Panasonic PT-51D31CE, PT-61D31CE Service Manual

ORDER NO. MTNC010420A1

B2

Service Manual

Color Video Projection System

S

m

i

p

l

i

f

i

e

d

Simplified Manual

P6

Panasonic

Models

PT-51D31CE AP821

PT-61D31CE AP821

Chassis

Note: Refer to Technical Guide (P6) for

functional descriptio ns and Bloc k Diag rams .

(MTNC010308G1).

This Simplified Se rvice Manual is issued to add listed model to the Main Ser vice Manual order No. MTNC010 307C1

(PT-51G36E). A full set of schematics, disassembly procedures, and a complete parts list are included in this Simplified

Manual. Please file and use this manual together with Main Service Manual, order No. MTNC010307C1 (PT-51G36E).

“WARNING! This Service Manual is desig ned for expe rienced repa ir technici ans only and is not de signed for u se by the general pub lic.

It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting to service a product.

Products powered by electricity should be serviced or repai red only by exp erienced profe ssional techn icians. Any attemp t to

service or repair the product or products dealt with in this Service Manual by anyone else could result in serious injury or death.”

The service technician is required to read and follow the “Safety Precautions” and “Important Safety Notice” in this Manual.

Copyright 2001 by Matsushita Electric Corporation of

America. All rights reserved. Unauthorized copying

and distribution is a violation of law.

Important Safety Notice

Special components are used in this projection television that are important for safety. These components are

identified on the schematic diagram by the symbol and printed in BOLD TYPE on the replacement part list. It is

essential that these c ritical parts be replace d with the manufactur er’s speci fied replacement part to prevent x-ray

radiation, shock, fire or other hazards. Do not modify the original design without the manufacturer’s permission.

Safety Precautions

General Guidelines

An

isolation transformer

during the servicing of a PTV whose chassis is not

isolated from AC power line. Use a transformer of

adequate power rating as this protects the technician

from accidents resulting in personal injury from

electrical shocks. It will also protect the PTV from being

damaged by accidental shorting that may occur

during servicing.

When servicing, observe the original lead dress,

especially in the high voltage circuit. Replace all

damaged parts (also parts that show signs of

overheating.)

Always replace protective devices, such as

fishpaper, isolation resistors and capacitors, and

shields after servicing the PTV. Use only

manufacturer ’s recommended r ating for fuses , circuits’

breakers, etc.

High potentials, as high as 32kV, are present when this

PTV is operating. Operation of the PTV without the rear

cover introduc es danger for el ectrical sho ck. Servicin g

should not be performed by anyone who is not

thoroughly familiar with the necessary precautions

when servicing high-voltage equipment.

Extreme care should be prac ticed when handling the

picture tube

due to atmospheric pres s ure. (1 4.7 lb s. per sq . i n.). Do

not nick or scratch the glass or subject it to any undu e

pressure. When handling, use safety goggles and

heavy gloves for protection. Discharge the picture

tube by shorting the anode to chassis ground (not to

the cabinet or to other mounting hardware). When

discharging, connect cold ground (i.e. DAG ground

lead) to the anode with a well-insulated wire or use a

grounding probe.

. Rough handling may caus e it to implod e

should always be used

X-ray Precautions

The front area (between the projection tube and the

lens) is enclosed by a metal box to ensure positive

safety during normal and abnormal conditions when

checking and repairing. To fully ensure safety, the

following precautions must be observed.

1. Do not remove the lens or metal box.

2. Make sure to turn the power “OFF” when the lens

is removed or when checking the cleanliness of the

lens.

3. Do not remove the lens or metal box to check the

projection tube for oper ati on by watc hi ng i t di rec tly.

Use a mirror or paper to view the image.

Before returning a serv iced PTV to the owner, the

service technician must thoroughly test the unit to

ensure that is completely safe to operate. Do not use a

line isolation transformer when testing.

Leakage Current Cold Check

Unplug the AC cord and connect a jumper between the

two plug prongs. Press the “POWER” switch “ON”.

Measure the re si stance betw e e n th e j um p ere d AC pl ug

and expose metallic parts such as screw heads,

Service Manual

antenna terminals, control shafts, etc. If the exposed

metallic part has a return path to the chassis, the

reading should be between 240kW and 5.2M W. If the

exposed metallic part does not have a return path to

the chassis, the reading should be infinite.

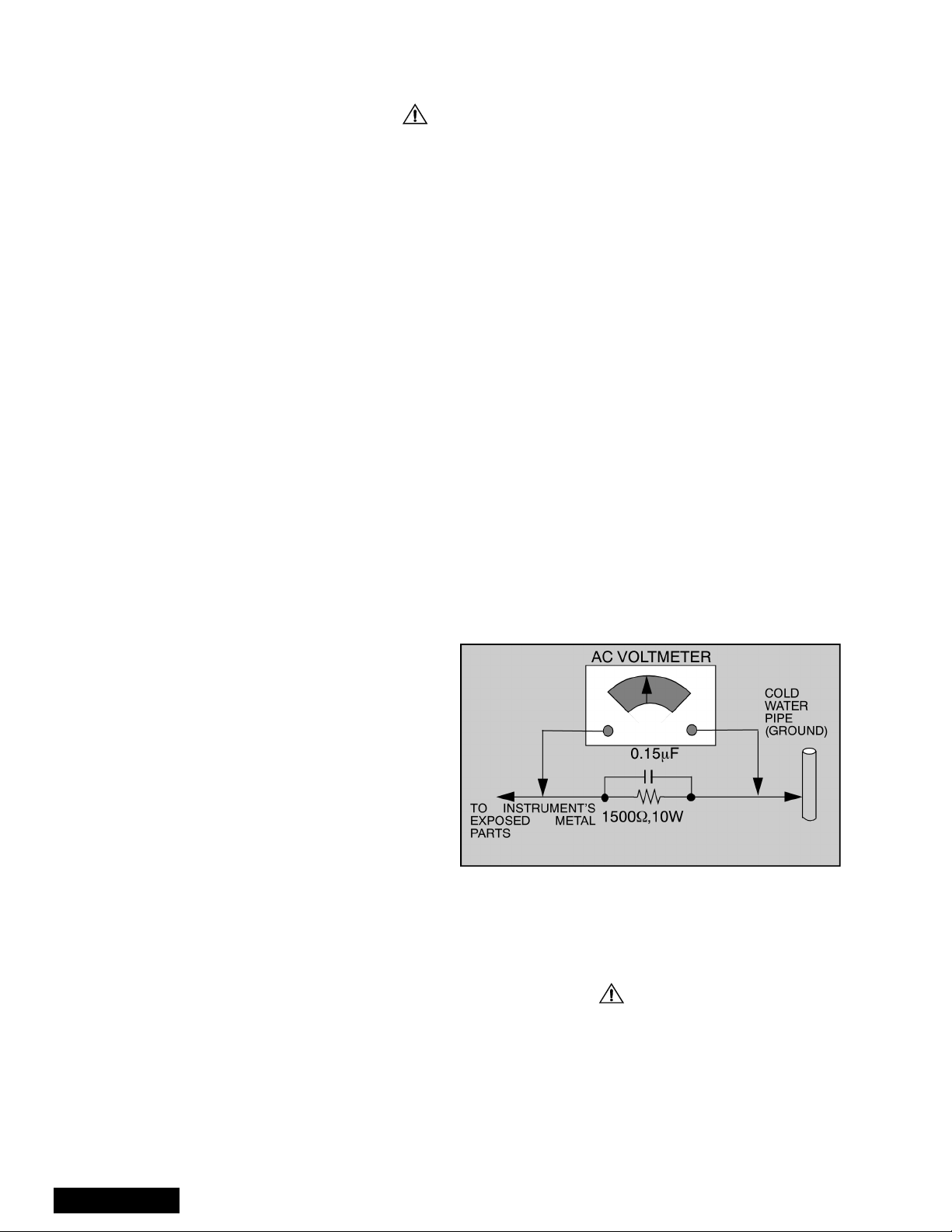

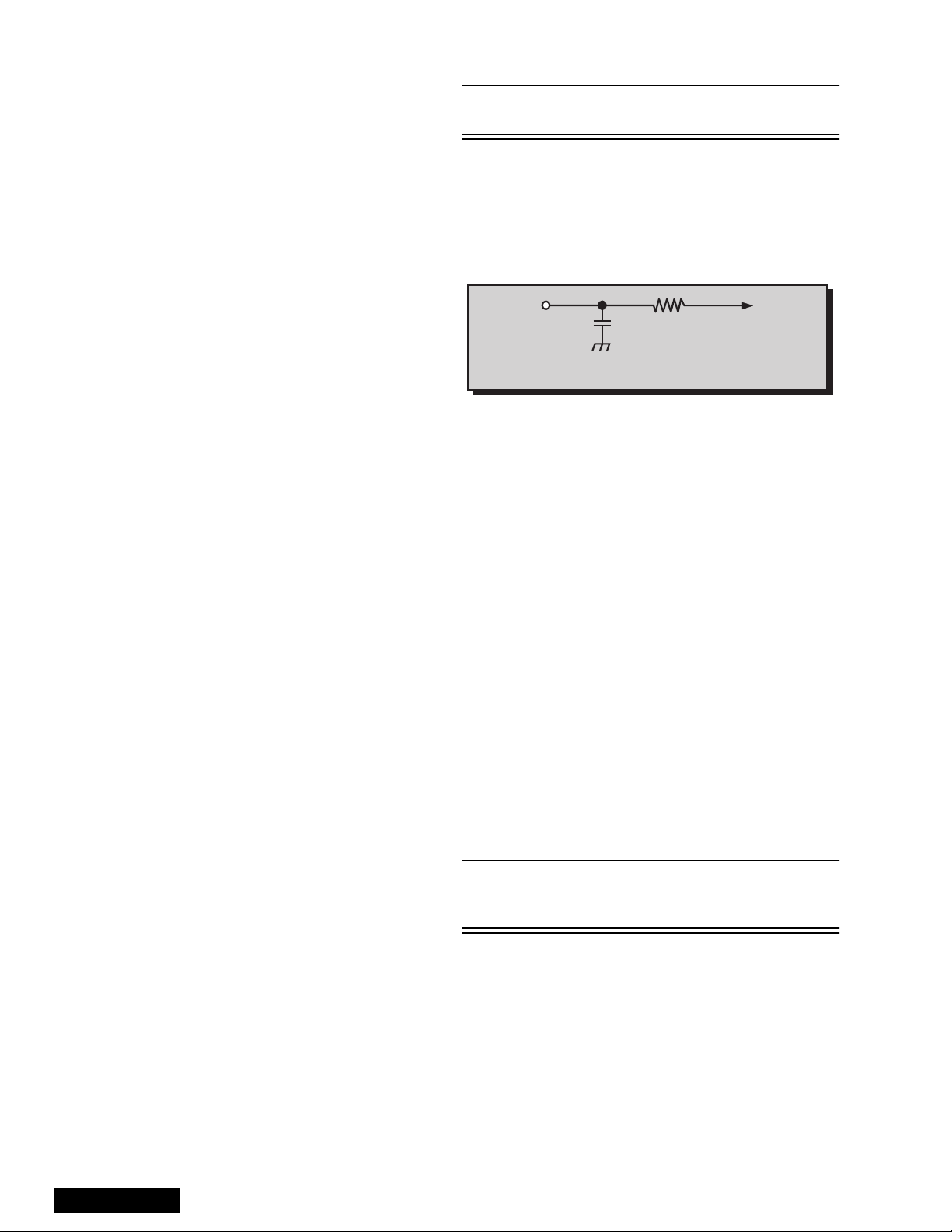

Leakage Current Hot Check (See Fig. 1)

Plug the AC cord directly into the AC outlet. Do not use

an isolation transformer during the check.

Connect a 1.5kW 10-watt resistor in parallel with a

0.15mF capacitor between and exposed metallic part

and ground. Use earth ground, for example a water

pipe.

Using a DVM with a 1000 ohms/volt sensitivity or

higher, measure the AC potential across the resistor.

Repeat the procedure and measure the voltage

present with all other expose metallic parts.

Verify any potential does not exceed 0.7 5 volt RMS. A

leakage current tester (such a Simpson Model 229,

Sencore Model PR57 or equivalent) may be used in

the above procedure, in which case any current

measure must not exceed 0.5 milliamp. If any

measurement is out of the specified limits, there is a

possibility of a shock hazard and the PTV must be

repaired and rechecked before it is returned to the

customer.

Figure 1. Hot Check Circuit

Insulation Test

Connect an insulation tester between an exposed

metallic part and AC line.

Apply 1080VAC/60Hz for 1 second. Confirm that the

current measurement is 0.5mA ~ 2.0mA. Repeat test

with other metallic exposed parts.

X-ray Radiation

WARNING: The potential source of X-ray radiation in the

PTV is in the hig h vo ltage section and t he pict ure t ube .

Note: It is important to use calibrated equipment.

Set brightness, picture, sharpness and color

controls to Minimum.

Measure the High Voltage. The high should be

31.5kV ± 1.0kV. If the upper limit is out of tolerance,

immediate servic e and correction is requ ired to insure

safe operation and to prevent the possibility of

premature component failu re.

- 2 -

Important Safety Tests

Measuring H.V.

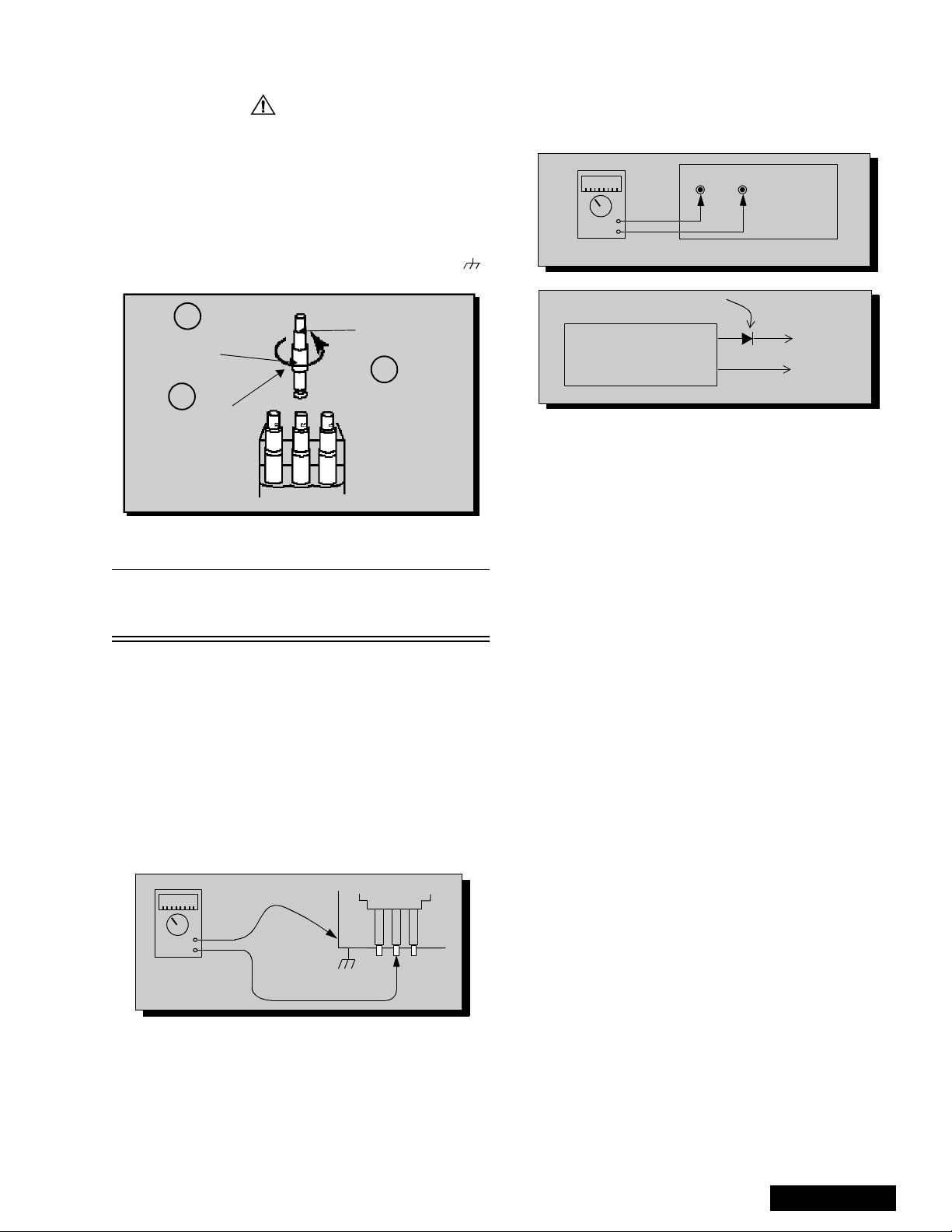

The anode caps are cemented to the CRTs. To gain

access for high v oltage measurement, remove the red

CRT’s anode lead from the flyback transforme r (FBT)

distributor. Grasp the anode lead protective cap at its

bottom and squeeze it against the locking cap body

inside. Rotate 1/4 turn coun ter clockwise and pull the

anode lead sleeve out of the FBT distributor. Connect a

high voltage lead (+) from y our H.V. meter to the FBT

distributor, and the common (-) to cold ground ( ).

See Fig. 2.

1

Grasp protective

Anode lead

rubber cap

3

2

Squeeze & rotate

Discharge to

CRT Chassis

cap counterclockwise

to remove

FBT Distributor

Figure 2. Removal of FBT leads

Note: Reinsert the anode lead into the FBT

distributor until it is tightly and fully seated.

T urn the locking cap clockwise to lock in place.

(EHT) Protector Operation Check

With the cabinet ba ck removed, apply a n ominal 120V

AC to the PTV.

Over Voltage Test

Preparation:

1. Turn PTV “OFF”

2. Connect an NTSC signal generator to the antenna

terminal.

3. Connect DVM (+) TPA18 and (-) TPA19 on

A-Board. See Fig. 4.

4. Connect a H.V. meter (static type, class 0.1 ) with

high voltage leads to high voltage distributor

on FBT. See Fig. 4.

TPA19 TPA18

-

+

A-Board

DVM

Variable

Power

Supply

MA150

(8~15DC)

(+)

(-)

P-Board

TPP21

TPP20

Figure 4. DVM & Power supply connection.

5. Connect the 8 ~ 15V DC variable power supply to

(+) TPP21 and (-) TPP20, on P-Board. See Fig.4.

Procedures:

1. Apply a monoscope pattern.

2. Turn PTV “ON”.

3. Adjust the Pict ure or Brightness controls until th e

DVM reads 16.5 volts ± 0.5 volts.

4. Increase the variable power su pply unti l PTV turns

“OFF”. The set should turn off at 16.5 volts ± 0.5

volts (DVM) and high voltage less than 36.4kV.

5. If the DVM reading is other than 16.5 v olts (±0.5

volts), readjust picture or brightness control and

repeat steps 3.

6. Turn off the variable supply and confirm that the

PTV will turn on with the Remote Control.

-

+

H.V. METER

Cold Ground

FBT Distributor

CRT

CHASSIS

Figure 3. Measuring H.V.

- 3 -

Service Manual

Important Safety Notice . . . . . . . . . . . . . . . . . . . 2

Safety Precautions . . . . . . . . . . . . . . . . . 2

General Guidelines . . . . . . . . . . . . . . . . . 2

X-ray Precautions . . . . . . . . . . . . . . . . . . 2

Leakage Current Cold Check . . . . . . . . . 2

Leakage Current Hot Check . . . . . . . . . . 2

Insulation Test . . . . . . . . . . . . . . . . . . . . . 2

X-ray Radiation . . . . . . . . . . . . . . . . . . . . 2

Important Safety Tests. . . . . . . . . . . . . . . . . . . 3

Measuring H.V. . . . . . . . . . . . . . . . . . . . . 3

(EHT) Protector Operation Check . . . . . . 3

Service Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Leadless Chip Component

(surface mount). . . . . . . . . . . . . . . . . 5

Component Removal. . . . . . . . . . . . . . . . 5

Chip Component Installation . . . . . . . . . . 5

How to Replace Flat-IC . . . . . . . . . . . . . . 5

Feature Table . . . . . . . . . . . . . . . . . . . . . . . . . . 6

PCB Designation . . . . . . . . . . . . . . . . . . . . . . . 7

PTV - Location of Controls . . . . . . . . . . . . . . . 8

Quick Reference Control Operation . . . . 8

Remote - Location of Controls . . . . . . . . . . . . . 9

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Description of Abbreviations Guide . . . . . . . . 27

Schematic Notes. . . . . . . . . . . . . . . . . . . . . . . . 27

A-Board layout & voltages . . . . . . . . . . . . . . . . . 31

A-Board schematic & waveforms . . . . . . . . . . . . 32

P-Board schematic & voltages . . . . . . . . . . . . . . 34

X-Board schematic & voltages . . . . . . . . . . . . . . 36

P-Board layout & waveforms . . . . . . . . . . . . . . . 38

X-Board layouts . . . . . . . . . . . . . . . . . . . . . . . . . 39

K, G & R-Board schematics & layouts . . . . . . . . 40

LB-Board schematic, layout & voltages . . . . . . . 41

LG-Board schematic, layout & voltages . . . . . . . 42

LR-Board schematic, layout & voltages . . . . . . . 43

Y-Board schematic, layout & voltages . . . . . . . . 44

Service Mode (Electronic Controls) . . . . . . . . 10

Quick Entry to Service Mode. . . . . . . . . 10

To toggle between Aging

and Service modes . . . . . . . . . . . . . 10

Exiting the Service Mode. . . . . . . . . . . . 10

To Check Purity . . . . . . . . . . . . . . . . . . . 10

B-Items, Service Sub Adjustments . . . . 11

C-Items, VCJ Cutoff Adjustments . . . . . 11

D-Items, Pincushion Adjustments . . . . . 11

P-Items, PIP Adjustments . . . . . . . . . . . 12

S-Option Items. . . . . . . . . . . . . . . . . . . . 12

X-Option Items. . . . . . . . . . . . . . . . . . . . 12

V-Option Adjustments . . . . . . . . . . . . . . 12

HV Feedback Voltage (D08) . . . . . . . . . 13

Sub-Bright Adjustment (B00). . . . . . . . . 13

Contrast Adjustment . . . . . . . . . . . . . . . 13

Red, Green & Blue Screen Cutoff . . . . . 14

White Balance Adjustment . . . . . . . . . . 14

Tint and Color Check. . . . . . . . . . . . . . . 14

MTS Circuit Adjustments . . . . . . . . . . . . 14

Input Level Adjustment (S06) . . . . . . . . 14

Stereo Separation Adjustment

(S07 & S08). . . . . . . . . . . . . . . . . . . 14

Clock Adjustment (S12). . . . . . . . . . . . . 15

PIP Adjustments . . . . . . . . . . . . . . . . . . 15

Service Manual

- 4 -

Service Notes

Note: Some components may be affixed wi th glue. B e careful not to bre ak or damag e foil un der the com ponent

or at the pins of th e ICs when removing . Usually applying he at to the component for a short time while

twisting with tweezers will break the component loose.

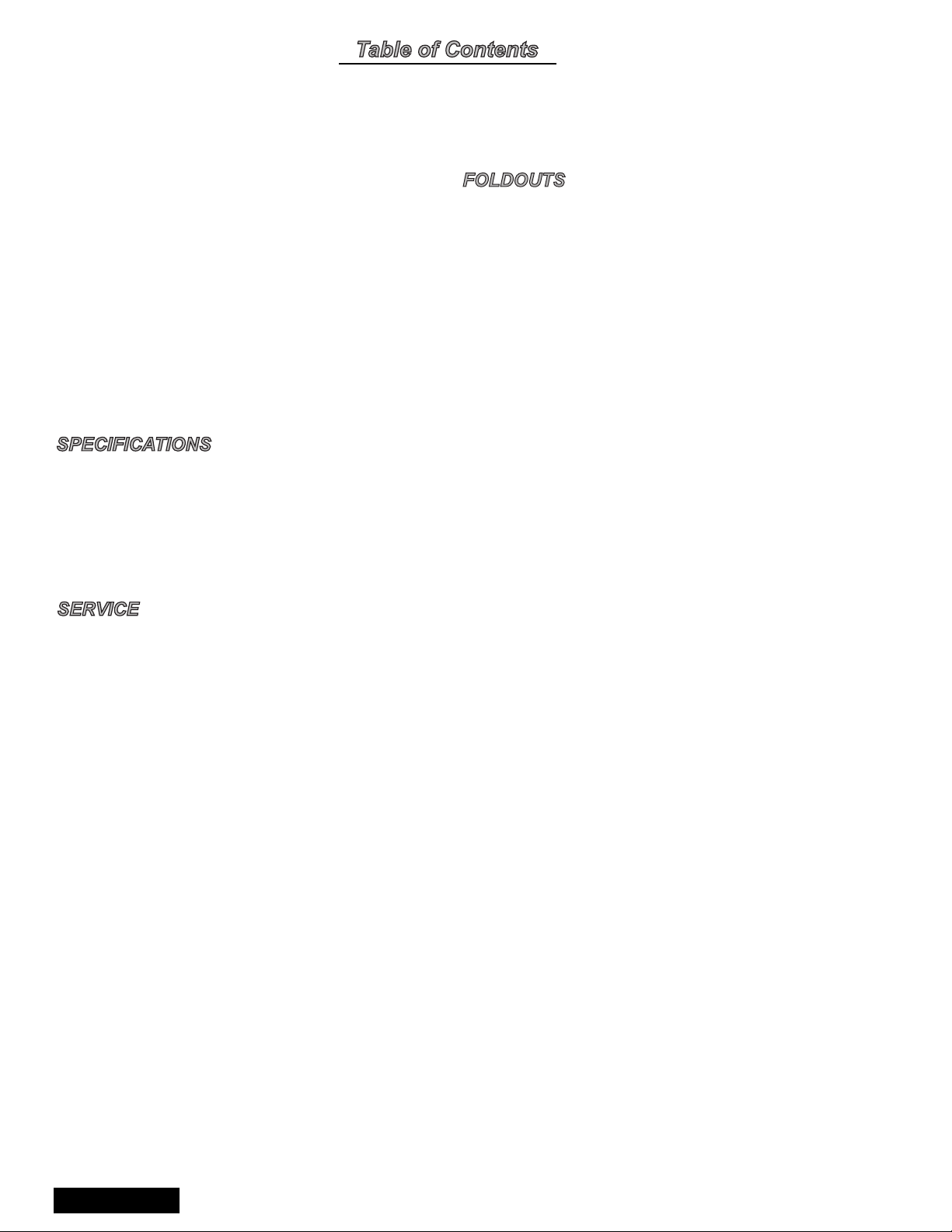

Leadless Chip Component

(surface mount)

Chip components must be replaced with identical chips

due to critical foil tr ack spacing. There are n o holes in

the board to mount standard transistors or diodes.

Some chips, capacitor or resistor board solder pads

may have holes t hrough the board, however the hol e

diameter limits standard resistor replacement to 1/8

watt. Standard capacitor may also be limited for the

same reason. It is recommended that identical

components be used.

Chip resistors have a three-digit numerical resistance

code - 1st and 2nd significant digits and a multiplier.

Example: 162 = 1600 or 1.6kW resistor, 0 = 0W

(jumper).

Chip capacitors generally do not have the value

indicated on the capacitor. The color of th e componen t

indicates the general range of the capaci tance.

Chip transistors are identified by a two-lett er co de. T h e

first letter indicates the type and the second lette r, the

grade of transistor.

Chip diodes have a two-letter identification code as per

the code chart an d are a dual diode pack with either

common anode or common cathode. Check the parts

list for correct diode number.

Component Removal

7. Use solder wick to remove s older from compo nent

end caps or terminal.

8. Without pulling up, carefully twist the component

with tweezers to break the adhesive.

9. Do not reuse removed leadless or chip

components since they are subject to stress

fracture during removal.

Chip Component Installation

1. Put a small amount of solder on the board

soldering pads.

2. Hold the chip component against the soldering

pads with tweezers or with a miniature alligator clip

and apply heat to the pad area with a 30 watt iron

until solder flows. Do not appl y heat for more than

3 s econds.

Chip Components

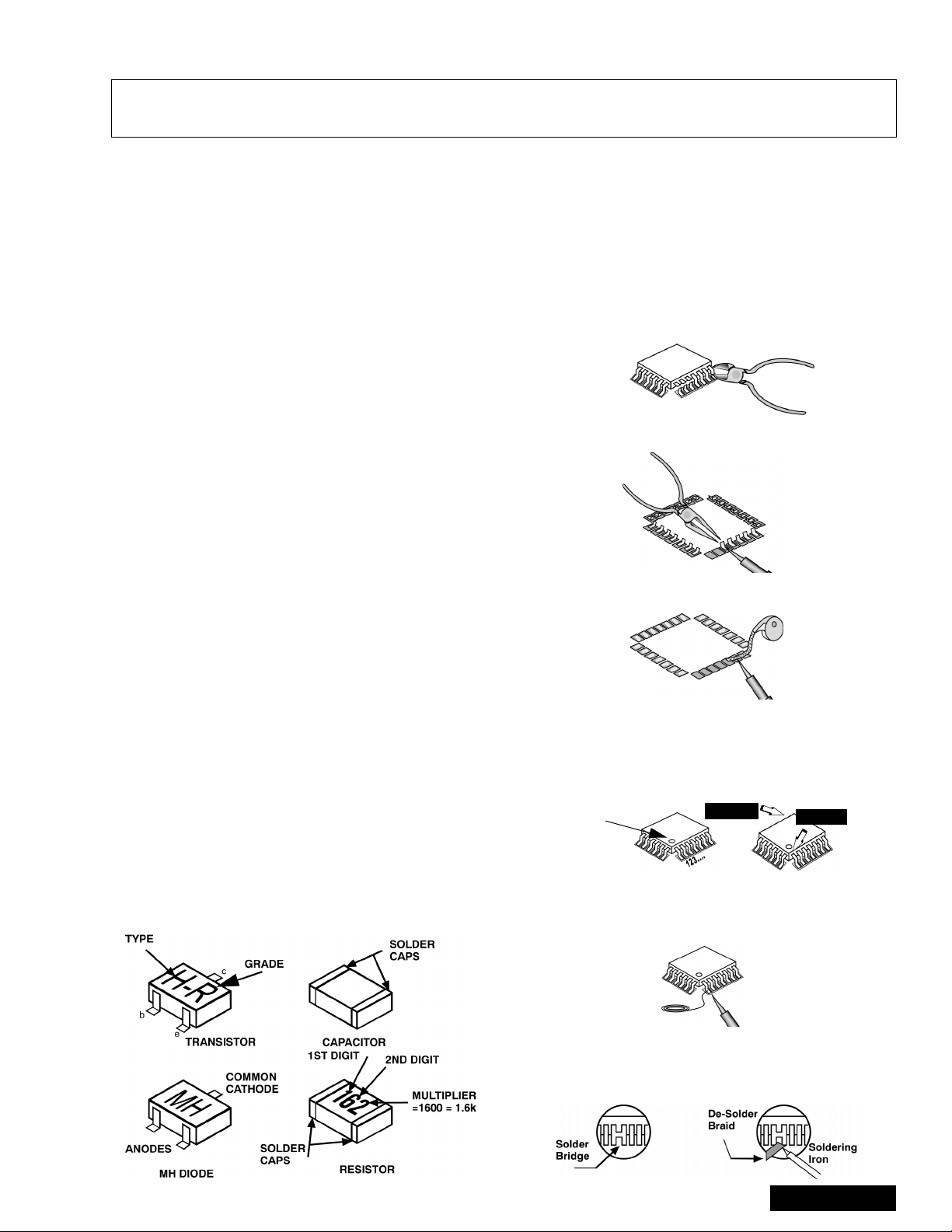

How to Replace Flat-IC

- Required Tools -

• Soldering iron • De-solder braids

• Needle nose pliers • Magnifier

• Wire cutters (sharp & small)

1. Cut the pins of a defective IC with wire cutters.

Remove IC from boar d. If IC i s glued to the boa rd,

heat the IC and release the IC. See Note above.

Flat IC

2. Using soldering iron and needle nose pliers

remove the IC pins from the board.

Soldering

Iron

3. Using de-soldering braid and soldering iron remove

solder from affected are on board (pads).

De-soldering

Braid

Soldering

Iron

4. Position the new Flat-I C in place (app ly the pins of

the Flat-IC to the soldering pads where the pins

need to be soldered). Determine the positions of

the soldering pads and pins by correctly aligning

the polarity symbol. Solder pin #1 first, align the IC.

Polarity

symbol

Solder the pin op posite to pin #1. This will ass ist

positioning the IC.

5. Solder all pins to the soldering pads using a fine

tipped soldering iron.

2nd solder

1st solder

Solder

6. Check with a magnifier for solder bridge between

the pins or for dry join t between pi ns and sold erin g

pads. To remove a solder bridge, u se a de-solder

braid as shown in the figure below.

- 5 -

Soldering

Iron

Service Manual

IMPORTANT: To protect against possible damage to

the solid state devices due to arcing or static discharge,

make certain that all ground wires and CRT DA G wire

are securely connected.

CAUTION: The power supply circuit is above earth

ground and the chassis cannot be polarized. Use an

isolation transformer when s ervicing the PTV to avoid

damage to the test equipment or to the chassis.

Connect the test equipment to the proper ground (( )

or ( )) when servicing, or incorrect voltages will be

measured.

WARNING: This PTV has been designed to meet or

exceed applicable safety and X-ray radiation protection

Feature Table

as specified by gove rnment a genci es and ind ependen t

testing laboratories.

To maintain original product safety design standards

relative to X-ray radiation and shock and fire hazard,

parts indicated with the s ymbol on the schematic

must be replaced with identi cal parts. Order parts from

the manufacturer’s parts center using the parts

numbers listed in this service manual, or provide the

chassis number and the part reference number.

For optimum performance and readability, all other

parts should be replaced with components of identical

specification.

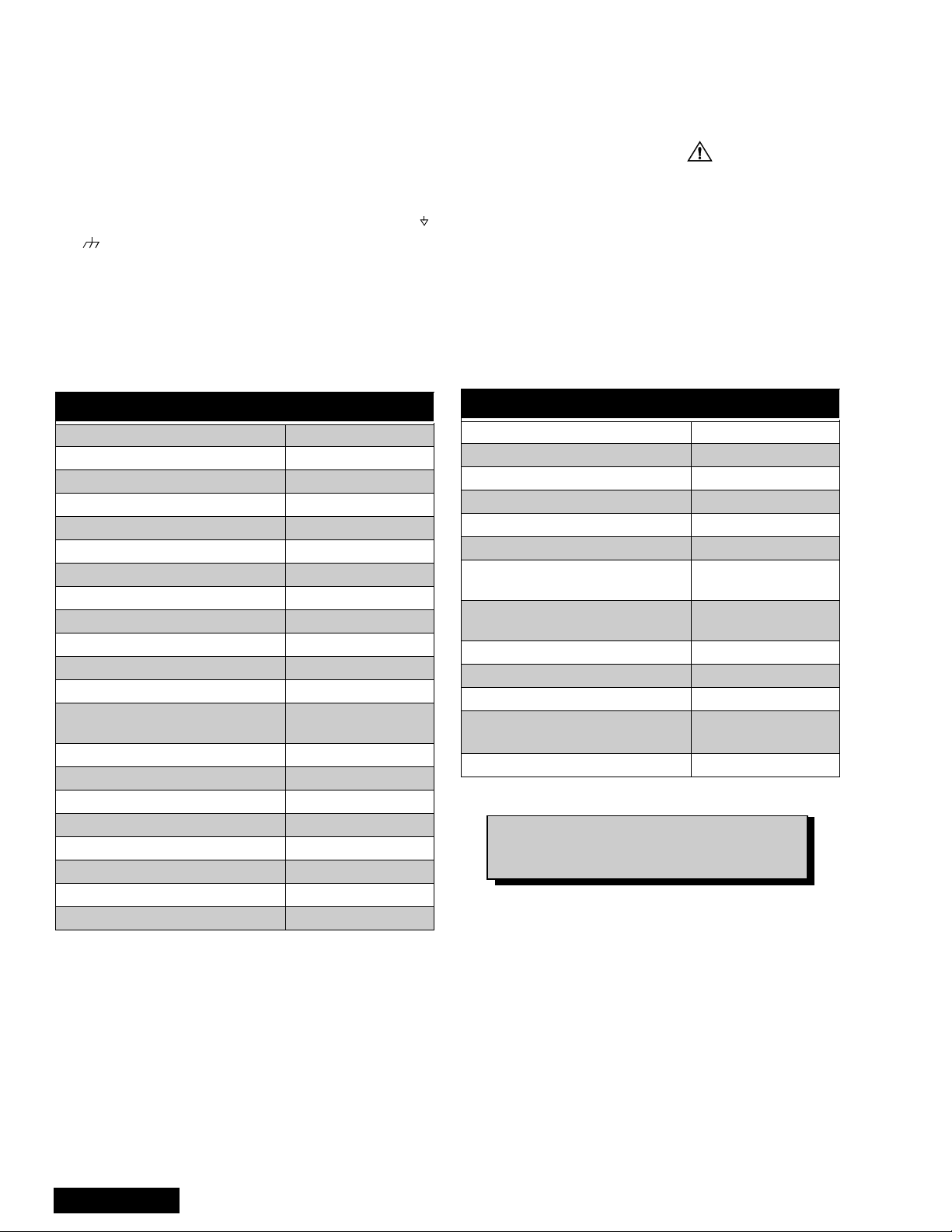

FEATURES

Chassis AP821

Tunning system 144K

# of channe ls 181

Menu language Eng/Span/Fr

Closed Caption X

V-Chip X

Picture in Picture (PIP) 2T

2 RF X

Remote model # EUR511500

CRT assembly - Red TXFCRT96SER

CRT assembly - Green TXFCRT95SER

CRT assembly - Blue TXFCRT94SER

Panablack picture tube

Comb filter 3 Line Digital

H. edge correction X

V/A Norm - Both X

Color temperature X

MTS/SAP/DBX X

AI sound X

Bass/Bl/Tre control X

Surround X

With Protective

Screen

FEATURES

BBE X

Built-in audio power 10W x 2 (10%)

# of speakers 2

A/V in (rear/front) 3(2/1)

S-VHS Input (rear/front) 1/0

Component Input 1

Audio Out

(FAO & VAO)

Dimensions mm

(WxDxH) in

Weight (kg/lbs) 86 / 189.6

Power source (V/Hz) 120 / 60

Anode voltage 31.5kV ± 1.0kV

Video input jack

Audio input jack 500mV RMS 47kW

1137 x 651 x 1361 .5

44.8 x 25.6 x 53.6

1V

X

75W, phono

p-p

jack

Table 1: PTV Feature Table

Specifications are subject to change

without notice or obligation.

Dimensions and weights are approximate.

Service Manual

- 6 -

PCBs Designation

BOARD PART NUMBER BOARD DESCRIPTION

X-Board TNPA2055S

P-Board TNPA2056S Power Supply

LR-Board TNPA2057S RED Driver

LG-Board TNPA2058S GREEN Driver

LB-Board TNPA2059S BLUE Driver

A-Board TNPH0423S

G-Board TNP2AA081S Front AV Inputs

K-Board TNP2AA076S Button Panel

R-Board TNPA0615S IR Sensor

Y-Board TNPA1059BCS PIP Processing

Table 2: PCB Designation

Video Signal Processing, MPU, VCJ, Digital

Convergence, Comb Filter

Main Board, Sound Signal Processing,

Vertical Out, Vertical Drive, Audio Amplifier

Note: Components on the X-Board (

IC101, IC002, IC6501, IC005 and IC7102 are non-serviceable.

Referring to foldouts on page 37 for voltages may help identifying

damaged components. If any of the listed ICs is defective

replace it with a ne w IC; see parts list for or dering replacement

components. If other components failed, replace the board.

TNPA2055

S) except to IC001,

Important Notice

When replacing the X-Boa rd - transfer IC7102 (EEP ROM) f rom the

defective board to the new board.

- 7 -

Service Manual

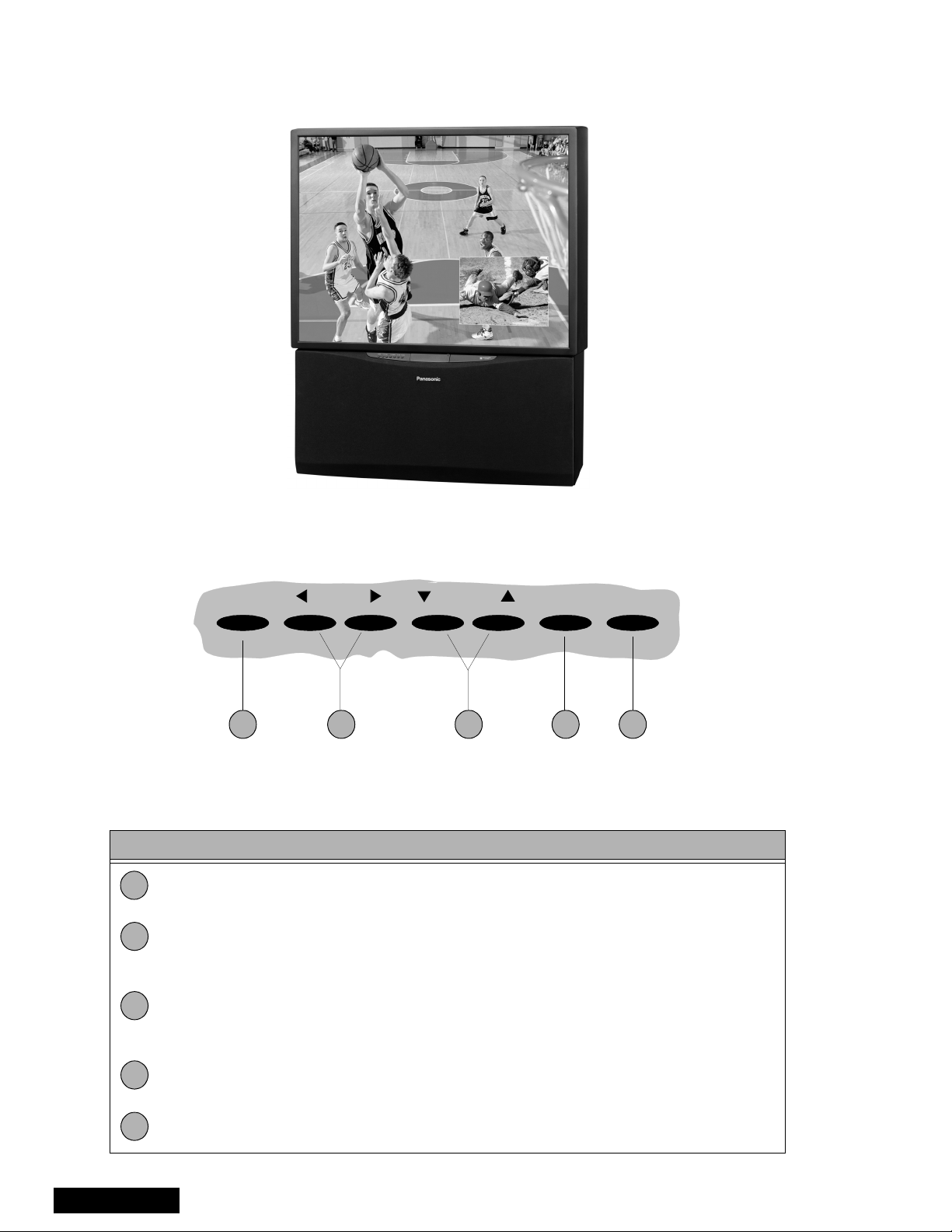

PTV - Location of Controls

POWER VOLUME CHANNEL ACTION TV/VIDEO

1 2 4 53

Figure 5. Location of Controls PTV

Quick Reference Control Operation

Quick Reference Control Operation

1

2

3

Power - Press to turn “ON” or “OFF”.

Vo lu m e - Press to adjust Sound Le vel, or to adjust A udio Menus, Video Menus , and

select operating features when menus are displayed.

Channel - Press to s elect programm ed channels. Pres s to highlight des ired features

when menus are displayed. Also use to select Cable Converter box channels after

programming Remote Control Infra-red codes (the TV/AUX/CABLE switch must be set

in CABLE position).

4

5

Service Manual

Action - Press to displ ay Main Menu and access On Screen f eature and Ad justment

Menus.

TV/Video - Press to select TV or one of the Video Inputs, for the Main Picture or the

PIP frame (when PIP frame is displayed).

- 8 -

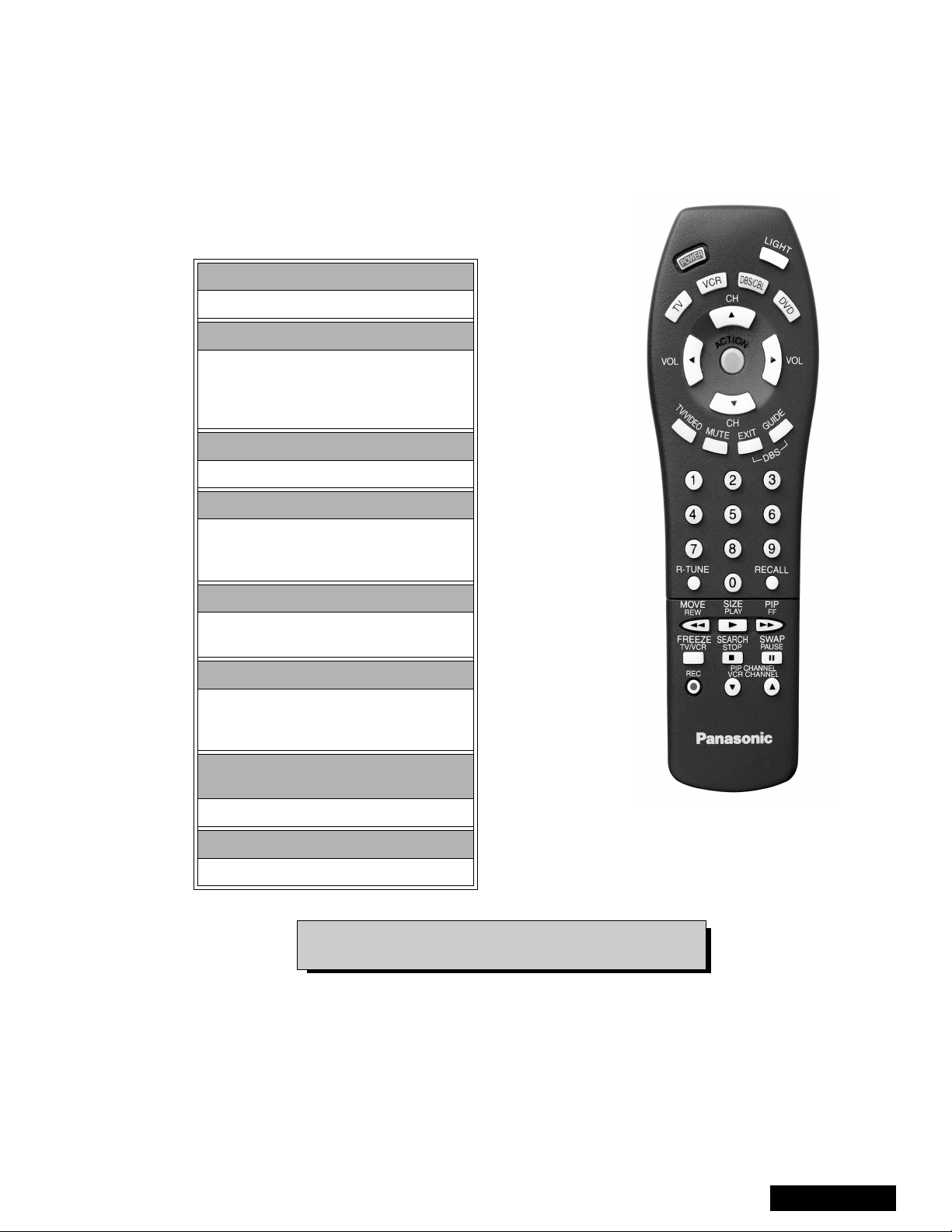

Remote - Location of Controls

POWER Button

Press to turn “ON” and “OFF”.

MUTE Button

Press to mute sound.

A second press resumes sound.

Press also to access and delete

Closed Caption display.

TV, VCR, DVD, CBS/CBL

Component function buttons

VOL (volume) Buttons

Press to adjust TV sound level.

Use with Channel buttons to

navigate in menus.

R-TUNE (Rapid Tune) Button.

Press to switch to the previous

channel.

ACTION Button

Press to display Main Menu and access or

exit On Screen features

and Adjustment Menus.

REW, PLAY, FF, TV/VCR, STOP, PAUSE,

REC & VCR CHANNEL Buttons

Component function buttons.

DBS EXIT& DBS GUIDE Buttons

DBS function buttons.

For additional information on this remote please refer to

the Remote Guide, listed on the parts list.

Figure 6. Location of Controls (EUR511500 Remote)

- 9 -

Service Manual

Service Mode (Electronic Controls)

To toggle between Aging and Service

modes:

While the “CHK” is di splayed on the left top corner

of the Screen, pressing “ACTION” and “VOL UP” on

the PTV simultaneously toggles between the

modes. Red “CHK” for Service and yellow “CHK” for

Aging.

This PTV has electronic techno logy using the I²C Bus

Concept. It performs as a control function and it

replaces many mechanical controls. Instead of

adjusting mechanical controls indivi dually, many of the

control functions are now performed by using “On

Screen Display Menu”. (The Service Adjustment

Mode.)

Note: It is suggested that th e techni cian rea ds all th e

way through and understand the following

procedure for Entering/Exiting the Service

Adjustment Mode and then proceed with the

instructions working with the PTV.

Quick Entry to Service Mode:

When minor adjustments need to be done to the

electronic controls, the me thod of Entering the S ervice

Mode without removal of th e cabi net bac k is as fo llows

using the Remote Control:

1. Select SET-UP icon and select CABLE mode.

2. Select TIMER icon and set SLEEP time for 30 Min.

3. Press “ACTION” twice to exit menus.

4. Tune to the Channel 124.

5. Adjust VOLUME to minimum (0).

6. Press VOL (decrease) on PTV. Red “CHK”

appears in upper corner.

8. “CHK” = Normal operation of CHANNEL

and VOLUME .

b

32 B 0 2 215 C 0

An address Menu appears in the right

hand corner of the screen

a

b

a

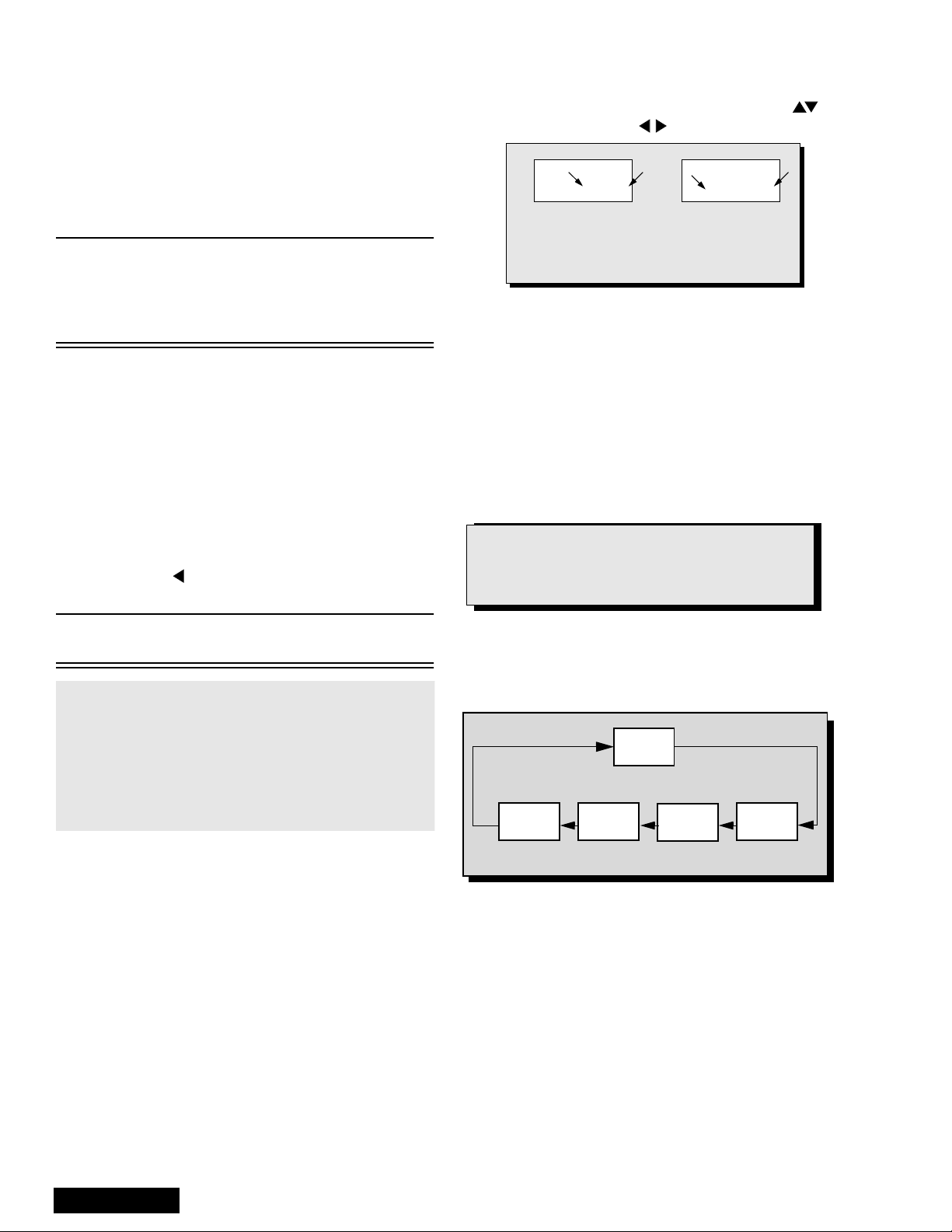

Figure 7. Service Mode Menu Adjustments.

Exiting the Service Mode:

Press “ACTION” and “POWER” on the PTV

simultaneously for at least 2 second s.

THE PTV EXITS SERVICE MODE.

The PTV momentarily shuts off; then comes back on

tuned to channel 3 with a preset level of audio.

Any programmed c hannel s, ch annels capt ion data an d

some others user defined settings will be erased.

NOTE

Always Exit the Service Mode

Following Adjustments.

Note: After PTV is set into SERVICE mode, set

TIMER back to NO.

7. Press “POWER” on the Remote Control to select

one of the Service Adjustment Modes.

1. B= Service VCJ SUB-DATA Adjustment s.

2. C= Service VCJ CUT-OFF Adjustments.

3. D= Service PINCUSHION Adjustments.

4. P= Servic e PIP Adjustments.

5. S =Service S OPTION Adjustments .

6. X =Service X OPTION Adjustments .

7. V= Service Y OPTION Adjustments.

To Check Purity:

Press “RECALL” on the Remote Control when in

Service Mode (red “CHK” is displayed) to enter the

Purity Field Check Mode.

NORMAL

SCREEN

Press “RECALL” again to select desired field.

BLUE

SCREEN

GRN.

SCREEN

RED

SCREEN

Figure 8. Purity Check Field Mode.

WHITE

SCREEN

Service Manual

- 10 -

Note: Registers marked as FIXED are factory preset.

The default value must not be changed.

Important Note:

Write down the original values (“b” in the

adjustment mode details, Fig. 7 ) for each address

adjustment before modifying values.

Follow the procedure bel ow to access various Servic e

adjustments. (Same procedures apply to each section.)

a. Press CH on the Remote Control to select

any of the seven Service Sub Adjustment

Addresses. (“a” in Fig. 7.)

b. Press on the Remote Control to adjust

the level of the selected Service Adj ustments.

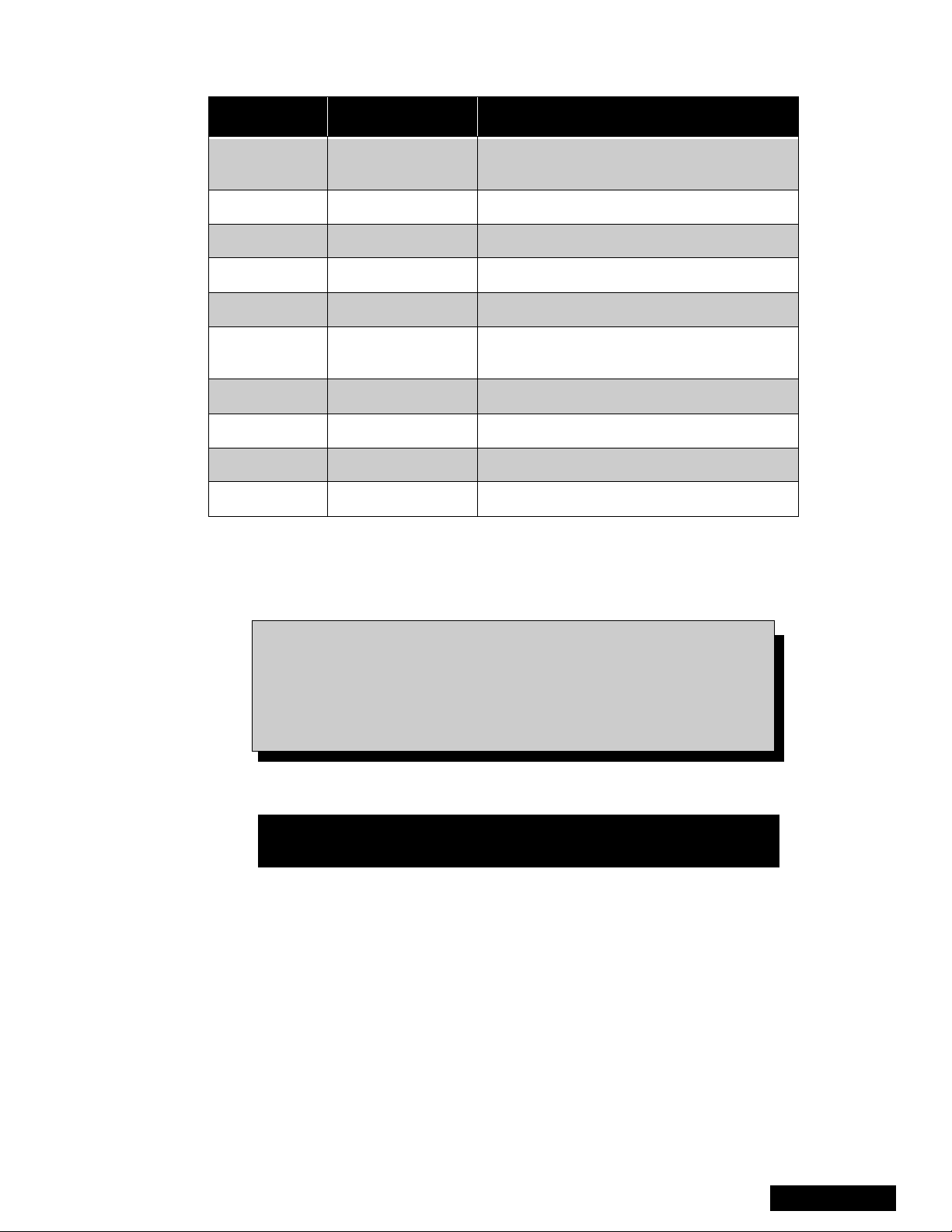

B Items: Service Sub Adjustments

Service Adjustment

B00 Sub B rightness 0 ~ 127 44

B01 Sub Contrast (RF) 0 ~ 15 5

B02 Sub C olor 0 ~ 63 18

B03 Sub Tint 0 ~ 63 34

B04

B05

B06 Sub Color (Video) FIXED 127

B07 Sub Tint (Video) FIXED 127

B08 Sub C olor (Component) FIXED 127

B09 Sub Tint (Component) FIXED 75

B0A

B0B

B0C Sub Contrast ---- ----

Sub Brightness

(Video/Component)

Sub Contrast

(Video/Component)

Sub Sharpness

(RF/Video)

Sub Sharpness

(Component)

Adj.

Range

FIXED 127

FIXED 16

FIXED 15

FIXED 20

Table 3: S e rvi ce Adj. B00 ~ B0C

Default

Level

Service Adjustment

C06 G CutOff (Video) FIXED 127

C07 B CutOff (Video) FIXED 127

C08 G Drive (Video) FIXED 127

C09 B Drive (Video) FIXED 127

C0A G CutOff (Component) FIXED 127

C0B B CutOff (Component) FIXED 127

C0C G Drive (Component) FIXED 127

C0D B Drive (Component) FIXED 127

C0E Drive Color Temp. FIXED 8

C0F Contrast Color Temp. FIXED 5

Adj.

Range

Default

Level

Table 4: Service Adj. C00 ~ C0F (Continued)

D Items: Pincushion Adjustments

Service Adjustment

D00 Vertical Amplitude 0 ~ 30 20

D01 Vertical Linearity 0 ~ 15 13

D02 Vertical S Correction 0 ~ 7 6

D03 Horizontal Amplitude 0 ~ 63 30

D04 Horizontal Centering 0 ~ 31 17

D05 EW Parabola 0 ~ 31 6

D06 Trapezoid 0 ~ 15 5

D07 EW Corner 2 0 ~ 15 8

D08 H EHT Correction 0 ~ 255 8

D09 Vertical Amplitude FIXED 3

D0A V BLK Start Phase FIXED 12

D0B V BLK Stop Phase FIXED 14

D0C V AGC FIXED 1

D0D Vertical Centering FIXED 63

Adj.

Range

Default

Level

C Items: VCJ Cutoff Adjustments

Service Adjustment

C00 R Cutoff 0 ~ 255 128

C01 G Cutoff (RF) 0 ~ 255 128

C02 B Cutoff 0 ~ 255 129

C03 Brightness FIXED 31

C04 G Drive (RF) 0 ~ 127 65

C05 B Drive (RF) 0 ~ 127 66

Adj.

Range

Table 4: Service Adj. C00 ~ C0F

Default

Level

D0E V Cent. DAC SW FIXED 0

D0F Conver. FIXED 0

D10 Free Run ON/OFF FIXED 0

D11 V Size Off Set FIXED 2

D12 V Lin Off Set FIXED 8

Table 5: Service Adj. D0 0 ~ D12

- 11 -

Service Manual

P Items: PIP Adjustments

X Option Items

Service Adjustment

P00 PIP Color FIXED 92

P01 PIP Tint FIXED 54

P02 PIP Brightness 0 ~ 31 22

P03 PIP Contrast 0 ~ 12 7 80

P04 PIP V Position 9 Up FIXED 27

P05 PIP V Position 9 Down FIXED 143

P06 PIP H Position 9 Left FIXED 12

P07 PIP H Position 9 Right FIXED 103

P08 PIP V Position 16 Up FIXED 27

P09 PIP V Posit 16 Down FIXED 161

P0A PIP H Position 16 Left FIXED 12

P0B PIP H Position 16 Right FIXED 118

P0C PIP Freerun ---- ---P0D PIP Y Delay FIXED 4

P0E PIP BG Start FIXED 17

Adj.

Range

Default

Level

Table 6: Service Adj. P00 ~ P0E

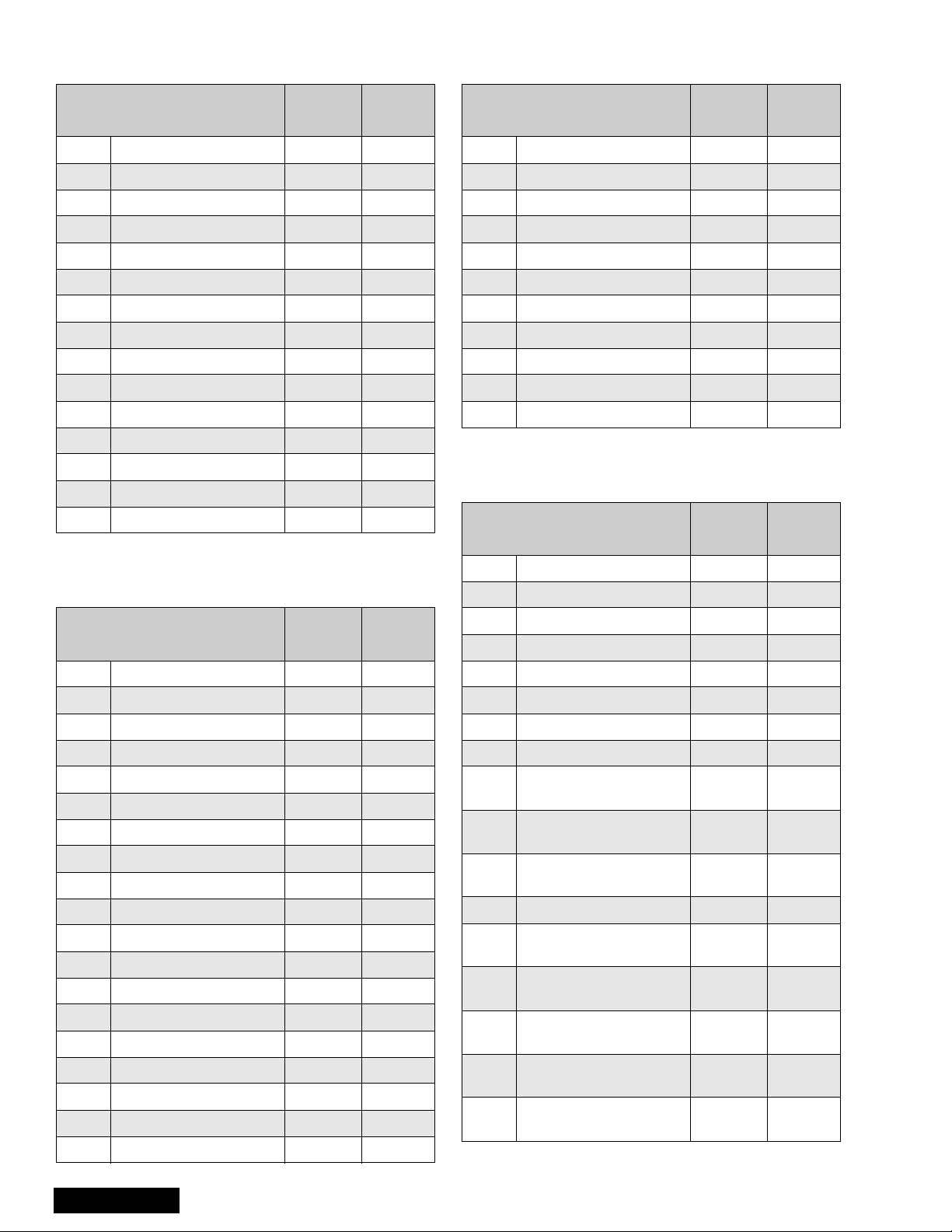

S Option Items

Service Adjustment

X00 Clip Level FIXED 8

X01 Correct Gain ---- ---X02 Limit Level FIXED 24

X03 Core Level FIXED 41

X04 C Delay (RF) FIXED 2

X05 C Delay (Video) FIXED 5

X06 VM Limit Level F IXED 90

X07 VM Core Level FIXED 8

X08 Sharpness FIXED 50

X09 VM Limit Level A FIXED 255

X0A VM Freq. SW FIXED 1

Adj.

Range

Default

Level

Table 8: Service Adj. X00 ~ X0A

V Option Adjustments

Service Adjustment

V00 Static Conv. Mode ---- ---V01 Point Conv . Mo de ---- ----

Adj.

Range

Default

Level

Service Adjustment

S00 B.S. Point FIXED 7

S01 RGB Gamma FIXED 1

S02 Col Gamma FIXED 0

S03 ABL Gain FIXED 2

S04 ABL Point FIXED 0

S05 RGB Brightness FIXED 10

S06 MTS Input Level 0 ~ 63 33

S07 MTS Low Separation 0 ~ 63 8

S08 MTS H i gh Separatio n 0 ~ 63 30

S09 Clock Adjustment 0 ~ 255 128

S0A Loudness Comp FIXED 7

S0B Caption Digital Filter SW FIXED 1

S0C Caption Scroll FIXED 1

S0D RGB MTX (RF/Video) FIXED 6

S0E RGB MTX (Component) FIXED 5

S0F BBE ON/OFF FIXED 1

S10 BBE Low Level FIXED 4

S11 BBE High Level FIXED 6

S12 Surround Effect FIXED 3

Adj.

Range

Default

Level

Table 7: Serviceman Adj. S00 ~ S12

Service Manual

V02 DAF Mode ---- ---V03 DAF ON/OFF FIXED 0

V04 ABL Input Level FIXED 10

V05 Blue Gamma FIXED 0

V06 VM ON/OFF FIXED 0

V07 ABL ON/OFF FIXED 0

V08

V09

V0A

V0B V1 Delay 0 ~ 255 1

V0C

V0D

V0E

V0F

V10

Test Pattern

Vertic al Phas e

Test Pattern

Vertical OSD

Test Pattern

Horizontal OSD

User St at ic Data

(Vertical, Red)

User St at ic Data

(Vertical, Green)

User St at ic Data

(Vertical, Blue)

User St at ic Data

(Horizon, Red)

User St at ic Data

(Horizon, Green)

0 ~ 255 20

0 ~ 255 29

0 ~ 255 65

FIXED 100

FIXED 100

FIXED 100

FIXED 100

FIXED 100

Table 9: Service Adj. V00 ~ V15

- 12 -

Service Adjustment

V1 1

V12

V13

V14

V15 Start Line (LOW) FIXED 11

User Static Data

(Horizon, Blue)

Test Pattern Horizon t al

Phase (LOW)

Test Pattern Fine

Horizontal Phase (LOW)

Test Pattern Coarse

Horizontal Phase (LOW)

Adj.

Range

FIXED 100

FIXED 90

FIXED 235

FIXED 0

Default

Level

Table 9: Service Adj. V00 ~ V15 (Continued)

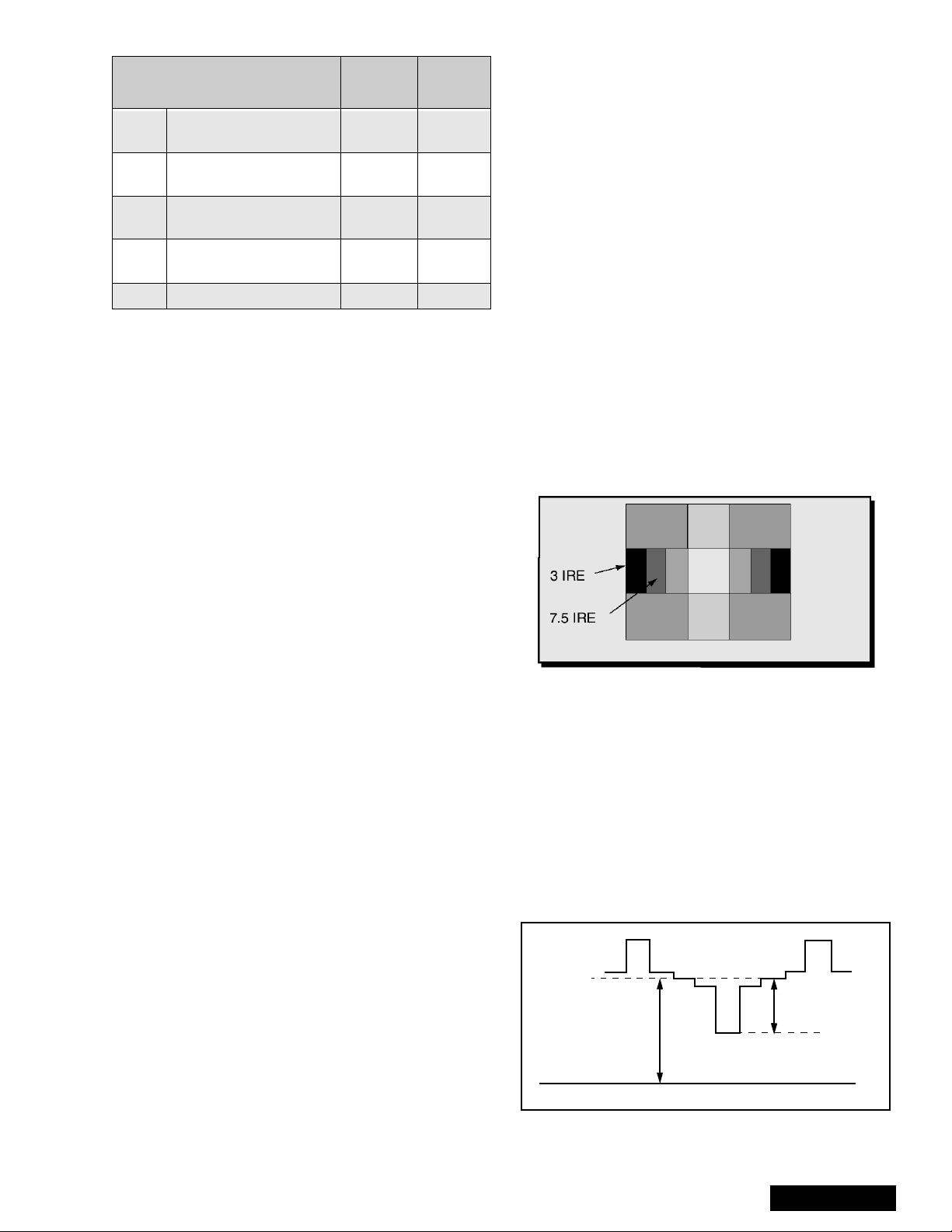

HV_Feedback Voltage (D08)

Procedure:

1. Apply a NTSC all black pattern.

2. Connect meter (+) to TPA38 and (-) to TPA20.

3. Adjust DAC D08 until reading on meter is

5.0V ± 0.2V.

Sub-Bright Adjustment (B00)

Procedure:

1. Normalize picture.

2. Connect meter (+) to TPA18 and (-) to TNPA19.

3. Apply a black level pattern.

4. Adjust DAC B00 (Sub-Brightn ess) until reading on

meter is 17.0V ± 1V (7.5 IRE part is same light

output as 3 IRE part. See Fig. 9.

5. Apply a monoscope pattern and adjust bright

control to max. and confirm same reading on

meter.

Contrast Adjustment

Preparation:

1. Set Auto Color and AI Picture to “OFF”.

2. Set the following in the user picture menu as

follows:

COLOR: min. (0)

PICTURE: max (63)

BRIGHT: center (31)

SHARPNESS: min. (0)

Set Cut Off Data:

• DAC C00 (R_CutOff) to 128.

• DAC C01 (G_RF CutOff) to 128.

• DAC C02 (B_CutOff) to 128.

• DAC C06 (G_Video CutOff) to 127.

• DAC C07 (B_Video CutOff) to 127.

• DAC C0A (G_Video Component) to 127.

• DAC C0B (B_Video Component) to 127.

Set Drive Data:

•DAC C04 (

•DAC C05 (B_Drive RF) to 64.

Procedure:

1. Use 100:1 probe for measurements.

2. Apply a black/white pattern. See Fig. 9.

G_Drive RF) to 64.

Figure 9. Black/white Pattern

3. Connect scope to TPLR1 and adjust Sub-Bright

(B00) data until voltage measured is 190V ± 2V.

See Fig. 10.

4. Connect scope to TPLG1 and adjust R-CutOff

(C00) data until voltage measured is 190V ± 2V.

See Fig. 10.

5. Connect scope to TPLB1 and adjust B-CutOff

(C02) data until voltage measured is 190V ± 2V.

See Fig. 10.

6. Connect scope to TPLR1 an d adjust Sub-Co ntrast

(B01) data to obtain 85V ± 2V between black

(7.5 IRE) and White level. See Fig. 10.

7.5 IRE

85V ± 2V (R)

190V±2V (R, G, B)

Use 100:1 Probe

GND

100 IRE

Figure 10. Contrast Adjustment.

- 13 -

Service Manual

Red, Green & Blue Screen Cutoff

1. Use either a no input signal condition or raster from

the NTSC generator.

2. Observing the green tube directly or via a reflective

surface, adjust the VR on the green tube for

minimum noise.

3. Adjust the noise level i n the red and blue tubes to

match the noise level in the green tube.

White Balance Adjustment

Prior to this adjustment, perform Contrast Adjustment.

This adjustment requires that the service technician

use skills in observing what a screen without color

should look like (White Picture).

1. Enter the service mode.

2. Apply a black a nd w hit e patter n t o one of the video

inputs.

High Light White Balance Adjustment

1. Adjust DAC C04 for green and C05 for blue

adjustments.

2. Make sure the screen is not blue or green. The

screen should be white in all areas.

3. Check the black and white pattern for a black and

white picture with even shades of gray and no color

tint in the picture.

Low Light White Balance Adjustment

1. Adjust DAC C01 for green and DAC C02 for blue.

2. Check the screen for even pure white in all areas.

3. Check the black and white pattern for a black and

white picture, even shades of gray and no color tint

in the low light areas.

4. Repeat the High Light and Low Light White

Balance again until the white bal ance tracks from

high light to low light.

Tint and Color Check

Again, the service technician ability to see color and

the balance of color is important for these adjustments.

Tint Check

1. In Picture Menu set Picture Norm to YES.

2. Apply color bars to the video input.

3. Magenta is composed of two colors, blue and red.

4. Check to see that magenta does not have too

much blue or too much red.

5. Check cyan. Cyan is c omposed of blu e and green .

It should not have too much blue or green.

6. Use a test signal from a V CR or la se r dis k that has

a pre-recorded close up of a sign al that has good

flesh tones.

7. The signal on the VCR or laser disk should look

normal.

Color Check

Using a clean RF or video s ignal, s et the col or level so

that it does not sat urate or appear harsh. Make sure

that color is n ot set so that it a ppears du ll and washed

out. Look for natural co lors; try to adjust the pic ture to

appear as a normal photograph.

MTS Circuit Adjustments

Note: It is important to a djust the MTS circuit in the

order shown below.

The MTS Circuit Adjustments require two steps:

1. Input Level Adjustment.

2. Stereo Separation Adjustment.

Input Level Adjustment (S06)

Preparation:

1. Connect an RMS meter (AC Range) with fil ter jig

as shown in Fig. 11.

RMS

METER

10k

TPE11

L_OUT

4700p

Figure 11. Filter Jig

2. Connect an RF signal generator to the RF

antenna input.

Procedure:

1. Apply the following signal from the RF signal

generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 300Hz, 100% modulation, monaural

(70 ± 5dB/mV, 75Ω OPEN, P/S 10dB). Make sur e

to turn off 75ms pre-emphasis.

2. Adjust (S6)

measured is 106mV ± 6.0mV rms.

MTS-INPUT

data until the voltage

Stereo Separation Adjustment (S07 & S08)

Preparation:

1. Connect an RF signal generator to the RF

antenna input.

2. Connect an oscilloscope probe to TPE10 (R_out).

Procedure:

1. Set PTV to Stereo Mode (in the Audio Menu).

2. Apply the following signal from the RF signal

generator:

Video: 100 IRE flat field, 30% modulation.

Audio: 300Hz, 30% modulation, stereo (left only)

(70 ± 5dB/mV, 75Ω OPEN, P/S 10dB).

Note: Set the 30% modulation with the pilot light SW

and N.R. switches “OFF” then turn the m “ON”

while testing.

3. Adjust MTS Low-Level Separation (S07) data (in

the Service Adjus tment Menu) until the amplitude

of the measured waveform on the scope is

minimum.

4. Apply the following signal from the RF

signal generator:

Video: 100 IRE flat field, 30% modulation. Audio:

3KHz, 30% modulation, stereo (left only).

(70 ± 5dB/mV, 75Ω OPEN, P/S 10dB).

Service Manual

- 14 -

Loading...

Loading...