Panasonic TX-21JT3P Schematic

ORDER No. SM-04019

Service Manual

Colour Television

Z-M3L Chassis

TX-21JT3P

SPECIFICATIONS

Power Source: 220 - 240V A.C., 50Hz Video/Audio Terminals:

Power Consumption: 60W AV1 IN Video (21 pin) 1V p-p 75Ω

Audio (21 pin) 500mV rms 10KΩ

Stand-by Power Consumption: 1W RGB (21 pin)

Audio (RCA x 1) 500mV rms 10KΩ

Video (RCA x 1) 1V p-p 75Ω

Receiving System: PAL B/G, D/K, 525/60

SECAM B/G, D/K AV1 OUT Video (21 pin) 1V p-p 75Ω

M.NTSC Audio (21 pin) 500mV rms 10K

NTSC (AV only)

Receiving Channels: VHF E2-E12 VHF H1-H2 (ITALY) Picture Tube: A51LZM10X16N45 51cm

VHF A-H (ITALY) VHF R1-R2

VHF R3-R5 VHF R6-R12 High Voltage: 29 ± 1kV

UHF E21-E68 CATV (S01-S05)

CATV S1-S10 (M1-M10)

CATV S11-S20 (U1-U10) Audio Output: 20W

CATV S21-S41 (HYPERBAND) (Music Power) 8Ω

Headphones: 8Ω Impedance

Intermediate Frequency: Video 38.9MHz, 34MHz 3.5mm

Video/Audio

Audio 32.9MHz, 33.16MHz, 33.4MHz Accessories: Remote Control

2 x R6 (UM3) Batteries

Colour 34.47MHz (PAL)

34.5MHz, 34.65MHz (SECAM) Dimensions:

Height: 482 mm

Width: 506 mm

Depth: 484 mm

Ω

Net Weight: 20kg

NOTE:

Specifications are subject to change witho ut notic e.

Weights and dimensions shown are approx imate .

CONTENTS

SAFETY PRECAUTIONS.........................................................................................................................................................2

SERVICE HINTS.......................................................................................................................................................................3

ALIGNMENT PROCEDURE.....................................................................................................................................................4

WAVEFORMS...........................................................................................................................................................................5

BLOCK DIAGRAM....................................................................................................................................................................7

PARTS LOCATION...................................................................................................................................................................8

REPLACEMENT PARTS LIST..................................................................................................................................................9

SCHEMATIC DIAGRAMS.......................................................................................................................................................13

PCB CONDUCTOR VIEWS....................................................................................................................................................18

SAFETY PRECAUTIONS

GENERAL GUIDE LINES

1. It is advisable to insert an isolation transformer in the

a.c. supply before servicing a hot chassis.

2. When servicing, observe the original lead dress in the

high voltage circuits. If a short circuit is found, replace

all parts that have been overheated or damaged by

the short circuit.

3. After servicing, see that all the protective devic es

such as insulation barriers, insulation papers, shields

and isolation R-C combinations are correctly

installed.

4. When the receiver is not being used for a long period

of time, unplug the power cord from the a.c. outlet.

5. Potentials as high as 30kV are present when this

receiver is in operation. Operation of the receiver

without the rear cover involves the danger of a shock

hazard from the receiver power supply. Servicing

should not be attempted by anyone who is not

familiar with the precautions necessary when working

on high voltage equipment. Always discharge the

anode of the tube.

6. After servicing make the following leakage current

checks to prevent the customer from being exposed

to shock hazard.

LEAKAGE CURRENT COLD CHECK

1. Unplug the a.c. cord and connect a jumper between

the two prongs of the plug.

2. Turn on the receiver’s power switch.

3. Measure the resistance value with an ohmmeter,

between the jumpered a.c. plug and each exposed

metallic cabinet part on the receiver, such as screw

heads, aerials, connectors, control shafts etc. When

the exposed metallic part has a return path to the

chassis, the reading should be between 4M ohm and

20M ohm. When the exposed metal does not have a

return path to the chassis, the reading must be

infinite.

LEAKAGE CURRENT HOT CHECK

1. Plug the a.c. cord directly into the a.c. outlet. Do not

use an isolation transformer for this check.

2. Connect a 2kΩ 10W resistor in series with an

exposed metallic part on the receiver and an earth,

such as a water pipe.

3. Use an a.c. voltmeter with high impedance to

measure the potential across the resistor.

4. Check each exposed metallic part and check the

voltage at each point.

5. Reverse the a.c. plug at the outlet and repeat each of

the above measurements.

6. The potential at any point should not exceed

1,4Vrms. In case a measurement is outside the limits

specified, there is a possibility of a shock hazard, and

the receiver should be repaired and rechecked before

it is returned to the customer.

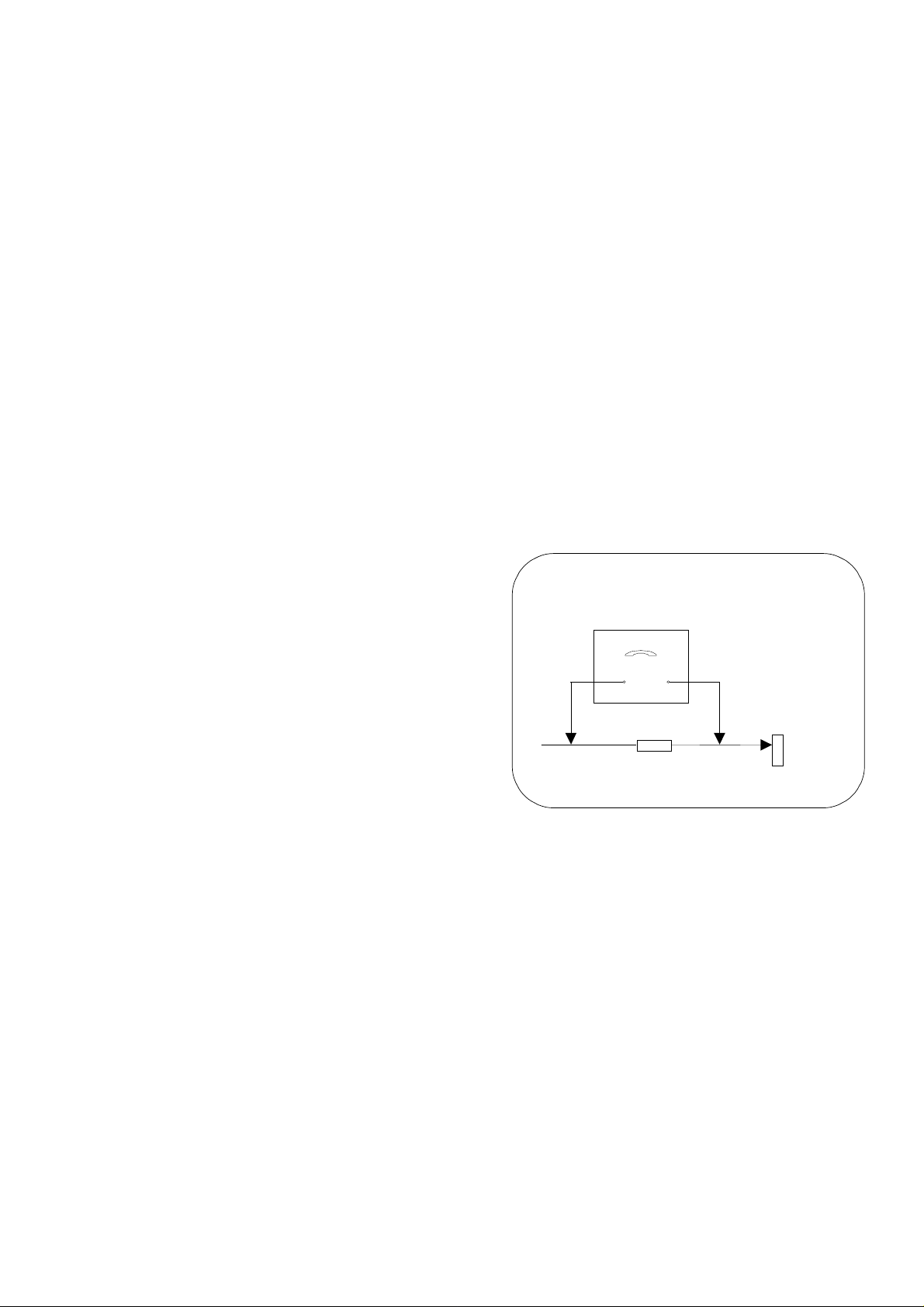

HOT CHECK CIRCUIT

a.c. VOLTMETER

ΩΩΩΩ

2k

10 Watts

TO INSTRUMENT'S EXPOSED

METALLIC PARTS

Fig. 1.

X-RADIATION WARNING

1. The potential sources of X-Radiation in TV sets are

the high voltage section and the picture tube.

2. When using a picture tube test jig for service, ensure

that the jig is capable of handling 30kV without

causing X-Radiation.

NOTE: It is important to use an accurate periodically

calibrated high voltage meter.

1. Set the brightness to minimum.

2. Measure the high voltage. The meter should indicate.

29kV ± 1kV.

If the meter indication is out of tolerance, immediate

service and correction is required to prevent the

possibility of premature component failure.

3. To prevent any X-Radiation possibility, it is essential

to use the specified tube.

WATER PIPE

(

EARTH)

2

SERVICE HINTS

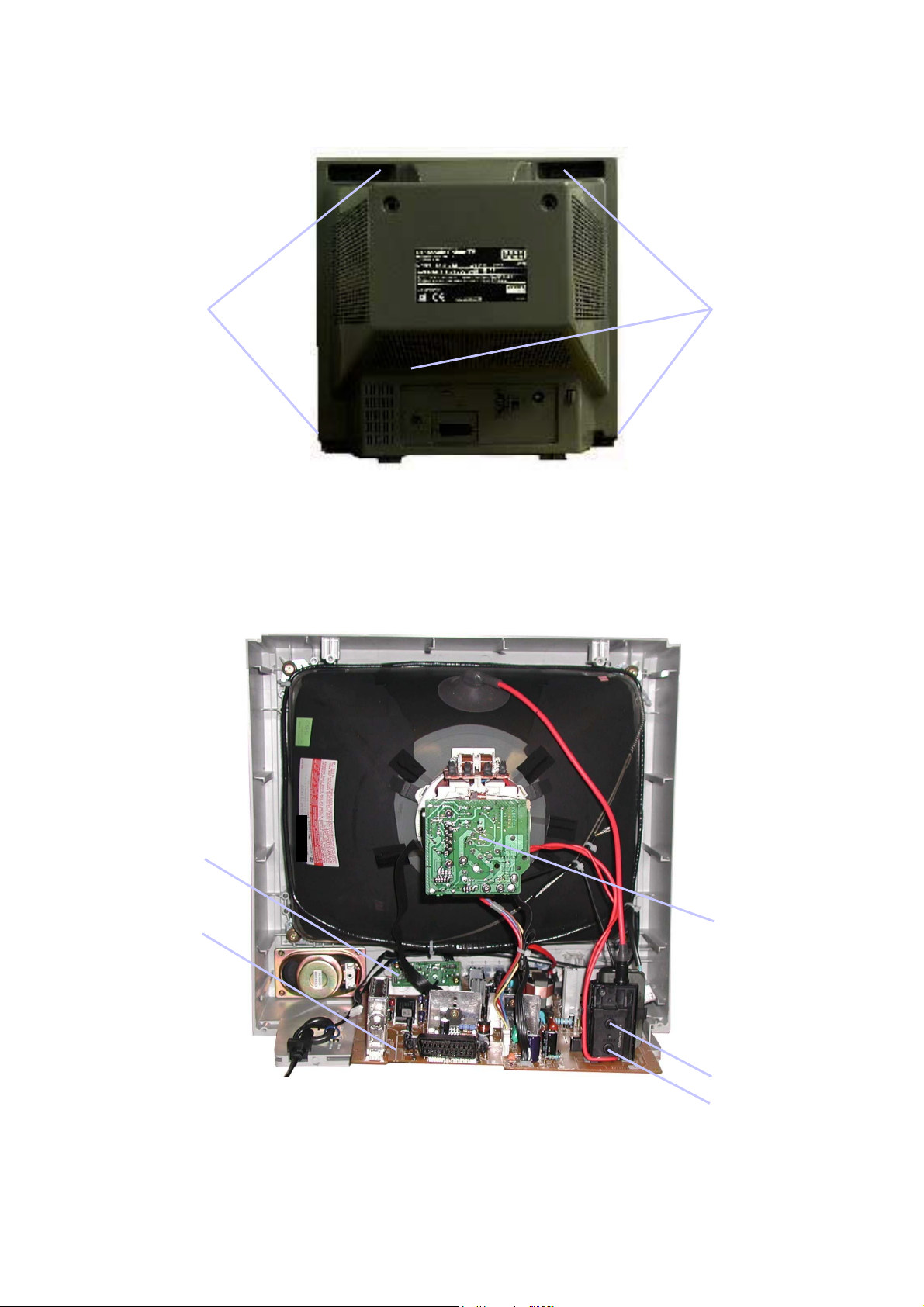

How to remove the rear cover

1. Remove the 5 screws as shown in Fig.2.

SCREWS

LOCATION OF CONTROLS

SCREWS

Fig. 2.

AV Board

Main Board

CRT Board

Focus

Screen

3

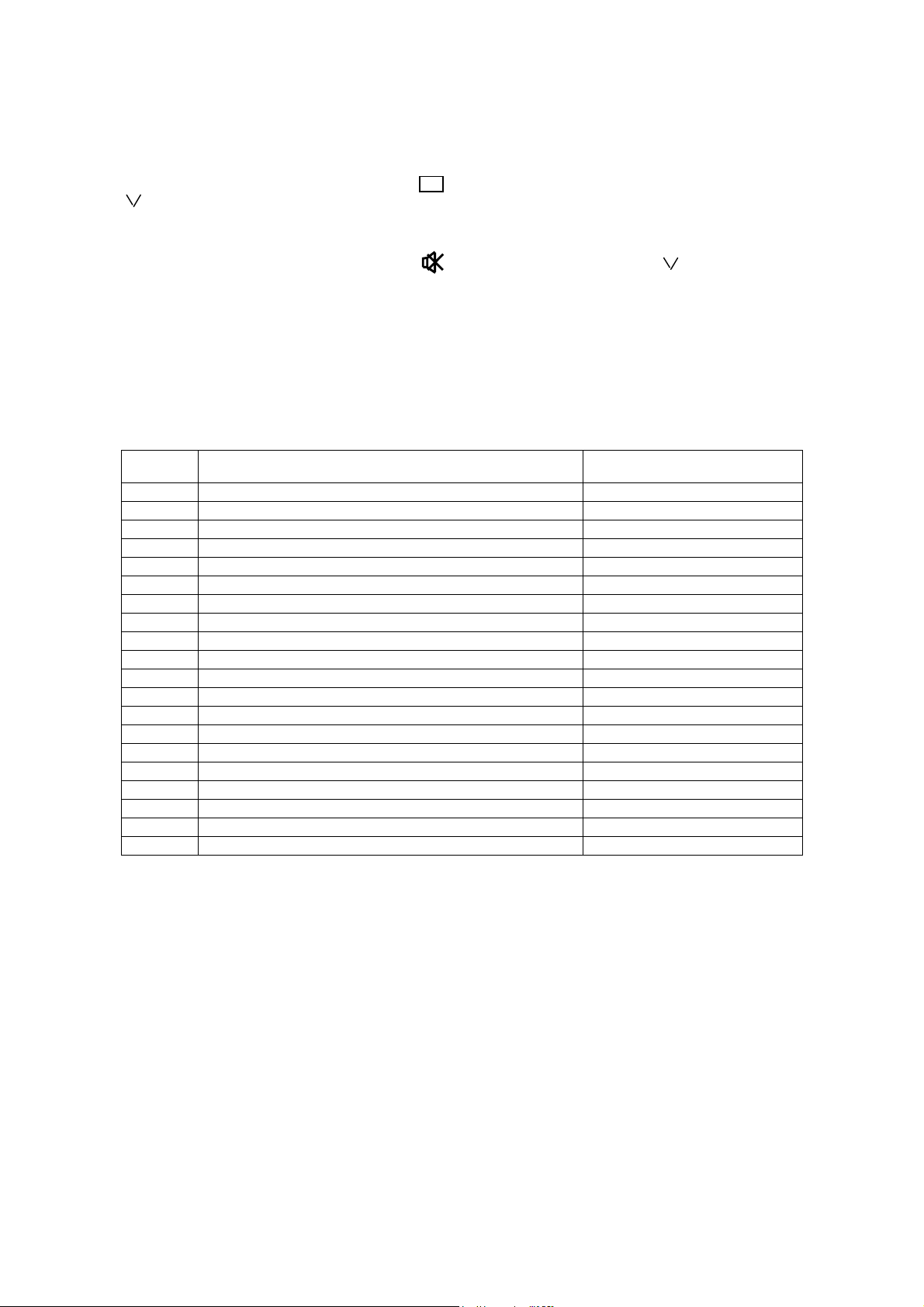

ALIGNMENT PROCEDURE AND OPTION SETTING

Self Check Mode

To enter self check mode, set the programme position to Channel 99.

Set sharpness to a minimum, press the status button ( ) on the remote contol whilst simultaneously pressing the down

button ( ) at the front of the set. This should bring the set into self check mode.

Entering SERVICE mode

Whilst in self check mode, press the mute remote key ( ) and local down button on the set ( ) simultaneously. The user

must make sure that Sharpness is set to a minimum and that the programme position is set to Channel 99 as well. This

should bring the user to service mode1. Scroll through the service items using the cursor up and down keys and adjust

accordingly using the - /+ keys on the r emote.

Service mode navigation

Up /Down remote keys :scroll through the service items available.

-/+ remote keys :Decrement/Increment the values within range.

TV/AV :Store the current data.

ORDER FUNCTIONS AND SETTINGS VALUES (NOMINAL VALUES)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Cut Off Alignment UG2

Vertical Slope V-Slo

Vertical Positio n V-Pos

Vertical Amplitud e V-Amp

Horizontal Position H-Ctr

Horizontal Parabola H-Par

Horizontal Bow H-Bow

Red Colour Cut R-Cut

Green Colour Cut G-Cut

Red Colour Drive R-Drv

Green Colour Drive G-Drv

Blue Colour Drive B-Drv

RF Automatic Gain Control AGC

Sub Colour S-Col

Sub Brightness S-Bri

East/West Width (Horizontal Amplitude) EW-WD

East/West Parabola EW-PR

East/West Upper Corner EW-UC

East/West Lower Corner EW-LC

East/West Trapezium EW-TP

+

TEST

033

005

045

039

030

021

037

031

063

048

038

035

011

040

017

039

044

042

034

Cut Off UG2 alignment: Adjust it on AV mode.

Set condition is in AV mode without signal.

Place the set into an Ageing Test for more than 15 minutes.

Adjust the unit to the following settings.

R-Cut=32, G-Cut=32, R-Drv=42, G-Drv=42, B-Drv=42.

Press the G2 button on the service remote.

Adjust the Screen Volum e on the FBT until the indicator on the set will be lit.

White Balance: Adjust this after performing CUT OFF UG2 alignment.

Place the set into an ageing test for approximately 15 minutes.

Generate a gray scale pattern from a Pattern Generator.

Set the colour balance to normal position.

Press the FACTORY button on the service remote.

Adjust accordingly using +/- button on the service remote to whiten the settings of

R-Cut, G-Cut, R-Drv and G-Drv at each section equally.B-Drv step number

however should be fixed at 42.

4

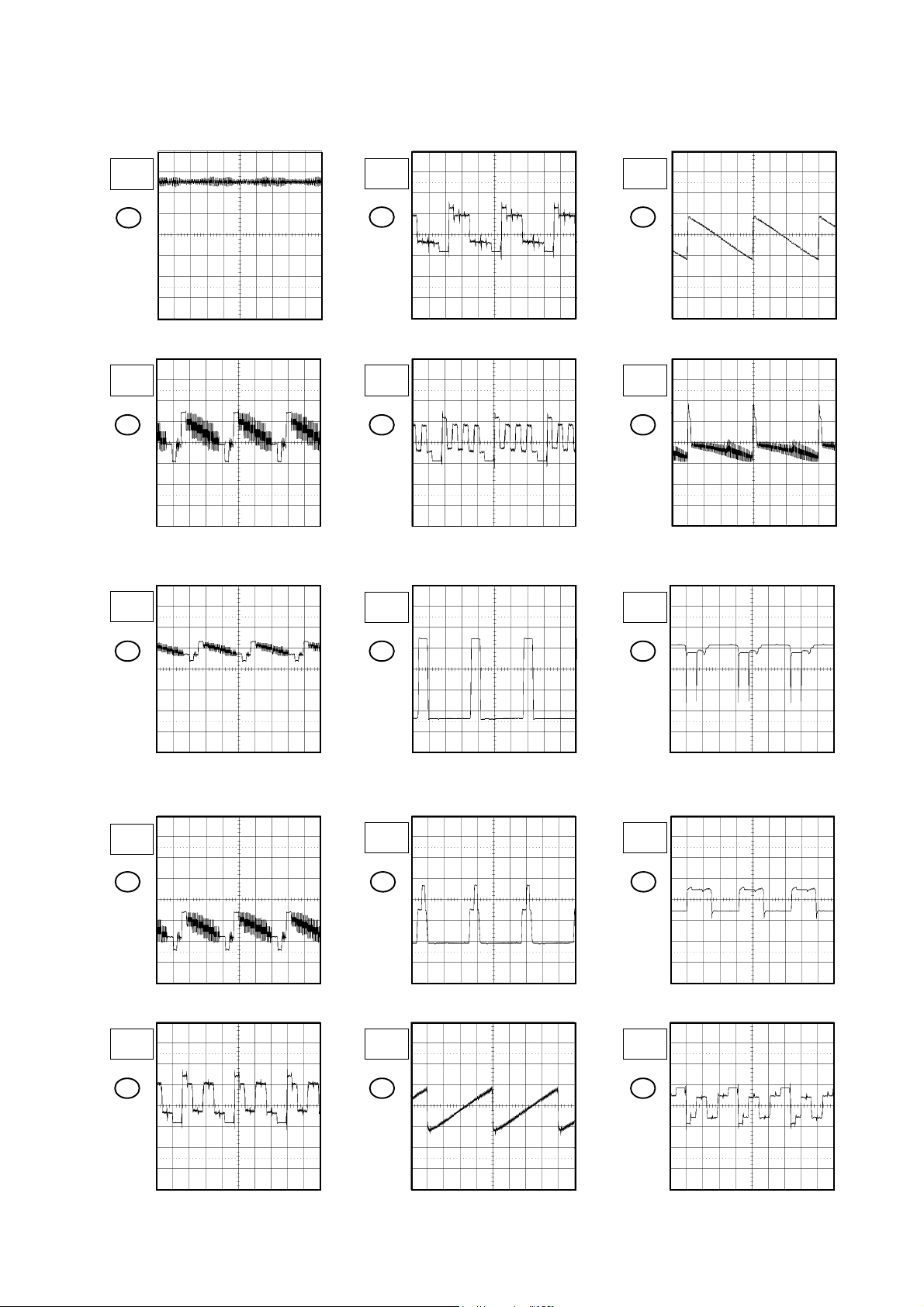

MICON/CHROMA

WAVEFORMS

20µs

1V

1

20µs

1V

2

20µs

1V

20µs

1V

5ms

0.5V

6 17

20µs

1V

7

20µs

2V

5ms

10V

18

20µs

5V

3

20µs

1V

4

20µs

1V

5

9

20µs

2V

10

DEFLECTION/CRT

5ms

0.5V

16

19

20µs

0.5V

20

20µs

50V

21

The following waveforms were measured at the point of the corresponding

NOTE:

balloon number in the schematic diagram.

H-1

20µs

50V

22

20µs

50V

23

WAVEFORMS

SOUND AMP/21PIN

1ms

200mV

24

1ms

0.5V

25

The following waveforms were measured at the point of the corresponding

NOTE:

balloon number in the schematic diagram.

H-2

Loading...

Loading...