ORDER NO. MTNC000524A1

B2

Service Manual

Color Video Projection Syste m

d

e

i

f

i

S

m

i

l

p

Simplified Manual

(P4C)

Panasonic

Models

PT-56SX30B FP816

PT-56SX30CB FP816

PT-56D30B GP816

PT-56D30CB GP816

Note: Appearance may

vary depending on model

characteristics.

This Simplified Service Manual is issued to add listed models to the Main Service Manual order No. MTNC000211C1.

(PT-61D30B/CB) A full set of schematics, disassembly procedures, and a complete parts list are included in this

Simplified Manu al. Please file and us e this Simplifi ed Service Manu al together with Ma in Service Ma nual, order No .

MTNC000211C1. (PT-61D30B/CB)

“WARNING! This Service Manu al is desi gned for ex perienced repai r technicia ns only and is not des igned for us e by the g eneral publi c.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be se rviced or repaired only by experie nced profes sional tec hnicians . Any attempt to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

Chassis

The service technician is required to read and follow the “Safety Precautions” and “Important Safety Notice” in the Main Manual.

Copyright 2000 by M atsus hita Electri c Corpo ration of

America. All rights reserved. Unauthorized copying

®

and distribution is a violation of law.

Important Safety Notice

Special components are used in this projecti on television which a re important for safety. These components are

identified on the schematic diagram by the symbol and printed in BOLD TYPE on the replacement part list. It is

essential that these critic al parts are replac ed with th e manufact urer ’s speci fied repla cement part to prevent x -ray

radiation, shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety Precautions

General Guidelines

An

isolation transformer

during the servicing of a PTV whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating as this protects the technician

from accidents resulting in personal injury from

electrical shocks. It will also protect the PTV from being

damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always replace protective devices, such as

fishpaper, isolation resistors and capacitors, and

shields after servicing the PTV. Use only

manufacturer ’s recommended rating for fuses, cir cuits

breakers, etc.

High potentials, as high as 32kV, are present when this

PTV is operating. Operation of the PTV without the rear

cover introduc es danger for el ectrical sho ck. Servicin g

should not be performed by anyone who is not

thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be prac ticed when handling the

picture tube

due to atmospheric pres s ure. (1 4.7 lb s. per sq . i n.). Do

not nick or scratch the glass or subject it to any undu e

pressure. When handling, use safety goggles and

heavy gloves for protection. Discharge the picture

tube by shorting the anode to chassis ground (not to

the cabinet or to other mounting hardware). When

discharging connect cold ground (i.e. DAG ground

lead) to the anode with a well insulated wire or use a

grounding probe.

. Rough handling may caus e it to implod e

should always be used

X-ray Precautions

The front area (between the projection tube and the

lens) is enclosed by a metal box to ensure positive

safety during normal and abnormal conditions when

checking and repairing. To fully ensure safety, the

following precautions must be observed.

1. Do not remove the lens or metal box.

2. Make sure to turn the power OFF when the le ns is

removed or when checkin g the cleanliness of the

lens.

3. Do not remove the lens or metal box to check the

projection tube for oper ati on by watc hi ng i t di rec tly.

Use a mirror or paper to view the image.

Before returning a serv iced PTV to the owner, the

service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage Current Cold Check

Unplug the AC cord and connect a jumper between the

two plug prongs. Press the POWER switch ON.

Measure the re si stance betw e e n th e j um p ere d AC pl ug

and expose metallic parts such as screw heads,

Service Manual

antenna terminals, control shafts, etc. If the exposed

metallic part has a return path to the chassis, the

reading should be between 240kΩ and 5.2MΩ. If the

exposed metallic part does not have a return path to

the chassis, the reading should be infinite.

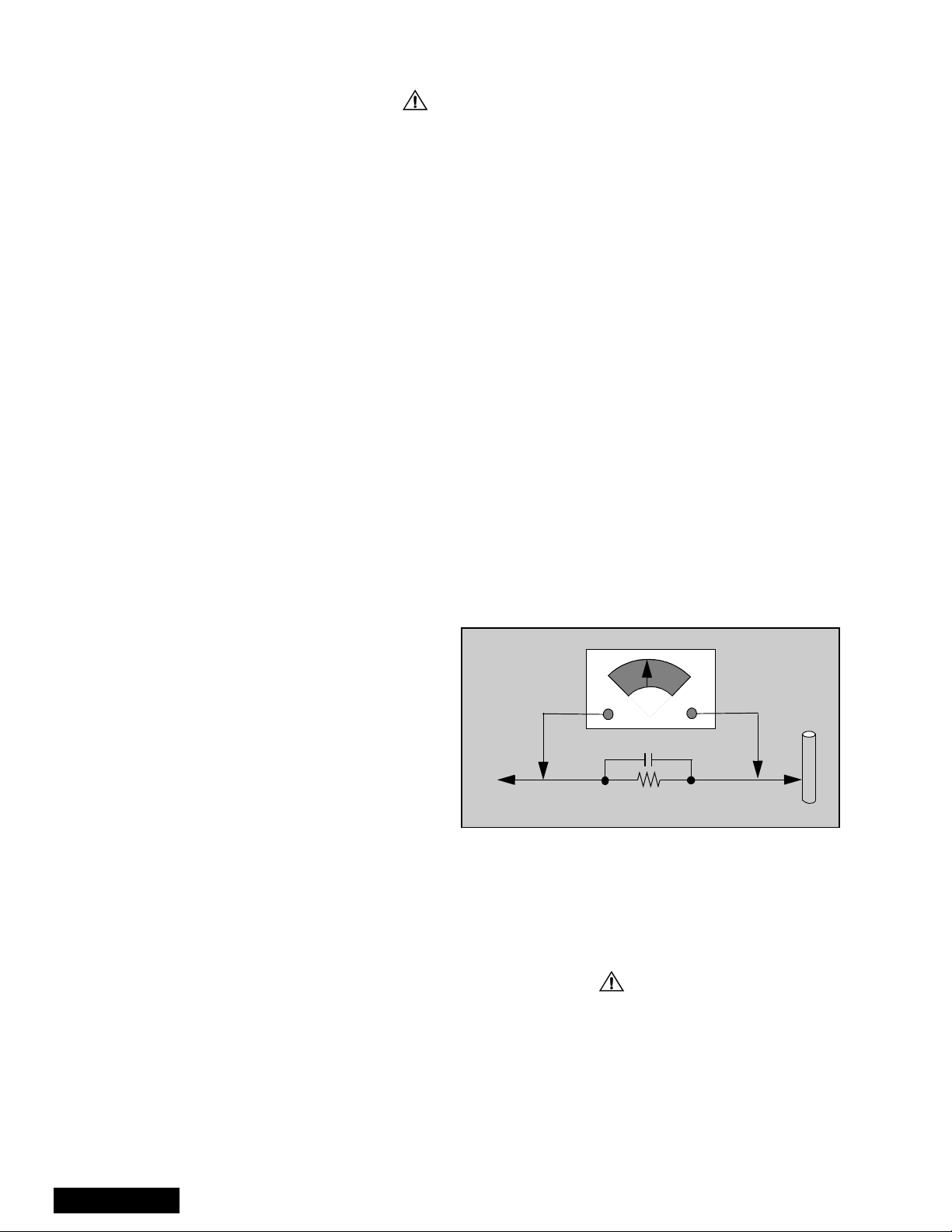

Leakage Current Hot Check (See Figure 1)

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5kΩ 10 watt resistor in parallel with a

0.15µF capacitor between and exposed metallic part

and ground. Use earth ground, for example a

water pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other expose metallic parts.

Verify any potential does not exceed 0.7 5 volt RMS. A

leakage current tester (such a Simpson Model 229,

Sencore Model PR57 or equivalent) may be used in

the above procedure, in which case any current

measure must not exceed 1/2 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the PTV must be

repaired and rechecked before it is returned to

the customer.

AC VOLTMETER

COLD

WATER

PIPE

(GROUND)

0.15µF

TO INSTRUMENT’S

EXPOSED METAL

PARTS

Figure 1. Hot Check Circuit

1500Ω,10W

Insulation Test

Connect an insulation tester between an exposed

metallic part and AC line.

Apply 1080VAC/60Hz for 1 second. Confirm that the

current measurement is 0.5mA ~ 2.0mA. Repeat test

with other metallic exposed parts.

X-ray Radiation

WARNING: The potential source of X-ray radiation in the

PTV is in the hig h vo ltage section and the pict ure t ube .

Note: It is important to use an accurate, calibrated

high voltage meter.

Set brightness, picture, sharpness and color

controls to Minimum. Apply a all black video signal.

Measure the High Voltage. The high should be 31.5kV

±1.0kV. If the upper limit is out of tolerance, immediate

service and correction is required to insure safe

operation and to prevent the possibility of premature

component failure.

- 2 -

Important Safety Tests

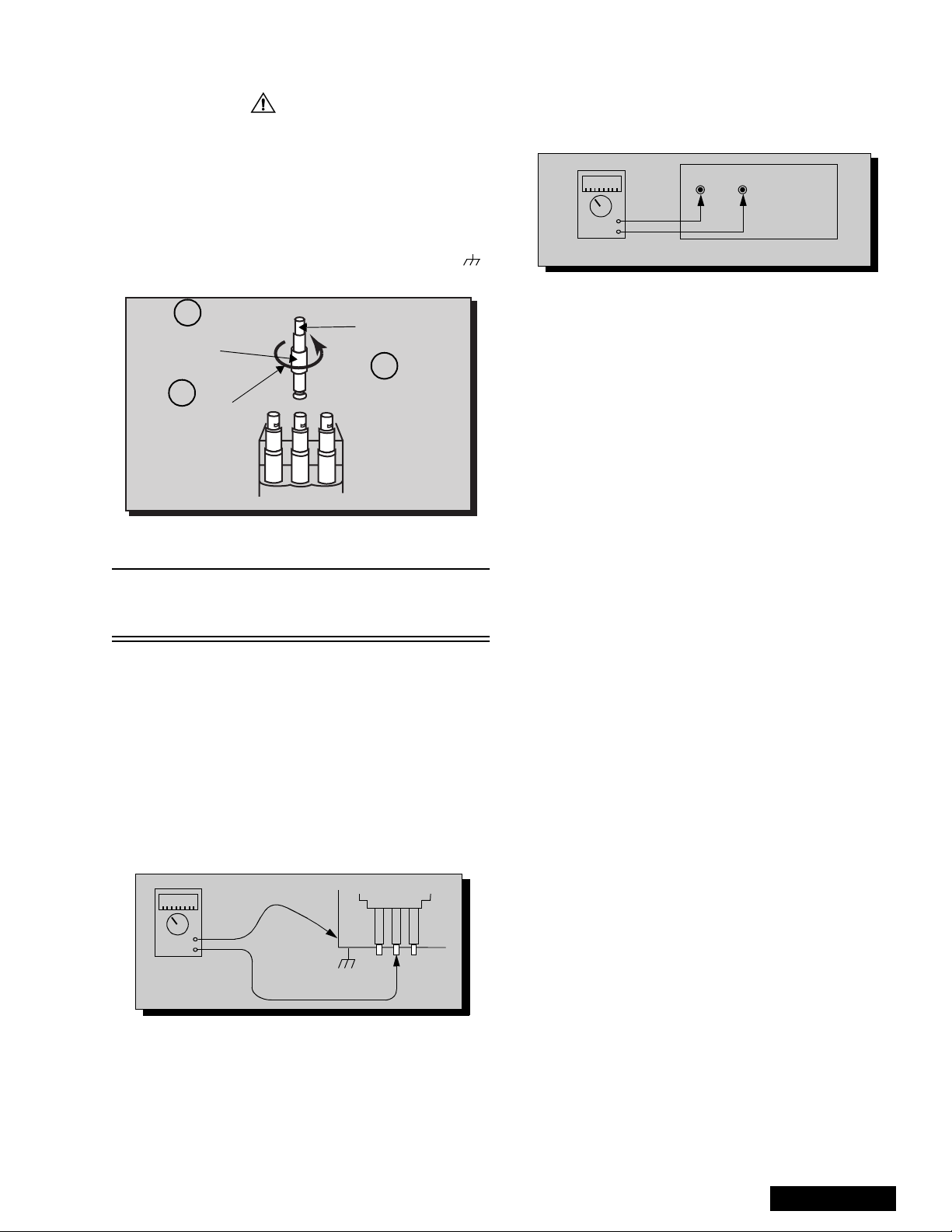

Measuring H.V.

The anode caps are cemented to the CRTs. To gain

access for high v oltage measurement, remove the red

CRT’s anode lead from the flyback transforme r (FBT)

distributor. Grasp the anode lead protective cap at its

bottom and squeeze it against the locking cap body

inside. Rotate 1/4 turn coun ter clockwise and pull the

anode lead sleeve out of the FBT distributor. Connect a

high voltage lead (+) from y our H.V. meter to the FBT

distributor, and the common (-) to cold ground ( ).

(See Figure 2).

1

Grasp protective

Anode lead

rubber cap

3

2

Squeeze & rotate

Discharge to

CRT Chassis

cap counterclockwise

to remove

FBT Distributor

Figure 2. Removal of FBT leads

Note: Reinsert the anode lead into the FBT

distributor until it is tightly and fully seated.

T urn the locking cap clockwise to lock in place.

(EHT) Protector Operation Check

With the cabinet ba ck removed, apply a n ominal 120V

AC to the PTV.

Over Voltage Test

Preparation:

1. Turn PTV “OFF”

2. Connect an NTSC signal generator to the

antenna terminal.

3. Connect DVM (+) TPD4 and ( -) TPD5 on D-Boa rd.

(See Figure 3)

4. Connect a H.V. meter (static type, class 0.1 ) with

high voltage leads to high voltage distributor

on FBT. (See Figure 4)

TPD5 TPD4

-

+

D-Board

DVM

Figure 4. DVM connected to D-Board.

5. Connect the 8 ~ 15 V DC variable power s upply to

(+) TPB10 and (-) TPBGND, on B-Board.

Procedures:

1. Apply a monoscope pattern.

2. Adjust the Picture or Brightness controls so that the

DVM reads 17.5 volts ± 0.5 volts.

3. Increase the variable po wer supply until set turns

off. The set should turn off at 17.5 volts ± 0.5 volts

(DVM) and high voltage less than 35.5kV.

4. If the DVM reading is other than 17.5volt (± 0.5

volts), repeat steps 2 and 3.

5. Turn off the variable supply and confirm that the set

will turn on with the Remote Control.

CRT Protect Circuit

This circuit blanks the CRT in the event that there is a

loss of vertical sweep. The circuit is not adjustable;

however the circuit should be checked each time

service is performed.

To check circuit:

1. Turn the PTV On an select an active channel.

2. Adjust Brightnes s and Picture control s for a visible

picture.

3. On D-Board momentarily connect a shor t-jumper

from TPD2 to TPDGND. The CRT shou ld blank. If

this does not occur, repair must be performed

before returning PTV to customer.

4. Remove short-jumper.

-

+

H.V. METER

FBT Distributor

CRT

CHASSIS

Figure 3. Measuring H.V.

- 3 -

Service Manual

Important Safety Notice . . . . . . . . . . . . . . . . . . .2

Safety Precautions . . . . . . . . . . . . . . . . . .2

Important Safety Tests . . . . . . . . . . . . . . .3

Service Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . .5

PTV Feature Table. . . . . . . . . . . . . . . . . . . . . . . .7

PCB Designation . . . . . . . . . . . . . . . . . . . . . . . . .8

PTV - Location of Controls

PTV Front Control Panel . . . . . . . . . . . . .9

Remote - Location of Controls

EUR511151C . . . . . . . . . . . . . . . . . . . . .10

Board description . . . . . . . . . . . . . . . . . . . . . . .11

B+ Voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Service Manual

- 4 -

Service Notes

Note: These components are affixed with glue. Be careful not to break or damage any foil under the

component or at the pins of the ICs when removing. Usually applying heat to the component for

a short time while twisting with tweezers will break the component loose.

Leadless Chip Component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil tr ack spacing. There are n o holes in

the board to mount standard transistors or diodes.

Some chip capacitor or resis tor board so lder pads may

have holes through the board, however the hole

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same reason. It is recommended that identical

components be used.

Chip resistor have a three digit numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1 60 0 o r 1 .6 kΩ resistor, 0 = 0Ω (jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color on the component

indicates the general range of the capaci tance.

Chip transistors are identified by a two let t er c ode . The

first letter indica ted the type an d the second letter, the

grade of transistor.

Chip diodes have a two lette r i den tif icati on c ode as per

the code chart an d are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

1. Use solder wick to remove s older from compo nent

end caps or terminal.

2. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

3. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal.

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to th e pad area wi th a 30 watts iro n

until solder flows. Do not appl y heat for more than

3 seconds.

TYPE

Chip Components

GRADE

c

c

SOLDER

CAPS

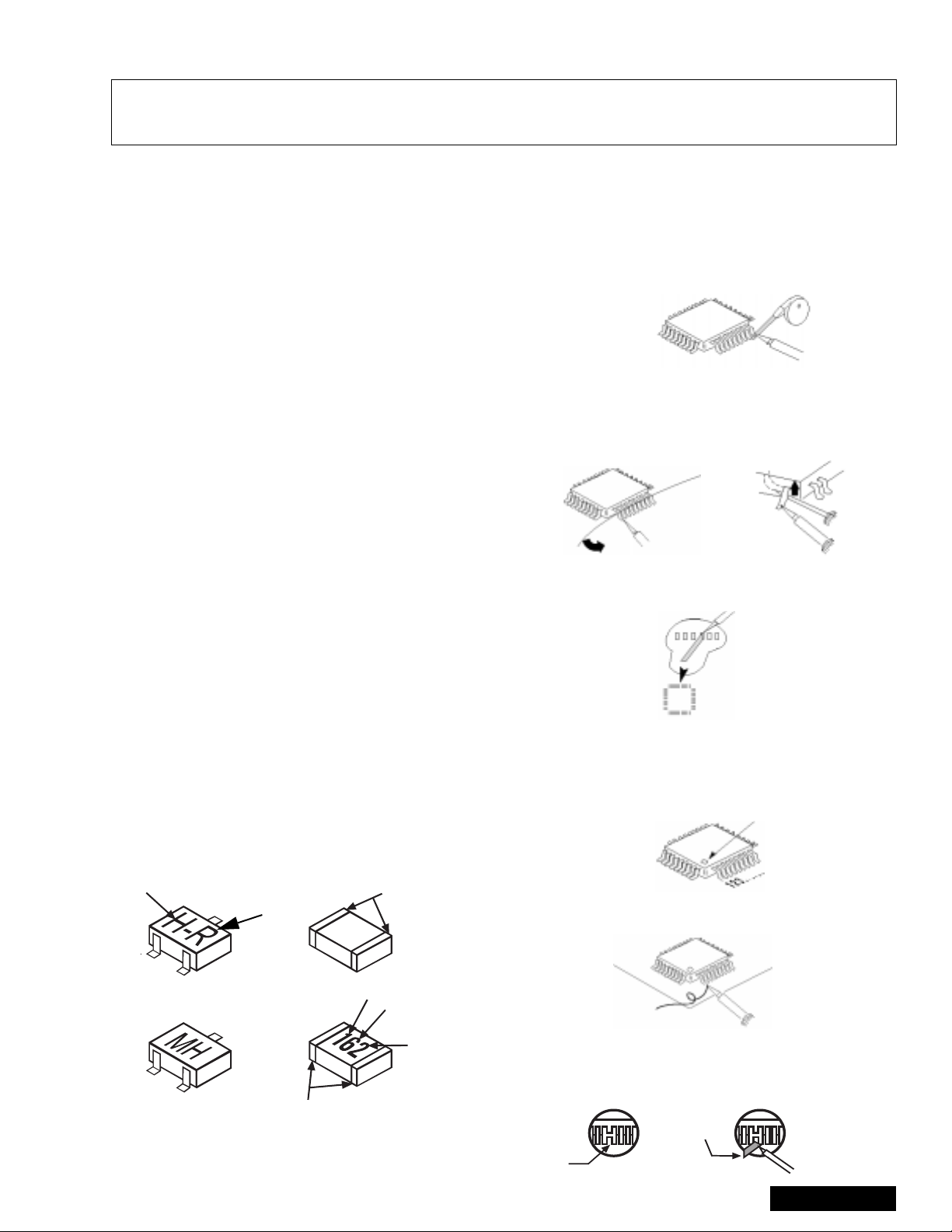

How to Replace Flat-IC

- Required Tools -

• Soldering iron • De-solder braids

• Iron wire or small awl • M agn ifi er

1. Remove the solder from all of the pins of a Fla t-IC

by using a de-solder braid.

De-Solder

Flat-IC

2. Put the iron wire under the pins of the Flat-IC and

pull it in the direction indicated while heating the

pins using a soldering iron. a small awl can be

used instead of the iron wire.

Iron

Wire

Pull

Soldering

Iron

Soldering

Iron

3. Remove the solder from all the pads of the Fla t-IC

by using a de-solder braid.

Soldering

Iron

De-Solder

Braid

Flat IC

4. Position the new Flat-I C in place (app ly the pins of

the Flat-IC to the soldering pads where the pins

need to be soldered). Properly determine the

position of the sold ering pads and pins by correctly

aligning the polarity symbol.

Polarity Symbol

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

Braid

Awl

b

b

ANODES

MH DIODE

e

e

TRANSISTOR

COMMON

CATHODE

SOLDER

CAPS

CAPACITOR

1ST DIGIT

RESISTOR

2ND DIGIT

MULTIPLIER

=1600 = 1.6k

Solder

Soldering

Iron

6. Check with a magnifier for solder bridge between

the pins or for dry join t between pi ns and sold erin g

pads. To rem ove a solder bridge, use a de-solder

braid as shown in the figure below.

De-Solder

- 5 -

Solder

Braid

Braid

Soldering

Iron

Service Manual

Service Notes (Continued)

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static discharge,

make certain that all ground wires and CRT DA G wire

are securely connected.

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when s ervicing the PTV to avoid

damage to the test equipment or to the chassis.

Connect the test equipment to the proper ground (( )

or ( )) when servicing, or incorrect voltages will

be measured.

WARNING: This PTV has been designed to meet or

exceed applicable safety and X-ray radiation protection

as specified by gove rnment a genci es and ind ependen t

testing laboratories.

To maintain original product safety design standards

relative to X-ray radiation and shock and fire hazard,

parts indicated with the s ymbol on the schematic

must be replaced with identi cal parts. Order parts from

the manufacturer’s parts center using the parts

numbers listed in this service manual, or provide the

chassis number and the part reference number.

For optimum performance and readability, all other

parts should be replaced with components of

identical specification.

Service Manual

- 6 -

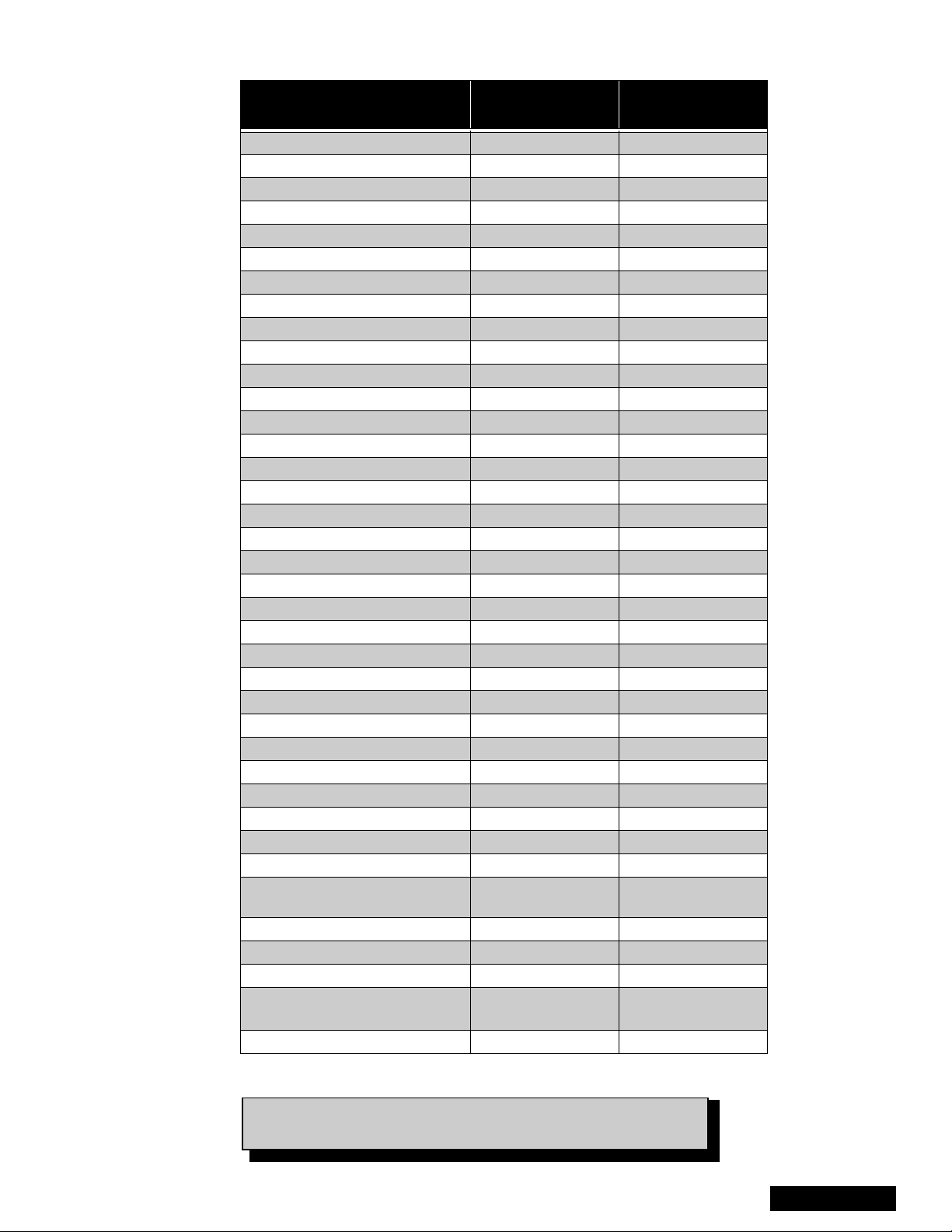

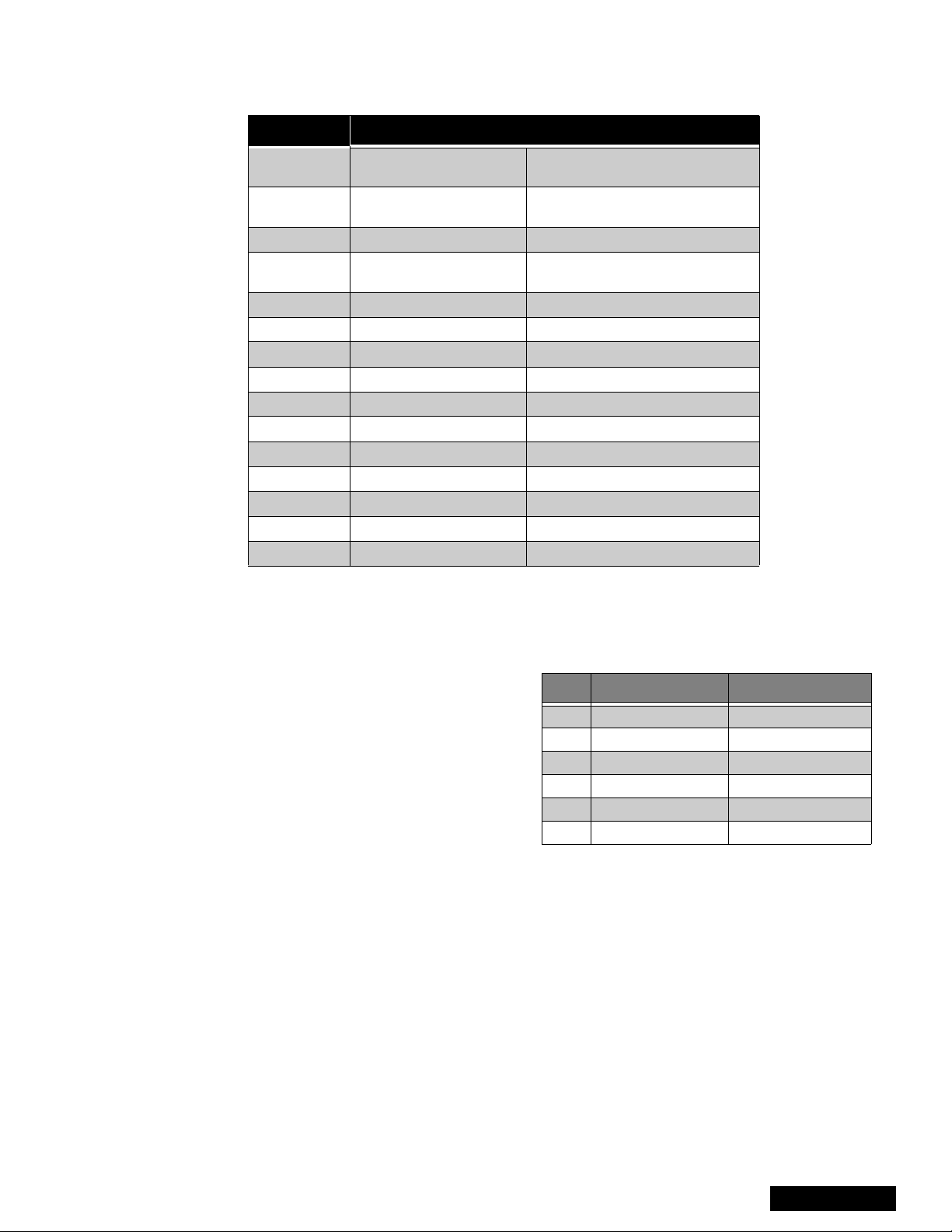

Feature Table

FEATURE

Chassis P4C P4C

Tunning system 144K 144K

# of channels 181 181

Menu language Eng/Span/Fr Eng/Span/Fr

Closed Caption (CC) X X

V-Chip (USA/Canada) X X

2RF X X

Antenna

Picture In Picture (PIP) 2T 2T

Remote control # EUR511151C EUR5111500

Screen protector X X

Comb filter 3DIG Y/C 3DIG

H. edge correction W/ VER W/ VER

Y NR X -VM X X

V/A norm Both Both

Color Temp X -Dyn color/Peak white X X

AIP X -Natural AI X -MTS/SAP/DBX X X

Bass/Bl/Treb control X X

AI sound Simple Simple

Spatializer X X

Built-in audio power 10W/CH (10%) 10W/CH (10%)

# of speakers 2 2

A/V in (rear/front) 4 (3/1) 3(2/1)

Component input 1 1

S-VHS in (rear/front) 2/1 1/0

Audio out Fixed & Variable Fixed & Variable

A/V Prog Out X -Dolby Center Ch In X -Dimensions mm

WxDxH in

Weight (kg/lbs) 116/255.7 116/255.7

Power source (V/Hz) 120V 60Hz 120V 60Hz

Anode voltage 31.5kV ± 1.0kV 31.5kV ± 1.0kV

Video input jack

Audio input jack 500mV RMS 47kΩ 500mV RMS 47kΩ

Input X X

PT-56SX30B

PT-56SX30CB

1196x683x1417

47x26.8x55.68

1V

75Ω, phono

p-p

jack

PT-56D30B

PT-56D30CB

1196x683x1417

47x26.8x55.68

1V

75Ω, phono

p-p

jack

Table 1: Feature Table

Specifications are subject to change without notice or obligation.

Dimensions and weights are approximate.

- 7 -

Service Manual

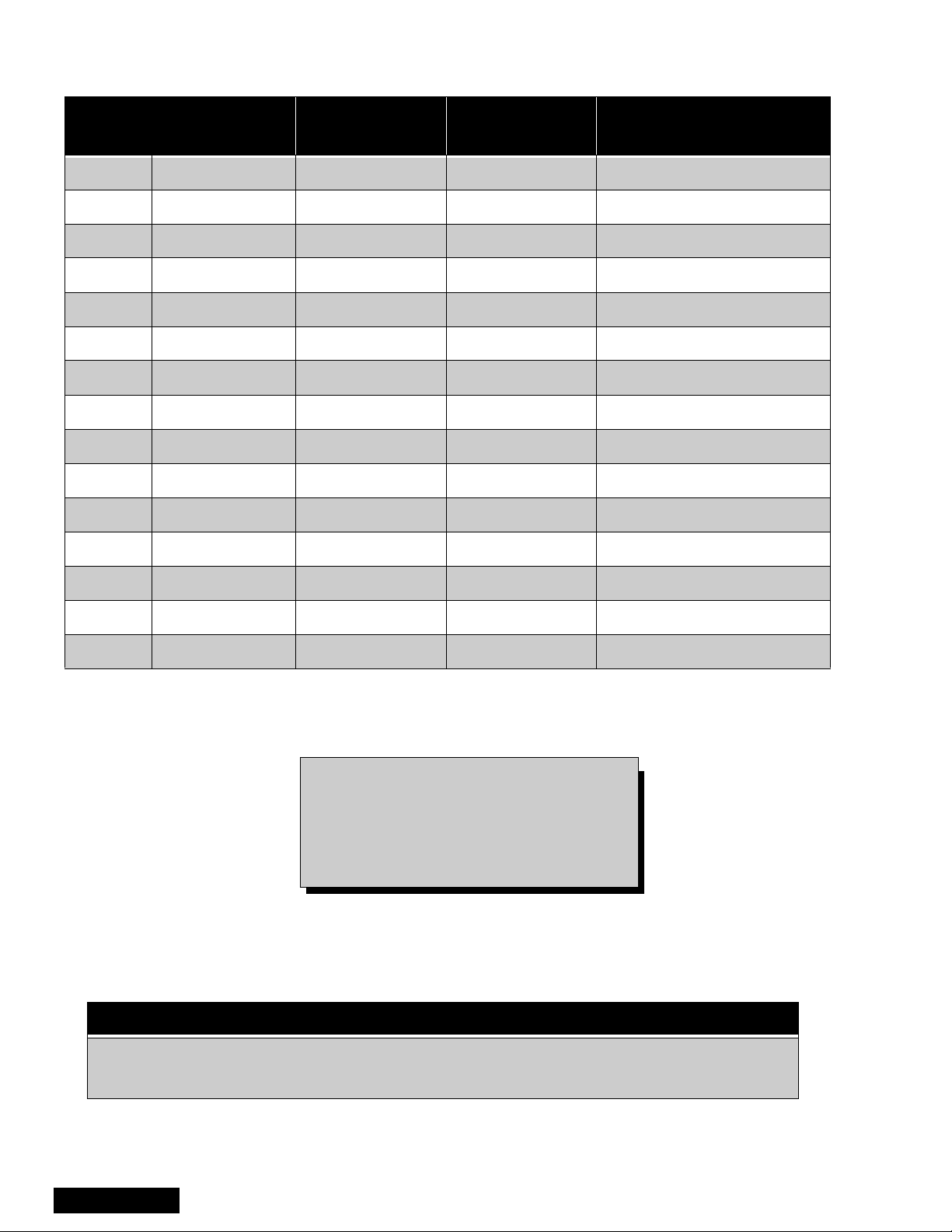

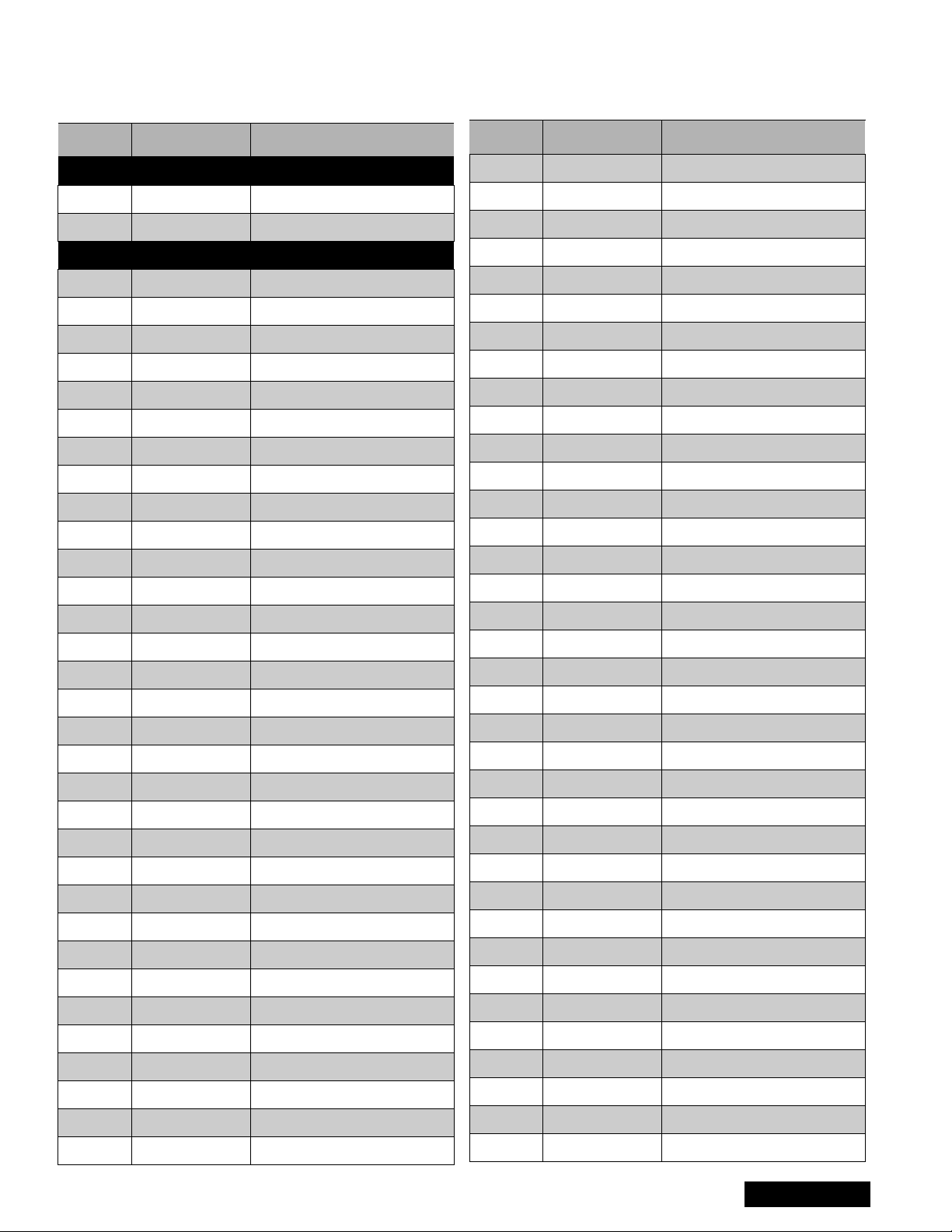

PCB Designation

BOARD

A-Board TNP2AH021 NIL AA Main chassis

B-Board TNPH0121 AG AG Power supply

C-Board TNPA1513 AB NIL Convergence

D-Board TNPA0609 AB AB Protection circuit

F-Board TNP2AA055 TNP2AA056AA Digital 3-line comb filter

G-Board TNP2AA049 AC NIL Front A/V connections

K-Board TNP2AA050 AC NIL Costumer controls

LB-Board TNPA0784 BA BA Blue CRT drive

LG-Board TNPA0783 BA BA Green CRT drive

LR-Board TNPA0782 BA BA Red CRT drive

N-Board TNP2AA027 AB AB 2nd tuner

R-Board TNPA0615 NIL NIL Remote sensor

PT-56SX30B

PT-56SX30CB

PT-56D30B

PT-56D30CB

BOARD DESCRIPTION

T-Board TNP2AA045 AD AD Line filter

X-Board TNP2AA063 NIL AA A/V inputs

Y-Board TNPA1059 AC AC PIP processing

Table 2: PCB Designation

Note: The C & F-Board (TNPA1513 &

TNP2AA055 & TNP2AA056AA) are

Non-Serviceable. If either board is

defective, replace the board with a

new one, and return the defective

board to the Service Center.

IMPORT ANT

This Simplified Service Manual includes only boards with particular application for the listed

models, for the rest of the schematics and PCBs, with gen eral use in this chassis, refer to

Main Service Manual MTNC000211C1 (PT-61D30B/CB)

Service Manual

- 8 -

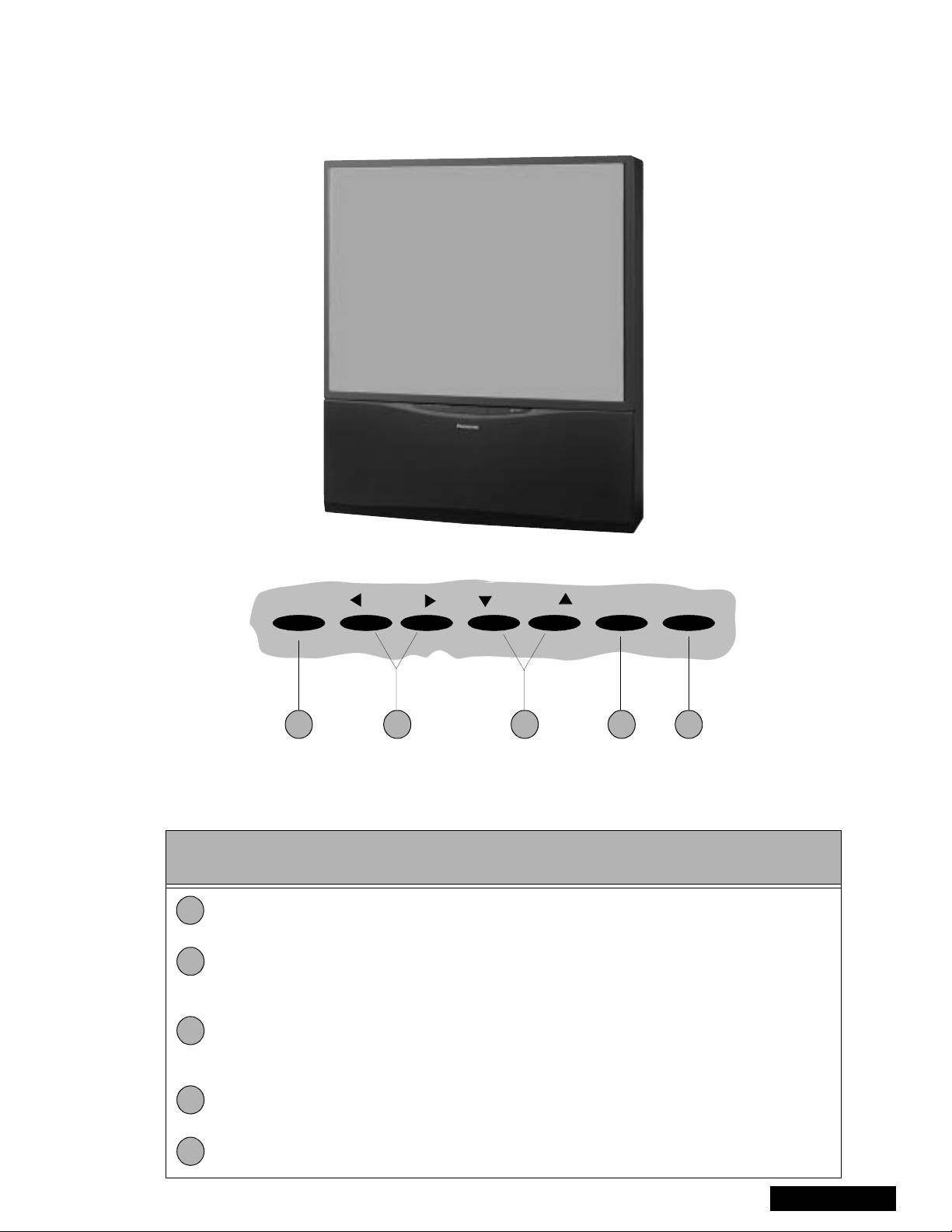

PTV - Location of Controls

Note: Appearance may vary

depending on models

characteristics.

POWER VOLUME CHANNEL ACTION TV/VIDEO

1 2 4 53

Figure 5. Location of Controls PTV

Quick Reference Control Operation

Quick Reference

Control Operation

1

2

3

Power - Press to turn ON or OFF.

Vo lu m e - Press to adjust Sound Le vel, or to adjus t Audio Menus, Video Me nus, and

select operating features when menus are displayed

Channel - Press to s elect programm ed channels. Pres s to highlight desired features

when menus are displayed. Also use to select Cable Converter box channels after

programming Remote Control Infra-red codes (the TV/AUX/CABLE switch must be set

in CABLE position).

4

Action - Press to displ ay Main Menu and access On Screen f eature and Ad justment

Menus.

5

TV/Video - Press to select TV or one of two Video Inputs, for the Main Picture or the

PIP frame (when PIP frame is displayed).

- 9 -

Service Manual

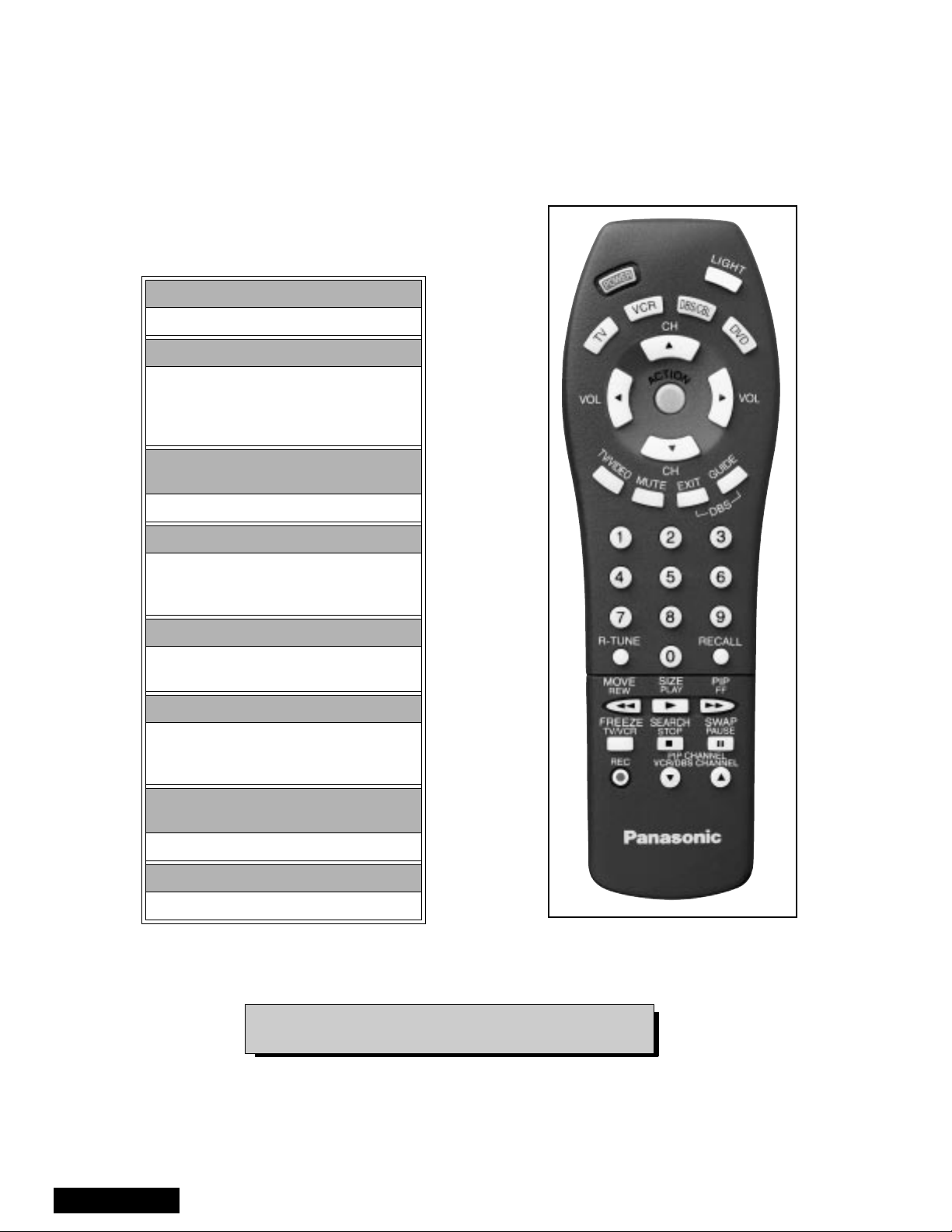

Remote - Location of Controls

POWER Button

Press to turn ON and OFF.

MUTE Button

Press to mute sound.

A second pres s resumes sound.

Press also to access and delete

Closed Caption display.

VCR, DVD, LD/CD, AUX, TV, CBL, DB S &

RCVR Buttons

Component function buttons

VOL (volume) Buttons

Press to adjust TV sound level.

Use with Channel buttons to

navigate in menus.

R-TUNE (Rapid Tune) Button.

Press to switch to the previous

channel.

ACTION Button

Press to display Main Menu and access or

exit On Screen features

and Adjustment Menus.

REW, PLAY, FF, TV/VCR, STOP, PAUSE,

REC & VCR CHANNEL Buttons

Component function buttons.

DBS EXIT& DBS GUIDE Buttons

DBS function buttons.

Figure 6. Location of Controls (Remote)

EUR511151C

Service Manual

For additional information for this rem ote please refer

to the Remote Guide, listed on the parts list.

- 10 -

BOARD DESCRIPTION

BOARD DESCRIPTION

A-Board Main chassis

B-Board Power supply

C-Board Convergence

D-Board Protection circuit

F-Board Comb filter

G-Board A/V connections

K-Board Costumer controls

LB-Board Blue CRT drive

LG-Board Green CRT drive

LR-Board Red CRT drive

N-Board 2nd tuner

R-Board Remote sensor

T-Board Line fil ter

X-Board A/V inputs

Y-Board PIP processing

MPU, Audio Amp, Convergence,

Amp and Volt Regulation

Horizontal Deflection and High

voltage protector

Digital Convergence

EHT protector, over deflection

blanking, Vertical stop blanking

Digital 3-line comb filter

Front A/V connections

Keyboard

2nd tuner processing

Remote control board

VAO,FAO

B+ Voltages Table

Preparation:

Set the following controls

Picture..........................Normal.

Bright ...........................Normal.

Volume.........................Min. (0).

Procedure:

1. Apply a monoscope pattern.

2. Connect the (-) Lead of the Digital Voltmeter to

TPBGND (Cold Ground) on B-Board.

3. Connect the (+) Lead of the Digital Voltmeter to

Test Point (On B-Board) and confirm the B+

Voltages (See Table 3).

No. Test Point Voltage

1 TPB140 138.5±1.0

2 TPB15 15.0

3 TPB7 7.0±0.5

4TP23 23.0

5 TPB23N -23.5±1.0

6 TPB32 16.5

±1.0

±1.0

±1.0

Table 3: B+ Voltages Table

- 11 -

Service Manual

REPLACEMENT PARTS LIST

Models: PT-56D30B, PT- 56D3 0CB, PT -5 6S X30 B & PT- 56 SX3 0CB

Important Safety Notice: Components printed in BOLD TYPE ha ve special characteristics important

for safety. When replacing any of these components use only manufacturer’s specified parts.

REF NO. PART NO. DESCRIPTION

CAPRISTORS

CR2801 EXNG131P365 RES-CAP 130PF/3.6 MEG

CR2802 EXNG131P365 RES-CAP 130PF/3.6 MEG

CAPACITORS

C001 ECA1CM101 CAP,E 100UF/16V

C004 TCUX1H103KBN CAP,C .01UF-K-50V

C005 ECA1CM101 CAP,E 100UF/16V

C006 ECA1HM4R7 CAP,E 4.7UF/50V

C010 ECA1CM101 CAP,E 100UF/16V

C011 ECJ2VC1H101J CAP,C 100PF-J-50V

C012 ECJ2VC1H101J CAP,C 100PF-J-50V

C013 ECA1HM220 CAP, E 22UF /50V

C014 ECA1HM220 CAP,E 22UF/50V

C015 ECJ2VC1H181J CAP,C 180PF-J-50V

C016 ECJ2VF1C105Z CAP,C 1.0UF-Z-16V

C017 ECJ2VF1C105Z CAP,C 1.0UF-Z-16V

C023 ECJ2VC1H181J CAP,C 180PF-J-50V

C024 ECA0JM102 CAP,E 1000UF/6.3V

C027 ECEA1HNR47U CAP,E .47UF-50V

C028 EEANA1E1R0B CAP,E 1.0UF-25V

C029 ECA1HM010 CAP,E 1.0UF/50V

C031 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C034 ECJ2VB1H272K CAP ,C .0027UF-K-50V

C039 ECJ2VC1H220J CAP,C 22PF-J-50V

C040 ECJ2VC1H270J CAP,C 27PF-J-50V

C041 ECA0JM331 CAP,E 330UF/6.3V

C042 TCUX1H103KBN CAP,C .01UF-K-50V

C043 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C045 ECA1CM101 CAP,E 100UF/16V

C046 ECJ2VF1H103Z CAP,C .01UF-Z-50V

PARTS LIST

C047 ECA0JM222 CAP,E 2200UF/6.3V

C048 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C049 ECA1EM101 CAP,E 100UF/25V

C050 ECA1EM471 CAP,E 470UF/25V

C051 EEUFC1E470B CAP,E 47UF-25V

C052 TACCX103T50V CAP,C .01UF/50V

REF NO. PART NO. DESCRIPTION

C053 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C054 TCUX1H103KBN CAP,C .01UF-K-50V

C055 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C056 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C081 ECA1HM010 CAP,E 1.0UF/50V

C101 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C140 ECJ2VC1H270J CAP,C 27PF-J-50V

C301 ECEA1CN470U CA P,E 47UF-16V

C302 ECA1HM010 CAP,E 1.0UF/50V

C304 ECA1HM010 CAP,E 1.0UF/50V

C305 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C306 ECA1HM220 CAP,E 22UF/50V

C307 ECJ2VF1H223Z CAP,C .022UF-Z050V

C308 ECA1HM3R3 CAP,E 3.3UF/50V

C309 ECEA1HN010U CA P,E 1UF/50V

C311 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C312 ECA1HM100 CAP,E 10UF/50V

C313 ECA1VM470 CAP,E 47UF/35V

C314 ECA1CM101 CAP,E 100UF/16V

C315 ECA1EM220 CAP,E 22UF/25V

C316 ECA1HM4R7 CAP,E 4.7UF/50V

C317 ECA1HM4R7 CAP,E 4.7UF/50V

C318 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C319 ECA1HM101 CAP,E 100UF/50V

C320 ECJ2VF1H103Z CAP,C .01UF-Z-50V

C321 ECA1CM101 CAP,E 100UF/16V

C330 ECJ2VC1H101J CAP,C 100PF-J-50V

C351 ECA2EM100 CAP,E 10UF/250V

C353 ECKD2H103PU CAP,C .01UF-P-500V

C354 ECA1CM101 CAP,E 100UF/16V

C356 ECKD3D332KB CAP,C .0033UF-K-2KV

C357 ECQB1H104JM CA P,P .1UF-J-50V

C359 ECKD3D102KB CAP,C .001UF-K-2KV

C360 ECA1CM470 CAP,E 47UF/16V

C361 TACCW1 01T50V CAP,C 100PF/50V

C363 ECKD3D102KB CAP,C .001UF-K-2KV

060-00

- 12 -

Parts List

Loading...

Loading...