Panasonic SA-HT80 Service Manual

ORDER NO. MD0005069C2

DVD Home Theater Sound System

SA-HT80

Colour

(S) ... Silver Type

Area

(E) ... Europe

(EB) ... Great Britain

(EG) ... Germany and Italy

(EE) ... Eastern Europe

Specifications

■ AMPLIFIER SECTION

RMS TTL POWER OUTPUT 300 W

(10% total harmonic distortion at 1 kHz)

FRONT 36 W per ch (6Ω)

CENTER 36 W (6Ω)

SURROUND 36 W per ch (6Ω)

SUBWOOFER 120 W (6Ω)

DIN TTL POWER OUTPUT 220 W

(1% total harmonic distortion at 1 kHz)

FRONT 26 W per ch (6Ω)

CENTER 26 W (6Ω)

SURROUND 26 W per ch (6Ω)

SUBWOOFER 90 W (6Ω)

Input sensitivity/ input impedance

AUX 250 mV, 10 kΩ

■ FM TUNER SECTION

Frequency range 87.5 - 108.0 MHz (50 kHz steps)

Sensitivity 16.3 dBf (1.8 µV, IHF)

Antenna terminals 75 Ω unbalanced

■ AM TUNER SECTION

Frequency range 522 - 1629 kHz (9 KHz steps)

Sensitivity

S/N 20 dB at 999 kHz 500 µV

CD SECTION :

DPT-3ATU-AD TRAVERSE DECK SERIES

■ DISC SECTION

Disc

DVD

8 cm/12 cm sin gle-sided, single-layer

8 cm/12 cm single-sided, double- layer

8 cm/12 cm double-sided, double-layer

(one layer per side)

CD/V-CD 8 cm/12 cm

Video

Signal system NTSC/PAL (depend on disc format)

Output level Composite video 1 Vp-p (75Ω)

S-video Y 1Vp-p(75Ω)

S-video C 0.300 Vp-p (75Ω/PAL)

0.286 Vp-p (75Ω/NTSC)

Audio

Sampling frequency

CD 44.1 kHz

DVD 48 kHz/96 kHz

Decoding 16/20/24 bit linear

Wow and flutter Less than possible measurement

data

Digital filter 8fs

D/A converter Delta-sigma DAC

© 2000 Matsushita Electronics (S) Pte Ltd. All rights

reserved. Unauthorized copying and distribution is a

violation of law.

SA-HT80

Pick up

Beam Source Semiconductor Laser

Wavelength 665 nm

■ GENERAL

Power supply AC 230-240 V, 50 Hz

Power consumption 178 W

Standby 0.50 W

Dimensions (W x H x D) 430 x 136 x 400 mm

Mass 8.7 kg

Note:

1. Specifications are subject to change without notice.

Weight and dimensions are approximate.

2. Total harmonic distortion is measured by the digital spectrum

analyzer.

■ System

■ Main Unit

■ Front, surround and center

speakers

■ Subwoofer

SC-HT80 (E)

SC-HT80 (EB)

SC-HT80 (EG)

SC-HT80 (EE)

SA-HT80 (E)

SA-HT80 (EB)

SA-HT80 (EG)

SA-HT80 (EE)

SB-AFC80 (E)

SB-AFC80 (EB)

SB-AFC80 (EG)

SB-AFC80 (EE)

SB-W80 (E)

SB-W80 (EB)

SB-W80 (EG)

SB-W80 (EE)

CONTENTS

Page Page

1 Before Repair and Adjustment

2 Protection Circuitry

3 Accessories

4 Handling Precautions For Traverse Deck

5 Precaution of Laser Diode

6 Caution for AC Mains Lead

7 Operation Procedures

8 Operation Checks and Main Component Replacement

Procedures

9 Self-Diagnosis and Replacement of Optical Pickup

10 Lock Mode for Demonstration

11 Tilt Adjustment for Optical Pickup

3

3

12 Self-Diagn osis Function and Service Mode

3

13 Power Adjustment

4

14 Measurem ent and Adjustments

15 Illustrations of ICs, Transistor and Diode

5

7

16 Terminal Functions of ICs

8

17 Block Diagrams

18 Schematic Diagram

10

19 Printed Circuit Boards

34

20 Wiring Diagram

21 Parts Location and Replacement Parts List

35

36

38

40

42

43

44

45

57

94

107

109

2

1 Before Repair and Adjustment

Disconnect AC power, discharge Power Supply Capacitors C554 ~ C557 and C782 through a 10 Ω, 5W resistor to ground.

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Current consumption at AC 230 V, 50 Hz in NO SIGNAL mode should be ~850mA.

2 Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is heard when the power is turned on.

• Sound stops during a performance.

The function of this circuitry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occurs, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the problem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not operate unless the power is first turned off and then on again.

SA-HT80

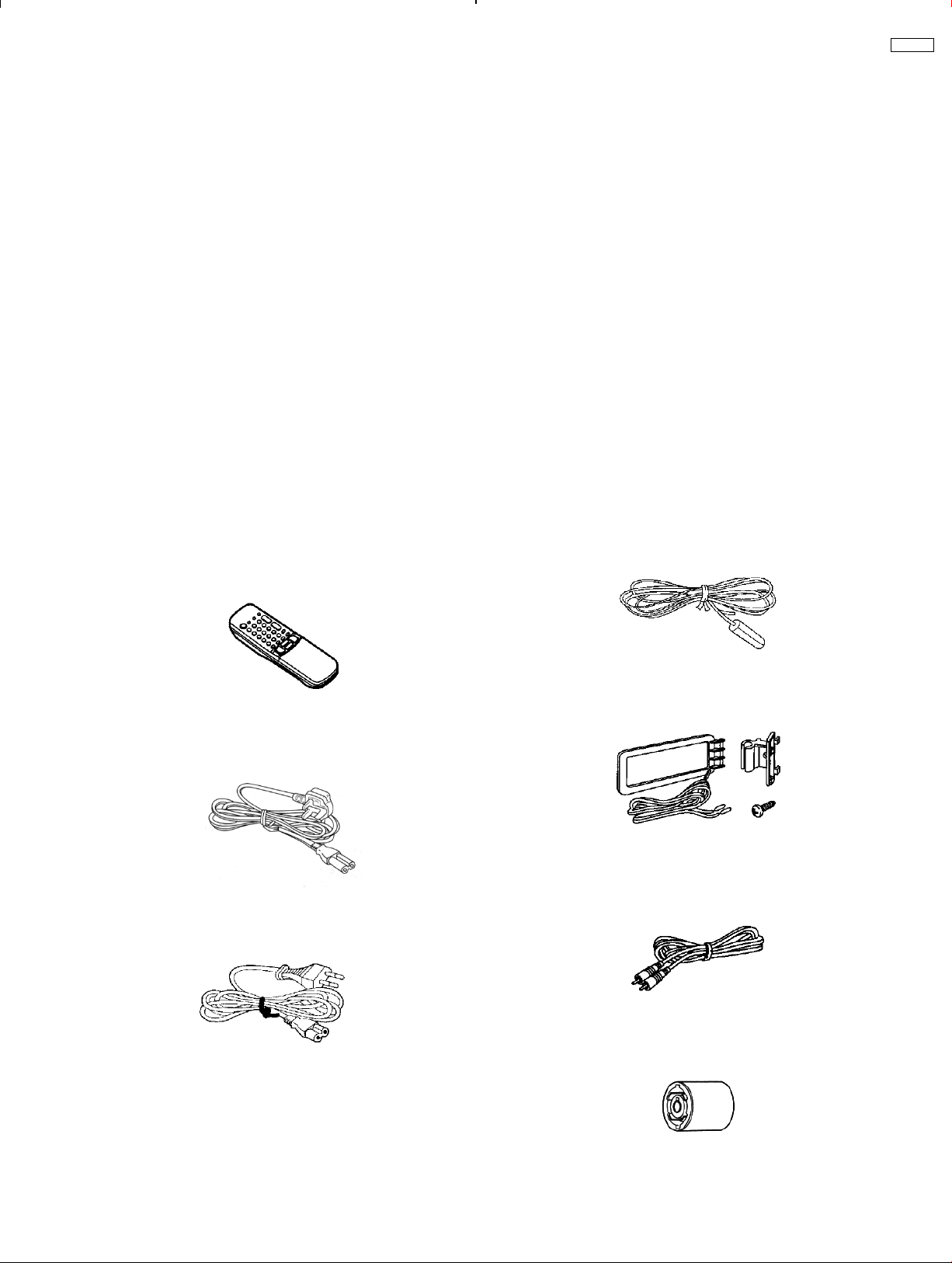

3 Accessories

Please refer to Accessories Parts List for part number.

REMOTE CONTROL

AC CORD (EB)

FM ANTENNA

AM LOOP ANTENNA

AC CORD (EE, EG, E)

VIDEO CABLE

ANTENNA

PLUG ADATER

3

SA-HT80

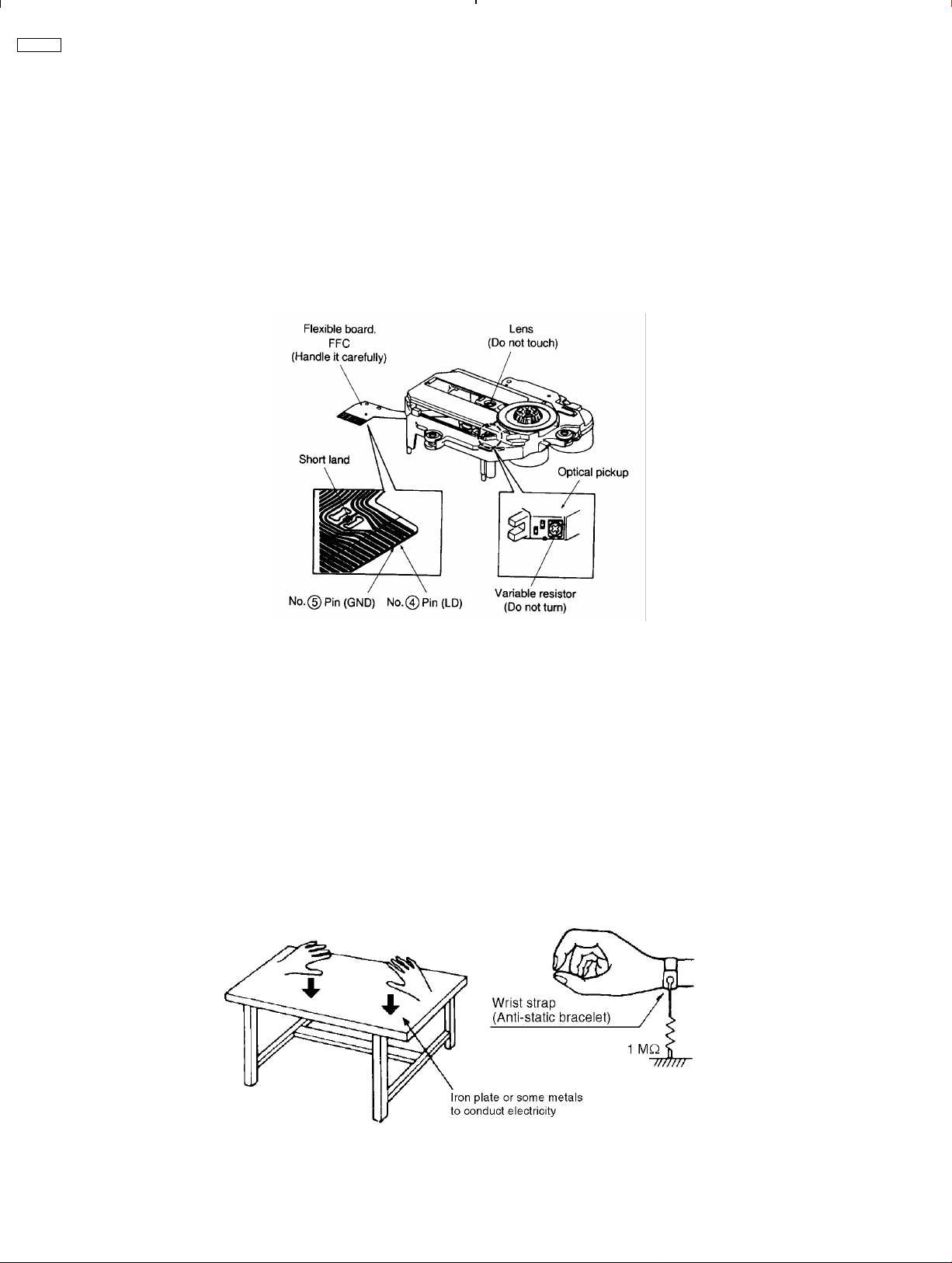

4 Handling Precautions For Traverse Deck

The laser diode in the traverse deck (optical pickup) may break down due to potential difference caused by static electricity of

clothes or human body.

So, be careful of electrostatic breakdown during repair of the traverse deck (optical pickup).

Handling of traverse deck (optical pickup)

•

1. Do not subject the traverse deck (optical pickup) to static electricity as it is extremely sensitive to electrical shock.

2. The short land between the No.4(LD) and No.5(GND) pins on the flexible board (FFC) is shorted with a solder build-up to

prevent damage to the laser diode.To connect to the PC board, be sure to open by removing the solder build-up, and finish the

work quickly.

3. Take care not to apply excessive stress to the flexible board (FFC).

4. Do not turn the variable resistor (laser power adjustment). It has already been adjusted.

Grounding for electrostatic breakdown prevention

•

1. Human body grounding

Use the anti-static wrist strap to discharge the static electricity from your body.

2. Work table grounding

Put a conductive material (sheet) or steel sheet on the area where the traverse deck (optical pickup) is placed, and ground

the sheet.

Caution:

The static electricity of your clothes will not be grounded through the wrist strap. So, take care not to let your clothes touch the

traverse deck (optical pickup).

Caution when Replacing the Traverse Deck:

The traverse deck has a short point shorted with solder to protect the laser diode against electrostatics breakdown. Be sure to

remove the solder from the short point before making connections.

4

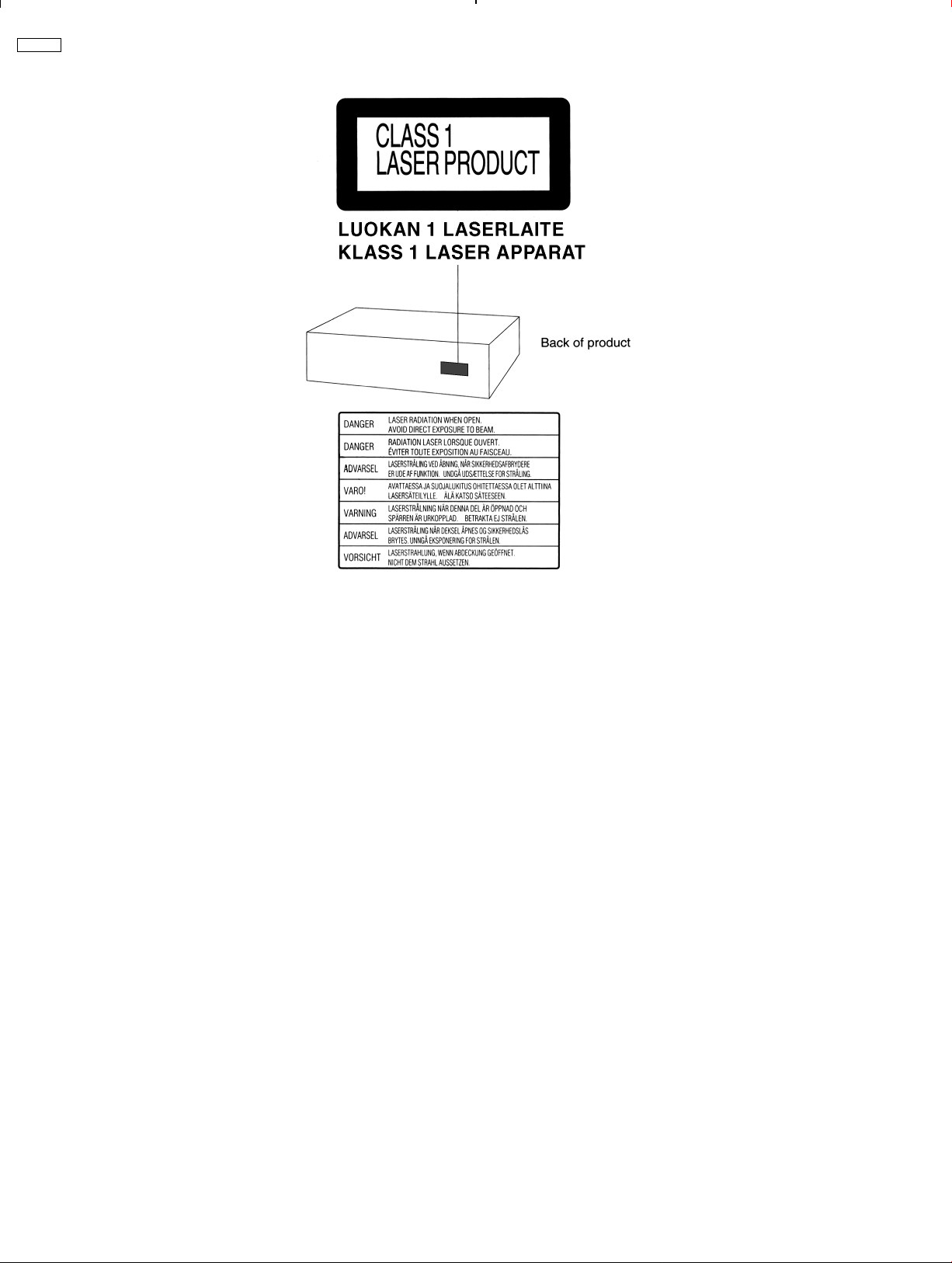

5 Precaution of Laser Diode

CAUTION :

This product utilizes a laser diode with the unit turned “ON”,invisible laser radiation is emmitted from the pickup lens.

Wavelength : 780 nm

Maximum output radiation power from pick up : 100µW/VDE

Laser radiation from pick up unit is safety level, but be sure the followings:

1. Do not disassemble the optical pick up unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pick up unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pick up lens for a long time.

ACHTUNG :

Dieses Produkt enthält eine Laserdiode. Im eingeschalteten Zustand wird unsichtbare Laserstrahlung von der Lasereinheit

abgestrahlt.

Wellenlänge : 780nm

Maximale Strahlungsleistung der Lasereinheit : 100µW/VDE

SA-HT80

Die Strahlung an der Lasereinheit ist ungefährlich, wenn folgende Punkte beachtet werden:

1. Die Lasereinheit nicht zerlegen, da die Strahlung an der freigelegten Laserdiode gefährlich ist.

2. Den werkseitig justierten Einstellregler der Lasereinhit nicht verstellen.

3. Nicht mit optischen Instrumenten in die Fokussierlinse blicken.

4. Nicht über längere Zeit in die Fokussierlinse blicken.

ADVARSEL : I dette a apparat anvendes laser.

CAUTION!

THIS PRODUCT UTILIZES A LASER.

USE OF CONTROLS OR ADJUSTMENTS OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED HEREIN MAY RESULT

IN HAZARDOUS RADIATION EXPOSURE.

5

SA-HT80

5.1. Use of Caution Labels

6

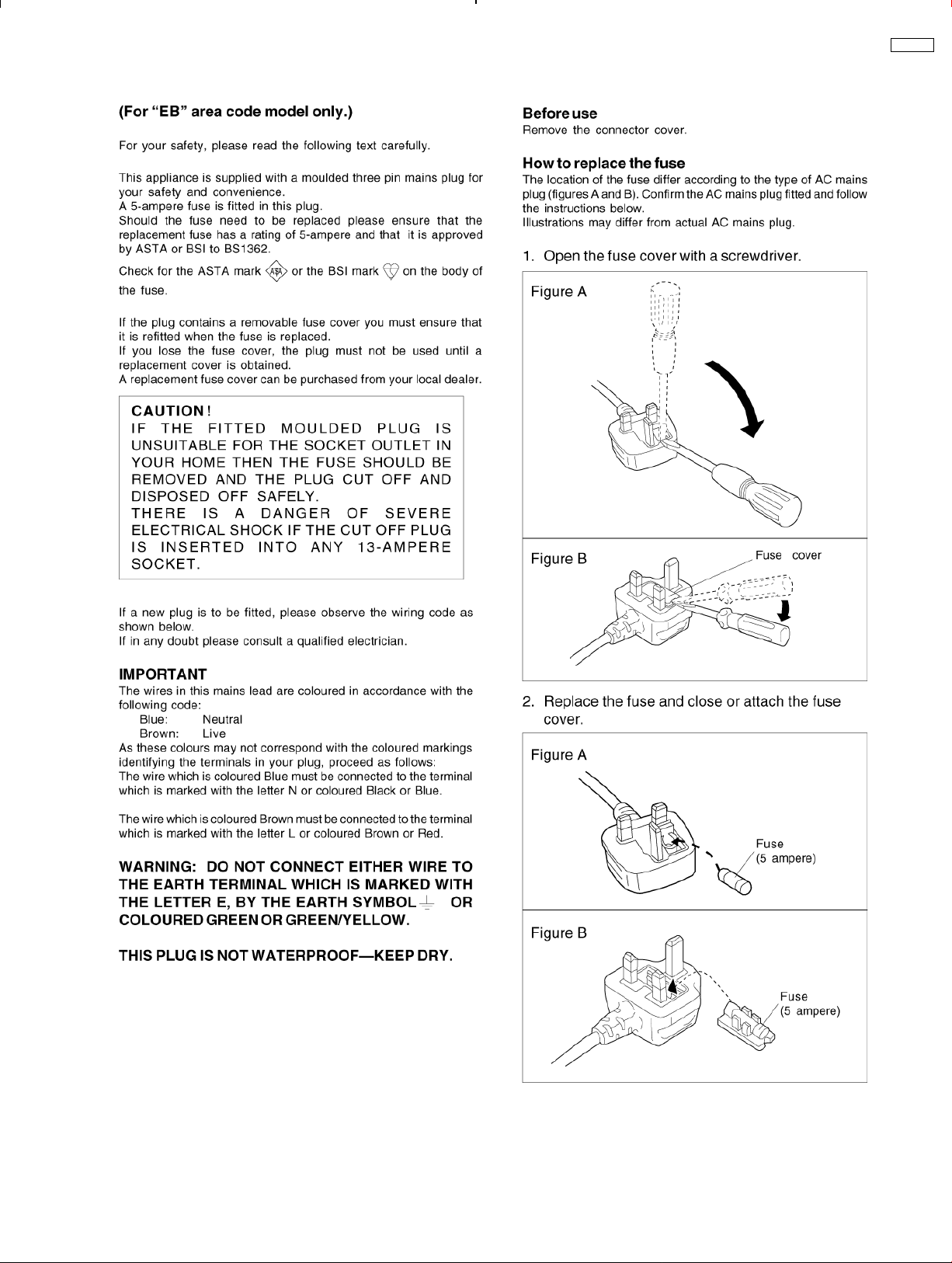

6 Caution for AC Mains Lead

SA-HT80

7

SA-HT80

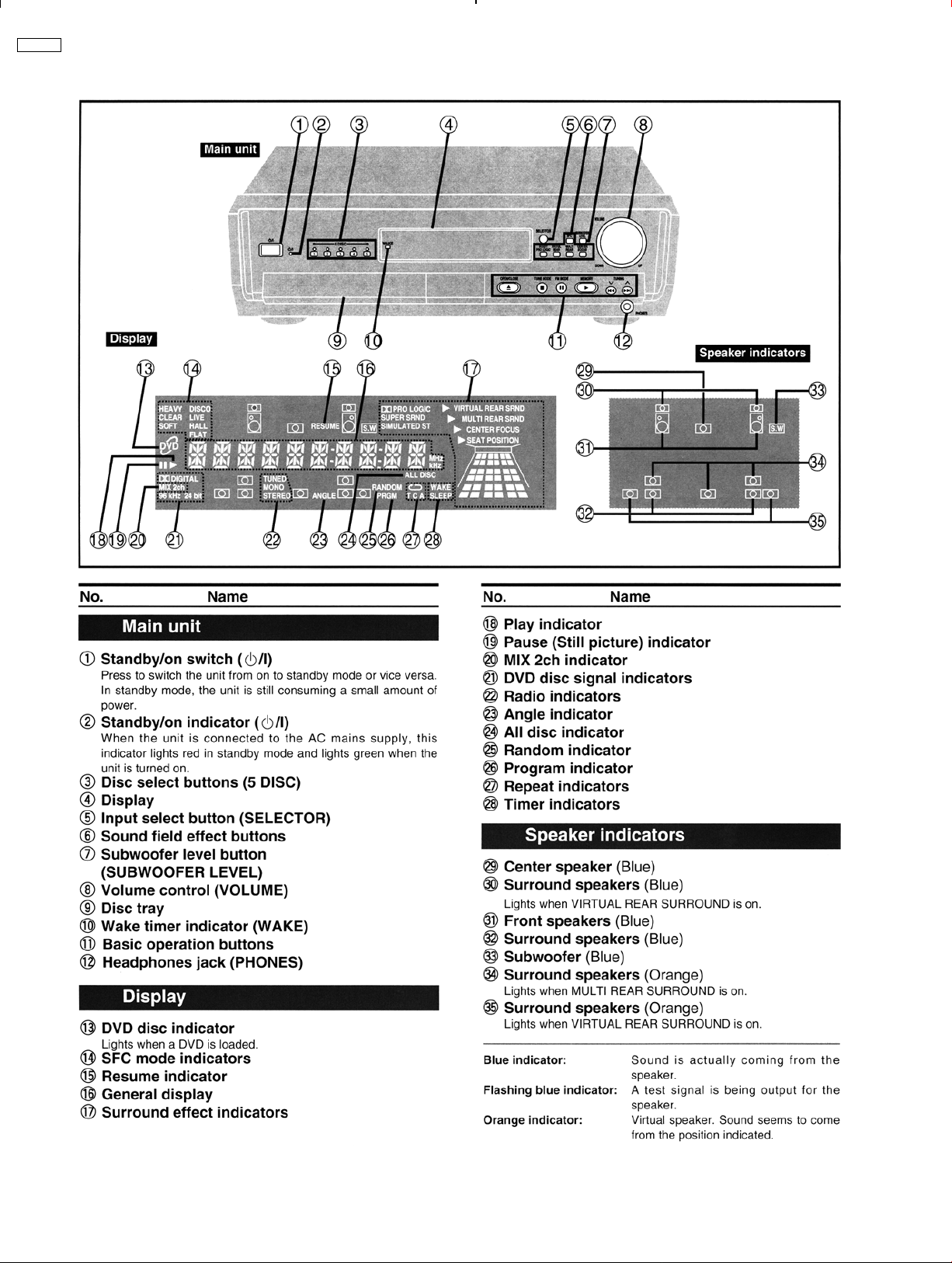

7 Operation Procedures

8

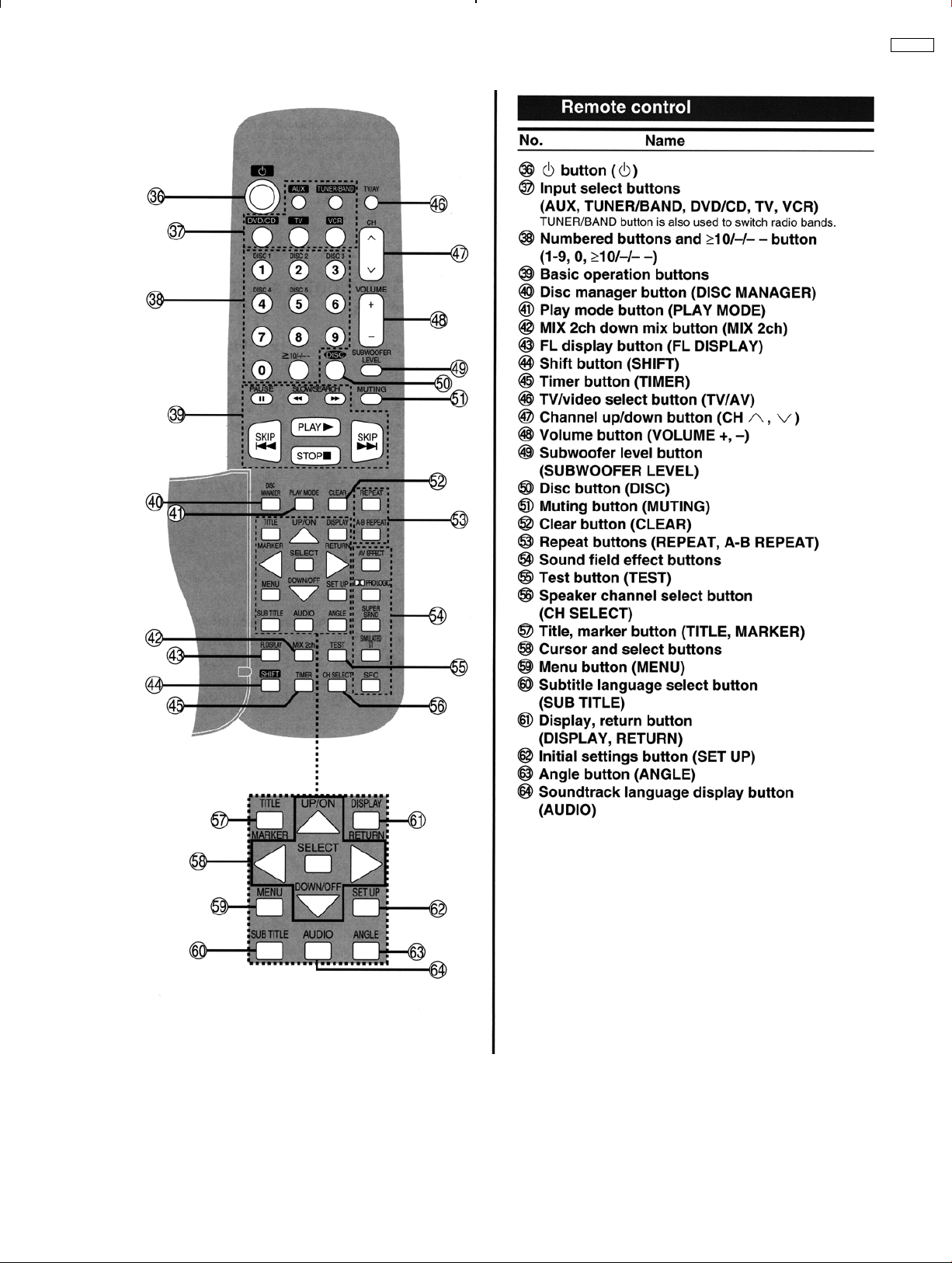

7.1. Remote Control

SA-HT80

9

SA-HT80

8 Operation Checks and Main Component Replacement

Procedures

“ATTENTION SERVICER”

Some chassis components may have sharp edges.

Be careful when disassembling and servicing.

1. This section describes procedures for checking the operation of the major printed circuit boards and replacing the

main components.

2. For reassembly after operation checks or replacement, reverse the respective procedures.

Special reassembly procedures are described only when required.

3. Select items from the following index when checks or replacement are required.

4. Refer the Parts No. on the page of “Main Component Replacement Procedures”, if necessary.

Contents

• Checking Procedure for each major P.C.B.

1. Checking of the DVD module board and the DAC board. (Pg11)

2. Checking the FL board. (Pg12)

3. Checking the DSP board. (Pg13)

4. Checking the tuner board and the main board. (Pg15)

• Procedures for replacement of main parts and disassembly/reassembly of parts.

1. Replacement of the Traverse deck (standard). (Pg16)

2. Replacement for the Disc Tray. (Pg18)

3. Disassembly and reassembly for the Mechanism Base Unit. (Pg20)

4. Replacement for the Motor. (Pg28)

5. Replacemnet for the Traverse motor, optical pickup and spindle motor. (Pg29)

6. Replacement of the Power IC and Constant-voltage Transistors. (Pg32)

Warning:

This product uses a laser diode. Refer to caution statement on page 5.

ACHTUNG :

• Die Lasereinheit nicht zerlegen.

• Die Lasereinheit darf nur gegen eine vom Hertsteller spezifizierte Einheit ausgetauscht werden.

10

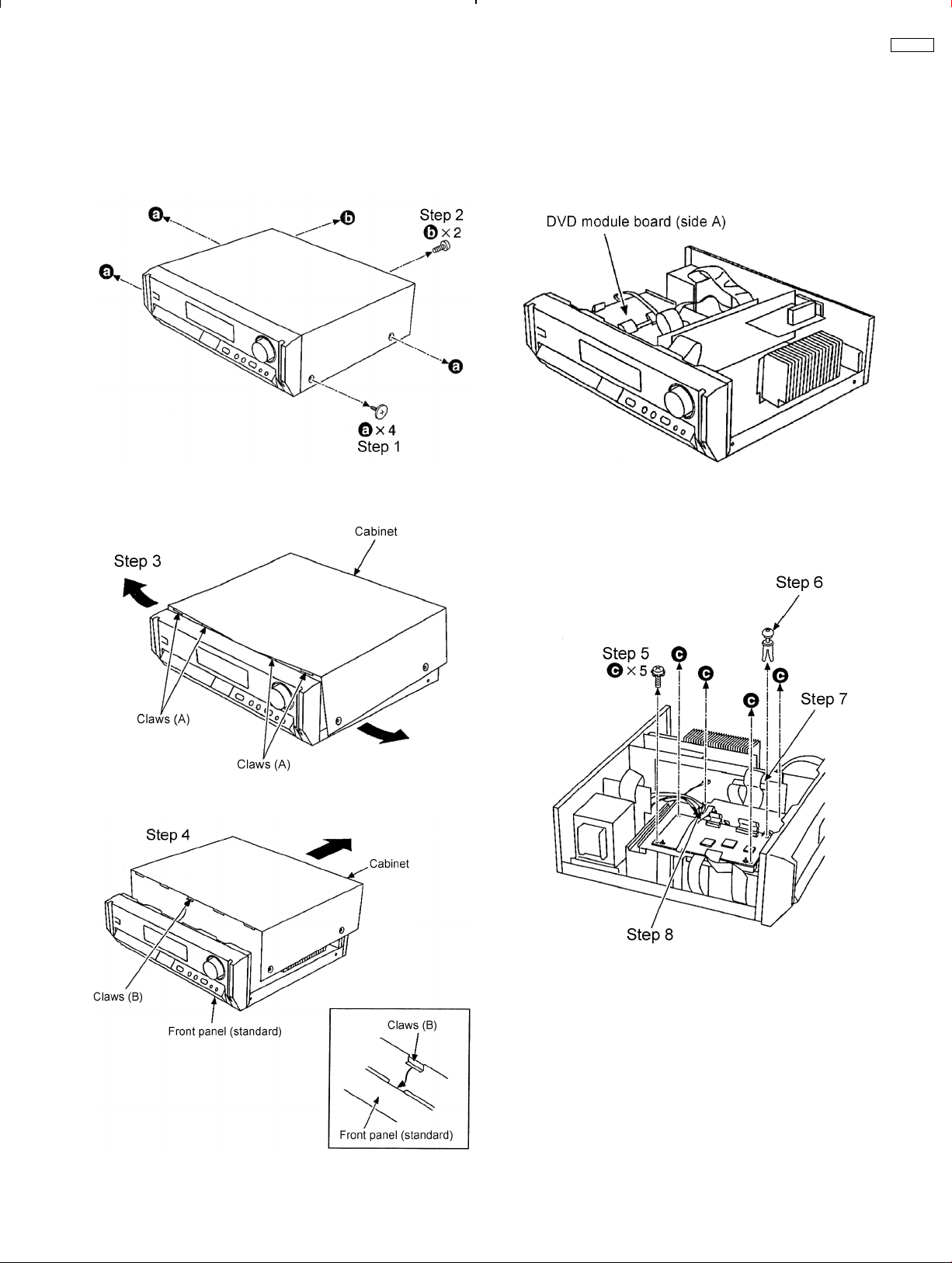

8.1. Checking Procedure for each major P.C.B.

SA-HT80

8.1.1. Checking the DVD module board

and the DAC board

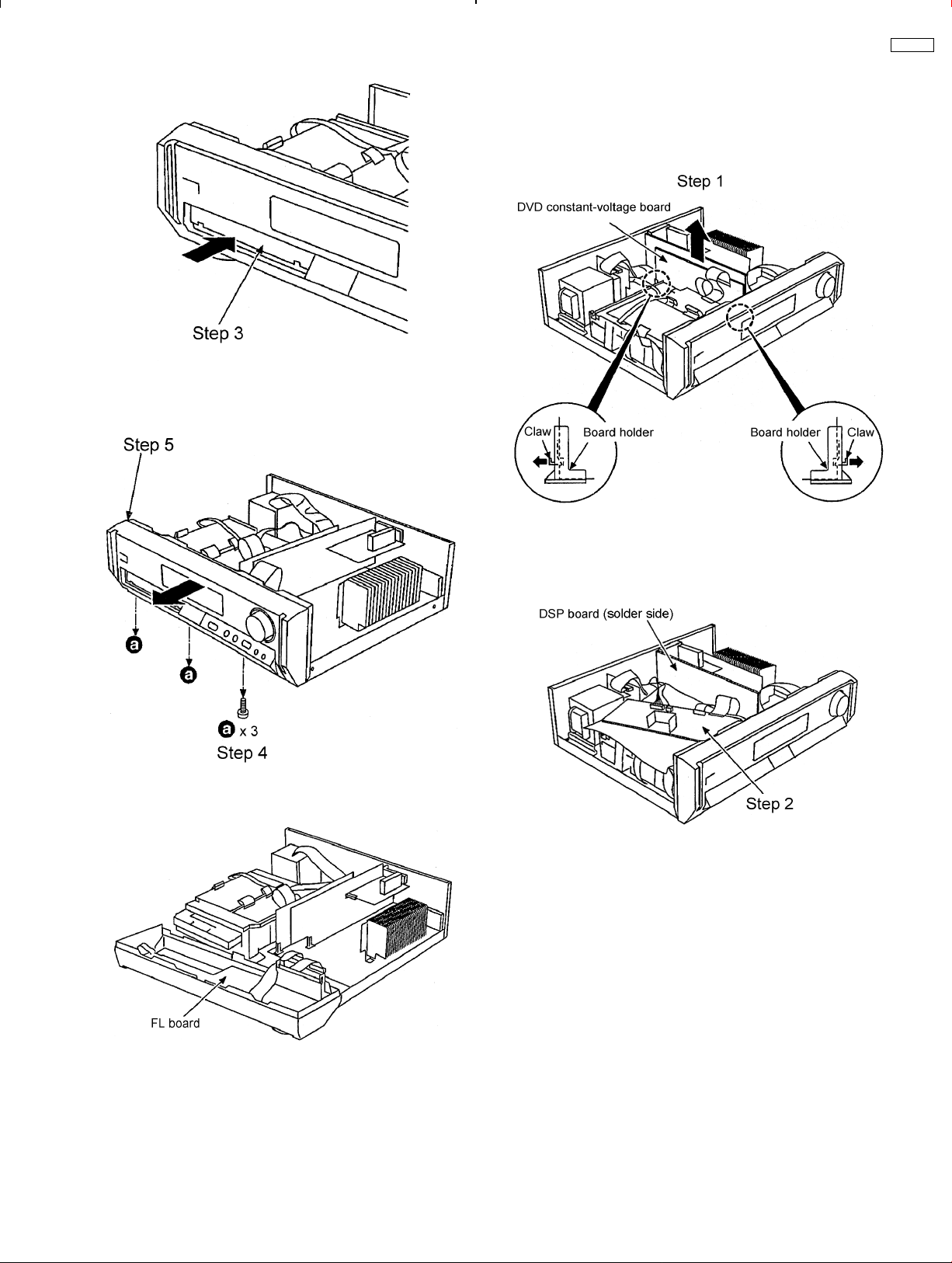

Step 1

Step 2

Step 3

claws (A).

Remove the screws.

Remove the screws.

Expand the both sides of the cabinet, and unlock the

CAUTION

When reassembling the cabinet, use the utmost care to

avoid scratching the front panel (standard) with the claws

(B).

• Check the condition of the DVD module board (side A) as

shown in the diagram below.

Step 5

Step 6

Step 7

Step 8

Remove the screws.

Remove the latches.

Pull out the FFC cable.

Remove the connector (CN1305).

Step 4

Pull the cabinet to the rear direction of the unit.

11

SA-HT80

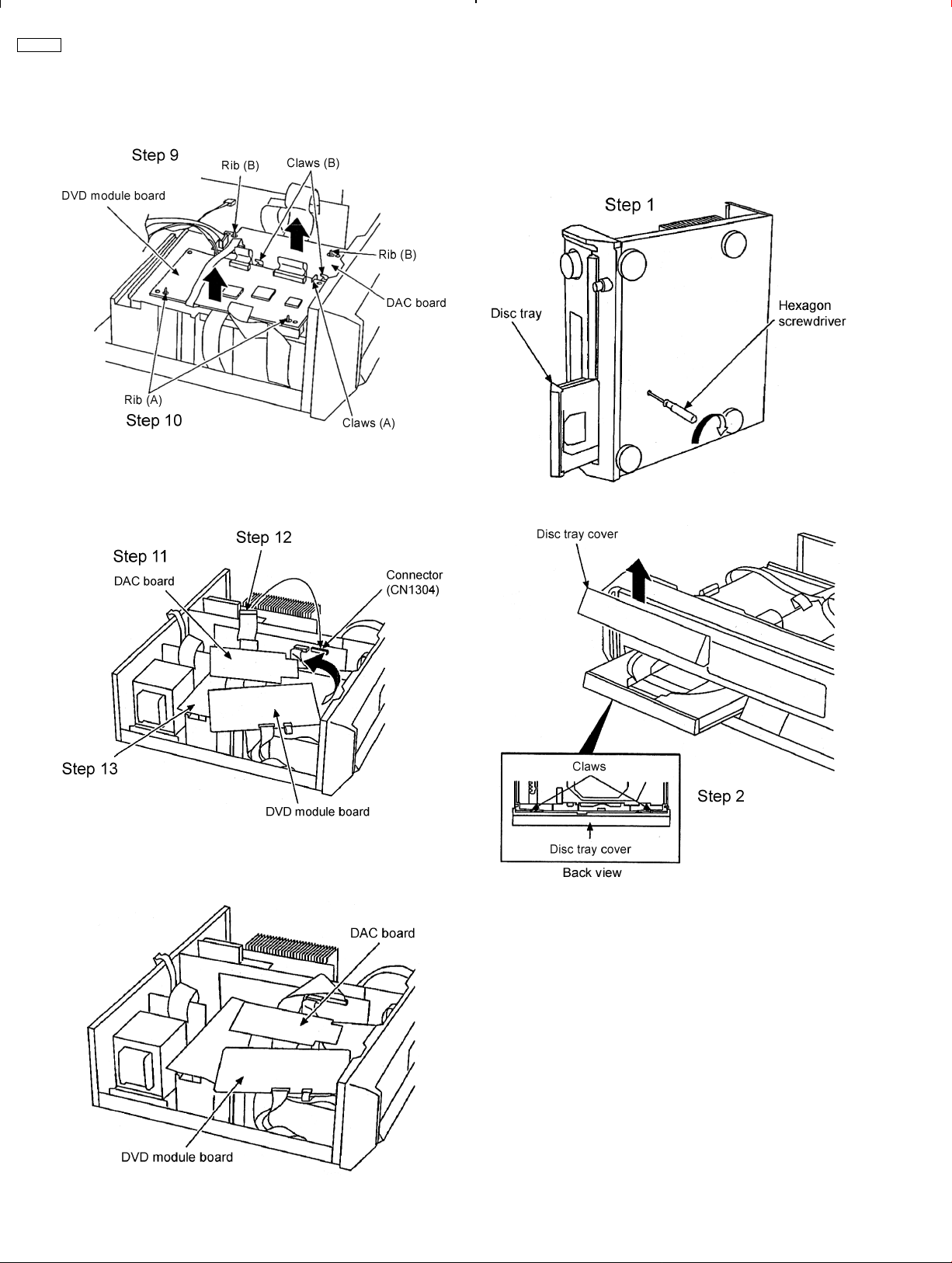

Step 9 Lift up and remove the DVD module board from the rib

(A). Then, remove the DVD module board from the claws (A).

Step 10 Lift up and remove the DAC board from the rib (B).

Then, remove the DAC board from the claws (B).

Step 11 Turn over the DVD module board and the DAC board.

Step 12 Connect the FFC cable to the connector (CN1304).

Step 13 Place cardboard.

8.1.2. Checking the FL board

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

Step 1 Insert a hexagon screwdriver (the jig with servicing gear)

into the hole located in the bottom of the unit, turn the driver to

the arrow direction to open the disc tray.

Step 2 Remove the two claws to remove the disc tray cover.

• Check the conditions of the DVD module board (side B) and

the DAC board (solder side) as shown in the diagram

below.

12

Step 3 Push in the disc tray.

Step 4 Remove the screws.

Step 5 Remove the front panel (standard).

SA-HT80

8.1.3. Checking the DSP board

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

Step 1 Remove the two claws of the board holder, and pull up

the DVD constant-voltage board.

• Check the condition of the FL board as shown in the

diagram below.

• Check the condition of the DSP board as shown in the

diagram below.

Step 2 Place the DVD constant-voltage board on the loading

unit.

CAUTION

Place cardboard.

13

SA-HT80

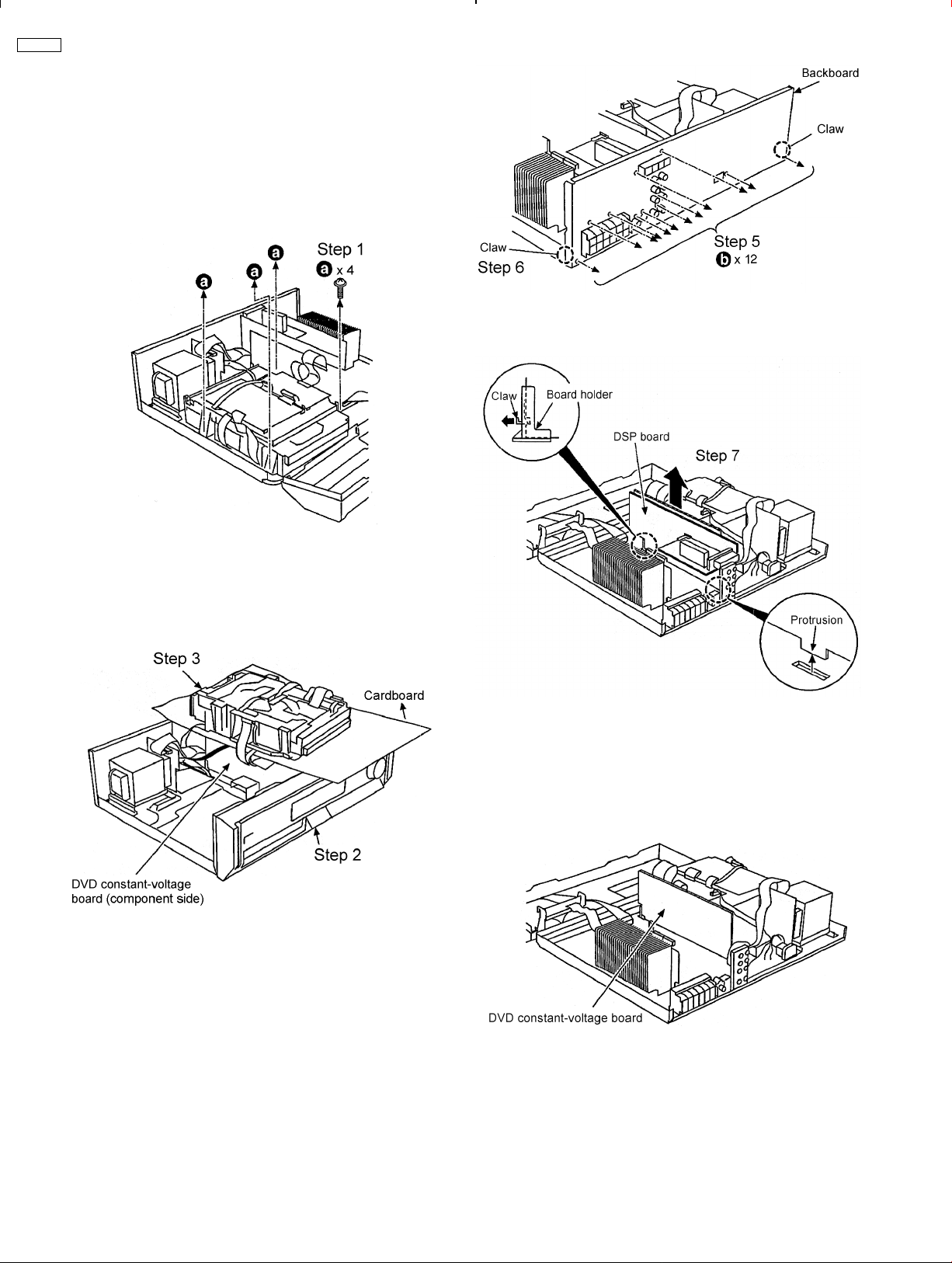

8.1.4. Checking the DVD constantvoltage board

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Checking Procedure for each major P.C.B.].

(Note: Clamp the disc to the loading unit in advance.)

Step 1

Remove the screws.

• Check the parts surface of the DVD constant-voltage board

as shown in the diagram below.

Step 2

Step 3

right side of the unit.

Attach the front panel (standard) to the unit.

Turn over the loading unit, and place it onto the upper

Step 7

board.

CAUTION

Pull upward the DSP board to avoid breaking the

protrusion on the DSP board.

Remove the board holder claws, and pull out the DSP

CAUTION

Place cardboard.

• If the conditions of other parts cannot be checked from the

component side on the DVD constant-voltage board, follow

the instructions below to check from the solder side of the

boards.

Step 4

Remove the front panel (standard), and reassemble the

loading unit.

Step 5

Step 6

Remove the screws.

Remove the two claws, and remove the backboard.

• Check the condition of the DVD constant-voltage board

from its solder side as shown in the diagram below.

14

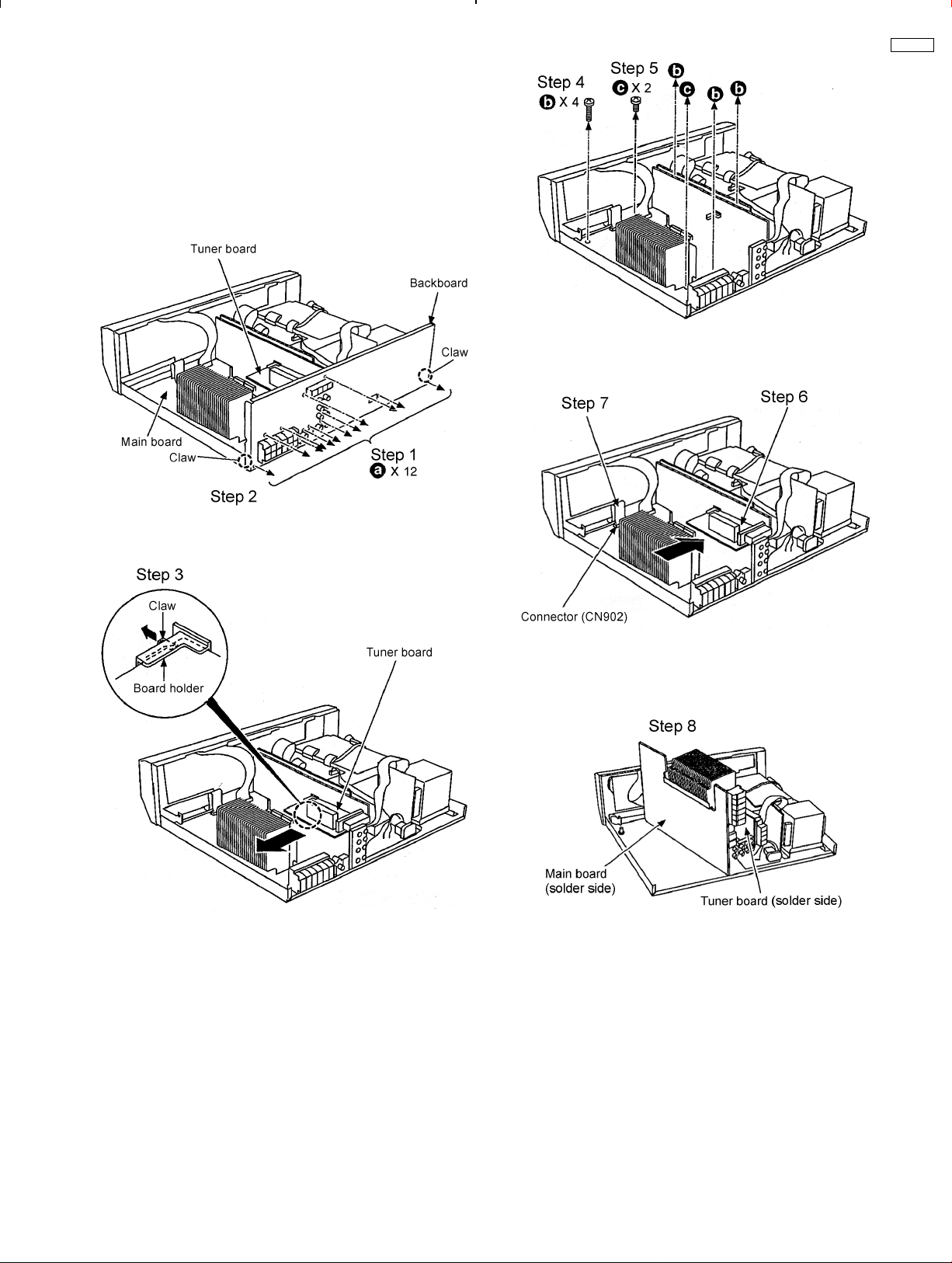

8.1.5. Checking the Tuner board and the

Main board

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

• Check the condition of the tuner board and the main board

as shown in the diagram below.

Step 1

Step 2

Remove the screws.

Remove the two claws, and remove the backboard.

SA-HT80

Step 3

out the tuner board.

Remove the claw located in the board holder, and pull

Step 6

Step 7

• Check the conditions of the solder side of the tuner board

Step 8

Reassemble the tuner board to its original position

Remove the parallel piece from the connector (CN902).

and main board as shown in the diagram below.

Place the main board in the parallel position.

Step 4

Step 5

Remove the screws.

Remove the screws.

15

SA-HT80

8.2. Procedure for replacement of main parts and disassembly/reassembly

of parts

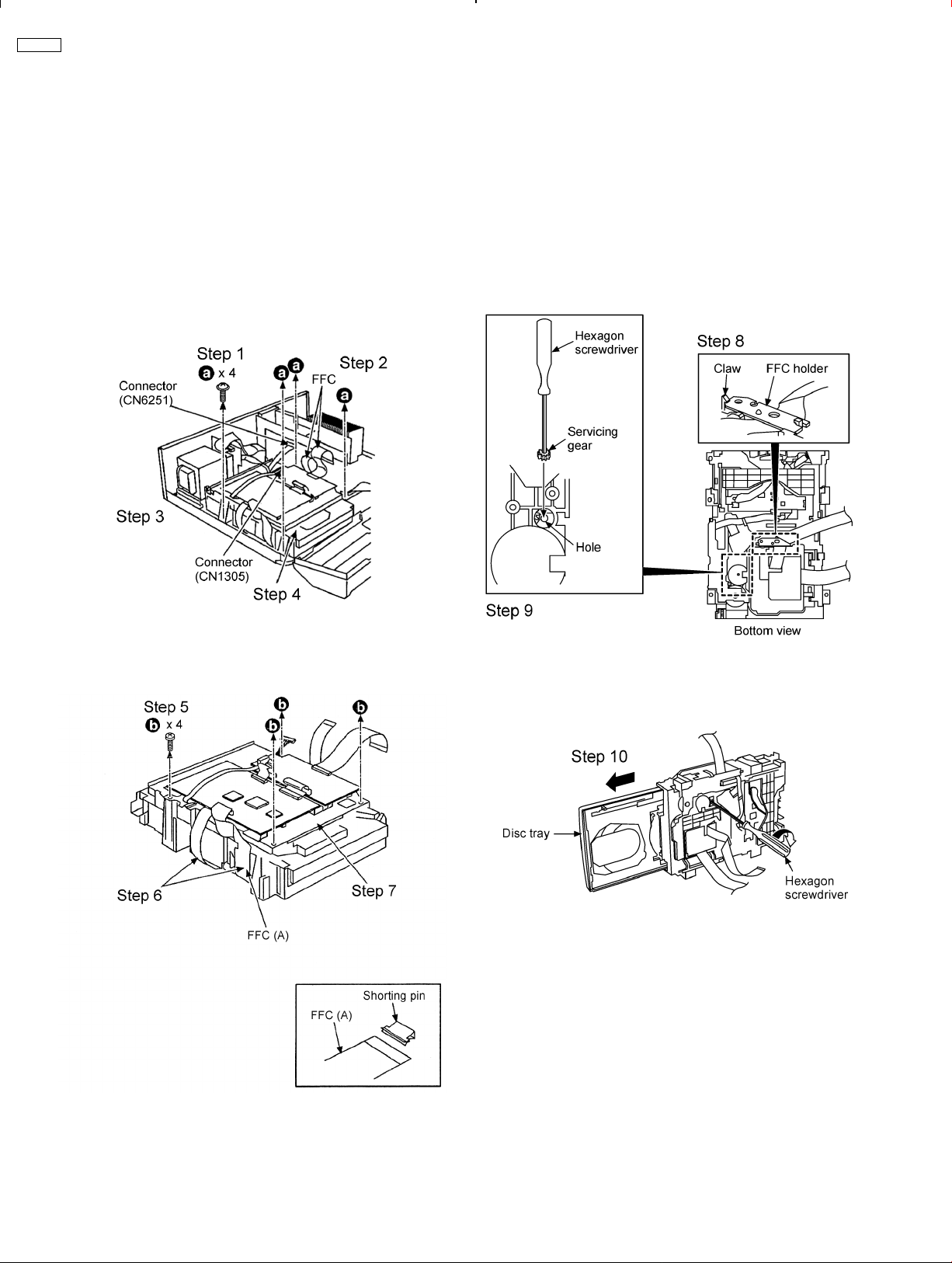

8.2.1. Replacement of the Traverse deck

(standard)

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Checking Procedure for each major P.C.B.].

Step 1

Step 2

Step 3

Step 4

Remove the screws.

Pull out the two FFC cables.

Remove the two connectors.

Remove the loading unit.

CAUTION

The FFC cable (A) is directly connected to the optical

pickup through the traverse backboard. After removing the

cable, immediately insert an antistatic shorting pin to the

FFC cable. (Refer to "Handling Precautions for Traverse

Deck Optical Pickup" for the details.)

Step 8

Step 9

Remove the claw, and remove the FFC holder.

Insert a hexagon screwdriver (with servicing gear).

Step 5

Step 6

Step 7

Remove the screws.

Pull out the two FFC cables.

Remove the upper board.

Step 10

disc tray fully.

Turn the hexagon screwdriver clockwise, and open the

16

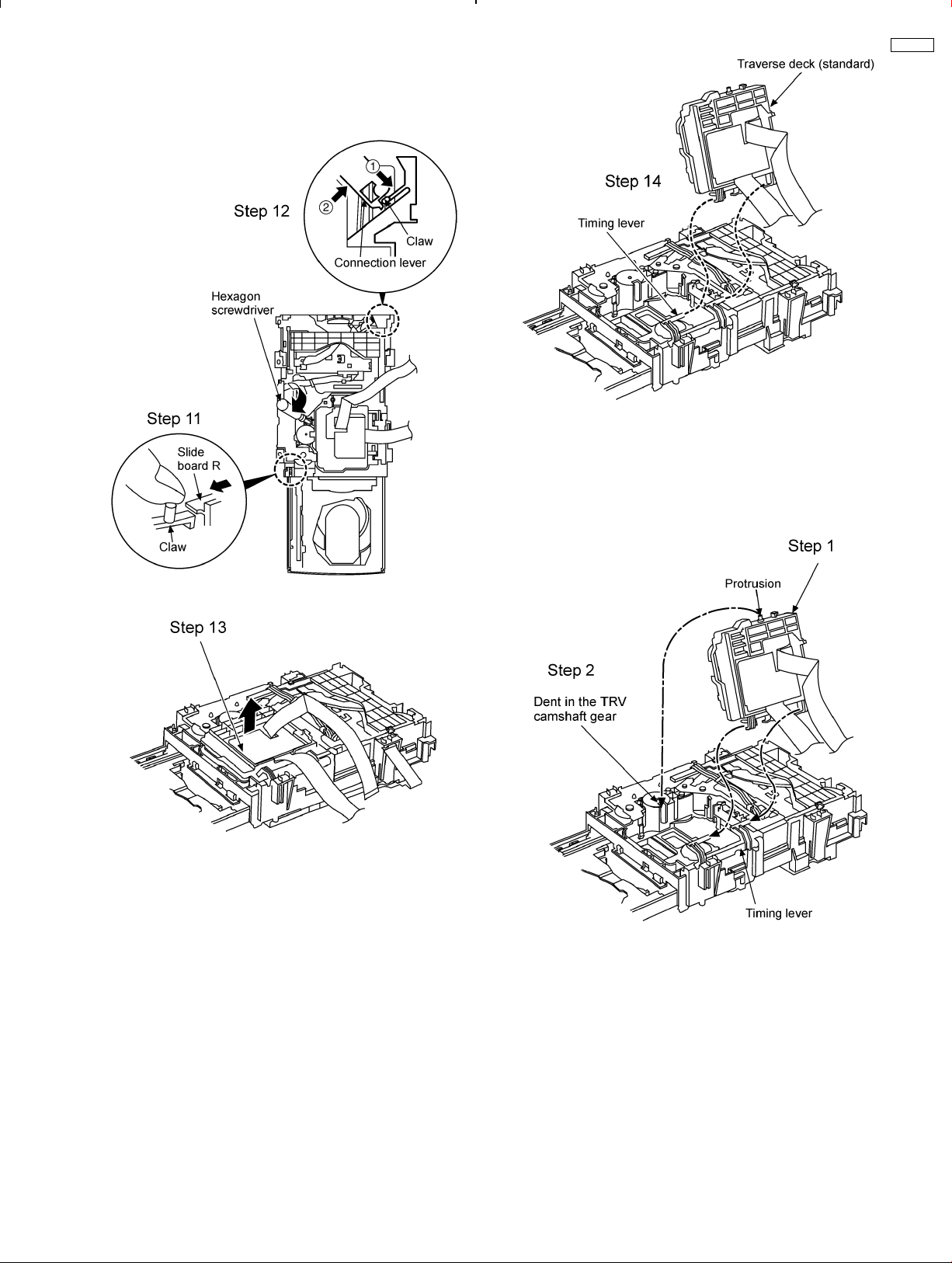

Step 11 Turn the hexagon screwdriver clockwise while the claw

(A) is pressed down.

Step 12 When the claw (B) is pressed to the arrow direction 1,

the connection lever moves to the arrow direction 2.

SA-HT80

8.2.1.1. Reassembly of Traverse Deck

(standard)

Step 1 Attach the traverse deck (standard) to the timing lever.

Step 2 Insert the protrusions of the traverse deck (standard)

into the dent of the TRV camshaft gear.

Step 13 Lift up the traverse deck (standard).

Step 14 Remove the traverse deck (standard) from the timing

lever.

17

SA-HT80

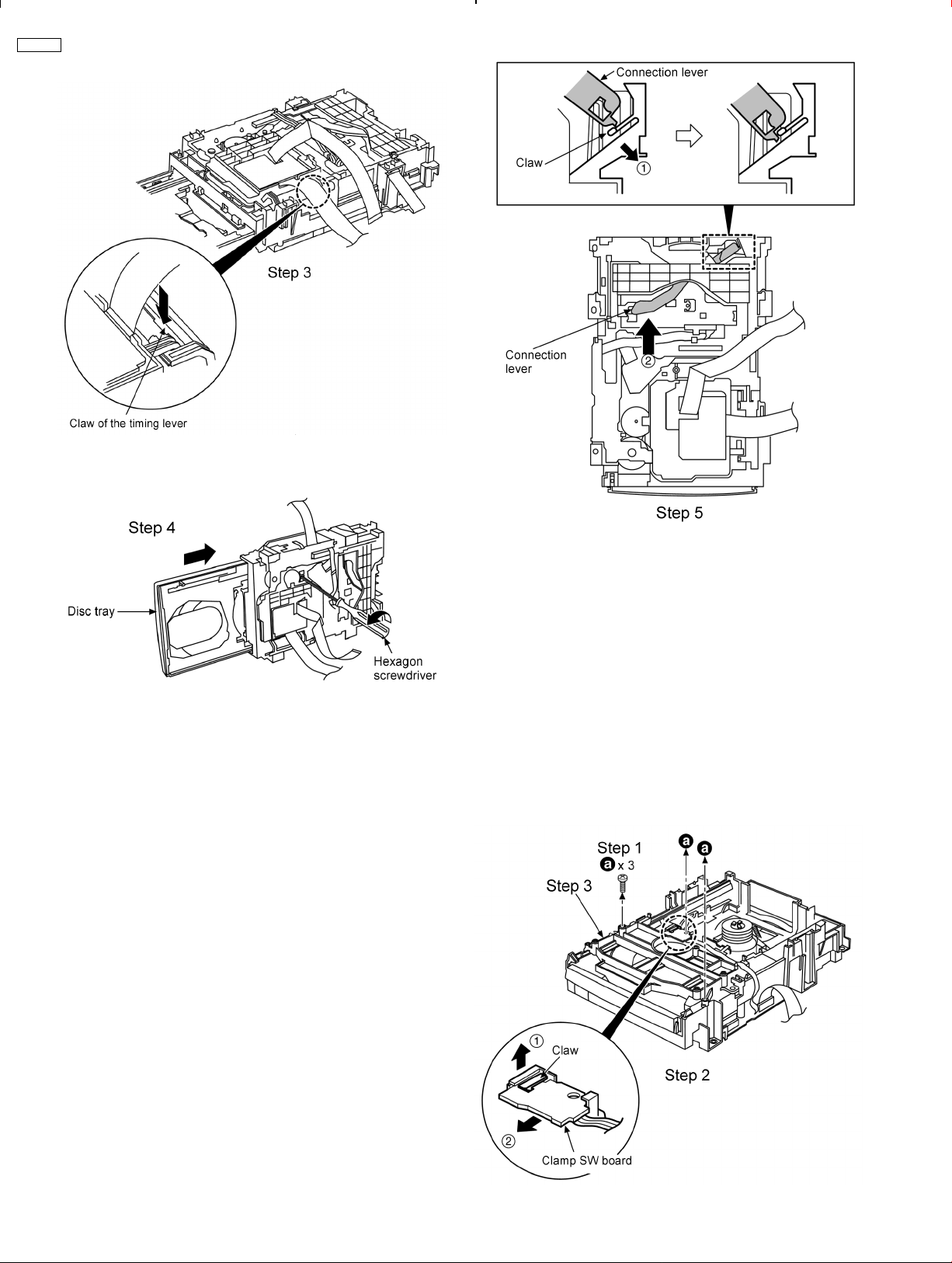

Step 3 Push into the claw of the timing lever.

Step 4 Turn the hexagon screwdriver fully to the arrow direction

to close the disc tray securely.

Step 5 While pushing the claw (B) to the arrow direction 1,

push the connection lever to the arrow direction 2.

8.2.2. Replacement for the Disc Tray

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Procedure for disassembly to board function

check].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 7 under Section 1 of

[Procedure for replacement of main parts and

disassembly/reassembly of parts].

Step 1 Remove the screws.

Step 2 While holding up the claw to the arrow direction 1, pull

out the clamp SW board to the arrow direction 2.

Step 3 Remove the mecha nical cover.

18

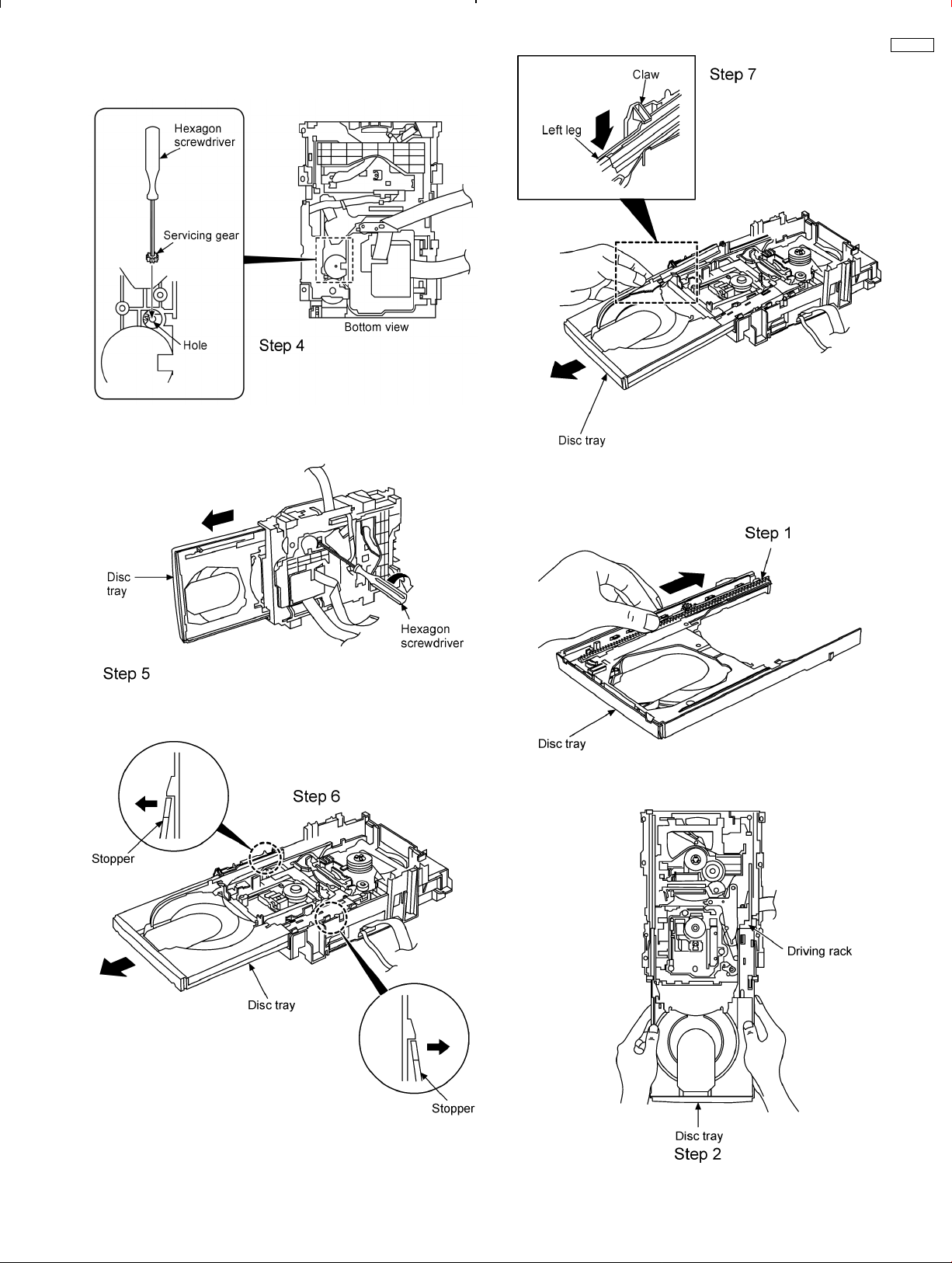

Step 4 Insert the hexagon screwdriver (with servicing gear) into

the hole.

Step 5 Turn the hexagon screwdriver clockwise, and pull out

the disc tray fully.

SA-HT80

8.2.2.1. Reassembly of Disc Tray

Step 6 Release the stoppers located in the both sides of the

unit, and pull out the disc tray.

Step 1 Slide the driving rack to the arrow direction completely.

Step 2 Insert the disc tray into the loading unit while holding the

driving rack securely.

Step 7 As the left leg of the disc tray contacts the claw, pull out

the disc tray while holding down the leg.

19

SA-HT80

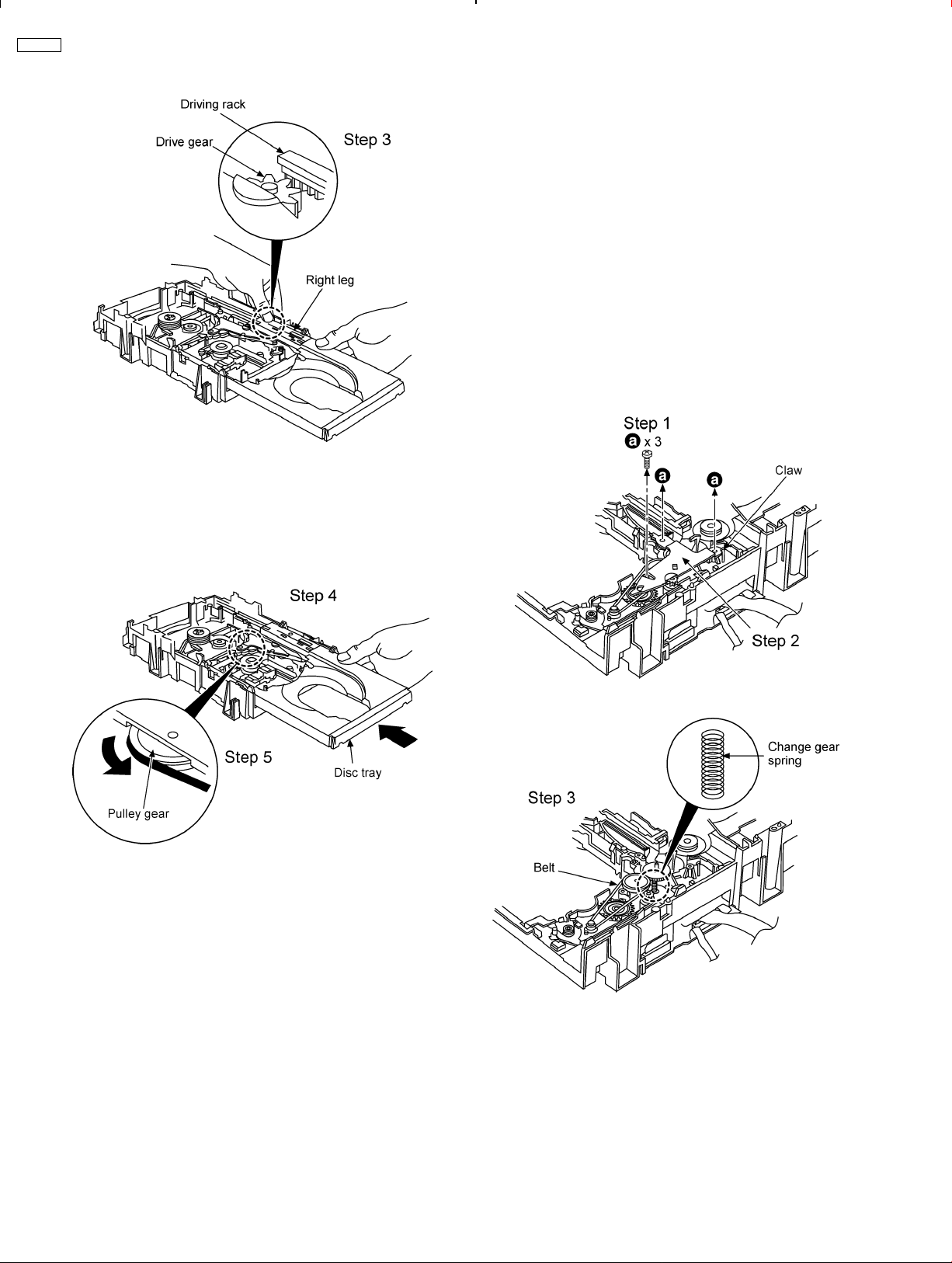

Step 3 The driving rack and the drive gear should engage with

each other.

CAUTION

Slightly hold down the right leg of the disc tray.

8.2.3. Disassembly and Reassembly for

the mechanical base unit

8.2.3.1. Disassembly of the mechanical

base driving section

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 14 under Section 1

of [Procedure for replacement of main parts and

disassembly/reassembly of parts].

• Follow the instructions, Step 1 to Step 7 under Section 2 of

[Procedure for replacement of main parts and

disassembly/reassembly of parts].

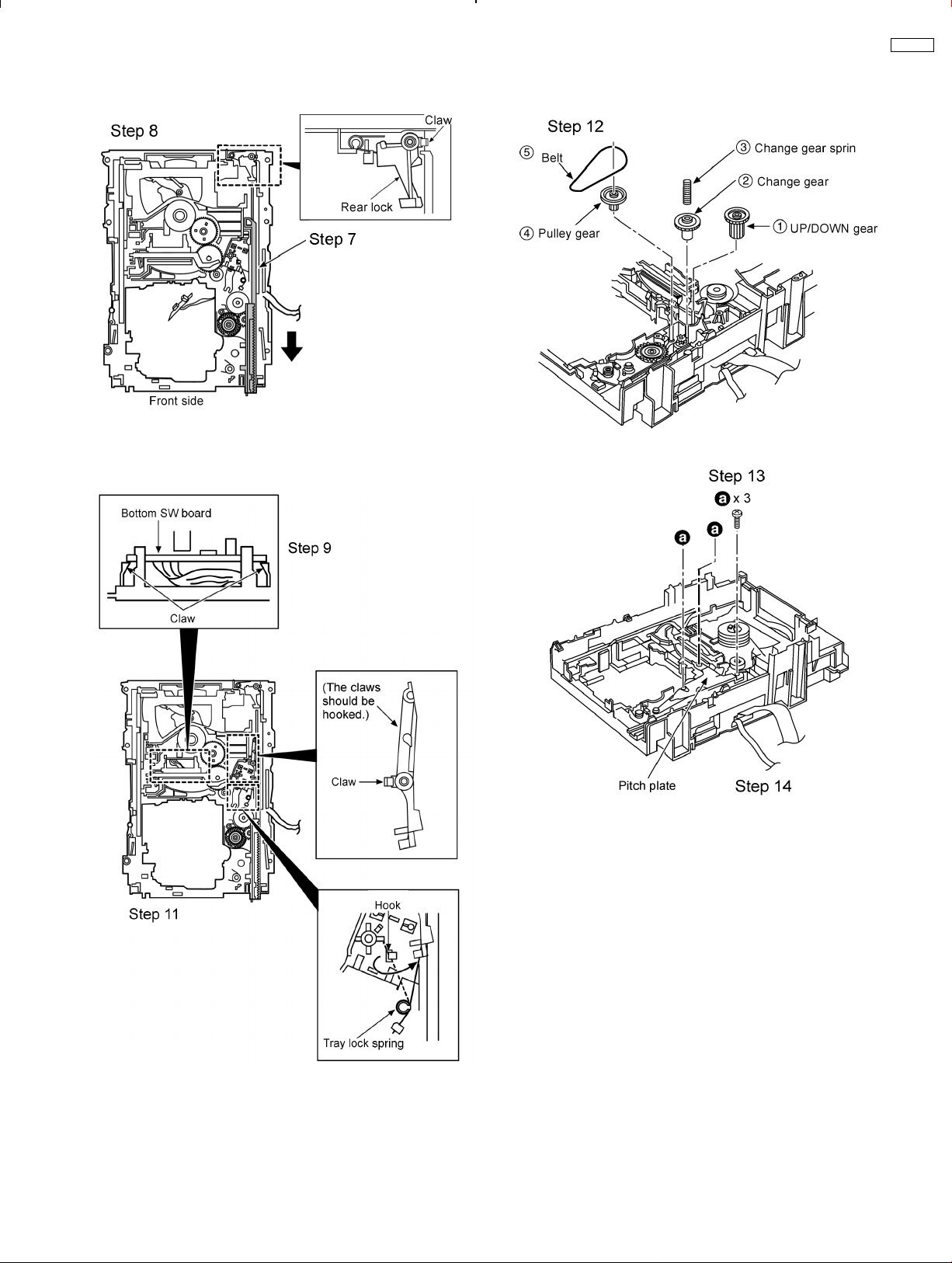

Step 1 Remove the screws.

Step 2 Remove a claw, and then the pitch plate.

Step 4 Insert the disc tray while holding the driving rack.

Step 5 Rotate the gear 5 or 6 times manually, and then push

the disc tray.

Step 3 Remove the belt and gear spring.

CAUTION

Take care to avoid losing the removed change gear spring.

20

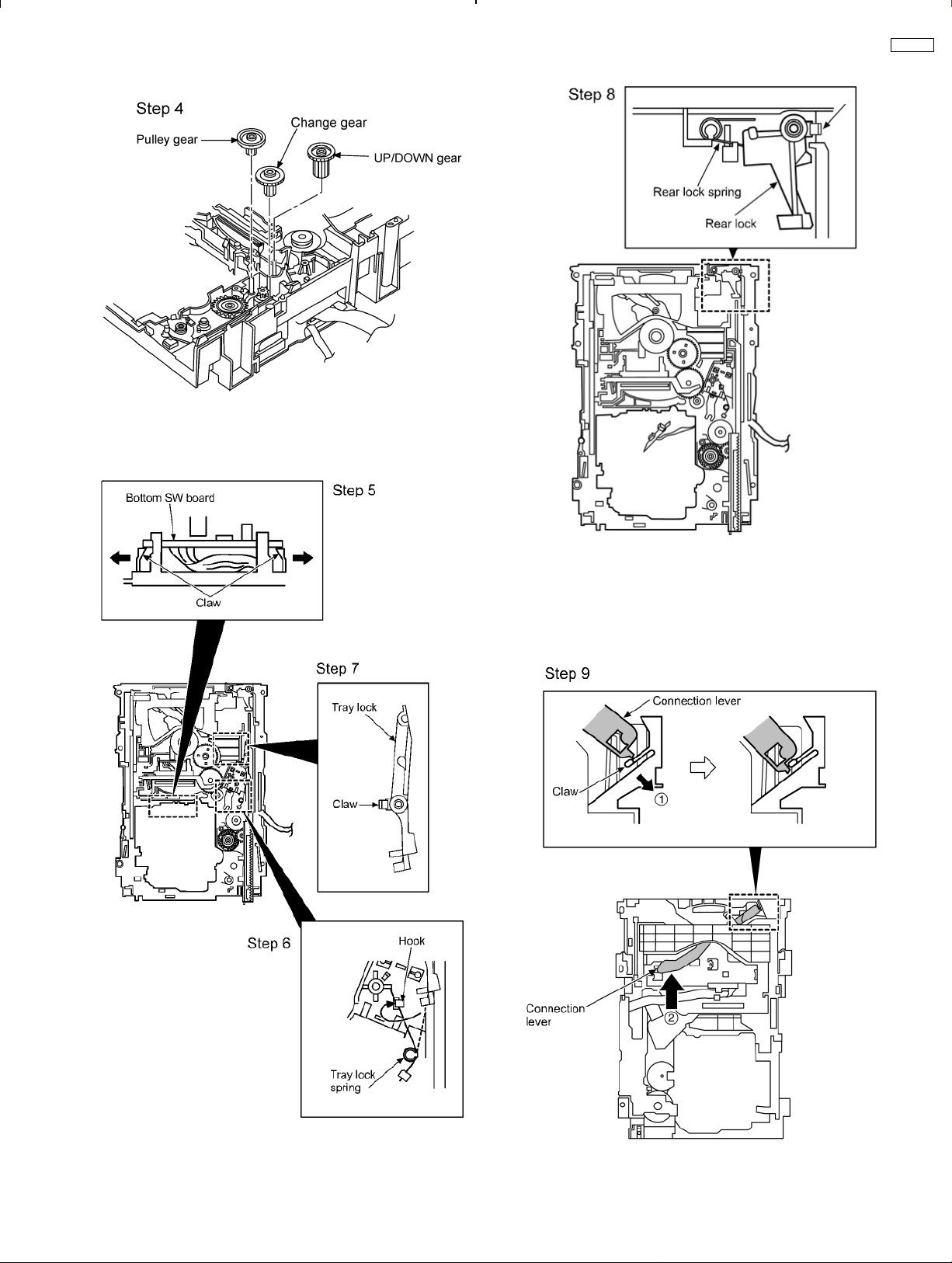

Step 4 Remove the pulley gear, change gear, and UP/DOWN

gear.

Step 5 Remove the two claws, and then the bottom SW board.

Step 6 Put the tray lock spring on the hook temporarily.

Step 7 Remove a claw, and then the tray lock.

SA-HT80

Step 8 Remove a claw, and then the rear lock.

CAUTION

Take care to avoid removing the rear lock spring.

Step 9 Push the connection lever into the arrow direction 2

while pressing the claw (B) to the arrow direction 1.

21

SA-HT80

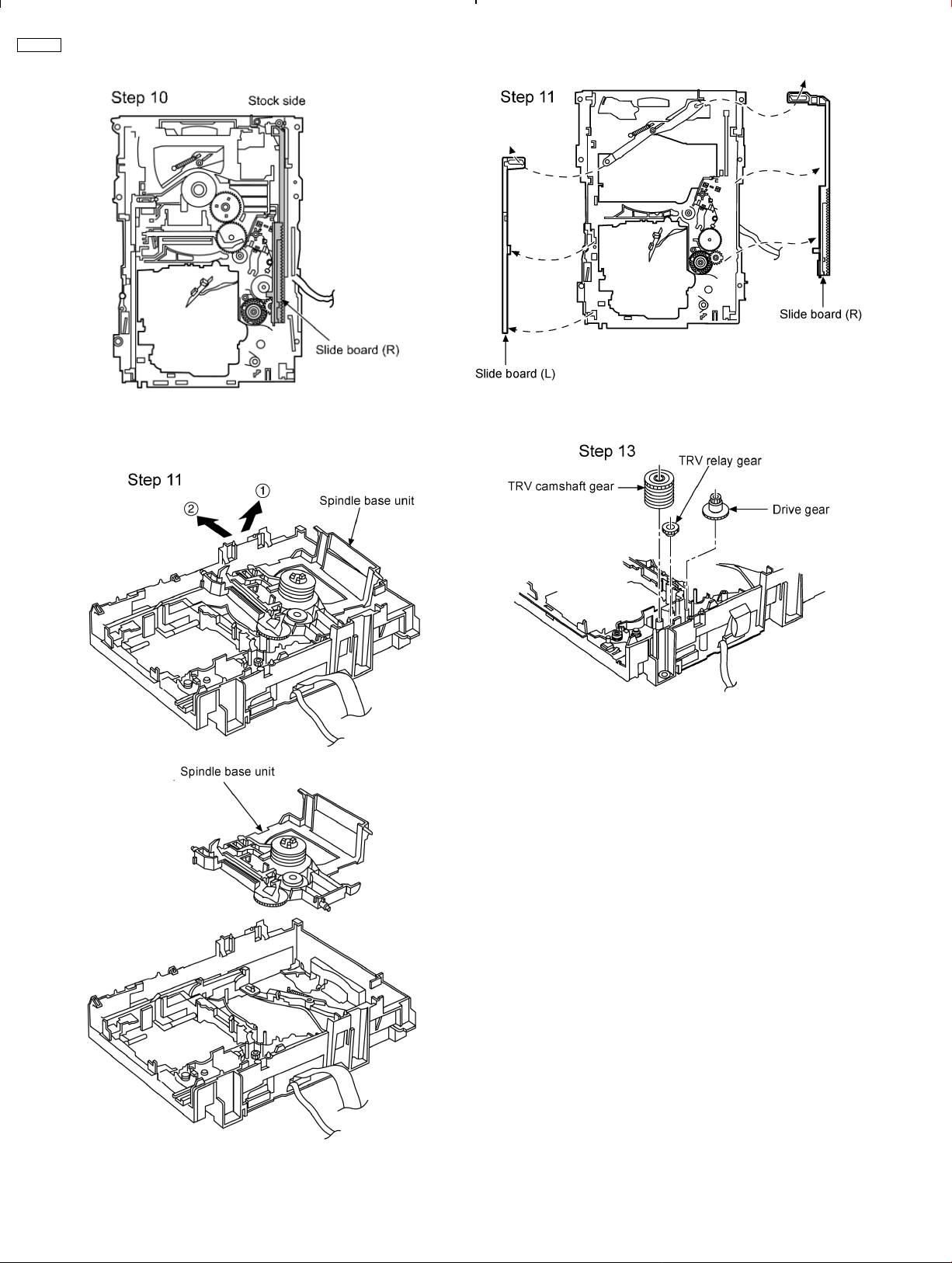

Step 10 Slide the slide board (R) to the end of the stock side.

Step 12 Remove the slide boards (R) and (L).

Step 11 Lift up the left side of the spindle base unit to the arrow

direction 1, and then remove the whole unit to the arrow

direction 2.

Step 13 Remove the TRV relay gear, TRV camshaft gear, and

drive gear.

22

8.2.3.2. Disassembly/Assembly of

Spindle Base Unit

SA-HT80

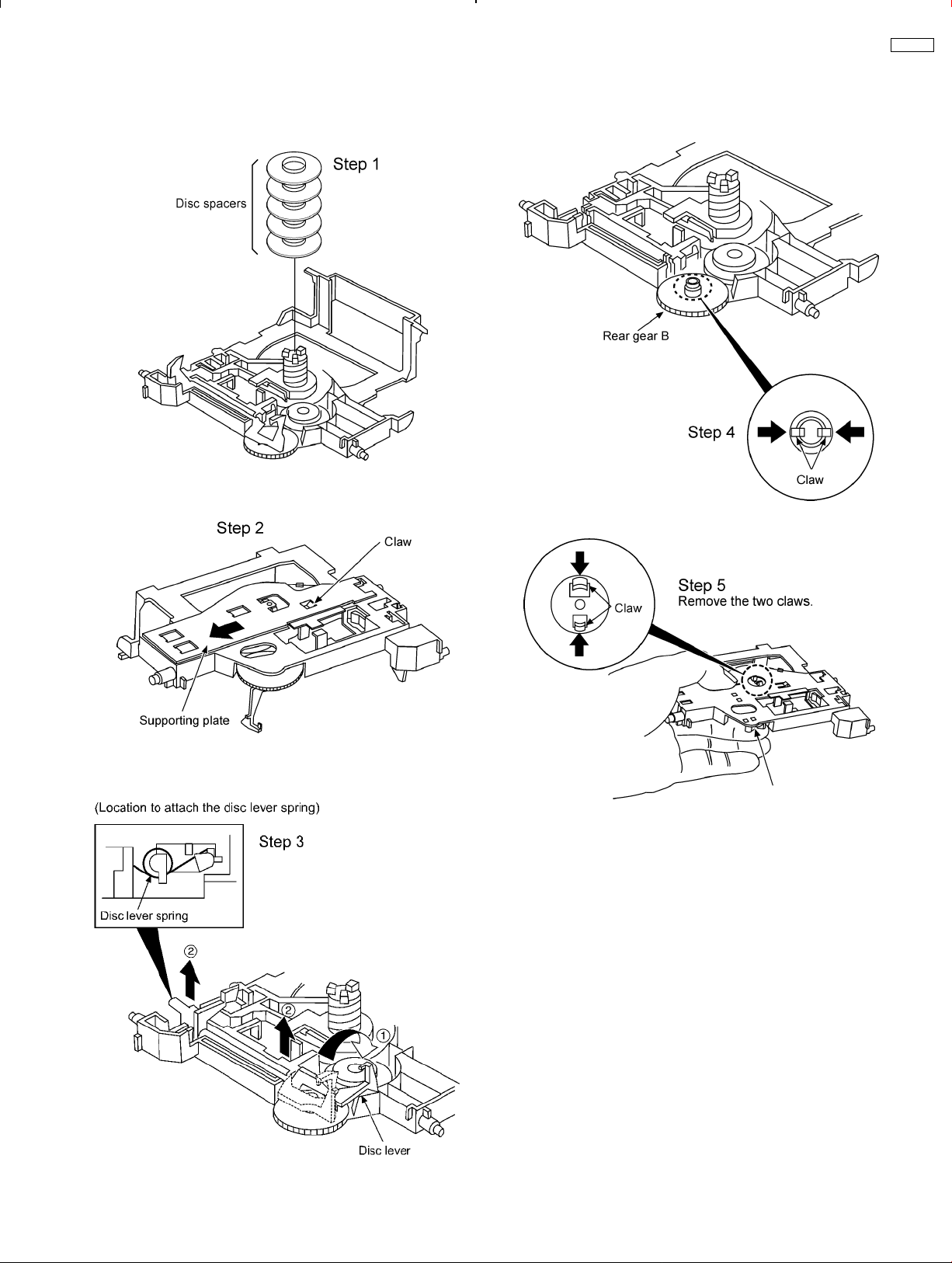

CAUTION

Take care to avoid losing the removed disc lever spring.

Step 1

with a thin tip, and remove the five disc spacers.

Step 2

pressing the claw, and remove the plate.

Push down the lower hook using a flat-slot screwdriver

Slide the supporting plate to the arrow direction while

Step 4

Step 5

Remove the two claws, and then the rear gear B.

Remove the two claws.

Step 3

position rotated to the arrow direction 1.

Pull out the disc lever while the disc lever is set to the

CAUTION

As the rotation stopper (standard) tends to jump by the

spring, hold down the area shown in the diagram.

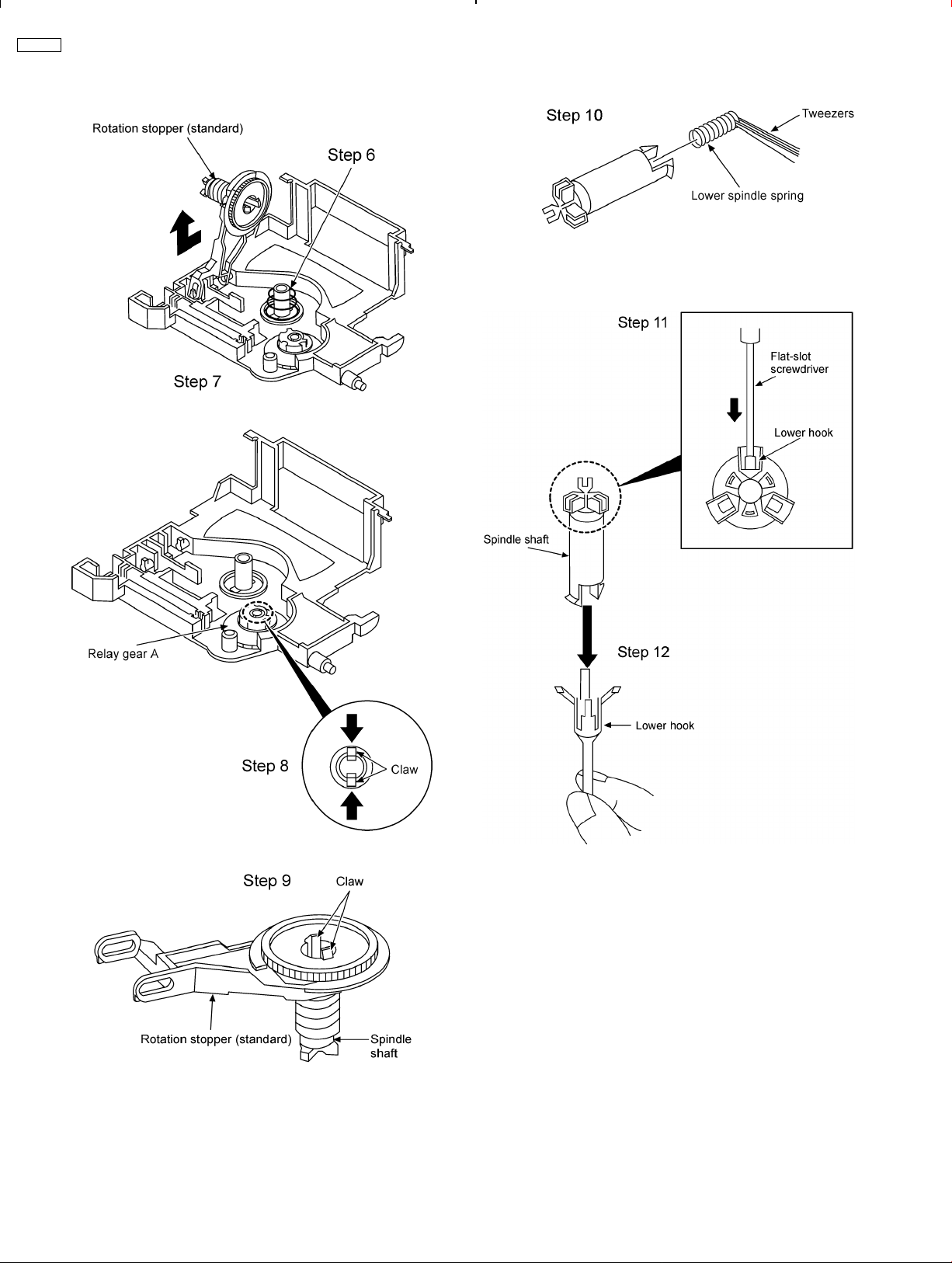

23

SA-HT80

Step 6 Remove the cushioning spring.

Step 7 Remove the rotation stopper (standard) to the arrow

direction.

Step 8 Remove the two claws, and pull out the relay gear A.

Step 10 Remove the lower spindle spring using tweezers.

Step 11 Push in the lower hook using a flat-slot screwdriver

with a thin tip, and remove the five disc spacers.

Step 12 Pull the shaft of the lower hook.

Step 9 Remove the two claws, and then spindle shaft.

24

Step 13 Rotate the lower spindle to the arrow direction till it

contacts the stopper.

Step 14 Insert a flat-slot screwdriver with a thin tip into the

space between the lower spindle and the UP/DOWN base so

that the lower spindle is slightly lifted up and the stopper is

unlocked. Then rotate and remove the lower spindle.

Step 15 Rotate the UP/DOWN base at the angle of 90 degree.

Then, open the protrusions of the rotation stopper to remove

the UP/DOWN base.

SA-HT80

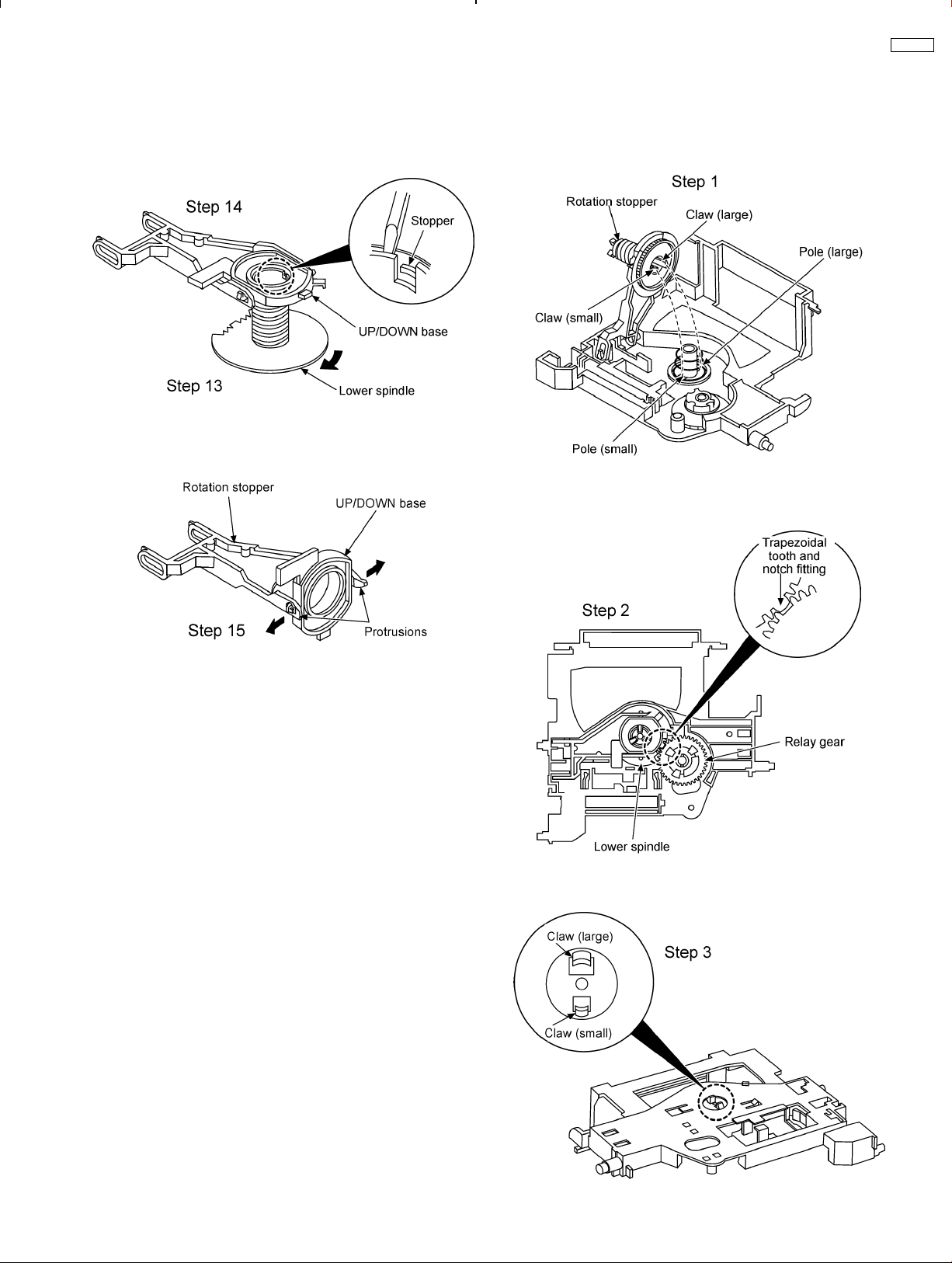

8.2.3.3. Reassembly of Rotation Stopper

(standard)

Step 1 Join the claw of the rotation stopper (standard) to the

pole of the spindle base. (Identify the large or small size of the

claws and poles.)

Step 2 Bring down the rotation stopper (standard), and fit the

trapezoidal teeth of the lower spindle into the notch of the relay

gear A.

Step 3 Push in the rotation stopper (standard), and hook the

claws securely.

25

SA-HT80

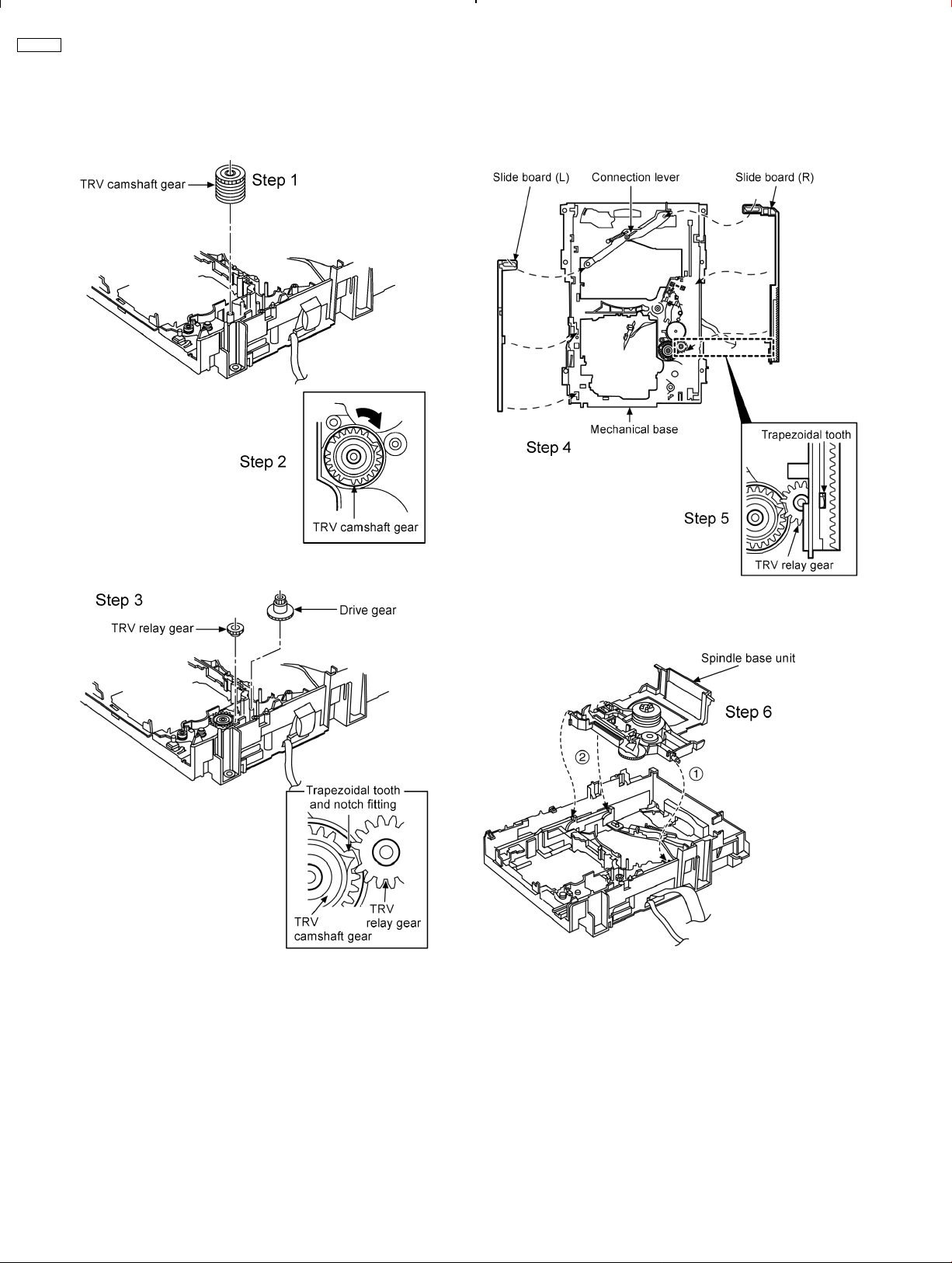

8.2.3.4. Reassembly of Mechanical

Driving Section

Step 1

Step 2

Attach the TRV camshaft gear.

Turn the TRV camshaft gear clockwise.

Step 4

fasten together with connection lever.

Step 5

fasten together with the connection lever. Then, position the

trapezoidal tooth of the TRV relay gear correctly.

Attach the slide board (L) to the mechanical base, and

Attach the slide board (R) to the mechanical base, and

Step 3

Be sure that the trapezoidal tooth of the TRV camshaft gear is

correctly fit into the notch as shown in the right diagram.

Attach the drive gear and TRV relay gear.

Step 6

(R) side first.)

Attach the spindle base unit. (Attach to the slide board

26

Step 7 Slide the slide board (R) to the front side completely.

Step 8 Attach the rear lock. (The claw should be hooked.)

Step 9 Attach the bottom SW board.

Step 11 Remove the tray lock spring from the hook, and put it

to the tray lock.

SA-HT80

Step 12 Attach the UP/DOWN gear, change gear, change gear

spring, pulley gear and belt in that order as shown in the

diagram below.

Step 13 Attach the pitch plate, and fasten with the screws (a).

Step 14 Attach the disc tray, traverse deck, mechanical cover,

etc. (Refer to Sections 1 and 2 under Procedure for

replacement of main components for the details.)

[Function Check after Completion]

Use a hexagon screwdriver (with a servicing gear) to rotate and

check the following functions.

1. Opening condition of the disc tray

2. Tray movement to the stock side

3. Up and down movements of the spindle base unit

4. Up and down movements of the traverse unit

27

SA-HT80

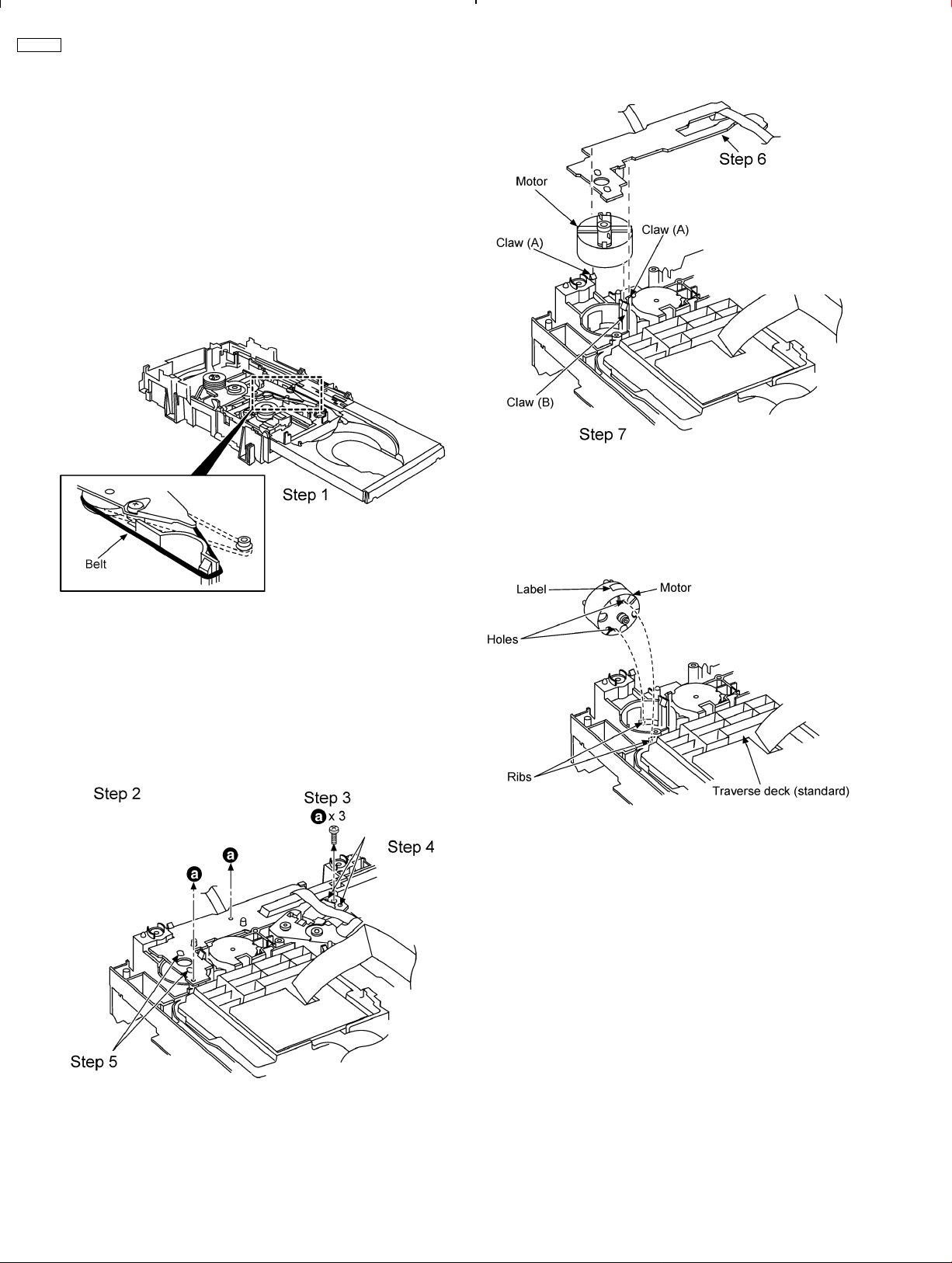

8.2.4. Replacement for the motor

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 7 under Section 1 of

[Procedure for replacement of main parts and

disassembly/reassembly of parts].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Procedure for replacement of main parts and

disassembly/reassembly of parts].

Step 6

Step 7

Remove the claws (A), and then the motor board.

Remove the claw (B), and then the motor.

Step 1

CAUTION

Keep track that the belt should be free from grease or other

agents.

Step 2

Step 3

Step 4

Step 5

Hook the belt temporarily.

Turn over the CD changer unit.

Remove the screws.

Remove the solders (2 places) of the plunger terminal.

Remove the solders (2 places) of the motor terminal.

8.2.4.1. Precautions: Motor Assembly

1. The motor label should be positioned in the traverse deck

side (standard).

2. The motor holes and ribs should be securely fitted with

each other.

28

8.2.5. Replacement for the Traverse

motor, optical pickup and spindle

motor.

• Follow the instructions, the above Step 1 to Step 4 under

Section 1 of [Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 5 under Section 2 of

[Checking Procedure for each major P.C.B.].

• Follow the instructions, Step 1 to Step 14 under Section 1

of [Procedure for replacement of main parts and

disassembly/reassembly of parts].

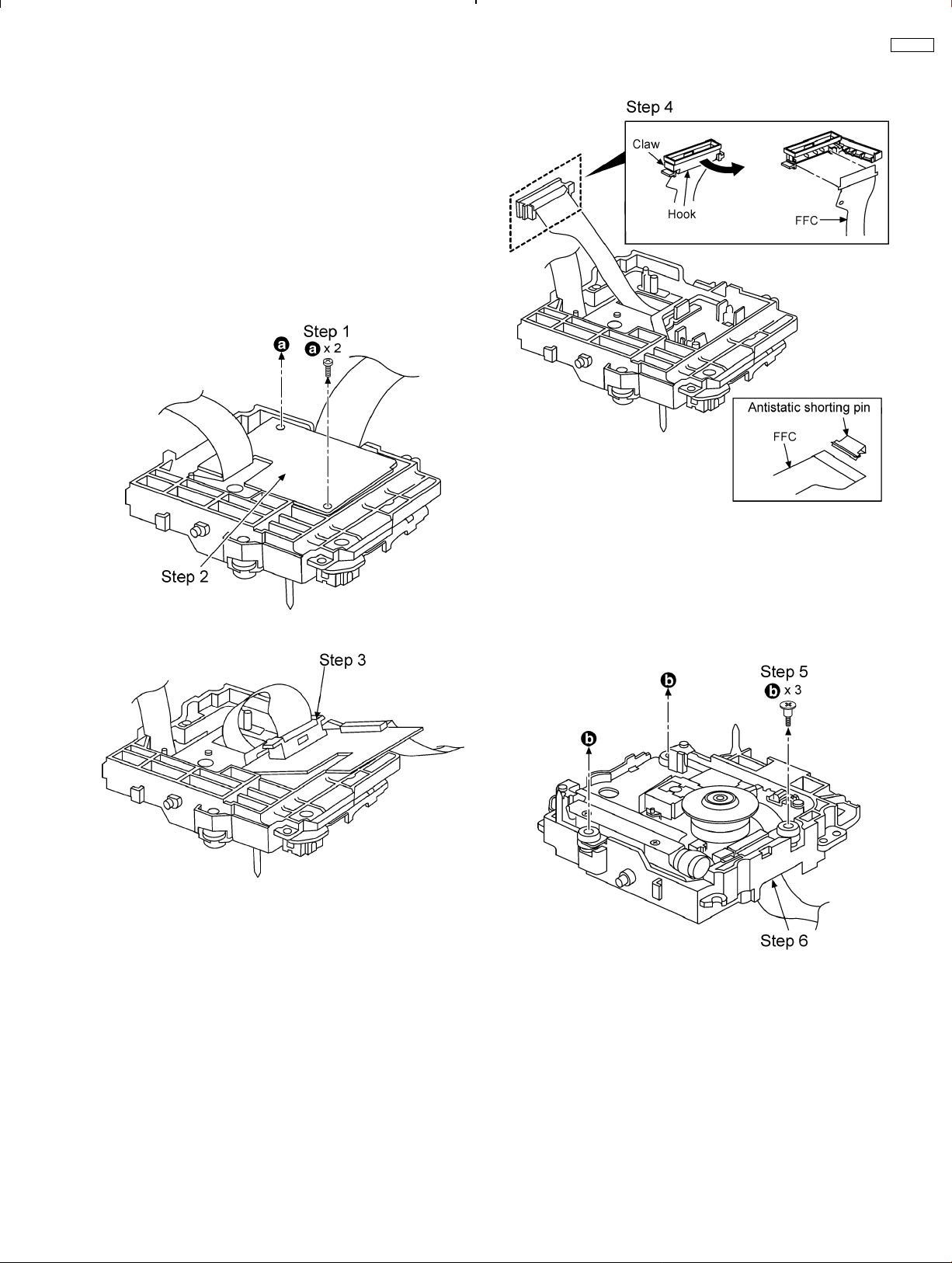

Step 1

Step 2

Remove the screws.

Remove the relay board.

Step 4

and remove the FFC cable.

Unfasten the claw to open the hook of the FFC holder,

SA-HT80

Step 3

Pull out the FFC holder.

CAUTION

Insert an antistatic shorting pin to the FFC cable of the

optical pickup. (Refer to "Handling Precautions for

Traverse Deck Optical Pickup" for the details.)

Step 5

Step 6

Remove the screws.

Remove the traverse chassis.

29

SA-HT80

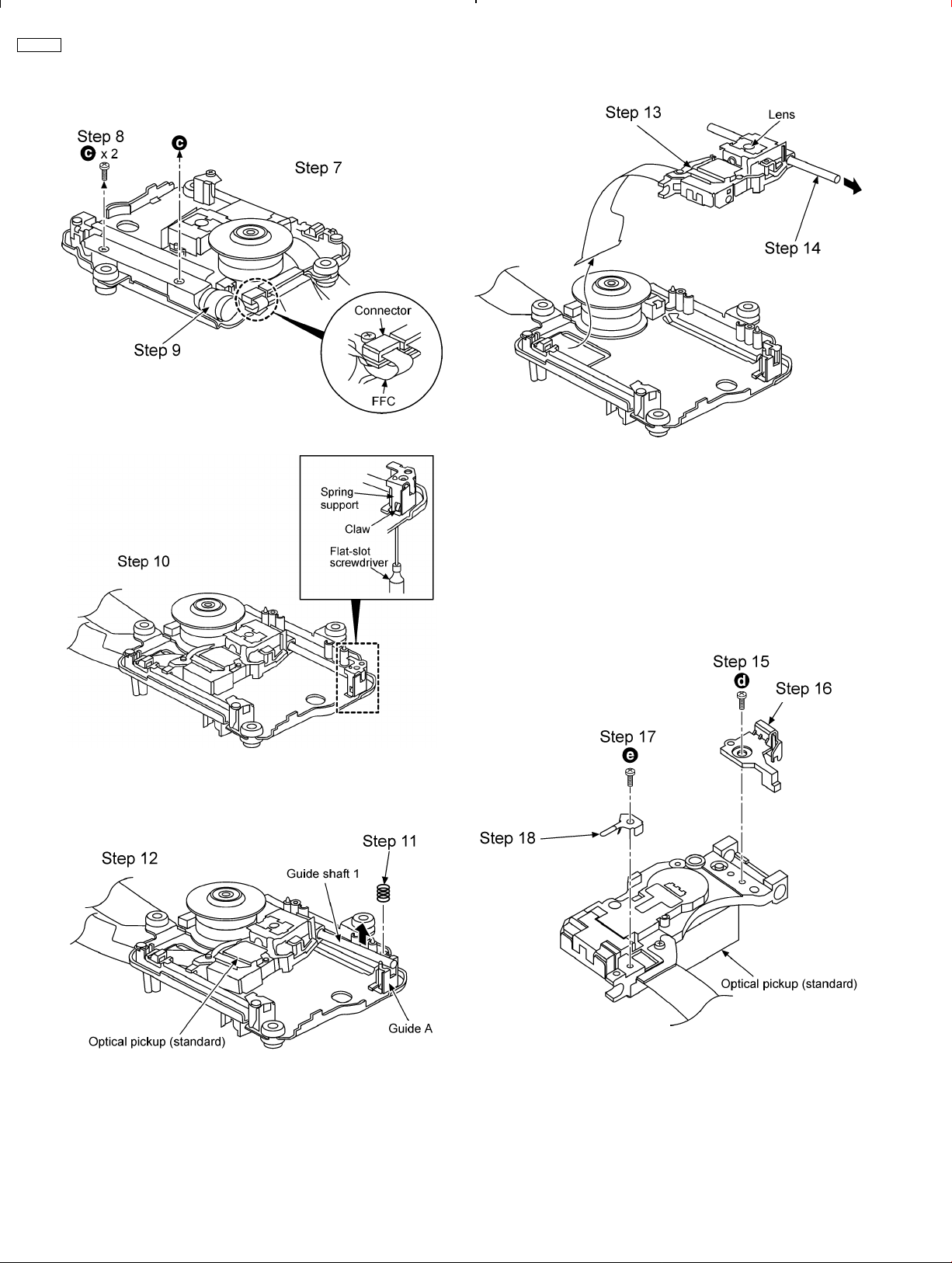

Step 7 Pull out the FFC cable from the connector.

Step 8 Remove the screws.

Step 9 Remove the traverse motor.

Step 10 Unfasten the claw to remove the spring support.

Step 13 Remove the optical pickup (standard).

Step 14 Pull out the guide shaft 1.

CAUTION

1. The optical pickup uses the extreme precision

technology, and is sensitive to shocks.

2. Do not touch the lens of the optical pickup.

Step 11 Remove the spring.

Step 12 Lift up the optical pickup (standard), and remove the

Guide shaft 1 from the Guide A.

Step 15 Remove the screw.

Step 16 Remove the nut unit.

Step 17 Remove the screw.

Step 18 Remove the spring.

CAUTION

Take care to avoid losing the removed spring.

CAUTION

After assembly, apply the screw lock.

30

Loading...

Loading...