Panasonic Sa-ak785lm-k Service Manual

© Panasonic Corporation 2009. All rights reserved.

Unauth

orized copying and distribution is a violation

of law.

MEX0911001CE

CD Stereo System

Mode

Rev. 01

l No. SA-AK785LM-K

Product Color: (K)...Black Type

Notes: This model’s CD Mechanism Unit (CR14C). Please refer to the Original Service Manual

(Order No. MD0805031CE) for this CD Mechanism Unit.

Nota: El idioma original de este Manual de Servicio es en idioma inglés, sin embargo algunas notas aquí mencionadas serán escritas en español

para mejor descripción para Centros de Servicio de México.

SH-FX785

SB-AK785 SB-AK785SB-AK780 SB-AK780SA-AK785

TABLE OF CONTENTS

1 Safety Precautions

1.1. G

eneral Guidelines

1.3. C

aution For Fuse Replacement

1.4. B

efore Repair and Adjustment

1.5. P

rotection Circuitry

1.6. S

afety Parts Information

2 Warning

2.1. Prevention of Electrostatic Dis

charge (ESD)

to E

lectrostatic Sensitive (ES) Devices

2.2. P

recaution of Laser Diode

2.3. Service caut

ion based on Legal restrictions

2.4. H

andling Precautions for Traverse Unit

3 Service Navi

gation

3.1. S

ervice Information

4 Spec

ifications

5 L

ocation of Controls and Components

5.1. Main U

nit Key Button Operation

5.2. R

emote Control Key Button Operation

5.3. D

isc Information

6 Self

-Diagnosis and Special Mode Setting

6.1. D

octor Mode Summary Table

6.2. D

octor Mode Table

6.3. S

ervice Mode Summary Table

6.4. S

ervice Mode Table

6.5. Reli

ability Test Mode (CD Mechanism Unit

CR14C)

6

.6. E

rror Code Table

7 Tr

oubleshooting Guide

7.1. Ju

piter USB

7.2. Troubleshooti

ng Guide

7.3. Troubleshoot

ing Guide for F61 and/or F76

8 Serv

ice Fixture & Tools

8.1. Service Tools and

Equipment

9 Dis

assembly and Assembly Instructions

9.1. D

isassembly Flow Chart

9.2. Main

Components and P.C.B. Locations

9.3. D

isassembly of Top Cabinet

9.4. Disassembly of

CD Mechanism Unit (CR14C)

9.5. D

isassembly of Rear Panel

9.6. D

isassembly of Fan Unit

9.7. D

isassembly of Front Panel Assembly

9.8. D

isassembly of Mic P.C.B.

9.9. D

isassembly of Panel P.C.B.

9.1

0. Disassembly of Dynamic Bass Knob &

Dyn

amic Bass Button Unit

9.11. Disassembly o

f Memory P.C.B.

9.1

2. Disassembly of MPort/Headphone P.C.B.

9.1

3. Disassembly of CD Servo P.C.B.

9.1

4. Disassembly of D-Amp P.C.B. & Fan

9.1

5. Replacement of Audio Digital Amp IC

(IC5400)

9.1

6. Replacement of Audio Digital Amp IC

(IC5000)

9.1

7. Replacement of Audio Digital Amp IC

(IC5200)

9.1

8. Disassembly of Main P.C.B.

9.1

9. Disassembly of SMPS P.C.B.

9.20. Replacement of Switching Regulator IC

9.21. Re

placement of Rectifier Diode (D5702)

9.22. Re

placement of Regulator Diode (D5801)

9.23. Re

placement of Regulator Diode (D5802)

9.24. Re

placement of Regulator Diode (D5803)

9.25. Disassembly of

AC Inlet P.C.B.

9.26. Disassembly of

Jupiter P.C.B.

9.27. Re

placement of Traverse Unit Assembly

9.28. Disassembly of

CD Lid

10 Service Position

10.

1. Checking and Repairing of Main P.C.B.

10.2. Ch

ecking and Repairing of Panel P.C.B., MIC

P.C.B

., Jupiter P.C.B. and MPort/Headphone

P.C.B.

10.

3. Checking and Repairing of D-Amp P.C.B.

10.

4. Checking and Repairing of SMPS P.C.B. and

AC Inlet P.C.B.

11 Vo

ltage & Waveform Chart

11.1. CD Servo P.C.B.

11.

2. Main P.C.B. (1/3)

11.

3. Main P.C.B. (2/3)

11.

4. Main P.C.B. (3/3)

11.

5. Panel P.C.B.

11.6. D-Amp P.C.B.

11.

7. Jupiter P.C.B. (1/2)

11.

8. Jupiter P.C.B. (2/2)

11.9. Mic P.C.B.

11.10. SMPS P.C.B.

11.11. Waveform Table (

1/3)

11.12. Waveform Table (

2/3)

11.13. Waveform Table (

3/3)

12 Ill

ustration of ICs, Transistor and Diode

13 Bloc

k Diagram

13.

1. CD Servo Block Diagram

13.

2. Jupiter Block Diagram

13.

3. Main(1/2) Block Diagram

13.

4. Main(2/2) Block Diagram

13.5. Panel / MPort/He

adphone / Mic / Memory

Block D

iagram

13.

6. D-Amp Block Diagram

13.

7. SMPS / AC Inlet Diagram

14 Wiring Conne

ction Diagram

15 Schematic Diagram Notes

16 Schematic Diagram

16.1. CD Servo Circuit

16.

2. Main Circuit (1/6)

16.

3. Main Circuit (2/6)

16.

4. Main Circuit (3/6)

16.

5. Main Circuit (4/6)

16.

6. Main Circuit (5/6)

16.

7. Main Circuit (6/6)

16.

8. Panel Circuit (1/2)

16.

9. Panel Circuit (2/2)

16.10. Memory / MPort/H

eadphone / Mic Circuit

16.11. D-Amp Circuit (1/2)

16.12. D-

16.13. Jupite

16.14. Jupite

16.15. Jupite

16.16. Jupite

16.17. SMP

16.18. SMP

16.19. AC

17 Printed Circu

17.

17.2. Main P.C.B.

17.

17.

17.

18 Termi

18.

18.

19 Exp

19.

19.

Amp Circuit (2/2)

r Circuit (1/4)

r Circuit (2/4)

r Circuit (3/4)

r Circuit (4/4)

S Circuit (1/2)

S Circuit (2/2

Inlet Circuit

it Board

1. CD Servo / Jupiter P.C.B.

3. Panel / Memory / MPort/Headphone / Mic

P.C.B.

4. D-Amp P.C.B.

5. SMPS/ AC Inlet P.C.B.

nal Function of ICs

1. IC2801 (MN101EF16KXW): IC

Microprocessor

2. IC6601(C0HBB0000057): IC FL Driver

loded View and Replacement Parts List

1. Exploded View and Mechanical Replacement

Parts List

2. Electrical Replacement Part List

4

1 Safety Precautions

1.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, carry out the following leakage current checks to prevent the customer from being exposed to shock hazards.

1.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MΩ and 5.2MΩ.

When the exposed metal does not have a return path to the chassis, the reading must be

1.1.2. Leakage Current Hot Check

1. Plug the AC cord directly into the AC outlet. Do not use an isolation transformer for this check.

2. Connect a 1.5kΩ, 10 watts resistor, in parallel with a 0.15μF capacitors, between each exposed metallic part on the set and a

good earth ground such as a water pipe, as shown in Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the above measurements.

6. The potential at any point should not exceed 0.75 volts RMS. A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must not exceed 1/2 milliamp. In case a measurement is outside of the

limits specified, there is a possibility of a shock hazard, and the equipment should be repaired and rechecked before it is

returned to the customer.

Figure 1

1.2. Before Use (For PH only)

Be sure to disconnect the mains cord before adjusting the voltage selector.

Use a minus(-) screwdriver to set the voltage selector (on the rear panel) to the voltage setting for the area in which the unit will be

used. (If the power supply in your area is 110V ~ 127V or 220V ~ 240V, set to the “110V ~ 127V or 220V ~ 240V” position.)

Note that this unit will be seriously damaged if this setting is not made correctly. (There is no voltage selector for some countries,

the correct voltage is already set.)

1.3. Caution For Fuse Replacement

1.4. Before Repair and Adjustment

K

Ó

Disconnect AC power to discharge unit AC Capacitors as such (C5700, C5701, C5703, C5704, C5705, C5706, C5707) through a

10 ? , 10 W resistor to ground.

C

aution:

DO NOT SHORT-CIRCUIT DIRECTLY (with a screwdriver blade, for instance), as this may destroy solid state devices.

After repairs are completed, restore power gradually using a variac, to avoid overcurrent.

Cur

rent consumption at AC 110V~127V / 220V~240V, 50/60 Hz in NO SIGNAL mode volume minimal should be ~ 500 mA (For PH

only).

Cur

rent consumption at AC 120V, 60 Hz in NO SIGNAL mode volume minimal should be ~ 500 mA (For PN only).

1.5. Protection Circuitry

The protection circuitry may have operated if either of the following conditions are noticed:

• No sound is hea

• Sound stops during a p

The function of this circu

rd when the power is turned on.

erformance.

itry is to prevent circuitry damage if, for example, the positive and negative speaker connection wires are

“shorted”, or if speaker systems with an impedance less than the indicated rated impedance of the amplifier are used.

If this occur

s, follow the procedure outlines below:

1. Turn off the power.

2. Determine the cause of the p

roblem and correct it.

3. Turn on the power once again after one minute.

Note:

When the protection circuitry functions, the unit will not op

erate unless the power is first turned off and then on again.

1.6. Safety Parts Information

Safety Parts List:

There are special components used in this equipment which are important for safety.

hese parts are marked by in the Schematic Diagrams & Replacement Parts List. It is essen

T

should be r

eplaced with manufacturer’s specified parts to prevent shock, fire or other hazards. Do not modify the original design

without permission of manufacturer.

Modelo:

SC-AK785LM-

tial that these critical parts

Safety

Nombre del componente

CABLE TOMACORRIENTE.

CONECTOR TOMACORRIENTE

TRANSFORMADOR DE PODER

TRANSFORMADOR DE

FUSIBLE PRIMARIO

CAPACITOR DE AC

CAPACITOR DE A

CAPACITOR DE AC

OPTOACOPLADOR

RESISTENCIA FUSIBLE

GAB. MET. SIN DOBLAR

LECTOR

RESPALDO

PCB SMPS

PTICO

(CD UNIT)

REAR PANEL

Numero de Parte

SJA168-1A

K2AA2B000017

ETS48AB12GAC

ETS19AB256AG

K5D802APA008

F0CAF334A087

C F1BAF1020020

F0CAF224A085

B3PBA0000402

RJBX0562T-1

K5G4013A0001

RKMX0144Z-KL

RD-DAC060-PX

RGRX0070R-AL

INSTRUCTIVO RQTM0171

BOBINA PRIMARIO ELF22V035B

SMPS FX785 N0AE6GY00001

7

2 Warning

2.1. Prevention of Electrostatic Discharge (ESD) to Electrostatic Sensitive

(ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electrostatic discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as “anti-static (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) suf-

ficient to damage an ES device).

8

2.2. Precaution of Laser Diode

Caution:

This product utilizes a laser diode with the unit turned “on”, invisible laser radiation is emitted from the pickup lens.

Wavelength: 795 nm (CD)

Maximum output radiation power from pickup: 100 μW/VDE

Laser radiation from the pickup unit is safety level, but be sure the followings:

1. Do not disassemble the pickup unit, since radiation from exposed laser diode is dangerous.

2. Do not adjust the variable resistor on the pickup unit. It was already adjusted.

3. Do not look at the focus lens using optical instruments.

4. Recommend not to look at pickup lens for a long time.

9

2.3. Service caution based on Legal restrictions

2.3.1. General description about Lead Free Solder (PbF)

The lead free solder has been used in the mounting process of all electrical components on the printed circuit boards used for this

equipment in considering the globally environmental conservation.

The normal solder is the alloy of tin (Sn) and lead (Pb). On the other hand, the lead free solder is the alloy mainly consists of tin

(Sn), silver (Ag) and Copper (Cu), and the melting point of the lead free solder is higher approx.30 degrees C (86°F) more than that

of the normal solder.

Definition of PCB Lead Free Solder being used

Service caution for repair work using Lead Free Solder (PbF)

• The lead free solder has to be used when repairing the equipment for which the lead free solder is used.

(Definition: The letter of “PbF” is printed on the PCB using the lead free solder.)

• To put lead free solder, it should be well molten and mixed with the original lead free solder.

• Remove the remaining lead free solder on the PCB cleanly for soldering of the new IC.

• Since the melting point of the lead free solder is higher than that of the normal lead solder, it takes the longer time to melt the

lead free solder.

• Use the soldering iron (more than 70W) equipped with the temperature control after setting the temperature at 350±30 degrees

C (662±86°F).

Recommended Lead Free Solder (Service Parts Route.)

• The following 3 types of lead free solder are available through the service parts route.

RFKZ03D01K-----------(0.3mm 100g Reel)

RFKZ06D01K-----------(0.6mm 100g Reel)

RFKZ10D01K-----------(1.0mm 100g Reel)

Note

* Ingredient: tin (Sn), 96.5%, silver (Ag) 3.0%, Copper (Cu) 0.5%, Cobalt (Co) / Germanium (Ge) 0.1 to 0.3%

The letter of “PbF” is printed either foil side or components side on the PCB using the lead free solder.

(See right figure)

10

2.4. Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode in the traverse unit.

2.4.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed

should be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible cable, cut off the antistatic FPC.

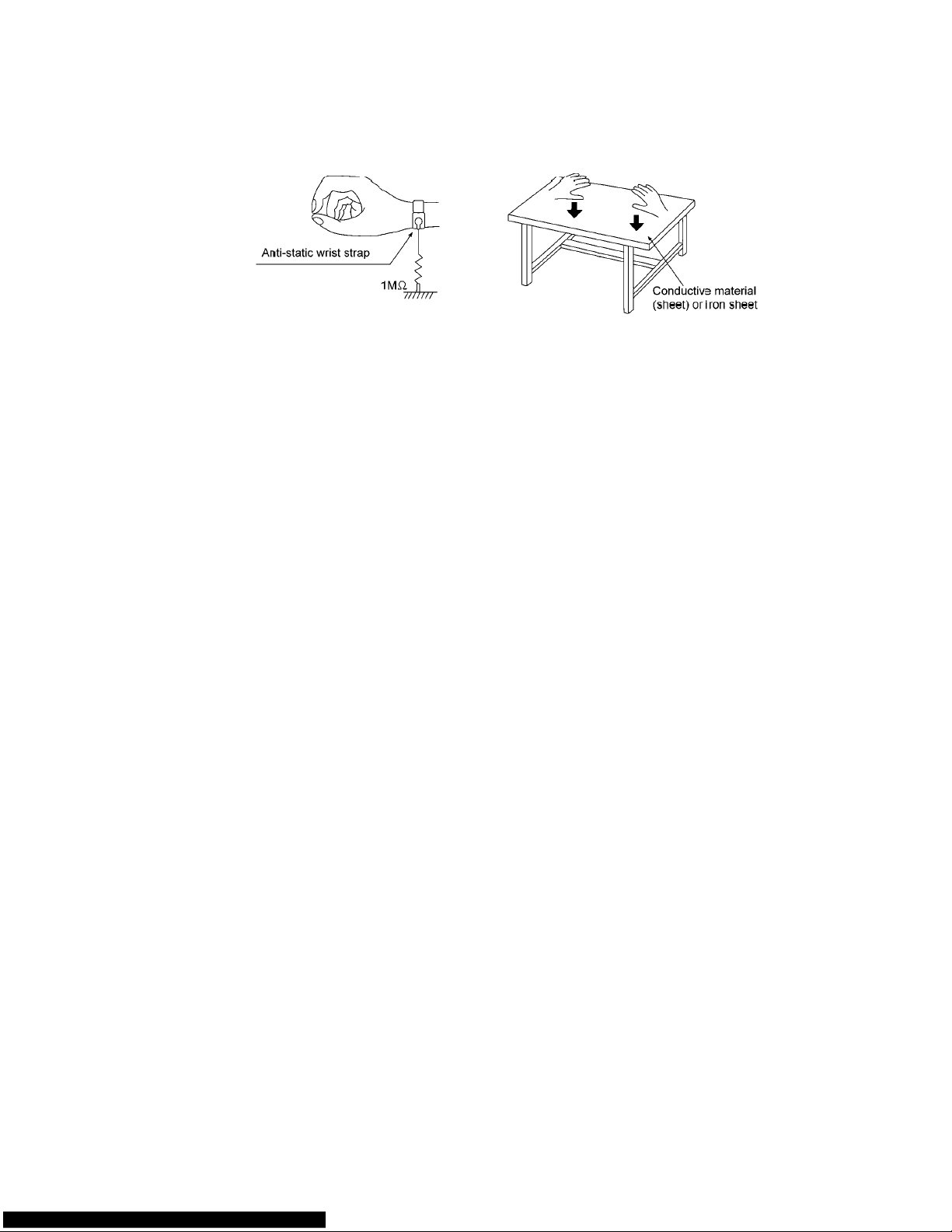

2.4.2. Grounding for electrostatic breakdown prevention

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static electricity in the working environment. Proceed servicing works under the working environment where grounding works is completed.

2.4.2.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

11

2.4.2.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

3 Service Navigation

3.1. Service Information

This service manual contains technical information which will allow service personnel’s to understand and service this model.

Please place order

he circuit is changed or modified, this information will be followed by supplement service manual to be filed with original service

If t

ma

nual.

• CD Mechanism unit (CR14C):

s using the parts list and not the drawing reference numbers.

1) This model uses CD Mechanism Unit

his service manual does not contain the following information on CD Mechanism Unit (CR14C)

2) T

- Schematic Diagram, Block Diagram an

- P

arts List for individual parts of CD Mechanism Unit (CR14C).

- Exp

Please r

• Micro-processor, EEPROM:

1) T

- E

Before replacement of micro-processor IC, please check the version no. It may need matching with ROM correction.

• Spe

1) T

loded View and Part List for individual parts of CD Mechanism Unit (CR14C).

efer to original service manual (Order No. MD0805031CE)

he following components are supplied as an assembled part.

- Micro-processor IC, IC2801 (MN101EF16KXW) * este material debe ser grabado.

EPROM IC, IC2200 (C3EBFY000006)

aker system:

he information, please refer to original service manual, SB-AK780 & SB-WAK780.

(CR14C).

d P.C.B. layout of CD Mechanism Unit (CR14C) P.C.B.

4 Specifications

Especificaciones

SECCIÓN DEL AMPLIFICADOR

AK780 AK785

Modo estéreo de potencia de salida RMS

Canal delantero (ambos canales controlados)

Canal de subwoofer

Potencial total del modo estéreo RMS

Potencia de salida PMPO

AK580

250 W por canal (6 Ω ), 1 kHz,

250 W por canal (6 Ω ),100 Hz,

750 W

8300 W

Modo estéreo de potencia de salida RMS

Canal delantero (ambos canales controlados)

Potencial total del modo estéreo RMS

Potencia de salida PMPO

250 W por canal(6 Ω), 1 kHz

500 W

5500 W

SECCIÓN DEL SINTONIZADOR DE FM/AM,

TERMINALES

Emisoras presintonizadas

15 emisoras de AM

Modulación de frecuencia (FM)

Gama de frecuencias

87,9 MHz a 107,9 MHz (en pasos de 200 kHz)

87,5 MHz a 108,0 MHz (en pasos de 100 kHz)

Terminal(es) de la antena 75 Ω (desbalanceado)

Modulación de amplitud (AM)

Gama de frecuencias

520 a 1710 kHz (en pasos de 10 kHz)

Entrada AUX

Toma puerto de música (delantero)

Sensibilidad 100 mV, 4,7 k Ω

Terminal

Toma de auriculares

Terminal Estéreo, toma de 3,5 mm

Nivel de salida (CD, 1 kHz, –20 dB) 32 Ω (Máx.)

Toma de micrófono

Sensibilidad 0,7 mV, 1,2 k Ω

Terminal Mono, toma de 3,5 mm (1 si

30 emisoras de FM

Clavija jack RCA

Estéreo, toma de 3,5 mm

stema)

SECCIÓN DE DISCOS COMPACTOS

Discos reproducidos (8 cm ó 12 cm)

(1) CD-Audio (CD-DA)

(2) CD-R/RW (CD-DA, disco formateado con MP3

*

(3) MP3

*

MPEG-1 Layer 3, MPEG-2 Layer 3

Lector

Longitud de onda 795 nm

Salida de audio (Disco)

Número de canales

AK780 AK785

AK580

FL = Canal frontal izquierdo

FR = Canal frontal derecho

SW = Canal de subwoofer

*

)

2,1 (FL, FR, SW)

2 (FL, FR)

SECCIÓN DE USB

Puerto USB

Estándar USB USB 2,0 velocidad total

Soporte de formato de archivos de medios MP3 (

Sistema de archivo de dispositivo USB FAT 12, FAT 16, FAT 32

Corriente puerto USB

Velocidad de bits

16 kbps a 320 kbps (P.B)

500 mA (Máx.)

*

.mp3)

Grabación en el USB

Formato de archivo de grabación MP3 (

Velocidad de bits

Velocidad de grabación USB 1x, máx. 4x (CD solamente)

128 kbps / 192 kbps / 320 kbps

*

.mp3)

SECCIÓN DE BAFLES

Bafles frontales (SB-AK780)

Tipo

Sistema de 2 altavoces de 2 vías (Refl ejo de sonidos graves)

Bafle(s)

Altavoz para agudos Tipo cónico de 6 cm

Altavoz para graves

Impedancia

Potencia de entrada (IEC)

Presión acústica de salida

Gama de frecuencias

Dimensiones (AnxAlxPrf)

Peso

5,0 kg

Subwoofer (SB-WAK780)

Tipo Sistema de 1 altavoz de 1 vía (Refl ejo de sonidos graves)

Bafle(s)

Altavoz para graves

Impedancia 6 Ω

Potencia de entrada (IEC) 250W (Máx.)

Presión acústica de salida 82 dB/W (1,0 m)

Gama de frecuencias 48 Hz a 250 Hz (–16 dB)

Dimensiones (AnxAlxPrf) 320 mm x 414 mm x 327 mm

Peso 7,0 kg

Bafles para Sistema Inalámbrico (SB-AK785)

Tipo

Sistema de 2 altavoces de 2 vías (Refl ejo de sonidos graves)

Bafle(s)

Altavoz para agudos Tipo cónico de 6 cm

Altavoz para graves

Impedancia

Potencia de entrada (IEC)

Presión acústica de salida

Gama de frecuencias

Dimensiones (AnxAlxPrf)

Peso

5,0 kg

Tipo cónico de 20 cm

6 Ω

250 W (Máx.)

87 dB/W (1,0 m)

49 Hz a 21 kHz (–16 dB)

68 Hz a 20 kHz (–10 dB)

250 mm x 414 mm x 298 mm

AK780 AK785

Tipo cónico de 25 cm

50 Hz a 200 Hz (–10 dB)

AK785

Tipo cónico de 20 cm

125 W (Máx.)

87 dB/W (1,0 m)

49 Hz a 21 kHz (–16 dB)

68 Hz a 20 kHz (–10 dB)

250 mm x 414 mm x 298 mm

GENERALIDADES

Alimentación

Consumo

Dimensiones (AnxAlxPrf)

Peso

4,6 kg

Gama de temperaturas de funcionamiento

Gama de humedades de funcionamiento

Consumo en el modo de espera: 0.3 W (aproximado)

Nota:

1) Las especifi caciones están sujetas a cambios sin previo aviso.

La masa y las dime

2) La distorsión armónica t

espec tro d

127 V ~ 60 Hz

AK785AK780

AK580

250 mm x 333 mm x 326 mm

35% a 80% humedad relativa (sin condensación)

nsiones son aproximados.

otal se mide con el analizador de

igital.

: 145 W

: 112 W

0°C a +40°C

3 Ω

Especificaciones

SECCIÓN DE SISTEMA INALÁMBRICO (SH-FX785)

AK785

Modo estéreo de potencia de salida RMS

Canal delantero (ambos canales controlados)

125 W por canal (3 Ω), 1 kHz,

Potencial total del modo estéreo RMS 250 W

Potencia de salida PMPO 2700 W

GENERALIDADES

Alimentación 127 V ~ 60 Hz

Consumo

Dimensiones (AnxAlxPrf) Transmisor 65 mm x 20 mm x 105 mm

Peso Transmisor 0,03 kg

Dimensiones (AnxAlxPrf) Receptor 165 mm x 90 mm x 164 mm

Peso Receptor 0,7 kg

Velocidad de bits 1 kbps

Receptor SH-FX785RM

Rango de frecuencia 2,400 a 2,4835 GHz

Número de canales 3 canales

Gama de temperaturas de funcionamiento

Gama de humedades de funcionamiento

5% a 90% humedad relativa (sin condensación)

Consumo en el modo de espera: 0,2 W (aproximado)

+5 °C to +35 °C (+41 °F to +95 °F)

: 45 W

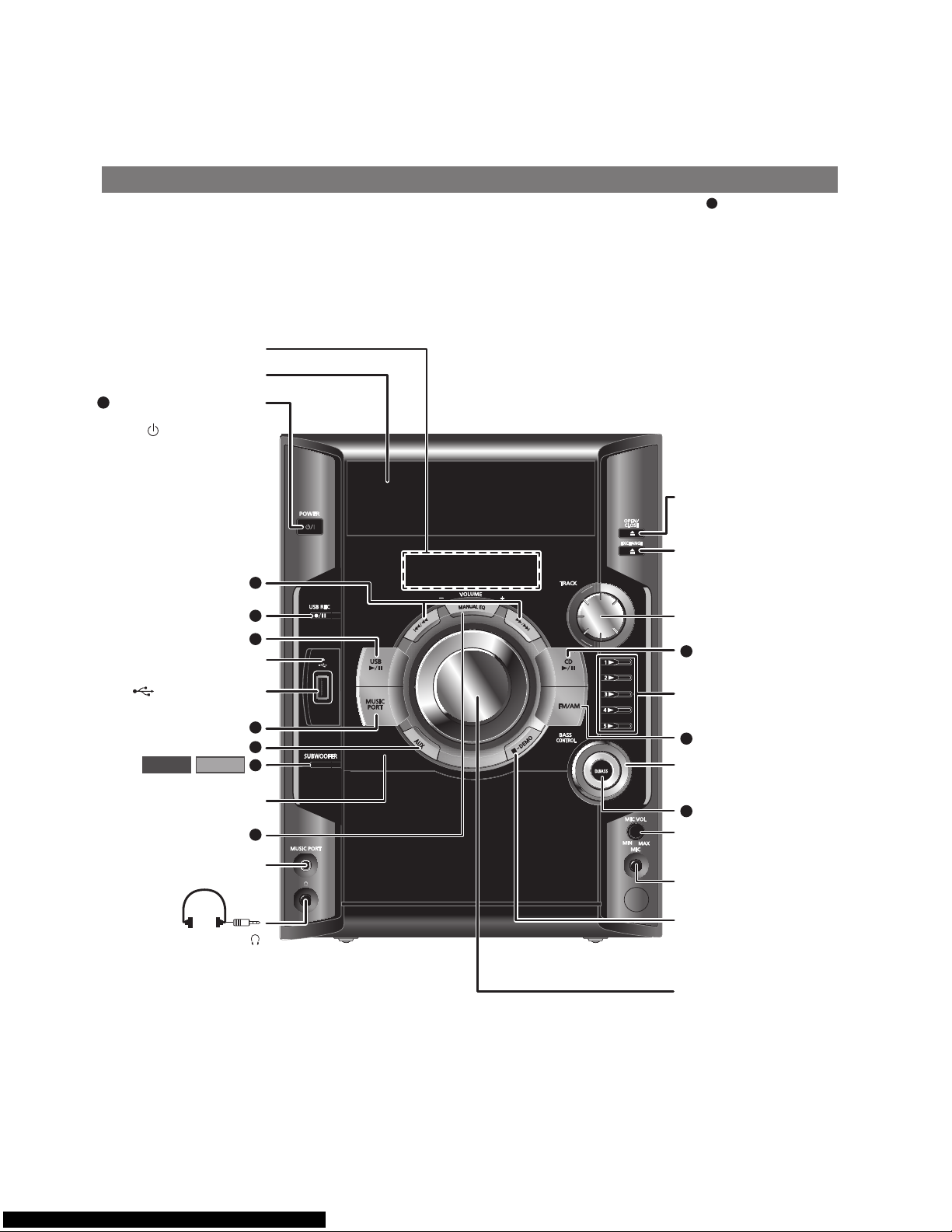

5 Location of Controls and Components

5.1. Main Unit Key Button Operation

Aparato principalAparato principal

Refiérase a los números entre paréntesis para la página de referencia. Los botones con etiquetas tales como funcionan de la misma

forma que los contro

Panel de visualización (10)

les del control remoto ( página 8).

1

Bandejas de d

Interruptor de alimentación

1

en espera/encendido

[ /

l, POWER] (6, 22)

Pulse este interruptor

para cambiar del modo de

modo de espera

y viceversa. En el

modo de espera,

el aparato consume

una pequeña cantidad de

Indicador de grabación

Puerto USB (12)

Sensor de señal de control

Toma puerto de música (17)

isco

encendido al

corriente.

USB (13)

AK785AK780

remoto

Abrir o cerrar bandeja de

d

isco (6, 9)

Cambio de d

10

6

2

3

9

11

Fun

ción saltar pista (9, 12)

8

Reproducción directa de

d

isco (9)

7

onfigurac

C

de soni

ecualiza

isco (9)

ión de control

dos graves de

dor manual (16)

5

Cont

4

rol de volumen del

rófono (16)

mic

Conector del m

(16)

icrófono

Toma de auriculares ( )

Procure evitar utilizarlos

iempo con el fi n de

mucho t

evitar lesiones auditivas.

La presión excesiva de los

auriculares puede causar

pérdida de au

Tipo de clavi

estéreo de Ø 3,5 mm

(no suministr

dición.

ja:

ada)

tención de la

De

reproducció

nción de demostración

Fu

(6)

Cont

n,

rol de volumen (16)

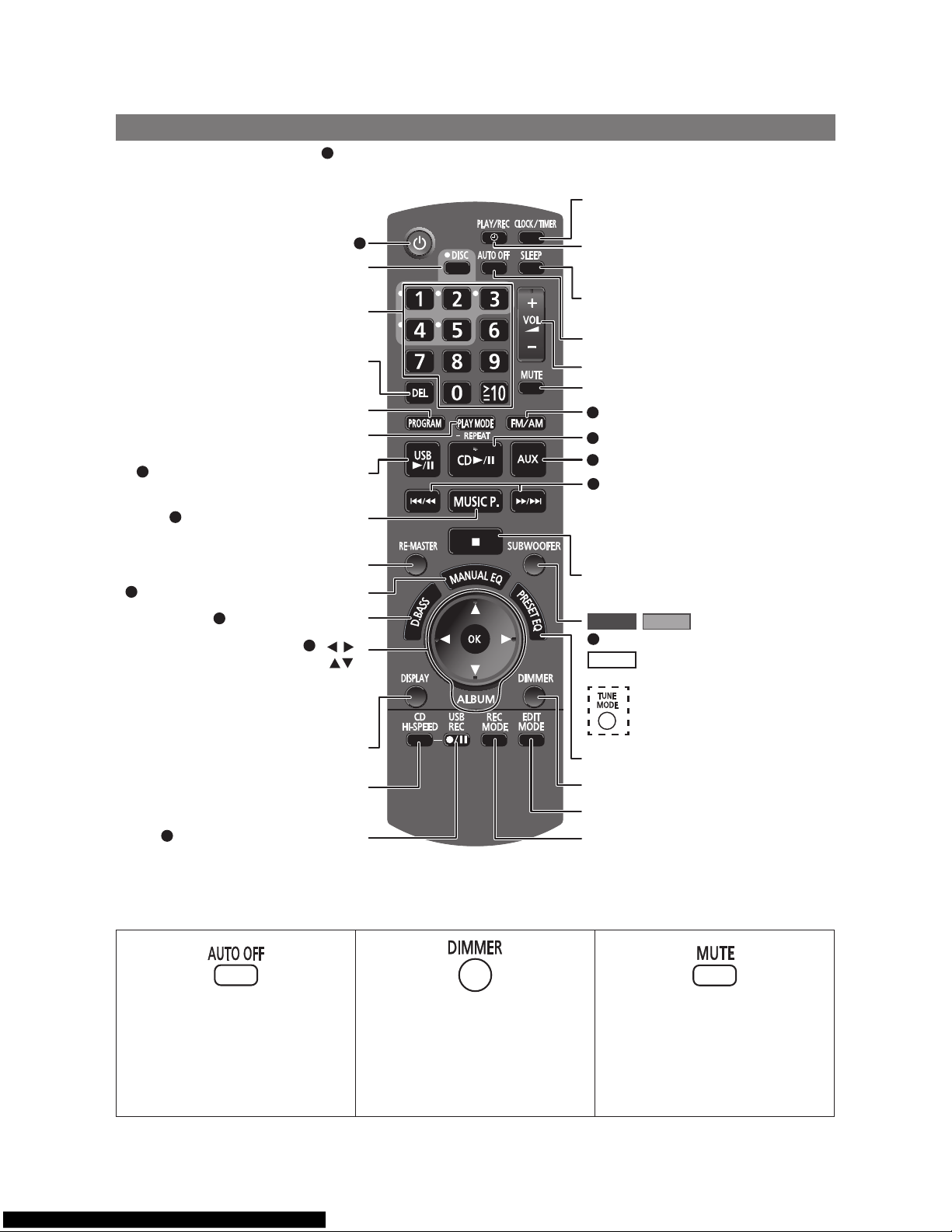

5.2. Remote Control Key Button Operation

Control remotoControl remoto

Los botones con etiquetas como el funcionan exactamente del mismo modo que los botones del aparato principal

página 7).

(

1

Confi guración de reloj o temporizador (15)

Selección del d

Selección numérica (9, 12, 17)

Fun

Fun

ción del programa (10, 12)

Función del modo de reproducción (9, 11, 13),

Reproducción o pausa del USB (12)

2

Selección puerto de música (17)

3

Selección de ecualiza

4

Selección de álbum (9, 12) [ ],

onfirmar selección (10, 12, 14, 17) [OK]

C

Fun

Selección RE-MASTER (16)

Selección D.BASS (16)

5

iscos (9)

ción borrar (10)

ción repetir (10)

dor manual (16)

10

[ ],

1

Configuración de temporizador de

reproducción o temporizador de grabación

(15)

Configuración de temporizador de apagado

automático (15)

Función de a

rol de volumen (12, 15)

Cont

Función de desactiva

Selección sintoniza

7

Reproducción o pausa del d

8

9

Selección AUX (17)

10

Saltar o buscar pista, verificar contenido

de programa, selección de canales

predeterminados, función de sintonización,

configuración de hora, configuración de

ecualizador manual (9 a 12, 15, 16)

Detener reproducción o borrar programa

(9, 10, 12)

AK780 AK785

Selección de nivel de subwoofer (16)

11

AK580

Selección del modo de sintonización (11)

pagado automático

ción de sonido

dor (FM/AM) (11)

isco (9)

Función visualiza

Función de graba

Graba

6

Esta función de apagado automático le

permite que el apa

o USB , se apague sólo después de 10

minutos sin utilizarse.

se el botón para activar la función.

• Pul

• P

ulse el botón nuevamente para cancelar.

• El ajuste se mantiene aunque el apa

esté apa

ción o pausa del USB (13)

rato en modo disco

gado.

ción (10, 12)

ción de CD a alta

veloc

idad (13)

Para reducir la iluminación del la pantalla.

• Pulse el botón para activar la función.

• Pulse el botón nuevamente para cancelar.

rato

Selección del ecualizador preajustado (16)

nción atenuador

Fu

Función modo editar (14)

Selección de modo de graba

Para sil

enciar el sonido.

se el botón para activar la función.

• Pul

• Pul

se el botón nuevamente o ajuste el

volumen pa

ra cancelar.

ción (14)

16

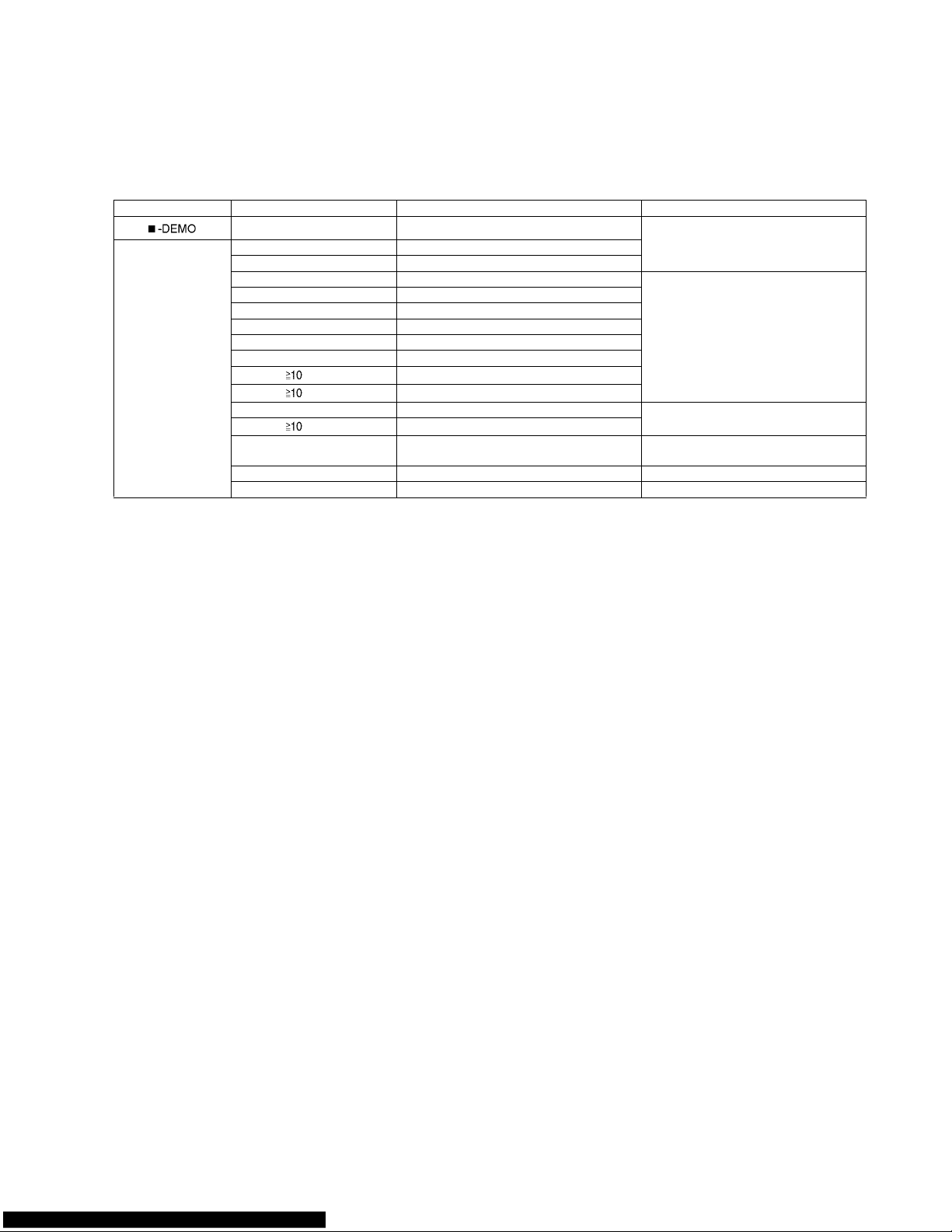

5.3. Disc Information

17

6 Self-Diagnosis and Special Mode Setting

This unit is equipped with features od self-diagnosis & special mode setting for checking the function & reliability.

Special Note: Checking of the reliability (ageing) & changer operation must be carry out to ensure good working condition in unit.

6.1. Doctor Mode Summary Table

Main unit buttons Remote control unit buttons Application Note

[]

[4], [7] Doctor Mode (Refer to the section “6.2.1 Doctor Mode

Table 1” for more information.)

Doctor Mode [DISPLAY] Cold Start

[2] Micro-P Version Display

[7] Volume 50 Setting Check (Refer to the section “6.2.2 Doctor Mode

Table 2” for more information.)

[8] Volume 35 Setting Check

[9] Volume 0 Setting Check

[PLAYMODE/-REPEAT] Volume 30 Setting Check

[1] FL Display Check

[DEL] CD Open Test

[ ], [1], [1]

CR14 Reliability Test 1 (no retry)

[ ], [1], [2]

CR14 Reliability Test 2 (with retry)

[DISC] CR14 Changer Mechanism Check (Refer to the section “6.2.3 Doctor Mode

Table 3” for more information.)

[ ], [9], [4]

CR14 Error Late Display

[4] CD to USB Recording & Playing Inspection (Refer to the section “6.2.4 Doctor Mode

Table 4” for more information.)

[FM/AM] Tuner Inspection

[OK] Exit Inspection Mode

18

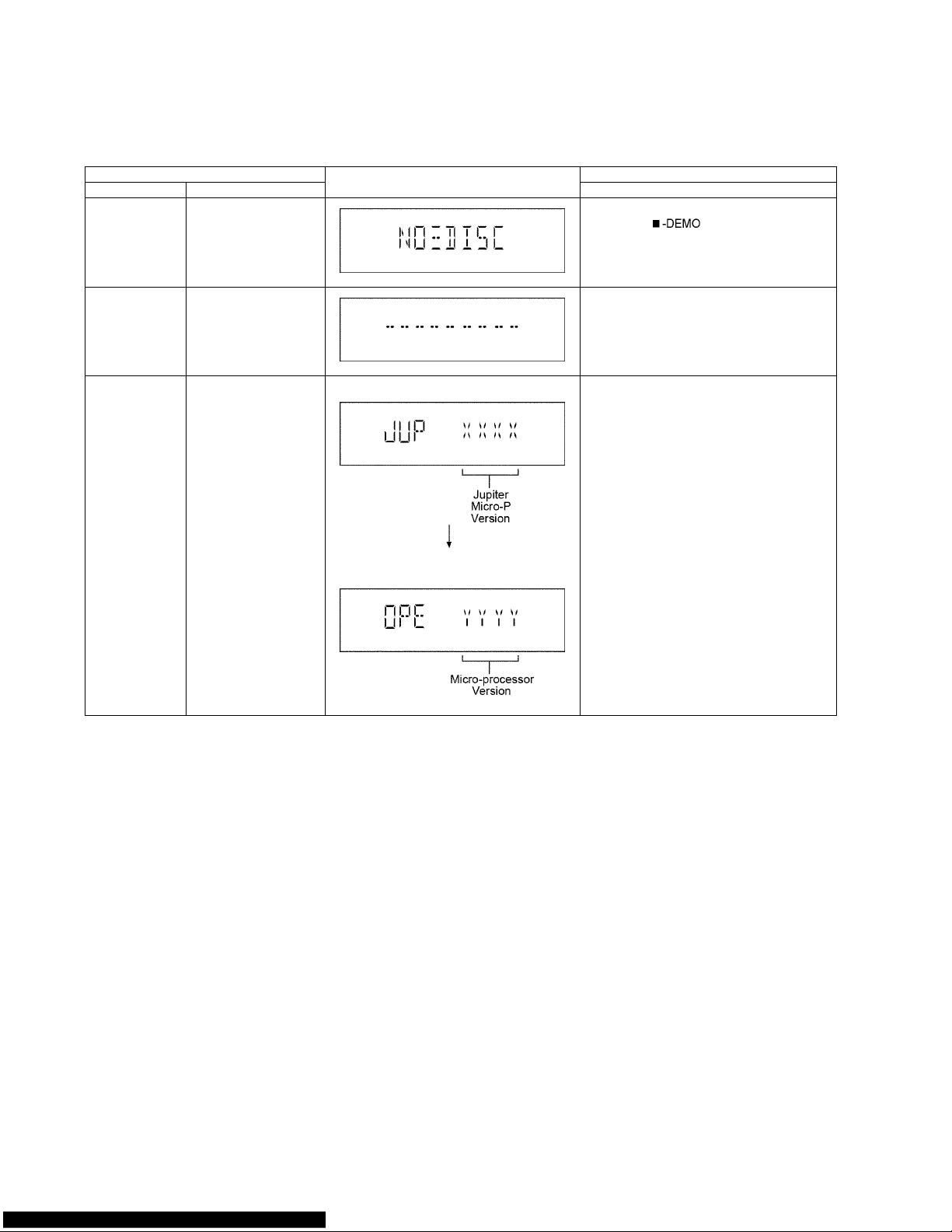

6.2. Doctor Mode Table

Below is the various special modes for checking:-

6.2.1. Doctor Mode Table 1

Item FL Display Key Operation

Mode Name Description Front Key

Doctor Mode To enter into Doctor

Mode.

In CD Mode:

1. Press [ ] button on main unit follow by [4] and [7] on remote control.

To exit Doctor Mode, press [OK] button on

remote control.

Cold Start To activate cold start upon

next power up when

reset is execute the next

time.

In Doctor Mode:

1. Press [DISPLAY] button on remote control.

Micro-P Version

Display

To check the firmware

version for Jupiter &

Microprocessor IC.

Display 1

Display 2

In Doctor Mode:

1. Press [2] button on remote control.

19

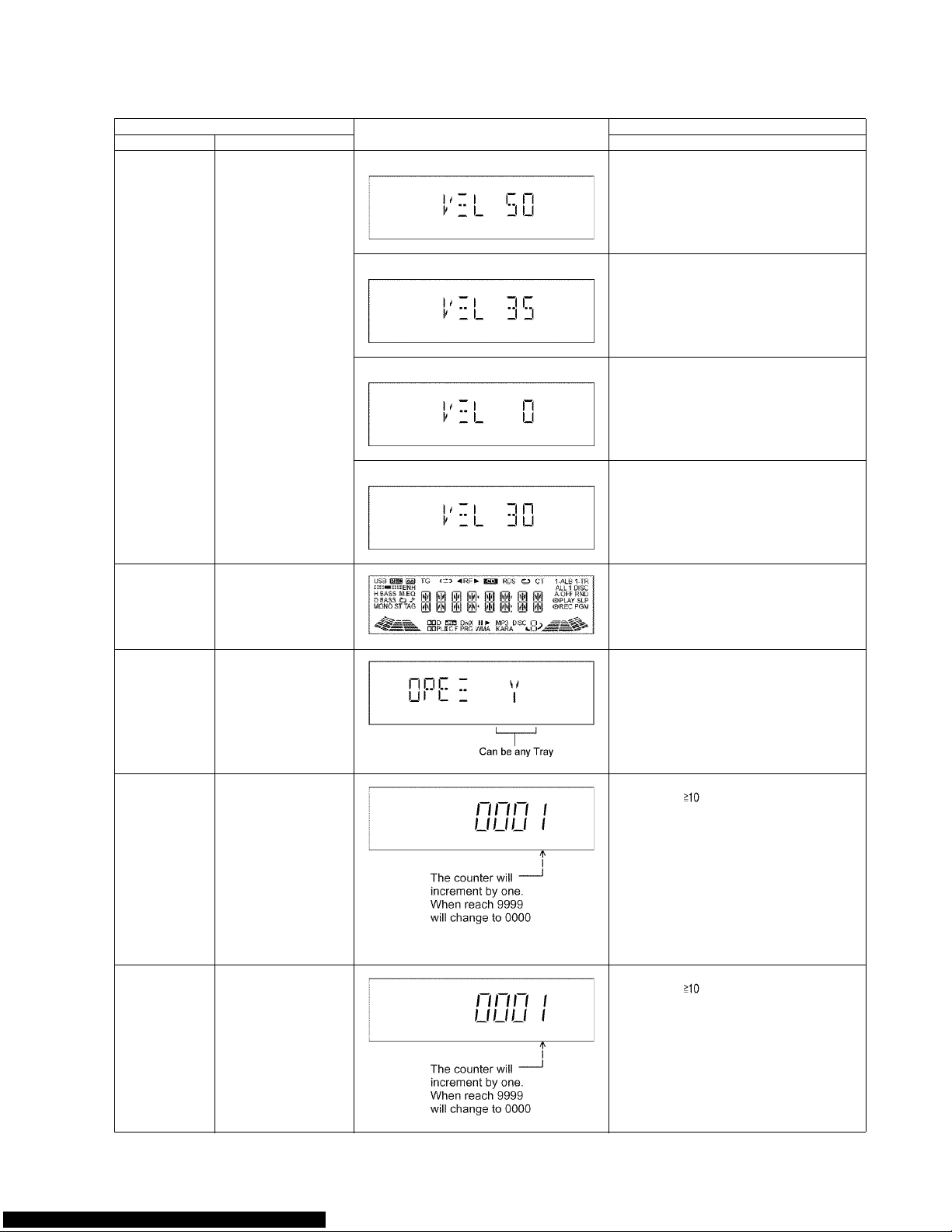

6.2.2. Doctor Mode Table 2

Item FL Display Key Operation

Mode Name Description Front Key

Volume Setting

Check

To check for the volume

setting of the main unit.

The volume will be automatically set to its respective level (in dB). During

this mode, treble/bass/EQ

will be set to ‘0’dB & OFF.

Display 1 In Doctor Mode:

1. Press [7] button on remote control.

To exit Doctor Mode, press [OK] button on main

unit or remote control.

Display 1 In Doctor Mode:

2. Press [8] button on remote control.

To exit Doctor Mode, press [OK] button on main

unit or remote control.

Display 1 In Doctor Mode:

3. Press [9] button on remote control.

To exit Doctor Mode, press [OK] button on main

unit or remote control.

Display 1 In Doctor Mode:

4. Press [PLAY MODE/-REPEAT] button on

remote control.

To exit Doctor Mode, press [OK] button on main

unit or remote control.

FL Display Check To check the FL

segments display (All

segments will light up)

In Doctor Mode:

1. Press [1] button on remote control.

CD OPEN Test To check the CD OPEN

operation.

In Doctor Mode:

1. Press [DEL] button on remote control.

2. Press [OPEN/CLOSE] button on main unit

to close the disc tray.

CR14 Reliability

Test1 (no retry)

Note:

1. If the mechanism

error occurs, it

should stop the

test.

(no retry, no recovery process).

2. The test mode is

cleared by power

OFF.

3. Reading and playback should not be

done.

In Doctor Mode:

1. Press [ ], [1], [1] button on remote control.

CR14 Reliability

Test2 (with retry)

Note:

1. Even if the mechanism error occurs, it

should retry as normal operation.

2. The test mode is

cleared by power

OFF.

3. Reading and playback should not be

done.

In Doctor Mode:

1. Press [ ], [1], [2] button on remote control.

20

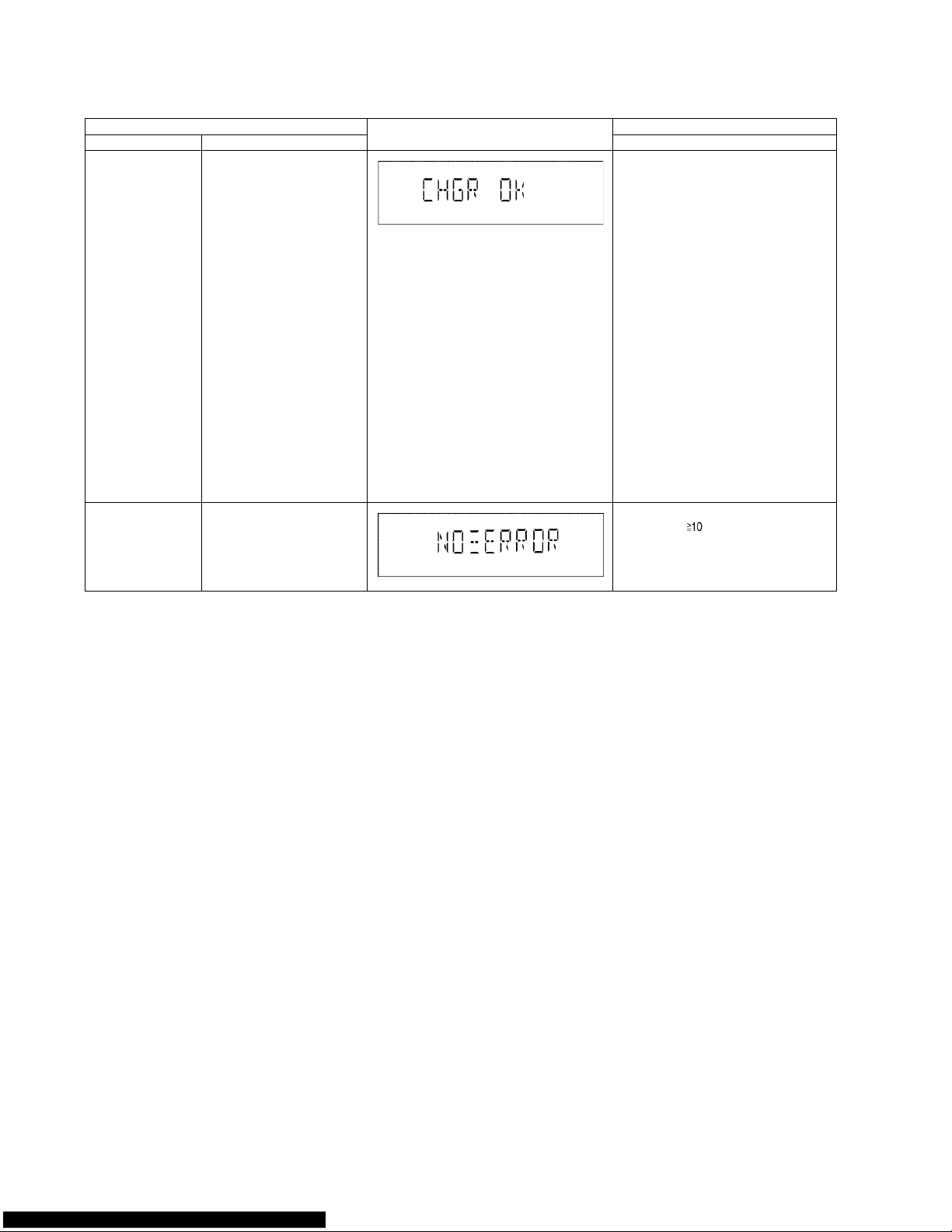

6.2.3. Doctor Mode Table 3

Item FL Display Key Operation

Mode Name Description Front Key

CR14 Inspection Below is the process:

1. Load TRAY 1 (Move to

PLAY position)

2. After that, TRAY 2 is

open (TRAY 1 still in

LOAD condition) and

close.

3. Next TRAY 3 is open

(TRAY 1 still in LOAD

condition) and close.

4. Then TRAY 4 is open

(TRAY 1 still in LOAD

condition) and close.

5. Finally TRAY 5 is open

(TRAY 1 still in LOAD

condition) and close.

6. Tray 1 is unloaded.

(Move to the STOCK

position)

7. Tray 1 is loaded. (Move

to the PLAY position)

When step 1 to 7 operates normally without any error, FL will

display [CHGR_OK_]

In Doctor Mode:

1. Press [DISC] button on remote control.

CR14 Error Code

Display

To display errors codes for

CR14 changer mechanism.

Refer to section 6.4.1 (CD

Mechanism (CR14) Error code

table).

In Doctor Mode:

1. Press [ ], [9], [4] button on

remote control.

21

6.2.4. Doctor Mode Table 4

Item FL Display Key Operation

Mode Name Description Front Key

CD to USB Recording

& Playing Inspection

-Automatically change to CD

-Set it to VOL 0

-Preset EQ Set to FLAT

USB Formatted

When high-speed recording

When analog recording

- Switches to the USB selector

after an analog recording ends

(TRACK 1 of ALBUM1)

During playback this track

- Sets to VOL 50 (0dB) and

start playback

- It is enabled to accept the

SKIP key and the ALBUM key

Next, play the track analog

recorded. (TRACK1 of

ALBUM2)

During playback this track

- It is enabled to accept the

SKIP key and the ALBUM key

In Doctor Mode:

1. Press [4] button on remote control.

22

6.3. Service Mode Summary Table

Main unit buttons Remote control unit buttons Application Note

[]

[]

Service Mode (Refer to the section “6.4.1 Service Mode

Table 1” for more information.)

Service Mode [1] Error Code History

[2] Micro-P Version Display

[5] USB Error Code History

[6] CD Self Adjustment Result (Refer to the section “6.4.2 Service Mode

Table 2” for more information.)

[3] Cold Start

23

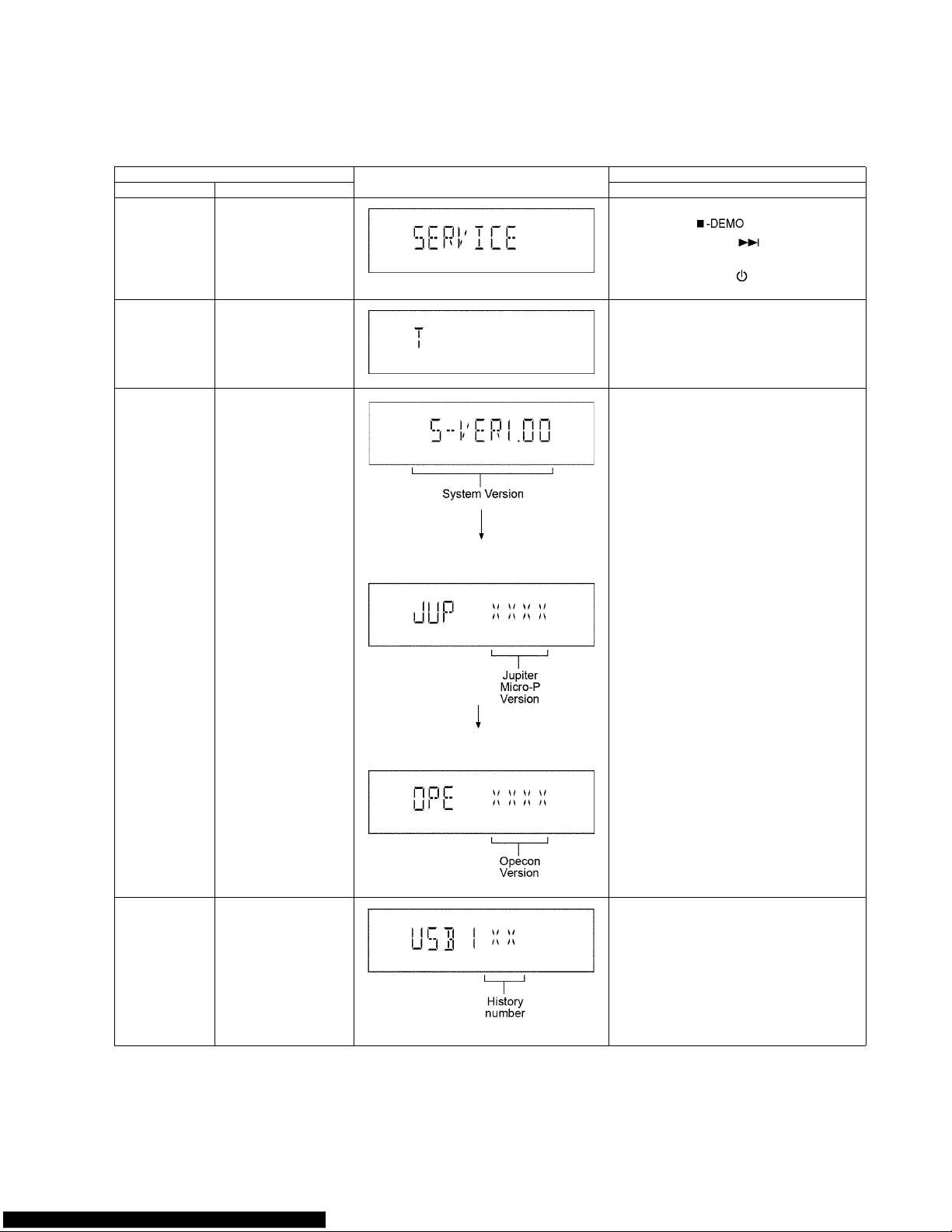

6.4. Service Mode Table

6.4.1. Service Mode Table 1

Below is the various special modes for checking:-

Item FL Display Key Operation

Mode Name Description Front Key

Service Mode To enter into Service

Mode.

In CD Mode:

Press and hold [ ] button on main unit

for 2 seconds follow by [ ] on remote control

for 2 seconds.

To exit, press [ON/OFF ] button on main unit

or remote control.

Error Code History Checking the records for

Error Code.

In Service Mode:

1. Press [1] button on remote control.

To clear history, press & hold [0] for 5 seconds or

more.

Micro-P Version

Display

To Check for following:

1) System Version.

2) Jupiter Micro-processor version.

3) Micro-processor Version

In Service Mode:

1. Press [2] button on remote control.

(Display 1)

(Display 2)

USB Error Code

History

To check for USB error

codes.

In Service Mode:

1. Press [5] button on remote control.

To clear history, press & hold [0] for 5 seconds or

more.

24

6.4.2. Service Mode Table 2

Item FL Display Key Operation

Mode Name Description Front Key

CD Self Adjustment Result

To check for CD operation

(self-adjusment).

In Service Mode:

1. Press [6] button on remote control.

Cold Start To reset to default setting. In Service Mode:

1. Press [3] button on remote control.

25

6.5. Reliability Test Mode (CD Mechanism Unit CR14C)

Below is the progress flow chart of ageing for the Mechanism unit (CR14C).

㪈㩷㫇㫃㪸㫐

㸣

㫌㫅㫃㫆㪸㪻

㸣㸣㸣㸣㸣

㪈㩷㫆㫇㪼㫅 㪈㩷㫆㫇㪼㫅 㪈㩷㫆㫇㪼㫅 㪈㩷㫇㫃㪸㫐 㪈㩷㫆㫇㪼㫅

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪚㫆㫌㫅㫋㩷㫌㫇 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼

㸣㸣㸣㸣㸣

㪈㩷㫇㫃㪸㫐 㪈㩷㫇㫃㪸㫐 㪈㩷㫇㫃㪸㫐 㪈㩷㫇㫃㪸㫐㩷㫆㫇㪼㫅 㪈㩷㫇㫃㪸㫐

㸣㸣㸣㸣㸣

㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪚㫆㫌㫅㫋㩷㫌㫇

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻

㸣㸣㸣㸣㸣

㪌㩷㫇㫃㪸㫐 㪌㩷㫇㫃㪸㫐 㪌㩷㫇㫃㪸㫐 㪌㩷㫇㫃㪸㫐 㪌㩷㫇㫃㪸㫐

㸣㸣㸣㸣㸣

㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㪌㩷㫇㫃㪸㫐㩷㫆㫇㪼㫅

㸣㸣㸣㸣㸣

㪌㩷㫆㫇㪼㫅 㪌㩷㫆㫇㪼㫅 㪌㩷㫆㫇㪼㫅 㪌㩷㫆㫇㪼㫅 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼

㸣㸣㸣㸣㸣

㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㫌㫅㫃㫆㪸㪻

㸣㸣㸣㸣㸣

㪊㩷㫇㫃㪸㫐 㪊㩷㫆㫇㪼㫅 㪊㩷㫆㫇㪼㫅 㪊㩷㫆㫇㪼㫅 㪊㩷㫆㫇㪼㫅

㸣㸣㸣㸣㸣

㪚㫆㫌㫅㫋㩷㫌㫇 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼

㸣㸣㸣㸣㸣

㪊㩷㫇㫃㪸㫐㩷㫆㫇㪼㫅 㪊㩷㫇㫃㪸㫐 㪊㩷㫇㫃㪸㫐 㪊㩷㫇㫃㪸㫐 㪊㩷㫇㫃㪸㫐

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇

㸣㸣㸣㸣㸣

㪺㫃㫆㫊㪼 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻

㸣㸣㸣㸣㸣

㪋㩷㫆㫇㪼㫅 㪋㩷㫇㫃㪸㫐 㪋㩷㫆㫇㪼㫅 㪋㩷㫆㫇㪼㫅 㪋㩷㫆㫇㪼㫅

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪚㫆㫌㫅㫋㩷㫌㫇 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㪺㫃㫆㫊㪼 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼

㸣㸣㸣㸣㸣

㪋㩷㫇㫃㪸㫐 㪋㩷㫇㫃㪸㫐㩷㫆㫇㪼㫅 㪋㩷㫇㫃㪸㫐 㪋㩷㫇㫃㪸㫐 㪋㩷㫇㫃㪸㫐

㸣㸣㸣㸣㸣

㪚㫆㫌㫅㫋㩷㫌㫇 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻

㸣㸣㸣㸣㸣

㪉㩷㫇㫃㪸㫐 㪉㩷㫇㫃㪸㫐 㪉㩷㫇㫃㪸㫐 㪉㩷㫇㫃㪸㫐 㪉㩷㫇㫃㪸㫐

㸣㸣㸣㸣㸣

㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇 㪚㫆㫌㫅㫋㩷㫌㫇

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻 㪉㩷㫇㫃㪸㫐㩷㫆㫇㪼㫅 㫌㫅㫃㫆㪸㪻 㫌㫅㫃㫆㪸㪻

㸣㸣㸣㸣㸣

㪉㩷㫆㫇㪼㫅 㪉㩷㫆㫇㪼㫅 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪉㩷㫆㫇㪼㫅 㪉㩷㫆㫇㪼㫅

㸣㸣㸣㸣㸣

㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪺㫃㫆㫊㪼 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋 㪌㪇㪇㫄㫊㩷㪮㪸㫀㫋

㸣㸣㸣㸣㸣

㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼 㫌㫅㫃㫆㪸㪻 㪺㫃㫆㫊㪼 㪺㫃㫆㫊㪼

㸣㸣㸣㸣㸣

26

6.6. Error Code Table

Self-Diagnosis Function (refer Section “6.4.1” Service Mode Table 1”) provides information on any problems occurring for the unit

and its respective components by displaying the error codes. These error code such as U**, H** and F** are stored in memory and

held unless it is cleared.

The error code is automatically display after entering into self-diagnostic mode.

6.6.1. CD Mechanism Unit (CR14C) Error Code Table

27

6.6.2. Error Code Table (For Power Supply)

28

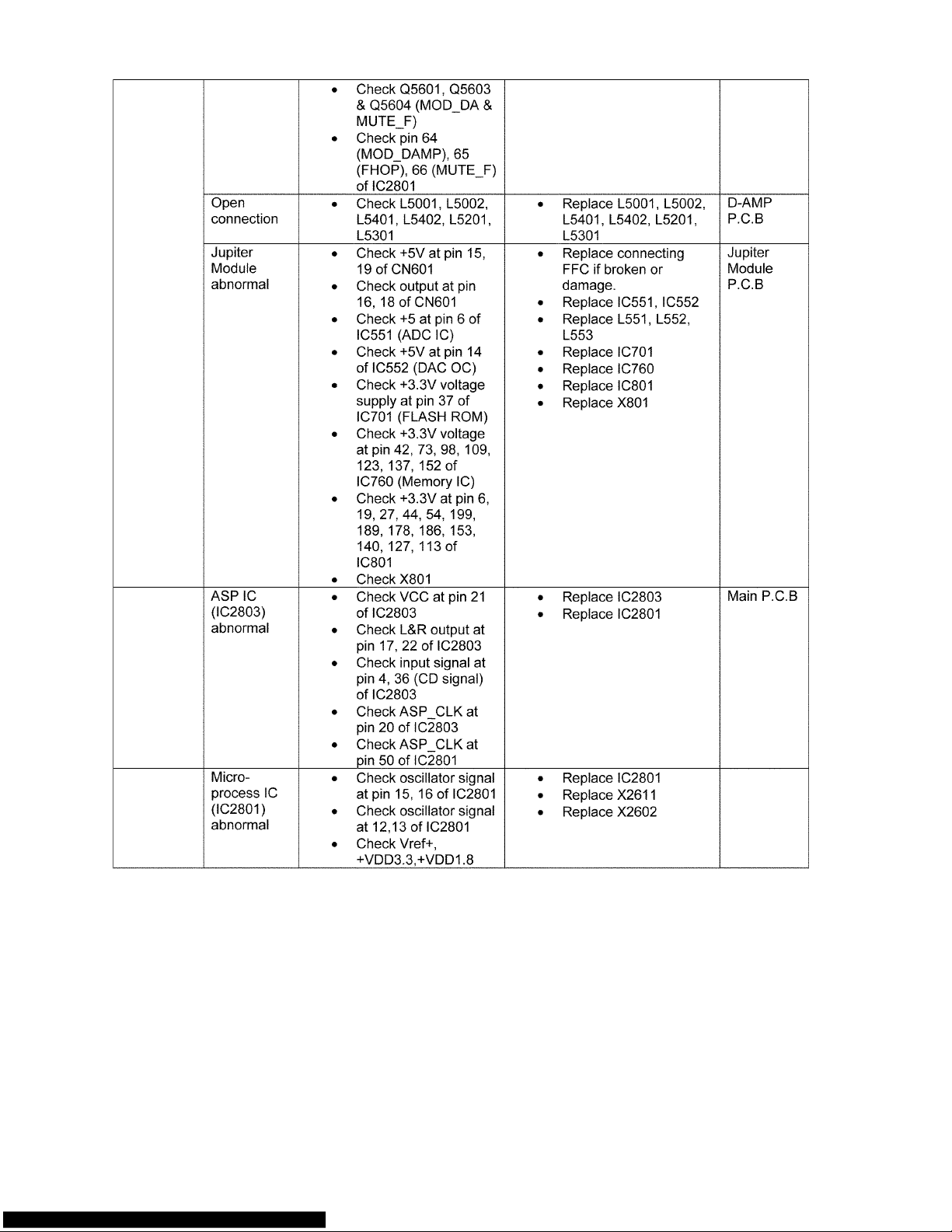

7 Troubleshooting Guide

7.1. Jupiter USB

29

7.2. Troubleshooting Guide

30

Loading...

Loading...