Page 1

Manufactured by:

81-IN3047-9922

Before attempting to connect or operate this product, please read these instructions completely.

for

MODEL: Miniature Camera

PCF2, PCV2, PCF6, PCV6,

PCF6W, PCV6W

DESCRIPTION: Dome Housing, Color Camera - PCF2, PCV2

Pendant Mount Dome Housing, Color Camera - PCF6, PCV6

Wall Mount Dome Housing, Color Camera - PCF6W, PCV6W

STANDARD INSTALLATION PROCEDURE

CONTENTS INCLUDE:

(1) Dome base

(1) Dome

(1) Dome liner

(1) Camera swivel plate

(1) Camera mount with camera, lens, and PC Board

(1) Camera adjustment arm

(1) Camera adjustment template

(2) 4-40 x 1/4" screws

(1) 8-32 x 3/8" screw

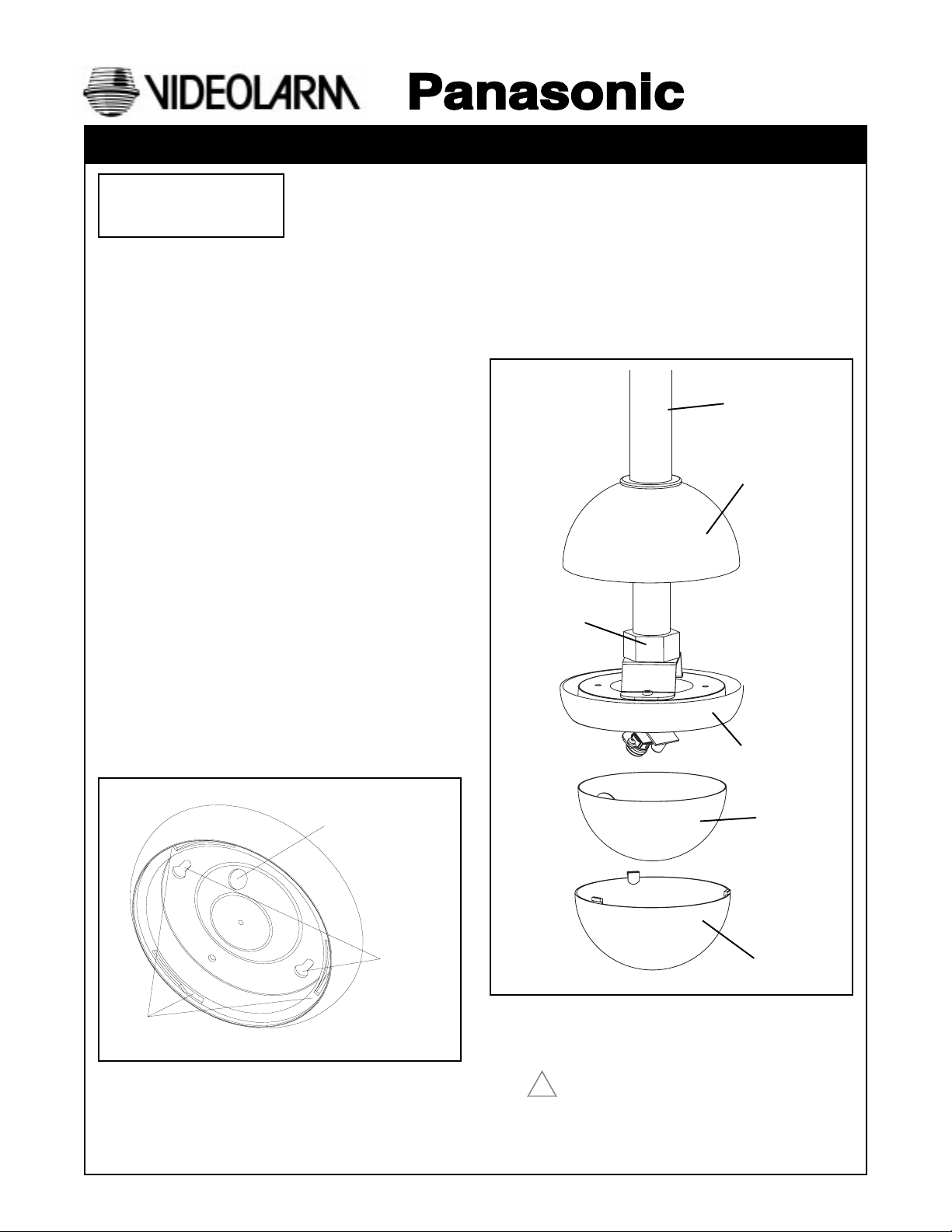

INSTALLATION

1. Locate the area on the ceiling or wall where the housing is

to be mounted. Cut a hole no larger than 2 1/4" in diameter and feed the necessary wires/cable through the hole.

2. Remove the dome and liner by turning the dome counterclockwise and gently pulling down.

3. Place the dome base against the ceiling/wall, with the

cutout in the center, and mark the keyhole slots. Insert a

screw on each mark and tighten down 3/4 of the length

of the screw.

4. Feed the wires/cable through the hole in the dome base.

5. Place the keyhole slots in the base over the screws and

slide forwared so that the screws hold the base to the surface. Tighten the screws.

PRODUCT INSTRUCTIONS

ATTACHING HOUSING (PCF6/PCV6 PENDANT MOUNT)

1. Install 3/4" EMT pipe (not provided) to the desired length.

2. Slide the top dome 10" to 12" onto the pipe, leaving enough

room to work. Run the wiring through the EMT connector

and wiring hole inside the top of the housing.

3. Slide complete unit onto the pipe. Tighten the set screw

when

in place.

4. Once the housing is secured to the pipe, slide the top dome

down onto the top of the housing.

3/4" EMT Pipe

(not provided)

Top Dome

EMT Clamp

Connector

Housing

Dome Tab Slots

Dome Tab Slots

Wire or Cable Entry

Wire or Cable Entry

Key Hole

Key Hole Slots

Slots

Liner

Dome

NOTE: Once the housing has been attached to the desired

location, connect the power and video wires as

required.

Connect Class 2 power supply only!

!

Page 2

Camera swivel plate

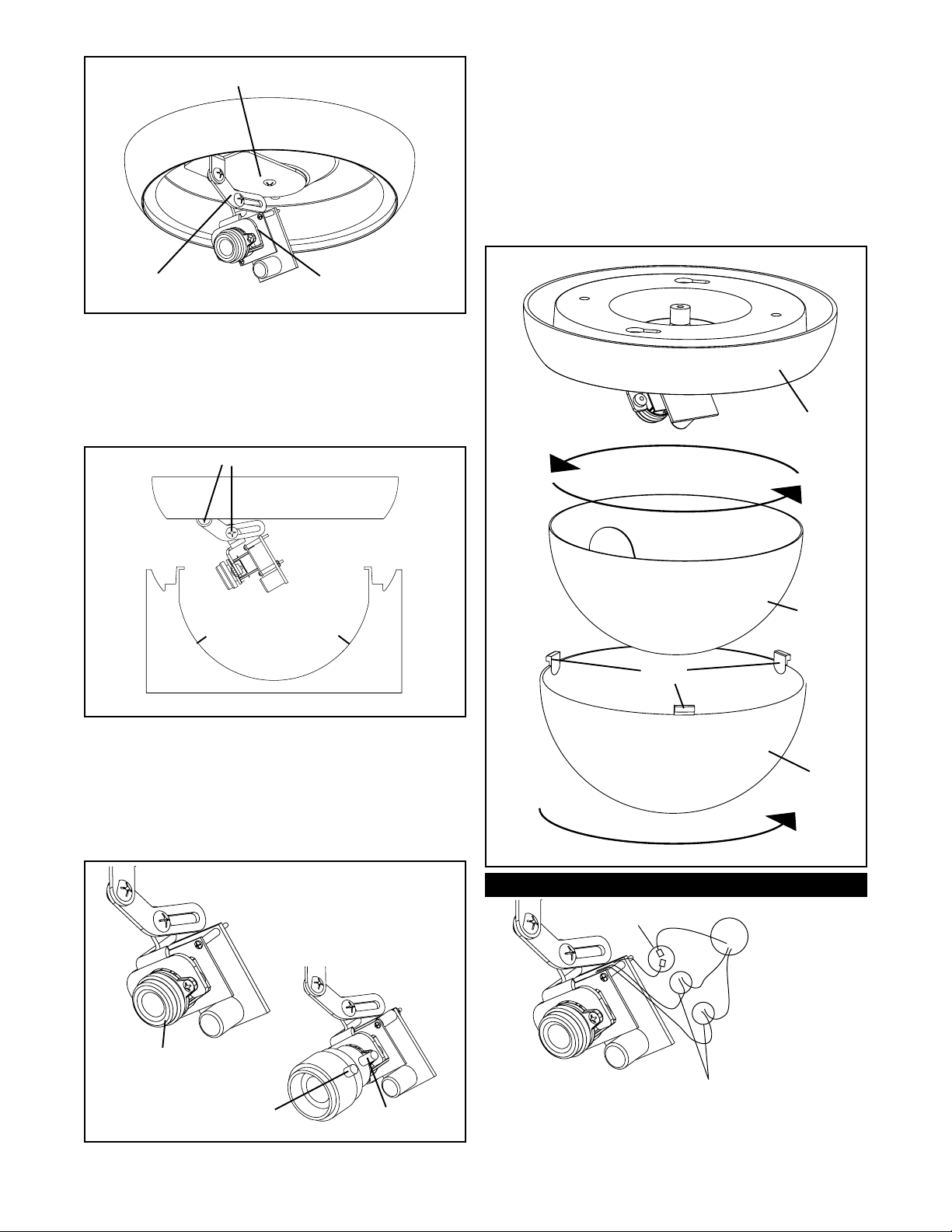

DOME REPLACEMENT

1. Rotate the liner inside the dome, so that when the dome is

secured to the base, the camera lens is in the center of the

viewing slot of the liner.

NOTE: It may be helpful to install the dome without the liner

the first time. This way you can visually determine

which direction the lens is pointing and adjust the liner

opening accordingly.

2. Align and insert the three tabs of the dome with the three tab

slots on the dome base. Rotate the dome clockwise until the

dome locks into place.

Camera Adjustment

Arm

CAMERA ADJUSTMENT

1. Clip the tabs of the template onto the swivel plate so that the

template is attached to the swivel plate.

2. Loosen the two 4-40 Phillips head screws, adjust the camera to

the desired position, and tighten the screws.

Note: Adjust camera lens as close as possible to the outline of

the bottom of the template.

Loosen screws to adjust camera

Tab

Place the lens as close to

this edge as possible

Camera Adjustment Template

3. Fine focusing (see diagram below):

Fixed Lens: Manually rotate the lens until a clear picture is

achieved.

Vari-Focal Lens: First, adjust the Magnification Lock Screw

to the desired magnification (telephoto

to wide angle). Tighten the Lock Screw.

Next, adjust the Focus Lock Screw until a

clear picture is achieved. Tighten the

Lock Screw.

Fixed Lens Camera

(PCF2, PCF6)

Camera Mount with

Camera and PC Board

Tab

Base

Liner

Tabs

Dome

Connections

Video

BNC Connectors

Manual focus

Focus Lock Screw

Vari-Focal Lens Camera

(PCV2, PCV6)

Magnification

Lock Screw

Power Connections

NOTE: Splice wiring according to

standard electrical guidlines.

Positive and Negative connections are

interchangeable with this PC Board.

- 2 -

Page 3

PCF2, PCV2 Dimensions

PCF6, PCV6 Dimensions

Specification

Lens Type

Model Number

Scanning Area

Scanning

Horizontal

Vertical

Synchronization

Video Output

Horizontal Resolution

Signal-to-Noise Ratio

Minimum Illumination

Angular Field of View

Horizontal

Vertical

AGC

ELC

White Balance

Ambient Operating

Temperature

Ambient Operating

Humidity

Power Source

at AC Source

at DC Source

Dimensions

Weight

6.0" Dia.

5.0" Dia.

6.0"

1.0"

5.0"

3 - 8mm Fixed Focal Lens Series 4 - 8mm Vari- -Focal Lens Series

PCF1 PCF6WPCF6PCF5PCF4PCF3PCF2 PCV6WPCV6PCV5PCV4PCV3PCV2PCV1

361 mm (H) x 272 mm (V) (Equivalent to scanning area of 1/4" pick-up tube)

525 lines / 60 fields / 30 frames

15.734 kHz

59.94 kHz

Internal Synchronization

1.0 V (p-p) NTSC Composite 75 ohms / BNC Connector

330 lines (at center area)

46 dB (with AGC OFF)

0.5 Footcandle (5 Lux) at F2.0 0.5 Footcandle (5 Lux) at F2.0 - 1.0 Footcandle

Horizontal 53.4˚

Vertical 40.0˚ Vertical 38.4 - 20.0˚

On (Preset)

On (Preset)

ATW (Preset)

-10˚C - +50˚C (14˚F - 122˚F)

Less than 90%

24 VAC, 40 ma

12 VDC, 80 ma

2.82"

W

H

D

kg

lbs

4.6"

2.82"

0.68

1.5

6.0"

6.0"

6.0"

0.45

1

3.15"

4.9"

3.2"

0.45

1

5.25"

3.0"

3.625"

0.45

1

15.9"

11.2"

15.9"

1.8

4

6.0"

6.0"

6.0"

0.68

1.5

6.0"

10.8"

7.0"

0.91

2

6.0"

5.75"

(10 Lux) at F2.8

Horizontal 51.7 - 26.7˚

2.82"

6.0"

3.15"

5.25"

4.6"

2.82"

0.68

1.5

6.0"

6.0"

0.45

1

4.9"

3.2"

0.45

1

3.0"

3.625"

0.45

1

15.9"

11.2"

15.9"

1.8

4

6.0"

6.0"

6.0"

0.68

1.5

6.0"

10.8"

7.0"

0.91

2

CAUTION: To prevent fire or shock hazard, the UL-Listed wire

VW-1, style 1007, should be used for the cable for

24 VAC input terminals.

Wiring Chart-Cable Distance

This Chart is based on a 12VDC power supply with the

maximum Amp draw at .500 amps.

WIRE 20 18 16

FT. 180' 300' 480'

- 3 -

Page 4

STANDARD INSTALLATION PROCEDURE, MV6W

CONTENTS INCLUDE:

(1) Wall mount Bracket

(1) Dome base

(1) Dome

(1) Dome liner

(1) Camera swivel plate

(1) Camera mount with camera, lens, and PC Board

(1) Camera adjustment arm

(1) Camera adjustment template

(2) 4-40 x 1/4" screws

(1) 8-32 x 3/8" screw

INSTALLATION

1. Locate the area on the wall where the bracket is to be

mounted. Cut a hole no larger than 1" in diameter and

feed the necessary wires/cable through (Figure 1).

2. Feed wires/cable through the hole in the back side of the

bracket and out through end of the pipe.

3. Attach the bracket to the wall with fasteners that best fit

the application.

2. Once the top dome has been placed on the bracket, feed all

wires/cable through the 3/4" conduit connector and camera

housing.

3. Slide the housing onto the bracket, then tighten down the screw

on the 3/4" conduit connector (Figure 3).

Note: The connector will need to be tightened completly

down to secure the housing to bracket.

4. Once the housing has been secured to the bracket, slide

the top dome back down along the bracket until it fits on

top of the housing. The grommet will keep the top dome in

place.

3/4" CONDUIT CONNECTOR

Figure 3

Make necessary camera adjustments and complete the

installation process as specified elsewhere in these instructions.

Figure 1

HOUSING INSTALLATION

1. Once the bracket is secure, feed all wires/cable through

the top dome. Slide the top dome onto the bottom of

the bracket; the grommet should be secure around the

bracket pipe (Figure 2).

GROMMET

TOP DOME

Figure 2

PCF6W, PCV6W Dimensions

3.4"

3.3"

10.8"

7.0"

5.4"

- 4 -

Page 5

1. Read Instructions - All the safety and operating instructions

!

should be read before the unit is operated.

2. Retain Instructions - The safety and operating instructions

should be retained for future reference.

3. Heed Warnings - All warnings on the unit and in the

operating instructions should be adhered to.

4. Follow Instructions - All operating and user instructions

should be followed.

5. Electrical Connections - Only a qualified electrician should

make electrical connections.

6. Attachments - Do not use attachments not recommended

by the product manufacturer as they may cause hazards.

7. Cable Runs - All cable runs must be within permissible

distance.

8. Mounting - This unit must be properly and securely mounted

to a supporting structure capable of sustaining the weight

of the unit. Accordingly:

a. The installation should be made by a qualified service

person, and should conform to all local codes.

b. Care should be exercised to select suitable hardware

to install the unit, taking into account both the

composition of the mounting surface and the weight of

the unit. Be sure to periodically examine the unit and the

supporting structure to make sure that the integrity of the

installation is intact. Failure to comply with the foregoing

could result in the unit separating from the support

structure and falling, with resultant damages or injury to

anyone or anything struck by the falling unit.

SAFETY PRECAUTIONSIMPORTANT SAFEGUARDS

CAUTION

RISK OF

ELECTRIC SHOCK!

CAUTION: TO REDUCE THE RISK OF

ELECTRICAL SHOCK, DO NOT EXPOSE

COMPONENTS TO WATER OR MOISTURE.

The lightning flash with an arrowhead symbol,

within an equilateral triangle, is intended to

alert the user to the presence of non-insulated

"dangerous voltage" within the product's

enclosure that may be of sufficient magnitude

to constitute a risk of electric shock to persons.

The exclamation point within an equilateral

triangle is intended to alert the user to

!

UNPACKING

Unpack carefully. Electronic components can be

damaged if improperly handled or dropped. If an item

appears to have been damaged in shipment, replace it

properly in its carton and notify the shipper.

presence of important operating and

maintenance (servicing) instructions in the

literature accompanying the appliance.

Be sure to save:

1. The shipping carton and packaging material. They are the

safest material in which to make future shipments of the

equipment.

2. These Installation and Operating Instructions.

SERVICE

For service on Panasonic/Videolarm equipment contact:

Panasonic Technical Center

54 West Gude Dr.

Rockville MD 20850-1150

Phone: 301-762-5125

Fax: 301-251-0347

PANASONIC TECHNICAL SUPPORT

1-800-528-6747

9:00 AM - 5:00 PM EASTERN TIME

- 5 -

Loading...

Loading...