Panasonic TH-L32X10M Service manual

Specifications

ORDER NO. MTV0901699CE

LCD TV

Model No. TH-L32X10M

Chassis: KM02

Destination: MIDDLE EAST

Power Source AC AUTO 110 - 240V, 50/60 Hz

Power Consumption

Average use 113 W

Standby condition 0.6 W

Display panel

Aspect Ratio 16:9

Visible screen size 80 cm (diagonal)

698 mm (W) × 392 mm (H)

(No. of pixels) 1,049,088 (1,366 (W) × 768 (H))

Sound

Speaker Full range × 2 pcs, 8 Ω

Audio Output 20 W (10 W + 10 W), 10% THD

Headphones M3 (3.5 mm) stereo mini Jack × 1

PC Signals VGA, SVGA, XGA

Receiving Systems / Band name 17 SYSTEMS FUNCTIONS

SXGA ...... (compressed)

Horizontal scanning frequency 31 - 69 kHz

Vertical scanning frequency 59 - 86 Hz

1 PAL B, G, H

2 PAL I

3 PAL D, K

4 SECAM B, G

5 SECAM D, K

6 SECAM K1

7 NTSC M (NTSC 3.58 / 4.5MHZ)

Reception of broadcast transmission and

playback from video cassette tape recorders.

© Panasonic Corporation 2009. Unauthorized

copying and distribution is a violation of law

TH-L32X10M

8 NTSC 4.43 / 5.5 MHz

9 NTSC 4.43 / 6.0 MHz

10 NTSC 4.43 / 6.5 MHz

11 NTSC 3.58 / 5.5 MHz

12 NTSC 3.58 / 6.0 MHz

13 NTSC 3.58 / 6.5 MHz

14 SECAM I

15 PAL 60 Hz / 5.5 MHz Playback from Special Disc Players and

16 PAL 60 Hz / 6.0 MHz

17 PAL 60 Hz / 6.5 MHz

Receiving Channels (Regular TV)

VHF BAND 2 - 12 (PAL / SECAM B, K1)

0 - 12 (PAL B AUST.)

1 - 9 (PAL B N.Z.)

1 - 12 (PAL / SECAM D)

1 - 12 (NTSC M JAPAN)

2 - 13 (NTSC M U.S.A.)

UHF BAND 21 - 69 (PAL G, H, I / SECAM G, K, K1)

28 - 69 (PAL B AUST.)

13 - 57 (PAL D, K)

13 - 62 (NTSC M JAPAN)

14 - 69 (NTSC M U.S.A.)

CATV S1 - S20 (OSCAR)

1 - 125 (U.S.A. CATV)

C13 - C49 (JAPAN)

S21 - S41 (HYPER)

Z1 - Z37 (CHINA)

5A, 9A (AUST.)

Aerial - Rear VHF / UHF

Operating Conditions Temperature : 0°C - 40°C

Humidity : 20 % - 80 % RH (non-condensing)

Connection Terminals

AV1 Input AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

VIDEO RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

COMPONENT Y 1.0 V[p-p] (including synchronization)

, PR/C

P

B/CB

R

AV2 Input AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

VIDEO RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

COMPONENT Y 1.0 V[p-p] (including synchronization)

, PR/C

P

B/CB

R

AV3 Input AUDIO L-R RCA PIN Type × 2 0.5 V [rms]

VIDEO RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

S-VIDEO Mini DIN 4-pin Y: 1.0 V[p-p] (75 Ω) C: 0.286 V[p-p] (75 Ω)

Others HDMI 1 / 2 Input TYPE A Connectors • This TV supports “HDAVI Control 4” function.

PC Input HIGH-DENSITY D-SUB 15 PIN R, G, B / 0.7 V[p-p] (75 Ω)

Card Slot SD Card slot × 1

Monitor

Output

AUDIO L-R RCA PIN Type × 2 0.5 V [rms] (High impedance)

VIDEO RCA PIN Type × 1 1.0 V [p-p] (75 Ω)

Dimension (W x H x D) 798 mm × 551 mm × 217 mm (With Pedestal)

798 mm × 511 mm × 93 mm (TV only)

Mass 13.5 kg Net (With Pedestal)

11.5 kg Net (TV only)

Design and specifications are subject to change without notice. Mass and dimensions shown are approximate.

Playback from special VCR’s or DVD.

Special VCR’s or DVD.

± 0.35 V [p-p]

± 0.35 V [p-p]

HD, VD / TTL LEVEL 2.0-5.0 V[rms] (high impedance)

2

TABLE OF CONTENTS

PAGE PAGE

1 Safety Precautions-----------------------------------------------5

1.1. General Guidelines---------------------------------------- 5

1.2. Touch-Current Check------------------------------------- 5

1.3. KM02 Chasis Block Diagram--------------------------- 6

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices------------------7

3 About Lead Free Solder (PbF) ------------------------------- 8

4 Power LED Blinking Timing----------------------------------- 9

5 Chassis Board----------------------------------------------------10

5.1. Chassis Installation --------------------------------------10

6 Location of Controls and Components ------------------11

6.1. Wire Dressing ---------------------------------------------11

7 Disassembly and Assembly Instructions---------------12

7.1. AC Cord Dressing----------------------------------------12

7.2. AC Cord Installation--------------------------------------13

7.3. VESA Metal Assembly ----------------------------------14

7.4. VESA (BC) Installation----------------------------------15

7.5. Pedestal Assembly------------------------------- --------16

7.6. LED Panel Installation & Fitting-----------------------18

7.7. Control Panel Assembly --------------------------------19

7.8. A-PB-MTG & Control Button Fixing------------------20

7.9. Side AV Bracket Assembly-----------------------------21

7.10. Speaker Installation--------------------------------------22

7.11. LCD Panel--------------------------------------------------23

7.12. LCD Mouting Fixing--------------------------------------24

7.13. LCD Panel Assembly Installation---------------------25

7.14. EMI Spec (LVDS)-----------------------------------------26

7.15. Back Cover Screw----------------------------------------27

7.16. Indication Sheet Sticking Position--------------------28

8 Service Mode Adjustment ------------------------------------29

8.1. Self Check Mode -----------------------------------------29

8.2. Hotel Mode Adjustment---------------------------------29

8.3. Hotel Mode-------------------------------------------------29

9 Measurements and Adjustments---------------------------30

9.1. Voltage Chart of A Board-------------------------------30

9.2. Voltage Chart of P Board-------------------------------30

9.3. Target of White Balance adjustment value---------30

10 Printed Circuit Board-------------------------------------------31

10.1. A-Board -----------------------------------------------------31

10.2. A-Board -----------------------------------------------------32

11 Schematic Diagram ---------------------------------------------33

11.1. Schematic Diagram Notes -----------------------------33

1 1 .2. A Board -----------------------------------------------------34

11.2.1. A Board - Sheet : 001 (1 / 1)----------------------34

11.2.2. A Board - Sheet : 002 (1 / 8)----------------------35

11.2.3. A Board - Sheet : 002 (2 / 8)----------------------36

11.2.4. A Board - Sheet : 002 (3 / 8)----------------------37

11.2.5. A Board - Sheet : 002 (4 / 8)----------------------38

11.2.6. A Board - Sheet : 002 (5 / 8)----------------------39

11.2.7. A Board - Sheet : 002 (6 / 8)----------------------40

11.2.8. A Board - Sheet : 002 (7 / 8)----------------------41

TH-L32X10M

11.2.9. A Board - Sheet : 002 (8 / 8) ---------------------42

11.2.10. A Board - Sheet : 003 (1 / 6) --------------------- 43

11.2.11. A Board - Sheet : 003 (2 / 6) --------------------- 44

11.2.12. A Board - Sheet : 003 (3 / 6) --------------------- 45

11.2.13. A Board - Sheet : 003 (4 / 6) --------------------- 46

11.2.14. A Board - Sheet : 003 (5 / 6) --------------------- 47

11.2.15. A Board - Sheet : 003 (6 / 6) --------------------- 48

11.2.16. A Board - Sheet : 004 (1 / 2) --------------------- 49

11.2.17. A Board - Sheet : 004 (2 / 2) --------------------- 50

11.2.18. A Board - Sheet : 005 (1 / 5) --------------------- 51

11.2.19. A Board - Sheet : 005 (2 / 5) --------------------- 52

11.2.20. A Board - Sheet : 005 (3 / 5) --------------------- 53

11.2.21. A Board - Sheet : 005 (4 / 5) --------------------- 54

11.2.22. A Board - Sheet : 005 (5 / 5) --------------------- 55

11.2.23. A Board - Sheet : 006 (1 / 4) --------------------- 56

11.2.24. A Board - Sheet : 006 (2 / 4) --------------------- 57

11.2.25. A Board - Sheet : 006 (3 / 4) --------------------- 58

11.2.26. A Board - Sheet : 006 (4 / 4) --------------------- 59

11.2.27. A Board - Sheet : 007 (1 / 9) --------------------- 60

11.2.28. A Board - Sheet : 007 (2 / 9) --------------------- 61

11.2.29. A Board - Sheet : 007 (3 / 9) --------------------- 62

11.2.30. A Board - Sheet : 007 (4 / 9) --------------------- 63

11.2.31. A Board - Sheet : 007 (5 / 9) --------------------- 64

11.2.32. A Board - Sheet : 007 (6 / 9) --------------------- 65

11.2.33. A Board - Sheet : 007 (7 / 9) --------------------- 66

11.2.34. A Board - Sheet : 007 (8 / 9) --------------------- 67

11.2.35. A Board - Sheet : 007 (9 / 9) --------------------- 68

11.2.36. A Board - Sheet : 008 (1 / 4) --------------------- 69

11.2.37. A Board - Sheet : 008 (2 / 4) --------------------- 70

11.2.38. A Board - Sheet : 008 (3 / 4) --------------------- 71

11.2.39. A Board - Sheet : 008 (4 / 4) --------------------- 72

11.2.40. A Board - Sheet : 009 (1 / 2) --------------------- 73

11.2.41. A Board - Sheet : 009 (2 / 2) --------------------- 74

11.2.42. A Board - Sheet : 010 (1 / 5) --------------------- 75

11.2.43. A Board - Sheet : 010 (2 / 5) --------------------- 76

11.2.44. A Board - Sheet : 010 (3 / 5) --------------------- 77

11.2.45. A Board - Sheet : 010 (4 / 5) --------------------- 78

11.2.46. A Board - Sheet : 010 (5 / 5) --------------------- 79

11.2.47. A Board - Sheet : 011 (1 / 2)----------------------80

11.2.48. A Board - Sheet : 011 (2 / 2)----------------------81

11.2.49. A Board - Sheet : 012 (1 / 3) --------------------- 82

11.2.50. A Board - Sheet : 012 (2 / 3) --------------------- 83

11.2.51. A Board - Sheet : 012 (3 / 3) --------------------- 84

11.2.52. A Board - Sheet : 013 (1 / 5) --------------------- 85

11.2.53. A Board - Sheet : 013 (2 / 5) --------------------- 86

11.2.54. A Board - Sheet : 013 (3 / 5) --------------------- 87

11.2.55. A Board - Sheet : 013 (4 / 5) --------------------- 88

11.2.56. A Board - Sheet : 013 (5 / 5) --------------------- 89

11.2.57. A Board - Sheet : 014 (1 / 4) --------------------- 90

11.2.58. A Board - Sheet : 014 (2 / 4) --------------------- 91

11.2.59. A Board - Sheet : 014 (3 / 4) --------------------- 92

3

TH-L32X10M

11.2.60. A Board - Sheet : 014 (4 / 4)----------------------93

11.2.61. A Board - Sheet : 015 (1 / 7)----------------------94

11.2.62. A Board - Sheet : 015 (2 / 7)----------------------95

11.2.63. A Board - Sheet : 015 (3 / 7)----------------------96

11.2.64. A Board - Sheet : 015 (4 / 7)----------------------97

11.2.65. A Board - Sheet : 015 (5 / 7)----------------------98

11.2.66. A Board - Sheet : 015 (6 / 7)----------------------99

11.2.67. A Board - Sheet : 015 (7 / 7)-------------------- 100

11.2.68. A Board - Sheet : 016 (1 / 1)-------------------- 101

11.3. K Board--------------------------------------------------- 102

11.3.1. K Board (1 / 2)-------------------------------------- 102

11.3.2. K Board (2 / 2)-------------------------------------- 103

11.4. P Board--------------------------------------------------- 104

11.4.1. P Board (1 / 7)-------------------------------------- 104

11.4.2. P Board (2 / 7)-------------------------------------- 105

11.4.3. P Board (3 / 7)-------------------------------------- 106

11.4.4. P Board (4 / 7)-------------------------------------- 107

11.4.5. P Board (5 / 7)-------------------------------------- 108

11.4.6. P Board (6 / 7)-------------------------------------- 109

11.4.7. P Board (7 / 7)---------------------------------------110

11.5. V Board----------------------------------------------------111

11.5.1. V Board (1 / 4)---------------------------------------111

11.5.2. V Board (2 / 4)---------------------------------------112

11.5.3. V Board (3 / 4)---------------------------------------113

11.5.4. V Board (4 / 4)---------------------------------------114

12 Exploded View and Replacement Parts List --------- 115

12.1. Exploded View and Mechanical Replacement

Parts List --------------------------------------------------115

12.2. Electrical Replacement Parts List-------------------115

12.2.1. Replacement Parts List Notes ------------------115

12.2.2. Electrical Replacement Parts List--------------116

4

TH-L32X10M

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a sh ort circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barri ers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

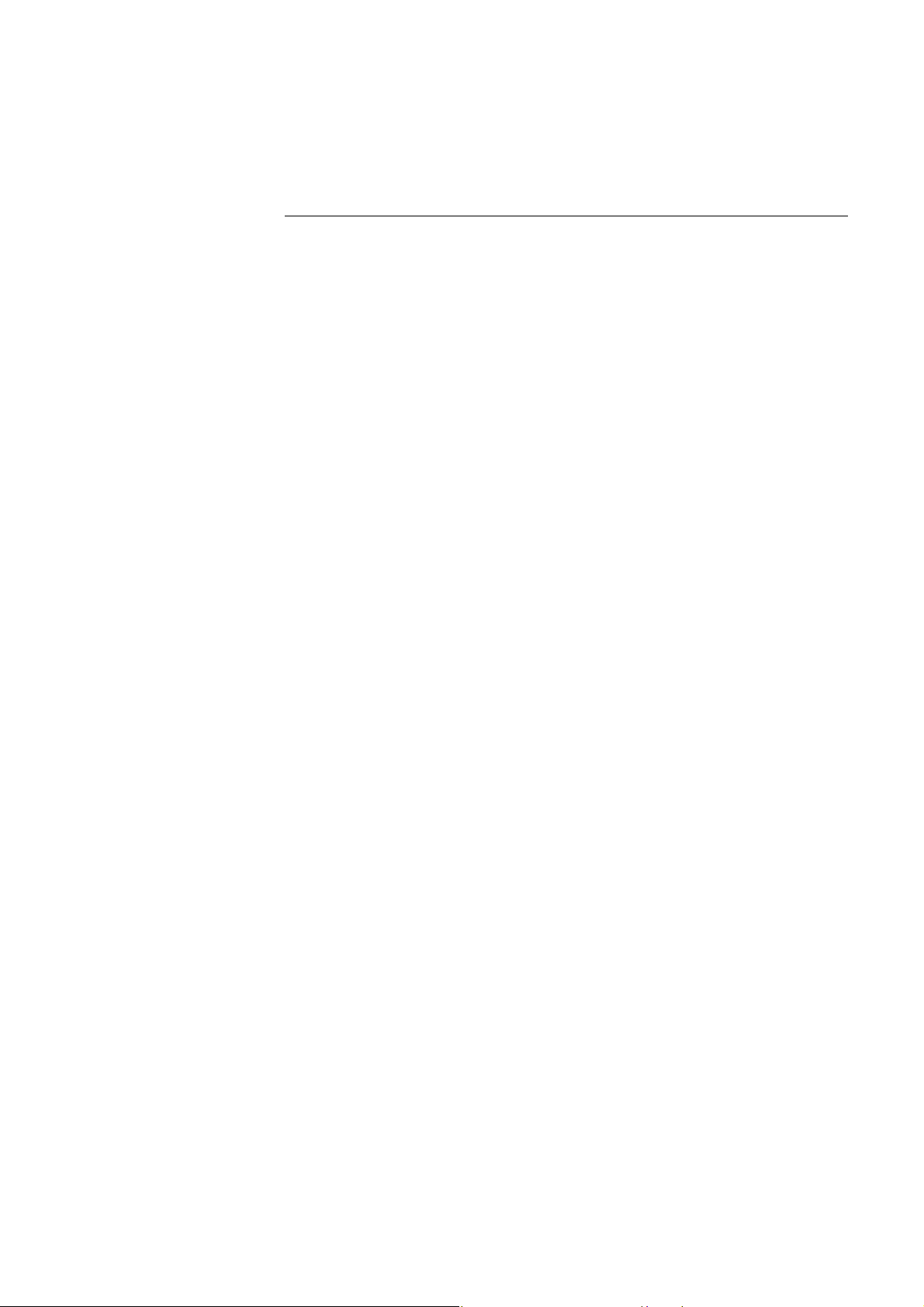

1.2. Touch-Current Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a measuring network for touch currents between each expo sed metallic part on the set and a good earth ground

such as a water pipe as shown in Figure 1.

3. Use the Leakage Current Tester (Simps on 228 or equivalent) to measure the potential across the measuring network.

4. Check each exposed metallic part and measure the voltage at each point.

5. The potential at any point (touch current) expressed as voltage U

For AC: U1 = 35 V (peak) and U2 = 0.35 V (peak);

For DC: U

NOTE :

The limit value of U

DC.

The limit value U

= 1.0 V,

1

= 0.35 V (peak) for AC and U1 = 1.0 V for DC correspond to the values 0.7 mA (peak) AC and 2.0 mA

2

= 35 V (peak) for AC correspond to the value 70 mA (peak) AC for frequencies greater than 100 kHz.

1

and U2, do not exceed the following values:

1

6. Should a measurement be out of the li mits specified, there is a possibility of a shock hazard , and the equipment should be

repaired and rechecked before it is returned to the customer.

5

TH-L32X10M

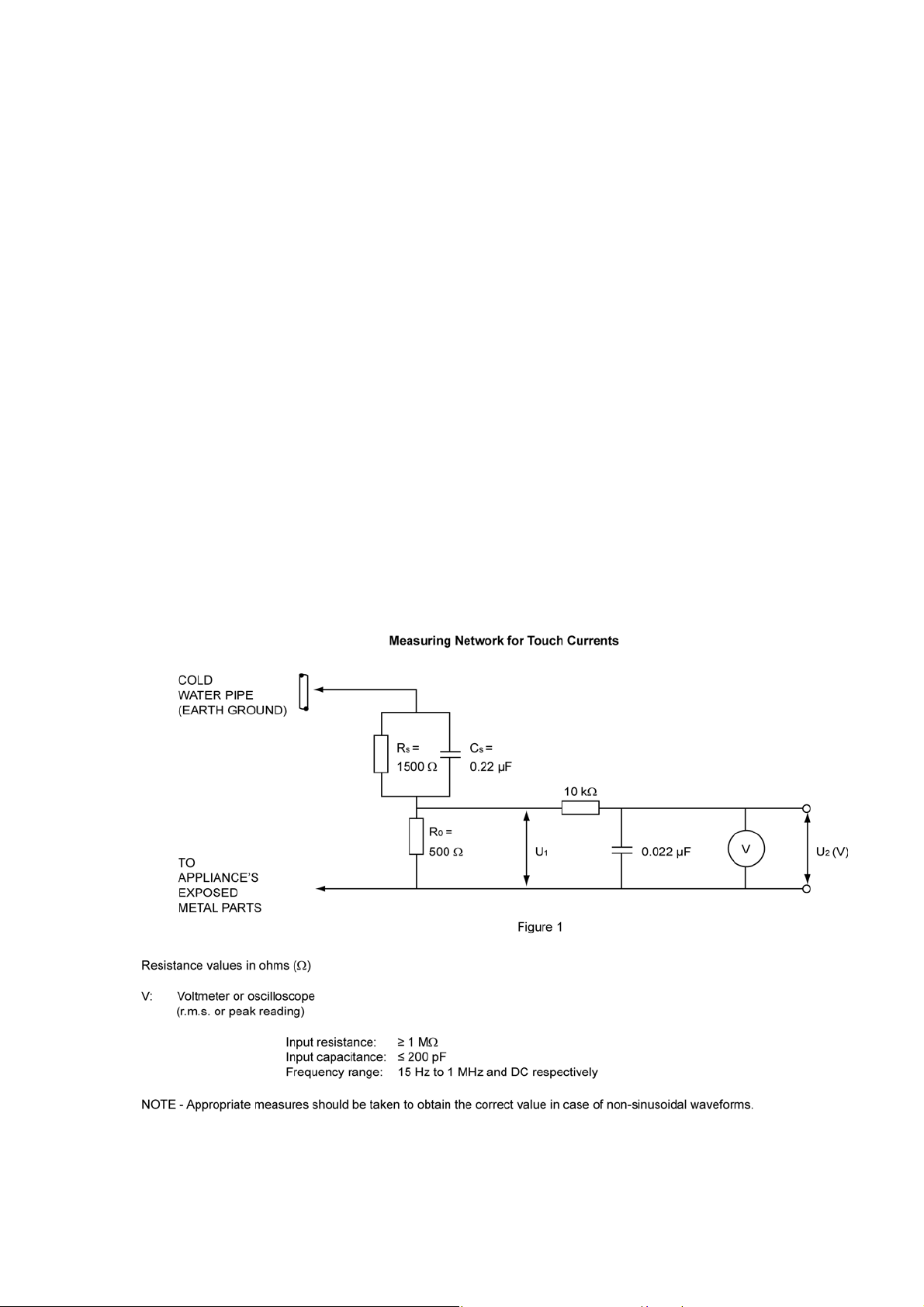

BT → Divide

A

LCD PANEL

IPK

Point Dip

Inspection

<Visual check>

*Voltage check

* LED Check Inverter (Blue LED)

<FACT-TEST>

*ANALOG TUNE

*VCXO ADJ

*LOCAL OSD

*AV_SW CHECK

*AV1/AV2/AV3---CVBS

*AV3---S(YC)

*MONITOR-OUT

*AV1/AV2---Component

*PC

*HDMI1

*HDMI2

*CEC_(HDMI1/HDMI2)

*Backlight

*SD Card

*Software & EEPROM version

check by self check (1 set only)

IP-PCB: 32” IPS ONLY

(Inverter & Power)

TNP4G455

P-PCB: 37” ONLY

(Power)

TNP4G454

BT → Divide

In coming check

Writing

Assembly

A-PCB

TNP4G460

(Degital main)

V-PCB

(LED)

TNPA4834

PEAKS NOR Flash

(Writing IC)

256Mbit

IC8554

Sum : only effective area

Add : 0 ~ 1FFFFFF

EEPROM Writing (On board)

*GENX

• EEPROM (8k) x 1

IC1101

*PEAKS

• EEPROM (16k) x 1

IC8601

<Write Protect command>

*GENX : Protect OFF = 70,88,00

Protect ON = 70,88,ff

*PEAKS : Protect OFF = 70,8B,00

Protect ON = 70,8B,ff

K-PCB

(Control)

TNPA4901

BT Inspection

FOR TNP4G455 ONLY

*Adjust the frequency to 56 ± 1kHz by using VR7851

*Check to the output : J102 or TP7871

*Check to the Over Voltage protection

*Check to the Arc protection

Inspection

LED CAT EYES,REMOCON RECEIVER

1.3. KM02 Chasis Block Diagram

6

TH-L32X10M

2 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easi ly by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and s ome fieldeffect transistors and semiconductor “chip” components. The following techniques should be used to help reduce the

incidence of component damage caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminium foil to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate el ectrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediate ly before you a re ready to install it (most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminium foil or

comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices (otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can gen erate static electricity (ESD)

sufficient to damage an ES device).

7

TH-L32X10M

3 About Lead Free Solder (PbF)

Note: Lead is listed as (Pb) in the periodic table o f elements.

In the information below, Pb will refer to Lead Solder and PbF will refer to Lead Free Solder.

The Lead Free Solder (PbF) used in our manufacturing proce ss and discussed below is (Sn+Ag+Cu).

Those are Tin (Sn), Silver (Ag) and Copper (Cu), although other types are available.

This model uses PbF in its manufacture due to environmental conservation issues. For service and repair work, we would suggest

the use of PbF as well, although Pb may be used.

PCBs manufactured using lead-free will have the “PbF within a leaf Symbol” stamped on their back.

Caution

• PbF has a higher melting point than that of standard solder. Typi cally the melting point is 50 ~ 70°F (30~40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20°F (370 ± 10°C).

• PbF will tend to splash when heated too high (about 1100°F or 600°C).

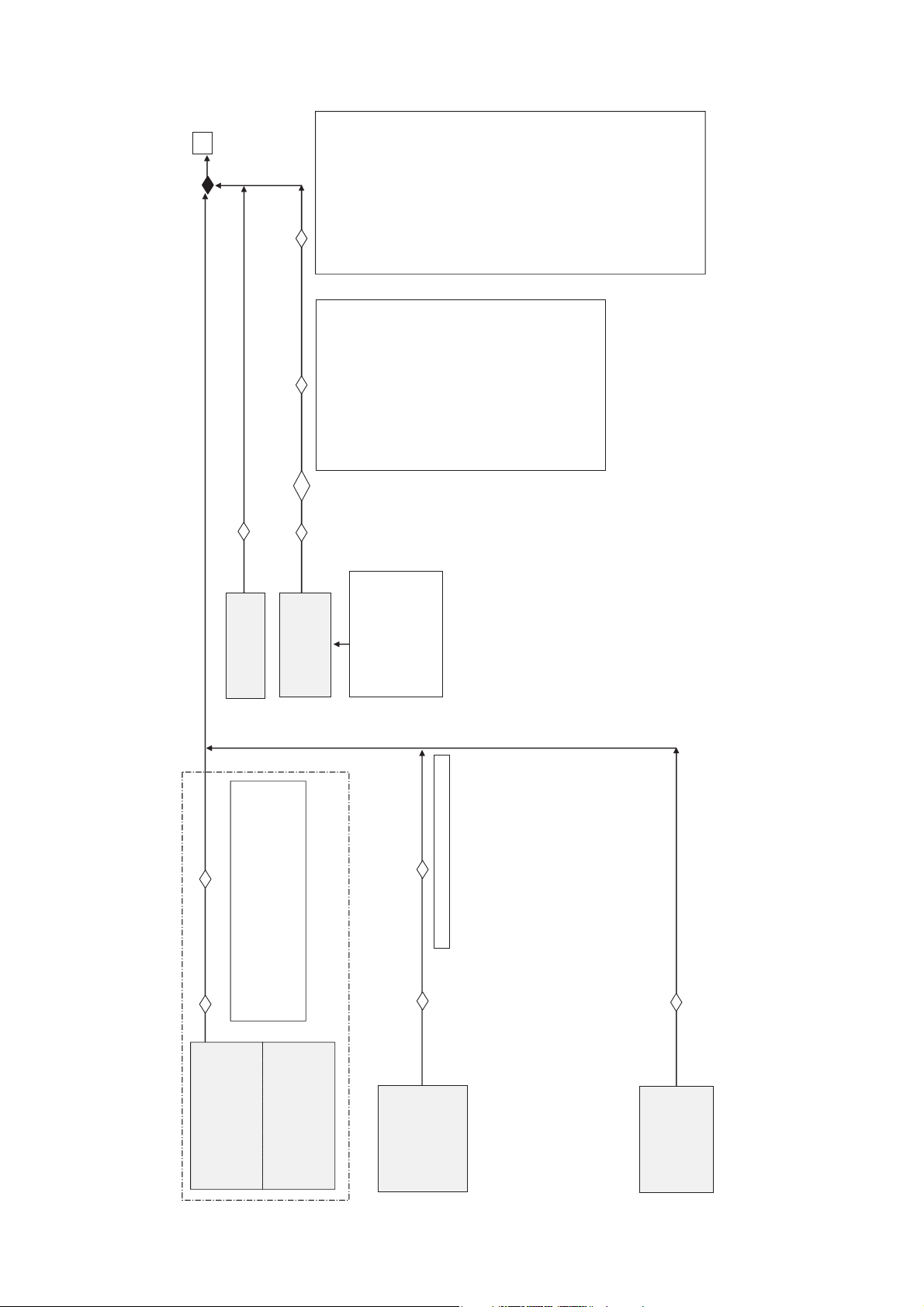

If you must use Pb solder, please completely remove all of the PbF on the pins or solder area before applying Pb. If this is no t

practical, be sure to heat the PbF until it melts, before applying Pb.

• After applying PbF to double layered boards, please check the component side for excess solder which may flow onto the

opposite side (see Figure 2).

Figure 2

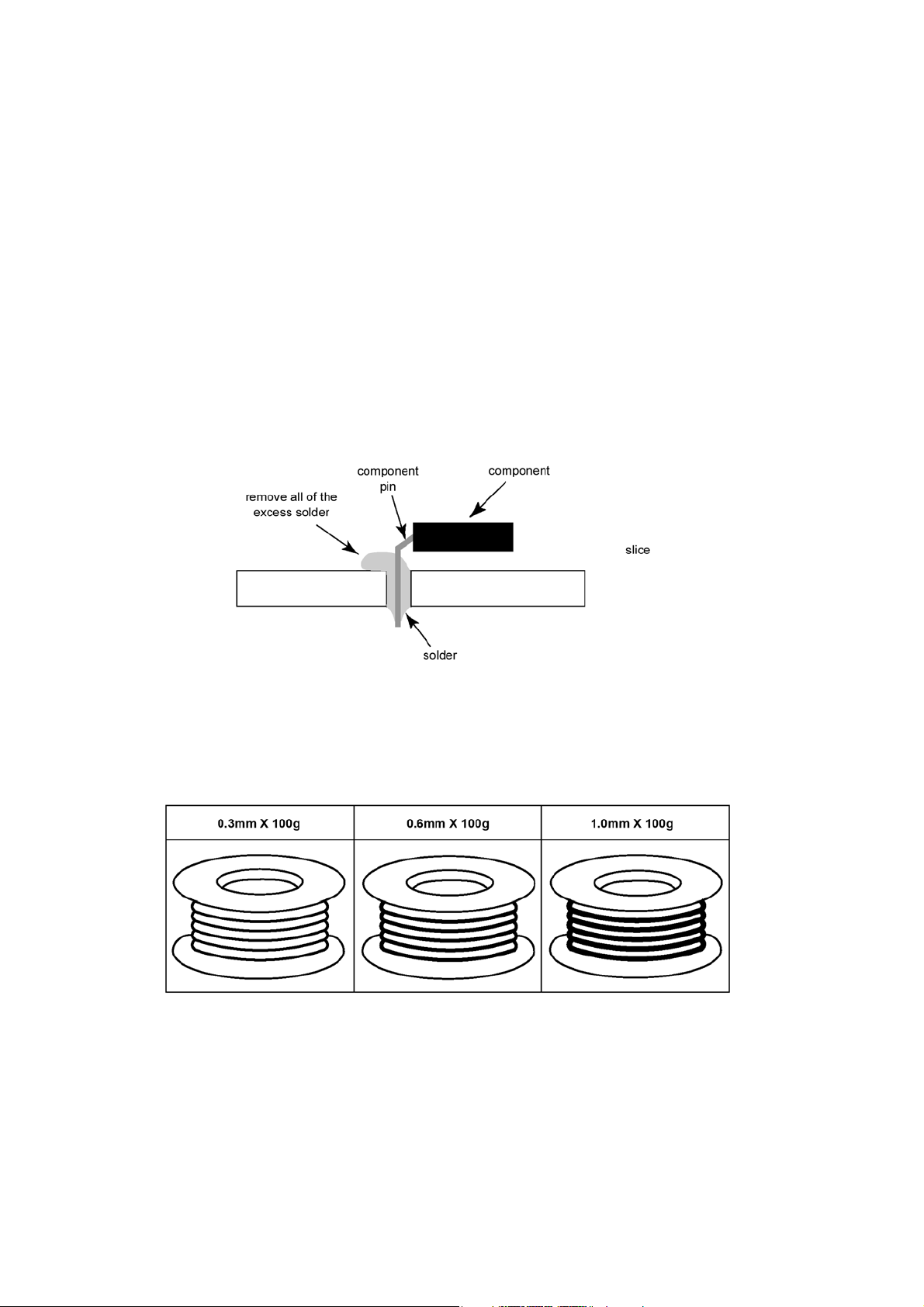

Suggested PbF

There are several kinds of PbF available for purchase. This product uses Sn+Ag+C u (tin, silver, copper) solder. However, Sn+Cu

(tin, copper) and Sn+Zn+Bi (tin, zinc, bismuth) solders can also be used.

Figure 3

8

TH-L32X10M

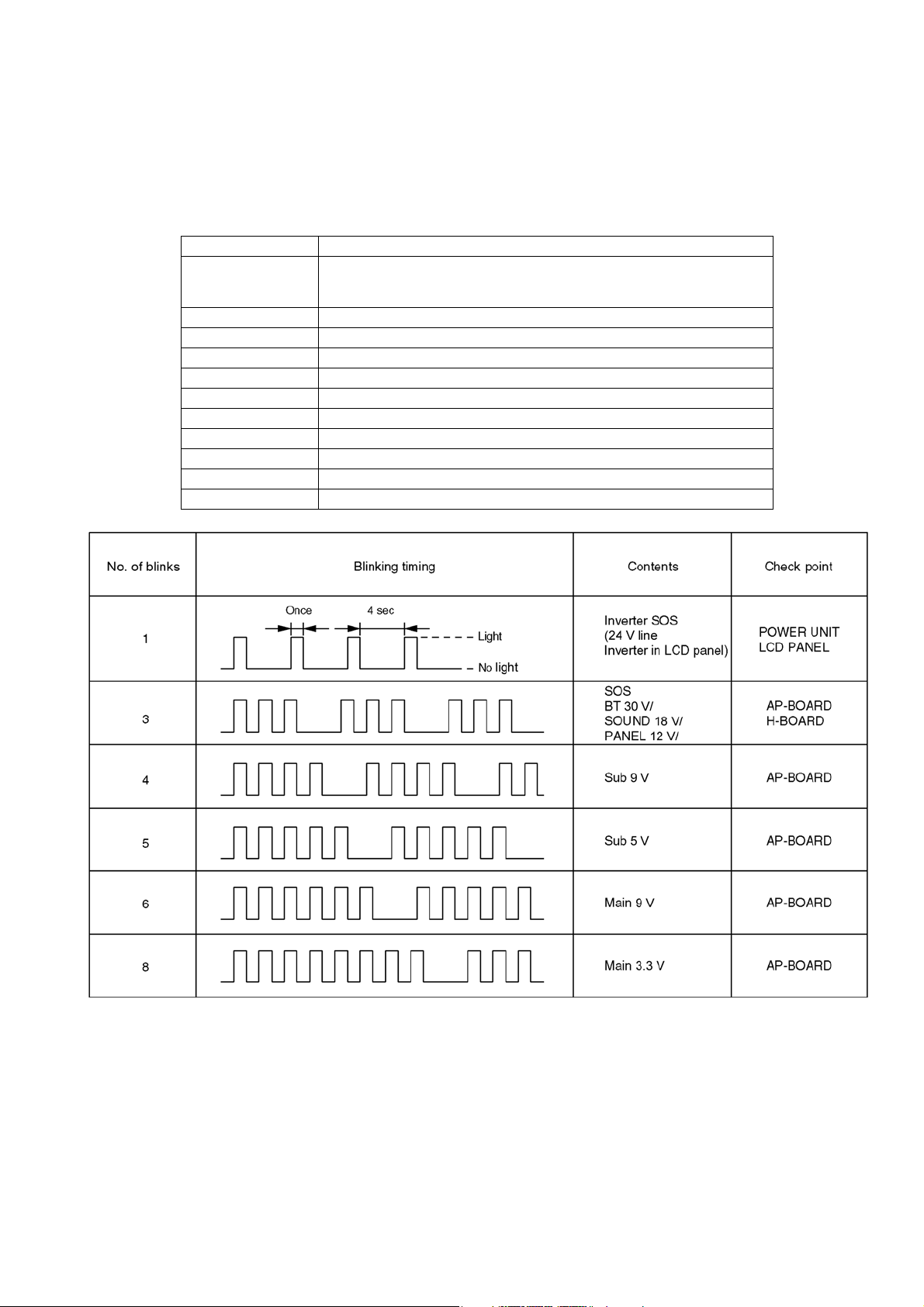

4 Power LED Blinking Timing

1. Subject

Information of LED Flashing timing.

2. Contents

When an abonormality has occurred in the unit, the protection circuit operates and resets to standby mode. At this time, the

defective block can be identified by the number of blinking of the Power LED on the front panel of the unit as follow:

Blinking times Contents

1 Lamp short circuit protection

2 Cooling fan SOS = incomplete connection - no function mode.

3 P board 30V / 18V / 9V decreased / short circuit detection.

4 DTV12V decreased / short circuit , main convertor stop detection.

5 Sub 5V decreased / short circuit detection.

6 Sub 5V decreased / short circuit detection. (same as 5 times LED blinking)

7 Sub 3.3V decreased / short circuit detection.

8 Sub 5V decreased / short circuit detection. (same as 5 times LED blinking)

9 Audio amp SOS.

10 HQ1 incomplete connection, no function mode.

13 When peaks communication error SOS.

Lamp open protection

Arc protection

9

TH-L32X10M

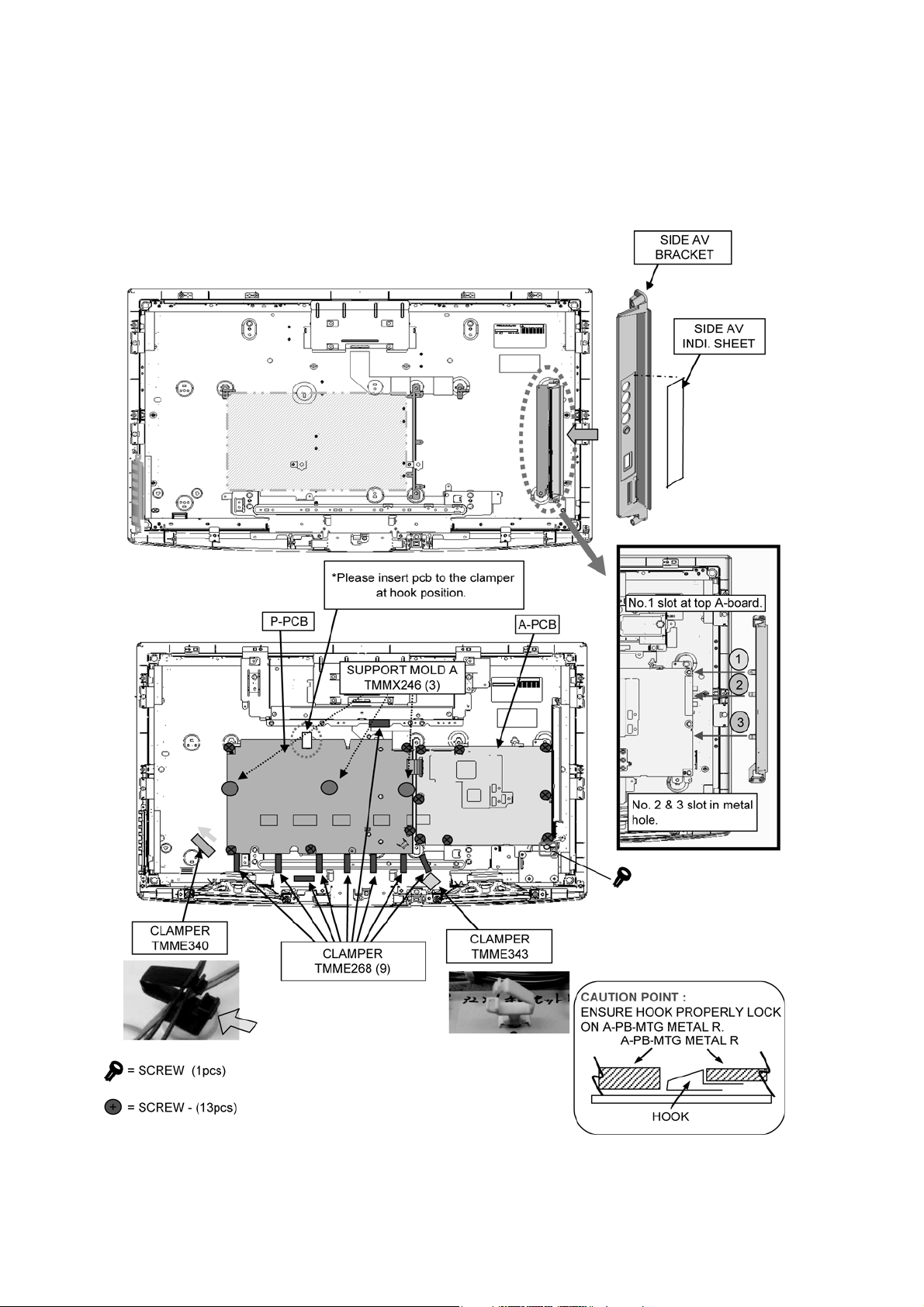

5 Chassis Board

5.1. Chassis Installation

1. Stick FELT to SIDE AV BRACKET.

- Stick the SIDE AV INDI. SHEET on the SIDE AV BRACKET.

- Insert the SIDE AV BRACKET from the side position of the A-PCB.

10

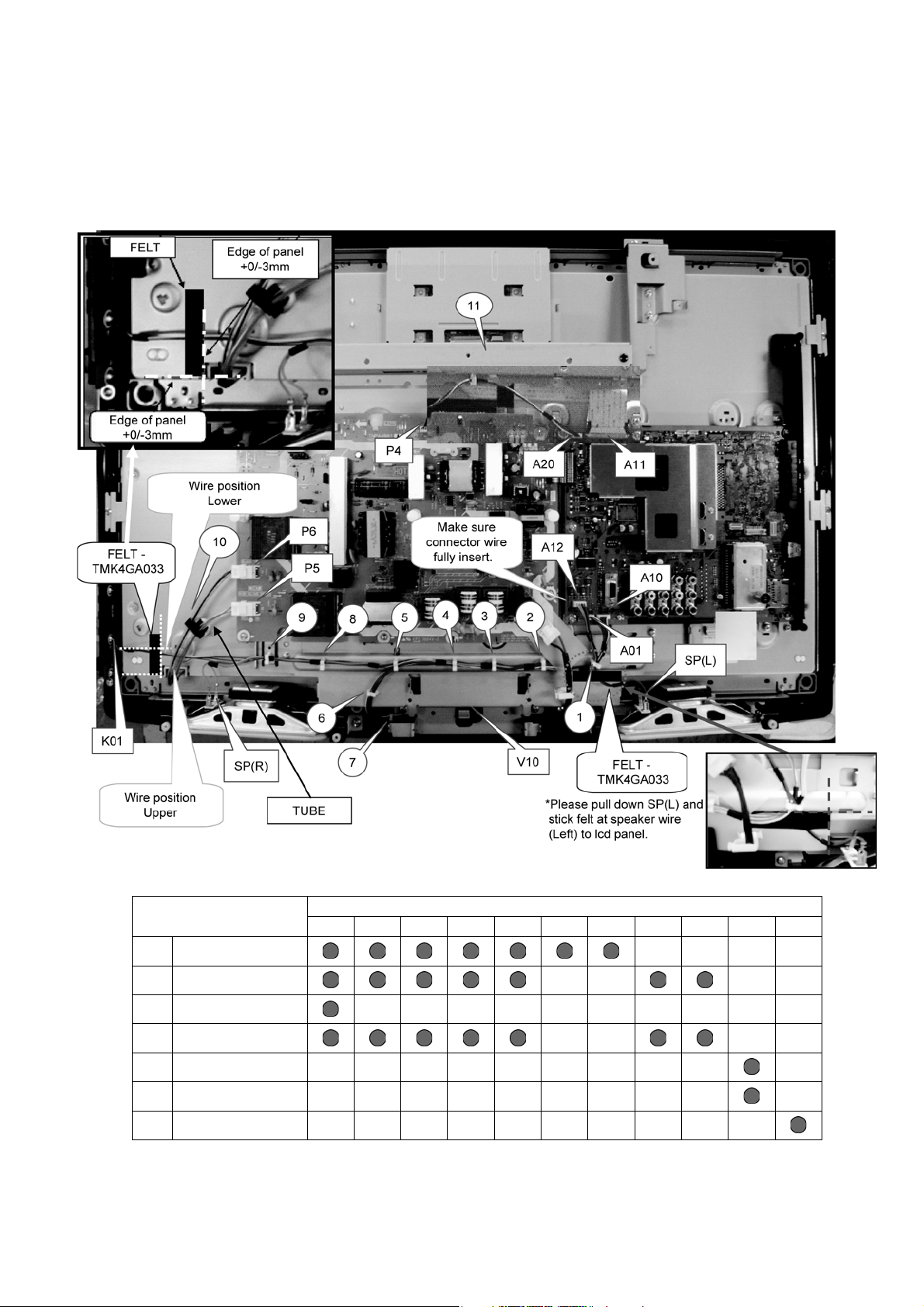

6 Location of Controls and Components

6.1. Wire Dressing

1. Wiring No. 1 ~ No.7

2. Remove dust of terminal of LVDS and PB connector. (by ion blow) Pos. A11

3. Insert LVDS into A11.

TH-L32X10M

Wire

No.1 A10 ~ V10

No.2 A01 ~ K01

No.3 A12 ~ SP(L)

No.4 A12 ~ SP(R)

No.5 ~ P5

No.6 ~ P6

No.7 A20 ~ P4

Clamper

1234567891011

11

TH-L32X10M

7 Disassembly and Assembly Instructions

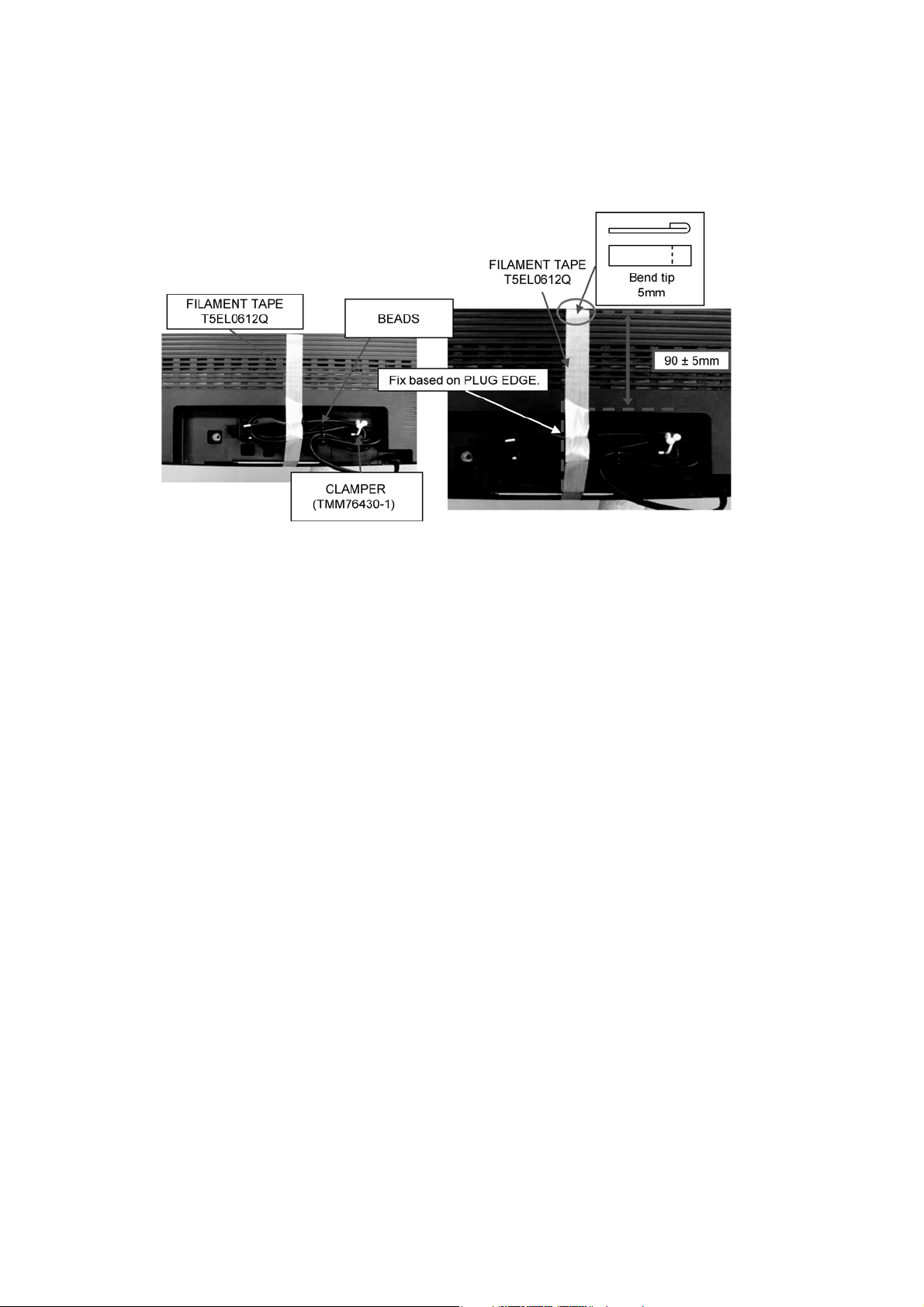

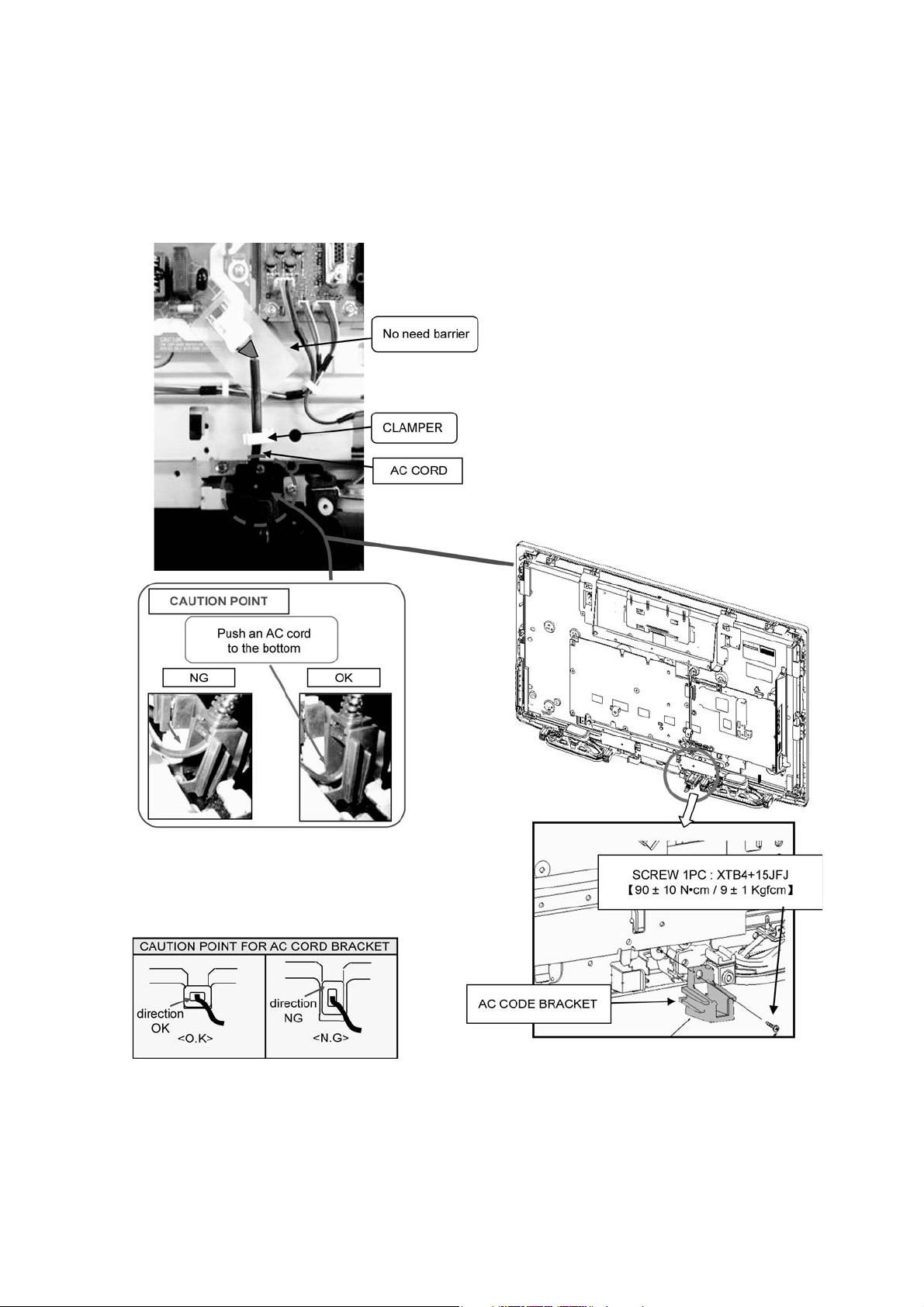

7.1. AC Cord Dressing

1. Clamp plug with clamper.

2. Insert beads 3pcs. And slide down to lower hole.

12

7.2. AC Cord Installation

1. Put on the AC CORD BRACKET on the CABINET.

2. Fix the AC CORD BRACKET with SCREW.

3. AC CORD BARRIER setting.

4. Insert AC CORD connector into P-PCB connector.

5. Clamp the AC CORD.

6. Insert AC CORD bushing into the AC CORD BRACKET.

TH-L32X10M

13

TH-L32X10M

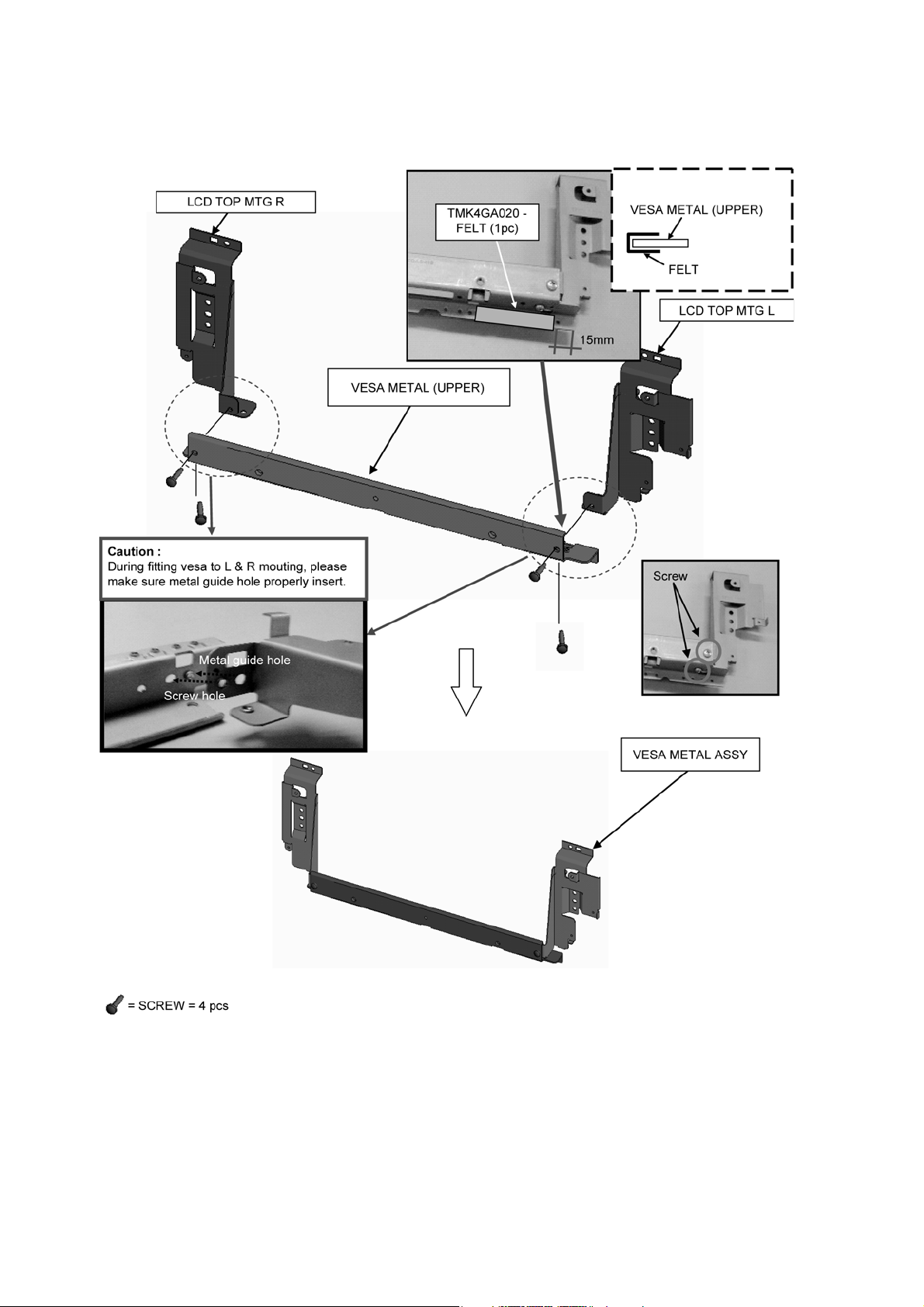

7.3. VESA Metal Assembly

1. Assemble LCD TOP MTG(L,R) , VESA METAL(upper) and fix them with screw. Please use jig for vesa metal assembly

preparation.

14

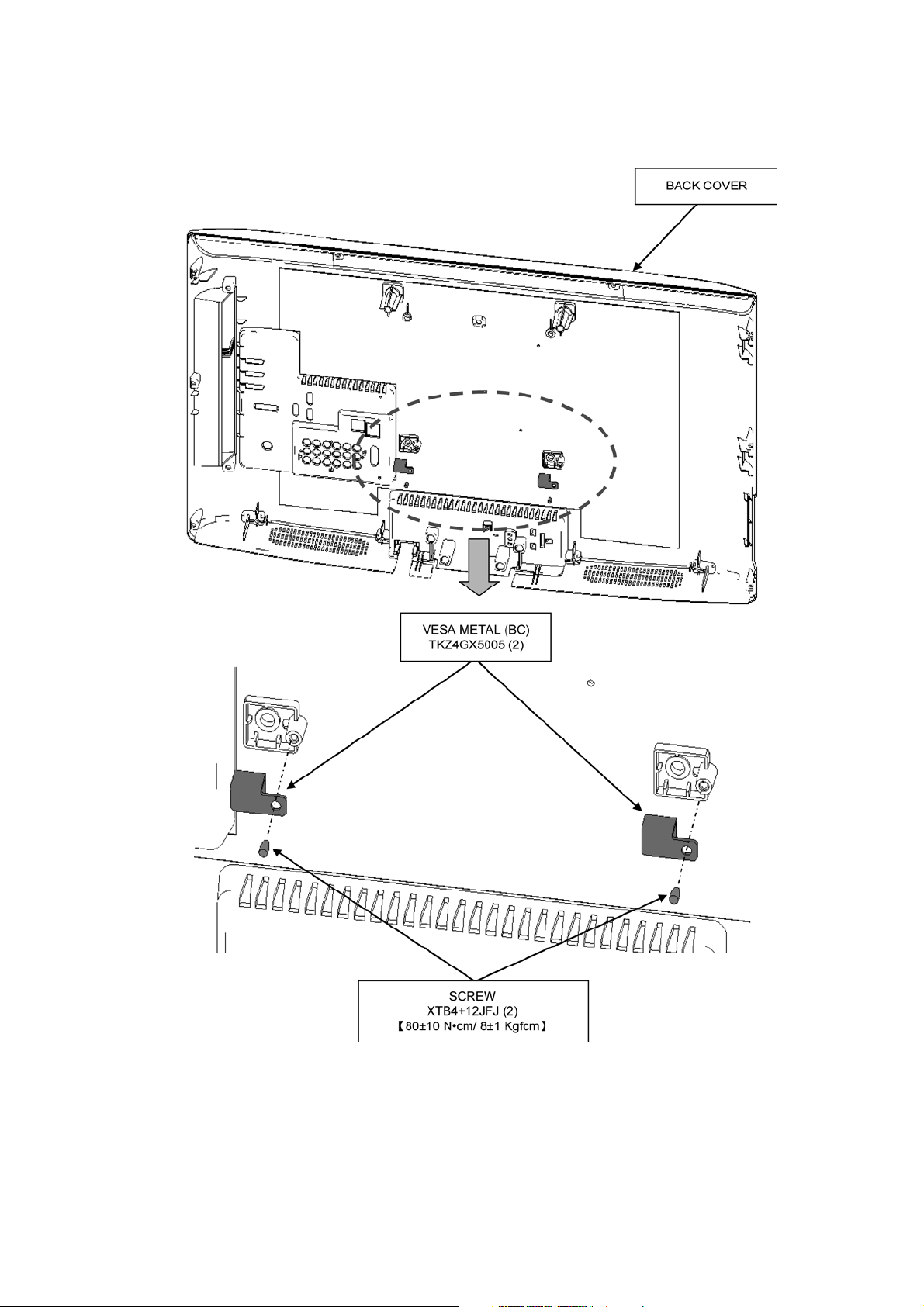

7.4. VESA (BC) Installation

1. Put VESA METAL(BC) on the BACK COVER.

2. Fix them with SCREWS.

TH-L32X10M

15

TH-L32X10M

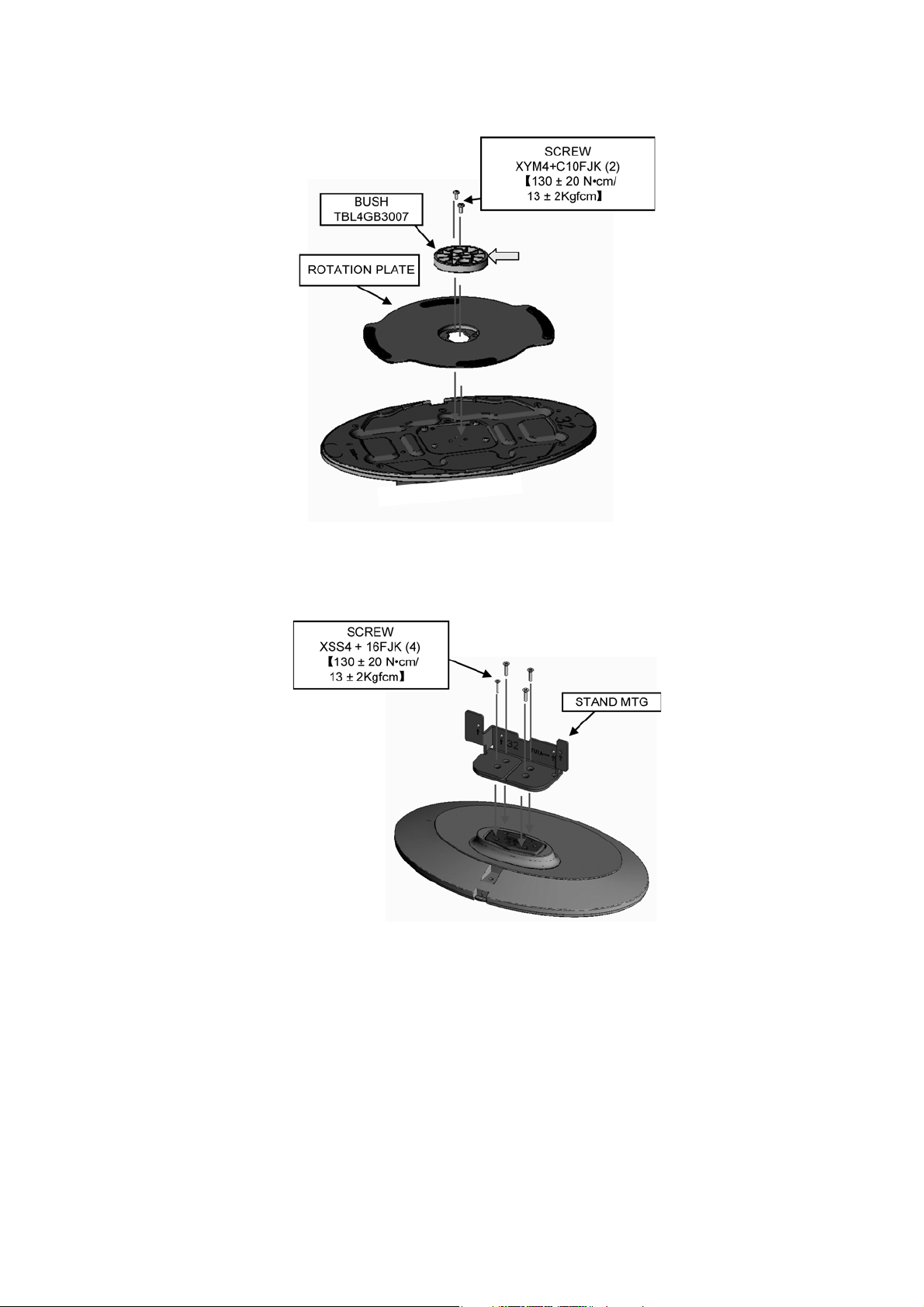

7.5. Pedestal Assembly

Step 1

Setting PEDESTAL COVER and STAND MTG SPACER and BASE PLATE with SCREWS.

Step 2

1. Stick the RUBBER FOOT at bottom ROTATION PLATE.

2. Make sure ROTATION PLATE surfacefully cover by grease. Follow the picture

16

Step 3

Setting ROTATION PLATE and BUSH with SCREWS.

TH-L32X10M

Step 4

Setting STAND MTG with SCREWS.

17

TH-L32X10M

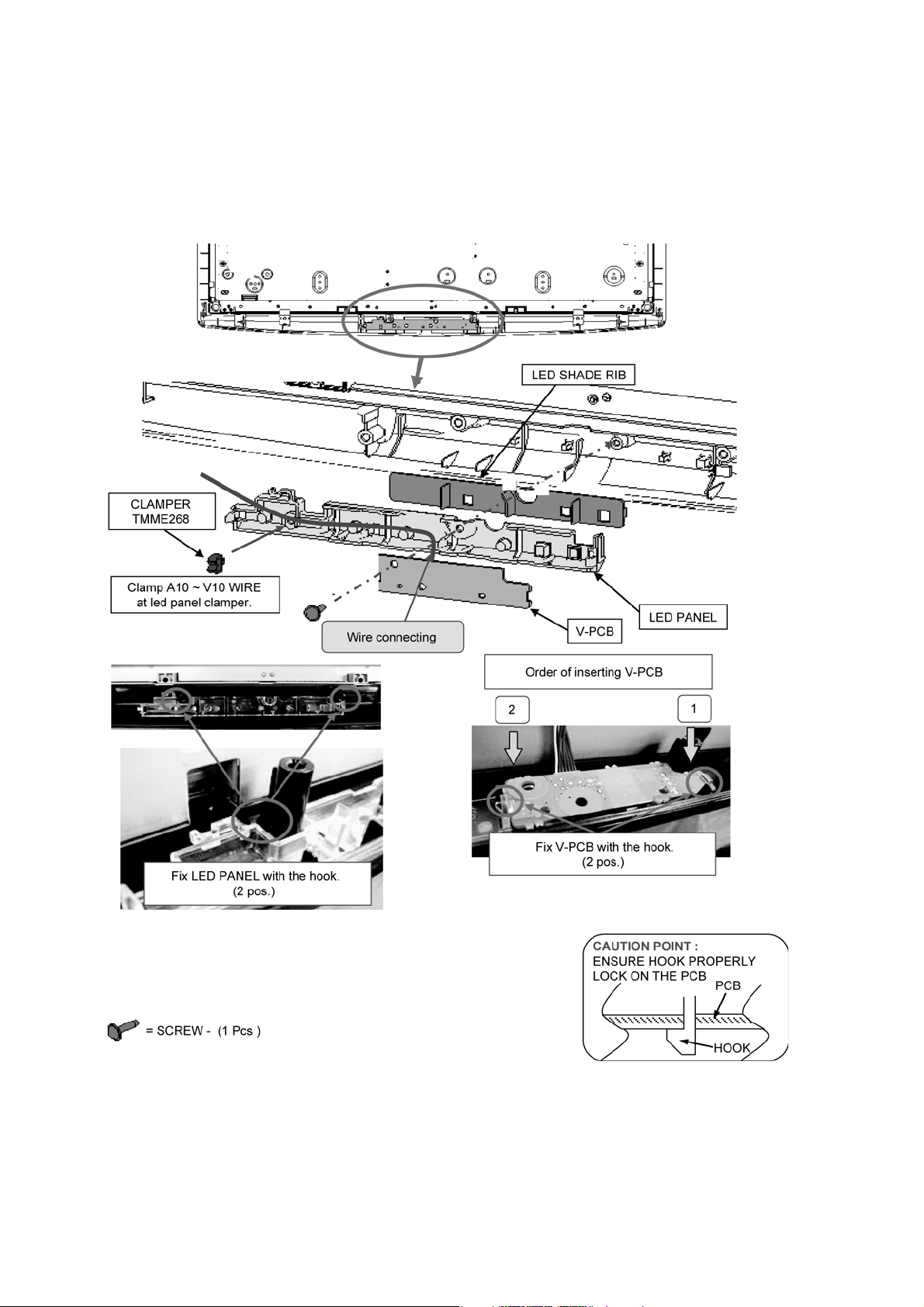

7.6. LED Panel Installation & Fitting

1. Put LED SHADE RIB on CABINET.

2. Fix LED PAN E L on CABINET.

3. Wire connecting. (V10)

4. Put V-PCB on CABINET.

5. Fix them with SCREW.

6. Insert the CLAMPER.

18

7.7. Control Panel Assembly

1. Wire connecting. (K1)

2. Assemble POWER BUTTON to the K-PRINT.

3. Assemble K-PRINT, CONTROL BUTTON, CONTROL PANEL BRACKET.

4. Fix them with SCREWS.

5. Stick the FELT.

TH-L32X10M

19

TH-L32X10M

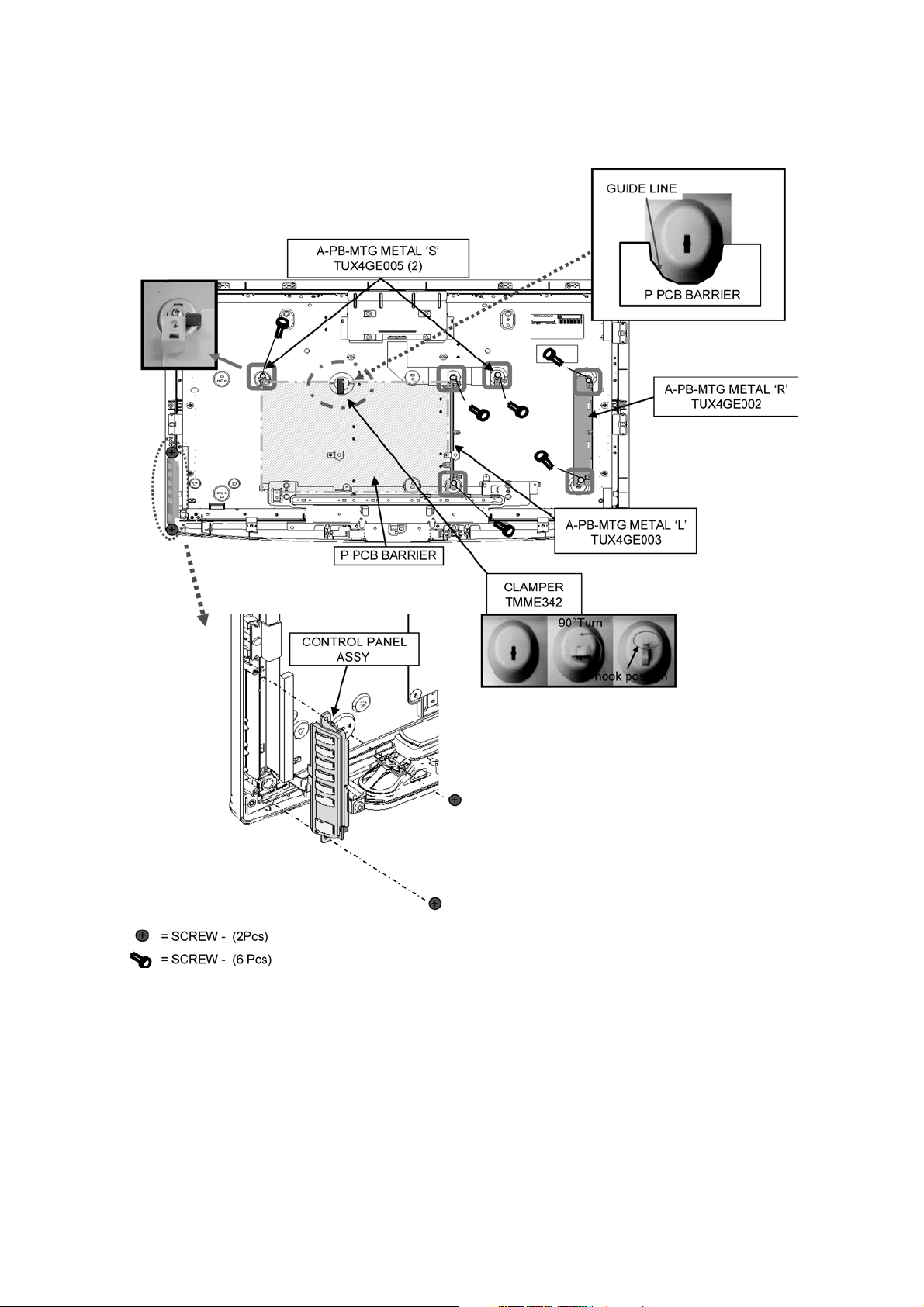

7.8. A-PB-MTG & Control Button Fixing

1. Stick P-PCB BARRIER and put all METAL part follow to the picture.Fix all metal part with screw.

2. Put CONTROL PANEL ASSY on the CABINET. Fix the CONTROL PANEL with SCREWS.

20

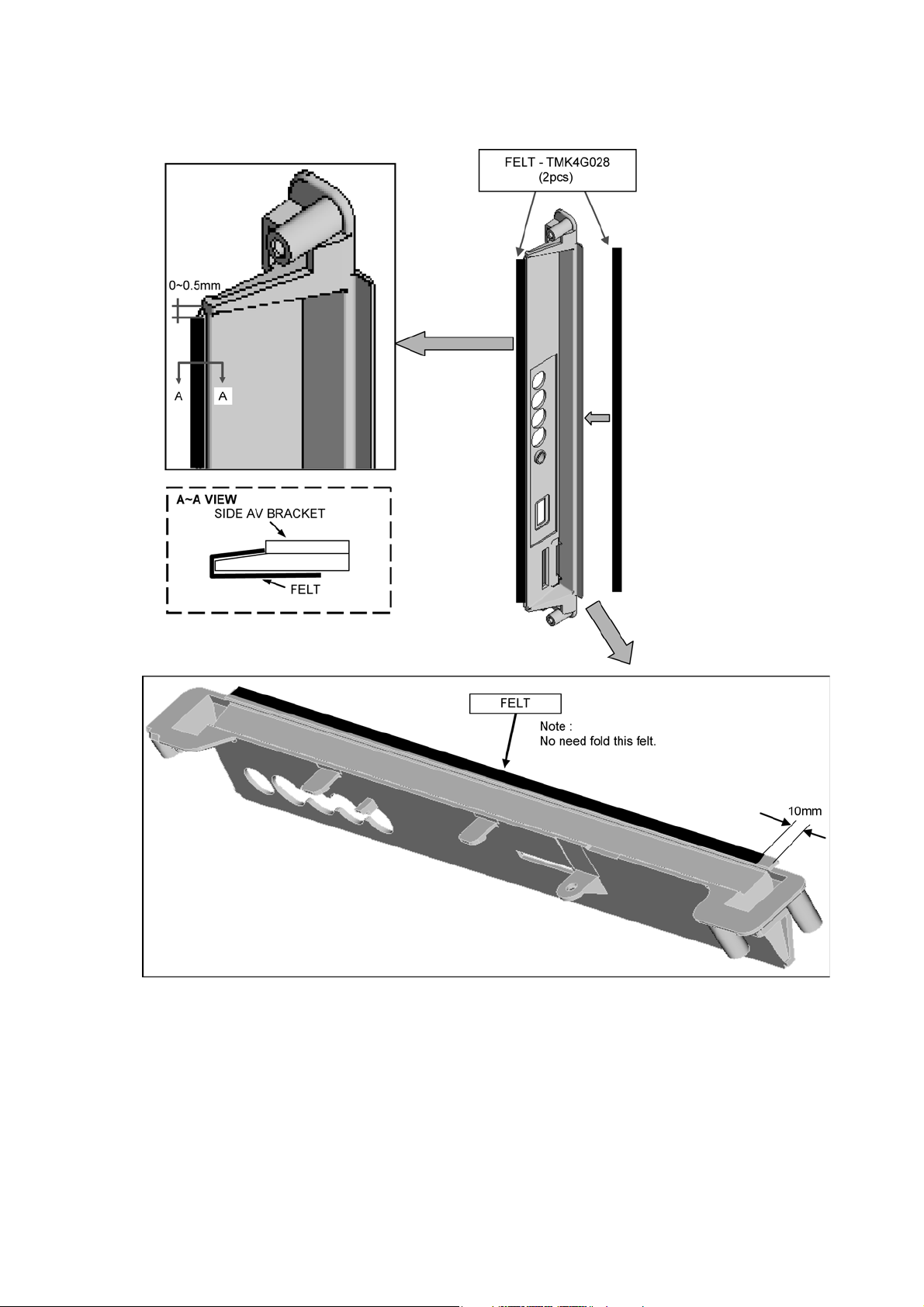

7.9. Side AV Bracket Assembly

• STICK FELT TMK4G028 (7 X 240 X 0.55t) - 2 PCS.

TH-L32X10M

21

TH-L32X10M

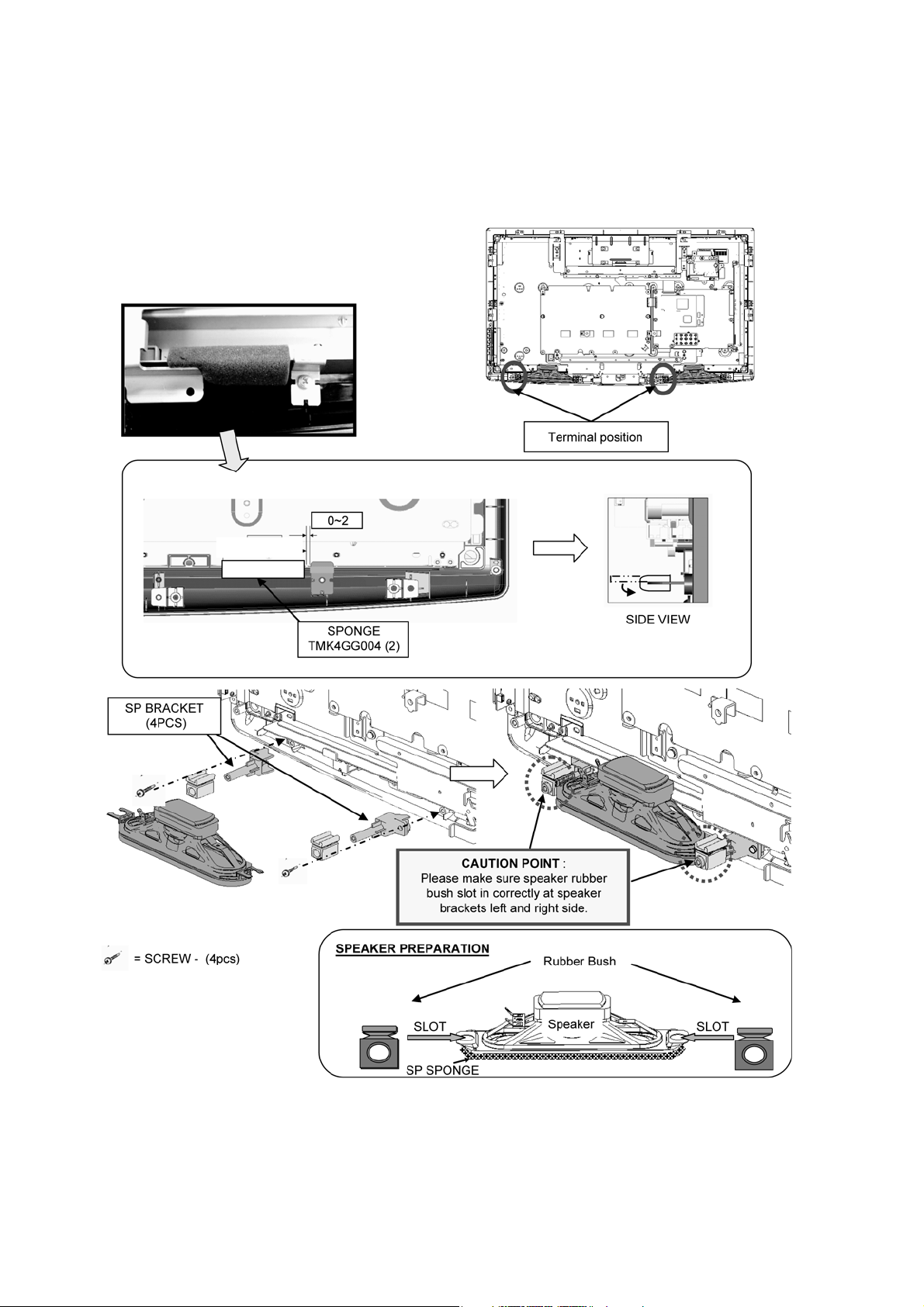

7.10. Speaker Installation

1. Stick the SPONGE. Follow the spec. below.

2. SP BRACKET slot at CABINET.

3. Insert the SP RUBBER BUSH into the SP UNIT.

4. Insert the SP UNIT to SP BRACKET.

5. Fix them with SCREWS.

22

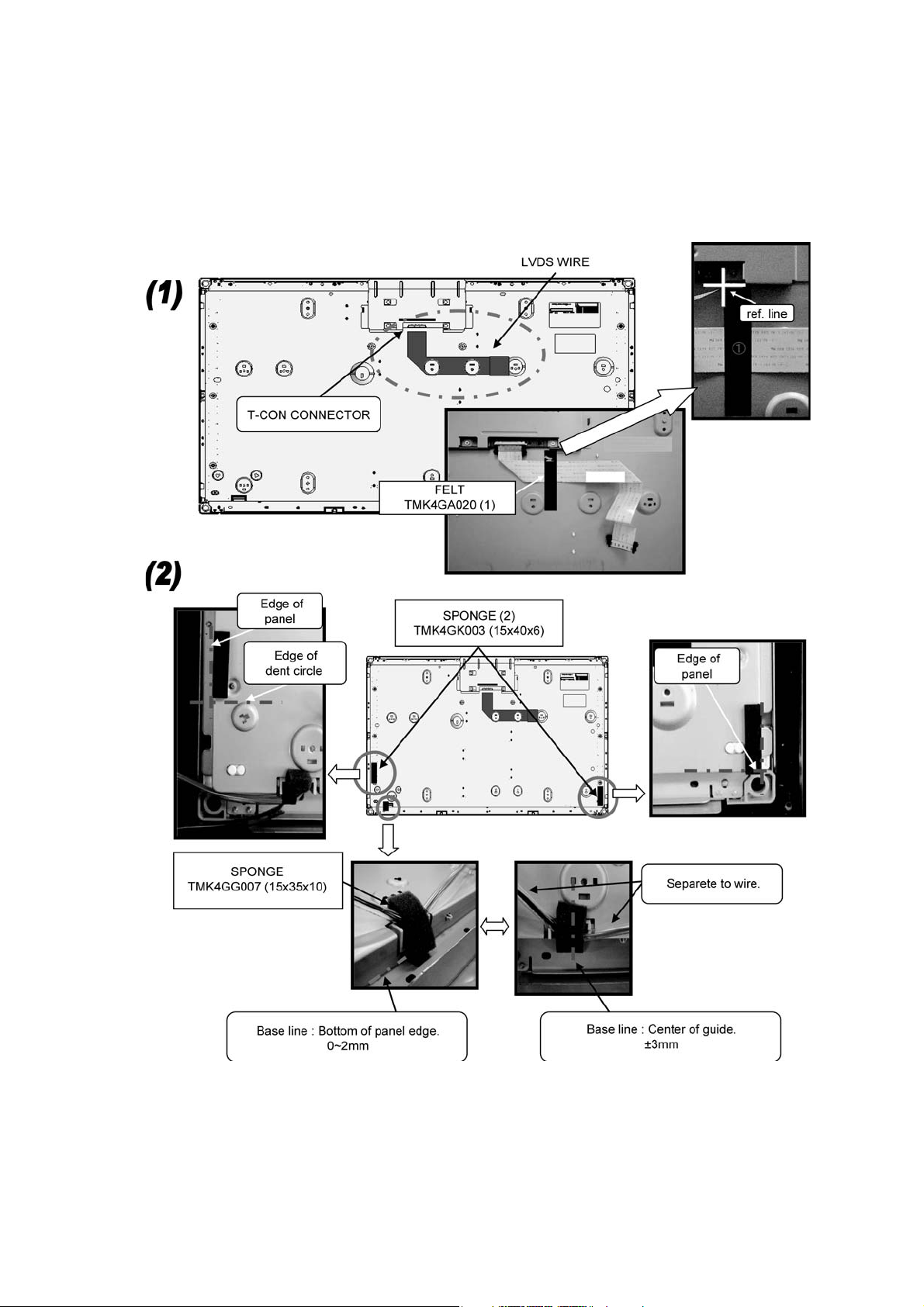

7.11. LCD Panel

1. Remove dust of terminal of LVDS. (by ion blow)

2. Remove dust of terminal of T-con connector. (by ion blow)

3. Insert LVDS into T-con connector.

4. Stick the tape to fix LVDS.

5. Stick the SPONGE at left and right lcd panel.

6. Stick 1pc SPONGE between lcd panel wire.

TH-L32X10M

23

TH-L32X10M

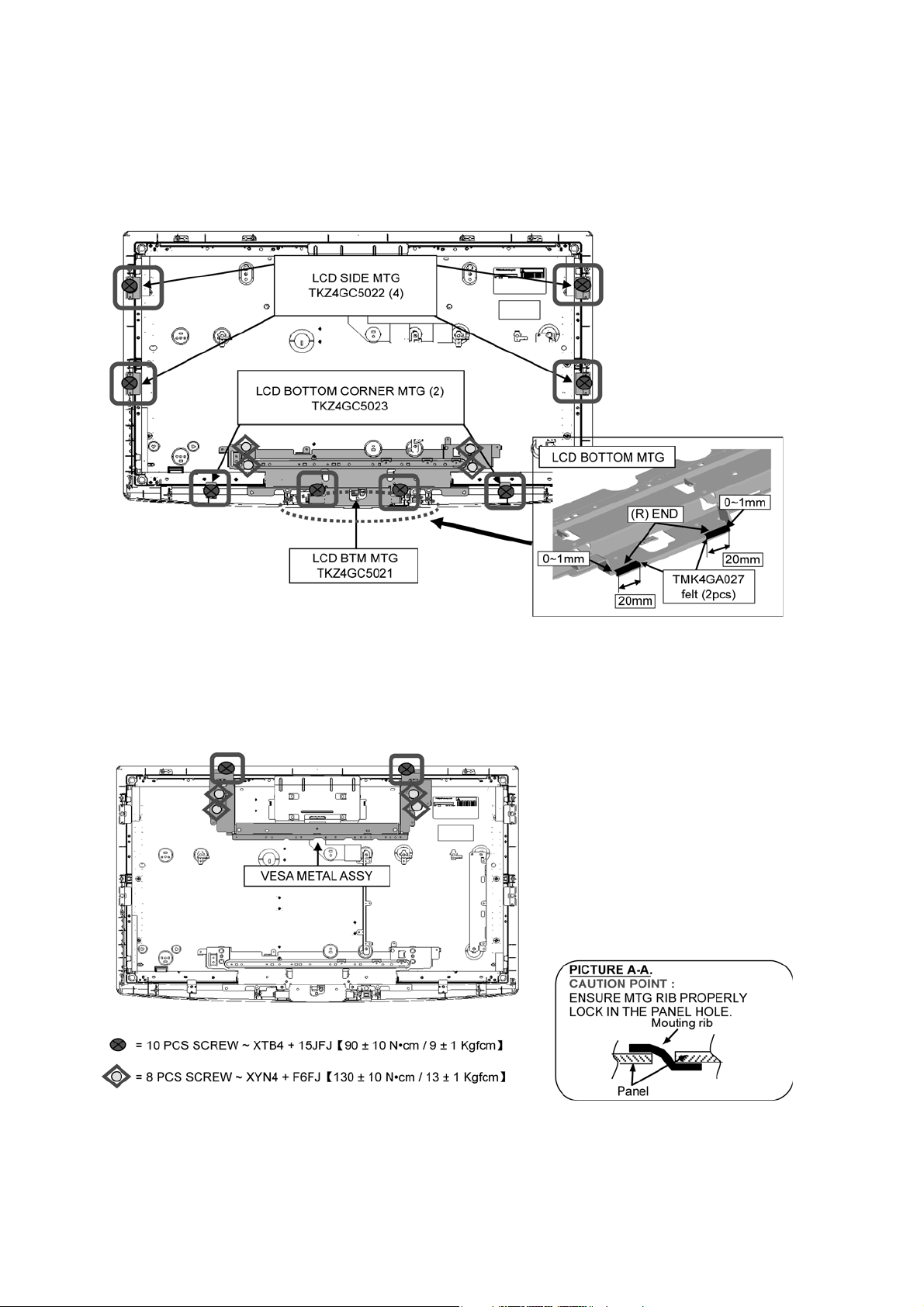

7.12. LCD Mouting Fixing

Step 1

1. LCD SIDE MTG on the CABINET.

2. LCD BTM MTG on the CABINET.

3. LCD BOTTOM CORNER MTG on the CABINET.

4. Fix them with SCREW.

Step 2

1. Assemble LCD TOP MTG (L, R), VESA METAL (upper) and fix them with SCREWS.

2. Put on the VESA METAL ASSY on the LCD PANEL.

3. Fix the VESA METAL ASSY with SCREW.

24

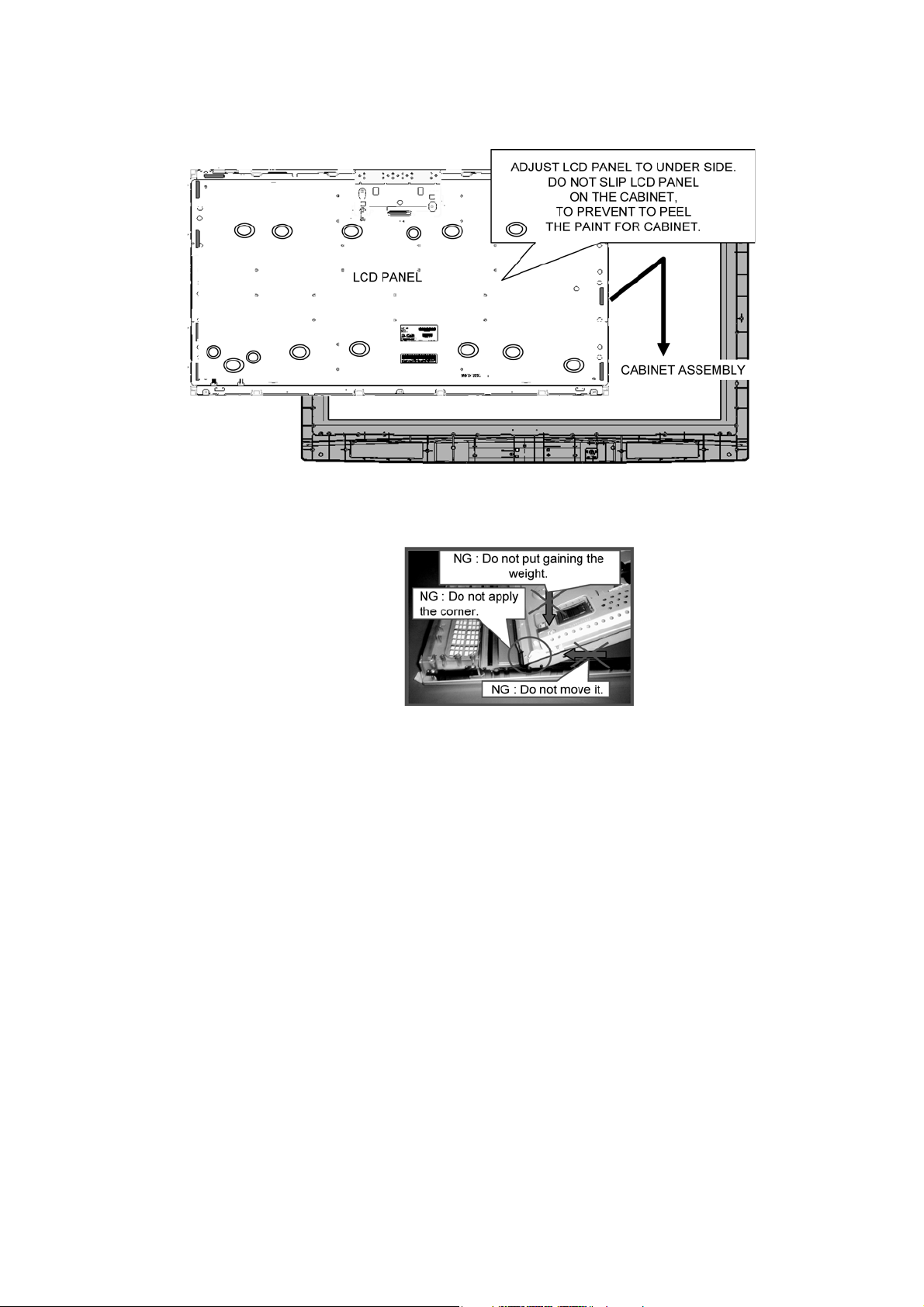

7.13. LCD Panel Assembly Installation

1. Put LCD panel to cabinet assembly.

TH-L32X10M

25

TH-L32X10M

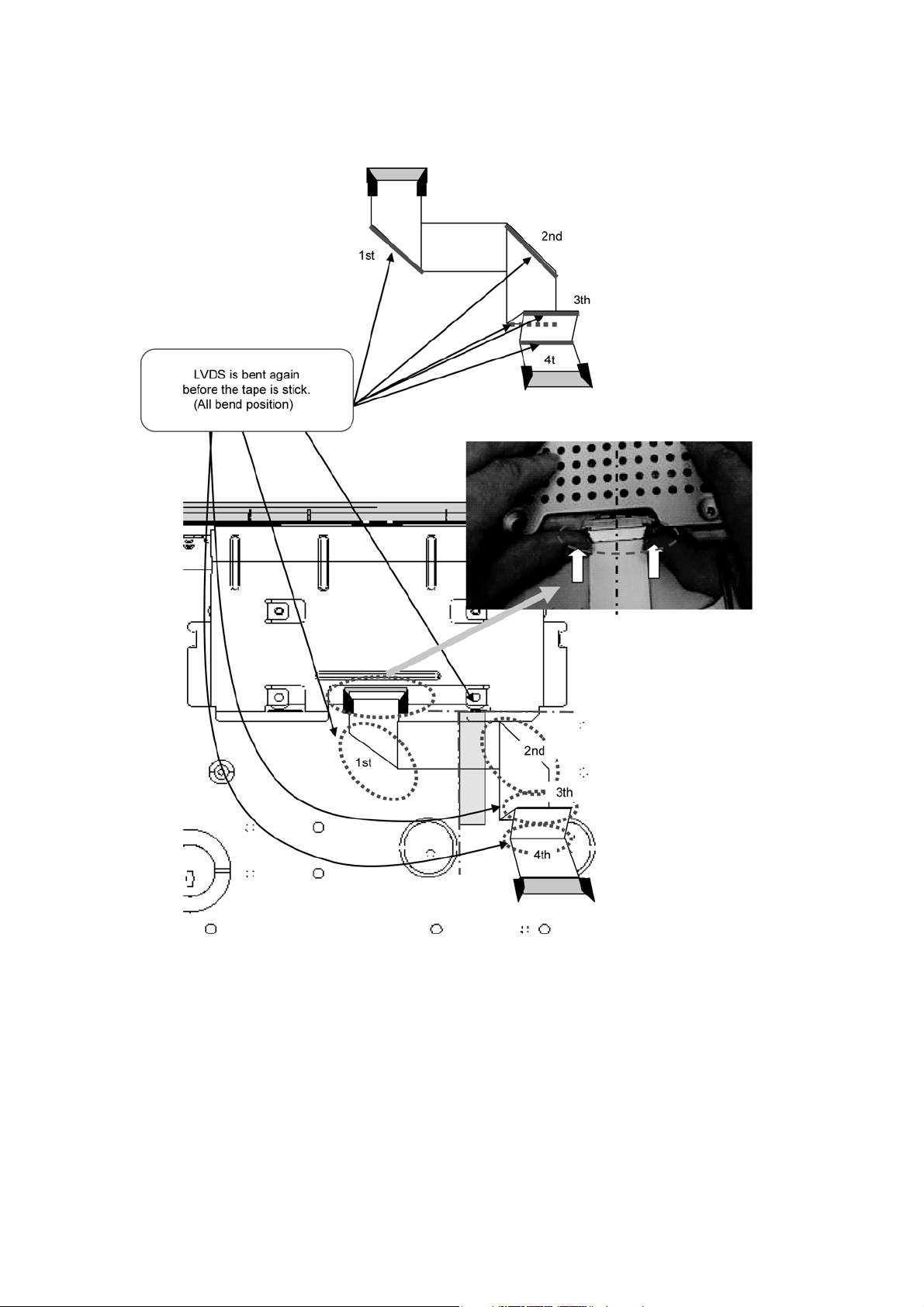

7.14. EMI Spec (LVDS)

1. When insert LVDS wire to T-con conector,make sure must center position follow bellow picture.

2. After fixing LVDS wire please bent again follow the picture.

26

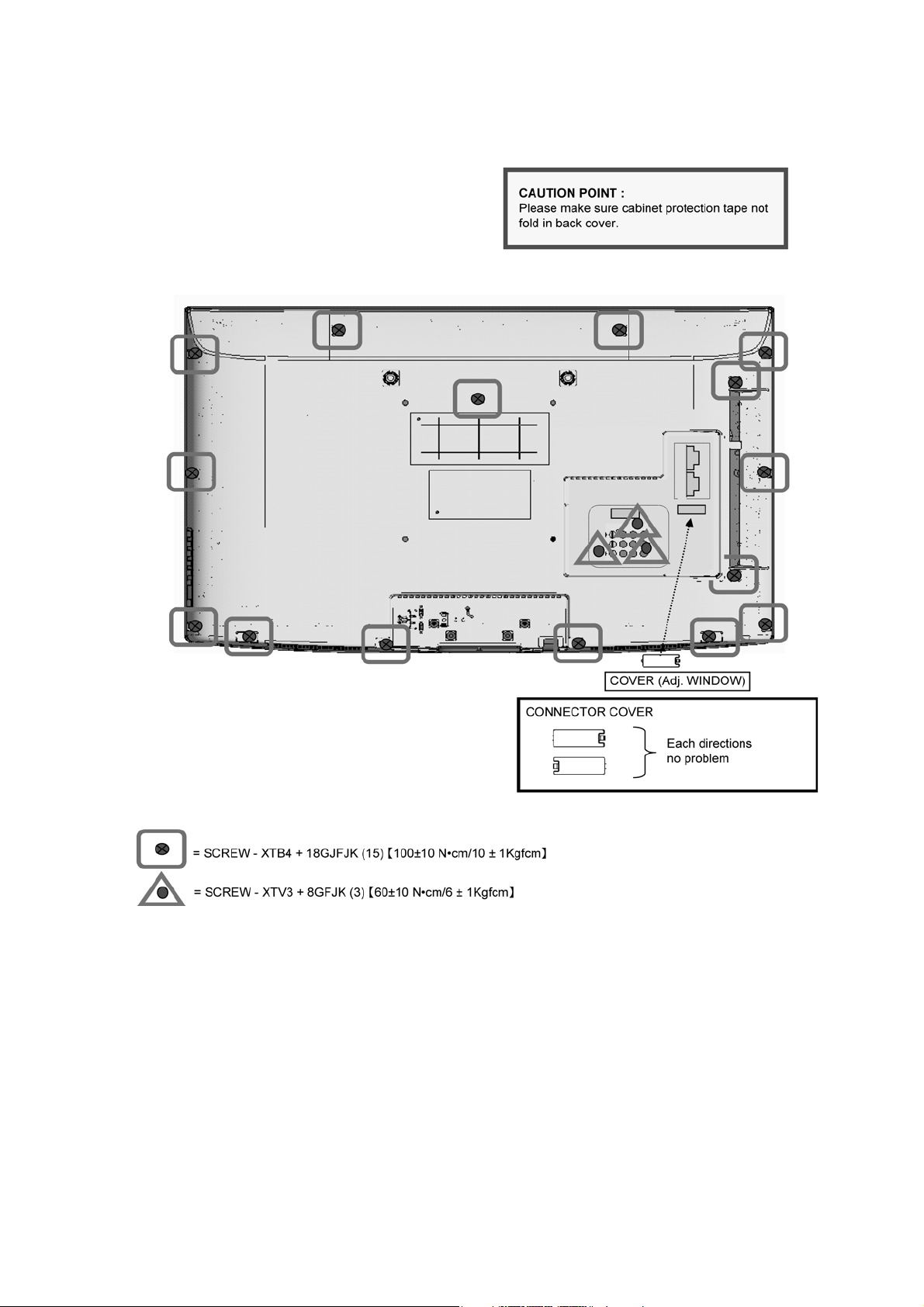

7.15. Back Cover Screw

1. Fix the BACK COVER with SCREWS.

2. Insert COVER (Adj.window).

TH-L32X10M

27

TH-L32X10M

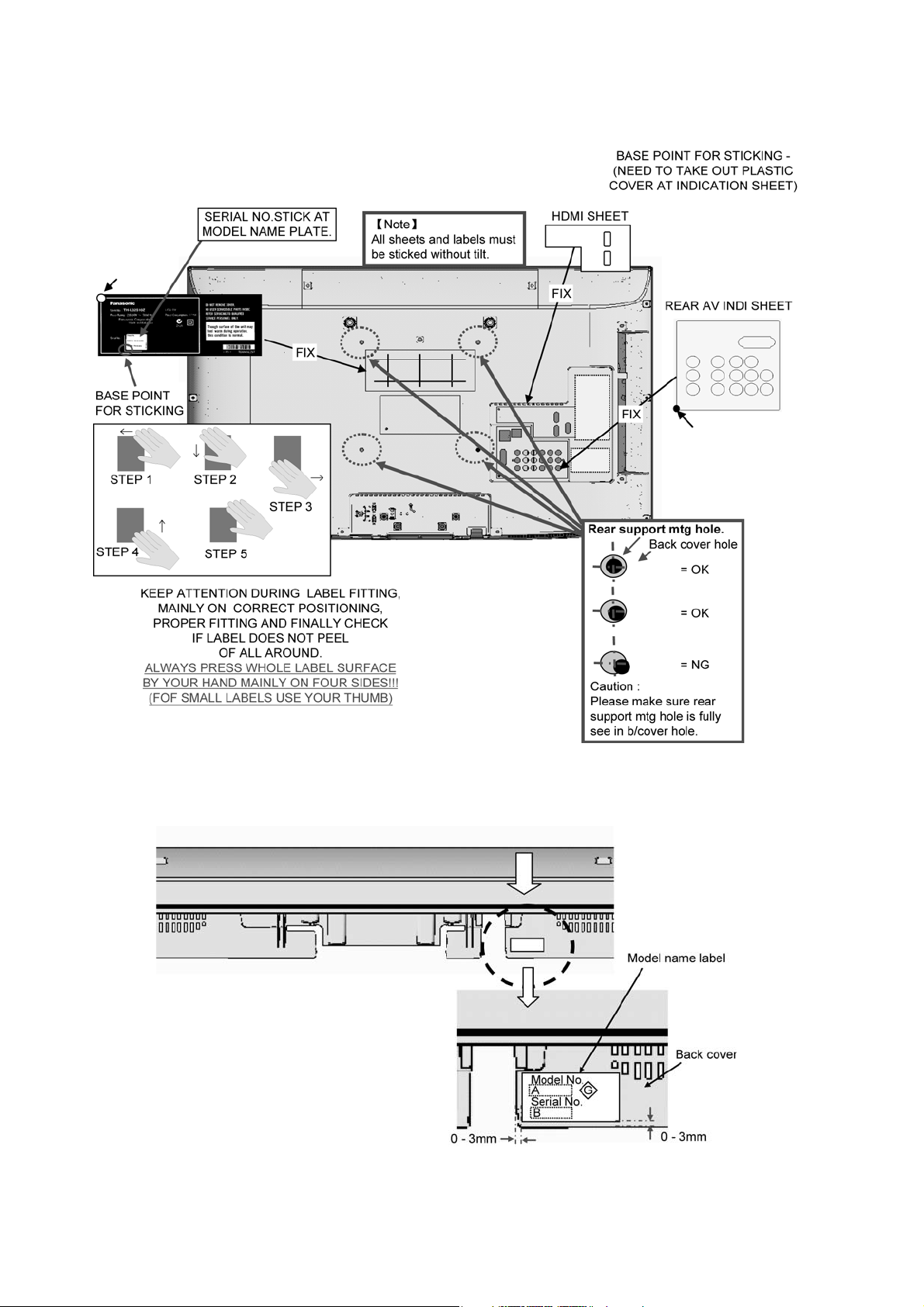

7.16. Indication Sheet Sticking Position

Stick the HDMI/REAR AV/MODEL NAME SHEET .

Stick model no. at bottom back cover (Stick area no etching).

28

TH-L32X10M

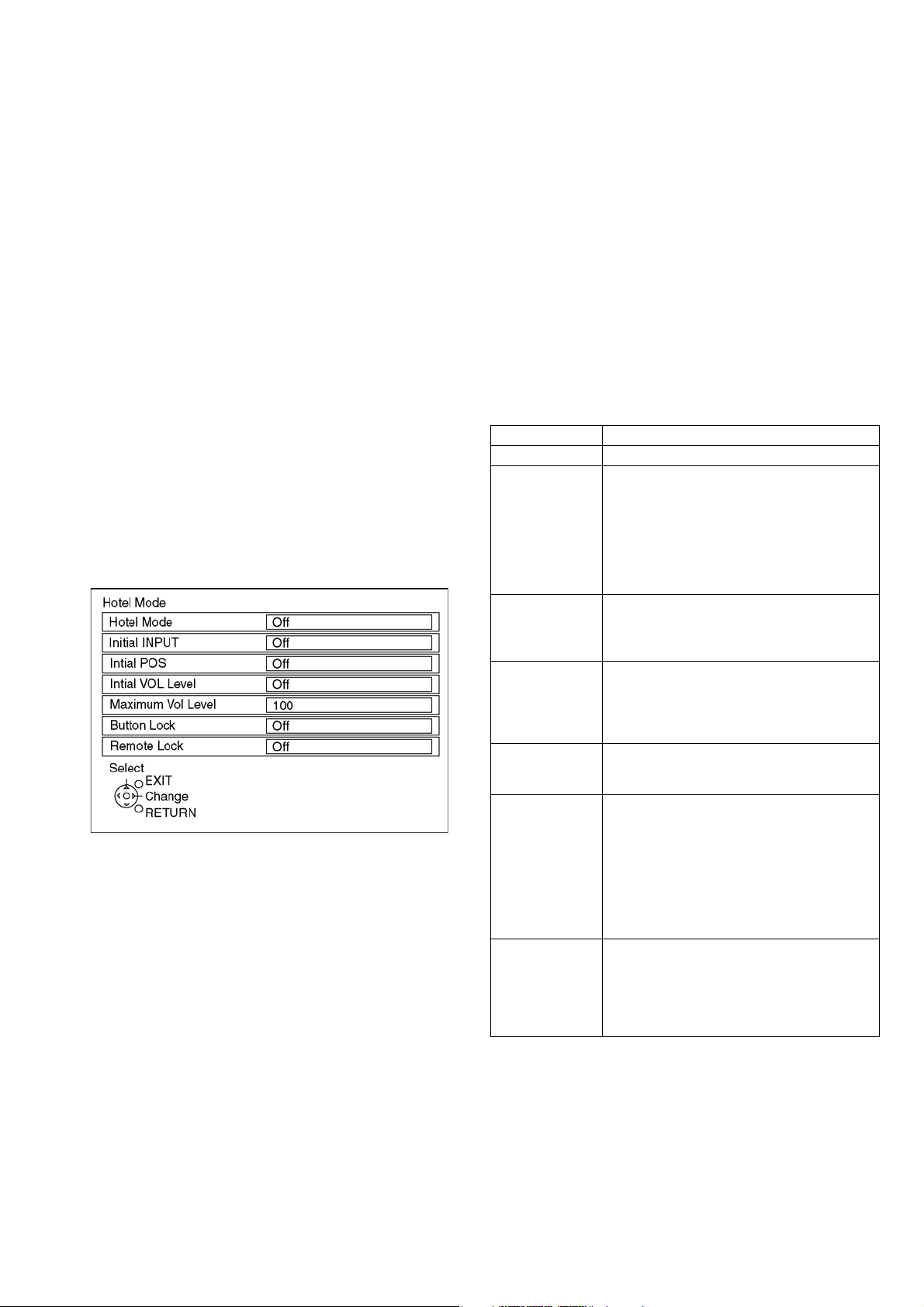

8 Service Mode Adjustment

Set timer to 30min, press the “RECALL” button on the remote control and press “-” vol button on the LCD panel.

• Press button R and G for adjustment.

8.1. Self Check Mode

1. Press the “MENU” button (on the remote control ) and the “DOWN” button on the LCD panel.

2. Press ON/OFF button on the panel to Exit.

8.2. Hotel Mode Adjustment

1. Press the “VOLUME DOWN” button on the TV panel and simultaneously press the AV button on the remote control 3 times to

enter Hotel Mode.

2. Set Hotel mode “on”, then press “EXIT” to come out.

8.3. Hotel Mode

1. Purpose

Restrict a function for hotels.

2. Access command to the Hotel mode setup menu.

In order to display the Hotel mode setup menu, please

enter the following command (within 2 second).

[TV] : Hold Vol [Down] + [Remote] : Press AV button 3

times.

Then, the Hotel mode setup menu is displayed.

Item Function

Hotel Mode Select hotel mode ON/OFF

Initial INPUT Select input signal modes.

Set the input, when each time power is switched

on.

Selection :

OFF/Analogue TV/Digital TV/AV1/AV2/AV3//PC/

HDMI1/HDMI2/HDMI3

• Off: give priority to a last memory.

• Selectable input is depend on the model.

Initial POS Select programme number.

Selection :

Off/0 to 100

• Off: give priority to a last memory.

Initial VOL level Adjust the volume when each time power is

switched on.

Selection/Range :

Off/0 to 100

• Off: give priority to a last memory.

Maximum VOL

level

Button lock Select local key conditions.

Remote lock Select remote control key conditions.

Adjust maximum volume.

Range :

0 to 100

Selection :

Off/SETUP/MENU/All

• Off: altogether valid.

• SETUP: only F-key is invalid.

(Tuning guide (menu) can not be selected.)

• MENU: only F-key is invalid.

(only Volume/Mute can be selected.)

• ALL: altogether invalid.

Selection :

Off/SETUP/MENU

• Off: altogether valid.

• SETUP: only Setup menu is invalid.

• MENU: Picture/Sound/Setup menu are invalid.

29

TH-L32X10M

9 Measurements and Adjustments

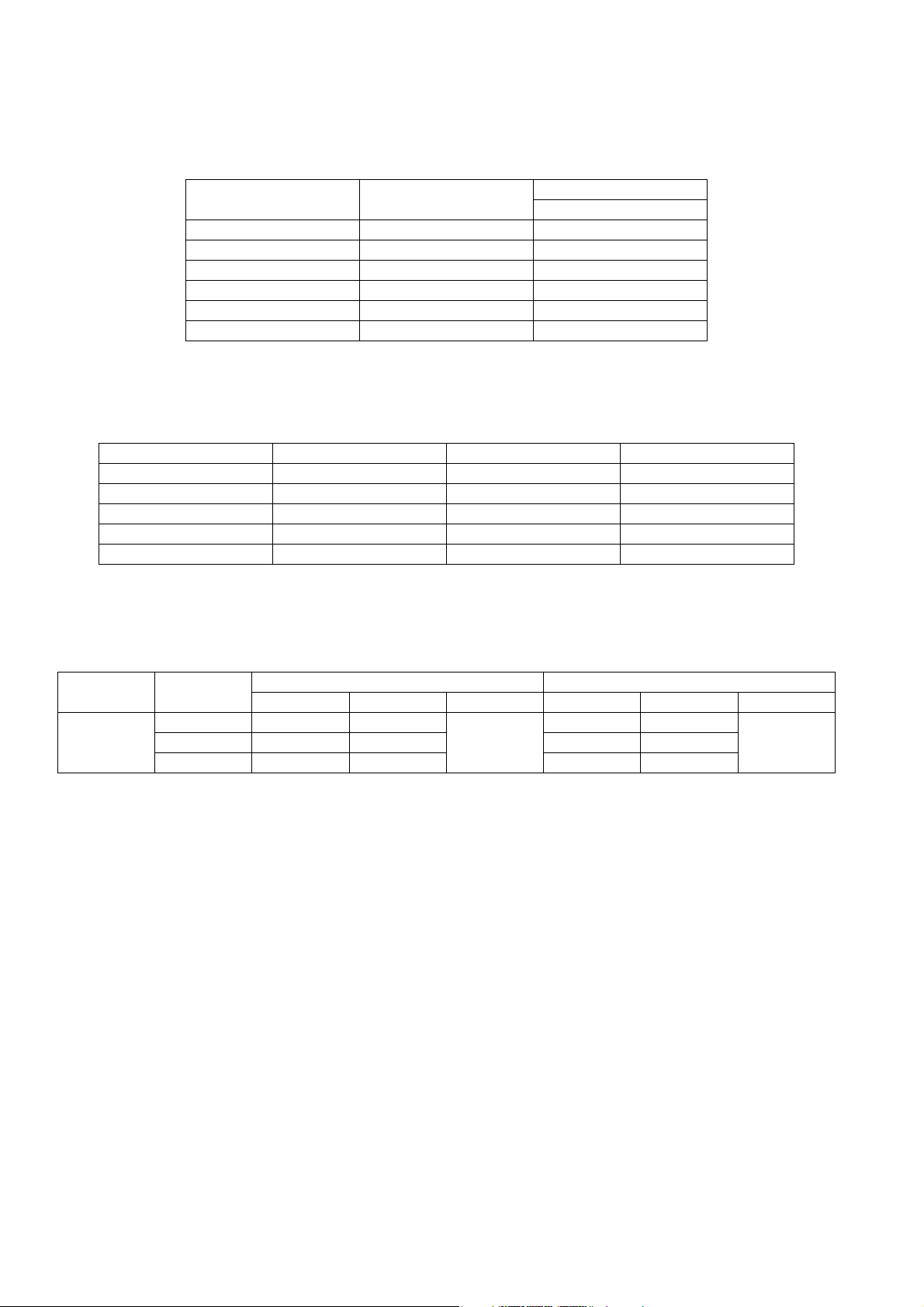

9.1. Voltage Chart of A Board

Set A-Board to a dummy set and check the satisfaction with the specified voltage as following table.

Power Supply Name Measurement Point

SUB1.2V TP5602 1.22 - 1.32

SUB1.8V TP5601 1.78 - 1.91

SUB3.3V TP5600 3.21 - 3.45

SUB9V TP5409 8.76 - 9.45

SUB5V TP5405 4.82 - 5.18

BT30V TP5482 29.3 - 31.5

Specification (V)

TNP4G460 / TNP4G461

9.2. Voltage Chart of P Board

Set P-Board to a dummy set and check the satisfaction with the specified voltage as following table.

Power Supply name Measurement Point Normal condition (V) Standby condition (V)

AUDIO_VCC TP866 17.0 ± 1.7 < 3.0

12V TP865 12.0 ± 0.6 < 1.0

5VS TP854 5.6 ± 0.3 5.6 ± 0.3

STBY_6V TP853 5.6 ± 0.3 5.6 ± 0.3

PFC Vout TP801 400 ± 10 NO CARE

After inspection, discharge the C7218 with 1kΩ resistor for 0.3 sec. or more.

9.3. Target of White Balance adjustment value

Ambient Temp. Colour Balance

Cool 0.271 0.275

22.5 - 27.5 deg.

Warm 0.314 0.324 0.314 0.324

x y Y (cd/m2) x y Y (cd/m2)

Clearance

x, y : +/-0.005 in Cool Colour Balance, +/-0.010 in Warm/Normal Colour Balance

White Gray

>300

0.271 0.275

Don’t CareNormal 0.284 0.297 0.284 0.297

30

Loading...

Loading...