Page 1

PC8

Panasonic Protocol Converter

Installation

Guide

Building Block Video Ltd

17 Apex Park,

Diplocks Industrial Estate,

Hailsham, East Sussex, BN27 3JU, UK

Tel: + 44 (0) 1323 842727

Fax: + 44 (0) 1323 842728

Support: + 44 (0) 1323 444600

www.bbvcctv.com

Page 2

1. PRE-INSTALLATION CHECKS AND SAFETY PROCEDURES

UNPACKING

Check packaging - Upon taking delivery of the unit, inspect the packaging for signs of

damage. If damage has occurred, advise the carriers and/or the suppliers immediately.

Check contents - Upon taking delivery of the unit, unpack the receiver carefully and

check that all the items are present and correct. If any items are missing or damaged,

contact your equipment dealer.

Retain packaging - The shipping carton is the safest container in which to transport the

unit. Retain undamaged packaging for possible future use.

IMPORTANT SAFETY PRECAUTIONS

Read & retain instructions - All relevant safety, installation and operating instructions

should be read before attempting to install, connect or operate the unit, and retained for

future reference.

Heed warnings - All warnings on the unit and any relevant safety, installation or

operating instructions should be adhered to.

Cleaning - Unplug the unit from the power outlet before cleaning. Do not use liquid

cleaners or aerosol cleaners. Use a damp cloth for cleaning.

Attachments - Do not use attachments not recommended by the product manufacturer

as they may cause hazards.

Water and moisture - Do not expose the internal electronics of this unit to water or

dampness; for example, in an unprotected outdoor installation, or in any area classified

as a wet location. The unit as supplied conforms to ingress protection rating IP67. This

rating will be affected by any holes made in the enclosure. Cable entry points should be

protected by the use of suitably rated glands and/or flexible conduit. It is not necessary to

make further holes in the enclosure for mounting purposes, as mounting holes are

provided at the corners of the enclosure outboard of the seal between enclosure and lid.

Accessories - Do not attach this unit to an unstable stand, bracket or mount. The unit

may fall, causing serious injury to a person and serious damage to the unit.

Power Sources - This unit should be operated only from the type of power source

indicated on the manufacturer’s label. If you are not sure of the type of power supply you

intend to use, consult your equipment dealer or local power company. For units intended

to operate from battery power or other sources, refer to operating instructions.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 2/16

Page 3

Overloading - Do not overload outlets and extension cords, as this can result in fire or

electric shock.

Object and liquid entry - Never push objects of any kind into the unit, as they may touch

dangerous voltage points or short out parts that could result in fire or electric shock.

Never spill liquid of any kind on or inside the unit.

Servicing - Servicing of the unit should only be undertaken by qualified service

personnel, as opening or removing covers may expose you to dangerous voltages or

other hazards.

Damage requiring service - Servicing by qualified personnel should be carried out under

the following conditions:

(a) When the power supply cord or plug is damaged;

(b) If liquid has been spilled, or objects have fallen into, the unit;

(c) If the internal electronics of the unit have been exposed to rain or water;

(d) If the unit does not operate normally by following the operating instructions. Adjust

only those controls that are covered by the operating instructions, as improper

adjustment of other controls may result in damage and will often require extensive

work by a qualified technician to restore the unit to normal operation;

(e) If the unit has been dropped or the enclosure is damaged;

(f) If the unit exhibits a distinct change in performance. This indicates a need for

service.

Replacement parts - If replacement parts are required, ensure that only replacement

parts recommended by the product manufacturer are used.

Safety check - Upon completion of any service or repairs to the unit, safety checks

should be performed to ensure that the unit is in proper operating condition.

Coax grounding - If an outside cable system is connected to the unit, be sure the cable

system is grounded.

Pre-installation checks - It is recommended that the unit be bench tested prior to

installation on the site.

Adhere to safety standards - All normal safety precautions as laid down by British

Standards and the Health and Safety at Work Act should be observed.

WARNING

TO PREVENT DANGER OF FIRE OR SHOCK, DO NOT EXPOSE THE INTERNAL

COMPONENTS OF THIS EQUIPMENT TO RAIN OR MOISTURE.

This symbol is used to warn the user of this equipment that there are

sufficiently high voltages within the enclosure to constitute a risk of an

This symbol is used to warn the user of this equipment to important

operating and maintenance (servicing) instructions in the literature

accompanying the appliance.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 3/16

Page 4

Technical Specification

Power Requirements 9Vdc 500mA

Input 2 or 4 wire RS485 (switch selectable, SW3/8)

Panasonic RS485 9600,N,8,1 or 19200,N,8,1

Outputs 8 * RS485, either 2 or 4 wire

Maximum cable run approx 4000 Feet/1200m

Facilities LED as power and data indication

Other Outputs RS232 monitor output via chassis mounted DB9 connector.

Boxed Dimensions 19” 1U rack 100mm deep rack mountable case.

Version History

V10.2 5 Mar 2009 Update to show new 00007-6 PCB format.

V10.1 6 Sept 2007 Addition of notes concerning Vicon dome integration and SX650 matrix firmware.

V10 17 August 2007 Added support for Vicon dome protocol at 4800 or 9600 baud

V9 11 May 2007 Added Wash/Wipe support for Pelco protocol

V8 14 July 2006 Added support for Dennard dome protocol at 9600 baud

V7 8 Sept 2005 Added support for Pelco P at 2400, 4800 or 9600 baud

V2 5 March 2004 Improved control, LED status improved, added support for patrol and path

V1 26 Mar 2003 VCL TP protocol (9600,N,8,1)

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 4/16

Page 5

2. INTRODUCTION

GENERAL

The unit is designed to allow control of 3

rd

party domes from a Panasonic

control system. It can be configured for either 2 wire, half duplex or 4 wire,

full duplex telemetry.

Site communications must be set to either 9600 or 19200 Baud, No parity, 8

data bits and 1 stop bit. (9600 is the preferred baud rate)

It has been tested with the Panasonic SX150 mini matrix, SX550 matrix,

SX650 matrix and HD316 DVR in both 2 and 4 wire modes.

A RS232 serial output is provided via a DB9F to aid with diagnostics and

trouble shooting.

Panasonic Camera Address Range

The converter is designed to respond to a range of 8 camera addresses.

SW5 is used to set the camera range that the converter will respond to. If

the switch is set incorrectly it is possible to cause intermittent or sluggish

control if any camera shares this address.

Output Protocol

SW5 is used to select the protocol of the dome that is to be controlled.

The following page shows the details of SW4 and SW5 switch settings.

SX650 matrix notes.

Poor control including just two speed control can be experienced if the wiring

or switch settings including the 2/4 wire switches on the rear of the matrix

are incorrect.

If these are checked to be correct and control is still poor the matrix firmware

may need upgrading. Please contact your Panasonic service department

who should be able to provide a link the firmware and upgrade software. The

matrix should be running at least V3.01.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 5/16

Page 6

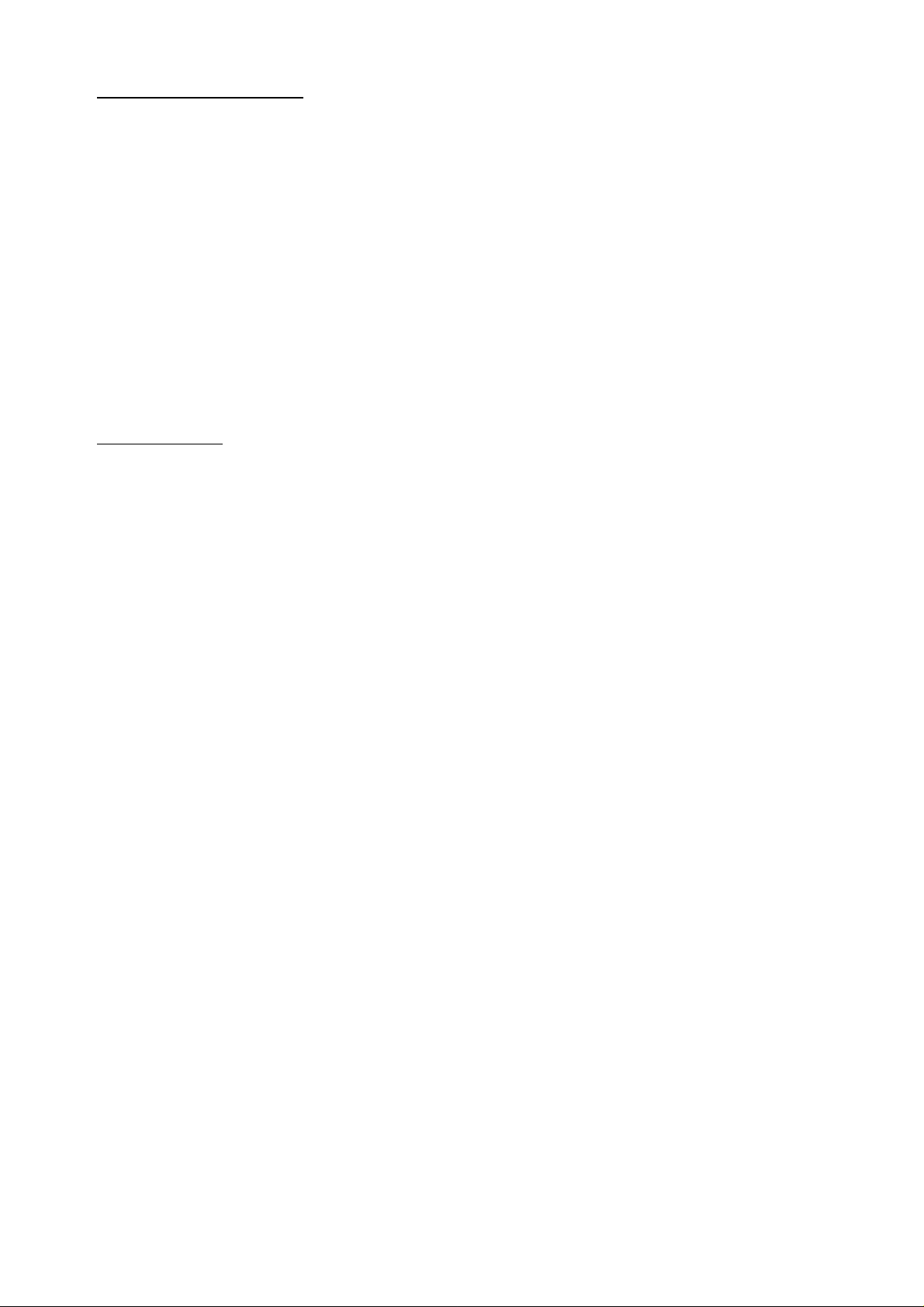

Internal view showing switches V12 Software

SD MICRO

Must be fitted

00007 -6

SW1 SW2

ON

12 34 567 8

Data OUT

TRA/TRB

LD1 = Dome RS422/485 out

Data OUT

TRA/TRB

Data OUT

TRA/TRB

LD2 = Panasonic RS422/485 in

Data OUT

TRA/TRB

LD3 = Checksum ERROR or

command for camera out of range

Data OUT

TRA/TRB

LD5 = Converter Mode

LD6 = Not used

SW4 Output Protocol

VCL - 9600,N,8,1

ON

12345678

Data OUT

TRA/TRB

Data OUT

TRA/TRB

Data OUT

TRA/TRB

Data OUT

TRA = A/+

TRB = B/-

SW5/1-4 Camera range

1 - 8

9 - 16

17 - 24

LD5

star_

J16

v*.

vhd

SW4 SW 5

LD1

LD2

LD3

Data IN

2 WIRE

TRA TA

TRB TB

4 WIRE

TRA RA

TRB RB

RA TA

RB TB

25 - 32

ON

12 3 4567 8

LD6

SW3

ON

12 34 567 8

PANA

CON

V**

LD4

ON

123456 78

RS232 DIAGNOSTICS PORT

ON = 2 W IR E

OFF = 4 WIRE

SW5 Camera Range

123456 78

SW5/8

Panasonic Baud

SW3/8

12 3456 78

PELCO P – 9600,N,8,1

12 3456 78

PELCO P – 4800,N,8,1

12 3456 78

PELCO P – 2400,N,8,1

12 3456 78

DENNARD – 9600,N,8,1

12 3456 78

1234

33 - 40

1234

65 - 72

1234

VICON – 4800,N,8,1

12 3456 78

VICON – 9600,N,8,1

12 3456 78

1234

41 - 48

1234

73 - 80

1234

1234

49 - 56

1234

81 - 88

1234

1234

57 - 64

1234

89 - 96

1234

97 - 99

1234

9600

8

19200

8

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 6/16

Page 7

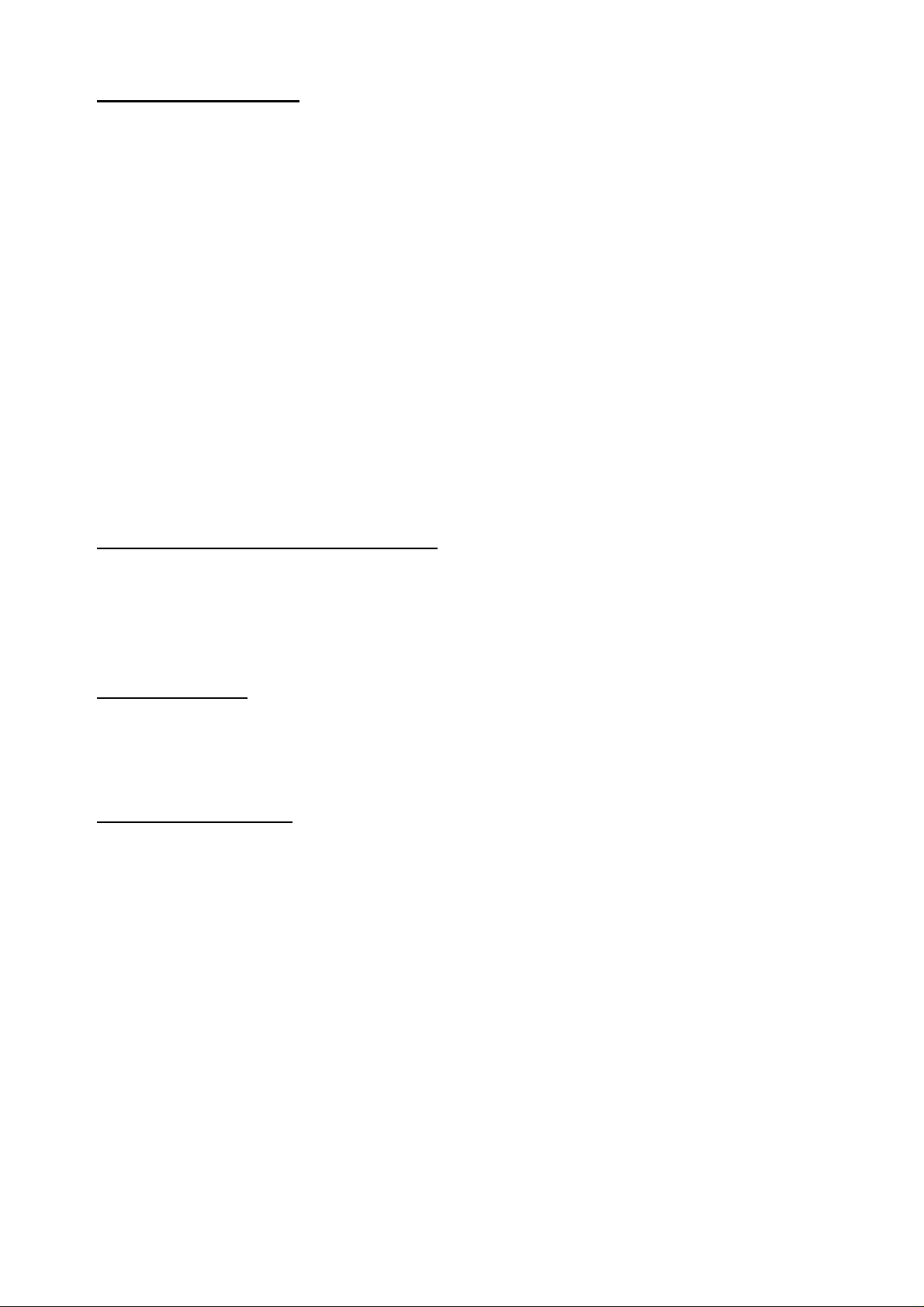

Switch details main Starcard PCB

SD MICRO

Must be fitted

00007 -6

SW1 SW2

ON

12 34 5678

ON

12345678

LD5

star_

J16

v*.

vhd

ON

SW4 SW 5

12 3 4567 8

LD6

LD1

LD2

LD3

Starcard PCB Switches

SW1 - RS485 line termination for outputs 1 - 4 ON = termination ON (Default)

SW1/1 & 1/2 = Output 1 termination

SW1 setting showing termination ON

SW1/3 & 1/4 = Output 2 termination

SW1/5 & 1/6 = Output 3 termination

SW1/7 & 1/8 = Output 4 termination

12345678

SW2 - RS485 line termination for outptus 5 - 8 ON = termination ON (Default)

SW2/1 & 2/2 = Output 5 termination

SW2 setting showing termination ON

SW2/3 & 2/4 = Output 6 termination

SW2/5 & 2/6 = Output 7 termination

SW2/7 & 2/8 = Output 8 termination

12345678

PANA

CON

V**

LD4

SW3

ON

12 34 567 8

ON

123 456 78

SW3/8

ON = 2 WIRE

OFF = 4 WIRE

SW3 - Option selection.

SW3/1 and SW3/2 - RS485 input line termination ON = termination ON (Default)

SW3/3-7 MUST BE OFF

SW3/8 - 2 or 4 wire selection. ON = 2 WIRE, OFF = 4 WIRE

SW3 setting showing 2 wire mode selected

and RS485 input termination ON

12345678

SW3 setting showing 4 wire mode selected

and RS485 input termination ON

12345678

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 7/16

Page 8

VCL TP protocol

Function Panasonic Procedure

Program preset 1 – 32 As normal

Goto preset 1 – 32 As normal

Enable Privacy zone 100 – 127 Program preset 64

Followed by goto preset 1 – 28 (1 = zone 100)

Disable Privacy zone 100 – 127 Program preset 63

Followed by goto preset 1 – 28 (1 = zone 100)

Define Preset Patrol – START Program preset 62

Followed by 3 preset commands per preset position

PRESET NUMBER - GOTO PRESET 1-32

SPEED - GOTO PRESET 1-63, 64 = fastest

DWELL – GOTO PRESET 1-64 (x 2 seconds)

Define Preset Patrol – STOP Program preset 61

Start Preset Patrol AUTOPAN

Path 5 LEARN start PATROL LEARN or Program preset 60

Use joystick to move dome around required path

Path 5 LEARN stop PATROL STOP or Program preset 59

Path 5 PLAYBACK PATROL PLAY

Preset positions

The unit supports 32 preset positions per dome. Use the standard Panasonic method to

program a preset and also to goto preset.

Preset Tour 1

The dome’s preset tour 1 can be defined as follows

PROGRAM PRESET 62 : the converter is now waiting for 3 preset calls per position

GOTO PRESET 1-32 : this is the preset position that is being programmed

GOTO PRESET 1-64 : this is the speed, 1-63 are increasing speeds and 64 is maximum

GOTO PRESET 1-64 : this is the dwell in 2 seconds to stay at the preset position

PROGRAM PRESET 61 : this is the end of the tour definition

Example presets 1,2,8,16

PROGRAM PRESET 62 – start definition

GOTO PRESET 1 – preset position 1

GOTO PRESET 64 – maximum speed

GOTO PRESET 10 – 20 second dwell

GOTO PRESET 2 – preset position 2

GOTO PRESET 20 – slowish speed

GOTO PRESET 15 – 30 second dwell

GOTO PRESET 8 – preset position 8

GOTO PRESET 1 – very slow speed

GOTO PRESET 2 – 4 second dwell

GOTO PRESET 16 – preset position 16

GOTO PRESET 63 – fast speed

GOTO PRESET 1 – 2 second dwell

PROGRAM PRESET 61 – end definition

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 8/16

Page 9

Privacy Zones

The dome’s 28 privacy zones can be set or cleared as follows:

To SET a zone

1. Move the camera to show the scene that is to be blanked.

2. PROGRAM PRESET 64 : SET PRIVACY COMMAND

3. GOTO PRESET 1-28 : PRIVACY ZONE TO USE

The screen will now be blank showing that the privacy zone has been set and enabled.

To CLEAR a zone

1. PROGRAM PRESET 63 : CLEAR PRIVACY COMMAND

2. GOTO PRESET 1-28 : PRIVACY ZONE TO CLEAR

The dome will now show the scene that the privacy zone was originally blanking. If you

have made a mistake and this zone must be blanked then without moving the dome just

follow the instructions above to SET the zone again.

Learned Path

A path is a learned tour that allows an operator to program the dome to move around

specific areas for example a fence line etc. The converter uses VCL tour 5 as the path.

To DEFINE a path

1. Move the dome to the position that you would like the dome to start from.

2. From the matrix keyboard select PATROL LEARN or PROGRAM PRESET 60

3. Use the joystick to move the dome around the required path

4. From the matrix keyboard select PATROL STOP or PROGRAM PRESET 59

To PLAY a path

Press AUTOPAN to start playback of the tour.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 9/16

Page 10

Pelco P specific functionality

Manual proportional control of pan/tilt and zoom/focus/iris

Support for preset 1 – 64 (preset 33 should not be used as this is a special Pelco preset)

The dome menu can be displayed using the conventional key strokes used to access

dome menus from the Panasonic controller. Please refer to the Panasonic manual for this

information.

Once the dome menu is displayed the joystick is used to navigate the cursor and the

CAM or ENTER key is used to simulate the Pelco IRIS OPEN key.

When navigating the dome menu you must wait for approx 2 seconds between repeated

ENTER key presses to allow control with the HD316 DVR range.

Once EXIT is selected from the dome menu you must perform a camera “setup off” from

the Panasonic controller otherwise pan/tilt control will be slow and fixed speed.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 10/16

Page 11

DENNARD protocol

Function Panasonic Procedure

Program preset 1 – 32 As normal – refer to Panasonic Manual

Goto preset 1 – 32 As normal – refer to Panasonic Manual

Display Menu As normal – refer to Panasonic Manual

Use the Joystick to move the dome cursor and either

the joystick button or ENTER. In addition GOTO

PRESET 1 can be used as enter.

Patrol playback Either AUTOPAN or PATROL

Ensure that the dome address matches the address that the Panasonic equipment is

sending using the Yellow and Blue rotary switches in the dome.

Preset positions

The unit supports 32 preset positions per dome. Use the standard Panasonic method to

program a preset and also to goto preset.

The dome may display a message asking “Edit Preset Text: YES/NO” after a program

preset is sent from the controller. Use the joystick to select YES or NO and send “GOTO

PRESET 1” as ENTER. This is a dome feature.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 11/16

Page 12

VICON protocol (4800 or 9600 baud)

Function Panasonic Procedure

Program preset 1 – 32 As normal – refer to Panasonic Manual

Goto preset 1 – 32 As normal – refer to Panasonic Manual

Display Menu

TOUR 80 playback PATROL

AUTOTOUR 88 playback AUTOPAN

Ensure that the dome address matches the address that the Panasonic equipment is

sending using the address switch on the dome base plate.

Supports 4800 and 9600 baud rates. Please select the baud rate required using SW1 as

diagram on page 6.

With a Vicon Surveyor 2000 dome ensure the following switch settings are used.

VPS

DUPLEX

RS422

Data connection between PC8 and dome

PC8 Dome

TRA COMM IN+

TRB COMM IN-

Notes

Some notes that can help installation of the PC8 with a Panasonic matrix to a site with

existing Vicon domes:

1. When star wiring a single dome from a PC8 output set the dome to RS422.

2. Daisy chaining multiple cameras from a PC8 output set the dome to RS485.

3. Some domes do not auto detect the baud rate on power up which will prevent

control if the dome is not set to the same baud rate as the PC8. To force the dome

to auto detect

a. power off dome

b. set dome to vicoax (Vicon up the coax instead of RS422/485 control)

c. power on dome then power off after 10 second

d. set dome to VPS and power on

4. If all else fails and you do can not control the dome just try swapping the data

cable between TRA & TRB on the PC8 output. It is possible that the data cable

may have a joint in a junction box between the PC8 and the dome.

As normal – refer to Panasonic Manual

Use the Joystick to move the dome cursor and either

the joystick button or SET.

SET sends an AP command

ESC sends an AI command

AUX1 & AUX2 are also used within the Vicon menu.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 12/16

Page 13

– blank for your notes –

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 13/16

Page 14

– blank for your notes –

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 14/16

Page 15

– blank for your notes –

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 15/16

Page 16

Other products in the Panasonic range:

d

PC8 Panasonic Protocol Converter – Designed to control 3

domes from a Panasonic control system.

RX450 Panasonic RS485 receiver –

Controls 24V ac / 230V ac operated pan/tilt

mechanisms from a Panasonic RS485

telemetry control system.

RX550 Panasonic RS485 receiver –

Controls 24V dc high/variable speed heads

from a Panasonic RS485 telemetry control

system.

r

party

RX100/Panasonic Dome interface receiver –

Telemetry interface converting BBV up-the-coax to

Panasonic RS485 protocol.

Panasonic Protocol Converter Manual V10.2 5Mar 09 Page 16/16

Loading...

Loading...