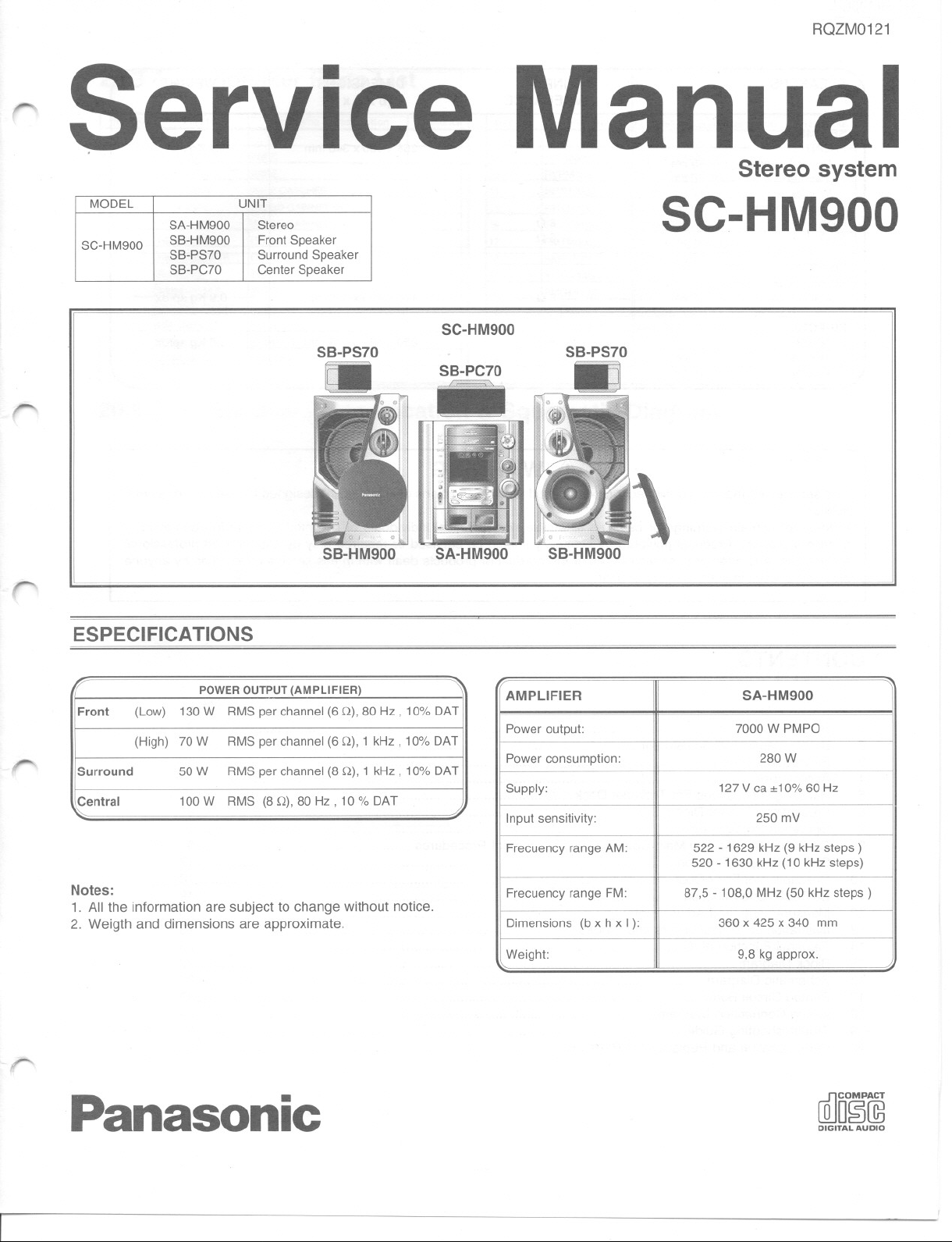

Panasonic SC-H M900 Diagram

r

r-

ROZMO121

Service Manual

Stereo system

MODEL UNIT

Stereo

Front Speaker

Surround Speaker

Cantar Speaker

SB-PS70

SC-H M900

SC-HM900

SC-HM900

SA-HM900

SB-HM900

SB-PS70

SB-PC70

r-

r'-

SB-HM900

ESPECIFICA TIONS

POWEROUTPUT(AMPLlFIER)

Front

Surround

Central 100W

Notes:

1. AIIthe informationaresubjecttochangewithoutnotice.

2. Weigthanddimensionsareapproximate.

130W

(Low)

(High) 70 W

50W

RMS par ehannel(6Q), 80 Hz , 10% DAT

RMS par ehannel (6Q), 1 kHz , 10% DAT

RMS par ehannel (8 Q), 1 kHz, 10% DAT

RMS (8 Q), 80 Hz, 10% DAT

SA-HM900

SB-HM900

AMPlIFIER

Power output:

Power eonsumption:

Supply:

Input sensitivity:

Freeueney ranga AM:

Freeueney ranga FM:

Dimensions (b x h xl):

Weight:

,

SA-HM900

7000 W PMPO

280 W

127V ea:t10% 60 Hz

250 mV

522 - 1629 kHz (9 kHz steps )

520 -1630 kHz (10kHz steps)

87,5 - 108,0 MHz (50 kHz steps )

360 x 425 x 340 mm

9,8 kg approx.

,......

Panasonic

(illol!@

DIGITAL AUDIO

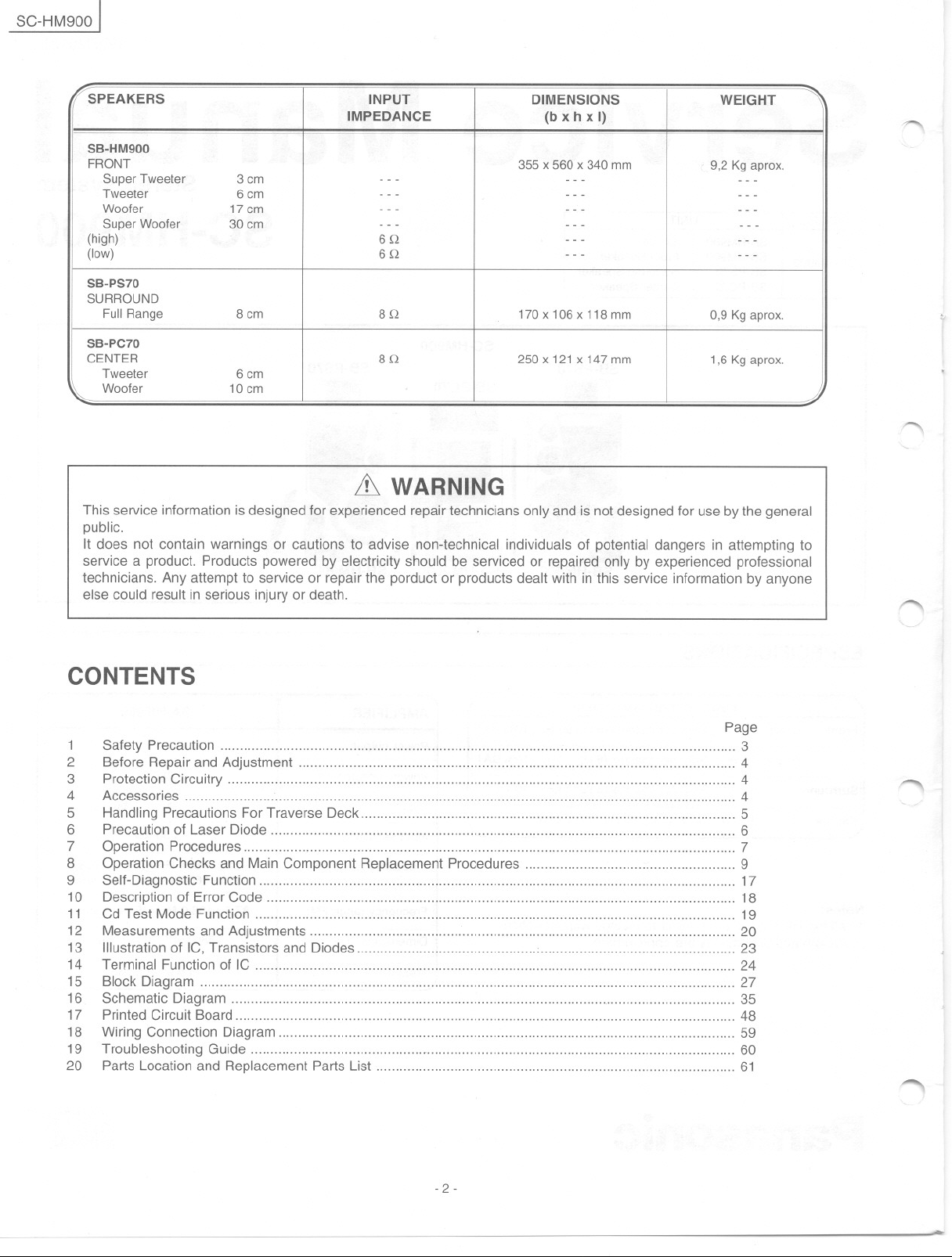

SC-HM900 I

P SPEAKERS

SB-HM900

FRONT

Super Tweeter

Tweeter

Woofer

Super Woofer

(high)

(Iow)

SB-PS70

SURROUND

FuI!Range

SB-PC70

CENTER 812

Tweeter

Woofer

3cm

6cm

17 cm

30 cm

8 cm 812

6cm

10 cm

INPUT DIMENSIONS

IMPEDANCE

- - -

(b x h x 1)

355 x 560 x 340 mm

- --

- --

- --

612

612

170 x 106 x 118 mm

250x121 x147mm

WEIGHT

- --

---

-- - - - -

- - - -- -

- - - -- -

- - -

9,2 Kg aprox.

-- -

- - -

-- -

0,9 Kg aprox.

1,6 Kg aprox.

Lh WARNING

This service information is designed for experienced repair technicians only and is not designed for useby the general

publico

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to

service a product. Producís powered by electricity should be serviced or repaired only by experienced professional

technicians. Any attempt to service or repair the porduct or producís dealt with in this service information by anyone

else could result in serious injury or death.

~

'"

A

"""'"

~

CONTENTS

1

Safety Precaution 3

2

Before Repair and Adjustment 4

3

Protection Circuitry 4

4

Accessories 4

5

Handling Precautions For Traverse Deck 5

6

Precaution of Laser Diode

7

Operation Procedures

8

Operation Checks and Main Component Replacement Procedures 9

9

Self-Diagnostic Function """""' 17

10

Descriptionof ErrorCede"""""""" 18

11

Cd Test Mode Function """"""""""" 19

12

Measurements and Adjustments

13

lIIustration of IC, Transistors and Diodes : 23

14

Terminal Function of IC 24

15

Block Diagram

16

Schematic Diagram 35

17

Printed Circuit Board 48

18

Wiring Connection Diagram

19

TroubleshootingGuide"""""""""" 60

20

París Location and Replacement París List 61

"" 27

' 6

""""""" 7

""""""' 20

"""""""' 59

page

~

~

- 2-

-

1 SC-HM900

,.-.

,.....

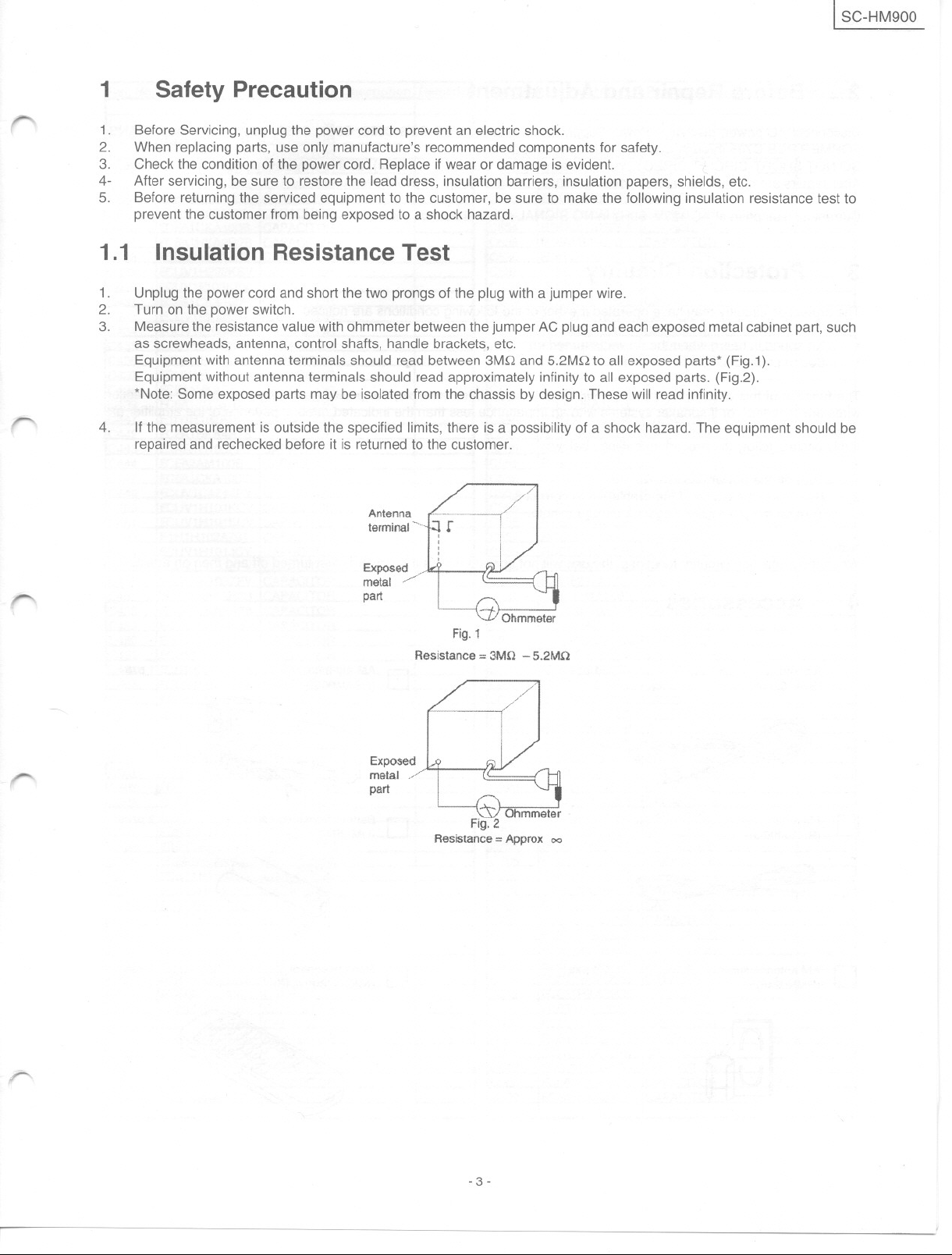

1

1.

2.

3.

4-

5.

1.1

1.

2.

3.

4.

Safety Precaution

Before Servicing, unplug the power cord to prevent an electric shock.

When replacing parts, use only manufacture's recommended components for safety.

Check the condition of the power cardoReplace if wear or damage is evident.

After servicing, be sure to restorethe lead dress, insulation barriers, insulation papers, shields, etc.

Before returning the serviced equipment to the customer, be sure to make the following insulation resistance test to

prevent the customer from being exposed to a shock hazard.

Insulation Resistance Test

Unplug the power cord and short the two prongs of the plug with a jumper wire.

Turn on the powerswitch.

Measure the resistancevalue with ohmmeter betweenthe jumper AC plugandeachexposedmetalcabinetpart, such

as screwheads, antenna, control shafts, handle brackets, etc.

Equipment with antenna terminals should read between 3MQ and 5.2MQ to all exposed parts* (Fig.1).

Equipment without antenna terminals should read approximately infinity to all exposed parts. (Fig.2).

*Note: Some exposed parts may be isolated from the chassis by designoThese will read infinity.

If the measurement is outside the specified limits, there is a possibility of a shock hazard. The equipment should be

repaired and rechecked before it is returned to the customer.

,......

,......

Exposed

metal,./'/

par!

Exposed

metal/'

par!

Fig.1

Resistance ==3MO - 5.2MO

Fig-:2

Resistance==Approx 00

r---

- 3-

SC-HM900 J

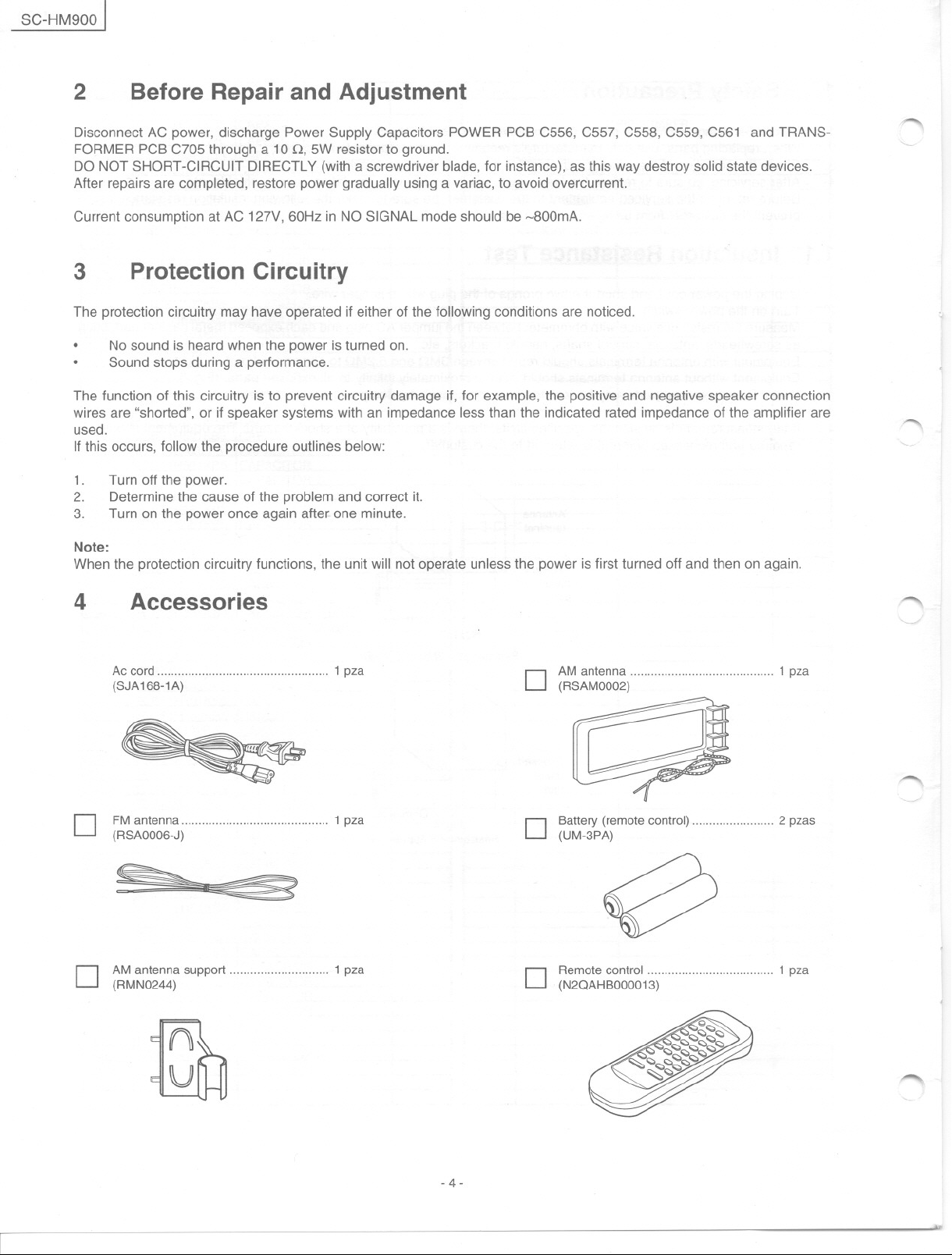

2

Disconnect AC power, discharge Power Supply Capacitors POWER PCB C556, C557, C558, C559, C561 and TRANS-

FORMER PCB C705 through a 10 Q, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLy (with a screwdriver blade, for instance), as this way destroy salid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 127V, 60Hz in NO SIGNAL mode should be ~800mA.

3

The protection circuitry may have operated if either of the following conditions are noticed.

.

.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection

wires are "shorted", or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are

used.

If this occurs, follow the procedure outlines below:

1.

2.

3.

Note:

Whentheprotectioncircuitryfunctions,theunitwillnotoperateunlessthepowerisfirstturnedoffandthenonagain.

Before Repair and Adjustment

Protection Circuitry

No sound is heard when the power is turned on.

Sound stops during a performance.

Turn off the power.

Determine the cause of the problem and correGíit.

Turn on the power once again after one minute.

'"'

~

4 Accessories

Ac cord 1 pza

(SJA168-1A) D tR~~~~~~~)""""""""""""""""""""" 1 pza

Battery(remote control) 2 pzas

D f~s~~~~~-~)""""""""""""""""""""" 1 pza

D

(UM-3PA)

e

D tRMM~~~~~~support 1 pza D ~~2~ol~~~~~~113)""""""""""""""""" 1 pza

'""

~

-4-

,..-".

..

[SC-HM900

f'"

f"

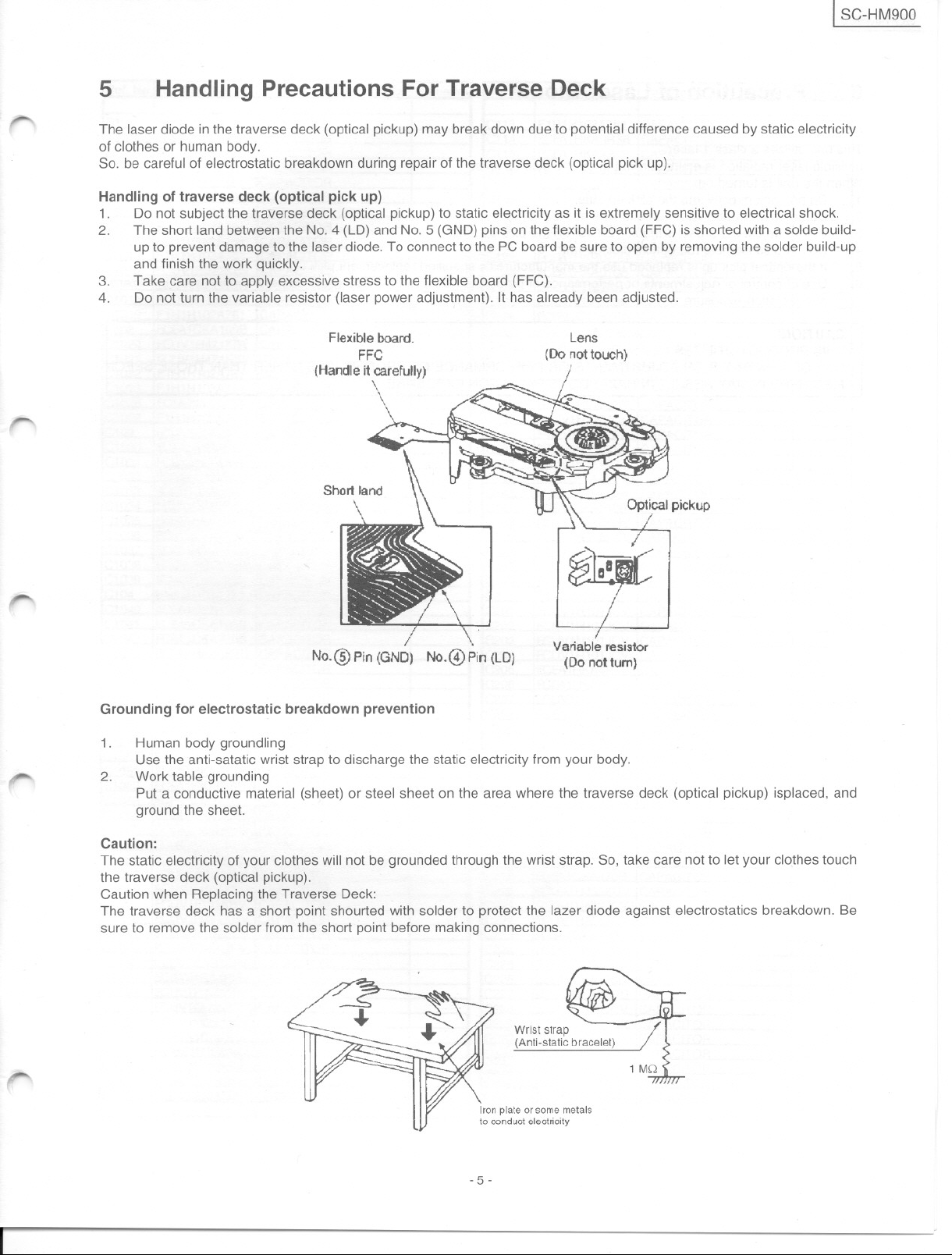

5

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by staticelectricity

of clothes or human body.

So. be careful of electrostatic breakdown during repairof the traverse deck (optical pick up).

Handling of traverse deck (optical pick up)

1. Donot subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. Theshort land betweenthe No. 4 (LO)and No. 5 (GND) pins onthe flexible board (FFC) is shorted with a solde build-

3. Take Gafenot to apply excessive stress to the flexible board (FFC).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

Handling Precautions For Traverse Deck

up to prevent damage to the laserdiode. To connect to the PC board be sure to open by removingthe solder build-up

and finish the work quickly.

Flexible board.

FFC

(Handle it carefully)

Lens

(Donottouch)

/

I

\

-

,

r

~

/

/

No.@Pin(GND) No.@)Pin(LO)

Grounding for electrostatic breakdown prevention

1.

Human body groundling

Use the anti-satatic wrist strap to discharge the static electricity from your body.

2.

Work table grounding

Pul a conductive material (sheet) or steel sheet on the afea where the traverse deck (optica! pickup) isplaced, and

ground the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take Gafenotto leí your clothes touch

the traverse deck (optical pickup).

Caution when Replacing the Traverse Deck:

The traverse deck has a short point shourted with solder to proteGíthe lazer diode against electrostatics breakdown. Be

sure to remove the solder from the short point before making connections.

Variable resistor

(Do not lum)

Wriststrap

(Anti-static bracelet)

,.....

Iron plate or some metals

to conduct electricity

- 5-

SC-HM900]

6 Precaution 01 Laser Diode

CAUTION:

This unit utilizes a class 1 laser.

Invisible laser radiation is emitted from the optical pick up lens.

When the unit is turned on:

1. Donot look directly into the pick up lens.

2. Do not use optical instruments to look at tlle pick up lens.

3. Do not adjust the preset variable resistor on the pick up lens.

4. Do not disassemble the optical pick up unit.

5. If the optical pick up is replaced use the manufactures's specified replacement pick up only.

6. Use of control or adjustments or performance of procedures other than those specified here in may result in hazard-

'1"""'\

ous radiation exposure.

CAUTION!

THIS PRODUCT UTILlZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECI

FIED HERE IN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

-"""

"""'"

" ,.

- 6-

~

...

I SC-HM900

..........

r

-

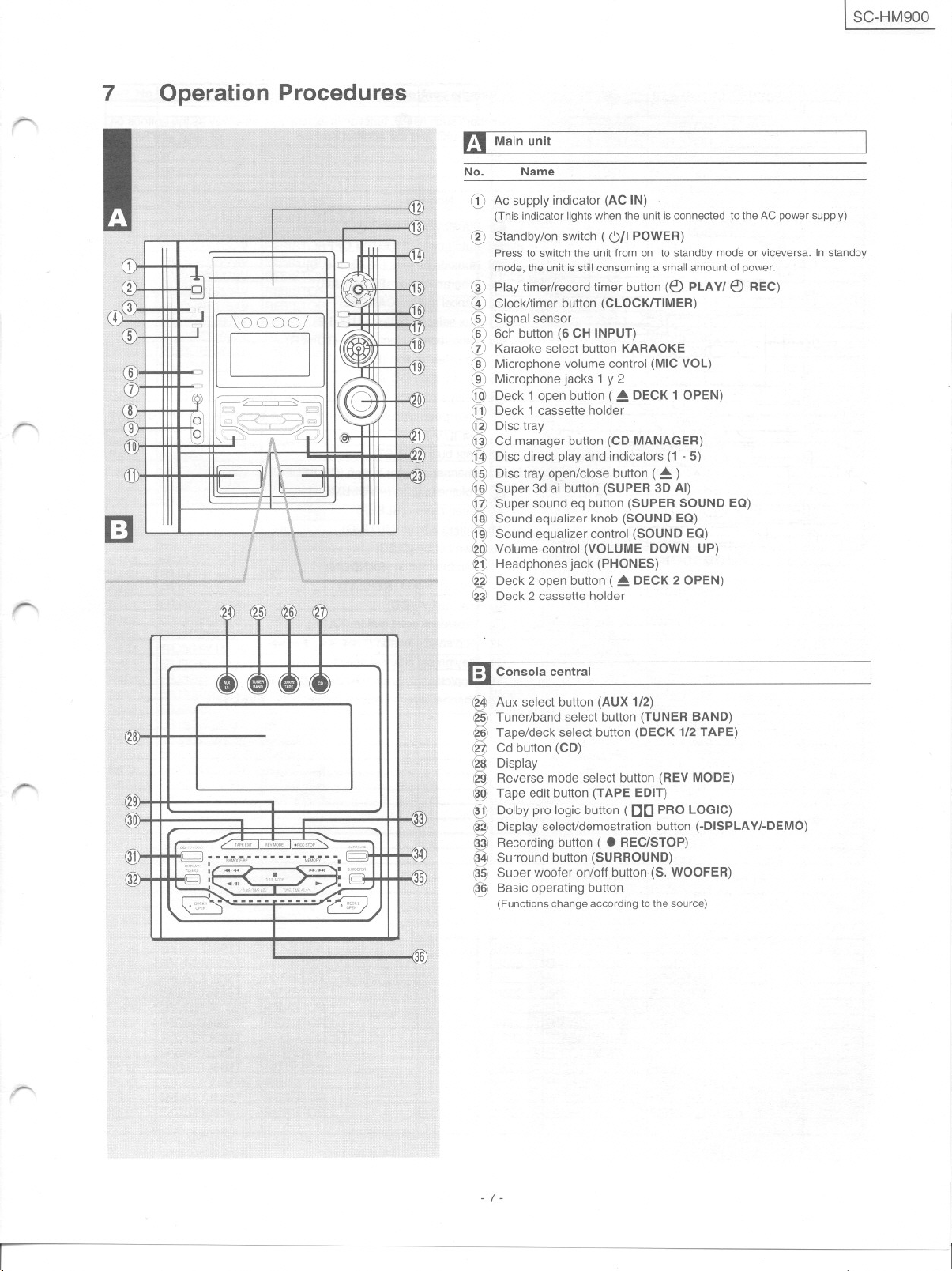

7

m

Operation Procedures

101

a Main unit

No. Name

CD Ac supply indicator (AC IN)

(This indicalor lighls when Ihe unil is connecled lo Ihe AC power supply)

(]) Standby/on switch (6/1 POWER)

Press lo switch Ihe unil Irom on lo slandby mode or viceversa. In slandby

mode, Ihe unil is slill consuming a small amounl 01 power.

@ Playtimer/record timer button (e) PLAY/ e) REC)

@ Clock/timer button (CLOCKlTIMER)

@ Signal sensor

@ 6ch button (6 CH INPUT)

(j) Karaoke select button KARAOKE

@ Microphone volume control (MIC VOL)

@ Microphonejacks 1 y 2

@ Deck 1 open button ( ~ DECK 1 OPEN)

@ Deck 1 cassette holder

@ Disctray

@ Cd manager button (CD MANAGER)

@J Disc direct play and indicators (1 - 5)

@ Disctray open/close button (~ )

@ Super3dai button (SUPER 3D Al)

@ Super sound eq button (SUPER SOUND Ea)

@ Sound equalizerknob (SOUND Ea)

@ Sound equalizercontrol (SOUND Ea)

@ Volumecontrol (VOLUME DOWN UP)

@ Headphonesjack (PHONES)

~ Deck 2 open button ( ~ DECK 2 OPEN)

e Deck 2 cassette holder

-

.

-.

""",,, I ",,"m, ,"",,'O"

rn Consola central

~ Aux select button (AUX 1/2)

@ Tuner/band select button (TUNER BAND)

@ Tape/deck select button (DECK 1/2TAPE)

@ Cd button (CD)

@ Display

@ Reverse mode select button (REV MODE)

@ Tape edil button (TAPE EDIT)

@ Dolby pro logic button ( [][JPRO LOGIC)

@ Display selectldemostration button (-DISPLAY/-DEMO)

@ Recordingbutton ( . REC/STOP)

@ Surroundbutton (SURROUND)

@ Super woofer on/off button (S. WOOFER)

@ Basic operating button

(Funclions change according lo Ihe source)

- 7-

SC-HM900 ]

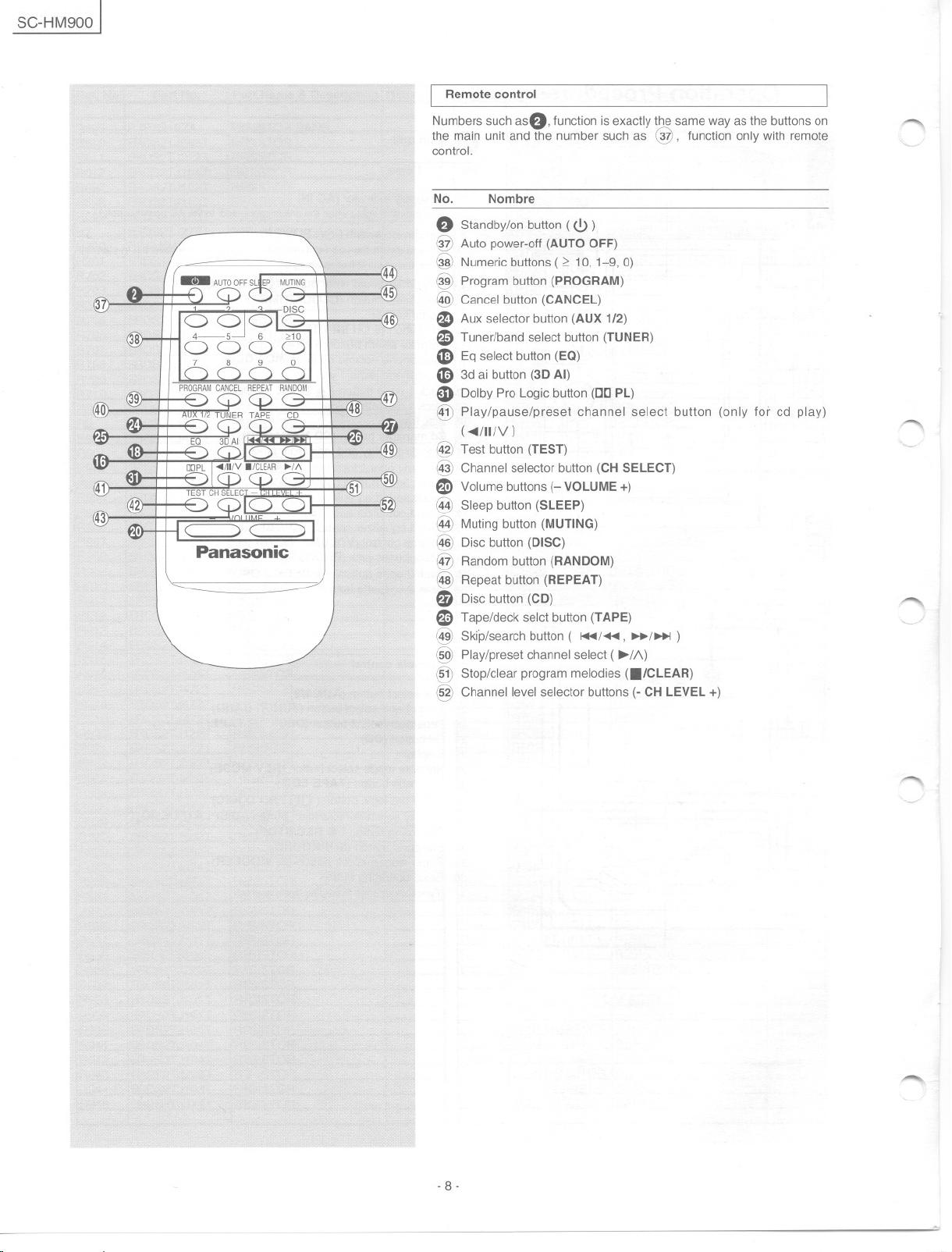

I Remote control

Numberssuch asO, lunction is exactlythe same way as the buttonson

the main unit and the number such as @, lunction only with remate

control.

No. Nombre

f) Standby/on button ( <!>)

@ Auto power-off (AUTO OFF)

@ Numeric buttons (;:::10,1-9, O)

@ Program button (PROGRAM)

@ Cancel button (CANCEL)

~ Aux selector button (AUX 1/2)

e Tuner/band select button (TUNER)

G) Eqselect button (Ea)

e 3d ai button (3D Al)

a. Dolby Pro Logic button ([][] PL)

@ Play/pause/preset channel select button (only lor cd play)

(""/11IV )

@ Test button (TEST)

@ Channel selector button (CH SELECT)

G> Volume buttons (- VOLUME +)

@ Sleep button (SLEEP)

@ Muting button (MUTING)

@ Disc button (DISC)

@ Random button (RANDOM)

@ Repeat button (REPEAT)

G Disc button (CD)

e Tape/deck selct button (TAPE)

@ Skip/search bullan ( 1+11/"-, ~/~ )

@ Play/preset channel select ( ~/¡\)

~ Stop/clear program melodies (8/CLEAR)

@ Channellevel selector buttons (-CH LEVEL +)

""'""

""'"

'"'"

"--

- 8-

,........

, ,.,

Z;

ISC-HM900

r"'-

~

8

Operation Checks and Main Component Replacement

Procedures

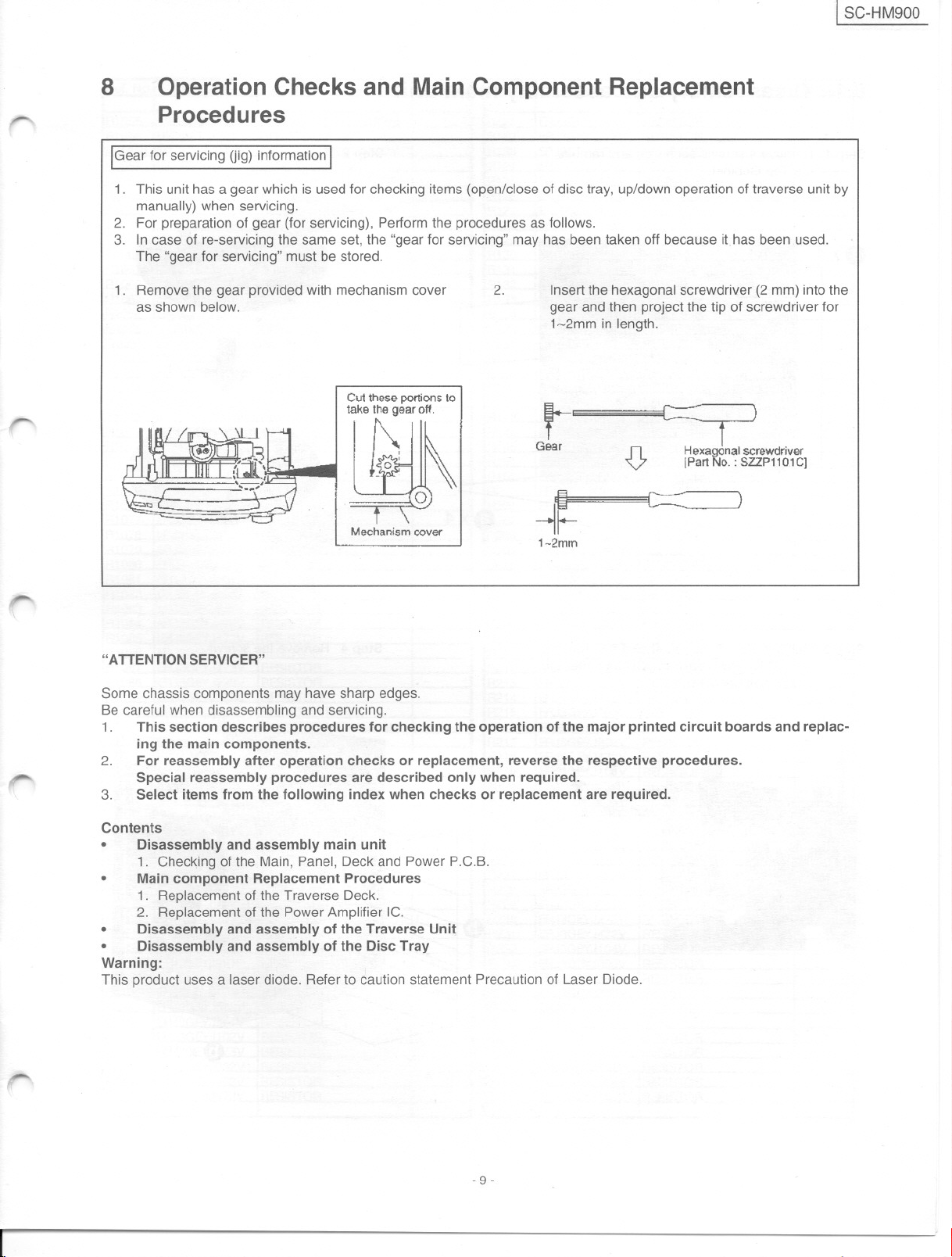

IGear for servicing (jig) informationI

1. This unít has a gear which is usedfor checking items (open/close of disc tray, up/down operation of traverse unit by

manually) when servicing.

2. For preparation of gear (for servicing), Performthe procedures as follows.

3. Incase of re-servicing the same gel, the "gear for servicing" may has been taken off because ithas been used.

The "gear for servicing" must be stored.

1. Remove the gear provided with mechanism cover

as shown below.

2.

Insertthe hexagonal screwdriver (2 mm) into the

gear and then project the tip of screwdriver for

1~2mm in length.

t-

Gear

~.

n Hexagonal screwdnver

V IPart No. : SZZP11 0.1C]

c=:

Mechanism caver

-1~

1-2mm

-

,

r

"ATTENTION SERVICER"

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the majar printed circuit boards and replac-

ing the main components.

2.

For reassembly alter operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Contents

e Disassemblyandassemblymain unit

1. Checking of the Main, Panel, Deck and Power P.C.B.

e

Main component Replacement Procedures

1. Replacementof the Traverse Deck.

2. Replacement of the Power Amplifier IC.

e Disassemblyand assemblyof theTraverseUnit

e Disassemblyandassemblyof the DiscTray

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

,-

- 9-

SC-HM900 I

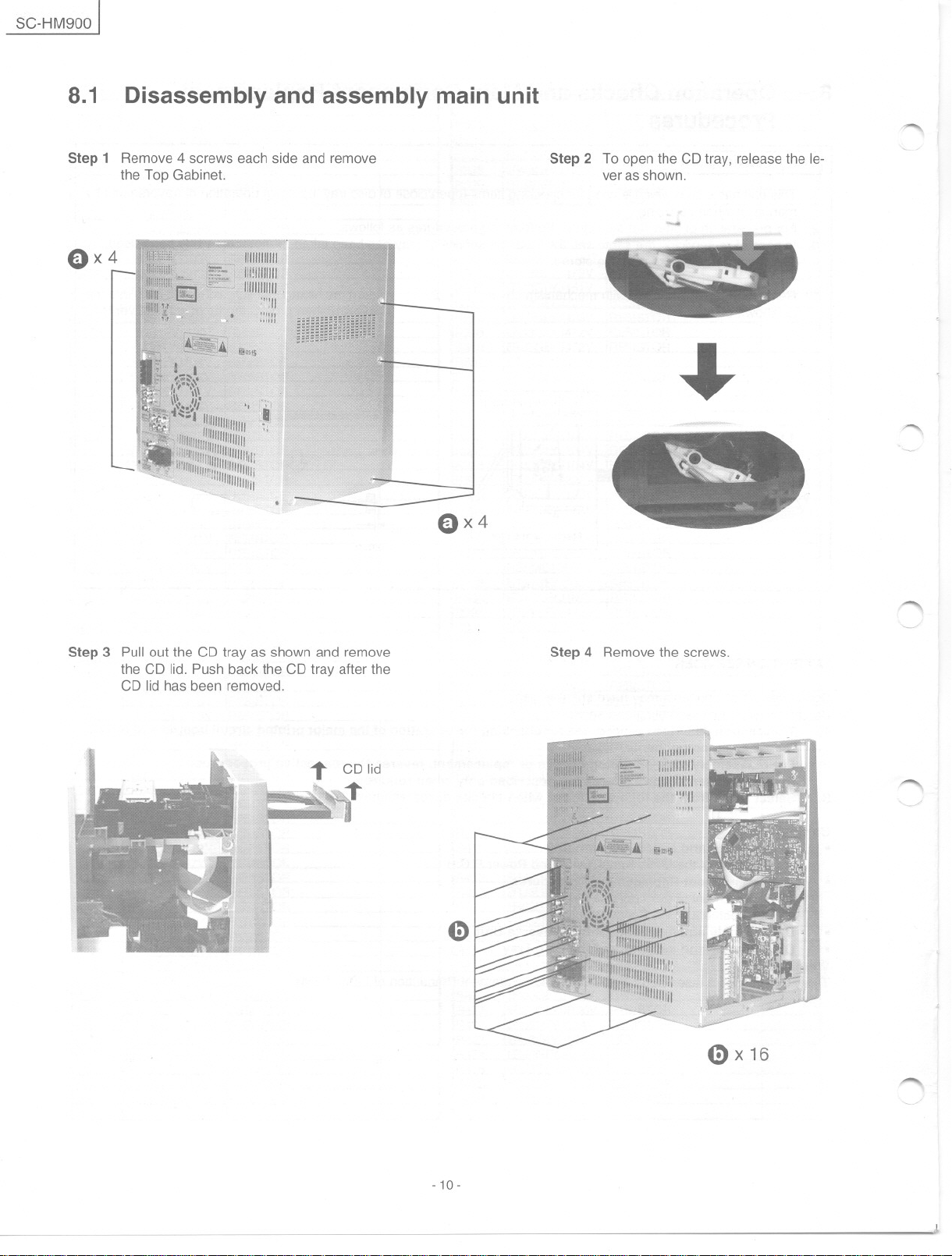

8.1

Step 1 Remove 4 screws each side and remove

E)x 4

Disassembly and assembly main unit

the Top Gabinet.

~

Step 2 To open the CD tray, releasethe le-

verasshown.

~

~

E)x 4

Step 3 Pul!out the CD tray as shown and remove

the CD lid. Push back the CD tray after the

CD lid has been removed.

~

Step 4 Remove the screws.

"'""'

G)

- 10-

0x 16

.......

~

I SC-HM900

r'

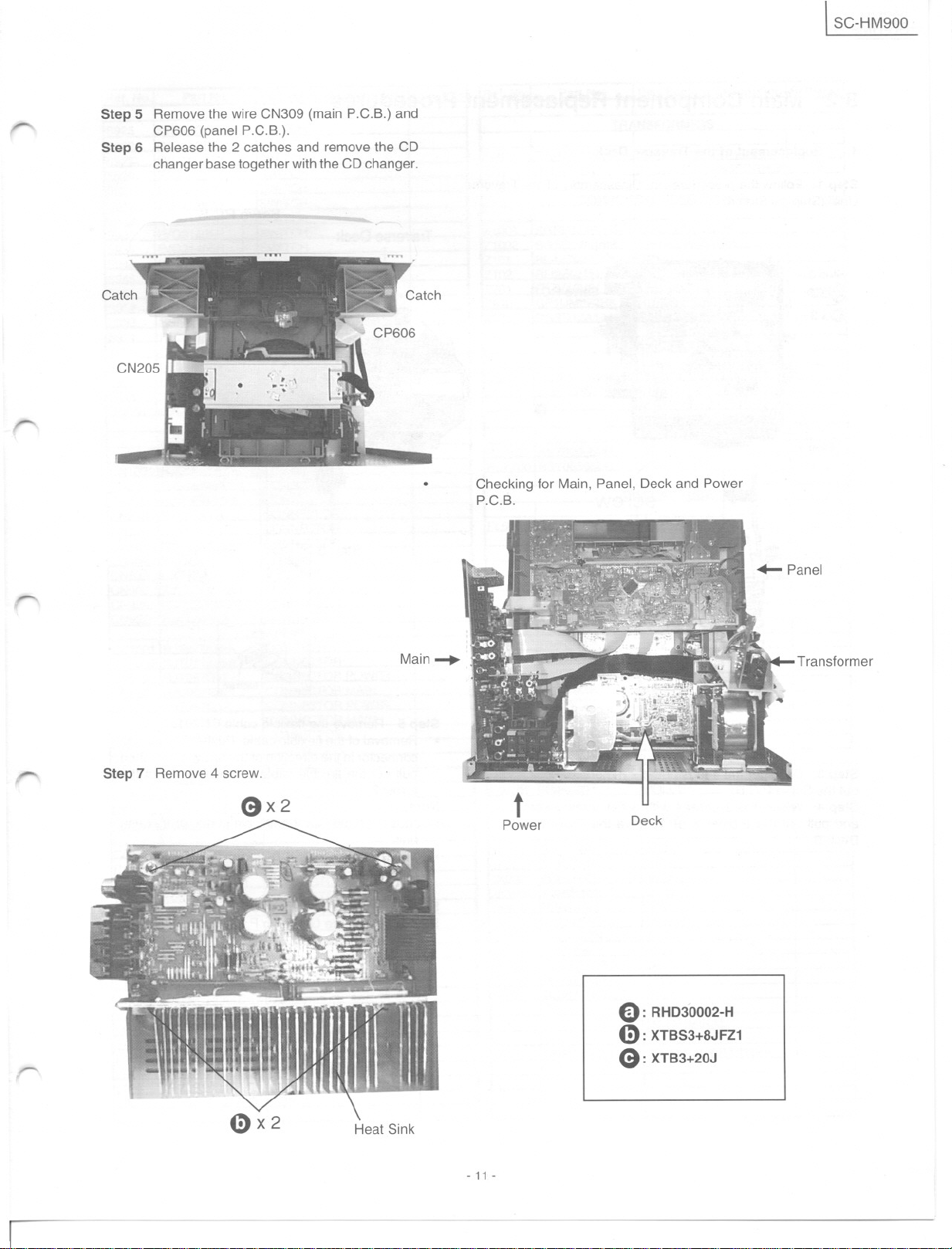

Step 5 Removethe wire CN309 (main P.C.B.) and

CP606 (panel P.C.B.).

Step 6 Releasethe 2 catches and removethe CD

changerbase togetherwiththe CDchanger.

,-

Checking tor Main, Panel, Deck and Power

P.C.B.

-.

-

,.......

Step 7 Remove4 screw.

Qx2

Main.....

Transtormer

Deck

E): RHD30002-H

4:): XTBS3+8JFZ1

ea: XTB3+20J

Heat Sink

- 11-

SC-HM900 I

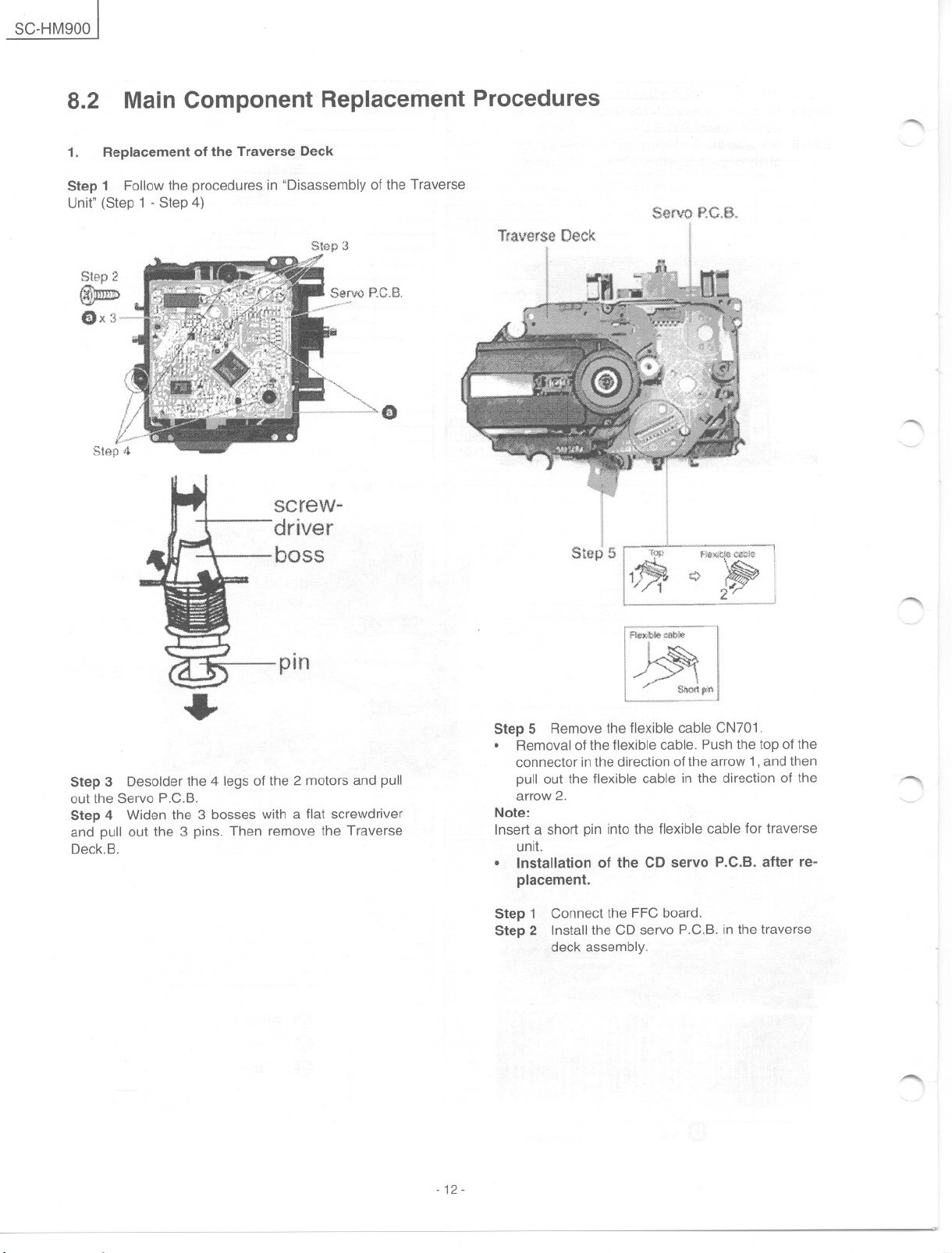

8.2

1.

Step 1 Follow the procedures in "Disassembly of the Traverse

Unit" (Step 1 - Step 4)

Main Component Replacement Procedures

Replacement 01 the Traverse Deck

Stap3

(1

screw..

driver

Tfaverse

"""'

SeNO P.C.B.

Deck

~

"'""'-

boss

pin

~

Step 3 Desolder the 4 legs of the 2 motors and pul!

out the Servo P.C.B.

Step 4 Widen the 3 bosses with a flat screwdriver

and pull out the 3 pins. Then remove the Traverse

Deck.B.

511~

Step 5 Remove the flexible cable CN701 .

e>

. Removal of the flexible cable. Pushthe top of the

connector inthedirection of the arrow 1,and then

pul! out the flexible cable in the direction of the

arrow 2.

Note:

Insert a short pin into the flexible cable for traverse

unit.

. Installation of the CD servo P.C.B. after re-

placement.

Step 1 Connect the FFC board.

Step 2 Instal!the CD servo P.C.B. in the traverse

deck assembly.

~

"'"

- 12-

~

1 SC-HM900

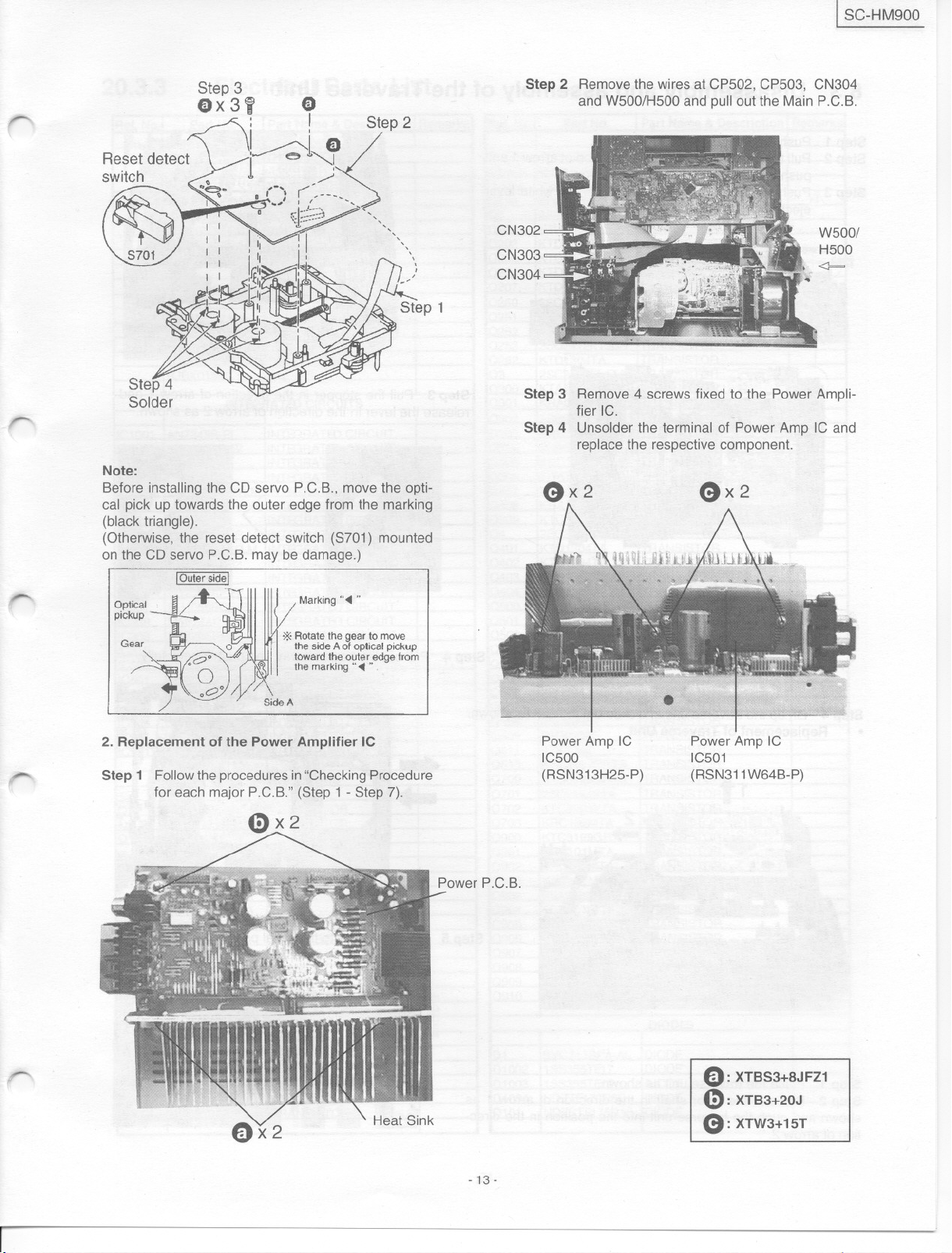

Step 2 Removethe wires at CP502, CP503, CN304

and W500/H500 and pull out the Main P.C.B.

r

..-

-

Note:

Before installing the CD servo P.C.B., move the opti-

cal pick up towards the outer edge from the marking

(black triangle).

(Otherwise, the reset detect switch (8701) mounted

on the CD servo P.C.B.may be damage.)

aptical

pickup

CN302

CN303

CN304

Step 3 Remove 4 screws fixed to the Power Ampli-

fier IC. .

Step 4 Unsolder the terminal of Power Amp IC and

replace the respective component.

ex2

ex2

W500/

H500

<J==

-

,

---

,

2. Replacement of the Power Amplifier IC

Step 1 Followthe proceduresin"CheckingProcedure

for each majar P.C.B." (8tep 1- 8tep 7).

-13-

Power Amp IC

IC500

(R8N313H25-P)

Power Amp IC

IC501

(R8N311W64B-P)

Q: XTBS3+8JFZ1

e: XTB3+20J

e: XTW3+15T

SC-HM900 I

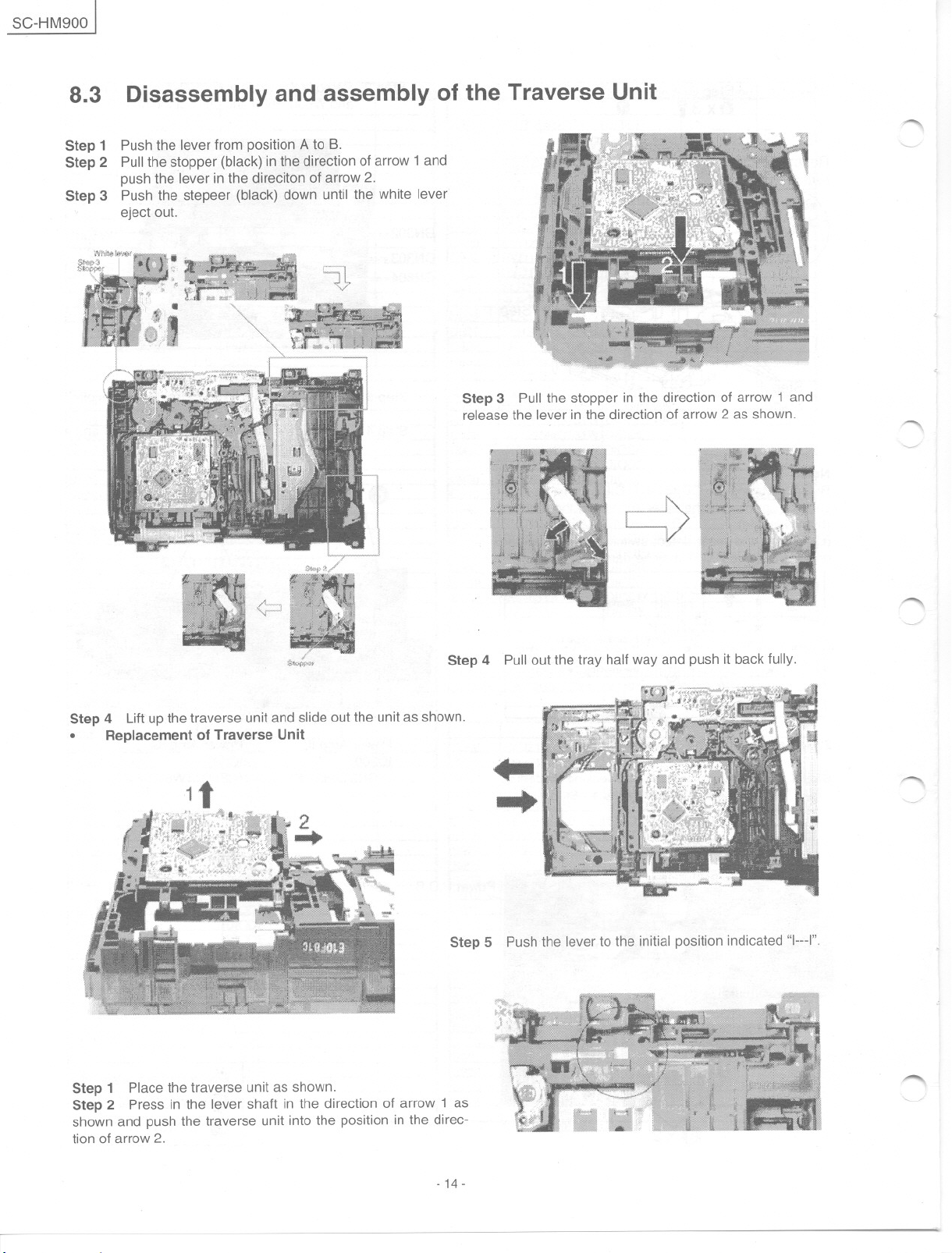

8.3

Step 1

Step 2

Step 3

Disassembly and assembly of the Traverse Unit

Push the lever from positionA to B.

Pullthe stopper (black) inthedirectionofarrow 1and

push the lever in the direciton of arrow 2.

Push the stepeer (black) down until the white lever

eject out.

Step 3 Pull the stopper in the direction of arrow 1 and

release the lever in the direction of arrow 2 as shown.

~

~

Step 4 Pull out the tray half way and push it back fully.

Step 4 Liftupthetraverse unit and slide out the unit as shown.

. Replacement 01 Traverse Unit

1t

....

....

Step 5 Push the lever to the initial position indicated "ln_I".

"""'"

'---'"

""'"

Step 1 Place the traverse unit as shown.

Step 2 Press in the lever shaft in the direction of arrow 1 as

shown and push the traverse unit into the position in the direc-

tion of arrow 2.

- 14-

,-.,.

'---~

I SC-HM900

r-

-..

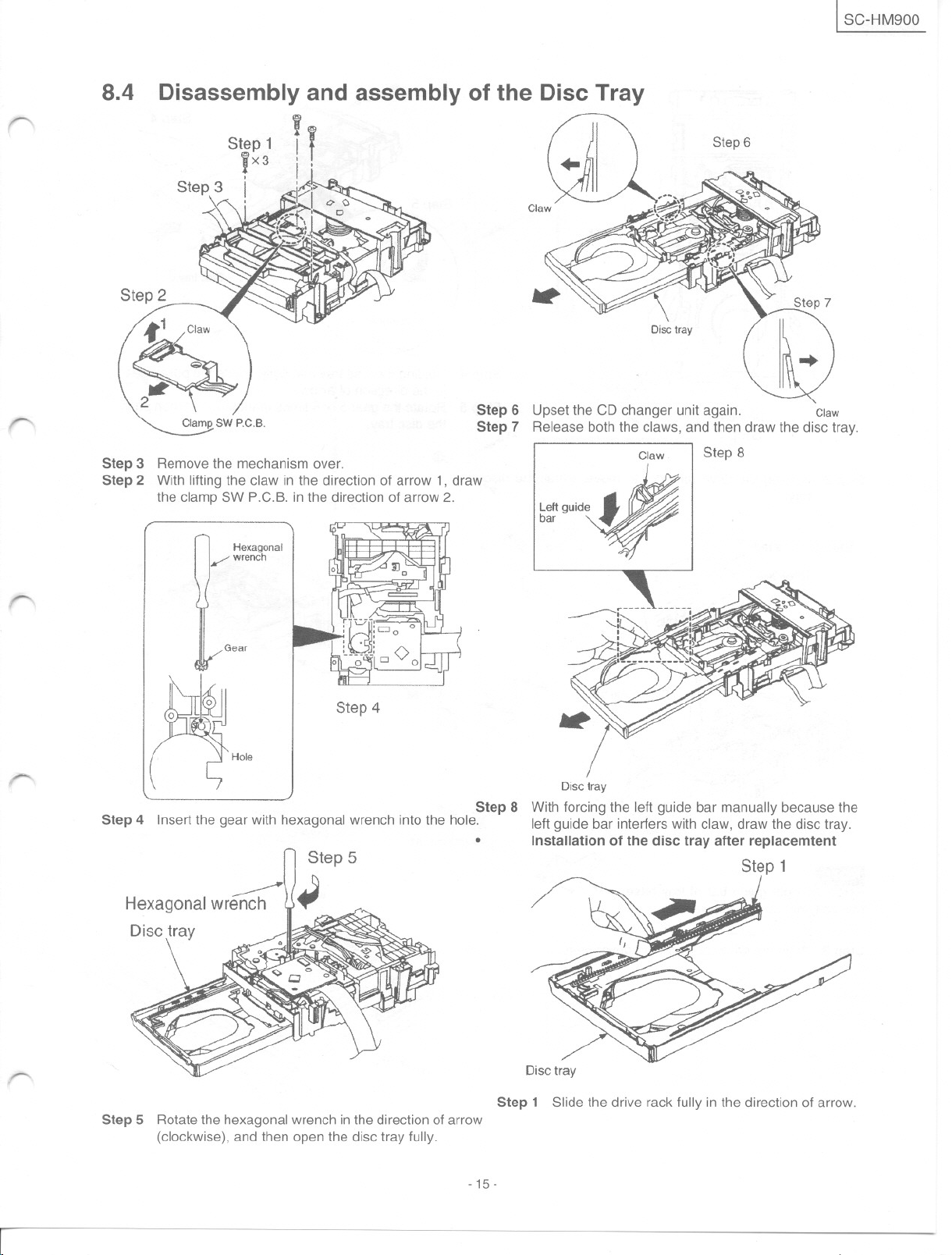

8.4

Disassembly and assembly 01 the Disc Tray

i

Step 1 If

iX3 i' ..

Step3 i

--

~

:'<;:' '

t.

'..,. ,- _.

I~i

._,"

Step 2

Clamp" SW P.C.B.

Step 3 Removethemechanismover.

Step 2 With lifting the claw in the direction of arrow 1, draw

the clamp SW P.C.B. in the direction of arrow 2.

Hexagonal

/ wreneh

<;) ,_o,"~

'~r

o Claw. ~~

~

l ~ o -~,-,

j

Step 6

Step 7

GU

O/setray

Claw

Step 6

).

..

Step 8

-.

--

Gear

Step 4

Hole

O/sefray

Step 8 With forcing the left guide bar manually beca use the

Step 4 Insert the gear with hexagonal wrench into the hojeo left guide bar interfers with claw, draw the disc tray.

. Installation of the dise tray alter replaeemtent

Step 1

~

Hexagonal wrench

Disctray

--.

Step 5 Rotatethe hexagonalwrench in the direction of arrow

(clockwise), and then open the disc tray fully.

- 15-

I

Disctray

Step 1 Slide the drive rack fully in the direction of arrow.

SC-HM900]

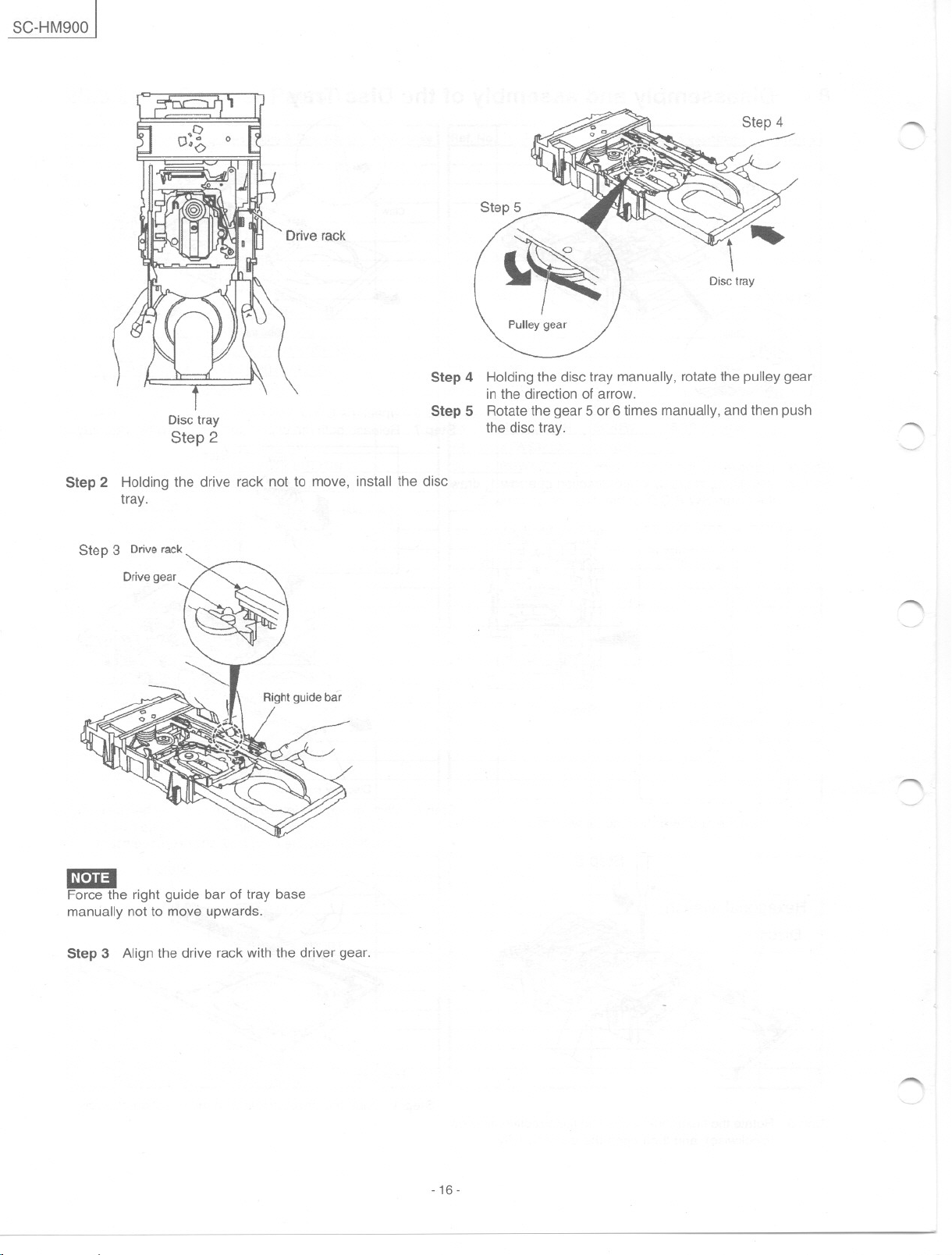

Step 4 Holdingthe disc tray manually, rotate the pulleygear

Disc tray

Step 2

Step 2 Holding the drive rack not to move, install the disc

tray.

Step 3 Driverack

Drive gear

Step 5 Rotatethe gear 5 or 6 times manually, andthen push

Step 5

in the direction of arrow.

the disc tray.

Step 4

Disctray

""'"

"

"---"

1"""""\

lmmI

Force the right guide bar of tray base

manually not to move upwards.

Step 3 Align the drive rack with the driver gear.

1"""""\

~

- 16-

1 SC-HM900

"......

--

9

9.1

This unit is equipped with a self-diagnostic display function which, if a problem occurs, will display an error code corres-

ponding to the problem.

Use this function when performing maintenance on the unit.

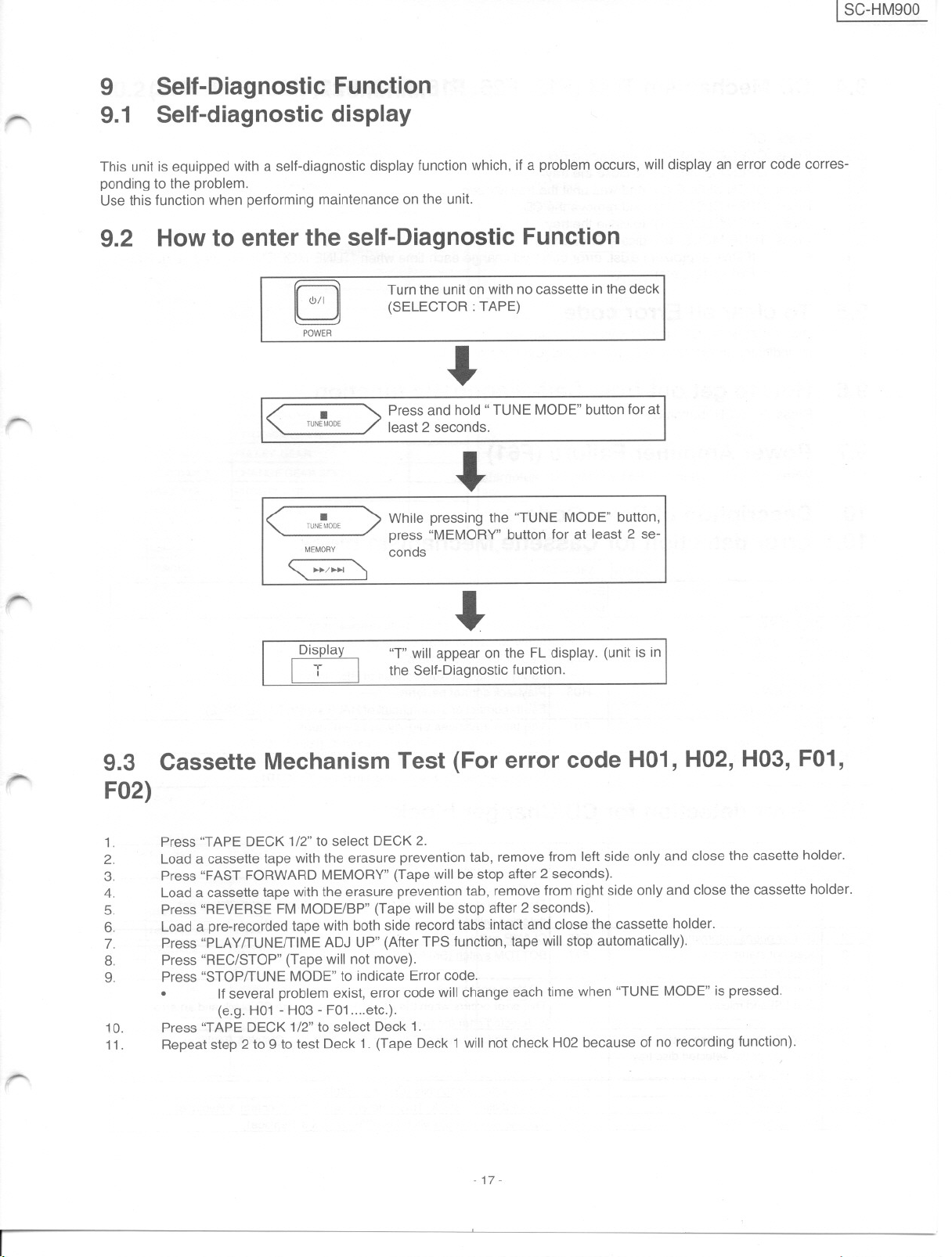

9.2

Self-Diagnostic Function

Self-diagnostic display

How to enter the self-Diagnostic Function

Turn the unit on with no cassette in the deck

G

POWER

(SELECTOR: TAPE)

.

.

TUNEMOOE

< >

Press and hold "TUNE MODE"buttonfor at

least 2 seconds.

.

.

¡UNEMOOE

<

MEMORY

"1*/»1 '1

> While pressing the "TUNE MODE" button,

press "MEMORY" button for at least 2 se-

conds

,-

r---

.

Display

I T

9.3 Cassette Mechanism Test (For error cede HO1, HO2, HO3, FO1,

FO2)

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

Press "TAPE DECK 1/2"to select DECK 2.

Load a cassette tape with the erasure prevention tab, remove from left side only and clase the casette holder.

Press "FAST FORWARD MEMORY" (Tape will be stop after 2 seconds).

Load a cassettetape withthe erasure prevention tab, remove from right side only and clase the cassette holder.

Press "REVERSE FM MODE/BP" (Tape will be stop after 2 seconds).

Load a pre-recordedtape with both side recordtabs intact and clase the cassette holder.

Press "PLAY/TUNEITIMEADJ UP" (After TPS function, tape will stop automatically).

Press "REC/STOP" (Tapewill not move).

Press "STOP/TUNE MODE"to indicate Error codeo

. If several problem exist, error code will change each time when "TUNE MODE" is pressed.

(e.g. H01 - H03 - F01 etc.).

Press "TAPE DECK 1/2"to select Deck 1.

Repeat step 2 to 9 to test Deck 1. (Tape Deck 1 will not check H02 because of no recording function).

"T" will appear on the FL display. (unit is in

the Self-Diagnostic function.

---

I

- 17-

SC-HM900 J

9.4

1.

2.

3.

4.

5.

6.

7.

CD Mechanism Test (F15, F26, F16, F17, F27, F28, F29, H15)

Press "CD".

Press "OPEN/CLOSE (1)" and place a CD.

Press "OPEN/CLOSE (1)" to clase the tray.

Press "OPEN/CLOSE(5)"and wait until the tray is apeno

Press "OPEN/CLOSE (1)" and remove the CD.

Press "OPEN/CLOSE (1)" to clase the tray.

Press "TUNE MODE"to indicate Error Codeo

. It several problem exist, error cede will change each time when "TUNE MODE" is pressed. (e.g. F15 -

F26 - F16... etc).

9.5

1.

2.

9.6

1.

9.7

1.

To clear all Error cede

Press "STOP /TUNE MODE" button tor 5 seconds.

FL indicator shows "CLEAR" tor 1 second and change to "T".

How to gel out from Self-Diagnostic function

Press "POWER" button OFF.

Power Amplifier Failure (F61)

When power amplitier tail, F61 will indicate automatically.

10 Description of Error Cede

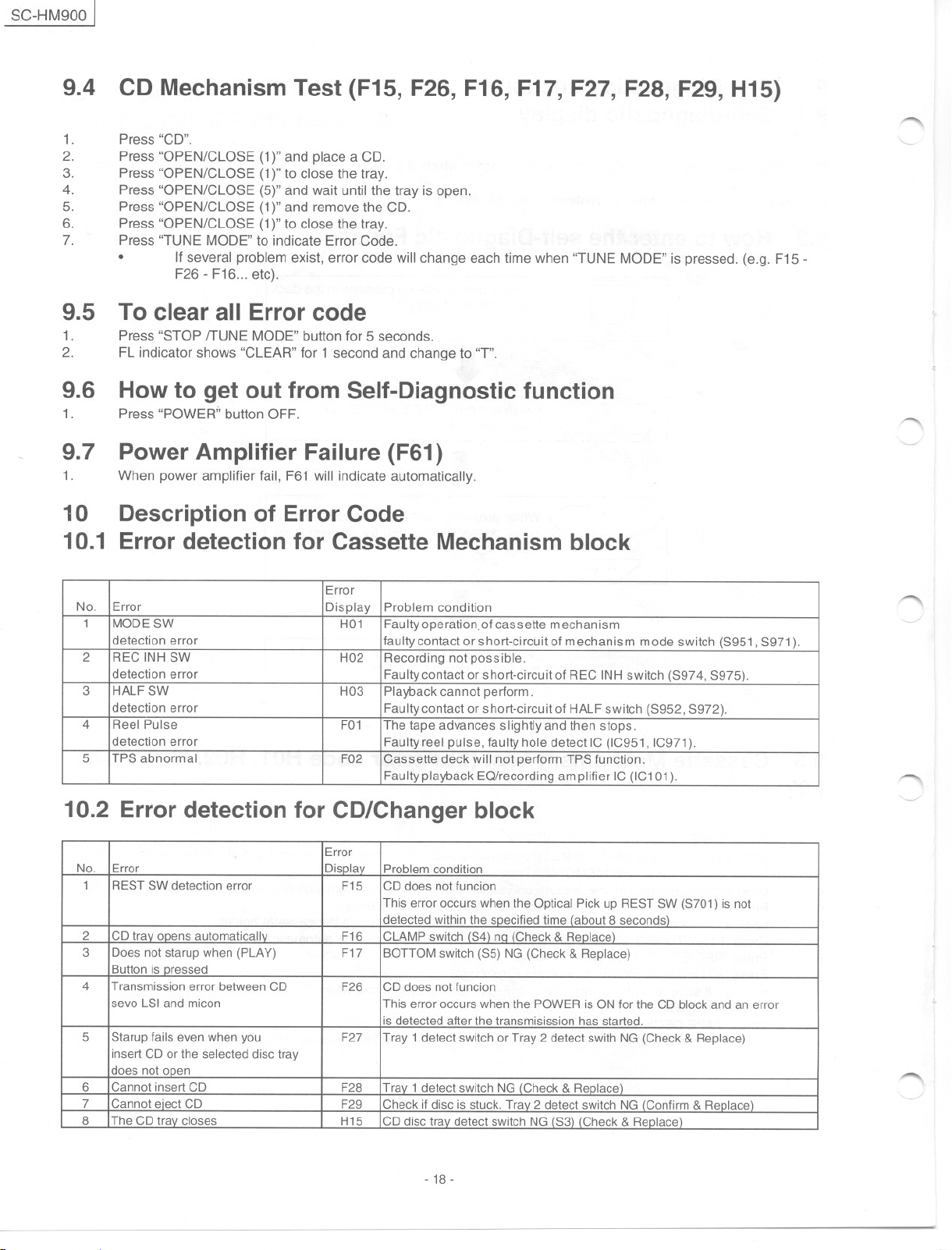

10.1 Error detection for Cassette Mechanism block

~

"

Error

No. Error

1 MODESW

detection error

2

REC INH SW

detection error

3

HALF SW

detection error

4

Reel Pulse

detection error

5 TPS abnormal

Display

Problem condition

H01

Faulty operation,ol cassette mechanism

laulty contact or short-circuit 01mechanism mode switch (S951, S971).

H02

Recording not possible.

Faultycontact or short-circuit 01REC INH switch (S974, S975).

H03

Playback cannot perform.

Faulty contact or short-circuit 01HALF switch (S952, S972).

F01

The tape advances slightly and then stops.

Faulty reel pulse, laulty hole detect IC (IC951, IC971).

F02

Cassette deck will not perform TPS lunction.

Faulty playback EQ/recording amplilier IC (IC101).

10.2 Error detection for CD/Changer block

Error

No. Error

1 REST SW detection error

2 CDtrav ooens automaticallv F16

3

Does not starup when (PLAY)

Button is aressed

4

Transmission error betweenCD

sevo LSI and micon

5

Starup lails even when you

insert CD or the selected disc tray

does not caen

6

Cannot insert CD

7 Cannot eiect CD F29

8

The CD trav clases H15

Displav Problemcondition

F15 CDdoes not luncion

This error occurs when the Optical Pick up REST SW (S701) is not

detected within the specilied time (about 8 seconds)

CLAMP switch (S4) no (Check& Replace)

F17

BOTTOM switch (S5) NG(Check & Replace)

F26

CD does not luncion

This error occurs when the POWER is ON lor the CD block andan error

is detected alter the transmisission has started.

F27

Tray 1detect switch or Tray 2 detect swith NG (Check & Replace)

F28 Trav 1detectswitch NG (Check& Replace)

Check il disc is stuck. Trav 2 detect switch NG (Conlirm & Replace)

CD disc trav detect switch NG (S3) (Check& Replace)

1""""\

..-....

---/

~

- 18-

r

--

I SC-HM900

10.3 Power Supply related error detection

Error

Error Displav

No.

1

POWER AMP

output abnormal During normal operation, if DC DEr become L, PCNT shall become

Problem condition

F61

When POWER is switched on, power become off automatically.

L and the error display on the left shall be displaved. IIC501)

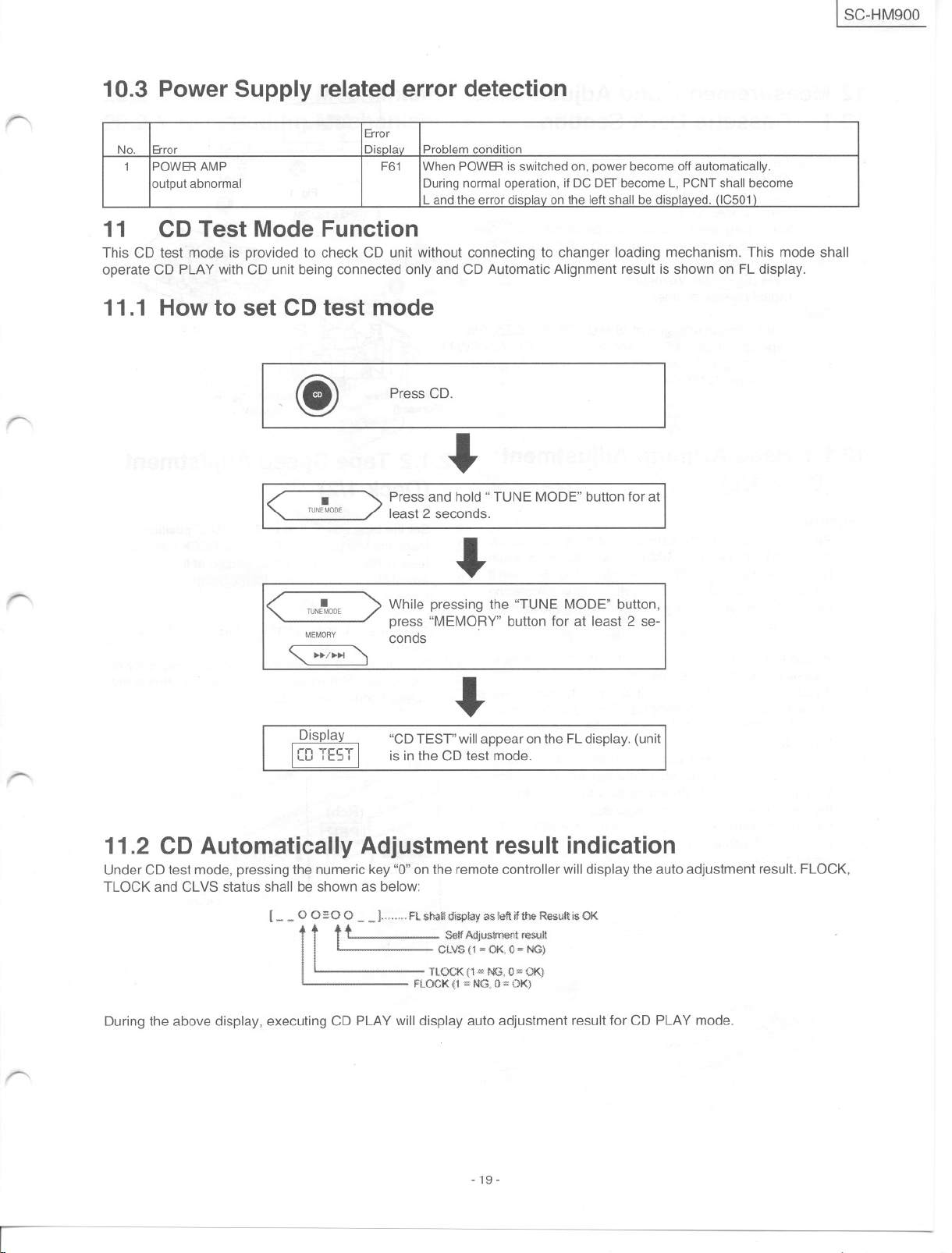

11 CD Test Mode Function

This CD test mode is provided to check CD unit without connecting to changer loading mechanism. This mode shall

operate CD PLAY with CD unit being connected only and CD Automatic Alignment result is shown on FLdisplay.

11.1 How to set CD test mode

Press CD.

(j)

.

-..

-..

Press and hold "TUNE MODE"buttonlor at

least 2 seconds.

>

<

.

TUNEMDOE

.

<

MEMORY

> While pressing the "TUNE MODE" button,

press "MEMORY" button lor at least 2 se-

conds

.

TUNEMQDE

"-1- ~

.

"CD TEST" will arrear on the FL display. (unit

is in the CD test mode.

11.2 CD Automatically Adjustment result indication

UnderCDtest mode,pressingthe numeric key"O"on the rematecontroller willdisplaytheauto adjustment result. FLOCK,

TLOCK and CLVS status shall be shown as below:

[- - O0",0 0- - ]." FLshaUdisplay as Mflifthe Result isOK

'

"

. CLV$(1'"OKú=NG}

.

t tt

."'",

~

se

lfAdJustme

.

TLQC.K(1 '" NO, O"'OKi

.

FLOCK{1 =NG,O= OK)

nt.teSl.

..

J

1I

.

..

During the above display, executing CD PLAY will display auto adjustment result lor CD PLAY mode.

-..

- 19-

r

SC-HM900 J

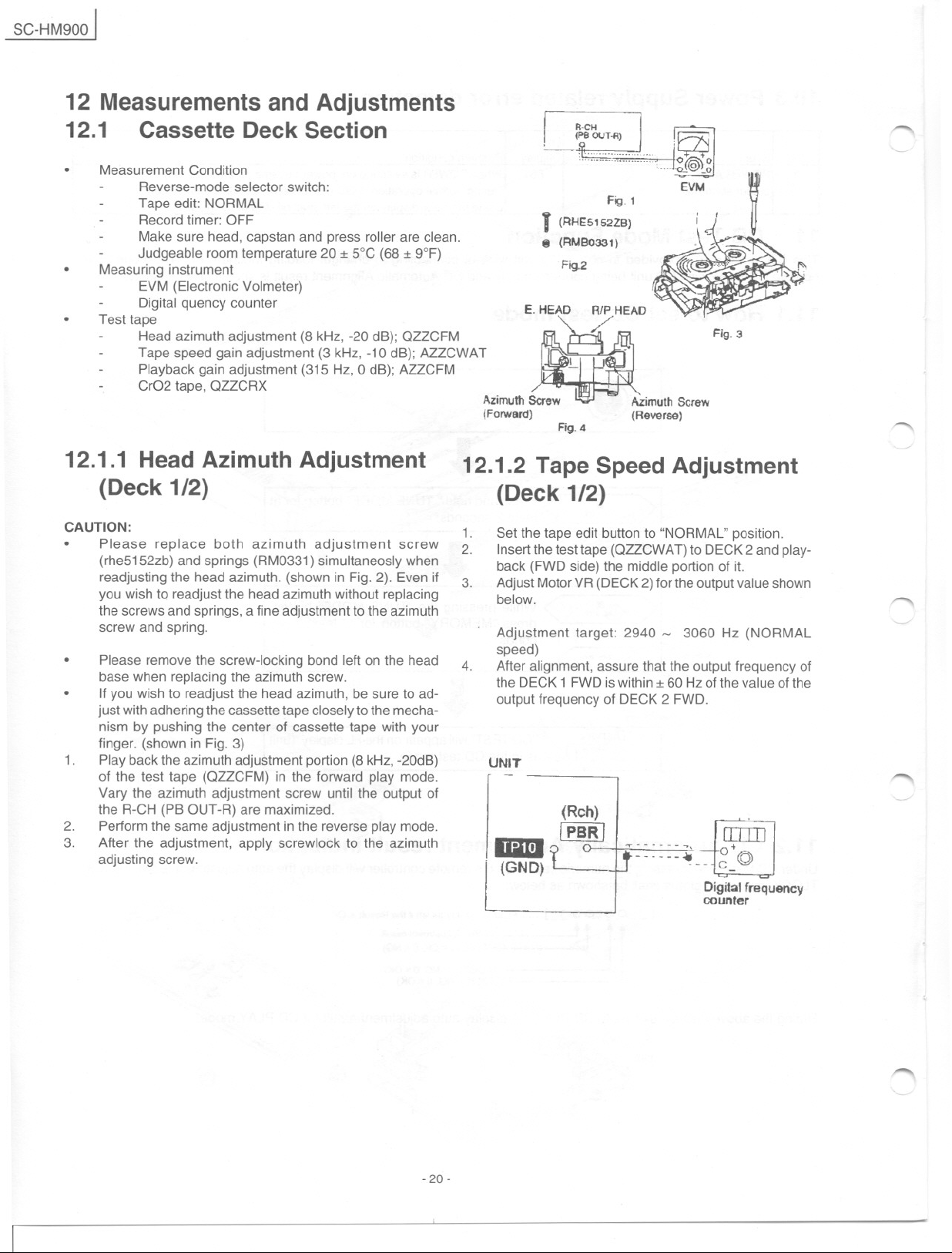

12 Measurements and Adjustments

CH

12.1 Cassette Deck Section

.

Measurement Condition

Reverse-mode selector switch:

Tape edit: NORMAL

Record timer: OFF

Make sure head, capstan and press rolier are clean.

Judgeable room temperature 20 :t 5°C (68 :t 9°F)

Measuring instrument

EVM (Electronic Volmeter)

.

12.1.1 Head Azimuth Adjustment

CAUTION:

. Please replace both azimuth adjustment screw

.

1.

2.

3.

Digital quency counter E.HEAD R/PHEAD

Test tape

- Head azimuth adjustment (8 kHz, -20 dB); QZZCFM /. Fig.:3

- Tape speed gain adjustment (3 kHz, -10 dB); AZZCWAT .

- Playback gain adjustment (315 Hz, OdB); AZZCFM L I

- CrO2tape,QZZCRX '

AzimuthScrew AzimuthScr8W

(Forward) (Reverso)

12.1.2 Tape Speed Adjustment

(Deck 1/2)

(rhe5152zb) and springs (RM0331) simultaneosly when

readjusting the head azimuth. (shown in Fig. 2). Even if

you wish to readjust the head azimuthwithout replacing

the screws and springs,afine adjustmentto the azimuth

screw and spring.

Please remove the screw-Iocking bond left on the head

base when replacing the azimuth screw.

If you wish to readjust the head azimuth, be sureto ad-

just withadheringthe cassettetapecloselytothe mecha-

nism by pushing the center of cassette tape with your

finger. (shown in Fig. 3)

Playbackthe azimuth adjustment portion(8kHz,-20dB)

of the test tape (QZZCFM) in the forward play mode.

Vary the azimuth adjustment screw until the output of

the R-CH (PB OUT-A) are maximized.

Perform the same adjustment in the reverse play mode.

After the adjustment, apply screwlock to the azimuth

adjusting screw.

(Deck 1/2)

1.

Set the tape edil button to "NORMAL" position.

2.

Ingeríthe test tape (QZZCWAT)to DECK2and play-

back (FWD side) the middle portion of i1.

3.

AdjustMotorVR (DECK2)forthe outputvalueshown

below.

, Adjustment target: 2940 - 3060 Hz (NORMAL

speed)

4.

After alignment, assure that the output frequency of

the DECK 1 FWDis within:t60Hzof thevalueof the

output frequency of DECK 2 FWD.

UNIT

liDI IPBRj

. (GND) L

A

(PeOUT-A) ;~

~

:",u"""':::::::uu, t@o""" u... """ - -

T (RHE5152ZB)

8 (RM80331)

Fig.2

~

Ag. 4

(Rch)

,'u o

Fig.1

~ ~-'-

-u-u.. O

;

EVM

i I

~

-.. - c-

~

Digital frequency

counter

--..

"'"""

--..

--..

- 20..

, ".

[SC-HM900

---

r'

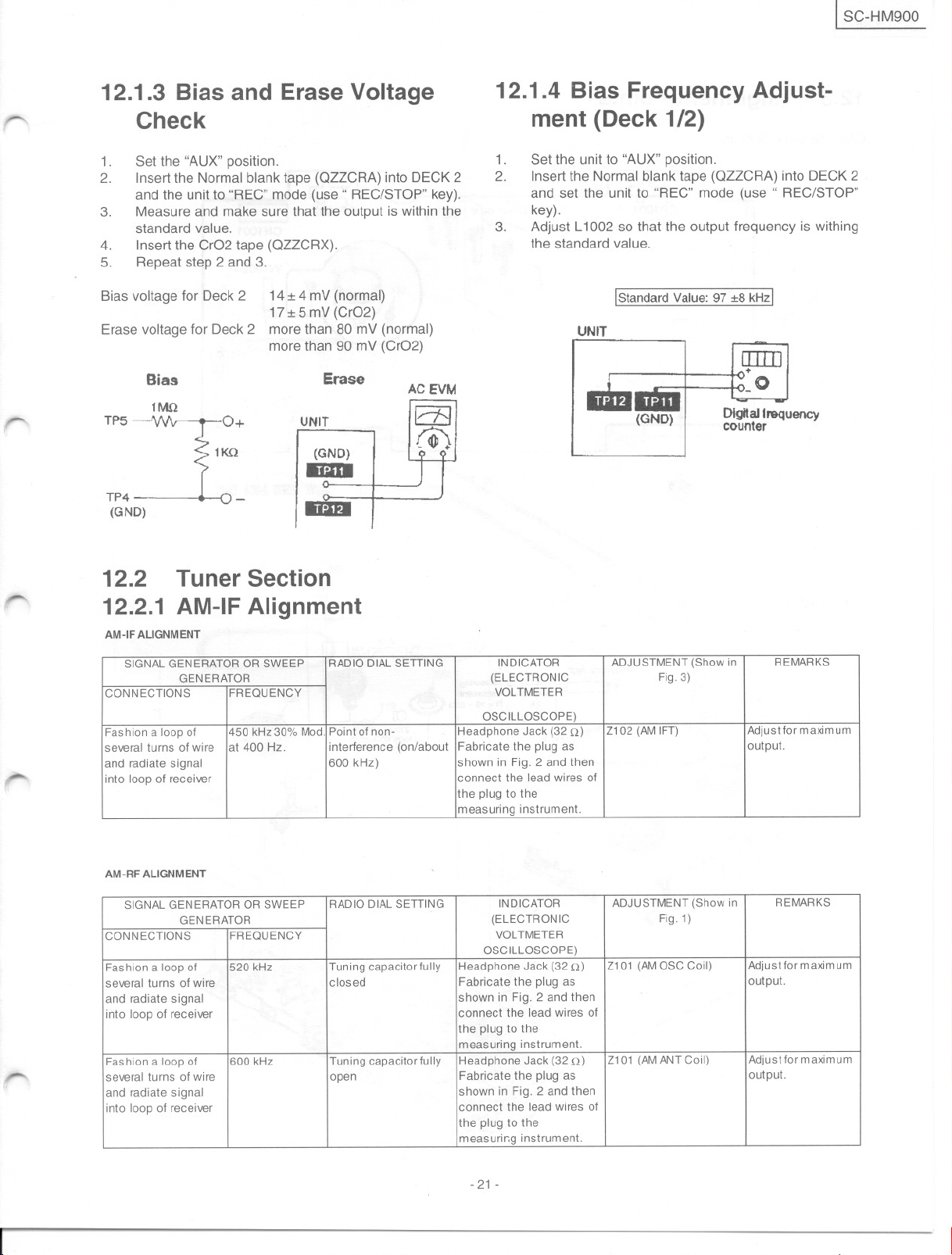

12.1.3 Bias and Erase Voltage

Check

1.

Set the "AUX" position.

2.

Insertthe Normal blank tape (OllCRA) into DECK2

and the unit to "REC" mode (use" REC/STOP" key).

3.

Measure and make sure that the output is within the

standard value.

4.

Insert the CrO2 tape (OllCRX).

5.

Repeat step 2 and 3.

Bias voltage tor Deck 2 14 :t 4 mV (normal)

17:t 5 mV (CrO2)

Erase voltage tor Deck 2 more than 80 mV (normal)

more than 90 mV (CrO2)

Bias

T :r.

1KQ

TP4

(GND) -

Erase

UNIT

r=l

BDI

1118

ACEVM

rm

12.1.4 Bias Frequency Adjust-

ment (Deck 1/2)

1.

Set the unit to "AUX" position.

2.

Insert the Normal blank tape (OllCRA) into DECK 2

and set the unit to "REC" mode (use" REC/STOP"

key).

3.

Adjust L1002 so that the output trequency is withing

the standard value.

¡Standard Value: 97 :t8 kHzl

UNIT

lIIllJ

+

_O

(GND)

Dlgltaltrequency

counter

12.2 Tuner Section

r

,-

r-

12.2.1 AM-IF Alignment

AM-IF ALlGNMENT

SIGNAL GENERATOR OR SWEEP

CONNECTIONS FREQUENCY

Fashion a loop 01

several turns 01wire

and radiate signal

into loop 01 receiver

AM-RF ALlGNMENT

SIGNAL GENERATOR OR SWEEP

CONNECTIONS

Fashion a loop 01

several turns 01wire

and radiate signal

into loop 01 receiver

Fashion a loop 01

several turns 01wire

and radiate signal

into loop 01 receiver

GENERATOR

450 kHz30% Mod.

at 400 Hz.

GENERATOR

FREQUENCY

520 kHz

600 kHz

RADIO DIAL SETTING INDICATOR

Point 01non-

interference (on/about Fabricate the plug as

600 kHz) shown in Fig. 2 and then

RADIO DIAL SETTING INDICATOR

Tuning capacitar lully Headphone Jack (32 n)

closed

Tuning capacitar lully Headphone Jack (32 n)

open

(ELECTRONIC Fig. 3)

VOLTMETER

OSCILLOSCOPE)

Headphone Jack (32 n)

connect the lead wires 01

the plug to the

measuring Instrument.

(ELECTRONIC Fig. 1)

VOLTMETER

OSCILLOSCOPE)

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires 01

the plug to the

measunng instrument.

Fabricate the plug as

shown in Fig. 2 and then

connect the lead wires 01

the plug to the

measurir.g Instrument.

ADJUSTMENT(Showin

Z102 (AM 1FT) Adjustlor maximum

ADJUSTMENT (Show in

Z101 (AMOSC Coil) Adjustlormaximum

Z101 (AMANTCoil)

REMARKS

output.

REMARKS

output.

Adjustlormaximum

output.

-21-

SC-HM900 I

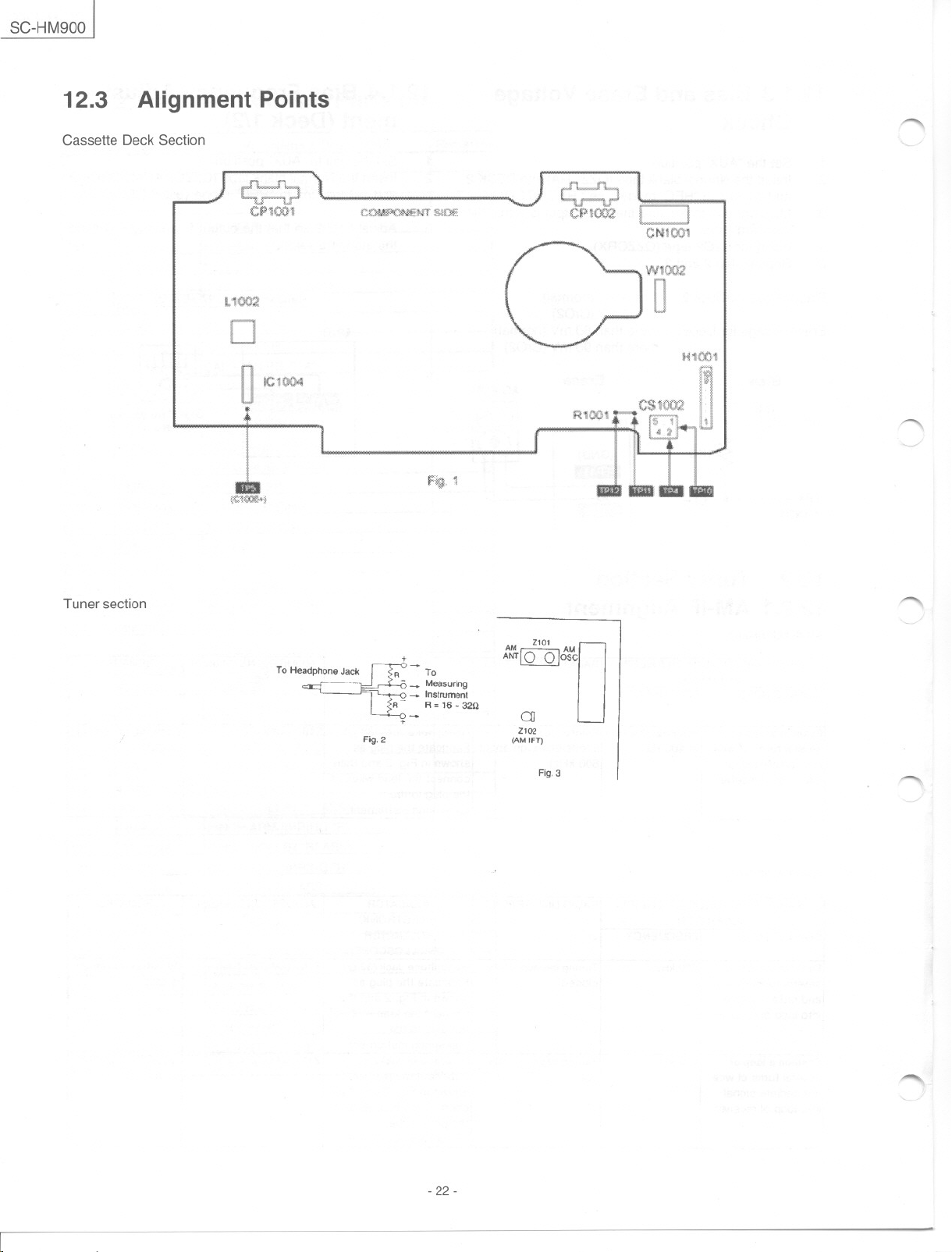

12.3

Cassette Deck Section

Alignment Points

1.1002

o le! lJO4

"

..

I

.

\C1@:1?;j

~

e~m

(:1'41(.*)1

H1oo1

~

Tuner section

R -To

--Measuring

. ~ -Instruman!

~R- R=16 -32G

+-o -

+

Fig.2

2101

AM AM

~: O~,

2102

(AMIFT)

Fig.3

"'"""

O

, ,....

- 22-

..........

-

ISC-HM900

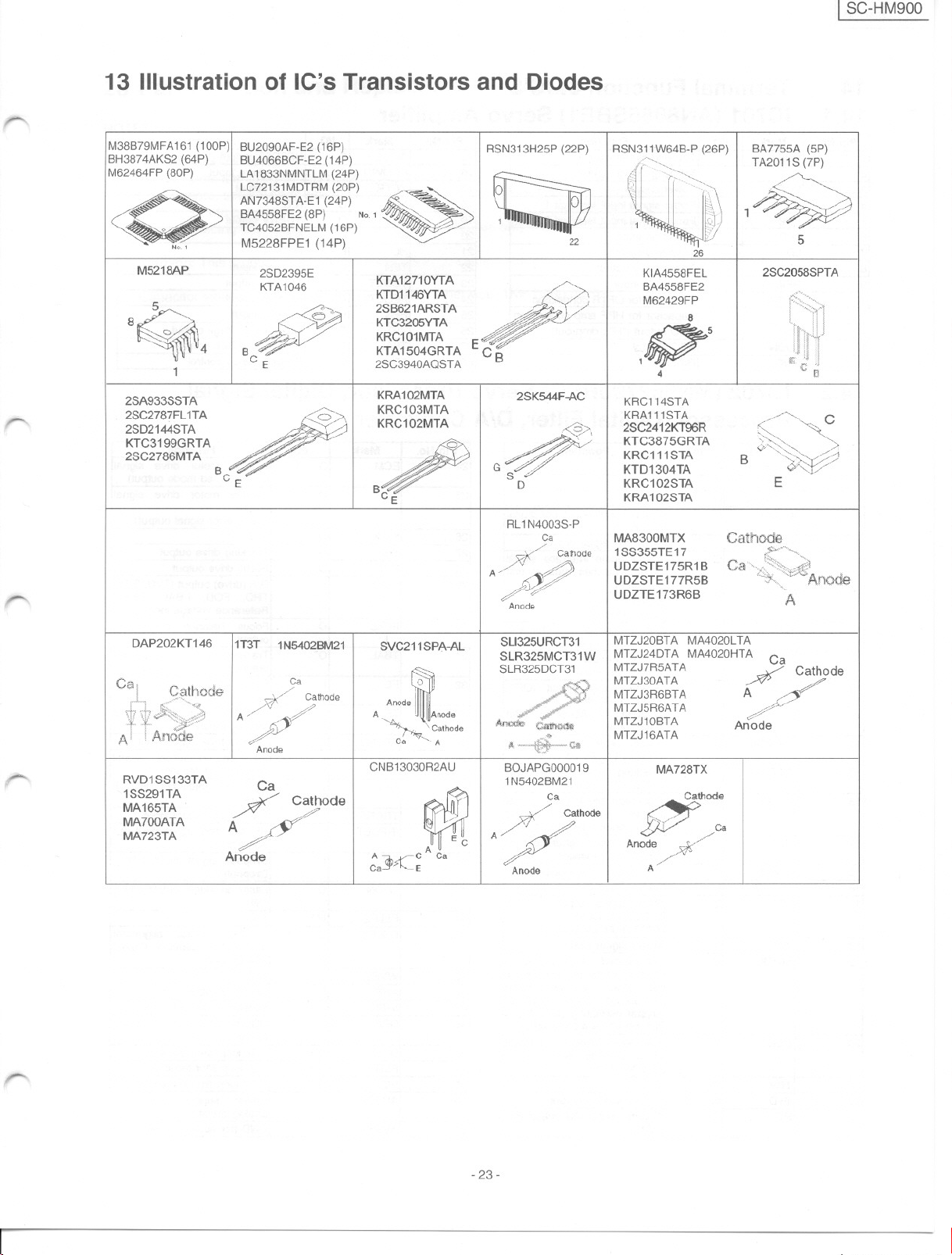

13 lIIustration of IC's Transistors and Diodes

-

-

M38B79MFA161 (100P)

BH3874AKS2 (64P)

M62464FP (80P)

N,.1

M5218AP

8,

1

2SC2787FL 1TA

I

2SD2144STA

KTC3199GRTA

2SC2786MTA

BU2090AF-E2 (16P)

BU4066BCF-E2 (14P)

LA 1833NMNTLM (24P)

LC72131MDTRM (20P)

AN7348STA-E1 (24P)

BA4558FE2 (8P)

TC4052BFNELM (16P)

M5228FPE1 (14P)

2SD2395E

KTA1046

t>lo.1

KTA12710YTA

2SB621ARSTA .)

KTD11<6YTA"

KTC3205YTA"

B

CE 2SC3940AOSTA

KRC101MTA E

KTA1504GRTA e B

KRA102MTA

KRC103MTA

KRC102MTA

RSN313H25P (22P) IRSN311W64B-P (26P) BA7755A (5P)

/:">-~

""

TA2

011S(7P)

.

~ (::::11 1~

~ 1 ~) ~./~~

2SK544F-AC

-P/#

G /./

s /.

D

RL 1N4003S-P

22 // 5

::::9>

4.

Ca

7/- Cathode

A'&

~?'-~

Anode

l

"'..'...".".""'.".

lJ

KIA4558FEL

BA4558FE2

M62429FP

8

15

4

KRC114STA2SA933SSTA

KRA111STA

2SC2412KT96R

/; KTC3875GRTA

KRC111STA

KTD1304TA

KRC102STA

KRA102STA

MA8300MTX

1SS355TE 17

UDZSTE175R1

UDZSTE177R5B

UDZTE173R6B

26

Cathode

B

2SC2058SPTA

.~ El

//-"'-<--- C

~ ~"

0'~_,

'" ~- / /

~

B ¿:'-"-':::1'/

E

A

//

-.

~-

DAP202KT146

RVD1SS133TA

1SS291TA

MA165TA

MA700ATA

MA723TA

11T3T

1N5402BM21I

Ca

. // MTZJ5R6ATA

7/' Cathode AnodeI

A'.f

$Y

Anode

Ca

./

A/

Anode

:Ode

SVC211SPA-AL I

o MTZJ30ATA

A Anode

' Cathode

Ca 'A

CNB13030R2AU

A j5rC Ca

Ca -E

SLl325URCT31

SLR325MCT31W

SLR325DCT31

BOJAPGOOOO19

1N5402BM21

Ca

/

'

7 Calhode

A/' //

¿::-

Anode

MTZJ20BTA MA4020L TA

MTZJ24DTA MA4020HTA

MTZJ7R5ATA

MTZJ3R6BTA

MTZJ10BTA

MTZJ16ATA

I

MA728TX

od:a

Anode /,0:;:/

A'

A //

,//

Anode

Ca

Cathode

-23-

SC-HM900 I

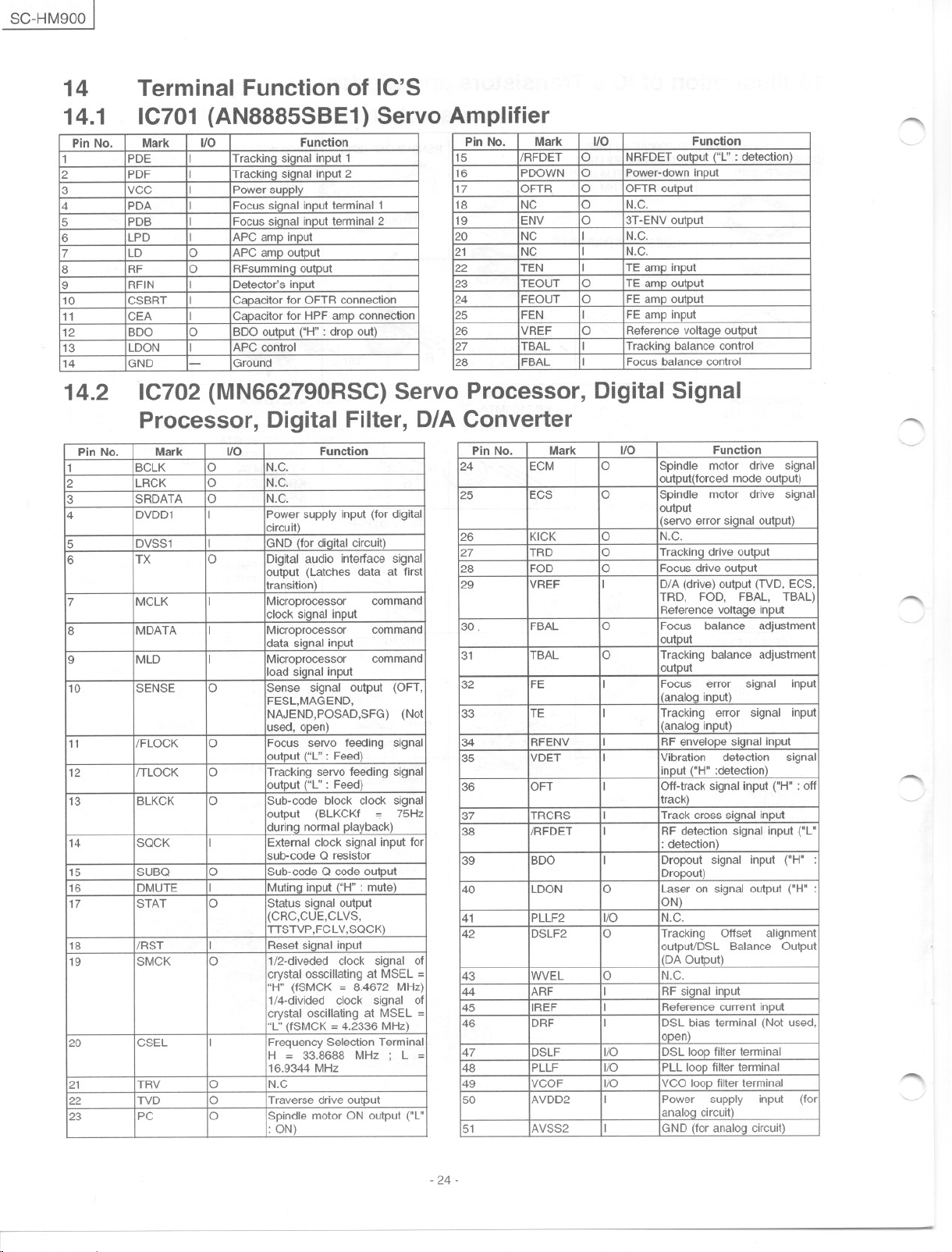

14

14.1

Pin No. Mark UO

1

2 PDF I

3 VCC I

4

5

6

7 LD O

8 RF O

9 RFIN

10 CSBRT

11

12 BDO O

13 LDON

14 GND

14.2

Terminal Function of IC'S

IC701 (AN8885SBE1) Servo Amplifier

PDE

PDA I

PDB I

LPD I

CEA

IC702 (MN662790RSC) Servo Processor, Digital Signal

I

Tracking signal input 1

Trackin¡:¡ signal input 2

Power supply

Focus signal input terminal 1

Focus signal input terminal 2

APC amp input

APC amp output

RFsummin¡:¡ output

I Detector's input

I

Capacitar for OFTR connection

I

Capacitar for HPF amp connection

BDO output ("H" : drop out)

I APC control

-

Ground

Processor, Digital Filter, D/A Converter

Pin No.

1 BCLK O N.C.

2

3

4

5 DVSS1

6

7 MCLK

8

9 MLD

10 SENSE O

11

12 /TLOCK

13

14 SQCK

15 SUBO O

16 DMUTE

17 STAT O

18 /RST 1

19

20 CSEL

21 TRV O N.C

22

23 PC

Mark UD

LRCK O

SRDATA O N.C.

DVDD1

TX

MDATA

/FLOCK

BLKCK O

SMCK O

TVD O

I

I

O

I

I

I

O

O

I

I

I

O

Function

Function

N.C.

Power supply input (for digital

circuit)

GND (for digital circuit)

Digital audio interface signal

output (Latches data at first

transition)

Microprocessor

clock signal input

Microprocessor

data si¡:¡nal input

Microprocessor

load signal input

Sense

signal output (OFT,

FESL,MAGEND,

NAJEND,POSAD,SFG) (Not

usad, open)

Focus servo feeding signal

output ("L" : Feed)

Tracking servo feeding signal

output ("L" : Feed)

Sub-cede block clock signal

output (BLKCKf

during normal playback)

External clock signal input for

sub-coda Q resistor

Sub-cede Q coda output

Muting input ("H" : muta)

Status signal output

(CRC,CUE,CLVS,

TTSTVP,FCLV,SOCK)

Reset signal input

1/2-diveded clock signal of

crystal osscillating at MSEL =

"H" (fSMCK = 8.4672 MHz)

1/4-divided clock

crystal oscillating at MSEL =

"L" (fSMCK = 4.2336 MHz)

Frequency Selection Terminal

H = 33.8688 MHz ;

16.9344 MHz

Traverse drive output

Spindle motor ON output ("L"

: eN)

command

command

command

75Hz

signal

L =

Pin No. Mark 1/0

15 /RFDET

16

17 OFTR O

18

19

20 NC

21

22 TEN

23

24 FEOUT O

25 FEN

26

27 TBAL

28 FBAL

Pin No.

24 ECM O

25

26 KICK O

27 TRD O

28 FOD O

29

30.

31

32

33

34 RFENV

35

36 OFT 1

37 TRCRS

38 /RFDET

39

40 LDON O

41

42 DSLF2 O

43

of

44

45

46

47 DSLF l/O

48 PLLF l/O

49 VCOF l/O

50 AVDD2 I

51 AVSS2

Function

O

NRFDET output ("L" : deleGUen)

PDOWN

NC

ENV

NC

TEOUT O

VREF

ECS

VREF

FBAL O Focus

TBAL O

FE

TE

VDET I Vibration detection

BDO

PLLF2 l/O N.C.

WVEL O N.C.

ARF 1

IREF 1

DRF I

O

Power-down input

OFTR output

N.C.

O

O

3T-ENV output

I N.C.

I N.C.

I

TE amp input

TE amp output

FE amp output

I

FE amp input

O

Reference voltage output

I

Tracking balance control

I Focus balance control

Mark 1/0 Function

Spindle

O

I

I

I

1

I

I

I

I

output(forced moda output)

Spindle

output

(servo error signal output)

N.C.

Tracking drive output

Focus drive output

D/A (drive) output (TVD, ECS,

TRD,

Reference voltage input

output

Tracking balance adjustment

output

Focus error

(analog input)

Tracking

(analog input)

RF envelope signal input

input ("H" :detection)

Qff-track signal input ("H" : off

track)

Track cross signal input

RF detection signal input ("L"

: detection)

Dropout signal input ("H" :

Dropout)

Laser on signal output ("H" :

eN)

Tracking

output/DSL Balance Output

(DA Output)

RF signal input

Reference current input

DSL bias terminal (Not usad,

open)

DSL loop filler terminal

PLL loop filter terminal

VCO loop filter terminal

Power

analog circuit)

GND (for analog circuit)

motor

motor drive

FOD,

balance

error

Offset

supply

drive

signal

signal

FBAL,

TBAL)

adjustment

signal input

signal

signal

alignment

input (for

~

"'"'"

'

-"""""'"

/

input

"'""

-.

'---

-24-

t SC-HM900

-

1

", ,

Pin No. Mark ./0 Function

52 EFM

53 PCK

54 VCOF2 1/0

55

56

57

58

59 X2 OUT O

60

61 BYTCK

62

63 FCLK

64 IPFLAG

65 FLAG

SUBC O

SBCK I Clock

VSS I GNO

X1 IN I

VDO I

/CLOCK

-

-

-

-

-

-

-

EFMsignaloutput

PLL extraction dock output

(fPCK = 4.321

normal playback)

VCO Loop filler tor 33.8688

MHz conversation terminal for

16.9344 MHz crystal moda,

must use other circuit

Sub-coda serial data output

input

serial data

Crystal oscillating circuit input

!(f = 16.9344MHz)

Crystal oscillating circuit input

(f = 16.9344 MHz)

Power

oscillating circuit)

Byte clock output

Sub-coda trame dock signal

output (fCLOCK = 7.35 kHz

during normal playback)

Crystal

output (fCLK = 7.35

double = 14.7 kHz)

Interpolation flag output ("H" :

Interpolation)

Flag output

supply input (tor

trame clock

MHz during

tor sub-coda

signal

kHz,

Pin No. Mark ./0 Function

66

67

68

69

70

71

72 AVO01 I

73 OUTL O Left channel audio

74 AVSS1 I GND

75 OUTR O

76

77

78

79 MSEL

80 SSEL

CLVS

CRC

OEMPH

RESY

lOSEL

/TEST

RSEL I

laVaD

PSEL I

-

-

-

-

I

I

I

I

I

Spindle

synchronizing signal output

("H" : CLV, "L" : rough servo)

Sub-coda CRC checked

output ("H':OK,"L" :NG)

Oe-emphassis

output ("H" :ON)

Frame re-synchronizing signal

output

Mode Switching Terminal

Test input

Power

analog circuit)

output

Right channel audio signal

output

RF signal polarity assignment

input (at "H" level, RSEL="H",

at "L" level, RESL="L")

5V supply input

Test terminal (connected to

Gnd)

SMCK oscillating trequency

designation input ("L":4.2336

MHz, "H":8.4672 MHz)

SUBO output

("H":O-code buffer

servo

ON

supply input (tor

moda select

phase

signaJ

signal

moda)

r

r-

r¡

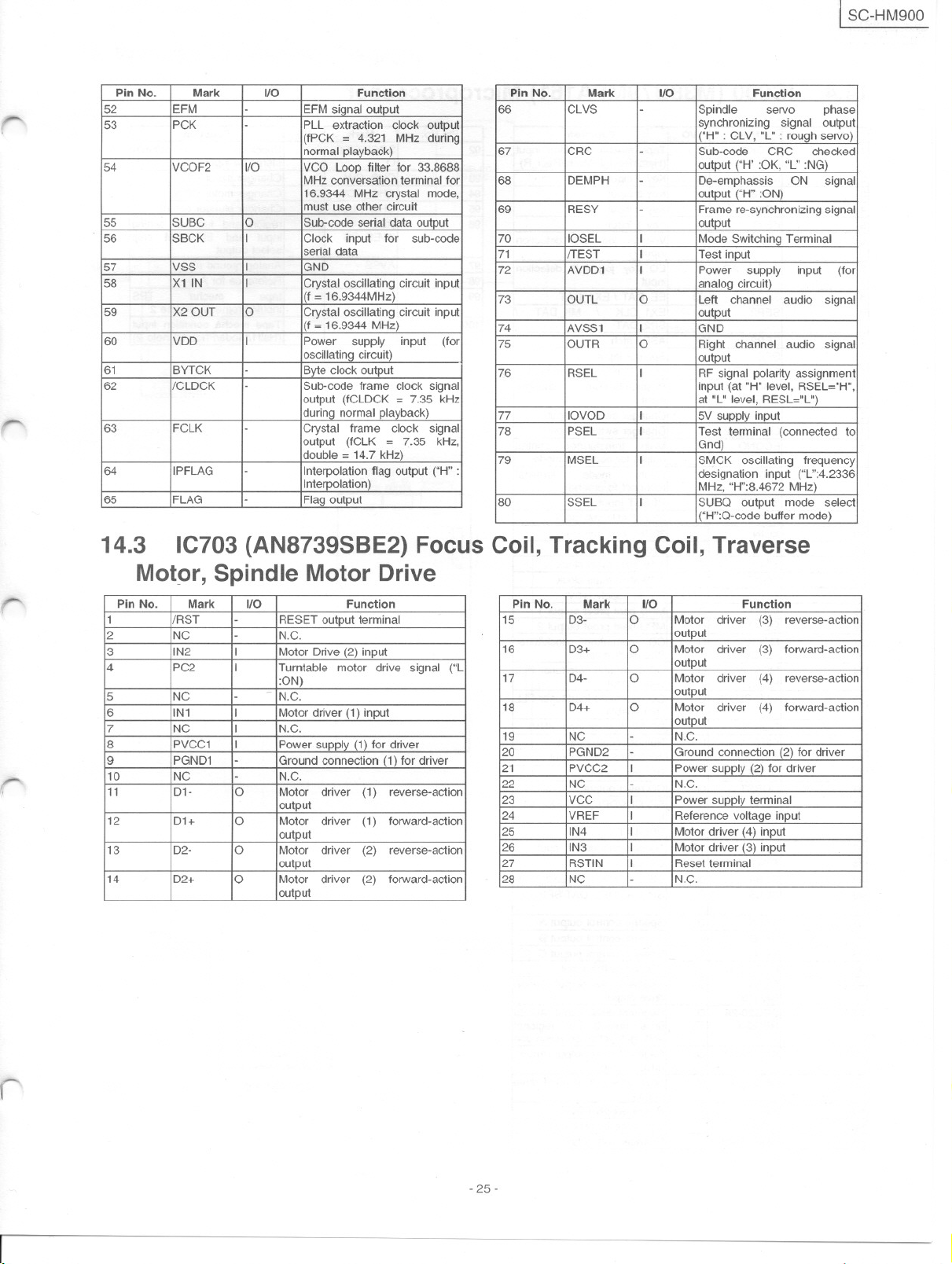

14.3 IC703 (AN8739SBE2) Focus Coil, Tracking Coil, Traverse

Mot9r, Spindle Motor Drive

Pin No. Mark ./0 Function

1

2

3 IN2

4

5 NC

/RST

NC

PC2 I

6 IN1 I

7

8

9

10

11

NC

PVCC1 I

PGN01

NC

01- O

-

RESET output terminal

-

N.C.

I

Motor Orive (2) input

Turntable motor drive signal ("L

:ON)

-

N.C.

Motordriver (1)input

I

N.C.

Powersupply(1)tordriver

-

Groundconnection(1) tordriver

-

N.C.

Motor driver

output

12 01+ O Motor

driver

output

13 02-

O

Motor driver

output

14

02+

O Motor driver

output

reverse-action

(1)

torward-action

(1)

reverse-action

(2)

forward-action

(2)

Pin No. Mark ./0 Function

15

16

17

18

19

20

21 PVCC2 I

22

23

24 VREF I

25 IN4 I

26 IN3

27 RSTIN

28

03- O Motor driver

03+

04- O Motor driver

04+ O Motor driver

NC

PGN02

NC

VCC

NC

output

O

Motor driver

output

output

output

-

N.C.

-

Groundconnection(2)tor driver

power supply(2)tor driver

-

N.C.

I

Power supply terminal

Reterence voltage input

Motor driver (4) input

I

Motor driver (3) input

I

Reset terminal

-

N.C.

reverse-actjon

(3)

torward-action

(3)

reverse-action

(4)

forward-action

(4)

r

-25-

Loading...

Loading...