Page 1

Table Of Contents

COVER

1 Before Use

2 Before Repair and

Adjustment

3 Protection Circuitry

4 Safety Precautions

4.1 General Guidelines

4.1.1 Leakage Current Cold

Check

4.1.2 Leakage Current Hot

Check (See Figure 1)

5 Prevention of Electro

Static Discharge (ESD) to

Electrostatically Sensitive

(ES) Devices

6 Handling the Lead-free

Solder

6.1 About lead free solder

(PbF)

7 Cautions to be taken

when handling Optical Pickup

7.1 Handling Optical Pickup

7.2 Replacing Precautions

for Optical Pickup Unit

7.3 Grounding for

Preventing Electrostatic

Destruction

8 Precaution of Laser Diode

9 Accessories

10 Operation Procedures

11 Disc information

12 About HighMAT

12.1 What is HighMAT?

12.2 Why use HighMAT?

12.3 The advantages of

using HighMAT

12.4 Outline of the

HighMAT standard

13 Procedure for repairing

the set

13.1 Distinguish the trouble

cause

13.2 Diagnosis of Optical

Pick-up Unit

14 Optical Pickup SelfDiagnosis and Replacement

Procedure

Service Manual

TOP NEXT

ORDER NO. MD0308338C3

DVD Stereo System

● SA-VK90DGCP

Colour

(S)... Silver Type

Specifications

AMPLIFIER SECTION

RMS Output power both channel driven: 10% Total Harmonic Distortion

1 kHz Front-HI CH

80 W per channel (6Ω)

100 Hz Front-LOW CH

60 W (12Ω)

1 kHz Surround CH

40 W per channel (8Ω)

1 kHz Center CH

100 W (8Ω)

100 Hz Subwoofer CH

100 W per channel (6Ω)

Total RMS Dolby Digital Mode Power

600 W

PMPO Output Power 7000 W

Input sensitivity/Input Impedance

AUX

250 mV, 13.3 kΩ

MIC

0.7 mV, 680Ω

FM TUNER SECTION

Page 2

14.1 Self-diagnosis

14.2 Cautions to Be Taken

During Replacement of

Optical Pickup and Spindle

Motor

14.2.1 Cautions to be taken

during replacement of optical

pickup

15 Self-Diagnosis Function

15.1 Automatic Displayed

Error Codes

15.1.1 Automatic Display

Function

15.1.2 Re-Display

15.1.3 Description of Error

Code

15.2 Memorized Error

Codes

15.2.1 Activating SelfDiagnosis Function and

Displaying Method

15.2.2 Re-Display

15.3 Mode Table 1

15.4 DVD / CD SelfDiagnosis Error Code

Description

15.5 Error Codes Stored

During No Play

15.6 Mode Table 2

15.7 Tray Lock Function

15.7.1 Setting

15.8 Things to Do After

Repair

16 Cautions To Be Taken

During Servicing

16.1 Recovery after the dvd

player is repaired

16.2 DVD Player Firmware

Version Upgrade Process

16.3 Firmware Version

Upgrade Process by Using

Disc and Recovery Process

16.3.1 Self-Diagnosis

Function

16.4 Using Recovery Disc

16.4.1 Recovery Process

16.4.2 Version Upgrade

Process

16.5 Total Usage Time

Frequency range 87.50 - 108.00 MHz (50 kHz steps)

Sensitivity 2.5•V (IHF)

S/N 26 dB 2.2•V

Antenna terminals

75Ω (unbalanced)

Preset station 15

AM TUNER SECTION

Frequency range 522 - 1629 kHz (9 kHz steps)

520 - 1630 kHz (10 kHz steps)

AM sensitivityy S/N 20 dB at 1000 kHz

560•V/m

Preset station 15

CASSETTE DECK SECTION

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s (1 7/8 ips)

Overall frequency response (+3 dB, -6 dB at DECK OUT)

Normal (TYPE I) 35 Hz - 14 kHz

S/N ratio 50 dB (A weighted)

Wow and flutter 0.18% (WRMS)

Fast forward and rewind time Approx. 120 seconds with

C-60 cassette tape

Disc SECTION

Disc

DVD-Video/Audio

8 cm/12 cm, single/double-sided, single/double-layer

DVD-RAM/R (DVD-Video formatted discs)

CD-DA/VCD/MP3/WMA 8 cm/12 cm, CD-R/RW

SVCD (Conforming to IEC62107)

HighMAT Level 2 (Audio and Image)

JPEG-Exif Ver 2.1 JPEG Baseline files

Video

Signal system NTSC

Output level

Composite video

1 Vp-p (75Ω)

S-Video Y

1 Vp-p (75Ω)

S-Video C

0.286 Vp-p (75Ω)(NTSC)

Component video

1 Vp-p (Y)(75Ω)

0.7 Vp-p (PB/CB PR/CR)(75Ω)

Audio

Sampling frequency

CD 44.1 kHz

MP3 32 kHz, 44.1 kHz, 48 kHz

Page 3

Display

17 Operation Checks and

Component Replacement

Procedures

17.1 Disassembly of Top

Cabinet

17.2 Disassembly for the

DVD changer ass ’ y

17.2.1 Disassembly for the

Top Ornament Unit

17.2.2 Disassembly for

DVD changer unit

17.3 Checking for the

changer unit operational

condition

17.3.1 Initial setting of CD

17.3.2 Checking for the

DVD Module (1) P.C.B.

17.3.3 Checking for Panel P.

C.B., Deck P.C.B. and LED P.

C.B.

17.3.4 Replacement of the

Power Amplifier IC

17.4 Main Component

Replacement Procedures

17.4.1 Replacement of the

Traverse Deck

17.5 Replacement for the

disc tray

17.6 Disassembly and

reassembly for mechanism

base drive unit

17.7 Replacement for the

motor ass ’ y

17.8 Replacement for the

pinch roller ass ’ y and head

block

17.9 Replacement for the

CD motor ass ’ y, capstan belt

A, capstan belt B and winding

belt

17.10 Replacement for the

CD motor ass ’ y, capstan belt

A, capstan belt B and winding

belt

17.11 Replacement for the

cassette lid ass ’ y

17.12 Measure for tape

trouble

18 Measurements and

DVD-Video 48 kHz, 96 kHz

DVD-Audio 192 kHz

MP3

Birate 32- 320 kbps

Decoding 16/20/24 bit linear

Number of channels

5.1 CH (FL, FR, SL, SR, C, SW)

Frequency response 20 Hz- 20 kHz (+1, -2 dB)

Pick up

Beam Source Semiconductor Laser

Wavelength

DVD 658 nm

CD/VCD 780 nm

Wow and flutter Less than possible measurement data

Digital filter 8 fs

D/A converter Delta sigma DAC

GENERAL

Power supply AC 110/127/220-230/240 V, 50/60Hz

Power consumption 313 W

Power consumption in standby mode:

0.9 W

Dimwnsions (W x H x D) 250 x 330 x 370 mm

Mass 10 kg

SYSTEM

SC-VK90D(GCP) Music Center: SA-VK90D(GCPS)

Front Speaker: SB-VK90(GC-S) x 2

Subwoofer: SB-WVK80(GC-S) x 2

Speaker System: SB-PT810(GC-s) x 1 Center Speaker: SB-PC810(GC-S) x 1

Surround Speaker: SB-PS810(GC-S) x 2

Notes:

1. Specifications are subject to change without notice. Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum analyzer.

© 2003 Panasonic AVC Networks Singapore Pte. Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

Page 4

Adjustments

18.1 Cassette Deck Section

18.1.1 Head Azimuth

Adjustment (Deck 1 / 2)

18.1.2 Tape Speed

Adjustment (Deck 1 / 2)

18.1.3 Bias and Erase

Voltage Check

18.1.4 Bias Frequency

Adjustment (Deck 1 / 2)

18.2 Tuner Section

18.2.1 AM-IF Alignment

18.2.2 AM RF Adjustment

18.3 Alignment Points

18.3.1 Cassette Deck

Section

18.3.2 Adjustment Point

19 Illustration of ICs,

Transistors and Diodes

20 Terminal Function of IC

20.1 IC600

(C2BBHF000070 ) System

Microprocessor

21 Block Diagram

22 Schematic Diagram

22.1 (A) DVD Module (1)

Circuit

22.2 (B) DVD Module (2)

Circuit

22.3 (C) Main Circuit & (D)

Tuner Extent Circuit

22.4 (E) Panel Circuit, (F)

LED Circuit & (G) Tact

Switch Circuit

22.5 (H) Tuner Circuit

22.6 (J) Deck Circuit & (K)

Deck Mechanism Circuit

22.7 (L) Power Supply

Circuit

22.8 (M) Power AMP

Circuit

22.9 (N) Power Circuit

22.10 (O) Transformer

Circuit, (P) AC Inlet Circuit,

(Q) Voltage Selector Circuit,

(R) CD Loading Circuit, (S)

CD Detect Circuit, (T)

Spindle Position Circuit

23 Printed Circuit Board

23.1 (A) DVD Module (1) P.

TOP NEXT

Page 5

C.B. (Component & Foil Side)

23.2 (B) DVD Module (2) P.

C.B. (Side A & B)

23.3 (C) Main P.C.B.

23.4 (D) Tuner Extent P.C.

B. , (F) LED P.C.B. (I) Tuner

Pack P.C.B., (R) CD Loading

P.C.B., (T) Spindle Position P.

C.B. & (S) CD Detect P.C.B.

23.5 (E) Panel P.C.B.

23.6 (G) Tact Switch P.C.B.

& (H) Tuner P.C.B.

23.7 (J) Deck P.C.B. & (K)

Deck Mechanism P.C.B.

23.8 (L) Power Supply P.C.

B. & (M) Power AMP P.C.B.

23.9 (N) Power P.C.B.

23.10 (O) Transformer P.C.

B.

23.11 (Q) Voltage Selector

P.C.B. & (P) AC Inlet P.C.B.

24 Wiring Connection

Diagram

25 Parts Location and

Replacement Parts List

25.1 Deck Mechanism

(RAA3412-S)

25.1.1 Deck Mechanism

Parts Location

25.1.2 Deck Mechanism

Parts List

25.2 CD Loading

Mechanism (RD-DAC036-S)

25.2.1 CD Loading

Mechanism Parts Location

25.2.2 CD Loading

Mechanism Parts List

25.3 Cabinet

25.3.1 Cabinet Parts

Location

25.3.2 Cabinet Parts List

25.4 Electrical Parts List

25.5 Packing Materials &

Accessories Parts List

25.6 Packaging

Page 6

Service Manual

TOP NEXT

ORDER NO. MD0308338C3

DVD Stereo System

● SA-VK90DGCP

Colour

(S)... Silver Type

Specifications

AMPLIFIER SECTION

RMS Output power both channel driven: 10% Total Harmonic Distortion

1 kHz Front-HI CH

100 Hz Front-LOW CH

1 kHz Surround CH

1 kHz Center CH

100 Hz Subwoofer CH

Total RMS Dolby Digital Mode Power

80 W per channel (6Ω)

60 W (12Ω)

40 W per channel (8Ω)

100 W (8Ω)

100 W per channel (6Ω)

Page 7

600 W

PMPO Output Power 7000 W

Input sensitivity/Input Impedance

AUX

MIC

FM TUNER SECTION

Frequency range 87.50 - 108.00 MHz (50 kHz steps)

Sensitivity 2.5•V (IHF)

S/N 26 dB 2.2•V

Antenna terminals

Preset station 15

AM TUNER SECTION

Frequency range 522 - 1629 kHz (9 kHz steps)

AM sensitivityy S/N 20 dB at 1000 kHz

Preset station 15

CASSETTE DECK SECTION

Track system 4 track, 2 channel

Heads

Record/playback Solid permalloy head

Erasure Double gap ferrite head

Motor DC servo motor

Recording system AC bias 100 kHz

Erasing system AC erase 100 kHz

Tape speed 4.8 cm/s (1 7/8 ips)

Overall frequency response (+3 dB, -6 dB at DECK OUT)

Normal (TYPE I) 35 Hz - 14 kHz

S/N ratio 50 dB (A weighted)

Wow and flutter 0.18% (WRMS)

Fast forward and rewind time Approx. 120 seconds with

Disc SECTION

Disc

DVD-Video/Audio

DVD-RAM/R (DVD-Video formatted discs)

CD-DA/VCD/MP3/WMA 8 cm/12 cm, CD-R/RW

SVCD (Conforming to IEC62107)

HighMAT Level 2 (Audio and Image)

75Ω (unbalanced)

520 - 1630 kHz (10 kHz steps)

8 cm/12 cm, single/double-sided, single/double-layer

250 mV, 13.3 kΩ

0.7 mV, 680Ω

560•V/m

C-60 cassette tape

Page 8

JPEG-Exif Ver 2.1 JPEG Baseline files

Video

Signal system NTSC

Output level

Composite video

S-Video Y

S-Video C

Component video

Audio

Sampling frequency

CD 44.1 kHz

MP3 32 kHz, 44.1 kHz, 48 kHz

DVD-Video 48 kHz, 96 kHz

DVD-Audio 192 kHz

MP3

Birate 32- 320 kbps

Decoding 16/20/24 bit linear

Number of channels

Frequency response 20 Hz- 20 kHz (+1, -2 dB)

Pick up

Beam Source Semiconductor Laser

Wavelength

DVD 658 nm

CD/VCD 780 nm

Wow and flutter Less than possible measurement data

Digital filter 8 fs

D/A converter Delta sigma DAC

GENERAL

Power supply AC 110/127/220-230/240 V, 50/60Hz

Power consumption 313 W

Power consumption in standby mode:

Dimwnsions (W x H x D) 250 x 330 x 370 mm

Mass 10 kg

0.286 Vp-p (75Ω)(NTSC)

0.7 Vp-p (PB/CB PR/CR)(75Ω)

5.1 CH (FL, FR, SL, SR, C, SW)

1 Vp-p (75Ω)

1 Vp-p (75Ω)

1 Vp-p (Y)(75Ω)

0.9 W

SYSTEM

SC-VK90D(GCP) Music Center: SA-VK90D(GCPS)

Front Speaker: SB-VK90(GC-S) x 2

Page 9

Subwoofer: SB-WVK80(GC-S) x 2

Speaker System: SB-PT810(GC-s) x 1 Center Speaker: SB-PC810(GC-S) x 1

Surround Speaker: SB-PS810(GC-S) x 2

Notes:

1. Specifications are subject to change without notice. Mass and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum analyzer.

© 2003 Panasonic AVC Networks Singapore Pte. Ltd. All rights reserved. Unauthorized copying and distribution is a violation of law.

TOP NEXT

Page 10

1 Before Use

TOP PREVIOUS NEXT

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the

area in which the unit will be used. (If the power supply in your area is 117V or 120V, set to the

“127V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage

selector for some countries, the correct voltage is already set.)

TOP PREVIOUS NEXT

Page 11

2 Before Repair and Adjustment

TOP PREVIOUS NEXT

Disconnect AC power, discharge Power Supply Capacitors C531~C534, C588~C589, C598~C599

and C954 through a 10Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may

destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 110/127/220~230V, 50/60 Hz in NO SIGNAL (vol. min, at CD mode) &

AC 240 V, 50 Hz should be ~770mA and ~370mA respectively.

TOP PREVIOUS NEXT

Page 12

3 Protection Circuitry

TOP PREVIOUS NEXT

The protection circuitry may have operated if either of the following conditions are noticed:

● No sound is heard when the power is turned on.

● Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative

speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the

amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note :

When the protection circuitry functions, the unit will not operate unless the power is first turned off

and then on again.

TOP PREVIOUS NEXT

Page 13

4 Safety Precautions

TOP PREVIOUS NEXT

4.1 General Guidelines

4.1.1 Leakage Current Cold Check

4.1.2 Leakage Current Hot Check (See Figure 1)

TOP PREVIOUS NEXT

Page 14

4.1 General Guidelines

TOP PREVIOUS NEXT

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts

which have been overheated or damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation

papers shields are properly installed.

3. After servicing, make the following leakage current checks to prevent the customer from

being exposed to shock hazards.

4.1.1 Leakage Current Cold Check

4.1.2 Leakage Current Hot Check (See Figure 1)

TOP PREVIOUS NEXT

Page 15

4.1.1 Leakage Current Cold Check

TOP PREVIOUS NEXT

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each

exposed metallic cabinet part on the equipment such as screwheads, connectors, control shafts,

etc. When the exposed metallic part has a return path to the chassis,the reading should be

between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be ·.

Figure 1

TOP PREVIOUS NEXT

Page 16

4.1.2 Leakage Current Hot Check

(See Figure 1)

TOP PREVIOUS NEXT

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this

check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15•F capacitor, between each exposed

metallic part on the set and a good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across

the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester

(Simpson Model 229 or equivalent) may be used to make the hot checks, leakage current must

not exceed 1/2 milliamp. In case a measurement is out ofthe limits specified, there is a

possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

TOP PREVIOUS NEXT

Page 17

5 Prevention of Electro Static Discharge (ESD)

to Electrostatically Sensitive (ES) Devices

TOP PREVIOUS NEXT

Some semiconductor (solid state) devices can be damaged easily by electricity. Such components

commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are

integrated circuits and some field-effect transistorsand semiconductor “chip” components. The

following techniques should be used to help reduce the incidence of component damage caused by

electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equiped

assembly, drain off any ESD on your body by touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging ESD wrist strap, whichshould be

removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equiped with ES devices, place the assembly on a

conductive surface such as aluminium foil, to prevent electrostatic charge build up or exposure

of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder remover device. Some solder removal devices not classified as

“anti-static (ESD protected)” can generate electrical charge to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to

damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before

you are ready to install it. (Most replacement ES devices are packaged with leads electrically

shorted together by conductive foam, aluminium foil orcomparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES

device, touch the protective material to the chassis or circuit assembly into which the device

will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize body motions when handling unpackaged replacement ES devices. (Otherwise

harmless motion such as the brushing together of your clothes fabric or the lifting of your foot

Page 18

from a carpeted floor can generate static electricity (ESD) sufficient todamage an ES device).

TOP PREVIOUS NEXT

Page 19

6 Handling the Lead-free Solder

TOP PREVIOUS NEXT

6.1 About lead free solder (PbF)

TOP PREVIOUS NEXT

Page 20

6.1 About lead free solder (PbF)

TOP PREVIOUS NEXT

Distinction of PbF P.C.B.:

P.C.B.s (manufactured) using lead free solder will have a PbF stamp on the P.C.B.

Caution:

● Pb free solder has a higher melting point than standard solder; Typically the melting point is

50 - 70°F (30 - 40°C) higher. Please use a high temperature soldering iron. In case of

soldering iron with temperature control,please set it to 700 ± 20°F (370 ± 10°C).

● Pb free solder will tend to splash when heated too high (about 1100°F/600°C).

● When soldering or unsoldering, please completely remove all of the solder on the pins or

solder area, and be sure to heat the soldering points with the Pb free solder until it melts

enough.

TOP PREVIOUS NEXT

Page 21

7 Cautions to be taken when handling Optical

Pickup

TOP PREVIOUS NEXT

The laser diode used inside optical pickup could be destroyed due to static electricity as a potential

difference is caused by electrostatic load discharged from clothes or human body. Handling the parts

carefully to avoid electrostatic destructionduring repair.

7.1 Handling Optical Pickup

7.2 Replacing Precautions for Optical Pickup Unit

7.3 Grounding for Preventing Electrostatic Destruction

TOP PREVIOUS NEXT

Page 22

7.1 Handling Optical Pickup

TOP PREVIOUS NEXT

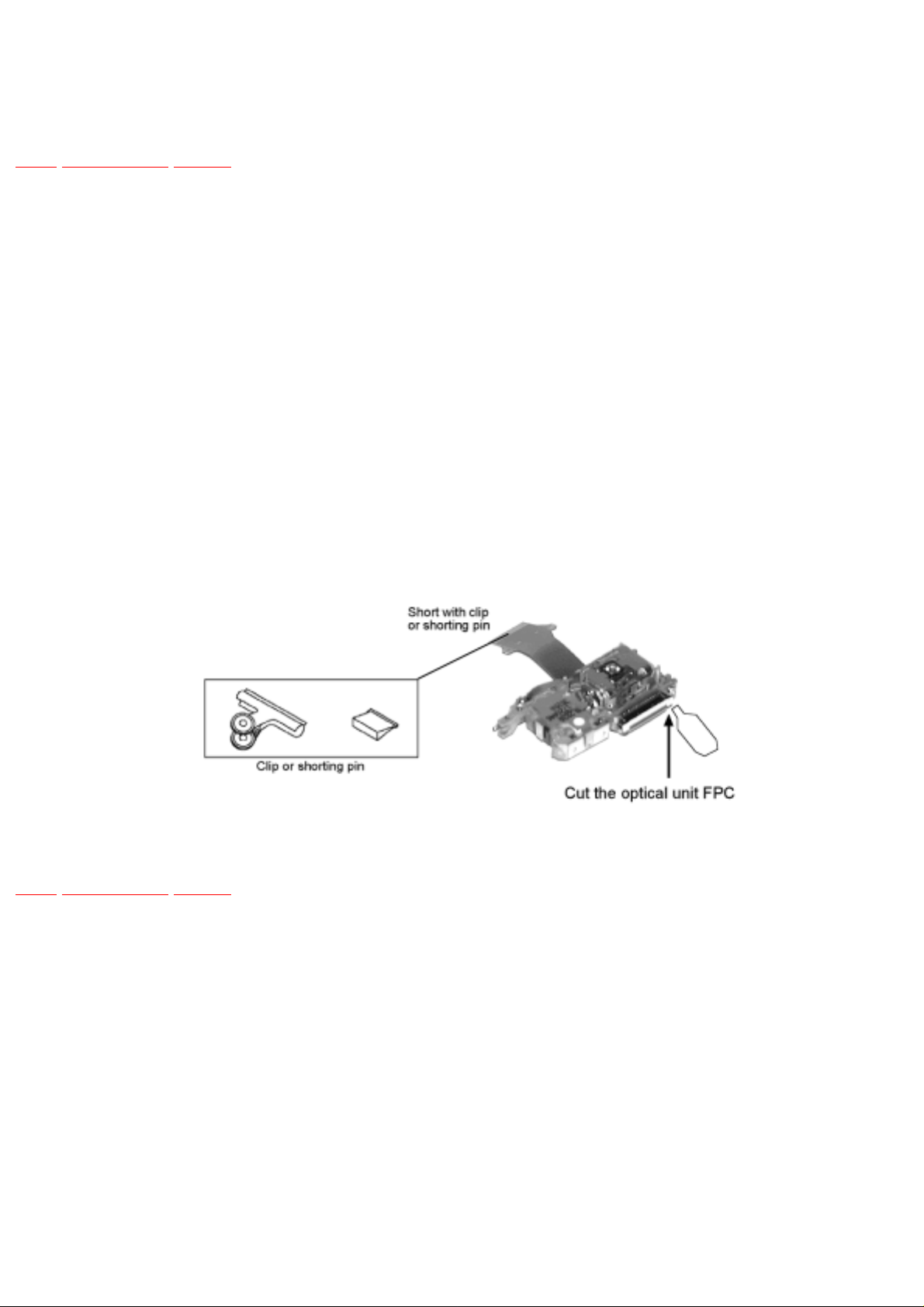

1. Do not impact on optical pickup as the unit structurally uses an extremely precise technology.

2. Short-circuit the flexible cable of optical pickup remove from the circuit board using a shortcircuit pin or clip in order to prevent laser diode from electrostatic destruction (Refer to Fig.

7.1 and Fig. 7.2)

3. Do not handle flexible cables forcibly as this may cause snapping. Handle the parts carefully

(Refer to Fig. 7.1)

4. A new optical pickup is equipped with an anti-static flexible cable. After replacing and

connecting to the flexible board, cut the anti-static flexible cable. (Refer to Fig. 7.1)

Fig. 7.1

TOP PREVIOUS NEXT

Page 23

7.2 Replacing Precautions for Optical Pickup

Unit

TOP PREVIOUS NEXT

DVD/CD Optical Pickup

The optical pickup by which part supply was carried out attaches the short clip to the flexible board

for laser diode electrostatic discharge damage prevention. Please remove a short clip and be sure to

check that the short land is open, beforeconnecting. (Please remove solder, when the short land shortcircuits.)

TOP PREVIOUS NEXT

Page 24

7.3 Grounding for Preventing Electrostatic

Destruction

TOP PREVIOUS NEXT

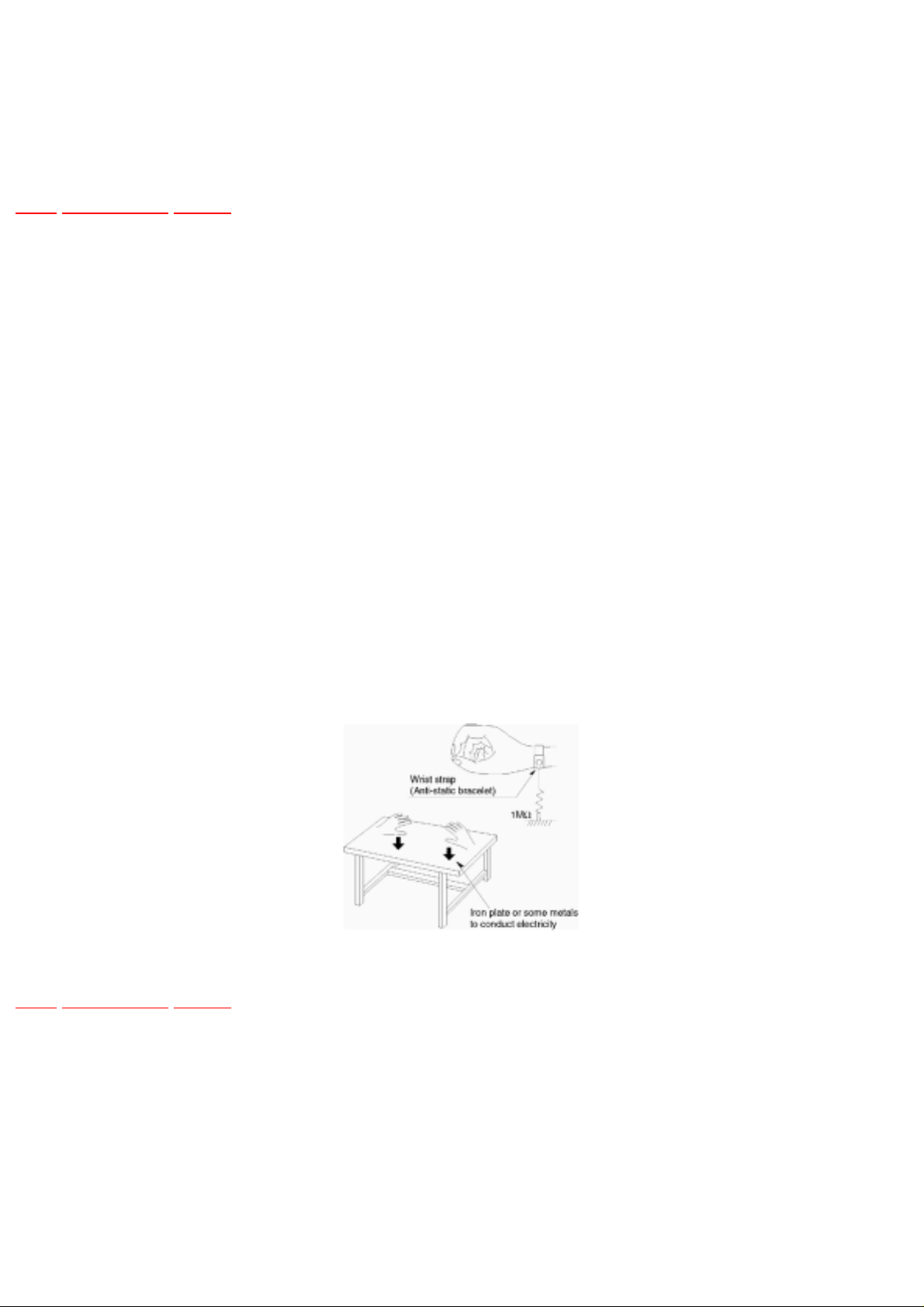

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity accumulated in your body.

(Refer to Fig. 7.2)

2. Work place grounding

Place a conductive material (conductive sheet) or ironboard where optical pickup is placed.

(Refer to Fig. 7.2)

Note :

Keep your clothes away from optical pickup as wrist strap does not release the static electricity

charged in clothes.

Fig. 7.2

TOP PREVIOUS NEXT

Page 25

8 Precaution of Laser Diode

TOP PREVIOUS NEXT

Caution :

This product utilizes a laser diode with the unit turned "ON", invisible laser radiation is emitted from

the pick up lens.

Wavelength : 780 nm(VCD/CD)/658 nm(DVD)

Maximum output radiation power from pick up : 100 •W/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is

dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

ACHTUNG :

Dieses Produkt enthält eine Laserdiode. Im eingeschalteten Zustand wird unsichtbare Laserstrahlung

von der Lasereinheit abgestrahlt.

Wellenlänge : 780 nm(VDC/CD)/658 nm(DVD)

Maximale Strahlungsleistungder Lasereinheit :100•W/VDE

Die Strahlung an der Lasereinheit ist ungefährlich, wenn folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten Laserdiode gefährlich ist.

2. Den werkseitig justierten Einstellregler der Lasereinhit nicht verstellen.

3. Nicht mit optischen Instrumenten in die Fokussierlinse blicken.

4. Nicht über längere Zeit in die Fokussierlinse blicken.

ADVARSEL :

I dette a apparat anvendes laser.

Page 26

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED

HEREIN MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

Use of Caution Labels

TOP PREVIOUS NEXT

Page 27

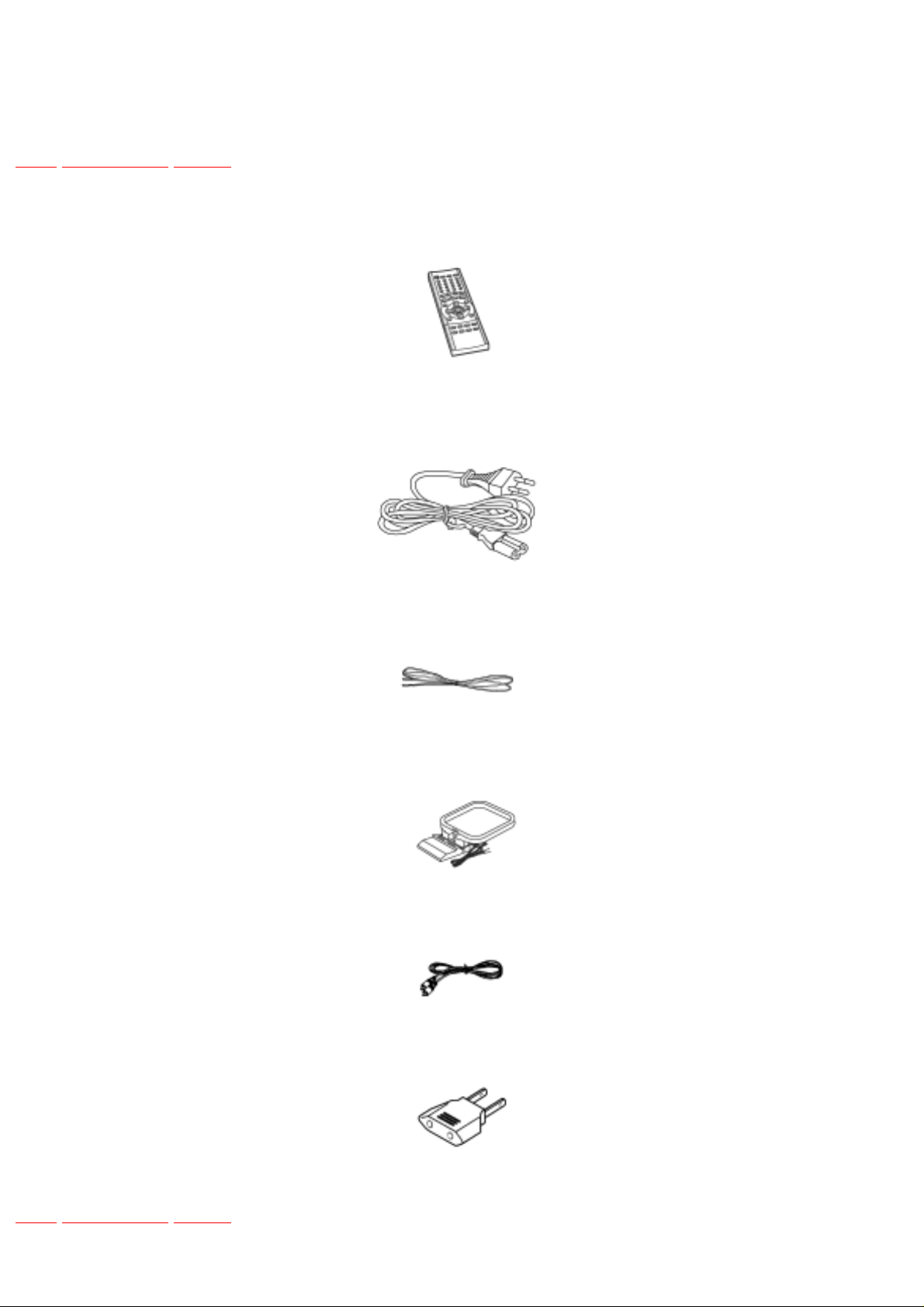

9 Accessories

TOP PREVIOUS NEXT

Remote Control

AC power supply cord

FM indoor antenna

AM indoor antenna

Video cable

Power plug adaptor

TOP PREVIOUS NEXT

Page 28

10 Operation Procedures

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 29

11 Disc information

TOP PREVIOUS NEXT

TOP PREVIOUS NEXT

Page 30

12 About HighMAT

TOP PREVIOUS NEXT

12.1 What is HighMAT?

12.2 Why use HighMAT?

12.3 The advantages of using HighMAT

12.4 Outline of the HighMAT standard

TOP PREVIOUS NEXT

Page 31

12.1 What is HighMAT?

TOP PREVIOUS NEXT

This word combines the abbreviations of Matsushita Electric Industrial Co. Ltd. and High

Performance Media Access Technology, and is a trademark of Microsoft Corporation. The products

with the HighMAT logo shown below are made according to the HighMATstandard.

HighMAT is a format that allows users to save digital contents such as photographs, audio, and

images on a CD. This gives consistency in the way of reading data when general consumer products

(such as DVD players) and PCs are used, and thus, itis easy to operate for the user.

TOP PREVIOUS NEXT

Page 32

12.2 Why use HighMAT?

TOP PREVIOUS NEXT

Up to now, there was no harmonized standard from playing digital content stored in CD-ROM

formats (including CD-R) on consumer products like DVD players.Therefore, we used to have

problems such as follow:

● There was no common play list or attached information on contents, which is called metadata.

● The data compression method differed according to the equipment.

● As the number of CD-ROMs recorded increased retrieved the contents became more difficult.

● Because display and operation methods were different depending on the equipment, the play

order of the content on the same disc could change.

TOP PREVIOUS NEXT

Page 33

12.3 The advantages of using HighMAT

TOP PREVIOUS NEXT

Applying the HighMAT standard will solve the following problems and will improve usability.

● It will create a common user interface for both PC and consumer products.

● Regardless of the types of consumer products, such as DVD players, portable CD players, car

stereos, and micro computers, a consistent way to pay for digital content will be created and it

will make it easier to retrieve data.

Page 34

● You can also play digital content on the disc, which was created in accordance with the

HighMAT format with a conventional CD-ROM player.

TOP PREVIOUS NEXT

Page 35

12.4 Outline of the HighMAT standard

TOP PREVIOUS NEXT

1. Recording medium

❍ CD-R/CD-RW

❍ Supports ISO 9660 Level Expanded Joliet

❍ For multiple session

2. Support data format

❍ Level 1 player: WMA, MP3 (MPEG-1 Audio Layer 3)

❍ Level 2 player: WMA, MP3 (MPEG-1 Audio Layer 3), JPEG

❍ Level 3 player: WMA, MP3 (MPEG-1 Audio Layer 3), JPEG, WMV, MPEG4 (optional)

3. Limitation of data format

❍ WMA, MP3 (MPEG-1 Audio Layer 3) 64 kbps - 160.999 kbps, 44.1 KHz, stereo, fixed bit

rate/ variable bit rate.

❍ WMA, V2 and above, excluding Lossless/Voice/Pro

❍ JPEG: Max 6M pixel, Maximum file size: 3 MB

Page 36

4. Limitations regarding the number of files on the media, etc.

❍ Total number of audio files: Maximum 450

❍ Total number of still picture files: Maximum 999

❍ Total number of animation files: Maximum 200

❍ Total number of directories: Maximum 400

❍ Length of a file name: Maximum 108 characters (Unicode)

❍ Total number of play lists: Maximum 200

❍ Number of contents in the playlist: Maximum 900

5. Composition of HighMAT disc

❍ Menu: Classified for the navigation of the HighMAT digital contents. When menu selected,

its submenu or the play list will be displayed.

❍ Play list: A list in which one or more digital contents are arranged in order

❍ Group: Sub-divided group of a play list.

❍ Digital Contents: Audio, still picture, and animation data.

TOP PREVIOUS NEXT

Page 37

13 Procedure for repairing the set

TOP PREVIOUS NEXT

13.1 Distinguish the trouble cause

13.2 Diagnosis of Optical Pick-up Unit

TOP PREVIOUS NEXT

Page 38

13.1 Distinguish the trouble cause

TOP PREVIOUS NEXT

How to distinguish the trouble

1. View mechanical part if visual damage occurred.

Confirm the movement of mechanical parts assembly (tray ass’y, loading mechanism ass’y,

etc.).

2. Diagnose if Optical Pickup Unit is faulty (refer to diagnosis of Optical Pickup Unit).

3. If mechanism and OPU are OK, it is P.C.B.

Cause 1 Possible fault

1. AC Inlet Circuit/Voltage Selector Circuit Fuse Blow (F1,F2), Power Transformer Problem(T501, T502), Wrong Selection of

Selector (S501)

2. Power Circuit F3, F4, FP951, FP950

3. Power Amp Circuit IC502 faulty

4. Power Supply Circuit IC500, IC501 faulty

Cause 2 Possible fault

1. Mechanical block Tray and loading mechanical block, traverse unit, deck unit

2. O.P.U. Refer to the diagnosis of OPU

Page 39

3. Circuit LD drive, servo (Traverse, Focus, Tracking)

4. Power circuit FP951

TOP PREVIOUS NEXT

Disc sensor

Signal processing (FORE, SODC, DV1 etc.)

Cause 3 Possible fault

1. Mechanical block Traverse block (Tilt adjustment)

2. O.P.U. Refer to the diagnosis of OPU

3. Mechanism Cirucit Servo (Focus, tracking)

Signal processing (FORE, SODC, DV1 etc.)

Page 40

13.2 Diagnosis of Optical Pick-up Unit

TOP PREVIOUS NEXT

How to distinguish Laser destruction/damage

Confirmation 1

Remove cover of mechanism block so that you will see the lens of optical pickup.

Confirm emission of laser at the moment when power switch is turned on.

If there is no laser emission, laser diode is faulty.

Confirmation 2

While holding “Pause” and “Open/Close” button, press “Display” button on the remote controller.

Unit display laser current on FL.

From the reading of display, you can judge if laser diode is damaged or not.

Reading on the right side should be less than 70. If reading is more than 70, laser is damaged.

Page 41

How to confirm if Optical Pickup is OK

Confirmation 1

1. Confirmation of jitter value with test disc. (Refer below for how to check jitter)

2. Lens cleaning.

3. Reconfirm jitter value.

4. Perform tile adjustment. (Refer to tilt adjustment)

5. Reconfirm jitter value. (To confirm jitter value, while pressing “Pause” and “Open/Close”

button, press numeric “5” on remote controller.)

Unit display jitter value on FL.

Confirmation 2

If servo is very unstable due to optical error and you cannot confirm jitter value, clean the lens and

check appearance of pick up unit (cutting coil of actuator, etc), then check circuitry.

TOP PREVIOUS NEXT

Page 42

14 Optical Pickup Self-Diagnosis and

Replacement Procedure

TOP PREVIOUS NEXT

14.1 Self-diagnosis

14.2 Cautions to Be Taken During Replacement of Optical Pickup and Spindle Motor

14.2.1 Cautions to be taken during replacement of optical pickup

TOP PREVIOUS NEXT

Page 43

14.1 Self-diagnosis

TOP PREVIOUS NEXT

This unit is equipped with the optical pickup self-diagnosis function and the tilt adjustment check

function. Follow the procedure described below during repair in order to perform self-diagnosis and

tilt adjustment effectively. Especially when “NODISC” is displayed, be sure to apply the selfdiagnosis function before replacing with an optical pickup. Replacement of optical pickup generally

requires when the present value of laser drive exceeds 45 (DVD) or 45 (CD).

Note:

Start diagnosis within three minutes after turning on the power (as diagnosis fails when the unit

becomes warm).

TOP PREVIOUS NEXT

Page 44

14.2 Cautions to Be Taken During Replacement

of Optical Pickup and Spindle Motor

TOP PREVIOUS NEXT

Before replacing the optical pickup and spindle motor, check a total usage time respectively. Follow

the checking method described below.

Item Status and Key Function Display

Checking DVD, CD laser usage

time

Checking spindle motor usage time With the unit stopped and no disc

Resetting DVD, CD laser usage

time

With the unit stopped and no disc

inserted, press the.

button on the player and the

buttonon the remote controller unit.

inserted, press the

button on the player and the

buttonon the remote controller unit.

While the DVD and CD laser usage

times are displayed, press the

button on the player and the

button on the remote controller unit.

T1_xxxx_yyyy

xxxx(DVD), yyyy(CD): total time is displayed with

a four-digit number by the ten hours.

T2_xxxxx

xxxxx: total time is displayed with a four-digit

number by the ten hours.

T1_0000_0000

Resetting spindle motor usage time While the spindle motor usage time

is displayed, press the

button on the player and the

buttonon the remote controller unit.

T2_0000

14.2.1 Cautions to be taken during replacement of optical pickup

TOP PREVIOUS NEXT

Page 45

14.2.1 Cautions to be taken during replacement

of optical pickup

TOP PREVIOUS NEXT

Optical pickup could be damaged due to the static electricity discharged from human body. Wear

proper protection gear against static electricity during optical pickup and its peripheral repair. (Refer

to “Cautions to Be Taken When HandlingOptical Pickup”.)

● Do not touch laser diode, actuator and their peripherals.

● Do not check laser diode with a tester and such. (The tester will be destroyed.)

● For short-circuiting or removing laser diode, the use of an anti-static soldering iron is

recommended. (Recommended model: HAKKO ESD product)

● Solder the land of the flexible cable in the optical pickup.

Note:

If an anti-static soldering iron is not available, short-circuit the terminal surface of the flexible cable

and then the land using a clip or equivalent device.

TOP PREVIOUS NEXT

Page 46

15 Self-Diagnosis Function

TOP PREVIOUS NEXT

This unit is equipped with the self-diagnosis function, which displays an error when it occurs, for use

during servicing.

15.1 Automatic Displayed Error Codes

15.1.1 Automatic Display Function

15.1.2 Re-Display

15.1.3 Description of Error Code

15.2 Memorized Error Codes

15.2.1 Activating Self-Diagnosis Function and Displaying Method

15.2.2 Re-Display

15.3 Mode Table 1

15.4 DVD / CD Self-Diagnosis Error Code Description

15.5 Error Codes Stored During No Play

15.6 Mode Table 2

15.7 Tray Lock Function

15.7.1 Setting

15.8 Things to Do After Repair

TOP PREVIOUS NEXT

Page 47

15.1 Automatic Displayed Error Codes

TOP PREVIOUS NEXT

15.1.1 Automatic Display Function

15.1.2 Re-Display

15.1.3 Description of Error Code

TOP PREVIOUS NEXT

Page 48

15.1.1 Automatic Display Function

TOP PREVIOUS NEXT

For a power unit error, the code is automatically displayed.

● F61:

Automatically displayed on the LCD of the player.

TOP PREVIOUS NEXT

Page 49

15.1.2 Re-Display

TOP PREVIOUS NEXT

● For F61 Display

❍ When the code, F61 is displayed, the power is automatically turned off.

❍ The code, F61 is displayed for three seconds, and then the current time appears.

❍ To retrieve the code, turn on the power button so that the code F61 appears, however,

is switched to time display after three seconds, and the power is automatically turned

off.

● For F76 Display

❍ The abnormalities is an output or the abnormalities in a power supply of POWER AMP.

TOP PREVIOUS NEXT

Page 50

15.1.3 Description of Error Code

TOP PREVIOUS NEXT

15.1.3.1 F61

● State, Condition

When the power is turned on, the unit is automatically turned off. The power does not turn on.

● Cause, Troubleshooting

Power circuit system failure and/or direct current flown to speaker terminal

Identify the cause and replace with new parts.

TOP PREVIOUS NEXT

Page 51

15.2 Memorized Error Codes

TOP PREVIOUS NEXT

15.2.1 Activating Self-Diagnosis Function and Displaying Method

15.2.2 Re-Display

TOP PREVIOUS NEXT

Page 52

15.2.1 Activating Self-Diagnosis Function and

Displaying Method

TOP PREVIOUS NEXT

1. Turn on the power.

2. Select DVD/CD function. With no DVD/CD inserted in the player, press and hold down the

button for at least two seconds, and press the “0” buttonon the remote control for at least two

seconds in order to display “DVD_F_ _ _ ”.

3. Press the

button. If a memorized error is detected, the result of self diagnosis is displayed. (Ex.: T

H15)

If several errors are detected, press the

button to display each.

TOP PREVIOUS NEXT

Page 53

15.2.2 Re-Display

TOP PREVIOUS NEXT

● Press the power button to turn off the power, and then turn on the power.

● The details of self diagnosis are stored in the unit memory.

To retrieve them, follow the procedure described the above, “Activating Self-Diagnosis

Function and Displaying Method”.

TOP PREVIOUS NEXT

Page 54

15.3 Mode Table 1

TOP PREVIOUS NEXT

Following modes are available with combinations of the pressed buttons on the player and on the

remote controller unit.

Player Remote Controller Unit Usage

button

0 Error code display (Refer to the Item 9.4. DVD Error Code Description)

5 Tilt adjustment

6 Region number and broadcasting system check

7 Bulit-in program version check

DISPLAY DVD laser drive current check

3 CD laser drive current check

PAUSE Writing of laser drive current value after replacement of optical pickup

TOP PREVIOUS NEXT

(Do use this function only when optical pickup is replaced.)

Initialization of the player (factory setting is restored.)

Used after replacement of micro-computer and its peripherals and printed circuit board.

Page 55

15.4 DVD/CD Self-Diagnosis Error Code

Description

TOP PREVIOUS NEXT

Error

Code

H15 The disc tray cannot be opened: it closes spontaneously. Disc tray open/close detection switch (S1001)

H16 The disc tray cannot be closed: it opens spontaneously.

Error

Code

U. H. Error

U11 Focus servo failure

H01 Tray loading failure

H02 Spindle servo failure (Spindle servo, DSC, SP motor, CLV servo failure)

H03 Traverse motor failure

H04 Tracking servo error

H05 Seek timeout failure

DSC system

State, Conditon Cause, Troubleshooting

failure.

(Check and replace)

Meaning Details

F500 DSC failure DSC stops due to servo failure.

(Startup, focus failure, etc.)

F501 DSC not Ready failure Communication failure between DSC and system computer

(No communication because DSC does not move)

F502 DSC Time out failure See F500.

F503 DSC communication failure Communication failure (Result failure occurs after communication

command is transmitted.)

F505 DSC Attention Error See F500.

F506 Invalid media Disc is placed upside down; TOC is unreadable or invalid disc is

inserted.

Disc Code

F103 Ilegal highlight position Disc standard is possibly illegal when highlight is displayed.

IIC Error

F4FF Forced initialization failure (Time out)

F880 Unsuitable task number When a message arrives from not existing task

F890 A message is sent during AV task transmission During transmission of a message to AV task

F891 Unable to transmit a message to AV task When transmission of a message to AV task starts

Page 56

F893 FROM altered

F894 EEPROM failure

F8A0 Unsuitable message command When transmission of a message to AV task starts

TOP PREVIOUS NEXT

Page 57

15.5 Error Codes Stored During No Play

TOP PREVIOUS NEXT

Error

Code

F0BF 6) Unable to replay due to

physical layer identification

failure

F0C0 8) DVD: Unable to replay due to

no DVD Video/Audio/VR

F0C1 9) DVD: Prohibited due to illegal

regional code

F0C2 A) DVD: No replay due to PAL

system

F0C3 B) DVD: All title replay

prohibited in parental setting

F0C4 C) VCD: Prohibited due to

PHOTO CD format

F0C5 D) VCD/CD: Prohibited due to

CD-ROM without CD-DA

Meaning System Computer Item Setting Task Internal error in system

computer

PCND_NOPLAY_PHYSICAL 0x50 DriveManager 0xD0BF

PCND_NOPLAY_VIDEO 0x70 DiscManager 0xD0C0

PCND_NOPLAY_RCD 0x80 DiscManager 0xD0C1

PCND_NOPLAY_PAL 0x90 DiscManager 0xD0C2

PCND_NOPLAY_PTL 0xA0 DiscManager 0xD0C3

PCND_NOPLAY_PHOTOCD 0xB0 DiscManager 0xD0C4

PCND_NOPLAY_CDROM 0xC0 DiscManager 0xD0C5

TOP PREVIOUS NEXT

Page 58

15.6 Mode Table 2

TOP PREVIOUS NEXT

Following modes are available with combinations of the pressed buttons on the player and on the

remote controller unit.

Item Operational

Condition and Key

Function

Jitter display While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button,

“5” on theremote

controller unit.

Error code display While the player is

stopped and no

disc is inserted,

press and hold

down the

Details Display TO Exit Mode

Jitter display

Measures and displays

jitter. Measurement is

repeated every second.

Read error counter starts

at 0 at the mode setting,

and increased by one as

data read fails at target

block. A small defectis

allowed to correct by

retry. Any possibility is

counted as one

increment. Repetitive

errors after retry

increase by two levels

or more.

Error code display

Displays the latest error

code stored in

EEPROM.

J*1 xxx*2 _yyy*3 _zz*4

*1 : Jitter display mode

*2 : Jitter measurement

value

*3 : Readerror counter

*4 : Focus driving value

Values are shown to one

decimal place in the

decimal digit.Focus driving

value is displayed in the

hexadecimal digit.

DVDnn_F--*nn: Error history

*--: Error number

DVD 01 FOBF

Press the STOP or

OPEN button.

Press the OPEN

button.

Measurement of laser

current electricity

initialization value

button on the

player and the

number button,

“0” on theremote

controller unit.

While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

button on the

remote controller

unit.

Measurement of laser

current electricity

initialization value

Memorizes each

initialization value of

DVD and CD in

EEPROM.

LDO*1 _013*2 _032*3

*1 : Laser current electricity

measurement mode

*2 : DVD current electricity

value

*3 : CDcurrent electricity

value

Values are shown in the

decimal digit. The above

example indicates that the

current electricity

initialization value is 13mA

at DVD laser and 32mA at

Automatically exits

the mode after five

seconds.

Page 59

CD laser when laser is

turned on.

Measurement of DVD

laser current electricity

ADSC internal RAM

display

While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

DISPLAY button

on the remote

controller unit.

While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button “1”

or “2” onthe

remote controller

unit.

Measurement of DVD

laser current electricity

Measures DVD laser

current electricity and

displays the result

together with the

initialization value

stored in EEPROM.

After measurement,

DVD laser is lit tillthe

power is turned off (or

goes off when the

primary power is turned

off).

ADSC internal RAM

display

Reads and displays the

RAM value inside

ADSC. The address is

renewed when the

CLEAR key is pressed

so that the values at

eleven points appear.

LDD*1 _012*2 _014*3

*1 : DVD laser current

electricity measurement

mode

*2 : Current electricity

initializationvalue stored in

EEPROM

*3 : Present value of current

electricity

Values are shown in the

decimal digit. The above

example indicates that the

current electricity

initialization value is 12mA

and its present valueis

14mA.

A*1 _FB0*2 _0000*3

*1 :ADSC internal RAM

display mode

*2 : Address

*3 : RAM value atdisplayed

address

Values are shown in the

hexadecimal digit. The

above example indicates

that ADSC value at the

address, FB0h is 0000h.

Automatically exits

the mode after five

seconds.

Press the STOP or

OPEN button.

Measurement of CD

laser current electricity

While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button “3”

onthe remote

controller unit.

Measurement of CD

laser current electricity

Measures CD laser

current electricity and

displays the result

together with the

initialization value

stored in EEPROM.

After measurement, CD

laser is lit tillthe power

is turned off (or goes off

when the primary power

is turned off).

LDC*1 _032*2 _032*3

*1 : CD laser current

electricity measurement

mode

*2 : Current electricity

initializationvalue stored in

EEPROM

*3 : Present value of current

electricity

Values are shown in the

decimal digit. The above

example indicates the

current electricity

initialization value is 28mA

and its present value is

26mAwhen laser is turned

on.

Automatically exits

the mode after five

seconds.

Page 60

User initialization While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button

on the remote

controller unit.

User initialization

The user setting

recovers the factory

setting.

“INITIALIZE” -

Region display While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button,

“6” onthe remote

controller unit.

Firmware version display While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button,

“7” on theremote

controller unit.

Region display [srrrxxyzzzz]

s : Panecon model type

rrr : Panecon release number

x : Syscon generation (45)

y: Syscon model type

zzz: Syscon release number

Firmware version

display

rrr*1 _xx*2 y*3 zzz*4

*1 : Panel computer release

number

*2 : System computer

generation

*3 : Systemcomputer model

type

*4 : System computer

release number

Automatically exits

the mode after five

seconds.

Automatically exits

the mode after five

seconds.

Region and firmware

display

While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

number button,

“8” on theremote

controller unit.

Region and firmware

version display

_r*1 __xx*2 y*3 zzz*4

*1 : Region number

*2 : System computer

generation

*3 : Systemcomputer model

type

*4 : System computer

release number

Automatically exits

the mode after five

seconds.

Page 61

Laser use time While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

button on the

remote controller

unit.

Laser usage time

Measures each for DVD

and CD respectively.

T1_1234_5678

The numbers in the left

show usage time for DVD

laser and those in the right

for CD laser. The four-digit

number is shown by the ten

hours in the decimal digit.

The number after 0000 is

9999.

Automatically exits

the mode after five

seconds.

Reset laser use time While the usage

time 1 is

displayed, press

and hold down the

button on the

player and the

button on the

remote controller

unit.

Spindle use time While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

Laser usage time reset

Resets both for DVD

and CD at once.

Spindle motor usage

time

T1_0000_0000 Automatically exits

the mode after five

seconds.

T2_12345

The four-digit number is

shown by the ten hours in

the decimal digit. The

number after 00000 is

99999.

Automatically exits

the mode after five

seconds.

button on the

remote controller

unit.

Reset spindle use time While the usage

time 2 is

displayed, press

and hold down the

button on the

player and the

button on the

remote controller

unit.

Usage time 2 reset

Spindle motor usage

time

T2_00000 Automatically exits

the mode after five

seconds.

Page 62

Communication error

display

While the player is

stopped and no

disc is inserted,

press and hold

down the

button on the

player and the

MENU button on

the remote

controller unit.

TOP PREVIOUS NEXT

Displays frequency of

communication errors

between system

computer firm IC and

mechanical computer IC

during DVD module.

ERR_00/30 Automatically exits

the mode after five

seconds.

Page 63

15.7 Tray Lock Function

TOP PREVIOUS NEXT

15.7.1 Setting

TOP PREVIOUS NEXT

Page 64

15.7.1 Setting

TOP PREVIOUS NEXT

● Disc Lock Function

1. With the SELECTOR on DVD/CD and POWER ON, hold down the [

STOP] KEY on the main unit, and then press the [POWER] KEY on the remote

control for 3 seconds to enter toLock mode A.[_ _ _LOCKED_] will be displayed for 3

seconds, and then current disc will begin playing.

2. In Lock mode A, the following key is disabled.

[OPEN/CLOSE]

● Operation Lock Function

1. With the SELECTOR on DVD/CD and POWER ON, hold down the [CD PLAY] KEY

on the main unit, and then press the [POWER] KEY on the remote control for 3

seconds to enter Lock mode B.

[_ _ _ LOCKED_] will be displayed for 3 seconds, and the current disc will begin

playing.

2. Lock mode B primarily controls the selector and disc operations, and disenables for the

following keys.

Note:

OPEN/CLOSE

button are invalid and the player displays “___LOCKED_” while the lock function mode is

entered.

● Prohibiting operation of selector and disk

1. Select the DVD/CD function.

2. Press and hold down the

button on the player and the power button on the remote controller unit for at least

Page 65

three seconds. (The message, “___LOCKED_” appearswhen the function is activated.)

Note:

The following buttons are invalid and the player displays “___LOCKED_” while the lock

function mode is entered.

TOP PREVIOUS NEXT

Page 66

15.8 Things to Do After Repair

TOP PREVIOUS NEXT

Follow the procedure described below after repair.

1. While the power is on, press the

button to close the tray.

2. Press the power button to turn off the power.

3. Unplug the power cable.

Note:

It is prohibited to unplug the power cable while the tray is opened and to close the tray manually.

TOP PREVIOUS NEXT

Page 67

16 Cautions To Be Taken During Servicing

TOP PREVIOUS NEXT

16.1 Recovery after the dvd player is repaired

16.2 DVD Player Firmware Version Upgrade Process

16.3 Firmware Version Upgrade Process by Using Disc and Recovery Process

16.3.1 Self-Diagnosis Function

16.4 Using Recovery Disc

16.4.1 Recovery Process

16.4.2 Version Upgrade Process

16.5 Total Usage Time Display

TOP PREVIOUS NEXT

Page 68

16.1 Recovery after the dvd player is repaired

TOP PREVIOUS NEXT

● When Flash ROM or module(2) P.C.B. is replaced, carry out the recovery processing to

optimize the drive. Playback the recovery disc to process the recovery automatically.

● Recovery disc (Product number=RFKZD03R004)

● Performing recovery

1. Load the recovery disc (Product number: RFKZD03R004) to the player and run it.

2. Recovery is performed automatically. When it is finished, a message appears on the

screen.

3. Remove the recovery disc.

4. Turn off the power.

Note:

This unit requires no initialization process carried out after the traditional DVD players were

repaired. When the recovery measures are taken, the customer setting will return to the factory setting

as same as the procedure described in item “Initialization” in9.6 is carried out. Write down the

contents of the setting before recovery processing, and reset the player.

TOP PREVIOUS NEXT

Page 69

16.2 DVD Player Firmware Version Upgrade

Process

TOP PREVIOUS NEXT

Firmware of DVD player may upgrade to conform to improvement of its performance and quality

including operational range, playability of non-standardized discs, etc. The version upgrade disc

contains the recovery function, and the recovery disc isnot necessary.

Note:

Version upgrade process cannot be complete if the AC power is cut off due to power failure and other

occasions during the process. If this occurs, replace FLASH ROM and restart version upgrade.

Version upgrade disc number is informed when ordered.

TOP PREVIOUS NEXT

Page 70

16.3 Firmware Version Upgrade Process by

Using Disc and Recovery Process

TOP PREVIOUS NEXT

● Recovery process

● Firmware version upgrade process

Both of the above procedures automatically start when the recovery disc is replayed.General CD-R

disc allows version upgrade process and recovery process, making version upgrade through disc

simple.

Recovery process: Optimization process ofplayer after replacement of FLASH ROM, EEPROM, or

module circuit board

Version upgrade process: Renewal of firmware for improvement of operational range and

performance

16.3.1 Self-Diagnosis Function

TOP PREVIOUS NEXT

Page 71

16.3.1 Self-Diagnosis Function

TOP PREVIOUS NEXT

● Total usage time display (spindle motor, DVD/CD laser)

● ADSC internal RAM display

● Others: Last error count......20 items

Efficiency of failure diagnosis is expected to improve by using the above functions together with the

repair process.

[Purpose of Use]

Total usage time display: used for estimating a failure due to exhausted spindle motor, laser, or other

parts.

ADSC internal RAM display: used for deciding servo system failure according to servo learning

values.

TOP PREVIOUS NEXT

Page 72

16.4 Using Recovery Disc

TOP PREVIOUS NEXT

16.4.1 Recovery Process

16.4.2 Version Upgrade Process

TOP PREVIOUS NEXT

Page 73

16.4.1 Recovery Process

TOP PREVIOUS NEXT

1. Insert the recovery disc (RFKZD03R004) to the player to replay.

2. The recovery process automatically starts, and a message of completion prompts on the

screen.

3. Remove the disc.

4. Turn off the power.

TOP PREVIOUS NEXT

Page 74

16.4.2 Version Upgrade Process

TOP PREVIOUS NEXT

1. Insert the recovery disc to the player to replay.

2. The version of player is automatically checked and prompts if necessary.

3. Select version upgrade process using the cursor keys on the remote controller unit. (Select

YES or NO)

4. a. If YES is selected, the process starts.

b. If NO is selected, only the recovery process is applied.

5. a. When the version upgrade process is complete, a message of completion appears on the

screen. Remove the disc.

b. Follow the instruction appearing on the screen, and remove the disc.

6. Turn off the power.

TOP PREVIOUS NEXT

Page 75

16.5 Total Usage Time Display

TOP PREVIOUS NEXT

1. Details of Operation/Display

Keys for Operation:

Laser usage time: While the player is stopped and no disc is inserted, press both the

button on the player and the

button on the remote controller unit.

Spindle motor usage time: While the player is stopped and no disc is inserted, press both the

button on the player andthe

button on the remote controller unit.

To reset the usage time, while the usage time is displayed:

Laser usage time: press both the

button on the player and the

button on the remote controller unit.

Spindle motor usage time: press both the

button on the player and the

button on the remote controller unit.

2. Purpose of Use

To obtain reference data of laser and spindle motor systems during failure diagnosis.

To check faulty parts during re-repair.

TOP PREVIOUS NEXT

Page 76

17 Operation Checks and Component

Replacement Procedures

TOP PREVIOUS NEXT

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit

boards and replacing the main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

Warning:

This product uses a laser diode. Refer to caution statement Precaution of Laser Diode.

17.1 Disassembly of Top Cabinet

Page 77

17.2 Disassembly for the DVD changer ass ’ y

17.2.1 Disassembly for the Top Ornament Unit

17.2.2 Disassembly for DVD changer unit

17.3 Checking for the changer unit operational condition

17.3.1 Initial setting of CD

17.3.2 Checking for the DVD Module (1) P.C.B.

17.3.3 Checking for Panel P.C.B., Deck P.C.B. and LED P.C.B.

17.3.4 Replacement of the Power Amplifier IC

17.4 Main Component Replacement Procedures

17.4.1 Replacement of the Traverse Deck

17.5 Replacement for the disc tray

17.6 Disassembly and reassembly for mechanism base drive unit

17.7 Replacement for the motor ass ’ y

17.8 Replacement for the pinch roller ass ’ y and head block

17.9 Replacement for the CD motor ass ’ y, capstan belt A, capstan belt B and winding belt

17.10 Replacement for the CD motor ass ’ y, capstan belt A, capstan belt B and winding belt

17.11 Replacement for the cassette lid ass ’ y

17.12 Measure for tape trouble

TOP PREVIOUS NEXT

Page 78

17.1 Disassembly of Top Cabinet

TOP PREVIOUS NEXT

Step 1 Remove 3 screws each side and 5 screws at rear panel.

Step 2 Lift up both sides of cabinet ass’y, push the cabinet ass’y toward the rear and remove the

cabinet ass’y.

● Checking the DVD Module (2) P.C.B. and Main P.C.B.

TOP PREVIOUS NEXT

Page 79

17.2 Disassembly for the DVD changer ass’y

TOP PREVIOUS NEXT

(The DVD changer unit can be removed after the Top Ornament Unit is removed)

17.2.1 Disassembly for the Top Ornament Unit

17.2.2 Disassembly for DVD changer unit

TOP PREVIOUS NEXT

Page 80

17.2.1 Disassembly for the Top Ornament Unit

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

When opening the disc tray automatically (Using Power Supply)

Step 1 Connect the AC power cord.

Step 2 Press the power button to power up the main unit.

Step 3 Press the OPEN/CLOSE button, the disc tray will be open automatically.

Step 4 Release the 2 claws, and then remove the Top Ornament Unit.

Page 81

Step 5 Press the power button to turn the power on.

Step 6 Press the OPEN/CLOSE button, the disc tray will be close.

[Open the disc tray manually (Using service tools)]

Step 1 Upset the unit as shown below.

Step 2 Insert the gear tool into the hole on the underside of changer chasis and then rotate in the

direction of arrow. The disc tray will be open.

Page 82

Step 3 Release the 2 claws, and then remove the CD lid cover.

Step 4 Repeat Step 2 but rotate the tools in anti-clockwise.

TOP PREVIOUS NEXT

Page 83

17.2.2 Disassembly for DVD changer unit

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the Disassembly for the Top Ornament Unit of Item 17.2.1.

Step 1 Remove 1 screw at rear cabinet as show below.

Step 2 Lift up the mechanism unit cover, and then push in the mechanism unit cover.

Step 3 Release the claws of both ends, and then lift up the DVD changer unit.

Step 4 Upset the DVD changer unit.

Step 5 Place the DVD changer unit on the unit.

Page 84

<The preparation of checking procedures in operational condition is completed>

TOP PREVIOUS NEXT

Page 85

17.3 Checking for the changer unit operational

condition

TOP PREVIOUS NEXT

17.3.1 Initial setting of CD

17.3.2 Checking for the DVD Module (1) P.C.B.

17.3.3 Checking for Panel P.C.B., Deck P.C.B. and LED P.C.B.

17.3.4 Replacement of the Power Amplifier IC

TOP PREVIOUS NEXT

Page 86

17.3.1 Initial setting of CD

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the Disassembly for the Top Ornament Unit of Item 17.2.1.

Step 1 Connect the AC power cord.

Step 2 Press power button to turn on power for main unit.

Step 3 Select the input select button to “DVD/CD”.

Step 4 Push the OPEN/CLOSE button, and then open the disc tray.

Page 87

Step 5 Put the CD into the disc tray.

Step 6 Press the OPEN/CLOSE button, and then close the disc tray. (Then, the CD will load.)

<The initial setting of CD unit is completed.>

TOP PREVIOUS NEXT

Page 88

17.3.2 Checking for the DVD Module (1) P.C.B.

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the Disassembly for the Top Ornament Unit of Item 17.2.1.

● The initial setting of CD unit must be completed. (Refer to the initial setting of CD unit in

Item 17.3.1).

● Check for DVD Module (1) P.C.B.

Step 1 Push the power button and the power turns off.

Step 2 Remove the FFC boards. (CN303, CN304, CN302 & CN309)

Step 3 Remove the DVD changer unit.

Step 4 Remove 4 screws.

Page 89

Step 5 Remove the mechanism unit cover.

● Check the DVD Module (1) P.C.B. as shown below

Step 6 Lay the unit.

Step 7 Connect the FFCs board from DVD Module (1) P.C.B..

TOP PREVIOUS NEXT

Page 90

17.3.3 Checking for Panel P.C.B., Deck P.C.B.

and LED P.C.B.

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the (Step 1) - (Step 6) of Disassembly for the Top Ornament Unit of Item 17.2.1.

● Follow the (Step 1) - (Step 7) of Checking for DVD Module (1) P.C.B. of Item 17.3.2.

Step 1 Lay the unit as shown below.

Step 2 Remove 2 screws at bottom chassis.

Step 3 Release the 2 claws, and then draw the front panel ass’y forward.

Page 91

● Check the Panel P.C.B., Deck P.C.B. and LED P.C.B. as shown below

TOP PREVIOUS NEXT

Page 92

17.3.4 Replacement of the Power Amplifier IC

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the (Step 1) - (Step 6) of Disassembly for the Top Ornament Unit of Item 17.2.1.

● Follow the (Step 1) - (Step 7) of Checking for DVD Module (1) P.C.B. of Item 17.3.2.

● Follow the (Step 1) - (Step 3) of Checking for Panel P.C.B., Deck P.C.B. & LED P.C.B. of

Item 17.3.3.

Step 1 Release the 14 screws, and then remove the rear cover.

● Checking the Power P.C.B., Power Amp P.C.B. and Power Supply P.C.B. as shown below

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the (Step 1) - (Step 6) of Disassembly for the Top Ornament Unit of Item 17.2.1.

● Follow the (Step 1) - (Step 7) of Checking for DVD Module (1) P.C.B. of Item 17.3.2.

● Follow the (Step 1) - (Step 3) of Checking for Panel P.C.B., Deck P.C.B. & LED P.C.B. of

Item 17.3.3.

● Follow the (Step 1) of Replacement of the Power Amplifier IC of Item 17.3.4.

Step 1 Remove the 4 screws.

Page 93

NOTE:

Insulate Power P.C.B. with insulation material to avoid short circuit.

● Checking the Power P.C.B.

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the (Step 1) - (Step 6) of Disassembly for the Top Ornament Unit of Item 17.2.1.

● Follow the (Step 1) - (Step 7) of Checking for DVD Module (1) P.C.B. of Item 17.3.2.

● Follow the (Step 1) - (Step 3) of Checking for Panel P.C.B., Deck P.C.B. & LED P.C.B. of

Item 17.3.3.

● Follow the (Step 1) of Replacement of the Power Amplifier IC of Item 17.3.4.

Page 94

Step 1 Remove the 2 screws fixed to the Power Amplifier IC.

Step 2 Remove 2 screws fixed to the Power Amplifier IC and Transistor Holders.

Step 3 Break the joint with a metal cutter as shown below.

Step 4 Unsolder the terminals of Power Amp IC, replace the component.

Page 95

Step 5 Fix back the bottom chasis with a screw as shown.

TOP PREVIOUS NEXT

Page 96

17.4 Main Component Replacement Procedures

TOP PREVIOUS NEXT

17.4.1 Replacement of the Traverse Deck

TOP PREVIOUS NEXT

Page 97

17.4.1 Replacement of the Traverse Deck

TOP PREVIOUS NEXT

● Follow the (Step 1) - (Step 2) of Item 17.1.

● Follow the Disassembly for the Top Ornament Unit of Item 17.2.1.

● The initial setting of CD unit must be completed. (Refer to the initial setting of CD unit in

Item 17.3.1).

● Follow the (Step 1) - (Step 7) of Checking for DVD Module (1) P.C.B. of Item 17.3.2.

Step 1 Push the power button and the power turns off.

Step 2 Disconnect cables. (FP3202, FP3203 & FP4202)

Step 3 Remove the DVD changer unit.

Page 98

Step 4 Insert the gear with hexagonal wrench into the hole.

Step 5 Rotate the hexagonal wrench in the direction of arrow (clockwise), and then open the disc tray

fully.

Page 99

Step 6 With pressing the claw (A), rotate the hexagonal wrench clockwise. (The slide plate R moves

for a little amount.)

Step 7 Pressing the claw (B) in the direction of arrow (1), the connection lever moves in the direction

of arrow (2).

Step 8 Lift up the traverse deck ass’y.

Step 9 Remove the traverse deck ass’y from the timing lever.

Caution:

When removing or inserting the traverse deck avoid touching the OPU lens and pressing onto the

turntable.

Step 10 Remove 3 screws.

Page 100

Step 11 Unsolder the motor terminals (4 points).

Step 12 Remove the holder pins.

Step 13 Remove the tab.

Step 14 Disengage the tabs from the traverse gear.

Step 15 Remove the traverse gear.

Loading...

Loading...