329 2SK198RTX

TRANSISTOR Q1331 2SK198RTX

TRANSISTOR Q1336 BC857B

TRANSISTOR Q1340 BC847B

TRANSISTOR Q2002 BC857B

TRANSISTOR Q2003 BC857B

TRANSISTOR Q2004 BC857B

TRANSISTOR Q2005 BC857B

TRANSISTOR Q2040 BC847B

TRANSISTOR Q2041 BC847B

TRANSISTOR Q2042 BC847B

TRANSISTOR Q2043 BC847B

TRANSISTOR Q2213 BC847B

TRANSISTOR Q2214 BC847B

TRANSISTOR Q2215 BC847B

TRANSISTOR Q2216 BC847B

TRANSISTOR Q2301 BC847B

TRANSISTOR Q2302 BC847B

TRANSISTOR Q2303 BC847B

TRANSISTOR Q2307 BC847B

TRANSISTOR Q2308 BC857B

TRANSISTOR Q2309 BC847B

TRANSISTOR Q2310 BC847B

TRANSISTOR Q2311 BC847B

TRANSISTOR Q2402 2SA684R

TRANSISTOR Q2403 2SA720-RS

TRANSISTOR Q2432 BC847B

TRANSISTOR Q2433 BC847B

TRANSISTOR Q2434 BC847B

TRANSISTOR Q2438 2SK198RTX

TRANSISTOR Q2439 2SK198RTX

TRANSISTOR Q2440 2SK198RTX

TRANSISTOR Q2441 BC857B

TRANSISTOR Q2503 BC847B

TRANSISTOR Q2506 BC847B

TRANSISTOR Q2507 BC847B

TRANSISTOR Q2508 BC847B

16

TRANSFORMERS

COILS

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

TRANSISTOR Q2509 BC847B

TRANSISTOR Q2510 BC857B

TRANSISTOR Q2511 BC847B

TRANSISTOR Q2512 BC847B

TRANSISTOR Q2513 BC847B

TRANSISTOR Q3001 BC847B

TRANSISTOR Q3002 BC847B

TRANSISTOR Q3006 BC857B

TRANSISTOR Q3007 BC847B

TRANSISTOR Q3011 BC847B

TRANSISTOR Q3071 BC847B

TRANSISTOR Q3072 BC847B

TRANSISTOR Q3130 BC847B

TRANSISTOR Q3131 BC857B

TRANSISTOR Q3132 BC847B

TRANSISTOR Q3401 BC857B

TRANSISTOR Q3410 BC847B

TRANSISTOR Q3411 BC847B

TRANSISTOR Q3807 BC847B

TRANSISTOR Q3808 BC847B

TRANSFORMER L810 ETQR45T001A

TRANSFORMER T501 ETH19Y187AY

TRANSFORMER T801 ETS39AG296AC

TRANSFORMER T841 ETS19AB1G6AG

TRANSFORMER T2401 ETS35AA457AD

COIL L002 ELESN2R2KA

COIL L003 ELESN2R2KA

COIL L004 EXCELDR35V

COIL L008 EXCELDR35V

COIL L009 EXCELDR35V

COIL L053 EXCELDR35V

COIL L055 ELESN2R2KA

COIL L056 ELESN2R2KA

COIL L351 EXCELSA24T

COIL L381 ELESN6R8JA

COIL L382 ELESN4R7KA

COIL L383 ELESN4R7KA

COIL L387 EXCELDR35V

COIL L559 EXCELDR35C

COIL L560 EXCELDR35V

COIL L561 EXCELDR35C

COIL L563 EXCELSA39V

COIL L568 EXCELDR35C

COIL L571 EXCELDR35C

COIL L701 TALFP15B152K

COIL L703 EXCELSA35T

COIL L704 EXCELDR35V

COIL L812 EXCELSA39V

COIL L815 EXCELSA39V

COIL L818 EXCELSA39V

COIL L860 TALL08T100KA

COIL L862 TALL08T680KA

COIL L874 EXCELSA35T

COIL L877 EXCELSA35T

COIL L883 TALL08T181KA

COIL L890 ELF18D486D

COIL L891 ELF18D486D

COIL L895 EXCELSA35T

COIL L904 TLT560K991R

COIL L953 EXCELSA35T

COIL L954 EXCELSA35T

COIL L956 EXCELSA35T

COIL L1103 TALC325T4R7M

COIL L1104 TALC325T4R7M

COIL L1106 ELESN4R7KA

COIL L1107 TALC325T4R7M

COIL L1108 TALC325T4R7M

COIL L1109 TALC325T4R7M

COIL L1110 TALC325T4R7M

COIL L1112 EXCELDR35V

COIL L1115 TALC325T3R3M

COIL L1116 TALC325T4R7M

COIL L1300 TALC325T4R7M

COIL L1303 TALC168T2R2K

COIL L1304 TALC325T4R7M

COIL L1305 TALC168T3R3K

COIL L1306 TALC325T4R7M

COIL L1308 TALC325T100K

COIL L1309 TALC325T4R7M

COIL L1310 TALC325T4R7M

COIL L1311 TALC325T4R7M

COIL L1312 EXCELDR35V

COIL L1313 TALC325T4R7M

COIL L1314 TALC325T4R7M

COIL L1315 TALC325T4R7M

COIL L1316 TALC325T4R7M

COIL L1317 TALC168T6R8K

COIL L1318 TALC325T4R7M

COIL L1319 TALC325T4R7M

COIL L1320 TALC325T100K

COIL L1321 TALC325T4R7M

COIL L1322 EXCELDR35V

COIL L1323 TALC325T4R7M

COIL L1324 TALC325T4R7M

COIL L1328 TALC325T4R7M

COIL L1330 TALC325T4R7M

COIL L2001 EXCELDR35V

COIL L2002 EXCELDR35V

COIL L2004 TLT068K991R

COIL L2005 EXCELDR35V

COIL L2007 EXCELDR35V

COIL L2008 EXCELDR35V

COIL L2009 TALC325T4R7M

COIL L2010 TALC325T4R7M

COIL L2278 EXCELSA35T

COIL L2301 TALL08T100KA

COIL L2302 TALL08T100KA

COIL L2303 TAL10RP390LB

COIL L2305 TAL10RP390LB

COIL L2308 TALL08T270KA

COIL L2309 TAL10RP390LB

COIL L2311 ELESN101KA

COIL L2312 TALL08T100KA

COIL L2313 TALL08T100KA

COIL L2314 EXCELDR35V

COIL L2316 EXCELDR35V

COIL L2319 EXCELDR35V

COIL L2320 EXCELDR35V

COIL L2321 EXCELDR35V

COIL L2322 EXCELDR35V

COIL L2323 EXCELDR35V

COIL L2324 EXCELDR35V

COIL L2325 EXCELDR35V

COIL L2406 EXCELDR35V

COIL L2407 EXCELSA35T

COIL L2409 EXCELSA35T

COIL L2410 EXCELSA35T

COIL L2412 EXCELSA35T

COIL L2414 EXCELDR35V

COIL L2431 TALL08T270KA

17

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

COIL L2433 TALL08T270KA

COIL L2435 TALL08T270KA

COIL L2436 TALL08T270KA

COIL L2437 TALL08T270KA

COIL L2438 TALL08T270KA

COIL L2440 EXCEMT271BT

COIL L2445 EXCELDR35V

COIL L2510 TALC325T1R5M

COIL L2511 TLK212T256AL

COIL L2515 TLTACT101J

COIL L2523 ELEBR6R8KA

COIL L2524 ELEBR6R8KA

COIL L2527 EXCELSA35T

COIL L2703 EXCELDR35V

COIL L2704 TALL08T330KA

COIL L2705 EXCELDR35V

COIL L2706 TAL10RP151LB

COIL L2707 EXCELDR35V

COIL L2708 EXCELDR35V

COIL L2709 TLPF095

COIL L2710 EXCELDR35V

COIL L2712 TAL10RP151LB

COIL L2713 EXCELDR35V

COIL L2714 EXCELDR35V

COIL L2715 EXCELDR35V

COIL L2716 TALL08T330KA

COIL L2717 TALL08T330KA

COIL L2718 TLPF095

COIL L2719 TLPF095

COIL L2722 EXCELDR35V

COIL L2724 EXCELDR35V

COIL L2725 EXCELDR35V

COIL L2727 EXCELDR35V

COIL L2729 EXCELDR35V

COIL L2730 EXCELDR35V

COIL L2732 EXCELDR35V

COIL L2734 EXCELDR35V

COIL L2735 EXCELDR35V

COIL L3004 ELESN4R7KA

COIL L3050 ELESN221KA

COIL L3401 EXCELSA35T

COIL L3402 EXCELSA35T

COIL L3403 EXCELDR35V

COIL L3404 EXCELDR35V

COIL L3405 EXCELDR35V

COIL L3406 EXCELDR35V

COIL L3407 EXCELDR35V

COIL L3408 EXCELDR35V

COIL L3409 EXCELDR35V

COIL L3410 EXCELDR35V

COIL L3411 EXCELDR35V

COIL L3412 EXCELDR35V

COIL L3413 EXCELDR35V

COIL L3414 EXCELDR35V

COIL L3415 EXCELDR35V

COIL L3416 EXCELSA35T

COIL L3417 EXCELSA35T

COIL L3418 EXCELSA35T

COIL L3419 EXCELSA35T

COIL L3420 ELESN4R7KA

COIL L3424 EXCELDR25V

COIL L3450 TLT470K991R

COIL L3451 TLT470K991R

COIL L4801 EXCELDR35V

COIL L4802 EXCELDR35V

COIL L4803 EXCELDR35V

FILTERS

CRYSTALS

RESISTORS

COIL L4804 EXCELDR35V

COIL LC1101 TLK212T256AL

COIL LC1102 TLK212T256AL

COIL LC1104 TLK212T256AL

COIL LC1105 TLK212T256AL

COIL LC1106 TLK212T256AL

COIL LC1110 TLK212T256AL

COIL LC1111 TLK212T256AL

COIL LC1112 TLK212T256AL

COIL LC1113 TLK212T256AL

COIL LC1114 TLK20LFA224M

COIL LC1115 TLK20LFA103M

COIL LC1116 TLK20LFA103M

COIL LC1117 TLK20LFA103M

COIL LC1118 TLK20LFA103M

COIL LC1119 TLK20LFA103M

COIL LC1120 TLK20LFA103M

COIL LC1121 TLK20LFA224M

COIL LC1122 TLK20LFA224M

COIL LC1123 TLK20LFA224M

COIL LC1124 TLK20LFA224M

COIL LC1125 TLK20LFA103M

COIL LC1126 TLK20LFA103M

COIL LC1127 TLK20LFA103M

COIL LC1128 TLK20LFA103M

COIL LC1130 TLK20LFA103M

COIL LC1131 TLK20LFA103M

COIL LC1132 TLK20LFA103M

COIL LC1133 TLK20LFA103M

COIL LC1134 TLK20LFA103M

COIL LC1135 TLK212T256AL

COIL LC1136 TLK20LFA103M

COIL LC1137 TLK20LFA103M

COIL LC1138 TLK20LFA103M

COIL LC1139 TLK20LFA103M

COIL LC1140 TLK212T256AL

COIL LC1141 TLK20LFA103M

COIL LC1142 TLK20LFA103M

COIL LC1143 TLK20LFA103M

COIL LC1144 TLK212T256AL

COIL LC1145 TLK212T256AL

COIL LC1146 TLK212T256AL

FILTER L893 ELF24V032B

FILTER L894 ELF24V034A

FILTER LC1107 ELKE103FA

FILTER LC1108 ELKE103FA

FILTER LC1109 ELKE103FA

FILTER LC1147 ELKE103FA

FILTER LC1329 ELKE103FA

FILTER LC1330 ELKE103FA

FILTER LC1331 ELKE103FA

FILTER LC1332 ELKE103FA

FILTER LC1333 ELKE103FA

EMI FILTER LC1343 QJT1090

EMI FILTER LC1344 QJT1090

CRYSTAL X1301 TSSA171

CRYSTAL X1302 TSSA171

CRYSTAL X2101 TSSA128

CRYSTAL X2501 TSSA172

CRYSTAL X3501 H0J600400006

S.M.CARBC025 ERJ6GEY0R00 0.1W 5% 0

CARBONC572 ERD25TC0T 0.25W 5% 0

18

DescriptionCct Ref Parts Number DescriptionCct Ref Parts Number

VARISTORD842 ERZV10D621CS 10W 20% 620

S.M.CARBJA1 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA2 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA3 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA3 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJA4 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA5 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA6 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA7 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA8 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA9 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA10 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA11 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA12 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA13 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA14 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA15 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA16 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA17 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA18 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA19 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA20 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA21 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA22 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA23 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA24 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA25 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA26 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA27 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA28 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA29 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA30 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA31 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA32 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA33 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA34 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA35 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA36 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA37 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA38 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA39 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA40 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA41 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA42 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJA43 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJHA2 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJHA3 ERJ8GEY0R00 .125W 5% 0

S.M.CARBJSA3 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA7 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA18 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA19 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA20 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA21 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA22 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA27 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA28 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA31 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA33 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA34 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA35 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA36 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA42 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA45 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA46 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA47 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA48 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA52 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA53 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA55 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA57 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA59 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA62 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA64 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA65 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA66 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA67 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA69 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA71 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA74 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA75 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA84 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA89 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA90 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSA101 ERJ6GEY0R00 0.1W 5% 0

CARBONJSA104 ERD25TC0T 0.25W 5% 0

S.M.CARBJSDG1 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG2 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG3 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG4 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG5 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG6 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG7 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG8 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG9 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG11 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG12 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG13 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG16 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG17 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG18 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG19 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG20 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG21 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG22 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG23 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG24 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG25 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG26 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG27 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG28 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG29 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG30 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG31 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG32 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG35 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG36 ERJ6GEY0R00 0.1W 5% 0

S.M.CARBJSDG55 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG56 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG57 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG58 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG59 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG60 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG61 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG62 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG63 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG64 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG65 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG66 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG67 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG68 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG69 ERJ3GEY0R00 0.1W 5% 0

S.M.CARBJSDG70 ERJ3GEY0R00 0.1W 5% 0

19

Loading...

Loading...