Page 1

Flexible Wire-Saving System

S-LINK V

USER’S MANUAL

WUME-SLINKV-9

2020.9

panasonic.net/id/pidsx/global

9th Edition

Page 2

2

Page 3

Contents

Before Using This System ·························5

Introduction ·············································· 6

Warnings ··············································· 6

Instructions for Safe Use ··························· 7

Ambient conditions ······························ 7

Instructions for Use ································ 8

Instructions for Designing ······················ 8

Fail-safe function ································· 8

Conformity to EC Directives ··················· 8

Use with S-LINK system ······················· 8

Instructions for Installation ························· 9

Hook-up cable connectors ····················· 9

Wiring ··············································· 9

Others ··············································· 9

Instructions for Disposal ···························· 9

Designing / Installation Procedures ············· 10

MEMO ··················································12

Chapter 1 ··············································· 13

Designing System ·································· 13

System Conguration ······························· 14

Outline of Design ···································· 16

Selection of Controller or Control board ·······16

I/O Control Points ···································16

Transmission Distance ·····························16

Outputting Error Signals ···························17

Connection of End Unit ····························18

Selection of Control Cable and Connector

Link Cable ·············································18

Control cable selection method:

(For use of

Connector link cable selection method: (For

use of

Making of Branch Lines Using Cable

Connectors ············································19

SL-VCU1

SL-VCU1

only) ··················18

only) ··························18

Power Supply Capacity of System ·············· 20

Calculation of Total Current Consumption

Value ··············································20

Example: Calculation of current consump-

tion ··················································22

Calculation of Voltage Drop Value ··············23

Rated voltage (V) ·······························23

Necessity of Local Power Supply Unit ·········24

Designing of system using local power sup-

ply method ········································24

Connection of DC 2-Wire Output Device to Input

Unit ······················································ 26

Example: Connection of DC 2-wire sensor 27

Transmission Delay Time ·························· 28

Response delay time ···························28

Operation at power-on ·························30

Error signal outputting delay time ···········30

System setting time ·····························31

Selection of Output Holding Function for Output

Unit ······················································ 32

Output holding function setting method ···32

Address Setting ······································ 33

Setting of PLC I/O connector numbers ····33

Setting of I/O unit addresses ·················33

Example: Address setting ····················· 34

Chapter 2 ··············································· 35

Wiring ··················································· 35

Flowchart ·············································· 36

Basic Procedures ···································· 37

Connector hook-up work ······················37

Cutting of exclusive 4-core at cable·······37

How to use exclusive hook-up pliers (SLJPS, SL-JPC, SL-JPE) ························38

Hook-up of Connector ······························39

Hook-up method of SL-JK connector for

cable end and SL-JK1 connector for ‘T’branch ·············································39

Hook-up method of

‘T’ - branch and SL-J3A connector for cable

extension

Hook-up method of

CP3 snap male connectors and

SL-CJ2

Connection to Terminal Block ····················46

Extension of Main / Branch Line Cable ········47

Extension of exclusive 4-core at cables ·47

Extension of cable excluding exclusive

4-core at cables ································47

Extension of cable to I/O device·············47

Installation ·············································48

Installation of each unit ························48

···········································41

snap female connectors ··················44

SL-J1A

SL-CP1, SL-CP2

connector for

SL-CJ1

, and SL-

and

Construction ··········································· 50

Power Supply ····································50

Power supply to system ·······················50

Connection of Each Unit ···························51

Connection of controller ·······················51

Connection of bus direct-connection type

controller and control board ··················52

Connection of PLC I/O Connector ··········53

Connection of I/O unit ··························55

Connection of I/O device ······················56

Connection of main line cable to end unit 57

Connection of local power supply unit ····58

Local power supply to system ···············58

Installation method of batteries ··············59

MEMO ··················································60

Chapter 3 ··············································· 61

Starting System ······································ 61

Flowchart ·············································· 62

Wiring Check ·········································· 64

Check before Starting ··························64

Check of wiring conditions of controller

and control board ·······························64

Check of PLC I/O connectors ················65

Check of cable for short-circuit ··············65

Starting ················································· 66

Power-on (Main Power and Local Power) 66

CONFIG mode ···································66

Check of Recognized Addresses ················70

CHECK mode ····································70

3

Page 4

Chapter 4 ··············································· 71

Specications ········································ 71

Specications ········································· 72

Common Specications ···························72

Address setting switches ······················72

Specications of Each Unit ·······················75

Controller ··········································75

Bus direct-connection type controller for FP2

/ FP2SH Series ··································79

Bus direct-connection type controller for FP7

Series ··············································83

Mitsubishi MELSEC-Q Series PLC bus direct-connection type controller ···············87

Control board ·····································91

Control module ··································95

PLC I/O connector ······························97

I/O unit ··········································· 100

Input terminal ··································· 103

Output terminal ································ 107

Connector input unit ·························· 111

Connector output unit ························ 11 5

MIL connector input unit ····················· 119

MIL connector output unit ··················· 122

Analogue input unit ··························· 125

Analogue output unit ························· 131

Relay output terminal ························ 136

Input module ··································· 139

Output module ································· 141

Picking switch ·································· 143

Picking switch for shutter ···················· 146

Address setting remote controller ········· 149

End unit ·········································· 151

Handy monitor ································· 153

Cable ············································· 157

Hook-up connector ··························· 157

List of programmable logic controllers (PLC)

(upper models) ································· 159

List of Models ········································160

Controller ········································ 161

Control board ··································· 161

Control module ································ 161

List of I/O units ································· 162

List of connectors ····························· 163

Handy monitor ································· 163

Address setting remote controller ········· 163

Others ············································ 164

Selection of connector link cable ·········· 176

Setting of connector numbers, ············· 180

addresses, and number of I/O control points

180

Glossary ········································· 181

FAX Sheet for Asking Question ·················183

MEMO ················································ 184

Chapter 5 ··············································165

Troubleshooting ····································165

Troubleshooting ·····································166

Flowchart for taking corrective action for detected error ····································· 166

Flowchart for power supply condition check

169

How to identify error unit after error detection

171

How to extinguish error indicator ·········· 172

Utilization of output holding function ····· 172

Appendix ··············································173

Appendix ··············································174

List of error numbers ························· 174

Flowchart for error detection ··············· 175

4

Page 5

Before Using This System

5

Page 6

Introduction

S-LINK V

The

highly reliable signal transmissions.

Fully understand the functions and performance of this system before constructing this system.

is a flexible wire-saving that uses our original transmission system to enable high-speed and

This manual provides information necessary for construction of the

Before constructing the

In addition, be sure to observe the cautions, and correctly use the system.

The controllers listed below have their own user’s manuals.

For a detailed description, refer to that documentation.

SL-VGU1-C, SL-VGU1-D : SL-VGU1-C

SL-VGU1-EC

SL-VGU1-485

SL-VMEL-Q

SL-VFP7

For other controllers, refer to the instruction manuals enclosed with the controllers.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany.

:

:

S-LINK V

SL-VGU1-EC

:

SL-VGU1-485

:

SL-VMEL-Q

SL-VFP7

system, carefully read this manual and fully understand the system.

SL-VGU1-D

/

User’s Manual

User’s Manual

User’s Manual

User’s Manual

User’s Manual

S-LINK V

Warnings

Before Using This System

This manual uses three types of warnings depending on the hazard level. They are ‘

CAUTION

‘

.’ To safely use the

S-LINK V

system, be sure to observe these warnings.

DANGER

exible wire-saving system.

DANGER

WARNING

,’ ‘

,’ and

Remarks

DANGER

‘

word is limitedly used in the extremely hazardous situations.

’ indicates that mishandling of this system may result in death or serious injury, and this

WARNING

WARNING

‘

’ indicates that mishandling of this system may result in death or serious injury.

CAUTION

CAUTION

‘

NOTE

’ indicates that mishandling of this system may result in injury or damage of the system.

‘NOTE’ provides caution or information to you in order to prevent operation errors.

1) Panasonic Industrial Devices SUNX Co., Ltd. holds the copyright of this document. For this reason, do not

copy this document without our permission.

2) The contents of this document may be subject to change without prior notice for the reasons of improvement.

3) The product specications shown in this document were determined in September 2020.

6

Page 7

Instructions for Safe Use

WARNING

S-LINK V

The

safety function. For this reason, do not use the

fect human lives or assets.

Even if this system is not used as an accident preventive system or safety system, if this system is

used for a nuclear power control system, railroad facility, aviation facility, vehicle, combustion system,

medical equipment, or the like, be sure to design a system having enough capacity, and adopt safety

measures for the system, such as a fail-safe function. In addition, please contact our sales division.

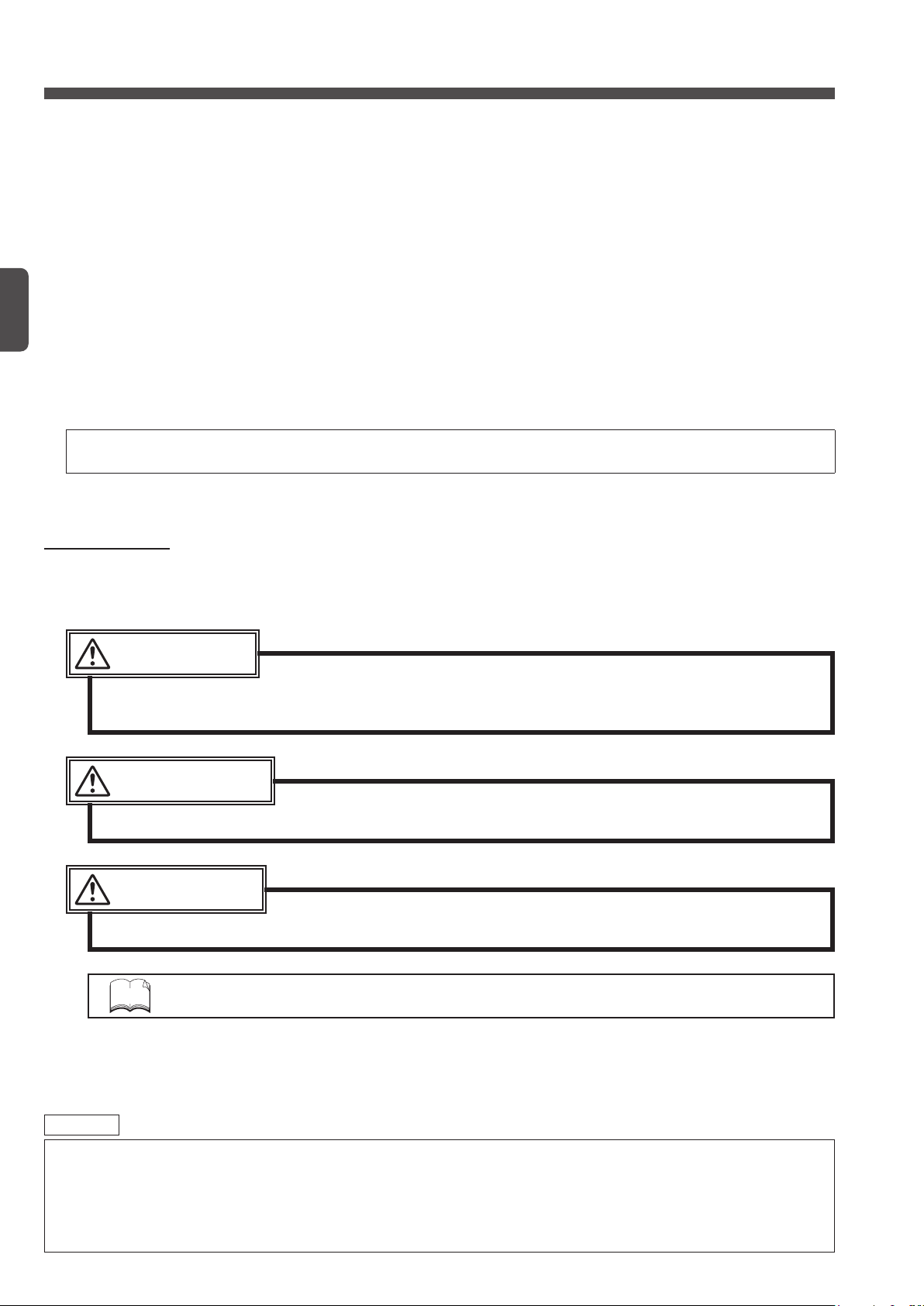

Ambient conditions

Do not use this system at the following places:

system does not have any control functions, such as accident preventive function and

Place where the ambient tem-

perature is out of the specied

range of 0 to +55°C (Note 1)

Notes:

1) The optimum ambient temperature depends on the product

type. For this reason, check

the specications of this product shown in Chapter 4.

2) If this product is incorporated

in the control box together with

the other unit, the unit may

generate heat to change the

ambient temperature. In this

case, install a cooling fan so

that the ambient temperature

cannot exceed the rated upper

limit temperature.

S-LINK V

Introduction

system if malfunction of the system may af-

Before Using This System

Place where the ambient temperature extremely varies and

dew condensation may be

caused.

Place where the ambient humidity is out of the specified

range of 35 to 85% RH (Note)

Note

The optimum ambient humidity

depends on the product type. For

this reason, check the specifications of this product shown in

Chapter 4.

Steamy or dusty place or

place near water, oil, or

chemical source

Place where direct sunlight

may enter

COR-

ROSIVE

GAS

FLAM-

MABLE

GAS

Place where there is a corro-

sive or ammable gas

Place where vibration or

shock of more than the specied level may be directly applied to the system main body

Closed place

However, if a ventilation

hole or a fan is installed,

such a place can be

used.

7

Page 8

Instructions for Use

Note:

supply unit and the surge absorber. Check whether a resistor is needed.

+24V DC

Recommended part: ERZV05D390 manufactured by Panasonic Corporation (Note)

Not good

Good

Instructions for Designing

Fail-safe function

CAUTION

Disconnection of a signal line, instantaneous power failure, or abnormal signal may cause a problem.

For this reason, please adopt a fail-safe function for the entire system by yourself.

To ensure safety, be sure to incorporate the interlock circuit, limit circuit, or the like, in the external circuit excluding the

S-LINK V

system circuit.

To incorporate the

Regarding the fail-safe function, if you have an unclear or doubtful point, please contact our sales division.

S-LINK V

system in your equipment, be sure to adopt a fail-safe function.

Conformity to EC Directives

WARNING

● Each unit of the

Before Using This System

To conform to the EC Directives, the

as EN 61000-6-4 of the EMI standard and EN 61000-6-2 of the EMS standard. When you incorporate the

tem in your machine or equipment, check that the wiring condition conforms to the requirements of the EC Directives.

To use the

tric Corporation and to conform to the requirements of the EMC Directive, install the system in accordance with

the PLC User’s Manual prepared by Mitsubishi, and be sure to observe the following items:

● Be sure to put the PLC and the

●

Be sure to ground the shielded cable that connects the PLC to the

● If the shielding eect is not enough, install a ferrite core.

the system, check that entire system can conform to various standards.

● The lightning surge preventive function is not adopted for the I/O module (

conform to the requirements of EN 61000-6-2, incorporate the following circuit in your board.

Power supply

● If it is not necessary for the relay output terminal (

use of 250V AC, 3A is possible.

SL-VGU1-C

S-LINK V

If a different part is used, a resistor may be needed between the power

together with the PLC (programmable logic controller) manufactured by Mitsubishi Elec-

series conforms to various standards. However, to incorporate a unit in

+

–

Surge absorber

S-LINK V

SL-VGU1-C

SL-VM

0V

SL-VTPR4/8

system is tested in accordance with the EMC Directive standards, such

in a conductive box.

SL-VGU1-C

) to conform to the EC Directives,

in the 300mm area of the

□ /

VMP

□). To

S-LINK V

SL-VGU1-C

sys-

.

Use with S-LINK system

S-LINK V

The

mal operation or damage. Separately construct the

However, if gateway controllers are used as the child station of the open network (CC-Link, DeviceNet, RS-485 /

RS-232C, EtherCAT), 2 systems can be used together on the same network.

8

system cannot be used together with the

S-LINK V

gateway

controller

S-LINK V

unit

S-LINK

unit

S-LINK

S-LINK V

system. Use with a system may cause abnor-

system and the

S-LINK V

gateway

controller

S-LINK V

unit

S-LINK

S-LINK V

unit

system.

S-LINK

gateway

controller

S-LINK

unit

S-LINK

unit

Page 9

Instructions for Installation

CAUTION

● Select a power supply unit equipped with the short-circuit protective function (fuse, etc.).

● The power of the

the main cable or I/O device side. However, the short-circuit protective function is not adopted for

this power supply circuit. For this reason, adopt a short-circuit protective function, such as a fuse,

for the power supply circuit.

● Take care that wrong wiring will damage the product.

● Before starting the following works, be sure to turn o the power of the PLC (programmable logic

controller), personal computer main body,

of the I/O device.

• Machine assembly (installation)

• Removal or reinstallation of a

• Cable connection

• Address setting / change

● Before handling this product, remove any electrostatic charge that may be present on your body.

There is a danger of this product getting damaged due to the electrostatic charge.

S-LINK V

system passes through the inside of each unit and is then supplied to

S-LINK V

S-LINK V

unit or connection of I/O device

units, and also turn o the power supply unit

Instruction for Use

Before Using This System

Hook-up cable connectors

To hook-up an exclusive cable connector, use the exclusive tool, and correctly hook-up the connector by follow-

ing the procedure specied in this manual.

If a connector is not correctly hooked-up, the

In addition, observe the following items:

● After checking the cable type and the purpose, select the right type of connector.

● Before hook-up a connector, be sure to check the colors of cables to be connected.

● Use the exclusive hook-up pliers (

For the hook-up procedure of each connector, refer to pages 37 to 45.

● If a connector is once hooked-up, do not reuse the connector.

The performance of such a connector may be deteriorated.

SL-JPS, SL-JPC

S-LINK V

system will not operate.

SL-JPE

or

) to hook-up the connectors.

Wiring

Observe the following items to distribute cables:

● Keep cables away from the power line and the high-voltage line.

● Do not completely fold down any cables.

● Do not pull any cables with a strong force.

● Do not apply any weight to any cable.

● Do not touch a cable to any other system cables.

This is because signals of dierent systems may interfere with each other.

● Do not bend cables many times.

● Wind insulation tape on the end of each cable, if necessary.

Others

● Apply the specied torque to tighten terminal screws of each unit.

● Check the connectors for looseness.

● Do not disassemble or modify this product.

Instructions for Disposal

● Request a waste disposal company to dispose of this product.

9

Page 10

Designing / Installation Procedures

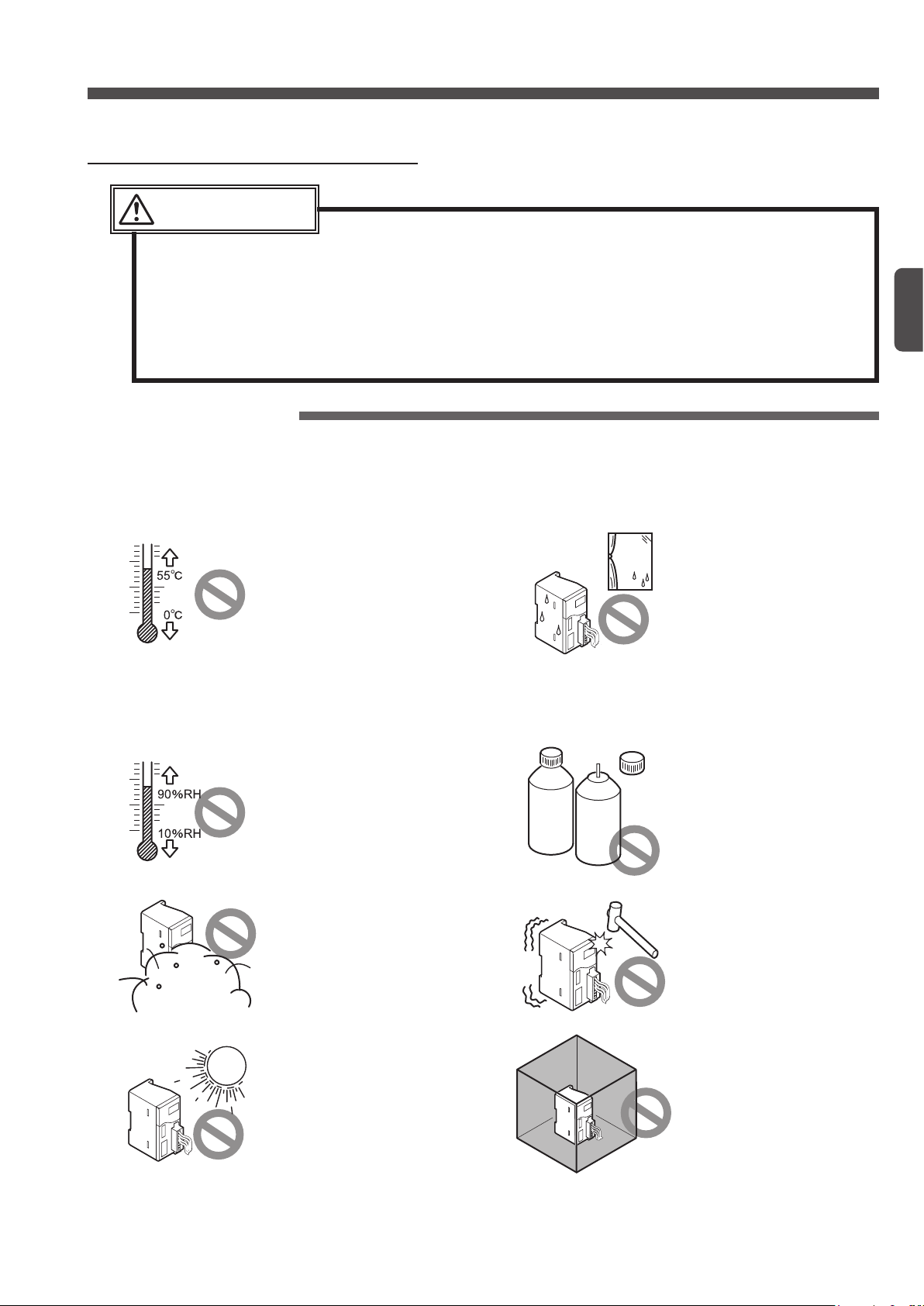

Local power supply unit

Chapter 1 Designing System

● Determine the system design.

● Determine the necessary number of I/O points for

the I/O device.

● Determine the cable length necessary for transmis-

sion.

● Select the transmission speed.

● Set the address.

● Calculate the power supply capacity of the system.

● Determine the connection method for the input de-

vice of DC 2-wire output type.

● Determine the transmission delay time.

● Set the output holding function.

How long?

Chapter 2 Wiring

Before Using This System

● This chapter describes the wiring methods to be used for actual installation.

● Caution regarding cutting of exclusive 4-core flat

cable

● Connector hook-up method

● Cable extension method

● Connection to I/O device

● Connection of local power supply unit

● Connection to terminal block

ON

256

128

16

ADDRESS

8

4

2

1

+

-

AC

F.G.

Insulated

Chapter 3 Starting System

● Check the system before starting.

● Check the cable for short-circuit.

● Check the system before starting.

● Caution regarding power-on

● Description of CONFIG mode

● Description of CHECK mode

10

D

(White)

+24V (Brown)

0V (Blue)

G

(Black)

Transmission cable

Analogue tester

Page 11

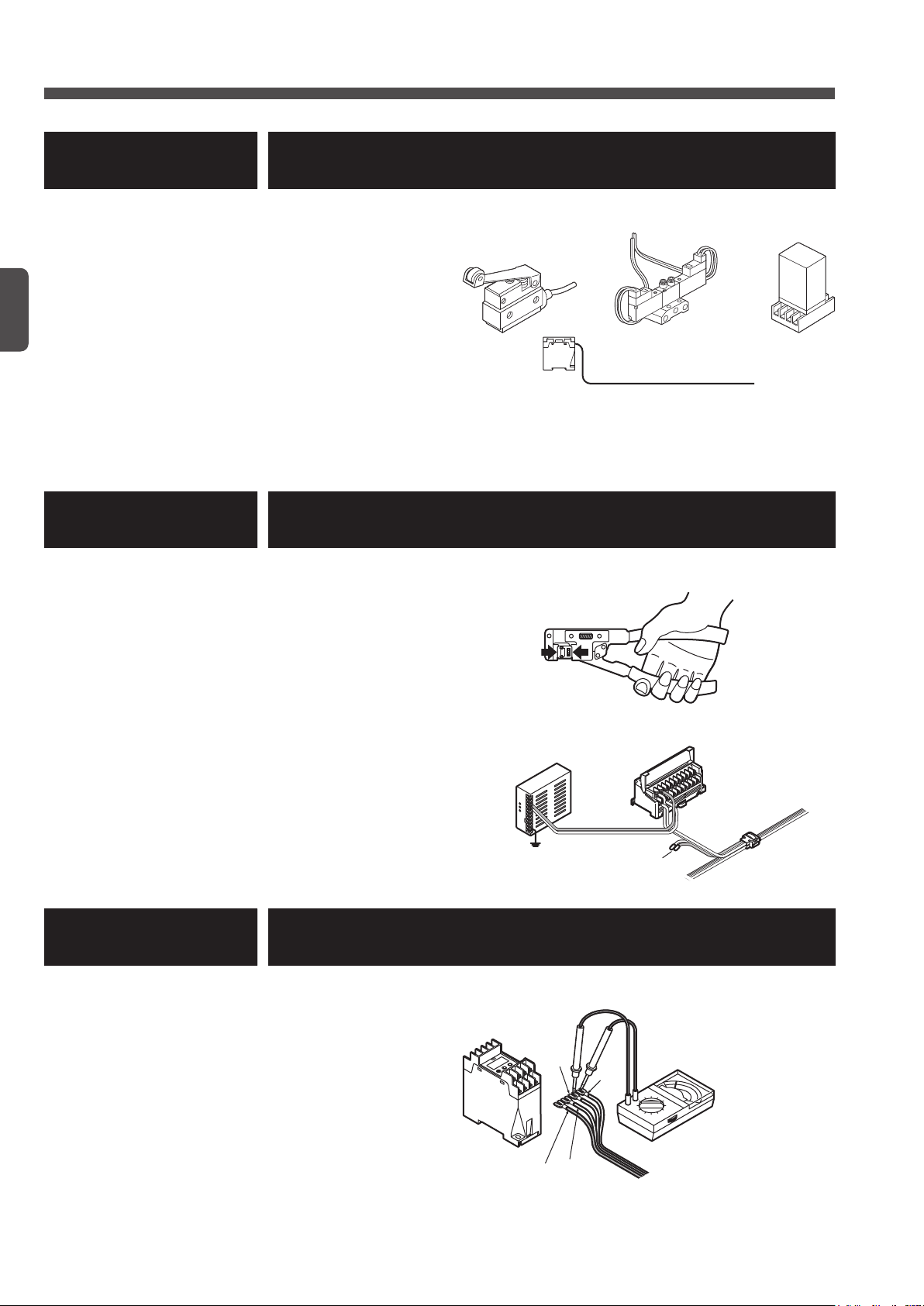

Designing / Installation Procedures

Chapter 4 Specications

● Select

S-LINK V

●

S-LINK V

●

S-LINK V

●

S-LINK V

control units

input units

output units

units optimum for the purpose of your system.

● Hook-up connector

● Exclusive 4-core at cable

Chapter 5 Troubleshooting

● This chapter describes how to solve the problem if the

not operate properly.

● Troubleshooting after error indication

● Power supply check procedure

● How to extinguish the error indicators

7

6

5

4

3

2

1

0

S-LINK V

1

Before Using This System

system does

Appendix

● List of error numbers

● Flowchart for error detection

● Selection of connector link cable for PLC

● Fax sheet for asking questions

This manual is prepared for the designer and the installer of the

mon to both the designer and the installer:

Before Using This System

●

Chapter 4 Specications

● ‘

Chapter 5 Troubleshooting

● ‘

Appendix

●

In addition, the designer should refer to ‘

Chapter 2 Wiring

‘

’ and ‘

’

’

Chapter 1 Designing System

Chapter 3 Starting System

.’

S-LINK V

system. The following items are com-

,’ and the installer should refer to

11

Page 12

MEMO

Before Using This System

12

Page 13

Chapter 1 Designing System

13

Page 14

4

3

2

1

0

7

6

5

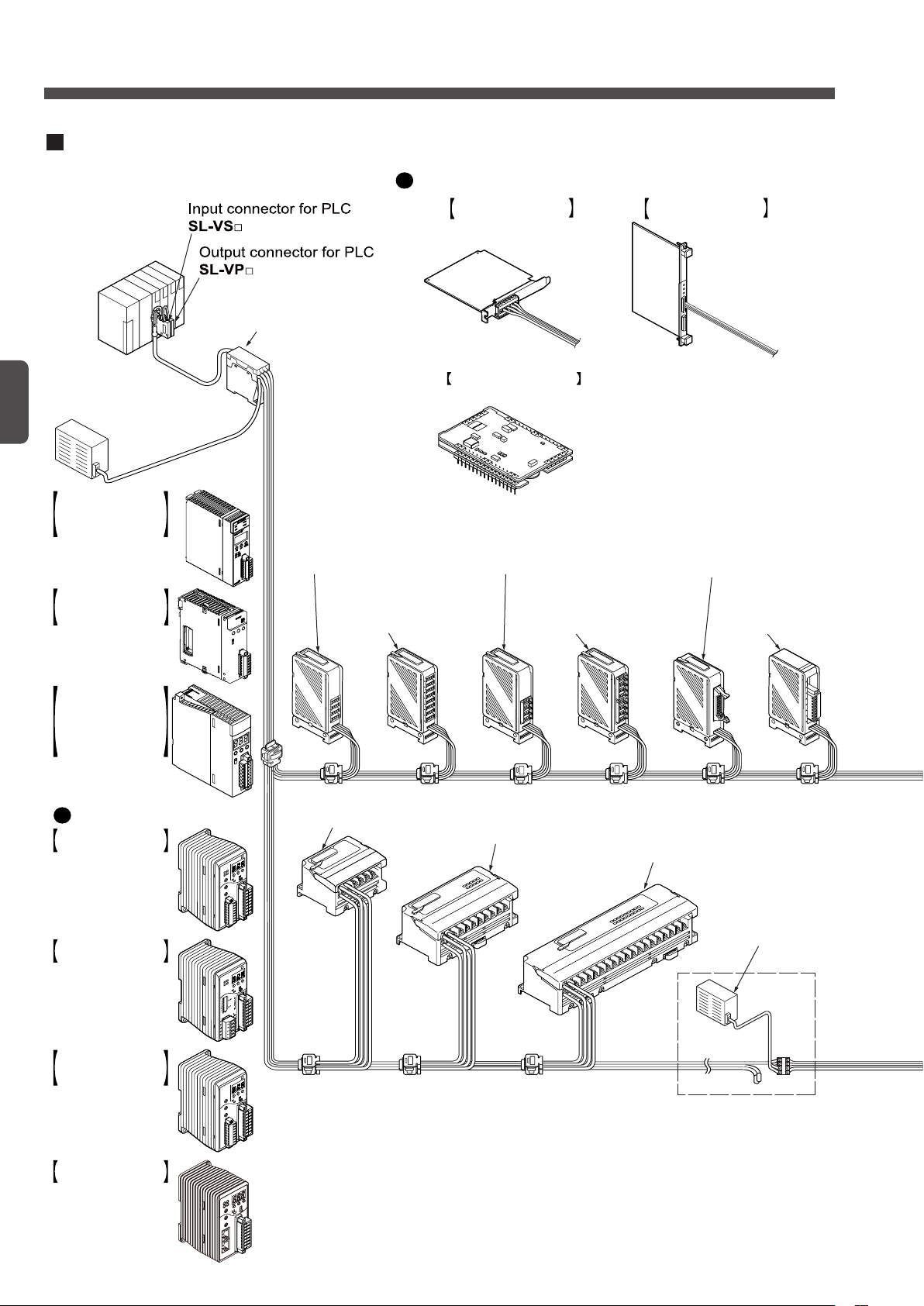

Example of system configuration

An example of the S-LINK V system is shown below.

For the specifications of each unit, refer to Chapter 4.

Controller

SL-VCU1

Power supply

unit

24V DC

+10

– 5

%

Bus direct-connection

type S-LINK V

controller for

MELSEC-Q series PLC

manufactured by

Mitsubishi Electric Corp.

SL-VMEL-Q

Bus direct-connection

type S-LINK V

controller for FP2 /

FP2SH series

SL-VFP2

Gateway controller (Note)

Control board

S-LINK V control board

for VME bus

SL-VVMES2

S-LINK V control board

for PCI bus

SL-VPCI

S-LINK V control module

SL-VMC1

4-channel connector

output unit

SL-VTP4J

e-CON type 4-channel

connector output unit

SL-VTP4E

e-CON type 8-channel

connector output unit

SL-VTP8E

8-channel connector

output unit

SL-VTP8J

16-channel MIL

connector

output unit

SL-VTP16C1(-S)

Analog output unit

SL-VTDA1

4-channel output terminal

SL-VTBP4

8-channel output terminal

SL-VTBP8

16-channel output terminal

SL-VTBP16

32-channel output terminal

SL-VTBP32

Local power

supply unit

4-channel relay output

terminal SL-VTPR4

S-LINK V gateway

controller for CC-Link

SL-VGU1-C

S-LINK V gateway

controller for

RS-485

/ RS-232C

SL-VGU1-485

S-LINK V gateway

controller for EtherCAT

SL-VGU1-EC

S-LINK V gateway

controller for DeviceNet

SL-VGU1-D

Bus direct-connection

type S-LINK V

controller for FP7 series

SL-VFP7

System Conguration

Chapter 1

14

Note: For a detailed description of the following controllers, refer to their respective user’s manuals.

SL-VGU1-C, SL-VGU1-D

SL-VGU1-EC

SL-VGU1-485

SL-VMEL-Q

SL-VFP7

:

:

:

:

SL-VGU1-C

:

SL-VGU1-EC

SL-VGU1-485

SL-VMEL-Q

SL-VFP7

SL-VGU1-D

/

User’s Manual

User’s Manual

User’s Manual

User’s Manual

User’s Manual

Page 15

1

2

3

4

4

3

2

1

0

7

6

5

Analog input unit

SL-VTAD1

I/O module

Input module

SL-VM8 / VM16

Output module

SL-VMP8 / VMP16

Hook-up connectors

SL-CP3

Cables and hook-up connectors

Flat cables are available so that

'T' - branch can be easily formed

by using hook-up connectors.

There are various types of hook-up connectors

that enable easy connection of cables.

Handy monitor

SL-VHM1

Picking switch

SL-VPK01 SL-VPK02

For flexible wire-saving system

e-CON type 4-channel

connector input unit

SL-VT4E

e-CON type 8-channel

connector input unit

SL-VT8E

4-channel connector

input unit SL-VT4J

16-channel

MIL connector

input unit

SL-VT16C1

8-channel connector

input unit SL-VT8J

1-channel output unit

SL-VCH11

2-channel output unit

SL-VCH22

1-channel input unit

SL-VCH10

2-channel input unit

SL-VCH20

2-channel I/O mixed unit

SL-VCH21

4-channel relay output

terminal SL-VTPR4

8-channel relay output

terminal SL-VTPR8

8-channel input terminal

SL-VTB8

4-channel input terminal

SL-VTB4

16-channel input terminal

SL-VTB16

32-channel input terminal

SL-VTB32

End unit

SL-VEU

System Conguration

Chapter 1

15

Page 16

Outline of Design

A

Transmission distance =

Selection of Controller or Control board

Select a

computer, VME bus computer, open network).

S-LINK V

controller or a

S-LINK V

control board optimum for the upper machines (PLC, PC, PCI bus

I/O Control Points

The system needs the following I/O control points. Design the system considering these points.

● Each controller or control board can control up to 256 nodes (number of I/O units connected to the system)

and 512 points (512 points × 2 for the

SL-VVMES2

● To cope with various PLC connection types of various manufacturers, we can provide 8 types of PLC input

connectors and 7 types of PLC output connectors. For a detailed description, refer to pages 159 and 160.

Each PLC I/O connector has 32 points for any model.

Chapter 1

NOTE

) of I/O device, connect two or more controllers as the other systems.

Each system needs one controller or one control board.

Two or more controllers or control boards cannot be connected to one system.

The above described number of I/O control points (512 points or 512 points × 2 for the

SL-VVMES2

This means that these values depend on the total cable length and the conditions of the connected machine (total current consumption, voltage drop, etc.).

For a detailed description, refer to pages 16 to 25.

) and the number of nodes (256 nodes) are the maximum values.

SL-VVMES2

). To control more than 512 points (512 points × 2 for the

Transmission Distance

The following two types of cables can be used for the

● Exclusive 4-core at cable (recommended cable)

● 4-core VCTF cable (0.3 to 2.0mm2, non-shielded) commercially available

Note: The VCTF cable is the vinyl cabtyre cable that conforms to the requirements of JIS C 3306 ‘Polyvinyl chloride insulated exible cords.’

To wire the

(+24V, 0V) and 2 signal transmission lines (D, G).

The cable length depends on the total cable length and the transmission distance.

S-LINK V

Control area

system, use 4-core cables so that the wire system can consist of 2 power supply lines

: S-LINK V I/O unit

(Branch line) (Branch line)

B C D

S-LINK V

(Main line)

A

system.

(Branch line)

16

Total cable length =

+

A

+B+

D

C

Page 17

Outline of Design

NOTE

● The main line is the longest route distributed from the controller or control board.

● The branch lines are the routes branched from the main line.

The total cable length should satisfy the conditions shown in the following table:

Transmission mode Total cable length (m)

A 100

B 400

C 1,600

The maximum transmission distance (between D and G) is as follows:

Mode A: 50m

●

The maximum length is 50m regardless of the cable conductor cross section (0.3 to 2.0mm2) and the number

of nodes (1 to 256 nodes).

Mode B

●

Conductor

cross

section

(mm2)

0.3 180

0.5

0.75

1.25

2.0

Number of nodes and maximum transmission length (m)

Up to 224 nodes Up to 256 nodes

200 (full specication for mode B)

Chapter 1

Mode C

●

Conductor

cross

section

(mm2)

0.3 570 440 350 300 260 220 200 180

0.5 710 580 490 420 370 330 300

0.75 780 670 590 530 480

1.25

2.0

NOTE

Up to 32

nodes

Up to 64

nodes

● Voltage drop between +24V and 0V is not considered. For this reason, calculate this volt-

age drop value, and use a local power supply unit, etc. to prevent voltage drop.

Number of nodes and maximum transmission length (m)

Up to 96

nodes

For a detailed description, refer to page 23.

● The conductor cross section of the exclusive 4-core at cable

● Wire the

S-LINK V

system while observing the communication distance specications de-

scribed above. In addition, use the cables that satisfy the specications described above.

● To select applicable cables, refer to the section describing cables.

For a detailed description, refer to page 157.

● The picking switch

SL-VPK0

Outputting Error Signals

Up to 128

nodes

800 (full specication for mode C)

Up to 160

nodes

Up to 192

nodes

SL-RCM

Up to 224

nodes

□ is 0.5mm2.

□ cannot be used in mode A (transmission mode).

Up to 256

nodes

If the controller is equipped with the error signal output function, the controller can output an error signal after

detection of an error.

To output an error signal, the

S-LINK V

system will be turned on properly. If an error occurs, the NPN output

transistor will be turned o.

For each type of error, you can select whether the error signal should be output.

For the Troubleshooting, refer to page 165.

For the error, refer to page 166.

17

Page 18

Outline of Design

Same length (Note 1)

Connect the end unit to the line

Main line

Connection of End Unit

CAUTION

Each system needs at least 1

not operate properly.

If the cable lengths are the same, connect the end unit to the line having fewer nodes (units).

Be sure to connect 1

If the branch line length exceeds 80% of the maximum transmission distance, connect 1

of the branch line, too.

Up to 2

<If the branch line length is equal to the main line length>

SL-VEU

SL-VEU

end units can be connected for 1 system.

end unit to the end of the main line.

SL-VEU

end unit. If the

SL-VEU

SL-VEU

unit is not connected, the system may

Chapter 1

having fewer nodes.

<If the branch line length is 80% of the main line length or more>

Maximum transmission distance

SL-VEU

SL-VEU

unit to the end

Connect the end unit to the main line

and branch line, respectively.

80% of the main line length or more

Notes: 1) The maximum transmission distance depends on the cable conductor cross section and the number of nodes.

For the maximum transmission distance, refer to page 17.

2) Even if the cable lengths are the same, if both the main and branch line lengths exceed 80% of the maximum transmission distance, connect two

SL-VEU

end units.

Selection of Control Cable and Connector Link Cable

Control cable selection method: (For use of SL-VCU1 only)

Check the distance from the

SL-VC1000

One control cable is needed for every 8 PLC I/O connectors.

(1m long) or

Connector link cable selection method: (For use of SL-VCU1 only)

The PLC I/O connector installation direction (vertical) and layout depend on the PLC manufacturers.

Check the connection distance of the PLC I/O connector, and then select the applicable connector link cable:

SL-VF70

For a detailed description, refer to page 176.

(70mm),

SL-VF150

SL-VCU1

SL-VC2000

(150mm), or

to the PLC I/O connector, and then select the applicable control cable:

(2m long).

SL-VF250

(250mm).

18

Page 19

Making of Branch Lines Using Cable Connectors

SL-VCU1

Intermediate connector

SL-JK

Branch lines can be made by using connectors and terminal blocks.

In addition, for this product, cables or connectors that are commercially available can be used.

CAUTION

The exclusive hook-up connectors can connect the exclusive 4-core at cables only.

Outline of Design

Exclusive 4-core at cable

Making of ‘T’ - branch line using exclusive hook-up

connector

SL-J1A

…1

Extension using exclusive hook-up connector

Exclusive 4-core at cable

4-core VCTF cable

commercially available

(non-shielded) (Note)

Note: The VCTF cord is the vinyl cabtyre cord that conforms to the requirements of JIS C 3306 ‘Polyvinyl chloride insulated exible cords.’

SL-J3A

…2

Connection of branch line using exclusive hook-up

connector

SL-JK1

SL-JK

Intermediate connector commercially available…5

Intermediate terminal block commercially available…6

and

and

SL-CP3

SL-CP3

…3

…4

SL-J1A

4-core VCTF cable commercially available (non-shielded) (Note)

Intermediate connector commercially available or

intermediate terminal block commercially available

Intermediate connector commercially available or

intermediate terminal block commercially available

Note: Use the same diameter cable.

1

6

SL-J1A

1

Intermediate connector

Intermediate terminal block

SL-CP3

3

SL-J3A

2

5

Chapter 1

SL-CP3

4

SL-JK1

SL-VEU

19

Page 20

Power Supply Capacity of System

This section describes how to calculate the total current consumption value and voltage drop value in order to

determine the power supply capacity (capacity of 24V DC power supply unit).

Calculation of Total Current Consumption Value

To determine the total current consumption, check the current consumption of each I/O unit.

Calculate the power supply capacity while referring to the list of current consumption values shown below.

Designation Model No. Current consumption (mA)

Controller

Bus direct-connection

Bus direct-connection

Mitsubishi MELSEC-Q PLC bus direct-connection

Control board for PCI bus

Control board for VME bus

Control module

Gateway controller for CC-Link

Gateway controller for DeviceNet

Gateway controller for RS-485 / RS-232C

Gateway controller for EtherCAT

Input connector for PLC

Chapter 1

Output connector for PLC

End unit

1-channel input unit

2-channel input unit

2-channel I/O mixed unit

1-channel output unit

2-channel output unit

4-channel connector input unit

8-channel connector input unit

16-channel MIL connector input unit

Analogue input unit

8-channel input module

16-channel input module

4-channel connector output unit

8-channel connector output unit

16-channel MIL connector output unit

Analogue output unit

8-channel output module

16-channel output module

4-channel relay output terminal

8-channel relay output terminal

Picking switch

Picking switch for shutter

Handy monitor

S-LINK V

S-LINK V

controller for

controller for

FP2

FP7

FP2SH

/

series

S-LINK V

series

controller

SL-VCU1

SL-VFP2

SL-VFP7

SL-VMEL-Q

SL-VPCI

SL-VVMES2

SL-VMC1

SL-VGU1-C

SL-VGU1-D

SL-VGU1-485

SL-VGU1-EC

SL-VS

□ 30

SL-VP

□ 73

SL-VEU

SL-VCH10

SL-VCH20

SL-VCH21

SL-VCH11

SL-VCH22

SL-VT4J, SL-VT4E

SL-VT8J, SL-VT8E

SL-VT16C1

SL-VTAD1

SL-VM8

SL-VM16

SL-VTP4J, SL-VTP4E

SL-VTP8J, SL-VTP8E

SL-VTP16C1(-S

SL-VTDA1

SL-VMP8

SL-VMP16

SL-VTPR4

SL-VTPR8

SL-VPK01

SL-VPK02

SL-VHM1

) 50 (Note 2)

25 (when shutter operation: 450)

135

60

80

70

85

88 (Note 1)

60

300

300

300

300

10

20

28

24

16

20

70 (Note 2)

105 (Note 2)

80 (Note 2)

80

18

20 (Note 2)

60 (Note 2)

90 (Note 2)

90

60

95 (Note 2)

90 (Note 2, 3)

150 (Note 2, 3)

25

500

20

Page 21

Power Supply Capacity of System

Designation Model No.

4-channel input terminal

8-channel input terminal

16-channel input terminal

32-channel input terminal

4-channel output terminal

8-channel output terminal

16-channel output terminal

32-channel output terminal

Notes: 1)

2) Regarding the

For a detailed description, refer to the specications of each product shown in

3) The

For the characteristics of the product when using PhotoMOS relay, refer to the ‘

4) The value shown in the ‘Unit side’ area indicates the current consumption in the main circuit.

The value shown in the ‘I/O side’ area indicates the current consumption in the I/O circuit.

SL-VVMES2

range, turning on of all the points may not be possible.

https://panasonic.net/id/pidsx/global

NOTE

, the value for 1 port is shown in the above table.

SL-VTPR

SL-VTPR

□ limits the output current depending on the ambient operation temperature and the number of ON points.

SL-VT□J, SL-VT□E, SL-VT□16C1(-S

□,

.’

The values shown in the above table does not include the current supplied to the PLC module and current consumption of sensors and loads.

SL-VTB4

SL-VTB8

SL-VTB16

SL-VTB32

SL-VTBP4

SL-VTBP8

SL-VTBP16

SL-VTBP32

SL-VM□16,

), and

if the ambient temperature is not in the specied

Specications

Panasonic Industrial Devices SUNX website:

In addition to the above units, when additional units (products) are connected, such as the

3-line sensor and output load, to the same 24V DC power supply unit, add the current consumption values of the additional units to the power supply capacity value.

Current consumption (mA)

Unit side I/O side (Note 4)

25 45

30 75

35 150

45 300

25 40

30 60

40 100

45 180

.

Chapter 1

21

Page 22

Power Supply Capacity of System

Input connector for PLC

8-channel connector input unit

SL-VTP4J

Example: Calculation of current consumption

<System conguration for control of 8 sensors and 4 output loads>

SL-VS1

Chapter 1

Controller

End unit

Input connector for PLC

Output connector for PLC

8-channel connector input unit

4-channel connector output unit

8-channel input terminal

Sensors

(Average current consumption: approx. 30mA )

Output loads

(Average current consumption: approx. 20mA )

Power supply unit

SL-VT8J

Designation Model No. Qty Current consumption (mA)

Output connector for PLC

SL-VP1

Controller

SL-VCU1

Sensors

4-channel connector output unit

SL-VCU1

SL-VEU

SL-VS1

SL-VP1

SL-VT8J

SL-VTP4J

SL-VTB8

—

—

1 135

1 10

1 30

1 73

1 105

1 60

1 30 + 75 = 105

8 30 × 8 = 240

4 20 × 4 = 80

Total 838

8-channel input terminal

SL-VTB8

Sensors

End unit

SL-VEU

Output loads

22

Page 23

Calculation of Voltage Drop Value

8

60

Allowable passing

Ambient temperature (˚C)

Power Supply Capacity of System

The transmission cables of the

cables themselves. For this reason, calculate the voltage drop value between +24V and 0V, and supply the rated voltage to all the

and G, and that of the control cables and connector link cables.

S-LINK V

S-LINK V

I/O units. However, it is not necessary to consider the voltage drop between the D

system may cause voltage drop due to the conductor resistance of the

CAUTION

Use of a longer cable will cause more voltage drop. If the voltage drops below the rated voltage, the

I/O units will not work. In this case, use the local power supply unit.

Elongation of the transmission distance will cause more voltage drop

at the line end (between +24V and 0V).

Voltage drop (V) = Cable length (m) × 2 × conductor resistance (Ω/m) × current (A)

Relation between the ambient temperature and allowable passing current when exclusive S-LINK V

cable SL-RCM100□ / RCM200 or SL-CBM100 / CBM200 (conductor cross section = 0.5mm

cable) is used.

2

for each

Chapter 1

Rated voltage (V)

CAUTION

The rated voltage depends on the unit. Check the rated voltage, and then select the right power supply unit and cables.

Supply the rated voltage to each unit.

Since the rated voltage to be supplied to the controller is +24V (-5%), the voltage supplied to the con-

●

troller should not be dropped below the following value:

24 - (24 × 0.05) =

Since the rated voltage to be supplied to the I/O units and end unit is +24V (-10%), the voltage sup-

●

plied to these units should not be dropped below the following value:

24 - (24 × 0.1) =

22.8V

21.6V

7

6

5

4

current (A)

0

5 10 15 20 25 30 35 40 45 50 55

23

Page 24

Power Supply Capacity of System

Necessity of Local Power Supply Unit

The 24V DC power supply unit that drives the system uses either the centralized power supply method (use of

only one power supply unit) or the decentralized power supply method (use of additional local power supply unit)

to supply power to each unit.

At rst, calculate the total current consumption value (sum total of current consumption values of all units ‘+’ sum

total of load current values of I/O devices).

After that, from the obtained calculation result, cable length, and conductor resistance, calculate the voltage

drop value, and determine the voltage to be supplied to each unit.

If the voltage supplied to each unit is above the rated voltage (22.8V or more for the controller, 21.6V or more for

the I/O unit), you can design the system using the centralized power supply method.

If the voltage supplied to a unit is out of the rated voltage range, connect a local power supply unit, and use the

local power supply method.

Designing of system using local power supply method

Chapter 1

CAUTION

To use a local power supply unit, turn on the local power supply unit rst, and then turn on the main

power supply unit, or turn on these power supply units at the same time.

If the main power supply unit is turned on rst, the system may not operate properly.

In the following cases, connect a local power supply unit:

● The communication distance is too long, and voltage drop is too large.

For this reason, it is not possible to supply the rated voltage to the I/O units.

● A 2-core cable is used for connection of the I/O unit (for the D-G line only).

● The main power supply unit and the local power supply unit should be the small capacity type.

● An I/O device that generates a large noise should be used.

<Reference value>

Conductor cross section (mm2) Conductor resistance (Ω/m)

0.3 Approx. 0.065

0.5 Approx. 0.040

0.75 Approx. 0.025

1.25 Approx. 0.015

2.0 Approx. 0.010

Notes: 1) The conductor resistance values shown in the above table are reference values.

To determine the conductor resistance values for the actual cables, contact the cable manufacturer.

2) The conductor cross section of the exclusive 4-core at cable should be 0.5mm2.

To determine whether a local power supply unit is necessary, refer to the owchart shown on the next page.

24

Page 25

Proposed system construction plan

Calculation of total current consumption value (refer to page 22)

Power Supply Capacity of System

ReexaminationReexamination

A unit should be changed

or removed

Out of rated range

of cable connector

(refer to page 157)

Calculation of voltage drop value

(refer to page 23)

Yes

A unit should be changed

or removed

A local power supply unit

is needed in view of the calculated

voltage drop value

Yes

No

Yes

Chapter 1

No

No

Necessary

Unnecessary

Decision 1

The I/O device should be

connected using 2-core cable

(for the D-G line only)

No

Decision 2

The main power supply unit and local

power supply machine should be the

small capacity type

No

Decision 3

An I/O device generates

large noise

No

Centrailzed power supply method Local power supply method

Yes

Yes

Yes

25

Page 26

Connection of DC 2-Wire Output Device to Input Unit

CAUTION

If you have to connect a DC 2-wire output device to an input unit, recommend our product.

If a product manufactured by another company is used, the conditions should be checked by follow-

ing the procedure shown in the following owchart.

This is because the output device of another company does not t our input unit.

DC 2-wire output device should be

used

Chapter 1

Our product is used

Check 1

21.6V-V

=In specied op-

THON

21.6V-V

THOFF

eration voltage range

Check 2

A

21.6V-V

≥

Minimum load current

i

R

Condition A

NO

≥ VA and

YES

YES

YES

NO

Connection to the

is not possible

NO

RB1 ≤

Normal connection

S-LINK V

system

The bleeder resistance is necessary

Calulation of bleeder resistance

A

21.6V-V

Minimum load current-

21.6V-V

i

R

Condition B

VA : Residual voltage in ON mode

A1 : Leakage current

VTH : Input voltage of input unit

THON

V

: Input unit ON voltage

THOFF

V

: Input unit OFF voltage

Ri : Input impedance

RB : Bleeder resistance

A

Check 3

THOFF

V

≥ A1 (Leakage current

i

R

in OFF mode)

YES

Decision of condition

Condition A

Connection is possible without any

bleeder resistor

26

NO

Condition B

Calulation of bleeder resistance

RB2 ≤

A1-

V

THOFF

i

R

THOFF

V

Decision of condition

Condition A

Connection is possible if the RB2

bleeder resistor is attached

Connection is possible if the RB1

bleeder resistor is attached

Condition B

Connection is possible if the RB1 or RB2

(small value) bleeder resistor is attached

Page 27

Connection of DC 2-Wire Output Device to Input Unit

21.6V - VA of DC 2-wire input device

R1

21.6V-3V

3.3kΩ 3.3kΩ

18.6V

3.3kΩ

4V

V

≥ 0.8mA

+24V

Input device

S-LINK V input unit

Example: Connection of DC 2-wire sensor

To connect DC 2-wire proximity sensor GX-12MU to 8-channel connector input unit SL-VT8J

●

THON

V

THOFF

V

R1 : Input impedance of

VA (residual voltage in ON mode) of

Specied operation voltage range of

Minimum load current of

A1 (leakage current) of

Check 1

21.6V - 17V = 4.6V ≥ 3V

21.6V - 4V = 17.6V (in range of 10.2 to 26.4V)

Since the requirements of both formulas are satised, carry out checks 2 and 3.

Check 2

Check 3

THOFF

R1

:

=

SL-VT8J

SL-VT8J

:

ON voltage = 17V or more (between +24V and data input)

OFF voltage = 4V or less (between +24V and data input)

≈

1.21mA

GX-12MU

GX-12MU

SL-VT8J

= 0.8mA

≈

= 3.3kΩ

GX-12MU

GX-12MU

= 3mA

= 3V or less

= 12 to 24V DC

=

≈

+10

% = 10.2 to 26.4V DC

– 5

5.64mA ≥ 3mA

Chapter 1

Since the requirements of Checks 2 and 3 are satised, the bleeder resistor is not necessary.

RB : Bleeder resistance

Main circuit

VTH

Input

Output

R1 : Input impedance

DC 2-wire

input device

0V

0V

27

Page 28

Transmission Delay Time

CAUTION

Due to dierence in communication protocols, the transmission delay time of the

diers from that of the conventional

S-LINK

system.

S-LINK V

For transmission, there are fastest transmission time and the slowest transmission time.

Since this product uses the serial transmission method, transmission will be carried out as shown in the follow-

ing gure.

For a detailed description of the following controllers, refer to their respective user’s manuals.

SL-VGU1-C, SL-VGU1-D : SL-VGU1-C

SL-VGU1-EC

SL-VGU1-485

SL-VMEL-Q

SL-VFP7

SL-VGU1-EC

:

SL-VGU1-485

:

SL-VMEL-Q

:

SL-VFP7

:

SL-VGU1-D

/

User’s Manual

User’s Manual

User’s Manual

User’s Manual

User’s Manual

Response delay time

<In case of SL-VCU1>

Chapter 1

I/O device

• Sensor

• Switch

• Relay, etc.

S-LINK V system

Input

1. Response time of input device (sensor, etc.)

2. Input

0.2ms

3. Filtration

4. Refresh time

8. Filtration

Output

10. Output

0.35ms

9. Refresh time

11. Response time of

output device

(actuator, etc.)

system

PLC

Response delay of S-LINK V system

●

• Input response time (2 + 3 + 4 + 5)

2 3 4 5

MIN. = 0.2 + From Table 1 + From Table 2 + 0.001 (ms)

MAX. = 0.2 + From Table 1 + From Table 2 + 0.001 (ms)

• Output response time (7 + 8 + 9 + 10)

7 8 9 10

MIN. = 0.015 + From Table 1 + From Table 2 + 0.35 (ms)

MAX. = 0.015 + From Table 1 + From Table 2 + 0.35 (ms)

5. Output to PLC

0.001ms

7. PLC to Input

0.015ms

6. PLC operation time (scanning time + PLC filtration time)

28

Page 29

<In case of SL-VFP2, SL-VMEL-Q, SL-VPCI, SL-VVMES2>

Input Output

I/O device

• Sensor

• Switch

• Relay, etc.

S-LINK V system

1. Response time of input device (sensor, etc.)

2. Input

0.2ms

3. Filtration

4. Refresh time

Transmission Delay Time

10. Response time of

output device

(actuator, etc.)

9. Output

0.35ms

8. Refresh time

PLC etc.

Response delay of S-LINK V system

●

• Input response time (2 + 3 + 4 + 5)

2 3 4 5

MIN. = 0.2 + From Table 1 + From Table 2 + From Table 2 (ms)

MAX. = 0.2 + From Table 1 + From Table 2 + From Table 2 (ms)

• Output response time (7 + 8 + 9)

MIN. = From Table 2 + From Table 2 + 0.35 (ms)

MAX. = From Table 2 + From Table 2 + 0.35 (ms)

<Table 1 Filtration time>

Filtration time (ms)

A mode B mode C mode

MIN. MAX. MIN. MAX. MIN. MAX.

0.05 0.06 0.19 0.26 0.77 1.02

5. Internal memory

Max. 1 refresh time

6. PLC / PC operation time (scanning time)

7 8 9

<Table 2 Refresh time, Internal memory max.1 refresh time>

Number of

I/O control

points

32

64 2.09 8.36 33.44

96 2.68 10.71 42.85

128 3.27 13.06 52.26

160 3.85 15.42 61.66

192 4.44 17.77 71.07

224 5.03 20.12 80.48

256 5.62 22.47 89.89

288 6.21 24.82 99.30

320 6.79 27.18 108.70

352 7.38 29.53 118.11

384 7.97 31.88 127.52

416 8.56 34.23 136.93

448 9.15 36.58 146.34

480 9.73 38.94 155.74

512 10.32 41.29 165.15

Refresh time, Internal memory max.1 refresh time (ms)

A mode B mode C mode

MIN. MAX. MIN. MAX. MIN. MAX.

1.50

0.29

7. Internal memory

Max. 1 refresh time

6.01

1.18

Chapter 1

24.03

4.70

29

Page 30

Transmission Delay Time

Power-on

S-LINK V

controller

Occurrence of error

2. Output

0.5ms

S-LINK V

controller

Operation at power-on

1. Time required for power-on

(Depends on the supplied power)

Completion of

transmission check

● READY output at normal starting

OFF

ON

● READY output at starting after shorting line

Chapter 1

between +24V and 0V or between D and G line

OFF

ON

● Error output 1 and 2

OFF

ON

2. Transmission

check

3. Output

0.5ms

READY

output

<Table 3 Time required for transmission check at starting controller>

Number of

I/O control

points

32 69.5 134.3 422.1

64 82.6 186.8 632.2

96 100.4 258.1 917.5

128 123.0 348.3 1278.1

160 150.2 457.2 1713.9

192 182.2 585.0 2225.0

224 218.8 731.6 2811.4

256 260.2 897.0 3473.0

288 306.2 1081.2 4209.9

320 357.0 1284.3 5022.1

352 412.4 1506.1 5909.5

384 472.6 1746.8 6872.2

416 537.5 2006.3 7910.1

448 607.1 2284.6 9023.4

480 681.3 2581.7 10211.8

512 760.3 2897.6 11475.6

Time required for transmission check at starting cotroller (ms)

A mode B mode C mode

READY output delay time (1 + 2 + 3)

●

1 (Depending on supplied power) + 2 (From Table 3) + 3 (0.5 ms)

Error signal outputting delay time

1. Error check

● Error output 1 and 2

OFF

ON

Error output delay time (1 + 2)

●

1 (From Table 4 or 5) + 2 (0.5ms)

Error output

<Table 4 Time required for error check (errors 3, 4, and 5)>

Number of

I/O control

points

32 43.5 174.0 695.8

64 93.4 373.6 1494.3

96 162.1 648.4 2593.8

128 249.6 998.6 3994.4

160 356.0 1424.0 5696.0

192 481.2 1924.7 7698.7

224 625.2 2500.6 10002.4

256 788.0 3151.8 12607.2

288 969.6 3878.3 15513.1

320 1170.0 4680.0 18720.0

352 1389.2 5557.0 22228.0

384 1627.3 6509.2 26037.0

416 1884.2 7536.8 30147.1

448 2159.9 8639.6 34558.2

480 2454.4 9817.6 39270.4

512 2767.7 11070.9 44283.6

Time required for error check (errors 3, 4, and 5) (ms)

A mode B mode C mode

30

<Table 5 Time required for error check (errors 1 and 2)>

Time required for error check (errors 1 and 2) (ms)

A mode B mode C mode

1.33 5.32 21.28

Page 31

System setting time

Setting of system

Transition to RUN / CHECK mode

S-LINK V

Controller

5. Transmission

Transmission Delay Time

● READY output in CONFIG mode (RUN → CONFIG)

● READY output in CONFIG mode (CONFIG mode at power-on)

(Pressing of button)

Canceling of

errors 3 and 4

OFF

ON

OFF

ON

(Using mode setting switch)

1. Time required for

transition to system

setting mode 3 sec.

2. System setting

Completion of

3. Refreshing

stop

4. Output

0.5ms

Error output OFF → ON

communication check

Indication of number

of nodes of PLC I/O

connector unit: 6.4 sec.

check

6. Output

READY

output

0.5ms

<Table 6 Time required for system setting>

Number of

I/O control

points

32 142.7 427.0 1593.0

64 235.3 797.4 3074.8

96 342.0 1224.3 4782.3

128 462.8 1707.7 6715.7

160 597.8 2247.5 8874.9

192 746.8 2843.7 11259.8

224 910.0 3496.4 13870.6

256 1087.3 4205.5 16707.1

288 1278.7 4971.1 19769.5

320 1484.2 5793.1 23057.6

352 1703.8 6671.6 26571.5

384 1937.6 7606.5 30311.2

416 2185.4 8597.9 34276.7

448 2447.4 9645.7 38468.0

480 2723.4 10750.0 42885.1

512 3013.6 11910.7 47528.0

Time required for system setting (ms)

A mode B mode C mode

<Table 7 Time required for refreshing stop>

Number of

I/O control

points

32 15.7 62.8 251.3

64 37.7 150.9 603.5

96 69.1 276.5 1106.2

128 110.0 439.9 1759.4

160 160.2 640.8 2563.2

192 219.8 879.4 3517.5

224 288.9 1155.6 4622.3

256 367.4 1469.4 5877.7

288 455.2 1820.9 7283.6

320 552.5 2210.0 8840.0

352 659.2 2636.7 10546.9

384 775.3 3101.1 12404.4

416 900.8 3603.1 14412.4

448 1035.7 4142.7 16570.9

480 1180.0 4720.0 18880.0

512 1333.7 5334.9 21339.6

Time required for refreshing stop (ms)

A mode B mode C mode

Chapter 1

<Table 8 Time required for transmission check>

Number of

I/O control

points

32 69.5 134.3 422.1

64 82.6 186.8 632.2

96 100.4 258.1 917.5

128 123.0 348.3 1278.1

160 150.2 457.2 1713.9

192 182.2 585.0 2225.0

224 218.8 731.6 2811.4

256 260.2 897.0 3473.0

288 306.2 1081.2 4209.9

320 357.0 1284.3 5022.1

352 412.4 1506.1 5909.5

384 472.6 1746.8 6872.2

416 537.5 2006.3 7910.1

448 607.1 2284.6 9023.4

480 681.3 2581.7 10211.8

512 760.3 2897.6 11475.6

Time required for transmission check (ms)

A mode B mode C mode

31

Page 32

ON

‘Opened’

‘Shorted’

Selection of Output Holding Function for Output Unit

Output units are equipped with the output holding function.

If a transmission error is detected, the output holding function will be activated to hold the output condition detected just before occurrence of the error.

Output holding function setting method

CAUTION

Before setting the output holding function, fully understand the function, and check the operation condition of the output-to device. If this function is not set correctly, a serious problem may occur.

The output hold setting switch is at the end of the address setting switch panel.

Set the ‘HOLD’ switch to ON / OFF to set the output holding function.

1

2

4

Chapter 1

Output hold setting switch

OFF

ON

8

16

32

Operation in normal

transmission mode

Output operation

64

HOLD

Operation in transmission error mode

Turning o of output

Holding of output condition detected

just before occurrence of error

<If output module is SL-VMP8 or SL-VMP16>

If the line between HOLD (pin No. 29) and ADD. (COM.) (pin No. 28) is opened, the output holding function will

be canceled (‘HOLD OFF’ mode).

If this line is shorted, the output holding function will be set (‘HOLD ON’ mode).

NOTE

HOLD OFF

ADD.

(COM.)

HOLD HOLD

2928

● Before delivery, the output hold setting switch is set to OFF (the ‘HOLD OFF’) mode is

set.

HOLD ON

ADD.

(COM.)

2928

● If it takes a long time to turn o the power of the controller, the output holding function

may not operate properly.

32

Page 33

Address Setting

S-LINK V

NOTE

The

SL-VVMES2

To clarify the sent-from and sent-to units, assign a number to each I/O device.

These numbers are referred to as ‘addresses.’

To properly operate the

Setting of PLC I/O connector numbers

CAUTION

Be careful not to set the same address for the PLC I/O connectors.

Considering the set connector numbers, set the optimum I/O control points for the controller.

For the address setting examples, refer to page 180.

Using the connector number setting switches, you can set a connector number consisting of 32 points for each PLC

I/O connector. (The same connector number setting method can be used for any types of PLC I/O connectors.)

For the connector number setting examples, refer to page 73.

system uses one controller to send up to 512 points (512 points × 2 for

) (256 nodes) of signal in the serial transmission mode.

S-LINK V

system, correctly set the addresses.

Chapter 1

Setting of I/O unit addresses

CAUTION

● Be careful not to set the same address for the

●

Set the addresses of

Note that any address exceeding the I/O control points cannot be set.

Using the address setting switches, assign addresses to I/O units.

For each I/O unit, the assigned address will be the rst number of the address, and the rest of the address will

be set depending on the specied number of I/O points.

For a detailed description, refer to page 74.

When using the picking switch SL-VPK0□

●

To assign the address, use the address setting remote controller

For a detailed description, refer to the User’s Manual that came with the address setting remote controller

SL-VAR1

.

S-LINK V

I/O units while observing the I/O area set by the PLC I/O connectors.

S-LINK V

I/O units.

SL-VAR1

and send it to the

SL-VPK0□

.

33

Page 34

SL-VCU1

SL-VS3

F side

SL-VP3

SL-VP3

Address Setting

Example: Address setting

If PLC I/O connector is connected to the A1SX42 (input module) and the A1SY42 (output module)

●

manufactured by Mitsubishi Electric Corporation:

L side

Chapter 1

Input

A1SX42

IN OUT

42 31

SL-VS3

'F side of A1SX42' and

Signal name Address Signal name Address Signal name Address Signal name Address

X00 0 X10 16 X20 32 X30 48

X01 1 X11 17 X21 33 X31 49

X02 2 X12 18 X22 34 X32 50

X03 3 X13 19 X23 35 X33 51

X04 4 X14 20 X24 36 X34 52

X05 5 X15 21 X25 37 X35 53

X06 6 X16 22 X26 38 X36 54

X07 7 X17 23 X27 39 X37 55

X08 8 X18 24 X28 40 X38 56

X09 9 X19 25 X29 41 X39 57

X0A 10 X1A 26 X2A 42 X3A 58

X0B 11 X1B 27 X2B 43 X3B 59

X0C 12 X1C 28 X2C 44 X3C 60

X0D 13 X1D 29 X2D 45 X3D 61

X0E 14 X1E 30 X2E 46 X3E 62

X0F 15 X1F 31 X2F 47 X3F 63

SL-VS3

1 'L side of A1SX42' and

PLC I/O connector

No. Connector No.

1 0

2 1

3 2

4 3

I/O

Input

Output

PLC I/O connector

model

SL-VS3

SL-VS3

SL-VP3

SL-VP3

SL-VS3

Address

0 to 31

32 to 63

64 to 95

96 to 127

2

Output

A1SY42

'F side of A1SY42' and

Signal name Address Signal name Address Signal name Address Signal name Address

Y40 64 Y50 80 Y60 96 Y70 11 2

Y41 65 Y51 81 Y61 97 Y71 11 3

Y42 66 Y52 82 Y62 98 Y72 11 4

Y43 67 Y53 83 Y63 99 Y73 11 5

Y44 68 Y54 84 Y64 100 Y74 116

Y45 69 Y55 85 Y65 101 Y75 117

Y46 70 Y56 86 Y66 102 Y76 118

Y47 71 Y57 87 Y67 103 Y77 119

Y48 72 Y58 88 Y68 104 Y78 120

Y49 73 Y59 89 Y69 105 Y79 121

Y4A 74 Y5A 90 Y6A 106 Y7A 122

Y4B 75 Y5B 91 Y6B 107 Y7B 123

Y4C 76 Y5C 92 Y6C 108 Y7C 124

Y4D 77 Y5D 93 Y6D 109 Y7D 125

Y4E 78 Y5E 94 Y6E 110 Y7E 126

Y4F 79 Y5F 95 Y6F 111 Y7F 127

SL-VP3

3 'L side of A1SY42' and

SL-VP3

4

To set addresses as shown in the above table, set the I/O control points of the controller to 128 points.

If the control points is set to under 128 points, transmission with a unit set to 128 points of I/O points or more will

not be possible.

For a detailed description, refer to page 180.

34

Page 35

Chapter 2 Wiring

35

Page 36

Flowchart

To wire each unit, follow the procedure shown in the following owchart:

DANGER

Before disconnecting or reconnecting a cable or connector, be sure to turn o the power.

Chapter 2

Recheck

Designing of

satisfactory (voltage drop,

Learning of basic procedure

Installation of each unit of

S-LINK V

Cutting of cable depending on

specied cable length

S-LINK V

Designing

All conditions are

address setting, etc.)

system

system

Yes

Redesigning

No

Refer to page 37 and following pages.

Connection of each unit

Setting of PLC I/O connector numbers

(in case of using

Setting of each unit address

Temporary starting of system

Error

SL-VCU1

Controller setting

Occurrence of error

(Error indication)

Normal

Refer to page 51 and following pages.

)

Refer to page 33

(For a detailed description, refer to page 73.)

Refer to page 33

(For a detailed description, refer to page 74.)

Refer to page 66.

36

System starting

Page 37

Basic Procedures

String

Not good Not good Not goodGood

Connector hook-up work

This section describes the knowledge and setup method to be learned before starting connector hook-up work.

CAUTION

● If a connector is not hooked-up correctly, the

● If a connector is once hooked-up, do not use the connector again.

This is because the performance of a used connector may be deteriorated.

● Before starting hook-up work, be sure to turn o the power.

● When you disconnect or reconnect a connector, be sure to grab the connector main body.

If you pull the cable to disconnect or reconnect a connector, the cable may be disconnected.

● Do not hook-up any connector in a cold weather, such as outdoors in winter.

S-LINK V

system will not work.

Cutting of exclusive 4-core at cable

Cut the exclusive 4-core at cable so that the end face of the cable can be orthogonal.

CAUTION

● Cut the exclusive 4-core at cable so that the end face of the cable can be orthogonal.

If the end face is not orthogonal, the connector may not be hooked-up properly.

● Do not peel the sheath of the exclusive 4-core at cable.

● After cutting the exclusive 4-core at cable, check that the cores are not in contact with each other.

Chapter 2

Orthogonal

Peeling of sheath

37

Page 38

Basic Procedures

Clearance

Not good

Guide

<SL-JPS> <SL-JPC> <SL-JPE>

How to use exclusive hook-up pliers (SL-JPS, SL-JPC, SL-JPE)

CAUTION

If there is a clearance between the guide of the exclusive hook-up pliers and the connector, the connector may not be hooked-up properly.

Adjust the protrusion of the connector to the guides of the hook-up pliers.

1.

Protrusion

Chapter 2

2.

3.

Protrusion

Protrusion

Protrusion

Slide the connector to the guides till it stops, and check if there is no clearance between them.

Adjust the exclusive hook-up pliers so that the pliers can be orthogonal to the cable.

After that, press the connector until it clicks.

38

Page 39

Hook-up of Connector

+24V indication line

Cover

Housing

<SL-JK

Touch the cable to the wall to fix the cable

+24V indication line

<

<SL-JK connector for cable end>

Hook-up method of SL-JK connector for cable end and SL-JK1 connector for ‘T’- branch

CAUTION

● Before starting the connector hook-up work, fully understand the hook-up work and the setup work

(See pages 37, 38.)

● Use the exclusive 4-core at cable.

Prepare a set of SL-JK or SL-JK1 connector housing and the cover.

1.

SL-JK

SL-JK1

hook-up connector for cable end: Light blue

hook-up connector for ‘T’ - branch: Blue

Basic Procedures

, SL-JK1> <SL-JK1>

NOTE

Hook-up the main / branch line at cable to the cover. Fix the cable using 4 claws.

2.

A hook-up connector consists of a housing and a cover.

Do not attach a housing to a cover having dierent color.

<SL-JK>

Wall

CAUTION

Fix the brown (+24V) line of the exclusive 4-core at cable to the recognition mark side of the cover

(▲ mark side on the top or the +24V indication line on the side.)

Claw

Brown (+24V)

+24V indication line

Wall

Chapter 2

NOTE

SL-JK1 cable for ‘T’ - branch>

Claw

Brown (+24V)

There are recognition marks on the top (▲ mark) and the side (+24V indication line) of the

cover so that the miswiring can be prevented.

<Top view of cover>

+24V line mark

+24V indication line

39

Page 40

Basic Procedures

Confirmation window

Cover

Confirmation window

Protrusion

Claw

Confirmation window

Place the housing on the cover, and then lightly press the cover to temporarily x it.

3.

Housing

*Check the engagement condition

4.

Chapter 2

5.

<Check items>

● Check that the claws of the housing are properly pressed to the cover.

● If the connector is attached to the cable end, check the condition of the main / branch line at cable through

the conrmation window. The cable should be in contact with the back of the connector.

NOTE

Hook-up the connector using the exclusive hook-up pliers (SL-JPS).

For the caution regarding the exclusive hook-up pliers and the hook-up procedure, refer to pages 37,

38.

Check the hook-up condition of the connector.

● If the housing is placed in a wrong direction, it will not be engaged with the cover.

● If the connector is attached to the cable end, check the cable condition through the conr-

mation window. The cable should be in contact with the back of the connector.

Protrusion

Claw

40

Page 41

Hook-up method of SL-J1A connector for ‘T’ - branch and

Cover Housing

A

Cover

B

HousingCover

A

Cover

B

Cover

A

Wall

SL-J3A connector for cable extension

CAUTION

● Before starting the connector hook-up work, fully understand the hook-up work and the setup work

(See pages 37, 38.)

● Use the exclusive 4-core at cable.

Basic Procedures

Prepare a set of SL-J1A or SL-J3A connector covers and

1.

SL-J1A

SL-J3A

<SL-J1A>

<SL-J3A>

Touch the end face of the at cable to cover

2.

hook-up connector for ‘T’ - branch: Gray

hook-up connector for cable extension: Black

, and then x the cable using the cable stopper.

, and housing.

Chapter 2

Cable stopper

Cable stopper

Touch the cable to the cover,

and then fix the cable.

41

Page 42

Basic Procedures

with the groove.

Confirmation window

Confirmation window

Cable stopper

Cable stopper

<SL-J1A> <SL-J3A>

Place the housing on cover , and then lightly press the cover to temporarily x it.

3.

4.

Chapter 2

Cover

A

Guide

Groove

0.5

NOTE

● If the housing is placed in a wrong direction, it will not be engaged with the cover.

● Check the cable condition through the conrmation window.

The cable should be in contact with the back of the connector.

Place another at cable on cover

the cable stopper.

Cover

A

Check that the guide is properly engaged

0.5

0.5

0.5

0.5

J3A

J3A

(for the

SL-J3A, touch the cable to the wall), and then x cable using

Touch the cable to the cover,

and then fix the cable.

0.5

0.5

Housing

42

Page 43

Basic Procedures

* Same color

<SL-J1A> <SL-J3A>

Protrusion

Protrusion

Confirmation window

<SL-J1A>

Place the temporarily xed housing (see step 3) on cover

5.

rarily x it.

CAUTION

Before temporarily xing the housing, be sure to check that the same color lines of both cables are

aligned with each other.

<SL-J1A>

* Same color

, and then lightly press the housing to tempo-

<SL-J3A>

Chapter 2

NOTE

Hook-up the connector using the exclusive hook-up pliers (SL-JPS).

6.

For the caution regarding the exclusive hook-up pliers and the hook-up procedure, refer to pages 37,

38.

Check the hooked-up condition.

7.

<Check items>

● Check that the claws are properly pressed.

● Check the condition of the at cable through the conrmation window.

The cable should be in contact with the back of the connector.

Check the cable condition through the conrmation window.