Panasonic TH-37PX50U, TH-42PD50U, TH-42PX50U Service Manual

Panel Replacement Procedure

TH-37PX50U

TH-42PD50U

TH-42PX50U

Plasma Panel Replacement Report Form Instructions

Requesting a Panel

1- Contact the Technical Hotline at 1-800-743-2335

2- Provide your account number

3- Provide the unit’s model and serial numbers

4- Confer with the Hotline agent, who will assist you

in troubleshooting and provide you with an

authorization number.

5- When possible, email a picture of the symptom or

a draft of the panel report.

Report Completion:

Before Removal of Defective Panel:

Note: The report is equipped with pop-up comment

fields to guide you. Instructions 1 through 30 below

provide additional details.

1. Skip all the fields above the "Symptom" box, and

all other gray shaded areas.

2. In the "Symptom" box indicate the defect as

noticed or as indicated by the customer.

3. Enter the customer's information in the

appropriate fields.

4. In the "Work Order #" field, indicate your Work

Order #.

9. Paste a digital image of the symptom in the

"Picture of Symptom" box or attach the picture to

the email sent to the Technical Hotline. Select

the “Settings” and “Connections” by deleting

those conditions that do not apply to the

symptom picture.

10. Picture Mode: If the defect does not appear in all

picture modes, the panel is not defective.

11. Aspect: If the defect does not appear in all

"Aspect" modes, the panel is not defective.

12. White Balance: If the defect does not appear in

all White Balance modes, the panel is not

defective.

13. Signal Format and Signal Source: If the defect

does not appear in all signal formats supplied

from any source, the panel is not defective.

14. Please complete all the Servicer informa t ion

fields.

15. From within the service mode, extract the number

of cumulative hours of operation, and the On/Off

times. Fill in the appropriate spaces. Refer to

the service manual for instructions about the

service mode.

5. In the "Model #" and "Serial #" fields, enter the

numbers as they appear on the back of the unit.

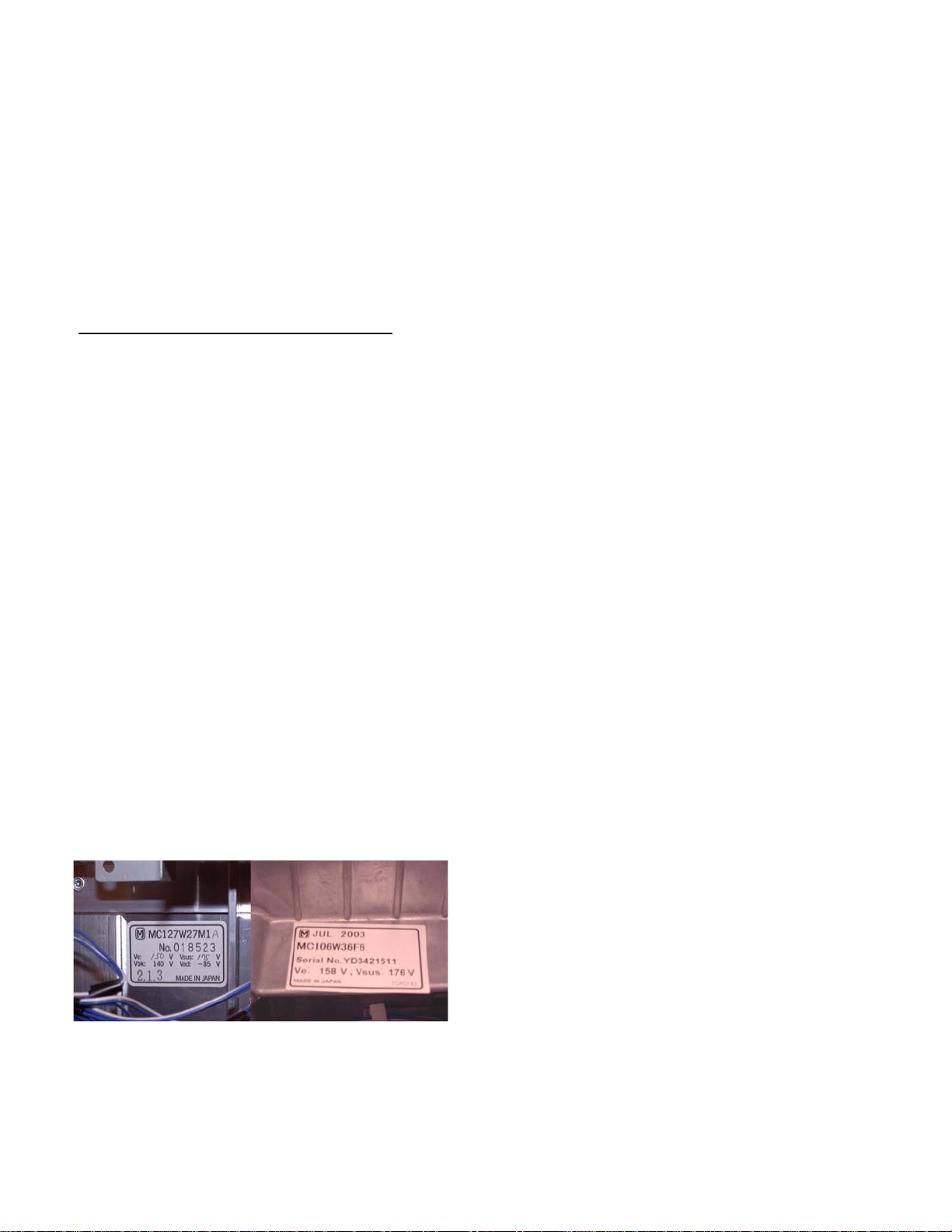

6. Fill in the "Panel’s serial number code" as

indicated on the label located on the back of the

panel. If the label resembles the depiction in fig.

1A, the code is the three-digit number "2.1.3" at

the bottom of the label. If it resembles the

depiction in fig. 1B, the code is the date at the top

of the label “JUL 2003”.

7. Enter "Date of Purchase" and "Date Service

Requested".

Fig. 1A

8. Enter the authorization number supplied by the

Hotline agent in the "Authorization #" field.

Fig. 1B

16. Verify the warranty repair status. Delete the

inappropriate status and then enter your name

next to "Confirmed by".

17. Skip the "Defective Parts Return Status" until the

repair is complete.

18. Skip the box labeled "Arrival Condition" (gray

shaded area)

19. In picture placeholder 1 on the top center of the

report, insert a clear digital picture, showing the

serial number label of the unit being serviced.

The serial number must be legible.

20. In picture placeholder 2, insert or attach a picture,

showing the serial number label of the panel.

Refer to figure 1. (The panel label is visible only

after the back cover of the unit is removed.) The

serial number must be legible.

21. In picture placeholder 4, insert a picture of the

defect as it appears when the Green and Blue

fields are turned off, and only the Red field is

active. (See the service manual of the unit for

instructions.)

Page 1 of 2

22. In picture placeholder 5, insert or attach a picture

of the defect as it appears when the Red and

Blue fields are turned off, and only the Green

field is active. (See the service manual of the unit

for instructions.)

23. In picture placeholder 6, insert or attach a picture

of the defect as it appears when the Red and

Green fields are turned off, and only the Blue

field is active. (See the service manual of the unit

for instructions.)

24. In the "Comments" section, describe the special

circumstances, troubleshooting and any repairs

attempted.

How to Insert an Image in a Picture

Box

Capture all images with a digital camera, using a

resolution high enough to show the desired details in

each image, but not excessively high, resulting in

excessive file sizes. ISP bandwidth and mailbox

sizes are often insufficient to accommodate large

files.

1. Click a picture box in the form.

2. From the menu, click "Insert" from Excel's menu*.

A scroll-box appears.

25. Save the Excel Workbook under a new name

using the customer's last name and the date.

(Example: "Smith 091703.xls")

After Replacing the Panel

26. The defective panel must be shipped to the

address provided on the prepaid return label

included with the replacement panel. Please

follow the instructions carefully.

IMPORTANT: Defective panel must be

returned to Panasonic before parts

warranty reimbursement can be made.

27. After shipping the defective panel to the address

indicated on the label and as per instructions

packaged with the new panel, complete the

report by deleting the word "NO" next to

"Returned", leaving the "YES" in the "Defective

Parts Return Status" box. Enter the name of the

person confirming the shipment, the carrier

information, and the tracking # in the appropriate

spaces.

3. From the scroll-box, select "Picture". Another

scroll-box appears.

4. Click "From File". An Explorer window opens.

5. Select the desired file.

6. Click "Insert".

7. If the picture is larger or smaller than the box in

the form, click a corner of the image and drag to

resize.

* Use the "insert" function from Excel's "Insert" menu,

not from the "Insert" available by right-clicking. When

using Windows' right-click function, a picture file

copied to the clip-board cannot be inserted or pasted,

unless the image itself (the file contents) is copied to

the clip-board.

Click here to open the Plasma Display Panel

Replacement Report form (for viewing)

Click here for an example of a completed Plasma

Display Panel Replacement Report

28. When the repair is complete and the defective

panel shipped, complete the remainder of the

report by entering the "Date Completed".

29. Review the report for completeness. Then email

the report to the appropriate address listed on the

bottom of the report.

30. When a completed report, with the six pictures is

received by the Hotline, and the defective panel

is returned, an additional $100.00 will be credited

to warranty claim.

Revised 11/22/2005

Page 2 of 2

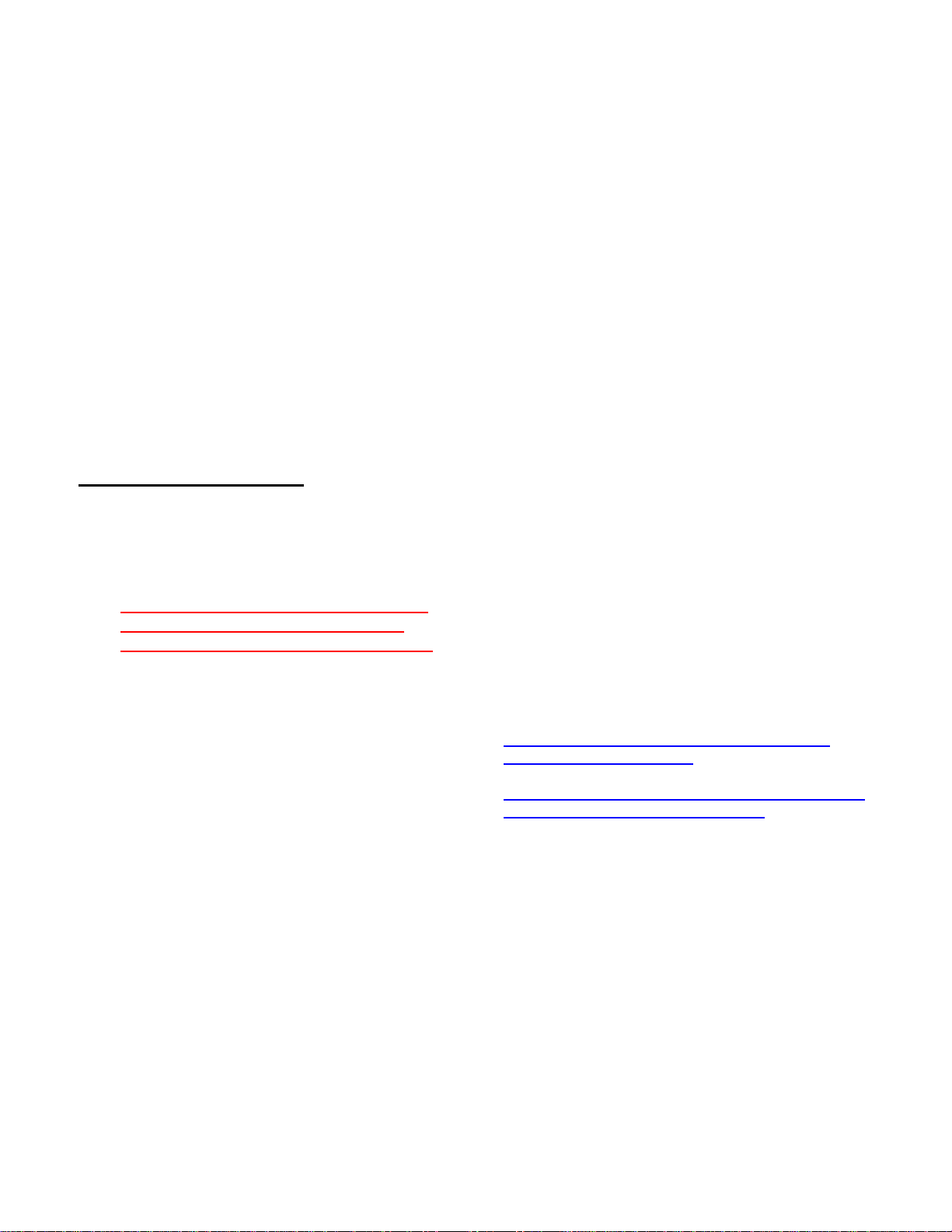

Plasma Display Panel Replacement Report

m

(Panasonic use only)

Company:

Panel Warranty: YES NO

Reporter: Fax:

Symptom:

Black bar, top center screen, halfway down.

Panel Serial No. Code:

Picture of Symptom:

mode must be attached here or attached

Telephone: E-Mail:

Customer Name:

Cust Address:

City / State / Zip:

Work Order # :

Model # :

Serial # :

This picture is for

A picture of the symptom as it

illustration only;

appears in normal operation

do not copy and

use in your panel

to the email with the report.

Servicer's Name:

Address:

City / State / Zip:

Telephone: Fax # : E-Mail:

Operation Time: Hours: 105

Warranty Status:

Defective Panel

Return Status:

report.

Contact:

PASC / PBTSC

John C. Consumer

123 Main St.

Anytown, CA 98765

11-562485-00

TH-42PX25

YJ1520161

YJ1520161

Service Center

John M. Servicer

563 Timbuktu Drive

New Town, CA 98764

574.123.4567

YES

Returned:

Carrier: World Shippers

Confirmed by:

YES

Replacement Date:

Report Date:

Date Service Requested:

Picture Mode:

Aspect:

White Balance:

Manual W/B:

Signal

Signal

Source:

NTSC VGA/SVGA

Format: RGB

CTV PC

DVC

Other

574.123.4568

66

John M. Servicer

Confirmed by:

Date of Purchase:

Date Completed:

Authorization # : 0118795487

Dynamic Normal

AUTO

ZOOM1

WARM

ON

CONNECTION

PAL/SECAM

COMPONENT

VCR

STB

Tracking # :

November 30, 2005

December 27, 2005

January 6, 2006

SETTING

Account # :

Power ON/OFF Times:

JUST

ZOOM2

NORMAL

OFF

PAL60

ALL

DVD

ALL

0054321-0012

JohnServicer@Provider.co

John M. Servicer

A1ZT546584525478

4:3

16:9

COOL

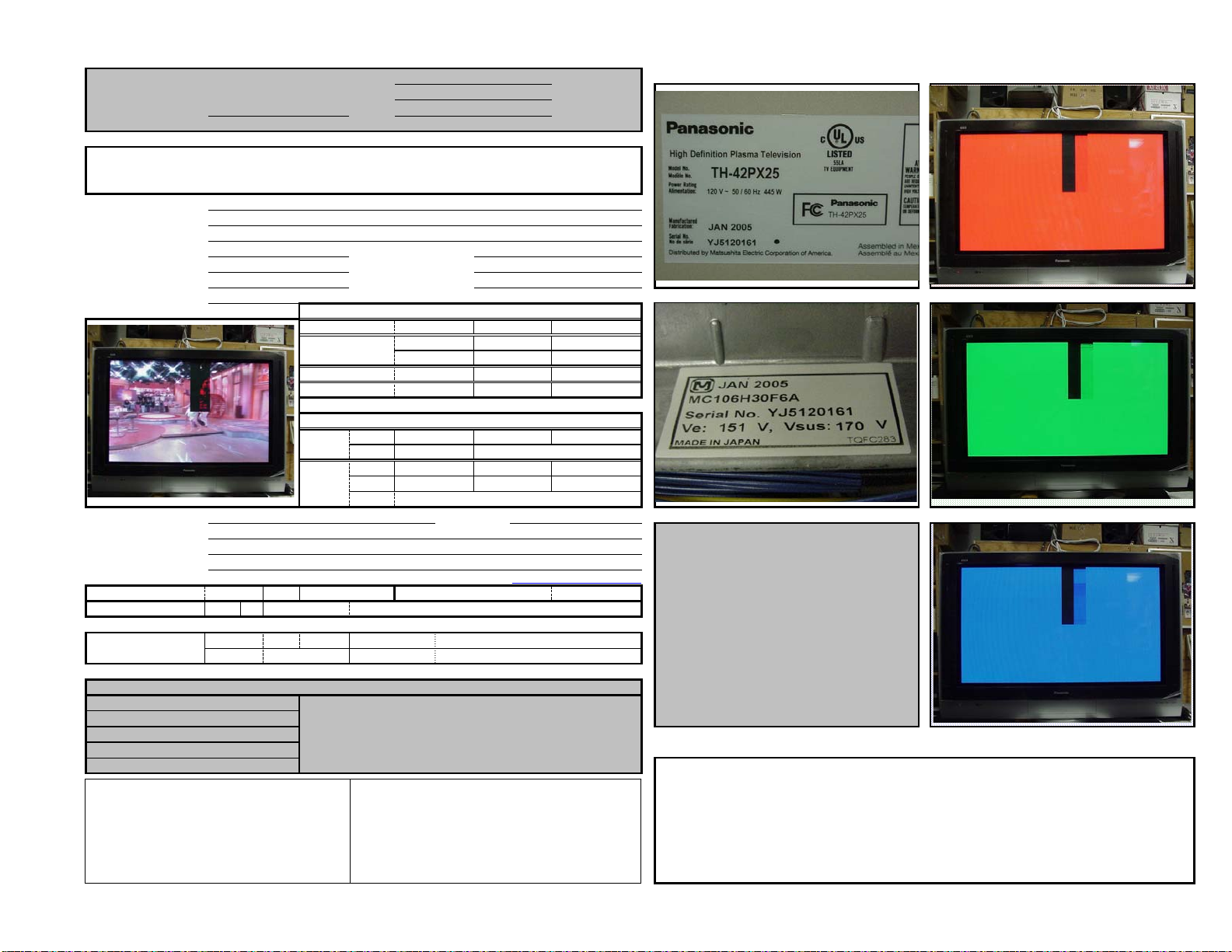

1- Serial Number of Unit

This picture is for

Pictures

illustration only;

Picture of the serial number of the

unit must be attached here or attached to

The unit serial number must be legible.

2- Serial Number of Panel

do not copy and

use in your panel

the email with the report.

report.

This picture is for

illustration only;

do not copy and

Picture of the Serial Number of the

defective panel must be attached here or

use in your panel

report.

attached to the email with the report.

The panel serial number must be legible.

3- Factory Use Only

( Factory Use Only )

4- Red Screen

This picture is for

A picture of the defect in Red Screen mode

must be attached here or attached to the email with

5- Green Screen

illustration only;

do not copy and

use in your panel

the report.

report.

This picture is for

illustration only;

A picture of the defect in Green Screen mode

must be attached here or attached to the email with

6- Blue Screen

do not copy and

use in your panel

the report.

report.

This picture is for

A picture of the defect in Blue Screen mode

must be attached here or attached to the email with

illustration only;

do not copy and

use in your panel

the report.

report.

ARRIVAL CONDITION ( Factory Use Only )

DATE:

COURIER:

International Operation Department

Television System Products Division Plasma Display Division

Matsushita Electric Industrial Co., Ltd. AVC company Matsushita Electric Industrial Co., Ltd.

PASCTECHHOTLINE@US.PANASONIC.COM

1-1 Matsushita-Cho, Ibaraki, Osaka 567-0026 JAPAN 1-1 Saiwai-cho Takatsuki, Osaka 569-1193 JAPAN

Tel 81-726-24-7743, Fax 82-726-22-8205 Tel 81-726-82-6647, Fax 81-726-82-6679

** Gray shaded areas are for Panasonic's use only

CONSUMER MODEL

E-Mail this report to:

Panasonic Technical Hotline

50 Meadowlands Parkway 2B-6

Secaucus, NJ 07094

(800) 743-2335

PANEL SERIAL # :

SYMPTOM:

Plasma Sales Group

BROADCAST MODEL

E-Mail this report to:

PEEKJ@US.PANASONIC.COM

Panasonic Broadcast & Television Systems Co.

50 Meadowlands Parkway 2A-4

Secaucus, NJ 07094

(201) 392-4355

Comments - Describe special circumstances, troubleshooting and repairs attempted:

Replaced the "C' board.

Form PR-20051201

PANASONIC SERVICES

SERVICE ADMINISTRATIVE BULLETIN

COMPANY

50 Meadowland Parkway

Secaucus, New Jersey 07094

SUBJECT: PLASMA PANEL

REPLACEMENT – ADDITIONAL HANDLING

CHARGE REIMBURSEMENT

NUMBER: 05-11-005

SERVICE POLICY

DEPARTMENT

DATE: November 22, 2005

BACKGROUND:

In the effort to continuously improve the performance of our products, we need your

cooperation in completing the PDP report, e-mailing digital pictures and returning the

defective panel. PASC recognizes the additional time to perform these tasks so we will be

adding $100 to the warranty claim at the time of processing to compensate for the extra

time and to show appreciation for the extra efforts in assisting Panasonic in improving the

quality of our product offerings.

POLICY & PROCEDURES:

1. This is effective as of December 1, 2005

2. This policy applies to all B34 servicers authorized to replace the Plasma panels.

3. The servicer will take 6 digital pictures of the defective panel showing the following:

x The symptom

x The serial number of the unit

x The serial number of the defective

x The red screen

x The blue screen

x The green screen

panel

4. The servicer will complete a PDP report, which details the problems with the panel.

The report is available in PASS from the Technical Resource Center:

x Log in to PASS

x Go to Technical Resource Center

x Click on CONTINUE

x Click on VIDEO

x Click on PLASMA

x On the right side, go the box: SERVICE POLICIES AND RELATED FORMS

x Click on PLASMA PANEL FIELD REPORT

x This will take you to the instructions and the PDP report.

5. The PDP report and the pictures are to be e-mailed to:

pasctechhotline@us.panasonic.com

6. Warranty Claims will verify that the PDP report and the digital pictures have been

received, as well as the defective Plasma panel.

7. Upon verification of receipt of all 3 items, Warranty Claims will add the $100 additional

handling charge to the claim in the “Other” field.

IMPORTANT NOTE:

The $100 will NOT be added to a claim unless ALL 3 items (the

completed PDP report, the required 6 pictures and the defective

panel) are returned to PASC.

1

Unpacking and Repacking the Plasma Panel

Panel Replacement Precautions

Handling

Use extreme care when handling the Plasma Display Panel. Due to the size and

fragility, it is recommended that two individuals handle the Plasma Panel to avoid

accidental damage.

The glass used in the plasma panel is thin, and its structure is extremely susceptible to

impact. Rough handling of the unit can crack the glass or cause pixel defect errors. Be

sure to transport the panel in the upright position. The unit is designed to absorb force

vertically not horizontally.

Numerous flexible printed leads with extremely soft structure are used around the panel.

Be very careful during handling not to damage these by pulling, bending, or subjecting

them to excessive force. When inserting a ribbon cable into a socket, verify that the

cable is straight. Angled insertion can create an electrical short circuit and permanently

damage the panel.

High Voltage

Plasma Display Panels use a high voltage power supply. Disconnect the AC from the

unit and wait one minute for the voltage to dissipate.

Static

Anti-static measures should be applied, especially when connecting and disconnecting

the ribbon cables.

Scratches

A protective sheet is attached to the back of the replacement panel to prevent scratches

and accumulation of debris. Be sure to remove the protective sheet and wipe the

surface with a soft cloth before installation.

Assembly

A low torque setting is recommended when installing screws in the panel assembly.

Preparation of the new panel

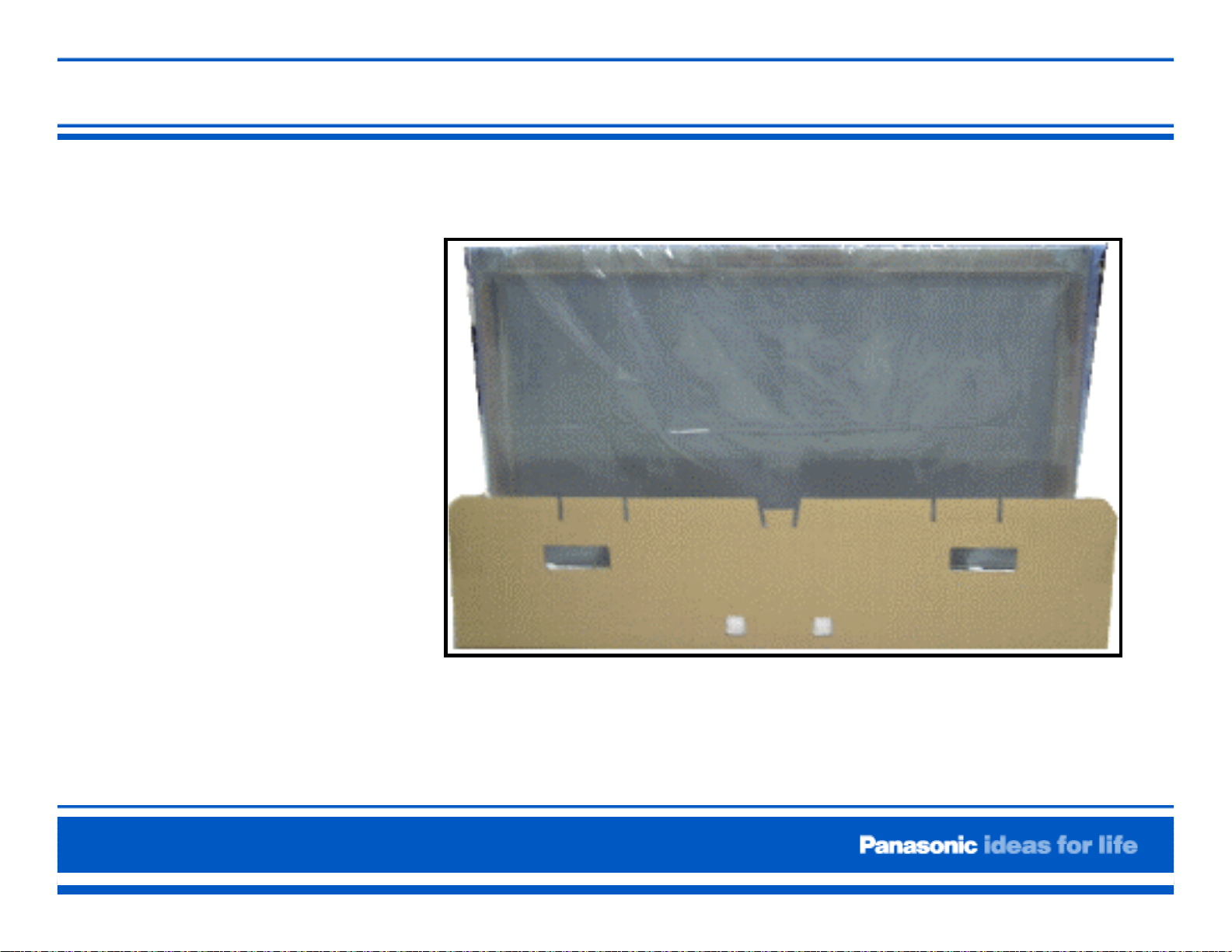

1) The replacement panel is shipped in a special

shipping crate. Retain this crate to return the

defective panel.

Page 1 of 2

Figure 1

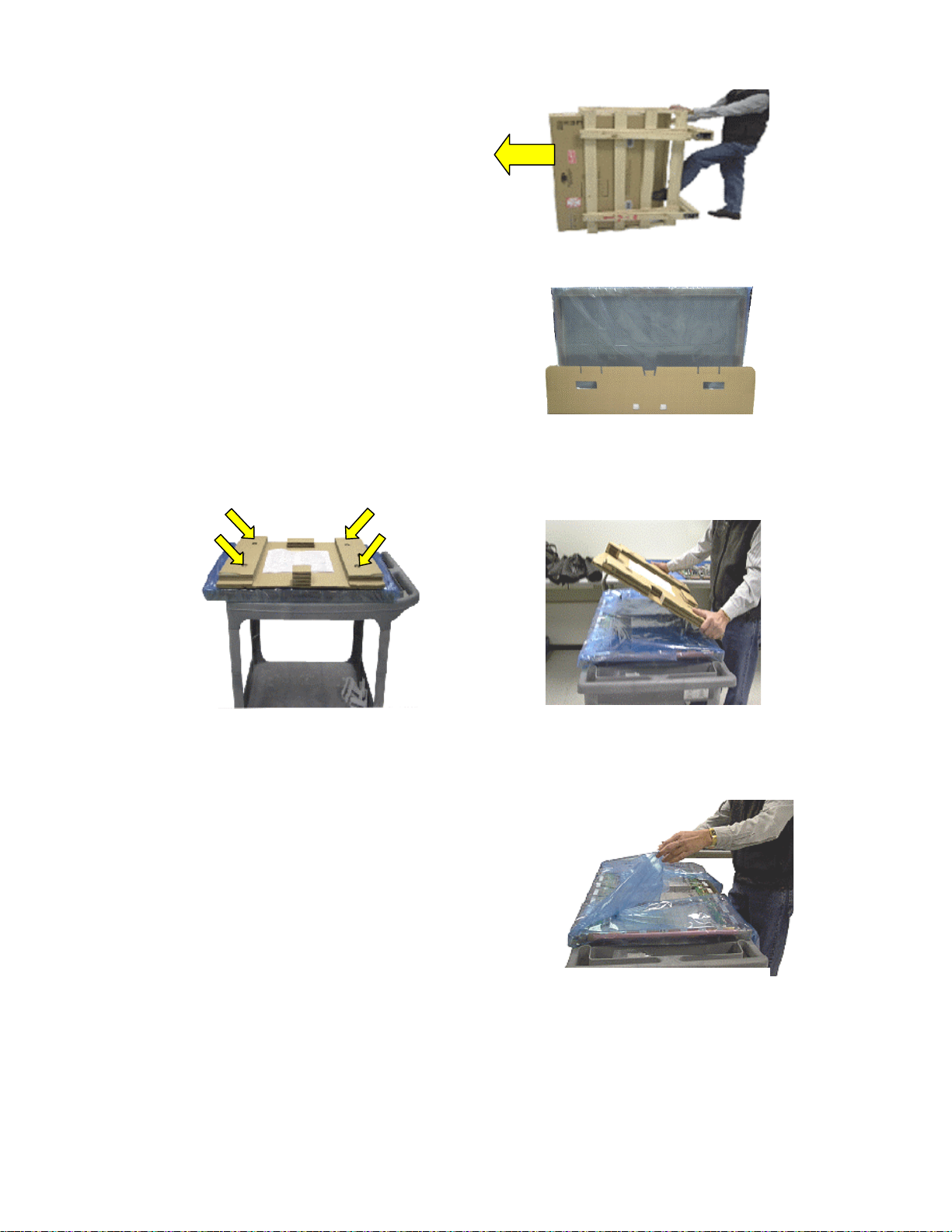

2) Carefully remove the top of the crate,

remember you will have to reuse the crate

to return ship the defective panel. Slide the

panel out the opened end.

Figure 2

3) The replacement panel is packed in an

escutcheon frame and a cardboard

panel. Protective cushioning surrounds the

panel. These items must be saved and

used to return the defective panel.

Figure 3

4) Remove the four screws that secure the protective cardboard on the new panel.

Place the protective cardboard aside.

Figure 4a

Unwrap the protective packaging from the new

panel.

Important Note:

The new panel comes with the “C” boards

preinstalled. However, the jumper ribbon

cables that connect the “C” boards may not be

included. Check for board jumpers. If missing,

remove them from the old panel and transfer

them to the new panel.

5) Reverse the order of the steps listed above to repack the defective panel for

return shipment to Panasonic.

Page 2 of 2

Figure 4b

Figure 5

Agenda

Equipment List

Panel Handling

Preparation of New Panel

PCB Description

Disassembly and Reassembly Procedure

Lead Dressing

Adjustment ( Driver Setup) Procedure

Adjustment (White Balance) of GP8DU Chassis)

Adjustment (White Balance) Procedure of older Panels

Examples of Defective Panels

Equipment List:

Electric Screwdriver (Part # EY6220B or equivalent)

Digital Volt Ohmmeter

Oscilloscope

Isolation Transformer

Anti-static 5 foot by 4 foot foam cushioning

Plasma Stand (Part # TY-ST05K or equivalent)

Screw storage bin

Large flat work area

Colorimeter for white balance adjustment (Sencore CP288 or

equivalent)

Video Signal Generator capable of providing NTSC, 480p, 720p and

1080i with adjustable brightness levels. (Sencore VP300 or

equivalent)

Page 1

Handling Precaution

Thin Glass = Susceptibility to impact

Rough Handling = Cracked glass or pixel defects

Improper Transportation = Unit should always be in the upright

position.

Leads or Ribbon Cables = No pulling, no bending, no excessive force

Ribbon cables must be straight when inserted into sockets. Angle

insertion can create an electrical short circuit.

Anti-static measures must be applied when disconnecting and

connecting ribbon cables.

Electric screwdrivers must have low torque setting to avoid damaging

the panel.

Page 1

Preparation of the New Panel (1)

Page 2

Preparation of the New Panel (2)

Preparation of the new Panel (2)

Caution: Use

extreme care when

handling the

Plasma Display

Panel. The glass

used in the plasma

panel is thin, and

its structure is

extremely

susceptible to

impact.

Page 3

Preparation of the New Panel (3)

Page 3

Preparation of the New Panel (4)

Page 3

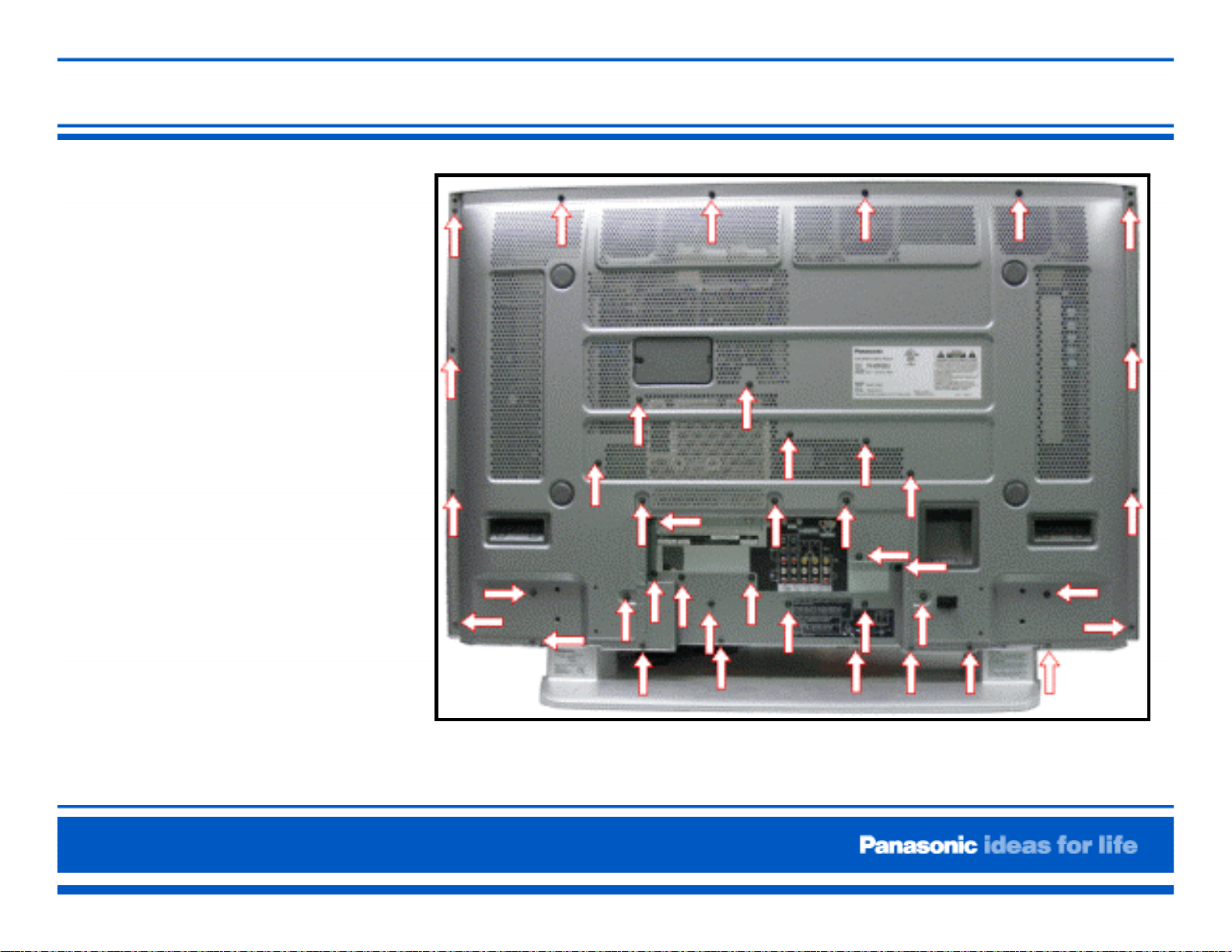

Rear Cabinet Removal

Remove the 43

screws as indicated

and then pull away

the rear cover. Place

it in a secure

location.

Weight:

TH-37PX50U = 66.14lb.

TH-42PX50U = 76.06lb.

TH-50PX50U = 99.21lb.

Figure 7. Back Cover Screws

Note:The unit can be awkward for one person, be sure to have someone assist you.

Page 4

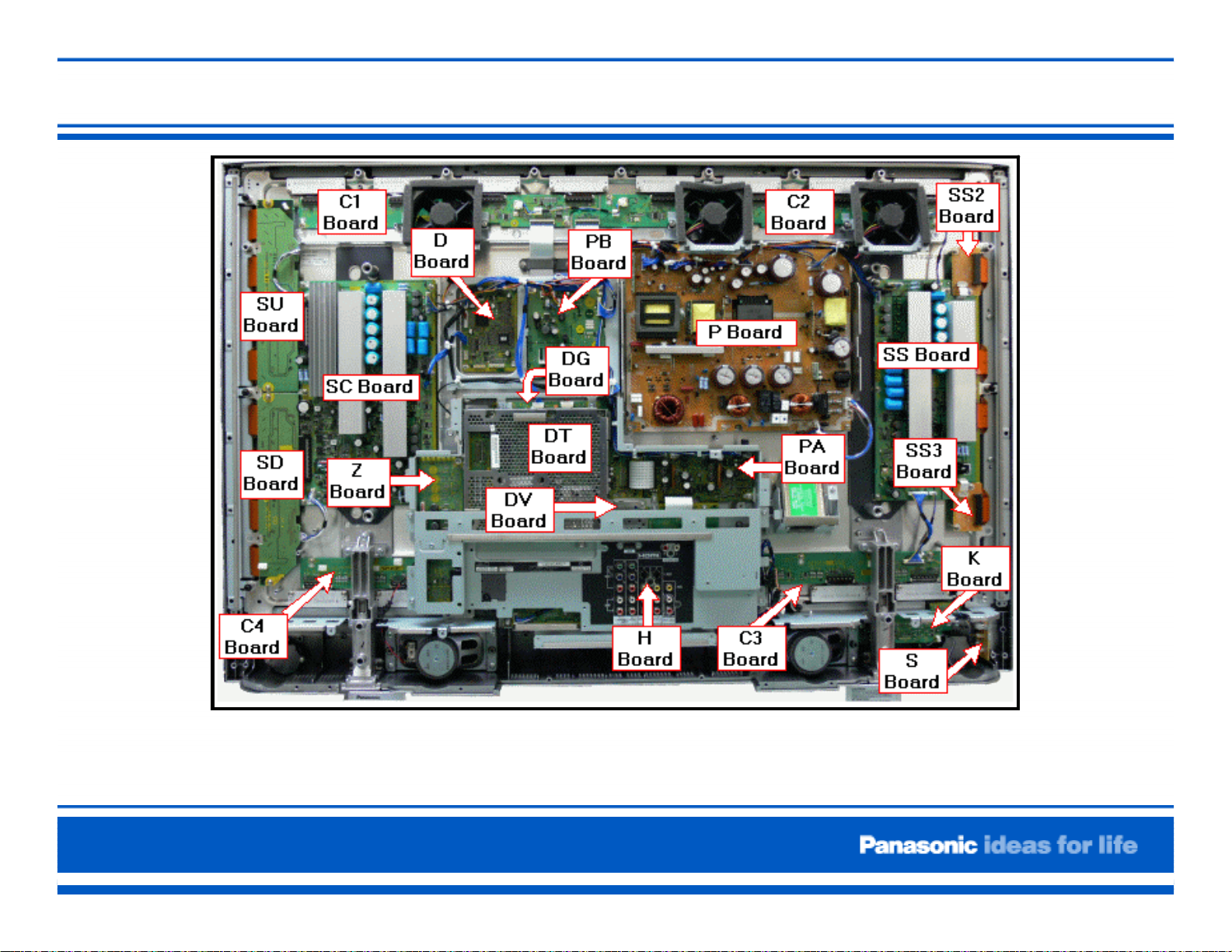

Board Layout

Page 4

Figure 8. Board Layout

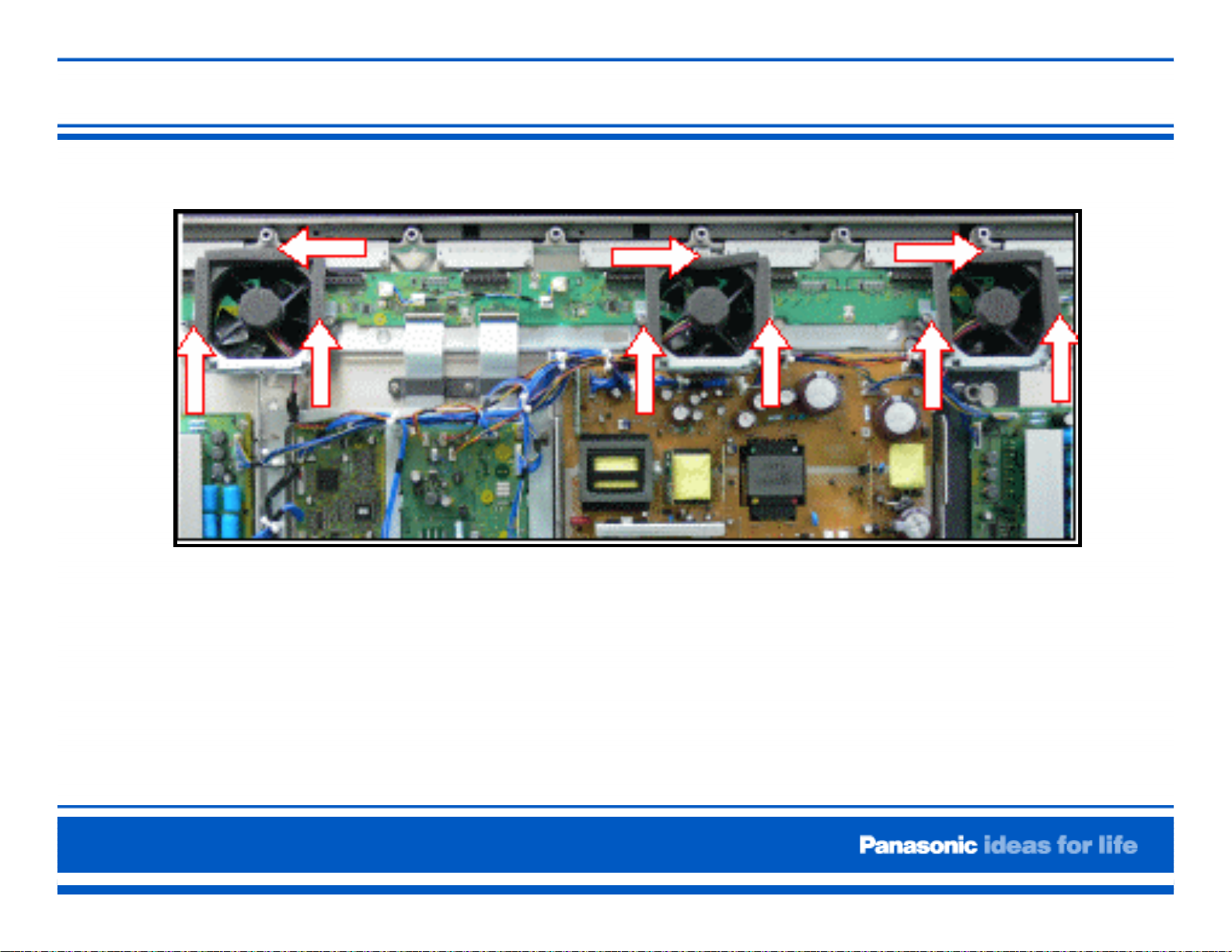

Removal of the fans

Figure 9. Fans Location

1. Remove the three screws that secure each of the

three fans.

2. Place the fans in a secure location

Page 5

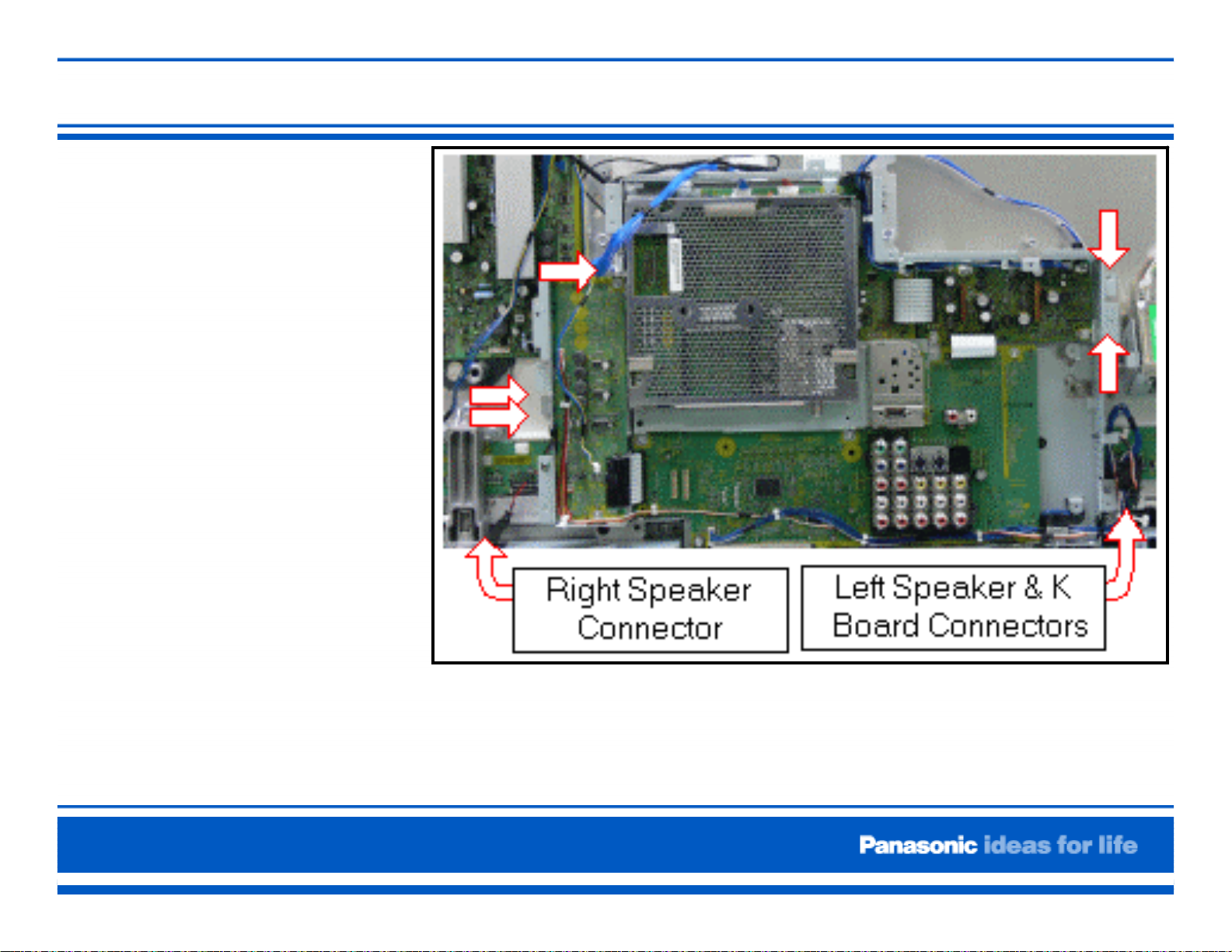

Removal of the Metal Frame

1. Disconnect the speaker

connectors (SP-L and

SP-R) and the black

connector that couples

the K board and the

DG board.

2. Disconnect the

connectors DG3 and

DG5 of the DG board,

PB7 of the PB board,

and PA10 of the PA

board.

3. Remove the five

screws that hold the

metal frame as

indicated in figure 11.

Page 6

Figure 11. Metal Frame

Loading...

Loading...