Page 1

Digital Video Camcorder

PV-GS250PP

A-MECHANISM

Color

(S)...... Silver Type

ORDER NO.MKE0501404C1

© 2005 Matsushita Kotobuki Electronics Industries

LTD. All rights reserved. Unauthorized copying and

distribution is a violation of law.

Page 2

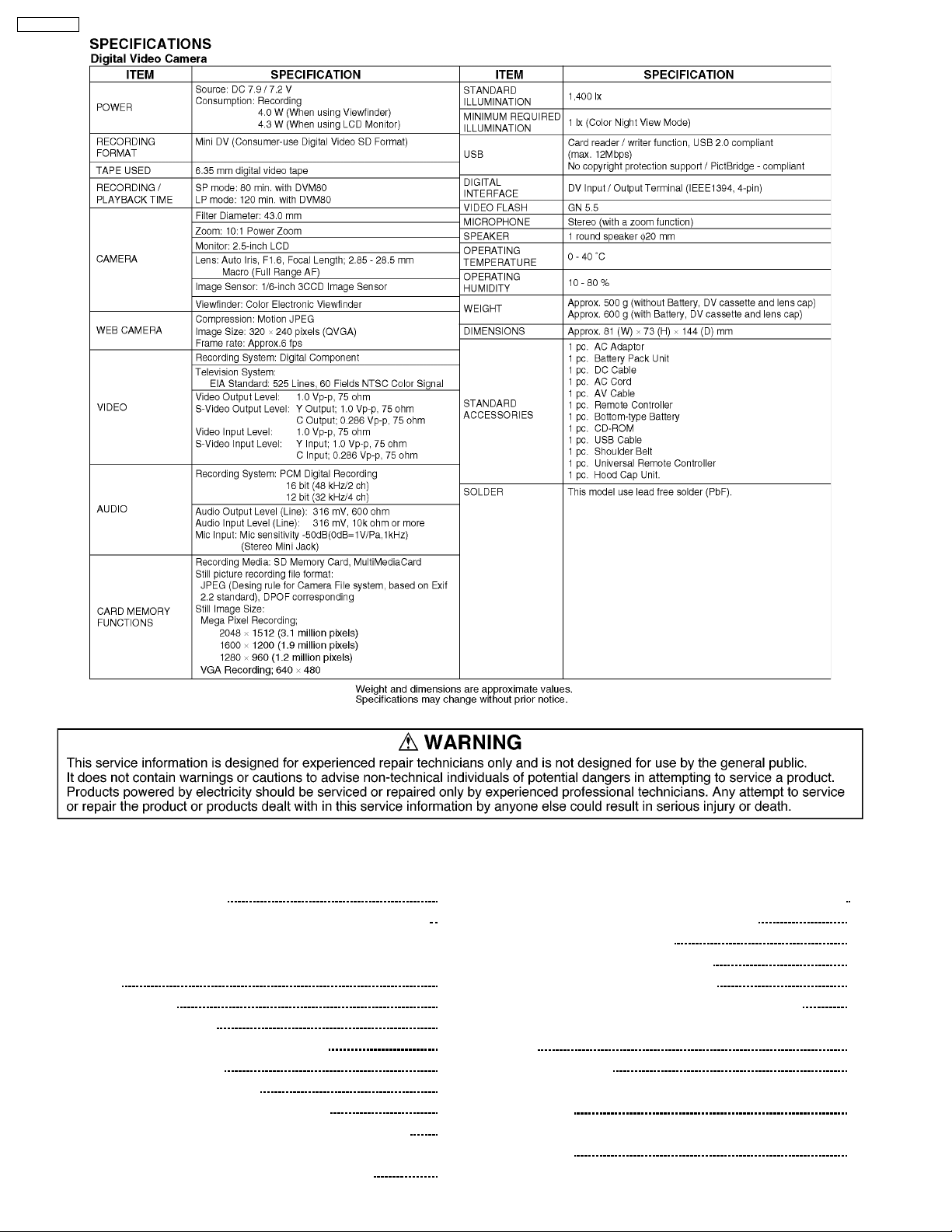

PV-GS250PP

CONTENTS

Page Page

1 SERVICE INFORMATION 4

1.1. Service Information Regarding IC2001 of PV-GS250PP

1.2. Service Information Regarding Simultaneous Exchange of

MONITOR C.B.A. and LCD PANEL UNIT of PV-GS250PP

2 INTRODUCTION

2.1. INTRODUCTION

2.2. ABOUT LEAD FREE SOLDER (PbF)

3 SAFETY PRECAUTIONS

3.1. GENERAL GUIDELINES

3.2. LEAKAGE CURRENT COLD CHECK

3.3. LEAKAGE CURRENT HOT CHECK (See Figure. 1)

4 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD) TO

ELECTROSTATICALLY SENSITIVE (ES) DEVICES

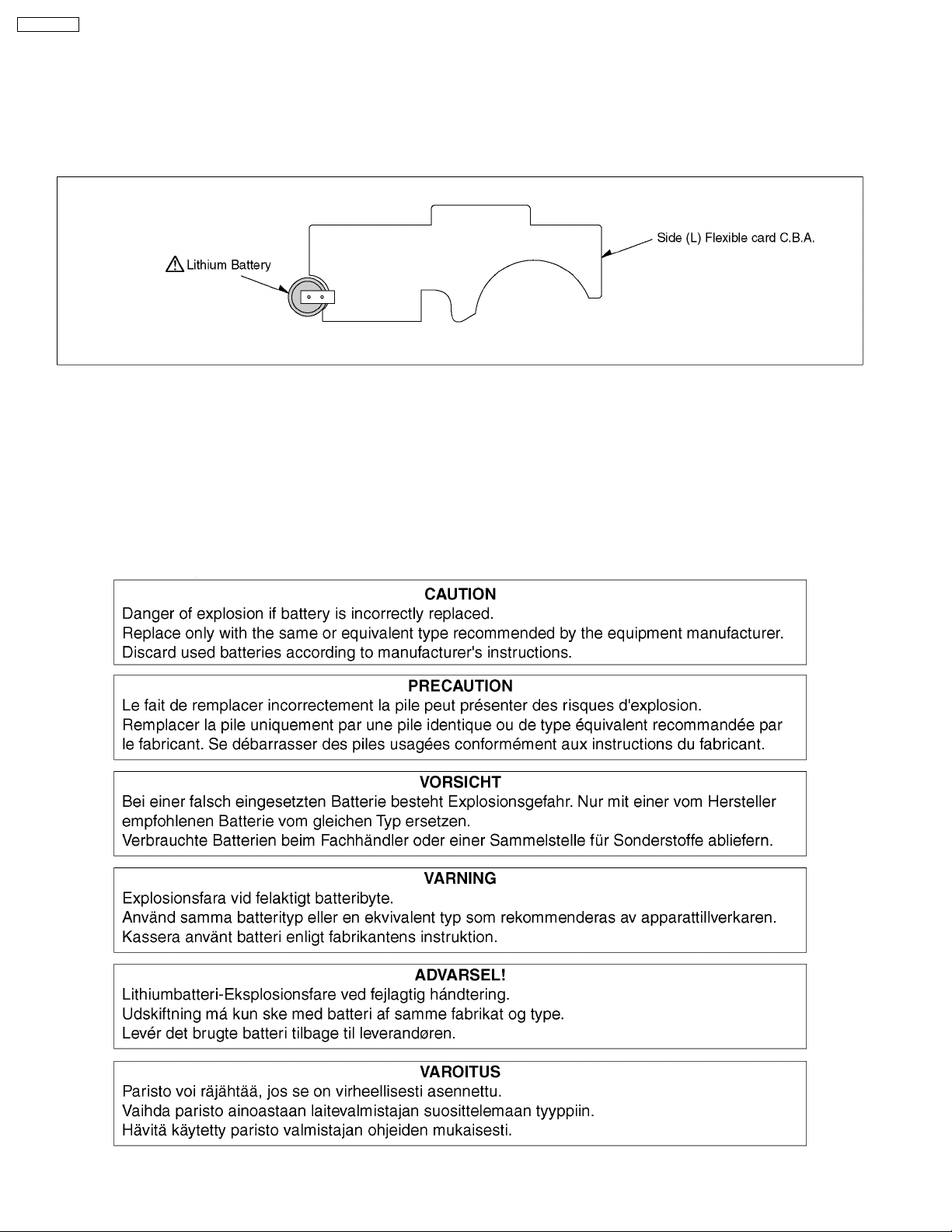

5 HOW TO REPLACE THE LITHIUM BATTERY (PROCEDURE) 10

4

6 HOW TO RECYCLE THE LITHIUM BATTERY

7 ADJUSTMENT PROCEDURES

7.1. DISASSEMBLE FLOW CHART

5

7

7

7

8

8

8

8

9

7.2. DISASSEMBLY PROCEDURES

7.3. DISASSEMBLY PROCEDURES MECHA. UNIT

7.4. DISASSEMBLY PROCEDURES OF CAMERA LENS UNIT

8 SERVICE CAUTION

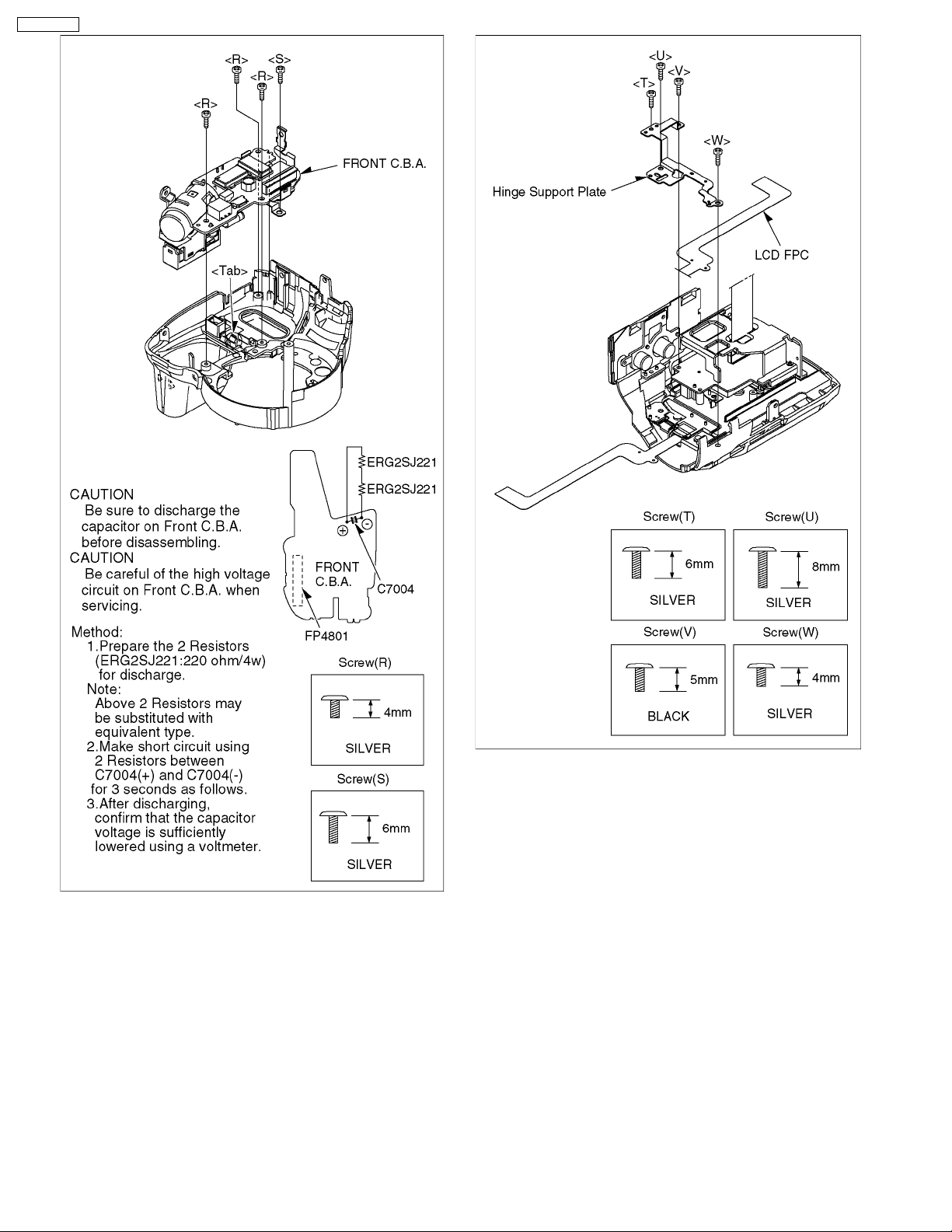

8.1. HOW TO DISCHARGE THE CAPACITOR ON FRONT

C.B.A.

8.2. EEPROM DATA FOR SPARE PARTS OF THE MAIN

C.B.A.

2

11

12

12

13

22

26

27

27

27

Page 3

8.3. SERVICE EXTENSION CABLE FOR ALL C.B.A.

INCLUDED IN MODULE UNIT

8.4. LOCATION FOR CONNECTORS OF THE MAIN C.B.A. &

SUB C.B.A.

8.5. CSP IC LOCATION OF THE MAIN C.B.A. & SUB C.B.A.

8.6. TEMPERATURE PROFILE FOR HEAT RESISTANCE OF

CSP IC

9 ELECTRICAL ADJUSTMENT PROCEDURES

9.1. COMPUTER ASSISTED ADJUSTMENT SYSTEM

<TATSUJIN> ADJUSTMENT.

9.2. SET-UP MANUAL FOR DV-Camcorder.

9.3. SET UP PC-EVR ADJUSTMENT PROGRAM

9.4. INITIAL GUIDELINE

10 MECH ANICAL ADJUSTMENT PROCEDUR ES

10.1. ADJUSTMENT ITEM

10.2. ADJUSTMENT PROCEDURES

11 SERV ICE MODE

11.1. ERROR DISPLAY

11.2. SERVICE MENU

12 ABBREVIATIONS

13 BLOCK DIAGRAM

13.1. OVERALL BLOCK DIAGRAM

13.2. CAMERA 1 BLOCK DIAGRAM (SENSOR BLOCK

DIAGRAM)

13.3. CAMERA 2 BLOCK DIAGRAM (PROCESS BLOCK

DIAGRAM)

13.4. LENS DRIVE BLOCK DIAGRAM

13.5. CONTROL 1 BLOCK DIAGRAM

13.6. CONTROL 2 BLOCK DIAGRAM

13.7. VIDEO BLOCK DIAGRAM

13.8. MONITOR BLOCK DIAGRAM

14 SCHE MATIC DIAGRAMS

14.1. INTERCONNECTION SCHEMATIC DIAGRAM

14.2. SIDE (L) FLEX. CARD / CASSETTE COVER

SCHEMATIC DIAGRAM

14.3. LCD HINGE (MONITOR FLEX.) SCHEMATIC DIAGRAM

14.4. MF SENSOR SCHEMATIC DIAGRAM

14.5. REAR OPERATION UNIT SCHEMATIC DIAGRAM

14.6. EVF SCHEMATIC DAIGRAM

14.7. CCD FLEX. CARD SCHEMATIC DIAGRAM

14.8. FRONT SCHEMATIC DIAGRAM

14.9. JACK SCHEMATIC DIAGRAM

14.10. SIDE (R) / LCD DET. SCHEMATIC DIAGRAM

27

14.11. MONITOR SCHEMATIC DIAGRAM

14.12. SUB (SUB CONNECTION) SCHEMATIC DIAGRAM

29

14.13. SUB (LCD) SCHEMATIC DIAGRAM

14.14. SUB (SUB POWER) SCHEMATIC DIAGRAM

31

14.15. SUB (LENS DRIVE) SCHEMATIC DIAGRAM

14.16. SUB (CAMERA) SCHEMATIC DIAGRAM

33

34

14.17. MAIN (MAIN CONNECTION) SCHEMATIC DIAGRAM

14.18. MAIN (AVIO) SCHEMATIC DIAGRAM

14.19. MAIN (EX INPUT) SCHEMATIC DIAGRAM

34

34

37

38

39

39

39

41

41

41

43

51

51

14.20. MAIN (VIDEO) SCHEMATIC DIAGRAM

14.21. MAIN (POWER) SCHEMATIC DIAGRAM

14.22. MAIN (CONTROL) SCHEMATIC DIAGRAM

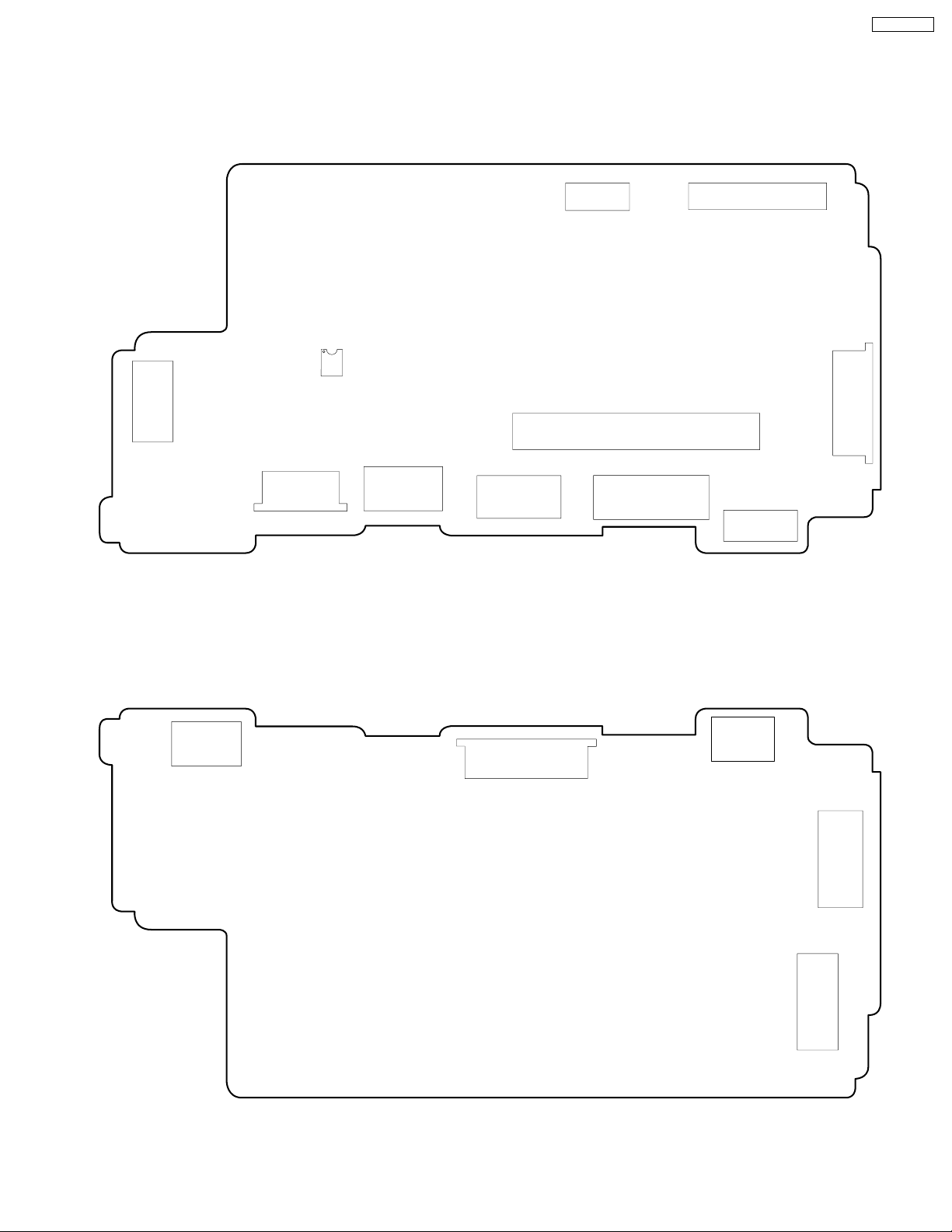

15 CIRCU IT BOARD ASSEMBLIES

15.1. EVF C.B.A.

15.2. LCD DET C.B.A.

15.3. SIDE (R) C.B.A.

15.4. CCD FLEX. CARD C.B.A.

15.5. FRONT C.B.A.

15.6. JACK C.B.A.

15.7. MONITOR C.B.A.

15.8. SUB C.B.A. (COMPONENT SIDE)

15.9. SUB C.B.A. (FOIL SIDE)

15.10. MAIN C.B.A. (COMPONENT SIDE)

52

15.11. MAIN C.B.A. (FOIL SIDE)

16 CHEC KING POINT OF THE CSP IC

53

54

55

56

57

58

59

59

16.1. CHECKING POINT TABLE

16.2. WAVEFORM TABLE (PLAY MODE)

17 EXPLO DED VIEWS

17.1. FRAME & CASING SECTION (1)

17.2. FRAME & CASING SECTION (2)

17.3. LCD SECTION

17.4. CAMERA LENS SECTION

17.5. VCR MECHANISM SECTION

17.6. PACKING PARTS & ACCESSORIES SECTION

61

18 REPL ACEMENT PARTS LIST

18.1. FRAME & CASING SECTION (1) PARTS LIST

61

61

62

62

63

64

65

18.2. FRAME & CASING SECTION (2) PARTS LIST

18.3. LCD SECTION PARTS LIST

18.4. CAMERA LENS SECTION PARTS LIST

18.5. VCR MECHANISM SECTION PARTS LIST

18.6. PACKING PARTS & ACCESSORIES SECTION PARTS

LIST

18.7. ELECTRICAL REPLACEMENT PARTS LIST

PV-GS250PP

66

67

68

70

71

72

74

80

83

84

86

90

92

97

97

97

97

98

99

100

101

102

103

105

106

109

109

124

130

130

131

132

133

134

135

136

136

136

136

137

137

137

138

3

Page 4

PV-GS250PP

1 SERVICE INFORMATION

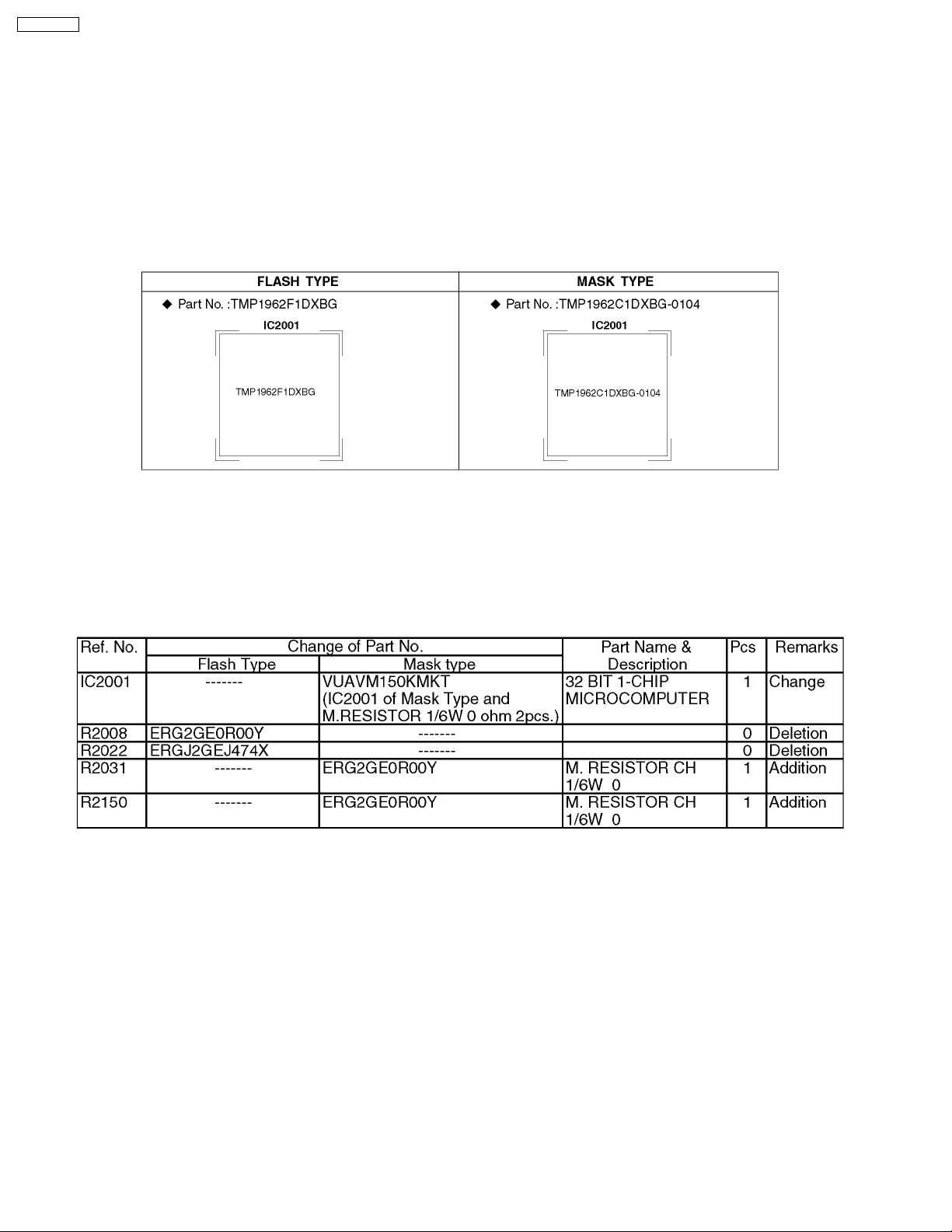

1.1. Service Information Regarding IC2001 of PV-GS250PP

1.1.1. Overview

· DVC model PV-GS250PP will be manufactured 2 distinctly different IC2001.

· These 2 version of IC2001 will be referred to as IC type “FLASH” and “MASK”.

· Supply of the replacement part asks to cause with only “MASK TYPE”.

1.1.2. How to Distinguish the Types of IC2001

1.1.3. Attention for exchanges the IC2001

· There are not the exchangeability between the “FLASH TYPE” and “MASK TYPE” of IC2001.

· Do the addition (R2031and R2150) and also deletion (R2008 and R2022) of the following part simultaneously, when exchange

to the “MASK TYPE” from the “FLASH TYPE” of IC2001.

· It exchange only IC, in the case that IC2001 is “MASK TYPE”. (The exchange of the chip resistor is not necessary.)

4

Page 5

PV-GS250PP

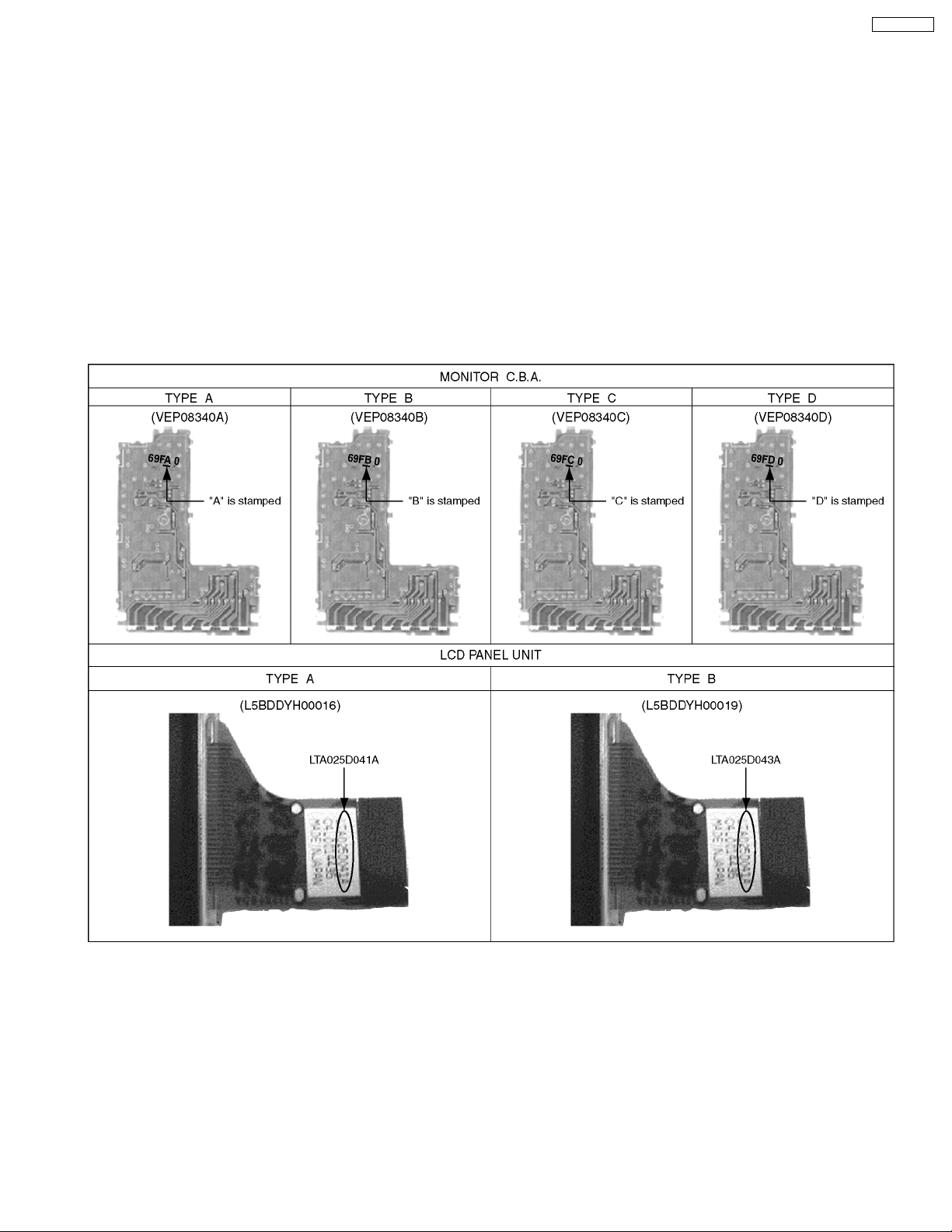

1.2. Service Information Regarding Simultaneous Exchange of MONITOR

C.B.A. and LCD PANEL UNIT of PV-GS250PP

1.2.1. Overview

· DVC model PV-GS250PP will be manufactured 4 distinctly different MONITOR C.B.A. and 2 distinctly different LCD PANEL

UNIT.

· These 4 version of MONITOR C.B.A. will be referred to as C.B.A. type “A”, “B”, “C” and “D”.

· These 2 version of LCD PANEL UNIT will be referred to as UNIT type “A” and “B”.

· There are not the exchangeability between the “A”, “B”, “C” and “D” of MONITOR C.B.A..

· There are not the exchangeability between the “A” and “B” of LCD PANEL UNIT.

· MONITOR C.B.A. and LCD PANEL UNIT supply it the kit.

(Do not supply it in one of each individually MONITOR C.B.A. and LCD PANEL UNIT.)

1.2.2. How to Distinguish the Types of MONITOR C.B.A. and LCD PANEL UNIT

5

Page 6

PV-GS250PP

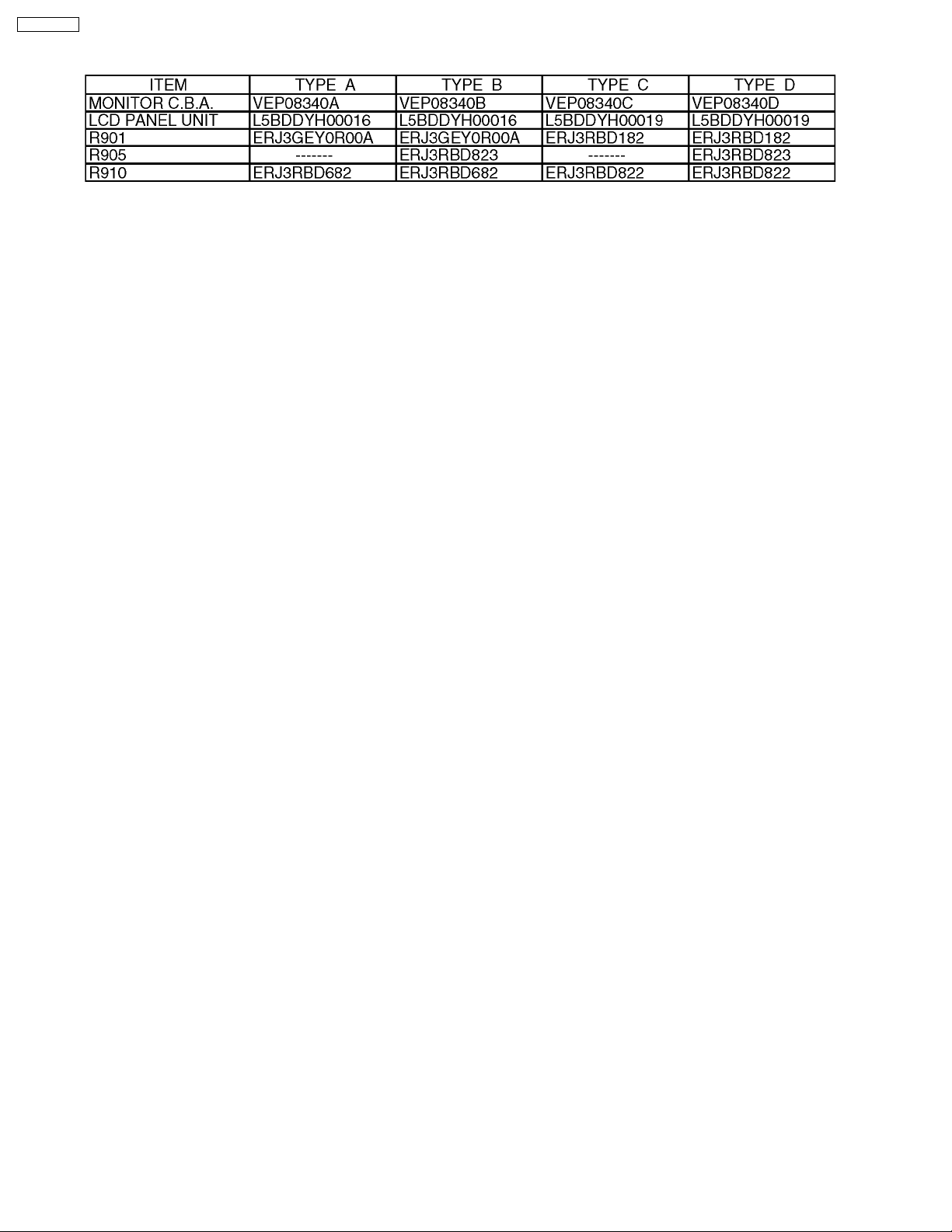

1.2.3. Difference Comparison Chart

1.2.4. Attention for exchange the MONITOR C.B.A..

· In the case that the LCD PANEL UNIT is TYPE “A”.

Replace the chip resistor of R901 and R910 to the chip resistor that is doing the same pack to the kit.

R901 ERJ3RBD182 ® ERJ3GEY0R00

R910 ERJ3RBD822 ® ERJ3RBD682

· In the case that the LCD PANEL UNIT is TYPE “B”.

Exchange only the MONITOR C.B.A..

1.2.5. Attention for exchange the LCD PANEL UNIT.

· In the case that the MONITOR C.B.A. is TYPE “A” and “B”.

Replace the chip resistor of R901 and R910 to the chip resistor that is doing the same pack to the kit.

R901 ERJ3RBD182 ® ERJ3GEY0R00

R910 ERJ3RBD822 ® ERJ3RBD682

· In the case that the MONITOR C.B.A. is TYPE “C” and “D”.

Exchange only the LCD PANEL UNIT.

CAUTION:

It does the confirmation of the MONITOR C.B.A. and LCD PANEL UNIT without fail on the occasion of the repair and please

do the part exchange.

6

Page 7

PV-GS250PP

2 INTRODUCTION

2.1. INTRODUCTION

This service manual contains technical information which will allow service personnel´s to understand and service this

model.Please place orders using the parts list and not the drawing reference numbers.

If the circuit is changed or modified, this information will be followed by supplement service manual to be filed with o riginal service

manual.

Note 1:

These movie camera uses AC Adaptor is PV-DAC14D

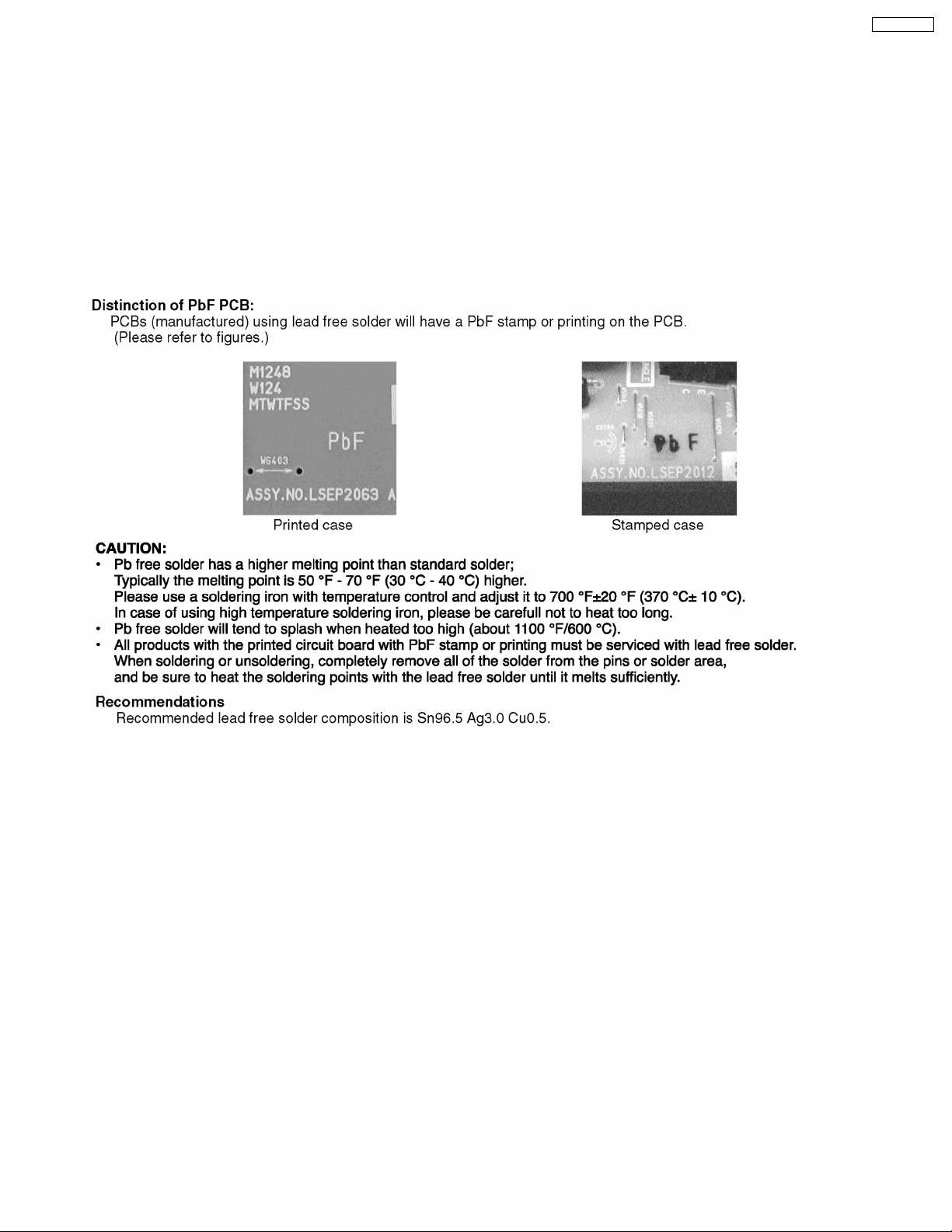

2.2. ABOUT LEAD FREE SOLDER (PbF)

7

Page 8

PV-GS250PP

3 SAFETY PRECAUTIONS

3.1. GENERAL GUIDELINES

1. IMPORTANT SAFETY NOTICE

There are special components used in this equipment which are important for safety. These parts are marked by

Schematic Diagrams, Circuit Board Layout, Exploded Views and Replacement Parts List. It is essential that these critical parts

should be replaced with manufacturer’s specified parts to prevent X-RADIATION, shock fire, or other hazards. Do not modify

the original design without permission of manufacturer.

2. An Isolation Transformer should always be used during the servicing of AC Adaptor whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in personal injury

from electrical shocks. It will also protect AC Adaptor from being damaged by accidental shorting that may occur during

servicing.

3. When servicing, observe the original lead dress. It a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

4. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

5. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

3.2. LEAKAGE CURRENT COLD CHECK

1. Unplug the AC cord and connect a jumper between the two prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between the jumpered AC plug and each exposed metallic cabinet part on

the equipment such as screwheads, connectors, control shafts, etc. When the exposed metallic part has a return path to the

chassis, the reading should be between 1MW and 5.2MW. When the exposed metal does not have a return path to the chassis,

the reading must be infinity.

in the

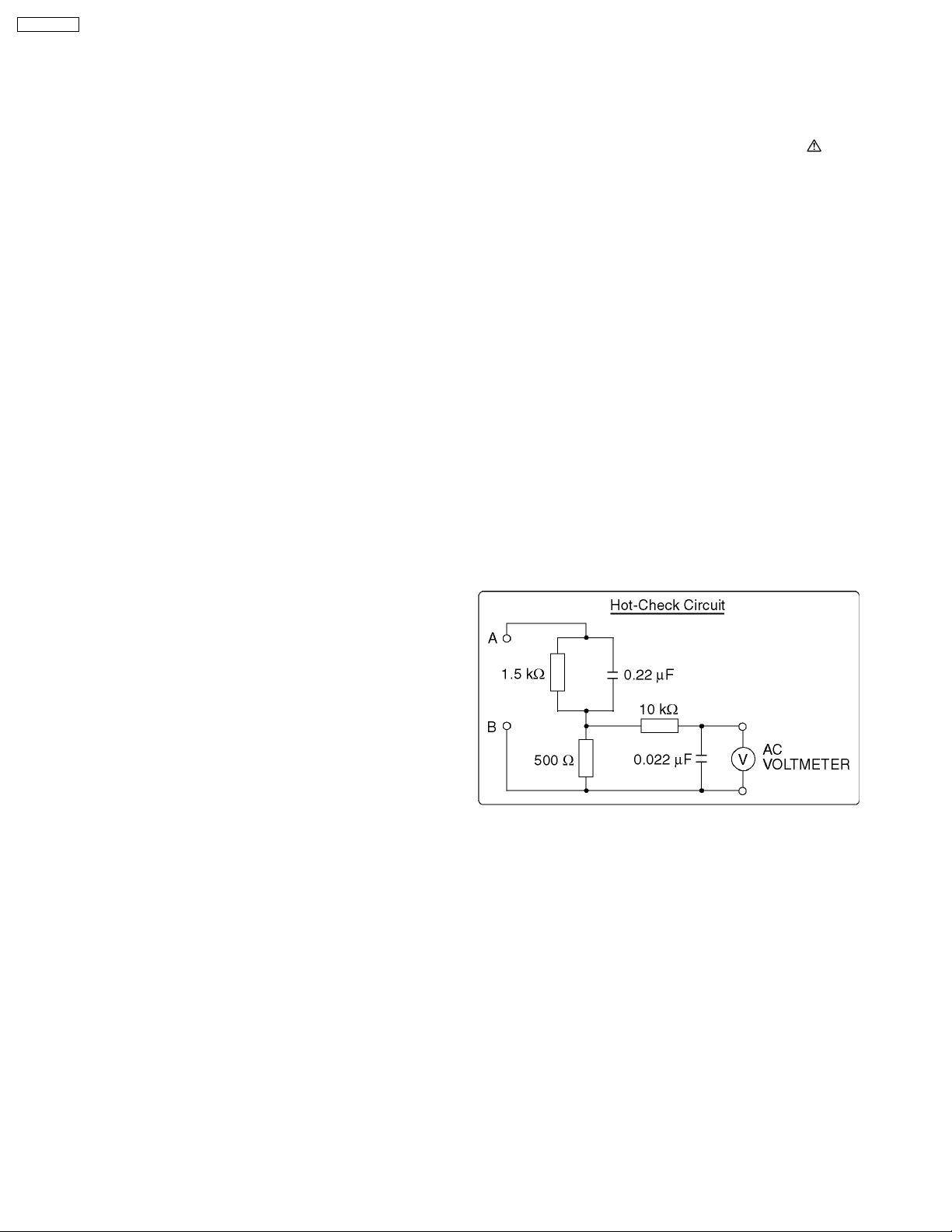

3.3. LEAKAGE CURRENT HOT CHECK (See Figure 1)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect “A” to exposed metallic part on the set. And

connect “B” to a good earth ground, as shown in Figure 1.

3. Use an AC voltmeter, with 1 kW/V or more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the ACplugin the ACoutlet and repeateach of the

above measurements.

6. The potential at any point should not exceed 0.25 V RMS.

A leakage current tester (Simpson Model 229 or equivalent)

may be used to make the hot checks, leakage current must

not exceed 1/2 mA. In case a measurement is outside of

the limits specified, there is a possibility of a shock hazard,

and the equipment should be repaired and rechecked

before it is returned to the customer.

Figure 1

8

Page 9

PV-GS250PP

4 PREVENTION OF ELECTRO STATIC DISCHARGE (ESD)

TO ELECTROSTATICALLY SENSITIVE (ES) DEVICES

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor “chip” components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an antistatic solder removal device. Some solder removal devices not classified as “antistatic (ESD protected)” can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD)

sufficient to damage an ES device).

9

Page 10

PV-GS250PP

5 HOW TO REPLACE THE LITHIUM BATTERY

(PROCEDURE)

1. Remove the Side Case (L) C.B.A.. (Refer to Disassembly Procedures.)

2. Unsolder the Lithium Battery “ML920S/F9D” and then replace the new one. (See Fig. B1.)

3. Danger of explosion if battery is incorrectly replaced. Replace only with the same or equivalent type.

Fig. B1

Note:

The lithium battery is a critical component. (Type No.: N9ZZ00000297.)

It must never be subjected to excessive heat or discharge.

It must therefore only be fitted in equipment designed specifically for its use.

Replacement batteries must be of the same type and manufacture.

They must be fitted in the same manner and location as the original battery, with the correct polarity contacts observed.

Do not attempt to re-charge the old battery or re-use it for any other purpose.

It should be disposed of in waste products destined for burial rather than incineration.

10

Page 11

6 HOW TO RECYCLE THE LITHIUM BATTERY

PV-GS250PP

11

Page 12

PV-GS250PP

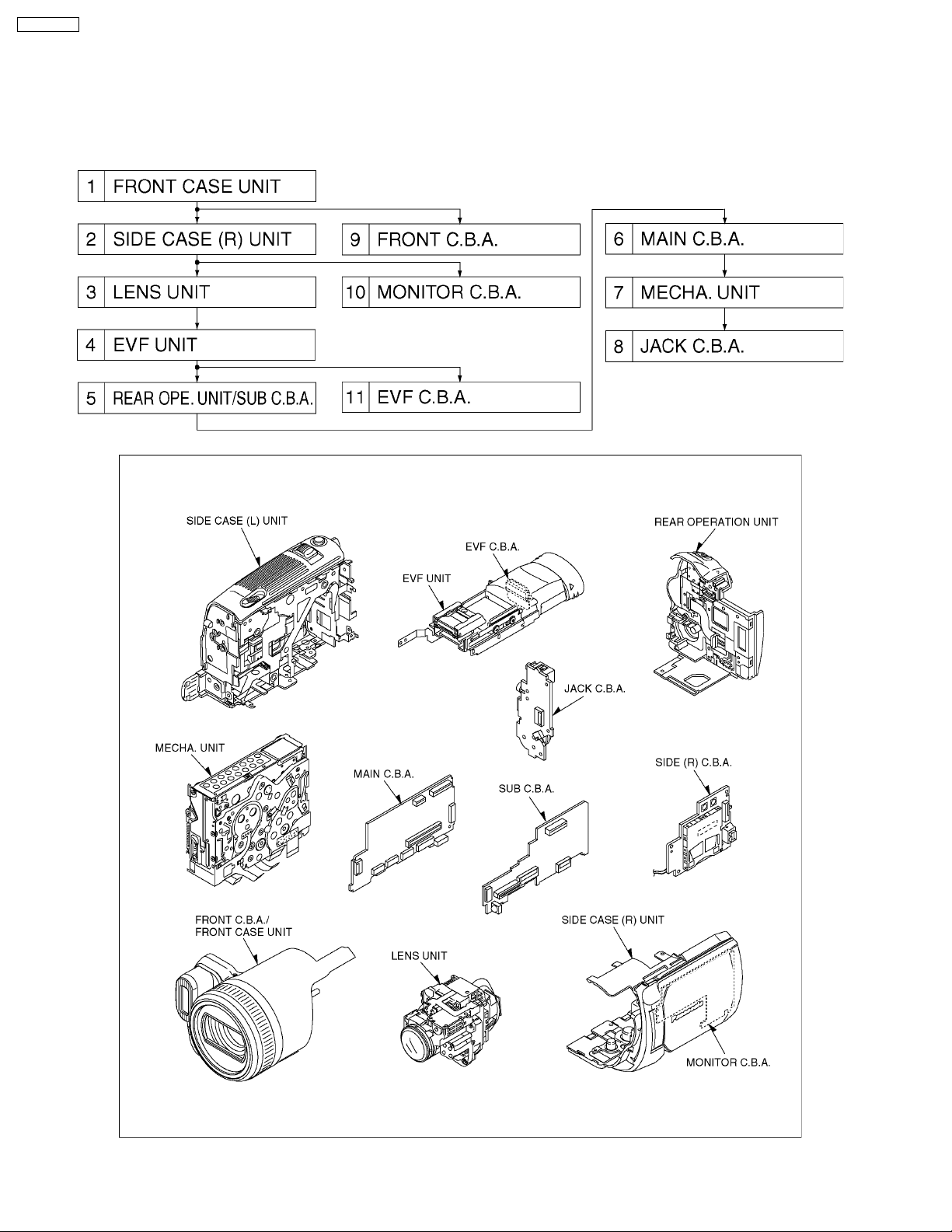

7 ADJUSTMENT PROCEDURES

7.1. DISASSEMBLE FLOW CHART

This flow chart indicates the disassembly steps the cabinet parts, C.B.A. and Mecha. Unit in order to access to be serviced. When

reinstalling, perform the steps in the reverse order.

12

Page 13

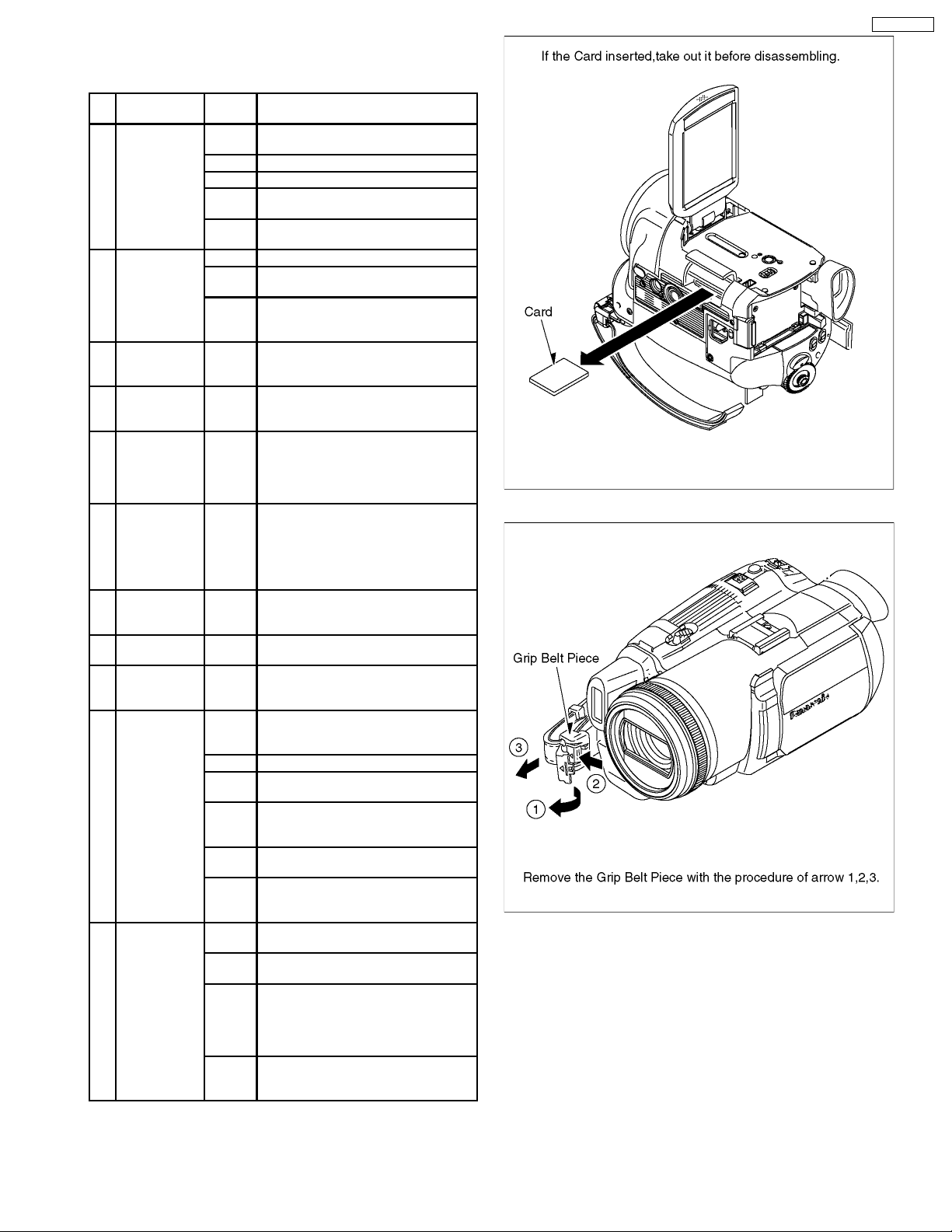

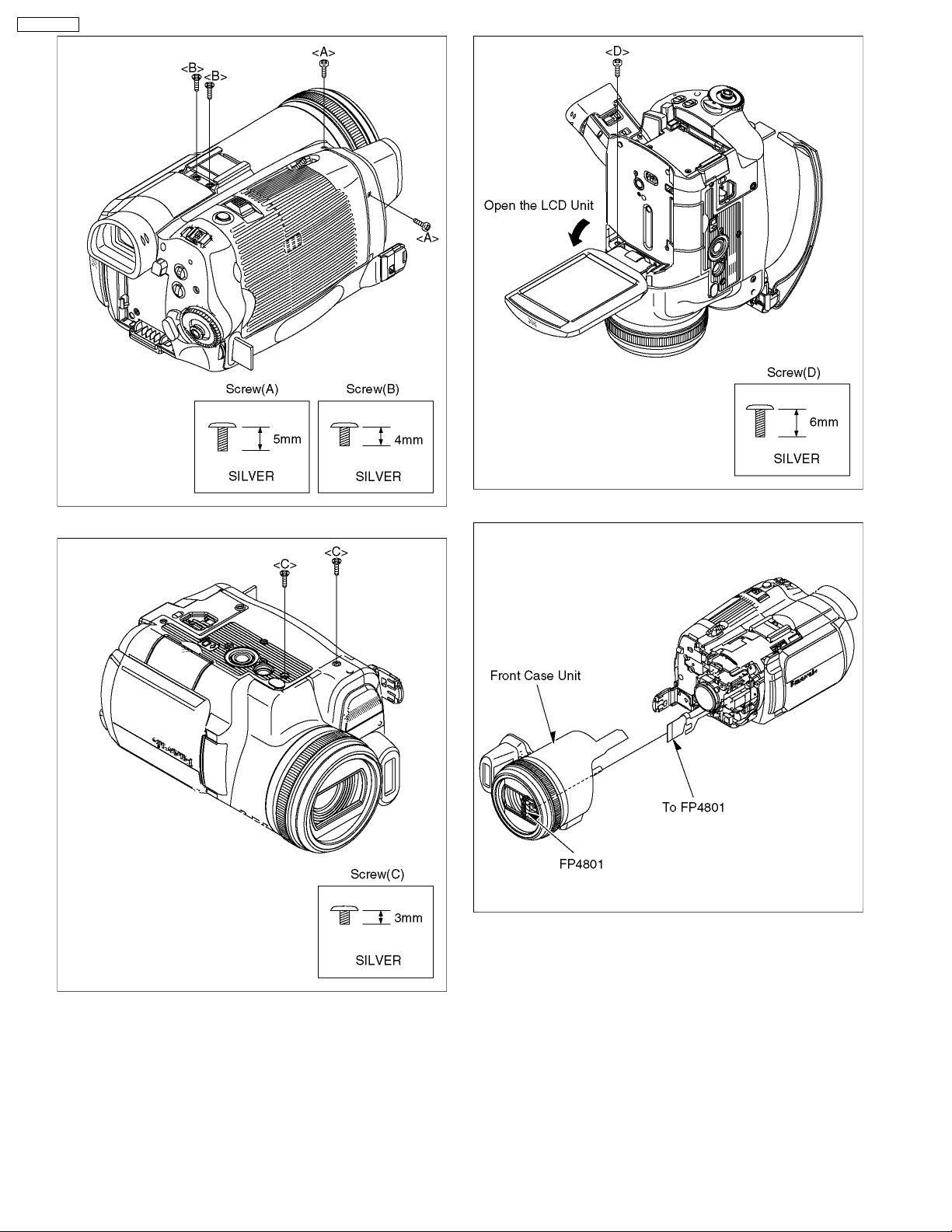

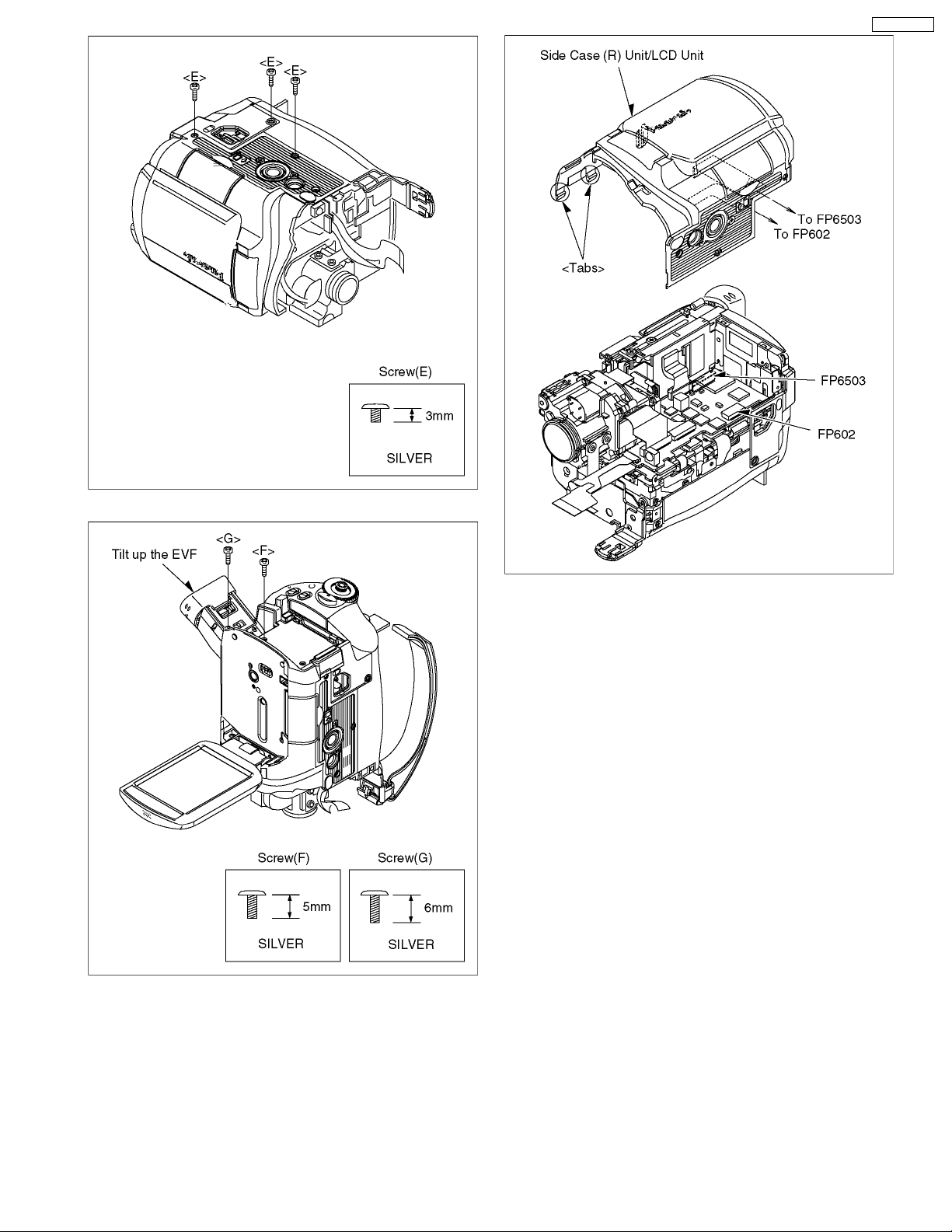

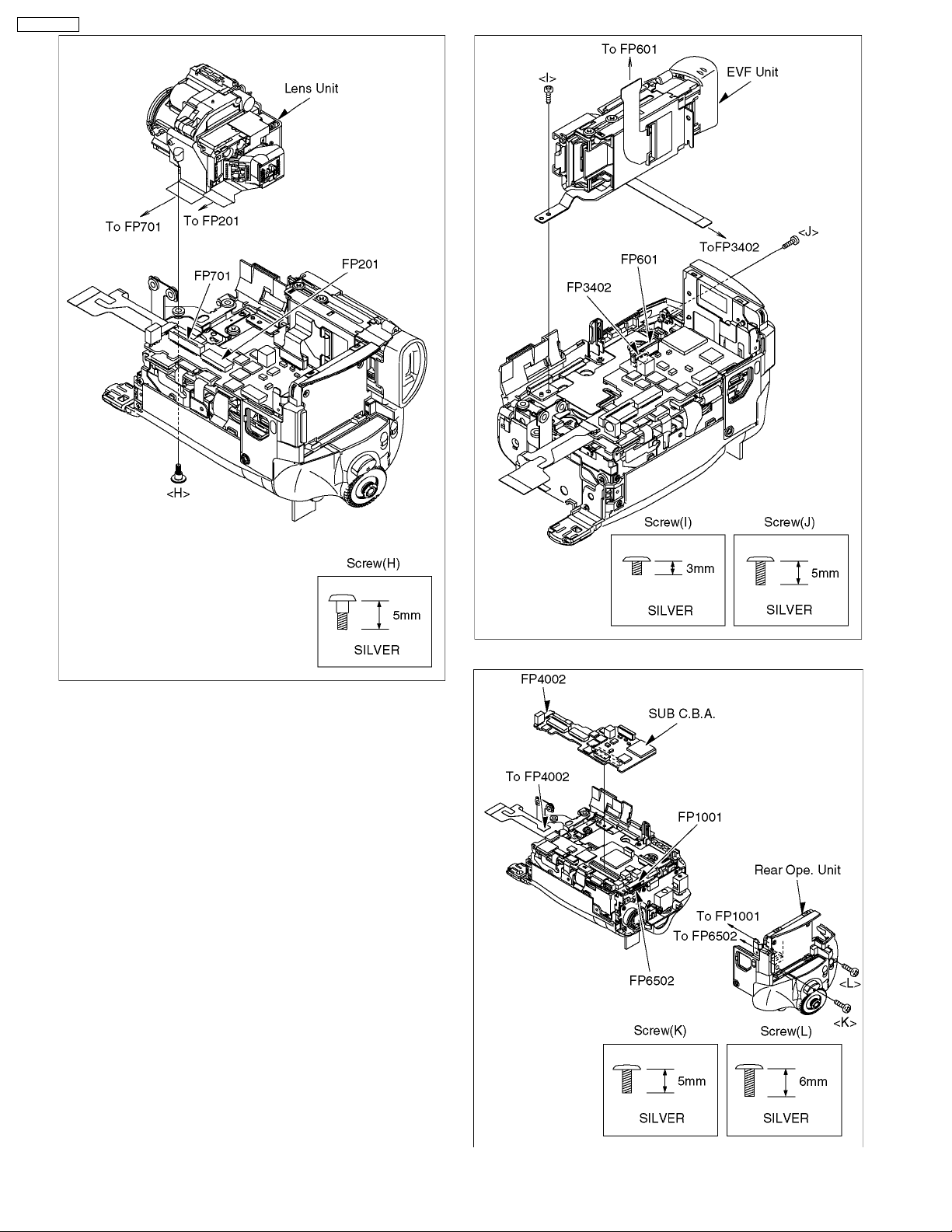

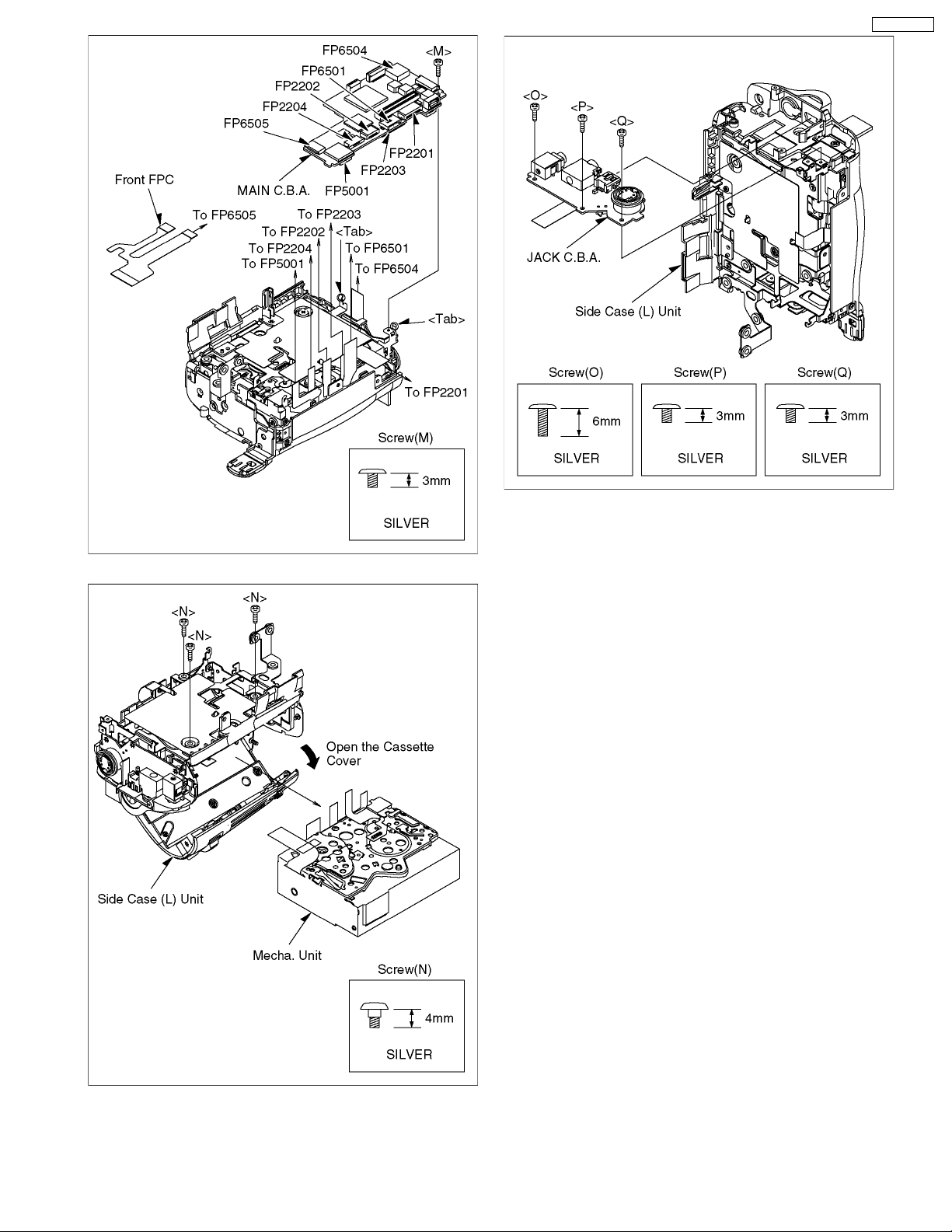

7.2. DISASSEMBLY PROCEDURES

Flow-Chart for Disassembly Procedure

No. Item / Part Fig. Removal (Screw,Connector,Flex. &

1 Front Case

Unit

2 Side Case (R)

Unit / LCD Unit

3 Lens Unit Fig. D10 1-Screw (H)

4 EVF Unit Fig. D11 1-Screw (I), 1-Screw (J)

5 Rear

Operation Unit

/ Sub C.B.A.

6 Main C.B.A. Fig. D13 8-Connectors FP2201, FP2202,

7 Mecha. Unit Fig. D14 Open the Cassette Cover

8 Jack C.B.A. Fig. D15 1-Screw (O), 1-Screw (P), 1-Screw (Q)

9 Front C.B.A. Fig. D16 3-Screws (R), 1-Screw (S)

10 Monitor C.B.A. Fig. D17 1-Screw (T), 1-Screw (U), 1-Screw (V),

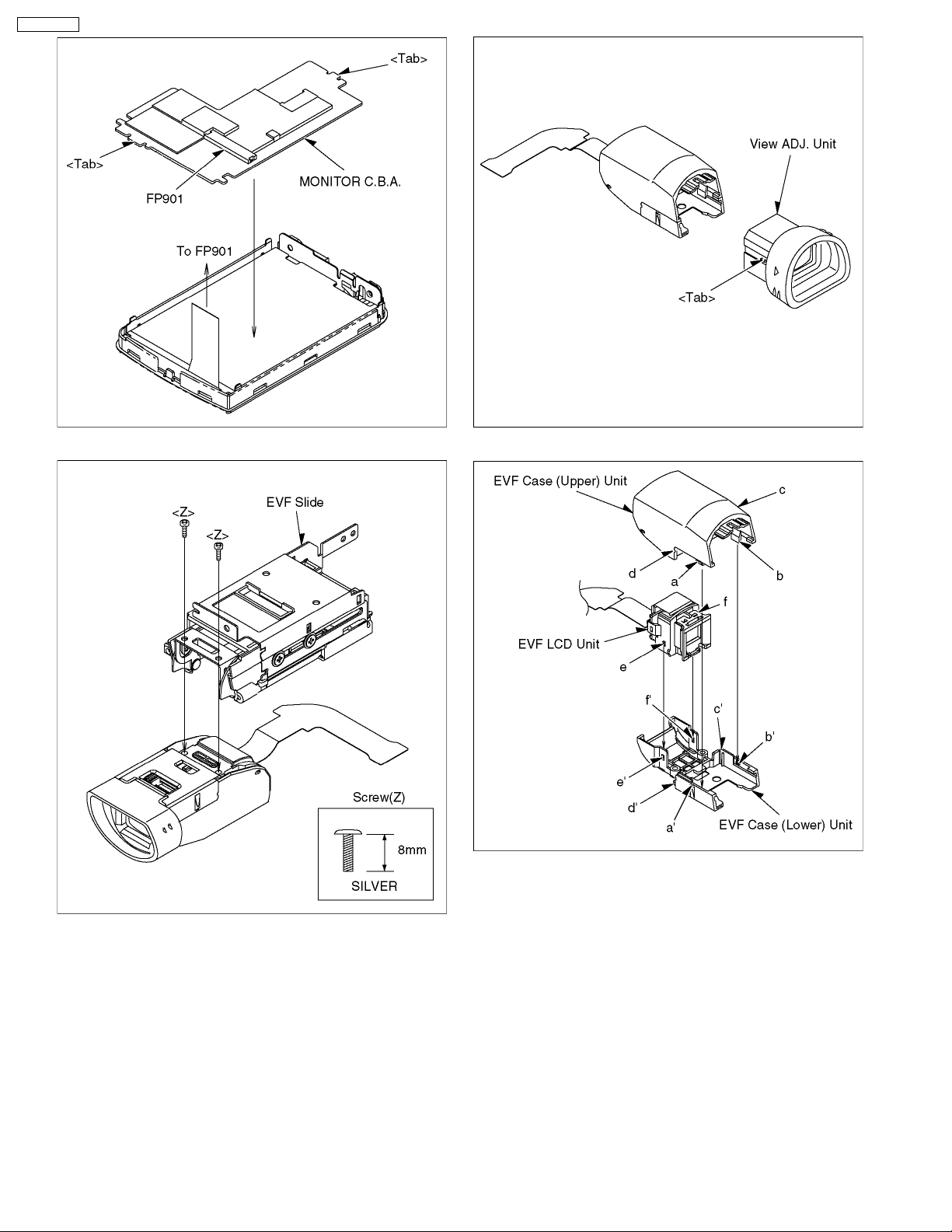

11 EVF C.B.A. Fig. D23 2-Screws (Z)

Fig. D2 Remove the Grip Belt Piece with the

procedure of arrow 1,2,3.

Fig. D3 2-Screws (A), 2-Screws (B)

Fig. D4 2-Screws (C)

Fig. D5 Open the LCD Unit

1-Screw (D)

Fig. D6 1-Connector FP4801

Front Case Unit

Fig. D7 3-Screws (E)

Fig. D8 Tilt up the EVF

1-Screw (F), 1-Screw (G)

Fig. D9 2-Connectors FP602, FP6503

2-Tabs

Side Case (R) Unit / LCD Unit

2-Connectors FP201, FP701

Lens Unit

2-Connectors FP601, FP3402

EVF Unit

Fig. D12 1-Screw (K), 1-Screw (L)

2-Connectors FP1001, FP6502

Rear Operation Unit

1-Connector FP4002

Sub C.B.A.

FP2203, FP2204, FP5001, FP6501,

FP6504, FP6505

1-Screw (M)

2-Tabs

Main C.B.A.

3-Screws (N)

Mecha. Unit

Jack C.B.A.

1-Tab

Front C.B.A.

1-Screw (W)

Hinge Support Plate

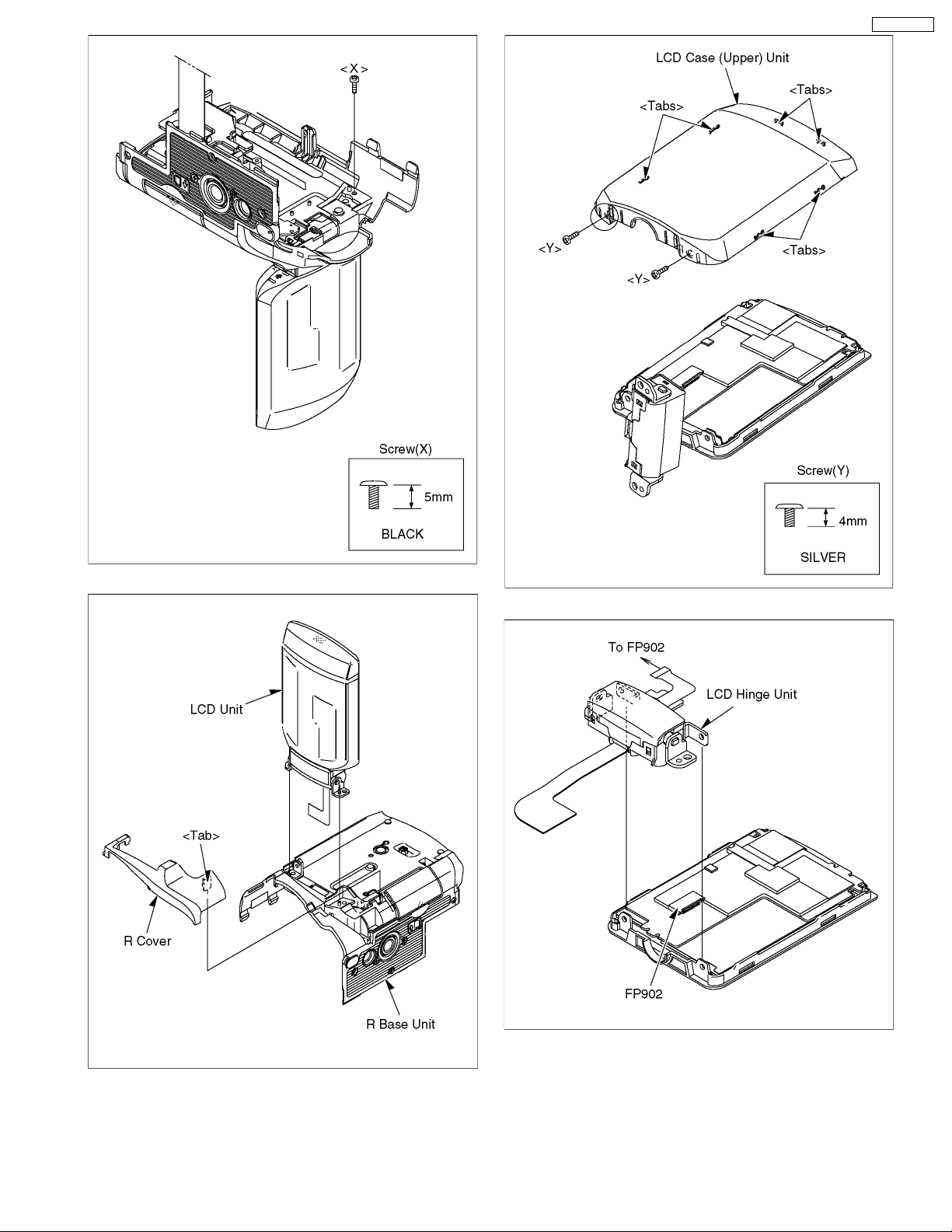

Fig. D18 1-Screw (X)

Fig. D19 1-Tab

R Cover / LCD Unit

Fig. D20 2-Screws (Y)

6-Tabs

LCD Case (Upper) Unit

Fig. D21 1-Connector FP902

LCD Hinge Unit

Fig. D22 1-Connector FP901

2-Tabs

Monitor C.B.A.

EVF Slide

Fig. D24 1-Tab

View ADJ. Unit

Fig. D25 Remove a,b,c,d department (remove

department previously).

EVF Case (Upper) Unit

Remove e,f department.

EVF Case (Lower) Unit

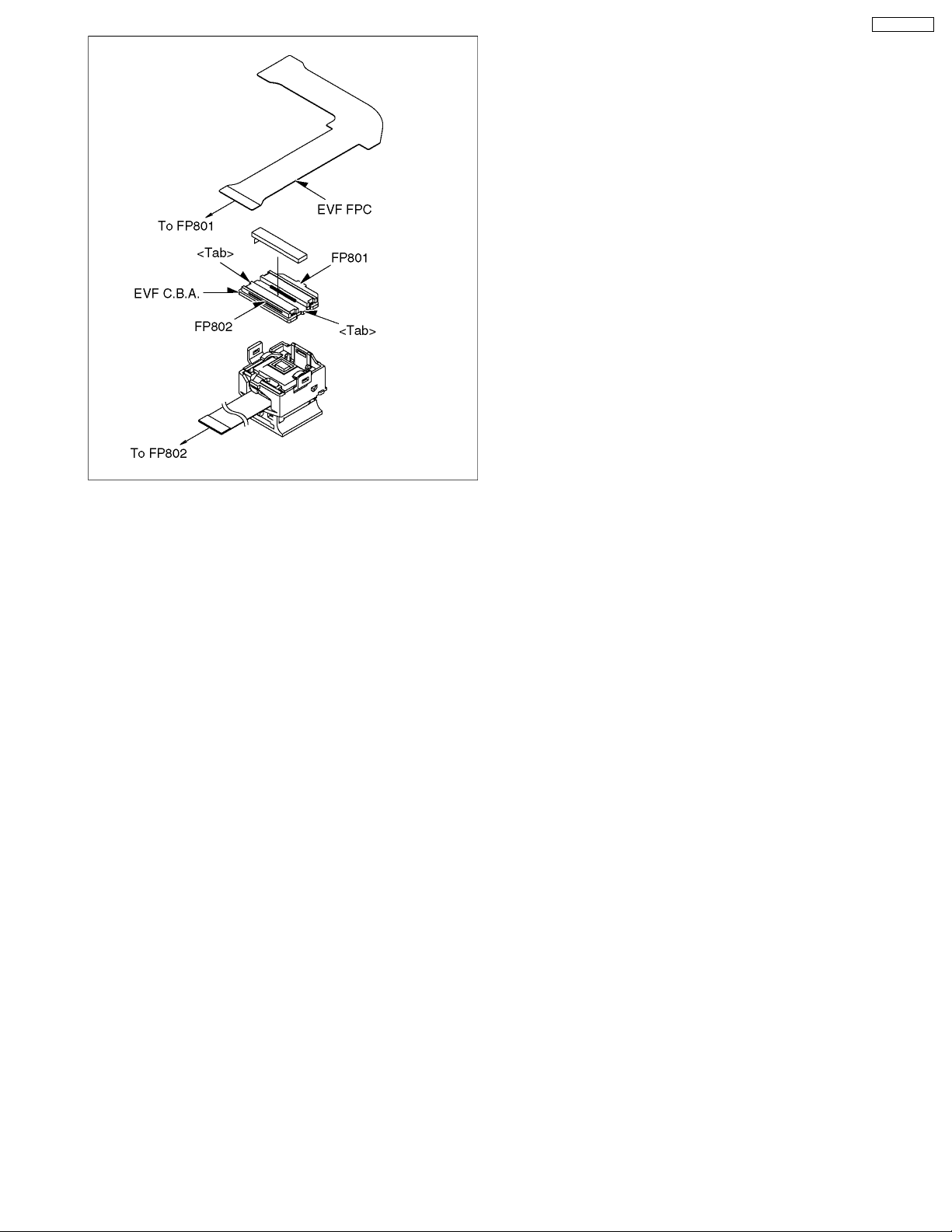

Fig. D26 2-Connectors FP801,FP802

2-Tabs

EVF C.B.A.

Other)

PV-GS250PP

Fig. D1

Fig. D2

13

Page 14

PV-GS250PP

Fig. D3

Fig. D5

Fig. D6

Fig. D4

14

Page 15

PV-GS250PP

Fig. D7

Fig. D9

Fig. D8

15

Page 16

PV-GS250PP

Fig. D10

Fig. D11

16

Fig. F12

Page 17

PV-GS250PP

Fig. D13

Fig. D15

Fig. D14

17

Page 18

PV-GS250PP

Fig. D16

Fig. D17

18

Page 19

PV-GS250PP

Fig. D18

Fig. D20

Fig. D19

Fig. D21

19

Page 20

PV-GS250PP

Fig. D22

Fig. D24

Fig.D25

Fig. D23

20

Page 21

PV-GS250PP

Fig. D26

21

Page 22

PV-GS250PP

7.3. DISASSEMBLY PROCEDURES MECHA. UNIT

Flow-Chart for Disassmbly Procedures

No. Item / Part Fig. Removal (Screw, Connector, Flex. & Other)

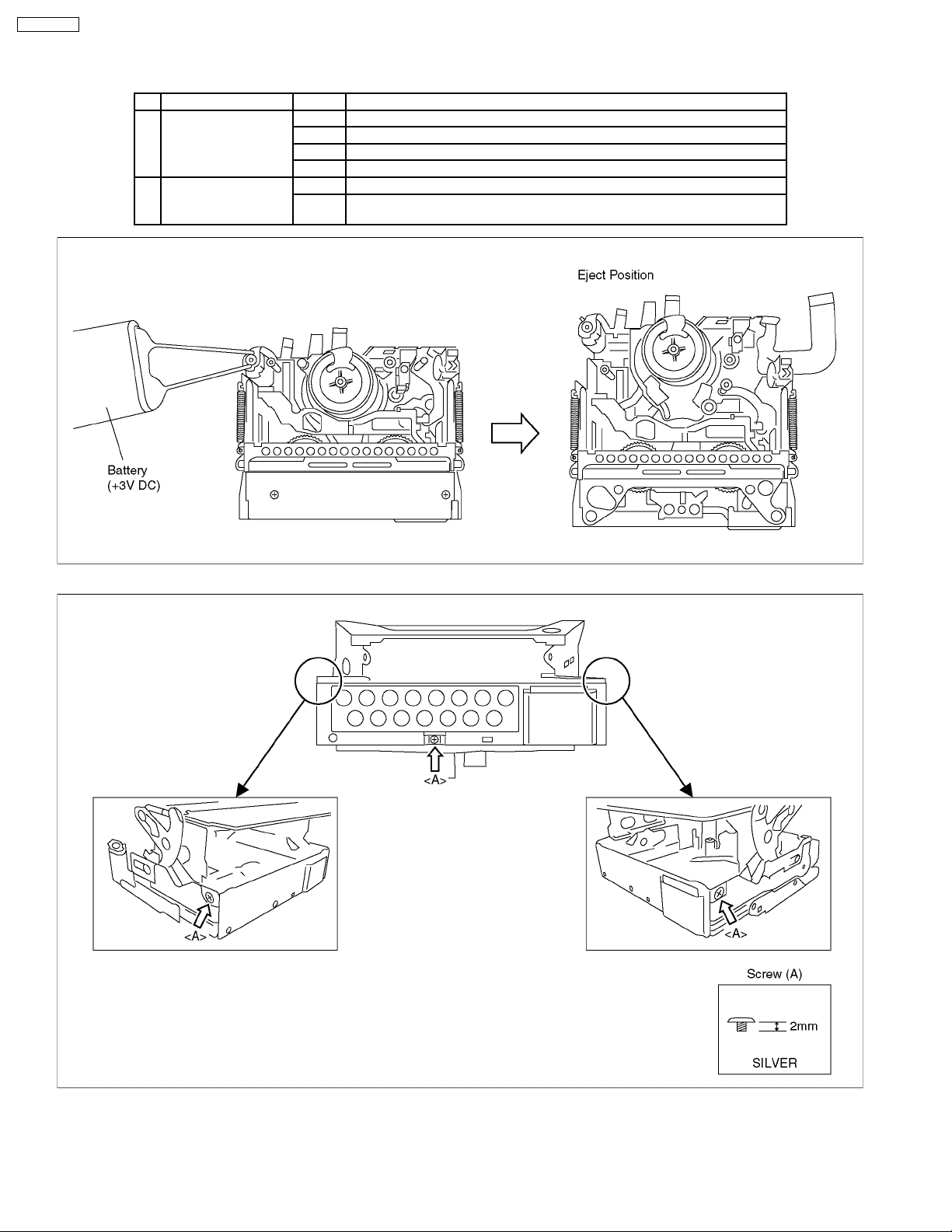

1 Cassette Up Unit Fig. M1 It makes the mechanism position in Eject condition (For Battery)

Fig. M2 3-Screws (A)

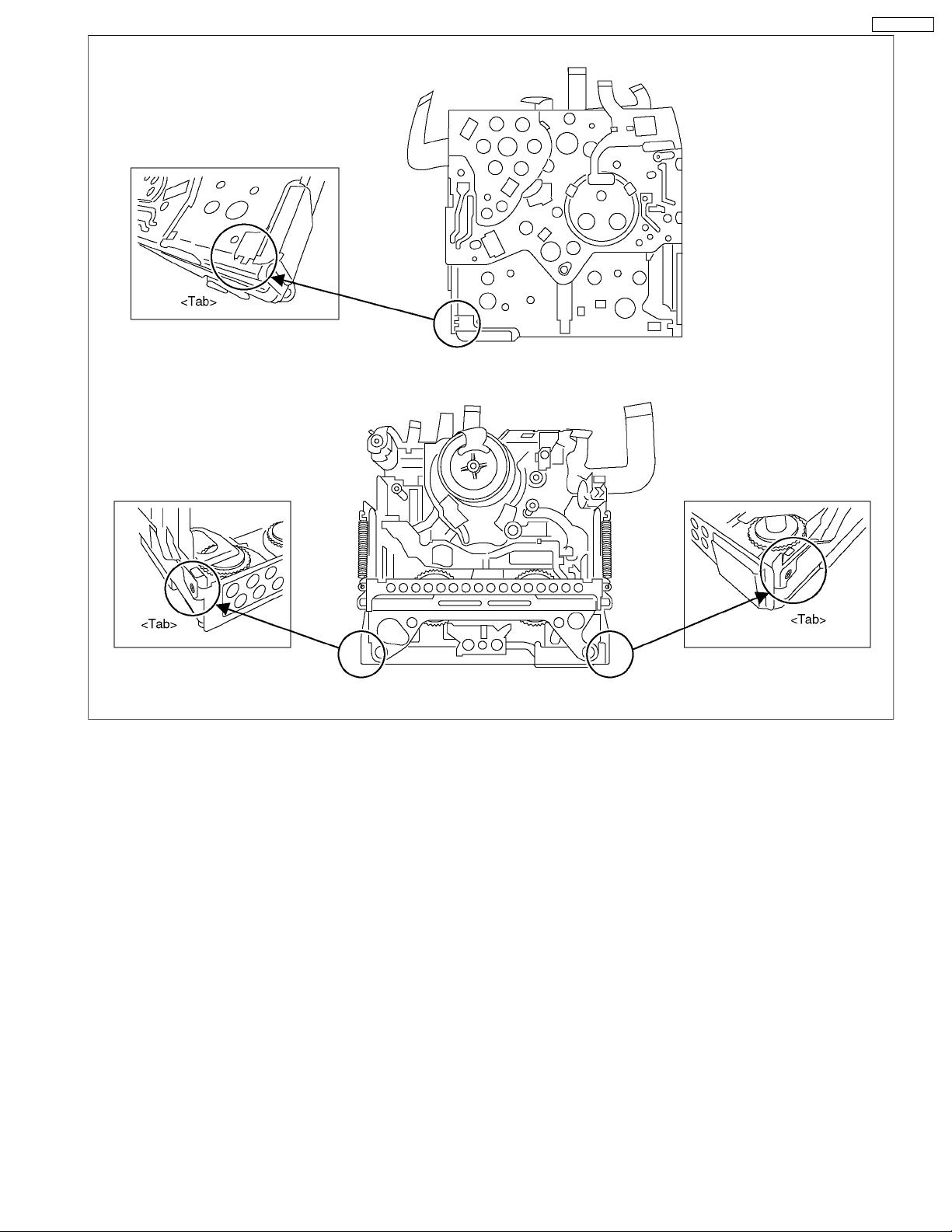

Fig. M3 3-Tabs

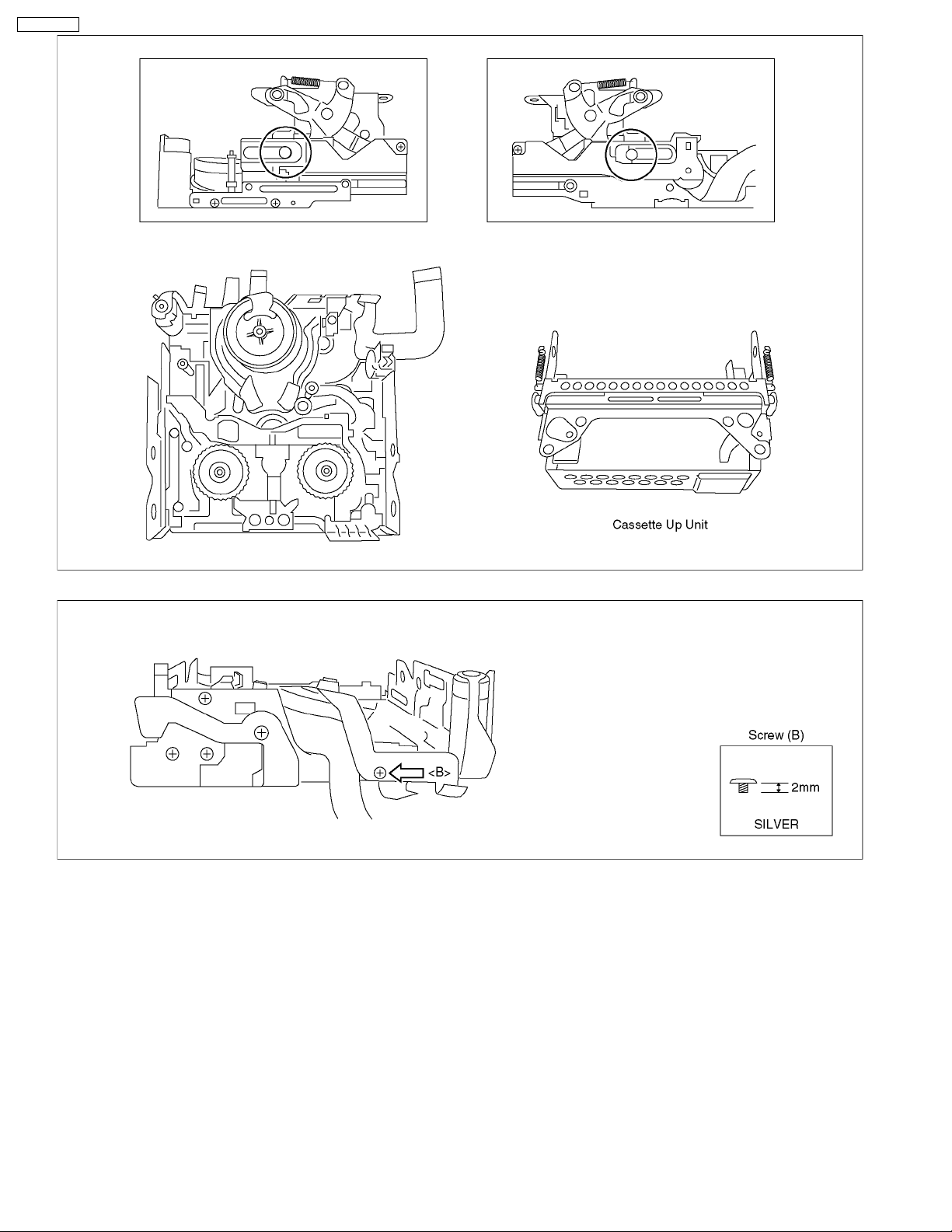

Fig. M4 It remove the piece arrangement unit from rail department

2 Cylinder Unit Fig. M5 1-Screw (B)

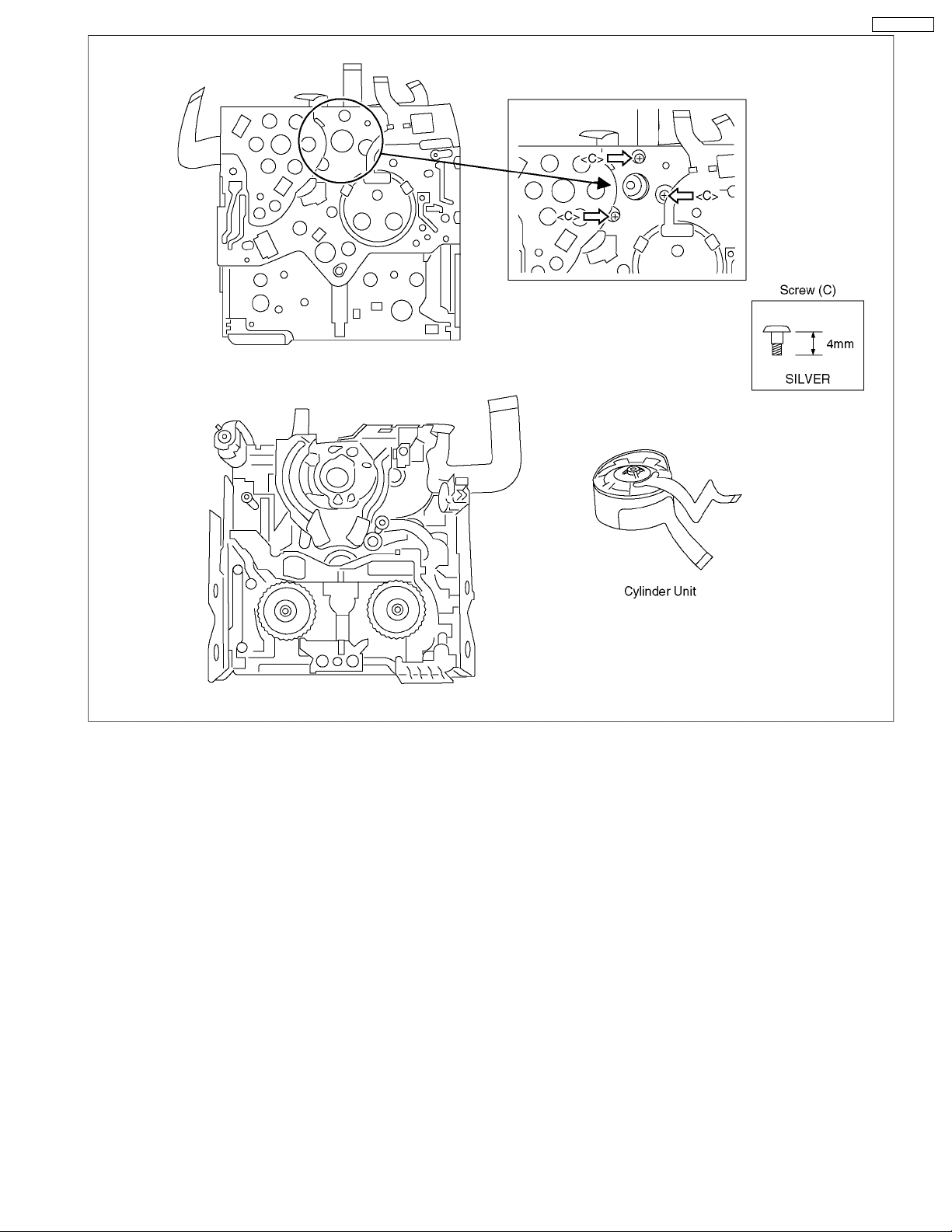

Fig. M6 3-Screw (C)

Cylinder Unit

Fig. M1

Fig. M2

22

Page 23

PV-GS250PP

Fig. M3

23

Page 24

PV-GS250PP

Fig. M4

Fig. M5

24

Page 25

PV-GS250PP

Fig. M6

25

Page 26

PV-GS250PP

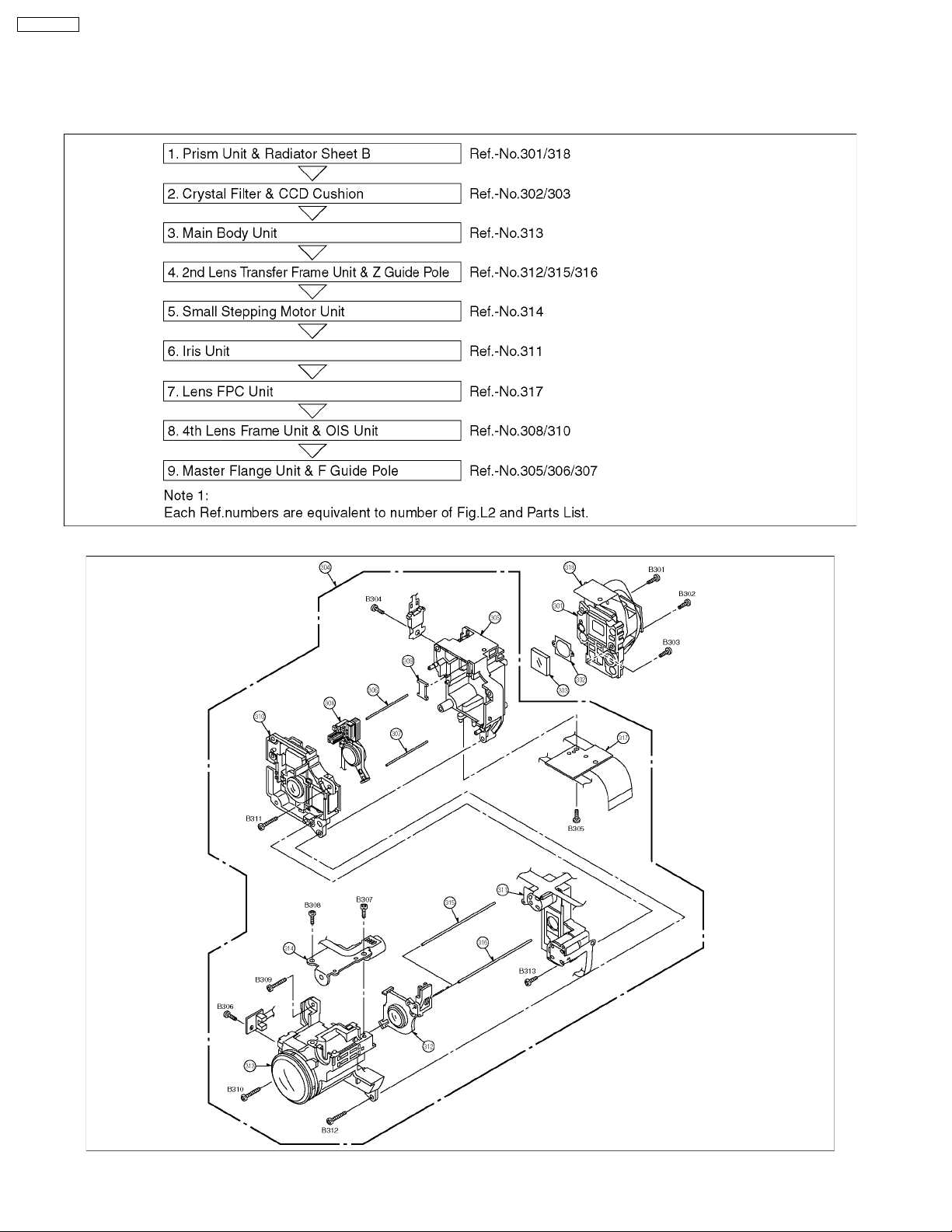

7.4. DISASSEMBLY PROCEDURES OF CAMERA LENS UNIT

The following flowchart describes order or steps for removing the Camera lens unit and certain printed circuit boards in order to

make access to the item needing service.

To reassemble the unit follow the steps in reverse order.

Fig. L1

Fig. L2

26

Page 27

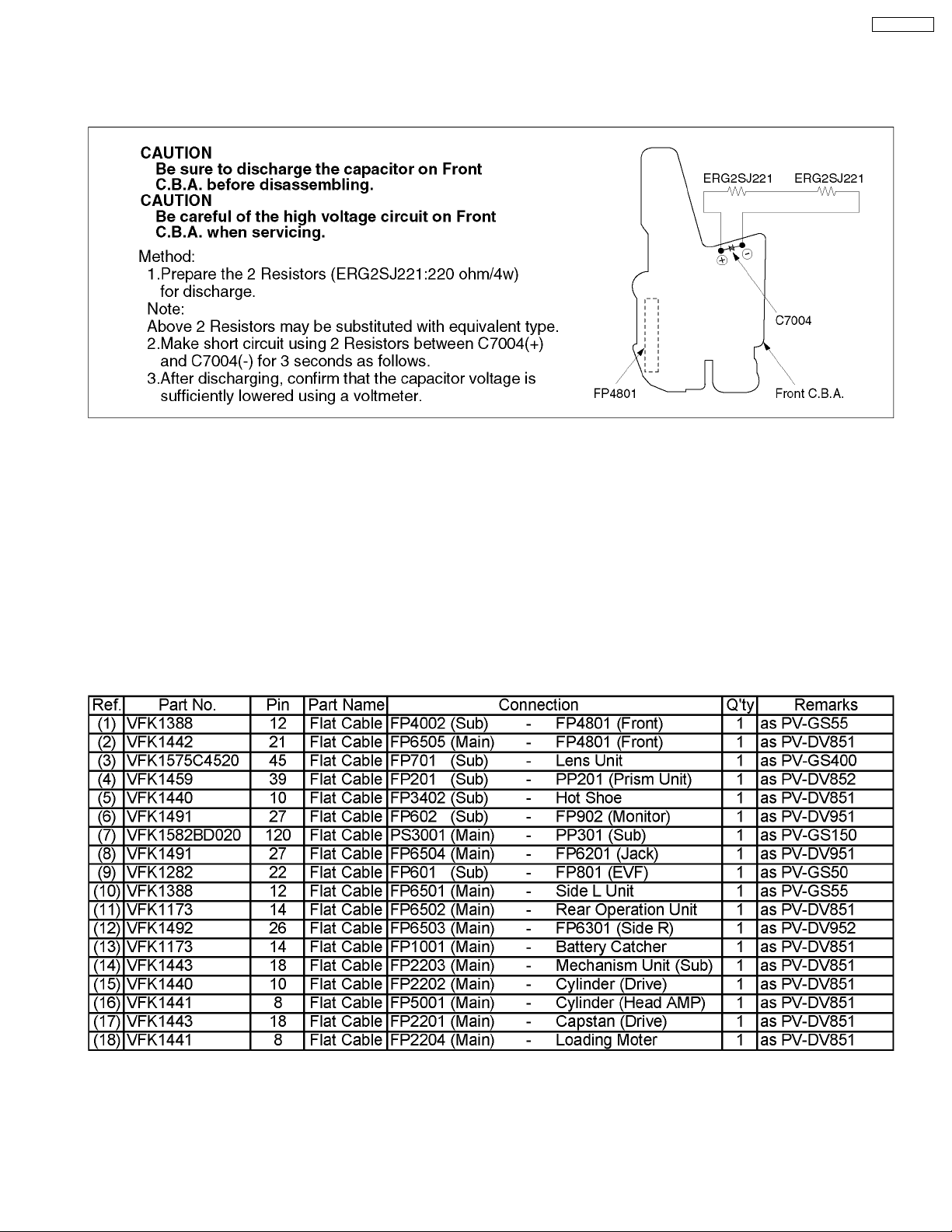

8 SERVICE CAUTION

8.1. HOW TO DISCHARGE THE CAPACITOR ON FRONT C.B.A.

8.2. EEPROM DATA FOR SPARE PARTS OF THE MAIN C.B.A.

PV-GS250PP

When the Main C.B.A. is replaced, the fixed and average data must be changed by Tatsujin kit according to the Movie Camera’s

suffix.

Then, confirm and/or adjust the VTR and Camera section one by one.

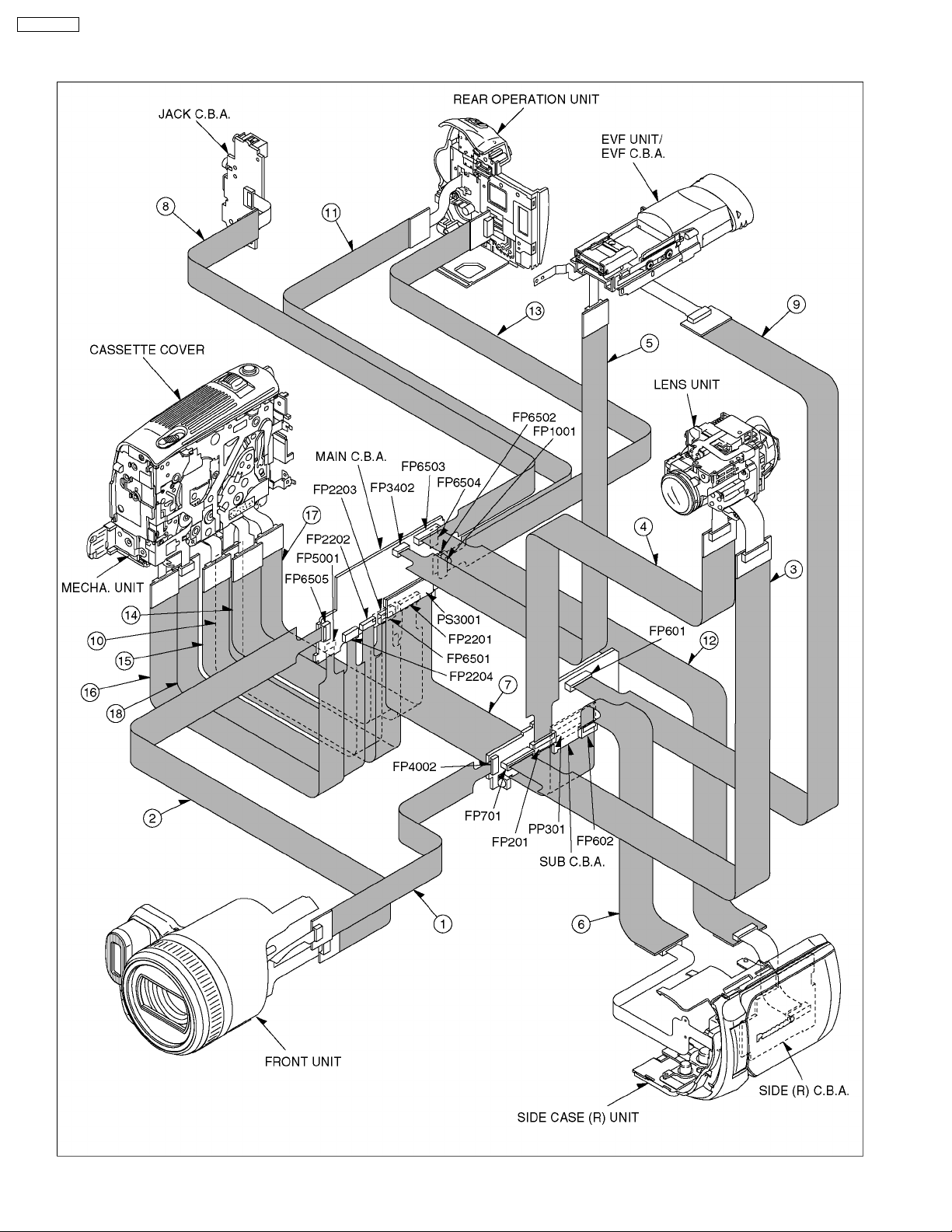

8.3. SERVICE EXTENSION CABLE FOR ALL C.B.A. INCLUDED IN MODULE

UNIT

This models is required the following extension cables for all connections.

Use the following extension cables when checking or adjusting individual circuit boards.

27

Page 28

PV-GS250PP

How to use extension cables.

Fig. T1

28

Page 29

8.4. LOCATION FOR CONNECTORS OF THE MAIN C.B.A. & SUB C.B.A.

8.4.1. MAIN C.B.A.

FP6503

K1MN26A00068

FP3402

K1MN10A00074

148

5

IC2006

(EEPROM)

FP6505

K1MN21BA0058

PS3001

K1KBC0A00037

PV-GS250PP

FP1001

K1MN14BA0062

FP5001

K1MN08BA0009

FP2204

K1MN08BA0010

FP2202

K1MN10BA0008

FP6501

K1MN12BA0059

FP2203

K1MN18BA0010

FP2201

K1MN18BA0008

PP3001

K1KA20B00154

(COMPONENT SIDE)

FP2001

K1MN06BA0107

FP6502

K1MN14BA0061

29

FP6504

K1MN27BA0058

(FOIL SIDE)

Page 30

PV-GS250PP

8.4.2. SUB C.B.A.

FP601

K1MN22A00065

FP4002

K1MN12BA0067

FP701

K1MN45AA0017

FP201

K1MN39BA0058

FP602

K1MN27BA0058

PP301

K1KAC0A00014

(COMPONENT SIDE)

30

(FOIL SIDE)

Page 31

8.5. CSP IC LOCATION OF THE MAIN C.B.A. & SUB C.B.A.

Make sure to install CSP IC in the correct position of the Main C.B.A. & Sub C.B.A. as shown.

8.5.1. MAIN C.B.A.

IC3001

IC3201

PV-GS250PP

IC3501

(COMPONENT SIDE)

IC2001

IC3801

31

(FOIL SIDE)

Page 32

PV-GS250PP

8.5.2. SUB C.B.A.

IC303

(COMPONENT SIDE)

IC305

(FOIL SIDE)

32

Page 33

8.6. TEMPERATURE PROFILE FOR HEAT RESISTANCE OF CSP IC

When using equipment other than the Pre-Heater, refer to the temperature profile.

CSP ICs for Model of PV-GS250 have the following temperature profile.

PV-GS250PP

8.6.1. IC TEMPERATURE PROFILE

(IC303)

8.6.2. IC TEMPERATURE PROFILE

(IC305)

8.6.4. IC TEMPERATURE PROFILE

(IC3001, IC3501)

8.6.5. IC TEMPERATURE PROFILE

(IC3201)

8.6.3. IC TEMPERATURE PROFILE

(IC2001)

8.6.6. IC TEMPERATURE PROFILE

(IC3801)

33

Page 34

PV-GS250PP

9 ELECTRICAL ADJUSTMENT PROCEDURES

9.1. COMPUTER ASSISTED ADJUSTMENT SYSTEM <TATSUJIN>

ADJUSTMENT.

This unit employs the computer assisted system named; “TATSUJIN PC-Adjustment” for Electrical adjustment.

9.2. SET-UP MANUAL FOR DV-Camcorder.

1. SAVE THE SOFTWARE

Install the effective model’s TATSUJIN Software to PC: Personal Computer.

2. SET-UP (CONNECTION)

a. Remove the EVR cover of the DV Camcorder.

Unlock the locking tab and remove the EVR cover as shown in Fig. E1.

b. Make a connection.

Connect the PC, the PC/IF Unit and the DV Camcorder as shown in Fig.E2 and E3.

c. Check the SW position on Measuning Board.

The position of SW on Measuning Board checks as shown in Fig. E4.

Fig. E1

Fig. E2 Necessary Equipment & Tools for Connection.

34

Page 35

Fig. E3 Rough image of set-up connection

PV-GS250PP

35

Page 36

PV-GS250PP

Fig. E4

(Extension cables (VFK1317 × 2pcs) ----- Measuring Board (VFK1308E) ----- 232C I/F Cable (VFK1395))

36

Page 37

9.3. SET UP PC-EVR ADJUSTMENT PROGRAM

1. Turn on the PC and install the TATSUJIN Adjustment

Program into the PC.

2. Execute the “Gs250.exe“ file by double clicking to start up

the PC-EVR Adjustment Program.

The main menu will be displayed.

3. Select the desired model.

4. Turn on the camcorder. Then, click “Start.”

Note:

The adjustment data is stored to the EEPROM IC after

each adjustment.

7. After adjustment, to end the software, select “Exit” in File

Fig. E5-1

5. The communication is complete, and the dialog will appear.

Then, click “VCR (V) or Cam (C)” to save the EEPROM

data,

menu or close the window.

PV-GS250PP

Fig. E5-3

Fig. E5-2

6. Saving for EEPROM data is complete, menu will appear.

To perform each adjustment, display the adjustment menu

by selecting the desired menu from “Camera Adjust,”

“Video Adjust,”“LCD Adjust” or “EVF Adjust” and select

each adjustment item.

Fig. E5-4

37

Page 38

PV-GS250PP

9.4. INITIAL GUIDELINE

The table below shows which adjustments are necessary according to the unit parts and individual parts to be replaced. Make sure

to perform these adjustments shown below as necessary.

38

Page 39

10 MECHANICAL ADJUSTMENT PROCEDURES

10.1. ADJUSTMENT ITEM

Item Adjustment at the time of the part exchange

Half finished goods mechanism Clyinder Remarks

Linearlty adjustment& BER value

10.2. ADJUSTMENT PROCEDURES

l

lLinearlty adjustment & BER value confirmation

ll

1. Remove the mechanism adjustment cover of tis machine as shown in Fig. D1.

2. The spcial tool at the time of electricity adjustment is connected.

Reference of the connection figure of electricity adjustment.

3. The enbelope detection spcial tool board (VFK1641) is connected to EVR adjustment board as shown in Fig. D2.

4. The enbelope detection spcial tool board is connected to oscilloscope as shown in Fig. D2.

5. The post is adjusted with the post driver(VFK1899) so that recycles the standard tape and the detection wave-link become

a flat as shown in Fig. D3.

*At the time of the clyinder unit exchange unnecessary.

6. The post is adjusted with the post driver so that recycles a alignment tape(VFM3010EDS) and the detection wave-link

become a flat once again.

7. Recycling the tape that video-taped it wirh this machine after adjustment, the BER value is confirmed withthe item of the

BER the item of the BER confirmation of expert soft inside.

confirmation

PV-GS250PP

Fig. D1

39

Page 40

PV-GS250PP

Fig. D2

Fig. D3

40

Page 41

11 SERVICE MODE

11.1. ERROR DISPLAY

“PUSH THE RESET SWITCH” is displayed automatically on the EVF or the LCD Monitor when an undesirable condition has

occured.

PV-GS250PP

11.2. SERVICE MENU

When abnormal detection contents are confirmed a When I do the following operation automatic diagnosis cord is

displayed. (Service Menu)

To enter the Service Menu

Press the [QUICK START] button and [JOYSTICK LEFT

(with no SD card inserted).

NOTE:

In the case that a tape or SD card is included the above operation does not work.

This function displays the following items in the Service Menu.

· *1 ... Cylinder elapsed time reset

After replacint the Cylinder Unit, clear the Cylinder elapsed time to 0.

Set to Service Menu.

Item [8] is selected with the [JOYSTICK UP or DOWN

It modes to the [OFF/ON] screen with the [JOYSTICK RIGHT

[ON] is selected with the [JOYSTICK UP or DOWN

Press the [JOYSTICK CENTER] button.

· *2 ... Cylinder elapsed time

This item displays the Cylinder elapsed time (in Base 16).

Set to Service Menu.

Item [3] is selected with the [JOYSTICK UP or DOWN

It modes to the [OFF/ON] screen with the [JOYSTICK RIGHT

[ON] is selected with the [JOYSTICK UP or DOWN

Press the [JOYSTICK CENTER] button.

] button and [PHOTO SHOT] button simultaneously for 3 seconds

/ ] button.

] button.

/ ] button.

/ ] button.

] button.

/ ] button.

41

Page 42

PV-GS250PP

Calculation method of the Cylinder elapsed time:

· *3 ... Mechanism lock code record

The current lock code, the last lock code and the lock code before last are displayed in the Item [3] screen.

· *4 ... Lens motor lock code record

The current lock code, the last lock code and the lock code before last are displayed in the Item [3] screen.

Cylinder elapsed time and lock code (Item [3] screen)

DISPLAY CONDITION

Mechanism & Lens motor lock code

01 T-REEL LOCK

02 S-REEL LOCK

03 UNLOADING LOCK

04 LOADING LOCK

05 CYLINDER

51 ZOOM MOTOR LOCK

52 FOCUS MOTOR LOCK

To exit the Service Menu

Unplug the AC Cord.

Please do the error cord backup record the clear after repair completion.

CLEAR METHOD

If the Card and Tape inserted, take out it before Service Mode operation.

Making the mode dial of This Machine a PC connection mode, push [QUICK START] button and [JOYSTICK LEFT

button and [RECORDING START/STOP] button simultaneously for 3 seconds.

NOTE:

Do not operate items 1 ~ 7(Except for 3) in the Service Menu.

]

42

Page 43

12 ABBREVIATIONS

PV-GS250PP

INITIAL/LOGO ABBREVIATIONS

A A GND Analogue GND

A HASW Audio Head Amp Switching Pulse

A HSW Audio Switching Pulse

A MUTE Audio Mute

A ORP Audio Overlap Pulse

A. TR Auto Tracking

A0-8, 0-17 Memory Address

A3V2 AD Converter Reference Voltage

AB0-4 Address Bus

AB0-4, AB12-15 Address Bus Line 0-4, 12-15

ABSF Focus Encoder Input

ACI Analogue Channel Cording IC

AD AD Converter

AD Auto Date, Analogue Digital Converter

AD CLK AD Clock

AD REC Audio Delayed REC

AD0-6 Address

AD0-6, ADR0-6 Address Data Line

ADCLK Analogue Digital Converter Clock

ADCNT Analogue Digital Control

ADCS Analogue Digital Chip Select

A-DET Audio Detect

ADREC Audio Delaied Rec

ADUB Audio Dubbing

AE Auto Expose

AECNT Auto Expose Control

AEE(H) Audio E-E (H)

AEH Audio Erase Head

AEIRQ Auto Expose Interrupt Request

AF/MF Auto Focus/Manual Focus

AF DIS CS AF DIS Chip Select

A-FADE(L) Audio Fade (L)

AF-AMP AF HALL Bias

AFCS Auto Focus Chip Select

AFRP Audio PLL Voltage Control

AF-VN Zoom Encoder V-Ref (–)

AF-VP Zoom Encoder VREF (+)

AGC Automatic Gain Control

AGCCNT Automatic Gain Control Control

AGND Analogue Ground/Audio Ground

AGS Anti Ground Shooting

AH(P) / (R) Audio Head (Play) / (Record)

AHASW Audio Head Amp Switch Pulse

AHSW Audio Head Switch Pulse

AI, AO Buffer Input, Output

AIBCK Bit Clock (to A/D Converter)

AIDAT Serial Data (to A/D Converter)

AILRCK L/R Clock (to A/D Converter)

AIMCK Master Clock (to A/D Converter)

ALC CNT Auto Level Control Control

INITIAL/LOGO ABBREVIATIONS

ALC MAIN Auto Level Control Drive

ALE Address Latch Enable

A-LOCK Full Auto Switch

A-MUT(H) Audio Mute (H)

ANLPTH Analogue Loop Through High

AORP Audio Overlap Pulse

APCNT Aperture Control

APS Auto Power Save

ART VH Artifical Vertical Sync

AT CNT Automatic Tracking Gain Adjust

ATF Automatic Track Finding

ATFCLK 41.85MHz Clock

ATFG Auto Track Gain

ATL Auto Lock Select

ATN Absolute Track Number

ATR OFF(H) Auto Tracking Off (H)

ATV Advanced TV

AUDIO(N) Audio (Normal)

AUX Auxiliary

AVDD Analogue VDD

AVSS Analogue Ground

AWTB Auto White Balance B-Y

AWTR Auto White Balance R-Y

B BACK Back-up

BACK UP Microcomputer Back-up

BACK VDD Back-up Power

BATT Battery

BATT ALARM Battery Alarm

BATT REF Reference Voltage for Battery

BCB B Carrier Balance

BCBM(B-Y) B-Y Carrier Balance

BCBM(R-Y) R-Y Carrier Balance

BD0-7 REC/Play In/Out Buss

BDCK Standard Bus Data Clock (9MHz)

BDEN Standard Bus Data Enable

BEND Data Block End Request

BF Burst Flag Pulse

BFA Burst Flag Pulse for Encorder

BFO/BFI Burst Flug Input/Output

BI, BO Buffer Input, Output

BL Back Light

BL ON Back Light ON (L)

BL4V Back Light 4V

BLC 0, 1 Back Light Y Control Out, In

BLDI/O Back Light Drive Input/Output

BLK Blanking Pulse

BLKA Blanking for Encorder

BLKA Blanking Pulse for Encorder

BLKI/O Blanking Pulse In/Out

43

Page 44

PV-GS250PP

BLKZ Blanking Pulse for Zoom Encorder

BM Balance Modulator

BQUIET Bus Out Control Signal

BUF IN/OUT Buffer In/Out

B-Y KB B-Y Carrier Balance

B-YO B-Y Signal Out

C C A In/Out Pre-Aperture In/Out

CAPSTP Capstan Stop Flag

C CNT Colour Control

C SYNC Composite Sync Signal

C/N Carrier/Noise

C0-7, C00-07 Chrominance Signal 0-7

CAGAIN Aperture Gain Control

CAM Camera

CAM CLK Camera Clock

CAM RST Camera Reset

CAM SIOC Camera Serial In/Out Contol

CAM T Camera Test

CAM TL Capstan Trque Limit

CAP EC Capstan Trque Control

CAP P(H) Capstan Power On (H)

CAP R/F/S Capstan Reverse (H)/Stop (M)/Forward (L)

CAP SW Capstan Power Control Switch

CAPSTP H Capstan Stop Flag (Stop High)

CAPVM Capstan Motor Current

CAPVS Capstan Motor Power Control Switch

CAS

Compresion, Audio Process, Shuffling/Deshuffling

CAS Memory Address Strobe (Active Low)

CASDOWN, DWN Cassette Down (L)

CB, CR Chroma B, Chroma R

CBLK Composite Blanking Pulse

CC Channel Cording

CCA Curent Drive Control

CCA Current Control Amp

CCD Charge Coupled Devise

CCW Counterclockwise

CD SP0-7 Digital Chroma

CDS Correlate Double Sampling Signal

CDS1, 2 Sampling Pulse for CCD Output Signal

CE Chip Enable

CE Control Pulse Erase

CEC Capstan Error Code

C-ERA(H) Control Erase (H)

CFEM Chrominance Memory Signal

CFM Chrominance Field Memory

CFM1-4 Chroma Field Memory Signal

CG CLK Character Generator Clock

CG CLK DATA Clock Generator Data

CG DATA Character Generator Data

CGC Chrominance Gain Control

CGCS Character Generator Chip Select

CGO Character Generator Serial Data

CH Charge

INITIAL/LOGOINITIAL/LOGO ABBREVIATIONS

ABBREVIATIONS

CH1 Channel 1 (Odd Field)

CHR Character

CHR BACK Character Back-up

CHR MIX Character Mix

CI, CO Buffer In/Out

CI,CO Buffer Input & Output

CIF Control Signal Forward Input

CIF, CIR

Positive Control Pulse, Negative Control Pulse

CIR Control Signal Reverse Input

CK Clock

CL/CLK Clock

CLASS

Classeffication Signal for Compress (DCT/VLC)

CLASS 0.1 Class Control Signal Durring DCT/VLC

CLK135 13.5MHz System Clock

CLK18 18MHz System Clock

CLK2 Clock 2 (824XFH: 12.875MHz)

CLK246 24.576MHz Clock

CLK27 27MHz System Clock

CLK450 450KHz Clock

CLKDCLK Digital Clock

CLK-PH Clock Phase Control

CLK-REF Reference Clock

CLP-RST-H Clamp Reset High Signal

CLX TFT X-axis Transmission Clock

CLX, CLX1-4 Shift Clock for X Direction (LCD Panel)

CLY Shift Clock for Y Direction (LCD Panel)

CLY TFT Y-axis Transmission Clock

CLY FG Cylinder FG Signal

CMEMO0-3 Chroma Memory Output Signal 0-3

CMIX Character Mix

CMO Chrominance Memory Output

COMPC Position Detection Pulse

COM RDY Serial Enable Signal

CMODE Camera Mode

CNCLK Clock

CNR Chrominance Noise Reduction

CNT, CONT Control

CO Control Out

CO0-7 Chrominance Output 0 to 7 (Digital)

COM Common

COM RDY Serial Transmission Enable

COMB Comb Filter

COS EQ Cosin Equalizer

CP Clamp Pulse

CP ON(H) Camera Power On(H)

CP2, 20 Clamp Pulse

CP2A, CP2O Encoder Clamp Pulse

CPN Component Signal

CPOB Clamp Pulse for Optical Blanking

CPS Composite Signal

CPV Gate Scan Clock

CR OUT Pre Apature Out

CR POW SW Camera Remote Power On Switch

CRA Aperture Gain Control

44

Page 45

CRA Pre Apature Gain Control

CRST Camera Reset

CS Chip Select

CS 0-7 Chrominance Signal Out 0-7

CSEL Clock Phase Select

CSI 0-7 Chrominance Signal In 0-7

CTSW Crosstalk Switch

CURR Current

CW Clockwise

CYL EC Cylinder Motor Trque Control

CYL PG Cylinder Motor PG

CYL VM Cylinder Motor Current or Power

D D CLK Digital Clock

D MODE Digital Mode Switch Signal

D01-03 Zoom 01-03

DA UV SEL D/A Convertor U/V Select

DAC Digital Analogue Converter

DAG Digital Analogue Ground

DB0-7 Data 0-7

DB0-7 Microprocessor Data

DCC DC Clamp Control

DCCNT DC Control

DCI Digital Channel Cording IC

DCLR Digital Clear

DCP Digital Clamp Pulse

DCS-CLK, DA CAS & DV I/F Serial Clock

DC-STP1 DCS Serial Start

DC-STP2 DCS Serial Stop

DCT Discrete Cosine Transform (Compression)

DCX7 Serial Data

DEDP 0-3 Playback Data

DEDR 0-3 Rec Data

DEMO Demodulation

DEMP A/D Convertor Empahsis Control

DEMP De-Emphasis

DFD 0-7

DFD0-7

Encode Data In/Out Between Shaffling Memory

Encode Input/Output Signal for Shuffling Memory

DIBDCK Bit Clock

DICLK Digital Clock

DIDAT Serial Data

DIDAT Serial Data Durring Digital Audio In

DIF Digital Interface

DILRCK L/R Clock

DILRCK Serial Clock Durring Digital Audio In

DIMCK Master Clock

DIMCK Mater Clock Durring Digital Audio In

DIO 1-8 Data In/Out

DIOS Data In/Out Select Control Signal

DIOS Select Signal for Digital In/Out

DIS Digital Image Stabilizer

DIS R/B Digital Image Stabilizer Read (H)/Busy (L)

DIS R/B DIS IC Rady/Busy

DIS/KAND Digital Image Stabilizer/Sensitivity

INITIAL/LOGOINITIAL/LOGO

ABBREVIATIONSABBREVIATIONS

DISCS Dis Chip Select

DISP Display

DL Delay Line

DOBCK Audio A/D Convertor Bit Clock

DOCTL Data Output Control Signal

DODAT Serial Data (to D/A Converter)

DOLRCK Audio A/D Converter LR Clock

DOLRCK L/R Clock (to D/A Converter)

DOMCK Audio A/D Converter Master Clock

DOMCK Master Clock (to D/A Converter)

DQ 1-16 Memory Data

DRAM CAS D-RAM Colum Address Strobe

DRAM OE D-RAM Out Enable

DRAM RAS D-RAM Read Address Strobe

DREC AV Delayed REC Start Pulse

DRK Dark (LPF Switch for Auto Focus)

DS1, 2 Double Sampling Pulse

DSF 0-7 Data In/Out for Shaffling Memory

DSF 0-7

Input/Output Data to Shuffling Memory (18MHz)

DSP Digital Signal Processor

DSP R/B DSP IC Rady/Busy

DSP-48K-H DSP IC Clock Select

DSTB Data Stobe Signal

DSV Digital Sum Variation

DV Digital Video

DVB Digital Video Broadcast

DVC Digital Video Cassette

DVDD Digital VDD

DVIO Digital Video Input Output

DVSS Digital Ground

DX Shift Data for X Direction (for LCD)

DY Shift Data for Y Direction (for LCD)

DY TFT Y-axis Shift Data

DZ Digital Zoom

E E Snap Electric Snap Shot

E ZM Electric Zoom

E2 CS or E2P CS EEPROM Chip Select

E2 R/B EEPROM Rady/Busy

E2P EEPROM

EARP Earphone

EC Torque Control

ECC Error Correction Cording

ECM Electric Condencer Mic

ECR Reference Voltage for Capstan Torque

EDA Error Correction, DCI, ATF Servo

EE CS EEPROM Chip Select

EE R/B EEPROM Read (H)/Busy (L)

EEPROM

Electric Erasable Programable Read Only Memory

EIS Electric Image Stabilizer (DIS)

EMP A/D Convertor Emphasis Control

ENAB Enable

ENV Enverope

EOB End of Block

PV-GS250PP

45

Page 46

PV-GS250PP

EQ Equalizer

EVF Electric View Finder

EXT DC External DC (AC Adaptor)

EXT DC(H) AC Adaptor DC (H)

EXT NOREG AC Adaptor 6V

EXT S DATA Serial Data for Edit

EXT SCK Serial Clock for Edit

EZOOM Electric Zoom

F

F ENC Lens F-Value

FACT MODE Factry Mode (not used in the service)

FB Feed Back

FC Saw Tooth Signal In

FCK Clock

FCO Saw Tooth Signal Generator

FENC Focus Encoder

FEND Frame End Pulse

FH2B FH/2 (15.625KHz / 2=7.8125KHz)

FIX OSD Auto Tracking Off (H)

FLICK Flicker Output

FM Field Memory

FM0-7 Field Memory 0-7

FMCO0-3 Field Memory Chrominance Out 0-4

FMDIR Focus Motor Direction

FMOEM Field Memory Enable

FMOEO Field Memory Enable

FMT1-4 Focus Motor Terminal 1-4

FMY00-07 Field Memory Luminance Out 0-7

FMYI0-07 Field Memory Luminance In 0-7

FNO F Value

FPS Frame Refference Signal

FR Capstan Reverse High

FRP Frame Refference Pulse

FRPSO Frame Start Pulse

G G1, G2, G3 Gap 1, 2 and 3

GCA Gain Control AMP

GCNT Gain Control

G-CNT AGC Adjustment

GCTRL Gain Control

GENE Generator

GF FG AMP Terminal

GSW Ground for Switching Power

H H/M/N Hi-Fi / Mix / Normal

H/N Hi-Fi / Normal

H1, 2 H. CCD Drive Pulse

HAP Horizontal Aperture

HASW Head AMP Switching Pulse

HB Hall Bias

HBR SET High Brightness Set

HBRST High Brightness Set

HCLR High Clear

HCP Shift Clock for Horizontal Drive

INITIAL/LOGOINITIAL/LOGO ABBREVIATIONS

ABBREVIATIONS

HD Horizontal Drive Pulse

HDTV High Definition TV

HEX Hexadecimal

HG Hall Gain

HID Head Switching Pulse

HLT High Bright Signal

HALL IN(+), (–) Input Signal from Hall IC

HP Headphone

HPF High Pass Filter

HSE Modulated Data Output

HSP Timing Pulse for Shaffling Memory

HSS Horizontal Sync Signal

HSW Head Switching Pulse

HS-WT High Speed Zoom

HSZ High Speed Zoom

I I/F Interface

I-2 C Inter Integrated Circuit

ID(H) Wide Television (H)

IMP Inter Microprocessor Protocol

INF CCD Input Signal 1

INF Input Frame Signal

INS CCD Input SIgnal 2

INTER Interval Recording

INV Inverter

IOU R-Y Analogue Signal Output

IOV B-Y Analogue Signal Output

IOY Y Analogue Signal Output

IR Infrared Rays

IRDET Imfrared Ray Detection

IREF Current Adjustment Terminal

IRIS/SH Iris / Shutter Control

IRQ Interrupt Request

ITI Insert & Track Information

J JPEG

Joint Photographic Image Cording Experts Group

K KANDO Digital Gain Up

KB Carrier Balance

KEY IN Key Scan

KND Digital Gain Up

KNEE Luminance Compensate

L LCD Liquid Crystal Display

LCD P(L) LCD Power On (L)

LD Load Pulse

LDD Liquid Direct Drive

LEDCNT LED Control

LI-BATT Lithium Battery

LOAD Loading

LOAD F, R Loading Direction (F: Forward / R: Reverse)

LPF Low Pass Filter

LRMONO Monoral Audio (L + R)

LSB Least Significant Bit

46

Page 47

LVL LPF Switch for Auto Focus

M M1-3 Motor Coil Terminal 1 to 3

MA0-5 Microprocessor Address Data 0-5

Mbps Megahertz Bit Per Second

MD Modulation

MD0-7 Microprocessor Data 0-7

MDT0-7 Microprocessor Data 0-7

ME (TAPE) Metal Evaporated (Tape)

MENB Focus Motor Enable

MFF Manual Focus Far

MFN Manual Focus Near

MHSYNC Monitor Horizontal Sync Signal

MIC Memory In Cassette

MIG Meta In Gap

MIX N.R.D. Non Rec Data Mix

MOD Modulation

MOUT Mic Out

MP (TAPE) Metal Particle (Tape)

MPEG Moving Picture Image Cording Experts Group

MPEG2

Moving Picture Image Cording Experts Group Phase 2

MRST Focus Motor Reset

MSB Most Signal Bit

MVSYNC Monitor Vertical Sync Signal

N N/F Near/Far Focus

N/P NTSC/PAL

NB1-3 Base for NPN Transistor

NC No Connection

NC1-3 Corrector of NPN Transistor

NCLR Power On Reset

NCP1 Clamp Pulse

NCP2+VDH Clamp Pulse + Horizontal Drive Pulse

NCP2+VDM Clamp Pulse + Gate Pulse

NDE Non Liner De-Emphasis

NE Emitor of NPN Transistor

NLE Non Liner Emphasis

NR Noise Reduction

NRD Non Rec Data

NRD BLK Non Rec Data Blanking

NRD CLK No Rec Data Clock

NRE Read Enable Input (Low Active)

NWE Write Enable (Low Active)

O OB Optical Black

OBCNT Optical Black Control

OBREF Reference Voltage for Optical Black Control

OE Output Enable

OFH

Horizontal Counted Down Clock Signal (Reference)

OFS Offset

OP Operation AMP Output

OSD ON Screen Display

OVL Overlap Pulse

OZ Optical Zoom

INITIAL/LOGOINITIAL/LOGO ABBREVIATIONS

ABBREVIATIONS

P P SW Power Switch

PB1-3 PNP Base 1-3

PBCTL Play Back Control

PBCTL Pre-Branking Control

PBH Head Amp Switch

PBLK Pre-Blanking (Pulse)

PC1-3 Corrector of PNP Transistor

PCBM Carrier Balance

PCH Phase Compensator (Hall AMP)

PCI Phase Compensator (Current)

PCO Phase Compensator Out

PCS Switching Power Control

PCV Phase Compensator (Voltage)

PE Emitter of PNP Transistor

PED Pedestal

PEDECNT Pedestal Control

PENO Alarm (L)

PFP Pilot Frame Position

PGA, B Power Ground A, B

PGC Pulse Generator Comparator

PGI Pulse Generator Input

PGMM Pulse Generator Monostable Multivibrator

PGO Output of Pulse Generator AMP

PMODE Select Signal for Normal / Wide Screen

PON Power On

POR Power On Reset

POSCOM Common Position

PREAMP Pre-AMP

PREBLK Pre-Blanking

PT Protect for V Voltage

PWM Pulse Width Modulation

PWMB Pulse Width Modulation Pulse

Q Q2H Source Output Select

R R CTL P Recorded Control Pulse (+)

R CTL R Recorded Control Pulse (–)

R/B Read/Busy

R/L Direction Control for Data Transmition

RA Recording AMP

RA1 Rec AMP 1

RAC AC Rec Audio Current

RAD Read Address Data

RAE Read Address Enable

RB Read Busy

R-B R Bias

RCB R Carrier Balance

RE Read Enable

RE(F), (S) Rotary Erase Head Transformer

REB R Bias

REC CC Rec Current Control

REC CCNT Rec Current Control

RECCTRL Recording Control Pulse

RECI Rec Amp Switch

PV-GS250PP

47

Page 48

PV-GS250PP

RENCF Lens Control (Forward)

RENCR Lens Control (Reverse)

RERASE Rotary Erase Head

RGBIV1-2 1V Inverted Signal 1-2

RGO R/G OFF Offset Voltage for AWT R

RSF Capstan Direction (Reverse / Stop / Forward)

RST Reset

RSTB R Strobe

RSTPWD Reset Power Down Input

RSTR Reset Read

RSTW Reset Write

RT Saw Tooth Terminal

RVCO Resister for Oscillation

RW Read Write

RWAE Read Write Enable

S S PHOT Supply Photo Transistor

S/H Sampling Hold

S/S Start/Stop

SBD Serial Data

SBI Serial Data Input

SBO Serial Data Output

SBT Serial Clock

SCAN0-5 Key Scan 0-5

SCK Serial Clock

SCR Search

SCR, S.C.R. Still Cue Review

SEG. Segment

SET White Balance Set

SH/IRIS Shutter/Iris Control

SHIFT Capasitor for Phase Shift

SI Serial Data Input

SIC Shift In Clock Input

SIOC Serial In/Out Control

SMCE Shaffling Memory Chip Enable

SMRS Shaffling Memory Read Strobe

SMWE Shaffling Memory Write Enable

SMWS Shaffling Memory Read Strobe

SNAP Snap Shot

SNS LED Sensor LED

SO Serial Data Output

SPA ATF Smapling Pulse

SPEN 8 Bit Shift Register Enable

SPK Speaker

SPO Reset for Switcing Power

SPST 8 Bit Shift Register Strobe

SREELP Supply Reel Pulse

SRT Start

SSA Start Sync block Area

SSW Select Signal for Low Pass Filter

ST5V Safety Tab 5V

STAB Safety Tab Switch

STB Stand by Signal

STB Strobe

INITIAL/LOGOINITIAL/LOGO ABBREVIATIONS

ABBREVIATIONS

SWB Switching Pre-Drive Pulse

SYL EC Cylinder Torque Control

SYL FG Cylinder FG

T T PHOT Take-up Photo Transistor

TBC Time Base Conntrol

TFT Thim Film Transistor

TH Thermostat for Battery

TI Test Mode Select

TL Torque Limit

TM Sub Code

TMD Sub Code Data

TRE Tracking Error Signal

TREEL(P) Take-up Reel (Pulse)

TRFIX Tracking Fix

TRIWAVE Tracking Wave

TRP Tracking Position

TRP Trap

TSR Head Switching Refference

TST Time Scale Transfer

U U/V SEL R-Y/B-Y Select Signal

UNLOAD Un-Loading

UNRE Microprocessor Read Enable

UNWE Microprocessor Write Enable

UV R-Y/B-Y

UV SEL R-Y/B-Y Select Signal

V V1-V4 V. CCD Drive Pulse

VB VH Filter Switching

VCE Power Terminal

VCNTL Video Control

VCO Voltage Control Oscillator

VCP Shift Clock Output for Vertical Drive

VCTLD Video Control

VCTRL Voltage Charge Control

VD Vertical Drive Pulse

VDDX X Drive Power for Colour LCD

VDDXY XY Drive Power for Colour LCD

VDDY Y Drive Power for Colour LCD

VDREC Video Delayed Rec

Vgg Voltage for Gate IC

Vgl Gate off Voltage

VID Video Signal Out

VIN Video In

VITC Vertical Interval Time Code

VITERBI One of Signal Detection Method

VL Low Voltage

VLC Variable Length Cording

VLOCKP Artificial Sync Pulse

VLP Artificial Sync Pulse

VM Motor Voltage

VMD Velocity Mode Data

VMD1-3 Electric Shutter Mode

48

Page 49

INITIAL/LOGO ABBREVIATIONS

VMODE NTSC/PAL Select Switch

VMVH VH Filter Switching

VORP Video Overlap

VRB Voltage Refference Bottom

VRBS Voltage Refference Bottom Output

VREF1R3V Refference Voltage 1.3V

VREF3R3V Refference Voltage 3.3V

VREFH Refference Voltage High Side

VREFL Refference Voltage Low Side

VRI Refference Voltage Input

VRO Refference Voltage Output

VRT Voltage Refference Top

VRTS Voltage Refference Top Output

VS Switching Comparator

VSS Vertical Sync Signal

VSSX X Driver Power for Colour LCD

VSSXY X-Y Driver Power for Colour LCD

W W/N Mode Select for Window Mode

W/N Wide / Normal

WAD Write Address Enable

WAE Write Address Enable

WAERAE Write Address Enable

WARI Interrupt

WB White Balance

WE Write Enable

WEM Memory Write Enable

WHD Wide Horizontal Drive Pulse

WIDE A Wide Zoom

WSB B AGC Control

WSR R AGC Control

WTV Wide TV

PV-GS250PP

X XP FG Logic Reset

Y Y FM0-7 Y Field Memory 0-7

YCE Cylinder Error Code

YGC Y Gain Control

YMO 0-7 Y Field Memory 0-7

YNCST Noize Canceller

YNR Luminance Noise Reduction

YSDP 0-7 Digital Y Out 0-7

Z Z.ENC Zoom Encoder

Z.MIC Zoom Mic

ZENC Zoom Encoder Output

ZMDIR Zoom Drive

ZMEN Zoom Enable

ZMT Zoom Motor Tele Side

ZMT (+)/(–) Zoom Motor (+)/(–)

ZMTER Zoom Motor Tele Side

ZMW Zoom Motor Wide Side

ZSW Zoom Switch

49

Page 50

PV-GS250PP

50

Page 51

13 BLOCK DIAGRAM

13.1. OVERALL BLOCK DIAGRAM

LENS UNIT

PV-GS250PP

ZOOM

CAMERA

IC101

(CG/SSG)

2FCK

X101

IC307

(EEPROM)

OIS

ND FOCUS

IC107,110

(INVERTER)

IC102

REG

IC305

(CAMERA

MICROCOMPUTER)

IRIS

IC103

REG

IC108

(V DRIVER)

IC104,105,106

(CDS,AGC,AD)

IC303

(DIGTAL

SIGNAL

PROCESSOR)

CCD

S VIDEO

IN/OUTPUT

IC3501

(A/D)

IC3502,3

(SW&)

EX INPUT

MMC/SD

VIDEO/AUDIO

IN/OUTPUT

IC3301 AVIO

(D/A,A/D,AV OUT AMP)

IC3001 DUO

(VIDEO I/O,VCO,COMPRESOR,

SHUFFLE,SHUFFLE MEMORY,

AUDIO PROCESSOR,ECC,

ECC MEMORY,1394 I/F,JPEG

COMPRESSION/EXPANSION,

CARD I/F,DAC)

SPEAKER

AVIO

IC3201

RIP

(MODULATION,

VITERBI,EQ,

MOTOR DRIVE

CONTROL)

FRONT(1/2) C.B.A.

IC4801

(MIC AMP)

IC5001

(HEAD AMP)

MIC

EXT MIC/

FREE STYLE

REMOTE

CONTROL

DV

TERMINAL

HEAD

HOT

SHOE

IC704

(OIS DRIVE)

IC705

(HOLE AMP)

IC706

(ND DRIVER)

IC702

(MOTOR DRIVE)

FRONT

(2/2)

C.B.A.

FLASH

IC701

(LPF)

LENS DRIVE

MONITOR

C.B.A.

2.5"LCD

POWER SUPPLY

CONTROL CIRCUIT

SUB POWER

IC601

(CONTROLLER & SIGNAL

PROCESSOR)

LCD

EVF

C.B.A.

0.33"LCD

SUB C.B.A.

IC2002

(RTC/POWER

CONTROL)

CONTROL

IC2001

(CONTROL

MICROCOMPUTER)

IC2006

(EEPROM)

IC2017

(RESET)

IC3801

(USB 2.0

DRIVER)

IC2201

(CYL/CAP/LOADING

MOTOR DRIVE)

VIDEO

POWER

IC1001

(POWER)

MAIN C.B.A.

USB

TERMINAL

CYLINDER

MOTOR

CAPSTAN

MOTOR

LOADING

MOTOR

PV-GS250PP

OVERALL BLOCK DIAGRAM

51

Page 52

PV-GS250PP

13.2. CAMERA 1 BLOCK DIAGRAM (SENSOR BLOCK DIAGRAM)

IC101-16 STOP

3.0Vp-p (20usec.div.)

IC101-27,28 STOP

3.0Vp-p (20usec.div.)

IC101-36 STOP

3.0Vp-p(20usec.div.)

:MAIN SIGNAL PATH IN REC MODE

LIGHT

LENS UNIT

3CCD METHOD

PRISM UNIT

G CCD

B CCD

R CCD

SUB

PP201 FP201

23,24

23,24

PP201 FP201

26,27

26,27

PP201 FP201

15

15

PP201 FP201

16

16

PP201 FP201

17

17

PP201 FP201

18

18

SUB

PP201 FP201

21

21

SUB

PP201 FP201

20

20

PP201 FP201

19

19

PP201 FP201

8

8

PP201 FP201

9

9

PP201 FP201

34

34

PP201 FP201

35

35

PP201 FP201

22

22

SUB

PP201 FP201

30

30

PP201 FP201

31

31

PP201 FP201

32

32

FP201PP201

33

33

PP201 FP201

10

10

FP201PP201

36

36

SUB

PP201 FP201

7

7

PP201 FP201

6

6

PP201 FP201

5445

FP201PP201

SUB

FP201PP201

25

25

FP201PP201

1

1

FP201PP201

39

39

SIG G

SIG R

SIG B

15V

PT

V1 G

V2 G

V3 G

V4 G

SUB G

H2 G

H1 G

H1 R

H2 R

H1 B

H2 B

R

V1 B

V2 B

V3 B

V4 B

SUB R

SUB B

V4 R

V3 R

V2 R

V1 R

IC101-17 STOP

3.0Vp-p (5msec.div.)

17

10

14

16

15

12

10

12

10

12

IC108

4

9

5

IC107

4

2

8

6

IC110

4

2

8

6

(V DRIVE)

IC101-29,30 STOP

3.0Vp-p (20usec.div.)

CH1

24

CH3

20

CH2

28

CH4

2

INPUT

V1

23

I/F

V2

27

V3

1

V4

25

SUB

26

3

11

13

1

9

5

11

3

13

1

9

5

TO

IC303

IC101-37 STOP

3.0Vp-p(20usec.div.)

IC101

CH1

31

CH2

32

V1

27

V2

28

V3

29

V4

30

SUB

33

H2

36

H1

37

R

38

FI

FI

18

HD

HD

16

VD

17

VD

(CCD DRIVE,PULSE GEN)

HIGHSPEED

PULSE

DECODER

CH PULSE

DECODER

V PULSE

DECODER

PROCESS

PULSE

DECODER

1/2

V TIMING

H TIMINGHCLR GEN

IC104-22 REC

0.25Vp-p(20usec.div.)

DS1R

DS2R

DS1G

DS2G

DS1B

DS2B

FCK2I

AD CLK1

ELECTRIC

SHUTTER

SUB PULSE

CONTROL

SERIAL

DATA IN

S CS

S CLK

S DATA

CPOB

IC105-22 REC

0.5Vp-p(20usec.div.)

44

45

42

43

46

47

X101

CG CS

OSC

FROM

IC305

CG CLK

CG DAT

APS1 CS

APS3 CS

APS2 CS

FROM

IC305

5

60

10

8

9

11

IC106-22 REC

0.2Vp-p(20usec.div.)

IC104-1 REC

4.0Vp-p (20usec.div.)

IC104

(CDS/AGC/AD,R)

DS1

16

TIMMING

DS2

GEN.

17

CDS IN

22

15

12

33

34

35

16

17

22

15

12

33

34

35

16

17

22

15

12

33

34

35

CDS AGC A/D R DATA

CPOB

AD CLK

CS

SERIAL

S DATA

DATA

S CK

INPUT

IC105

(CDS/AGC/AD,G)

DS1

TIMMING

DS2

GEN.

CDS IN

CDS AGC A/D G DATA

CPOB

AD CLK

CS

SERIAL

S DATA

DATA

S CK

INPUT

IC106

(CDS/AGC/AD,B)

DS1

TIMMING

DS2

GEN.

CDS IN

CDS AGC A/D B DATA

CPOB

AD CLK

CS

SERIAL

S DATA

DATA

S CK

INPUT

IC105-1 REC

4.0Vp-p (20usec.div.)

IC106-1 REC

4.0Vp-p (20usec.div.)

36

1

9

36

1

9

36

1

9

TO

PROCESS

PV-GS250PP

CAMERA 1 BLOCK DIAGRAM

(SENSOR BLOCK DIAGRAM)

52

Page 53

13.3. CAMERA 2 BLOCK DIAGRAM (PROCESS BLOCK DIAGRAM)

PV-GS250PP

:MAIN SIGNAL PATH IN REC MODE

FROM

IC105(G)

IC104(R)

IC106(B)

G DATA

R DATA

B DATA

IC303(DIGITAL SIGNAL PROCESSOR)

251

---

242

264

263

261

258

256

254

252

241

239

233

231

230

-

+

Y/C

PROCESSOR

YCP

CNR

H

ZOOM

DD

CONVERTER

MEMORY

D NR

V ZOOM

D/D

DSC

I/F

DSP

uCOM

I/F

MEGA PIX

DSTBO

BUSY

DD FCK

VTR 45M

BEND

160

159

161

174

172

171

169

165

184

177

185

162

271

18

281

7

5

4

2

-

CLK27A

CLK45

43

2

-

17

BEND

ADDRESS

DATA

MEGA Y C DATA

Y C DATA

IC304

MAIN

SUB

PP301

PS3001

8181

PP301

PS3001

8080

PP301

PS3001

7979

MAIN

SUB

PP301

PS3001

45 - -

52 45 52

PP301

PS3001

--

37 44 37 44

MAIN

SUB

PP301

PS3001

3636

PP301

PS3001

53 53

TO/FROM

VIDEO

TO

VIDEO

TO/FROM

VIDEO

IC305(CAMERA MICROCOMPUTER)

IC307(EEP ROM)

SUB

PP301

56

PP301

55

PP301

72

PP301

73

PP301

59

PP301

PP301

6

5

2

1

3

SK

CS

WP

MAIN

PS3001

56

PS3001

55

PS3001

72

PS3001

73

PS3001

59

PS3001

7676

PS3001

7777

E2 SCK

200

199

E2 SDO DI

E2 SDI DO

198

E2 CS

79

E2 RB

25

C V DATA

55

V C DATA

56

CAM SCLK

57

CAM RTN

120

RTN FLD

44

WINK END

MEMO END

39

203

TO/FROM

CONTROL

278

280

279

53

RE H

36

WE

32

L

DAS

38

PV-GS250PP

CAMERA 2 BLOCK DIAGRAM

(PROCESS BLOCK DIAGRAM)

Page 54

PV-GS250PP

13.4. LENS DRIVE BLOCK DIAGRAM

MF SENSOR

+5V

Q710Q711

FRONT

FP7001

MF LED

6

FP7001

MF L1

2

FP7001

MF L2

4

LENS UNIT

ND DRV(+)

ND DRV(-)

ND H IN(-)

ND H IN(+)

ND HO(-)

ND HO(+)

H IN(+)

H OUT(-)

H OUT(+)

ALC M(+)

ALC M(-)

FM T(+)

FM T(-)

ENC

HALL

SENSOR

HALL

SENSOR

IC482

(GYRO Y)

IC481

(GYRO X)

4

1

4

1

IRISND

Y SENS

Y REF

X SENS

X REF

MR

MM

FRONT

SUB

FP4801

FP4002

28

FP4801

FP4002

26

FP4801

FP4002

27

SUB

FP701

FP701

SUB

FP701

FP701

FP701

FP701

SUB

FP701

H IN(-)

FP701

FP701

FP701

FP701

FP701

FP701

FP701

FMR A

FP701

FP701

FMR B

SUB

ZAN

FP701

ZAP

FP701

ZBN

FP701

ZBP

FP701

SUB

Z ABS FP701

Z LED

FP701

FRONT SUB

FP480122FP4002

FP480123FP4002

FRONT SUB

FP480124FP4002

FP480125FP4002

IC305

PWM HZB

PWM HZA

211212204218219220216217214213210

(CAMERA MICROCOMPUTER)

MF LED CTL47

46

MF RING1

21

MF RING2

ND FNO

151

FM A

153

FM B

154

Z ABS

37

LED CONT

181

162

GYRO Y

SENS SW

40

163

GYRO X

Z SW

CAM RTN

CAM SCLK

C V DATA

V C DATA

SHOE DET

SHOE SCK

SHOE SDI

SHOE SDO

SHOE ON

X POS

Y POS

OIS DA SDO

OIS DA SCK

OIS DA LD

SIDE L FLEX. CARD

3V

SUB MAIN

PP301

148

PS3001

102

102

AVREF

ZOOM AD

VTR KEY5

MAIN

FP6501

6

FP6501

5

FP6501

8

FP6501

7

PHOTO SHOT1

PHOTO SHOT2

AVREF

ZOOM AD

GND

ZOOM SW

T

W

REAR OPERATION

IC2001

VTR

271

SUB MAIN

PP30173PS3001

120

57

55

56

159

65

64

63

35

H

161

160

72

74

129

73

PS3001

PP301

72

72

PS3001

PP301

5656

PP30155PS3001

55

PP301

PP301

PP30184PS3001

PP301

IC704

(OIS DRIVE)

31

6

41

42

43

CAM

104

RTN

CAM

116

SCK

C V

111

DATA

V C

109

DATA

STANDBY LED

85

DECODER

SS SW

POWER SW

POWER LED

GUI LED

VTR KEY4

MAINSUB

PS3001

85

PS3001

8383

84

MAINSUB

PS3001

8686

KEY5

DEW

VTR

KEY1

VTR

KEY2

VTR

KEY3

DAC

276

263

272

269

121

59

71

72

66

264

QR451

QR2006

QR2005

QR2010

X

DRIVE

Y

DRIVE

Q451

3

MAIN

DEW

FP6502

FP6502

VTR KEY1

VTR KEY2

VTR KEY3

SS SW

GUI LED

STANDBY

LED

POWER

LED

POWER

SW

QR2007

+B

4

1

2

5

6

FP6502

FP6502

FP6502

FP6502

FP6502

FP6502

FP6502

FP6502

FP6502

FP6502

LB456

+B

+B

5V

S

G

D

DEW

14

10

9

6

5

START/STOP

12

11

8

7

4

3

1

VTR KEY4

+B

QUICK START

STANDBY LED

POWER LED

POWER SW

MAIN

FP3402

6

FP3402

7

FP3402

8

FP3402

9,10

MAIN

FP65036FP6301

FP6503

4

LENS UNIT

SUB

X DRIVE (-)

22

24

34

33

18

20

3

4

FP701

24

FP701

11

FP701

22

FP701

20

FP701

12

FP701

13

FP701

15

FP701

19

X DRIVE (+)

X HO(+)

X HO(-)

Y DRIVE (-)

Y DRIVE (+)

Y HO(+)

Y HO(-)

OIS UNIT

SIDE R

21

FP6301

23

HOT SHOE

HALL

SENSOR

HALL

SENSOR

MODE DIAL

MANUAL FOCUSAUTO

STOP

MENU

QUICK

START

S6304

TAPE

RECORDING MODE

TAPE

PLAYBACK MODE

CARD

RECORDING MODE

PICTURE

PLAYBACK MODE

PC MODE

SET

FF

REV

PLAY

JOYSTICK

IC303

(DIGITAL SIGNAL PROCESSOR)

251

G DATA

242

264

263

261

R DATA

IC702

(LENS DRIVE)

NDHG

NDHB

H3O

H1O

H1-

H2+

IRM+

IRM-

FM+

FM-

A IN

B IN

ZA-

ZA+

ZB-

ZB+

FROM

SENSOR

IRIS

DRIVE

ZOOM

DRIVE

B DATA

FOCUS

DRIVE

IC701

12

13

258

256

254

252

241

239

233

231

230

+

-

MOD

QR302

12

10

11

LENS 3V

IC706

Q704

4

9

4

6

8

5

7

32

34

31

33

35

30

18

17

43

41

37

39

38

36

27

26

Q703

REF

IC705

7

IC705

3

2

12

13

QR303

+

-

+

-

IC306

4

2

+

1

-

3

+

5

-

6

1

14

62

15

17

16

18

36

34

38

40

60

61

44

42

47

45

14

EAF

H5+

I CLOSE

I OPEN

FC A

FC B

F2 C

MIXO

LCMP

EZA

EZB

+

31

2922

28

27

53

54

55

MA

57

MB

58

IC701

2

52

3

LCI

51

50

IC701

32

8

33

7

63

DI

64

CK

PWM LIN

PWM ND

+

PWM IRIS

1

-

9

+

10

+

5

-

6

Y/C

PROCESSOR

AF/ZOOM

FC A

IRIS OPEN

IRIS CLOSE

FC B

F2 C

SIG

IC308

-

6

7

+

5

6

7

8

9

Q303

3

4

6

1

5

2

IC308

2

3

1

+

54

PV-GS250PP

LENS DRIVE BLOCK DIAGRAM

Page 55

13.5. CONTROL 1 BLOCK DIAGRAM

MECHA.UNIT

3V3V

Q2003

3V

+B

+B

5

+

-

6

+

3

-

2

IC3201

(RIP)

NOREG

S.PHOTO

MIC

T.REEL

SENSOR

S.REEL

SENSOR

MODE SW

T.PHOTO

CASSETTE DOWN

S TAB

65

ADM(5)

ADM(6)

67

ADM(7)

68

ADM(4)

64

XWE H

83

XWE L

82

POS1

POS2

POS3

S TAB

S-REEL

T-REEL

MAIN

FP2203

11

FP2203

1

FP2203

3

MAIN

FP2203

14

FP2203

16

FP2203

15

MAIN

FP2203

12

3V

MAIN

FP2203

7

FP2203

5

MAIN

FP2203

17

MAIN

FP2204

5

FP2204

6

FP2204

7

IC2202

7

1

Q2005

X2202

13.5MHz

FROM/TO

VIDEO/USB

IC2001

(CONTROL MICROCOMPUTER)

115

SNS LED

256

T PHOTO

258

S PHOTO

87

T PHOTO SW2

80

T PHOTO SW1

79

S PHOTO SW2

85

S PHOTO SW1

261

MIC AD3

260

MIC AD2

259

MIC AD1

81

MIC CLK

82

MIC DATA

112

MIC ON

124

C DOWN

212

X1

214

X2

154

159

162

163

166

ADDRESS/

DATA

169

171

176

179

188

L

PS

POWER ON

BATTERY

BATT REF

BATT D

EEP CS

ERF DI

ERF DO

ERF CLK

TIMER INT

RTC CS

DEW

VTR KEY1

VTR KEY2

VTR KEY3

SS SW

POWER SW

STANDBY LED

POWER LED

GUI LED

POWER LCD SW

RESET

LCD OPEN SW

P LCD LED

ACCESS LED

TALLY LED

REMOCON

M RVS

EJECT SW

PV-GS250PP

L

POWER ON

0V PROTECT

X2001

32.768MHz

QR2007

PS

VREF

INN BATT

MAIN

FP6501

1

+B

TO IC305

L

FROM/TO

POWER

L

LITHIUM

BATTERY

DEW

VTR KEY1

VTR KEY2

VTR KEY3

SS SW

GUI LED

STANDBY LED

POWER LED

POWER SW

POWER LCD

RESET

P LCD LED

LCD OPEN

ACCESS LED

TALLY

IR OUT

REAR OPERATION

MAIN

FP6502

14

FP6502

10

FP6502

9

FP6502

6

FP6502

5

FP6502

12

FP6502

11

FP6502

8

FP6502

7

FP6502

4

FP6502

3

FP6502

1

SIDE R

MAIN

FP6301

FP6503

1

26

FP6301

FP6503

25

2

FP6301

FP6503

24

3

FP6301

FP6503

22

5

FP6303

FP6301

7

20

FRONT

MAIN

FP650513FP4801

8

SUB

FP40025FP4801

21

DEW

D6301

D6601

D6801

START/STOP

QUICK START

STANDBY LED

POWER LED

POWER SW

POWER LCD LED

CARD ACCESS LED

TALLY LED

Q491,492

AMP

MODE DIAL

D6802

WHITE

BALANCE

SENSOR

TAPE RECORDING MODE

TAPE PLAYBACK MODE

CARD RECORDING MODE

PICTURE PLAYBACK MODE

PC MODE

STOP

MENU

QUICK

START

S6302

POWER LCD

1

2

1

2

S6301

RESET

JOYSTICK

3

4

3

4

SET

FF

REV

PLAY

S6701

LCD OPEN

86

122

270

268

257

92

96

95

94

128

114

276

263

272

269

121

59

71

72

66

228

24

51

113

74

69

84

48

60

QR2008

QR2006

QR2001

PS3001

93 1

IC2006

(EEPROM)

SO

4

CS

SI

3

2

IC2002

(RTC/POWER CONTROL)

5

6

3

4

1

14

15

PS3001 PP301

FP6504 FP6201

SCK

SIO

SCLK

/INTR

CE

2.4/1.62.5V

2.8V2.8V

3.4V3.4V

QR2005

QR2010

QR2005

QR2006

MAIN SUB

68 68

SUBMAIN SUB

PP301 FP602

93

MAIN JACK

27 1

1

VDD

OSC OUT

OSC IN

VCC

11

12

13

2

+B

+B

IR6401

REMOTE

CONTROL

SENSOR

S601

LCD REV

S6212

EJECT SW

3V

5V

PV-GS250PP

CONTROL 1 BLOCK DIAGRAM

55

Page 56

PV-GS250PP

13.6. CONTROL 2 BLOCK DIAGRAM

IC2201-54 REC/PLAY

1.8Vp-p (0.5msec.div.)

IC2201-55 REC/PLAY

1.8Vp-p (2msec.div.)

IC2201-57 REC/PLAY

1.8Vp-p (1msec.div.)

TO

POWER

(CYL/CAP LOADING DRIVE)

IC2201

CAP SW

163CYL SW

DRIVE CLK

62

CYL ON L

3

CYL FG

54

CYL ERR

11

CYL PG

55

UNLOAD

8

LOAD

9

ACTIVE

COIL

SWITCHING

LOGIC

FG AMP

COMPARATOR

PG AMP

COMPARATOR

DECORDER

:CAPSTAN SERVO SPEED LOOP

:CAPSTAN SERVO PHASE LOOP

SLOPE

ADDITION

M1A

DRIVE

TRANSISTOR

CONTROL

DRIVE

TRANSISTOR

CONTROL

M2A

M3A

22

21

19

FG+

52

PG+

51

M UNLOAD

26

M LOAD

23

:CYLINDER SERVO SPEED LOOP

:CYLINDER SERVO PHASE LOOP

MECHA.UNIT

DD CYLINDER MOTOR

S

MAIN

FP2202

5,6

FP2202

7,8

FP2202

3,4

FP2202

10

FP2202

1

MAIN

FP2204

3,4

FP2204

1,2

S

N

S

N

MAIN COIL 1

MAIN COIL 2

MAIN COIL 3

N

M2

M3

M1

M2

S

M

M1

M3

N

FG

PG

LOADING

MOTOR

N

M3

M2

M1

S

S

N

TO/FROM

CONTROL

IC2001,IC3801

IC3001

( DUO)

28

26

24

22

19

16

13

11

8

DATA/

ADDRESS

DATA/

ADDRESS

HID

DD CAPSTAN MOTOR

N

S

M2

M3

S

M1

N

M2

MAIN COIL 1

MAIN COIL 2

MAIN COIL 3

FG

HALL

IC1

FG

S

DIRECTION

LOGIC

M1

27

DRIVE

DIRECTION

DETECTOR

IC3201

(RIP)

CYL PG

LOAD

LIMIT

DRIVE CLK

58

56

72

55

36

61

63

37

35

71

69

17

41

40

57

CAP RSF

CAP ERR

TORQUE

LIMIT

CAP FG

ATFIN

FROM

IC5001

159

TO

IC5001

173

171

169

168

REC

11

44

48

74

76

78

DRIVE

DATA/

ADDRESS

CYL ON

CYL FG

CYL ERR

UNLOAD

CAP RSF

CAP ERR

TORQUE

CAP FG

MATRIX

DIRECTION

SWITCHING

LIMITER

-

+

FG AMP

COMP.

TRANSISTOR

CONTROL

M2

28

M3

29

3V

AFG-

47

H1+

37

H1-

36

H2+

32

H2-

35

H3+

31

H3-

30

AFG+

45

MAIN

FP2201

1,2

FP2201

13,14

FP2201

11,12

MAIN

FP2201

4

FP2201

18

FP2201

8

FP2201

6

FP2201

10

FP2201

7

FP2201

5

FP2201

3

FP2201

15

FP2201

17

HALL

IC2

N

M1

S

M3

N

HALL

IC3

PV-GS250PP

CONTROL 2 BLOCK DIAGRAM

56

Page 57

13.7. VIDEO BLOCK DIAGRAM

IC3001

PV-GS250PP

(DUO)

MAIN SIGNAL PATH IN REC MODE

MAIN SIGNAL PATH IN PLAYBACK MODE

JK4001

<AV4P>

SIDE L FLEX. CARD

<SPEAKER>

ECM L

ECM R

JK3001

<S JACK>

JK4901

<EX MIC/MP>

+

-

+

-

CLAMP

IC3301

34

32

36

39

40

48

45

47

44

19

20

60

51

52

61

53

54

IC3503

2

751

C OUT

Y OUT

V OUT

HP R

HP L

L IN

L OUT

R IN

R OUT

SP OUT1

SP OUT2

H MIC L

EX MIC L

EX

MIC R

H MIC R

MIC L

MIC R

Y/C

SEP

(AVIO)

AFC TBC

GCA

MIX

GCA

LPF

LPF

1

3

CLK

CHANGE

BUFF CLAMP

AMP

AMP

AMP

AMP

FROM

CAMERA

BUFF

AUDIO

I/F

CONTROLLER

DAC

HPF

ADC

Y OUT0 Y C0

Y OUT7 Y C7

C OUT0 MEGA Y C0

C OUT7 MEGA Y C7

111

112

115

116

118