Panasonic S-07MM2U6, S-09MM2U6, S-12MM2U6, S-15MM2U6, S-18MM2U6 installation

INSTALLATION INSTRUCTIONS

VRF System Air Conditioner

This air conditioner uses the refrigerant R410A.

Model No.

|

Indoor Units |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Type |

Indoor Unit Type |

|

|

Nominal Capacity |

|

|

|

7 |

9 |

12 |

15 |

18 |

|||

|

|

||||||

M2 |

Slim Low Static Ducted |

S-07MM2U6 |

S-09MM2U6 |

S-12MM2U6 |

S-15MM2U6 |

S-18MM2U6 |

|

|

|

|

|

|

|

|

Read through the Installation Instructions before you proceed with the installation.

In particular, you will need to read under the “IMPORTANT!” section at the top of the page.

F616519

IMPORTANT!

Please Read Before Starting

This air conditioning system meets strict safety and operating standards. As the installer or service person, it is an important part of your job to install or service the system so it operates safely and efficiently.

For safe installation and trouble-free operation, you must:

●Carefully read this instruction booklet before beginning.

●Follow each installation or repair step exactly as shown.

●This air conditioner shall be installed in accordance with National Wiring Regulations.

●Pay close attention to all warning and caution notices given in this manual.

This symbol refers to a hazard or WARNING unsafe practice which can result in severe personal injury or death.

This symbol refers to a hazard or

CAUTION unsafe practice which can result in personal injury or product or

property damage.

If Necessary, Get Help

These instructions are all you need for most installation sites and maintenance conditions. If you require help for a special problem, contact our sales/service outlet or your certified dealer for additional instructions.

In Case of Improper Installation

The manufacturer shall in no way be responsible for improper installation or maintenance service, including failure to follow the instructions in this document.

SPECIAL PRECAUTIONS

WARNING When Wiring

ELECTRICAL SHOCK CAN CAUSE

SEVERE PERSONAL INJURY OR DEATH.

ONLY A QUALIFIED, EXPERIENCED

ELECTRICIAN SHOULD ATTEMPT TO

WIRE THIS SYSTEM.

•Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

•Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

•Ground the unit following local electrical codes.

•Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

• To prevent possible hazards from insulation failure, the unit must be grounded.

•This equipment is strongly recommended to be installed with Earth Leakage Circuit Breaker (ELCB) or Residual Current Device (RCD). Otherwise, it may cause electrical shock and fire in case of equipment breakdown or insulation breakdown.

When Transporting

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and bend your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on the air conditioner can cut your fingers.

When Installing…

Select an installation location which is rigid and strong enough to support or hold the unit, and select a location for easy maintenance.

…In a Room

Properly insulate any tubing run inside a room to prevent “sweating” that can cause dripping and water damage to walls and floors.

|

Keep the fire alarm and the air |

|

CAUTION |

outlet at least 5 feet (1.5 m) away |

|

from the unit. |

||

|

…In Moist or Uneven Locations

Use a raised concrete pad or concrete blocks to provide a solid, level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

…In an Area with High Winds

Securely anchor the outdoor unit down with bolts and a metal frame. Provide a suitable air baffle.

…In a Snowy Area (for Heat Pump-type Systems)

Install the outdoor unit on a raised platform that is higher than drifting snow. Provide snow vents.

When Connecting Refrigerant Tubing

•Ventilate the room well, in the event that is refrigerant gas leaks during the installation. Be careful not to allow contact of the refrigerant gas with a flame as this will cause the generation of poisonous gas.

•Keep all tubing runs as short as possible.

•Use the flare method for connecting tubing.

•Apply refrigerant lubricant to the matching surfaces of the flare and union tubes before connecting them, then tighten the nut with a torque wrench for a leak-free connection.

•Check carefully for leaks before starting the test run.

WARNING

•When performing piping work do not mix air except for specified refrigerant (R410A) in refrigeration cycle. It causes capacity down, and risk of explosion and injury due to high tension inside the refrigerant cycle.

•Check for a leaking refrigerant!

Refrigerant gas may produce a toxic gas if it comes in contact with fire.

•Do not add or replace refrigerant other than specified type. It may cause product damage, burst and injury etc.

2

•Do not leak refrigerant while piping work for an installation or re-installation, and while repairing refrigeration parts.

Handle liquid refrigerant carefully as it may cause frostbite.

When Servicing

•Turn the power OFF at the main power box (mains) before opening the unit to check or repair electrical parts and wiring.

•Keep your fingers and clothing away from any moving parts.

•Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have been left inside the unit being serviced.

WARNING

•This product must not be modified or disassembled under any circumstances. Modified or disassembled unit may cause fire, electric shock or injury.

•Do not clean inside the indoor and outdoor units by users. Engage authorized dealer or specialist for cleaning.

•In case of malfunction of this appliance, do not repair by yourself. Contact to the sales dealer or service dealer for a repair.

CAUTION

• Do not touch the air inlet or the sharp aluminum fins of the outdoor unit. You may get injured.

•Ventilate any enclosed areas when installing or testing the refrigeration system. Escaped refrigerant gas, on contact with fire or heat, can produce dangerously toxic gas.

•Confirm after installation that no refrigerant gas is leaking. If the gas comes in contact with a burning stove, gas water heater, electric room heater or other heat source, it can cause the generation of poisonous gas.

Others

CAUTION

• Do not sit or step on the unit, you may fall down accidentally.

• Do not touch the air inlet or the sharp aluminum fins of the outdoor unit. You may get injured.

• Do not stick any object into the FAN CASE.

You may be injured and the unit may be damaged.

Check of Density Limit

The room in which the air conditioner is to be installed requires a design that in the event of refrigerant gas leaking out, its density will not exceed a set limit.

The refrigerant (R410A), which is used in the air conditioner, is safe, without the toxicity or combustibility of ammonia, and is not restricted by laws imposed to protect the ozone layer. However, since it contains more than air, it poses the risk of suffocation if its density should rise excessively. Suffocation from leakage of refrigerant is almost non-existent. With the recent increase in the number of high density buildings, however, the installation of multi air conditioner systems is on the increase because of the need for effective use of floor space, individual control, energy conservation by curtailing heat and carrying power, etc.

Most importantly, the multi air conditioner system is able to replenish a large amount of refrigerant compared to conventional individual air conditioners. If a single unit of the multi air conditioner system is to be installed in a small room, select a suitable model and installation procedure so that if the refrigerant accidentally leaks out, its density does not reach the limit (and in the event of an emergency, measures can be made before injury can occur).

ASHRAE and the International Mechanical Code of the ICC as well as CSA provide guidance and define safeguards related to the use of refrigerants, all of which define a Refrigerant Concentration Level (RCL) of

25 pounds (11.3 kg) per 1,000 cubic feet (28.3 m3) for R410A refrigerant.

For additional guidance and precautions related to refrigerant safety, please refer to the following documents:

International Mechanical Code 2012 (IMC-2012) (or more recently revised)

ASHRAE 15

ASHRAE 34

3

CONTENTS

Page

IMPORTANT. . . . . . . . . . . . . . . . . 2

Please Read Before Starting

1.GENERAL. . . . . . . . . . . . . . . . . 5

1-1. Tools Required for Installation (not supplied)

1-2. Accessories Supplied with Unit

1-3. Type of Copper Tube and Insulation Material 1-4. Additional Materials Required for Installation

2.SELECTING THE INSTALLATION SITE. . . . . 6

Indoor Unit

3.HOW TO INSTALL THE INDOOR UNIT. . . . . . 7

■Slim Low Static Ducted Type (Type M2) . . . . . 7

3-1. Required Minimum Space for Installation and Service

3-2. Preparations Before Installation

3-3. For Bottom Intake

3-4. Installing the Duct

3-5. Suspending the Indoor Unit

3-6. Installing the Drain Pipe

3-7. Checking the Drainage

4.ELECTRICAL WIRING. . . . . . . . . . . . 12

4-1. General Precautions on Wiring

4-2. Recommended Wire Length and Wire Diameter for Power Supply System

4-3. Wiring System Diagrams

5.HOW TO PROCESS TUBING . . . . . . . . . 16

5-1. Connecting the Refrigerant Tubing

5-2. Connecting Tubing Between Indoor and Outdoor Units

5-3. Insulating the Refrigerant Tubing

5-4. Taping the Tubes

5-5. Finishing the Installation

6. PRECAUTIONS ON TEST RUN . . . . . . . . 19

7.HOW TO INSTALL THE TIMER REMOTE CONTROLLER (CZ-RTC2) OR HIGH-SPEC WIRED REMOTE CONTROLLER (CZ-RTC3)

(OPTIONAL PART) . . . . . . . . . . . . . 19

NOTE

Refer to the Operating Instructions attached to the optional Timer Remote Controller or optional Highspec Wired Remote Controller.

Page

8.HOW TO INSTALL WIRELESS REMOTE CONTROLLER RECEIVER. . . . . . . . . . 19

NOTE

Refer to the Operating Instructions attached to the optional Wireless Remote Controller Receiver.

9.EXTERNAL STATIC PRESSURE SETTING. . . 20

9-1. How to Set on PC Board

9-2. Operating the Timer Remote Controller (CZRTC2)

9-3. Operating the High-spec Wired Remote Controller (CZ-RTC3)

10.APPENDIX . . . . . . . . . . . . . . . . 24

■Names of Parts

■Care and Cleaning

■Troubleshooting

■Tips for Energy Saving

4

1. General

This booklet brieflly outlines where and how to install the air conditioning system. Please read over the entire set of instructions for the indoor and outdoor units and make sure all accessory parts listed are with the system before beginning.

1-1. Tools Required for Installation (not supplied)

1.Flathead screwdriver

2.Phillips head screwdriver

3.Knife or wire stripper

4.Tape measure

5.Carpenter’s level

6.Sabre saw or keyhole saw

7.Hacksaw

8.Core bits

9.Hammer

10.Drill

11.Tube cutter

12.Tube flaring tool

13.Torque wrench

14.Adjustable wrench

15.Reamer (for deburring)

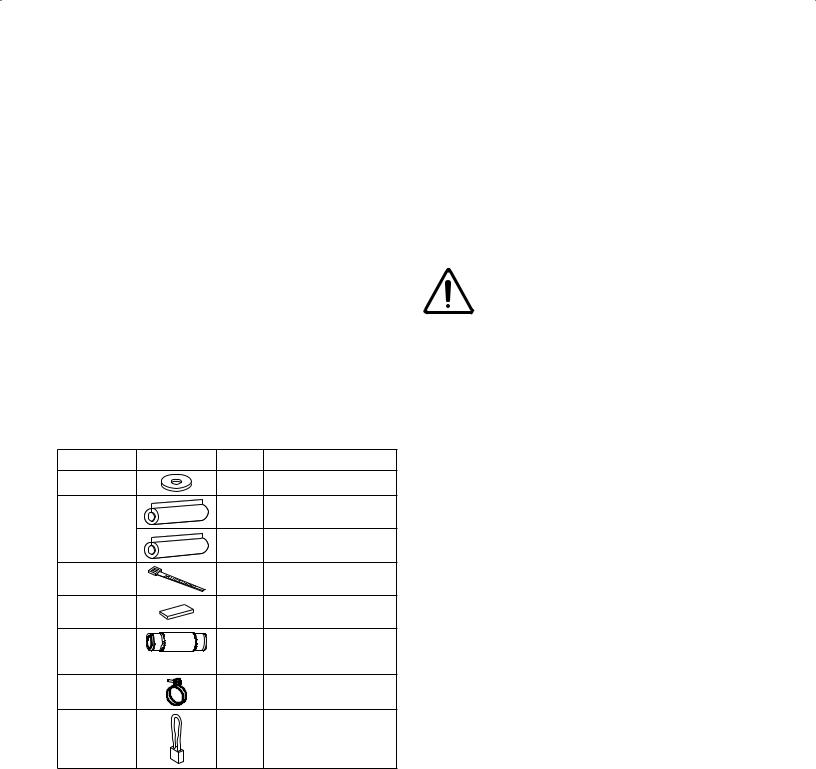

1-2. Accessories Supplied with Unit

Part Name |

Figure |

Q’ty |

Remarks |

|

Washer |

|

8 |

For suspension fitting |

|

|

|

1 |

For gas pipe / |

|

Flare |

|

liquid pipe connection |

||

|

|

|||

insulator |

|

1 |

For gas pipe / |

|

|

|

liquid pipe connection |

||

|

|

|

||

Clamper |

|

4 |

For flare connection |

|

Drain hose |

|

2 |

For drain pipe |

|

insulation |

|

connection |

||

|

|

|||

Drain hose |

|

1 |

For unit & PVC pipe |

|

L=131 |

connection |

|||

|

|

|||

|

|

|

||

Hose band |

|

2 |

For drain hose |

|

|

connection |

|||

|

|

|

||

|

|

|

For high static pressure |

|

Short-circuit |

|

1 |

(Located on the |

|

connection |

|

back of the electrical |

||

|

|

|||

|

|

|

component box lid. ) |

●Use 3/8”(M10) for suspension bolts.

●Suspension bolts and nuts are field supply.

1-3. Type of Copper Tube and Insulation Material

If you wish to purchase these materials separately from a local source, you will need:

1.Deoxidized annealed copper tube for refrigerant tubing.

2.Foamed polyethylene insulation for copper tubes as required to precise length of tubing. Wall thickness of the insulation should be not less than 5/16”(8 mm).

3.Use insulated copper wire for field wiring. Wire size varies with the total length of wiring. Refer to 4. ELECTRICAL WIRING for details.

CAUTION

Check local electrical codes and regulations before obtaining wire. Also, check any specified instructions or limitations.

1-4. Additional Materials Required for Installation

1.Refrigeration (armored) tape

2.Insulated staples or clamps for connecting wire (See your local codes.)

3.Putty

4.Refrigeration tubing lubricant

5.Clamps or saddles to secure refrigerant tubing

6.Scale for weighing

5

2. SELECTING THE INSTALLATION SITE

Indoor Unit

AVOID:

●areas where leakage of flammable gas may be expected.

●places where large amounts of oil mist exist.

●direct sunlight.

●locations near heat sources which may affect the performance of the unit.

●locations where external air may enter the room directly. This may cause “condensation” on the air discharge ports, causing them to spray or drip water.

●locations where the remote controller will be splashed with water or affected by dampness or humidity.

●installing the remote controller behind curtains or furniture.

●locations where high-frequency emissions are generated.

DO:

●select an appropriate position from which every corner of the room can be uniformly cooled.

●select a location where the ceiling is strong enough to support the weight of the unit.

●select a location where tubing and drain pipe have the shortest run to the outdoor unit.

●allow room for operation and maintenance as well as unrestricted air flow around the unit.

●install the unit within the maximum elevation difference above or below the outdoor unit and within a total tubing length (L) from the outdoor unit as detailed in the installation manual packed with the outdoor unit.

●allow room for mounting the remote controller about 3.3 ft. (1 m) off the floor, in an area that is not in direct sunlight nor in the flow of cool air from the indoor unit.

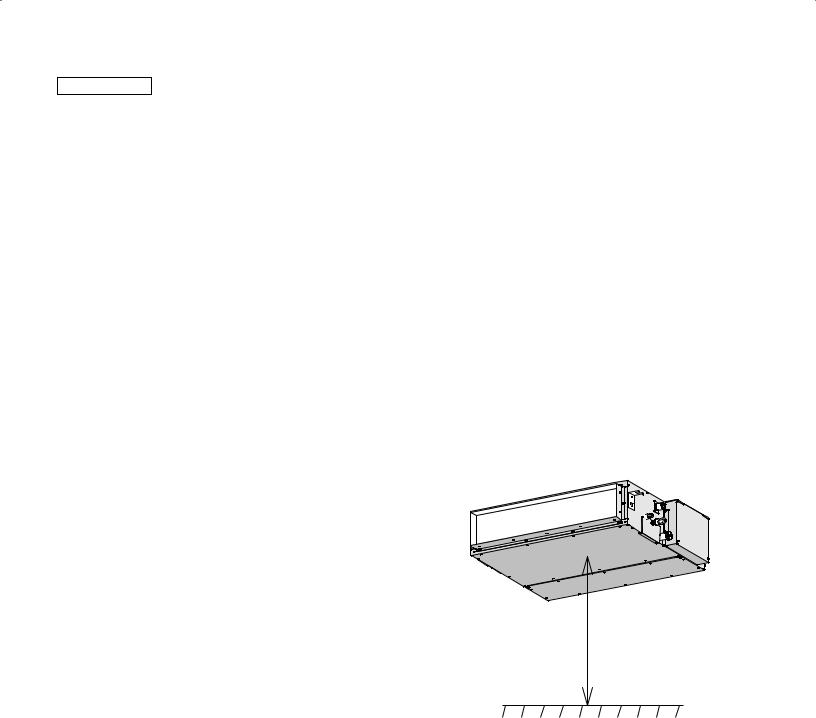

●The elevation (Slim Low Static Ducted) between the bottom unit and the floor surface should be at least 8 feet (2.4 m).

●If the elevation (Slim Low Static Ducted) between them is less than 8 feet (2.4 m), install a filter or a protective device (field supply) not to touch the electrical parts or fan with hands.

8 feet (2.4 m) or more

Floor

Fig. 2-1

●●If the indoor unit is installed on the ceiling where the temperature or humidity inside is high (over 86°F(30°C)/RH: 70%), add insulating material to the surface of the unit to avoid dew condensation.

6

3. HOW TO INSTALL THE INDOOR UNIT

■ Slim Low Static Ducted Type (Type M2)

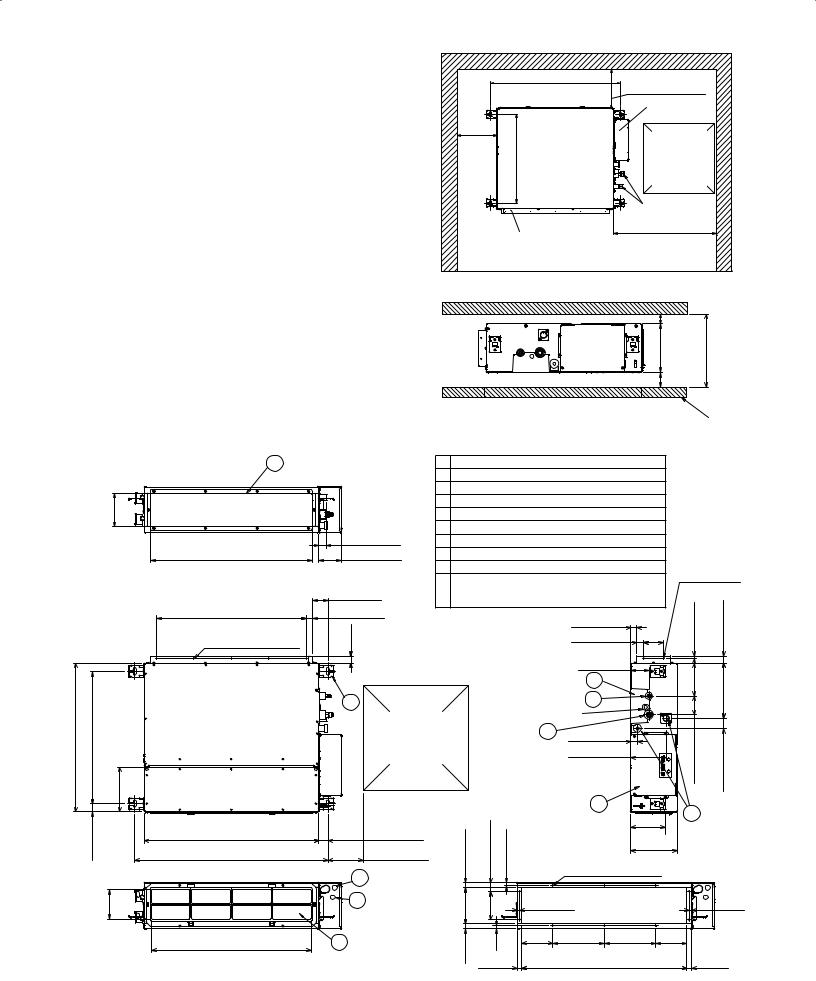

3-1. Required Minimum Space for Installation and Service

●This air conditioner is usually installed above the ceiling so that the indoor unit and ducts are not visible. Only the air intake and air outlet ports are visible from below.

●The minimum space for installation and service is shown in the diagram. (Fig. 3-1)

●*H dimension means the minimum height of the unit.

●Select the *H dimension such that a downward slope of at least 1/100 is ensured as indicated in “3-6. Installing the Drain Pipe”.

●The diagram shows the detailed dimensions of the indoor unit. (Fig. 3-2)

|

32-7/16” (824) |

Min. 7-7/8” (200) |

(Suspension bolt pitch) |

or more |

|

|

|

Electrical |

Min. |

|

component box |

|

|

|

7-7/8” |

|

Inspection |

(200) |

(564) |

access |

13/64”-22 |

17-23/32” |

|

or more |

|

|

|

|

x |

|

|

17-23/32” |

|

|

(450x450) |

|

|

Refrigerant tubing |

Flange for air |

Min. 25-5/8” (650) |

|

or more |

||

outlet duct |

|

|

|

Unit: inch (mm) |

|

Min. 25/32” (20) or more |

|

*H=Min.9-1/2” *H=Min.(240) |

7-7/8” |

(200) |

|

Min. 25/32” (20) or more |

|

|

Min. 4” (100 mm) or more for bottom air intake |

|

|

|

|

Ceiling |

for air outlet duct |

5-45/64 (145) |

Flange |

|

25-13/64 (640) 22-13/64 (564) |

(Suspension bolt pitch) |

7-41/64 (194) |

1-1/2 (38) |

|

|

|

4-61/64 |

(126) |

Fig. 3-1

6 |

1 Refrigerant tubing joint (liquid tube) |

Unit: inch (mm) |

2 Refrigerant tubing joint (gas tube)

3 Upper and bottom drain port (O.D.1.05 inch (26.7 mm))

4 Suspension lug

5 Power supply outlet (for conduit ø7/8” (ø22 mm))

1-9/64 (29) |

6 |

Flange for air outlet duct |

7 |

Cover plate |

27-1/4 (692) |

3-51/64 (96) |

8 Electrical component box |

|

|

|

|

|

|

|||||

(Flange for air outlet duct) |

|

9 Filter |

|

|

|

|

|

|

|

|

2-ø1/8 (ø3.1) |

||

|

|

Control wiring outlet |

|

|

|

|

|||||||

|

2-19/32 (66) |

0 (for inter-unit control wiring, group control wiring |

(Hole) |

||||||||||

25-13/64 ((6-19/64)x4) |

and remote controller wiring)(ø11/16” (ø17 mm)) |

|

(10) |

(30) |

|||||||||

1-1/32 (26) |

|

||||||||||||

|

|

|

|

|

|

1-7/64 (28) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||

640 (160x4) |

|

|

|

|

|

|

|

|

|

|

|||

1/16-1 (27) |

|

|

|

|

|

|

(84) |

25/64 |

3/16-1 |

||||

5-ø1/8 (ø3.1(Hole)) |

|

|

|

|

|

|

|

1-3/16 (30) |

3-5/16 |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

3-3/16 (81) |

|

|

-55/8 |

(143) (238) |

|

|

|

|

|

|

|

|

|

7 |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

|

|

|

|

|

|

1 |

|

|

|

|

9-3/8 |

|

Inspection access |

|

|

|

|

Water inlet |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

(17-23/32”x17-23/32”) |

|

|

|

2 |

1-19/64 (33) |

|

|

(80) |

(44) |

|||

|

(450x450) |

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

6-1/32 (153) |

|

|

|||||

|

|

|

|

|

|

|

|

|

|

||||

|

(Field supply) |

|

|

|

|

|

|

|

3-5/32 |

-47/64 |

|||

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

|

|

|

|

8 |

|

|

|

3 |

|

|

|

|

|

37/64-1 (40) |

|

|

|

|

|

5-29/32 |

|||

|

|

55/64(22) |

|

35/64(14) |

|

|

|

|

|

||||

29-17/32 (750) |

1-29/64 (37) |

|

|

|

|

(150) |

|

|

|||||

(Suspension bolt pitch) |

5-29/32 (150) |

|

|

|

|

7-7/8 |

|

|

|||||

|

|

10-ø1/8 (ø3.1)(Hole) |

|

|

|||||||||

32-7/16 (824) |

|

|

|

|

|

|

|

|

(200) |

|

|

||

|

5 |

7/64-6 |

(155) |

23/32-4 |

(120) |

|

|

|

|

|

|

|

|

|

10 |

|

|

|

|

|

|

(14) |

|||||

|

|

|

|

|

|

35/64 (14) |

|

|

|

|

35/64 |

||

26-49/64 (680) |

9 |

29/32 |

(23) |

19/32 |

(15) |

5-13/64 |

8-21/32 |

8-21/32 |

5-13/64 |

|

|||

(132) |

(220) |

(220) |

(132) |

|

|||||||||

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

||||||

|

|

|

|

(29/32) |

|

27-23/32 (704) |

|

|

29/32 |

||||

|

|

|

|

|

|

(23) |

* |

Filter Uninstalled |

|

|

(23) |

||

|

|

|

|

|

|

|

|

|

Fig. 3-2 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

|

|

3-2. Preparations Before Installation

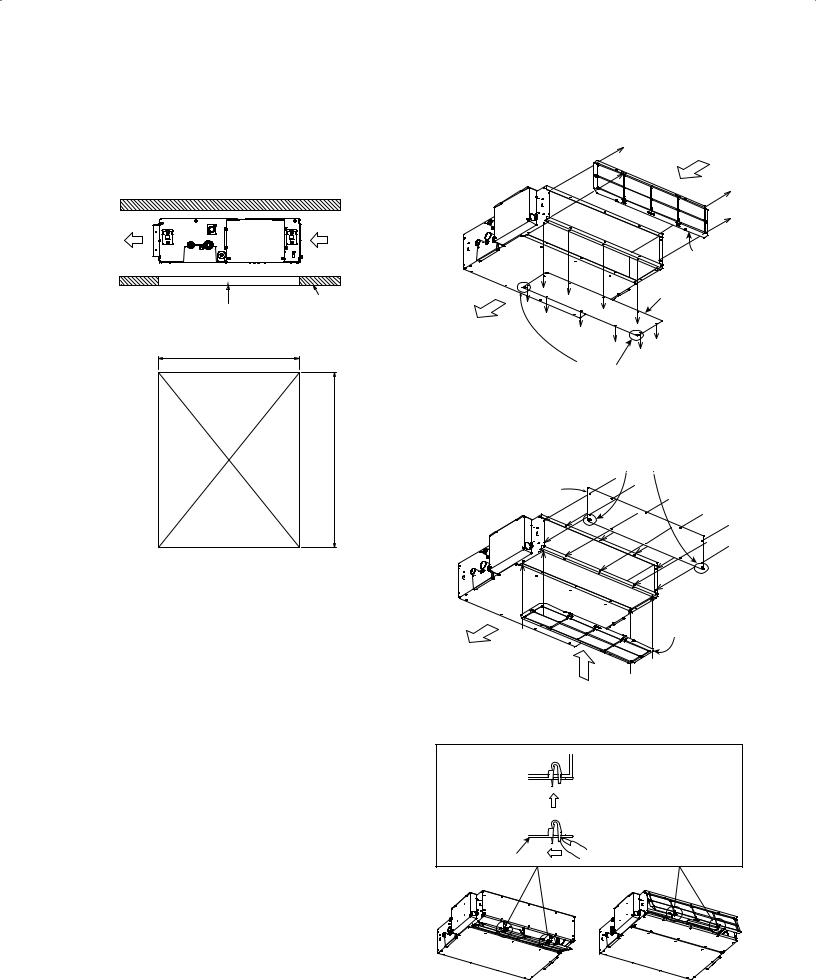

(1)Confirm the positional relationship between the unit and suspension bolts. (Fig. 3-3)

●Install the inspection opening on the control box side where maintenance and inspection of the control box and drain pump are easy. Install the inspection opening also in the lower part of the unit.

Air discharge |

|

Air intake |

|

A |

Ceiling |

|

|

|

|

(Inspection access) |

|

27-1/2 (700)

|

Allow view A |

(800) |

|

Inspection access |

|

|

-1/2 |

|

|

(Field supply) |

|

|

|

31 |

|

|

|

Unit: mm

Fig. 3-3

(2)Make sure the range of the unit’s external static pressure is not exceeded.

(See the technical documentation for the range of the external static pressure setting.)

(3)Open the installation hole. (Pre-set ceilings)

●Once the installation hole is opened in the ceiling where the unit is to be installed, pass refrigerant piping, drain piping, inter-unit control wiring, and remote controller wiring to the unit’s piping and wiring holes. See “5. HOW TO PROCESS TUBING”, “3-6. Installing the Drain Pipe” and “4. ELECTRICAL WIRING”.

●After opening the ceiling hole, make sure ceiling is level if needed. It might be necessary to reinforce the ceiling frame to prevent shaking.

Consult an architect or carpenter for details.

3-3. For Bottom Intake

For bottom intake, replace the cover plate and Frame Filter Assy net in the procedure shown in the diagram.

(1)Remove the frame filter assy. Remove the cover plate. (Fig. 3-4)

Air intake

Frame

Filter Assy

Cover plate

Air discharge

Dummy hole

Fig. 3-4

(2)Refer to the diagram to attach the cover plate and frame filter assy in the direction of the arrow. (Fig. 3-5) Note: Attach the cover plate with the dummy holes downward.

Dummy hole

Cover plate

Frame

Filter Assy

Air discharge

Air intake

Fig. 3-5

(3)Attach the frame filter assy (supplied) in the manner shown in the diagram. (Fig. 3-6)

Main unit

Attach the Frame Filter Assy to the main unit while pushing the tip of the latches in the direction of the arrow.

Frame Filter Assy

In case of bottom side |

In case of back side |

8 |

Fig. 3-6 |

|

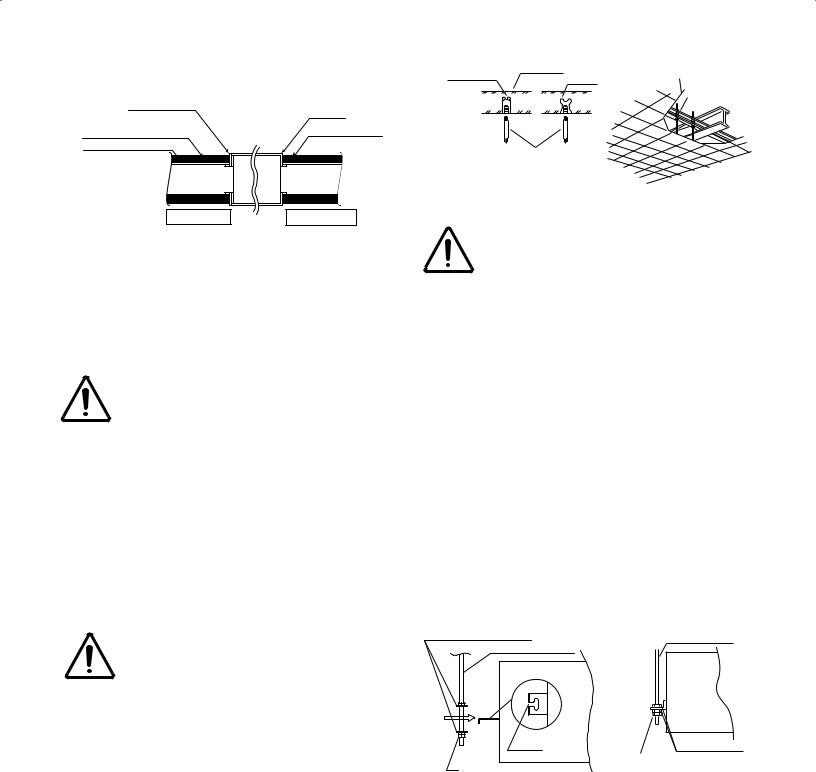

3-4. Installing the Duct

Connect the duct supplied in the field as shown in Fig. 3-7.

Flange |

|

Flange |

|

(Field supply) |

|

||

|

Insulation material |

||

Connection screw (x10) |

Main unit |

||

Rectangular solid duct |

(Field supply) |

||

|

|||

(Field supply) |

|

|

|

Air inlet side |

|

Air outlet side |

Fig. 3-7

Air inlet side

•Attach the duct and intake-side flange (field supply).

•Connect the flange to the main unit with 10 - ø1/8” (ø3.1) (Hole) screws.

•Wrap the intake-side flange and duct connection area with aluminum tape or something similar to prevent air escaping.

CAUTION

When attaching a duct to the intake-side, be sure to attach an air filter inside the air passage on the intake-side. (Use an air filter whose dust collecting

efficiency is at least 50% in a gravimetric technique.) The included filter is not used when the intake duct is attached.

Air outlet side

•Connect the duct according to the air outside of the outlet-side flange.

•Wrap the outlet-side flange and the duct connection area with aluminum tape or something similar to prevent air escaping.

CAUTION

●Be sure to insulate the duct to prevent condensation from forming. (Material: glass wool or polyethylene foam, 1 inch (25 mm) thick)

●Use electric insulation between the duct and the wall when using metal ducts to pass metal laths of the net or fence shape or metal plating into wooden buildings.

●Be sure to explain about the way of maintaining and cleaning local procurements (air filter, grille [both air outlet and suction grille], etc.) to your customer.

3-5. Suspending the Indoor Unit

Depending on the ceiling type:

•Insert suspension bolts as shown in the diagram. (Fig. 3-8)

or

•Use existing ceiling supports or construct a suitable support as shown in the diagram. (Fig. 3-9)

Hole-in-anchor |

Concrete |

|

Ceiling tiles |

Hole-in-plug |

|

Insert |

|

|

|

|

Ceiling support

Suspension bolt (M10 or 3/8”) (field supply)

Fig. 3-8 |

Fig. 3-9 |

WARNING

It is important that you use extreme care in supporting the indoor unit inside the ceiling. Ensure that the ceiling is strong enough to support the weight of the unit. Before hanging the unit, test the strength of each attached suspension bolt.

(1)When placing the unit inside the ceiling, determine the pitch of the suspension bolts referring to the dimensional data as shown in Fig. 3-1.

Tubing must be laid and connected inside the ceiling when suspending the unit. If the ceiling is already constructed, lay the tubing into position for connection to the unit before placing the unit inside the ceiling.

(2)Screw in the suspension bolts allowing them to protrude from the ceiling as shown in Fig. 3-8. (Cut the ceiling material, if necessary.)

(3)Thread the 3 hexagonal nuts and 2 washers (field supply) onto each of the 4 suspension bolts as shown in Fig. 3-10 and 3-11. Use 1 nut and 1 washer for the upper part, and 2 nuts and 1 washer for the lower part, so that the unit will not fall off the suspension lugs.

Nuts and washers (use |

|

for upper and lower) |

Suspension bolt |

Suspension bolt |

|

Suspension lug |

|

|

Notch |

Hexagonal nut |

|

Double nuts |

|

Double nuts |

|

|

|

|

Fig. 3-10 Fig. 3-11

9

Loading...

Loading...