Panasonic S-200PE2E5, S-250PE2E5, U-250PE2E8A, S-100PU2E5A, S-125PU2E5A Service Manual

...

TECHNICAL DATA& SERVICE MANUAL

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Order No. SBPAC1607004CE

Outdoor UnitIndoor Unit

High Static Pressure

Ducted Type

Type E2

S-200PE2E5, S-250PE2E5

Type U2

S-100PU2E5A, S-125PU2E5A

4-Way Cassette Type

U-200PE2E8A, U-250PE2E8A

85464849352001

REFERENCE NO

.

SM830252-01

IMPORTANT!

WARNING

WARNING

…In a Snowy Area (for Heat Pump-

type Systems)

Install the outdoor unit on a raised

platform that is higher than drifting snow.

Provide snow vents.

…At least 2.5 m

Indoor unit of this air conditioner shall be

installed in a height of at least 2.5 m.

…In laundry rooms

Do not install in laundry rooms. Indoor

unit is not drip proof.

When Connecting Refrigerant Tubing

WARNING

WARNING

•

When performing piping work do not

mix air except for specified refrigerant

(R410A) in refrigeration cycle. It

causes capacity down, and risk of

explosion and injury due to high

tension inside the refrigerant cycle.

• Refrigerantgasleakagemaycausefire.

• Donotaddorreplacerefrigerant

other than specified type. It may

cause product damage, burst and

injury, etc.

• Ventilatetheroomwell,intheevent

that is refrigerant gas leaks during

the installation. Be careful not to allow

contact of the refrigerant gas with a

flame as this will cause the generation

of poisonous gas.

• Keepalltubingrunsasshortas

possible.

• Usetheflaremethodforconnecting

tubing.

• Applyrefrigerantlubricanttothe

matching surfaces of the flare and union

tubes before connecting them, then

tighten the nut with a torque wrench for

a leak-free connection.

• Checkcarefullyforleaksbeforestarting

the test run.

• Donotleakrefrigerantwhilepiping

work for an installation or re-installation,

and while repairing refrigeration parts.

Handle liquid refrigerant carefully as it

may cause frostbite.

When Servicing

• TurnthepowerOFFatthemain

power box (mains) before opening

the unit to check or repair electrical

parts and wiring.

• Keepyourfingersandclothingaway

from any moving parts.

• Cleanupthesiteafteryoufinish,

remembering to check that no metal

scraps or bits of wiring have been left

inside the unit being serviced.

WARNING

WARNING

• Thisproductmustnotbe

modified or disassembled under

any circumstances. Modified or

disassembled unit may cause fire,

electric shock or injury.

• Donotcleaninsidetheindoorand

outdoor units by users. Engage

authorized dealer or specialist for

cleaning.

• Incaseofmalfunctionofthis

appliance, do not repair by yourself.

Contact the sales dealer or service

dealer for repair.

WARNING

CAUTION

• Donottouchtheairinletorthe

sharp aluminum fins of the

outdoor unit. You may get injured.

• Ventilateanyenclosedareaswhen

installing or testing the refrigeration

system. Escaped refrigerant gas,

on contact with fire or heat, can

produce dangerously toxic gas.

• Confirmafterinstallationthatno

refrigerant gas is leaking. If the gas

comes in contact with a burning

stove, gas water heater, electric

room heater or other heat source,

it can cause the generation of

poisonous gas.

Others

WARNING

CAUTION

• Donotsitorstepontheunit,you

may fall down accidentally.

• Donottouchtheairinletorthe

sharp aluminum fins of the

outdoor unit. You may get injured.

• Donotstickanyobjectintothe

FAN CASE.

You may be injured and the unit

may be damaged.

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Please Read Before Starting

This air conditioner must be installed by the sales dealer

or installer.

This information is provided for use only by authorized

persons.

For safe installation and trouble-free operation, you must:

●

Carefully read this instruction booklet before beginning.

●

Follow each installation or repair step exactly as shown.

●

This air conditioner shall be installed in accordance with

National Wiring Regulations.

●

Pay close attention to all warning and caution notices

given in this manual.

WARNING

CAUTION

If Necessary, Get Help

These instructions are all you need for most installation

sites and maintenance conditions. If you require help for a

special problem, contact our sales/service outlet or your

certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for

improper installation or maintenance service, including

failure to follow the instructions in this document.

This symbol refers to a hazard or unsafe

practice which can result in severe

personal injury or death.

This symbol refers to a hazard or unsafe

practice which can result in personal injury

or product or property damage.

SPECIAL PRECAUTIONS

WARNING

When Wiring

•Donotsupplypowertotheunituntil

all wiring and tubing are completed or

reconnected and checked.

•Highlydangerouselectricalvoltagesare

used in this system.

Carefully refer to the wiring diagram and

these instructions when wiring. Improper

ELECTRICAL SHOCK CAN

CAUSE SEVERE PERSONAL

INJURY OR DEATH. ONLY A

QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD

ATTEMPT TO WIRE THIS

SYSTEM.

connections and inadequate grounding

can cause accidental injury or death.

•Connectallwiringtightly.Loosewiring

may cause overheating at connection

points and a possible fire hazard.

• Provide a power outlet to be used

exclusively for each unit.

• Provide a power outlet exclusively for

each unit, and full disconnection means

having a contact separation in all poles

must be incorporated in the fixed wiring

in accordance with the wiring rules.

• To prevent possible hazards from

insulation failure, the unit must be

grounded.

• This equipment is strongly recommended

When Transporting

Be careful when picking up and moving

the indoor and outdoor units. Get a partner

to help, and bend your knees when lifting

to reduce strain on your back. Sharp

edges or thin aluminum fins on the air

conditioner can cut your fingers.

When Installing…

to be installed with Earth Leakage

Circuit Breaker (ELCB) or Residual

Current Device (RCD). Otherwise, it may

cause electrical shock and fire in case

of equipment breakdown or insulation

breakdown.

Select an installation location which is

rigid and strong enough to support or hold

the unit, and select a location for easy

maintenance.

…In a Room

Properly insulate any tubing run inside a

room to prevent “sweating” that can cause

dripping and water damage to walls and

floors.

CAUTION

Keep the fire alarm and

the air outlet at least

1.5 m away from the unit.

…In Moist or Uneven Locations

Use a raised concrete pad or concrete

blocks to provide a solid, level foundation

for the outdoor unit. This prevents water

damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down

with bolts and a metal frame. Provide a

suitable air baffle.

i

…In a Snowy Area (for Heat Pump-

WARNING

WARNING

WARNING

WARNING

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

type Systems)

Install the outdoor unit on a raised

platform that is higher than drifting snow.

Provide snow vents.

…At least 2.5 m

Indoor unit of this air conditioner shall be

installed in a height of at least 2.5 m.

…In laundry rooms

Do not install in laundry rooms. Indoor

unit is not drip proof.

When Connecting Refrigerant Tubing

WARNING

•

When performing piping work do not

mix air except for specified refrigerant

(R410A) in refrigeration cycle. It

causes capacity down, and risk of

explosion and injury due to high

tension inside the refrigerant cycle.

• Refrigerantgasleakagemaycausefire.

• Donotaddorreplacerefrigerant

other than specified type. It may

cause product damage, burst and

injury, etc.

• Ventilatetheroomwell,intheevent

that is refrigerant gas leaks during

the installation. Be careful not to allow

contact of the refrigerant gas with a

flame as this will cause the generation

of poisonous gas.

• Keepalltubingrunsasshortas

possible.

• Usetheflaremethodforconnecting

tubing.

• Applyrefrigerantlubricanttothe

matching surfaces of the flare and union

tubes before connecting them, then

tighten the nut with a torque wrench for

a leak-free connection.

• Checkcarefullyforleaksbeforestarting

the test run.

• Donotleakrefrigerantwhilepiping

work for an installation or re-installation,

and while repairing refrigeration parts.

Handle liquid refrigerant carefully as it

may cause frostbite.

When Servicing

• TurnthepowerOFFatthemain

power box (mains) before opening

the unit to check or repair electrical

parts and wiring.

• Keepyourfingersandclothingaway

from any moving parts.

• Cleanupthesiteafteryoufinish,

remembering to check that no metal

scraps or bits of wiring have been left

inside the unit being serviced.

WARNING

• Thisproductmustnotbe

modified or disassembled under

any circumstances. Modified or

disassembled unit may cause fire,

electric shock or injury.

• Donotcleaninsidetheindoorand

outdoor units by users. Engage

authorized dealer or specialist for

cleaning.

• Incaseofmalfunctionofthis

appliance, do not repair by yourself.

Contact the sales dealer or service

dealer for repair.

CAUTION

• Donottouchtheairinletorthe

sharp aluminum fins of the

outdoor unit. You may get injured.

• Ventilateanyenclosedareaswhen

installing or testing the refrigeration

system. Escaped refrigerant gas,

on contact with fire or heat, can

produce dangerously toxic gas.

• Confirmafterinstallationthatno

refrigerant gas is leaking. If the gas

comes in contact with a burning

stove, gas water heater, electric

room heater or other heat source,

it can cause the generation of

poisonous gas.

Others

CAUTION

• Donotsitorstepontheunit,you

may fall down accidentally.

• Donottouchtheairinletorthe

sharp aluminum fins of the

outdoor unit. You may get injured.

• Donotstickanyobjectintothe

FAN CASE.

You may be injured and the unit

may be damaged.

ii

Check of Density Limit

The room in which the air conditioner is to be installed

—— CONTENTS ——

Section 1. SPECIFICATIONS .................................................................................................

1-1. Unit Specifications ...............................................................................................................

1-2. Major Component Specifications .......................................................................................

1-3. Other Component Specifications .....................................................................................

1-4. Dimensional Data ...............................................................................................................

1-5. Refrigerant Flow Diagram .................................................................................................

1-6. Operating Range ................................................................................................................

1-1

2-1

3-1

1-12

1-14

1-18

1-20

1-21

1-23

1-28

1-34

1-95

1-98

1-98

1-99

1-100

1-100

1-101

3-2

3-3

1-6

1-2

1-7. Capacity Correction Graph According to Temperature Condition ................................

1-8. Noise Criterion Curves ......................................................................................................

1-25

1-26

1-9. Airflow Distance Chart .......................................................................................................

1-10. Fresh Air Intake ................................................................................................................

1-11. ELECTRICAL WIRING ......................................................................................................

1-12. Installation Instructions ...................................................................................................

Section 2. TEST RUN .............................................................................................................

Section 3. ELECTRICAL DATA ..............................................................................................

3-2. Indoor Units (Electric Wiring Diagram) ..............................................................................

3-1. Outdoor Units (Electric Wiring Diagram) ...........................................................................

4-1

4-2

4-8

Section 4. PROCESS AND FUNCTIONS................................................................................

4-2. Outdoor Unit Control PCB (ACXA73-04770, ACXA73-04750)...........................................

4-1. Control Functions ................................................................................................................

5-1

5-2

5-4

Section 5. TROUBLE DIAGNOSIS.........................................................................................

5-5

5-32

5-33

5-34

5-35

5-36

5-37

5-38

5-1. Contents of Remote Controller Switch Alarm Display .....................................................

5-2. Outdoor Unit Control Panel LED Display ...........................................................................

5-3. PAC System Alarm Codes ...................................................................................................

5-4. Inspection of Parts (Outdoor Unit) ...................................................................................

5-5. Symptom: Thermostat in OFF continues or cycles OFF & ON too frequently..............

5-6. Sensor Temperature Display Function

(Displayed regardless of operation and stop)

...

5-7. Table of Thermistor Characteristics .................................................................................

5-8. How to Remove the Compressor ......................................................................................

5-9. How to Remove the Electrical Component Box ..............................................................

5-10. Symptom: Thermostat in OFF continues cycles OFF & ON too frequently.................

6-1

6-2

6-2

Section 6. OUTDOOR UNIT MAINTENANCE REMOTE CONTROLLER..............................

6-3

6-8

6-10

6-11

6-1. Overview ...............................................................................................................................

6-2. Functions .............................................................................................................................

6-3. Normal Display Operations and Functions ........................................................................

6-4.

Monitoring Operations: Display of Indoor Unit and Outdoor Unit Sensor Temperatures

...

6-5. Monitoring the Outdoor Unit Alarm History: Display of Outdoor Unit Alarm History...

6-6. Settings Modes: Setting the Outdoor Unit EEPROM ......................................................

2-2

2-22-2. Caution...................................................................................................................................

2-22-3. Test Run Procedure..............................................................................................................

2-32-4. Items to Check Before the Test Run...................................................................................

2-32-5. Test Run Using the Remote Controller...............................................................................

2-42-6. Precautions............................................................................................................................

2-52-7. Table of Self-Diagnostic Functions and Corrections.........................................................

2-62-8. System Control......................................................................................................................

2-122-9. Caution for Pump Down.....................................................................................................

2-1. Preparing for Test Run ........................................................................................................

Indoor Units

4-124-3. Outdoor Unit HIC Board (ACXA73-04760)........................................................................

4-134-4. Indoor Unit Control PCB Switches and Functions..........................................................

1-13. HOW TO PROCESS TUBING ...........................................................................................

1-14. VACUUM PURGING .........................................................................................................

1-15. REGARDING REFRIGERANT FILLING ...........................................................................

1-16. PRECAUTIONS REGARDING TEST RUN .......................................................................

1-17. CHECKS AFTER INSTALLATION HAVE COMPLETED ................................................

1-18. REGARDING DELIVERY TO THE CUSTOMER .............................................................

1-19. Supplement .....................................................................................................................

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

requires a design that in the event of refrigerant gas

leaking out, its density will not exceed a set limit.

The refrigerant (R410A), which is used in the air conditioner,

is safe, without the toxicity or combustibility of ammonia, and

is not restricted by laws imposed to protect the ozone layer.

However, since it contains more than air, it poses the risk of

suffocation if its density should rise excessively. Suffocation

from leakage of refrigerant is almost non-existent. With the

recent increase in the number of high density buildings,

however, the installation of multi air conditioner systems is

on the increase because of the need for effective use of floor

space, individual control, and energy conservation by curtailing

heat and carrying power, etc.

Most importantly, the multi air conditioner system is able

to replenish a large amount of refrigerant compared to

conventional individual air conditioners. If a single unit of the

multi air conditioner system is to be installed in a small room,

select a suitable model and installation procedure so that if the

refrigerant accidentally leaks out, its density does not reach the

limit (and in the event of an emergency, measures can be made

before injury can occur).

In a room where the density may exceed the limit, create an

opening with adjacent rooms, or install mechanical ventilation

combined with a gas leak detection device. The density is as

given below.

Min. volume of the indoor unit installed room (m

The density limit of refrigerant which is used in multi air

conditioners is 0.3 kg/m

NOTE

1. If there are 2 or more refrigerating systems in a single

refrigerating device, the amount of refrigerant should be as

charged in each independent device.

For the amount of charge in this example:

e.g., charged

amount (10 kg)

Total amount of refrigerant (kg)

< Density limit (kg/m

3

(ISO 5149).

Indoor unit

Room A Room B Room C Room D Room E Room F

The possible amount of leaked refrigerant gas in rooms A,

B and C is 10 kg.

The possible amount of leaked refrigerant gas in rooms D,

E and F is 15 kg.

3

)

Outdoor unit

e.g., charged

amount (15 kg)

2. The standards for minimum room volume are as follows.

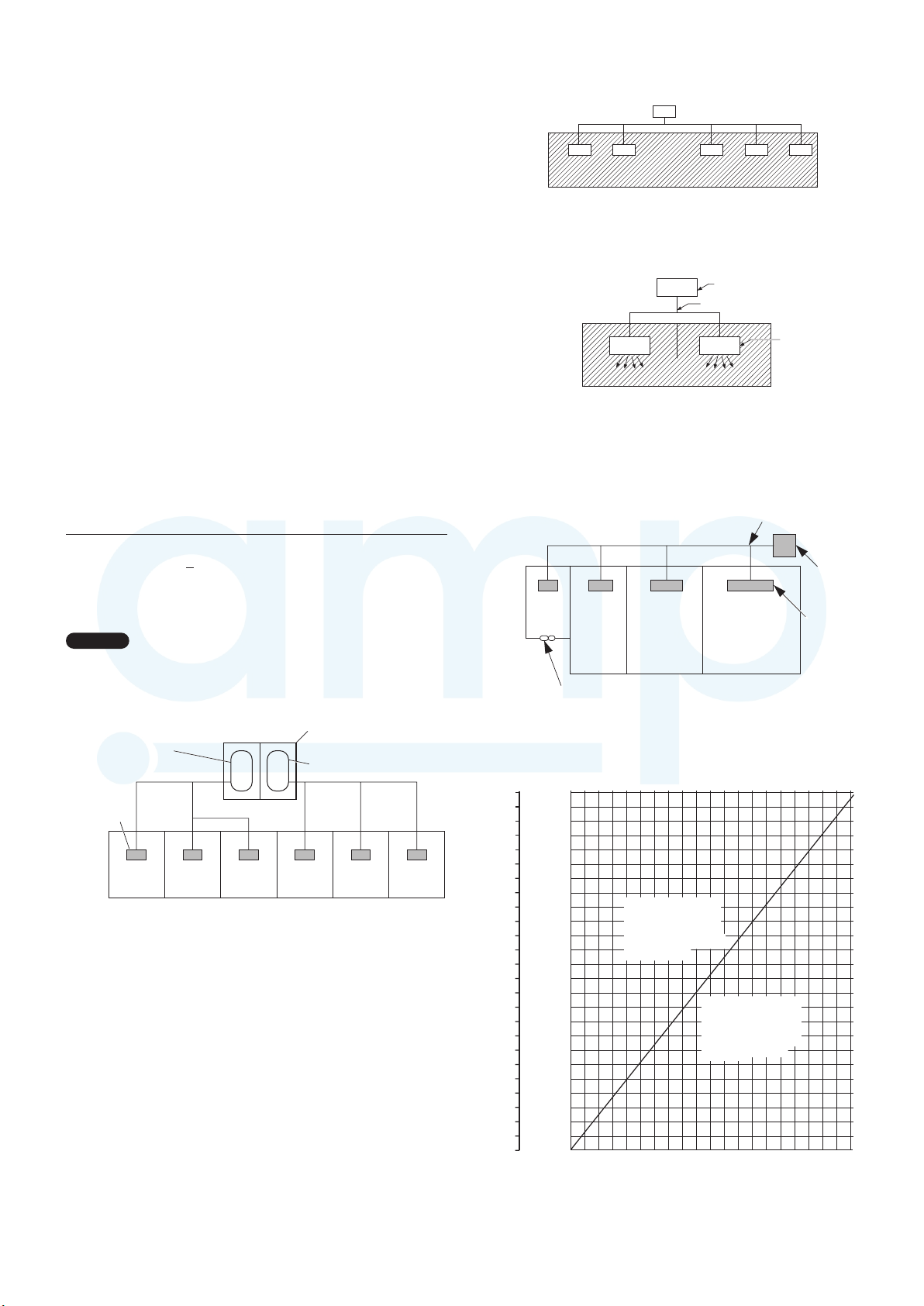

(1)No partition (shaded portion)

(2)When there is an effective opening with the adjacent room

for ventilation of leaking refrigerant gas (opening without

a door, or an opening 0.15% or larger than the respective

floor spaces at the top or bottom of the door).

Outdoor unit

Refrigerant tubing

Indoor unit

(3) If an indoor unit is installed in each partitioned room and

the refrigerant tubing is interconnected, the smallest room

of course becomes the object. But when mechanical

ventilation is installed interlocked with a gas leakage

detector in the smallest room where the density limit is

exceeded, the volume of the next smallest room becomes

the object.

3

)

Very

small

room

Small

room

Mechanical ventilation device – Gas leak detector

3. The minimum indoor floor space compared with the

amount of refrigerant is roughly as follows: (When the

ceiling is 2.7 m high)

3

2

m

m

337.5

125

324.0

120

310.5

115

297.0

110

283.5

105

100

270.0

95

256.0

90

243.0

85

229.5

80

216.0

75

202.5

70

189.0

65

175.5

60

162.0

55

148.5

50

135.0

Min. indoor volume

45

Min. indoor floor area

(when the ceiling is 2.7 m high)

121.5

40

108.0

35

94.5

30

25

20

15

10

81.0

67.5

54.0

40.5

27.0

5

13.5

0

0.0

Medium

room

Range below the

density limit of

0.3 kg/m³

(Countermeasures

not needed)

Range above the

density limit of 0.3

kg/m³

(Countermeasures

needed)

20100304060708090 10050

Total amount of refrigerant

Refrigerant tubing

Large room

iii

Outdoor unit

Indoor unit

kg

—— CONTENTS ——

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Section 1. SPECIFICATIONS .................................................................................................

1-1. Unit Specifications ...............................................................................................................

1-2. Major Component Specifications .......................................................................................

1-3. Other Component Specifications .....................................................................................

1-4. Dimensional Data ...............................................................................................................

1-5. Refrigerant Flow Diagram .................................................................................................

1-6. Operating Range ................................................................................................................

1-7. Capacity Correction Graph According to Temperature Condition ................................

1-8. Noise Criterion Curves ......................................................................................................

1-9. Airflow Distance Chart .......................................................................................................

1-10. Fresh Air Intake ................................................................................................................

1-11. ELECTRICAL WIRING ......................................................................................................

1-12. Installation Instructions ...................................................................................................

1-13. HOW TO PROCESS TUBING ...........................................................................................

1-14. VACUUM PURGING .........................................................................................................

1-15. REGARDING REFRIGERANT FILLING ...........................................................................

1-16. PRECAUTIONS REGARDING TEST RUN .......................................................................

1-17. CHECKS AFTER INSTALLATION HAVE COMPLETED ................................................

1-18. REGARDING DELIVERY TO THE CUSTOMER .............................................................

1-19. Supplement .....................................................................................................................

Section 2. TEST RUN .............................................................................................................

2-1. Preparing for Test Run ........................................................................................................

Indoor Units

Section 3. ELECTRICAL DATA ..............................................................................................

3-1. Outdoor Units (Electric Wiring Diagram) ...........................................................................

3-2. Indoor Units (Electric Wiring Diagram) ..............................................................................

Section 4. PROCESS AND FUNCTIONS................................................................................

4-1. Control Functions ................................................................................................................

4-2. Outdoor Unit Control PCB (ACXA73-04770, ACXA73-04750)...........................................

Section 5. TROUBLE DIAGNOSIS.........................................................................................

5-1. Contents of Remote Controller Switch Alarm Display .....................................................

5-2. Outdoor Unit Control Panel LED Display ...........................................................................

5-3. PAC System Alarm Codes ...................................................................................................

5-4. Inspection of Parts (Outdoor Unit) ...................................................................................

5-5. Symptom: Thermostat in OFF continues or cycles OFF & ON too frequently..............

5-6. Sensor Temperature Display Function

5-7. Table of Thermistor Characteristics .................................................................................

5-8. How to Remove the Compressor ......................................................................................

5-9. How to Remove the Electrical Component Box ..............................................................

5-10. Symptom: Thermostat in OFF continues cycles OFF & ON too frequently.................

(Displayed regardless of operation and stop)

...

Section 6. OUTDOOR UNIT MAINTENANCE REMOTE CONTROLLER..............................

6-1. Overview ...............................................................................................................................

6-2. Functions .............................................................................................................................

6-3. Normal Display Operations and Functions ........................................................................

6-4.

Monitoring Operations: Display of Indoor Unit and Outdoor Unit Sensor Temperatures

6-5. Monitoring the Outdoor Unit Alarm History: Display of Outdoor Unit Alarm History...

6-6. Settings Modes: Setting the Outdoor Unit EEPROM ......................................................

...

1-1

1-2

1-6

1-12

1-14

1-18

1-20

1-21

1-23

1-25

1-26

1-28

1-34

1-95

1-98

1-98

1-99

1-100

1-100

1-101

2-1

2-2

2-22-2. Caution...................................................................................................................................

2-22-3. Test Run Procedure..............................................................................................................

2-32-4. Items to Check Before the Test Run...................................................................................

2-32-5. Test Run Using the Remote Controller...............................................................................

2-42-6. Precautions............................................................................................................................

2-52-7. Table of Self-Diagnostic Functions and Corrections.........................................................

2-62-8. System Control......................................................................................................................

2-122-9. Caution for Pump Down.....................................................................................................

3-1

3-2

3-3

4-1

4-2

4-8

4-124-3. Outdoor Unit HIC Board (ACXA73-04760)........................................................................

4-134-4. Indoor Unit Control PCB Switches and Functions..........................................................

5-1

5-2

5-4

5-5

5-32

5-33

5-34

5-35

5-36

5-37

5-38

6-1

6-2

6-2

6-3

6-8

6-10

6-11

iv

Section 7. REMOTE CONTROLLER FUNCTIONS SECTION...............................................

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

7-1. Simple Settings Function ....................................................................................................

7-2. List of Simple Setting Items.................................................................................................

7-1

7-2

7-4

7-57-3. Detailed Settings Function ..................................................................................................

7-77-4. List of Detailed Setting Items ..............................................................................................

7-117-5. Simple Setting Items ..........................................................................................................

7-137-6. Detailed Setting Items ........................................................................................................

7-177-7. Remote Controller Servicing Functions ..........................................................................

7-197-8. Test Run Function ..............................................................................................................

Section 8. HOW TO INSTALL THE WIRELESS REMOTE CONTROLLER RECEIVER.......

Important Safety Instructions ...............................................................................................

Optional Controller (Remote Controller) ..............................................................................

8-1. Names and Functions ..........................................................................................................

8-2. Installing Batteries ...............................................................................................................

8-3. Setting the Current Time .....................................................................................................

8-4. Operation ..............................................................................................................................

8-5. Timer Operation ...................................................................................................................

8-6. Adjusting the Wind Direction ..............................................................................................

8-7. Operating Multiple In/Outdoor Units Simultaneously (Group Control) ..........................

8-8. Using the Remote Controller ..............................................................................................

8-9. For Best Results ..................................................................................................................

8-10. Addresses ..........................................................................................................................

8-11. Emergency Operation ......................................................................................................

8-12. Miscellaneous Settings ....................................................................................................

8-13. Before Requesting Service ..............................................................................................

How to Install the Wireless Remote Controller Receiver ..................................................

8-14. Common to All Models ....................................................................................................

8-15. CZ-RWSC3 ........................................................................................................................

8-16. CZ-RWSU3 ........................................................................................................................

8-17. Common to All Models ....................................................................................................

8-1

8-2

8-3

8-3

8-5

8-5

8-6

8-7

8-8

8-8

8-9

8-9

8-9

8-11

8-12

8-13

8-14

8-14

8-16

8-20

8-22

v

1. SPECIFICATIONS

1-1. Unit Specifications.....................................................................................................

1-2

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

11

1-2.Major Component Specifications .............................................................................

1-4. Dimensional Data .....................................................................................................

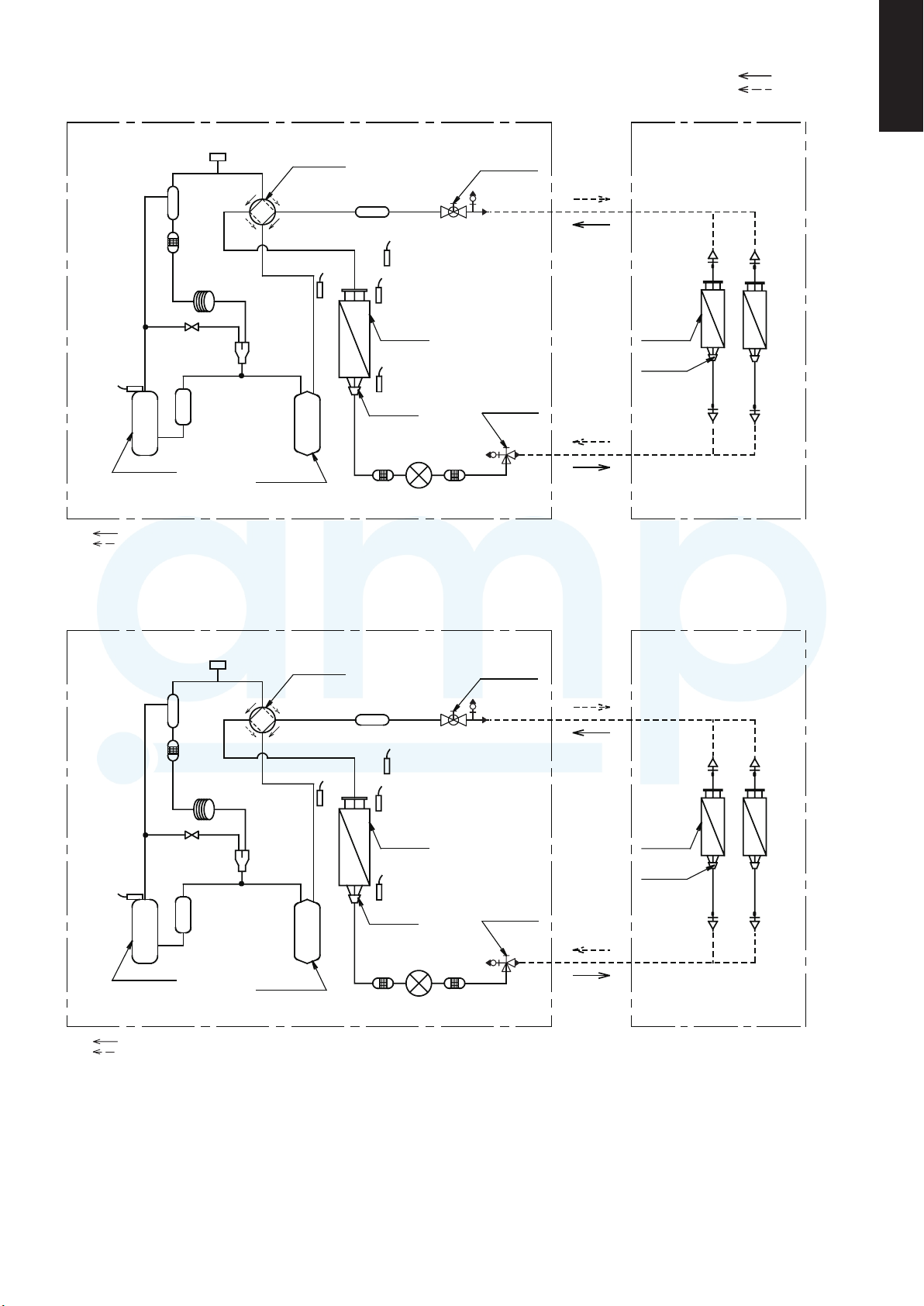

1-5. Refrigerant Flow Diagram .......................................................................................

1-6. Operating Range ......................................................................................................

1-7. Capacity Correction Graph According to Temperature Condition .....................

1-8. Noise Criterion Curves ............................................................................................

1-10. Fresh Air Intake .......................................................................................................

1-11. ELECTRICAL WIRING ..............................................................................................

1-12. Installation Instructions ..........................................................................................

Outdoor Unit

1. Tubing Length ....................................................................................................................................

2. Check of limit density .........................................................................................................................

3. SELECTING THE INSTALLATION SITE .......................................................................................... 1-40

4. INSTALLTION SERVICE SPACE ......................................................................................................

5. TRANSPORT AND INSTALL THE OUTDOOR UNIT ........................................................................

1-6

1-121-3. Other Component Specifications ...........................................................................

1-14

1-18

1-20

1-21

1-23

1-251-9. Airflow Distance Chart ............................................................................................

1-26

1-28

1-34

1-34

1-36

1-41

1-42

6. REFRIGERANT INSTALLATION .......................................................................................................

7. SELECTING THE LOCATION FOR INSTALLATION SERVICE .......................................................

Indoor Unit

Type E2

8. SELECTING THE INSTALLATION SITE .......................................................................................... 1-47

9. HOW TO INSTALL THE INDOOR UNIT ............................................................................................

Type U2

10. SELECTING THE INSTALLATION SITE ........................................................................................ 1-57

11. HOW TO INSTALL THE INDOOR UNIT ..........................................................................................

1-13. HOW TO PROCESS TUBING ...................................................................................

1-14. VACUUM PURGING .................................................................................................

1-15. REGARDING REFRIGERANT FILLING ...................................................................

1-16. PRECAUTIONS REGARDING TEST RUN ...............................................................

1-17. CHECKS AFTER INSTALLATION HAVE COMPLETED .......................................

1-18. REGARDING DELIVERY TO THE CUSTOMER ....................................................

1-43

1-46

1-48

1-58

1-95

1-98

1-98

1-99

1-100

1-100

1-1011-19. Supplement ............................................................................................................

1-1151-20. Capacity Table ........................................................................................................

1-1

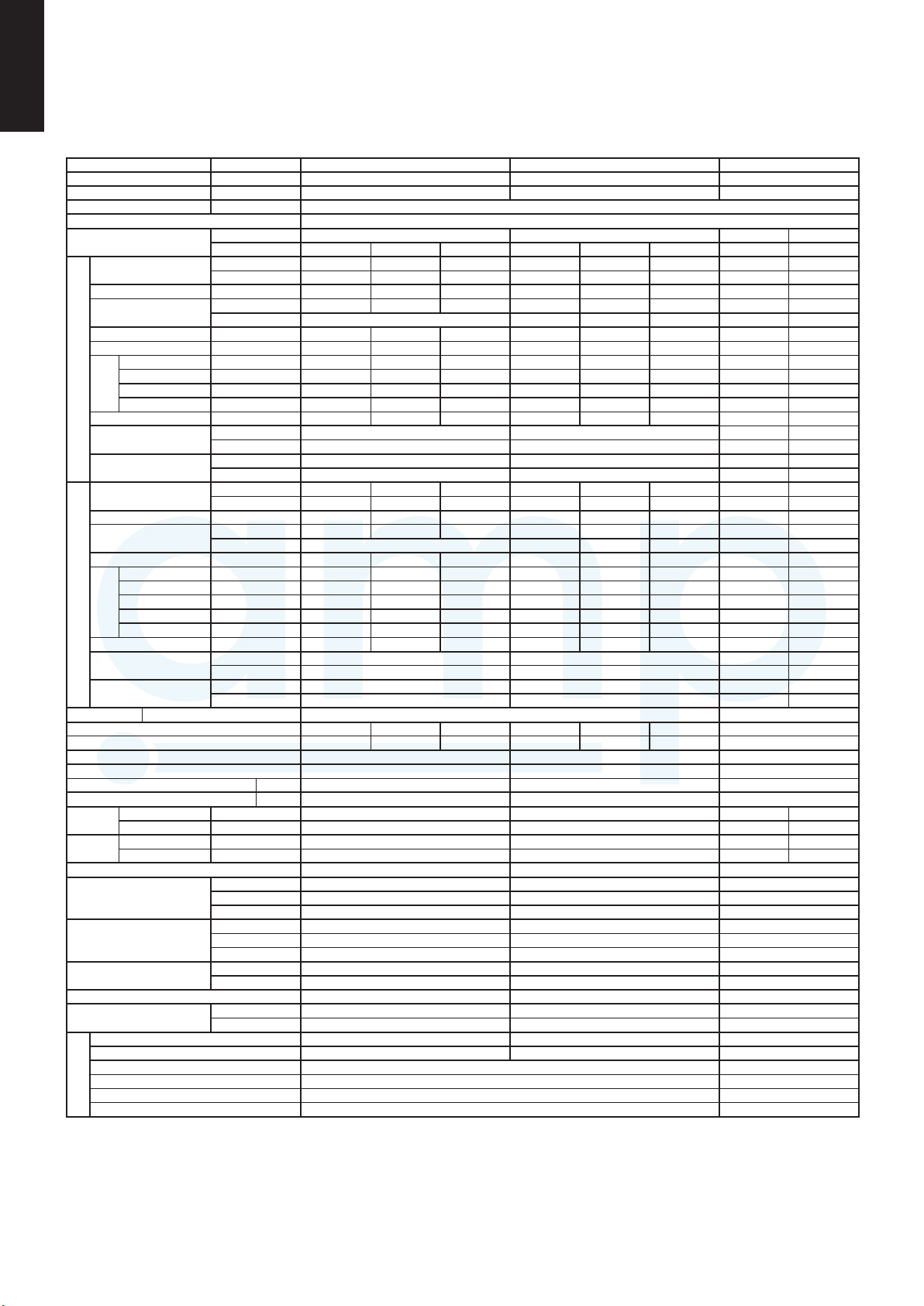

Single-Type

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

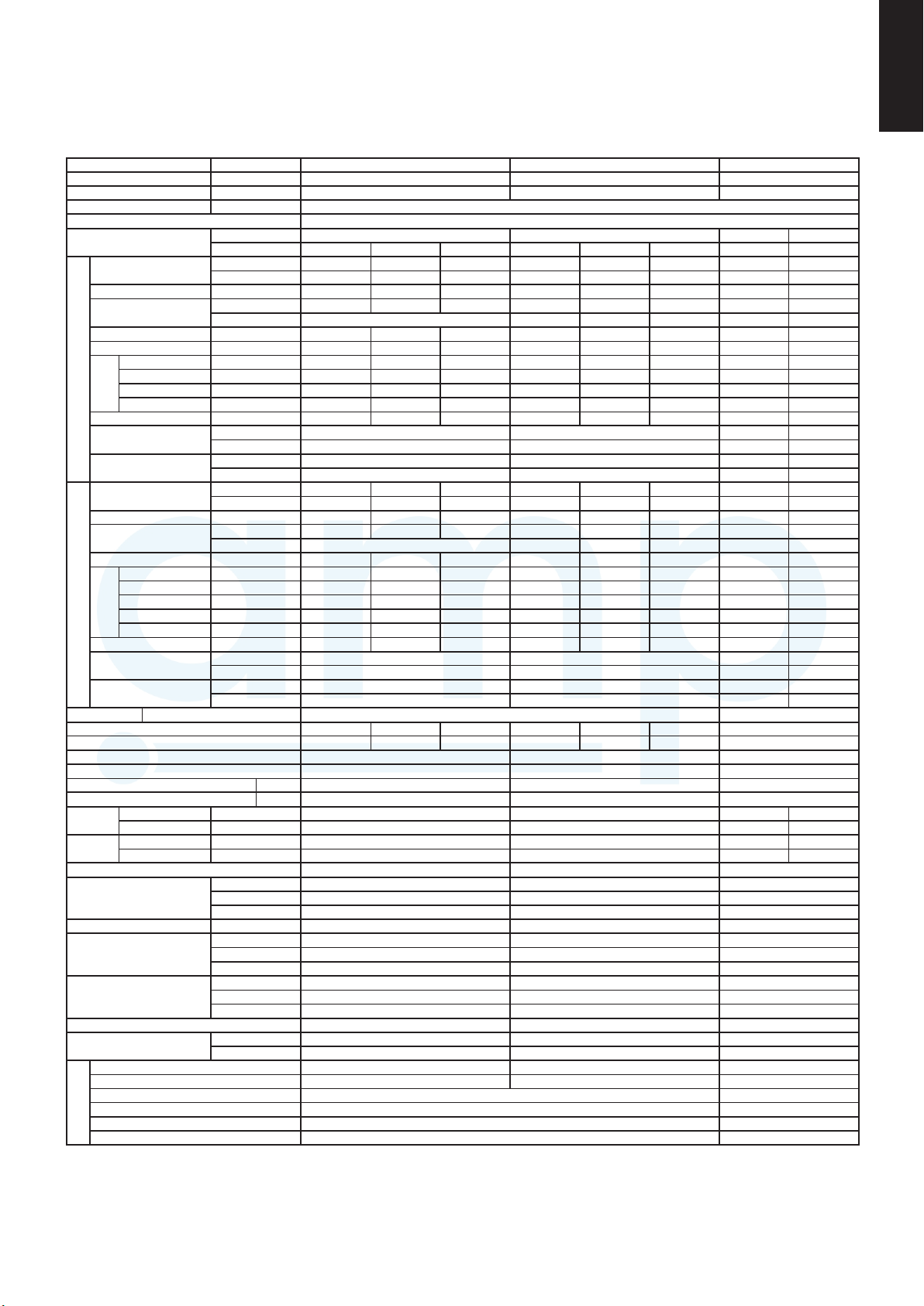

1-1. Unit Specications

High Static Pressure Ducted Type S-200PE2E5 / U-200PE2E8A

INDOOR MODEL S-200PE2E5 - -

PANEL MODEL - - -

OUTDOOR MODEL - U-200PE2E8A -

Branch pipe MODEL -

Performance test condition ISO13253 / EN14511 / EN12102

Power supply

Capacity

Current A 1.95 1.90 1.85 9.75 9.35 9.00 - -

Input power

C

Annual consumption TOTAL kWh *4 - - - - 3135 - - -

O

EER/EER CLASS

O

N

G

H

E

A

T

N

G

EXTRA LOW TEMP

Air ow

Outdoor

Air ow

P

P

N

G

*1 In case it is necessary to indicate the air ow volume in (l/s), the value in (m

*2 If the EUROVENT Certied models can be operated under the "extra-low" temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage

*3 Network Impedance shall be applicable for EUROPE and CHINA models.

*4 The annual consumption is calculated by multiplying the input power at 230V(400V) by an average of 500 hours per year in cooling mode.

*5 EER and COP classication is at 230V(400V) only in accordance with EU directive 2002/31/EC.

*6 SEER and SCOP classication is at 230V(400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Pdesign kW - - - - - - - -

L

SEER (W/W) - - - - - - - -

Erp

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 93 92 92 - -

Noise indoor

Noise outdoor

Capacity

Current A 1.95 1.90 1.85 9.85 9.45 9.10 - -

Input power

COP/COP CLASS

Pdesign at -10°C kW - - - - - - - Tbivalent °C - - - - - - - -

Erp

SCOP

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 93 92 92 - -

Noise indoor

Noise outdoor

Max Current(A) / Max Input power(W) 6.90/1.27k 6.60/1.27k 6.30/1.27k 20.0/12.2k 20.0/12.8k 20.0/13.2k Startring current(A) / Comp output(W) - - - 9.85/4.2k 9.45/4.2k 9.10/4.2k -

Fan motor output (Indoor/Outdoor) W 560 120 × 2 -

Indoor

Product dimension

Packing dimension

Operation condition

Connecting method, Standard length m (ft)

I

I

Indoor unit & Outdoor unit height difference m (ft)

230V shall be used.

Other che data indicates in an attached sheet.

Total capacity(kW)/Input power(W)/COP

Network Impedance(ΩMAX.) - - -

Moisture removal volume

External static pressure Pa 60 / (140/270) - -

Cooling

Heating

Cooling m

Heating m

Refrigerrant type / amount g(oz) - R410A 56.0k (197.5) -

Weight

Layers limit (actually) 4 (5) 1 (2) -

Pipe diameter mm (inch) (Liquid)Ø9.52(3/8) (Gas)Ø25.4(1) (Liquid)Ø9.52(3/8) (Gas)Ø25.4(1) -

Pipe length range m (ft) 5~120m (16.4~393.7) -

Add gas amount g/m (oz/ft) (Liquid)Ø9.52(3/8): 50g (0.54) -

Pipe length for additional gas m (ft) 30m (98.4) -

Ø, Hz 1Ø 50Hz 3Ø 50Hz

V 220V 230V 240V 380V 400V 415V Min Max

kW 19.5 19.5 19.5 - - - 5.4 22.4

BTU/h 66500 66500 66500 - - - 18400 76400

W 305 305 305 5.965k 5.965k 5.965k - -

TOTAL W - 6.270k 6.270k 6.270k - -

TOTAL (W/W) *5 / ("A"~"G")

kWh - - - - - - - -

dB-A (H/M/L) 43/41/38 - - -

Power Level dB 75/73/70 - - -

dB-A (H/L) - 60/- - -

Power Level dB - 78/- - -

kW 22.4 22.4 22.4 - - - 5.6 25.0

BTU/h 76400 76400 76400 - - - 19100 85300

W 305 305 305 6.015k 6.015k 6.015k - -

TOTAL W - 6.320k 6.320k 6.320k - -

TOTAL (W/W) *5/ ("A"~"G")

(W/W) - - - - - - - -

kWh - - - - - - - -

dB-A (H/M/L) 43/41/38 - - -

Power Level dB 75/73/70 - - -

dB-A (H/L) - 62/- - -

Power Level dB - 80/- - -

L/h(Pt/h)

m3/min (m3/h) (H/M/L)

m3/min (m3/h) (H/M/L)

3

/min (m3/h) - 164 (9840) - -

3

/min (m3/h) - 164 (9840) - -

Height

mm(inch)

mm(inch)

Width

mm(inch)

Depth

Height

mm(inch)

mm(inch)

Width

mm(inch)

Depth

(NET) kg(lb) 100 (221) 127 (280) -

(GROSS)

kg(lb) 132 (291) 139 (306) -

Cool (DBT) 18°C ~ 32°C -15°C ~ 46°C Heat (DBT) 16°C ~ 30°C -20°C ~ 24°C -

- - - 3.11 3.11/B 3.11 - -

- - - 3.54 3.54/B 3.54 - -

- -

11.1 (23.3) - -

56/51/44 (3360/3060/2640) - - 56/51/44 (3360/3060/2640) - - -

479 (18-27/32) 1500 (59-1/16) 1453 (57-7/32) 980 (38-37/64) 1205 (47-7/16) 370 (14-9/16) -

614 (24-3/16) 1642 (64-41/64) 1536 (60-15/32) 1095 (43-7/64) 1339 (52-23/32) 529 (20-53/64) -

(Liquid)&(Gas)brazing connection, 7.5(24.6)

30m(Outdoor unit located lower)/30m(Outdoor unit located higher) (98.4/98.4) -

3

/min.) shall be multiplied by 16.7 and rounded down the decimal point.

(Liquid)ared type (Gas)brazing connection, 7.5(24.6)

-

1-2

Single-Type

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

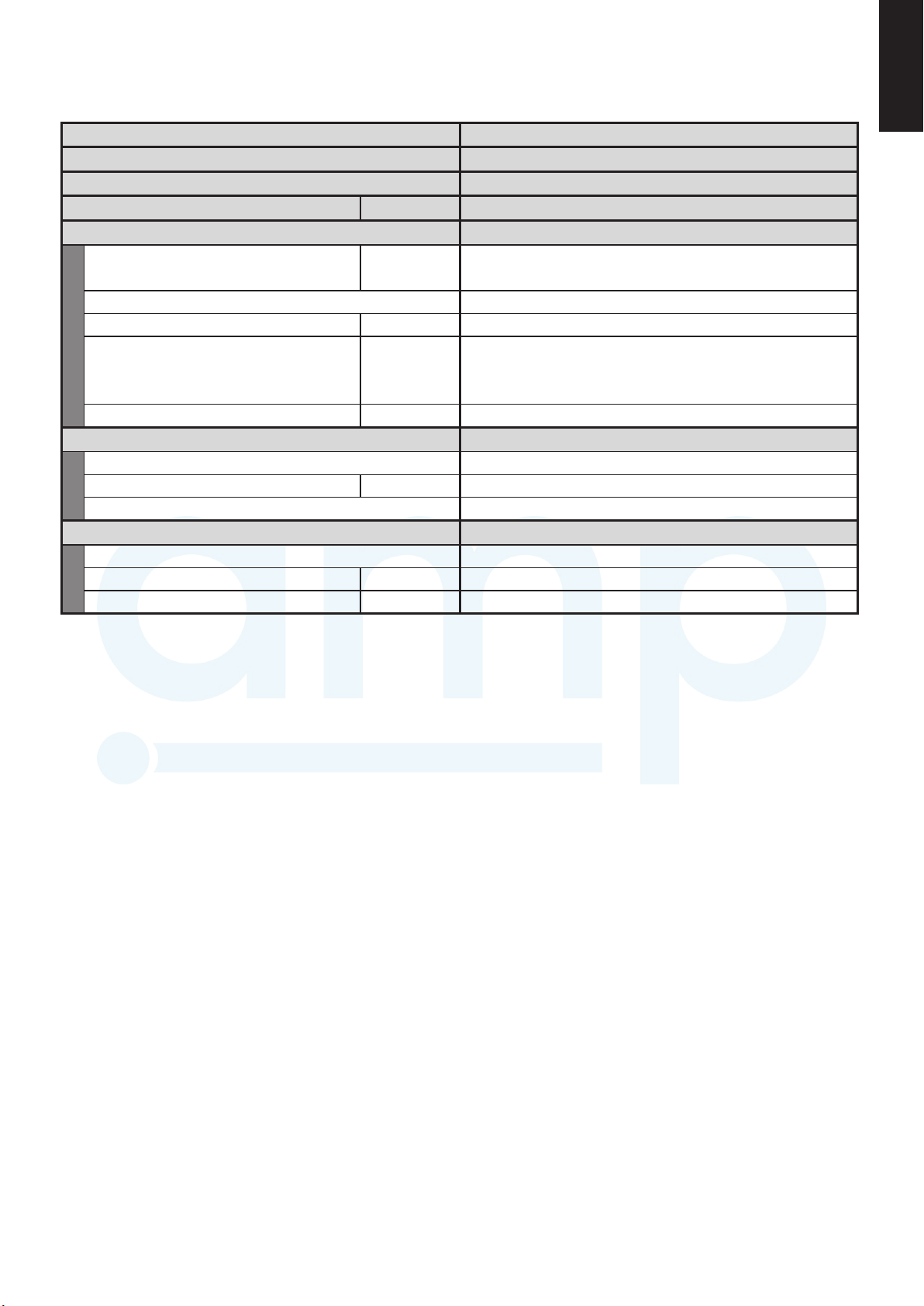

High Static Pressure Ducted Type S-250PE2E5 / U-250PE2E8A

INDOOR MODEL S-250PE2E5 - -

PANEL MODEL - - -

OUTDOOR MODEL - U-250PE2E8A -

Branch pipe MODEL -

Performance test condition ISO13253 / EN14511 / EN12102

Power supply

Capacity

Current A 3.30 3.20 3.10 13.0 12.5 12.0 - -

Input power

C

Annual consumption TOTAL kWh *4 - - - - 4300 - - -

O

EER/EER CLASS

O

N

G

H

E

A

T

N

G

EXTRA LOW TEMP

Air ow

Outdoor

Air ow

P

P

N

G

*1 In case it is necessary to indicate the air ow volume in (l/s), the value in (m

*2 If the EUROVENT Certied models can be operated under the "extra-low" temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage

*3 Network Impedance shall be applicable for EUROPE and CHINA models.

*4 The annual consumption is calculated by multiplying the input power at 230V(400V) by an average of 500 hours per year in cooling mode.

*5 EER and COP classication is at 230V(400V) only in accordance with EU directive 2002/31/EC.

*6 SEER and SCOP classication is at 230V(400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

Pdesign kW - - - - - - - -

L

SEER (W/W) - - - - - - - -

Erp

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 94 93 93 - -

Noise indoor

Noise outdoor

Capacity

Current A 3.30 3.20 3.10 11.5 11.1 10.7 - -

Input power

COP/COP CLASS

Pdesign at -10°C kW - - - - - - - Tbivalent °C - - - - - - - -

Erp

SCOP

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 94 93 93 - -

Noise indoor

Noise outdoor

Max Current(A) / Max Input power(W) 7.30/1.66k 7.30/1.74k 7.30/1.81k 20.0/12.4k 20.0/12.9k 20.0/13.4k Startring current(A) / Comp output(W) - - - 13.0/5.5k 12.5/5.5k 12.0/5.5k -

Fan motor output (Indoor/Outdoor) W 750 120 × 2 -

Indoor

Product dimension

Packing dimension

Operation condition

Connecting method, Standard length m (ft)

I

I

Indoor unit & Outdoor unit height difference m (ft)

230V shall be used.

Other che data indicates in an attached sheet.

Total capacity(kW)/Input power(W)/COP

Network Impedance(ΩMAX.) - - -

Moisture removal volume

External static pressure Pa 72 / (140/270) - -

Cooling

Heating

Cooling m

Heating m

Refrigerrant type / amount g(oz) - R410A 6.4k (225.8) -

Weight

Layers limit (actually) 4 (5) 1 (2) -

Pipe diameter mm (inch) (Liquid)Ø12.7(1/2) (Gas)Ø25.4(1) (Liquid)Ø12.7(1/2) (Gas)Ø25.4(1) -

Pipe length range m (ft) 5~120m (16.4~393.7) -

Add gas amount g/m (oz/ft) (Liquid)Ø12.7(1/2): 80g (0.860) -

Pipe length for additional gas m (ft) 30m (98.4) -

Ø, Hz 1Ø 50Hz 3Ø 50Hz

V 220V 230V 240V 380V 400V 415V Min Max

kW 25.0 25.0 25.0 - - - 6.3 28.0

BTU/h 85300 85300 85300 - - - 21500 95500

W 560 560 560 8.040k 8.040k 8.040k - -

TOTAL W - 8.600k 8.600k 8.600k - -

TOTAL (W/W) *5 / ("A"~"G")

kWh - - - - - - - -

dB-A (H/M/L) 47/45/42 - - -

Power Level dB 79/77/74 - - -

dB-A (H/L) - 61/- - -

Power Level dB - 80/- - -

kW 28.0 28.0 28.0 - - - 7.1 31.5

BTU/h 95500 95500 95500 - - - 24200 107500

W 560 560 560 7.140k 7.140k 7.140k - -

TOTAL W - 7.700k 7.700k 7.700k - -

TOTAL (W/W) *5/ ("A"~"G")

(W/W) - - - - - - - -

kWh - - - - - - - -

dB-A (H/M/L) 47/45/42 - - -

Power Level dB 79/77/74 - - -

dB-A (H/L) - 63/- - -

Power Level dB - 82/- - -

L/h(Pt/h)

m3/min (m3/h) (H/M/L)

m3/min (m3/h) (H/M/L)

3

/min (m3/h) - 160 (9600) - -

3

/min (m3/h) - 160 (9600) - -

Height

mm(inch)

mm(inch)

Width

mm(inch)

Depth

Height

mm(inch)

mm(inch)

Width

mm(inch)

Depth

(NET) kg(lb) 104 (230) 138 (304) -

(GROSS)

kg(lb) 136 (300) 150 (331) -

Cool (DBT) 18°C ~ 32°C -15°C ~ 46°C Heat (DBT) 16°C ~ 30°C -20°C ~ 24°C -

- - - 2.91 2.91/C 2.91 - -

- - - 3.64 3.64/A 3.64 - -

- -

13.9 (29.2) - -

72/63/53 (4320/3780/3180) - - 72/63/53 (4320/3780/3180) - - -

479 (18-27/32) 1500 (59-1/16) 1453 (57-7/32) 980 (38-37/64) 1205 (47-7/16) 370 (14-9/16) -

614 (24-3/16) 1642 (64-41/64) 1536 (60-15/32) 1095 (43-7/64) 1339 (52-23/32) 529 (20-53/64) -

(Liquid)ared type (Gas)brazing connection, 7.5(24.6) (Liquid)ared type (Gas)brazing connection, 7.5(24.6)

30m(Outdoor unit located lower)/30m(Outdoor unit located higher) (98.4/98.4) -

3

/min.) shall be multiplied by 16.7 and rounded down the decimal point.

-

11

1-3

Twin-Type

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

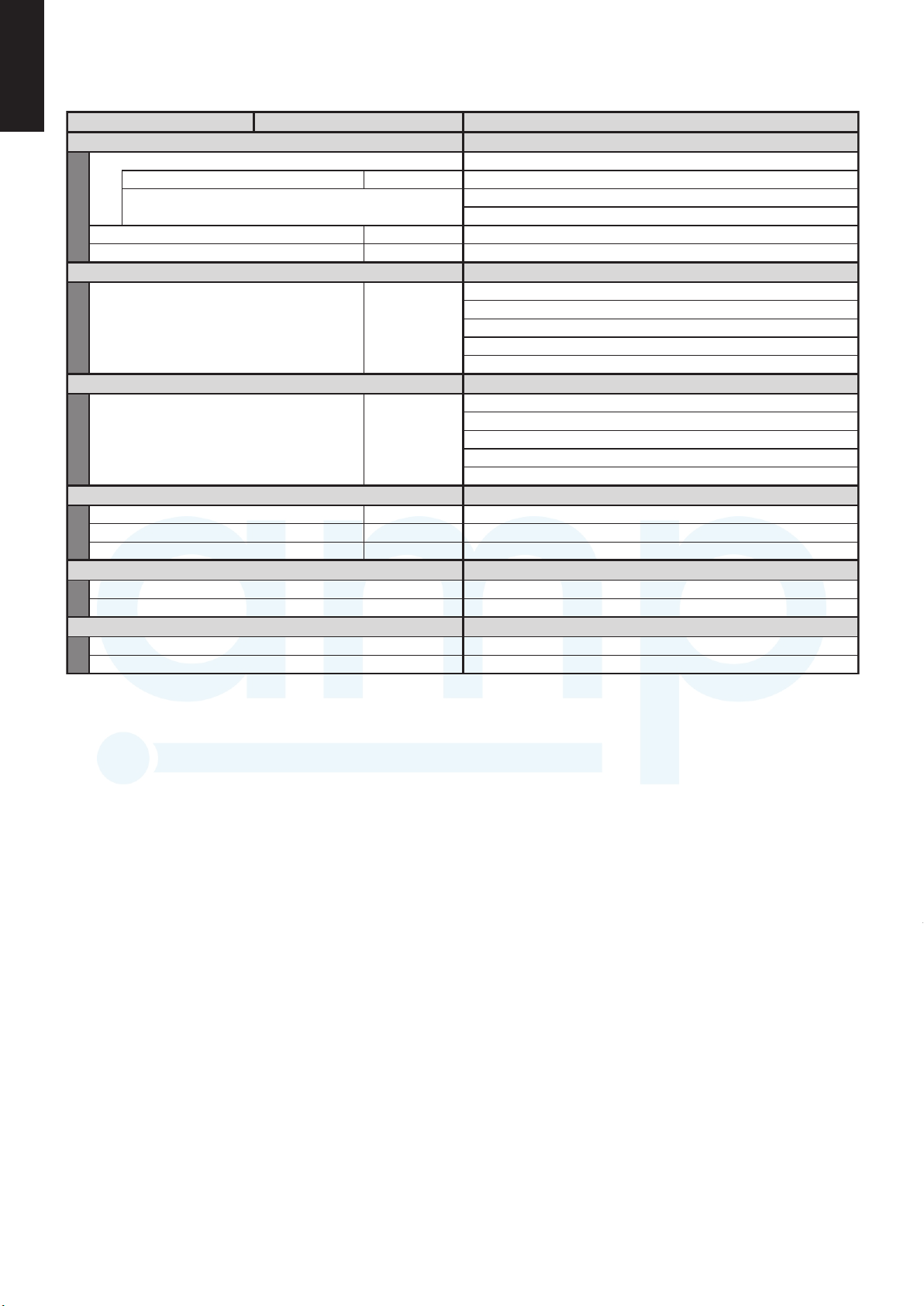

4-Way Cassette Type S-100PU2E5A ×2 / U-200PE2E8A

INDOOR MODEL S-100PU2E5A×2 - -

PANEL MODEL

OUTDOOR MODEL - U-200PE2E8A -

Branch pipe MODEL -

Performance test condition ISO5151 / EN14511 / EN12102

Power supply

Capacity

Current A 0.82 ×2 0.79 ×2 0.76 ×2 9.70 9.30 9.00 - -

Input power

C

Annual consumption TOTAL kWh *4 - - - - 3020 - - -

O

EER/EER CLASS

O

N

G

H

E

A

T

N

G

EXTRA LOW TEMP

Air ow *7

Outdoor

Air ow

Product dimension (Panel) H×W×D

P

P

N

G

*1 In case it is necessary to indicate the air ow volume in (l/s), the value in (m

*2

*3 Network Impedance shall be applicable for EUROPE and CHINA models.

*4 The annual consumption is calculated by multiplying the input power at 230V(400V) by an average of 500 hours per year in cooling mode.

*5 EER and COP classication is at 230V(400V) only in accordance with EU directive 2002/31/EC.

*6 SEER and SCOP classication is at 230V(400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

*7 H: High at setting 5 stage (Level 5), M: Middle at setting 5 stage (Level 3), L: Low at setting 5 stage (Level 1)

Pdesign kW - - - - - - - -

L

SEER (W/W) - - - - - - - -

Erp

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 93 92 92 - -

Noise indoor

Noise outdoor

Capacity

Current A 0.81 ×2 0.78 ×2 0.75 ×2 8.55 8.20 7.90 - -

Input power

COP/COP CLASS

Pdesign at -10°C kW - - - - - - - Tbivalent °C - - - - - - - -

Erp

SCOP

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 92 91 91 - -

Noise indoor

Noise outdoor

Max Current(A) / Max Input power(W)

Startring current(A) / Comp output(W) - - - 9.70/4.2k 9.30/4.2k 9.0/4.2k -

Fan motor output (Indoor/Outdoor) W 90 120 × 2 -

Indoor

Product dimension

Packing dimension

Operation condition

Connecting method, Standard length m (ft) ared type, 7.5(24.6)

I

I

Indoor unit & Outdoor unit height difference m (ft)

If the EUROVENT Certied models can be operated under the "extra-low" temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage 230V shall be used.

Other che data indicates in an attached sheet.

Total capacity(kW)/Input power(W)/COP

Network Impedance(ΩMAX.) - - -

Moisture removal volume

External static pressure Pa - - -

Cooling

Heating

Cooling m

Heating m

Refrigerrant type / amount g(oz) - R410A 5.60k (197.5) -

Weight

Layers limit (actually) 11 (12) 1 (2) -

Pipe diameter mm (inch) (Liquid)Ø9.52(3/8) (Gas)Ø15.88(5/8) (Liquid)Ø9.52(3/8) (Gas)Ø25.4(1) -

Pipe length range m (ft) 5~120m (16.4~393.7) -

Add gas amount g/m (oz/ft) (Liquid)Ø9.52(3/8): 50g (0.54) -

Pipe length for additional gas m (ft) 30m (98.4) -

Ø, Hz 1Ø 50Hz 3Ø 50Hz

V 220V 230V 240V 380V 400V 415V Min Max

kW 20.0 20.0 20.0 - - - 5.4 22.4

BTU/h 68200 68200 68200 - - - 18400 76400

W 100 ×2 100 ×2 100 ×2 5.940k 5.940k 5.940k - -

TOTAL W - 6.040k 6.040k 6.040k - -

TOTAL (W/W) *5 / ("A"~"G")

kWh - - - - - - - -

dB-A (H/M/L) *7 45/38/32 - - -

Power Level dB 60/53/47 - - -

dB-A (H/L) - 60/- - -

Power Level dB - 78/- - -

kW 22.4 22.4 22.4 - - - 5.6 25.0

BTU/h 76400 76400 76400 - - - 19100 85300

W 95 ×2 95 ×2 95 ×2 5.165k 5.165k 5.165k - -

TOTAL W - 5.260k 5.260k 5.260k - -

TOTAL (W/W) *5/ ("A"~"G")

(W/W) - - - - - - - -

kWh - - - - - - - -

dB-A (H/M/L) *7 45/38/32 - - -

Power Level dB 60/53/47 - - -

dB-A (H/L) - 62/- - -

Power Level dB - 80/- - -

m3/min (m3/h) (H/M/L)

m3/min (m3/h) (H/M/L)

3

/min (m3/h) - 164 (9840) - -

3

/min (m3/h) - 164 (9840) - -

Height

Width

Depth

Height

Width

Depth

(NET) kg(lb) 25 (55) 127 (280) (GROSS)

Panel (NET) kg(lb) 5 (11) - -

Cool (DBT) 18°C ~ 32°C -15°C ~ 46°C Heat (DBT) 16°C ~ 30°C -20°C ~ 24°C -

Standard type: CZ-KPU3 / ECONAVI type: CZ-KPU3A

- - - 3.31 3.31/A 3.31 - -

- - - 4.26 4.26/A 4.26 - -

0.82 ×2/ 100 ×2 0.79 ×2/ 100 ×2

L/h(Pt/h)

mm(inch)

mm(inch)

mm(inch)

mm(inch)

33.5×950×950 (1-11/32 × 37-13/32 × 37-13/32)

mm(inch)

mm(inch)

mm(inch)

kg(lb) 32 (71) 139 (306) -

5.4 (2.7×2) (11.3) - -

36/26/18×2 (2160/1560/1080 ×2) - - 36/26/18×2 (2160/1560/1080 ×2) - - -

319 (12-9/16) 1500 (59-1/16) 840 (33-5/64) 980 (38-37/64) 840 (33-5/64) 370 (14-9/16) -

365 (14-3/8) 1642 (64-41/64) 898 (35-3/8) 1095 (43-7/64) 898 (35-3/8) 529 (20-53/64) -

30m(Outdoor unit located lower)/30m(Outdoor unit located higher) (98.4/98.4) -

0.76 ×2/ 100 x2

3

/min.) shall be multiplied by 16.7 and rounded down the decimal point.

- -

20.0/12.2k 20.0/12.8k 20.0/13.2k -

(Liquid)ared type (Gas)brazing connection, 7.5(24.6)

- -

- -

1-4

-

Twin-Type

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

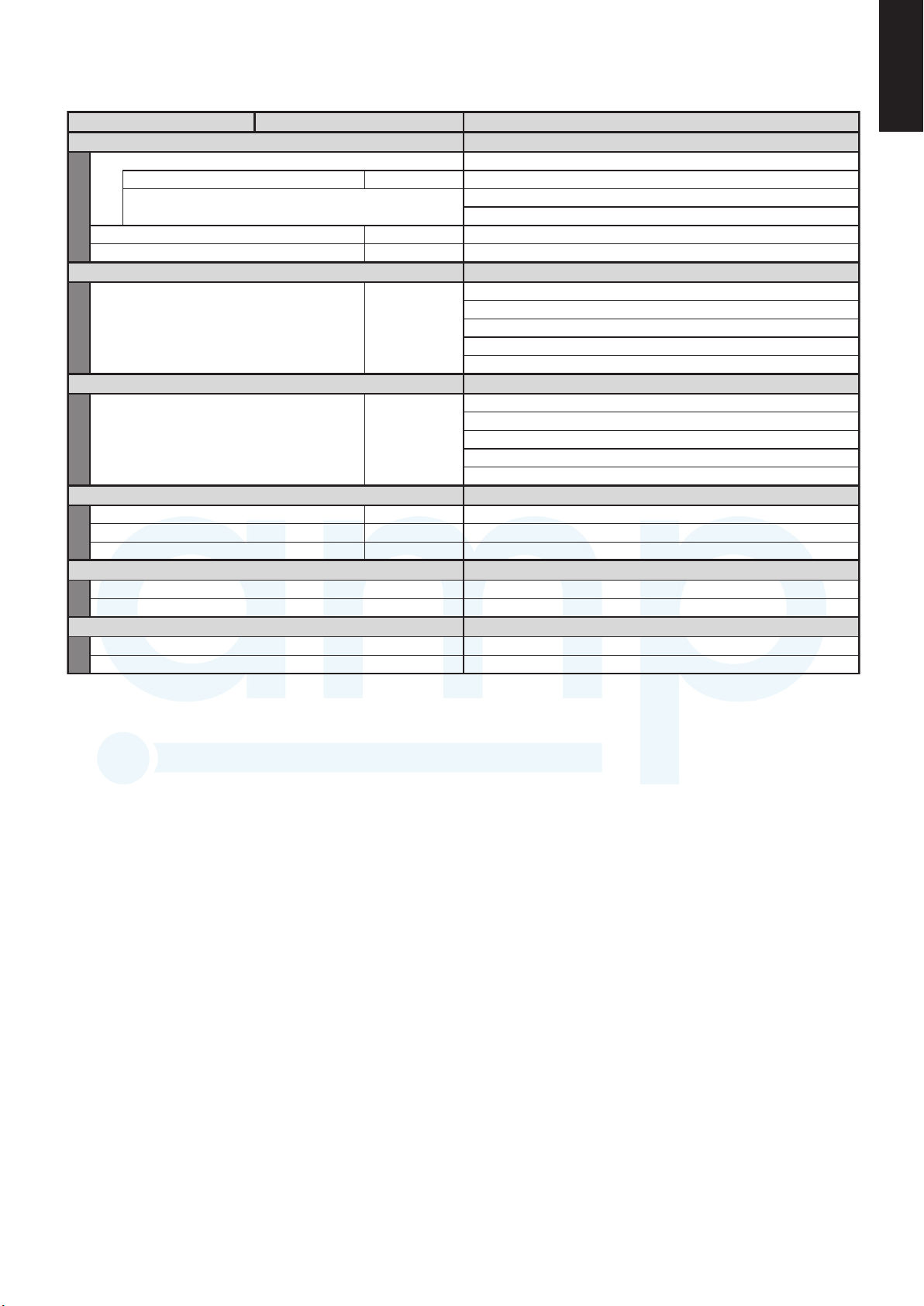

4-Way Cassette Type S-125PU2E5A ×2 / U-250PE2E8A

INDOOR MODEL S-125PU2E5A×2 - -

PANEL MODEL

OUTDOOR MODEL - U-250PE2E8A -

Branch pipe MODEL -

Performance test condition ISO5151 / EN14511 / EN12102

Power supply

Capacity

Current A 0.91 ×2 0.88 ×2 0.85 ×2 13.6 13.1 12.6 - -

Input power

C

Annual consumption TOTAL kWh *4 - - - - 4265 - - -

O

EER/EER CLASS

O

N

G

H

E

A

T

N

G

EXTRA LOW TEMP

Air ow *7

Outdoor

Air ow

Product dimension (Panel) H×W×D

P

P

N

G

*1 In case it is necessary to indicate the air ow volume in (l/s), the value in (m

*2

*3 Network Impedance shall be applicable for EUROPE and CHINA models.

*4 The annual consumption is calculated by multiplying the input power at 230V(400V) by an average of 500 hours per year in cooling mode.

*5 EER and COP classication is at 230V(400V) only in accordance with EU directive 2002/31/EC.

*6 SEER and SCOP classication is at 230V(400V) only in accordance with EN-14825. For heating, SCOP indicates the value of only Average heating season,

*7 H: High at setting 5 stage (Level 5), M: Middle at setting 5 stage (Level 3), L: Low at setting 5 stage (Level 1)

Pdesign kW - - - - - - - -

L

SEER (W/W) - - - - - - - -

Erp

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 94 93 93 - -

Noise indoor

Noise outdoor

Capacity

Current A 0.90 ×2 0.87 ×2 0.84 ×2 11.6 11.1 10.7 - -

Input power

COP/COP CLASS

Pdesign at -10°C kW - - - - - - - Tbivalent °C - - - - - - - -

Erp

SCOP

I

*6

Annual consumption

Class - - - - - - - -

Power factor % - - - 93 92 92 - -

Noise indoor

Noise outdoor

Max Current(A) / Max Input power(W)

Startring current(A) / Comp output(W) - - - 13.6/5.5k 13.1/5.5k 12.6/5.5k -

Fan motor output (Indoor/Outdoor) W 90 120 × 2 -

Indoor

Product dimension

Packing dimension

Operation condition

Connecting method, Standard length m (ft) ared type, 7.5(24.6)

I

I

Indoor unit & Outdoor unit height difference m (ft)

If the EUROVENT Certied models can be operated under the "extra-low" temperature condition, -7°C dry bulb and -8°C wet-bulb temperatures with rated voltage 230V shall be used.

Other che data indicates in an attached sheet.

Total capacity(kW)/Input power(W)/COP

Network Impedance(ΩMAX.) - - -

Moisture removal volume

External static pressure Pa - - -

Cooling

Heating

Cooling m

Heating m

Refrigerrant type / amount g(oz) - R410A 6.40k (225.8) -

Weight

Layers limit (actually) 11 (12) 1 (2) -

Pipe diameter mm (inch) (Liquid)Ø9.52(3/8) (Gas)Ø15.88(5/8) (Liquid)Ø12.7(1/2) (Gas)Ø25.4(1) -

Pipe length range m (ft) 5~120m (16.4~393.7) -

Add gas amount g/m (oz/ft) (Liquid)Ø12.7(1/2): 80g (0.860) -

Pipe length for additional gas m (ft) 30m (98.4) -

Ø, Hz 1Ø 50Hz 3Ø 50Hz

V 220V 230V 240V 380V 400V 415V Min Max

kW 25.0 25.0 25.0 - - - 6.3 28.0

BTU/h 85300 85300 85300 - - - 21500 95500

W 110 ×2 110 ×2 110 ×2 8.420k 8.420k 8.420k - -

TOTAL W - 8.530k 8.530k 8.530k - -

TOTAL (W/W) *5 / ("A"~"G")

kWh - - - - - - - -

dB-A (H/M/L) *7 46/39/33 - - -

Power Level dB 61/54/48 - - -

dB-A (H/L) - 61/- - -

Power Level dB - 80/- - -

kW 28.0 28.0 28.0 - - - 7.1 31.5

BTU/h 95500 95500 95500 - - - 24200 107500

W 105 ×2 105 ×2 105 ×2 7.095k 7.095k 7.095k - -

TOTAL W - 7.200k 7.200k 7.200k - -

TOTAL (W/W) *5/ ("A"~"G")

(W/W) - - - - - - - -

kWh - - - - - - - -

dB-A (H/M/L) *7 46/39/33 - - -

Power Level dB 61/54/48 - - -

dB-A (H/L) - 63/- - -

Power Level dB - 82/- - -

m3/min (m3/h) (H/M/L)

m3/min (m3/h) (H/M/L)

3

/min (m3/h) - 160 (9600) - -

3

/min (m3/h) - 160 (9600) - -

Height

Width

Depth

Height

Width

Depth

(NET) kg(lb) 25 (55) 138 (304) (GROSS)

Panel (NET) kg(lb) 5 (11) - -

Cool (DBT) 18°C ~ 32°C -15°C ~ 46°C Heat (DBT) 16°C ~ 30°C -20°C ~ 24°C -

Standard type: CZ-KPU3 / ECONAVI type: CZ-KPU3A

- - - 2.93 2.93/C 2.93 - -

- - - 3.89 3.89/A 3.89 - -

0.91 ×2/ 110 ×2 0.88 ×2/ 110 ×2

L/h(Pt/h)

mm(inch)

mm(inch)

mm(inch)

mm(inch)

33.5×950×950 (1-11/32 × 37-13/32 × 37-13/32)

mm(inch)

mm(inch)

mm(inch)

kg(lb) 32 (71) 150 (331) -

9.6 (4.8×2) (20.2) - -

37/27/19 ×2 (2220/1620/1140 ×2) - - 37/27/19 ×2 (2220/1620/1140 ×2) - - -

319 (12-9/16) 1500 (59-1/16) 840 (33-5/64) 980 (38-37/64) 840 (33-5/64) 370 (14-9/16) -

365 (14-3/8) 1642 (64-41/64) 898 (35-3/8) 1095 (43-7/64) 898 (35-3/8) 529 (20-53/64) -

30m(Outdoor unit located lower)/30m(Outdoor unit located higher) (98.4/98.4) -

0.85 ×2/ 110 ×2

3

/min.) shall be multiplied by 16.7 and rounded down the decimal point.

- -

20.0/12.4k 20.0/12.9k 20.0/13.4k -

(Liquid)ared type (Gas)brazing connection, 7.5(24.6)

- -

- -

1-5

-

11

1-2. Major Component Specifications

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

(A) Indoor Units

High Static Pressure Ducted Type S-200PE2E5

MODEL No.

Source

Controller P.C.B. Ass'y

Fan (Number...diameter)

Fan motor

Power source

mm

WModel...Nominal output

rpmNo. of pole...r.p.m. (230V, High)

S-200PE2E5

220 - 230 - 240V, single-phase, 50Hz

CR-280ME2E5

SIROCCO (2...ø250)

DMUB6D1AC...560W

DMUB6D2AC...560W

100 - 391 VDC

8P...860

Coil resistance

(Ambient temperature 20°C)

Electronic expansion valve

Coil

Coil resistance (at 20°C)

Valve body

Heat exchanger

Coil

Ω

VAC, µFRun capacitor

Ω

Aluminium plate fin / Copper tube

mmRows...fin pitch

2

mFace area

–

–

–

–

–

3...1.8

0.648

1-6

(A) Indoor Units

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

High Static Pressure Ducted Type S-250PE2E5

MODEL No.

Source

Controller P.C.B. Ass'y

Fan (Number...diameter)

Fan motor

Power source

mm

WModel...Nominal output

rpmNo. of pole...r.p.m. (230V, High)

11

S-250PE2E5

220 - 230 - 240V, single-phase, 50Hz

CR-280ME2E5

SIROCCO (2...ø250)

DMUB8D1AC...560W

DMUB8D2AC...560W

100 - 391 VDC

8P...1020

Coil resistance

(Ambient temperature 20°C)

Electronic expansion valve

Coil

Coil resistance (at 20°C)

Valve body

Heat exchanger

Coil

Ω

VAC, µFRun capacitor

Ω

Aluminium plate fin / Copper tube

mmRows...fin pitch

2

mFace area

–

–

–

–

–

4...1.8

0.648

1-7

(A) Indoor Units

(A) Indoor Units

4-Way Cassette Type S-125PU2E5A

MODEL No.

S-125PU2E5A

Source

220 - 230 - 240 V, single-phase, 50 Hz

Controller P.C.B. Ass'y

ACXA73-02060(Microprocessor)

Fan (Number...diameter)

mm

Turbo (1...ø485)

Fan motor

SIC-72FW-D895-1…90W

280 VDC

rpm

8P…620

VAC, μF

overcurrent, rotating signal detection, fuse

Aluminium plate fin / Copper tube

mm

3...1.15

Face area

m

2

0.560

CZ-KPU3

MSBPC20A20

Coil resistance

Ω

300 Ω ± 7% / phase

PMD-12D13ST-7

V, W

DC 13 V, 4.2 W

Drain piping rise height from unit bottom, capacity

850 mm, 400 cc/min

Safety device

Model No.

Model...Nominal output

W

Power source

No. of pole...r.p.m. (230V, High)

Run capacitor

Rows...fin pitch

Heat exchanger

Coil

Rated

Auto louver motor

Drain pump

Panel

Model No.

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

4-Way Cassette Type S-100PU2E5A

MODEL No.

Source

Controller P.C.B. Ass'y

Fan (Number...diameter)

Fan motor

Model...Nominal output

Power source

No. of pole...r.p.m. (230V, High)

Run capacitor

Safety device

Heat exchanger

Coil

Rows...fin pitch

Face area

Panel

Model No.

Auto louver motor

Coil resistance

Drain pump

Model No.

Rated

Drain piping rise height from unit bottom, capacity

mm

W

rpm

VAC, μF

mm

2

m

Ω

V, W

S-100PU2E5A

220 - 230 - 240 V, single-phase, 50 Hz

ACXA73-02060(Microprocessor)

Turbo (1...ø485)

SIC-72FW-D895-1…90W

280 VDC

8P…600

overcurrent, rotating signal detection, fuse

Aluminium plate fin / Copper tube

3...1.15

0.560

CZ-KPU3

MSBPC20A20

300 Ω ± 7% / phase

PMD-12D13ST-7

DC 13 V, 4.2 W

850 mm, 400 cc/min

1-8

(A) Indoor Units

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

4-Way Cassette Type S-125PU2E5A

MODEL No.

Source

Controller P.C.B. Ass'y

Fan (Number...diameter)

Fan motor

mm

11

S-125PU2E5A

220 - 230 - 240 V, single-phase, 50 Hz

ACXA73-02060(Microprocessor)

Turbo (1...ø485)

Model...Nominal output

Power source

No. of pole...r.p.m. (230V, High)

Run capacitor

Safety device

Heat exchanger

Coil

Rows...fin pitch

Face area

Panel

Model No.

Auto louver motor

Coil resistance

Drain pump

Model No.

Rated

Drain piping rise height from unit bottom, capacity

W

rpm

VAC, μF

mm

2

m

Ω

V, W

SIC-72FW-D895-1…90W

280 VDC

8P…620

overcurrent, rotating signal detection, fuse

Aluminium plate fin / Copper tube

3...1.15

0.560

CZ-KPU3

MSBPC20A20

300 Ω ± 7% / phase

PMD-12D13ST-7

DC 13 V, 4.2 W

850 mm, 400 cc/min

1-9

(B) Outdoor Units

(B) Outdoor Units

U-250PE2E8A

MODEL No.

Source

Controller P.C.B. Ass'y

Control circuit fuse

Compressor

Model....number

Source

WNominal output

ccCompressor oil

Coil resistance

(Ambient temperature 25°C)

Ω

U-V 0.678 U-W 0.700 V-W 0.691

Safety control

Overload relay models

Operation temperature

Open °C

Close °C

WCrank case heater

Refrigerant amount at shipment

kg

High pressure switch

Set pressure

MPaOFF 4.15

3.05±0.2MPa ON

Fan

mmNumber...diameter

m

3

/ hAir circulation

Fan speeds (Max.)

Fan motor

Model No.

Source

No. of pole

WNominal output

Safety device

Operating temperature

Open °C

Close °C

VAC, µF

Heat exchanger

Coil

mmRows...fin pitch

m

2

U-250PE2E8A

380/400/415V 3-Phase 50Hz

ACXA73C07260

30A

5JD650XDB22

520V DC MOTOR

5,500

2,050

Discharge temperature control

–

–

–

230V-36W

2...ø540

160

NFD-81FW-D8120-1,NFD-81FW-D8120-2

~280V / 1-phase

8

120

–

–

–

–

Aluminium plate fin / Copper tube

3..17FPI

1.367Face area

Run capacitor

+0

-0.2

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

U-200PE2E8A

MODEL No.

Source

Controller P.C.B. Ass'y

Control circuit fuse

Compressor

Model....number

Source

Coil resistance

(Ambient temperature 25°C)

Safety control

Refrigerant amount at shipment

High pressure switch

Overload relay models

Operation temperature

Set pressure

Fan

Fan speeds (Max.)

Fan motor

Model No.

Source

No. of pole

Safety device

Heat exchanger

Operating temperature

Run capacitor

Coil

Open °C

Close °C

Open °C

Close °C

VAC, µF

380/400/415V 3-Phase 50Hz

WNominal output

ccCompressor oil

Ω

U-V 0.678 U-W 0.700 V-W 0.691

Discharge temperature control

WCrank case heater

kg

MPaOFF 4.15

mmNumber...diameter

3

/ hAir circulation

m

WNominal output

NFD-81FW-D8120-1,NFD-81FW-D8120-2

Aluminium plate fin / Copper tube

mmRows...fin pitch

2

m

U-200PE2E8A

ACXA73C07280

30A

5JD650XDB22

520V DC MOTOR

4,200

2,050

–

–

–

230V-36W

+0

-0.2

3.05±0.2MPa ON

2...ø540

164

~280V / 1-phase

8

120

–

–

–

–

2..17FPI

1.367Face area

1-10

(B) Outdoor Units

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

U-250PE2E8A

MODEL No.

Source

Controller P.C.B. Ass'y

Control circuit fuse

Compressor

Model....number

Source

Coil resistance

(Ambient temperature 25°C)

Safety control

Overload relay models

Operation temperature

Refrigerant amount at shipment

High pressure switch

Set pressure

Fan

Fan speeds (Max.)

Fan motor

Model No.

Source

No. of pole

Safety device

Operating temperature

Run capacitor

Heat exchanger

Coil

Open °C

Close °C

Open °C

Close °C

VAC, µF

380/400/415V 3-Phase 50Hz

520V DC MOTOR

WNominal output

ccCompressor oil

Ω

WCrank case heater

kg

MPaOFF 4.15

mmNumber...diameter

3

/ hAir circulation

m

WNominal output

mmRows...fin pitch

2

m

U-V 0.678 U-W 0.700 V-W 0.691

Discharge temperature control

NFD-81FW-D8120-1,NFD-81FW-D8120-2

Aluminium plate fin / Copper tube

U-250PE2E8A

ACXA73C07260

30A

5JD650XDB22

5,500

2,050

–

–

–

230V-36W

+0

-0.2

3.05±0.2MPa ON

2...ø540

160

~280V / 1-phase

8

120

–

–

–

–

3..17FPI

1.367Face area

11

1-11

1-3. Other Component Specifications

Outdoor Units U-250PE2E8A

MODEL No.

Outdoor Unit

Power Transformer

Rated

VAC, HzSource

Secondary

Coil resistance

Ω

Thermistor (Coil / Air sensor): TH1, TH2, TH3, TH4

Resistance

kΩ

-20°C: 38.48±2% 20°C: 6.517±2%

-10°C: 23.67±2% 30°C: 4.448±2%

0°C: 15.00±2% 40°C: 3.100±2%

5°C: 12.06±2% 45°C: 2.607±2%

10°C: 9.765±2% 50°C: 2.203±2%

Thermistor (Discharge gas sensor): TH5

Resistance

kΩ

60°C: 1.593±2% 85°C: 0.7598±2%

65°C: 1.363±2% 90°C: 0.6623±2%

70°C: 1.171±2% 95°C: 0.5793±2%

75°C: 1.010±2% 100°C: 0.5083±2%

80°C: 0.8746±2% 105°C: 0.4473±2%

Relay (Comp. Magnetic Contactor)

VACCoil rated

VAC, AContact rating

Coil resistance (at 20°C)

Ω

Sol-Control-Valve

4 way valve

4 way valve

Electro magnetic coil

Thermal cut off temperature

Sol-control-valve

Magnetic coil

U-250PE2E8A

–

–

–

–

–

–

–

–

–

UKV32D322

SHF-35B-67-03

SQ-A2522G-005129 AC220-240V 50/60Hz

UKV-A392

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

Outdoor Units U-200PE2E8A

MODEL No.

Outdoor Unit

Power Transformer

Rated

VAC, HzSource

Secondary

Coil resistance

Thermal cut off temperature

Thermistor (Coil / Air sensor): TH1, TH2, TH3, TH4

Resistance

kΩ

Thermistor (Discharge gas sensor): TH5

Resistance

kΩ

Relay (Comp. Magnetic Contactor)

VACCoil rated

VAC, AContact rating

Coil resistance (at 20°C)

Sol-Control-Valve

Sol-control-valve

Magnetic coil

4 way valve

4 way valve

Electro magnetic coil

Ω

Ω

U-200PE2E8A

–

–

–

–

–

–

-20°C: 38.48±2% 20°C: 6.517±2%

-10°C: 23.67±2% 30°C: 4.448±2%

0°C: 15.00±2% 40°C: 3.100±2%

5°C: 12.06±2% 45°C: 2.607±2%

10°C: 9.765±2% 50°C: 2.203±2%

60°C: 1.593±2% 85°C: 0.7598±2%

65°C: 1.363±2% 90°C: 0.6623±2%

70°C: 1.171±2% 95°C: 0.5793±2%

75°C: 1.010±2% 100°C: 0.5083±2%

80°C: 0.8746±2% 105°C: 0.4473±2%

SQ-D23015-002283 DC15.4V(898mA)

–

–

–

UKV32D322

UKV-A392

SHF-20B-46-DC

1-12

Outdoor Units U-250PE2E8A

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

MODEL No.

Outdoor Unit

Power Transformer

Rated

VAC, HzSource

Secondary

Coil resistance

Thermal cut off temperature

Thermistor (Coil / Air sensor): TH1, TH2, TH3, TH4

Resistance

Thermistor (Discharge gas sensor): TH5

Resistance

Relay (Comp. Magnetic Contactor)

VACCoil rated

VAC, AContact rating

Coil resistance (at 20°C)

Sol-Control-Valve

Sol-control-valve

Magnetic coil

4 way valve

4 way valve

Electro magnetic coil

Ω

kΩ

kΩ

Ω

11

U-250PE2E8A

–

–

–

–

–

–

-20°C: 38.48±2% 20°C: 6.517±2%

-10°C: 23.67±2% 30°C: 4.448±2%

0°C: 15.00±2% 40°C: 3.100±2%

5°C: 12.06±2% 45°C: 2.607±2%

10°C: 9.765±2% 50°C: 2.203±2%

60°C: 1.593±2% 85°C: 0.7598±2%

65°C: 1.363±2% 90°C: 0.6623±2%

70°C: 1.171±2% 95°C: 0.5793±2%

75°C: 1.010±2% 100°C: 0.5083±2%

80°C: 0.8746±2% 105°C: 0.4473±2%

–

–

–

UKV32D322

UKV-A392

SHF-35B-67-03

SQ-A2522G-005129 AC220-240V 50/60Hz

1-13

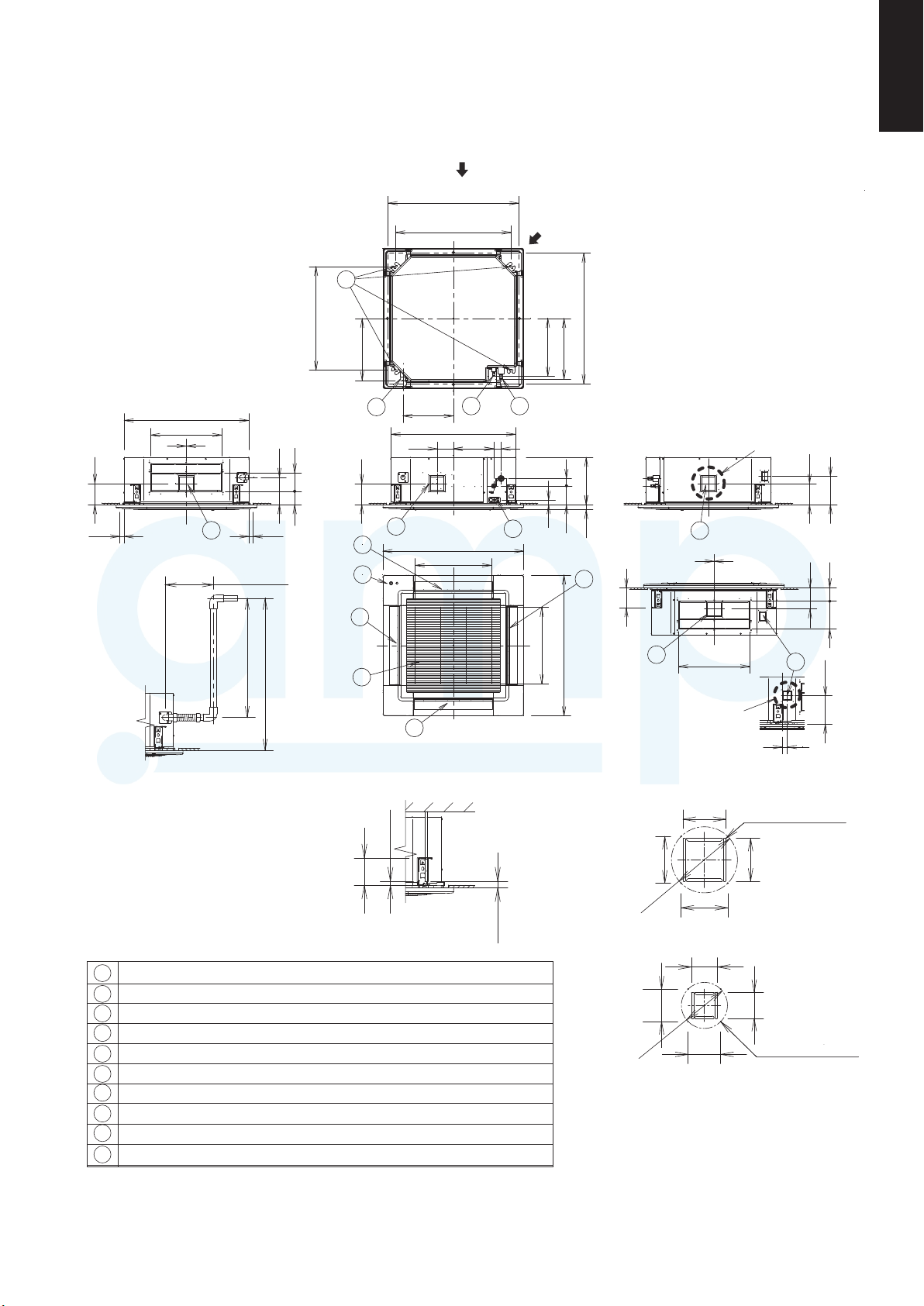

1-4. Dimensional Data

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

(A) Indoor Units: High Static Pressure Ducted Type

Required Minimum Space for Installation and Service

(1) Dimensions of suspension bolt pitch and unit

1170

(Suspension bolt pitch)

1100

Unit: mm

(60)(60)

Inspection access (600 × 600)(Field supply)

467

For power supply

wiring port

For

communication

wiring port

Port for

optional

wiring part

27

65

264

479

(2) Dimensions of indoor unit

Types 200 / 250

4-37×12 hole

(For suspension bolt)

28-ø3.2 hole

467

service)

Min. 600

(Space for

1070

1310

77

45

132

Drain

port

Refrigerant

tubing joint

Min. 800

(Space for service)

Min. 1100

(Space for service)

1138

467

7

(Suspension bolt pitch)

(60) (60)

1170

1100

* Space for removing

drain pan

1334

1453

964

67

1200

1310

Min. 610*

(Space for

service)

(Suspension bolt pitch)

67

200

Ceiling face

Electrical

component box

Inspection access (600 × 600)(Field supply)

Refrigerant liquid tubing (Flare)

1

(Type 200 : Connection Tubing ø12.7ø12.7 → ø9.52)

Refrigerant gas tubing (Brazing) ø25.4

2

Power supply port

3

Communication wiring port

422

8

4

Port for optional wiring part

5

Drain port 25A

6

Air intake duct connecting side flange

7

Air discharge duct connecting side flange

8

26-ø3.2 hole

67

Unit : mm

1070

4

1310

5

77

479

40

300

23

132

50

100

100

43

65

264

27

3

479

10 ×100 pitch = 1000

45

6

2

1

1220

156

45

131207

1205

1-14

964

1200

1310

9 ×100 pitch = 900

(Suspension bolt pitch)

67

100

Electrical component box

41

60

320

434

100

1334

1453

(A) Indoor Units: 4-Way Cassette Type

Dimensional Data

Indoor Units: S-100PU2E5A / S-125PU2E5A / S-140PE2U5A

AMP Air Conditioning

www.ampair.co.uk | sales@ampair.co.uk

S-100PU2E5A / S-125PU2E5A

860~910

(Ceiling opening dimensions)

(Suspension bolt pitch)

8

780

11

X

unit: mm

XX

840

480

2

143

7

Less than 300

Less than 666

Raise dimension of drain tube

184

90 124

Less than 35Less than 35

Less than 850

700

418

(Suspension bolt pitch)

5

143

2

10

2

1

860~910

(390)

(410)

(Ceiling opening dimensions)

340

3

840

272110

7

950

(Air intake)

515

4

51

319

32

6

127 50

33.5

7

2

134

950

(Air intake)

515

7

480

View X

Y

143

192

2

90

143

187

9

(192)

Z

2

35

View XX

The length of the suspension bolts

should be selected so that there is

a gap of 30 mm or more below the

lower surface of the ceiling (18 mm

122

Over 18

or more below the lower surface of

the main unit), as shown in the